Page 1

SEWING MACHINE

PQ1500

OPERATION MANUAL

Page 2

“IMPORTANT SAFETY INSTRUCTIONS”

“Read all instructions before using.”

When using a sewing machine, basic safety precautions should always be taken,

including the following:

DANGER – To reduce the risk of electric shock.

● The sewing machine should never be left unattended while plugged in. Always unplug the sewing machine from the electrical outlet immediately after using and before

cleaning.

● Always unplug before changing the light bulb. Replace bulb with same type rated 120V 15 watts for 120V model or rated 240V 15watts for 220-240V model.

WARNING – To reduce the risk of burns, fire, electric shock, or injury.

● Do not allow this sewing machine to be used as a toy. Close attention is necessary when the sewing machine is used by or near children.

● Use this sewing machine only for its intended use as described in this manual. Use only accessories recommended by the manufacturer as contained in this manual.

● Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. Return the

sewing machine to the nearest authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

● Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing machine and foot control free from the accumulation of lint,

dust, and loose cloth.

● Never drop or insert any object into any opening.

● Do not use outdoors.

● Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

● To disconnect, turn the main switch to the symbol “O” position which represents off, then remove plug from outlet.

● Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

● Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

● Always use the proper needle plate. The wrong plate can cause the needle to break.

● Do not use bent needles.

● Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

● Turn off power to the machine by flipping the ON/OFF switch to the symbol “O” before making any adjustments in the needle area, such as threading the needle,

changing the needle, threading the bobbin or changing the presser foot etc.

● Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or when making any other user servicing adjustments mentioned in the

instruction manual.

● This sewing machine is not intended for use by young children or infirm persons without supervision.

● Young children should be supervised to ensure that they do not play with this sewing machine.

CAUTION For U.S.A. only– This appliance has a polarized plug (one blade wider than the other) to reduce the risk of electric shock, this plug

is intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit. Contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

“SAVE THESE INSTRUCTIONS”

“This sewing machine is intended for household use.”

Page 3

CONGRATULATIONS ON CHOOSING

A BROTHER SEWING MACHINE

Your machine is the home use sewing machine available.

To fully enjoy all the features incorporated into it, we suggest that you study this booklet.

PLEASE READ BEFORE USING YOUR SEWING MACHINE

For safe operation

● Be sure to watch the needle while sewing. Do not touch moving parts such as the balance wheel, thread take-up or needle while the machine is operating.

● Remember to turn off the power switch and unplug the cord when:

●

Operation is completed

●

Replacing or removing the needle or any other parts

●

A power failure occurs during use

●

Maintaining the machine

●

Leaving the machine unattended

● Do not place anything on the foot controller.

● Plug the machine directly into the wall. Do not use extension cords.

For a longer service life

● When storing your sewing machine, avoid direct sunlight and high humidity locations. Do not store the sewing machine beside a space heater, iron, or other hot

objects.

● Use only neutral soaps or detergents to clean the case. Benzene, thinner, and scouring powders can damage the case and machine, and should never be used.

● Do not drop or hit the machine.

● Always consult the operation manual when replacing any accessories, the presser feet, needle or other parts to assure correct installation.

For repair or adjustment

In the event that a malfunction occurs or adjustment is required, first follow the troubleshooting table in the back of the operation manual to inspect and adjust the machine

yourself. If the problem persists, please consult your nearest authorized Brother service center.

Page 4

CONTENTS

Accessories .......................................................................1

Name of Parts ....................................................................2

Before You Begin ..............................................................3

Tension Dial ..............................................................3

Power Cord and Foot Controller ...............................3

Power Switch ............................................................3

Hand Wheel ..............................................................3

Stitch Length Regulator ............................................3

Reverse stitch lever ..................................................3

Presser Foot Lift Lever..............................................4

Knee Lift....................................................................4

Pressure Adjustment Dial .........................................4

Thread Cutter Button ................................................5

Needle Stop Position Button.....................................5

Light Switch...............................................................5

Feed Dog Adjustment Knob......................................5

Changing Needles and Light Bulb...................................6

Changing the Needle ................................................6

Changing the Feed Pin .............................................6

Changing Light Bulbs................................................6

Threading...........................................................................7

Bobbin Winding.........................................................7

Bobbin Insertion ........................................................8

Upper Threading .......................................................9

Using the Automatic Needle Threader......................9

How to Pull Out the Bobbin Thread ........................10

Stitch Samples and Needle Chart..................................11

Stitch Samples ........................................................11

Thread Tension.......................................................11

Changing Presser Feet ...................................................12

Changing Presser Feet ...........................................12

Presser Feet ...........................................................12

Basic Sewing ...................................................................13

