Page 1

R

LASER PRINTER

SERVICE MANUAL

MODEL:HL-1260

Page 2

No part this publication may be reproduced in any form or by any means without permission in writing

from the publisher.

Trademarks:

• BR-Script, and DX-1200 are registered trademarks of Brother Industries, Ltd.

• Centronics is a registered trademark of Genicom Corporation.

• PostScrip is a registered trademark of Adobe Systems Incorporated.

• IBM Proprinter XL is a registered trademark of International Business Machines Corporation.

• EPSON FX-850 is a registered trademark of Seiko Epson Corporation.

• HP-GL and HP Laser Jet 4 are registered trademarks of Hewlett Packard Company.

Page 3

PREFACE

This service manual contains basic information required for after-sales service of the laser printer

(hereinafter referred to as ”this machine” or ” the printer”). This information is vital to the service technician

in maintaining the high printing quality and performance of the printer.

This manual consists of the following chapters:

Chapter I : General

Features, specifications, etc.

Chapter II : Theory of Operation

Basic operation of the mechanical system and the electrical system, and their timing.

Chapter III : Electrical System

Theory of the electronics circuit

Chapter IV : Mechanical System

Requirements for a suitable location, disassembling and reassembling procedure of

mechanical system.

Chapter V : Maintenance and Servicing

Parts replacement schedule, list of tools, lubricants and cleaners.

Chapter VI : Troubleshooting

Reference values and adjustment, troubleshooting for image defects, troubleshooting

for malfunctions, etc.

Appendices : Engine Block Diagram, PCB Circuitry Diagrams, etc.

Information in this manual is subject to change due to improvement or re-design of the product. All relevant

information in such cases will be supplied in service information bulletins (Technical Information).

A thorough understanding of this printer, based on information in this service manual and service

information bulletins, is required for maintaining its quality performance and for fostering the practical ability

to find the cause of troubles.

Page 4

CONTENTS

CHAPTER I GENERAL

1. FEATURES ........................................................................................................................ I-1

2. SPECIFICATIONS.............................................................................................................. I-1

3. SAFETY INFORMATION.................................................................................................... I-6

3.1 Laser Safety (110 - 120V Model only)...................................................................... I-6

3.2 CDRH Regulations (110 - 120V Model only)............................................................ I-7

3.3 Additional Information .............................................................................................. I-7

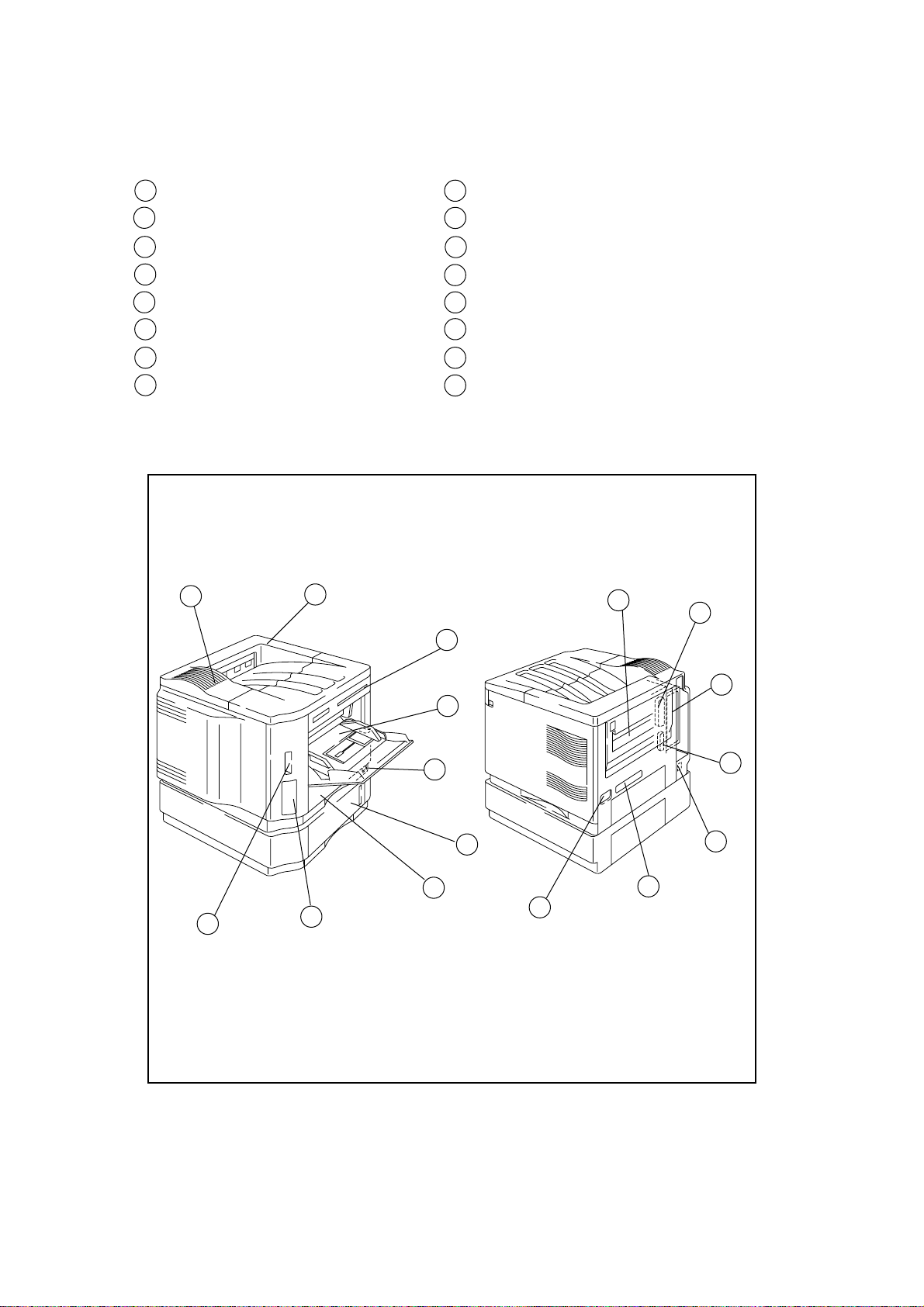

4. PAR TS OF THE PRINTER................................................................................................. I-8

4.1 External Views ......................................................................................................... I-8

