Page 1

MD-6020

Single-phase power specifications

$4SEI!illl.

Especiflcaciones de alimentaci6n de fase unica

MD-6120

Three-phase power specifications

:4SEI!iill~

Especificacion~s

AC SERVOMOTOR

Please read this instruction manual before using the machine.

Please keep this instruction manual within easy reach for quick reference.

SERVOMOTOR DE AC

Por favor lea este manual de instrucciones antes de usar

Por favor guarde este

de alimentaci6n de tres fases

manual de instrucciones al alcance de

Ia

maquina.

Ia

mano para una rapida referencia.

INSTRUCTION MANUAL

-fi,EijljtP.,ij~

MANUAL DE INSTRUCCIONES

Page 2

AC SERVOMOTOR

MD-6020

MD-6120

Single-phase power specifications

Three-phase power specifications

CONTENTS

SAFETY INSTRUCTIONS ..............................

1. SAFETY INDICATIONS

MEANINGS

2.

CAUTIONS WITH REGARD TO

SAFETY.......................................................... ii

3. WARNING I..ABEL ........................................ ii

1. SPECIFICATIONS .......................................

2.

UNDERSTANDING

3. INSTALI..ATION ............................................. 2

3-1. Installing the

table......................................................... 2

3-2. Attaching the belt................................... 2

Installing the belt cover......................... 3

3-3.

3-4. Connecting the connecting rod ............ 3

3-5. Adjusting the

mechanisms ............................................ 3

3-5-1. Adjusting the

3-5-2. Adjusting the finger guard......... 3

3-6. Connecting the cords............................. 4

3-6-1. Connecting the power cord,

3-6-2. Connecting the sewing machine

Installing the head lamp........................ 6

3-7.

3·8. Connecting the external operation

panel........................................................ 6

4. ADJUSTING THE TREADLE

4-1. Operating the treadle............................. 7

4-1-1. For treadles

4-1-2. For treadles

.................................................. .

motor

prevention guide......................... 3

power

cord............................................... 4

and control box ........................... 4,5

and one rear stage...................... 7

and

switch and ground

two

AND

THEIR

THE

RATING

to

belt cover safety

belt casting

with

with

rear stages.................... 7

PLATE

the work

UNIT

one forward

two

forward

..

..

......

.......... 7

4-2. Adjusting the

4-2-1. Adjusting the treadle pressure

4-2-2. Adjusting the

pressure....................................... 8

4-2-3. Adjusting the

4-3. When using the automatic presser

lifter device ............................................. 8

5. USING THE CONTROL BOX .................... 9

5-1.

Power switch and power indicator....... 9

5-2.

Setting the sewing speed ...................... 9

5-3.

1

6.

7.

8.

Control box

procedure................................................ 9

5-4.

Description

5-4-1. Backtacking function using

the

operation

5-4-2. Other

5-5.

Periodic checks .......................................

CONNECTING OPTIONS ...........................

6-1.

Connecting the pedal

operations .......... ........ ............. ........ ........

6-2.

Connecting the material edge sensor

TROUBLESHOOTING ................................. 14

7-1.

Error display and their meanings ......... 14

USING THE OPERATION PANEL F-40

8-1.

Changing the machine head

settings .........................

8-1-1. Setting procedure ....................... 15

8-1-2.

Initializing the machine head

setting

8-1-3. Machine head setting mode

list ............................................. 15,16

Other machine sewing

8-1-4.

speeds .......................................... 16

8-2. Setting the sewing speed

the machine head ...................................

treadle ............................. 8

treadle return

treadle stroke ...... 8

DIP

switch setting

of

functions ........................

control box when no

panel is installed .......

DIP

switch functions ........

for

standing

·...

........................

value ................................

to

match

..

foot

..

...

8

10

10

11

11

12

12

13

15

15

15

17

MD-6020, 6120

Page 3

Thank you for purchasing this Brother general-purpose sewing machine motor. Before using the motor, please be sure to read

the Safety

Furthermore, because we are continually improving our products as a result of continuing research, the specifications for the

product which you have purchased may differ

Instructions and the explanations of how to use the motor which are contained

slightly from those listed in this manual.

in

this manual.

SAFETY INSTRUCTIONS

1. SAFETY INDICATIONS AND THEIR MEANINGS

This instruction manual and the indications and symbols that are used on the machine itself are provided

operation of this machine and to prevent accidents and injury to

The meanings of these indications and symbols are given below.

Indications

yourself

or

other people.

in

order to ensure safe

A WARNING

A CAUTION

Symbols

The symbols which are used in this manual and their meanings are shown below.

~

Lh

This symbol is used to indicate the danger of

This symbol is used to indicate general cautions that should be observed .

This symbol is used to indicate that the ground connection must be made.

Failure to observe the instruction which appears after this indication while using the motor

will result in death

Failure to observe the instructions which appear after this indication while using the motor

may

result in slight to moderate injury to the user,

or

severe injury to the user.

~lectric

shocks.

or

physical damage.

•

0

2.

CAUTIONS WITH REGARD TO SAFETY

Following is a compilation of all the warnings and cautions which appear throughout this manual.

This symbol is used to indicate general actions which you must do.

A WARNING

A Wait at least 5 minutes after turning off the power switch before opening the cover of the control box. Touching areas

~

where high voltages are present can result in severe injury.

A CAUTION

Do not use the motor near sources of strong electrical interference. If the motor is installed

to sources of strong electrical interference such as high-frequency welders, it may cause problems with correct operation of the sewing machine.

Disconnect the power cord

~

The motor and control box weigh approximately 12 kg. Take care not to drop them on your feet when installing

Lll

removing them from the work table.

Be sure to tighten the nuts securely.

If

0

they are not tightened properly, it could cause the sewing machine to vibrate

plug from the wall outlet before installing the motor.

MD-6020, 6120

in

a location which is close

or

shift its position while sewing.

or

Page 4

A CAUTION

Turn off the power switch and wait

disconnecting any

0

Turn off the power switch before inserting

of

the connectors.

for

the power indicator on the panel display to turn

or

removing the AC power cord plug.

off

before connecting and

0

Be sure to connect the power supply to a secure ground. If the ground is not securely connected, electric shocks may

result.

•

Use a lamp which is rated at 6 V AC and

a lamp with a higher rating than this is used, it could cause the lamp wires and the transformer to overheat and burn

If

0

out.

Confirm that the power supply matches the motor and the control box specifications before turning

The motor,

0

~

Do not clamp the cords inside the control box when closing the control box cover.

Turn off the power switch before connecting the cords, otherwise damage to the control box, synchronizer, operation

panel or material edge sensor may result.

0

Any fluctuations in the power supply voltage should be within

Voltage fluctuations which are greater than this may cause problems with correct operation

0

Use a power

Insufficient power supply capacity may cause problems with correct operation of the sewing machine.

0

The ambient temperature

Temperatures which are

0

The

devices.

0

Excessively dry or humid environments and dew formation may cause problems with correct operation of the sewing

machine.

Avoid exposure to direct

Exposure to direct

0

In

the event of an electrical storm, turn off the power and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct operation of the sewing machine.

0

control box

supply with a capacity which is in excess of the motor power capacity.

relative humidity should be within the range of 45% to 85% during use, and no dew formation should occur in any

or

sewing machine could be damaged if the supply voltage is too high.

should be within the range of

lower or higher than this may cause problems with correct operation of the sewing machine.

sunlight during use.

sunlight may cause problems with correct operation of the sewing machine.

20

W or less as the head lamp.

±1

0% of the rated voltage for the motor.

soc

to 35°C during use.

on

the power switch.

of

the sewing machine.

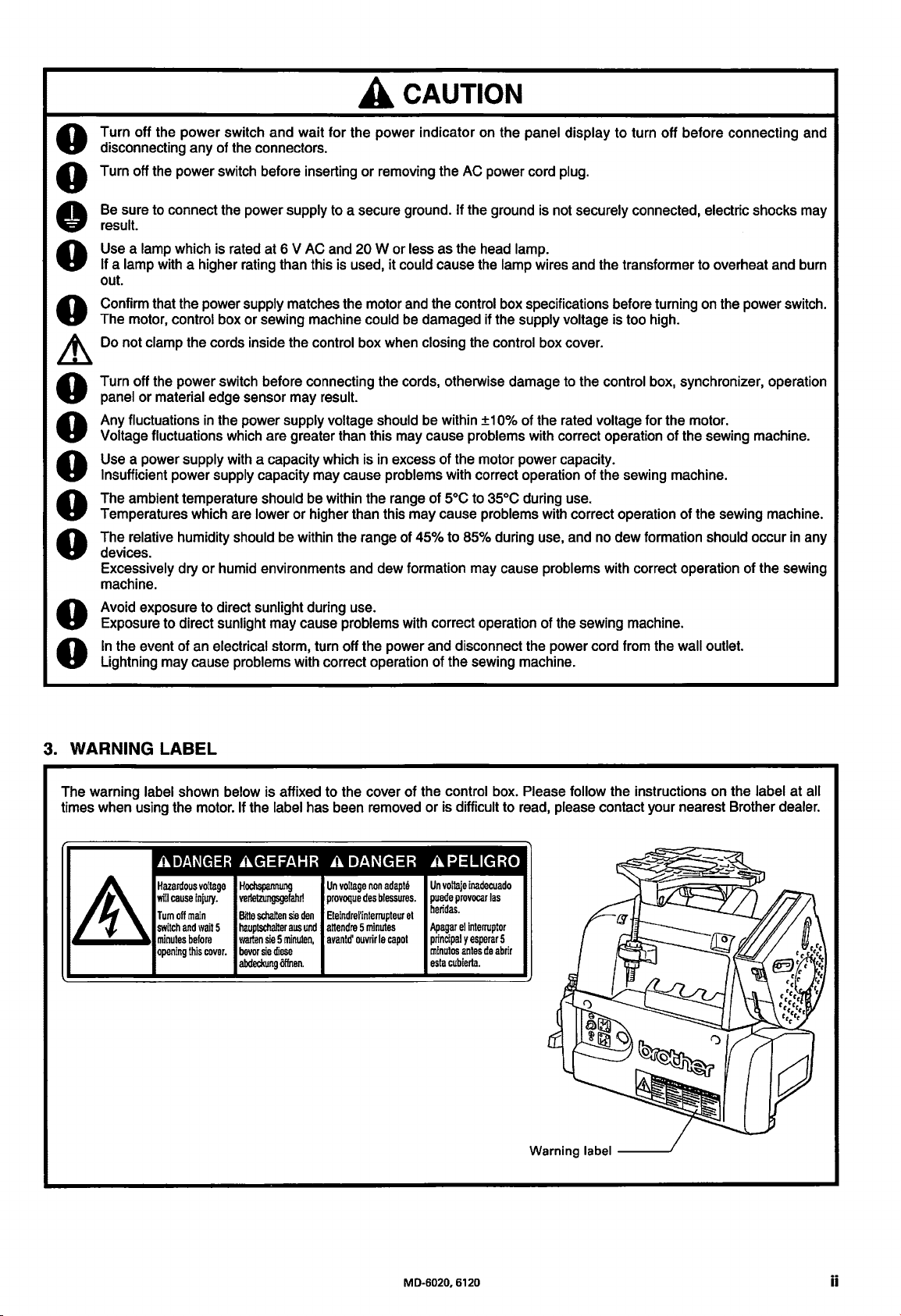

3.

WARNING LABEL

The warning label shown below is affixed to the cover of the control box. Please follow the instructions on the label

times when using the motor. If the label has been removed

A

DANGER

Hazardous

will

cause

Tum

off

main

switch

and

minutes

before

opening

this

AGEFAHR A DANGER A PELIGRO

voltage

injury.

wait

cover.

5

Hochspannung

verletzungsgefaM

Bitte

schalten

hauptschalter

warten

sie 5 minuten,

bevor

sie

diese

abdeckung

offnen.

Un

voltage

provoque

sie

den

Eteindrel'interrupteur

ailS

und

attendre 5 minutes

avantd'

non

des

ouvrir

blessures.

le

adapte

et

capot

or

is difficult to read, please contact your nearest Brother dealer.

Un

voltaje

inadecuado

puede

provocar

el

interrupter

antes

cubierta.

de

las

abrir

5

Warning label

---./

heridas.

