Page 1

Operating Instructions

Indicating and adjustment module

Page 2

Contents

Contents

1 About this document

1.1 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 For your safety

2.1 Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Warning about misuse . . . . . . . . . . . . . . . . . . . . . . .

2.4 General safety instructions . . . . . . . . . . . . . . . . . . . .

2.5 CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Fulfillment of NAMUR recommendations . . . . . . . . . .

3 Product description

3.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Packaging, transport and storage . . . . . . . . . . . . . . .

4 Prepare setup

4.1 Insert indicating and adjustment module. . . . . . . . . . .

4.2 Adjustment system . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Setup - Sensors up to software 3.99

5.1 Common adjustment menu for all signal outputs. . . . .

5.2 Adjustment menu 4 … 20 mA/HART . . . . . . . . . . . . .

4

4

4

5

5

5

5

6

6

7

7

8

9

10

11

18

6 Setup - sensors from software 4.0.0

6.1 Common adjustment menu for all signal outputs. . . . .

6.2 Adjustment menu 4 … 20 mA/HART . . . . . . . . . . . . .

7 Maintenance and fault rectification

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 How to proceed in case of repair. . . . . . . . . . . . . . . .

8 Dismounting

8.1 Dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Supplement

9.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Indicating and adjustment module

22

27

30

30

31

31

32

41787-EN-120316

Page 3

Contents

Safety instructions for Ex areas

Please note the Ex-specific safety information for installation and

operation in Ex areas. These safety instructions are part of the

operating instructions manual and come with the Ex-approved

instruments.

Editing status: 2012-02-29

41787-EN-120316

Indicating and adjustment module 3

Page 4

1 About this document

1 About this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important

instructions for maintenance and fault rectification. Please read this

information before putting the instrument into operation and keep this

manual accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained qualified

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can

result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

l List

The dot set in front indicates a list with no implied sequence.

à Act

1 Sequence

4 Indicating and adjustment module

ion

This arrow indicates a single action.

Numbers set in front indicate successive steps in a procedure.

41787-EN-120316

Page 5

2 For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must be

carried out only by trained specialist personnel authorised by the plant

operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

The pluggable indicating and adjustment module is used for measured

value indication, adjustment and diagnosis.

You can find detailed information on the application range in chapter

"Product description".

Operational reliability is ensured only if the instrument is properly used

according to the specifications in the operating instructions manual as

well as possible supplementary instructions.

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to system

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a state-of-the-art instrument complying with all prevailing

regulations and guidelines. The instrument must only be operated in a

technically flawless and reliable condition. The operator is responsible

for the trouble-free operation of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the necessary occupational safety measures with the

current valid rules and regulations and also take note of new

regulations.

The safety instructions in this operating instructions manual, the

national installation standards as well as the valid safety regulations

and accident prevention rules must be observed by the user.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbitrary

conversions or modifications are explicitly forbidden.

The safety approval markings and safety tips on the device must also

be observed.

41787-EN-120316

Indicating and adjustment module 5

Page 6

2 For your safety

2.5 CE conformity

The device fulfills the legal requirements of the applicable EC

guidelines. By attaching the CE mark, we provide confirmation of

successful testing.

2.6 Fulfillment of NAMUR recommendations

The device fulfills the requirements of the applicable NAMUR

recommendations.

6 Indicating and adjustment module

41787-EN-120316

Page 7

3 Product description

1

3.1 Structure

3 Product description

pe of the operating

Sco

instructions manual

Instrum

ent versions

Sco

pe of delivery

Appli

cation area

Installa

tion in the sensor

housing

This operating instructions manual applies to the following hardware

and software versions of the indicating and adjustment module:

l Hardware from 1.0.0

l Software from 1.0.0

The indicating/adjustment module consists of a display with full dot

matrix as well as four keys for adjustment.

A background lighting is optionally integrated and can be adjusted via

the adjustment menu.

The scope of delivery encompasses:

l Indicating and adjustment module

l Documentation

- this operating instructions manual

- Supplementary instructions manual 31708 "Heating for in-

dicating and adjustment module" (optional)

3.2 Principle of operation

The indicating and adjustment module is used for measured value

indication, adjustment and diagnosis for the following sensors:

l Level Transmitter 8136, 8137, 8138

l Level Transmitter 8176, 8177, 8178

l Level Transmitter 8185, 8186

The indicating and adjustment module is mounted into the respective

sensor housing.

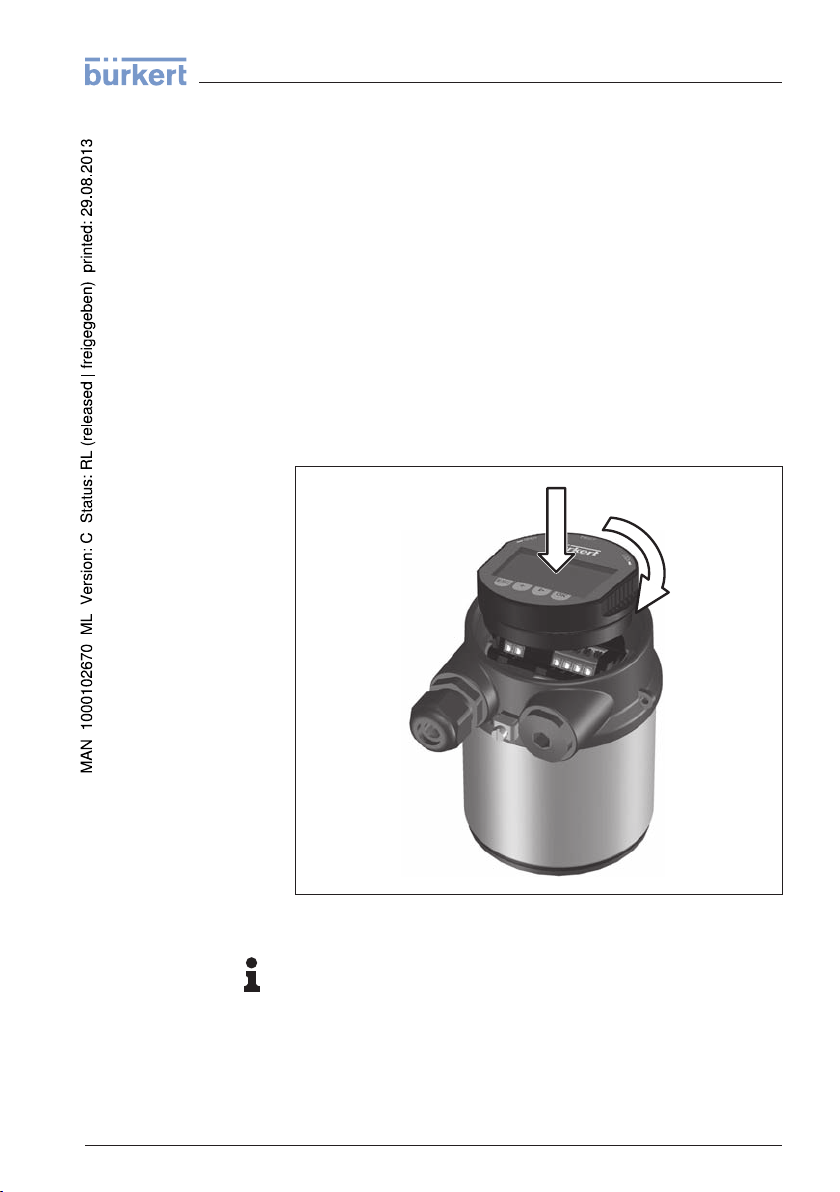

Fig. 1: Mounting the indicating and adjustment module in the single chamber

housing

1 Mounting in the electronics compartment

41787-EN-120316

Indicating and adjustment module 7

Page 8

3 Product description

The electrical connection is carried out via spring contacts in the

sensor and contact surfaces in the indicating and adjustment module.

After mounting, the sensor and indicating and adjustment module are

also splash-water protected without housing cover.

Range

of functions

Volta

ge supply

Packag

ing

Tr

ansport

Tr

ansport inspection

The range of functions of the indicating and adjustment module is

determined by the sensor and depends on the respective software

version of the sensor.

Power is supplied directly via the respective sensor or the external

indicating and adjustment unit. An additional connection is not

required.

The backlight is also powered by the sensor. Prerequisite for this is an

operating voltage at a certain level. The exact voltage specifications

can be found in the operating instructions manual of the respective

sensor.

3.3 Packaging, transport and storage

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE foil

is also used. Dispose of the packaging material via specialised

recycling companies.

Transport must be carried out under consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or

concealed defects must be appropriately dealt with.

Storage

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

l Not in the open

l Dry and dust free

l Not exposed to corrosive media

l Protected against solar radiation

l Avoiding mechanical shock and vibration

Stora

ge and transport

temperature

l Storage and transport temperature see chapter "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

8 Indicating and adjustment module

41787-EN-120316

Page 9

4 Prepare setup

4 Prepare setup

4.1 Insert indicating and adjustment module

The indicating and adjustment module can be inserted into the sensor

and removed any time. Four positions displaced by 90° can be

selected. It is not necessary to interrupt the power supply.

Proceed as follows:

1 Unscrew the housing cover

2 Place the indicating and adjustment module in the requested

position onto the electronics and turn to the right until it snaps in

3 Screw housing cover with inspection window tightly back on

Removal is carried out in reverse order.

The indicating and adjustment module is powered by the sensor, an

additional connection is not necessary.

Fig. 2: Insertion of the indicating and adjustment module with single chamber

housing

Note:

If you intend to retrofit the instrument with an indicating and adjustment

module for continuous measured value indication, a higher cover with

an inspection glass is required.

