Page 1

SpeedDigester K-439

Operation Manual

11593351 en

Page 2

Imprint

Product Identification:

Operation Manual (Original), SpeedDigester K-439

11593351B en

Publication date:

10.2019, Version B

BÜCHI Labortechnik AG

Meierseggstrasse 40

Postfach

CH-9230 Flawil 1

E-Mail: quality@buchi.com

BUCHI reserves the right to make changes to the manual as deemed necessary in the light of experience; especially in respect to structure, illustrations and technical detail.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of this

manual without prior written agreement is also prohibited.

Page 3

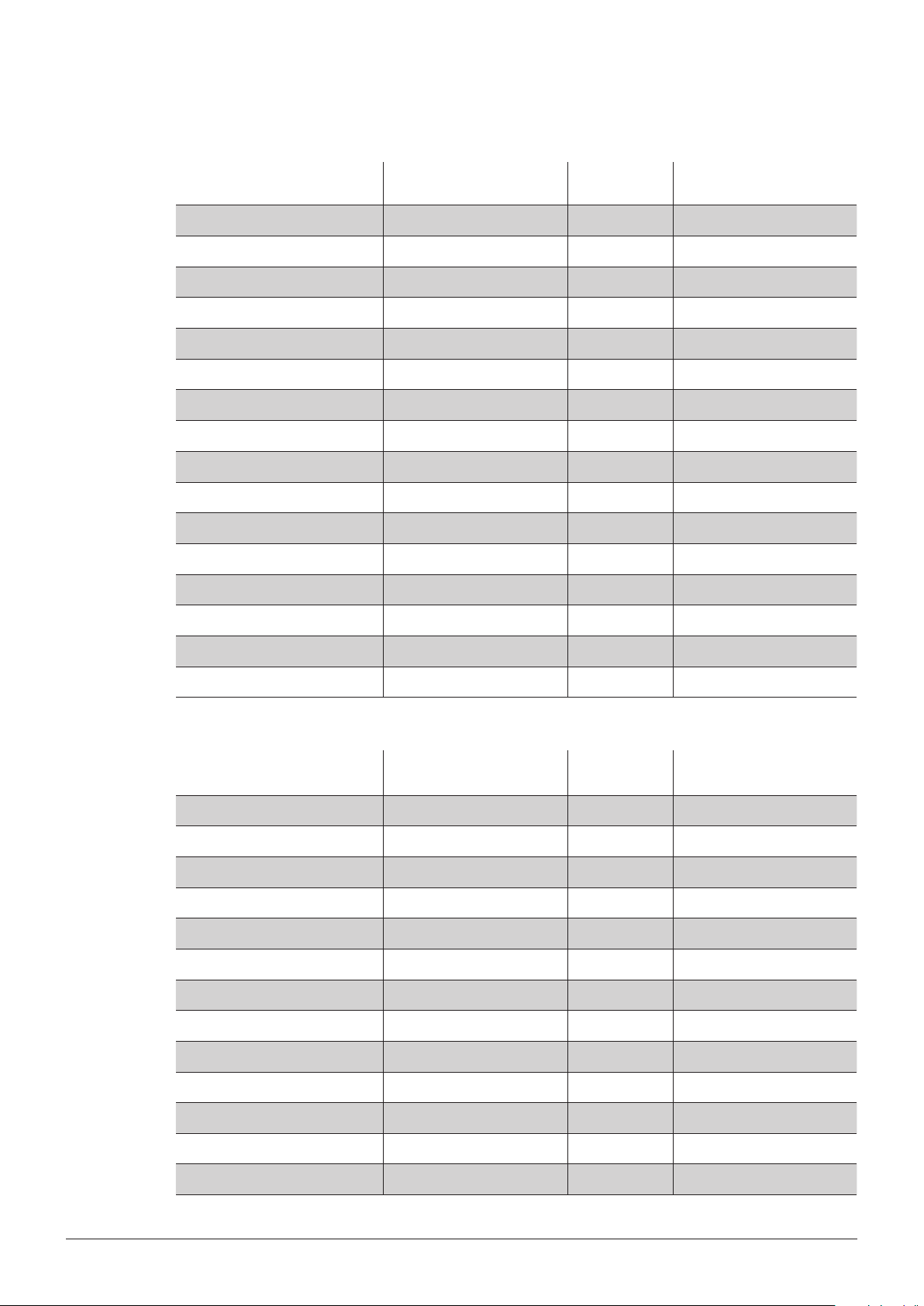

Table of contents

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Safety warnings and safety signs used in this manual . . . . . . . . . . . . . . . . . . 7

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.1 General hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.2 Warning labels on housing and assemblies . . . . . . . . . . . . . . . . . . . . . . 11

2.5.3 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.4 Built-in safety elements and measures . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Scope of application and delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Available system configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.2 Accessories for 300 ml sample tubes (for standard applications) . . . . . . . . . . . 14

3.1.3 Accessories for 500 ml sample tubes (for large sample volumes / at low nitrogen level) 14

3.1.4 Accessories for 3rd party production, 250 ml sample tubes . . . . . . . . . . . . . . 15

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Materials used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 System fixation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.1 SpeedDigester connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.2 Scrubber/water jet pump connection . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Operating controls and housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1.1 SpeedDigester K-439 — front side . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1.2 System rear side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3 Program structure overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4 Software buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.5 Software icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.1 General icons (used in automatic and manual mode) . . . . . . . . . . . . . . . . . 27

6.5.2 Icons in automatic mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.3 Icons in manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.6 How to prepare the software for routine digestion . . . . . . . . . . . . . . . . . . . 28

6.6.1 Standard instrument settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.6.2 Digestion in Manual Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.6.3 Methods menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.6.4 Digestion in Automatic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.6.5 History menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.7 Preparing of SpeedDigester, suction module(s) and sample tubes. . . . . . . . . . . 36

3 K-439 Operation Manual, Version B

Page 4

Table of contents

6.7.1 Kjeldahl digestion —preparing sample tubes. . . . . . . . . . . . . . . . . . . . . . 37

6.7.2 Peroxide digestion —preparing sample tubes . . . . . . . . . . . . . . . . . . . . . 38

6.7.3 Installing a suction module and sample tubes (300 ml). . . . . . . . . . . . . . . . . 39

6.7.4 Installing 500 ml sample tubes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.7.5 Starting up the SpeedDigester . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.8 Performing a Kjeldahl digestion process. . . . . . . . . . . . . . . . . . . . . . . . 43

6.8.1 Preparational steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.8.2 Starting a digestion process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.9 Performing a peroxide digestion process . . . . . . . . . . . . . . . . . . . . . . . 44

6.9.1 Preparational steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.9.2 Starting a digestion process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.10 Finishing a digestion process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.11 Optional 'Stand with drip tray' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7 Maintenance and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.2 General condition and cleaning instructions . . . . . . . . . . . . . . . . . . . . . . 51

7.2.1 Breakage of glassware inside a housing chamber . . . . . . . . . . . . . . . . . . . 52

7.2.2 Liquid ingress into the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3 Glass component conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.3.1 Sample tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4 Sealing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.5 Rack system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.5.1 300 ml sample tube support spring . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.5.2 500 ml sample tube support spring . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.6 Display cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.1 Malfunctions and their remedy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.1 Actors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.2 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.3 Operating Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.4 Unit Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.5 Service Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.3 Device fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 60

9.1 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.2 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.1 Spare parts, optional accessories and consumables . . . . . . . . . . . . . . . . . 63

11 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

11.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . . 66

4 K-439 Operation Manual, Version B

Page 5

1 About this manual

This manual describes the SpeedDigester K-439 and provides all information required for its safe

operation and to maintain it in good working order.

It is addressed to laboratory personnel and operators in particular.

Read this manual carefully before installing and running your system and note the safety precautions

in chapter 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be

consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of

Buchi. Unauthorized modifications may affect the system safety or result in accidents. Technical data

are subject to change without notice.

NOTE

The symbols pertaining to safety (WARNINGS and ATTENTIONS) are explained in chapter 2.

1 About this manual

This manual is copyright. Information from it may not be reproduced, distributed or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of

this manual without prior written agreement is also prohibited.

The English manual is the original language version and serves as basis for all translations into other

languages. If you need another language version of this manual, you can download available versions

at www.buchi.com.

5 K-439 Operation Manual, Version B

Page 6

2 Safety

This chapter introduces the safety concept of the instrument and contains general rules of behavior

and warnings from direct and indirect hazards concerning the use of the product.

For the users safety, all safety instructions and safety messages in the individual chapters shall

be strictly observed and followed. Therefore, the manual must always be available to all persons

performing any tasks described herein.

2.1 User qualification

The instrument may only be used by laboratory personnel and other persons who on account of

training and professional experience know the potential dangers that can develop when operating the

instrument.

Untrained personnel, or persons who are currently being trained, require careful supervision by a

qualified person. Operation Manual serves as a basis for training.

2 Safety

2.2 Proper use

The SpeedDigester K-439 has been designed and built for laboratory use only. Its intended use is to

allow digestion of samples with concentrated acids or peroxides by heating up the probe.

A suction unit (e.g. Scrubber or water jet pump) has to be connected to the suction module to safely

withdraw fumes which will emerge during digestion. In any case, all exhausts and fumes leaving the

system or assemblies such as Scrubber or water jet pump have to be removed instantly inside a

fume hood. This is mandatory to remove all possibly hazardous substances (e.g. acid fumes) from the

working area. The ventilation system of the fume hood has to be equipped with safety measures such

as outlet filters to avoid contamination of the environment.

When the SpeedDigester K-439 is used in combination with other instruments (e.g. Scrubber and

fume hood) all related manuals are to be fully observed.

