Page 1

Brother Color Laser Printer

SERVICE MANUAL

MODEL: HL-3450CN

Read this manual thoroughly before commencing any maintenance work.

Keep this manual in a convenient place for quick and easy reference at all times.

January, 2002

SM-PRN028

Page 2

© Copyright Brother 2002

All rights re served.

No part of this publication may be reproduced in any form or by any means without permission in

writing from the publisher.

Specifications are subject to change without notice.

Trademarks:

The brother logo is a registered trademark of Brother Industries, Ltd.

Apple, the Apple Logo, and Macintosh are trademarks, registered in the United States and other

countries, and True Type is a trademark of Apple computer, Inc.

Epson is a registered trademark and FX-80 and FX-850 are trademarks of Seiko Epson Corporation.

Hewlett Packard is a registered trademark and HP Laser Jet is a trademark of Hewlett Packard

Company.

IBM, IBM PC and Proprinter are registered trademarks of International Business Machines

Corporation.

Microsoft and MS-DOS are registered trademarks of Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.

Page 3

HL-3450CN SERVICE MANUAL

i

PREFACE

This service manual contains basic information required for after-sales service of the color laser printer

(here-in-after referred to as "this machine" or "the printer"). This information is vital to the service

technician to maintain the high printing quality and performance of the printer.

This service manual covers the HL-3450CN color laser printer.

This manual consists of the following chapters:

CHAPTER 1: OUTLINE OF PRODUCT

Features, parts names, internal structure, and description of the control panel.

CHAPTER 2: SPECIFICATIONS

Specifications, etc.

CHAPTER 3: INSTALLATION

Installation conditions and installation procedures.

CHAPTER 4: STRUCTURE OF SYSTEM COMPONENTS

Basic operation of the mechanical system, the electrical system and the electrical

circuits and their timing information.

CHAPTER 5: CONTROL PANEL OPERATION

Operation and setting procedures on the control panel.

CHAPTER 6: PERIODIC MAINTENANCE

Description of periodic maintenance parts and procedures for periodic replacement

and cleaning.

CHAPTER 7: DISASSEMBLY

Procedures for replacement of the mechanical system parts.

CHAPTER 8: TROUBLESHOOTING

Description of error messages on the control panel, troubleshooting image failure,

etc.

APPENDICES : SERIAL NO. DESCRIPTIONS, ETC.

Information in this manual is subject to change due to improvement or re-design of the product. All

relevant information in such cases will be supplied in service information bulletins (Technical

Information).

A thorough understanding of this printer, based on information in this service manual and service

information bulletins, is required for maintaining its print quality performance and for improving the

practical ability to find the cause of problems.

Page 4

TABLE OF CONTENTS

TABLE OF CONTENTS

REGULATIONS..................................................................................vi

SAFETY INSTRUCTIONS................................................................viii

SHIPMENT OF THE PRINTER.........................................................xiii

CHAPTER 1 PRODUCT OUTLINE ................................................. 1-3

1. FEATURES.....................................................................................................1-3

2. PARTS NAMES & FUNCTIONS.....................................................................1-6

3. INTERNAL STRUCTURE...............................................................................1-8

4. DESCRIPTION OF CONTROL PANEL ..........................................................1-9

4.1 Video Controller Mode .........................................................................................................1-9

4.2 Engine Controller Mode .......................................................................................................1-9

CHAPTER 2 SPECIFICATIONS...................................................... 2-3

1. RATING ..........................................................................................................2-3

2. GENERAL SPECIFICATIONS........................................................................2-4

2.1 Printing.................................................................................................................................2-4

2.2 Functions .............................................................................................................................2-4

2.3 Electrical and Mechanical ....................................................................................................2-5

2.4 Paper....................................................................................................................................2-6

2.5 Printing Area ........................................................................................................................2-8

3. ENVIRONMENTAL CONDITIONS.................................................................2-11

3.1 Ambient Temperature / Humidity / Altitude ........................................................................2-11

CHAPTER 3 INSTALLATION ......................................................... 3-3

1. CONDITIONS REQUIRED FOR INSTALLATION...........................................3-3

1.1 Environmental Conditions....................................................................................................3-3

1.2 Basic Layout of Printer Set-up Location...............................................................................3-3

2. UNPACKING...................................................................................................3-5

2.1 Unpacking the Printer ..........................................................................................................3-5

2.2 Unpack the Starter Kit..........................................................................................................3-7

3. INSTALLATION WORK ..................................................................................3-8

3.1 Install the Oil Bottle and Fuser Cleaner ...............................................................................3-8

3.2 Install the OPC Belt Cartridge..............................................................................................3-9

3.3 Install the Toner Cartridge into the Printer.........................................................................3-11

3.4 Install the Media Cassette and Adaptor.............................................................................3-12

3.5 Test Print............................................................................................................................3-14

ii

Page 5

HL-34500CN SERVICE MANUAL

CHAPTER 4 STRUCTURE OF SYSTEM COMPONENTS.............. 4-3

1. BASIC STRUCTURE......................................................................................4-3

1.1 Mechanical Structure ...........................................................................................................4-3

1.2 Basic Mechanism of Color Printing......................................................................................4-5

1.3 Structure of the OPC Belt ....................................................................................................4-7

1.4 Print System and Transfer System ......................................................................................4-8

1.5 Scanning System...............................................................................................................4-23

1.6 Paper Transportation System ............................................................................................4-25

1.7 Fusing Unit.........................................................................................................................4-26

2. STRUCTURE OF THE CONTROL SYSTEM.................................................4-28

2.1 Basic Structure - Electrical System and Functions............................................................4-28

2.2 Control System - Control of the Print Process ...................................................................4-37

2.3 Main PCB (Video Controller PCB) .....................................................................................4-46

2.4 Low-voltage Power Supply Unit.........................................................................................4-60

2.5 High-voltage Power Supply Unit ........................................................................................4-63

2.6 Connection Diagram ..........................................................................................................4-65

CHAPTER 5 CONTROL PANEL OPERATION............................... 5-3

1. PANEL LAYOUT.............................................................................................5-3

2. VIDEO CONTROLLER MODE........................................................................5-4

2.1 Configuration of Operational Mode......................................................................................5-4

2.2 Line Test Mode ....................................................................................................................5-5

2.3 DRAM Test Mode ................................................................................................................5-9

2.4 Test Print Mode..................................................................................................................5-10

2.5 NVRAM Reset Mode..........................................................................................................5-10

3. ENGINE CONTROLLER MODE...................................................................5-11

3.1 Configuration of Operational Mode....................................................................................5-11

3.2 Operation of Normal Mode.................................................................................................5-13

3.3 Service Mode.....................................................................................................................5-20

3.4 Adjustment Work Procedures ............................................................................................5-44

CHAPTER 6 PERIODIC MAINTENANCE....................................... 6-3

1. GENERAL.......................................................................................................6-3

1.1 Handling Precautions...........................................................................................................6-3

1.2 List of Maintenance Tools

1.3 List of Consumables for Maintenance..................................................................................6-5

6-4

2. PERIODIC MAINTENANCE CLEANING .........................................................6-6

2.1 Cleaning the Register Roller................................................................................................6-9

2.2 Cleaning the Paper Guide..................................................................................................6-10

2.3 Cleaning the Paper Exit Roller...........................................................................................6-11

2.4 Cleaning the Transfer Roller..............................................................................................6-12

iii

Page 6

TABLE OF CONTENTS

2.5 Cleaning the Paper Discharger..........................................................................................6-13

2.6 Cleaning the OPC Belt Cartridge.......................................................................................6-14

2.7 Cleaning the Transfer Drum...............................................................................................6-15

2.8 Cleaning the Dustproof Glass in the Laser Unit.................................................................6-16

2.9 Cleaning the Printer Interior...............................................................................................6-17

2.10 Cleaning the Oil Pad........................................................................................................6-18

3. PERIODIC MAINTENANCE PARTS..............................................................6-19

4. PERIODIC MAINTENANCE PROCEDURES ................................................6-21

4.1 OPC Belt Cartridge Replacement......................................................................................6-21

4.2 Fusing Unit Replacement...................................................................................................6-23

4.3 Transfer Roller Replacement.............................................................................................6-26

4.4 Paper Discharger Replacement.........................................................................................6-28

4.5 Drum Cleaner Replacement ..............................................................................................6-30

4.6 Ozone Filter Replacement .................................................................................................6-32

4.7 Paper Feeding Roller and Separator Pad Replacement....................................................6-33

4.8 Transfer Drum Replacement..............................................................................................6-34

4.9 Oil Pad Replacement.........................................................................................................6-35

CHAPTER 7 DISASSEMBLY & RE-ASSEMBLY............................ 7-4

1. BEFORE STARTING DISASSEMBLY............................................................7-4

1.1 Precautions..........................................................................................................................7-4

1.2 Preparation of Disassembly.................................................................................................7-4

2. PARTS NAME.................................................................................................7-6

2.1 Cover ...................................................................................................................................7-6

2.2 Circuit Boards (PWBs).........................................................................................................7-7

2.3 Motor Units...........................................................................................................................7-7

2.4 Clutches...............................................................................................................................7-8

2.5 Sensors................................................................................................................................7-8

3. DISASSEMBLY FLOW................................................................................... 7-9

4. DISASSEMBLY PROCEDURE.....................................................................7-10

4.1 Right Side of the Printer.....................................................................................................7-10

4.2 Top of the Printer ...............................................................................................................7-23

4.3 Left Side of the Printer .......................................................................................................7-32

4.4 Paper Exit Unit...................................................................................................................7-42

4.5 Front of the Printer.............................................................................................................7-47

4.6 Rear of the Printer..............................................................................................................7-50

4.7 Fusing Unit.........................................................................................................................7-54

iv

Page 7

HL-34500CN SERVICE MANUAL

v

CHAPTER 8 TROUBLESHOOTING ............................................... 8-3

1. OUTLINE OF TROUBLESHOOTING .............................................................8-4

2. OPERATOR CALL..........................................................................................8-5

2.1 Video Controller Mode .........................................................................................................8-5

2.2 Engine Controller Mode .......................................................................................................8-8

3. PAPER TRANSPORT ERROR.....................................................................8-10

3.1 Feed Jam...........................................................................................................................8-10

3.2 Inner Jam...........................................................................................................................8-11

3.3 Outer Jam ..........................................................................................................................8-13

3.4 Others ................................................................................................................................8-13

4. SERVICE CALL............................................................................................8-14

4.1 Video Controller Mode .......................................................................................................8-15

4.2 Engine Controller Mode .....................................................................................................8-18

5. IMAGE FAILURE..........................................................................................8-47

APPENDIX 1 ...................................................................................A-1

APPENDIX 2 ...................................................................................A-6

APPENDIX 3 ...................................................................................A-7

APPENDIX 4 ...................................................................................A-8

APPENDIX 5 .................................................................................A-11

APPENDIX 6 .................................................................................A-14

APPENDIX 7 .................................................................................A-21

APPENDIX 8 .................................................................................A-36

APPENDIX 9 .................................................................................A-38

Page 8

REGULATIONS

REGULATIONS

LASER SAFETY (FOR 110-120 V MODEL ONLY)

This printer is certified as a Class I laser product under the U.S. Department of Health and Human

Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health and

Safety Act of 1968. This means that the printer does not produce hazardous laser radiation.