41787-EN-120316

Indicating and adjustment module 9

Page 10

1

2

4 Prepare setup

4.2 Adjustment system

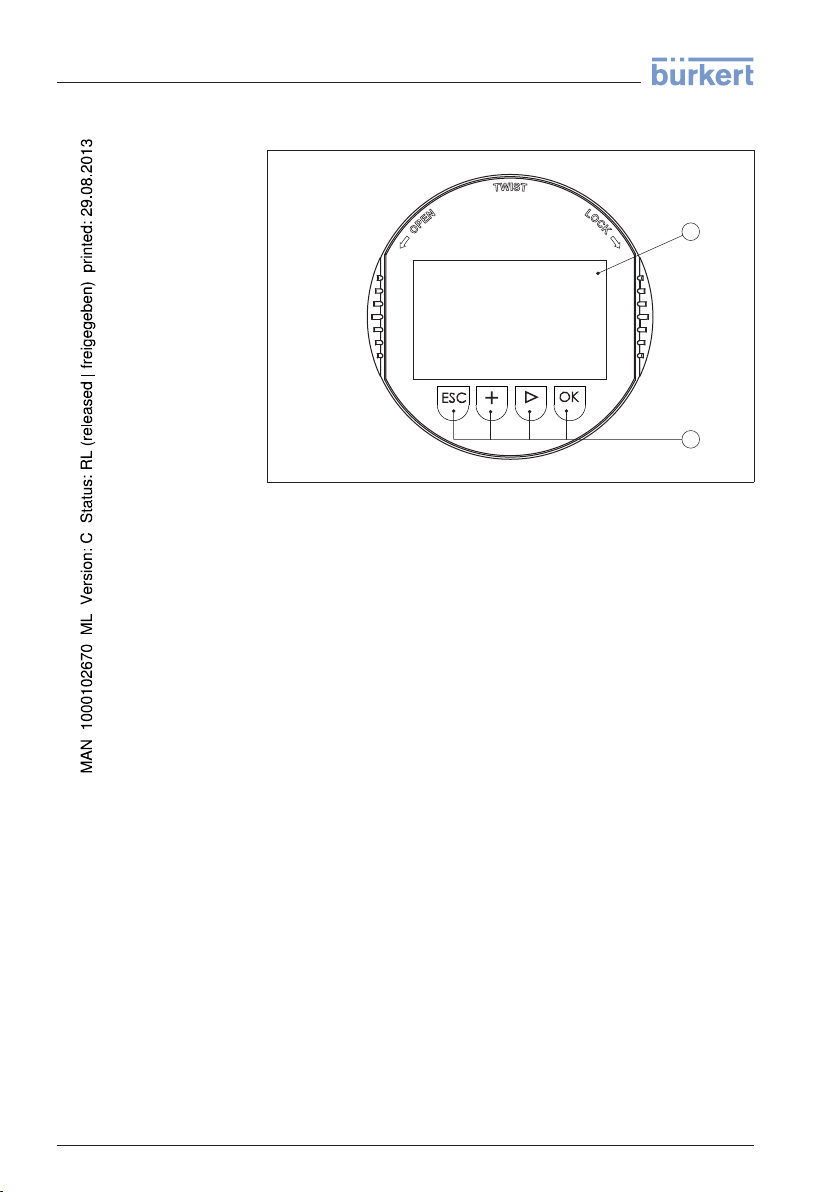

Fig. 3: Indicating and adjustment elements

1 LC display

2 Adjustment keys

Key

functions

l [OK] key:

- Move to the menu overview

- Confirm selected menu

- Edit parameter

- Save value

l [->] key:

- Presentation change measured value

- Select list entry

- Select editing position

l [+] key:

- Change value of the parameter

l [ESC] key:

- interrupt input

- Return to higher-ranking menu

Adjus

tment system

The sensor is adjusted via the four keys of the indicating and

adjustment module. The LC display indicates the individual menu

items. The functions of the individual keys are shown in the above

illustration. Approx. 10 minutes after the last pressing of a key, an

automatic reset to measured value indication is triggered. Any values

not confirmed with [OK] will not be saved.

10 Indicating and adjustment module

41787-EN-120316

Page 11

5 Setup - Sensors up to software 3.99

5 Setup - Sensors up to software 3.99

5.1 Common adjustment menu for all signal

outputs

Through the parameter adjustment the instrument is adapted to the

application conditions. The parameter adjustment is carried out via an

adjustment menu.

Information:

In this operating instructions, all general parameters are described.

Additional instrument-specific parameters are described in the

operating instructions of the respective sensor.

red value indica-

Measu

tion

Main

menu

Basic

adjustment/Damp-

ing

The following presentations are available in the measured value

display:

l Level as digital value, sensor TAG

l Level as digital value and bar graph, sensor TAG

l Only with pressure transmitters: Level or pressure as digital value,

temperature value

With [->] you select different presentations of the measured value.

From each of these presentations, you can reach with [OK] the menu

overview. With [ESC] you move from the menu overview again to the

measured value indication.

The main menu is divided into five sections with the following

functions:

▶

Basic adjustment

Display

Diagnostics

Service

Info

To damp process-dependent measured value fluctuations, you have to

set an integration time of 0 … 999 s in this menu item.

Depending on the sensor type, the factory setting is 0 s or 1 s.

Damping

0 s

Basic

adjustment/Linea-

rization curve

In this menu item you select the linearization curve:

l Linear

l Horizontal cylindrical tank

l Spherical tank

l User programmable

41787-EN-120316

Indicating and adjustment module 11

Page 12

5 Setup - Sensors up to software 3.99

User programmable means: Switching on a linearization curve

programmed via PC and PACTware

A linearization is necessary for all vessels in which the vessel volume

does not increase linearly with the level - e. g. with a horizontal

cylindrical or spherical tank - and the indication or output of the volume

is required. Corresponding linearization curves are preprogrammed for

these vessels. They represent the correlation between the level

percentage and vessel volume. The linearisation applies to the

measured value indication and the current output. By activating the

appropriate curve, the volume percentage of the vessel is displayed

correctly. If the volume should not be displayed in percent but e.g. in l

or kg, a scaling can be also set in the menu item "Display".

Factory setting is linear.

Linearisation curve

Linear

Caution:

Note the following, if the respective sensor is used as part of an overfill

protection system according to WHG:

If a linearisation curve is selected, the measuring signal is no longer

compulsorily linear proportional to the level. This must be taken into

consideration by the user, particularly when adjusting the switching

point on the level switch.

Basic adjustment/Sensor TAG

In the menu item "Sensor-TAG" you edit a 12-digit measurement loop

name. An unambiguous designation can hence be assigned to the

sensor, e.g. the measurement loop name or the tank or product

designation. In digital systems and in the documentation of larger

plants, a singular designation should be entered for exact identification

of individual measuring sites.

The available digits comprise:

l Letters from A … Z

l Numbers from 0 … 9

l Special characters +, -, /, -

Factory setting is "Sensor".

Sensor-TAG

Sensor

12 Indicating and adjustment module

41787-EN-120316

Page 13

5 Setup - Sensors up to software 3.99

y/Lighting

Displa

Diagno

sis/Peak value

Diagno

sis/Measurement

reliability

Diagno

sis/Device status

An integrated background lighting can be adjusted via the adjustment

menu. The function depends on the height of the supply voltage, see

operating instructions of the respective sensor.

In the default setting, the lightning is switched off.

The respective min. and max. measured values are saved in the

sensor. The values are displayed in the menu item "Peak values".

l Min. and max. distance in m(d): Radar, guided microwave,

ultrasonic sensors

l Min. and max. pressure: pressure transmitter

l Min. and max. temperature: ultrasonic sensors, pressure trans-

1)

mitters

Peak value

When non-contact level sensors are used, the measurement can be

influenced by the respective process conditions. In this menu item, the

measurement reliability of the level echo is displayed as dB value. The

measurement reliability equals signal strength minus noise. The higher

the value, the more reliable the measurement. With a functioning

measurement, the values are > 10 dB.

The instrument status is displayed in this menu item. If no failure is

detected by the sensor, "OK" will be displayed. If a failure is detected,

there will be a sensor-specific flashing fault signal, for example "E013".

The failure is also displayed in clear text, for example "No measured

value available".

Information:

The fault message as well as the clear text indication are also carried

out in the measured value display.

Meas. reliability

Sensor status

1)

Pressure: -50 … +150 % of the nominal pressure range; temperature:

-50 … +150 °C.

41787-EN-120316

Indicating and adjustment module 13

Page 14

5 Setup - Sensors up to software 3.99

sis/Curve selec-

Diagno

tion

Diagno

sis/Curve pre-

sentation

In ultrasonic and radar sensors as well as sensors with guided

microwave, the "Echo curve" represents the signal strength of the

echoes over the measuring range. The units of the signal strength are

"dB" (ultrasonic and radar) and "Volt" (guided microwave). The signal

strength allows an assessment of the quality of the measurement.

With ultrasonic and radar sensors, the "False echo curve" represents

the saved false echoes (see menu " Service") of the empty vessel with

signal strength in "dB" over the measuring range.

Up to 3000 measured values are recorded (depending on the sensor)

when starting a "Trend curve". Then the values can be displayed on a

time axis. The oldest measured values are always deleted.

In the menu item "Choose curve", the respective curve is selected.

Curve selection

Echo curve

▼

Information:

The trend recording is not activated when being shipped. It must be

started by the user via the menu item "Start trend curve".

A comparison of the echo curve and the false echo curve allows a

more detailled specification of measurement reliability. The selected

curve is updated continuously. With the [OK] key, a submenu with

zoom functions is opened.