2.3 Improper use

Applications not mentioned in section 2.2 are considered to be improper. Applications which do not

comply with the technical data (see section 3 of this manual) are also considered to be improper.

The operator bears the sole risk for any damages or hazards caused by improper use!

The following uses are expressly forbidden:

• Digestion operations outside an active fume hood.

• Digestion of samples (e.g. food and feed) in nitrosulfuric acids which can produce explosive nitro

compounds.

• Digestion of sample material of unknown composition in nitrosulfuric acids.

• Use of samples which can explode or ignite due to shocks, friction, heat or sparks.

• Installation or use of the instrument in rooms, which require ex-protected instruments.

• Use of glassware which is not specified in section 2.5.4.

6 K-439 Operation Manual, Version B

Page 7

2.4 Safety warnings and safety signs used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of

hazard seriousness of risks related to personal injury and property damage. All signal words, which are

related to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the table below with the different signal

words and their definitions!

Sign Signal word Definition Risk level

DANGER

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

2 Safety

★★★★

WARNING

CAUTION

no NOTICE

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see below example).

Space for

supplementary

safety

information

symbols.

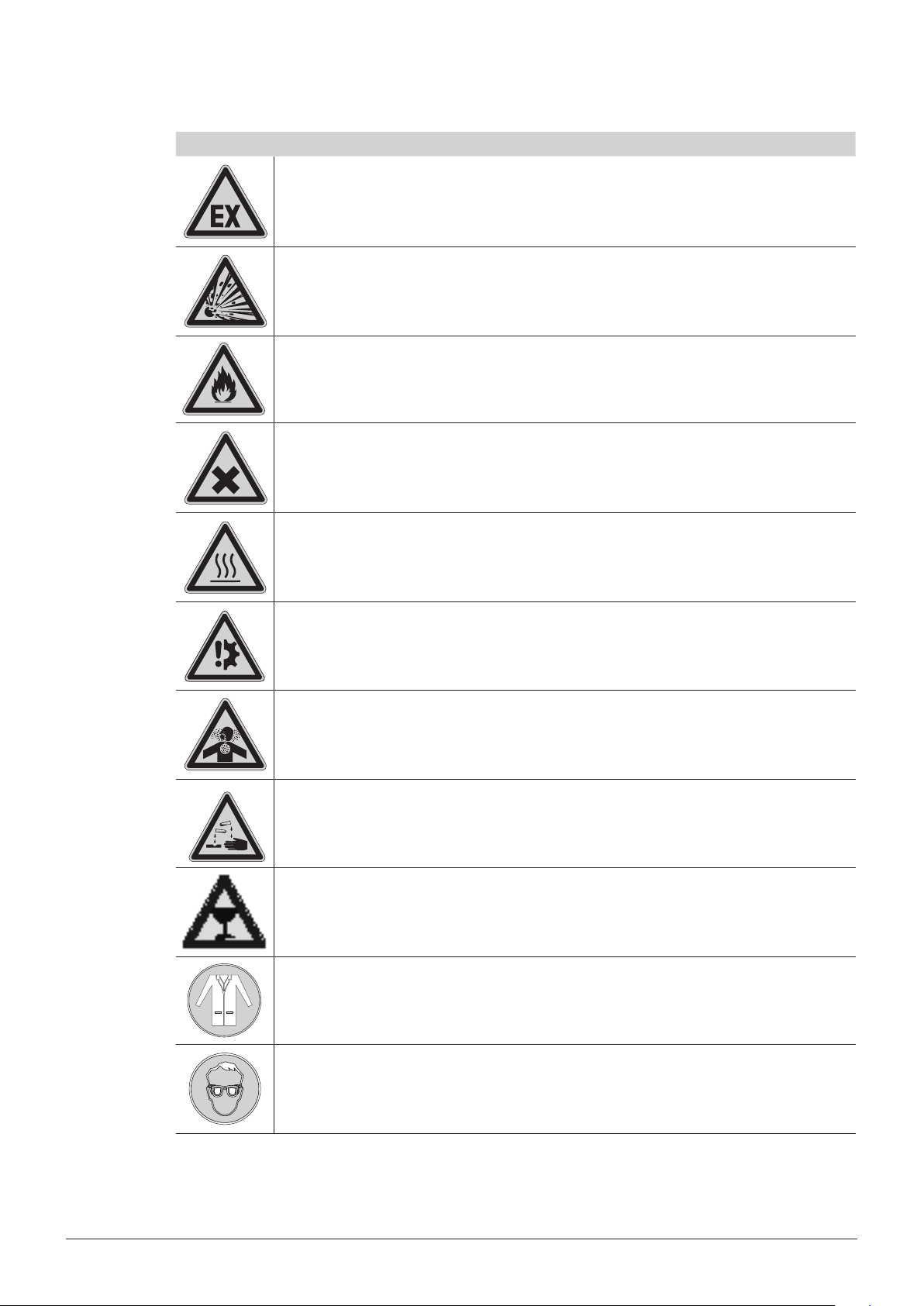

Table of supplementary safety information symbols

The reference list below incorporates all safety information symbols used in this manual and their

meaning.

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation which, if not avoided, may result

in minor or moderate injury.

Indicates possible property damage, but no

practices related to personal injury.

!

SIGNAL WORD

Supplementary text, describing the kind and level of hazard / risk seriousness.

• List of measures to avoid the herein described, hazard or hazardous situation.

• ...

• ...

(property damage only)

★★★☆

★★☆☆

★☆☆☆

Symbol Meaning

General warning

Electrical hazard

Heavy weight, avoid overexertion

7 K-439 Operation Manual, Version B

Page 8

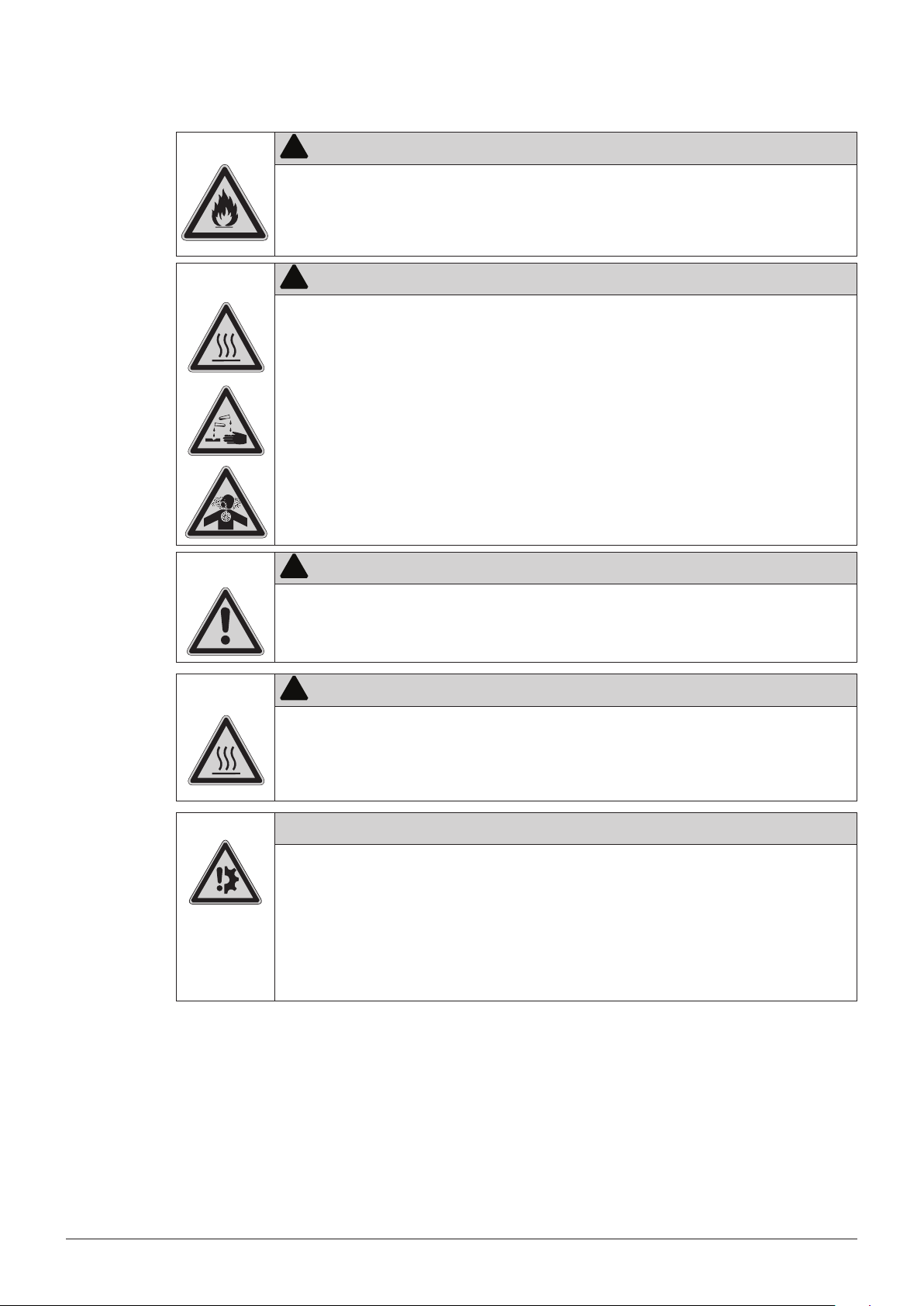

Symbol Meaning

Explosive gases, explosive environment

Explosive material

Fire hazard

Harmful to life-forms

2 Safety

Hot item, hot surface

Device damage

Inhalation of substances

Chemical burns by corrosives

Fragile components

Wear laboratory coat

Wear protective goggles

8 K-439 Operation Manual, Version B

Page 9

2 Safety

Symbol Meaning

Wear protective gloves

Heavy weight, lifting requires more than one person

Additional user information

Paragraphs starting with Note transport helpful information for working with the device / software or its

supplementaries. Notes are not related to any kind of hazard or damage (see following example).

