Page 1

SpeedExtractor E-916 / E-914

Operation Manual

093218F en

Page 2

Imprint

Product Identification:

Operation Manual (Original), SpeedExtractor E-916 / E-914

093218F en

Publication date: 05.2019

BÜCHI Labortechnik AG

Meierseggstrasse 40

Postfach

CH-9230 Flawil 1

E-Mail: quality@buchi.com

BUCHI reserves the right to make changes to the manual as deemed necessary in the light of experience; especially in respect to structure, illustrations and technical detail.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of this manual without

prior written agreement is also prohibited.

Page 3

Table of contents

Table of contents

1 About this manual .............................................................................................................................................................. 5

1.1 Reference documents ......................................................................................................................................... 5

1.2 Trademarks .............................................................................................................................................................. 5

1.3 Abbreviations ......................................................................................................................................................... 6

2 Safety ...................................................................................................................................................................................... 7

2.1 User qualication .................................................................................................................................................. 7

2.2 Proper use ................................................................................................................................................................ 7

2.3 Improper use .......................................................................................................................................................... 7

2.4 Safety warnings and safety signs used in this manual ............................................................................ 8

2.5 Product safety ......................................................................................................................................................10

2.5.1 General hazards .....................................................................................................................................10

2.5.2 Warning labels on housing and assemblies ................................................................................11

2.5.3 Personal protective equipment .......................................................................................................11

2.5.4 Built-in safety elements and measures .........................................................................................12

2.6 General safety rules ............................................................................................................................................13

3 Technical data .................................................................................................................................................................... 15

3.1 Scope of delivery .................................................................................................................................................15

3.2 Instrument congurations ...............................................................................................................................15

3.3 Materials used ......................................................................................................................................................18

3.4 Technical data overview ...................................................................................................................................18

4 Description of function .................................................................................................................................................. 21

4.1 Functional principle ...........................................................................................................................................21

4.2 Overview of the instrument ............................................................................................................................ 21

4.3 Overview of the extraction process ............................................................................................................. 23

4.4 Schematic representation of the process ..................................................................................................24

4.5 Controls and connections ................................................................................................................................25

4.5.1 Instrument controls ..............................................................................................................................25

4.5.2 Main displays of the instrument ......................................................................................................26

4.5.3 General information on buttons ......................................................................................................29

4.5.4 Rear connections ................................................................................................................................... 30

4.5.5 Side connections ................................................................................................................................... 30

5 Putting into operation .................................................................................................................................................... 31

5.1 Installation site .....................................................................................................................................................31

5.2 Electrical connections ....................................................................................................................................... 32

5.3 Gas and solvent connections..........................................................................................................................33

5.4 Dehydration ..........................................................................................................................................................34

5.5 Functional test .....................................................................................................................................................34

2 SpeedExtractor E-916 / E-914 Operation Manual

Page 4

Table of contents

6 Operation ............................................................................................................................................................................35

6.1 Method development .......................................................................................................................................35

6.2 Preparing the instrument ................................................................................................................................36

6.2.1 Solvent reservoir ....................................................................................................................................36

6.2.2 Modifying the SOLVENT LIST ............................................................................................................37

6.2.3 Preheating the instrument ................................................................................................................38

6.2.4 Activating/deactivating positions ...................................................................................................39

6.2.5 Leak test ....................................................................................................................................................40

6.2.6 Flushing the instrument .....................................................................................................................43

6.2.7 Activating the EcoMode .....................................................................................................................44

6.3 Preparing the sample ........................................................................................................................................45

6.3.1 Sample preparation ..............................................................................................................................45

6.3.2 Extraction cell selection ...................................................................................................................... 46

6.3.3 Packing of the cells ...............................................................................................................................46

6.4 Extraction process ..............................................................................................................................................49

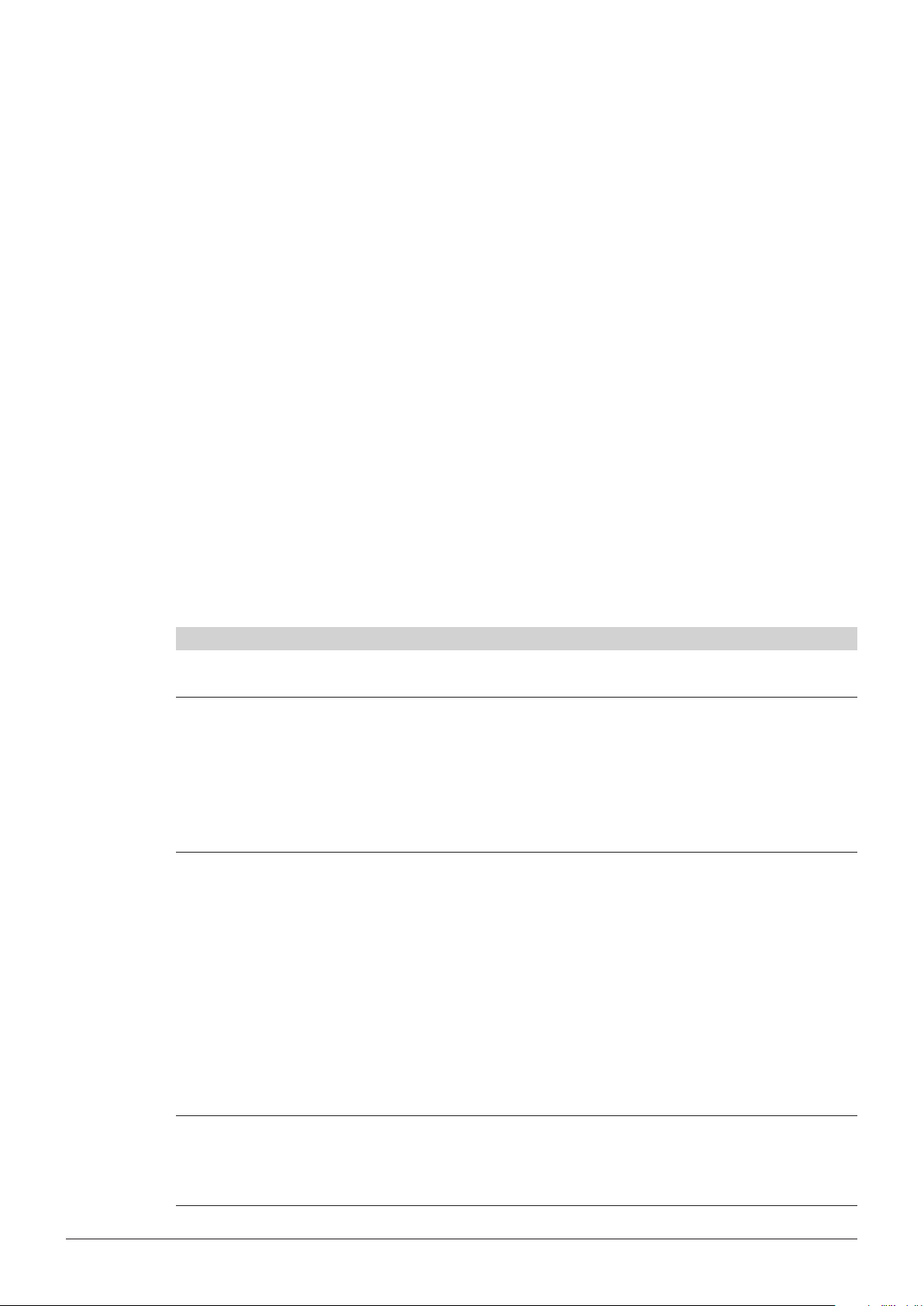

6.4.1 Placing the cells and bottles/vials into the instrument ...........................................................49

6.4.2 Stages of an extraction cycle ............................................................................................................ 50

6.4.3 Creating new methods ........................................................................................................................51

6.4.4 Summary of operating parameters ................................................................................................54

6.4.5 Example of an extraction method ..................................................................................................56

6.4.6 Open an existing method ..................................................................................................................56

6.4.7 Optimize a process ...............................................................................................................................57

6.4.8 Start, pause, stop and abort extraction .........................................................................................58

6.4.9 Post-extraction procedures ...............................................................................................................58

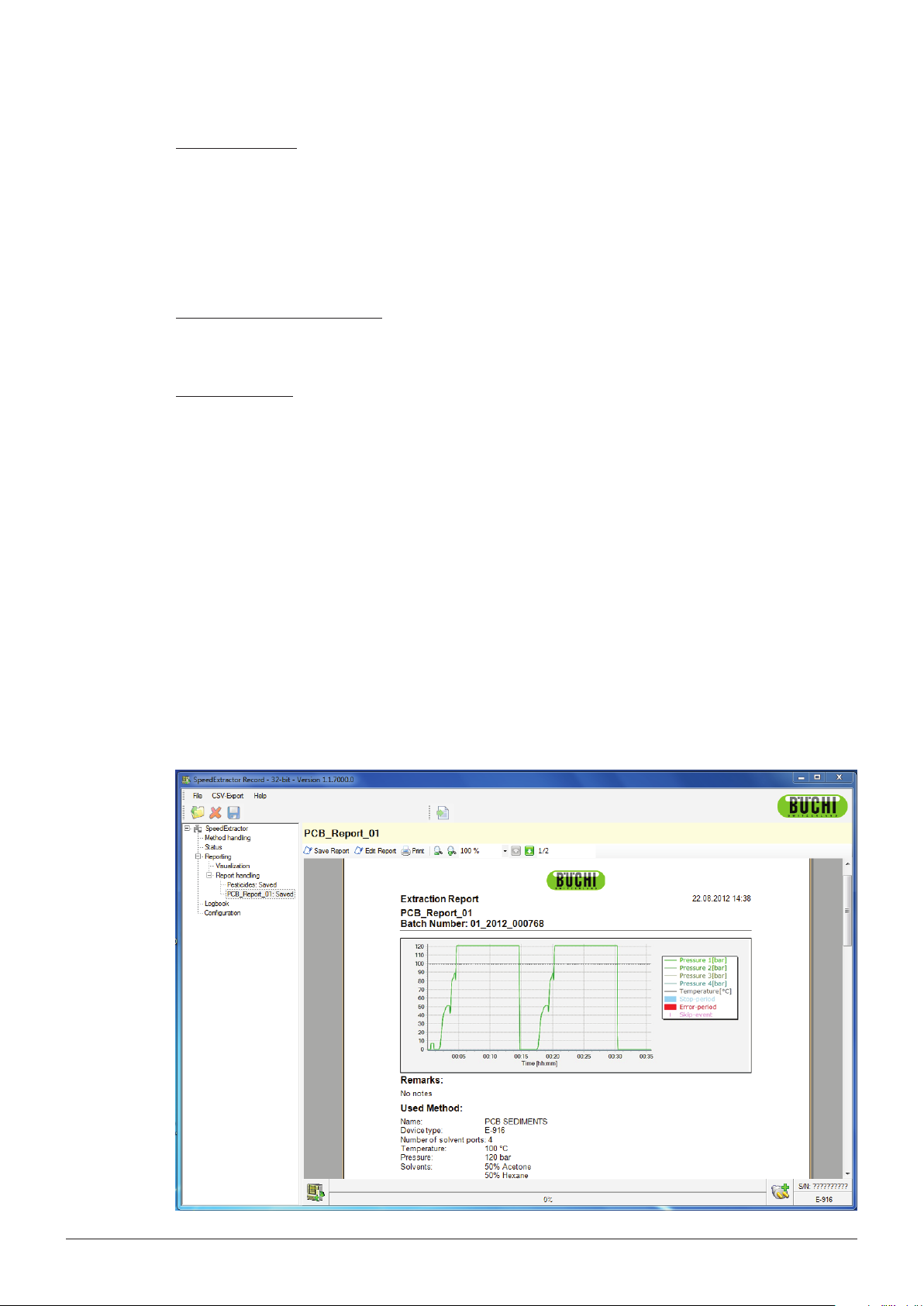

6.5 Creating a report (optional) ............................................................................................................................59

7 Maintenance ....................................................................................................................................................................... 61

7.1 Daily maintenance ..............................................................................................................................................61

7.2 Periodic maintenance .......................................................................................................................................62