Since radiation emitted inside the printer is completely confined within protective housings and external

covers, the laser beam cannot escape from the machine during any phase of user operation.

FDA REGULATIONS (FOR 110-120 V MODEL ONLY)

U.S. Food and Drug Administration (FDA) has implemented regulations for laser products

manufactured on and after August 2, 1976. Compliance is mandatory for products marketed in the

United States. One of the following labels on the back of the printer indicates compliance with the FDA

regulations and must be attached to laser products marketed in the United States.

Caution

Use of controls, adjustments or performance of procedures other than those specified in this manual

may result in hazardous radiation exposure.

vi

Page 9

HL-3450CN SERVICE MANUAL

IEC 60825 SPECIFICATION (FOR 220-240 V MODEL ONLY)

This printer is a Class 1 laser product as defined in IEC 60825 specifications. The label shown below

is attached in countries where required.

This printer has a Class 3B Laser Diode which emits invisible laser radiation in the Scanner Unit. The

Scanner Unit should not be opened under any circumstances.

Caution

Use of controls, adjustments or performance of procedures other than those specified in this manual

may result in hazardous radiation exposure.

The following caution label is attached near the laser unit.

5mW

780nm-800nm

DANGERVORSICHT

DANGERPELIGRO-

INVISIBLE LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG, WENN ABDECKUNG

-

GEÖFFNET UND SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

RAYON LASER INVISIBLE LORS DE L’OUVER TURE.

EVITER L’EXPOSITION DIRECTE.

RADIACION LASER INVISIBLE AL ABRIR. EVITAR

LA EXPOSICION DIRECTA AL HAZ.

MAS

For Finland and Sweden

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

Varoitus! Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa

käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

Varning – Om apparaten används på annat sätt än i denna Bruksanvisning specificerats, kan

användaren utsättas för osynlig laserstrålning, som överskrider gränsen för laserklass 1.

vii

Page 10

SHIPMENT OF THE PRINTER

SAFETY INSTRUCTIONS

SAFETY PRINCIPLE

1) Before starting any operations, read this manual thoroughly. Especially read the safety instructions

in this section carefully and ensure that you understand the contents.

2) Perform all the operations by following the procedures described in this manual. Follow all the

cautions and warnings set out in the procedures and on safety labels affixed to the machine.

Failure to do so may result in human injury or equipment damage.

3) Perform only the procedures explained in this manual. Refrain from opening or touching any

portions that are not related to your required operation(s).

4) Repair and replacement of parts should be performed by trained and qualified persons only.

Operators should not attempt to do such repair or replacement work.

5) It must be appreciated that the above-mentioned cautions and warnings do not cover every

circumstance because it is impossible to evaluate all the conditions of repair situations.

SPECIAL SAFETY INFORMATION

Introductory Information

Cautions and warnings are made clear by them following a ‘Safety Alert Symbol’ or ‘Signal Word’ such

as DANGER, WARNING and CAUTION.

<SAFETY ALERT SYMBOL>

This is the safety alert. When you find this symbol placed on the equipment or marked in this manual,

be aware of the potential of human injuries. Follow the recommended precautions and safety

operation practices.

<Understanding Signal Words>

DANGER is used to indicate the presence of a hazard which will cause severe human injuries or a fatal

accident if the warning is ignored.

WARNING is used to indicate the presence of a hazard or unsafe practices which may cause severe

human injuries or a fatal accident if the warning is ignored.

CAUTION is used to indicate the presence of a hazard or unsafe practices which may cause minor

human injuries if the warning is ignored. CAUTION also calls your attention to safety messages in this

manual.

<Follow Safely Instructions>

Carefully read all the safety messages set out in this manual and also in the safety warning signs

placed on the equipment. In this manual, the safety instructions (safety alert symbols and signal

words) are enclosed in a rectangular enclosure to bring them to your attention. Keep the safety signs

on the equipment in good condition and ensure none are missing or damaged. Replace the safety

signs if unreadable or damaged. Learn how to operate the equipment and how to use the controls

properly. Do not let anyone operate this equipment without following the instructions. Keep the

equipment in proper working condition. Unauthorized modification to the equipment may impair the

function & safety and affect the life of the equipment.

Listed below are the various kinds of “WARNING” messages contained in this manual.

<Caution for the batteries>

There is a danger of explosion if the battery is incorrectly replaced.

Do not replace the battery.

Do not disassemble, recharge or dispose of in fire.

Used battery should be disposed of according to local regulations.

viii

Page 11

HL-3450CN SERVICE MANUAL

WARNING

HAZARDOUS VOLTAGE

May cause serious injuries or fatal accidents. Voltage is now applied from the power

supply of printer. There is a danger of electrical shock if you touch the active area

inside the printer.

Be sure to turn the power supply switch OFF and pull the plug out from the power

outlet before starting maintenance work on the printer.

WARNING

HARMFUL OZONE GAS

Inhalation of an excessive amount of ozone gas may adversely affect the respiratory

organs.

An Ozone Filter is fitted to this printer to reduce the exhausted ozone. This filter

must be replaced with a new filter periodically in accordance with the manual

supplied with the printer.

WARNING

HOT SURFACE

The Fusing Unit reaches a temperature of approx.160°C and adjacent parts are also

very hot.

When you need to change the cleaning pad or remove jammed paper, wait about 20

minutes after opening the paper exit unit to allow the unit to cool down.

CAUTION

ROTATING PARTS

Be aware of the potential danger of various rollers and take care not to get your

fingers or hand caught in the machine, this can cause serious injuries. Note that the

exit roller that ejects the printed paper rotates during printing.

Be careful not to get your hair, fingers, hands, sleeve or necktie caught in the

machine while operating the machine.

ix

Page 12

SHIPMENT OF THE PRINTER

CAUTION

HAZARDOUS POWDER

Toner is a fine powder which can cause a powder explosion if disposed of into a fire.

Under no circumstances dispose of toner into a fire.

CAUTION

HAZARDOUS POWDER

Toner is a fine powder which may cause irritation to the eyes and respiratory organs

if inhaled.

Handle the toner cartridge, waste toner pack and developing unit carefully so as not

to spill the toner.

CAUTION

POWER CORDS & PLUGS

This printer is equipped with a 3-wire power cord fitted with a 3-pronged plug (bipolar plug with grounding) for the user’s safety.

Use these power cords in conjunction with a properly grounded electrical outlet to

avoid an electrical shock.

CAUTION

SAFETY INTERLOCK

The front cover, paper exit unit and transfer unit of this printer have electrical safety

interlocks to turn the power off whenever they are opened. Do not attempt to

circumvent these safety interlocks.

CAUTION

N Do not step on or lean against the media cassette. It may cause the product to tilt

or fall over and result in injuries.

N Do not lean against or apply any excessive force to the media cassette or open

covers, otherwise it may cause the product to tilt or fall over and result in injuries.

x

Page 13

HL-3450CN SERVICE MANUAL

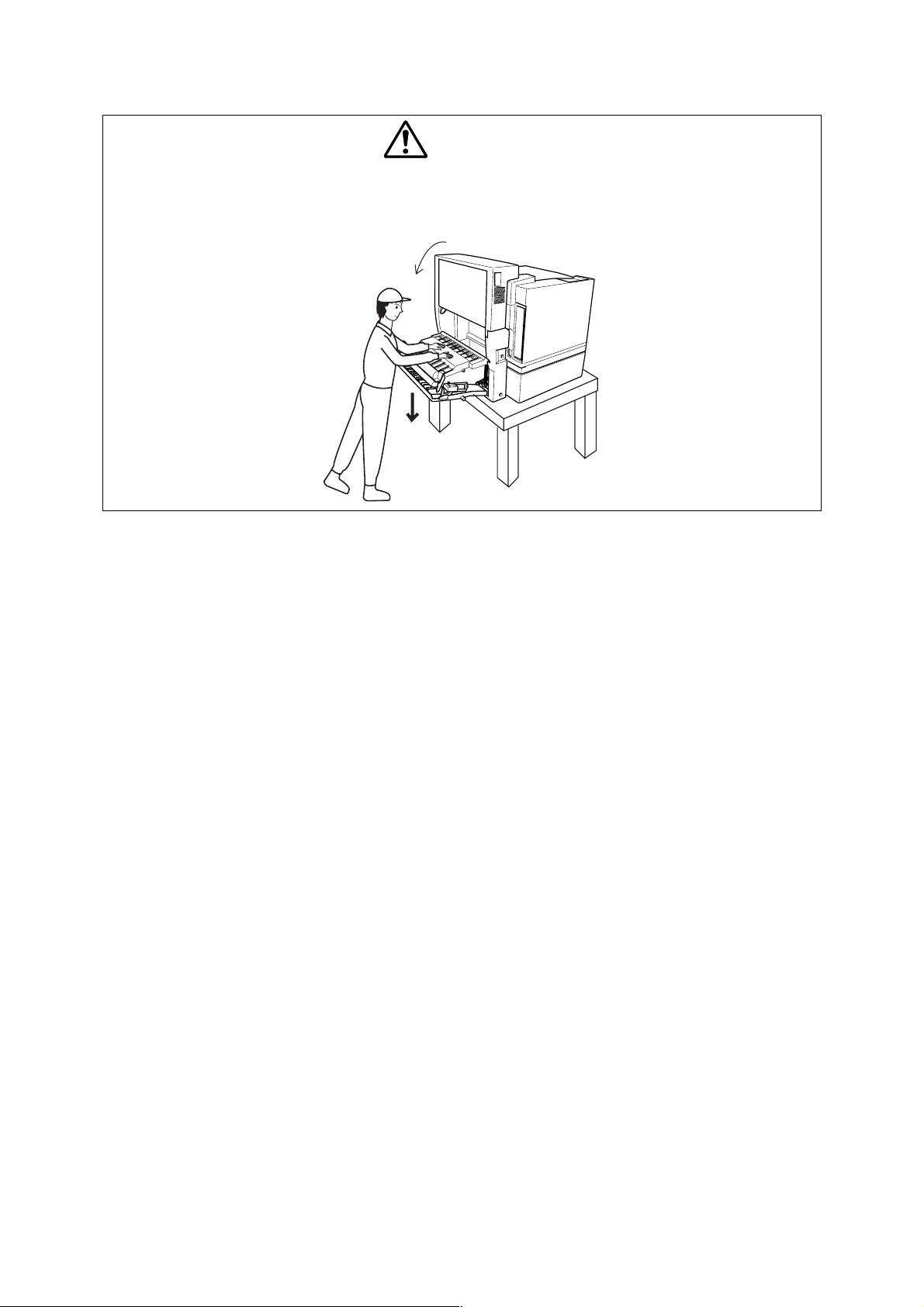

CAUTION

Do not lean against or apply any excessive force to the paper cassette, open cover

of Duplex unit. Otherwise it may cause the product to decline or fall down and result

in the injuries.