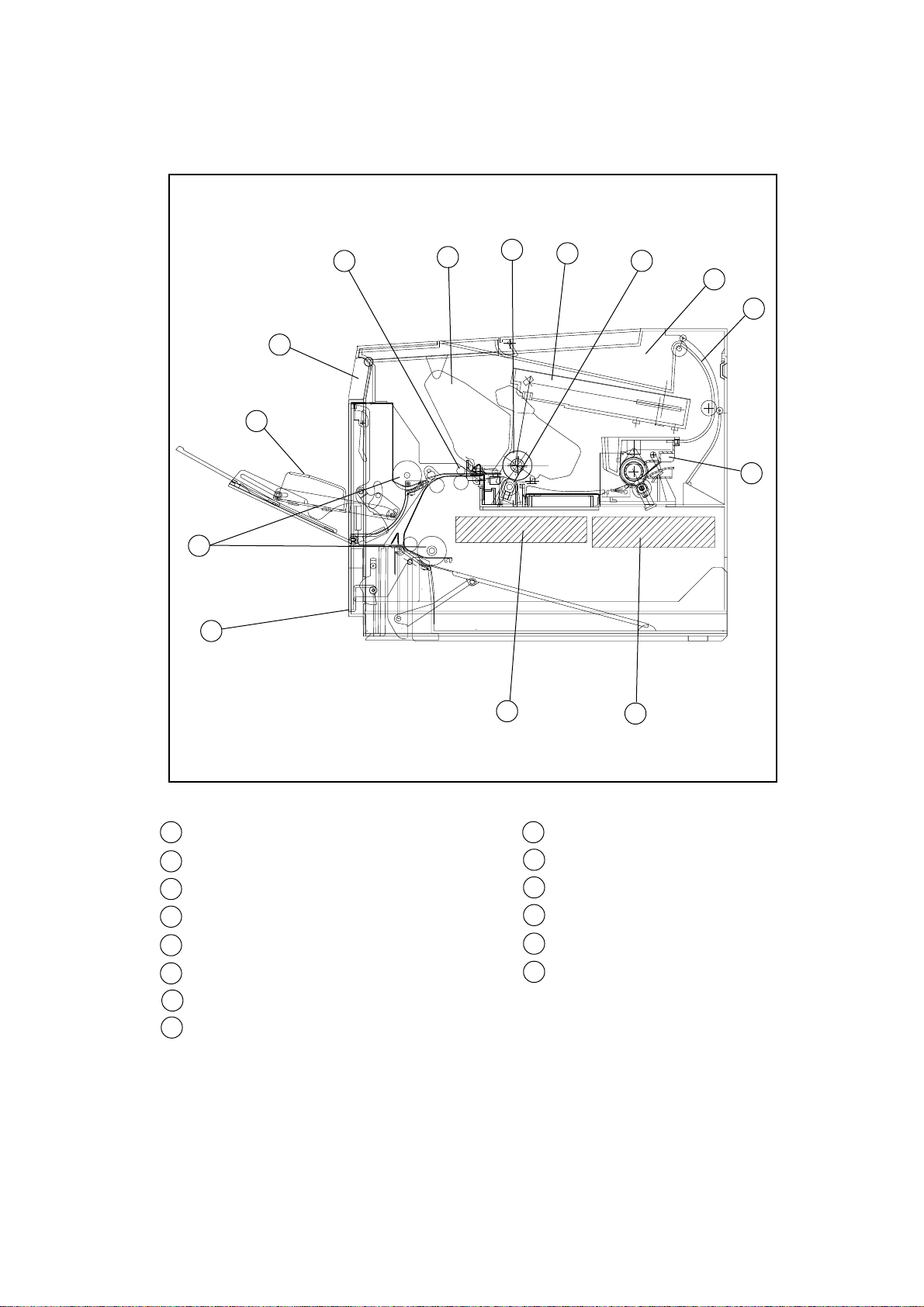

4.2 Cross Sectional View ............................................................................................... I-9

5. STORAGE AND HANDLING OF EP-ED CARTRIDGES.................................................. I-10

5.1 Storage of Sealed EP-ED Cartridges ..................................................................... I-10

5.2 Storage of Unsealed EP-ED Cartridges ................................................................. I-10

CHAPTER II THEORY OF OPERATION

1. BASIC OPERATIONS ....................................................................................................... II-1

1.1 Mechanical Configuration........................................................................................ II-1

1.2 Main Drive ............................................................................................................... II-2

1.3 Basic Sequence of Operations................................................................................ II-3

2. LASER/SCANNER SYSTEM ............................................................................................ II-4

3. IMAGE FORMATION SYSTEM......................................................................................... II-5

3.1 Outline..................................................................................................................... II-5

3.2 Printing Process ...................................................................................................... II-5

3.2.1 Electrostatic latent image formation stage ................................................ II-6

3.2.2 Developing stage ...................................................................................... II-8

3.2.3 Transfer stage ........................................................................................... II-9

3.2.4 Fixing stage ............................................................................................ II-10

3.2.5 Drum cleaning stage...............................................................................II-10

3.3 Operation ..............................................................................................................II-11

4. PAPER PICK-UP/FEED SYSTEM................................................................................... II-12

4.1 Outline...................................................................................................................II-12

4.2 Cassette Feed.......................................................................................................II-13

4.3 MP Tray Feed ........................................................................................................II-14

4.4 Paper Jam Detection.............................................................................................II-15

i

Page 5

CHAPTER III ELECTRICAL SYSTEM

1. MAIN PCB........................................................................................................................III-1

1.1 Outline.................................................................................................................... III-1

1.2 Video Controller Circuit ..........................................................................................III-2

1.3 Engine Controller Circuit ........................................................................................III-7

2. PAPER FEED DRIVE CIRCUIT ....................................................................................... III-9

3. DISPLAY CIRCUIT.........................................................................................................III-11

3.1 Outline..................................................................................................................III-11

3.2 Operation .............................................................................................................III-11

4. LOW-VOLTAGE POWER SUPPL Y ASSY.......................................................................III-12

4.1 Outline..................................................................................................................III-12

4.2 Protection Functions ............................................................................................III-12

5. HIGH-VOLTAGE POWER SUPPLY ASSY......................................................................III-14

5.1 Outline..................................................................................................................III-14

5.2 Operation of the Components of the High-Voltage Power Supply Assy ...............III-14

CHAPTER IV MECHANICAL SYSTEM

PRINTER DISASSEMBLING PROCEDURE

PRINTER BODY

1.1 Configuration.......................................................................................................... IV-3

1.2 Toner Cartridge Lid ................................................................................................IV-3

1.3 Side Cover L .......................................................................................................... IV-3

1.4 Font Cover Assy..................................................................................................... IV-4

1.5 Upper Cover Assy, Rear Cover Assy......................................................................IV-4

1.5.1 Upper cover assy, rear cover assy ...........................................................IV-4

1.5.2 Changeover guide, jam remove cover......................................................IV-5

1.6 Side Cover R.......................................................................................................... IV-5

1.7 DC Fan Motor......................................................................................................... IV-6

1.8 Main PCB ...............................................................................................................IV-6

1.9 Control Panel Unit .................................................................................................. IV-8

1.10 Scanner Unit .......................................................................................................... IV-9

1.11 Cartridge Stopper Assy .......................................................................................... IV-9

1.12 Paper Feed Chassis Unit .....................................................................................IV-10

1.13 Separation Pad Assy............................................................................................IV-11

1.14 MP PE Sub Actuator ............................................................................................ IV-12

1.15 P Feed /Size-SW PCB Assy................................................................................. IV-12

1.16 Side-Switch Spring ...............................................................................................IV-12

1.17 Regist Sensor Actuator ........................................................................................IV-13

1.18 MP Paper Detection Actuator...............................................................................IV-13

1.19 PE Sensor Actuator MP ....................................................................................... IV-13

1.20 Tray Sensor Holder .............................................................................................. IV-14

1.21 Roller Holder ........................................................................................................IV-14

1.22 Paper Pick-up Roller Assy, Bearing...................................................................... IV-15

1.23 Paper Pick-up Solenoid ........................................................................................IV-16

1.24 Paper Feed Motor Assy........................................................................................IV-16

1.25 MP Tray Cover......................................................................................................IV-17

1.26 MP Tray Assy ....................................................................................................... IV-17

1.27 Paper Path Separation Plate, Paper Path Separation Film .................................. IV-18

1.28 Latch .................................................................................................................... IV-19

1.29 Fixing Unit (for both 120V and 230V, the only difference is the halogen heater). IV-19

1.30 Transfer Unit......................................................................................................... IV-22

ii

Page 6

1.31 DC Gear Holder Assy........................................................................................... IV-23

1.32 PS Switch Wire, Remote Switch .......................................................................... IV-23

1.33 High-Voltage Power Supply PCB Assy................................................................. IV -24

1.34 Low-Voltage Power Supply PCB Assy.................................................................. IV-24

1.35 Toner Cartridge (EP-ED Cartridge)...................................................................... IV-25

1.36 Paper Tray ............................................................................................................ IV-25

CHAPTER V MAINTENANCE AND SERVICING

1. PERIODICAL REPLACEMENT PARTS ............................................................................ V-1

2. CONSUMABLE PARTS STANDARD ENDURANCE TABLE............................................. V-1

3. LIST OF STANDARD TOOLS............................................................................................ V-2

4. LIST OF LUBRICANTS AND CLEANERS ........................................................................ V-3

CHAPTER VI TROUBLESHOOTING

1. INTRODUCTION ..............................................................................................................VI-1

1.1 Initial Check............................................................................................................VI-1

1.2 Basic Procedure.....................................................................................................VI-2

2. TEST PRINTING AND MECHANICAL CHECK ...............................................................VI-2

2.1 Test Printing ...........................................................................................................VI-2

3. IMAGE DEFECTS ............................................................................................................VI-3