Basic Sewing ..........................................................13

Pin Feeding (for hard-to-handle fabrics) .................13

Pin Feeding Unit .....................................................13

Rolled Hem Foot .....................................................14

Zipper Foot..............................................................15

Invisible Zipper Foot................................................16

1/4” Foot..................................................................16

Quilting Foot............................................................17

Walking Foot ...........................................................17

Lining ......................................................................18

Seam Guide ............................................................18

Caring for Your Machine ................................................19

Cleaning the Machine .............................................19

Lubrication Points ...................................................19

Trouble Shooting ............................................................20

CONTENTS

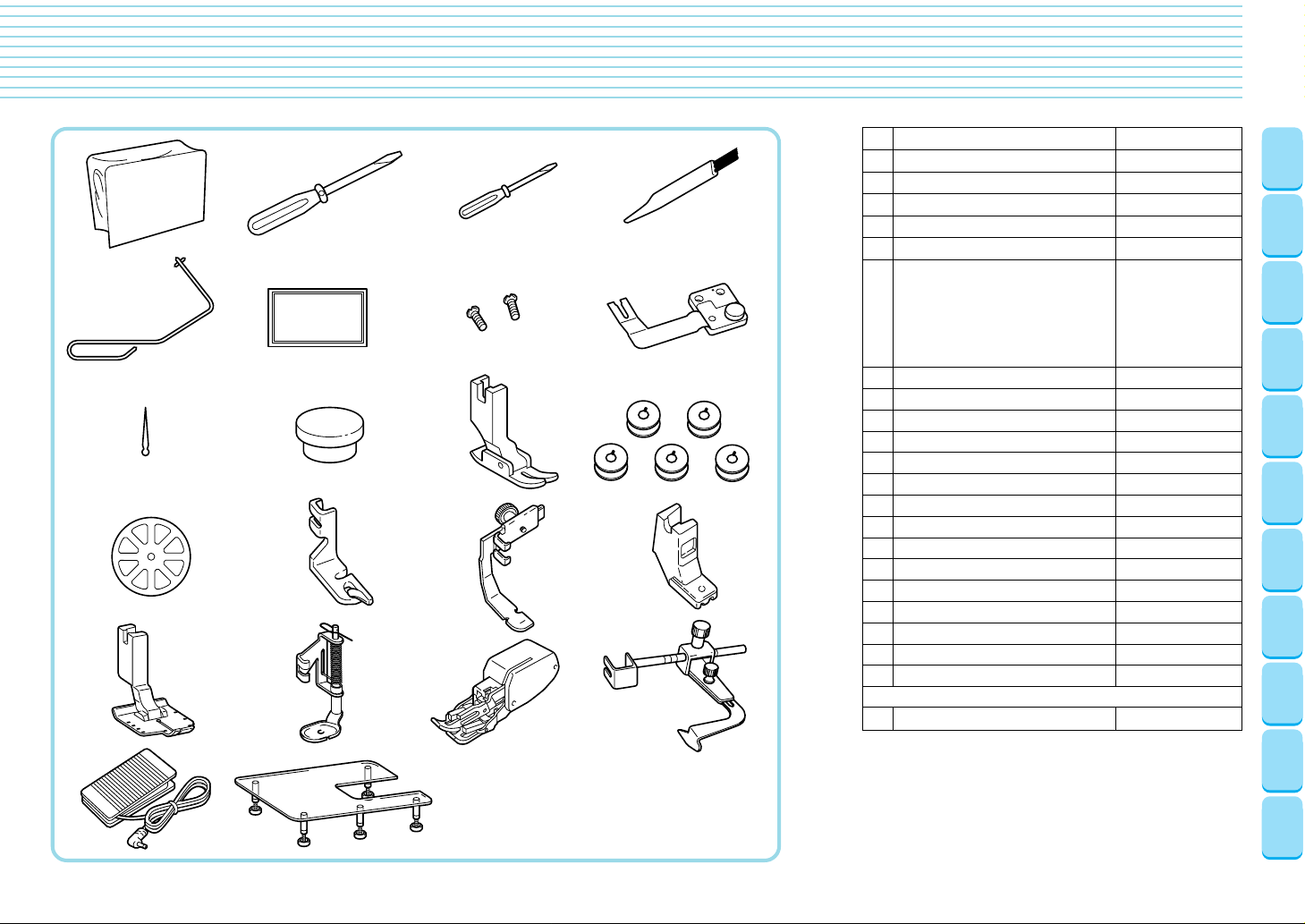

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 5

Accessories

1234

5678

9101112

13 14 15 16

17 18

21

22

19 20

No. Part Name Part Code

1 Cover XA0917-052

2 Medium Screwdriver 125877-001

3 Small Screwdriver 125878-001

4 Cleaning Brush XA4527-001

5 Knee Lift XA0830-001

6 Needles and Case 1 Size 9

(ORGAN HLX5) 2 Size 11

1 Size 14 X80805-001

1 Size 16

1 Ballpoint Needle

7 Lining Plate Screw (2) 062670-812

8 Fabric Separator 184720-001

9 Feed Pin 138483-001

10 Feed Pin Changer 117934-009

11 General Purpose Foot XA1425-001

12 Bobbin (5) SA159

13 Spool Cap XA2111-000

14 Rolled Hem Foot X57138-001

15 Zipper Foot 112797-001

16 Invisible Zipper Foot 148475-001

17 1/4” Foot XA7258-001

18 Quilting Foot XA7255-101

19 Walking Foot XA7253-001

20 Seam Guide XA7256-001

21 Foot Controller XA3931-051

Optional Accessories

22 Fabric Extension Table SA506

Note

Foot controller: Model N5V

This foot controller can be used for sewing machine

model PQ1500.