The following functions are available with "Echo and false echo

curve":

l "X-Zoom": Zoom function for the meas. distance

l "Y-Zoom": 1, 2, 5 and 10x signal magnification in "dB"

l "Unzoom": Reset the presentation to the nominal measuring range

with single magnification

In the menu item "Trend curve" the following are available:

l "X-Zoom": Resolution

- 1 minute

- 1 hour

- 1 day

l "Stop/Start": Interrupt a recording or start a new recording

l "Unzoom": Reset the resolution to minutes

As default setting, the recording pattern has 1 minute. With the

adjustment software PACTware, this pattern can be also set to 1 hour

or 1 day.

41787-EN-120316

14 Indicating and adjustment module

Page 15

Echo curve

5 Setup - Sensors up to software 3.99

ice/Simulation

Serv

In this menu item you simulate a user-defined level or pressure value

via the current output. This allows you to test the signal path, e.g.

through connected indicating instruments or the input card of the

control system.

The following simulation variables are available:

l Percent

l Current

l Pressure (with pressure transmitters)

l Distance (with radar and guided microwave)

With Profibus PA sensors, the selection of the simulated value is made

via the "Channel" in the menu "Basic adjustments".

How to start the simulation:

1 Push [OK]

2 Select the requested simulation variable with [->] and confirm with

[OK].

3 Set the requested numerical value with [+] and [->].

4 Push [OK]

The simulation is now running, with 4 … 20 mA/HART a current is

outputted and with Profibus PA or Foundation Fieldbus a digital value.

How to interrupt the simulation:

à Push [ESC]

Information:

The simulation is terminated automatically 10 minutes after the last key

has been pushed.

Simulation

Start simulation?

Serv

ice/Reset

With the reset function, modified values are reset. Three subfunctions

are available:

l Basic adjustment

- Reset the values modified with the indicating and adjustment

module to the sensor-specific basic setting

l Factory setting

41787-EN-120316

Indicating and adjustment module 15

Page 16

5 Setup - Sensors up to software 3.99

ice/Adjustment unit

Serv

- As basic adjustment, but also reset of special parameters to

the default values

l Peak values measured value and temperature

2)

3)

- Reset of the min./max. values of pressure, level and temper-

ature to the current values

Information:

Because the reset values are nearly sensor-specifc, they are listed in

the operating instructions manual of the respective sensor.

Reset

Select reset?

In this menu item you select the internal arithmetic unit of the sensor.

With radar, guided microwave and ultrasonic sensors this is m(d) or

ft(d).

For pressure transmitters more comprehensive units are available.

They are described in the operating instructions manual of the

respective sensor in the menu "Basic adjustments".

Unit of measurement

m(d)

Serv

ice/Language

The sensor is already set to the ordered national language. In this

menu item you can change the language. The following languages are

available, e.g. in software version 3.50:

l Deutsch

l English

l Français

l Espanõl

l Pycckuu

l Japanese

l Italiano

l Netherlands

l Japanese

l Chinese

2)

Special

parameters are parameters which are set customer-specifically on

the service level with the adjustment software PACTware.

3)

Temperature

only with pressure transmitters and ultrasonic sensors.

16 Indicating and adjustment module

41787-EN-120316

Page 17

Language

German

5 Setup - Sensors up to software 3.99

Serv

ice/Copy sensor

data

With this function

l Load parameter adjustment data from the sensor into the

indicating and adjustment module

l Write parameter adjustment data from the indicating and adjust-

ment module into the sensor

The data are permanently saved in an EEPROM memory in the

indicating and adjustment module and remain there even in case of

power failure. From there, they can be written into one or several

sensors or kept as backup for a possible sensor exchange.

Kind and volume of the copied data depend on the respective sensor.

Information:

Before data are written into the sensor, a check is carried out to

determine whether the data fit the sensor. If the data do not fit, a fault

signal is triggered or the function is blocked. When writing data into the

sensor, you will see which instrument type the data originate from and

which TAG-no. this sensor had.

The following items are checked:

l Software version

l WHG approval

l SIL activated

l Measuring principle

l Radar C-band/K-band

l Radar measuring range < 30 m or > 30 m

l Signal output

l Pressure measuring range

Copy sensor data

Copy sensor data?

Serv

ice/PIN

In this menu item, the PIN is activated/deactivated permanently.

Entering a 4-digit PIN protects the sensor data against u nauthorized

access and unintentional modifications. If the PIN is activated

permanently, it can be deactivated temporarily (i.e. for approx. 60 min.)

in any menu item. The instrument is delivered with the PIN set to 0000.

41787-EN-120316

Indicating and adjustment module 17

Page 18

5 Setup - Sensors up to software 3.99

PIN

Disable permanently?

Only the following functions are permitted with activated PIN:

l Select menu items and show data

l Read data from the sensor into the indicating/adjustment module.

Info/Inf

o

In this menu item the most important sensor information can be

displayed:

l Instrument type

l Serial number: 8-digit number, e.g. 12345678

Instrument type

Serial number

12345678

l Date of manufacture: Date of the factory calibration

l Software version: Edition of the sensor software

Calibration date

Software version

l Date of last change using PC: Date of the last change of sensor

parameters via PC

Last change using PC

l Sensor details, e.g. approval, process fitting, seal, measuring cell,

measuring range, electronics, housing, cable entry, plug, cable

length etc.

Sensor characteristics

Display now?

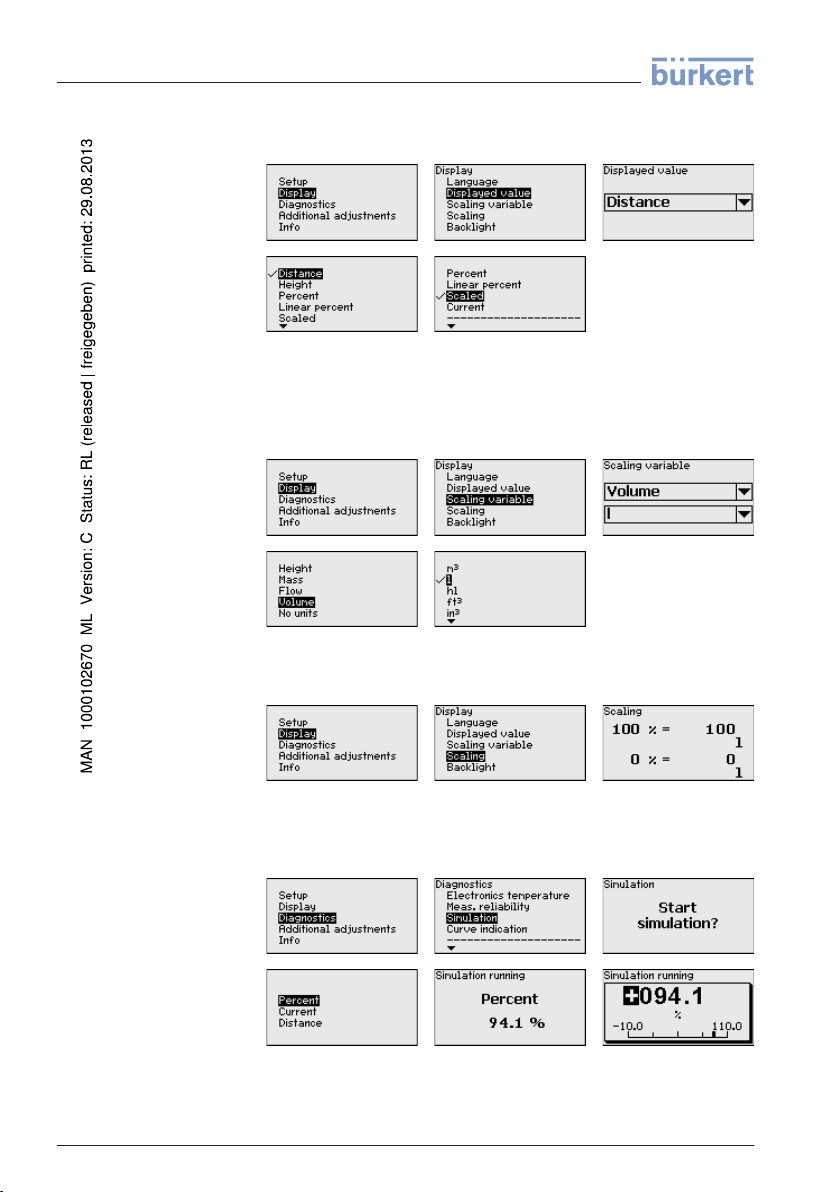

5.2 Adjustment menu 4 … 20 mA/HART

Displa

y/Display

18 Indicating and adjustment module

In the menu item "Display" you can define how the measured value

should be presented on the display.

41787-EN-120316

Page 19

5 Setup - Sensors up to software 3.99

The following values can be displayed:

l Height

l Pressure (only with pressure transmitters)

l Distance (only with radar, guided microwave, ultrasonics)

l Current

l Scaled

l Percent

l Lin. percent

l Temperature (only with pressure transmitters).

The selection "scaled" opens the menu items "Display unit" and

"Scaling". In "Display unit" there are the following options:

l Height

l Ground

l Flow

l Volume

l Without unit

Depending on selection, the different units are in turn available.

In the menu item "Scaling", the requested numerical value with

decimal point is entered for 0 % and 100 % of the measured value.

There is the following relationship between the indication value in the

menu "Display" and the adjustment unit in the menu "Device settings":

l With radar, guided microwave and ultrasonics, displayed value

"Distance" means: presentation of the measured value in the

selected adjustment unit, e.g. m(d)

l With pressure, displayed value "Pressure" or "Height" means:

presentation of the measured value in the selected adjustment

unit, e.g. bar or m.