3.1 Image Defect Examples .........................................................................................VI-3

3.2 Troubleshooting Image Defects..............................................................................VI-4

4. TROUBLESHOOTING OF MALFUNCTIONS ................................................................ VI-11

5. TROUBLESHOOTING PAPER TRANSPORT PROBLEMS ...........................................VI-19

5.1 Paper Jams..........................................................................................................VI-19

5.2 Incomplete Paper Feed ........................................................................................VI-22

6. OPERATION ..................................................................................................................VI-23

6.1 Line Inspection Mode Procedure .........................................................................VI-23

6.2 DRAM Test ...........................................................................................................VI-25

7. STATUS MESSAGE LIST...............................................................................................VI-26

APPENDICES

1. Engine Block Diagram ....................................................................................................... A-1

2. Paper Feed/Size-SW PCB Circuitry Diagram (1/1)............................................................ A-2

3. Main PCB Circuitry Diagram (1/8) .....................................................................................A-3

4. Main PCB Circuitry Diagram (2/8) .....................................................................................A-4

5. Main PCB Circuitry Diagram (3/8) .....................................................................................A-5

6. Main PCB Circuitry Diagram (4/8) .....................................................................................A-6

7. Main PCB Circuitry Diagram (5/8) .....................................................................................A-7

8. Main PCB Circuitry Diagram (6/8) .....................................................................................A-8

9. Main PCB Circuitry Diagram (7/8) .....................................................................................A-9

10. Main PCB Circuitry Diagram (8/8) ................................................................................... A-10

11. Control Panel PCB Circuitry Diagram (1/1) ..................................................................... A-11

12. Scanner LD PCB Circuitry Diagram (1/1) ........................................................................ A-12

iii

Page 7

CHAPTER I GENERAL

1. FEATURES

A. This high-speed, non-impact (low-noise) printer is based on electrophotography, electronics

and laser technology.

B. The printer is compact and easy to carry. The internally-storable, front-loading paper

cassette enables you to save an occupation space for the machine; the printer can now

be installed in a smaller place.

C. The charging roller, developing cylinder, photosensitive drum and cleaner of the printer

are combined into a single assembly called an ”EP-ED cartridge”. The cartridge can be

replaced by the user when necessary without a need of service call. High printing quality

is maintained by a simple cleaning procedure.

D. Laser beam safety is designed into the printer. The printer is approved by the US Center

for Devices and Radiological Health (CDRH).

E. Paper can be fed in two ways, by the multi-purpose paper feed tray and paper cassette.

F. Maintenance is easy with print component units which are directly detachable, and they

require no adjustment after reassembly.

2. SPECIFICATIONS

(1) Type Desktop page printer

(2) Printing method Electrophotography (single-component dry toner)

(3) Printing speed

Cassette feed 12 pages/minute (A4/Letter size by cassette feed)

10.2 pages/minute (Legal size)

(4) First print time Approx. 20 seconds

(A4 size by face-down print delivery from the paper cassette)

(5) Warm-up (WAIT) time Max. 1 minute at 20°C (68°F)

(6) Optical system

Laser Semiconductor laser

Output power : 5mW max.

Wave length

Scanning system Rotating six-faced polygon mirror

(7) Resolution

Horizontal 600 dots/inch and high resolution control (HRC)

Vertical 600 raster lines/inch

: 780 nm

I - 1

Page 8

(8) Printing system

Photosensitive drum OPC

Charging Charging Roller

Exposure Laser scanning system

Development Toner projection development system

Paper feed Cassette or manual feed

Image transfer Roller method

Separation Natural(utilizing a small drum radius), Static charge eliminator

Fixing Heated fixing roller

Toner supply Included in the replaceable EP-ED cartridge

Life expectancy 6000 pages/cartridge

(9) Paper

Cassette feed Plain paper for Letter, Legal, A4, ISO B5, A5, ISO B6, A6,

Multi-purpose Tray Plain paper of 90 x 148 mm 216 x 356 mm (recommended:

(10) Cassette (Tray 1)

Executive (A4 or letter size paper with the print density set at

2

level 8 with 4% coverage, recommended: 60 g/m

105 g/m )

and Envelope (com10, monarch, C5, DL, ISO B5)

2

60g/m 135 g/m , overhead projector (OHP) film, postcards,

2

label stock and envelopes (specified sizes)

2

Universal cassette A4, Letter, Legal, ISO B5, Executive, A5, ISO B6, and A6

Maximum load height 55 mm (500 sheets of 80 g/m paper)

Feedable paper type 60 105 g/m

2

Envelopes 40 envelopes

(11) Print delivery Face-down or (face-up)

(12) Print delivery tray capacity

Face-down 250 sheets (80 g/m )

2

Face-up Discharge only

2

I - 2

Page 9

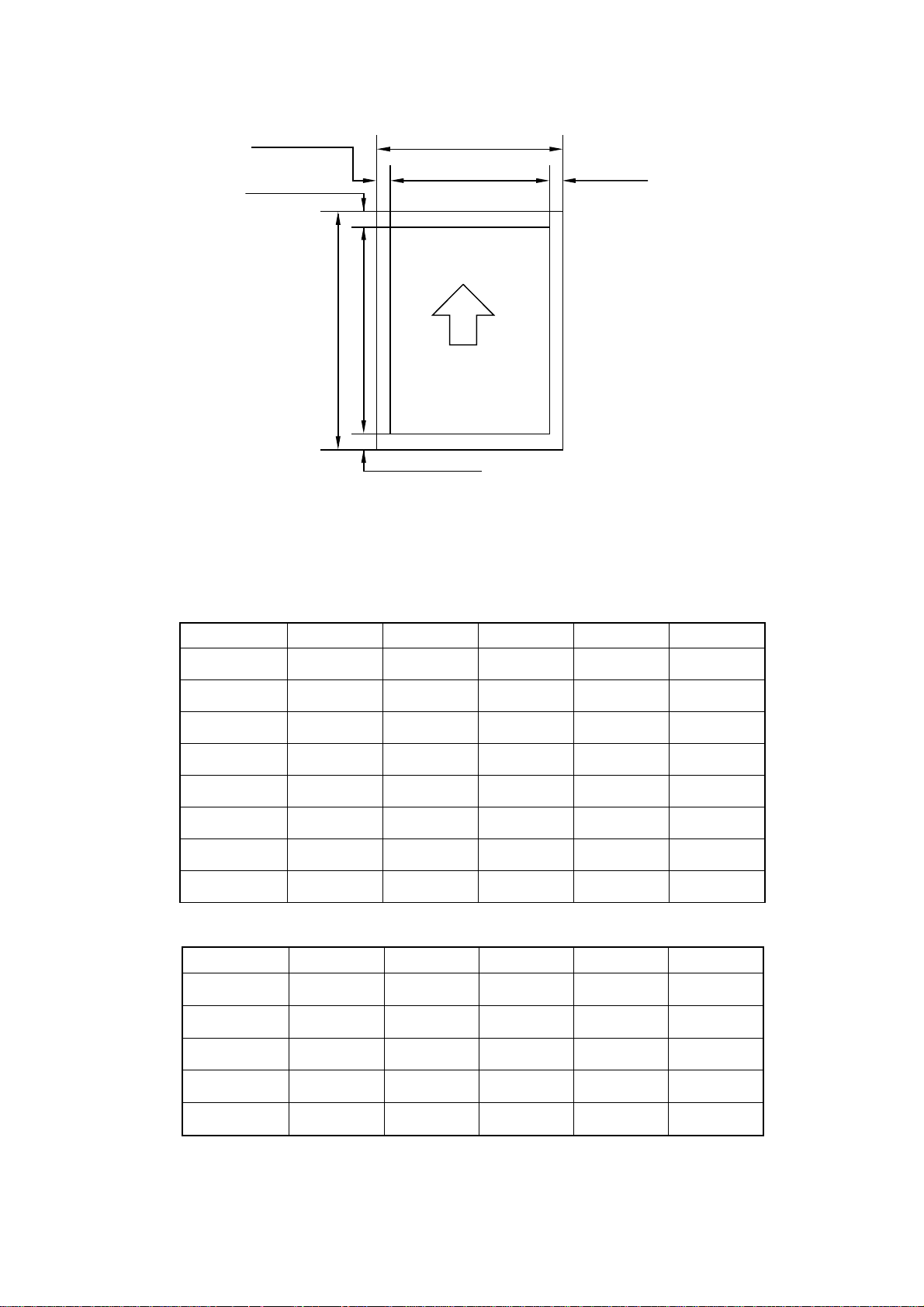

(13) Effective printing area

E

E

A

C

E

Printable area

D

B

E

Figure 1.1 Printable Area

Effective printable area is referred to as a area within which is guaranteed the printing of all

interface signal data on a hard copy without any omission.