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

1

Page 6

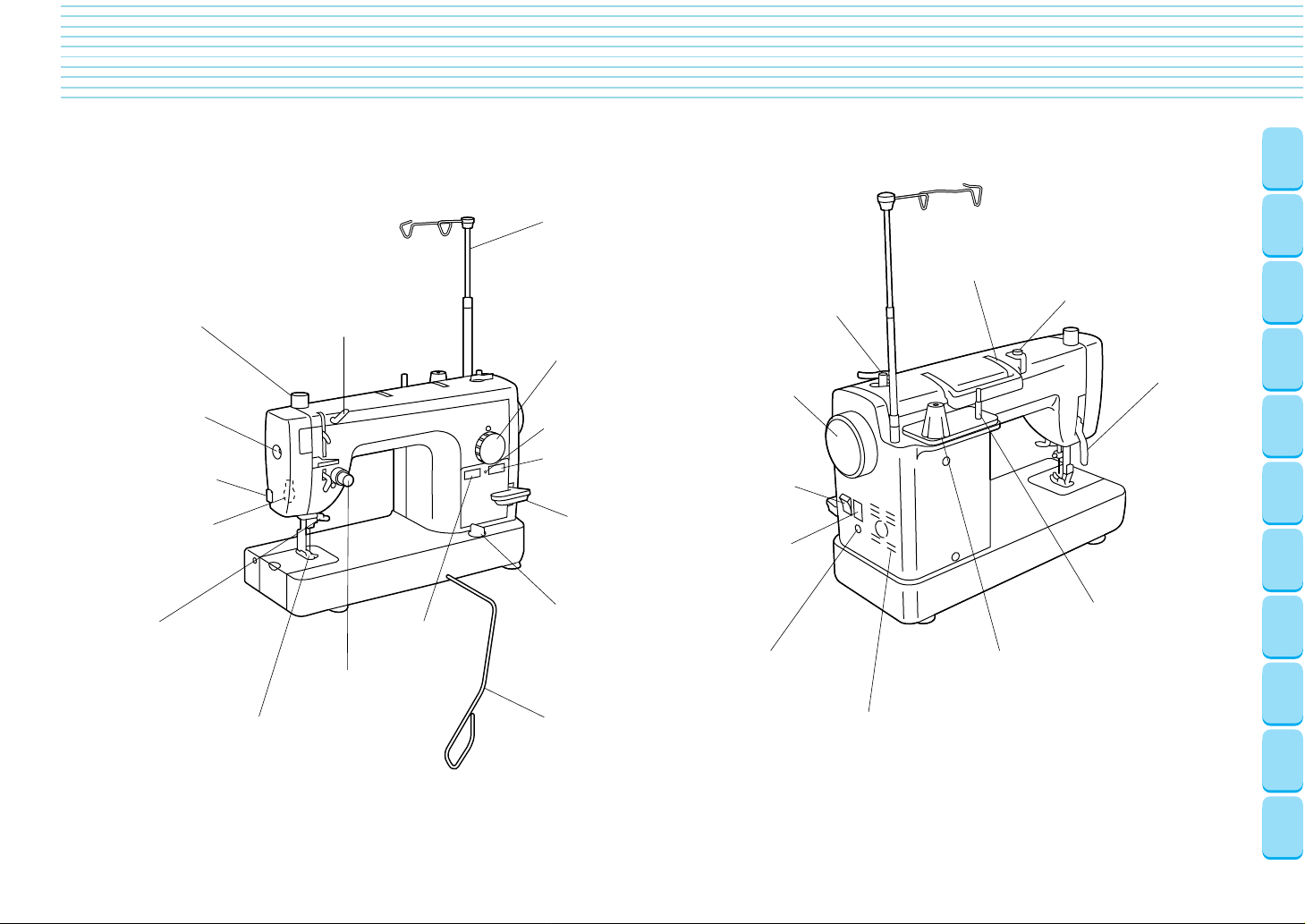

Names of Parts

CONTENTS

Pressure Adjustment Dial

(Page 4)

Light Switch

(Page 5)

Thread Trimmer

Sewing Area

Light (Page 6)

Automatic Needle

Threader (Page 9 and 10)

Feed Dogs

(Page 5 and 13)

Three Holed

Thread Guide (Page 9)

Thread Cutter

Button (Page 5)

Tension Dial

(Page 3 and 11)

Thread Guide Bar

(Page 7)

Stitch Length

Regulator (Page 3)

Indicator Lamp

Needle Stop Position

Button (Page 5)

Reverse Stitch

Lever (Page 3)

Feed Dog Adjustment

Knob (Page 5)

Foot Controller Jack

(Page 3)

Knee Lift

(Page 4)

Bobbin Winder

(Page 7)

Hand Wheel

(Page 3)

Power Switch

(Page 3)

Power Socket

(Page 3)

Air Vents

Handle

Spool Cushion

(Page 7)

Thread Guide for

Bobbin Winding (Page 7)

Presser Foot Lifter

(Page 4)

Spool Pin

(Page 7)

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

2

Shooting

Trouble

Page 7

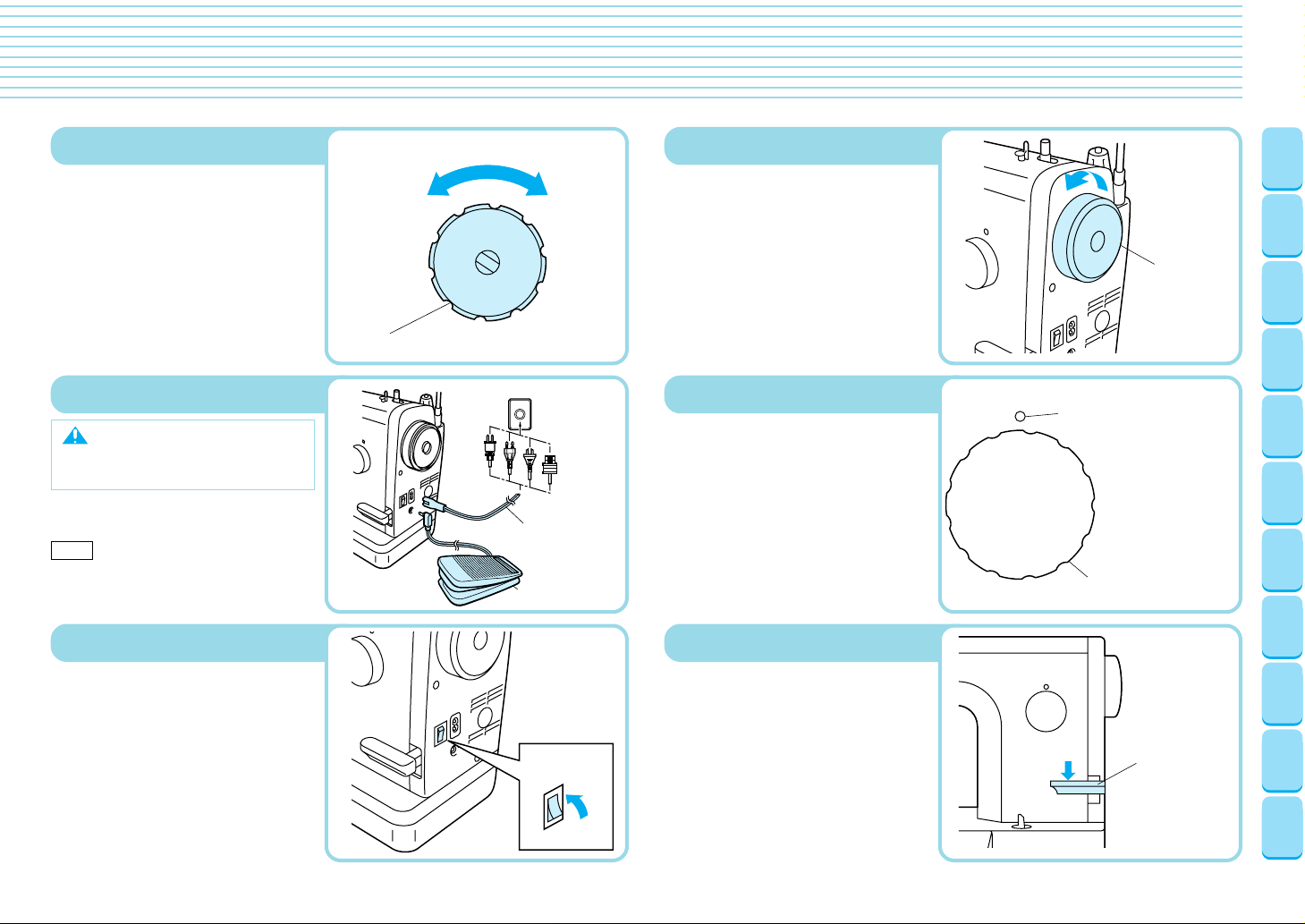

Before You Begin (1)

Tension Dial

Upper Thread Tension

CONTENTS

Hand Wheel

● When tighter tension is desired,

turn the tension dial to the right.