Displayed value

Scaled

▼

Display unit

Volume

▼

l

▼

Scaling

0 % = 0.0 l

100 % = 100.0 l

Serv

ice/Current output

In the menu item "Current output" you determine the behaviour of the

current output during operation and in case of failure. The following

options are available:

41787-EN-120316

Indicating and adjustment module 19

Page 20

5 Setup - Sensors up to software 3.99

Current output

Characteristics 4 … 20 mA

Failure mode

Min. current

Max. current

The values in bold font represent the data of the factory setting.

In HART multidrop mode, the current is constantly 4 mA. This value

does not change even in case of failure.

Current output

20 … 4 mA

4)

5)

6)

Hold value

20.5 mA

22 mA

< 3.6 mA

3.8 mA

4 mA

20 mA

20.5 mA

ice/Functional

Serv

safety (SIL)

Serv

ice/HART mode

Output mode: 4-20 mA

Failure mode: 22 mA

Min. current 3.8 mA

▼

▼

▼

The functional safety is already activated Ex factory for instruments

with SIL qualification. For instruments Ex factory without SIL

qualification, the functional safety must be activated by the user for

applications according to SIL via the indicating and adjustment

module. The SIL factory setting cannot be deactivated by the user.

The activation of SIL has the following impact:

l In the menu item "Failure mode" under "Current output", the

parameters "Hold value" and "20.5 mA" are blocked

l In the menu item "HART mode", the function "Multidrop" is blocked

Note:

For such applications, it is absolutely necessary to take note of "Safety

Manual".

HART offers standard and multidrop mode.

The mode standard with the fixed address 0 means output of the

measured value as 4 … 20 mA signal.

4)

5)

6)

of the current output in case of failure, e.g. if no valid measured value

Value

is delivered.

value is not underrun during operation.

This

value is not exceeded during operation.

This

41787-EN-120316

20 Indicating and adjustment module

Page 21

5 Setup - Sensors up to software 3.99

In Multidrop mode, up to 15 sensors can be operated on one two-wire

cable. An address between 1 and 15 must be assigned to each

7)

sensor.

In this menu item you determine the HART mode and enter the

address for multidrop.

HART mode

Standard

Address 0

The default setting is standard with address 0.

7)

The 4 … 20 mA signal

consumes a constant current of 4 mA. The measuring signal is transmitted

exclusively as digital HART signal.

of the HART sensor is switched off. The sensor

41787-EN-120316

Indicating and adjustment module 21

Page 22

6 Setup - sensors from software 4.0.0

6 Setup - sensors from software 4.0.0

6.1 Common adjustment menu for all signal

outputs

Through the parameter adjustment the instrument is adapted to the

application conditions. The parameter adjustment is carried out via an

adjustment menu.

Information:

In this operating instructions, all general parameters are described.

Additional instrument-specific parameters are described in the

operating instructions of the respective sensor.

red value indica-

Measu

tion

Main

menu

The following presentations are available in the measured value

display:

l Level as digital value, sensor TAG

l Level as digital value and bar graph, sensor TAG

With [->] you select different presentations of the measured value.

From each of these presentations, you can reach with [OK] the menu

overview. With [ESC] you move from the menu overview again to the

measured value indication.

The main menu is divided into five sections with the following

functions:

Setup: Contains measurement loop name, settings to the medium,

application, vessel, adjustment, damping, signal output

Display: Contains language changeover, settings to the indicated

measured value as well as for lighting

Diagnosis: Contains information to the device status, peak value,

electronics temperature, reliability, simulation and echo curve

Additional settings: Contains measuring units of the instrument, fault

signal suppression, linearization curve, sensor length, PIN, date/time,

reset, HART mode/Profibus PA settings, copy function for sensor data

Info: Shows instrument name, instrument version, calibration date,

sensor features

41787-EN-120316

22 Indicating and adjustment module

Page 23

6 Setup - sensors from software 4.0.0

Setup/Measurement

loop name

Loc

k setup/adjustment

In the menu item "Sensor-TAG" you edit a 12-digit measurement loop

name. An unambiguous designation can hence be assigned to the

sensor, e.g. the measurement loop name or the tank or product

designation. In digital systems and in the documentation of larger

plants, a singular designation should be entered for exact identification

of individual measuring sites.

The available digits comprise:

l Letters from A … Z

l Numbers from 0 … 9

l Special characters +, -, /, -

In this menu item, the PIN is activated/deactivated permanently.

Entering a 4-digit PIN protects the sensor data against u nauthorized

access and unintentional modifications. If the PIN is activated

permanently, it can be deactivated temporarily (i.e. for approx. 60 min.)

in any menu item.

Only the following functions are permitted with activated PIN:

l Select menu items and show data

l Read data from the sensor into the indicating/adjustment module.

Caution:

With active PIN, the adjustment via PACTware/DTM as well as other

systems is also blocked.

In delivery status, the PIN is "0000".

Displa

y/Language

This menu item enables the setting of the requested national

language.

41787-EN-120316

Indicating and adjustment module 23

Page 24

6 Setup - sensors from software 4.0.0

In the delivery status, the sensor is set to the ordered national

language.

y/Lighting

Displa

Diagno

sis/Device status

Diagno

sis/Electronics

temperature

Addition

vice units

al settings/De-

The optionally integrated background lighting can be adjusted via the

adjustment menu. The function depends on the height of the supply

voltage, see operating instructions of the respective sensor.

The lighting is switched off in the delivery status.

In this menu item, the device status is displayed.

The respective min. and max. measured value of the electronics

temperature is saved in the sensor. These values as well as the actual

temperature value are displayed in the menu item "Peak values".

In this menu item you select the measured variable of the system and

the temperature unit.

Fur

ther settings/Lineari-

zation

24 Indicating and adjustment module

A linearization is necessary for all vessels in which the vessel volume

does not increase linearly with the level - e. g. with a horizontal

cylindrical or spherical tank - and the indication or output of the volume

is required. Corresponding linearization curves are preprogrammed for

these vessels. They represent the correlation between the level

percentage and vessel volume. The linearisation applies to the

41787-EN-120316

Page 25

6 Setup - sensors from software 4.0.0

measured value indication and the current output. By activating the

appropriate curve, the volume percentage of the vessel is displayed

correctly. If the volume should not be displayed in percent but e.g. in l

or kg, a scaling can be also set in the menu item "Display".

Caution:

Note the following, if the respective sensor is used as part of an overfill

protection system according to WHG:

If a linearisation curve is selected, the measuring signal is no longer

compulsorily linear proportional to the level. This must be taken into

consideration by the user, particularly when adjusting the switching

point on the level switch.

Addition

al settings/PIN

Entering a 4-digit PIN protects the sensor data against u nauthorized

access and unintentional modification. In this menu item, the PIN is

displayed or edited and changed. However, this menu item is only

available if adjustment is enabled in the menu "Setup".

In delivery status, the PIN is "0000".

Fur

ther settings/Date

In this menu item, the internal clock of the sensor is adjusted.

time

Fur

ther settings/Copy

instrument settings

The instrument settings are copied with this function. The following

functions are available:

l Store data from the sensor into the indicating/adjustment module.

l Store data from the indicating and adjustment module in the

sensor

The following data or settings for adjustment of the indicating and

adjustment module are saved:

41787-EN-120316

Indicating and adjustment module 25

Page 26

6 Setup - sensors from software 4.0.0

l All data of the menu "Setup" and "Display"

l In the menu "Additional settings" the items "Distance unit,

temperature unit and linearization"

l The values of the user programmable linearisation curve

The copied data are permanently saved in an EEPROM memory in the

indicating and adjustment module and remain there even in case of

power failure. From there, they can be written into one or more sensors

or kept as backup for a possible sensor exchange.

Kind and volume of the copied data depend on the respective sensor.

Note:

Before the data are stored in the sensor, a check is carried out to

determine if the data fit the sensor. If the data do not fit, a fault signal is

triggered or the function is blocked. When data are being written into

the sensor, the display shows which instrument type the data originate

from and which TAG-no. this sensor had.

Info/Instrument name

In this menu, you read out the instrument name and the instrument

serial number:

Inf/Ins

trument version

In this menu item, the hardware and software version of the sensor is

displayed.

Info/Cali

bration date

In this menu item, the date of factory calibration of the sensor as well

as the date of the last change of sensor parameters are displayed via

the indicating and adjustment module or via the PC.

26 Indicating and adjustment module

41787-EN-120316

Page 27

6 Setup - sensors from software 4.0.0

ent features

Instrum

Set

up/Damping

Set

up/Current output

mode

In this menu item, the features of the sensor such as approval, process

fitting, seal, measuring range, electronics, housing and others are

displayed.

6.2 Adjustment menu 4 … 20 mA/HART

To damp process-dependent measured value fluctuations, you have to

set an integration time of 0 … 999 s in this menu item.

Depending on the sensor type, the factory setting is 0 s or 1 s.

In the menu item "Current output mode" you determine the output

characteristics and reaction of the current output in case of failure.

The default setting is output characteristics 4 … 20 mA, failure mode

< 3.6 mA.

Set

up/Current output

Min./Max.

41787-EN-120316

Indicating and adjustment module 27

In the menu item "Current output Min./Max.", you determine the

reaction of the current output during operation.

The default setting is min. current 3.8 mA and max. current 20.5 mA.

Page 28

6 Setup - sensors from software 4.0.0

y/Displayed value

Displa

Displa

y/Scaling size

Displa

y/Scaling

In this menu item you can define the indication of the measured value

on the display.