The tables below shows the effective printable area for each paper size.

Table 1.1 Plain Paper

SIZE A (mm) B (mm) C (mm) D (mm)

A 4

Letter

Legal

B 5 (ISO)

Executive

A 5

B 6 (ISO)

A 6

210.0 297.0 203.2

215.9 279.4 207.4 270.9

215.9 355.6 207.4 347.1

176.0 250.0 167.5 241.5

184.2 266.7 175.7 258.2

148.0 210.0 139.5 201.5

125.0 176.0 116.5 167.5

105.0 148.0 96.5 139.5

Table 1.2 Envelope

SIZE A (mm) B (mm) C (mm) D (mm)

COM-10

MONARCH

DL

104.8 241.3 96.3

98.4 190.5 89.9 182.0

110.1 221.0 101.6 212.5

288.5

232.8

E (mm)

3.39 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

E (mm)

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

C5

B5 (ISO)

162.2 228.6 154.1 220.1

176.0 250.0 167.5 241.5

(The sizes above are nominal sizes according to ISO.)

An A4 sheet accepts 80 PICA-pitch characters (203.2mm).

I - 3

4.23 ± 1.0

4.23 ± 1.0

Page 10

(14) Standard interfaces Automatic interface selection

• Centronics, Bi-directional parallel

• RS-232C serial

Baud rate : 150, 300,1200, 2400, 4800, 9600

19200, 38400, 57600 bps

Stop bit : 1 bit

Start bit : 1 bit or 2 bits

Data length : 7 bits or 8 bits

Parity : Odd, Even, or None

Protocol : Xon/Xoff or DTR

(15) Emulation Automatic emulation selection

• HP Laser Jet 4 (PCL Level 5

• EPSON FX-850

• IBM Proprinter XL

• BR-Script level 2 (PostScript language emulation interpreter)

• HP- GL

e

)

(16) CPU 79R3041 (20MH

Z)

(17) Resident fonts 75 scalable fonts and 12 bitmapped fonts

HP Laser Jet 4, EPSON FX-850, IBM Proprinter XL

Scalable Fonts:

Intellifont Compatible Fonts:

• Albertville, Extrabold

• Antique Oakland, Oblique, Bold

• Brougham, Oblique, Bold,

Bold Oblique

• Cleveland Condensed

• Connecticut

• Guatemala Antique, Italic, Bold,

Bold Italic

• Letter Gothic, Oblique, Bold

• Maryland

• Oklahoma, Oblique, Bold,

Bold Oblique

Windows 3.1 Compatible Fonts:

• Tennessee Roman, Italic, Bold,

Bold Italic

• Helsinki, Oblique, Bold, Bold Oblique

• BR Symbol

• W Dingbats

BR-Script Fonts:

• Atlanta Book, Book Oblique, Demi,

Demi Oblique

• Copenhagen Roman, Italic, Bold,

Bold Italic

• Portugal Roman, Italic, Bold, Bold Italic

• Calgary Medium Italic

• PC Brussels Light, Light Italic, Demi,

Demi Italic

• PC Tennessee Roman, Italic, Bold,

Bold Italic

• Utah, Oblique, Bold, Bold Oblique

• Utah Condensed, Oblique, Bold,

Brother Original Fonts:

• Bermuda Script

• Germany

• San Diego

• US Roman

Bold Oblique

Bitmapped Fonts (Portrait and Landscape):

• Letter Gothic 16.66 Medium, Italic, Bold, Bold Italic

• OCR-A

• OCR-B

I - 4

Page 11

BR-Script Level 2 Mode

Scalable Fonts:

• Atlanta Book, Book Oblique, Demi,

Demi Oblique

• Brussels Light, Light Italic, Demi,

Demi Italic

• Brougham, Oblique, Bold, Bold Oblique

• Helsinki, Oblique, Bold, Bold Oblique

• Helsinki Narrow, Oblique, Bold,

Bold Oblique

• Copenhagen Roman, Italic, Bold,

Bold Italic

• Portugal Roman, Italic, Bold, Bold Italic

• Tennessee Roman, Italic, Bold, Bold Italic

• Calgary Medium Italic

• BR Symbol

• BR Dingbats

• Albertville, Extrabold

• Antique Oakland, Oblique, Bold

• Cleveland Condensed

• Conecticut

• Guatemala Antique, Italic, Bold, Bold Italic

• Letter Gothic, Oblique, Bold

• Maryland

• Oklahoma, Oblique, Bold, Bold Oblique

• Utah, Oblique, Bold, Bold Oblique

• Utah Condensed, Oblique, Bold,

Bold Oblique

• Bermuda Script

• Germany

• San Diego

• US Roman

(18) RAM 2M bytes (expandable to 26M bytes)

(19) Font cartridge/card slots Two slots

One font cartridge slot and one font card slot

(20) Power souse USA and Canada : AC 110 to 120 V, 60 H

Europe and Australia : AC 220 to 240 V, 50 HZ

(21) Power consumption Printing : 500 WH or less

Stand-by : 80 WH or less

Sleep : 20 WH

(22) Noise Printing : 49 dB A or less

Stand-by : 40 dB A or less

(23) Dimensions (W x H x D) 371.6 x 326.5 x 393 mm (14.6 x12.9 x 15.5 inches)

(24) Weight Approx. 15 kg (32.6 Ibs)

(25) Environmental conditions

Operating Temperature 10 ~ 32.5°C

environment Relative humidity 20 ~ 80%RH

(No condensation allowed)

Air pressure 613 ~ 1013 hPa

(0 ~ 2,500 m above sea level)

Non-operating Temperature 0 ~ 35°C

environment Relative humidity 10 ~ 80%RH

(No condensation allowed)

Storage conditions

Z

• Printer Temperature

Normal (total storage time x 9/10)

0 ~ 35°C

Severe (total storage time x 1/10)

High Low

35°C ~ 60°C -20°C ~ 0°C

Temperature change (within 3 minutes)

High Low

60°C 15°C -20°C 25°C

I - 5

Page 12

Relative humidity

Normal (total storage time x 9/10)

35 ~ 85%RH

Severe (total storage time x 1/10)

High Low

85 ~ 95%RH 10 ~ 35%RH

Air pressure 613 ~ 1013 hPa

Total storage time 0.5 years

• EP-ED cartridge Temperature

Normal (2.45 years max.)

0 ~ 35°C

Severe (0.05 years max.)

High Low

35°C ~ 40°C -20°C ~ 0°C

Temperature change (within 3 minutes)

High Low

40°C 15°C -20°C 25°C

Relative humidity

Normal (2.45 years max.)

35 ~ 85%RH

Severe (0.05 years max.)

High Low

85 ~ 95%RH 10 ~ 35%RH

Air pressure 613 ~ 1013 hPa

Maximum total storage time: 2.5 years including used time

3. SAFETY INFORMATION

3.1 Laser Safety (110 ~ 120V Model only)

This printer is certified as a Class 1 laser product under the US Department of Health and

Human Services (DHHS) Radiation Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. This means that the printer does not produce

hazardous laser radiation,

Since radiation emitted inside the printer is completely confined within the protective

housings and external covers, the laser beam cannot escape from the machine during any

phase of user operation.

I - 6

Page 13

3.2 CDRH Regulations (110 ~ 120V Model only)

The center for Devices and Radiological Health (CDRH) of the US Food and Drug

Administration implemented regulations for laser products on August 2, 1976. These

regulations apply to laser products manufactured from August 1, 1976. Compliance is

mandatory for products marketed in the United States. The label shown below indicates

compliance with the CDRH regulations and must be attached to laser products marketed in

the United States.