Apagar

principal y esperar

minutos

esta

at

all

MD-6020, 6120

ii

Page 5

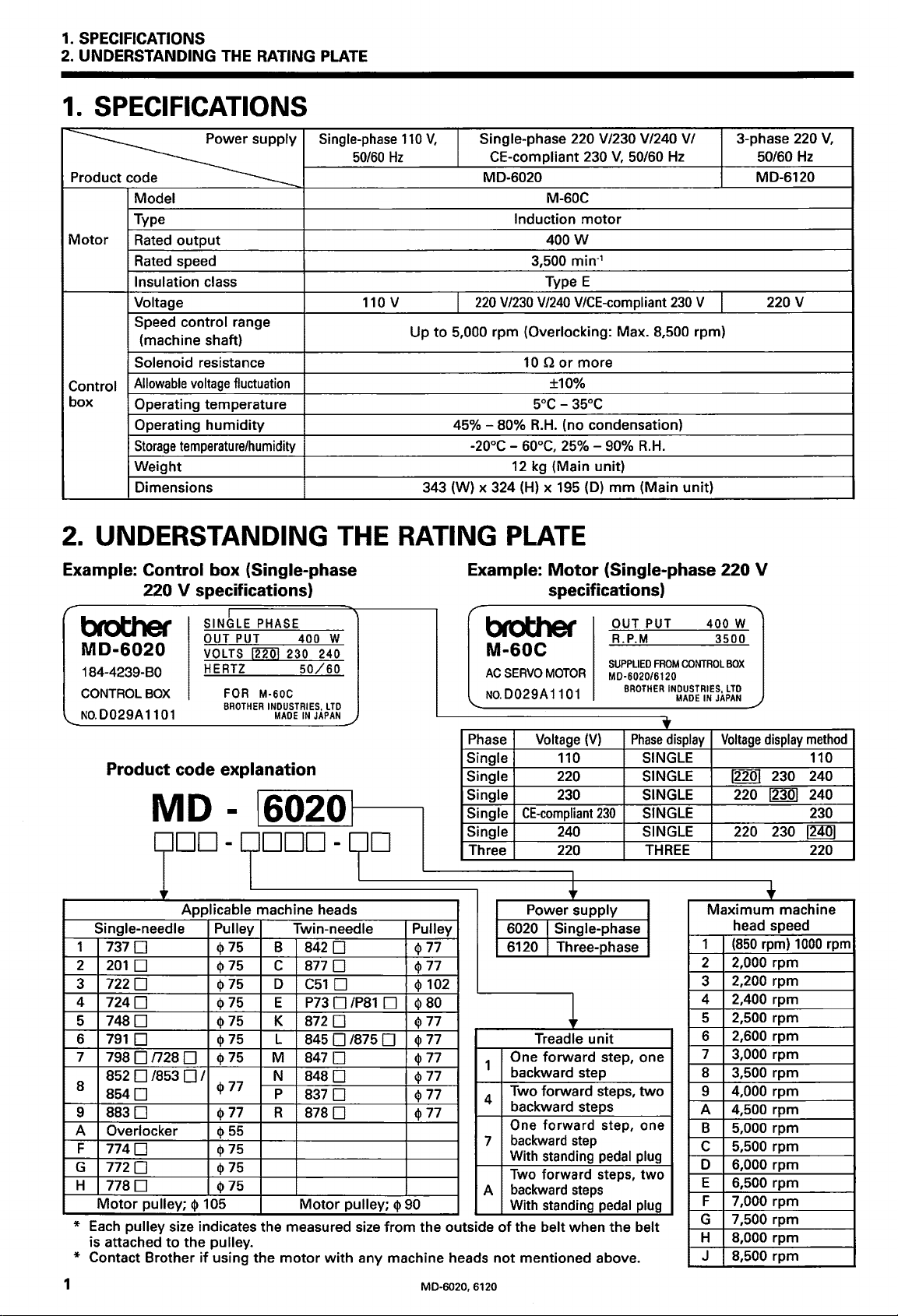

1. SPECIFICATIONS

2. UNDERSTANDING THE RATING PLATE

1.

SPECIFICATIONS

Single-phase

50/60Hz

p

~

Model

Type

Motor

Control

box

2.

Example: Control

Rated

output

Rated speed

Insulation class

Voltage

Speed control range

(machine shaft)

Solenoid resistance

Allowable

Operating temperature

Operating

Storage

Weight

Dimensions

voltage

fluctuation

humidity

temperature/humidity

UNDERSTANDING THE RATING PLATE

box

(Single-phase

220

V specifications)

110 v

110

V,

Up

343 (W) x 324

Single-phase 220 V/230 V/240 V/

CE-compliant 230

I

MD-6020

220

V/230 V/240

I

to

5,000 rpm (Overlocking: Max. 8,500 rpm)

45% - 80%

-20°C - 60°C, 25% - 90%

12

Example:

M-60C

Induction

3,500 min·

10 Q or

5°C-

R.H.

kg

(H)

motor

400W

Type E

VICE-compliant

more

±10%

35°C

(no condensation)

(Main unit)

x 195

(D)

Motor

specifications)

3-phase

V,

50/60Hz 50/60Hz

1

230

V

R.H.

mm

(Main unit)

(Single-phase 220 V

220

MD-6120

220 v

V,

brother

MD-6020

184-4239-BO

CONTROL

NO.

BOX

0029A

1101

Product code explanation

MD

SINGLE PHASE

OUT

PUT

VOLTS

HERTZ

FOR

BROTHER

-

400 W

rnQJ

230 240

50/60

M-60C

INDUSTRIES,

MADE

IN

LTD

JAPAN

6020!------,

DD-~DDD-?D

Phase

Single 110 SINGLE

Single

Single

Single

Single

Three

,,

Applicable machine heads

Single-needle

1

7370

2

2010

3

7220

4

7240

5

7480

6

7910

7

798

On28

0/853

852

8

8540

9

8830

A Overlocker

F

7740

G

7720

H

7780

Motor

pulley;

* Each pulley size indicates the measured size from the outside

is attached

to

* Contact Brother

Pulley Twin-needle

cp

75

B

cp

75

c

cp

75

D

cp

75

E

cp

75

K

cp

75

cp

75

0

0/

cp

77

cp

77

cp

55

cp

75

cp

75

cp

75

cp

105

the pulley.

if

using

the

L

M

N

p

R

Motor

motor

8420

8770

C51

P73

8720

845

8470

8480

8370

8780

with

Pulley

cp

77

cp

77

cp

0

0/P81

01875

pulley;

any machine heads

102

cp

80

0

cp

77

cp

77

0

cp

77

cp

77

cp

77

cp

77

cp

90

4

7

A

brother

M-60C

AC

SERVO

MOTOR

NO.

0029A 1101

Voltage

CE-compliant

Power supply

6020 Single-phase

6120 Three-phase

One

backward step

Two forward steps,

backward steps

One forward step, one

backward

With standing

Two

backward

With standing

of

the belt when

not

mentioned above.

(V)

220

230

230

240

220

forward

forward steps, two

step, one

step

pedal

steps

pedal

OUT PUT 400 W

R.P.M

SUPPLIED

FROM

MD-6020/6120

BROTHER

INDUSTRIES,

Phase

display

SINGLE

SINGLE

SINGLE

SINGLE

THREE

two

plug

plug

the

belt

3500

CONTROL

BOX

MADE

LTD

IN

JAPAN

Voltage

12201

Maximum

(850

1

2

2,000 rpm

2,200 rpm

3

4

2,400 rpm

5

2,500 rpm

2,600 rpm

6

3,000 rpm

7

3,500 rpm

8

4,000 rpm

9

A

4,500 rpm

5,000 rpm

B

C 5,500 rpm

6,000 rpm

D

6,500 rpm

E

7,000 rpm

F

G 7,500 rpm

8,000 rpm

H

8,500 rpm

J

display

230 240

220

12301

220 230

machine

head speed

rpm)

1000

method

110

240

230

~

220

rpm

1

M0-6020, 6120

Page 6

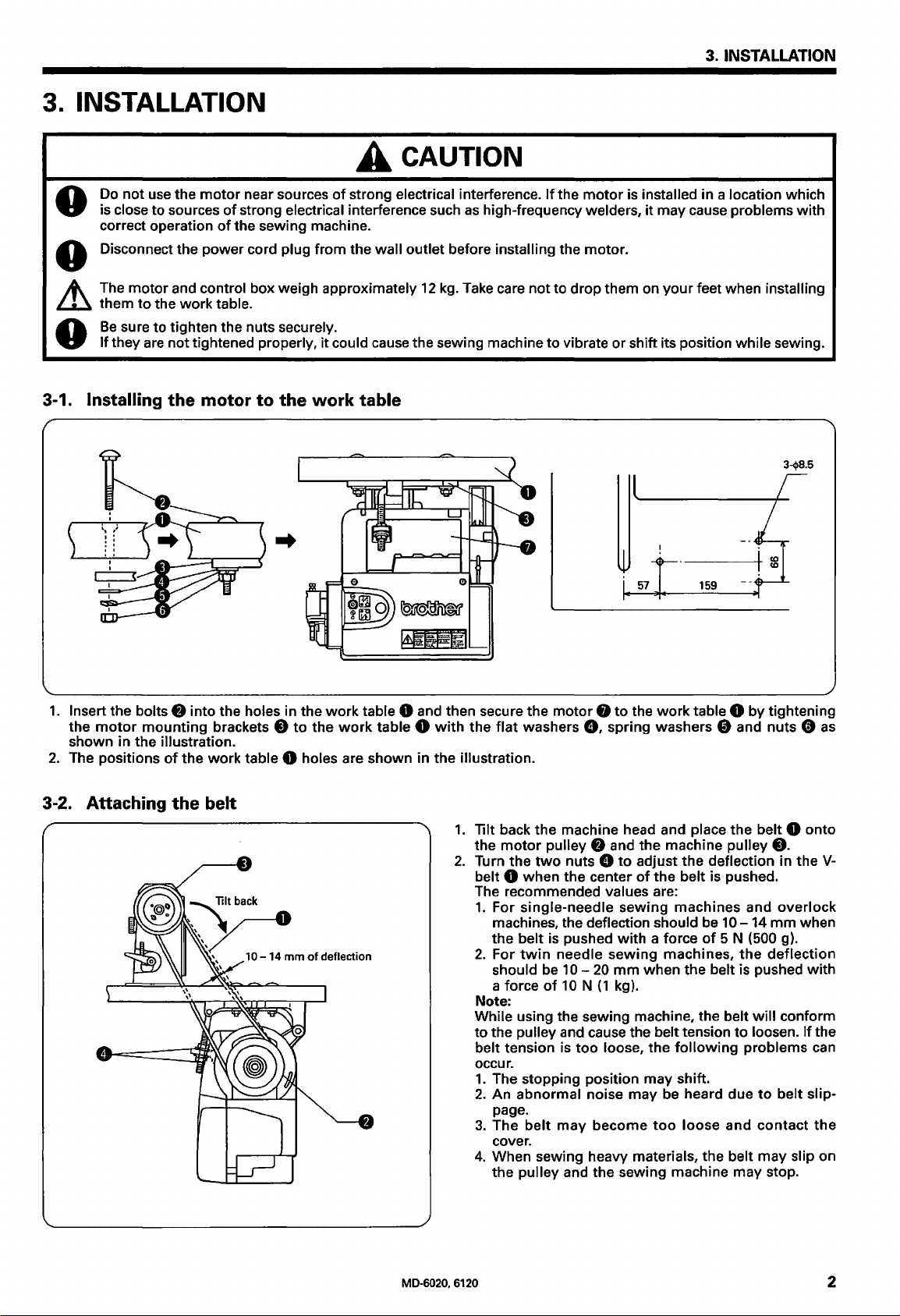

3.

INSTALLATION

Do

not

use the

is

close

to

0

correct operation

Disconnect

sources

the

0

£ The

~

0

motor

them

Be

sure

If

they are

and control box weigh approximately 12 kg. Take care

to

the

work

to

tighten the nuts securely.

not

tightened properly,

A CAUTION

motor

near sources

of

strong electrical interference such as high-frequency welders,

of

the sewing machine.

power

cord plug

table.

of

strong electrical interference.

from

the wall

it

could cause the sewing machine

outlet

before installing the motor.

If

not

to

the

to

drop

vibrate

3. INSTALLATION

motor

is installed in a location which

it

may

cause problems

them on

or

your

feet when installing

shift its position

while

with

sewing.

3-1. Installing

1.

Insert the bolts

motor

the

shown

2.

The positions

mounting

in

the

3-2. Attaching

the

motor

f)

into the holes in the

the

the

brackets 8

work

table 8 holes are

belt

illustration.

of

to

the

..

to

work

work

the

work

table

table 8 and then secure the

table 8 with

shown

in

the

flat

washers

the

illustration.

1.

Tilt back

the

motor

2.

Turn

the

belt 8

The recommended values are:

1.

2.

Note:

While using the sewing machine, the belt

to

belt tension is

occur.

2.

3.

4.

when

For

single-needle

machines, the deflection should be

the

belt is pushed

For

twin

should be

a force

the pulley and cause the belt tension

1.

The stopping position

An

abnormal

page.

The

belt

cover.

When sewing heavy materials,

the

pulley

motor 8 to

8,

the

machine head and place

pulley

two

nuts 8

the center

needle

10-

of

10 N

too

may

and

the

work

spring washers 0 and

f)

and the machine pulley

to

adjust

of

the

sewing

with

a force

sewing

20

mm

when

(1

kg).

loose,

the

noise

become

the

may

may

too

sewing machine

159

table 8

the

belt is pushed.

machines

machines,

the belt is pushed

following

shift.

be heard

loose

by

the

deflection in

and

10-14

of

5 N (500 g).

the

to

problems

due

and

the

belt

may

3-418.5

tightening

nuts

belt 8

8.

the

overlock

mm

deflection

will

conform

loosen.

to

belt

contact

may

slip on

stop.

0 as

onto

V-

when

with

If

the

can

slip-

the

MD-6020, 6120

2

Page 7

3.

INSTALLATION

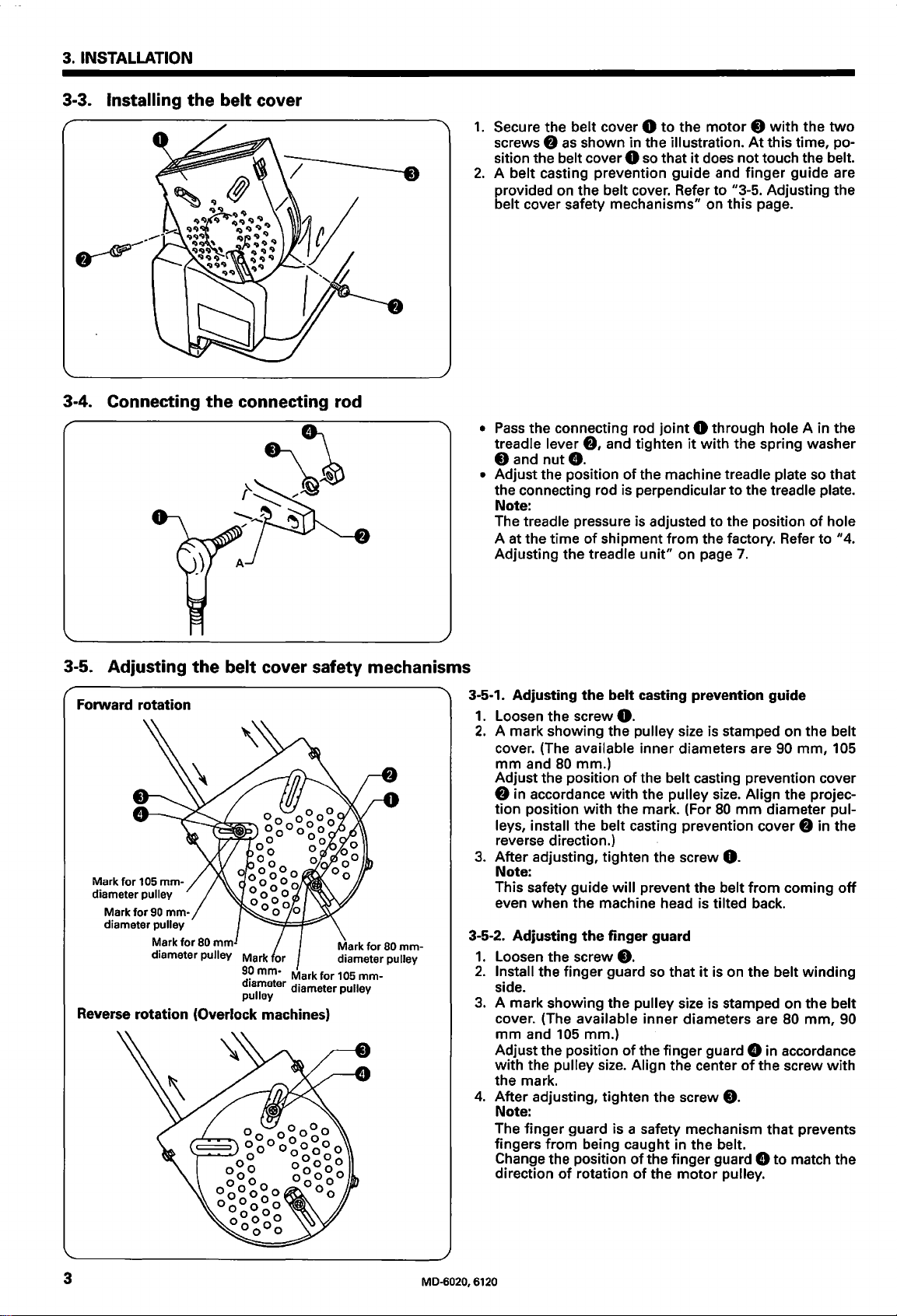

3-3. Installing

the

3-4. Connecting

belt

cover

the

connecting rod

1.