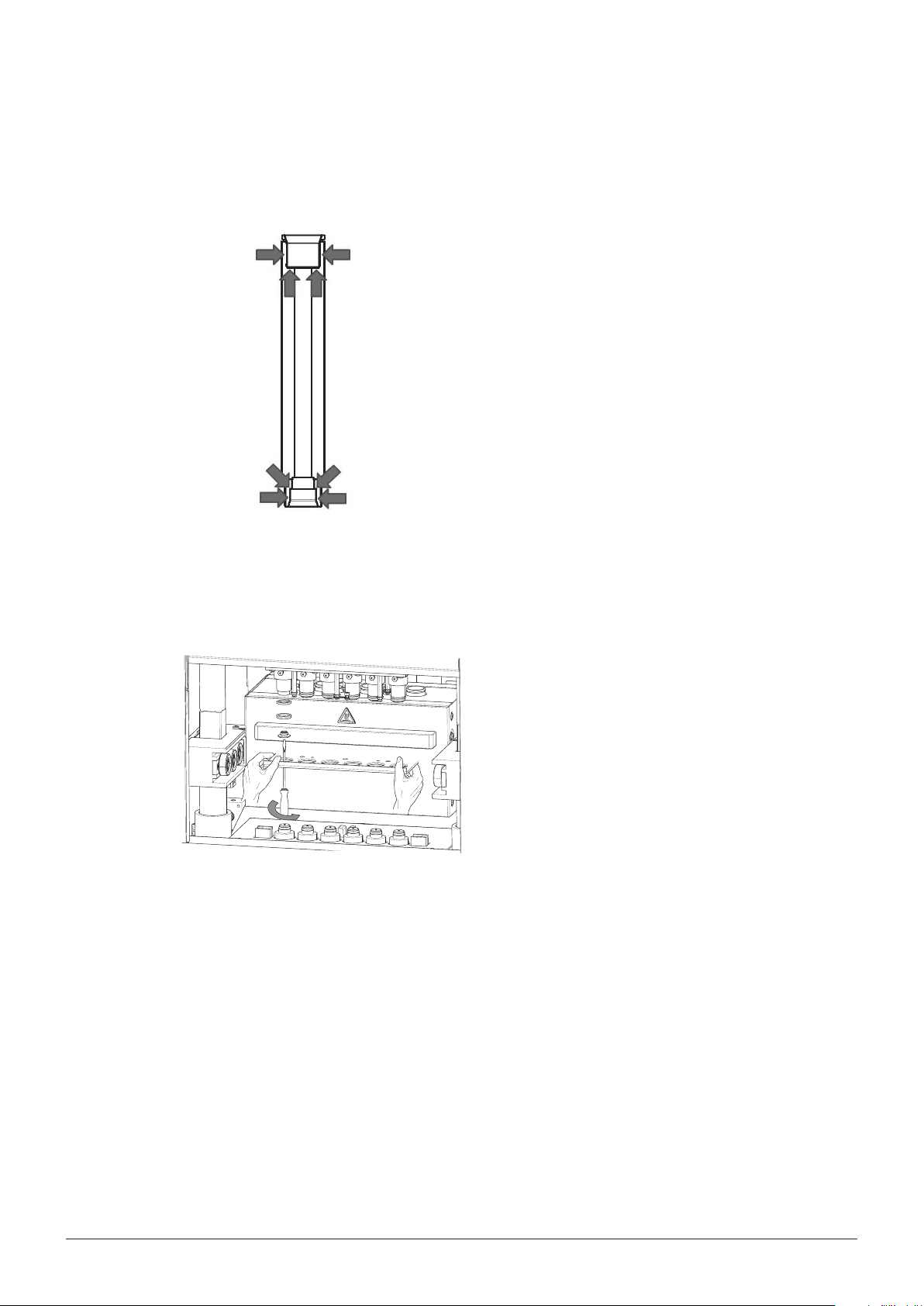

7.2.1 Sealing system........................................................................................................................................62

7.2.2 Replacing the cup seals ......................................................................................................................62

7.2.3 Tube connections and needles ........................................................................................................63

7.2.4 Septum ...................................................................................................................................................... 65

7.3 Pump maintenance ............................................................................................................................................66

7.3.1 Connections ............................................................................................................................................66

7.3.2 Back washing ..........................................................................................................................................67

8 Troubleshooting................................................................................................................................................................69

8.1 Malfunctions and their remedy ..................................................................................................................... 69

8.1.1 Action in case of a re ..........................................................................................................................69

8.1.2 General malfunctions and their remedy .......................................................................................69

8.1.3 Handling and resolving blockages ................................................................................................. 74

8.1.4 The pump is not aspirating properly .............................................................................................79

8.1.5 Replacement of check valves ............................................................................................................80

8.1.6 Precipitation in the outlet lines ........................................................................................................81

8.1.7 Malfunctions of the rotating valves ................................................................................................82

8.1.8 Upgrading a 2-port mixer to a 4-port mixer ................................................................................82

3 SpeedExtractor E-916 / E-914 Operation Manual

Page 5

Table of contents

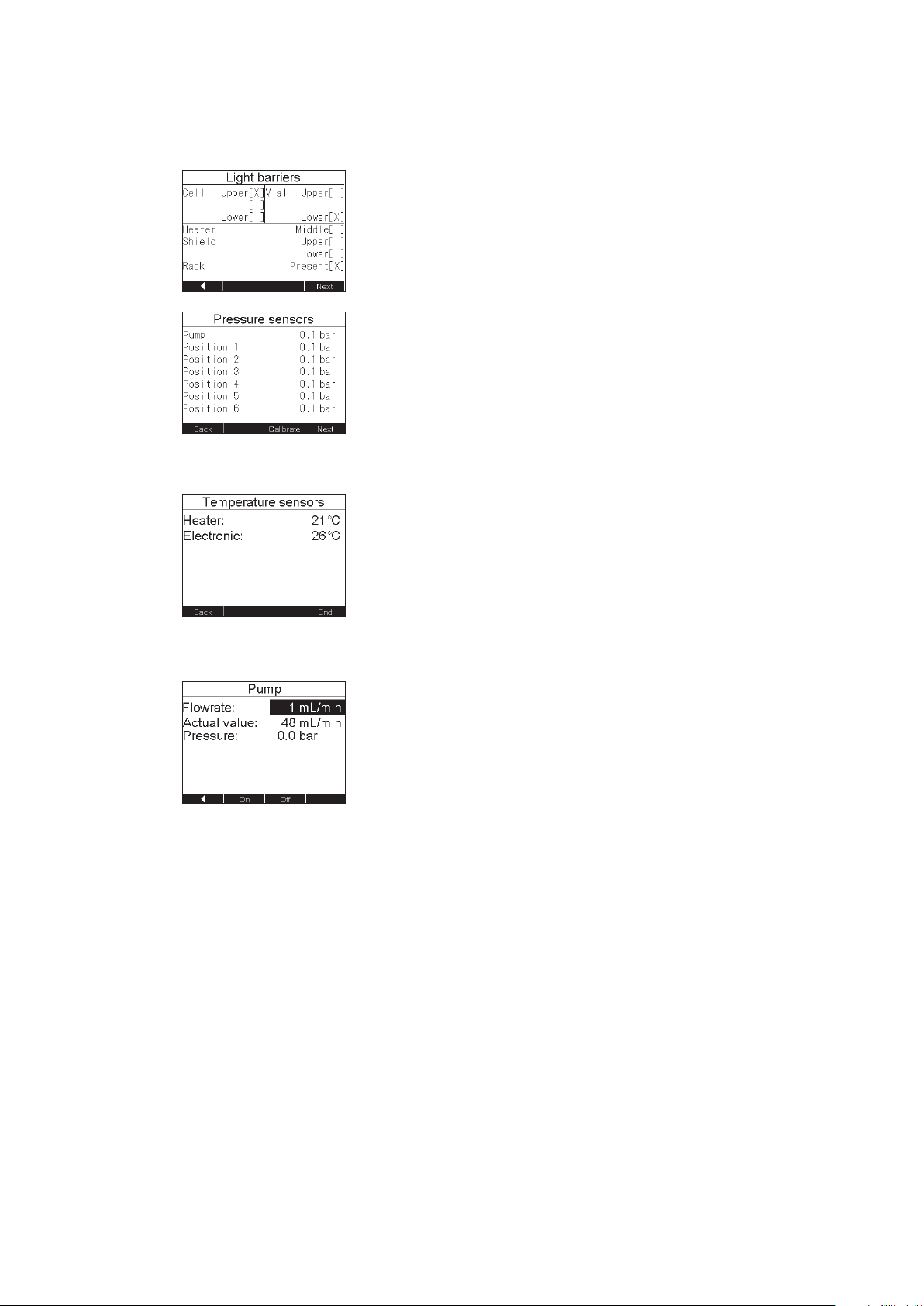

8.2 Description of the service menu ................................................................................................................... 83

8.2.1 Checking the valves .............................................................................................................................84

8.2.2 Checking the sensors ........................................................................................................................... 85

8.2.3 Running the pump ...............................................................................................................................85

8.2.4 Inspecting the lines (ow test) ......................................................................................................... 86

8.2.5 Moving the cell and vial lift ...............................................................................................................88

8.2.6 Changing the fan performance........................................................................................................88

8.2.7 Displaying the operating hours .......................................................................................................88

8.2.8 Unit information ....................................................................................................................................88

8.3 Customer service.................................................................................................................................................89

9 Shutdown, storage, transport and disposal ............................................................................................................91

9.1 Storage and transport ....................................................................................................................................... 91

9.2 Disposal ..................................................................................................................................................................92

9.3 Health and safety clearance ............................................................................................................................93

10 Spare parts .......................................................................................................................................................................... 95

11 Declarations and requirements .................................................................................................................................105

11.1 FCC requirements (for USA and Canada) ................................................................................................105

Read this manual carefully before installing and running your system and note the safety precautions in chapter 2

in particular. Store the manual in the immediate vicinity of the instrument, so that it can be consulted at any time.

No technical modications may be made to the instrument without the prior written agreement of BUCHI. Unauthorized modications may aect the system safety or result in accidents.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of this manual without

prior written agreement is also prohibited.

The English manual is the original language version and serves as basis for all translations into other

languages. If you need another language version of this manual, you can download available versions

at www.buchi.com.

4 SpeedExtractor E-916 / E-914 Operation Manual

Page 6

1 About this manual

This manual describes the SpeedExtractor E-916 / E-914 and provides all information required for

its safe operation and to maintain it in good working order. It is addressed in particular to laboratory

personnel and operators.

NOTE

The symbols pertaining to safety are explained in chapter2.

1.1 Reference documents

For information on complementary BUCHI devices, please refer to the corresponding manuals:

Complementary devices

Multivapor P-6 / P-12, Operation Manual

Vacuum Controller, Operation Manual

Vacuum Pump, Operation Manual

Syncore Platform, Operation Manual

Syncore Accessories, Operation Manual

1 About this manual

NOTE

• All manuals are available via www.buchi.com

• For download a free online registration is required

1.2 Trademarks

The following product names and any registered and unregistered trademarks mentioned in this

manual are used for identication purposes only and remain the exclusive property of their respective

owners:

• SpeedExtractor is a registered trademark of BÜCHI Labortechnik AG

• ASE is a registered trademark of Dionex Corporation

5 SpeedExtractor E-916 / E-914 Operation Manual

Page 7

1.3 Abbreviations

Process-related

ASE Accelerated Solvent Extraction

PSE Pressurized Solvent Extraction

Materials and chemicals

FEP Combination of tetrauoroethylene and hexauoropropylene

FFPM Peruoro caoutchouc

PTFE Polytetrauoroethylene

POM Polyoxymethylene (commercialized as Delrin® by DuPont)

PEEK Polyether ether ketone

THF Tetrahydrofurane

Miscellaneous

FW rm ware

qty quantity

DT Temperature dierence

Dp Pressure dierence

1 About this manual

6 SpeedExtractor E-916 / E-914 Operation Manual

Page 8

2 Safety

This chapter highlights the safety concept of the SpeedExtractor and contains general rules of behavior and warnings about hazards concerning the use of the product.

The safety of users and personnel can only be ensured if these safety instructions and the safety related warnings in the individual chapters are strictly observed and followed, therefore, the manual must

always be available to all persons performing the tasks described herein.

2.1 User qualication

The instrument may be used only by laboratory personnel or other persons who on account of instruction or professional experience have an overview of the dangers that can develop when operating the

instrument.

Personnel without such instruction or persons who are currently being trained require careful supervision.

The present Operation Manual serves as a basis for instruction.

2 Safety

2.2 Proper use

The instrument has been designed and built for laboratory use only. It serves for activities associated

with the parallel extraction of multiple samples by means of heating under pressure. The pressure is

typically applied by the HPLC pump.

2.3 Improper use

Applications beyond those described above are improper. Furthermore, applications that do not

comply with the technical data are also considered improper. The operator bears the sole risk for any

damage caused by such improper use.

The following applications are expressly forbidden:

• Use of solvents with an self ignition point between 40 to 220°C.

• Use of the instrument in rooms that require ex-protected instruments.

• Use as a calibrating instrument for other instruments.

• Preparation of samples that can explode or iname due to shock, friction, heat, or spark formation.

• Use in high pressure situations, i.e. > 200bar.

• Use in conjunction with solvents that have a low self ignition point or contain peroxides, such as

diethyl ether or THF.

• Use of cells, seals, hoses, and tubes other than the originals from BUCHI.

7 SpeedExtractor E-916 / E-914 Operation Manual

Page 9

2.4 Safety warnings and safety signs used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of

hazard seriousness of risks related to personal injury and property damage. All signal words, which are

related to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the table below with the dierent signal

words and their denitions!

Sign Signal word Definition Risk level

!

DANGER

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

2 Safety

★★★★

WARNING

!

CAUTION

!

NOTICE

no

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see below example).