xi

Page 14

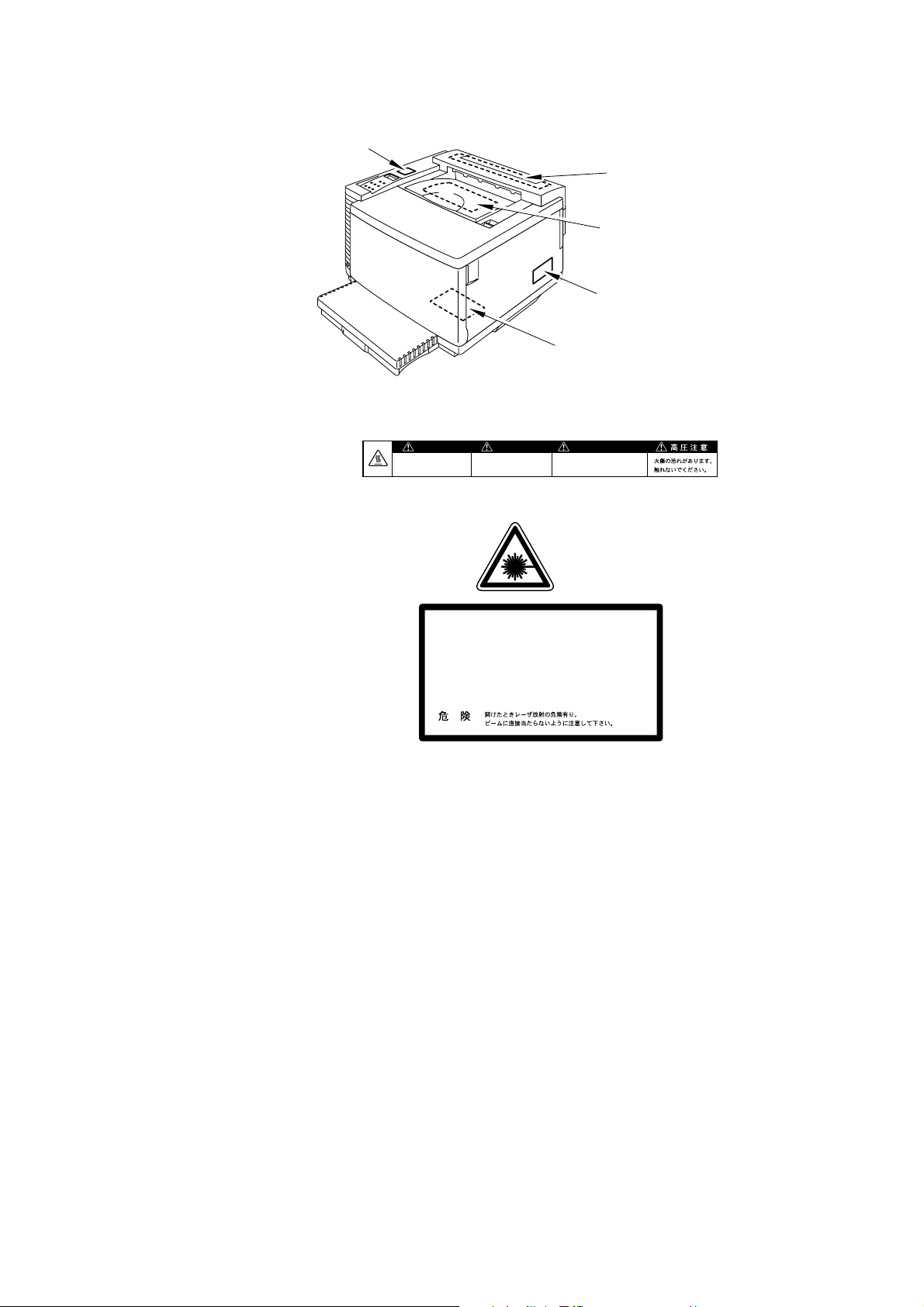

SHIPMENT OF THE PRINTER

1

2

4 3

<Label Location>

1. Hot Caution Label

5

WARNING WARNUNG

Hot surface.

Avoid contact.

Heiße oberfiäche.

Bei beseitigung.

AVERTISSEMENT

Surface chaude.

Eviter tout contact.

2. Laser Caution Label

DANGERVORSICHT

DANGERPELIGRO-

5mW

780nm-800nm

INVISIBLE LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG, WENN ABDECKUNG

-

GEÖFFNET UND SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

RAYON LASER INVISIBLE LORS DE L’OUVER TURE.

EVITER L’EXPOSITION DIRECTE.

RADIACION LASER INVISIBLE AL ABRIR. EVITAR

LA EXPOSICION DIRECTA AL HAZ.

MAS

xii

Page 15

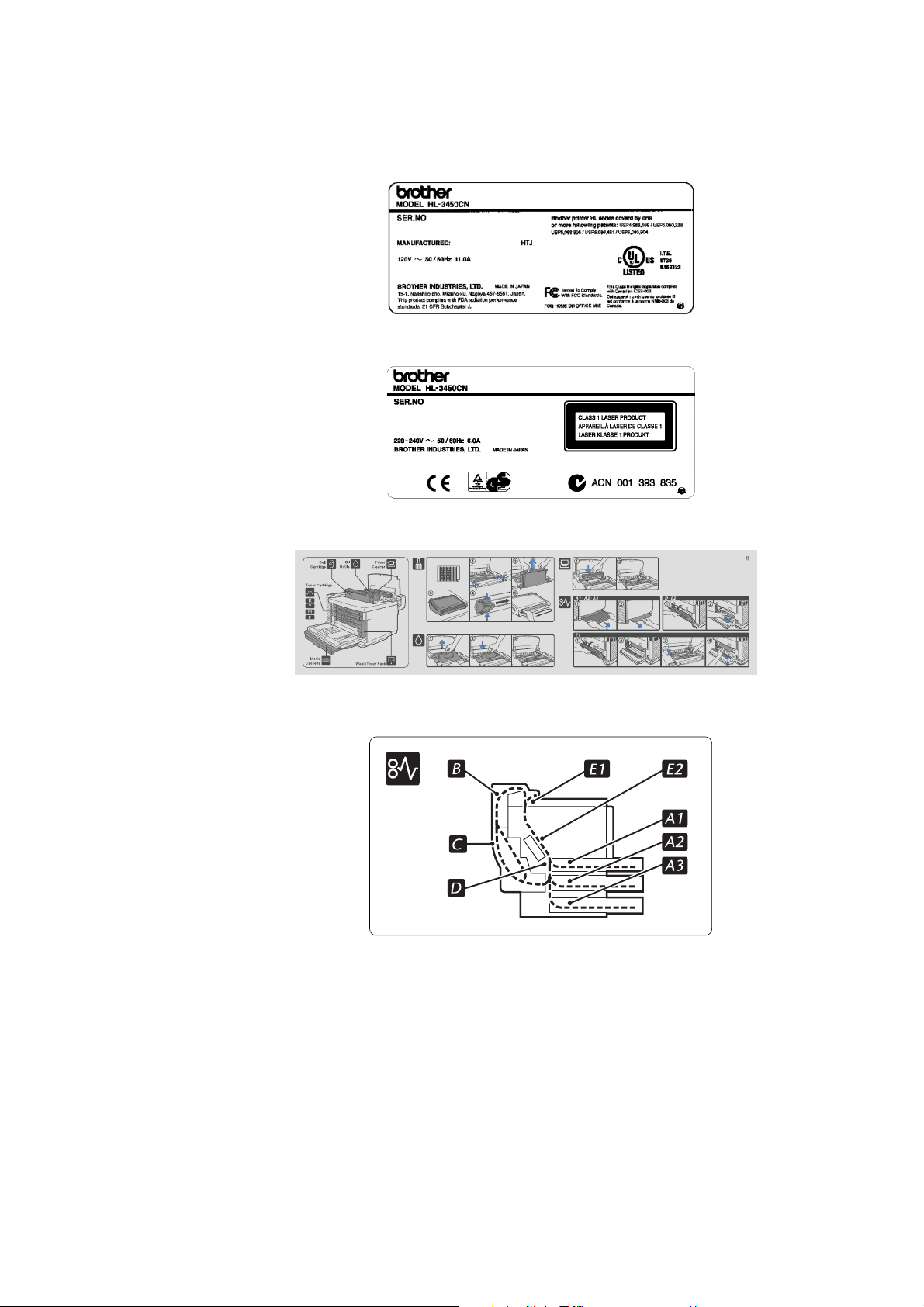

HL-3450CN SERVICE MANUAL

3. Rating Label

4. Operation Label

(For US)

(For Europe)

5. Jam Label

xiii

Page 16

SHIPMENT OF THE PRINTER

SHIPMENT OF THE PRINTER

If for any reason you must ship the printer, carefully package the printer to avoid any damage during

transit. It is recommended that you save and use the original packaging. The printer should also be

adequately insured with the carrier.

CAUTION

N When shipping the printer, remove the toner cartridges, the OPC belt cartridge

and the waste toner pack from the printer to prevent toner spill in the printer or

damage of the toner cartridge and the OPC belt cartridge.

N When shipping the printer, remove the oil bottle and the fuser cleaner from the

fusing unit. After removing the oil bottle, be sure to remove the oil remaining in the

fusing unit with the supplied syringe. Failure to do so will cause severe damage to

the printer.

xiv

Page 17

CHAPTER 1

PRODUCT OUTLINE

HL-3450CN SERVICE MANUAL

Page 18

CHAPTER 1 PRODUCT OUTLINE

1-2

CONTENTS

CHAPTER 1 PRODUCT OUTLINE .....................................................1-3

1. FEATURES..........................................................................................................1-3

2. PARTS NAMES & FUNCTIONS..........................................................................1-6

3. INTERNAL STRUCTURE....................................................................................1-8

4. DESCRIPTION OF CONTROL PANEL ...............................................................1-9

4.1 Video Controller Mode.................................................................................................................1-9

4.2 Engine Controller Mode...............................................................................................................1-9

Page 19

1-3

CHAPTER 1 PRODUCT OUTLINE

1. FEATURES

This printer has the following features:

2400 x 600 dpi Class Resolution

The printer prints pages with a resolution of 600 dots per inch (dpi) as default. It also

provides higher quality printout which is the equivalent of 2400 x 600 dpi resolution when

using High Resolution Control (HRC) or Color Advanced Photoscale Technology (CAPT).

High Speed Color Laser Printing

The printer allows crisp printing in 24 bit brilliant color. The printer prints at a speed of 24

pages per minute in monochrome mode and 6 pages per minute in full color mode when

printing A4 or Letter size paper in Landscape orientation. The controller utilizes a high speed

32-bit RISC microprocessor and special hardware chips, which provides a very fast

processing speed.