Secure the belt cover 0

screws

sition the

2.

A belt casting prevention guide and

provided on the

f)

as

shown in the illustration.

belt cover 0 so that

belt cover. Refer

to

the

motor 8 with

it

does not touch the belt.

to

"3-5. Adjusting the

belt cover safety mechanisms" on this page.

•

Pass

the connecting rod

treadle lever

8and

nut8.

f),

and tighten

• Adjust the position

the connecting rod is

joint

0 through hole A in the

it

with

the spring washer

of

the machine treadle plate so that

perpendicular

to

Note:

treadle pressure is adjusted

The

A at the time

Adjusting the treadle

of

shipment from the factory. Refer

unit"

to

on page

the position

7.

the

At

this time, po-

finger

two

guide are

the treadle plate.

of

hole

to

"4.

3-5.

Adjusting

the

belt

cover safety mechanisms

Forward rotation

Mark

for

105

diameter pulley

Mark

diameter pulley

mm-

for

90

mm-

Mark

for

diameter pulley

80

mm

or

Mark

9

~

mm-

deameter

pulley

Mark for

diameter pulley

Reverse rotation (Overlock machines)

Mark for

80

diameter pulley

105

mm-

mm-

3·5-1. Adjusting

1.

Loosen the screw

2.

A mark showing the pulley size is stamped on the belt

the

belt

casting prevention guide

0.

cover. (The available inner diameters are 90

mm

and 80 mm.)

Adjust the position

f)

in accordance

tion

position

leys, install

the belt casting prevention cover

of

with

with

the mark. (For

the belt casting prevention cover

the pulley size. Align the projec-

80

mm

diameter pul-

reverse direction.)

3.

After adjusting, tighten the screw

0.

Note:

This safety guide

will

prevent the belt

from

coming

even when the machine head is tilted back.

3-5-2. Adjusting

1.

Loosen the screw

2.

Install the finger guard

the

finger

8.

guard

so

that

it

is on the belt winding

side.

3.

A mark showing the pulley size is stamped on the belt

cover. (The available inner diameters are 80

mm

and

105

mm.)

Adjust the position

with

the pulley size. Align the center

of

the finger guard 8 in accordance

of

the screw

the mark.

4.

After adjusting, tighten the screw

8.

Note:

The

finger

fingers

from

being caught in the belt.

Change the position

guard is a safety mechanism

direction

of

rotation

of

the finger guard 8

of

the

motor

pulley.

that

to

match the

mm,

105

f)

in the

off

mm,

90

with

prevents

3

MD-6020,

6120

Page 8

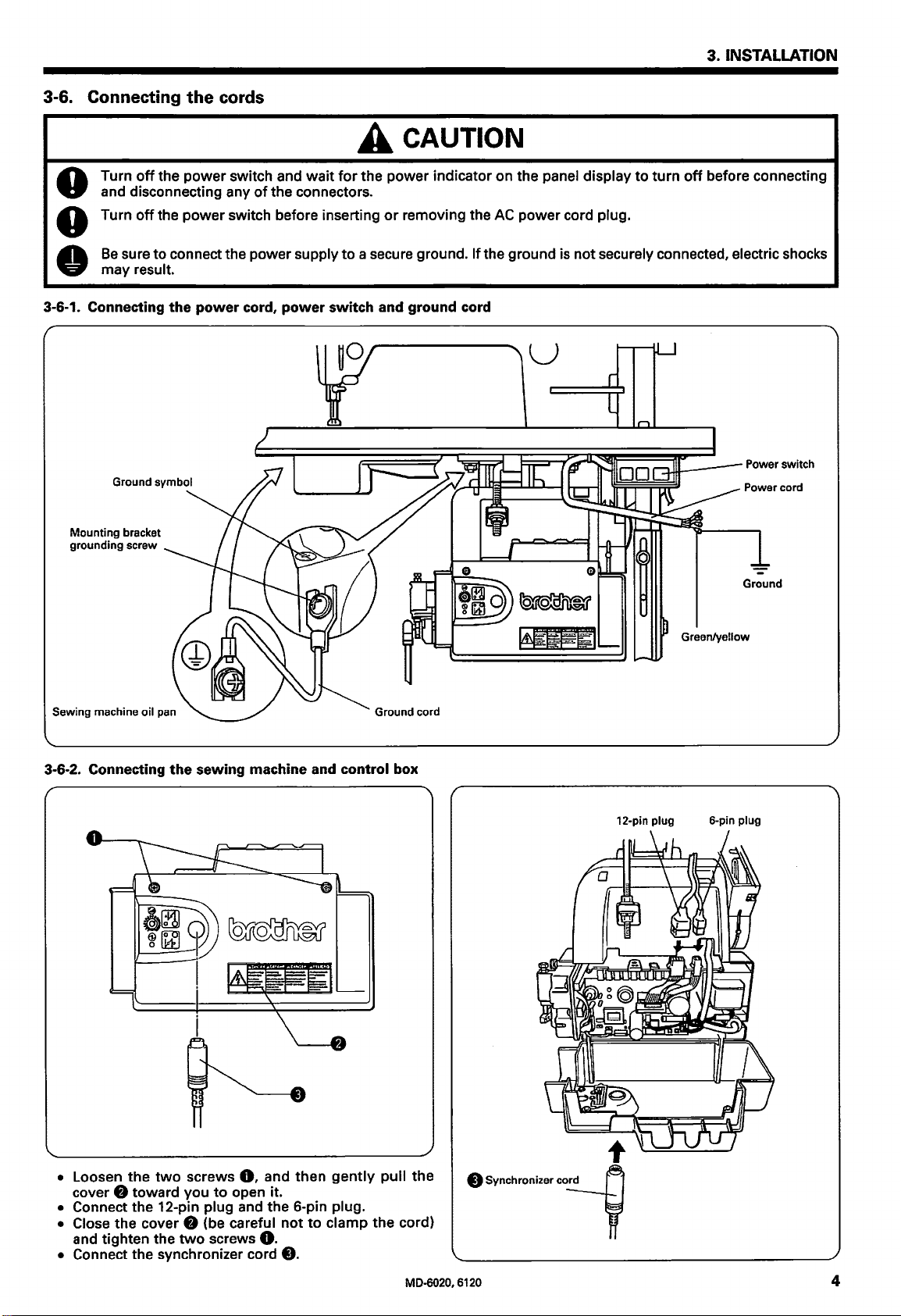

3. INSTALLATION

3-6. Connecting

Turn

off

the

and disconnecting any

0

Turn

off

the

0

Be

sure

to

connect the power supply

the

•

Connecting

3-6-1.

Mounting bracket

grounding screw

may result.

the

cords

power

switch and

of

the connectors.

power

switch before inserting

power

cord,

wait

power

A CAUTION

for

the power indicator on the panel display

or

removing the

to

a secure ground. If the ground is not securely connected, electric shocks

switch

and ground cord

AC

power cord plug .

u

to

turn

off

before connecting

Sewing machine oil pan

3-6-2. Connecting

the

sewing machine and

control

box

12-pin plug

Ground

Green/yellow

6-pin plug

• Loosen

cover

• Connect the 12-pin plug and the 6-pin plug.

• Close the cover 8 {be careful

and tighten the

• Connect the synchronizer cord

the

two

screws

8 toward you

two

0,

to

open it.

screws

and then

not

to

0.

8.

gently

clamp the cord)

pull the

MD-6020, 6120

0 Synchronizer

coi

t

4

Page 9

3. INSTALLATION

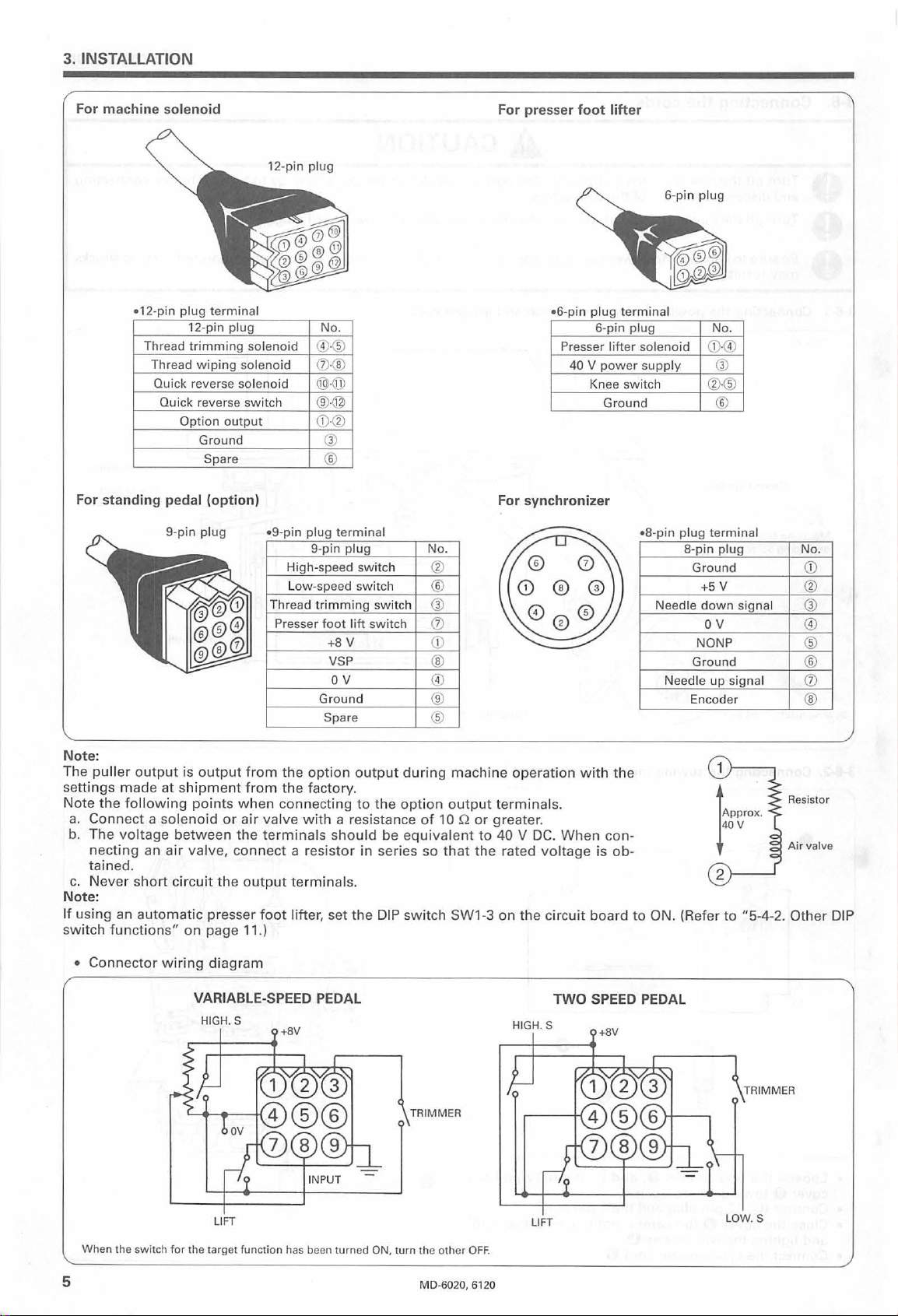

For machine solenoid

•12-pin plug

Thread

Thread

Quick reverse sole

Quick reverse

terminal

12-pin

trimming

wiping

Option

Ground

Spare

plug

out

sol

sol

switc

put

For standing pedal (option)

9-pin

plug

12-pin

eno

id

enoid

noid

h

•9-pin

High-speed s

L

Thr

ead

Presser

plug

No.

®·®

CV

·®

®·@

®·@

(i}@

Q)

®

plug termin

9-p

in

ow-s

peed switch

trimming

foot lift switch

+8 v

VSP

OV

Gro

und

Spare

plug

al

witch

switch

No.

®

®

Q)

cv

CD

®

®

®

®

For presser

•6-pin

Pr

esser

40 V

foot

plug termin

6-pin

power

Knee

For synchronizer

lifter

plug

lifter

switch

Ground

6-

al

sole

noid

supply

•8

-pin plug

Needle d

Needle

pin

plug

8-pin

Ground

NONP

Gr

Encoder

No

.