Note

Useful tips for the easy operation of the instrument / software.

2.5 Product safety

The SpeedDigester K-439 has been designed and built in accordance with current state-of-the-art

technology. Safety warnings in this manual (as described in section 2.4) serve to make the user alert

to and avoid hazardous situations emanating from residual dangers by giving appropriate counter

measures.

However, risks to users, property and the environment can arise when the instrument is damaged,

used carelessly or improperly.

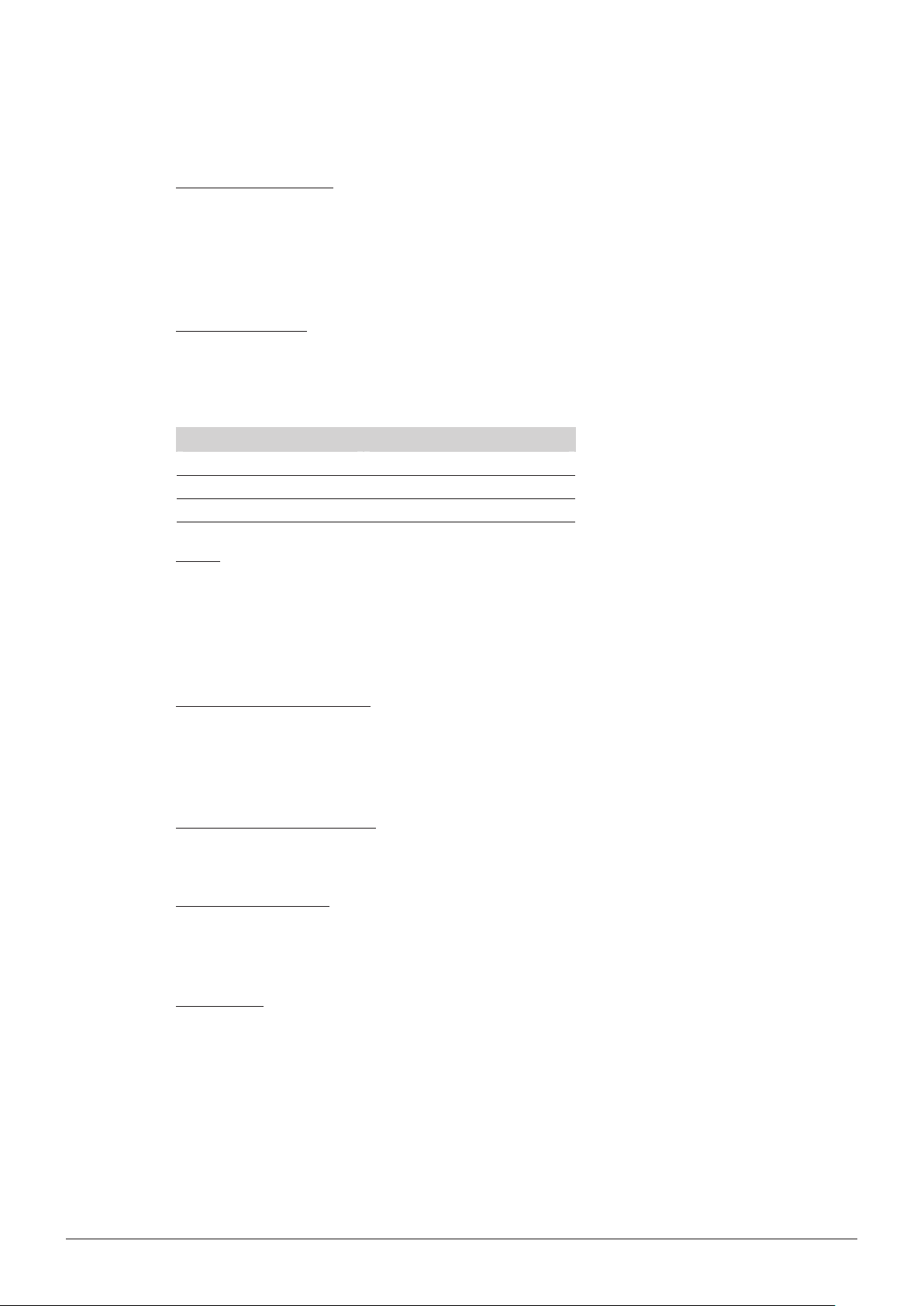

2.5.1 General hazards

The following safety messages show hazards of general kind which may occur when handling the

instrument. The user shall observe all listed counter measures in order to achieve and maintain the

lowest possible level of hazard.

Additional warning messages can be found whenever actions and situations described in this manual

are related to situational hazards.

!

DANGER

Death or serious injuries by use in explosive environments.

• Do not store or operate the instrument in explosive environments

• Do not store chemicals in the vicinity of the device

• Operate the device in a fume hood with sufcient ventilation to directly withdraw fumes

9 K-439 Operation Manual, Version B

Page 10

!

WARNING

Death or serious burns by ammable vapors.

• Remove all sources of ammable vapors

• Do not store ammable chemicals in the vicinity of the device

!

WARNING

Risk of death or serious chemical burns by hot acid or peroxide fumes.

• Do not operate the system with faulty parts

• Check instrument setup for proper sealing before use

• Do not inhale process fumes

• Operate the instrument inside an active fume hood

• Do not move the instrument or parts of it during digestion

2 Safety

!

CAUTION

Risk of minor or moderate cuts by sharp edges.

• Do not touch defective or broken glassware with bare hands

• Do not touch thin metal edges

!

CAUTION

Risk of burns by hot machine parts and glassware.

• Do not touch hot parts or surfaces

• Let the system and inserted glassware cool down safely

• Do not move the instrument or parts of it when hot

Risk of instrument damage by liquids or mechanical shocks.

• Do not spill liquids over the instrument or its components

• Do not move the instrument when it is loaded with sample liquid

• Do not drop the instrument or its components

• Keep external vibrations away from the instrument

• Safely attach the instrument to the bench in earthquake prone regions

• Do not operate the instrument without the display cover installed

NOTICE

10 K-439 Operation Manual, Version B

Page 11

2.5.2 Warning labels on housing and assemblies

The following warning sticker(s) can be found on the housing or assemblies of the SpeedDigester:

Symbol Meaning Location

2 Safety

Hot item, hot surface

Do NOT put rack into side cooling position Label on 500 ml racks

2.5.3 Personal protective equipment

Always wear personal protective equipment such as protective eye goggles, protective clothing and

gloves. The personal protective equipment must meet all requirements of the supplementary data

sheets for the chemicals used.

!

WARNING

Serious chemical burns by corrosives.

• Observe supplementary data sheets of all used chemicals.

• Handle corrosives in well ventilated environments only.

• Always wear protective goggles.

• Always wear protective gloves.

• Always wear protective clothes.

• Do not use damaged glassware.

Sticker / label, located on top of the housing and

at the racks

11 K-439 Operation Manual, Version B

Page 12

2.5.4 Built-in safety elements and measures

Buchi glassware design

• All original Buchi digestion glassparts are made of high temperature and chemical resistant borosilicate glass.

• Acid fumes generated during digestion accumulate in the suction module

• The fumes must be safely withdrawn from the suction module via one or more hoses to a Scrubber

(e.g. Scrubber B-414) or via water jet pump into a sink or sufficient suction flow.

3rd party glassware

The quality of the material is an essential part of the safety concept of the SpeedDigester K-439. For

the special rack (order no. 11055440), the following qualified vendors offer sample tubes of sufficient

quality grade to withstand the temperatures and the aggressive chemical digestion agents:

Qualified vendor Tested sample tube(s)

Gerhardt 250 ml / 6100

Velp ø 42×300 mm / A00000144

Foss 250 ml / 10014278

2 Safety

Heater

Each heating chamber is equipped with a safety overtemperature switch. In case of an emergency the

switch cuts off the power of the corresponding chamber.

2.6 General safety rules

Responsibility of the operator

The head of the laboratory is responsible for training his/her personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during operation of the instrument or its accessories. Legal regulations, such as local, state and

federal laws applying to the instrument or its accessories must be strictly followed.

Duty of maintenance and care

The operator is responsible for the proper condition of instrument. This includes maintenance, service

and repair jobs that are performed on schedule by authorized personnel only.

Spare parts to be used

Use only genuine consumables and spare parts for maintenance to assure good system performance,

reliability and safety. Any modifications of spare parts or assemblies are only allowed with the prior

written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation and with the written approval

of the manufacturer. Modifications and upgrades shall only be carried out by an authorized Buchi technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

12 K-439 Operation Manual, Version B

Page 13

3 Technical data

This chapter introduces the reader to the SpeedDigester K-439 and its specifications. It contains the

scope of delivery, technical data, requirements and performance data.

3.1 Scope of application and delivery

All system configurations come with a limited set of accessories as a starter kit. Within a system family,

additionally available accessories (see section 3.1.2 and the following) can be used to easily reconfigure your system to every configuration listed in section 3.1.1.

Parts that are required to change a system configuration:

• Rack

• Suction module

• Insulation plate (fireclay insert)

• Sample tubes

3 Technical data

The scope of delivery depends on the ordered system configuration and can be checked according to

the individual delivery note and the listed order numbers.

Note

For additional information about the listed products, see www.buchi.com or contact your local dealer.