MANUFACTURED :

BROTHER INDUSTRIES, LTD.

15-1, Naeshiro-cho, Mizuho-ku Nagoya 467, Japan.

This product complies with FDA radiation

performance standards , 21 CFR chapter 1

subchapter J.

Figure 1.2

Caution: Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

3.3 Additional Information

When servicing or adjusting the optical system of the printer, be careful not to place

screwdrivers or other reflective objects in the path of the laser beam. Be sure to take off any

personal accessories such as watches and rings before working on the printer. A reflected

beam, though invisible, can permanently damage the eyes.

Since the beam is invisible, the following label is attached to the inside of covers where

danger of exposure to laser radiation exist.

Figure 1.3

I - 7

Page 14

4. PARTS OF THE PRINTER

4.1 External Views

1 Upper cover

2 Control panel

3 MP tray

4 Tray 1

5 Tray 2 (Option)

6 Font card slot

7 Font cartridge slot

8 Power switch

11

9 AC inlet

10 Face-up print delivery port

11 Fan outlet port

12 Rating label

13 Optional I/O slot

14 RS-232C interface connector

15 Centronics interface connector

16 Optional interface connector

1

2

10

15

13

3

8

5

4

6

7

Figure 1.4

9

12

14

16

I - 8

Page 15

4.2 Cross Sectional View

12

11

13

14

1

2

3

4

5

6

7

8

1 Registration rollers

2 EP-ED cartridge

3 Photosensitive drum

4 Laser scanner unit

5 Transfer unit

6 Face-down tray

7 Print-delivery path

8 Fixing unit

10

Figure 1.5

9

9 Low-voltage power supply assy

10 High-voltage power supply assy

11 Paper cassette (Tray 1)

12 Pick-up rollers

13 MP tray

14 Control panel

I - 9

Page 16

5. STORAGE AND HANDLING OF EP-ED CARTRIDGES

An EP-ED cartridge is influenced by the storage conditions even if it is sealed in its package,

so its life depends on the way in which it is used or stored. EP-ED cartridges should be

handled carefully.

5.1 Storage of Sealed EP-ED Cartridges

When storing sealed EP-ED cartridges in a warehouse or workshop, the storage conditions

shown in (25) Environmental conditions on Page 1-5 must be met. Follow the instructions

below:

1) Avoid direct sunlight.

2) Do not store cartridges on a surface that is subject to vibration.

3) Do not hit or drop the packages containing cartridges.

4) The cartridges should be stored horizontal when they are removed from the body (with

their label side upside).

5) Avoid putting the cartridges near a CRT screen, a disk or a floppy disk (to keep their data

from being destroyed).

5.2 Storage of Unsealed EP-ED Cartridges

Each EP-ED cartridge contains a photosensitive drum that has an organic photoconductor

(OPC) which deteriorates when exposed to strong light. It also contains toner. The user,

therefore, should be fully informed about the correct storage and handling of EP-ED

cartridges.

(1) Storage requirements

1) Avoid places exposed to direct sunlight or near a window. Do not leave an EP-ED

cartridge in a car in warm or hot weather even if it is in its storage box.

2) Avoid places with a too-high or too-cool temperature and/or humidity. Also avoid

places exposed to sudden temperature or humidity changes (such as near an air

conditioner outlet).

3) Avoid dusty places or places exposed to ammonia fumes or other harmful fumes.

4) Do not store an EP-ED cartridge in a temperature above 40°C.

(2) EP-ED cartridge life

The effective life of an EP-ED cartridge is 2.5 years from the date of manufacture

(printed on the cartridge.) The expiry year and month (date of manufacture plus 2.5

years) is shown on the EP-ED cartridge box. An EP-ED cartridge used after the expiry

may produce low-quality printing, so a cartridge should be used within the stated

period.

I - 10

Page 17

CHAPTER II THEORY OF OPERATION

This chapter describes the printer functions, the relationship between the electrical systems and

mechanical systems, and the timing of operations. Striped conduits ( ) indicate mechanical

linkages; solid thin arrows ( ) appearing with a signal name indicate the transmission of

single control signals and outlined thick arrows ( ) indicate the transmission of groups of

signals.

1. BASIC OPERATIONS

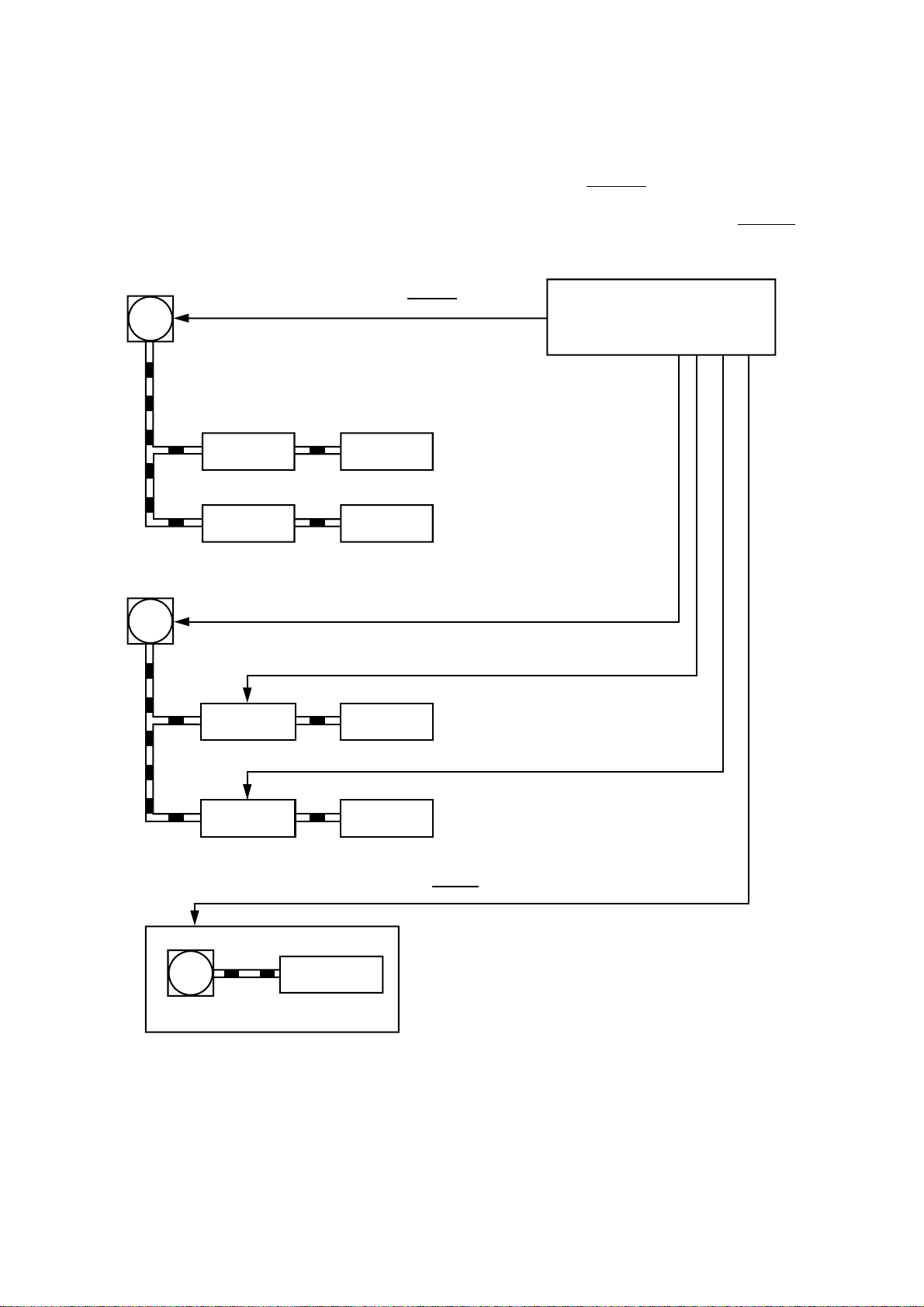

1.1 Mechanical Configuration

The printer functions can be divided into four blocks: the laser/scanner system, the image

formation system, the paper pick-up/feed system and the control system.