CD

·®

Q)

®·®

®

terminal

plug

+5 v

own

ov

ound

up

signal

signal

No

CD

®

Q)

®

®

®

cv

®

.

Note:

The

puller output

se

ttings

made at shipment

the following

Note

a.

Connect a sole

b. The

c.

vo

n

ecting

tain

ed.

Never sh

is

output

points

noid

or

ltage

between

an air valve, conn

ort circuit

the

Note:

If

usi

ng

switch

an auto

functions"

mati

c presser f

on

page 11.)

• Connector wiring diagram

VARIABLE-SPEED PEDAL

HIGH. S

from

the

option outp

from the factory.

when

co nnec

ting

to

the

air valve with a resistan

the te

rminal

s sho

uld

ect

a resistor in series so

outp

ut

termin

als.

oot lifte

r, set the

DIP swit

ut

be

during

opt

ce

equival

machine operation w

ion

output terminals.

of

10 Q or greater.

ent

that the rated

ch SW1

TRI

MMER

to

40 V DC. When

voltage

-3

on

the

circu

TWO

HIGH. S

ith

the

con-

is ob-

it

board

to ON. (R

SPEED PEDAL

+8V

efer

to "5-4-2. Oth

Resistor

Air

valv

er

e

DIP

LI

FT

Wh

en the s

wit

ch

for

the

target function has been turned ON,

5

turn

the other

MD

-6020, 6120

OFF.

LI

FT

Page 10

3. INSTALLATION

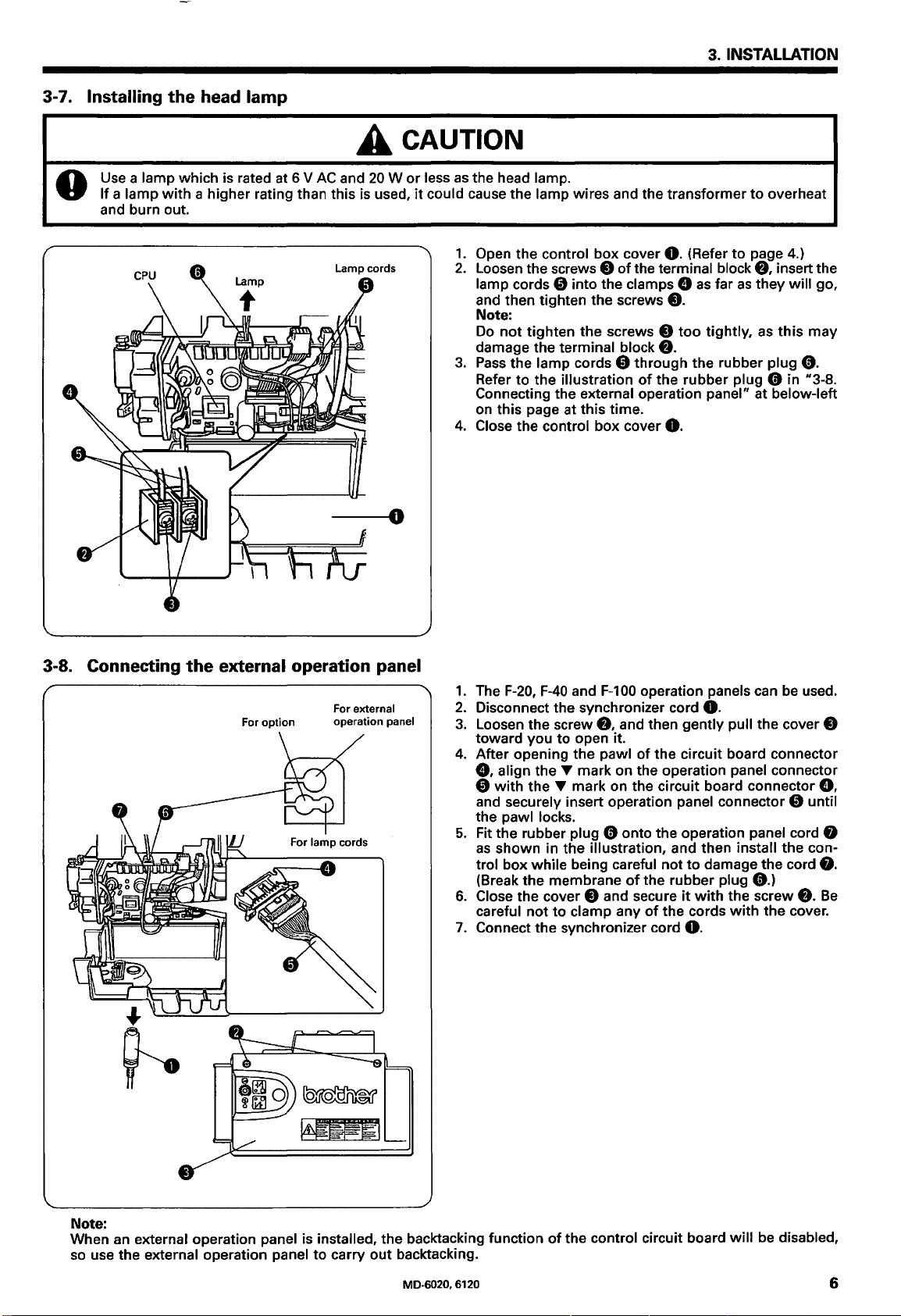

3-7. Installing

Use a lamp which is rated at 6 V

If

0

a lamp

and burn out.

the

head

lamp

AC

with

a higher rating than this is used,

A CAUTION

and

20 W or

less

as

the head lamp.

it

could cause the lamp wires and the transformer

1.

Open the control box cover

2.

Loosen the screws 0

lamp cords

and then tighten the screws

Note:

Do

damage the terminal block

3.

Pass

Refer

Connecting the external operation panel" at below-left

on

4.

Close the control box cover

to

0.

(Refer

to

far

as

page 4.)

8,

they will go,

of

the terminal block

0 into the clamps 8

as

0.

not

tighten the screws 0

too

tightly,

as

8.

the lamp cords 0 through the rubber plug

to

the illustration

this

page at this time.

of

the rubber plug 0 in "3-8.

0.

overheat

insert the

this

may

0.

3-8. Connecting

the

external operation panel

For external

For option

operation panel

1.

The

F-20,

F-40

and

F-1

00

operation panels can

2.

Disconnect the synchronizer cord

3.

Loosen the screw

toward you

4.

After opening the pawl

8,

align the

0

with

the

and securely insert operation panel connector 0 until

the pawl locks.

5.

Fit the rubber plug 0 onto the operation panel cord 8

as

shown in the illustration, and then install the con-

trol box while being careful not

(Break the membrane

6.

Close the cover 0 and secure

careful not

7.

Connect the synchronizer cord

8,

to

'Y

'Y

to

clamp any

and then gently pull the cover 0

open it.

mark on the operation panel connector

mark on the circuit board connector

of

the circuit board connector

of

the rubber plug 0.)

of

0.

to

damage the cord

it

with

the cords

0.

the screw

with

be

the cover.

used.

8.

8,

8.

Be

Note:

When

an

external operation panel is installed, the backtacking function

so

use the external operation panel

to

carry out backtacking.

MD-6020, 6120

of

the control circuit board

will

be

disabled,

6

Page 11

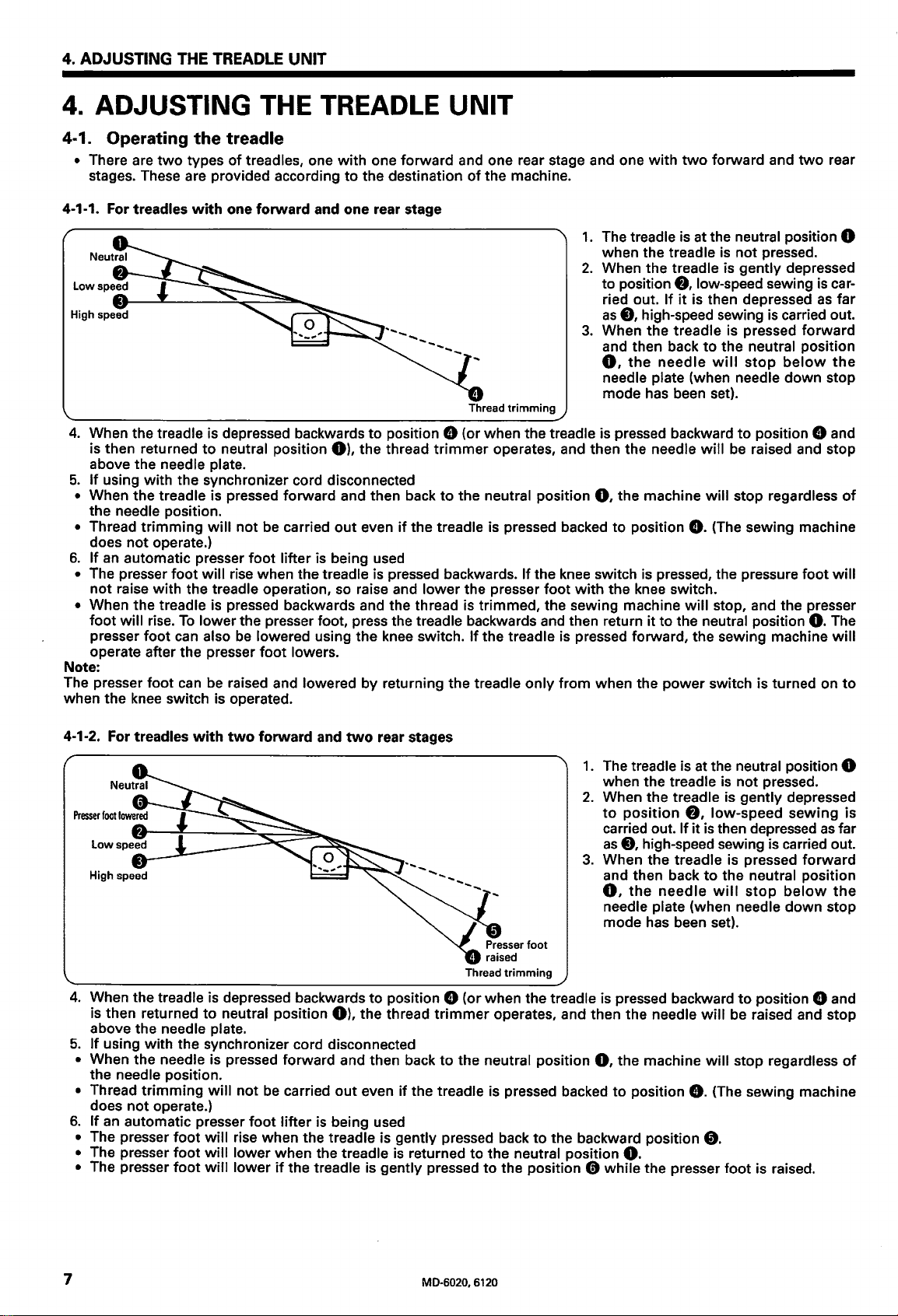

4. ADJUSTING THE TREADLE

4.

ADJUSTING THE TREADLE

UNIT

UNIT

4-1. Operating

• There are

stages. These are provided according

4-1-1. For treadles

4.

When the treadle is depressed backwards

is then returned

above the needle plate.

5.

If

using with the synchronizer cord disconnected

• When the treadle is pressed forward and then back

the needle position.

• Thread

does

6.

If an automatic presser

• The presser foot

not raise with the treadle operation,

• When the treadle is pressed backwards and the thread is trimmed, the sewing machine

foot

presser

operate after the presser

Note:

The presser

when the knee switch is operated.

trimming

not

will

foot

the

treadle

two

types

of

treadles, one

with

one

forward

to

neutral position

will

not

operate.)

will

rise.

To

lower the presser foot, press the treadle backwards and then return

can also

foot

can be raised and lowered

be carried

foot

lifter is being used

rise when the treadle is pressed backwards. If the knee switch is pressed, the pressure foot

be

lowered using the knee switch.

foot

with

one forward and one rear stage and one

to

the destination

and one rear stage

to

0),

out

so

lowers.

position 8 (or when the treadle is pressed backward

the thread

even

raise and

by

returning the treadle

of

the machine.

Thread

trimming

trimmer

to

if

the treadle is pressed backed

lower

operates, and then the needle

the neutral position

the presser foot

If

the treadle is pressed forward, the sewing machine

only

with

from

1.

The treadle is at the neutral position 0

when the treadle

2.

When the treadle is gently depressed

to

position

ried out.

as

e,

high-speed sewing is carried out.

3.

When

and then back

0,

the

needle plate (when needle down stop

mode has been set).

0,

the machine

to

position

the knee switch.

when the

with

two

forward and

is

not pressed.

f),

low-speed sewing is car-

If

it

is then depressed

the

treadle is pressed

to

the neutral position

needle

it

to

power

will

will

be

will

stop regardless

8.

(The sewing machine

will

stop, and the presser

the neutral position

switch is turned on

two

as

forward

stop

below

to

position 8 and

raised and stop

0.

rear

far

the

of

will

The

will

to

with

two

4-1-2. For treadles

4.

When the treadle is depressed backwards

foot

foot

foot

to

will

will

will

will

is then returned

above the needle plate.

5.

If using with the synchronizer cord disconnected

• When the needle is pressed forward and then back

the needle position.

• Thread

does

6.

If

• The presser

• The presser

• The presser

trimming

not

operate.)

an automatic presser

forward

neutral position

not be carried

foot

rise when the treadle is gently pressed back

lower when the treadle is returned

lower

and

two

rear stages

to

position 8 (or when the treadle is pressed backward

0),

the thread

out

even

if

lifter is being used

if

the treadle is gently pressed

1.

2.

3.

Thread

trimming

trimmer

to

the treadle is pressed backed

operates, and then the needle

the neutral position

to

to

to

the neutral position

the position 0

0,

the backward position

The treadle is at the neutral position 0

when the treadle is

When the treadle is gently depressed

to

position

carried out.

as

e,

When

and then back

0,

the

needle plate (when needle down stop

mode has been set).

the machine

to

position

f),

If

high-speed sewing is carried out.

the

treadle is pressed

needle

8.

not

pressed.

low-speed

it

is then depressed

to

the neutral position

will

to

will

be raised and stop

will

stop regardless

(The sewing machine

sewing

forward

stop

below

position 8 and

as

is

far

the

of

8.