Space for

supplementary

safety

information

symbols.

Table of supplementary safety information symbols

The reference list below incorporates all safety information symbols used in this manual and their

meaning.

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation which, if not avoided, may result

in minor or moderate injury.

Indicates possible property damage, but no

practices related to personal injury.

!

SIGNAL WORD

Supplementary text, describing the kind and level of hazard/risk seriousness.

• List of measures to avoid the herein described, hazard or hazardous situation.

• ...

• ...

★★★☆

★★☆☆

★☆☆☆

(property damage only)

Symbol Meaning

General warning

Electrical hazard

Harmful to life-forms

8 SpeedExtractor E-916 / E-914 Operation Manual

Page 10

Symbol Meaning

Fire hazard

Hot item, hot surface

Device damage

Inhalation of substances

2 Safety

Chemical burns by corrosives

Wear laboratory coat

Wear protective goggles

Wear protective gloves

Heavy weight, lifting requires more than one person

Additional user information

Paragraphs starting with Note transport helpful information for working with the device/software or its

supplementary. Notes are not related to any kind of hazard or damage.

NOTE

Useful tips for the easy operation of the instrument/software.

9 SpeedExtractor E-916 / E-914 Operation Manual

Page 11

2.5 Product safety

The SpeedExtractor has been designed and built in accordance with current state-of-the-art technology. Safety warnings in this manual (as described in section 2.4) serve to make the user alert to and

avoid hazardous situations emanating from residual dangers by giving appropriate counter measures.

However, risks to users, property and the environment can arise when the instrument is damaged,

used carelessly or improperly.

2.5.1 General hazards

The following safety messages show hazards of general kind which may occur when handling the

instrument. The user shall observe all listed counter measures in order to achieve and maintain the

lowest possible level of hazard.

Additional warning messages can be found whenever actions and situations described in this manual

are related to situational hazards.

2 Safety

!

WARNING

Death or serious injuries by formation of explosive atmospheres inside the instrument.

• Before operation, check all gas connections for correct installation

• Regularly discharge the waste bottle to avoid overow

• Check for proper system tightness

!

DANGER

Death or serious injuries by use in explosive environments.

• Do not store or operate the instrument in explosive environments

• Provide sucient ventilation and make sure to directly withdraw fumes

!

WARNING

Death or serious burns by ammable vapors.

• Remove all sources of ammable vapors

• Do not store ammable chemicals in the vicinity of the device

!

CAUTION

Risk of burns by hot heating block and extraction cells.

• Do not touch hot parts or surfaces

• Let the system and inserted extraction cells cool down safely

• Do not move the instrument or parts of it when hot

10 SpeedExtractor E-916 / E-914 Operation Manual

Page 12

2 Safety

Risk of instrument damage by liquids or mechanical shocks.

• Do not spill liquids over the instrument or its components

• Do not move the instrument when it is loaded with sample liquid

• Do not drop the instrument or its components

• Keep external vibrations away from the instrument

• Safely attach the instrument to the bench in earthquake prone regions

• Do not operate the instrument without the safety shield installed

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for sucient grounding

2.5.2 Warning labels on housing and assemblies

The following warning sticker(s) can be found on the housing or assemblies of the SpeedExtractor:

Symbol Meaning Location

NOTICE

NOTICE

Hot item, hot surface Sticker/label, located at the heating block

2.5.3 Personal protective equipment

Always wear personal protective equipment such as protective eye goggles, protective clothing and

gloves. The personal protective equipment must meet all requirements of the supplementary data

sheets for the chemicals used.

!

Serious chemical burns by corrosives.

• Observe supplementary data sheets of all used chemicals.

• Handle corrosives in well ventilated environments only.

• Always wear protective goggles.

• Always wear protective gloves.

• Always wear protective clothes.

• Do not use damaged glassware.

WARNING

11 SpeedExtractor E-916 / E-914 Operation Manual

Page 13

2.5.4 Built-in safety elements and measures

• The heating element is equipped with overtemperature protection which is activated at

260°C±10°C.

• The pressure parts are protected by a mechanical pressure control valve which is activated at

200bar±20bar.

• To start a program at least one extraction position must be activated.

• Safety shield sensor: To start an extraction the protection shield must be closed.

• Vial rack sensor: To start an extraction the vial rack must be installed.

• The presence of extraction cells in the heating block is checked in the tightness test at the beginning of each extraction process.

2 Safety

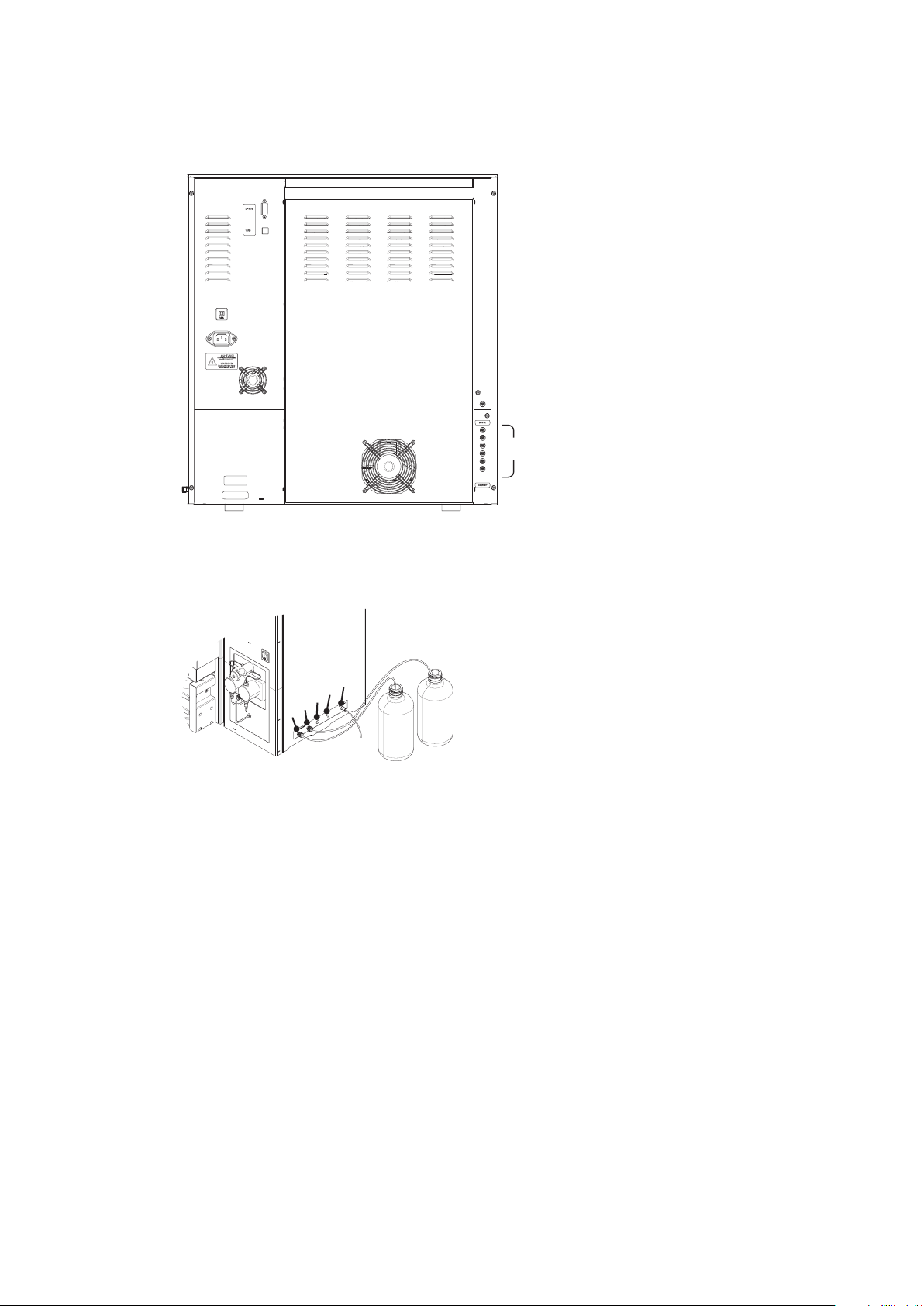

Seismic tie-down

In earthquake-susceptible regions the instrument

should be tied down by the ventilation slot on the

rear of the instrument.

12 SpeedExtractor E-916 / E-914 Operation Manual

Page 14

2.6 General safety rules

Responsibility of the operator

The head of the laboratory is responsible for training his/her personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during operation of the instrument or its accessories. Legal regulations, such as local, state and

federal laws applying to the instrument or its accessories must be strictly followed.

Duty of maintenance and care

The operator is responsible for the proper condition of instrument. This includes maintenance, service

and repair jobs that are performed on schedule by authorized personnel only.

Spare parts to be used

Use only genuine consumables and spare parts for maintenance to assure good system performance,

reliability and safety. Any modications of spare parts or assemblies are only allowed with the prior

written permission of the manufacturer.

Modications

Modications to the instrument are only permitted after prior consultation and with the written approval

of the manufacturer. Modications and upgrades shall only be carried out by an authorized BUCHI

technical engineer. The manufacturer will decline any claim resulting from unauthorized modications.

2 Safety

13 SpeedExtractor E-916 / E-914 Operation Manual

Page 15

2 Safety

14 SpeedExtractor E-916 / E-914 Operation Manual

Page 16

3 Technical data

This chapter introduces the reader to the SpeedExtractor and its main components. It contains technical data, requirements and performance data.

3.1 Scope of delivery

Check the scope of delivery according to the order number and your shipping note.

NOTE

For detailed information on the listed products, see www.buchi.com or contact your local dealer.

3.2 Instrument congurations

The SpeedExtractor is available in 18 dierent congurations diering in the number of positions (E-916:

6 positions, E-914: 4 positions), the type of solvent mixer (2 ports or 4 ports), and the size of the extraction

cells (E-916: 10 – 40mL, E-914: 10 – 120mL). The SpeedExtractor E-914 is available with and without pedestal (the pedestal allows to accommodate large volume collection recipients).

3 Technical data

E-914 without and with pedestal

15 SpeedExtractor E-916 / E-914 Operation Manual

Page 17

3 Technical data

1 1

5 1

c

Number of positions

4 E-914: 4 positions

5 E-914: 4 positions mounted on pedestal

6 E-916: 6 positions

Size of extraction cells

01 10mL (E-916 only)

02 20mL (E-916 only)

04 40mL

08 80mL (E-914 only)

12 120mL (E-914 only)

Number of solvent ports

2 Ports

4 Ports

d

e

f

i

p

j

q

b

k

r

s

m

l

t

053691 053690

a

h

g

n

o

List of loose parts

Position Item PU Universal Order no. E-914 Order no. E-916

a

b

c

d

e

f

g

h

i

FEP tube D3.2/1.6, 5m 2 110556 0 4

FEP waste tube 1/16", 0.5m 4/6 053303

Solvent bottle 1 L 1 053203

Quartz sand 0.3–0.9mm, 2.5kg 1 037689

Extraction Record demo license 1 053074

Extraction cell carrier 1

Solvent lter 4 044340

Turix wrench 1 044349

Allen wrench 3mm 1 000610

16 SpeedExtractor E-916 / E-914 Operation Manual

Page 18

c

3 Technical data

d

e

f

i

p

j

q

b

k

r

s

l

t

m

053671 053669

051249 049572

1

110 55342

053038 053037

a

h

g

n

o

List of loose parts

Position Item PU Universal Order no. E-914 Order no. E-916

j

k

l

m

n

o

p

p

q

q

r

s

s

t

t

Spanner wrench 1/4" 1 053204

Spanner wrench 8/10mm 1 053608

Torx screwdriver TX20 1 053668

USB cable 2.0 A-B, 4.5m 1 049226

Plug screws 2 053209

Metal frit 25 049568

Cup seals, top 12

Cup seals, bottom 12 053670

Cellulose lter, top 100

Glass ber lter, bottom 100 110 5 59 32

Swagelok nut and ferrules 1/8"

UNF-28 Fitting 1/8", green 10 053663

UNF-28 Ferrule 1/8", green 10 053664

UNF-28 Fitting 1/16", gray 25 044816

UNF-28 Ferrule 1/16", gray 25 044269

Supporting ring PEEK 2 053667 053666

Filter hook 1 053316

Plunger 1

Syringe 60mL 1 034882

Brush small 1 053256

Brush large 1 053257

Gripper extraction cell 1

Bit wrench 1 052783

Extruder rod 1 1105528 4

Tub e cutter 1 019830

17 SpeedExtractor E-916 / E-914 Operation Manual

053026 053030

Page 19

3.3 Materials used

Materials used

Component Material designation

Housing SpeedExtractor Stainless steel

Lines to pump FEP

Solvent valve PEEK, FFPM

Mixer PEEK, FFPM

Media valve PEEK, PTFE

Lines to and from heating block Stainless steel

Pressure gauges Stainless steel

Position valves Stainless steel, PTFE

Outlet valves PEEK, PTFE

Heating block Aluminum

Heating block cover PTFE

Cup seals PTFE

Extraction cells Stainless steel

Lines to waste FEP

Needles Stainless steel

Collection vials Glass

Septa for vials Silicon, PTFE

Collection unit Stainless steel, POM

Pump PTFE, ceramic, stainless steel

Protective shield Glass, POM

3 Technical data

3.4 Technical data overview

Technical data of the SpeedExtractor

Description

Dimensions (W×H×D)

Weight

Connection voltage

Max. power consumption

Mains connection

Frequency

Fuse

Interface

Installation category

Degree of protection

Pollution degree

Temperature control range

Temperature accuracy

Technical data

670×725×500mm

90kg

100 – 240VAC ±10%

max. 1750W

3-pole (P, N, E) via power cord

50/60Hz

14 A/240V

USB 2.0

II

IP21

2

30 – 200°C

±3°C

18 SpeedExtractor E-916 / E-914 Operation Manual

Page 20

Technical data of the SpeedExtractor

Description

Pressure range

Pressure accuracy

Primary pressure nitrogen connection

Flow rate pump

Precision ow rate

Precision mixer

Extraction cell size

Environmental conditions

Temperature

Altitude

Humidity

Noise level

3 Technical data

Technical data

50 – 150bar

±5bar

6 – 10bar

1 – 50mL/min

±2%

±2% (±5% for isopropanol)

E-916: 10, 20, 40mL; E-914: 10*, 20*, 40, 80, 120mL

For indoor use only

5 – 40°C

up to 2000m

maximum relative humidity 80% for temperatures

up to 31°C, and then linearly decreasing to 50%

at 40°C

<70dB

*Accessories

19 SpeedExtractor E-916 / E-914 Operation Manual

Page 21

3 Technical data

20 SpeedExtractor E-916 / E-914 Operation Manual

Page 22

4 Description of function

This chapter explains the basic principle of the SpeedExtractor E-916 / E-914 and provides a functional

description of the assemblies.