Upper and bobbin threads will

Loosen Tighten

meet on right side of the fabric.

● When looser tension is desired,

turn tension dial to the left. Upper

and lower threads will then meet

on wrong side of fabric.

Tension Block

Power Cord and Foot Controller

Note

Please use common household

current.

● Plug in cord.

● Plug foot controller into machine.

Note

Foot controller: Model N5V

This foot controller can be used for

sewing machine model PQ1500.

Power Switch

● Flip power switch to “I” position to

turn on.

● To switch power off, flip switch to

“O” position.

Power Cord

Foot Controller

Power Switch

I

O

● Position needle using hand

wheel.

✽ Always turn hand wheel towards

you.

Stitch Length Regulator

● Adjust desired stitch length using

stitch regulator dial.

Reverse Stitch Lever

● Sewing in reverse is possible

when the reverse stitch lever is in

the lowered position.

✽ Make sure to push the lever all

the way down when reverse sewing is desired.

✽ Stitch length for reverse stitches

is set for at least 5 mm.

Stitch length

Reference Mark

1

7

6

2

3

4

5

Stitch Length Regulator

Hand Wheel

Lower number

= shorter stitches

Higher number

= longer stitches

Reverse Stitch

Lever

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

3

Page 8

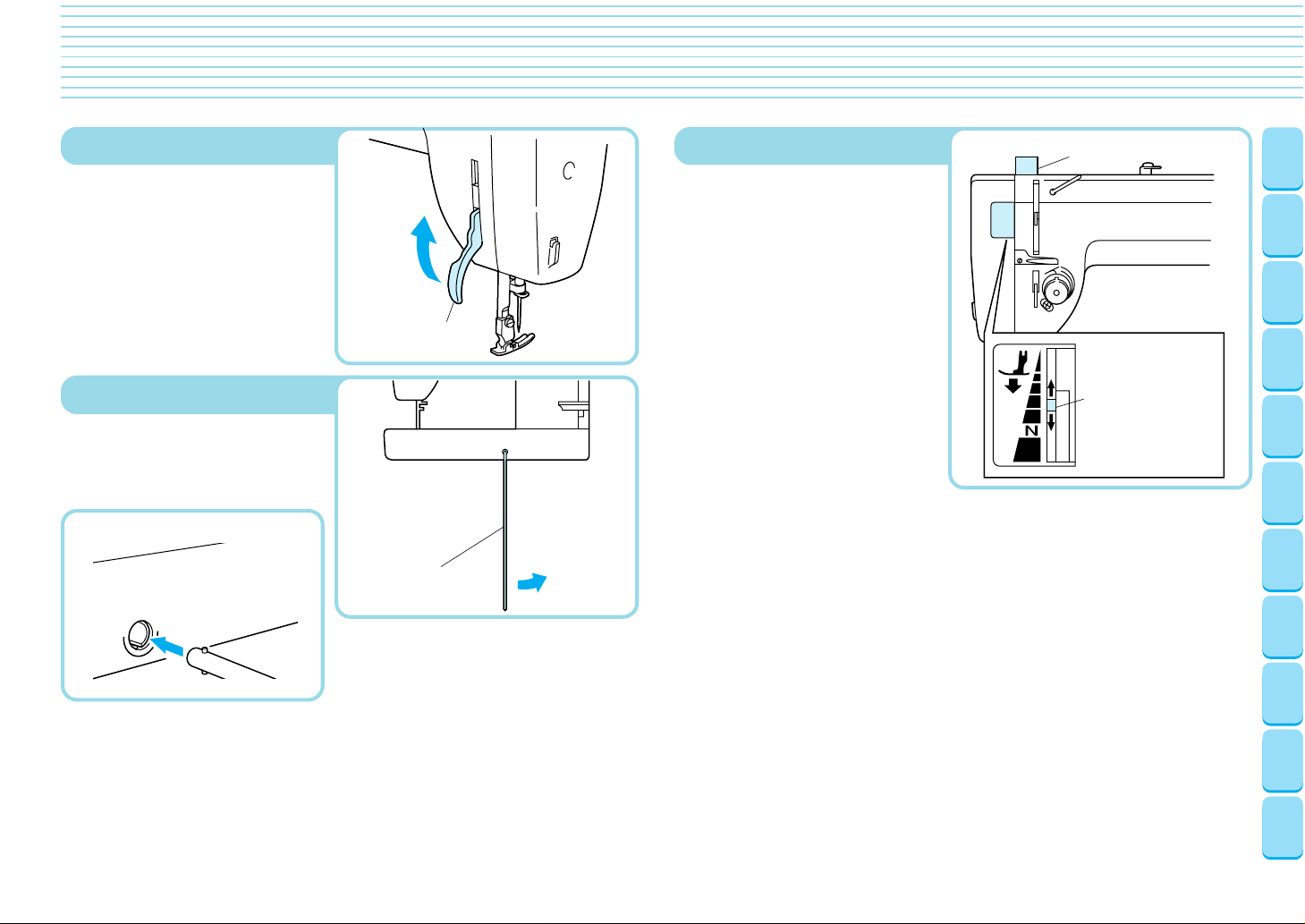

Presser Foot Lift Lever

Pressure Adjustment Dial

CONTENTS

Pressure Adjustment Dial

● Lowering the presser foot lift lever lowers the sewing foot down

onto the fabric and engages the

tension function.

✽ When working with heavy fabrics

or other fabrics that don’t slide

easily under the foot, raise the

presser foot lever to position the

fabric.

Knee Lift

● Using the convenient knee lift enables you to lift the presser foot

easily leaving your hands free to

work with the fabric.

Setting up the knee control.

Presser Foot

Lift Lever

Knee Lift

● Turning the pressure adjustment

dial raises and lowers the pressure indicator needle.

See also: “Feed Dog Adjustment

Knob” on page 5.

Pressure indicator

needle

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

✽ Push the knee lift all the way in.

4

Caring for

Machine

Your

Shooting

Trouble

Page 9

Before You Begin (2)

Thread Cutter Button

CONTENTS

Feed Dog Adjustment Knob

Note

When the machine stops due to jammed

threads and so forth, do not step on the

foot controller until turning the power off

and moving the needle with the hand

wheel to check the situation. Otherwise

broken needles could result.

●

The thread cutter trims upper and

bobbin threads at the end of seams.

Needle Stop Position Button

●

When indicator lamp is lit up, the

machine will stop sewing with the

needle lowered through the fabric.