0.

while

the presser

foot

is raised.

7

MD-6020, 6120

Page 12

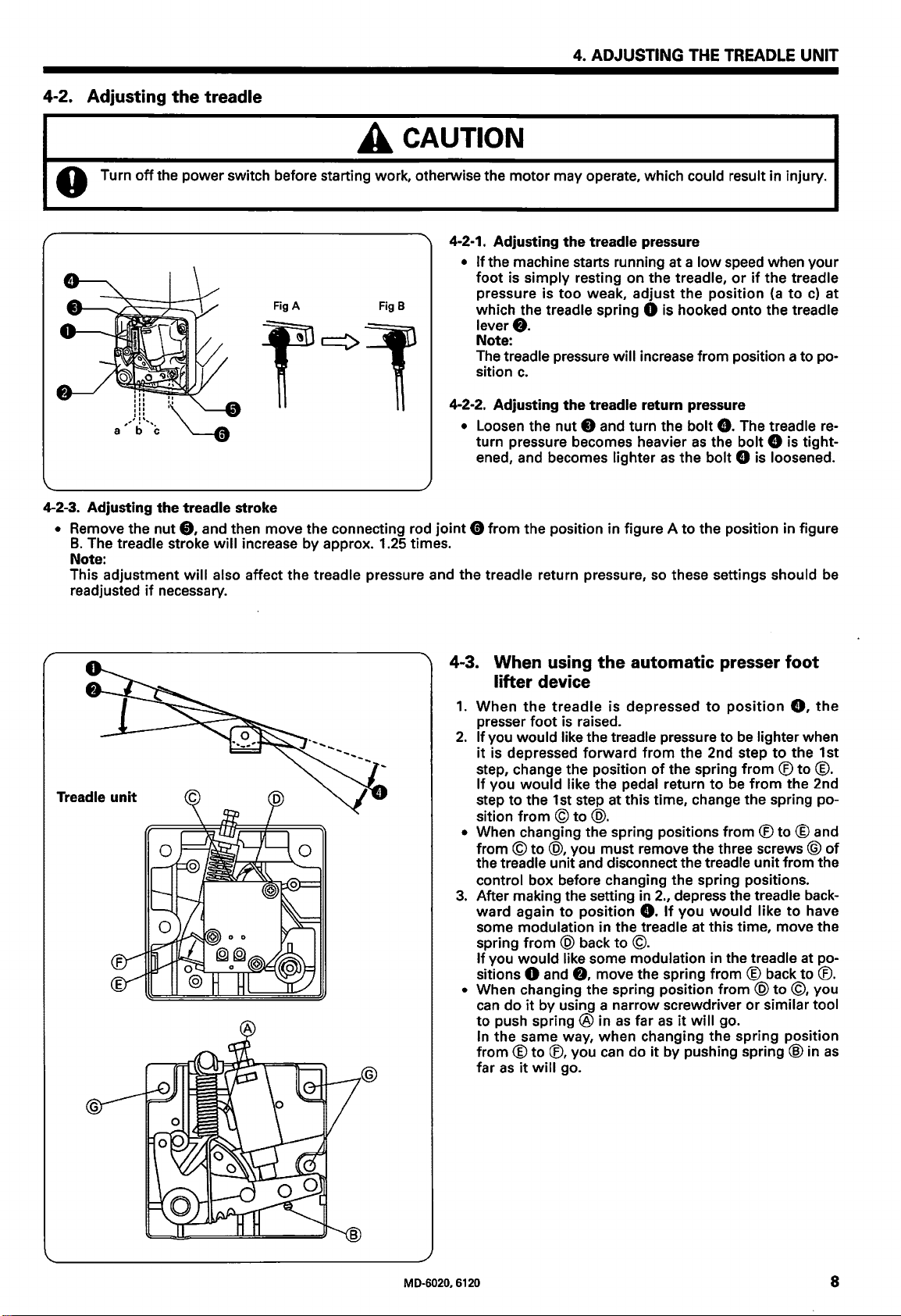

4. ADJUSTING THE TREADLE

UNIT

4-2. Adjusting

o Turn

4-2-3. Adjusting

Remove the nut

•

B.

The treadle stroke

Note:

This adjustment

readjusted

off

the power switch before starting work, otherwise the

the

if

necessary.

the

treadle

A

CAUTION

motor

may operate, which could result in injury.

the

4-2-1. Adjusting

• If the machine starts running at a

foot

is

Fig A Fig 8

treadle stroke

0,

and then move the connecting rod

will

increase

will

also affect the treadle pressure and the treadle return pressure, so these settings should be

by

approx. 1.25 times.

pressure is

which the treadle spring 0 is hooked onto the treadle

lever&.

Note:

The

sition

4-2-2. Adjusting

• Loosen the nut 8 and turn the bolt

turn pressure becomes heavier

ened, and becomes lighter

joint 0 from

simply

treadle pressure

c.

the position in figure A

treadle pressure

resting on the treadle,

too

weak,

adjust

will

the

treadle return pressure

the

increase from position a to po-

as

the bolt 8 is loosened.

to

low

speed when

or

position

8.

as

The treadle re-

the

bolt

the position in figure

if

the

{a

to

8 is tight-

your

treadle

c)

at

Treadle

unit

4-3. When using

lifter

device

1.

When

2.

• When changing the spring positions

the treadle unit and disconnect the treadle

3.

• When changing the spring position

the

presser

If you would like the treadle pressure to

it

step, change the position

If you

step

sition

from©

control box before changing the spring positions.

After making the setting in 2., depress the treadle backward

some

spring

If you

sitions 0 and

can

to

In the same way, when changing the spring position

from

far

foot

is depressed

would

to

the 1st step at this time, change the spring po-

from © to

to@,

again

modulation in the treadle at this time, move the

from

would

do

it

by

push

spring®

®to

®,

as

it

will

the

automatic

treadle

to

@ back

using a narrow screwdriver

go.

is depressed

is raised.

forward

like the pedal return

@.

you must remove the three

position

like some modulation in the treadle at po-

8,

you can do

from

of

the spring

8.

If

to

©.

move the spring

in

as

far

as

it

by pushing spring @ in as

the

you

it

will

presser

to

position

be

2nd step

from

to

be

from

from®

would

from

® back

from

or

go.

lighter when

to

screws@

unit

like

@to

similar tool

foot

8,

the

the

1st

®to

@.

the 2nd

to®

and

from the

to

have

to

®.

©, you

of

MD-6020, 6120

8

Page 13

5. USING THE CONTROL BOX

5.

USING THE CONTROL BOX

A CAUTION

Confirm

power switch. The motor, control box

0

that

the

power

supply matches the

or

sewing machine could

Power indicator

motor

and the control box specifications before

be

damaged

if

the supply voltage is

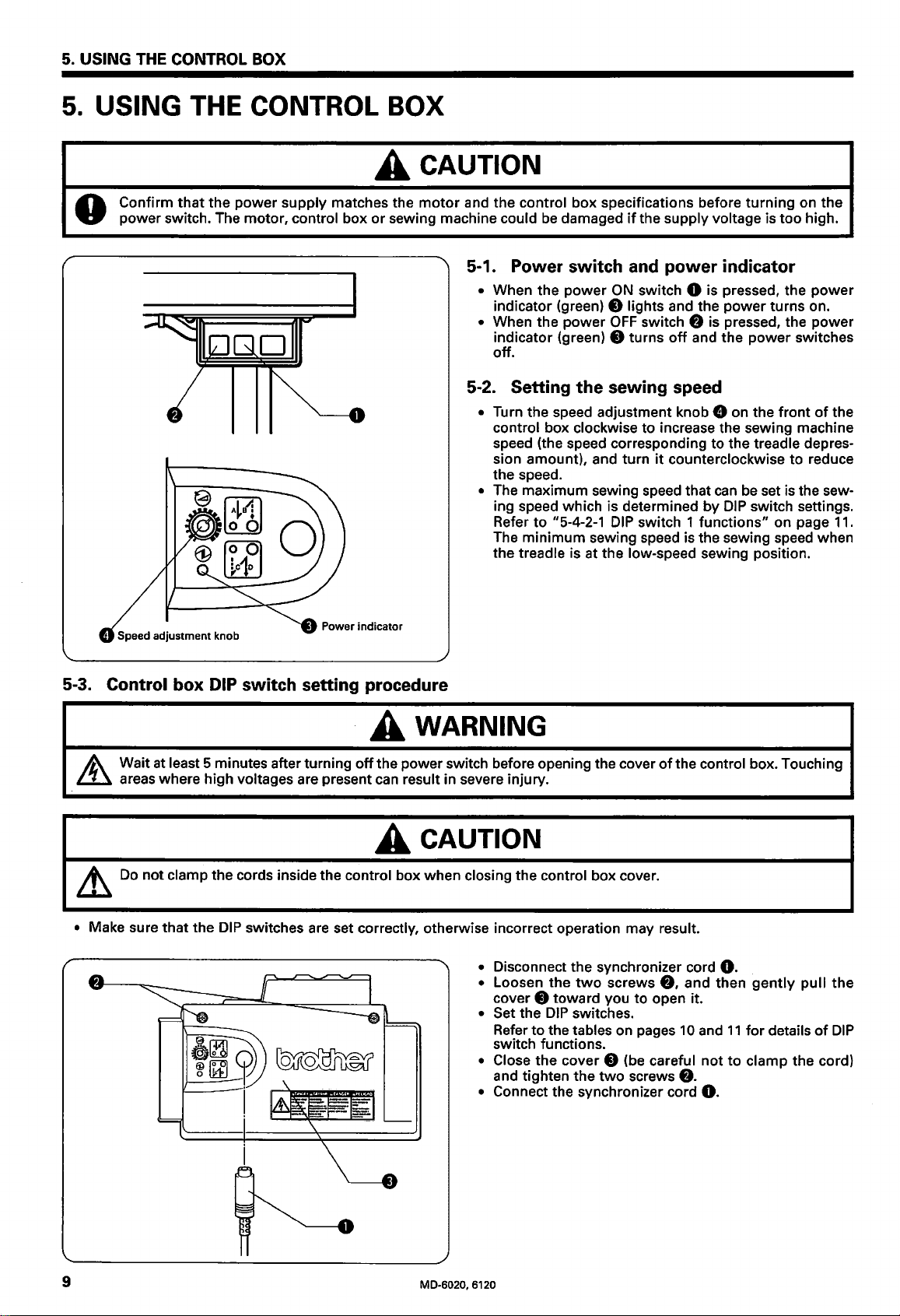

5-1. Power switch and power indicator

• When

• When the

the

power

indicator (green) 0 lights and the

power

indicator (green) 0 turns

off.

ON

switch 0 is pressed, the

OFF

switch 8 is pressed, the

5-2. Setting the sewing speed

• Turn the speed adjustment knob 8 on the

control box clockwise

speed (the speed corresponding

sion amount), and turn

the speed.

• The maximum sewing speed that

ing speed which is determined by

to

Refer

The

the treadle is at the low-speed sewing position.

"5-4-2-1

minimum

sewing speed is the sewing speed when

DIP

to

switch 1

turning

power

off

and the

increase the sewing machine

it

counterclockwise

functions"

power

to

the treadle depres-

can

be

DIP

switch settings.

on the

too

high.

power

turns on.

power

switches

front

of

the

to

reduce

set is the sew-

on page 11.

5-3. Control box

/A.

Wait at least 5 minutes after turning

~

areas where high voltages are present can result in severe injury.

~

Do not clamp the cords inside the control box when closing the control box cover.

• Make sure

that

the

DIP

switch setting procedure

A WARNING

off

the power switch before opening the cover

A CAUTION

DIP

switches are set correctly, otherwise incorrect operation may result.

• Disconnect the synchronizer cord

• Loosen the

cover 0 toward you

• Set the

Refer

switch functions.

• Close the cover 0 (be careful

and tighten the

• Connect the synchronizer cord

two

screws

DIP

switches.

to

the tables on pages

two

of

the control box. Touching

0.

8,

and then

to

open it.