Expansion memory

(SIMM)

Control panel

Font cartridge/card

Main PCB

IMAGE FORMATION SYSTEM

Photosensitive drum

Cleaning unit

Optional I/O

(MIO)

External Device

CONTROL SYSTEM

Laser/scanner

unit

Developing

unit

Delivery rollers

PAPER PICK-UP/FEED SYSTEM

Fixing unit

Feeder

LASER/SCANNER

SYSTEM

Transfer

separation

unit

MP tray

Tray 1

Tray 2

(Option)

Figure 2.1

II - 1

Page 18

1.2 Main Drive

The power necessary for driving the printer is supplied by the main motor, the paper feed motor

and the scanner motor.

The main motor is controlled by the main motor drive signal (MDRIVE) output from the main

PCB, and the paper feed motor is controlled by the paper feed motor drive signal output from

the main PCB, and the scanner motor is controlled by the scanner motor drive signal (SDRIVE)

output from the main PCB.

Main motor

Main motor drive signal (MDRIVE)

Main PCB

Paper feed motor

Drum gear

Fixing unit

Paper feed motor drive signal

MP tray pick-up roller solenoid drive signal (MPSOL)

MP tray pick-up

roller solenoid

Tray1 pick-up roller solenoid drive signal (PUCL1)

Tray1 pick-up

roller solenoid

Photosensitive

drum

Paper delivery

rollers

MP tray

pick-up roller

Tray1

pick-up roller

Scanner motor

Scanner unit

Scanner motor drive signal (SDRIVE)

Note: There are cases, in the following pages, that

Scanning mirror

Figure 2.2

II - 2

a main motor is referred to as a DC motor, but

they are identical.