● When indicator lamp is off, position of the needle when sewing

stops will be random.

● If the safety mechanism is activated, for example if the thread

becomes tangled, the red lamp

flashes.

Light Switch

● Push light switch to turn the light

over the sewing area on and off.

Light Switch

Thread Cutter Button

Indicator Lamp

Needle Stop Position Button

● Height of feed dogs can be adjusted to coincide with fabric

weights.

Feed Dog Adjustment Knob

Foot Pressure and Feed Dog Position

(Feed Dogs Down)

Velvet

(Pin Feeding)

Lightweight Fabrics

Middleweight Fabrics

Heavyweight Fabrics

Select one of four feed dog positions according to your needs.

Note

If a setting other than

is selected, the feed pin will not operate.

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

5

Page 10

Changing Needles and Light Bulb

Light

Bulb

Note

Please make sure power is off before carrying out

the following operations. There is a chance of injury

if the machine accidentally starts running during

this operation.

Changing the Needle

1 Turn the sewing ma-

chine off. Raise needle

to highest position using hand wheel, and

lower presser foot.

2 Loosen screw with

screwdriver, and remove needle.

3 Hold the needle with

the flat side to the right,

and insert the needle as

far as it will go. Make

sure needle is screwed

in tightly.

✽ Check needles on a flat

surface to make sure

they’re not bent.

Note

HLX5 needles should be uses; however, Schmetz 130/

705H may also be used under normal circumstances.

6

Screwdriver

The needle should lay

parallel to a surface.

Lay needle on

a flat surface

(such as the needle

plate or a plate

of glass).

Flat surface

Changing the Feed Pin

1

Set the feed dogs to “velvet” position. (see Page 5)

2

Remove needle, presser

foot and needle plate.

3

Lower presser foot and

turn hand wheel until feed

pin is in its highest position.

4

Insert small screwdriver (included) as shown in diagram.

5 While holding spring

with fingertip, lower the

feed pin changer onto

the needle to pick it up.

Attach new feed pin to

6

feed pin changer, lower

and attach while holding

spring with fingertip.

7 Remove screwdriver.

8 Re-attach needle plate,

needle and presser foot.

Note

Please make sure power is off before carrying out

the following operation. The glass plate over the

light bulb will be hot immediately after using the

machine, so you should wait until the machine has

had a chance to cool down before changing bulbs.

Changing Light Bulbs

1 Turn off power.

2 Remove screw from

head.

3 Remove bulb housing.

4 Unscrew bulb and re-

move.

5 Screw in new bulb.

Sewing Light:

See page 19.

6 Re-attach bulb housing

and tighten screw.

Screwdriver

230V

120V

Light

Bulb

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 11

Threading (1)

Bobbin Winding

Note

Do not move bobbin stop while machine is running.

2

Spool Cushion

CONTENTS

Spool Cap

Accessories

3

2

2 Lift thread guide bar all the way up,

and run thread through triangular

thread guide as shown in drawing.

1

4 - 9: See following illustrations.

1

3Run thread through bobbin winding

thread guide as shown in drawing.

1 Put spool of thread on spool pin.

✽ Use spool cushion when using cross

wound thread.

Thread Notch 1

Thread Notch 2

Bobbin

Bobbin Winder

Shaft

Guide Pin

4 Run thread through top thread notch

1, and align bottom thread notch 2

with guide pin on bobbin winder

shaft.

Spool of Thread

✽ Use spool cap when using parallel-

wound thread.

Bobbin Stop

5 Press bobbin stop up against empty

bobbin. If the bobbin stop does not

slide easily between the top and bottom of the bobbin, check that the bobbin is seated properly with the guide

pin (4) inserted into the lower notch.

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

7

Page 12

CONTENTS

Accessories

*

Place the thread end so that it

does not protrude from the bobbin.

6

While holding the end of the thread, step on

the foot controller for a few seconds. Once

enough thread has wound itself around the

bobbin to hold itself in place, release the

foot controller and trim the excess thread.

Bobbin Insertion

Bobbin Door

1 Lift slide plate (and open bobbin

door).

8

Bobbin Stop

7 Stop winding when bobbin is full.

8 Manually move bobbin stop back to

Take foot off foot controller.

CAUTION – Moving parts –

To reduce risk of injury, switch off before servicing. Replace cover.

Latch Spring

Slide Plate

Thread Notch

✽Bobbin should be

positioned so it

winds to the left

2 Put bobbin into the bobbin case.

✽ Run thread through thread notch and

under latch spring, so that a length of

about 10 cm is exposed.

✽ Use a bobbin case with an idling pre-

vention spring.

3

✽ If the latch lever is not all the way on

original position.

Pull the latch lever of the bobbin case

out and push the bobbin case into the

shuttle race and release the latch lever.

the hook, it may fly off during sewing

and cause lower thread breakage.

9 Cut thread and remove bobbin.

1

2

4 Lower slide plate and close bobbin

door, following numbers 1 2 above

in order.

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 13

Threading (2)

Note

Please turn power is off before using automatic needle threader. Accidentally stepping on the foot controller during this operation could cause bodily injury or damage to the machine.

CONTENTS

1

Upper Threading

7

6

8

4

2

3

5

9

0

A

Using the Automatic Needle Threader

Automatic

Needle

Threader

1

5

●

Make sure thread take-up lever is in

highest position and presser foot is up.

✽

When using polyester thread or thread

that tangles or breaks, run the thread

through all three holes of the thread guide.

4

6

2

3

7

8

✽ If the thread is still

tangles or breaks, run

the thread through the

holes backwards as

shown in diagram.

9

0

A

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

1

Pull hand wheel towards you until needle is in

the highest position, and lower presser foot.

2 Take thread in your left hand, and

gently pull it forwards.

Thread

Pin

3 Lower automatic needle threader.

Pull thread along the right side of the pin.

✽

✽

Do not force the needle threader lower than the

4 Catch thread with hook.

✽ Pull thread to the right, and make

eye of the needle which is in the highest position.

Hook

sure it has been caught with the hook.

5 Turn the hook and raise needle

threader lever while gently holding

the end of the thread.

Caring for

Machine

Your

Shooting

Trouble

9

Page 14

CONTENTS

Needle (HLX5) Thread

#11

#14

#16

6 Pull loop to the right.

How to Pull Out the Bobbin Thread

#9

#30

#30

#30

#20

#50 #60

● The automatic needle threader

cannot be used with the threadneedle combinations illustrated in

the chart to the left. Transparent

nylon thread can be used regardless of the chart, providing the

needle used is a #14 or #16.