HL-3450CN SERVICE MANUAL

High Resolution Control (HRC)

The high resolution control (HRC) technology provides clear and crisp printouts and improves

even the 600 dpi resolution. This mode is effective when printing text data.

Color Advanced Photoscale Technology (CAPT)

®

The printer can print graphics in 256 shades for each color in HP

color printer PCL5C™ and

BR-Script 3 emulations, producing nearly photographic quality. This mode is effective when

printing photographic images.

Maintenance-Free & Economical Tone r Cartridge

A toner cartridge can print up to 14,000 (Black) and 8,500 (Cyan, Magenta and Yellow)

single-sided pages at 5% coverage. The one piece, easy-to-replace toner cartridges do not

require difficult maintenance.

Universal Media Cassette

This printer loads paper automatically from the media cassette. Since the media cassette is

a universal type, a number of different sizes of paper can be used. Even envelopes can be

loaded from the media cassette.

Three Interfaces

This printer has a high speed, bi-directional parallel interface, USB and Ethernet

10/100BaseTX.

If your application software supports the bi-directional parallel interface, you can monitor the

printer status. It is fully compatible with the industry-standard bi-directional parallel interface.

The Brother network board (NC-4100h) is factory installed in the HL-3450CN, which enables

you to use this printer in the TCP/IP, IPS/SPX, Apple Talk, DLC/LLC, Banyan VINES, DEC

LAT and NetBEUI environments. Also, many useful utilities, such as BRAdmin Professional

for the administrator and Brother network printing software, are included in the CD-ROM

supplied with the HL-3450CN printer. For setup, see the Network User’s Guide.

Page 20

CHAPTER 1 PRODUCT OUTLINE

1-4

Automatic Interface Selection

The printer can automatically select the bi-directional parallel, USB, or Ethernet 10/100 Base

TX depending on the interface port through which it receives data. With this feature, the

printer can be connected to more than one computer.

Five Emulation Modes

®

The printer can emulate Hewlett-Packard

mode), PostScript

®

3 language emulation (Brother BR-Script 3) printers, the industry-

standard HP-GL™ plotter as well as EPSON

Color PCL® 5C language (PCL6® in monochrome

®

FX-850™, and IBM® Proprinter XL® printers (in

monochrome mode). It is possible to print with all application programs that support one of

these printers.

Automatic Emulation Selection

The printer can automatically select the printer emulation mode depending on the print

commands it receives from the computer software. With this feature, many users can share

the printer on a network.

Data Compression Technology

The printer can internally compress the received graphics and font data in its memory so that

it can print larger graphics and more fonts without additional memory.

Various Fonts

The printer has 66 scalable and 12 bitmapped fonts. The fonts that can be used will vary

according to the selected emulation mode.

In PCL mode, you can also print the 13 kinds of bar codes listed below. In BR-Script mode,

the printer has 165 scalable fonts.

< Bar Code Printing >

This printer can print the following 13 types of bar codes:

x

Code 39

x

Code 128

x

Interleaved 2 of 5

x

Codabar

x

ISBN (EAN)

x

ISBN (UPC-E)

x

UPC-A

x

UPC-E

x

EAN-8

x

EAN-13

x

EAN-128

x

FIM (US-PostNet)

x

Post Net

(US-PostNet)

CCITT G3/G4

Since the printer supports the CCITT G3/G4 format in addition to HP-compatible formats, it

can quickly receive and print data compressed in this format.

Lock Panel

If the panel button settings have been changed, the printer may not work as expected. It is

possible for the administrator of the printer to lock the settings to prevent changes from being

made.

Power Save Mode

The printer has a power save mode. As laser printers consume power to keep the fixing

assembly at a high temperature, this feature can save electricity when the printer is on but

not being used. The factory setting of the Power Save mode is ON so that it complies with

the new EPA Energy Star new specification.

Page 21

HL-3450CN SERVICE MANUAL

1-5

Toner Save Mode

The printer has an economical toner save mode. This mode allows you to reduce the printer

running cost substantially in addition to the improved life expectancy of the toner cartridge.

Reprint Function

A touch of a panel button allows reprinting of the last print job without sending the data again

from the computer. When there is not enough memory to print the last complete job out, the

last print page can be reprinted. Data can be stored in an IDE HDD that can be optionally

installed. It can be reprinted by selecting a document from the control panel or the browser.

When the private print driver is selected, Secure Printing can be executed which allows you

to print only when a password is entered.

Saving User Settings

It is possible to operate the printer differently from other users with the panel button settings.

One set of user settings can be stored.

*PANTONE

®

Calibrated

There are many variables in process reproduction of colors generated by the HL-3450CN,

any one of which may affect the quality of the PANTONE Color simulation, including;

x

Type of paper used

x

Type of toner used

x

Effective final resolution

x

Dot structure/halftones

For optimal results, it is recommended that the following materials and settings are used.

1) NEUSIEDLER color copy paper

2) Brother Toner Cartridges TN-02 BK/C/M/Y

3) 600 x 600 dpi resolution

Page 22

CHAPTER 1 PRODUCT OUTLINE

1-6

1

3

M

6

8

7

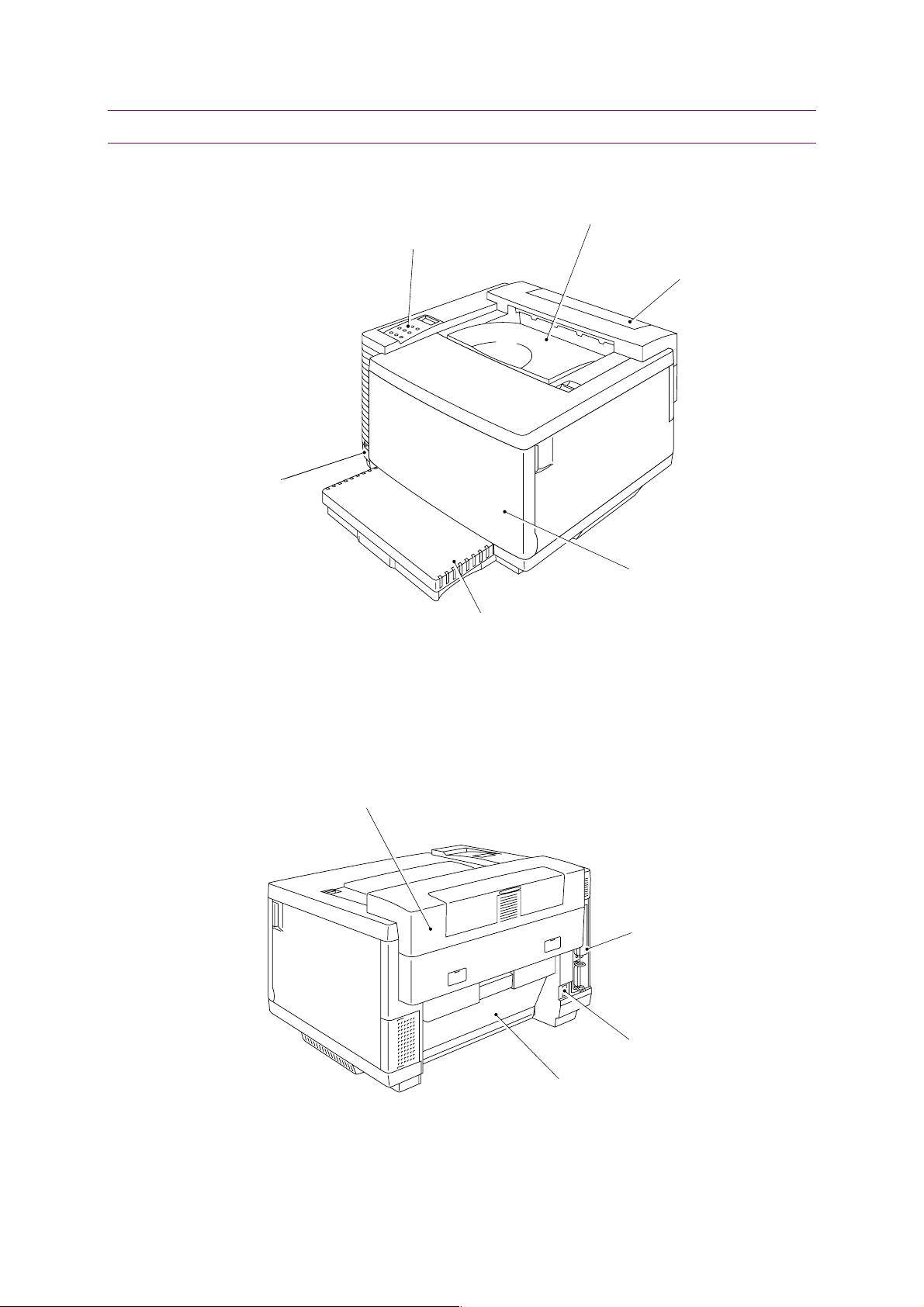

2. PARTS NAMES & FUNCTIONS

<Front View>

5. Power button

. Upper cover

2. Control panel

4. Top cover

(Paper Exit Unit)

<Rear View>

. Front cover

edia cassette

Fig. 1-1

Paper exit unit

. Controller box

. Power inlet

. Rear access cover

Fig. 1-2

Page 23

1-7

No. Part Name Outline of Functions

HL-3450CN SERVICE MANUAL

1 Upper cover

2 Control panel

3 Front cover

To act as an upper enclosure and also as a

paper tray for printed paper.

To display the status of printer operations and

control the printer directly.

To act as a front enclosure, opened when

replacing a toner cartridge or waste toner pack.

To exit the printed paper onto the upper cover,

Top cover (Paper exit

4

unit)

acting also as part of the paper tray for printed

paper. To be opened when replacing an OPC

belt cartridge or Drum cleaner.

5 Power button

To operate power-on and off to the printer.

(Push for On/Off operation)

6 Power inlet To connect a power supply cable.

7 Re ar access cover

8 Controller box

To act as a rear enclosure, opened when

clearing an internal jam or doing maintenance

work.

Space where the main (video controller) PCB is

installed.