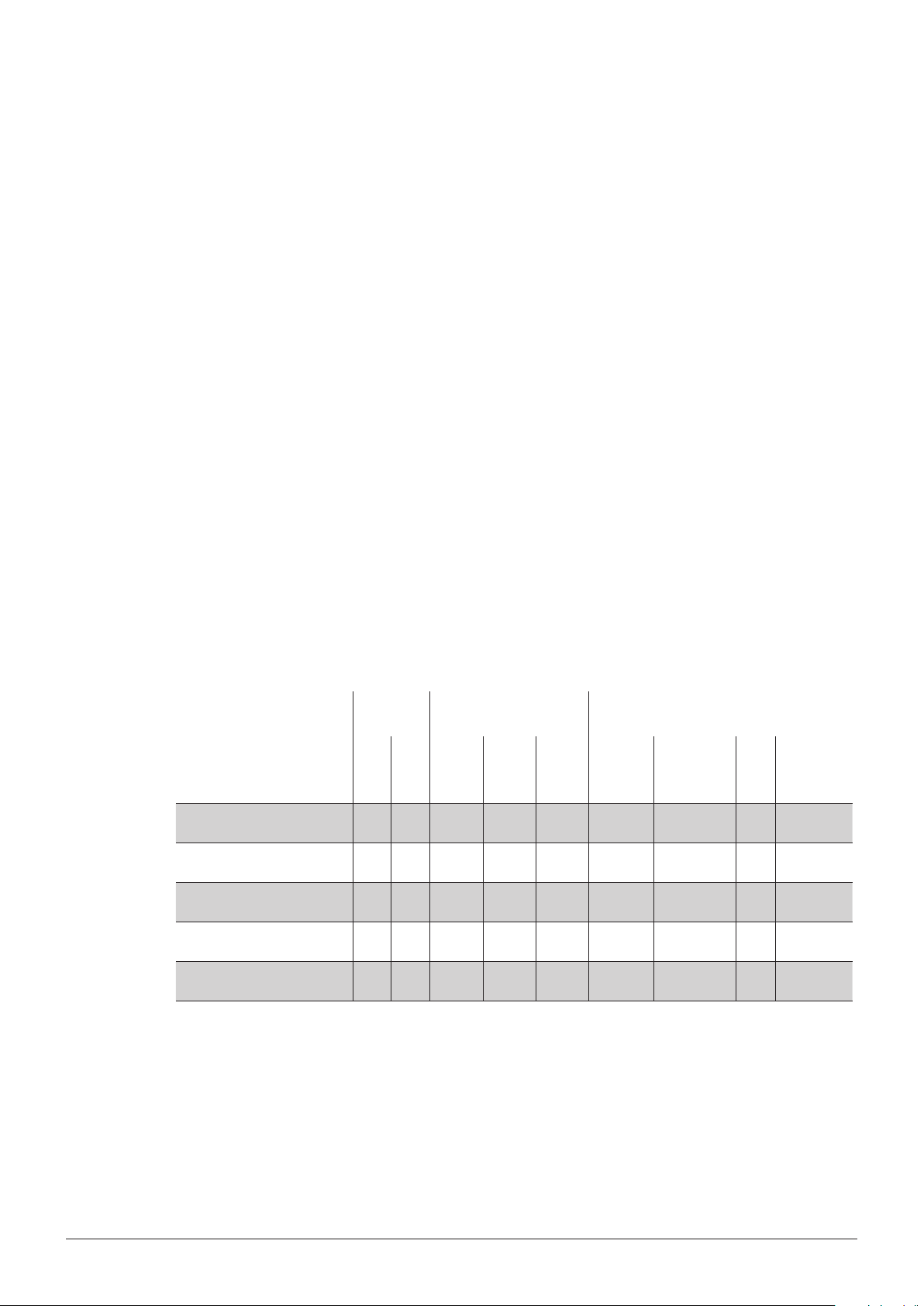

3.1.1 Available system configurations

Configuration

order number

220 – 240 V 5 6 250 ml 300 ml 500 ml Standard

1154392500

1154392100

1154392200

1154392300

1154392400

Sample

positions

Sample tube sizes Suction modules

Condensate

trap

• • •

• • •

• • •

• • •

• •* •*

H2O

Module for

3rd party

2

tubes

* Third party sample tubes require special accessories such as the BUCHI “Module for 3rd party

tubes” and the matching rack / insulation plate. Tubes are not included in the set!

13 K-439 Operation Manual, Version B

Page 14

3.1.2 Accessories for 300 ml sample tubes (for standard applications)

3 Technical data

Item Additional info Order number

Recommended quantity to

order

Set of sample tubes 300 ml, 4 tubes 037377 3x

Suction module standard 6 place 11055849 2x

Suction module condensate trap 6 place 11055865 2x

Suction module H2O

2

6 place, cpl. 11055853 2x

Connectors to suction module Adapter and plug 11055367 2x

EPDM hose set Hoses and t-piece 11056219 1x

Insulation plate (reclay) Insertion, for 300 ml tubes 11055142 2x

Rack 6 place, for 300 ml tubes 11055248 2x

Glass caps (set of 4) OPTIONAL 040049 —

Insulation cap OPTIONAL 11056024 —

Sealing FKM (set of 6) Spare part 038122 —

Sealing PTFE (1 pcs) OPTIONAL 022442 —

Rubber GUKOs for H2O2 suc. mod. Spare part set of 6 044495 —

Filter funnel for H2O2 suc. mod. Spare part set of 6 044494

Set circular spring and holder Spare part set of 6 11055984 —

Bed-plate for 300ml racks OPTIONAL 11055943 —

3.1.3 Accessories for 500 ml sample tubes (for large sample volumes / at low nitrogen level)

Standard items Additional info Order number

Recommended quantity

to order

Sample tubes 500 ml, single tube 026128 10x

Set of sample tubes 500 ml, 4 tubes 043982 3x

Suction module condensate trap 5 place 11055851 2x

Connectors to suction module Adapter and plug 11055367 2x

EPDM hose set Hoses and t-piece 11056219 1x

Insulation plate (reclay) Insertion, for 500 ml tubes 11055143 2x

Rack 5 place, for 500 ml tubes 11055327 2x

Base for rack For 500 ml tubes rack 11055612 1x

Glass caps (set of 4) OPTIONAL 040049 —

Insulation cap OPTIONAL 11056024 —

Sealing FKM (set of 6) Spare part 038122 —

Sealing PTFE (1 pcs) OPTIONAL 022442 —

Interlock spring for 500 ml rack Spare part 11055385 —

14 K-439 Operation Manual, Version B

Page 15

3.1.4 Accessories for 3rd party production, 250 ml sample tubes

3 Technical data

Item Additional info Order number

3rd party sample tubes 250 ml n.a. 12x

Suction module for 3rd party tubes 6 place 11055850 2x

Connectors to suction module Adapter and plug 11055367 2x

EPDM hose set Hoses and t-piece 11056219 1x

Insulation plate (reclay) Insertion, for 250 ml tubes 11055877 2x

Rack 6 place, for 250 ml tubes 11055440 2x

Sealing FKM (set of 6) Spare part 038125 —

Set circular spring and holder 6× OPTIONAL 11055985 —

Note

Tested 3rd party sample tubes (listed in section 2.5.4) are not available at Buchi. Please contact your

local OEM vendor for these type of tubes.

Recommended quantity

to order

15 K-439 Operation Manual, Version B

Page 16

3.2 Technical data

The table below lists all main design parameters of the SpeedDigester K-439.

Technical data

Power consumption max. 2000 W

Temperature control range 50 – 580°C

Temperature accuracy ± 5 K at 200 °C / ± 10 K at 550 °C

Connection voltage 220 – 240 VAC

Frequency 50 / 60 Hz

Input fuse T 10A L 250 V

Scrubber output max. 0,7 A

Display QVGA 240×320 pixels

IP degree of protection (two digits) IP 20

3 Technical data

Explanation of protection level:

2 Protection provided by the enclosure against access

to hazardous parts (e.g., electrical conductors,

moving parts) and the ingress of solid foreign objects

with a diameter of > 12,5 mm.

0 No protection of the equipment inside the enclosure

against harmful ingress of water.

Insulation category II

Environmental conditions:

Pollution degree 2 (for indoor use only)

Temperature 5 – 40°C

Altitude (above sea level) up to 2000 m

Humidity (curve parameter) Maximum relative humidity 80% up to 31°C, then

decreasing linearly to 50% relative humidity at 40°C

Dimensions in mm (W × D × H) 310 × 620 × 540

Net weight 15,5 kg

Rack 2,5 kg (per rack)

Note

The SpeedDigester K-439 is suited to work with an input power range of 220 V to 240 V mains

voltage. Check your local voltage requirements prior to installation!

16 K-439 Operation Manual, Version B

Page 17

3.3 Materials used

Materials used

Component Material designation Material code

Stainless steel Housing

Silicic acid Heating chamber SiO2, SiC

Ceramic ber felt Heating chamber

Calcium silicate Insulation plate

Phlogopite mica Preheat cover

Plastic Front hood PBT

Borosilicate glass 3.3 Protective glass display

Aluminium Front bottom

3 Technical data

Heating chamber

Heating element

Rack

Hose clamp

Front panel under keypad PP

Display cover PVC

Suction hoses EPDM

Drip tray PP

Rack PPS

Sealings suction tube FKM/PFE

Hose coupling PP

Digestion tubes

Suction tube

Heat sink front

17 K-439 Operation Manual, Version B

Page 18

4 Description of function

This chapter explains the basic working principle of the SpeedDigester K-439. It also shows how the

instrument is structured and provides a general functional description of its assemblies.