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

✽ Insert threaded bobbin in sewing

machine and then begin.

1 While gently holding the end of the

needle thread, turn the hand wheel

towards you to raise the needle.

10

Turn the hand wheel once completely.

✽

2 Pull up the upper thread to pull the

bobbin thread out.

3 Pull approximately 15 cm of upper

and bobbin threads out.

✽ Lift foot and run both upper and bob-

bin threads under and behind

presser foot.

Caring for

Machine

Your

Shooting

Trouble

Page 15

Stitch Samples and Needle Chart

Stitch Samples

1 Set stitch length regulator to de-

sired stitch length.

2 Make sure approximately 15 cm

of upper and bobbin threads are

pulled out and laying behind

presser foot. While needle is in

raised position, insert a test strip

from the garment fabric under

the foot.

3 Lower presser foot.

4 Lower needle through fabric,

then step gently on presser foot

and begin.

5 Raise needle to highest point.

6 Lift presser foot, remove fabric

and then cut thread.

✽ When using thread cutter:

5 Push thread cutter button

6 Lift foot and remove fabric.

✽

Bobbin thread should feed smoothly. Adjust bob-

Thread Tension

bin thread to match that of upper thread. (If bobbin

thread is too tight it may cause fabric to bunch up)

Correct thread tension

Fabric

Upper

Thread

Bobbin tension . . .

Lower

Thread

Using the thread tension can lead

to such undesirable results as

messy stitches, puckered seams

and thread breakage.

●

Selecting the proper needle for use with the fabric and thread you are working with.

Bobbin tension . . .

Wrong side of fabric

Right side of Fabric

Wrong side of fabric

Right side of Fabric

Lower

Thread

Upper

Thread

Proper

When it is strong

Lower

Thread

Upper

Thread

Proper

When it is week

Adjust needle thread tension with dial

to increase

needle

thread

tension

Adjust needle thread tension with dial

to reduce

needle thread tension

to reduce

bobbin

tension

to increase

bobbin

tension

✽ The following chart applies to many different sewing methods.

Cloth Thread Needle (HLX5)

Velvet Silk, Polyester #30 – #50 #11 – #14

Special

fabric

Light

weight

fabrics

Middle Gingham Cotton #60 – #80 #11 – #14

weight Lightweight Jersey Polyester #60

fabrics Gabardine, Flannel Silk #50

Heavy Denim Cotton #20 – #50 #14 – #18

weight Jersey Polyester #20 – #50

fabrics Tweed Silk #20 – #50

Quilt Polyester #20 – #50

Synthetic Suede Polyester #20 – #50 #11 – #16

Knit Polyester #20 – #50

Coating Polyester #50 #11 – #14

Lawn Cotton #80

Tricot Polyester #60 #9

Silk Georgette Silk #50

Wool Georgette Silk, Polyester #50 #11

Fabric - Thread - Needles

#11

#11 – #16

HLX5

#9

#11

#14

#16

Schmetz

130/705H

#65

#75

#90

#100

✽ HLX5 needles are recommended; however, Schmetz 130/705H needles may

also be used under normal sewing conditions.

✽ Adjust pressure of sewing foot and drop feet height according to chart.

✽ When sewing on knit fabrics such as jersey or tricot, use a ballpoint needle or

other needle designed for use with knit fabrics.

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Threading

Samples and

Needle Chart

Presser Feet

Changing

Sewing

Basic

Machine

Your

Shooting

Trouble

11

Changing

Stitch

Caring for

Page 16

Changing Presser Feet

Note Make sure the power is off before changing presser feet.

Changing Presser Feet

(Zipper Foot)

1 Raise presser foot, and raise

needle to highest position.

2 Loosen and remove screw using

screwdriver.

3 Attach zipper foot and tighten

screw.

✽ Use the same method to attach

the other feet that come with your

PQ1500.

✽ See page 17 for directions on at-

taching the Walking Foot.

✽ Use the position knob on back of

the zipper foot to adjust position

of foot in relation to needle.

✽ Only the zipper foot has a posi-

tion knob. You can begin sewing

with all other presser feet immediately after attaching.

Presser Feet

● Pin Feed Foot

For perfect stitching on otherwise

difficult fabrics like

velvet, leather and

suede.

● Rolled Hem Foot

Use on the edges

of fabric, such as

on hems of dress

shirts, to fold the

edge of the fabric in

three while sewing.

● Invisible Zipper

Foot

Use to attach concealed fasteners.

● Quilting Foot

Spring action foot

for darning, quilting

or free-motion embroidery.

✽

Use only feet supplied with your PQ1500. Each foot is specially designed for this machine and has clearance for the pin

at the rear of each foot. Use of other presser feet with the PQ

series machines may damage or break the pin mechanism.

●

General purpose Foot

This foot is used for

most sewing. (Can also

be used for sewing

thick fabrics or seams.)

✽

When sewing thick

seams, lightly guide

the fabric with your

hand and on the downward side of the seam.

✽ Can also be used

with pin feeding

● Zipper Foot

Use to attach fasteners other than concealed fasteners.

● 1/4” Foot

For quilt and patchwork piecing with

1/4” or 1/8” seam

allowance.

● Walking Foot

For sewing or quilting on fabrics which

stick or tend to slip

Useful for sewing

multiple layers as in

quilting.

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

12

Page 17

Basic Sewing (1)

Basic Sewing

CONTENTS

Before

sewing.

1 Lift foot, pull about 15 cm of upper

and bobbin thread under and behind

foot, and position fabric under foot.

Begin

sewing.

2 Lower foot.

3 While needle is pierced all the way

through fabric, step gently on foot

controller.

Pin Feeding (for hard-to-handle fabrics)

Indicator Needle

Fabric:

Velvet

Quilt

Synthetic Suede

Knit

Coading

Others

✽ The above fabrics

can be sewed

neatly by sewing

by pin feeding.

1

Move feed adjustment knob

to pin feeding position.

2 Adjust pressure ad-

justment dial until indicator needle is in

the right position.

Finish

Sewing.

4 Raise needle to highest position.

5 Lift foot, remove fabric and cut

thread.

✽ When using thread trimmer:

4 Push thread trimmer button (this will

cause the upper and bobbin threads

to be cut automatically and the

needle to stop in a raised position.)

5 Lift presser foot and remove fabric.

3 Gently pull thread until feed pin

catches fabric and sew.