Page 24

CHAPTER 1 PRODUCT OUTLINE

1-8

2

1

(

1

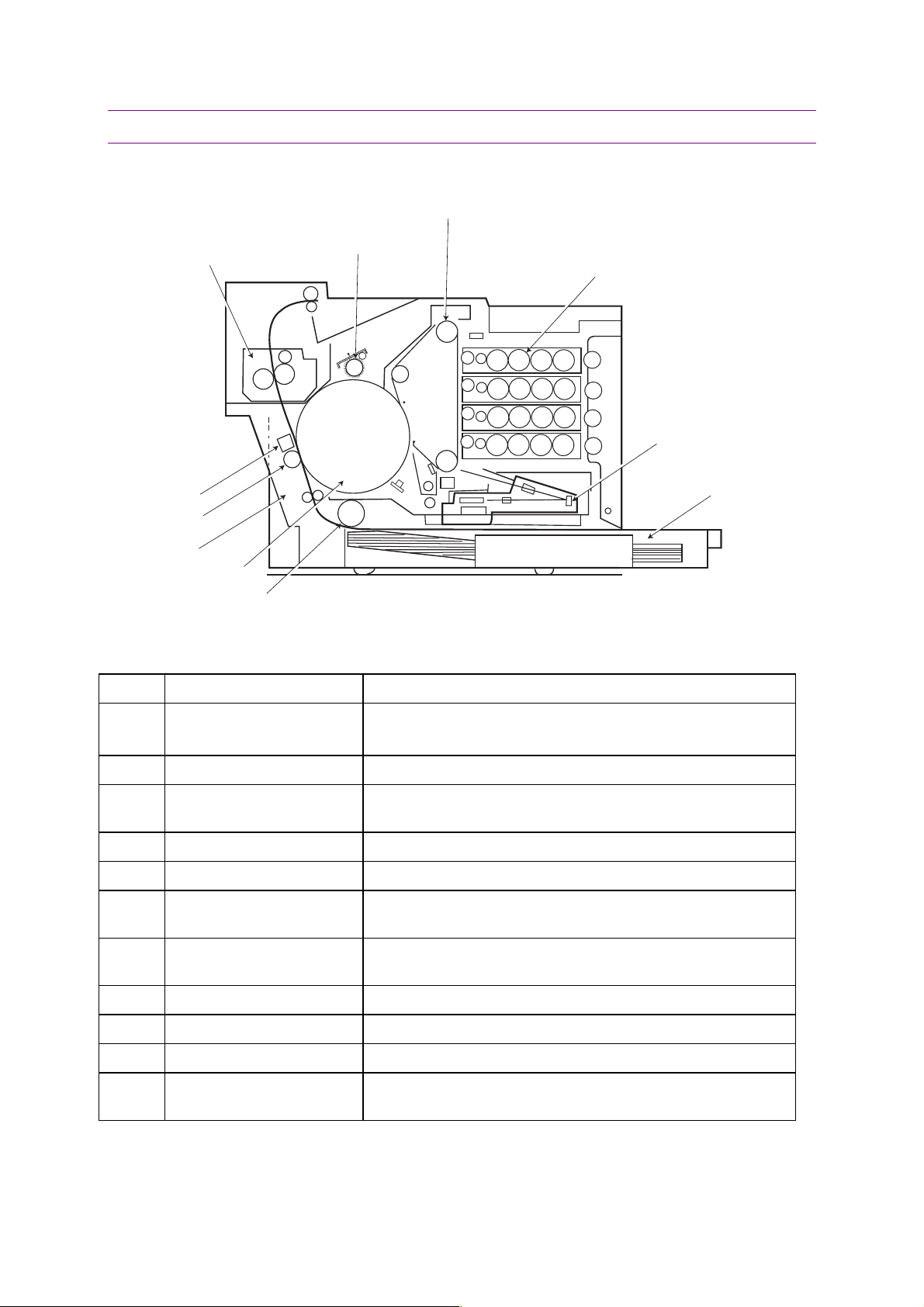

3. INTERNAL STRUCTURE

<Cross Sectional View >

. OPC Belt Cartridge

4. Fusing Unit

3. Drum Cleaner

K

Y

M

C

7. Paper Discharger

8. Transfer Roller

5. Transfer Unit

6. Transfer Drum

10. Paper Pick-up

Roller

Fig. 1-3

No. Components Name Outline of Functions

. Toner Cartridge

K, Y, M, C)

1. Laser Unit

9. Media Cassette

1 Toner Cartridge

Contain the toner (K, Y, M, C) for developing.

Each toner cartridge (K, Y, M, C) is independent.

2 OPC Belt Cartridge Forms images and includes the OPC belt.

3 Drum Cleaner

Cleans and collects waste toner adhering to the transfer

drum.

4 Fusing Unit Fixes by heat and pressure the toner image onto the paper.

5 Transfer unit Transfers toner images from the transfer drum to the paper.

6 Transfer Drum

7 Paper Discharger

Forms color images, combining the toner images from the

OPC belt on the drum.

Emits a corona charge for separating the paper from the

transfer drum.

8 Transfer Roller Transfers the toner image on the transfer drum to the paper.

9 Media Cassette Feeds paper automatically.

10 Paper Pick-up Roller Feeds paper automatically from the media cassette.

11 Laser Unit

Generates a modulated laser beam and scans the OPC belt

to produce the image.

Page 25

1-9

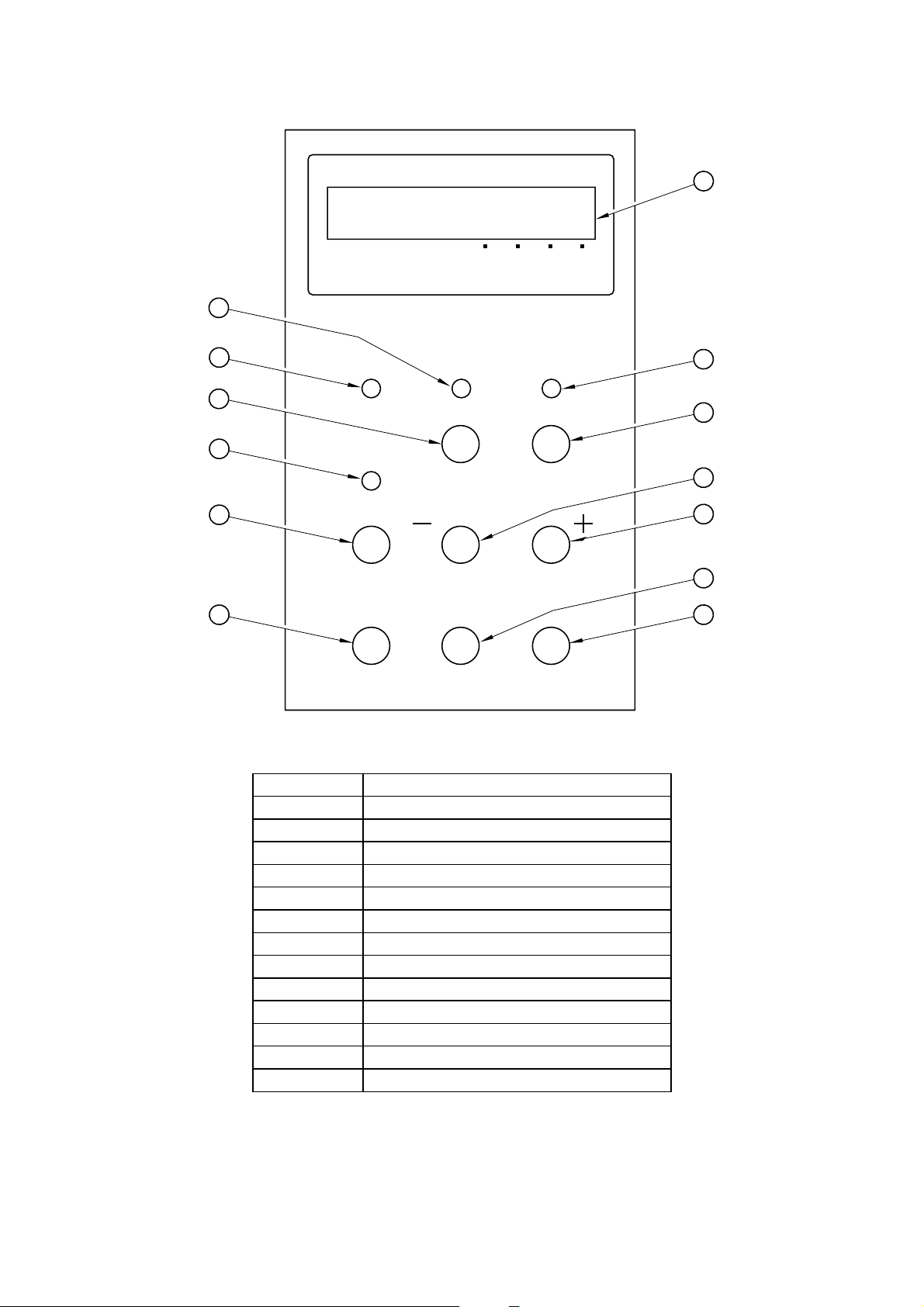

4. DESCRIPTION OF CONTROL PANEL

The printer control panel provides control of the printer including test printing, maintenance

operations performed by the video controller and also the ones which are performed by the

engine controller.

The Video Controller Mode and the Engine Controller Mode have some common functions.

Under normal circumstances the functions in the Video controller mode will be used. Refer to

CHAPTER 5 for further information.

4.1 Video Controller Mode

The printer goes into the Video Controller Mode when the power is turned on by pressing the

power button.

The Video Controller Mode supplies the general test printing and setting functions and some

of the maintenance operations. If further engine settings are required, use the Engine

Controller Mode.

HL-3450CN SERVICE MANUAL

4.2 Engine Controller Mode

The printer goes into the Engine Controller Mode when power is turned on by pressing the

power button at the same time as holding down the

(Refer to Fig.1-4.)

NOTE:

This mode provides unique control panel display and operation functions which are

completely different from the ones described on the actual control panel labels or in the

user’s guide. Refer to CHAPTER 5 for detailed information.

Secure print, Back

and

Set

buttons.

Page 26

CHAPTER 1 PRODUCT OUTLINE

1

3

1

KCMY

2

Power DataReady

4

5

6

7

8

11

No. LED / Button Name

1 LCD: 16 character by 2 lines

2 Power LED

3 Ready LED

4 Data LED

5 Go button

6 Job Cancel button

7 Alarm LED

8 Secure Print button

9 - button

10 + button

11 Reprint button

12 Back button

13 Set button

Alarm

Secure

Print

Reprint

Go

Back

Fig. 1-4

Menu

Job

Cancel

Set

9

10

12

13

-10

Page 27

CHAPTER 2

SPECIFICATIONS

HL-3450CN SERVICE MANUAL

Page 28

CHAPTER 2 SPECIFICATIONS

2-2

CONTENTS

CHAPTER 2 SPECIFICATIONS..........................................................2-3

1. RATING ..............................................................................................................2-3

2. GENERAL SPECIFICATIONS............................................................................2-4

2.1 Printing .......................................................................................................................................2-4

2.2 Functions....................................................................................................................................2-4

2.3 Electrical and Mechanical...........................................................................................................2-5

2.4 Paper..........................................................................................................................................2-6

2.4.1 Printable media....................................................................................................................2-6

2.4.2 Media cassette capacity ......................................................................................................2-8

2.4.3 Printed output.......................................................................................................................2-8

2.5 Printing Area...............................................................................................................................2-8

2.5.1 Effective printable area........................................................................................................2-8

2.5.2 Print guarantee area..........................................................................................................2-10

3. ENVIRONMENTAL CONDITIONS.....................................................................2-11

3.1 Ambient Temperature / Humidity / Altitude...............................................................................2-11

Page 29

CHAPTER 2 SPECIFICATIONS

1. RATING

HL-3450CN SERVICE MANUAL

WARNING

Use the power supply cable supplied with the printer, or a similar cable complying

with the following specification (3-wire power cable with ground).