The default setting for the indication value is for example distance with

radar sensors.

In this menu item you can define the scaling unit of the measured value

on the display.

In the menu item "Scaling", the requested numerical value with

decimal point is entered for 0 % and 100 % of the measured value.

Diagno

sis/Simulation

28 Indicating and adjustment module

In this menu item you can simulate measured values via the current

output. This allows the signal path to be tested, e.g. via downstream

indicating instruments or the input card of the control system.

How to start the simulation:

1 Push [OK]

41787-EN-120316

Page 29

6 Setup - sensors from software 4.0.0

2 Select the requested simulation variable with [->] and confirm with

[OK].

3 With [OK] you start the simulation, first of all the actual measured

value is displayed in %

4 Start the editing mode with [OK]

5 Set the requested numerical value with [+] and [->].

6 Push [OK]

Note:

During simulation, the simulated value is outputted as 4 … 20 mA

current value and digital HART signal.

How to interrupt the simulation:

à Push [ESC]

Information:

The simulation is terminated automatically 10 minutes after the last key

has been pushed.

ther settings/HART

Fur

mode

The sensor offers the HART modes standard and Multidrop. In this

menu item you determine the HART modes and enter the address with

Multidrop.

The mode standard with the fixed address 0 means output of the

measured value as 4 … 20 mA signal.

In Multidrop mode, up to 63 sensors can be operated on one two-wire

cable. An address between 1 and 63 must be assigned to each

8)

sensor.

The default setting is standard with address 0.

8)

The 4 … 20 mA signal

consumes a constant current of 4 mA. The measuring signal is transmitted

exclusively as digital HART signal.

of the HART sensor is switched off. The sensor

41787-EN-120316

Indicating and adjustment module 29

Page 30

7 Maintenance and fault rectification

7 Maintenance and fault rectification

7.1 Maintenance

If the device is used correctly, no maintenance is required in normal

operation.

7.2 How to proceed in case of repair

If it is necessary to repair the instrument, please contact the agency

serving you.

30 Indicating and adjustment module

41787-EN-120316

Page 31

8 Dismounting

8 Dismounting

8.1 Dismounting steps

Warning:

Before dismounting, be aware of dangerous process conditions such

as e.g. pressure in the vessel, high temperatures, corrosive or toxic

products etc.

Take note of chapters "Mounting" and "Connecting to power supply"

and carry out the listed steps in reverse order.

8.2 Disposal

The instrument consists of materials which can be recycled by

specialised recycling companies. We use recyclable materials and

have designed the electronics to be easily separable.

Correct disposal avoids negative effects on humans and the environment and ensures recycling of useful raw materials.

Materials: see chapter "Technical data"

If you have no way to dispose of the old instrument properly, please

contact us concerning return and disposal.

WEEE directive 2002/96/EG

This instrument is not subject to the WEEE directive 2002/96/EG and

the respective national laws. Pass the instrument directly on to a

specialised recycling company and do not use the municipal collecting

points. These may be used only for privately used products according

to the WEEE directive.

41787-EN-120316

Indicating and adjustment module 31

Page 32

9 Supplement

9 Supplement

9.1 Technical data

General data

Weight approx. 150 g (0.33 lbs)

Ambient conditions

Ambient temperature -15 … +70 °C (+5 … +158 °F)

Storage and transport temperature -40 … +80 °C (-40 … +176 °F)

Indicating and adjustment module

Voltage supply and data transmission through the sensor

Indication LC display in dot matrix

Adjustment elements 4 keys

Protection rating

- unassembled IP 20

- mounted into the sensor without cover IP 40

Materials

- Housing ABS

- Inspection window Polyester foil

Display light

Voltage supply through the sensor, voltage range see sensor

operating instructions manual

32 Indicating and adjustment module

41787-EN-120316

Page 33

9.2 Dimensions

27,6mm

(1.09")

ø 66,3mm

(2.61")

45,1mm

(1.78")

9,7mm

(0.38")

Fig. 4: Dimensions PLICSCOM

9 Supplement

41787-EN-120316

Indicating and adjustment module 33

Page 34

Index

INDEX

A

Adjus

tment system 10

Application area 7

C

Copy sensor data 17

Copy sensor settings 25

Current output 19

Current output Min./Max. 27

Current output mode 27

D

Damping 11, 27

Date/Time 25

Device units 24

Display 18

E

Echo curve 14

Electronics temperature 24

F

Functional safety (SIL) 20

H

HART mode 29

- Multidrop 20

- Standard 20

Measured value indication 11, 22, 28

Measured value presentation 18

Measurement loop name 23

P

Packaging 8

Peak value 13

PIN 17, 23, 25

R

Range of functions 8

Read out info 26

Reset 15

S

Scaling measured value 28

Sensor status 13, 24

Sensor-TAG 12

Simulation 15, 28

Storage 8

U

Unit of measurement 16

V

Voltage supply 8

I

Info 18

Instrument version 26

Instrument versions 7

K

Key function 10

L

Language 16, 23

Lighting 13, 24

Linearisation 24

Linearisation curve 11

Lock operation 23

M

Main menu 11, 22

Meas. reliability 13

34 Indicating and adjustment module

41787-EN-120316

Page 35

Index

41787-EN-120316

Indicating and adjustment module 35

Page 36

The smart choice

of Fluid Control Systems

www.burkert.com

41787-EN-120316

Page 37

Bedienungsanleitung

Anzeige- und Bedienmodul

Page 38

Inhaltsverzeichnis

Inhaltsverzeichnis

diesem Dokument

1 Zu

1.1 Funktion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Zielgruppe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Verwendete Symbolik . . . . . . . . . . . . . . . . . . . . . . . .

2 Zu Ihrer Sicherheit

2.1 Autorisiertes Personal . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Bestimmungsgemäße Verwendung . . . . . . . . . . . . . .

2.3 Warnung vor Fehlgebrauch . . . . . . . . . . . . . . . . . . . .

2.4 Allgemeine Sicherheitshinweise. . . . . . . . . . . . . . . . .

2.5 CE-Konformität. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Erfüllung von NAMUR-Empfehlungen. . . . . . . . . . . . .

3 Produktbeschreibung

3.1 Aufbau. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Arbeitsweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Verpackung, Transport und Lagerung . . . . . . . . . . . .

4 Inbetriebnahme vorbereiten

4.1 Anzeige- und Bedienmodul einsetzen . . . . . . . . . . . .

4.2 Bediensystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 In Betrieb nehmen - Sensoren bis Software 3.99

5.1 Gemeinsames Bedienmenü für alle Signalausgänge..

5.2 Bedienmenü 4 … 20 mA/HART. . . . . . . . . . . . . . . . .

4

4

4

5

5

5

5

6

6

7

7

8

10

11

12

19

6 In Betrieb nehmen - Sensoren ab Software 4.0.0

6.1 Gemeinsames Bedienmenü für alle Signalausgänge..

6.2 Bedienmenü 4 … 20 mA/HART. . . . . . . . . . . . . . . . .

7 Instandhalten und Störungen beseitigen

7.1 Wartung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Vorgehen im Reparaturfall. . . . . . . . . . . . . . . . . . . . .

8 Ausbauen

8.1 Ausbauschritte . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Entsorgen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Anhang

9.1 Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . .

Sicherheitshinweise für Ex-Bereiche

Beachten Sie

hinweise. Diese sind Bestandteil der Betriebsanleitung und liegen

jedem Gerät mit Ex-Zulassung bei.

Redaktionsstand: 2012-02-29

2 Anzeige- und Bedie

bei Ex-Anwendungen die Ex-spezifischen Sicherheits-

23

28

31

31

32

32

33

41787-DE-120229

nmodul •

Page 39

1 Zu diesem Dokum

ent

1 Zu diesem Dokum

ent

1.1 Funktion

Die vorliegende Betriebsanleitung liefert Ihnen die erforderlichen

Informationen für Montage, Anschluss und Inbetriebnahme sowie

wichtige Hinweise für Wartung und Störungsbeseitigung. Lesen Sie

diese deshalb vor der Inbetriebnahme und bewahren Sie sie als

Produktbestandteil in unmittelbarer Nähe des Gerätes jederzeit

zugänglich auf.

1.2 Zielgruppe

Diese Betriebsanleitung richtet sich an ausgebildetes Fachpersonal.

Der Inhalt dieser Anleitung muss dem Fachpersonal zugänglich

gemacht und umgesetzt werden.

1.3 Verwendete Symbolik

Information, Tip

Dieses Symbol kennzeichnet hilfreiche Zusatzinformationen.

Vorsicht: Bei Nich

Störungen oder Fehlfunktionen die Folge sein.

Warnung: Bei Nichtbeachten dieses Warnhinweises kann ein Perso-

nenschaden und/oder ein schwerer Geräteschaden die Folge sein.

Gefahr: Bei Nichtbeachten dieses Warnhinweises kann eine ernst-

hafte Verletzung von Personen und/oder eine Zerstörung des Gerätes

die Folge sein.

p, Hinweis

tbeachten dieses Warnhinweises können

41787-DE-120229

Anzeige- und Bedie

endungen

Ex-Anw

Dieses Sym

dungen.

l Liste

Der vorangestellte Punkt kennzeichnet eine Liste ohne zwingende

Reihenfolge.

bol kennzeichnet besondere Hinweise für Ex -Anwen-

à Handlungsschritt

Dieser Pfeil kenn

1 Handlungsfolge

Vorangestellte Zahlen kennzeichnen aufeinander folgende Handlungsschritte.

nmodul • 3

zeichnet einen einzelnen Handlungsschritt.