4.1 Functional principle

The SpeedDigester K-439 is a special heating device to digest samples. It can generate max. temperatures of 580 °C. This allows e.g. acid digestion of organic sample components in a concentrated

sulfuric acid / catalyst mixture, known as 'Kjeldahl digestion'. During the processing the sample

material can reach peak temperatures of up to 370 °C at the bottom area of the sample tubes. The

maximum temperature of the sample highly depends on its composition i.e. the ratio of catalyst to

acid and can change during the digestion process.

Digestion process overview

Environmental

air inlet

dangerous vapors are drawn away

4 Description of function

Acid vapor

outlet to

suction unit

(e.g. Scrubber)

4

2

Safety

zone

Insulation plate

(reclay insertion)

3

Infrared heating

(≈ 5 cm)

Condensation

zone

Boiling / digesting

sample

1

Processing steps:

• The infrared heating 1 generates high temperatures in the sample.

• Inside the sample tubes the digestion process takes place 2 while the acid is constantly boiling.

• Hot acid fumes rise into the condensing zone 3. After reflux, the acid flows back down to the

sample material, establishing a constant cycle.

• Residual fumes which escapes the condensation zone is highly corrosive (!) and hazardous to life

forms. It must be withdrawn by a suction unit that deliveres sufficient flow (i.e. with a Scrubber

B-414 or a water jet pump) 4.

Note

The condensation should not take place inside the safety zone in order to prevent digestion of the

sealing rings. In case the condensation is too close to the suction module (e.g. due to very high

temperature settings) the digestion fumes may escape and the sample can dry out!

18 K-439 Operation Manual, Version B

Page 19

5 Putting into operation

This chapter describes how the instrument has to be installed. It also gives instructions for the initial

startup.

Note

Inspect the instrument for damage during unpacking. If necessary, prepare a status report immediately to inform your Buchi representative. In some countries it is necessary to additionally inform the

postal company, railway company or transportation company. Keep the original packaging for future

transportation.

5.1 Installation site

Put the instrument into a fume hood onto a clean, stable and horizontal surface. Consider the

maximum product dimensions and weight. Obtain the environmental conditions as described in

section 3.2, technical data.

5 Putting into operation

Installation prerequisites and installation steps:

• The fume hood must be equipped with a heat- and acid-resistant lining.

• Do not place any objects on top or below the instrument.

• The instrument must be installed with a safety clearance of not less than 5 cm to any other

objects or walls to allow sufficient cooling.

• Do not place containers, chemicals or other items behind the instrument.

• When using a Scrubber B-414 it must be placed on the left side of the SpeedDigester.

Note

• T o cut the power in case of an emergency by unplugging, the instruments or any other items

must not block the mains plug!

• Any cooling of the SpeedDigester can disturb the digestion process. When switched 'On', the

Scrubber B-414 cooling fan emits from the left side of the housing. Hence the Scrubber B-414

should not be installed on the right side of the SpeedDigester.

!

DANGER

Death or serious injuries by use in explosive environments.

• Do not store or operate the instrument in explosive environments

• Do not store chemicals in the vicinity of the device

• Operate the device in a fume hood with sufcient ventilation to directly withdraw fumes

19 K-439 Operation Manual, Version B

Page 20

WARNING

!

Risk of death or burns by electric current.

• Check for proper grounding before use

• Exchange defective cabling instantly

CAUTION

!

Risk of minor or moderate injury by heavy weight of the instrument.

• Lift the instrument carefully and avoid over exertion

• Do not drop the instrument or its transport box

• Place the instrument on a stable, even and vibration-free surface

• Keep limbs out of crushing zone

5 Putting into operation

5.2 System fixation

In earthquake prone regions the instrument must be fixed to the fume hood bench. The penetration

depth of the stainless steel fixation screw must not be more than 10 mm.

System xation point

(insert nut)

Risk of instrument damage by earthquakes

• Safely attach the instrument to the bench in earthquake prone regions

• Use acid resistant stainless steel screws

Notice

2×

M4×10

20 K-439 Operation Manual, Version B

Page 21

5.3 Electrical connections

5.3.1 SpeedDigester connection

After the installation procedure has been completed successfully, the power plug of the SpeedDigester

must be connected to the mains for the digestion process.

5 Putting into operation

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for proper grounding

The used mains circuit has to:

• provide the voltage that is given on the type plate of the instrument.

• be able to handle the load of the connected instruments.

• be equipped with adequat fusage and electrical safety measures, in particular proper earthing.

See also technical data of all components regarding the different minimum system requirements!

Note

Additional electrical safety measures such as residual current breakers may be necessary to meet

local laws and regulations! External connections and extension lines must be provided with an

earthed conductor lead (3-pole couplings, cord or plug equipment). All used power cords shall be

equipped with moulded plugs only to avoid risks due to unobservant defective wiring.

5.3.2 Scrubber/water jet pump connection

To start the Scrubber B-414 automatically when the digestion process starts, directly connect it to the

SpeedDigester K-439 with the optional connection cable (Art. No. 14738).

Make sure that the voltage of the Scrubber B-414 corresponds to the voltage of the K-439.

Notice

1

2

Mains socket for

Scrubber connection

To connect a Scrubber/water jet pump the plastic adapter piece must be installed to the suction

module and the hose connector must be mounted at the EPDM hose of the suction module 1 (see

section 6.7.3).

Now connect the EPDM hose coming from the T-piece 2 to the Scrubber B-414 or the water jet

pump to exhaust the digestion fumes (for a more detailed description see the corresponding instruction manuals of these devices). Make sure that the hose connection is as short as possible.

21 K-439 Operation Manual, Version B

Page 22

6 Operation

This chapter gives examples of typical instrument applications and instructions on how to operate the

instrument properly and safely. See also section 2.5 “Product safety” for general warnings.

6.1 Operating controls and housing

The SpeedDigester K-439 is equipped with electronic temperature control, an integrated LC-display

and a membrane keypad with multifunctional keys.

Up to 50 methods can be programmed, 20 of which are already predefined by default.

A method consists of Preheat step, 4 possible temperature steps and cooling-down time.

The programmed method is visualized graphically and during the digestion process the actual temperature and the set temperature as well as the remaining time are displayed. The current status during

digestion is visualized by the icons at any time.

6 Operation

6.1.1 SpeedDigester K-439 — front side

Heating chambers

LC- display

Membrane keypad

USB interface

Mains switch

• The mains switch is illuminated green when the system is switched on

• USB interface — for service purposes only

• Membrane keypad — covered by anti-corrosion foil

• Graphical LC- display

• Two heating chambers

22 K-439 Operation Manual, Version B

Page 23

6.1.2 System rear side

6 Operation

Bracket with magnetic

(elbow) suction plugs

T-piece with

suction hoses

Type plate

Mains socket for

Scrubber connection

Power socket

Fuse holders

Fuse type:

T 10A L 250 V

• To access the glass fuses on the rear side use a slotted screwdriver.

➥ Slightly push in the slotted insert and turn it approx. a quarter-turn counterclockwise.

➥ Release the pressure off the insert — it will pop out by weak spring force.

23 K-439 Operation Manual, Version B

Page 24

6.2 User interface

Start

6 Operation

Stop

Multipurpose buttons

Button Functionality

Start

Stop

Starts a process

Stops a process

• Increases values such as time or temperature

+

• Selects adjustments

+

–

–

• Decreases values such as time or temperature

• Selects adjustments

Functionality changes on the basis of the corresponding button description on the display

24 K-439 Operation Manual, Version B

Page 25

6.3 Program structure overview

Main menu 1st submenu 2nd submenu 3rd submenu 4th submenu

Automatic - choose one or both rows to be

active

- activate timer

- activate Preheat continue/

Preheat wait

Start the digestion method

Methods List of methods

- user methods

- Buchi methods

History View the last 3 digestion

processes

Select the required

method

- Delete Methods

- Load Methods

6 Operation

Congure and

save a method

Manual Start a manual digestion

- choose one or both rows to be

active

- start the heating

- reset time

Settings Language

Display Contrast 15 to 85

Buzzer On/Off

Scrubber present Yes/No

Device Type K-439

Demo Mode: Yes/No

Acceleration 1 to 60

Diagnostics Actors Heaters temp.

Scrubber On/Off

Backlight On/Off

Sensors Voltage, Triac, Temp.

Sensor 1 and 2

Operating hours Power-on Time,

Heating Time, Row

Left, Row Right

Unit Information Version Firmware,

Test Date Print,

Version Print, Max.

Temp. Triac/LCD

Service Test Start Service Test

(IQ/OQ)

25 K-439 Operation Manual, Version B

Page 26

6.4 Software buttons

The following control buttons are available in the software for navigation and input confirmation:

6 Operation

Next

OK

ESC

Save

Enter

Preheat

Row

Go on to the next screen, go to the next stored digestion process in the "History"

Confirm and/or save a setting and get back to the main/previous screen

Get back to the main/previous screen without saving possible settings

Back button to move backward within in the submenu structure

Forward button to move forward within in the submenu structure

Back button to move backward in the lower submenu structure

Forward button to move forward in the lower submenu structure

Move up within the entries of a screen

Move down within the entries of a screen

Save a method

Confirm the entry of a character when naming a method

.. wait: hold temp. after preheat, start step 1 of digestion by pressing START

.. continue: start step 1 of digestion automatically after preheat is done

Select left, right or both rows to be heated

Timer

+ 10 min

Set °C

Delete

Load

Edit

Cancel

Prev

Reset

Yes

No

Set required time for the delayed start time in h : min

Extend the digestion for an additional 10 minutes

Adjust the temperature during a running digestion in Automatic mode

Delete a method

Load a method

Edit a method/settings

Cancel the latest entry

Go back to the previous screen/go to the previously stored digestion in the History menu

Reset time during Manual mode

Check rows individually (OQ Service test)

Check both rows at once (OQ Service test)

Start a temperature test (OQ Service test) / affirm a question

Negate a question

26 K-439 Operation Manual, Version B

Page 27

6.5 Software icons

The software icons explained in the following are visible during a digestion process. Most of them are

displayed in the upper part of the software screen and also remain visible when leaving the digestion

screen.