Use of an “out of specification” cable may result in an electric shock.

Destination Voltage (V) Frequency (Hz) Input Current (A) Power Cord (Piece)

US / Canada 120 50/60 11 1

Europe 220 - 240 50/60 6 1 *

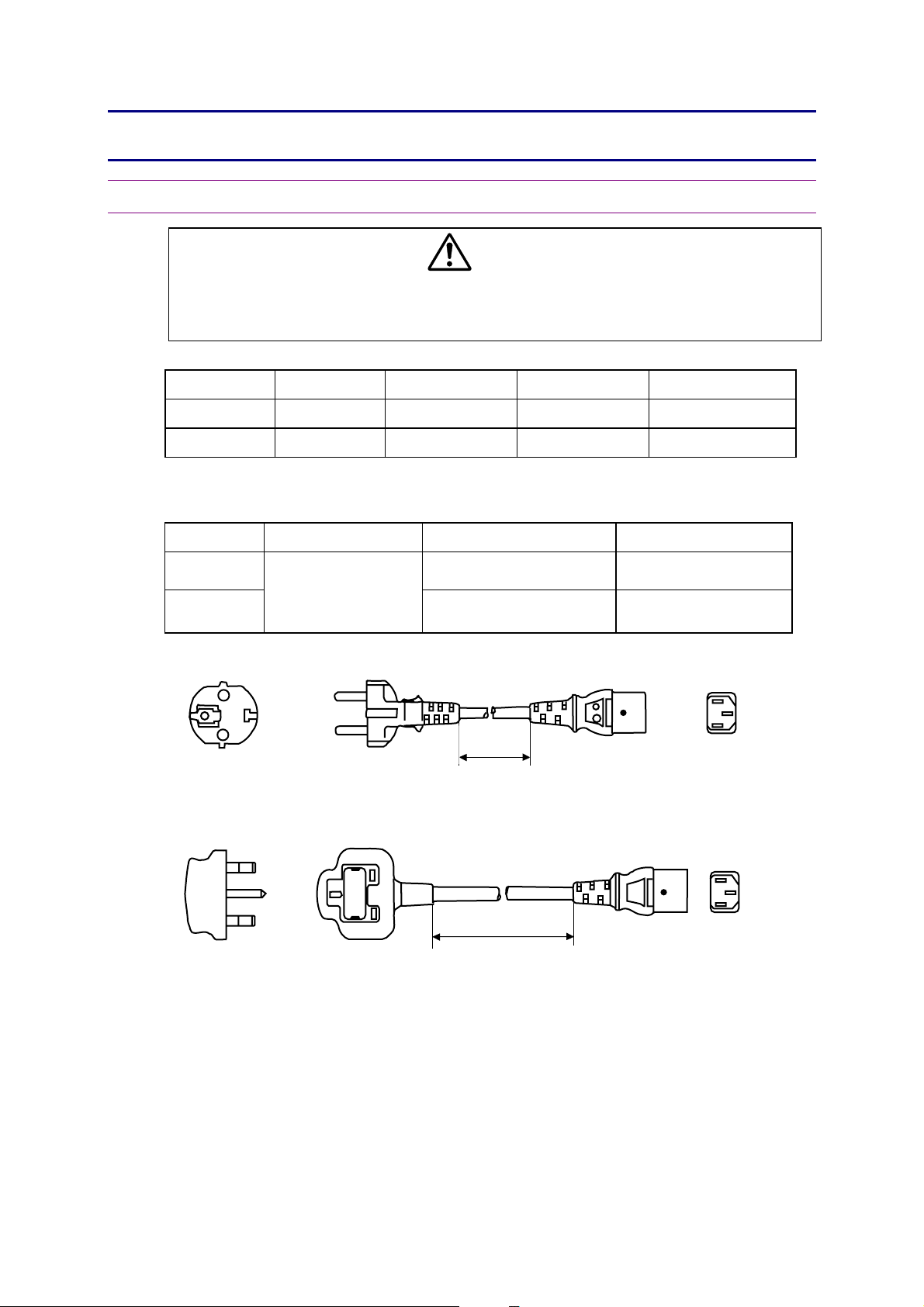

* For European models, the power supply cable depends on the country as follows;

Figure Rating Approval Agency Applicable Area

A

B

Figure A: For Europe (Sample)

250VAC, 6A

VDE, DEMKO, SEV Europe (Continent)

BS UK

2.5m

Figure B: For UK

2.5m

NOTE:

For details of other power supply cables, refer to the parts reference list.

** For rating labels, refer to ‘Safety Instruction’ on Page viii.

2-3

Page 30

CHAPTER 2 SPECIFICATIONS

2. GENERAL SPECIFICATIONS

2.1. Printing

Print method Electro photography by semiconductor laser beam scanning

Laser Wavelength: 780nm

Output: 5mW max.

Resolution 600 x 600 dots per inch (Fine)

2400 x 600 dots per inch (using HRC and CAPT)

Print speed Monochrome mode: 24 page/minute

Full color mode: 6 page/minute

(when printing A4/Letter-size paper in Landscape orientation)

Monochrome mode: 12 page/minute

Full color mode: 3 page/minute

(when printing A3/Ledger-size paper in Portrait orientation)

Warm-up Max. 210 seconds at 20°C (68°F)

First print Monochrome mode: 19 seconds or less

Full color mode: 34 seconds or less

(when loading A4/Letter-size plain paper in Landscape orientation by

Print media Toner in a single-color single-component cartridge.

Life Expectancy: 14,000 single-sided pages/cartridge (Black)

8,500 single-sided pages/cartridge (C/M/Y)

(when printing on A4/Letter-size paper with 5% coverage)

Resident printer fonts <HP PCL, EPSON FX-850, and IBM Proprinter XL modes>

66 scalable fonts and 12 bitmapped fonts,11 bar codes

<BR-Script 3 mode>

165 scalable fonts

(The resolution can be enhanced to 2400dpi class by using Brother

exclusive HRC (High Resolution Control) and CAPT (Color Advanced

Photoscale Technology).)

face down print delivery from standard upper cassette feed)

2.2. Functions

CPU Toshiba TMPR4955-266 (TX4955-266MHz)

Emulation Automatic emulation selection

Interface Automatic interface selection among the bi-directional parallel,

RAM 64 Mbytes

(Expandable up to 384Mbytes with DIMMs)

The standard memory fitted can vary depending on the printer model

HDD option 2.5 inch IDE HDD

Compact Flash 1 card slot: Compact Flash Type II

Control panel 8 buttons, 4 LEDs and a 16-column x 2 lines liquid crystal display

Diagnostics Self-diagnostic program

x

HP Color Printer (PCL5C) including HP LaserJet 4+ (PCL5e) and

HP LaserJet 5 (PCL6 monochrome)

x

BR-Script 3 (Adobe PostScript 3 compatible)

x

HP-GL

x

EPSON FX-850

x

IBM Proprinter XL

Universal Serial Bus (USB) and Ethernet 10/100 Base TX.

and country.

2-4

Page 31

2-5

2.3. Electrical and Mechanical

Power source U.S.A. and Canada: AC 120V, 50/60Hz

Europe and Australia: AC 220 to 240V, 50/60Hz

Power consumption Printing (peak*): 1350W or less

Printing (average): 600W or less

Standing by (peak*): 1350W or less

Standing by (average): 200W or less

Sleep: 30W or less

Noise: Printing: 55dB A or less

Standing by: 48dB A or less

Temperature: Operating: 10 to 32.5°C (50 to 90.5°F)

Non operating: 5 to 35°C (41 to 95°F)

Storage: 0 to 35°C (38 to 95°F)

Humidity: Operating: 20 to 80% (non condensation)

Storage: 10 to 90% (non condensation)

HL-3450CN SERVICE MANUAL

Dimensions: 615 x 540 x 420 mm (24.2 x 21.3 x 16.5 inches)

(W x D x H) 615 x 620 x 610 mm (24.2 x 24.4 x 24.0 inches)

with the Duplex Unit and one optional lower tray unit fitted

615 x 620 x 750 mm (24.2 x 24.4 x 30.6 inches)

with the Duplex Unit and two optional lower tray units fitted

Weight: Approx. 46kg (101lbs.)

Approx. 54kg (119lbs.) including consumables*

*Consumables are defined as:

Belt cartridge, Toner cartridge (Y, M, C, K), Fuser oil bottle,

Fuser cleaning roller, Waste toner Pack

Optional Units:

x

Lower Tray Unit: Approx. 11kg (24lbs.)

x

Duplex Unit: Approx. 12kg (26lbs.)

x

Standard Media Cassette: Approx. 2.1kg (4.6lbs.)

x

Lower Tray Unit Media Cassette: Approx. 2.7kg (6.0lbs.)

*NOTE:

x

The peak figure of power consumption is worked out when the halogen heater lamp is

turned ON.

x

The peak figure of power consumption is worked out excluding inrush current value.

x

The peak figure of power consumption is a reference value and should be used internally

at Brother offices only.

x

The power consumption figure quoted for sleep mode is when the fan has stopped.

Page 32

CHAPTER 2 SPECIFICATIONS

2.4. Paper

The standard media cassette (upper cassette) is supplied with the printer. The optional lower

tray unit and the optional A4/Letter cassette can also be installed.

NOTE:

The standard upper cassettes and the optional A4/Letter cassette are interchangeable

between the upper and the lower feeder.

2.4.1 Printable media

(1) Type & size

Paper source Paper type Paper Size

Standard upper cassette

Plain paper A3, B4, A4, Ledger, Executive, Legal,

Letter, B5 (ISO/JIS), 330x483mm

(13”x19”)

Envelope COM10, DL,

Transparency A4, Letter

Label A4, Letter

Other size width 210-330mm (8.2”-12.9”)

length 176-483mm (6.9”-18.8”)

Optional lower cassette Plain paper A3, B4, A4, B5 (ISO/JIS), Legal, Ledger,

Letter

Optional A4/Letter cassette Plain paper A4, Letter, B5 (ISO/JIS), Executive

Envelope: COM10, DL

Transparency A4, Letter

Label A4, Letter

Other size: width 210-297mm (8.2”-11.7”)

length 176-297mm (6.9”-11.7”)

(2) Paper weight specifications

Paper cassette Optional lower tray Optional duplex unit

Normal paper

60 to 90 g/m

2

m

m

(16 to 24 lbs)

Thick stock

90 to 160 g/m

(24 to 43 lbs)

2

90 to 105 g/m

(24 to 28 lbs)

2-6

2

Page 33

2-7

(3) Recommended paper specifications

!