10

and

11

not

screws

8.

to

0.

gently

for

clamp the cord)

pull

details

of

the

DIP

9

MD-6020, 6120

Page 14

5. USING THE CONTROL BOX

5-4. Description

5-4-1. Backtacking

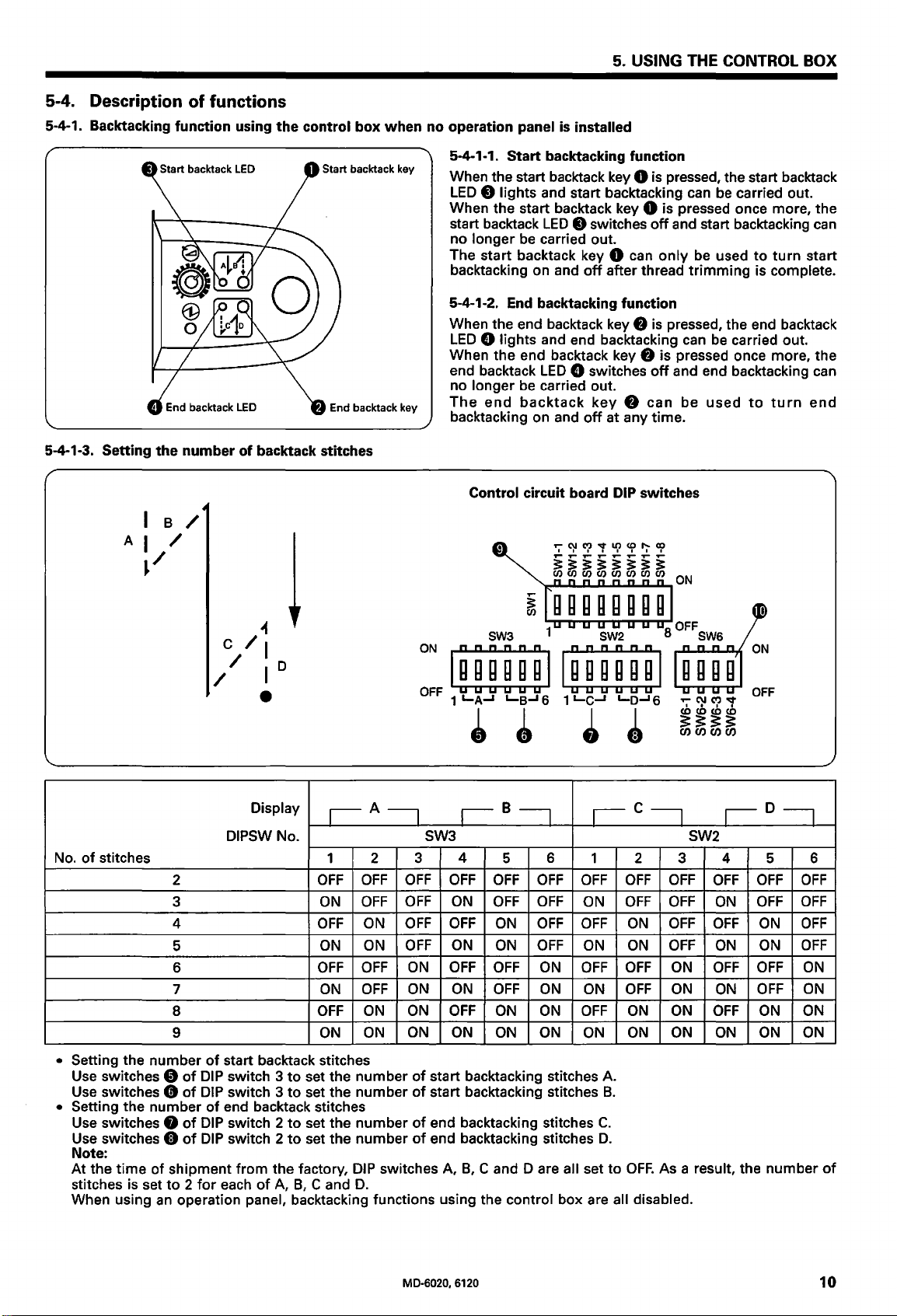

5-4-1-3.

Setting

function

the

I a /

AI/

~/

of

functions

number

using

the

control

of

backtack stitches

box

when

End backtack key

no

operation panel is installed

5-4-1-1.

When the start backtack

LED

When the start backtack key

start backtack

no longer be carried out.

The start backtack key

backtacking on and

5-4-1-2. End backtacking

When the end backtack key

LED

When the end backtack key

end backtack

no longer be carried out.

The

backtacking on and

Start

backtacking

0 lights and start backtacking can

LED

0 switches

off

8 lights and end backtacking can

LED

8 switches

end

Control

backtack

circuit

off

board DIP

function

key

0 is pressed, the start backtack

be

carried out.

0 is pressed once more, the

off

and start backtacking

0 can

after thread

only

be used

trimming

function

fJ

is pressed, the end backtack

be

carried out.

fJ is pressed once more, the

off

and end backtacking can

key

fJ

can be

at any time.

switches

used

to

turn

turn

start

end

is complete.

to

can

No.

of

stitches

2

3

4

5

6

7

8

9

• Setting the number

8

Use switches

Use switches

• Setting the number

Use switches

Use switches 0

Note:

At the

time

stitches is set to 2

When using

of

0

of

8

of

of

of

shipment from the factory,

an

operation panel, backtacking functions using the control box are all disabled.

Display

DIPSW No. SW3

of

start backtack stitches

DIP

switch 3

DIP

switch 3

of

end backtack stitches

DIP

switch 2

DIP

switch 2

for

each

of

A, 8, C and

IAI

1 2 3

OFF OFF

ON

OFF

ON

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

ON

ON

to

set the number

to

set the number

to

set the number

to

set the number

DIP

D.

switches A,

8

1

4

OFF OFF

OFF

OFF

OFF

ON

OFF

ON ON

ON

OFF

ON ON

ON

OFF

ON ON

of

start backtacking stitches A.

of

start backtacking stitches

of

end backtacking stitches

of

end backtacking stitches

B,

5

OFF

OFF

ON

OFF

OFF

ON ON

ON

C and

1

6

OFF

OFF

OFF

OFF

ON

ON

ON

Dare

lei

1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

B.

C.

D.

all set to

IDI

SW2

2 3 4 5 6

OFF

OFF

OFF OFF

ON

ON

OFF

OFF

ON

ON

OFF.

As a result, the number

OFF

OFF

ON

ON

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

ON ON

ON ON

OFF

OFF

OFF

OFF

ON

ON

of

MD-6020, 6120

10

Page 15

5. USING THE CONTROL BOX

5-4-2. Other

5-4-2-1.

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

Setting

\ Speed (rpm)

DIP

Pulley

Note:

When an operation panel has been connected, the operation panel setting has priority, regardless

switch 1-4.

Only

the

Refer

DIP

switch

DIP

switch 1 0 functions

Presser

ON

f---

---------------------------------------------------------

Presser

OFF

ON

Motor

f---

---------------------------------------------------------

Motor

OFF

Automatic

ON

f---

---------------------------------------------------------

OFF

Automatic

Stopping position when treadle is at neutral is needle up stop position.

ON

---------------------------------------------------------

OFF

Stopping position when treadle is at neutral is needle

Twin needle

ON

---

---------------------------------------------------------

OFF

Single needle

Limit

ON

---------------------------------------------------------

OFF

Limit

ON

---------------------------------------------------------

OFF

Limit

ON

f---

--------------------------------------------------------

OFF

for

limit

speed (sewing machine's

switch

SW1-6

SW1-7

SW1-8

diameter

to

"5-4-2-2.

\

105

maximum

DIP

functions

foot

is

lowered

foot

is

raised

pulley diameter

pulley diameter 105

presser

presser

speed setting 1

speed setting 2

speed setting 3

1,000 2,000

(5,000) (5,500) (6,000) (6,500) (7,000)

OFF

OFF

OFF

mm

sewing speed can be changed using the

switch 6

when

treadle

when

treadle

90

mm

foot

lifter

foot

lifter device

ON

OFF

OFF

for single-needle

41>

functions"

is

returned

is

returned

mm

device used

maximum

2,500

OFF

ON

OFF

machines

on this page

to

neutral

position

to

neutral

position

immediately

not

used

down

sewing speed) ( ) is

3,000 3,500 4,000

ON

ON

OFF

and

overlock machines

for

OFF

OFF

ON

DIP

switch 1-5 setting.

other speed selection settings.

immediately

after

stop position.

for

(7,500)

ON

OFF

ON

(90

mm

after

thread

trimming.

thread

trimming.

overlock machines

for twin-needle

(Domestic

4,500

(8,000) (8,500)

OFF

ON

ON

(Export

Japan

4,700

ON

ON

ON

machines)

of

the

specifications)

specifications)

setting

for

DIP

5-4-2-2.

Note:

DIP

sewing speed

If

the above settings match the specifications

DIP

switch

DIP

switch

SW6-1

SW6-2

SW6-3 Backtacking speed

SW6-4

switches

using the

motor

6

«!>

functions

Low

speed

(inching speed)

Thread

speed

Improved stopping

speed

1-2,

for

trimming

1-5

and 6

the machine head, and so should not be changed.

after changing over the machine head, check that

(1-

4)

are set

ON

OFF

ON

OFF

ON

OFF

ON

OFF

5-5. Periodic checks

• Clean the dust

the

motor

•

If

not

using

may

the

out

of

the dust cover at periodic intervals.

overheat.

motor

for

long periods,

Setting speed

250 rpm

215 rpm

185 rpm

215 rpm

1,000 rpm

1,800 rpm

1,500 rpm

1,700 rpm

to

match the

of

the

machine head.

turn

off

the

Single-needle machine and overlock machines setting

-1

-2 -3 -4 -5 -6 -7 -8

SW1

I B lij B B lij

SW6

Twin-needle machine setting

-1

-2 -3 -4 -5 -6 -7 -8

SW11B~BB~BBBI

optimum

sw&~~~~~~

If

the dust cover becomes blocked, there is

power

and disconnect

the

motor

EH3

B I

-1

-2 -3 -4

llij lij lij lij I

-1

-2

-3 -4

from

the

power

the

supply.

danger

that

11

MD-6020, 6120

Page 16

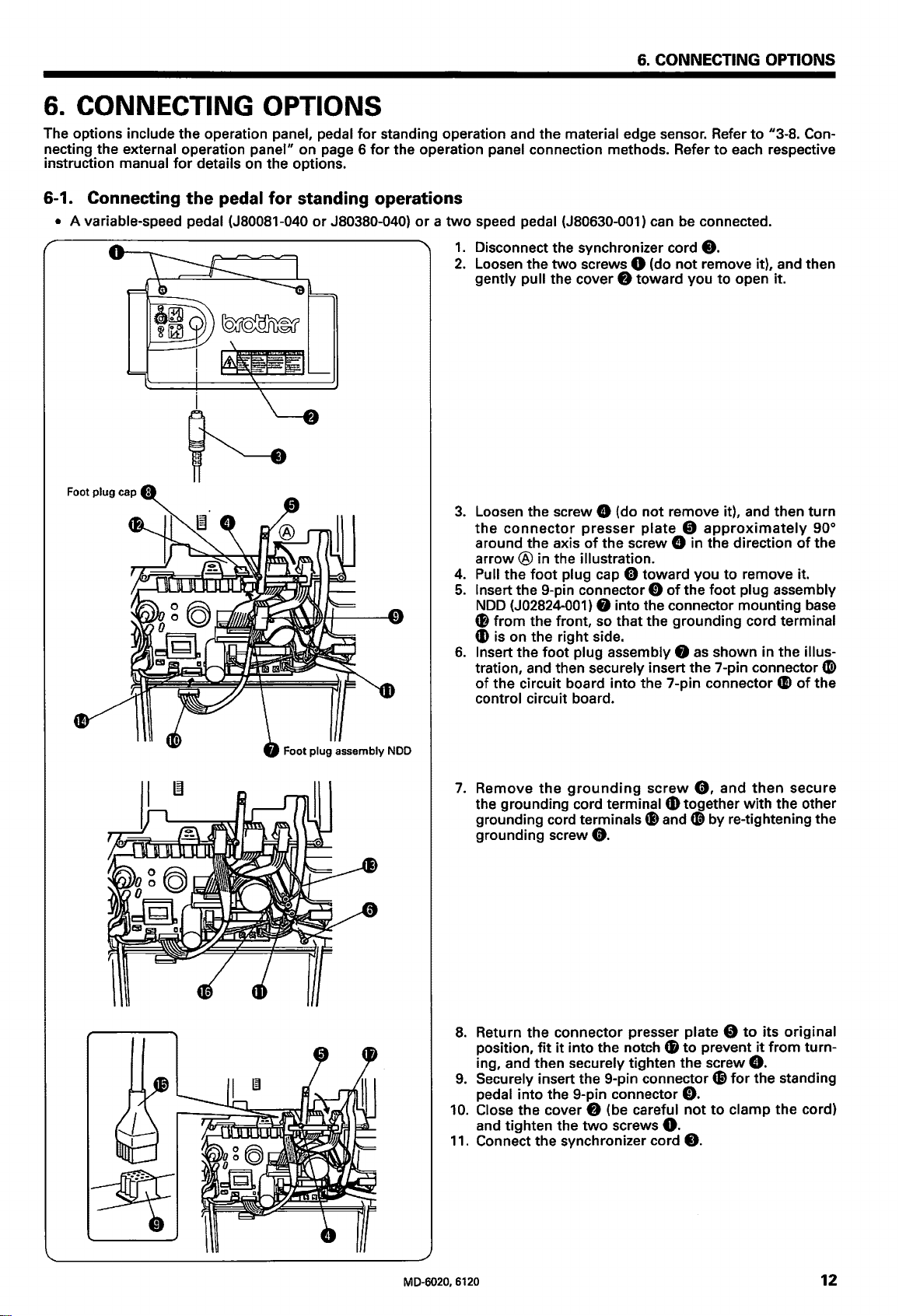

6.

CONNECTING OPTIONS

The options include the operation panel, pedal

necting the

instruction

external operation panel

manual

for

details on the options.

II

on page 6

for

standing operation and the material edge sensor. Refer

for

the operation panel connection methods. Refer

6-1. Connecting the pedal for standing operations

• A variable-speed pedal (J80081-040

or

J80380-040}

or a two

&.

CONNECTING

to

speed pedal (J80630-001} can be connected.

1.

Disconnect the synchronizer cord

2.

Loosen the

gently pull the cover

3.

Loosen the screw 8 (do not remove it}, and then turn

the

connector

around the axis

arrow

4.

Pull the

5.

Insert the 9-pin connector 0

NOD

tB

from

4D

is on the right side.

6.

Insert the

tration, and then securely insert the 7-pin connector

of

the circuit board into the 7-pin connector

control circuit board.

two

screws 0 (do

f)

toward you

presser

of

plate 0 approximately

the screw 8 in the direction

@ in the illustration.

foot

plug cap 0 toward you

(J02824-001} 8 into the connector mounting base

the front, so

foot

that

the grounding cord terminal

plug assembly 8

8.

not

remove it}, and then

to

of

the foot plug assembly

as

shown in the illus-

OPTIONS

11

to

3-8. Con-

each respective

open it.

to

remove it.

41)

of

of

90°

the

tD

the

-ftC

---.,

Foot plug assembly NOD

7.

Remove

the grounding cord

grounding cord

grounding screw

8.

Return

position,

ing, and then

9.

Securely insert the 9-pin connector 4i

pedal

10. Close

and tighten the

11.

Connect the synchronizer cord

the

grounding

terminals

screw

terminal

41

0.

the

connector presser plate 0

fit

it

into the notch

securely tighten the screw

into

the 9-pin connector

the

cover

f)

(be careful

two

screws

4D

and

CB

0.