4.1 Functional principle

The SpeedExtractor E-916 / E-914 is an automated instrument for parallel extraction of primarily organic

compounds from a variety of solid or semi-solid samples. Conventional methodologies are accelerated

by using a solvent at elevated temperatures. In order to maintain the solvent in a liquid state during the

extraction process, the solvent inside the extraction cell is put under pressure. Generally, to achieve

high recoveries multiple extraction cycles are applied. Once the extraction step is nished, the extracts

are cooled down in a cooling unit and ushed into collection vials which then can easily be evaporated

in parallel using the Multivapor™ P-6 or Syncore Analyst R-12. Hence the whole process workow can

be performed in parallel with up to 6 samples.

4 Description of function

The SpeedExtractor E-916 accommodates 6 samples with a maximum volume of 40mL, whereas the

E-914 can be used for up to 4 samples with a limited maximum volume of 120mL. The total volume of

the collection recipients are from 60 mL vials to 240mL bottles. Using a specially designed rack, it is

also possible to use large volume round bottom asks to collect the extracts.

Typical applications are carried out in environmental substances (environmental pollutants such as those

listed in EPA Method 3545A for instance), food (recovery of fat from meat, oil seeds, feeds, dairy products, snack foods, etc.), pharmaceuticals (extracting analytes from natural products, drugs from drug

formulations, pharmaceutical additives from feeds) and polymers (monomeric compounds, oligomers

or additives).

4.2 Overview of the instrument

e

g

d

a

h

b

f

c

21 SpeedExtractor E-916 / E-914 Operation Manual

N

2

j

i

Page 23

4 Description of function

a Main power switch

The instrument is protected by a 14 A (240V) circuit breaker. The main fuse button at the rear of the

instrument must be pushed in.

b Solvent reservoir

The maximum possible number of solvent bottles depends on the type of mixer. With the 2-port mixer

up to 2 dierent solvents, with the 4-port mixer up to 4 dierent solvents can be connected allowing

any user-dened solvent ratios.

c Solvent pump and solvent mixer

A self-priming HPLC pump transfers the extraction solvent from dierent solvent reservoirs to the mixer

and from there into the extraction cell. With the control panel arbitrary solvent ratios can be chosen.

d Heating block

The heating block accommodates 6 or 4 extraction cells and guarantees an accurate and uniform

heat distribution across all extraction positions independent of the placement. The whole block is easily pulled out horizontally facilitating the accommodation of the extraction cells. Magnetic connections

on the heating block and on guide rail make sure that the heating block is correctly placed in a dened

middle position, ready for operation. The protection shield protects the operator from hot surfaces and

movable parts during operation.

e Extraction cells

The extraction cells are tailored to the dimensions of the holes in the heating block guarantying an efcient and accurate heat transfer into the sample. The sample volume of the cells diers from 10–40mL

for the E-916 and from 10 – 120mL for the E-914.

f Collection rack

Up to 6 collection vials are loaded into the collection unit. After extraction, the extracts containing the

analytes are collected in these bottles. Dierent collection units and adapters are available to accommodate small vials up to large volume round bottom asks. See chapter 10.

g Control panel

The control panel containing a liquid crystal display (LCD) and membrane keypads allows to program

the full extraction process. Detailed schematic representations inform the operator about the current

stage of the process as well as possible errors.

h Nitrogen inlet

The nitrogen gas inlet connection is located on the right hand side next to the solvent connections. It

is used to get rid of residual solvent by ushing the lines and cells thoroughly with nitrogen and/or to

inerting the system. Inerting the receiving vials is for the stability of some analytes benecial. Nitrogen

pressure of 6 – 10bar is required for proper operation. To avoid any contamination by ushing with

nitrogen 5.0 quality (i.e. vol.-% > 99.999) is recommended for trace analysis and 4.5 (i.e. vol.-% >

99.995) for other applications.

i Waste outlets

An 18-port valve located between the heating block and the collection rack allows collecting the

extract leaving the extraction cells either in the collection bottle or a waste bottle. The latter is in particular benecial when the solvent is changed or the lines are ushed upon contamination. The number

of waste outlets is determined by the instrument conguration! The E-916 features 6, the E-914 only 4

outlet ports.

j Exhaust

The collection vials are sealed by septum. A stainless steel needle pierces this septum allowing the

extract to ow from the extraction cell into the collection bottle. To compensate the pressure a second

needle connects the collection bottle with an exhaust joint situated on the rear of the instrument.