Just the general icon for the selected rows and the temperature reached as well as the heating icons

in the manual mode are only visible in the digestion screen.

6.5.1 General icons (used in automatic and manual mode)

The temperature of the heating chamber is ≥ 70 °C, i.e. the heating elements are hot

Scrubber is running

6 Operation

6.5.2 Icons in automatic mode

6.5.3 Icons in manual mode

Manual mode

Selected row(s)

Data of last, last but one and last but two digestion process in History menu

Preheat function "Preheat ..wait" active. Preheating in progress.

Preheat function "Preheat ..continue" active. Preheating in progress.

Preheating finished, preheat temperature reached

Step in progress

Heating off, cool down step running

Temperature reached, i.e. actual temperature equals set temperature

Heating, i.e. set temperature higher than actual temperature

Heating off, i.e. set temperature lower than actual temperature

27 K-439 Operation Manual, Version B

Page 28

6.6 How to prepare the software for routine digestion

Configure the software according to the following steps to prepare it for routine digestion:

1. Standard instrument settings

2. Manual mode (development of digestion method)

3. Digestion methods (storage of developed method)

4. Preheating

5. Start digestion

6.6.1 Standard instrument settings

This configuration consists of typical settings, which have to be defined before the instrument is used

for the first time. These settings do not have to be changed, as long as the instrument is not updated

or extended by any additional accessory (e.g. Scrubber B-414).

Select Main Menu > Settings.

The following screen appears:

6 Operation

The following settings can be entered:

• Language (select the required language (de, en, fr, it, es, jp, zh)

• Display Contrast (15 to 85)

• Buzzer (On or Off)

• Scrubber present (Yes, if connected / No, if not connected)

• Device Type (K-439, predefined, cannot be changed)

• Demo Mode (must be set to "No" for operation)

• Acceleration (only needed for Demo Mode)

28 K-439 Operation Manual, Version B

Page 29

6.6.2 Digestion in Manual Mode

The manual digestion mode is mainly used for the development of new digestion methods. The

temperature is set manually and can be changed at any time. The total runtime of the digestion is

displayed and can be reset.

Select Main Menu > Manual.

The following dialog appears:

6 Operation

• Set the required temperature by using the ± buttons.

• Select the row(s) to be active, by pressing Row and then the ± buttons. Then press OK to confirm.

• Now press START. The digestion is started. Set and actual temperatures as well as the total digestion time are displayed. The digestion temperature must be adjusted manually, if required.

• Once the digestion solution has become clear, continue to boil the solution for about 30 minutes.

• Press Reset to reset the run time to zero.

• Press STOP (to stop the heating).

If a Scrubber B-414 is connected, it keeps running until the STOP button is pressed again.

29 K-439 Operation Manual, Version B

Page 30

6.6.3 Methods menu

The software of the SpeedDigester K-439 provides 20 predefined Buchi methods, which can be used

for immediate digestion and as a basis for method development. Their names are always written in

lower case letters. They cannot be deleted but modified and stored under a new name.

When customer methods are available, the Buchi methods are always listed behind them.

Buchi methods

The following Buchi methods are available, e.g.:

• animal feed (for e.g. cat feed, dog feed)

• beer (for e.g. lager, wheat beer)

• beverages (for e.g. juices)

• cereal products (for e.g. flour, bran)

• chocolate (for e.g. dark and milk chocolate)

• creme (for e.g. copper lotion, face cream)

• dairy products (for e.g. milk, cheese, cream cheese)

• egg

• fertilizer (for e.g. solid and liquid fertilizers)

• function test (OQ)

• meat products (for e.g. salami, boiled sausage)

• micro kjeldahl (for e.g. milk)

• npn / ncn in milk

• nuts (for e.g. hazelnuts, almonds)

• pasta (for e.g. tortellini)

• pharma products (for e.g. tablets, drops)

• soy and tofu (for e.g. soy milk, soy sauce)

• tkn 300 (100 ml) (for e.g. water, waste water)

• tkn 500 (250 ml) (for e.g. water, waste water)

• whey powder (for e.g. WPC, whey powder)

6 Operation

In the following the definition of the method dairy products is listed as an example:

Preheat: 480 °C

Step 1: 480 °C 10 min

Step 2 550 °C 10 min

Step 3 490 °C 65 min

Step 4 50 °C 0 min (not used)

Cool down 80 min

Note

For all Buchi methods a cool down time of 80 minutes is defined in case the customer cools his

samples within the heating chambers. If the samples are cooled in the cooling postion, a cool down

time of 30 minutes is sufficient and the corresponding Buchi method can be adapted accordingly

and saved under a new name.

30 K-439 Operation Manual, Version B

Page 31

6 Operation

Defining/Editing a method

It is possible to enter 30 user specific methods. For this purpose an existing Buchi method can be

modified and saved under a new method name.

• Select Main Menu > Methods.

• Highlight the method that should be edited by using the up or down buttons.

• Press >> and afterwards >.

• Now press Edit.

• Select the temperature for preheating, time and temperature for the 4 possible digestion steps and

the cooling down time using the ± buttons.

31 K-439 Operation Manual, Version B

Page 32

6 Operation

Note

If the rack(s) is/are cooled down inside the heating chamber, the time for the cool down step in the

corresponding method must be set to ≥ 80 min, so that no harmful vapors can escape. If the racks

are cooled outside the heating chamber, the cool down step in the corresponding method must be

set to ≥ 30 min.

• Press Save.

• Now enter a name for the new method by highlighting individual letters on the virtual keyboard with

the ± buttons and press Enter to confirm a letter.

• Repeat this procedure until the name is completed.

• Press Save.

The new method now appears in the method list and can be loaded to start a digestion.

32 K-439 Operation Manual, Version B

Page 33

6 Operation

Deleting a method

The 20 Buchi standard methods predefined in the instruments software cannot be deleted.

A customer specific method can be deleted as follows:

• Select Main Menu > Methods.

• Highlight the method that should be deleted by using the up or down buttons.

• Press >>.

• Now press Delete. The following message appears:

• Press Yes to confirm. The selected method is now deleted.

33 K-439 Operation Manual, Version B

Page 34

Starting an automatic digestion by loading a method

• Select Main Menu > Methods.

• Highlight the method that should be loaded by using the up or down buttons.

• Press >>.

6 Operation

• Now press Load. The “Automatic” screen appears.

• Select the row(s) to be active, by pressing Row and then the ± buttons. Then press OK to confirm.

• To define an optional delay time for the start of the digestion, press Timer and enter the corresponding time (in hh:mm) using the ± buttons. Then press OK to confirm. The preheat function is

automatically set to "Preheat ..continue" when the timer is activated.

• To change the Preheat function, press Preheat and select "..wait" or "..continue" using the ±

buttons. Then press OK to confirm.

• Press the START button to start the preheating. As soon as the temperature entered for preheating

is reached, the system is ready to start the digestion. The display starts blinking and the buzzer

beeps three times to indicate the ready status.

• When the preheat function "Preheat ..wait" is selected, press the START button to start the digestion process.

When the preheat function "Preheat ..continue" is selected, the digestion process starts directly.

34 K-439 Operation Manual, Version B

Page 35

All entered steps are now run through automatically. The set and actual temperature as well as the

remaining time, which includes the entered cooling-down time, are indicated on the display

• As soon as the heating process is finished, the display starts blinking, the buzzer beeps and the

info message "Heating finished" appears. Confirm the message by pressing OK. The racks now

have to cool down.

• When the cooling time is over the display starts blinking, the buzzer beeps and the info message

"Digestion done" appears. Confirm the end of the process by pressing the OK button.

6.6.4 Digestion in Automatic Mode

A digestion in Automatic mode can be started in two different ways:

– Loading a method from the methods menu (see description above).

– Selecting the Automatic menu to start the method that was last used to carry out a digestion.

For this purpose:

• Select Main Menu > Automatic. The Automatic screen appears with the same settings as used for

the last digestion process.

• You can now select the row(s) to be active, by pressing Row and then the ± buttons. Then press

OK to confirm.

• To define an optional delay time for the start of the digestion, press Timer and enter the

corresponding time using the ± buttons. Then press OK to confirm. The preheat function is automatically set to "Preheat ..continue" when the timer is activated.

• To change the Preheat function, press Preheat and select "..wait" or "..continue" using the ±

buttons. Then press OK to confirm.

• Press the START button to start the preheating. As soon as the temperature entered for preheating

is reached, the system is ready to start the digestion. The display starts blinking and the buzzer

beeps three times to indicate the ready status.

• When the preheat function "Preheat ..wait" is selected, press the START button to start the digestion process.

When the preheat function "Preheat ..continue" is selected, the digestion process starts directly.

All entered steps are now run through automatically. The set and actual temperature as well as the

remaining time, which includes the entered cooling-down time, are indicated on the display.

The icons show, whether the heating elements are hot, the Scrubber is running, which step is

currently in progress and which rows are active. The current process status is indicated on a

progressive diagram.

6 Operation

• As soon as the heating process is finished, the display starts blinking, the buzzer beeps and the

info message "Heating finished" appears. Confirm the message by pressing OK. The racks now

have to cool down.