0,

and

then

together

«0

to

with

by re-tightening the

to

prevent

its

it

from

8.

for

the standing

0.

not

to

clamp

0.

secure

the other

original

turn-

the

cord}

M0-6020, 6120 12

Page 17

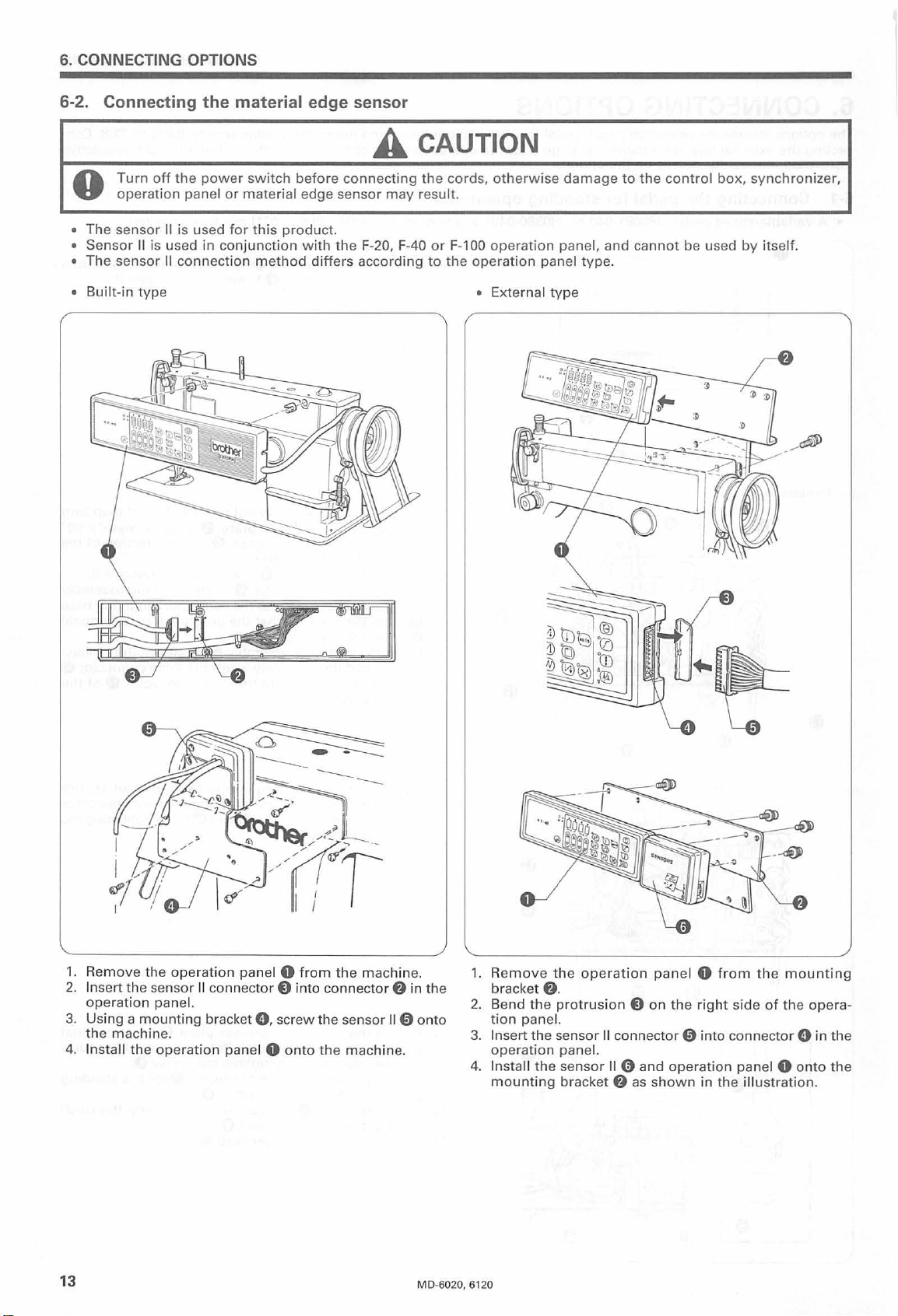

6. CONNECTING OPTIONS

6-2. Connecting

Turn

off

the

operation

•

The

sensor

•

Sensor

• The

• Built-in type

II

sensor

panel

II

is used

is

used in

II

connection

the

material edge sensor

power

switch

or

material edge sensor

for

conjunction

this

product.

method

before

with

differs

A

connecting

may

the

F-20, F-40

according

CAUTION

the

cords,

otherwise

result.

or

F-100

operation

to

the

operation

• External

damage

panel, and

panel

type.

type

to

the

cannot

control

be used

box,

synchronizer,

by

itself.

1. Remove

2.

Insert

operation

3.

Using a

the machine

Install

4.

13

the operation

the

sensor

panel.

mounting

.

the

operation

panel 0

II

connector

bracket

panel 0

from

f)

into connector 8 in

0,

screw

the

onto

the

the

machin

sensor

machine.

110

e.

the

onto

MD

-6020, 6120

1. Remove the

bracket

2.

Bend

tion

3. Ins ert

operation

4.

Install

mounting

8.

the

protrusion

panel.

the sensor

panel.

the sen

bracket 8

operation

f)

II

connector 0

sor

II

0 and

as

panel 0 from

on

the

right side of

into

connector 0 in

operation

shown

in

the

the

panel 0

illu

stration.

mounting

the

opera-

the

onto

the

Page 18

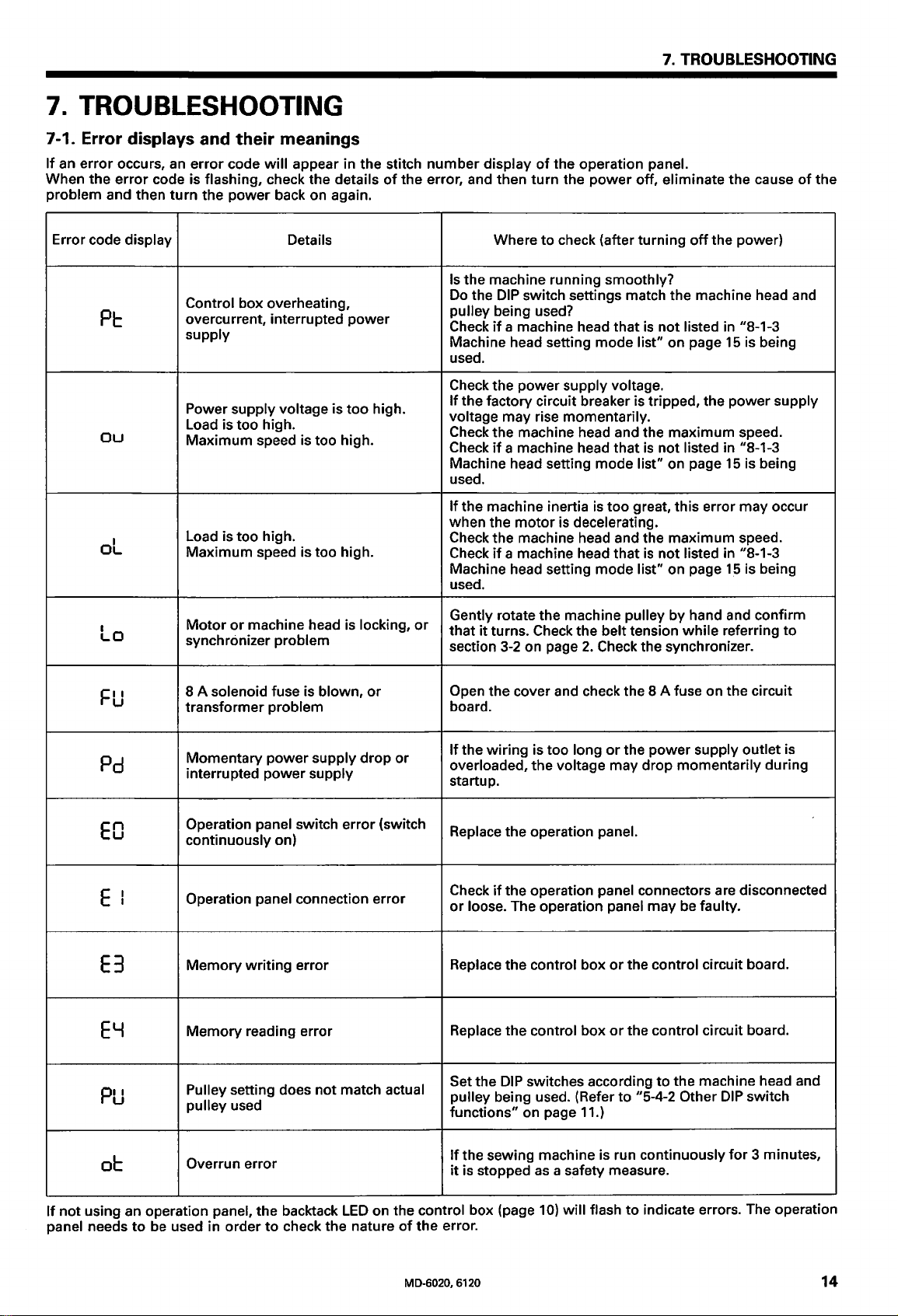

7.

TROUBLESHOOTING

7.

TROUBLESHOOTING

7-1. Error displays and

If

an error occurs,

When the error code is flashing, check the details

problem and then turn the power back on again.

Error code display

PI:

ou

oL

an

Control box overheating,

overcurrent, interrupted power

supply

Power supply voltage is

Load is too high.

Maximum speed is too high.

Load is too high.

Maximum speed is too high.

error

their

code

meanings

will

appear in the stitch

Details

too

number

of

the error, and then turn the

high.

display

Where

Is

the machine running smoothly?

Do

the

pulley being used?

Check

Machine head setting mode

used.

Check the power supply voltage.

If

voltage may rise momentarily.

Check the machine head and the maximum speed.

Check

Machine head setting mode

used.

If

when the

Check the machine head and the maximum speed.

Check

Machine head setting mode

used.

DIP

if

a machine head that

the factory circuit breaker is tripped, the power supply

if

a machine head that

the machine inertia

motor

if

a machine head that

of

the operation panel.

power

off, eliminate the cause

to

check (after turning

switch settings match the machine head and

list" on page

list"

is

too

great, this error may occur

is

decelerating.

list"

off

the power)

is

not listed in "8-1-3

is

not listed in "8-1-3

on page

is

not listed in "8-1-3

on page

15

15

15

is being

is being

is being

of

the

Lo

FU

Pd

EO

I

I

E

E3

ELl

Motor

or

synchronizer problem

8 A solenoid fuse is blown,

transformer problem

Momentary power supply drop

interrupted

Operation panel switch error (switch

continuously on)

Operation panel connection error

Memory

Memory reading error

machine head is locking,

power

supply

writing

error

or

or

or

Gently rotate the machine pulley by hand and confirm

that

it

turns. Check the belt tension while referring

section 3-2 on page

Open the cover and check the 8 A fuse on the circuit

board.

If

the wiring is too long

overloaded, the voltage may drop momentarily during

startup.

Replace the operation panel.

Check

if

the operation panel connectors are disconnected

or

loose. The operation panel may be faulty.

Replace the control box

Replace the control box

2.

Check the synchronizer.

or

the power supply outlet is

or

the control circuit board.

or

the control circuit board.

to

PU

ol::

If not using an operation panel, the backtack

panel needs

to

Pulley setting does not match actual

pulley used

Overrun error

be

used in order

to

check the nature

Set the

pulley being used. (Refer

functions" on page 11.)

If

it

LED

on the control box (page 1

of

the error.

MD-6020, 6120

DIP

switches according

the sewing machine is run continuously

is stopped as a safety measure.

0)

will flash

to

to

to

the machine head and

"5-4-2 Other

indicate errors. The operation

DIP

for

switch

3 minutes,

14

Page 19

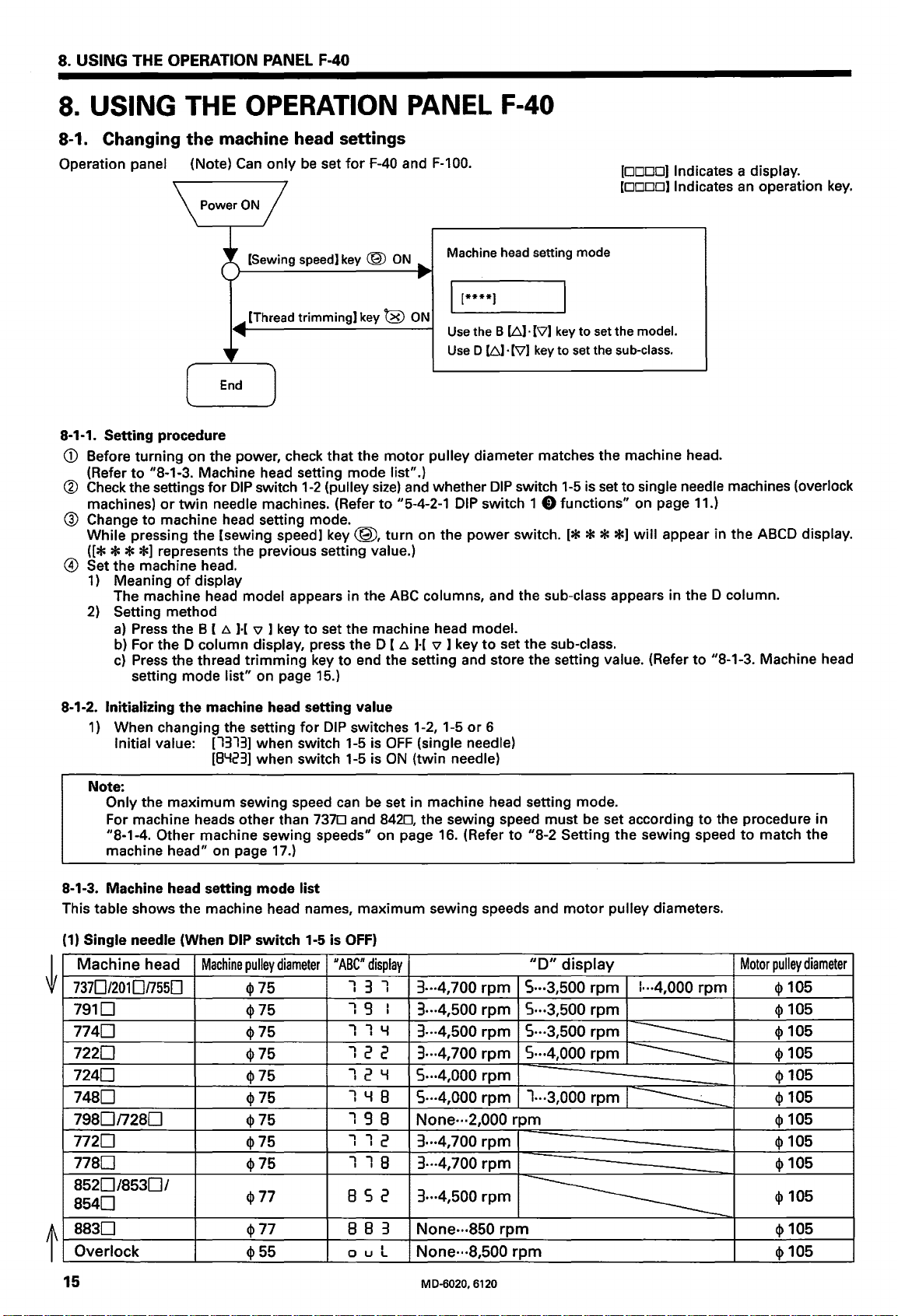

8. USING THE OPERATION PANEL F-40

8.