22 SpeedExtractor E-916 / E-914 Operation Manual

Page 24

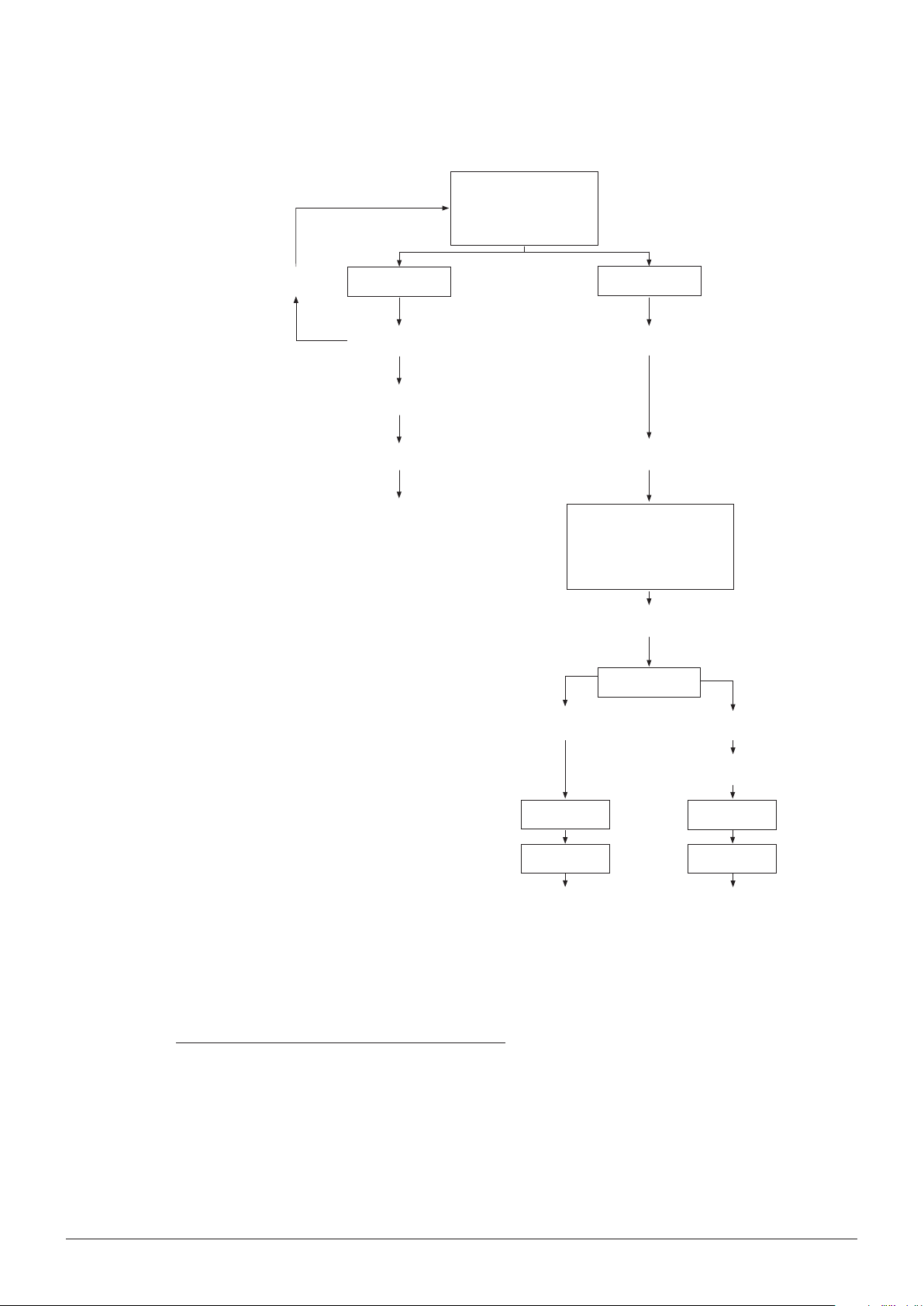

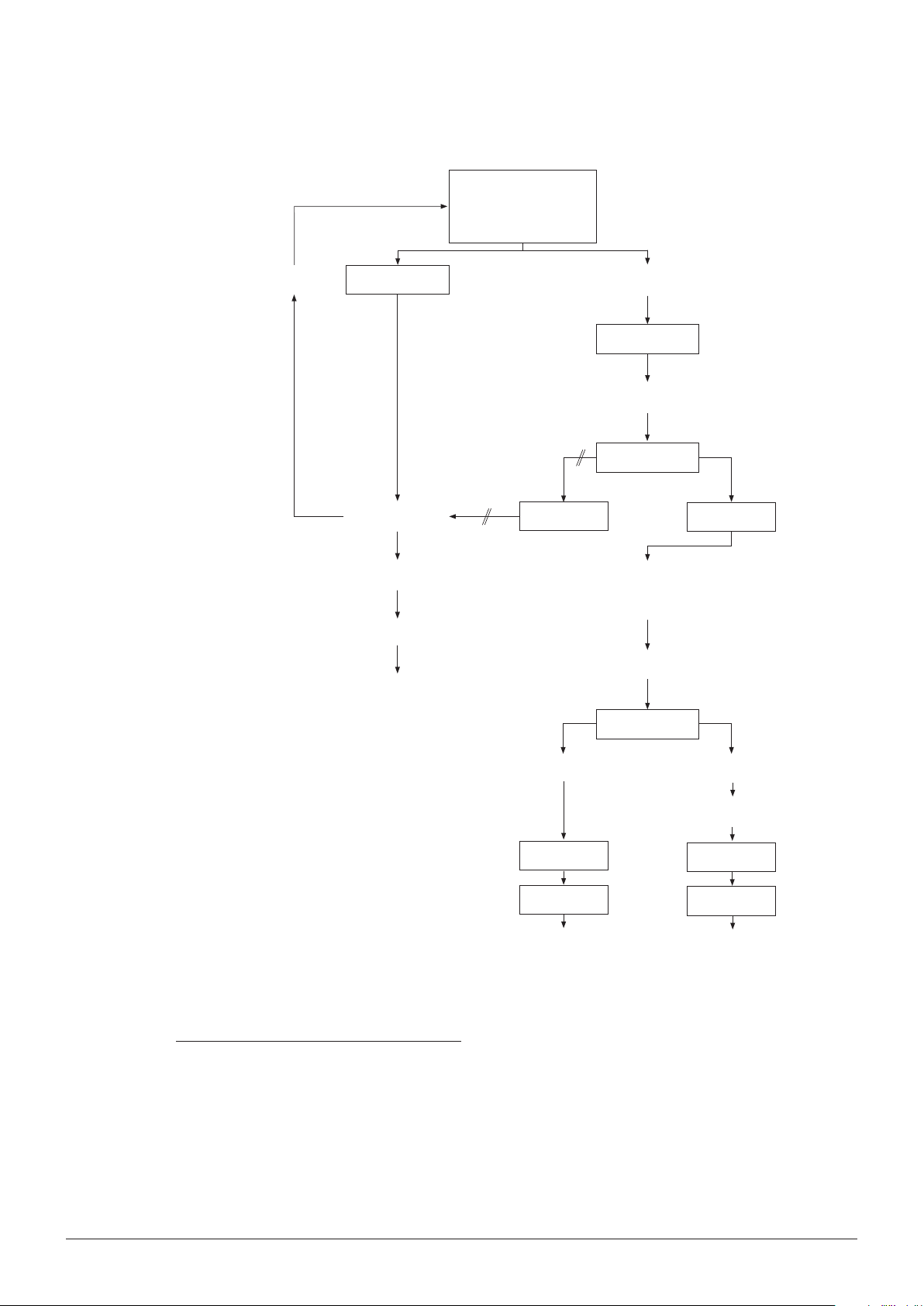

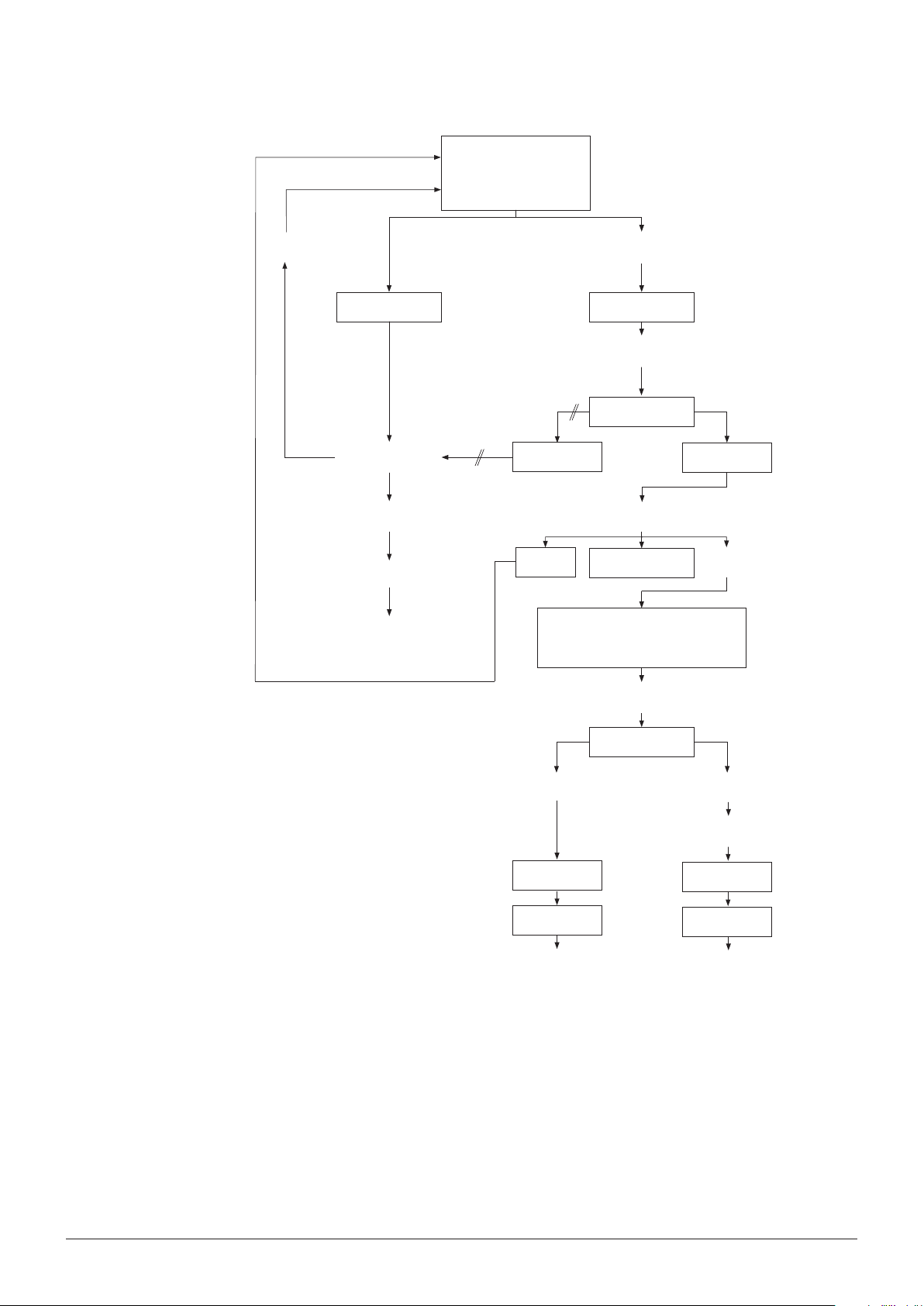

4.3 Overview of the extraction process

A complete extraction process involves the following phases:

Phase 1: Preparation

• Creating an extraction method (see section 6.2.3).

• Preparing the instrument for operation. This involves lling the solvent reservoirs and preheating

the instrument to the temperature of operation (equilibration), see section 6.2.3.

• Packing the extraction cell with the sample (see section 6.2.3).

• Placing the collection vials in the collection tray (see section 6.4.1).

• Placing the extraction cell into the preheated heating block (see section 6.4.1).

Phase 2: Extraction cycles

• Start extraction method (see section 6.4.8).

An extraction cycle involves three steps with a user-dened time period (except for HEAT UP):

In a rst HEAT UP step the pressure and temperature inside the extraction cell is slowly increased to

the set parameters of extraction program.

During HOLD step these parameters remain constant. This corresponds with the literal extraction step

at constant temperatures and pressures. After this step the outlet valve opens and the liquid extract

is DISCHARGEd and collected in collection vials or a waste bottle by means of pressure compensation. All three steps are repeated several times according to the extraction program. A complete run

may consist of 1 – 10 extraction cycles. The presence of extraction cells is checked in the TIGHTNESS

TEST at the beginning of each extraction process.

4 Description of function

The HEAT UP step is not accessible by the user but is determined by the instrument software. The

absolute time of this period depends on the temperature, pressure, size of the extraction cell and type

of sample. Additional time is needed to ll the extraction cell. The HOLD and the DISCHARGE time

can be dened by the user individually for each cycle.

The actual time used for a complete process is shown in the STATUS menu and/or recorded by

SpeedExtractor Record software, where it can be exported to a report and printed out.

Phase 3: Flushing the lines and unloading the heating block

• Flushing the lines with fresh solvent and collecting the liquid in the collection vials (see section 6.4.2).

• Flushing with nitrogen to remove residual solvent (see section 6.4.2).

• Unloading the heating block (see section 6.4.9).

NOTE

Preheating the instrument to the temperature of operation prior to loading it with the extraction

23 SpeedExtractor E-916 / E-914 Operation Manual

Page 25

cells is absolutely mandatory. Placing the cells in the cold instrument followed by heating up the

closed system might damage the cup seals. It is therefore crucial to note that the temperature of the

instrument must not be changed once the system is closed. The instrument is ready once the set

temperature is reached (which is shown in the main display) and the extraction process is started by

pressing START. In order to achieve reproducible results, it is recommended that the same procedure always be followed. As the time used to reach the set temperature is depending on the absolute

set temperature, it is suggested that the extraction cells never be placed in the heating block until the

instrument is ready and to start the extraction process right away. This procedure guarantees that

the sample is not unnecessarily exposed to the hot environment and that this time period before the

actual process starts does not signicantly inuence the recovery of the extraction process.

In addition, placing extraction cells in all positions is highly recommended even though not all positions are used. This improves the heat uniformity of the heating block. It is possible to deactivate the

positions with the empty cells to avoid needless solvent consumption.

4.4 Schematic representation of the process

4 Description of function

The following illustration provides a schematic representation of the pathways of the dierent media

for the E-916. Up to four dierent solventsa and nitrogenb are connected to the E-916. A media

valvef switches between solvent and nitrogen. The mixerd mixes the solvents that are selected

with the help of the solvent valvesc.

The pumpe transfers the solvent mixture to dividerg where it is equally distributed to each of the

activated positions. Once the system is sealed by closing the extraction cellsl with the upper and

lower tightening device that holds the cup sealsk andm, the outlet valveo is closed in order to

increase the pressure inside the system. The pressure of each position is displayed by the pressure

sensorsj. When the set pressure is reached (at the end of the heat-up step) the position valvesi

are permanently closed, and the sample is extracted (hold step). In the discharge step the outlet

valveo opens, the hot mixture is cooled down by the cooling unitsn and nally transferred to the

collection vialsp. Pressure compensation is achieved by the lines to the exhaustq. In case of an

overpressure, the outlet valve opens and releases solvent into the collection vials. Residual solvent

is optionally ushed with fresh solvent. An additional thorough ushing step with nitrogen removes

residual solvent in the lines. In addition, another optional ushing with solvent into waste instead of the

collection vials is possible by setting the outlet valve to waster. This is usually done to prepare the

system for another run with a dierent solvent. For a thorough description of each step please refer to

section 6.4.

24 SpeedExtractor E-916 / E-914 Operation Manual

Page 26

r

N

h

n

4 Description of function

a Solvent reservoirs (3 and 4 optional)

b

2

a

b Nitrogen tank

c Solvent valves

d Mixer

e Pump

c

f Media valve

g Divider

f

e

d

h Overpressure valve

i Position valves

j Pressure sensors

j

g

k Upper cup seals

l Extraction cells

i

m Lower cup seals

n Cooling units

j

k

l

o Outlet valve

p Collection vials

q Exhaust

r Waste

m

o

q

4.5 Controls and connections

4.5.1 Instrument controls

a

b

c

d

e

p

a Display to view the instrument software.

b Function buttons to operate the instrument soft-

ware.

c START button to start an extraction.

d The STOP button comprises 3 functions:

• press once: pause the process and continue by

pressing START again

• press twice: interrupts the process and continues

with ushing using solvent and gas

• press three times: stops the process immediately,

i.e. the system remains at the very position of the

process

For more information see section 6.4.8.

e Selection knob to dene values within the instru-

ment software.

25 SpeedExtractor E-916 / E-914 Operation Manual

Page 27

NOTE

The START and STOP buttons are used only for the extraction method but have no eect on functions such as preheat, leak test, or ush. All functions apart from extractions are initiated by function

buttonsb.

4.5.2 Main displays of the instrument

4 Description of function

A

B C D

A The main display shows the most important parameters of the extraction process, such as the

activated positions in the heating block, the maximum pressure at the position valves, the temperature of the heating block, the number of extraction cycles, as well as the current cycle and the time

remaining to the end of the process. The status and total remaining time are also shown in the main

display. With the function buttons the three main displays STATUS, EXTRACTION and MENU are

accessible.

B STATUS shows a diagram of the lines, valves, solvent reservoirs, extraction cells, and collection vials

of the instrument. The valves open and close according to the stage of the method and the number of activated positions. As the name already indicates, this menu is very benecial to get a quick

overview of the current status of operation.

C EXTRACTION is used to edit and save a new method or to open or delete an existing method. It

also includes two functions that are required prior to operation: activation of the extraction positions

(OCCUPIED POSITIONS) and preheating of the instrument to the operating temperature (PREHEAT).

D MENU involves all functions that are not directly involved in an extraction method but are typically

used at start-up, during maintenance, and service, and for product information.

These four main displays contain the following elements:

26 SpeedExtractor E-916 / E-914 Operation Manual

Page 28

4 Description of function

c

f

g

i

k

l

a b

i

h g f

j

o

d

n

j

m

a Current extraction cycle/total extraction cycles

b Name of the current extraction method. When the name is

d

e

h

b

e

c

a

crossed out (DEFAULT), the current method has been changed

and not yet saved (see section 6.4.3).

c Total remaining time of the extraction process.

d Status: PREHEAT, READY, all methods steps, PAUSE, and

ABORT.

e System symbols like HEATING ( ), PUMPING ( ) or PC

CONNECTION ( ) are reversed or in case of PUMPING rotating when being active.

f Extraction positions. When the symbol is crossed out the cor-

responding position is deactivated (see section 6.4.2).

g Temperature of the heating block.

h Maximum pressure.

i Function buttons for the STATUS, EXTRACTION and MENU

submenus.

j To skip extraction steps or to stop running leak test

a Solvent reservoirs (2 or 4 ports depending on the mixer)

b Nitrogen tank

c Solvent valves

d Mixer

e Pump

f Media valve

g Overall pressure sensor

h Divider

i Position valves

j Pressure sensors for each extraction position

k Extraction cells (E-916: 6 pos.; E-914: 4 pos.)

l Outlet valve: Discharging into waste or collection vials

m NEXT opens a submenu where the progress of extraction run is

shown (see below).

n Waste bottle

o Collection vials

a Remaining time to nish the current extraction cycle.

a

b

c

d e

a

b

c

d

e

f

27 SpeedExtractor E-916 / E-914 Operation Manual

b Remaining time for the next manual override, i.e. exchange

of the collection vials. This only applies to methods where the

function VIAL CHANGE is activated (see section 6.4.3).

c Total remaining time to nish the extraction run.

d BACK goes to the previous STATUS overview.

e END goes back to the main display.

a Denition of the number of positions (see section 6.2.4).

b Heating up the instrument to operation temperature (see sec-

tion 6.2.3).

c Editing an existing (or default) extraction method (see section

6.4.3).

d Open an existing extraction method (see section 6.4.6).

e Save a previously edited extraction method (see section 6.4.3).

f Delete an existing extraction method (see section 6.4.3).