• When the cooling time is over the display starts blinking, the buzzer beeps and the info message

"Digestion done" appears. Confirm the end of the process by pressing the OK button.

35 K-439 Operation Manual, Version B

Page 36

6.6.5 History menu

The data of the last three digestions can be viewed/checked within the History menu

For this purpose select Main Menu > History. The History screen appears.

You can now navigate through the available digestion data using the Prev or Next button.

To view the set and actual temperature of a certain time within the digestion process use the ± buttons

to move forward or backward on the progressive diagram.

6 Operation

6.7 Preparing of SpeedDigester, suction module(s) and sample tubes

Section 6.7.1 and 6.7.2 describes the standard procedure for preparing a rack with sample tubes of

300 ml or 250 ml. When 500 ml tubes are being used, additionally refer to section 6.7.4.

Note

A rack may achieve a weight of up to 7.5 kg when loaded with samples and equipped with a suction

module. Be prepared for the weight when lifting a rack!

!

WARNING

Serious chemical burns by corrosives and peroxides.

• Observe supplementary data sheets of all used chemicals

• Handle corrosives and other chemicals in well ventilated environments only

• Always wear protective goggles

• Always wear protective gloves

• Always wear protective clothes

• Do not use damaged glassware

• Use only glassware from qualied vendors (see 2.5.4)

36 K-439 Operation Manual, Version B

Page 37

6 Operation

!

WARNING

Death or serious poisoning by contact or incorporation of harmful substances at use.

• Before operation, check the instrument for correct assembling

• Close unused suction module positions with glass caps

• Rinse suction modules, hoses and connectors before use

• Before operation inspect sealings and tubes for good condition and tightness

• Exchange worn out or defective parts immediately

• Only operate the instrument in a fume hood

• Directly withdraw released gases and gaseous substances by a Scrubber or a water jet pump

• Dispose of condensate in tubings and glassware safely after use

CAUTION

!

Risk of minor or moderate cuts when handling damaged glass parts.

• Handle glass parts with care

• Do not heat up empty sample tubes in the device

• Visually inspect every glass part before mounting

• Exchange damaged glass parts immediately

• Do not touch cracks or bits of broken glass with bare hands

6.7.1 Kjeldahl digestion —preparing sample tubes

During the preparation process, handling with strong acid and other dangerous substances is inevitable. Thus, all steps must be performed under safe laboratory conditions!

Prerequisites

• All sample tubes must be clean and free of damage.

• To achieve a reliable and reproducible digestion result the quality of sample material and additives

(e.g. acid and catalyst) must be free of impurities and of adequate amount.

Filling of a sample tube

• Take the sample tubes sequentially and weigh in sample material.

Add calatyst to the samples (e.g. Kjeldahl tablets, order no. 028765).

• Carefully(!) add sulfuric acid (≈ 98 %) of sufficient amount for the samples.

➡ The sample tubes can now be installed in the rack.

Note

• Note down the sample weight and position to keep the probe processing and its analysis reproducible. All racks are marked on top with a "1" for the first sample position.

• The rack(s) can be used as a temporary storage for empty tubes during the preparation process.

• When adding the sulfuric acid, rotate the tube to wash down any sticky sample material to the

bottom and to coat the inside of the tube.

37 K-439 Operation Manual, Version B

Page 38

6.7.2 Peroxide digestion —preparing sample tubes

During the preparation process, handling with peroxides and other dangerous substances is inevitable. Peroxides are strong oxidants and can form explosives! All steps must be performed under safe

laboratory conditions.

!

WARNING

Death or serious injuries by toxic and explosive peroxides.

• Use only damage free sample tubes

• Exchange worn out or defective parts immediately

• Handle peroxides in a fume hood

• Do not bring peroxides into contact with highly combustible material

6 Operation

Prerequisites

• All sample tubes must be clean and free of damage.

• To achieve a reliable and reproducible digestion result the quality of sample material and the

peroxide must be free of impurities and of adequate amount.

Filling of a sample tube

• Take the sample tubes sequentially and weigh in sample material.

• Carefully(!) add diluted sulfuric acid (e.g. 69%) of sufficient amount to the samples.

• Carefully(!) add peroxide (e.g. H2O2 30%) of sufficient amount to the samples.

➡ The sample tubes can now be installed in a rack.

Note

• Note down the sample weight and position to keep the probe processing and its analysis reproducible. All racks are marked on top with a "1" for the first sample position.

• The rack(s) can be used as a temporary storage for empty tubes during the preparation process.

• When adding the sulfuric acid and peroxide, rotate the tube to wash down any sticky sample

material to the bottom and to coat the inside of the tube.

38 K-439 Operation Manual, Version B

Page 39

6.7.3 Installing a suction module and sample tubes (300 ml)

To withdraw hazardous fumes and vapors a suction module must be installed.

Prerequisites:

All hoses and connectors must be unclogged.

Installation steps:

For installation and handling all parts must be < 40 °C!

• Install the plastic adapter piece to the suction module 1.

• Mount the hose connector at the EPDM hose 2 of the suction module (i.e. Scrubber B-414 or

water jet pump).

• The connector at the EPDM hose can be stored temporarily at the magnetic bracket at the rear

side of the SpeedDigester.

6 Operation

1

Rear side

Front side

2

• Insert the prepared sample tubes into the rack(s) — start with the first (front) position.

• When the digestion session does not require a full set of samples, then fit unused positions with a

glass cap to seal the suction circuit!

39 K-439 Operation Manual, Version B

Page 40

Note

• Make sure the adapter piece is tightened well without damaging the glassware.

• Keep suction hose(s) as short as possible under the given circumstances.

• Unused positions should be arranged at the rear end of the rack.

4

3

3

6 Operation

Rear side

• Lift the metal clips to unlock and shift the black handles 3 aside.

• Carefully push down the suction module 4 straight onto the sample tubes and shift the handles

back into locking position.

➥ The metal clips must snap in to securely lock the handles position!

5

*

6

C

*

K

C

I

L

Example with two glass

caps installed!

To Scrubber or

water jet pump

• Check for proper and tight seating of each rubber sealing 5.

➥ If necessary unlock the handles again and readjust the suction module!

• Plug the suction hose with plug onto the suction module 6.

➥ The plug catches with a noticable *click* sound.

40 K-439 Operation Manual, Version B

Page 41

• If applicable, follow the previous steps to install a suction module on a second rack.

• Switch on the Scrubber or water jet pump and activate the fume hood ventilation.

➡The rack(s) can now safely be processed in the SpeedDigester.

Note

• Clean all glass parts before mounting to avoid cross contamination.

• When a water jet pump is used, hazardous vapours can escape into the environmental air if the

suction is inadequate.

• If a Scrubber without condensation step is used, the condensate that accrues must be absorbed

by means of a Woulff bottle between the SpeedDigester K-439 and the Scrubber.

• When operating with 3rd party sample tubes no insulation caps and glass caps are available. In

this case, all positions must be equipped with samples!

• When operating with 300 ml sample tubes, close unused positions with a glass cap towards the

suction unit.

6.7.4 Installing 500 ml sample tubes

Unlike 300 ml (and 250 ml) sample tubes, 500 ml tubes can not simply be inserted into the appropriate rack. The information in this section serves to set up this type of sample tube properly and

safely in the rack.

6 Operation

Installation steps:

For installation and handling all parts must be < 40 °C!

2

rear side

1

C

*

*

K

C

I

L

3

frontside

• Plug the rack into the carrier 1.

➥ Two audible *click* sounds will appear as soon as the rack is securely locked at the carrier!

➥ Check the locking by lifting the rack together with the carrier (carrier must follow the rack)

41 K-439 Operation Manual, Version B

Page 42

6 Operation

• Insert the prepared sample tubes into the rack(s) 2— start with the first (front) position.

• Install the rake 3 to interlock the sample tubes at their head side. Check for secure interlocking!

• To separate the rack from the carrier, pull the unlock buttons 4 on both sides of the rack and lift it

off the carrier.

!

WARNING

Risk of death or serious chemical burns by acids or peroxides when rack tilts.

• Do not use faulty parts

• Install the rack on an even and stable surface

• Support the rack at the handlebars when installing the rake

• Check for proper seating and safe position of the glassware before lifting the rack from the

carrier

Glass cap (for unused positions)

5

4

• When the digestion session does not require a full set of samples equip unused positions with a

glass cap to tighten the suction circuit 5!

• Follow the installation steps in section 6.7.3 to install the suction module.

• If applicable, follow the previous steps to install sample tubes in a second rack.

➡ The sample tubes are now securely installed in the rack(s) and can now safely be processed in the

SpeedDigester.

Note

• Unused positions should be arranged at the rear end of the rack.

• Close unused positions with a glass cap towards the suction unit.

42 K-439 Operation Manual, Version B

Page 43

6.7.5 Starting up the SpeedDigester

System preconditions

The system must be correctly installed and fully functional. All parts must be in proper condition (e.g.

clean and free of damage). See also section 2.5 “Product safety” for general warnings!

Start-up procedure

• Select and install insulation plate(s) according to the type of sample tubes.

• Install insulation caps at unused positions of the insulation plate(s) for 300 / 500 ml racks.

• Make sure the SpeedDigester K-439 is properly connected to the mains supply.

• Make sure the Scrubber B-414 is properly connected to the K-439 or to the mains supply.

• Start the ventilation of the fume hood.

• Switch on the SpeedDigester K-439 at the mains switch at the front.

• The digestion can now be started in the Automatic or in the Manual Mode of the system.

Note

For operation with 3rd party sample tubes no insulation plates and glass caps are available. Hence,

all positions must be equipped with samples!