Page 40

2 Zu Ihrer Sich

erheit

2 Zu Ihrer Sicherheit

2.1 Auto

Sämtliche in dieser Betriebsanleitung beschriebenen Handhabungen

dürfen nur durch ausgebildetes und vom Anlagenbetreiber autorisiertes Fachpersonal durchgeführt werden.

Bei Arbeiten am und mit dem Gerät ist immer die erforderliche

persönliche Schutzausrüstung zu tragen.

risiertes Personal

2.2 Bestimmungsgemäße Verwendung

Das steckbare Anzeige- und Bedienmodul dient zur Messwertanzeige,

Bedienung und Diagnose.

Detaillierte Angaben zum Einsatzbereich finden Sie im Kapitel

"Produktbeschreibung".

Die Betriebssicherheit des Gerätes ist nur bei bestimmungsgemäßer

Verwendung entsprechend den Angaben in der Betriebsanleitung

sowie in den evtl. ergänzenden Anleitungen gegeben.

2.3 Warnung vor Fehlgebrauch

Bei nicht sachgerechter oder nicht bestimmungsgemäßer Verwendung können von diesem Gerät anwendungsspezifische Gefahren

ausgehen, so z. B. ein Überlauf des Behälters oder Schäden an

Anlagenteilen durch falsche Montage oder Einstellung.

2.4 Allgemeine Sicherheitshinweise

Das Gerät entspricht dem Stand der Technik unter Beachtung der

üblichen Vorschriften und Richtlinien. Es darf nur in technisch

einwandfreiem und betriebssicherem Zustand betrieben werden. Der

Betreiber ist für den störungsfreien Betrieb des Gerätes verantwortlich.

Der Betreiber ist ferner verpflichtet, während der gesamten Einsatz-

dauer die Übereinstimmung der erforderlichen Arbeitssicherheitsmaßnahmen mit dem aktuellen Stand der jeweils geltenden Regelwerke festzustellen und neue Vorschriften zu beachten.

Durch den Anwender sind die Sicherheitshinweise in dieser Betriebsanleitung, die landesspezifischen Installationsstandards sowie

die geltenden Sicherheitsbestimmungen und Unfallverhütungsvorschriften zu beachten.

Eingriffe über die in der Betriebsanleitung beschriebenen Handhabungen hinaus dürfen aus Sicherheits- und Gewährleistungsgründen nur durch vom Hersteller autorisiertes Personal vorgenommen

werden. Eigenmächtige Umbauten oder Veränderungen sind ausdrücklich untersagt.

41787-DE-120229

4 Anzeige- und Bedie

nmodul •

Page 41

2 Zu Ihrer Sicherhe

it

Weiterhin sind die auf dem G

zeichen und -hinweise zu beachten.

erät angebrachten Sicherheitskenn-

2.5 CE-Konformität

Das Gerät erfüllt die gesetzlichen Anforderungen der zutreffenden EGRichtlinien. Mit der Anbringung des CE-Zeichens bestätigen wir die

erfolgreiche Prüfung.

2.6 Erfüllung von NAMUR-Empfehlungen

Das Gerät erfüllt die Anforderungen der zutreffenden NAMUREmpfehlungen.

41787-DE-120229

Anzeige- und Bedie

nmodul • 5

Page 42

1

3 Produktbeschreibung

3 Produktbeschreibung

Geltungsbereich dieser

Betriebsan

Geräteausführungen

Lieferumf

Einsatzbereich

Einbau in das Sensor-

gehäus

leitung

ang

e

3.1 Aufb

Die vorliegende Betriebsanleitung gilt für folgende Hard- und

Softwareversionen des Anzeige- und Bedienmoduls:

l Hardware ab 1.0.0

l Software ab 1.0.0

Das Anzeige- und Bedienmodul ist mit einem Display mit Voll-Dot-

Matrix sowie vier Tasten zur Bedienung ausgestattet.

Optional ist eine Hintergrundbeleuchtung integriert und über das

Bedienmenü zuschaltbar.

Der Lieferumfang besteht aus:

l Anzeige- und Bedienmodul

l Dokumentation

- Dieser Betriebsanleitung

- Zusatzanleitung 31708 "Heizung für Anzeige- und Bedien-

au

modul" (optional)

3.2 Arbeitsweise

Das Anzeige- und Bedienmodul dient zur Messwertanzeige, Bedienung und Diagnose für folgende Sensoren:

l Level Transmitter 8136, 8137, 8138

l Level Transmitter 8176, 8177, 8178

l Level Transmitter 8185, 8186

Das Anzeige- und Bedienmodul wird in das jeweilige Sensorgehäuse

eingebaut.

Abb. 1: E

inbau des Anzeige- und Bedienmoduls in das Einkammergehäuse

1 Einbau in Elektronikraum

6 Anzeige- und Bedie

41787-DE-120229

nmodul •

Page 43

3 Produktbeschreibung

Funk

tionsumfang

Spannungsversorgung

Verpackung

Transport

Die elektrische Verbi

ndung erfolgt über Federkontakte im Sensor und

Kontaktbahnen im Anzeige- und Bedienmodul. Nach dem Einbau sind

Sensor und Anzeige- und Bedienmodul auch ohne Gehäusedeckel

spritzwassergeschützt.

Der Funktionsumfang des Anzeige- und Bedienmoduls wird durch den

Sensor bestimmt und hängt von der jeweiligen Softwareversion des

Sensors ab.

Die Versorgung erfolgt direkt durch den jeweiligen Sensor bzw. über

die externe Anzeige- und Bedieneinheit. Ein weiterer Anschluss ist

nicht erforderlich.

Die Hintergrundbeleuchtung wird ebenfalls durch den Sensor gespeist. Voraussetzung ist hierbei eine bestimmte Höhe der Betriebsspannung. Die genauen Spannungsangaben finden Sie in der

Betriebsanleitung des entsprechenden Sensors.

3.3 Verpackung, Transport und Lagerung

Ihr Gerät wurde auf dem Weg zum Einsatzort durch eine Verpackung

geschützt. Dabei sind die üblichen Transportbeanspruchungen durch

eine Prüfung nach DIN EN 24180 abgesichert.

Bei Standardgeräten besteht die Verpackung aus Karton, ist umweltverträglich und wieder verwertbar. Bei Sonderausführungen wird

zusätzlich PE-Schaum oder PE-Folie verwendet. Entsorgen Sie das

anfallende Verpackungsmaterial über spezialisierte Recyclingbetriebe.

Der Transport muss unter Berücksichtigung der Hinweise auf der

Transportverpackung erfolgen. Nichtbeachtung kann Schäden am

Gerät zur Folge haben.

Transportinspektion

Lagerung

Lager- und Tr

temp

eratur

41787-DE-120229

Anzeige- und Bedie

Die Lieferung ist bei Erhalt unverzüglich auf Vollständigkeit und

eventuelle Transportschäden zu untersuchen. Festgestellte Transportschäden oder verdeckte Mängel sind entsprechend zu behandeln.

Die Packstücke sind bis zur Montage verschlossen und unter

Beachtung der außen angebrachten Aufstell- und Lagermarkierungen

aufzubewahren.

Packstücke, sofern nicht anders angegeben, nur unter folgenden

Bedingungen lagern:

l Nicht im Freien aufbewahren

l Trocken und staubfrei lagern

l Keinen aggressiven Medien aussetzen

l Vor Sonneneinstrahlung schützen

l Mechanische Erschütterungen vermeiden

ansport-

l Lager- und Transporttemperatur siehe Kapitel "Anhang - Techni-

sche Daten - Umgebungsbedingungen"

nmodul • 7

Page 44

3 Produktbeschreibung

l Relative Luf

tfeuchte 20 … 85 %

8 Anzeige- und Bedie

41787-DE-120229

nmodul •

Page 45

4 Inbetriebnahme vorbereiten

4 Inbetriebnahme

vorbereiten

4.1 Anzeige- und Bedienmodul einsetzen

Das Anzeige- und Bedienmodul kann jederzeit in den Sensor

eingesetzt und wieder entfernt werden. Dabei sind vier Positionen im

90°-Versatz wählbar. Eine Unterbrechung der Spannungsversorgung

ist hierzu nicht erforderlich.

Gehen Sie wie folgt vor:

1 Gehäusedeckel abschrauben

2 Anzeige- und Bedienmodul in die gewünschte Position auf die

Elektronik setzen und nach rechts bis zum Einrasten drehen

3 Gehäusedeckel mit Sichtfenster fest verschrauben

Der Ausbau erfolgt sinngemäß umgekehrt.

Das Anzeige- und Bedienmodul wird vom Sensor versorgt, ein

weiterer Anschluss ist nicht erforderlich.

41787-DE-120229

Anzeige- und Bedie

insetzen des Anzeige- und Bedienmoduls beim Einkammergehäuse

Abb. 2: E

Hinweis:

Falls Sie das G

ständigen Messwertanzeige nachrüsten wollen, ist ein erhöhter Deckel

mit Sichtfenster erforderlich.

nmodul • 9

erät mit einem Anzeige- und Bedienmodul zur

Page 46

1

2

4 Inbetriebnahme vorbereiten

stenfunktionen

Ta

Bediensystem

4.2 Bediensystem

Abb. 3: Anzeige- und Bedienelemente

1 LC-Display

2 Bedientasten

l [OK

]-Taste:

- In die Menüübersicht wechseln

- Ausgewähltes Menü bestätigen

- Parameter editieren

- Wert speichern

l [->]-Taste:

- Darstellung Messwert wechseln

- Listeneintrag auswählen

- Editierposition wählen

l [+]-Taste:

- Wert eines Parameters verändern

l [ESC]-Taste:

- Eingabe abbrechen

- In übergeordnetes Menü zurückspringen

Sie bedienen den Sensor über die vier Tasten des Anzeige- und

Bedienmoduls. Auf dem LC-Display werden die einzelnen Menü-

punkte angezeigt. Die Funktionen der einzelnen Tasten entnehmen

Sie bitte der vorhergehenden Darstellung. Ca. 10 Minuten nach der

letzten Tastenbetätigung wird ein automatischer Rücksprung in die

Messwertanzeige ausgelöst. Dabei gehen die noch nicht mit [OK]

bestätigten Werte verloren.