Page 29

4 Description of function

a

b

c

d

e

a Performing a LEAK TEST (see section 6.2.5).

b Flushing the lines with solvent in collection vials or a waste

bottle. Parameters like time, ow rate and solvent mixtures are

dened in submenus (see section 6.2.6).

c Dening instrument settings like language, contrast of the dis-

play, acoustic signals, preheat demand when the instrument is

turned on.

d SOLVENT LIST shows the default solvent list which includes the

10most frequently used solvents. This list can be edited and

modied as needed (see section 6.2.2).

e The SERVICE FUNCTIONS submenu provides access to

main instrument components for rst quick trouble shooting

purposes. All valves can individually be opened or closed. All

safety sensors which check the position of the heating block,

safety shield or collection rack as well as all pressure sensors

are listed. The pump can be directly operated with dierent

ow rates. With the help of a ow test faulty lines can easily be

located. The lift of the heating block and collection rack can

be driven independently. The performance of the fan can be

changed. Information about instrument and operating hours are

shown. For further information see section 8.2.

NOTE

Some submenus contain hidden lines as it is not possible to

show all information on the display. In this case a scroll bar

on the right hand side indicates the presence of hidden lines.

Move down with down button to get access to this information.

28 SpeedExtractor E-916 / E-914 Operation Manual

Page 30

4.5.3 General information on buttons

The following control buttons are available in the software for navigation and input conguration:

Open the extraction menu

Open the menu functions like leak test, instrument settings etc.

Open the status menu

Get back to the previous screen

Get on to the next screen or entries of a screen

Leave the current screen and get back to the main display

Get back to the start screen without saving possible settings

Backward button to move backward within the submenu structure

Forward button to move forward within the submenu structure

Move up within the entries of a screen

4 Description of function

Move down within the entries of a screen

Arm a screen message

Negate a screen message

Switch on the position or function

Switch o the position of function

Switch on all extraction positions

Copy the entry of currently active parameter of the extraction method to the LEAK

TEST or copy the entries of an extraction cycles

Paste the entries of a copied extraction cycle to a new cycle

Start process except for the extraction process (leak test, ush etc.)

Open the solvent list to select a default solvent

Edit the name of a solvent in the solvent list or the entries of an extraction cycle

Delete all characters of an entry when naming a solvent/program

Conrm the selection of a character when naming a solvent/program

Save a solvent/program under the entered name

Load the predened solvents by replacing the rst 10 entries of the list

Move lift (heating block or rack) up

Move lift (heating block or rack) down

Stop moving the lift

Skip an extraction step or stop the running leak test

29 SpeedExtractor E-916 / E-914 Operation Manual

Page 31

4.5.4 Rear connections

4 Description of function

4.5.5 Side connections

b

a

c

d

b

c

d

e

a

a Mains supply

b Main fuse

c RS232 port

d USB 2.0 port

e Exhaust outlet for purging with nitrogen,

discharge and tightness test

f Waste outlet for ushing with solvent or

collecting extracts

e

f

a Nitrogen inlet

b Solvent 1

c Solvent 2

d Optional (with 4-port mixer only): solvent 3

e Optional (with 4-port mixer only): solvent 4

N

2

30 SpeedExtractor E-916 / E-914 Operation Manual

Page 32

5 Putting into operation

This chapter describes the installation of the SpeedExtractor and gives instructions on initial start-up.

NOTE

Inspect the instrument for damages during unpacking. If necessary, prepare a status report immediately to inform the postal company, railway company or transport company. Keep the original

packaging for future transport.

5.1 Installation site

Put the instrument on a stable, horizontal surface. Consider the maximum product dimensions and

weight. Obtain the environmental conditions as described in section 3.4, technical data.

Installation prerequisites:

• Do not place any objects on top or below the instrument or parts of it.

• The instrument must be installed with 5cm clearance to any other objects or walls to allow sufcient cooling.

• Do not store containers, chemicals or other items behind the instrument.

5 Putting into operation

!

WARNING

Death or serious injuries by use in explosive environments.

• Do not operate the instrument in explosive environments

• Do not operate the instrument with explosive gas mixtures

• Before operation, check all gas connections for correct installation

• Directly withdraw released gases and gaseous substances by sucient ventilation

CAUTION

!

Risk of minor or moderate injury by heavy weight of the instrument.

• Consult three further persons to transport the instrument

• Do not drop the instrument

• Place the instrument on a stable, even and vibration-free surface

• Keep limbs out of crushing zone

Risk of instrument damage by liquids or mechanical shocks.

• Do not spill liquids over the instrument or its components

• Do not move the instrument when it is loaded with sample liquid

• Do not drop the instrument or its components

• Keep external vibrations away from the instrument

• Safely attach the instrument to the bench in earthquake prone regions

• Do not operate the instrument without the protection cover installed at the front

NOTICE

31 SpeedExtractor E-916 / E-914 Operation Manual

Page 33

5 Putting into operation

NOTE

The instrument does not have to be operated under

a fume hood but the exhaust must lead into some

kind of ventilation device.

Never hold the instrument on the collection rack or

pump heads to move the instrument. Always use the

handles on the side.

5.2 Electrical connections

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for sucient grounding

NOTE

• External connections and extension lines must be provided with a grounded conductor lead

(3-pole couplings, cord or plug equipment). All used power cords must meet the input power

requirements.

NOTICE

32 SpeedExtractor E-916 / E-914 Operation Manual

Page 34

5.3 Gas and solvent connections

5 Putting into operation

• Connect nitrogen gas by means of the provided

hose. The corresponding joint contains a quicklock mechanism. The nitrogen gas connection

is located on the right hand side panel. The

required pressure range is 6 – 10bar. This

pressure has to be set at the external pressure

reduction valve.

• Connect the other end of the nitrogen line

to a nitrogen tank by means of the provided

1/8” Swagelok brass nut and ferrule

N

2

(P/N11055342).

• Connect the solvent reservoirs on the right hand

side panel. Make sure that the ferrule is pointed

towards the tting to avoid leaking, and ush

with the end of the tubing.

NOTE

Close vacant ports with a blind tting (P/N 035665) to avoid any unwanted contamination.

Never use technical grade solvent. It is strongly recommended to use p.a. quality or HPLC grade

solvents. To avoid contamination by the nitrogen use 5.0 quality for trace analysis and 4.5 for other

applications.

Risk of instrument damage by excess pressure within the instrument.

• Make sure that the maximum pressure of the nitrogen does not exceed 10bar

Risk of instrument damage by dry running instrument parts, especially valves.

• Never run the instrument or parts of it without any solvent

NOTICE

NOTICE

• Connect the EXHAUST and WASTE outlets on

the back of the instrument accordingly.

EXHAUST

WASTE

33 SpeedExtractor E-916 / E-914 Operation Manual

Page 35

5.4 Dehydration

NOTE

At initial start-up or after a long period of no use (>1month), the instrument should be dehydrated

for proper operation. To do so, heat up the instrument to 100°C for 1 hour (heater open, no cells).

Proceed as described in section 6.3.2.

5.5 Functional test

To make sure that the installation procedure has been carried out properly and the system is tight,

carry out a leak test (see section 6.2.5) before putting the instrument into operation for the rst time.

5 Putting into operation

34 SpeedExtractor E-916 / E-914 Operation Manual

Page 36

6 Operation

This chapter explains the operating elements and possible operating modes. It gives instructions on

how to operate the SpeedExtractor properly and safely.

The following table provides a quick overview of main step typically being involved in an extraction:

Overview of main step typically being involved

Step Action Section

1 Create a new method with default operating parameters 6.4.3

2 Preheat the instrument 6.2.3

3 Activate the positions 6.2.4

4 Flush the system (optional) 6.2.6

5 Activating the EcoMode (optional) 6.2.7

6 Prepare the sample 6.3.1

7 Select an extraction cell size 6.3.2

8 Pack the extraction cell 6.3.3

9 Insert the sample and collection vials 6 .4.1

10 Run the process 6.4.8

11 Optimize the process (optional) 6.4.7

12 Flush the system with the solvent used for the next run (optional) 6.2.6

6 Operation

6.1 Method development

A method must be developed before beginning an extraction to dene the operating parameters for a

run. When developing a new method it is often advisable to collect the extracts of the rst three cycles

followed by a vial change for the fourth cycle. If the second collection vial does not contain any analyte

the vial change is shifted between the second and third cycle. Depending on the amount of analyte

found in the second vials, optimization of the extraction time is recommended. For further information

regarding the vial change, see section 6.4.3.

Further information about how to optimize the extraction process is given in section 6.4.7. BUCHI's

SpeedExtractor Application booklet and Application notes give detailed information about method development and method parameters for a waste range of applications. Please contact your local dealer

or BUCHI for these documents.

35 SpeedExtractor E-916 / E-914 Operation Manual

Page 37

6.2 Preparing the instrument

This section involves all steps required to make the instrument ready for operation.

!

3

6.2.1 Solvent reservoir

Death or serious poisoning by contact or incorporation of harmful substances at use.

• Before operation, check the instrument for correct assembling

• Before operation inspect sealings and tubes for good condition and tightness

• Exchange worn out or defective parts immediately

• Provide sucient ventilation and make sure to directly withdraw fumes

6 Operation

WARNING

As already mentioned, when developing a new method, select a solvent or solvent mixture that is

already known from a classical method such as Soxhlet extraction or another high pressure method

such as ASE. Generally, the analytes should show high solubility in the extraction liquid, but not the

sample matrix.

Do not use solvents with an self ignition point of 40 to 220°C.

Particularly, do not use the following solvents with the SpeedExtractor. If there is any question about

solvent suitability, contact BUCHI.

Solvents NOT being compatible with the process

Component Formula Reason

Carbon disulde CS

Diethyl ether C4H10O Contains peroxide

1.4-Dioxane C4H6O Contains peroxide

Strong mineral or organic acids and bases Corrosive to metallic components

THF C4H8O Contains peroxide

Further aspects to consider:

• Use HPLC- or p.a. grade solvents.

• Generally, solvents do not need to be degassed; only if the analytes of interest oxidize easily.

• Weak acids and bases, such as acetic acid or potassium hydroxide, or other non-corrosive additives may be used in small portions, i.e. <5% by volume, added to the solvent system. Hydrolyzed

food samples for fat determination can be used without any problems since the hydrolysed residue is washed to a neutral pH prior to extraction.

2

Autoignition temperature 100°C

NOTE

Prior to an extended shutdown after an extraction ush the system (both INTO VIAL and INTO

WASTE):

• with chlorinated organic solvents for 2min with methanol

• with acidic or basic solvents with pure organic solvents such as ethanol or distilled water

See section 6.2.6 for a description of the ushing process.

36 SpeedExtractor E-916 / E-914 Operation Manual

Page 38

Never use technical grade solvent. It is strongly recommended to use particle free solvents such as

p.a. quality or HPLC grade solvent to guarantee proper operation of the valves, lters and frits.