Page 19

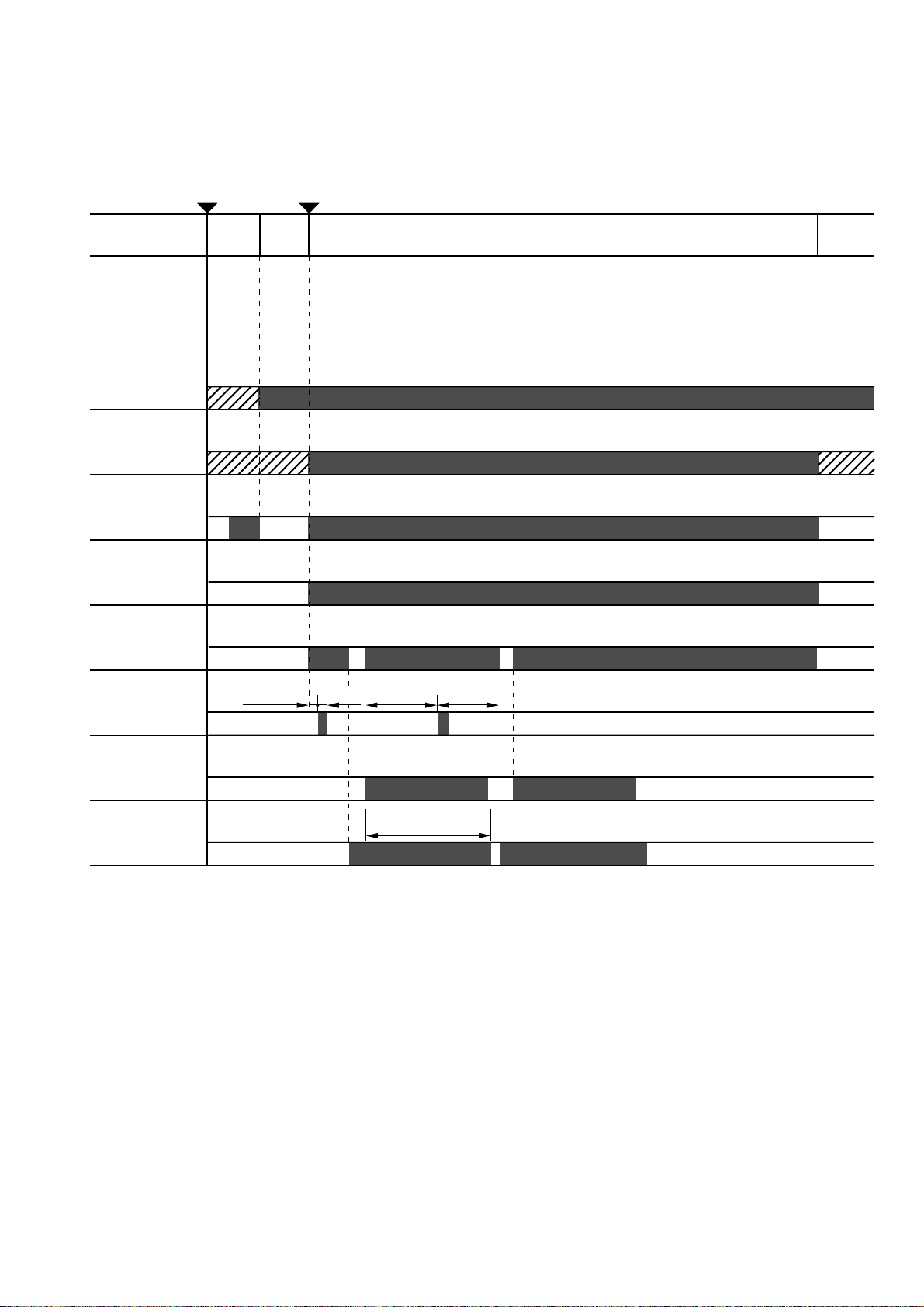

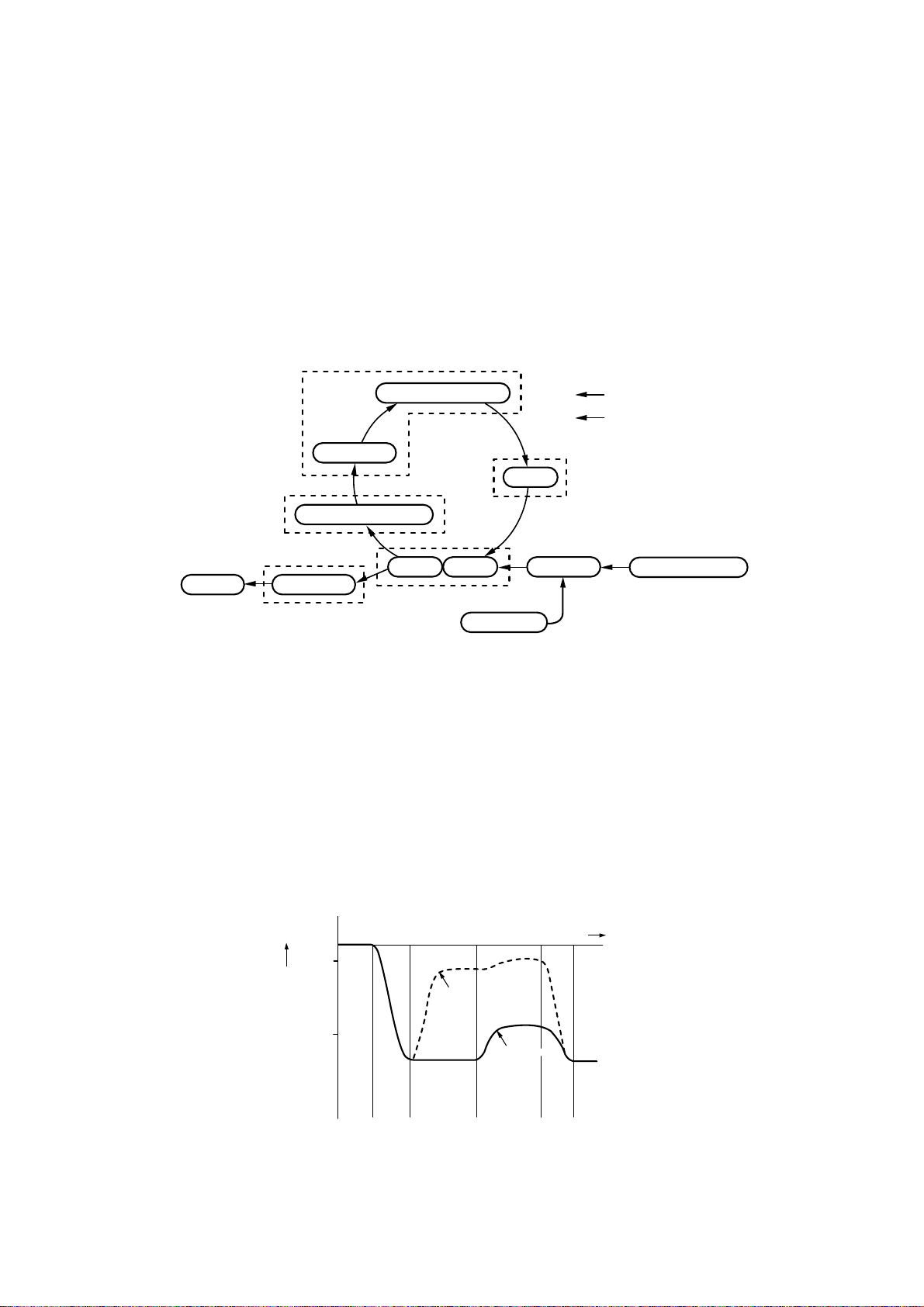

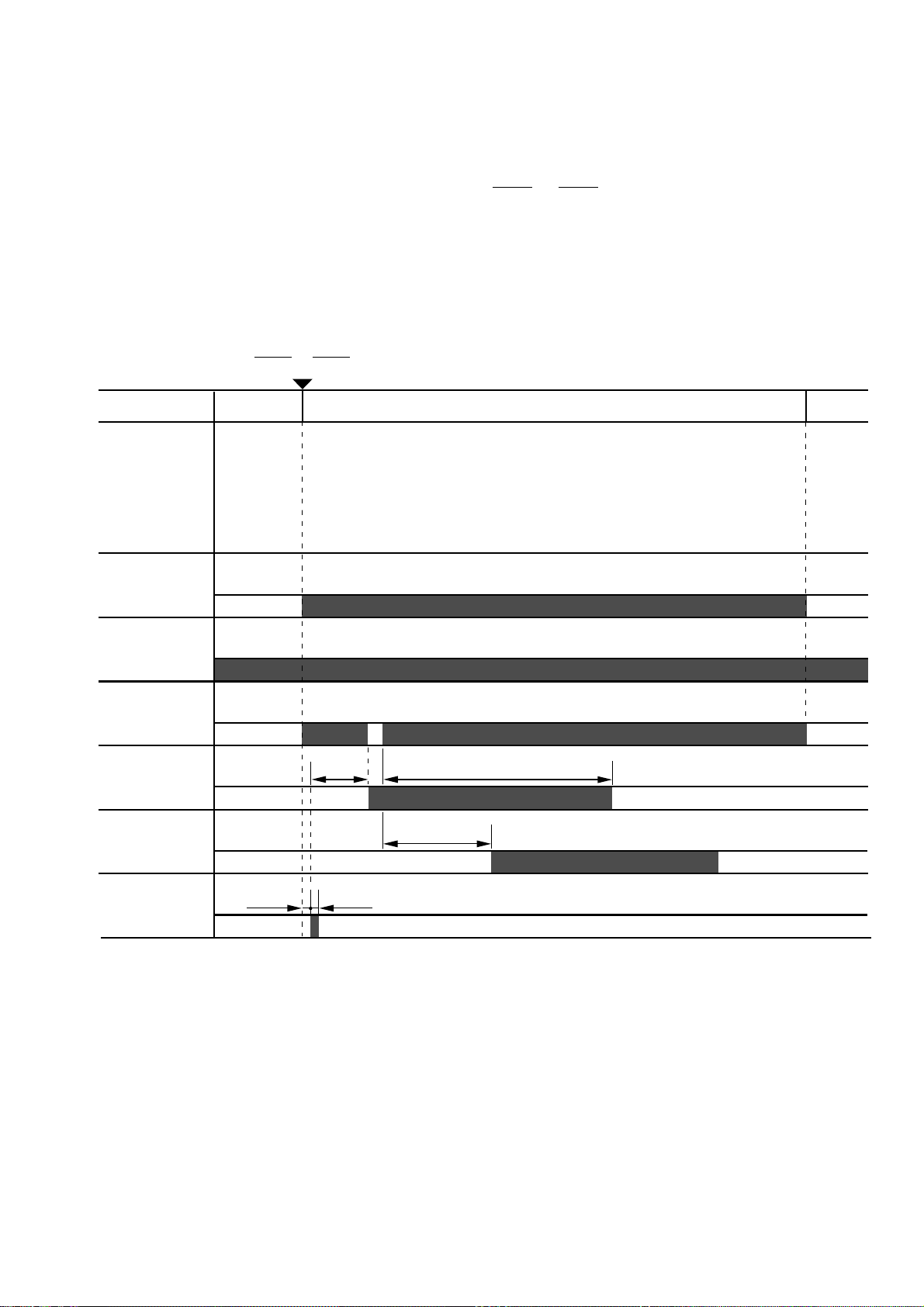

1.3 Basic Sequence of Operations

Power on Print

WAIT STBY PRINT

Ready lamp

Fixing heater

Main motor

170°C control 190°C

STBY

control

170°C

control

Scanner motor

Paper feed

motor

Pick-up roller

solenoid

Laser diode

Registration

sensor

0.2 sec

0.2 sec

2.5 sec

2.3 sec

4.24 sec

Timing for two consecutive prints on A4 paper.

Figure 2.3

II - 3

Page 20

2. LASER/SCANNER SYSTEM

To external device

SBD DATA VOFF

Collimator lens

Main PCB

Scanner driver

Cylindrical lens

Scanning mirror

Optical sensor

Figure 2.4

In response to the print signal transmitted from the external device, the main PCB generates the

drive signals (DATA,VOFF) for the laser diode and sends the signals to the scanner unit.

The laser diode in the scanner unit generates a laser beam modulated by DATA.

The modulated laser beam is aligned into a parallel beam by a collimator lens and a cylindrical

lens and then brought to the scanning mirror which is rotating at a constant speed.

The laser beam reflected by the scanning mirror focuses on the photosensitive drum via the

focusing lenses arranged in front of the scanning mirror.

The path of the beam coming through the focusing lenses is reflected by the reflective mirror.

Scanner motor

Focusing lenses

Beam detect mirror

As the scanning mirror rotates at a constant speed, the laser beam scans the photosensitive

drum at a constant speed.

As the photosensitive drum rotates at a constant speed and the laser beam scans the drum, an

images is formed on the drum.

II - 4

Page 21

3. IMAGE FORMATION SYSTEM

3.1 Outline

The image formation system is the main part of the printer. The print information, after input from

the video controller circuit into the engine controller circuit as a TVDO signal, forms a toner image

on the photosensitive drum.

Then the toner image is transferred onto the paper by the transfer charging roller. The image

formation system is composed of the photosensitive drum the charging unit, the developing unit

and the cleaning unit.

3.2 Printing Process

The major part of the image formation system is contained in the cartridge, as shown in Figure

2.5.

Laser beam

Cartridge

Primary charging roller

Cleaning blade

Photosensitive drum

Static charge eliminator

Blade

Developing cylinder

Paper

Transfer charging roller

Figure 2.5

The cartridge used by the printer has a seamless photosensitive drum with the structure shown

in Figure 2.6. The outer layer of the drum consists of an organic photoconductor (OPC); the base

is aluminum.