✽

When changing sewing directions.

Reinforcement stitches

1 cm

1 cm

1 Make sure needle is pierced all the

way through fabric.

2 Lift presser foot, and turn fabric us-

ing needle as an axis.

3 Lower foot continue sewing.

✽ At the beginning of a seam, sew a

few stitches with the hand wheel, hit

the reverse stitch button and sew a

few stitches back to reinforce your

seam, then go back to normal sewing and finish the seam. Do the

same at the end of a seam.

Pin Feeding Unit

Fabric

Feed Pin

Feed Pin

The feed pin passes up through all layers of fabric moving with the feed dog’s motion

to feed all layers of the fabric evenly.

✽ For safety, the feed pin is automatically lowered when presser foot is raised.

Feed Dog

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Threading

Samples and

Needle Chart

Presser Feet

Changing

Sewing

Basic

Machine

Your

Shooting

Trouble

13

Changing

Stitch

Caring for

Page 18

Basic Sewing (2)

Note Make sure power is off before changing feet.

Rolled Hem Foot

1 Attach rolled hem foot.

✽ Refer to page 12 for instructions

on changing sewing feet.

2 Insert needle approximately 0.5

cm from the edges of the fabric

and sew 2 stitches.

3 Raise needle and foot, pull fabric

towards you.

0.5 cm

0.5 cm

5 With your right hand, put the

edge of the rolled hem under the

presser foot, from the spot where

the threads come out. Insert the

edge so that it lies directly under

the needle.

Rolled Hem

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

4 Hold the 4 threads in your left

hand.

14

6 Pull gently on threads in left hand

while sewing the first 3-4 stitches

to hold them in place.

7 Fold hem over about 0.5 cm and

continue feeding folded hem under foot while sewing.

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 19

Basic Sewing (3)

Note

• Make sure power is off before changing feet.

• When attaching zippers to stretch fabrics, use the pin feed method

and adjust foot pressure accordingly.

Zipper Foot

1 Attach zipper foot.

2 Turn hand wheel to lower needle

and adjust position of foot to

needle.

CONTENTS

5 Sew zipper onto fabric along

mark.

Accessories

Make sure the needle does

not strike the metal part of the

zipper when sewing. The

needle may break and cause

Names of

Parts

injury.

6 Line up folded seam to stitches.

A

Before You

Begin

Needles and

Light Bulb

Changing

3 Line up zipper to the section of

fabric it will be attached to, and

mark the base of the opening on

the fabric. It should be set approximately 0.5 cm below zip

stop.

4 Fold hem about 0.2 cm from

mark, and make a mark along the

edge. Separate the seam allowance.

Slide

0.5 cm

0.2 cm

Stop

Base of

Opening

7 Change position of zipper foot.

8 Turn hand wheel to lower needle

and make sure the needle and

position of the foot are lined up

properly.

Baste zipper onto fabric and sew

9

along edge with fabric right side up.

✽ Reinforce base of opening by

sewing over it twice.

✽ If the zipper slide gets in the way,

lower the needle all the way

through the fabric, lift the foot, and

move the slider out of the way.

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

B

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

15

Page 20

Invisible Zipper Foot

Top of fabric

Seam

(1/8”, 3.2 mm)

Teeth

CONTENTS

1/4” Foot

1 Attach invisible zipper foot.

2 Align zipper with fabric. Mark the

base of the opening approximately 2 cm above the end of the

zipper.

3 Separate the seam allowance.

4 Line up zipper with fabric on the

wrong side of the fabric, open

zipper, and baste zipper to the

fabric.

5 Sew the zipper to the fabric with

the wrong side of the zipper and

fabric up.

Slide

Basting

Base of

Opening

2cm

● Sewing machine settings:

Stitch length = 2 - 2.5

• Sew a consistent seam allowance (1/4”, 6.4 mm) when piecing together a quilt.

• Use guides (mark) to begin, end,

or pivot 1/4” from edge of fabric.

• Accurately top stitch 1/8” from

seam.

Beginning

of

stitching

Seam allowance

(1/4”, 6.4 mm)

Align this

mark with

edge of

fabric

End of

stitching

Align this

mark with

edge of

fabric

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

✽ When sewing with the teeth to

the right, the left side of the foot

should line up with the left teeth

of the zipper.

16

Caring for

Machine

Your

Shooting

Trouble

Page 21

Quilting Foot

Forked part

of operation

lever

Secure the

capscrew

with a

screwdriver.

1

2

CONTENTS

Walking Foot

Reduce the foot presser and turn the

dial on the machine lowering the feed

dogs for free motion quilting.

Also the needle threader will not work

when this foot is in use.

Note

• Do not press the pedal all the

way down.

Try to keep the sewing speed below 70% of the maxinum speed.

• The cloth may not feed if you

sew at high speeds.

• The feed dog for feeding the

cloth may not move if the clamping pressure on the cloth is too

strong.

• It is not advisable or necessary

to use the Pin Feed mode with

the walking foot.

1 Insert the forked part of the op-

eration lever while raised in an

upright position onto the screw

as shown and then insert the

capscrew.

2 Tighten the screw securely with a

screwdriver. Tightening adequately is important as the

screw might loosen due to the

foot and forked operation lever

vibration.

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

17

Page 22

Lining

1 Raise needle and foot.

2 Move separator so it sits under

presser foot.

3 Make sure it is lined up so that

the needle passes through the

slot of the separator without hitting the plate itself.

4 Secure liner plate in place with

lining plate screws.

5 Set pressure of sewing feet and

feed position to pin feeding position.

6 Pull thread until lower needle

catches fabric.

✽ Sew 2-3 reinforcement stitches.

Separator

Fabric

Separator

Lining

Separator

Velvets

Needle

Needle

• Use the separator to neatly sew 2 hard to manage fabrics together by keeping

them from interacting with one and other before the needle sews them together in a perfect seam.

Seam Guide

1 Tighten the screw securely with a

screwdriver since it might otherwise loosen due to vibration.

1

CONTENTS

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

7 When not using separator, it can

be swung off to the side as illustrated in drawing.

Note

• Lighten the presser foot pressure slightly when using the fabric separator.

18

To be able to adjust the position of

the foot towards the arrow.

Installation

Adjustment

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 23

Caring for Your Machine

Cleaning the Machine

CONTENTS

Lubrication Points

Note

Make sure power is off before

cleaning sewing machine.

1 Turn machine off.

2 Remove foot.

3 Remove needle plate.

4 Clean out dust and thread

scraps.