Item Description

Basis Weight (g/m2) 82 ± 5

Thickness (µ m) 95 ± 6

Smoothness (Bekk) (seconds) 90 ± 20

Stiffness (Clark) 100 ± 15

Brightness (%) 85 ± 2

10

10

Surface Resistance (:)

Grain Direction Long

Measurement Condition: 17.5 ~ 27.0°C, 50 ~ 70%RH

~ 1011

HL-3450CN SERVICE MANUAL

CAUTION:

When you are choosing print media, be sure to it is designed for use with a laser printer and

load the media cassette correctly. Also follow the information given below to prevent any

paper jams, print quality problems or printer damage;

<Paper type to avoid>

x

Highly textured paper.

x

Smooth or shiny paper.

x

Paper that is coated or has a chemical finish.

x

Damaged, wrinkled or pre-folded paper.

x

Paper exceeding the recommend weight specification in the manual.

x

Paper with tabs and staples.

x

Letterheads using low temperature dyes or thermography.

x

Multipart or carbonless paper.

<Envelopes type to avoid>

x

Envelopes constructed with a paper with a weight that exceeds the paper weight

specifications for the printer.

x

Poorly manufactured envelopes with edges that are not straight or consistently square.

x

Envelopes with ‘baggy’ construction of folds that are not sharply creased.

x

Envelopes with transparent windows, holes, cutouts or perforations.

x

Envelopes with clasps, snaps or tie strings.

x

Envelopes made with smooth or shiny paper.

x

Envelopes that are rough, highly textured, or deeply embossed.

x

Envelopes that do not lie flat or that are curled, wrinkled, or irregularly shaped.

x

Envelopes having an open flap with an adhesive that seals the envelope.

<Transparencies / labels type to avoid>

x

Transparencies / labels that cannot withstand a temperature of 200 degrees centigrade

(392 degrees Fahrenheit) for a period of 0.1 seconds.

NOTE:

Keep the paper sealed in the bag as supplied and do not open the bag until the paper is

required for use.

Page 34

CHAPTER 2 SPECIFICATIONS

2.4.2 Media cassette capacity

Maximum load height: 27mm (1.06 inches)

x

Plain paper: 250 sheets of 75g/m

x

Envelopes : 15 sheets

x

Transparency: 50 sheets

x

Label: 80 sheets

2.4.3 Printed output

(1) Capacity

250 sheets of 75g/m

(2) Delivery

Face-down print delivery

Note: Face down: Delivers the printed side of the paper downwards.

2

(20lb) paper for the standard/optional A4/Letter

cassette

500 sheets of 75g/m

2

(20lb) paper (plain paper stacked in the output tray)

2

(20lb) for the optional lower cassette

2.5 Printing Area

2.5.1 Effective printable area

The effective printing area means the area within which the printing of all the data received

without any omissions can be guaranteed. (Refer to Table 2-1 for details.)

F

E

B

D

A

CE

F

Fig. 2-1

2-8

Page 35

HL-3450CN SERVICE MANUAL

2-9

Table 2-1: Effective Printing Areas

Size A B C D E F

A 4

Letter

Legal

B 5 (JIS)

B 5 (ISO)

Executive

COM-10

D L

13x19 330mm

A 3 297mm

B 4 257mm

Ledger 279.4mm

210.0mm

8.27”

(2,480 dots)

215.9mm

8.5”

(2,550 dots)

215.9mm

8.5”

(2,550 dots)

182.0mm

7.16”

(2,149 dots)

176.0mm

6.93”

(2,078 dots)

184.2mm

7.25”

(2,175 dots)

104.8mm

4.125”

(1,237 dots)

110.1mm

4.33”

(1,299 dots)

13”

(3,900 dots)

11.7”

(3,507 dots)

10.1”

(3,035 dots)

8.5”

(3,300 dots)

297.0mm

11.69”

(3,507 dots)

279.4mm

11.0”

(3,300 dots)

355.6mm

14.0”

(4,200 dots)

257.0mm

10.12”

(3,035 dots)

250.0mm

9.84”

(2,952 dots)

266.7mm

10.5”

(3,150 dots)

241.3mm

9.5”

(2,850 dots)

221mm

8.66”

(2,598 dots)

482.6mm

19”

(5,700 dots)

420mm

16.5”

(4,960 dots)

364mm

14.3”

(4,298 dots)

432mm

14”

(5,100 dots)

203.2mm

8.0”

(2,400 dots)

207.44mm

8.16”

(2,450 dots)

207.44mm

8.16”

(2,450 dots)

173.54mm

6.82”

(2,049 dots)

167.54mm

6.59”

(1,978 dots)

175.74mm

6.91”

(2,075 dots)

96.34mm

3.785”

(1,137 dots)

101.64mm

3.99”

(1,199 dots)

306.5mm

12.1”

(3,620 dots)

288.5mm

11.4”

(3,407 dots)

248.9mm

9.8”

(2,935 dots)

270.9mm

10.7”

(3,200 dots)

288.5mm

11.36”

(3,407 dots)

271.0mm

10.67”

(3,200 dots)

347.1mm

13.67”

(4,100 dots)

248.5mm

9.78”

(2,935 dots)

241.5mm

9.5”

(2,852 dots)

258.3mm

10.17”

(3,050 dots)

232.8mm

9.16”

(2,750 dots)

211.5mm

8.33”

(2,498 dots)

475.8mm

18.7”

(5,620 dots)

411.5mm

16.2”

(4,860 dots)

355.4mm

14”

(4,198 dots)

423.3mm

16.7”

(5,000 dots)

3.4mm

0.13”

(40 dots)

4.23mm

0.17”

(50 dots)

Ç

Ç

Ç

Ç

Ç

Ç

11.85mm

0.47”

(140 dots)

4.23mm

0.17”

(50 dots)

Ç

Ç

4.23mm

0.17”

(50 dots)

Ç

Ç

Ç

Ç

Ç

Ç

Ç

Ç

Ç

Ç

Ç

NOTE:

x

The paper sizes indicated here should conform to the nominal dimensions specified by

JIS.

x

A4 paper must accommodate 80 characters printed in pica pitch (203.2 mm).

x

The dot size is based on 300 dpi resolution.

x

Organizer is not supported by any printer emulation (command).

Page 36

CHAPTER 2 SPECIFICATIONS

P

O

P

O

3

5

N

a

N

a

N

a

4

4

#

D

2.5.2 Print guarantee area

<Plain paper>

3mm

5mm

Print

guarantee

area

Fig. 2-2

mm

on printable

rea

on guarantee

rea

mm

mm

mm

aper: 5mm

ther: 10mm

aper: 4mm

ther: 10mm

<Envelope>

42mm

16mm

3mm

4mm

Non guarantee

area

#10: 68mm

DL: 40mm

on printable

rea

Print guarantee

area

4mm

10: 68mm

L: 40mm

Fig. 2-3

2-10

Page 37

2

3. ENVIRONMENTAL CONDITIONS

R

1

5

3.1 Ambient Temperature / Humidity / Altitude

(1) Under Operational conditions: 10.0 a 32.5qC (50 ~ 90.5qF), 20 a 80%RH (See the

figure below)

80

70

HL-3450CN SERVICE MANUAL

60

50

ecommended Condition;

27.0qC

a

7.5

0 a 70%RH

40

20

Ambient Humidity (%RH)

100 17.5 20 27 30 32.5 40

Ambient Temperature ( )

C

(2) Under Non Operational conditions: 5.0 a 35.0qC (41 ~ 95qF), 10 a 80%RH (See the

figure below.)

80

60

40

30

Ambient Humidity (%RH)

20

10

5

10020303540

Ambient Temperature( )

C

-11

Page 38

CHAPTER 2 SPECIFICATIONS

(3) Storage and transportation environment of printer

The following defines the storage and transportation environment of printers that have been

packed according to Brother specification. However, this section does not cover the OPC

belt cartridge, toner cartridges and developer cartridges.

In particular, since consumables such as the toner cartridges and OPC belt are individually

packaged, the following environmental conditions should be respected. During

transportation, strictly refrain from leaving the goods on the ground or under the sun.

Temperature

Humidity

Normal

Conditions

Severe

Conditions

0qC a 35qC (32qF a 95qF)

High Temperature: 35qC a 40qC (95qF a 104qF)

Low Temperature: -10qC a 0qC (14qF a 32qF)

10% a 90%RH

Period of Storage One Year

Other No condensation

Atmosphere

613 a 1,067hpa (460 a 800mmHg)

The period under the severe conditions should not be continuous, and is assumed as an

accumulation of intermittent time. However, an individual period of intermittent time under

severe conditions should not be allowed to exceed 48 hours.

NOTE:

Normal conditions should occupy more than 90% of total storage period.

Severe conditions should be less than 10% of total storage period.

2-12

Page 39

CHAPTER 3

INSTALLATION

Page 40

CHAPTER 3 INSTALLATION

3-2

CONTENTS

CHAPTER 3 INSTALLATION .........................................................3-3

1. CONDITIONS REQUIRED FOR INSTALLATION...........................................3-3

1.1. Environmental Conditions.....................................................................................................3-3

1.2. Basic Layout of Printer Set-up Location ...............................................................................3-3

2. UNPACKING...................................................................................................3-5

2.1 Unpacking of Printer..............................................................................................................3-5

2.2 Unpack the Starter Kit ...........................................................................................................3-7

3. INSTALLATION WORK ..................................................................................3-8

3.1 Install the Oil Bottle and Fuser Cleaner.................................................................................3-8

3.2 Install the OPC Belt Cartridge ...............................................................................................3-9

3.3 Install the Toner Cartridge into the Printer...........................................................................3-11

3.4 Install the Media Cassette and Adaptor...............................................................................3-12

3.4.1 Install the media cassette .............................................................................................3-12

3.4.2 Install the envelope adaptor..........................................................................................3-13

3.5 Test Print.............................................................................................................................3-14

Page 41

3-3

CHAPTER 3 INSTALLATION

1. CONDITIONS REQUIRED FOR INSTALLATION

Any Laser beam printer is likely to be influenced by the environment of the set-up location. If

the printer is set-up in an inappropriate location, the printer may not perform as expected.

Therefore, the following factors should be taken into consideration before deciding where to

set-up the printer.

1.1. Environmental Conditions

The printer should not be set up in the locations referred to in the following items (1) through

(8) which specify inappropriate locations for set-up.

(1) Where it is likely to receive direct sunlight or similar light. (For example, next to a

window)

(2) Where it is likely to suffer a big difference in temperature and humidity between the

maximum and minimum levels. (Normal operation environment is within 10qC a 32.5qC,

20 a 80%RH and without any condensation.)

HL-3450CN SERVICE MANUAL

(3) Where it is likely to be in a draft of cold air from an air-conditioner or warm air from a

heater, or to receive direct radiant heat.

(4) Where it is likely to be excessively dusty or be subject to corrosive gases such as

ammonia.

(5) Where it is likely that an ultrasonic humidifier will be used.

(6) Where it is likely to have poor ventilation.

(7) Where it is likely to have unstable conditions such as when the set-up table is not strong

enough.

(8) Where it is likely to be tilted (angle from the horizontal should not be greater than r1q).