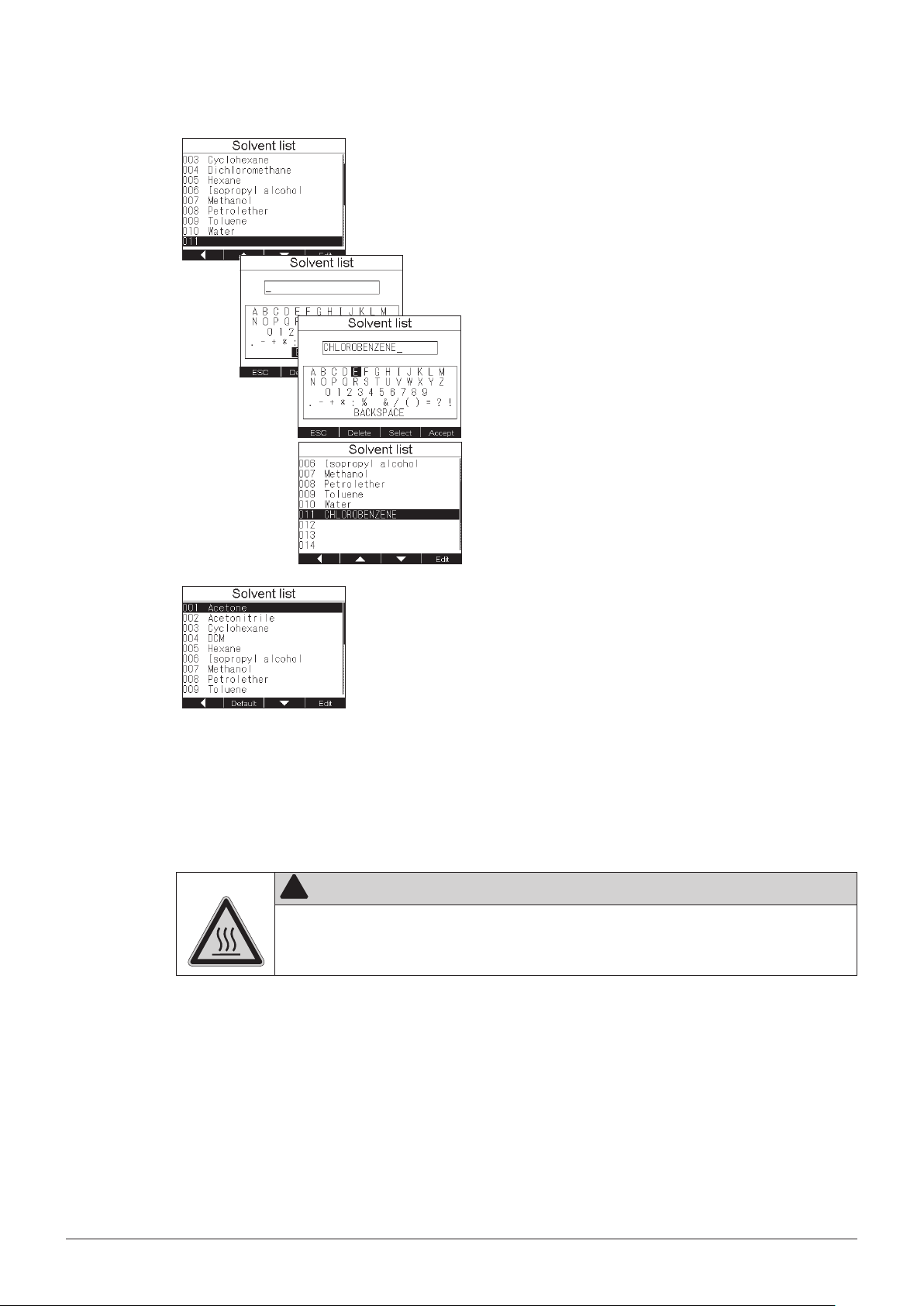

6.2.2 Modifying the SOLVENT LIST

When creating an extraction method (see section 6.4.3) the solvent used for extraction needs to be

determined. It is possible to create a list of up to 20 solvents for this purpose. The ten most frequently

used solvents are programmed in the SOLVENT LIST by default. However, this list can be expanded

or changed to include your own solvents or solvent mixtures.

6 Operation

Filling the solvent reservoir:

To prevent air from being drawn though the lines, insert

the inlet line (approx. 1m) equipped with an intake lter

(P/N 044340) into the reservoir until the lter touches

the bottom.

N

2

FILTER

Open the list:

• Go to MENU SOLVENT LIST to open the default

solvent list consisting of 10 entries.

Changing an entry:

It is possible to change the default solvent list as needed. For example, to change DICHLOROMETHANE into

DCM proceed as follows:

• Go to DICHLOROMETHANE and press EDIT. A

submenu with dierent characters appears. To erase

the whole name press DELETE. Move the cursor

to D using the selection knob and press SELECT.

Proceed similarly with C and M. To save the name

press ACCEPT. The modied name now appears on

the same position as previously Dichloromethane as

DCM.

• To modify a name (e.g. Dichloromethane_1) open

the EDIT menu, choose the corresponding characters and press SELECT. Conrm the changes with

ACCEPT. The modied name now appears on the

same position as previously Dichloromethane.

37 SpeedExtractor E-916 / E-914 Operation Manual

Page 39

6 Operation

Adding a new solvent:

• To add new solvents to the list go to an empty position (e.g. no. 11) and press EDIT. The editing display

is now empty. You can create your own names now

using the selection knob. For example: An extraction is performed with chlorobenzene which does

not belong to the standard list. Type CHLOROBENZENE as described above and press ACCEPT to

add the name to the solvent list. Chlorobenzene now

appears on position 011 on the solvent list.

6.2.3 Preheating the instrument

Preheating the instrument to the temperature of the subsequent extraction procedure is a mandatory

operation as it equilibrates the instrument and hence prevents the cells and cup seals from damage.

Risk of burns by hot heating block and extraction cells.

• Do not touch hot parts or surfaces

• Do not move the instrument or parts of it when hot

NOTE

Never preheat the instrument when the system is closed. Always equilibrate the instrument with

vacant positions rst.

!

CAUTION

Resetting the default list:

It is possible to reset the rst 10 entries back to the

default solvent list.

• Move the cursor to position 001. The move up

function button is now replaced by DEFAULT. Press

DEFAULT and conrm the message “Load default

solvent list? First 10 entries replaced”. The rst 10

entries are now replaced by the default solvent list.

The following entries (011 – 020) remain untouched.

38 SpeedExtractor E-916 / E-914 Operation Manual

Page 40

6 Operation

Setting the preheat temperature:

• Go to EXTRACTION PREHEAT to open the

preheat submenu. CURRENT METHOD indicates

the temperature setting of the current method. Use

COPY to copy this value in the preheat entry to heat

up the instrument to the temperature for the next

run. Alternatively, set a new temperature using the

selection knob.

Activating the ECO MODE:

The ECO MODE automatically turns o the heater

after the next extraction run. It is recommend that the

EcoMode be activated for unattended operation of an

extraction run (e.g. starting a last run overnight).

• Use the selection knob to tick the ECO MODE. For

more information see section 6.2.7.

Start heating:

• Press ON to start heating. The software goes

back to the main display where the temperature

slowly converges to the set temperature. To abort

preheating go to EXTRACTION PREHEAT and

press OFF. The red STOP button on the control

panel has no inuence on the preheat function.

NOTE

When the temperature of a previous run is higher than actually required by the subsequent extraction method, long cooling o times are required. Placing empty and cold extraction cells into the

heating block is a fast and eective measure to cool down a hot heating block to a lower temperature.

6.2.4 Activating/deactivating positions

Reducing the amount of solvent used for an extraction run is of vital interest. It is therefore possible to

deactivate unused positions. The position valve of a deactivated position remains closed throughout

the whole extraction process. Only the activated positions are ushed with solvent. It is important to

note that an empty extraction cell has to be placed into a deactivated position. This is to achieve uniform temperature distribution throughout the whole heating block and to make sure that the lift is not

at an incline when closed.

All extraction positions are deactivated by default. It is possible to activate all positions

together or each individually.

Preheat on demand:

Preheating the instrument is usually the rst task when

turning on the instrument. It is therefore possible to

congure the instrument so that PREHEAT submenu

appears as soon as the instrument is turned on.

• To activate this function open MENU INSTRUMENT SETTINGS. Go to PREHEAT DEMAND and

tick the function using the selection knob. Press OK

to conrm.

39 SpeedExtractor E-916 / E-914 Operation Manual

Page 41

6 Operation

Activate all positions together:

• Open EXTRACTION OCCUPIED POSITIONS.

Conrm “Occupy all positions?” with YES. The main

display shows all activated positions as numbered

cylinders.

Deactivate positions:

• To activate only the four middle positions, activate

all positions rst and then deactivate the positions 1

and 6. Go to EXTRACTION OCCUPIED POSITIONS and this time negate with NO. All positions

are deactivated now. Press ALL ON and move

the cursor to the vacant positions (in the current

example 1 and 6) and deactivate it by pressing OFF

or using the selection knob. The main display now

shows the vacant positions as crossed out cylinders.

NOTE

Never run the instrument with empty positions. In order to achieve uniform conditions, always place

identical empty extraction cells in the vacant positions. Therefore, using dierent sized extraction

cells in the same run is not recommended.