USING THE OPERATION PANEL F-40

8-1. Changing

Operation panel (Note)

8-1-1.

Setting

CD

Before turning on the power, check

to 118-1-3. Machine head setting mode list".)

(Refer

® Check the settings for

machines)

® Change

While pressing the [sewing speed]

U*

* *

@)

Set the machine head.

1)

Meaning

The machine head model appears in the

2)

Setting method

a)

Press the B [

b)

For the D column display, press the D [

c)

Press the thread

setting mode

the

machine head

Can

[Sewing speed]

[Thread

procedure

DIP

switch

or

twin

needle machines. (Refer

to

machine head setting mode.

*1

represents the previous setting value.)

of

display

t:.

H " l key

trimming

list"

on page 15.)

only

settings

be

set

for

F-40

and

F-100.

key~

ON

Machine head setting mode

I [****]

trimming]

1-2

to

key

key ~ ON

that

the

motor

(pulley

set the machine head model.

size)

to 115-4-2-1

key@,

to

turn

ABC

t:.

end the setting and store the setting value. (Refer

Use the B

Use D

pulley diameter matches the machine head.

and whether

DIP

on the

columns, and the sub-class appears in the D column.

H " l key

[DODD] Indicates a display.

[DODD] Indicates an operation

~]

· [\7] key

~]

· [\7] key

DIP

switch

switch 1 0 functions" on page 11.)

power

to

switch.

set

the

to

set the model.

to

set the sub-class.

1-5

is set

l*

* *

*1

sub-class.

to

single needle machines (overlock

will

appear in

the

ABCD display.

to

"8-1-3. Machine head

key.

Initializing

8-1-2.

1)

When changing the setting

Initial value: [1313] when switch 1-5 is

Note:

Only the

For machine heads other than

"8-1-4. Other machine sewing speeds" on page 16. (Refer

machine head" on page 17.)

8-1-3. Machine head setting

This table shows the machine head names,

(1)

Single needle (When

Machine head

t

7370/201

7910

7740

7220

7240

7480

7980n280

7720

7780

8520/8530/

8540

8830

Overlock

onsso

the

machine head setting value

for

[8Y23]

when switch 1-5 is

maximum

sewing speed can be set in machine head setting mode.

mode

list

DIP

Machine

pulley

<1>75

<1>75

<1>75

<!>75

<1>75

<1>75

<!>75

<!>75

<1>75

<1>77

<1>77

<!>55

switch

1-5 is

diameter

DIP

switches 1-2, 1-5

OFF

(single needle)

ON

(twin needle)

7370 and 8420, the sewing speed must be set according

maximum

OFF)

u

ABCn

display

l 3 l

l g

l l y

l 2 2

l 2

l

'-1

l g 8

.,

I

l 2 3 ...

l l 8 3 ...

8 s 2

3···4,700 rpm

I

I

3 ...

3 ...

3···4,700 rpm

'1

s ...

8

s

None-

3 ...

or

6

to

"8-2 Setting

sewing speeds and

II

D"

s ...

4,500

rpm

5···3,500 rpm

4,500

rpm

5···3,500 rpm

s ...

4,000

rpm

..

-4,000 rpm

..

2,000 rpm

4,700

rpm

4,100

rpm

4,500

rpm

===--======--:.

1

...

===-=

motor

display

3,500

4,000

3,000

-

the

sewing speed

pulley diameters.

rpm

rpm

1···4,000 rpm

-----

------

rpm

~

~

8 8 3 None-

o u L

None

..

850

..

·8,500

rpm

rpm

to

the procedure in

to

match

Motor

pulley

<I>

<I>

<I>

<I>

<I>

<I>

<I>

<I>

<I>

<I>

<I>

<I>

the

diameter

105

105

105

105

105

105

105

105

105

105

105

105

15

M

D-6020,

6120

Page 20

(2)

Twin needle (When

Machine head

8420

8720

8450/8750

8470

8480

8370

8770

8780

P730/P810

C510

t

Note:

1.

When carrying

the setting

• When

2.

The machine head

3.

The machine head

4.

The

head type.

DIP

switch 1-2 on

switch 1-2 should match.

5.

The maximum sewing speed cannot

6.

When

for

the

settings

motor

pulley diameter shown is the

[oul]

(overlock machines) has been set,

DIP

Machine

out

the next operation,

DIP

switch 1-5.

type

type

the

switch

pulley

q,

q,

<1>77

<1>77

q,

q,

q,

q,

q,

q,

for

control circuit board is used

1-5

is

ON)

diameter

77

77

77

77

77 8 1 1

77

80

102

DIP

switches 1-2, 1-5 and 6 have been changed

displayed moves

displayed moves

"ABC"

display

8

'-1

2

8 1 2 3 ... 3,000 rpm

8

'-1

5

8

'-1

1

8

'-1

8

8 3 1

8 1 8

Po

I

r 1 I

L L I

the

setting

down

up

the list each

outer

be

set to a speed that is higher than the speed set by

8. USING THE OPERATION PANEL F-40

11

D" display

3···4,000 rpm

3···3,000 rpm

'···4,000 rpm

'···3,000 rpm

5···3,000 rpm

None-

..

3,000

None-

..

2,500

2···2,200 rpm

2···2,200 rpm

will

return

the list each

diameter. Attach the appropriate pulley depending on

the

motor

time

to

select the pulley size. The pulley size and

will

5···3,500 rpm

5···3,000 rpm

5···3,000 rpm l-··3,000

'···4,000 rpm

-

-

---

---

rpm

rpm

'-~···2,400

'-~···2,400

to

[1313]

or

time

the

B [L}.] key is pressed.

the

B

[\7]

operate in the reverse direction.

---

---

rpm

6···2,600 rpm

---

rpm

6···2,600 rpm

[8'-123].

key is pressed.

The return setting

DIP

switches

Motor

rpm

the

pulley

q,

q,

q,

q,

q,

<1>90

q,

q,

q,

q,

will

depend on

the

setting

1-6,

1-7

diameter

90

90

90

90

90

90

90

90

90

machine

for

DIP

and

1-8.

8-1-4.

Other

machine

(1)

Single needle

Machine head

7370/201

7910

7740

7220

7240

7480

7980n280

7720

7780

8520/8530/8540

8830

Overlock 215

(2) Twin needle

Machine head

8420

8720

8450/8750

8470

8480

8370

8770

8780

P730/P810

C510

Speeds marked

Refer

0fl550

to

"8-2. Setting

sewing

Inching speed

215

215

215

215

215 rpm

215 rpm

215 rpm

215 rpm

215 rpm

215 rpm

250

Inching speed

250

250 rpm

250 rpm

250 rpm

250 rpm

250 rpm

250

250

250 rpm

250 rpm

with * must

the

sewing speed

speeds

Thread

[lo]

rpm

rpm

rpm

rpm

rpm*

rpm

Thread

[Lo]

rpm

rpm

rpm

be set after the machine head has been set.

to

trimming

[l:r]

215

rpm

215

rpm

215

rpm

215

rpm

215 rpm 500

215 rpm

215 rpm

215 rpm

215 rpm 215

185

rpm*

170

rpm*

215 rpm 215 rpm

trimming

[l:r]

185

rpm

185

rpm

185 rpm

185 rpm

185 rpm

185 rpm

185 rpm

185 rpm

185 rpm

185 rpm

match

the

machine head" on page 17.

MD-6020, 6120

Slow

215 rpm

215 rpm

215 rpm

215 rpm

rpm*

215

215

215

215 rpm

250

rpm*

Slow

250 rpm

250 rpm

250 rpm

250 rpm

250

rpm

250

rpm

250 rpm

250 rpm

250 rpm

250 rpm

[5L]

rpm

rpm

rpm

rpm

[5L]

Start/end

[l

1,800 rpm

1,800 rpm

1,800 rpm

1,800 rpm

1,600

1,200

1,000

1,800

1,800 rpm

1,200

250

1,800 rpm

Start/end

[L

1,000 rpm

1,000 rpm

1,000 rpm

1,000 rpm

1,000 rpm

1,000

800

800

1,000 rpm

1,000 rpm

backtacking

~1

[Eb1

rpm*

rpm*

rpm*

rpm

rpm*

rpm*

bac!<tacking

~1

[Eb1

rpm

rpm*

rpm*

Improved

Improved stopping

stopping

[Po]

1,700

rpm

1,700

rpm

1,700

rpm

1,700

rpm

1,700

rpm

1,700 rpm

1,700 rpm

1,700 rpm

1,700 rpm

1,700 rpm

500

rpm*

1,500

rpm*

[Po]

1,500

rpm

1,500

rpm

1,500

rpm

1,500

rpm

1,500

rpm

1,500 rpm

1,500 rpm

1,500 rpm

1,500 rpm

1,500 rpm

16

Page 21

8.

USING

THE

OPERATION

PANEL

F-40

8-2. Setting

(Example: changing the start backtack speed

Can

(Note)

1.

Turn on the power switch.

2.

Turn

*1

Press operation keys 8

Press the [Sewing speed)

ing speed indicator

3.

While holding

[Thread

4.

While holding

[Half stitch)

5.

Press the [Thread

6.

The

is pressed. Press

changes

only

c

F-40

off

all

trimming)

ABCD

the

sewing speed

be

set

of

the

ABCD

down

down

key@

LED

display changes

[b-

] ~ [SL

to

to

match

for

F-40

and

F-100.

LED

indicators.

to 0 to

key~

«8

and backtack indicator tl.

the [AUTO) key e

key

<:8)

0.

the [AUTO) key 8

•·

trimmer)

it

several

key

] ~ [L

turn

(D

to

turn

<:8)

tD.

each

time

times

so

that

1 ] and then stop.

the

from

1,800 rpm

off

the

LEOs.

off

the sew-

0,

press the

0,

press the

the B [6.) key

the display

machine head

to

1,000 rpm)

Display

A 8 C D

I I I I I

ldiSI

- - - - -

lsi

ILiol

ILI·I

PI

I I

I I

I I

I

I

[DODO] Indicates a display.

[DODO) Indicates an operation

Note:

If the

ABCD

LED

display is lit, carry out the

*1

to

operation at

of

Type

Inching

Thread

Slow

Start

End backtacking speed

Maximum

Automatic speed

Stopping

sewing speed

speed

trimming

speed

backtacking

speed

improvement

turn the display off.

speed

limit

speed

limit

speed

speed

ABCD

[L

[t

[5 L

[L

[E

[H

[AU ]

[Po

key.

display

]

o

,...

]

]

]

I

b ]

I ]

]

7.

Press the [Thread

8. Press the B ['\7) key so that [

LED

display.

9.

Press the [Thread

10.

Press the B [6.) key several times

display changes

11.

Press the [Thread trimmer) key

12.

Press the B [6.) key several times

display changes

13.

Press the [Thread

14.

Press the B [b.)

15.

Press the B [b.)

16.

Press the [Thread

the ABCD

LED

trimmer)

trimmer)

to

[H

1 ]

to

[CP

trimmer)

key.

key.

trimmer)

indicators.

key

1000]

key

~

[AU

] ~ [r-o

key

<:8)

<:8)

0.

appears in the ABCD

<:8)

0.

so

that the

]

~

<:8)

tD.

so

that the ABCD

] ~ [En

<:8)

tl>.

key 0

[Po

to

]

].

turn

ABCD

~

[En

off

LED

LED

all

IIIBIDIDI

IIIDIDIDI

ILI·I

IEinl

].

ISIPI

PIAl-

Elnl

of

I I I I I

I I

I I

I I

-

Note:

• The setting

on the

takes priority in determining

the maximum sewing speed,

and so the speed cannot be

set above this.

•

If

you

maximum sewing speed and

the

start backtacking speed

to

be

which

switch 1

speed setting mode

The speed can be changed

easily

speed key

tion

panel.

•

The automatic sewing speed

can

only

than

speed.

for

DIP

control

would

lower

has been set

using

the

circuit

like

than

or

the

speed set in

the

tD

on

be set

maximum

switch 1

to

the speed

sewing

the

to

be

board

set

the

by

DIP

[SP

]:

opera-

lower

sewing

17

MD-6020, 6120

Page 22

MD-6020

MD-6120

7:.1

710la9i:~il.m

1.

i:~i!.m

2.

i:~$I9iJ:.a9~~~~

3.

m~~16:

1.

~-

.................................................................... 1

2.

~Jtl\!a9*

3.

~•nit

3-1.

!14ffb~~~{£I

3-2 .

.lt1W'~~~

3-3.

~~lt'Hr

3-4

.)iff~li~

3-5 .

.lt'Mflil~~~ft~iJ]~

3-5-1 .

3-5-2.tFm~a3iJJ~

3-6.

!l~~Ji;Jt

3-6-1.lt!.ill!l, lt!.ill7f*

3-6-2.

3-7.

ftfti!JJ~~~~

3-8.

9~fttlfF1lt~:it~

4.