41787-DE-120229

10 Anzeige- und Bedie

nmodul •

Page 47

5 In Betrieb neh

men - Sensoren bis Software 3.99

Messwe

rtanzeige

Hauptmenü

5 In Betrieb nehmen - Sensoren

bis

Software 3.99

5.1 Gemeinsames Bedienmenü für alle

Signalausgänge

Durch die Parametrierung wird das Gerät an die Einsatzbedingungen

angepasst. Die Parametrierung erfolgt über ein Bedienmenü.

Information:

In

dieser Betriebsanleitung werden die allgemeinen Parameter be-

schrieben. Weitere, gerätespezifische Parameter werden in der

Betriebsanleitung des jeweiligen Sensors beschrieben.

In der Messwertanzeige stehen folgende Darstellungen zur Verfügung:

l Füllstand als Digitalwert, Sensor-TAG

l Füllstand als Digitalwert und Bargraf, Sensor-TAG

l nur bei Druckmessumformern: Füllstand oder Druck als Digital-

wert, Temperaturwert

Mit [->] wählen Sie die unterschiedliche Darstellungen des Messwer-

tes aus. Von jeder dieser Darstellungen gelangen Sie mit [OK] in die

Menüübersicht. Mit [ESC] wechseln Sie aus der Menüübersicht

wieder in die Messwertanzeige.

Das Hauptmenü ist in fünf Bereiche mit folgender Funktionalität

aufgeteilt:

▶

Grundeinstellung

Display

Diagnose

Service

Info

Grundeinstellung/Däm

fung

Grundein

arisierung

stellung/Line-

skurve

41787-DE-120229

Anzeige- und Bedie

Zur Dämpfung von prozessbedingten Messwertschwankungen stellen

p-

Sie in diesem Menüpunkt eine Integrationszeit von 0 … 999 s ein.

Die Werkseinstellung ist je nach Sensortyp 0 s bzw. 1 s.

Dämpfung

0 s

In diesem Menüpunkt wählen Sie die Linearisierungskurve:

l Linear

l Liegender Rundtank

l Kugeltank

l Frei programmierbar

nmodul • 11

Page 48

5 In Betrieb

nehmen - Sensoren bis Software 3.99

Frei programmierbar bedeutet: Eins

chalten einer per PC und

PACTware programmierten Linearisierungskurve.

Eine Linearisierung ist bei allen Behältern erforderlich, bei denen das

Behältervolumen nicht linear mit der Füllstandhöhe ansteigt - z. B. bei

einem liegenden Rundtank oder Kugeltank - und die Anzeige oder

Ausgabe des Volumens gewünscht ist. Für diese Behälter sind

entsprechende Linearisierungskurven hinterlegt. Sie geben das Verhältnis zwischen prozentualer Füllstandhöhe und dem Behältervolumen an. Die Linearisierung gilt für die Messwertanzeige und den

Stromausgang. Durch Aktivierung der passenden Kurve wird das

prozentuale Behältervolumen korrekt angezeigt. Falls das Volumen

nicht in Prozent, sondern beispielsweise in Liter oder Kilogramm

angezeigt werden soll, kann zusätzlich eine Skalierung im Menüpunkt

"Display" eingestellt werden.

Die Werkseinstellung ist linear.

Linearisierungskurve

Linear

Vorsicht:

Bei

m Einsatz des jeweiligen Sensors als Teil einer Überfüllsicherung

nach WHG ist folgendes zu beachten:

Wird eine Linearisierungskurve gewählt, so ist das Messsignal nicht

mehr zwangsweise linear proportional zur Füllhöhe. Dies ist vom

Anwender insbesondere bei der Einstellung des Schaltpunktes am

Grenzsignalgeber zu berücksichtigen.

Grundeinstellung/Sensor-TAG

Im Menüpunkt "Sensor-TAG" editieren Sie ein zwölfstelliges Messstellenkennzeichen. Dem Sensor kann damit eine eindeutige Bezeichnung gegeben werden, beispielsweise der Messstellenname

oder die Tank- bzw. Produktbezeichnung. In digitalen Systemen und

der Dokumentation von größeren Anlagen sollte zur genaueren

Identifizierung der einzelnen Messstellen eine einmalige Bezeichnung

eingegeben werden.

Der Zeichenvorrat umfasst:

l Buchstaben von A … Z

l Zahlen von 0 … 9

l Sonderzeichen +, -, /, -

Die Werkseinstellung ist "Sensor".

Sensor-TAG

Sensor

12 Anzeige- und Bedie

41787-DE-120229

nmodul •

Page 49

5 In Betrieb neh

men - Sensoren bis Software 3.99

y/Beleuchtung

Displa

Diagnose/Schleppz

eiger

Diagnose/Messsicherheit

Diagnose

/Geräte

status

Eine integrierte Hintergrundbeleuchtung ist über das Bedienmenü

zuschaltbar. Die Funktion ist von der Höhe der Versorgungsspannung

abhängig, siehe Betriebsanleitung des jeweiligen Sensors.

In der Werkseinstellung ist die Beleuchtung ausgeschaltet.

Im Sensor werden jeweils minimale und maximale Messwerte

gespeichert. Im Menüpunkt "Schleppzeiger" werden die Werte angezeigt.

l Min.- und Max.-Distanz in m(d): Radar-, Geführte Mikrowelle-,

Ultraschallsensoren

l Min.- und Max.-Druck: Druckmessumformer

l Min.- und Max.-Temperatur: Ultraschallsensoren, Druckmessum-

1)

former

Schleppzeiger

Bei berührungslos arbeitenden Füllstandsensoren kann die Messung

durch die Prozessbedingungen beeinflusst werden. In diesem Menü-

punkt wird die Messsicherheit des Füllstandechos als dB-Wert

angezeigt. Die Messsicherheit ist Signalstärke minus Rauschen. Je

größer der Wert ist, desto sicherer funktioniert die Messung. Bei einer

funktionierenden Messung sind die Werte > 10 dB.

In diesem Menüpunkt wird der Gerätestatus angezeigt. Wird durch

den Sensor kein Fehler erkannt, so erfolgt die Anzeige "OK". Wird ein

Fehler festgestellt, so erfolgt sensorspezifisch eine blinkende Fehlermeldung, z. B. "E013". Der Fehler wird zusätzlich im Klartext angezeigt

z. B. "Kein Messwert vorhanden".

41787-DE-120229

Anzeige- und Bedie

Information:

Die Fehlerm

eldung sowie die Klartextanzeige erfolgen ebenfalls in der

Messwertanzeige.

Messsicherheit

Gerätestatus

1)

Druck: -50 … +150 % des Nennmessbereichs; Temperatur: -50 … +150 °C.

nmodul • 13

Page 50

5 In Betrieb

nehmen - Sensoren bis Software 3.99

Diagno

wahl

Diagno

stellung

se/Kurv

/Kurvend

se

enaus-

ar-

Bei Ultraschall- und Rad

arsensoren sowie bei Sensoren mit geführter

Mikrowelle stellt die "Echokurve" die Signalstärke der Echos über den

Messbereich dar. Die Einheiten der Signalstärke sind "dB" (Ultraschall

und Radar) und "Volt" (Geführte Mikrowelle). Die Signalstärke

ermöglicht eine Beurteilung der Qualität der Messung.

Die "Störechokurve" stellt bei Ultraschall- und Radarsensoren die

gespeicherten Störechos (siehe Menü "Service") des leeren Behälters

mit Signalstärke in "dB" über den Messbereich dar.

Mit dem Start einer "Trendkurve" werden je nach Sensor bis zu 3000

Messwerte aufgezeichnet. Die Werte können anschließend über einer

Zeitachse dargestellt werden. Die jeweils ältesten Messwerte werden

wieder gelöscht.

Im Menüpunkt "Kurvenauswahl" wird die jeweilige Kurve ausgewählt.

Kurvenauswahl

Echokurve

▼

Information:

Bei

der Auslieferung vom Werk ist die Trendaufzeichnung nicht aktiv.

Sie muss vom Anwender über den Menüpunkt "Trendkurve starten"

gestartet werden.

Ein Vergleich von Echo- und Störechokurve lässt eine genauere

Aussage über die Messsicherheit zu. Die gewählte Kurve wird laufend

aktualisiert. Mit der Taste [OK] wird ein Untermenü mit ZoomFunktionen geöffnet.

Bei der "Echo- und Störechokurve" sind verfügbar:

l "X-Zoom": Lupenfunktion für die Messentfernung

l "Y-Zoom": 1-, 2-, 5- und 10-fache Vergrößerung des Signals in

"dB"

l "Unzoom": rücksetzen der Darstellung auf den Nennmessbereich

mit einfacher Vergrößerung

Bei der "Trendkurve" sind verfügbar:

l "X-Zoom": Auflösung

- 1 Minute

- 1 Stunde

- 1 Tag

l "Stopp/Start": Abbruch einer laufenden Aufzeichnung bzw. Beginn

einer neuen Aufzeichnung

l "Unzoom": zurücksetzen der Auflösung auf Minuten

Das Aufzeichnungsraster beträgt als Werkseinstellung 1 Minute. Mit

der Bediensoftware PACTware lässt sich dieses Raster auch auf 1

Stunde oder 1 Tag einstellen.