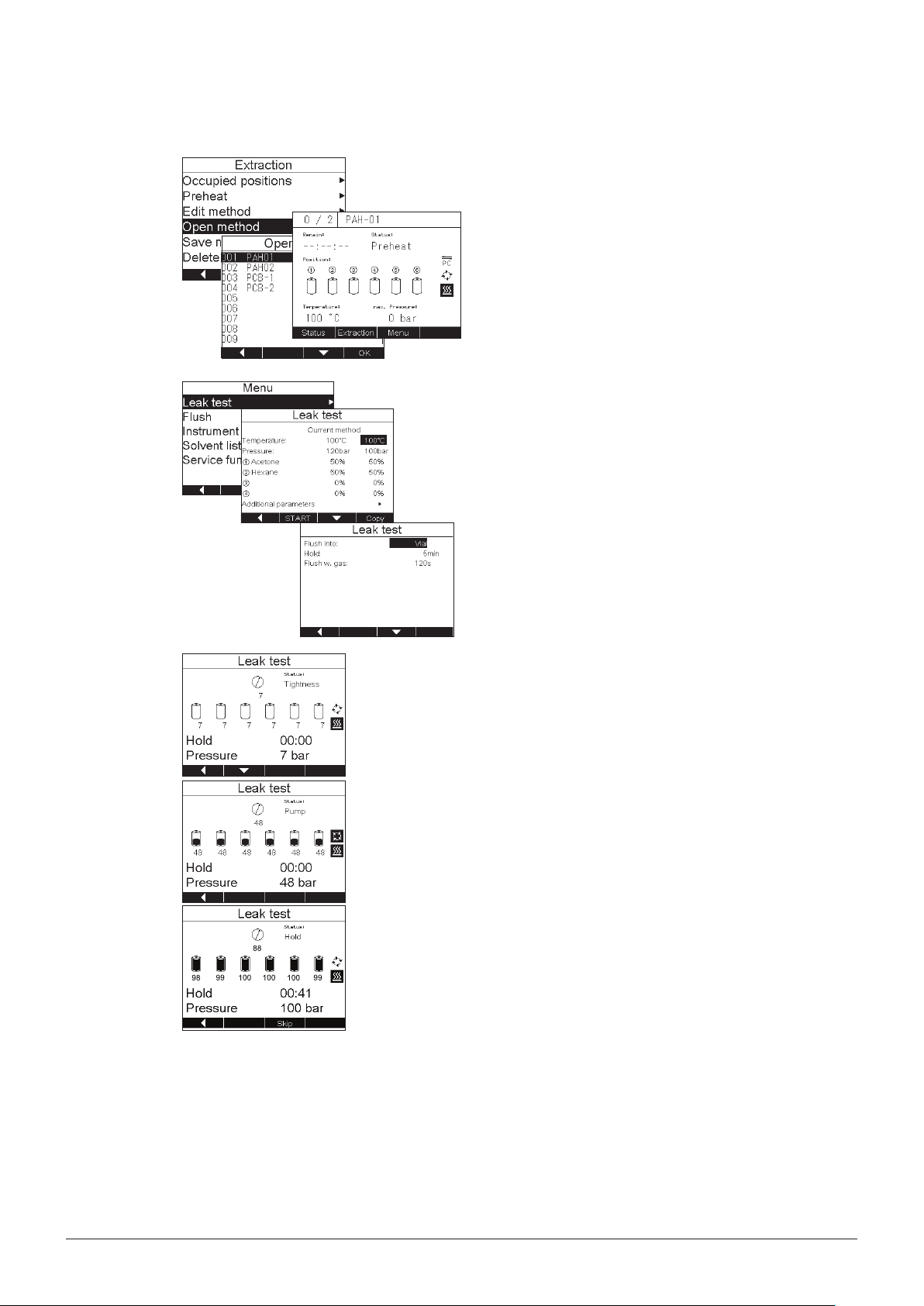

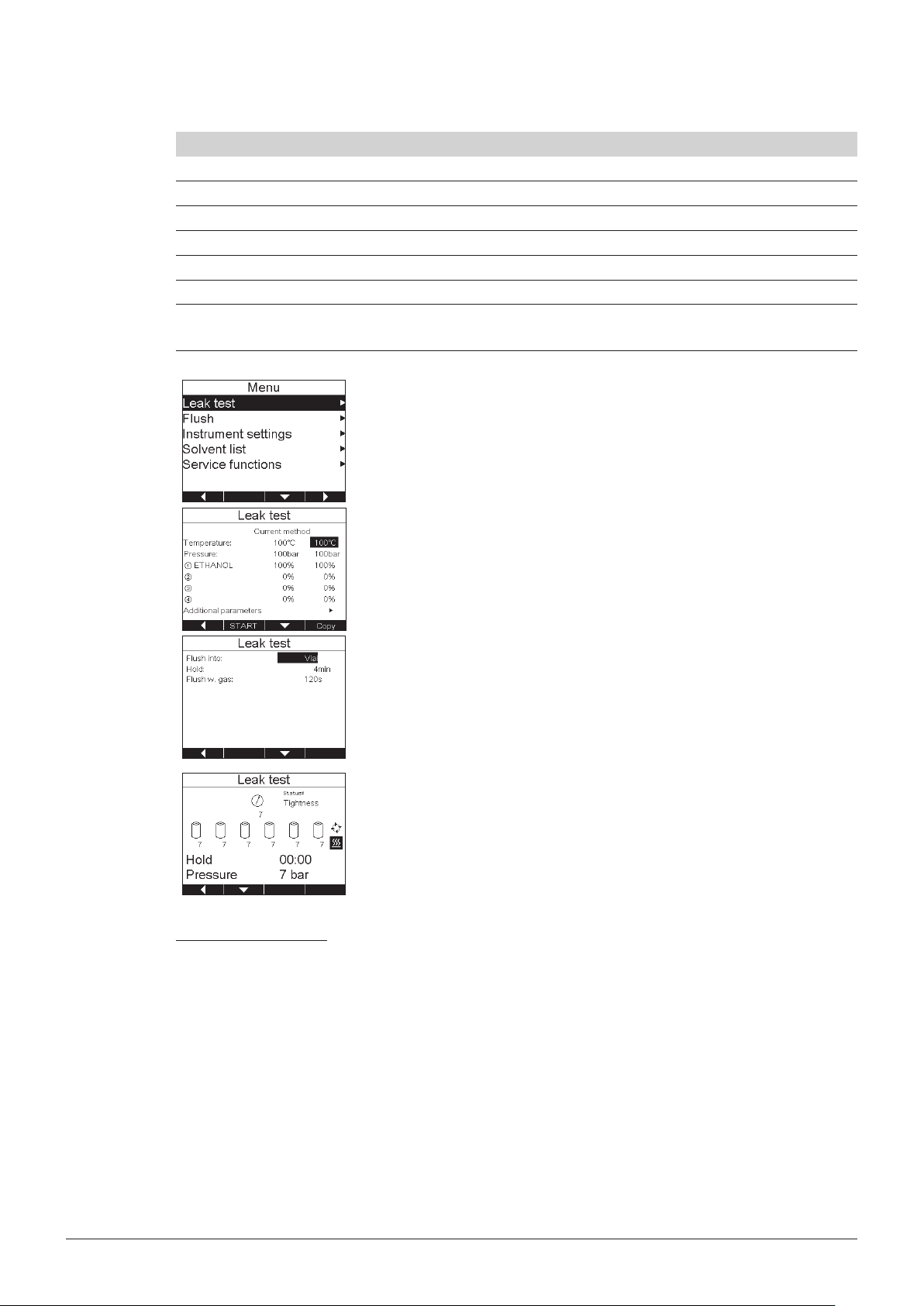

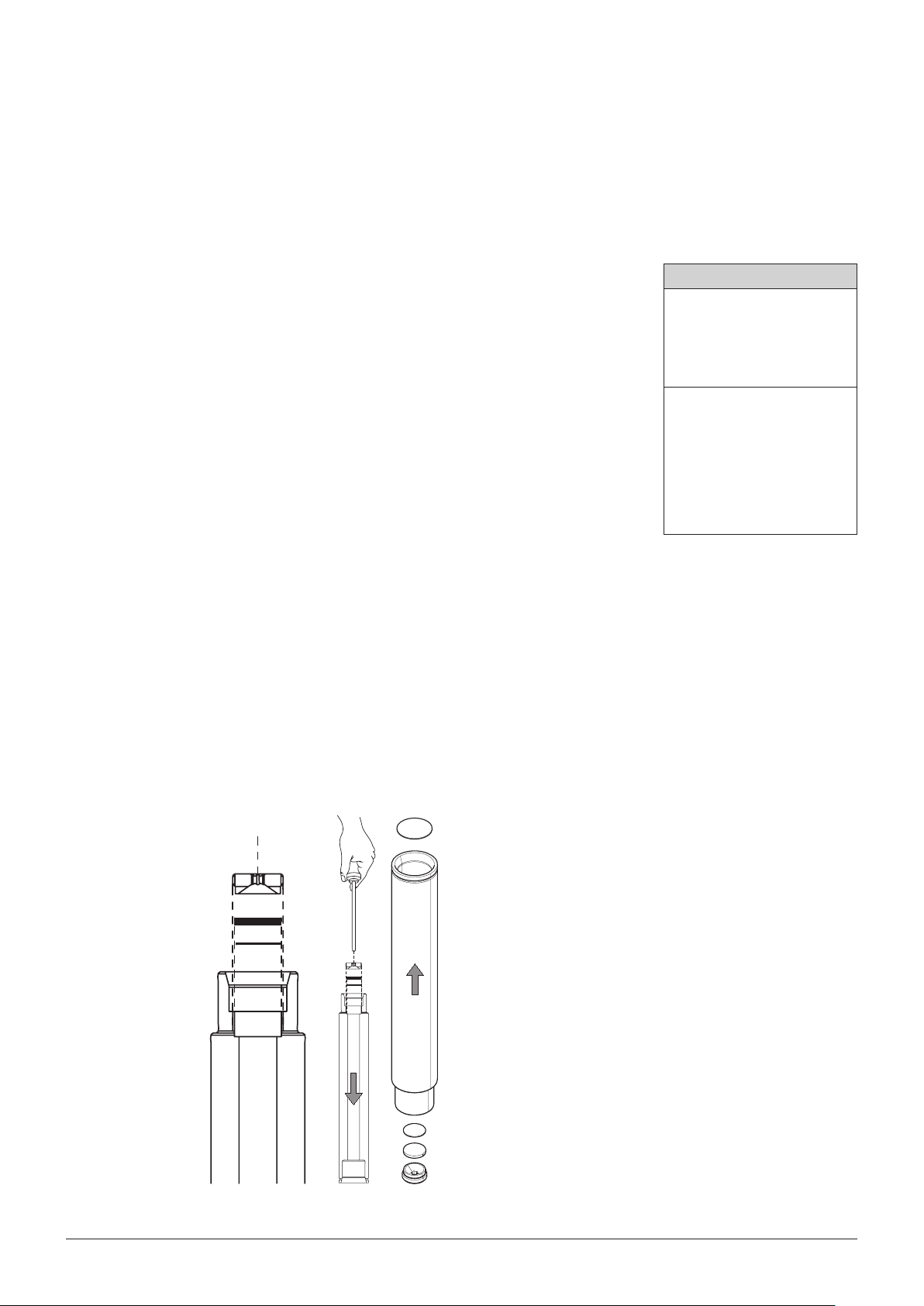

6.2.5 Leak test

The LEAK TEST feature allows the operator to check quickly and safely whether the instrument is

ready for operation. It is also a reliable measure to check the quality of the cup seals. A regular check

before operation is therefore recommended, and is mandatory after a longer period of non-use and/

or after replacement of the cup seals. There are two distinct approaches to perform a leak test. Firstly,

very commonly the tightness of the system is checked using the very same parameters as for the

subsequent extraction procedure. This allows the operator to evaluate the tightness on the basis of his

own operating parameters.

Secondly, in a more absolute approach the leak test is always performed using the same reference

settings. Thus, it is possible to reach conclusions on the basis of constant parameters. This is recommended in order to observe the long term behavior of the instrument, particularly of the seals or to

ensure correspondence on a method-independent basis, relative to the same set of parameters. In

contrast to a regular extraction method, to perform a leak test it is recommended to preheat the instrument with the extraction cells placed in the heating block for 15min to avoid thermal uctuations.

Common to both approaches is the sample and instrument preparation:

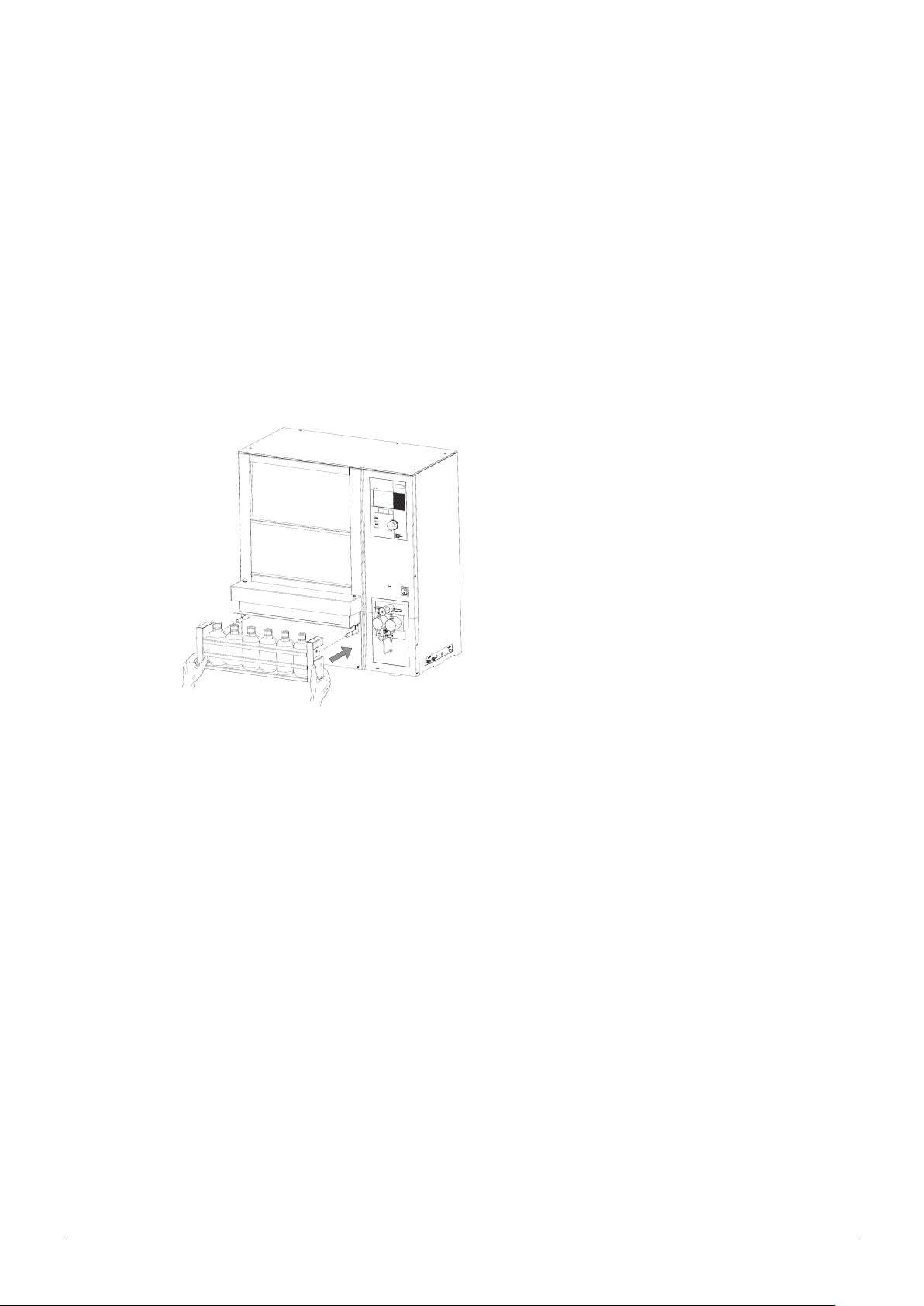

• Preheat the instrument with the extraction cells placed in the heating block. It is not necessary to

• Activate all positions (see section 6.2.4).

• Place empty collection vials into the collection rack and put it on the instrument as described in

equip the cell with the plug screw (see section 6.2.3 and 6.4.1).

section 6.4.1.

40 SpeedExtractor E-916 / E-914 Operation Manual

Page 42

Method-based leak test

6 Operation

Open the method:

• Go to EXTRACTION OPEN METHOD and select

the requested method (e.g. PAH-01) and conrm

with OK. The name of the selected method now

appears in the main display.

Copy the parameters into the leak test:

• Open MENU LEAK TEST. The LEAK TEST menu

consists of two columns. CURRENT METHOD

includes all settings of the currently active extraction method (for instance PAH-01). SELECT shows

the parameters of the last used leak test. To copy

all parameters of the current method to the leak

test press COPY. The cursor skips to the next entry.

Proceed similarly for all entries.

• Under ADDITIONAL PARAMETERS the ushing

conditions can be set, i.e. the receptacle to ush

into, the hold time and the ushing time are dened.

Start the leak test:

• Pressing START on the function buttons (not the

green START button) closes the extraction cells and

starts elevating the pressure by pumping solvent

into the cells. A rst TIGHTNESS test checks the

presence of the extraction cells using nitrogen (see

section 6.4.2). The pressure remains constant at

7bar (pre-pressure) before it elevates the pressure

to the set value (for example 100bar) during the

PUMP step. In the hold step the position valves and

outlet valve are closed and the pressure is observed

over a constant time (approx. 5min). The pressure

of each position as well as the overall pressure is

shown below the extraction cell. In addition, the

maximum pressure is designated by PRESSURE.

The leak test is stopped after the set hold time is

elapsed. Alternatively, the process can be stopped

by pressing SKIP (not the red STOP button). The

outlet valve opens, the solvent is discharged and

the system is ushed with nitrogen. The measured

pressure remains on the display. The evaluation of

leak tests is described later in this section.

Standard leak test

The reference settings are used for the standardized leak test.