1.2. Basic Layout of Printer Set-up Location

CAUTION

In the case when the printer is set on a table, confirm that the media cassette does not to

protrude out beyond the edge of the table.

x

Any protrusion of the media cassette may catch a passersby and result in damage to the

printer.

x

Protrusion of the media cassette may cause the printer to tilt or fall over if the operator

leans against or applies excessive force to the media cassette, which may cause injuries.

Page 42

CHAPTER 3 INSTALLATION

3-4

Fig.3-1 shows the basic layout of the printer set-up location that is suitable for smooth

operation and maintenance of the printer.

Table

20cm (8")

Paper Exit Side

80cm (32")

50cm (20")

20cm (8")

16cm

(6.4")

70cm

(28")

70cm

(28")

Front Side

10cm (4")

Fig. 3-1

x

A space in front of the printer of 70cm is necessary to open the front cover.

x

A space at back of the printer of 20cm is necessary to open / close the rear access cover.

x

The space on both sides of the printer of 10cm is necessary for general access.

Page 43

3-5

2. UNPACKING

The package containing a printer weighs approximately 66kg (145lbs), so it is too heavy

x

for one person to carry. It needs two adults or more to move the printer. Since the printer

is a precision machine, make sure that it is carried slowly with care so that no impact

occurs to the printer while moving it.

Do not attempt to lift a printer when it is covered by the polyethylene bag because it is

x

slippery and may result in damage and injury if dropped.

2.1 Unpacking the Printer

Refer to Fig.3-2 on the next page.

1) Cut the two bands from around the packing carton.

2) Remove the binding tape from the top of the package.

3) Open the top of the package and take the ST packing set out.

HL-3450CN SERVICE MANUAL

WARNING

4) Remove the upper packing (4 locations).

5) Take the customisation kit** out of the box.

6) Take the power cable out of the box. (for US / Canada only).

7) Open up the polyethylene bag enclosing the printer and remove it.

8) Remove the silica gel.

9) Lift up and set up the printer in a suitable location using at least two persons.

** For USA/Canada, the kit contains the use’s guide and printer driver disks.

For other countries, the kit contains the use’s guide, printer driver disks and the

powercable.

Page 44

CHAPTER 3 INSTALLATION

3-6

STARTER KIT

(ST PACKING SET 3 (B))

STARTER PACKING

SLEEVE

STARTER KIT PACKING (U)

Media cassette

OUTER BOX

Toner cartridges

STARTER KIT PACKING (M)

OPC belt cartridge

Oil bottle

L-SHAPED

PAPER SUPPORT

Toner cartridges

Fuser cleaner

L-SHAPED

PAPER SUPPORT

BASE SET 3 (B)

SILICA GEL

Power cable

POLYETHYLENE

BAG (EN)

PALLET 3 (B)

STARTER KIT

PACKING (L)

BAND

SHIPPING TAPE

TAPE

PROTECTIVE

PACKING

Fig. 3-2

Page 45

HL-3450CN SERVICE MANUAL

3-7

Y

M

C

K

2.2 Unpack the Starter Kit

<Unpacking Procedure>

1) Open the vinyl bag and slide off the cardboard sleeve covering the starter kit.

2) Confirm all of the following parts are inside the starter kit packing box.

No. Kit Name Appearance Quantity

Toner Cartridge (Y, M,

1

C, K)

(Yellow)

(Magenta)

(Cyan)

(Black)

4

2 OPC Belt Cartridge 1

3 Oil Bottle 1

4 Fuser Cleaner & Syringe 1

Media Cassette with

5

Envelope Adapter

PRECAUTION

When shipping the printer, remove the oil bottle and the fuser cleaner from the fusing unit.

After removing the oil bottle, be sure to remove the oil remaining in the fusing unit with the

supplied syringe. Failure to do so will cause severe damage to the printer.

1

Page 46

CHAPTER 3 INSTALLATION

3-8

3. INSTALLATION WORK

Do not lean against or apply any excessive force to the media cassette or open covers;

otherwise it may cause the product to tilt or fall over and result in injuries.

Install the parts of the starter kit into the printer according to the following procedures:

3.1 Install the Oil Bottle and Fuser Cleaner

(1) Release the two sets of retainer lock

levers for both the oil bottle and the

fuser cleaner.

(2) Set the fusing unit pressure release

levers to the SET position.

CAUTION

Pressure release

lever

(3) Install the oil bottle into the fusing unit.

NOTE:

When installing the oil bottle, be sure not to

touch the oil feed connection at the bottom

of the bottle to avoid oil leakage.

(4) Install the fuser cleaner into the fusing

unit.

(5) Secure the oil bottle and the fuser

cleaner with the retainer lock levers.

(6) Close the top cover.

Oil bottle

Fuser cleaner

Fig. 3-3

Fig. 3-4

Pressure release

lever

Fig. 3-5

Page 47

HL-3450CN SERVICE MANUAL

3-9

NOTE:

The retainer lock levers for the fuser cleaner and oil bottle are located as shown in the figure

below;

Retainer lock levers

Fuser cleaner

Oil bottle

3.2 Install the OPC Belt Cartridge

x

Do not directly touch the OPC belt surface with bare

hands or gloves.

x

If the belt is exposed for more than two minutes to a light

source of 800 lux, the belt may be damaged.

(1) Open the front cover and the top cover

by releasing the latches.

Retainer lock levers

Fig. 3-6

PRECAUTION

Top cover

PRECAUTION

When installing or removing the OPC

belt, be sure to open the front cover first.

Failure to do so will cause the OPC belt

to be damaged due to contact with the

toner cartridges.

Front cover

Fig. 3-7

Page 48

CHAPTER 3 INSTALLATION

3

O

P

T

r

(2) Release the belt cartridge lock levers

(left & right).

(3) Pull and remove the tension release

pins on both sides (left & right) of the

OPC belt cartridge.

(4) Remove the protective sheet from the

OPC belt cartridge.

Belt cartridge

lock lever (L)

ension

elease pin

OPC belt

cartridge

Fig. 3-8

Belt cartridge lock

lever (R)

(5) Install the OPC belt cartridge into the

guides at both sides in the printer.

(6) Set the belt cartridge lock lever at both

sides (left and right).

rotective sheet

Fig. 3-9

PC belt cartridge

Fig. 3-10

Tension

release pin

-10

Page 49

3

3.3 Install the Toner Cartridges into t he Pri nt er

HL-3450CN SERVICE MANUAL

(1) Rock each of the cartridge 3 to 4 times

through 30

o

to the horizontal.

(2) Pull off the tape labeled ‘REMOVE’ from

the toner cartridge.

(3) Remove the protective cover from the

toner cartridge.

o

30

Protective label

Fig. 3-11

Fig. 3-12

o

30

Protective

cover

(4) Install the four toner cartridges by

sliding them gently along the guides into

the printer. DO NOT USE FORCE TO

INSERT THE CARTRIDGES AND DO

NOT PUSH THEM FULLY INTO THE

PRINTER, THEY WILL BE

POSITIONED CORRECTLY WHEN

THE FRONT COVER IS CLOSED.

NOTE:

The installation order of the four toner

cartridges should be from the bottom to the

top, in terms of colors this is in the order

Cyan (C), Magenta (M), Yellow (Y), and

Black (K).

(3) Close the front cover.

?

Fig. 3-13

Fig. 3-14

@

K

Y

M

C

Fig. 3-15

-11

Page 50

CHAPTER 3 INSTALLATION

3

C

P

3.4 Install the Medi a Casset t e and Adapt er

3.4.1 Install the media cassette

(1) Remove the cassette cover from the

media cassette.

(2) Set the paper guide according to the

print paper size.

i) Horizontal direction; Holding the

green side plate to meet the paper

size position.

ii) Vertical direction; Holding the green

color lever, adjust the end plate to

meet the paper size position.

assette cover

Fig. 3-16

Paper guide

aper guide

(3) Load the paper into the cassette.

PRECAUTION

Loading capacity of the cassette is

subject to the type of media in use.

Keep the loading level below the upper

limit marked on the label. Excessive

loading of media over the upper limit will

result in paper feed jams or print quality

problems.

(4) Install the cassette cover.

(5) Install the cassette into the printer.

Fig. 3-17

PAPER

LABEL

OHP FILM

Fig. 3-18

-12

Page 51

3

3.4.2 Install the envelope adapter

P

C

H

NOTE:

The specification of envelopes feedable from the envelope adapter are as follows;

Capacity: 15 envelopes

x

Size: DL (110 x 220 mm), #10 (105 x 241 mm)

x

HL-3450CN SERVICE MANUAL

(1) Prepare the media cassette and

envelope adapter.

(2) Put the adapter on the cassette base

and engage the hooks provided on the

leading edge of the adapter (left and

right) into the cassette base.

(3) Move the envelope guide to meet the

adapter base.

(4) Move the paper guides to meet the

desired envelope size.

(5) Load the envelopes into the adapter.

Envelope adapter

Envelope guide

Paper guide

Cassette base

Fig. 3-19

Adaptor base

Fig. 3-20

aper guide

PRECAUTION

Do not load media in the adapter higher

than the specified capacity limit,

otherwise it may result in paper feed

jams or print quality problems.

Fig. 3-21

CAUTION

When removing the envelope adapter from the media cassette, pull the adapter toward you

while holding the trailing edge of the adapter up approximately 10mm.

Do not hold up the trailing edge of the adapter by force, otherwise it may result in damage to

the hooks provided at the leading edge of the adapter.

Envelope adaptor

Cassette base

ook

Fig. 3-22

assette base

-13

Page 52

CHAPTER 3 INSTALLATION

3

F

3.5 Test Print

(1) Make sure the printer power button is off. Do not connect the interface cable.

(2) Connect the AC power cord to the printer, and then plug it into the AC outlet.

ig. 3-23

Fig. 3-24

(3) Turn on the power button.

Fig. 3-25

-14

Page 53

3

(4) After the printer warms, the READY message will appear.

KCMY

NETWORK READY

HL-3450CN

DataReadyPo wer

HL-3450CN SERVICE MANUAL

Alarm

Secure

Print

Reprint Back Set

Job

Go

Cancel

Fig. 3-26

(5) Press the Go button. The printer will print a test page. Check that the test page is

printed correctly.

KCMY

NETWORK READY

HL-3450CN

DataReadyPow er

Alarm

Job

Go

Cancel

Back Set

Fig. 3-27

-15

Page 54

HL-3450CN SERVICE MANUAL

CHAPTER 4

STRUCTURE OF

SYSTEM

COMPONENTS

Page 55

CHAPTER 4 STRUCTURE OF SYSTEM COMPONENTS

4-2

CONTENTS

CHAPTER 4 STRUCTURE OF SYSTEM COMPONENTS..................4-3

1. BASIC STRUCTURE.......................................................................................4-3

1.1 Mechanical Structures ............................................................................................................4-3

1.2 Basic Mechanism of Color Printing.........................................................................................4-5

1.2.1 Principle of color printing..................................................................................................4-5

1.2.2 Basic color printing process .............................................................................................4-5