41787-DE-120229

14 Anzeige- und Bedie

nmodul •

Page 51

Echokurve

5 In Betrieb neh

men - Sensoren bis Software 3.99

Serv

ice/Simulat

ion

In diesem Menüpunkt simulieren Sie beliebige Füllstand- und Druckwerte über den Stromausgang. Damit lässt sich der Signalweg, z. B.

über nachgeschaltete Anzeigegeräte oder die Eingangskarte des

Leitsystems testen.

Folgende Simulationsgrößen stehen zur Auswahl:

l Prozent

l Strom

l Druck (bei Druckmessumformern)

l Distanz (bei Radar und Geführte Mikrowelle)

Bei Profibus PA-Sensoren erfolgt die Auswahl des simulierten Wertes

über den "Channel" im Menü "Grundeinstellungen".

So starten Sie die Simulation:

1 [OK] drücken

2 Mit [->] die gewünschte Simulationsgröße auswählen und mit [OK]

bestätigen.

3 Mit [+] und [->] den gewünschten Zahlenwert einstellen.

4 [OK] drücken

Die Simulation läuft nun, dabei wird bei 4 … 20 mA/HART ein Strom

bzw. bei Profibus PA oder Foundation Fieldbus ein digitaler Wert

ausgegeben.

So brechen Sie die Simulation ab:

à [ESC] drücken

Information:

10 Minute

n nach der letzten Tastenbetätigung wird die Simulation

automatisch abgebrochen.

Serv

ice/Reset

41787-DE-120229

Anzeige- und Bedie

Simulation

Simulation starten?

Mit der Reset-Funktion werden geänderte Werte zurückgesetzt. Dabei

stehen drei abgestufte Unterfunktionen zur Verfügung:

l Grundeinstellung

- Rücksetzen der mit dem Anzeige- und Bedienmodul ge-

änderten Werte auf die sensorspezifische Grundeinstellung

l Werkseinstellung

nmodul • 15

Page 52

5 In Betrieb

nehmen - Sensoren bis Software 3.99

Serv

ice/Abgleic

heinheit

- Wie Grun

zialparametern auf die Defaultwerte

l Schleppzeiger Messwert und Temperatur

deinstellung, darüber hinaus Rücksetzen von Spe-

2)

3)

- Rücksetzen der Min.-/Max.-Werte von Druck, Füllstand und

Temperatur auf die aktuellen Werte

Information:

Da

die Reset-Werte weit gehend sensorspezifisch sind, werden sie in

der Betriebsanleitung des jeweiligen Sensors aufgeführt.

Reset

Reset auswählen?

In diesem Menüpunkt wählen Sie die interne Recheneinheit des

Sensors.

Bei Sensoren mit Radar, geführter Mikrowelle und Ultraschall ist dies

m(d) oder ft(d).

Bei Druckmessumformern stehen umfangreichere Einheiten zur Verfügung. Diese werden in der Betriebsanleitung des jeweiligen

Sensores im Menü "Grundeinstellungen" beschrieben.

Abgleicheinheit

m(d)

Service/Sprache

Der Sensor ist werkseitig auf die bestellte Landessprache eingestellt.

In diesem Menüpunkt ändern Sie die Landessprache. Folgende

Sprachen stehen z. B. in der Softwareversion 3.50 zur Auswahl:

l Deutsch

l English

l Français

l Espanõl

l Pycckuu

l Japanese

l Italiano

l Netherlands

l Japanese

l Chinese

2)

Spezialparameter

auf der Serviceebene kundenspezifisch eingestellt werden.

3)

Temperatur

sind Parameter, die mit

nur bei Druckmessumformern

der Bediensoftware PACTware

und Ultraschallsensoren.

16 Anzeige- und Bedie

41787-DE-120229

nmodul •

Page 53

Sprache

Deutsch

5 In Betrieb neh

men - Sensoren bis Software 3.99

Service/Sensorda

pieren

ten ko-

Mit dieser Funktion werden:

l Parametrierdaten aus dem Sensor in das Anzeige- und Bedien-

modul gelesen

l Parametrierdaten aus dem Anzeige- und Bedienmodul in den

Sensor geschrieben

Die Daten werden in einem EEPROM-Speicher im Anzeige- und

Bedienmodul dauerhaft gespeichert und bleiben auch bei Span-

nungsausfall erhalten. Sie können von dort aus in einen oder mehrere

Sensoren geschrieben oder zur Datensicherung für einen eventuellen

Sensortausch aufbewahrt werden.

Die Art und der Umfang der kopierten Daten hängen vom jeweiligen

Sensor ab.

Information:

Vor

dem Schreiben der Daten in den Sensor wird geprüft, ob die Daten

zum Sensor passen. Falls die Daten nicht passen, so erfolgt eine

Fehlermeldung bzw. wird die Funktion blockiert. Beim Schreiben der

Daten in den Sensor wird angezeigt, von welchem Gerätetyp die

Daten stammen und welche TAG-Nr. dieser Sensor hatte.

Folgende Punkte werden geprüft:

l Softwareversion

l WHG-Zulassung

l SIL aktiviert

l Messprinzip

l Radar C-Band/K-Band

l Radarmessbereich < 30 m oder > 30 m

l Signalausgang

l Druckmessbereich

Sensordaten kopieren

Serv

ice/PIN

41787-DE-120229

Anzeige- und Bedie

Sensordaten kopieren?

In diesem Menüpunkt wird die PIN dauerhaft ak tiviert/deaktiviert. Mit

der Eingabe einer 4-stelligen PIN schützen Sie die Sensordaten vor

unerlaubtem Zugriff und unbeabsichtigten Veränderungen. Ist die PIN

dauerhaft aktiviert, so kann sie in jedem Menüpunkt temporär (d. h. für

ca. 60 Minuten) deaktiviert werden. Die PIN bei Auslieferung ist 0000.

nmodul • 17

Page 54

5 In Betrieb

nehmen - Sensoren bis Software 3.99

PIN

Jetzt dauerhaft aktivieren?

Bei aktiver PIN sind nur noch folgende Funktionen zulässig:

l Menüpunkte anwählen und Daten anzeigen

l Daten aus Sensor in das Anzeige- und Bedienmodul einlesen

Info/Inf

o

In diesem Menü lesen Sie die wichtigsten Information zum Sensor aus:

l Gerätetyp

l Seriennummer: 8-stellige Zahl, z. B. 12345678

Gerätetyp

Seriennummer

12345678

l Kalibrierdatum: Datum der werkseitigen Kalibrierung

l Softwareversion: Ausgabestand der Sensorsoftware

Kalibrierdatum

Softwareversion

l Letzte Änderung über PC: Das Datum der letzten Änderung von

Sensorparametern über PC

Letzte Änderung über PC

l Sensormerkmale, z. B. Zulassung, Prozessanschluss, Dichtung,

Messzelle, Messbereich, Elektronik, Gehäuse, Kabeleinführung,

Stecker, Kabellänge etc.

Sensormerkmale

Jetzt anzeigen?

5.2 Bedienmenü 4 … 20 mA/HART

Displa

y/Display

18 Anzeige- und Bedie

Im Menü "Display" definieren Sie, wie der Messwert auf dem Display

dargestellt wird.

Folgende Werte können angezeigt werden:

41787-DE-120229

nmodul •

Page 55

5 In Betrieb neh

men - Sensoren bis Software 3.99

l Höhe

l Druck (nur

l Distanz (nur bei Radar, Geführte Mikrowelle, Ultraschall)

l Strom

l Skaliert

l Prozent

l Lin.-Prozent

l Temperatur (nur bei Druckmessumformern)

bei Druckmessumformern)

Die Wahl "Skaliert" öffnet die Menüpunkte "Anzeigeeinheit" und

"Skalierung". In "Anzeigeeinheit" gibt es folgende Auswahlmöglichkeiten:

l Höhe

l Masse

l Durchfluss

l Volumen

l Ohne Einheit

Je nach Auswahl stehen wiederum unterschiedliche Einheiten zur

Verfügung.

Im Menüpunkt "Skalierung" wird der gewünschte Zahlenwert mit

Dezimalstelle für 0 % und 100 % des Messwertes eingegeben.

Zwischen dem Anzeigewert im Menü "Display" und der Abgleich-

einheit im Menü "Grundeinstellungen" gibt es folgenden Zusammenhang:

l Bei Radar, Geführte Mikrowelle und Ultraschall bedeutet Anzei-

gewert "Distanz": Darstellung des Messwertes in der gewählten

Abgleicheinheit, z. B. m(d)

l Bei Druck bedeutet Anzeigewert "Druck" bzw. "Höhe": Darstellung

des Messwertes in der gewählten Abgleicheinheit, z. B. bar bzw.

m.

Anzeigewert

41787-DE-120229

Anzeige- und Bedie

Skaliert

▼

Anzeigeeinheit

Volumen

▼

l

▼

Skalierung

0 % = 0.0 l

100 % = 100.0 l

nmodul • 19

Page 56

5 In Betrieb

nehmen - Sensoren bis Software 3.99

ice/Stromausga

Serv

Serv

ice/Funktion

cherheit (SIL)

ng

ale Si-

Im Menüpunkt "Strom

ausgang" legen Sie das Verhalten des Strom-

ausgangs im Betrieb und bei Störungen fest. Die folgende Tabelle

zeigt Ihnen die Auswahlmöglichkeiten.

Stromausgang