6 Operation

6.8 Performing a Kjeldahl digestion process

This section is divided into two consecutive sub-sections (6.8.1 and 6.8.2) and follow-up actions in

section 6.10. Do not skip or mix up these steps to ensure safe handling and best performance.

Note

Application notes are available for various samples at Buchi. These notes work as digestion recipes

and give detailed instructions how to process specific sample materials. For application notes,

contact your Buchi application specialist or your local distributor.

The 20 predefined Buchi standard methods help to operate the instrument "plug and play" and as a

basis to develop your own methods.

6.8.1 Preparational steps

1. Start-up the SpeedDigester.

2. Let the system heat up (Preheat function in Automatic mode)

3. Prepare the sample tubes according to the type of digestion under safe conditions.

➡ The samples are now ready to be digested.

6.8.2 Starting a digestion process

4. Install the rack(s) according to the chosen sample tube size.

➥ Place glass caps (order no. 040049) into every unused position of the rack

➥ Place insulation caps (order no. 11056024) into every unused position at the insulation plate

➥ To securely withdraw harmful fumes, switch on the suction unit (Scrubber or water jet pump)

before inserting the racks into the instrument!

5. The digestion process starts, as soon as the sample tubes heat up in the instrument.

➥The Scrubber must be switched on.

➥If the Scrubber is directly connected to the K-439, it will start as soon as "Step 1" of the

selected method starts and stops after the cooling-down time defined within the method is

finished.

43 K-439 Operation Manual, Version B

Page 44

➥ Depending on the sample material and acid / catalyst composition it might be necessary to vary

the digestion temperature at different time intervals (digestion method).

6. At the end of an Automatic digestion confirm the corresponding info message "Digestion done" by

pressing OK. At the end of a Manual digestion press Stop to finish the process, then switch off the

instrument via the mains switch.

➡ The samples are now digested. Follow-up actions are described in section 6.10.

6.9 Performing a peroxide digestion process

This section is divided into two consecutive sub-sections (6.9.1 and 6.9.2) and follow-up actions in

section 6.10. Do not skip or mix up these steps to ensure safe handling and best performance.

Note

Application notes are available for various samples at Buchi. These notes work as digestion recipes

and give detailed instructions how to process specific sample materials. For application notes,

contact your Buchi application specialist or your local distributor.

6 Operation

The 20 predefined Buchi standard methods help to operate the instrument "plug and play" and as a

basis to develop your own methods.

6.9.1 Preparational steps

1. Start-up the SpeedDigester.

2. Let the system heat up (Preheat function in Automatic mode)

3. Prepare the sample tubes according to the type of digestion under safe conditions.

➡ The samples are now ready to be digested.

6.9.2 Starting a digestion process

4. Install the rack(s) according to section 6.7.3. For peroxide digestion a 'Suction module H2O2' with

funnels must be installed!

➥ Place glass caps (order no. 040049) into every unused position of the rack

➥ Place insulation caps (order no. 11056024) into every unused position at the insulation plate

➥ To securely withdraw harmful fumes, switch on the suction unit (Scrubber or water jet pump)

before inserting the racks into the instrument!

5. The digestion process starts, as soon as the sample tubes heat up in the instrument.

➥The Scrubber must be switched on.

➥If the Scrubber is directly connected to the K-439, it will start as soon as "Step 1" of the

selected method starts and stops after the cooling-down time defined within the method is

finished.

➥ Depending on the sample material and acid / peroxide composition it might be necessary to vary

the digestion temperature at different time intervals (digestion method).

➥ During the digestion process it is necessary to add peroxide. Carefully and slowly(!) add peroxide

into every sample probe via the funnel of the suction module (see following illustration).

6. At the end of an Automatic digestion confirm the corresponding info message "Digestion done" by

pressing OK. At the end of a Manual digestion press Stop to finish the process, then switch off the

instrument via the mains switch.

44 K-439 Operation Manual, Version B

Page 45

➡ The samples are now digested. Follow-up actions are described in section 6.10.

!

DANGER

Risk of death or serious injuries by toxic and explosive peroxides.

• Use only original glassware and funnels

• Do not use damaged lter funnels

• Only add peroxides directly into the hot sample via lter funnel

• Exchange worn out or defective parts before digestion

• Handle peroxides in a fume hood

• Do not bring peroxides into contact with highly combustible material

6 Operation

Dispenser

with peroxide

Filter funnel

Rubber

GUKO

The funnels are placed decentralized (shifted out of the middle) above the sample tubes to prevent

peroxide dripping directly into the hot sample. The filter funnel ensures that the peroxide can not flush

into the hot sample to avoid dangerous deflagration of the peroxide and the sample.

45 K-439 Operation Manual, Version B

Page 46

6.10 Finishing a digestion process

WARNING

!

Risk of dangerous or moderate burns when handling hot parts and sample tubes.

• Do not touch any hot parts

• Let the system cool down

• Cover unused positions with insulation cap(s) at the insulation plate(s)

After the digestion process has been completed, the sample tubes must cool down!

Metal surfaces of the rack and the SpeedDigester might be hot!

➥When the Scrubber is directly connected to the SpeedDigester it is still running until the cooling-

down time is completed. Then it stops automatically.

➥ Let the rack cool down inside the heating chamber (can take more than 60 minutes!) or

(for racks with 300 ml / 250 ml tubes only) use the black handles at the rack to put one or more racks

into the cooling position of the SpeedDigester (see illustration below) as soon as the info message

"Heating finished" appears. Confirm the message by pressing OK.

• If the Scrubber is not connected, let the rack(s) cool down below 40 °C first, then switch off the

Scrubber or water jet pump.

• When the info message "Digestion done" appears, confirm it with OK. The suction module(s) can

now be removed. Be careful to avoid acid drops.

➥ The suction modules should be safely stored e.g on a "Stand with drip tray" (order no.

11055216) to safely collect remaining acid condensate. or

➥ Unplug the suction hose connector(s) from the suction module, place them on the

magnetic bracket and lift off the complete rack(s) including the suction module(s).

• To take the sample tubes off its rack, proceed with section 6.7.3 and 6.7.4 (for 500 ml sample

tubes only) in reverse order.

6 Operation

Caution

!

Risk of moderate chemical burns by splashing acid or peroxide drops.

• Carefully unplug the suction hose connectors

• Wipe off any liquid drops from the suction hose connectors

• Carefully store the magnetic suction hose connectors on top of the bracket at the

device rear side

• Avoid fast snapping of the magnetic catch

• Wear safety goggles

• Wear safety gloves

➡ The digestion output can now be processed (e.g. by a Kjeldahl distillation system).

46 K-439 Operation Manual, Version B

Page 47

6 Operation

Cooling positions of SpeedDigester K-439

The side position shown in the drawing below is only applicable for 300 ml and 250 ml sample tubes

and racks. Due to the larger diameter of 500 ml sample tubes the glassware does not fit between rack

and housing. Racks with 500 ml sample tubes must not be installed in this position (see illustration)!

300/250 ml rack in side position

(DO NOT USE THIS POSITION FOR 500 ml RACKS / TUBES)

Note

• A color change takes place during the cooling. At this time, the sample is still too hot to proceed!

• Digested samples which are left undistilled over a long period tend to solidify.

If this happens:

➥ Carefully add a small quantity of distilled water

➥ Alternatively: Slightly warm up the sample in the SpeedDigester again

47 K-439 Operation Manual, Version B

Page 48

Do NOT use the side positions with 500 ml rack / glasses!

!

6 Operation

!

500 ml racks must be placed beside the SpeedDigester K-439 to avoid a crash between the sample

tubes and the housing. Nonobservance will lead to hazardous situations especially when the sample

tubes are filled and hot!

!

WARNING

Death or serious injuries at glass breakage by hot acid and catalyst or peroxide.

• Do not place racks with 500 ml sample tubes into side position

• Place racks onto a stable horizontal surface inside a fume hood for cooling

48 K-439 Operation Manual, Version B

Page 49

6.11 Optional 'Stand with drip tray'

The optional accessory drip tray serves to collect condensated acid which might drip off the suction

module(s) after a digestion process and as a space saving way to securely store a suction module.

Stand with drip tray (illustration with suction unit)

6 Operation

Screw and holder-knob

Installing a drip tray

1. Screw the two holder-knobs into the designated threads at the side of your SpeedDigester.

2. Hook-in the frame of the drip tray.

➡ The tray is now ready to use.

49 K-439 Operation Manual, Version B

Page 50

7 Maintenance and repairs

This chapter gives instructions on maintenance work to be performed in order to keep the instrument in a good and safe working condition. All maintenance and repair work requiring the opening or

removal of the instrument housing must be carried out by trained service personnel and only with the

tools provided for this purpose.

Note

Use only genuine consumables and spare parts for any maintenance and repair work in order to

assure warranty and continued system performance. Any modifications of the SpeedDigester K-439

or parts of it need prior written permission of the manufacturer.

!

WARNING

Serious chemical burns by corrosives.

• Observe supplementary data sheets of all used chemicals

• Handle corrosives in well ventilated environments only

• Always wear protective goggles

• Always wear protective gloves

• Always wear protective clothes

• Do not use damaged glassware

7 Maintenance and repairs

WARNING

!

Death or serious burns by electric current.

• Switch off the instrument, disconnect the power cord and prevent unintentional restart before

touching the heating elements

• Do not spill liquids over the device

CAUTION

!

Risk of minor or moderate cuts when handling damaged glass parts.

• Handle glass parts with care

• Visually inspect every glass part for good condition before mounting

• Exchange damaged glass parts immediately

• Do not touch cracks or bits of broken glass with bare hands

50 K-439 Operation Manual, Version B

Page 51

7 Maintenance and repairs

Risk of housing and instrument damage by liquids and detergents.