✽ Thread scraps can be swept out

through the bobbin door.

5 When the area under the needle

plate is cleaned out, oil hook of

bobbin case with sewing machine oil.

✽ Use a cloth to clean the machine

of any excess oil.

6 Attach needle plate and foot.

Hook

● Oil the machine approximately

once per month.

✽ Use a cloth to wipe the machine

clean of any oil spilled near the

lubrication points.

■ Keep Your Sewing Machine Clean

Please use a soft, dry cloth to wipe off light dirt and

dust. If sewing machine is very dirty, wipe with a cloth

soaked in warm water, or in warm water containing a

neutral detergent. Then wipe off any detergent residue,

and wipe off water with a dry cloth.

■ Precautions

Please keep sewing machine away from heat sources

such as irons and space heaters. Do not use chemicals

like benzine or thinner to clean your machine. When

machine is not in use, please keep machine out of direct sunlight.

Item

Sewing Speed

(maximum)

Stitch Length

(pitch)

Stroke of

Needle

Stroke of

Thread

Take-Up Lever

Foot Height

Specification

1,500 stitches per minute

0 – 7 mm

34.1 mm

64.7 mm

Foot Lift One 6 mm

Knee control Over 10 mm

Two 9 mm

Item

Height of feed dog

Height of

lower needle

Needles that

may be used

Bed dimensions

Total weight

Sewing Light

Sewing area

Specification

0.7 mm 1.1 mm

3 mm – 3.5 mm

HLX5#9 – #18

SCHMETZ 130/705H #65 – #100

439 mm × 178 mm

120V model:

220-240V model:

11 kg

120V/15W

Parts code: X53061-000

240V/15W

Parts cord: 205336-000

595 mm × 285 mm

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Threading

Samples and

Needle Chart

Presser Feet

Changing

Sewing

Basic

Machine

Your

Shooting

Trouble

19

Changing

Stitch

Caring for

Page 24

Trouble Shooting

✽ Before taking your sewing machine in for service, check the following chart.

Thread

Breakage

Bobbin Thread

Breakage

Skipped

Stitches

Fabric

Puckers

Fabric Won’t Feed

Properly or Irregular

Stitches

Loop In

Seam

Needle

Breakage

Sewing Machine

Doesn’t Run

Machine Is

Noisy

Automatic Needle

Threader Doesn’t

Work

Thread Cutter

Doesn’t Work

Upper threading is not

threaded correctly.

Re-thread machine

properly.

Bobbin thread is not passing

correctly from bobbin case.

Reinsert bobbin

properly.

Needle is not attached

correctly.

Reattach.

Threading is incorrect.

Rethread machine.

Stitch length is too short.

Adjust stitch length.

Upper threading is

incorrect.

Re-thread machine

properly.

Needle is not attached

correctly.

Reattach.

The power isn’t on.

Turn the power on.

The area under the needle

plate needs to be cleaned.

Clean feed dog and

bobbin case.

Needle is not raised

all the way up.

Turn hand wheel to

raise needle.

Needle is not properly

attached.

Reattach.

8-10

19

Thread is getting tangled.

Rethread machine.

Clean bobbin case and under

9

needle plate. Oil the machine.

Thread is getting tangled.

Rethread machine.

Clean bobbin case and

8

under needle plate.

Wrong needle.

See chart on p.11 to choose the

needle that best fits your

6

fabric-thread combination.

Wrong needle for the fabric

and thread you are using.

See chart on p.11 to choose the

needle that best fits your

fabric-thread combination.

Pressure of sewing foot is

too weak.

Increase foot pressure.

3

Thread is not passing through

bobbin case correctly.

Reset bobbin case.

9

Wrong needle.

Change needles.

6

Machine’s not plugged in.

Check to make sure the

machine’s plugged in.

3

Machine is out of oil.

Oil the machine.

Wrong needle for the

thread you’re using.

See chart on p.11.

3

Wrong needle.

See chart on p.11 to choose the

needle that best fits your

6

fabric-thread combination.

8-10.19

8-10.19

20

19

11

11

11

11

Upper thread tension is

too high.

Reduce tension.

Bobbin tension is too high.

Reduce tension.

Needle is bent, or tip is

dulled.

Change needles.

Upper thread tension is

too high.

Reduce tension.

Sewing heavyweight fabric with

feed dogs in lightweight fabric

position.

Adjust feed dogs.

4

Improper fabric/needle/

thread combination.

See chart on p.11 for the right

needle to use with your

8

fabric and thread.

Improper fabric/needle/

thread combination.

See chart on p.11 for the right

needle to use with your

6

fabric and thread.

The foot controller has

come unplugged.

Reattach foot controller.

3

Hook of needle threader doesn’t

pass through eye of needle.

Check to make sure the

hook isn’t bent.

Needle is bent, or tip is

dulled.

Change needles.

11

11

11

11

11

Improper fabric/needle/

thread combination.

See chart on p.11 for the right

needle to use with your

fabric and thread.

Bobbin case is scratched.

Remove needle plate and

check bobbin case.

Area under needle

plate needs to be cleaned.

Clean feed dog and bobbin

case. Oil the machine.

6

Bobbin tension is too high.

Reduce tension.

Thread is getting tangled.

Rethread machine. Clean needle

plate and bobbin case.

5

You’re pulling the fabric

too hard.

Pull the fabric

more gently.

Machine is out of oil.

Clean and oil the

machine.

3

Using the automatic needle

threader incorrectly.

Check the use of the automatic needle threader.

Area under needle plate

needs to be cleaned.

Clean feed dog and

bobbin case.

6

11

19

11

8-10.19

13-16

19

9

19

Bobbin case is scratched.

Remove needle plate and

check bobbin case.

Machine is not threaded

properly.

Rethread machine.

You’re sewing a lightweight fabric with

feed dogs in heavyweight position.

Adjust feed dogs.

The automatic safety

device has operated.

Upper threading is

incorrect.

Rethread.

8-10

5

9

CONTENTS

If you still cannot find the problem, please take your sewing machine into the

shop where you purchased it, or your nearest Brother dealer for repair.

Accessories

Names of

Parts

Before You

Begin

Needles and

Light Bulb

Changing

Threading

Samples and

Needle Chart

Stitch

Presser Feet

Changing

Sewing

Basic

Caring for

Machine

Your

Shooting

Trouble

Page 25

ENGLISH

116-635

193635-0061

Printed in Japan

Loading...

Loading...