The printing process can be divided into five major stages:

Photoconductive layer

Figure 2.6

1. Electrostatic latent image formation stage

Step 1 Primary charge (-)

Step 2 Scanning exposure

2. Developing stage

Step 3 Development

II - 5

Base

Page 22

3. Transfer stage

Step 4 Transfer (+)

Step 5 Separation

4. Fixing stage

Step 6 Fixing

5. Drum cleaning stage

Step 7 Drum cleaning

Electrostatic latent image

formation stage

2. Scanning exposure

1. Primary charge

6. Fixing

7. Drum cleaning

5. Separa tion

4. Transfer

Drum cleaning stage

Fixing stage

Print delivery

Transfer stage

Figure 2.7

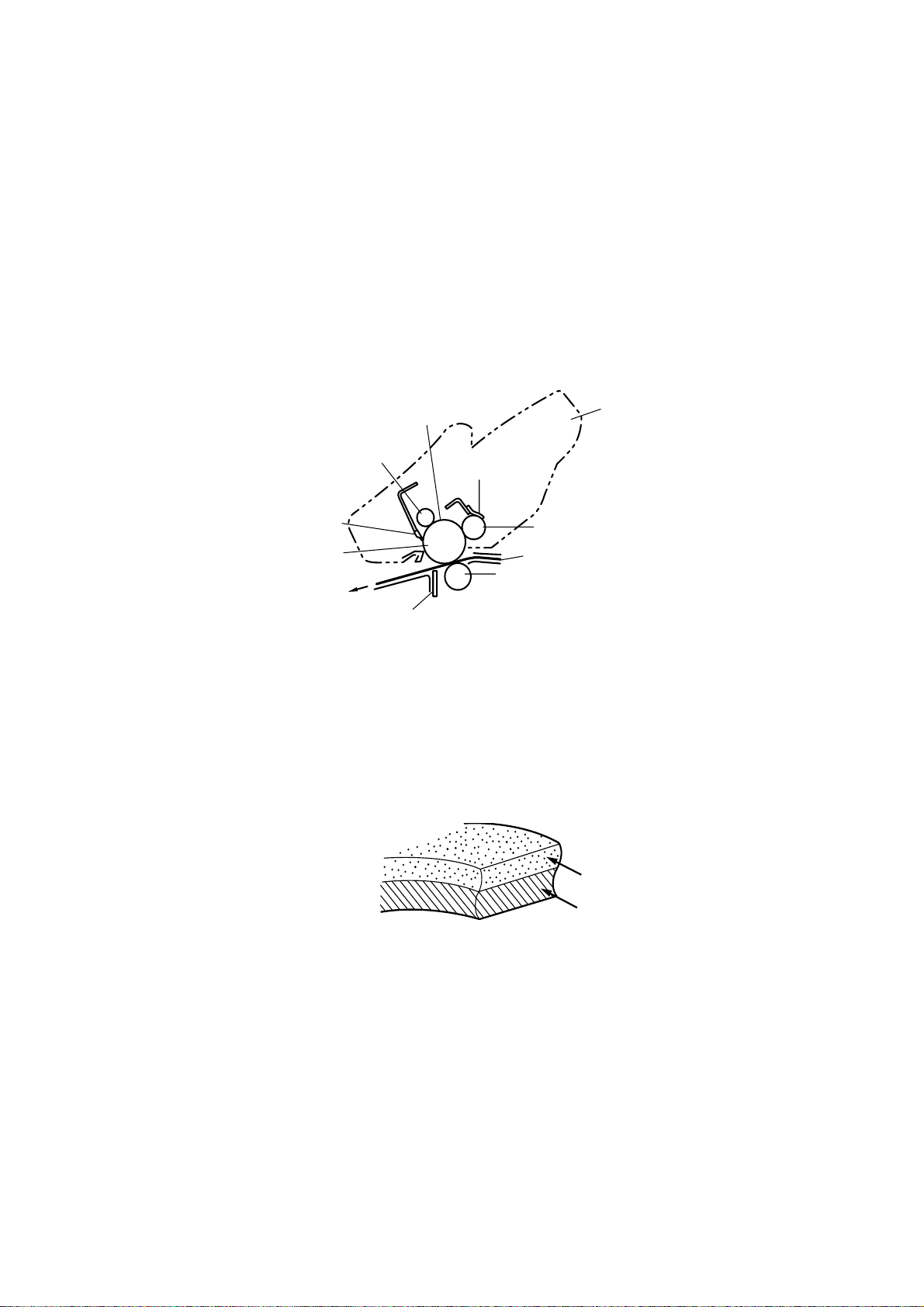

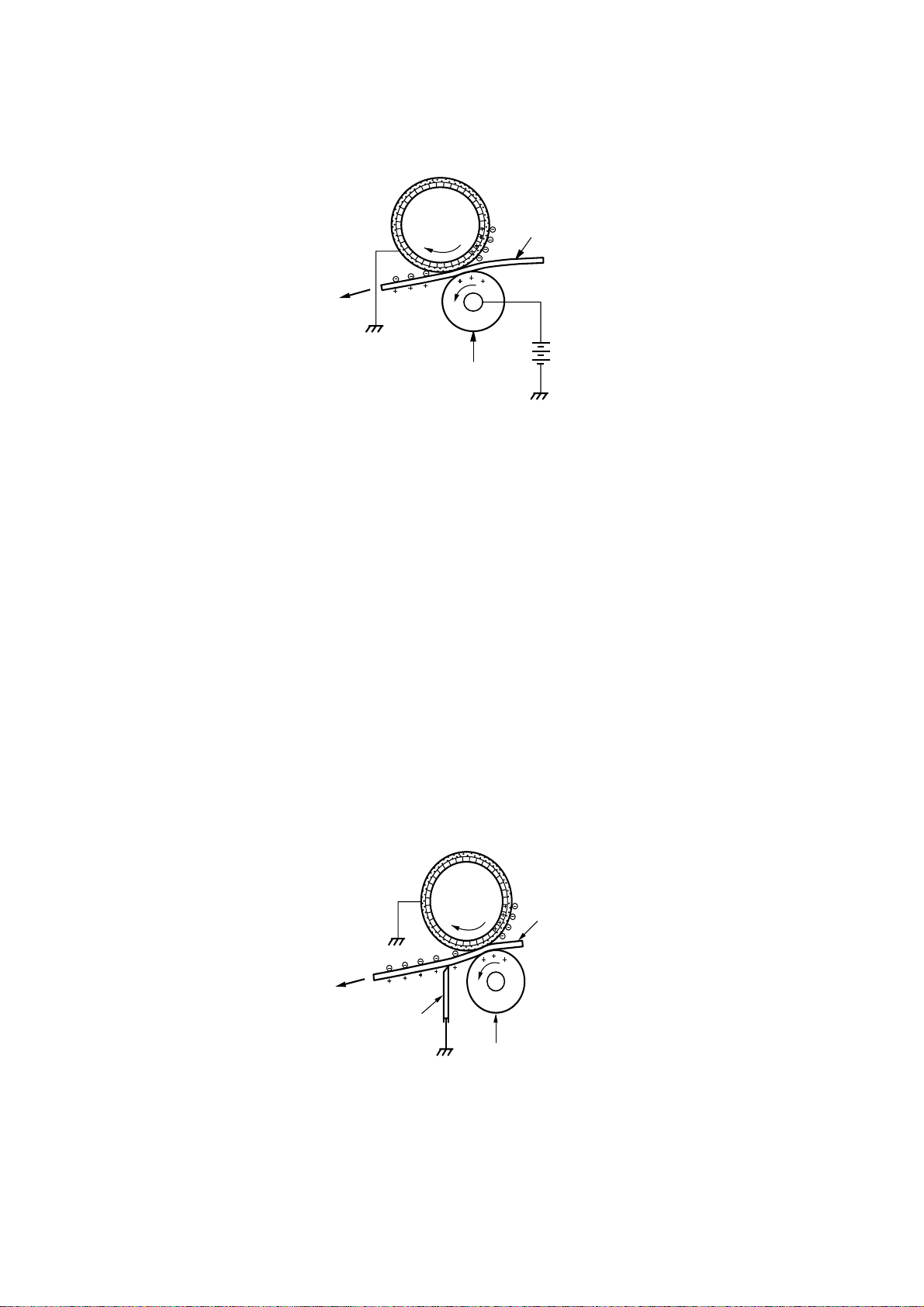

3.2.1 Electrostatic latent image formation stage

This stage has two steps, which together produce a pattern of electrical charges on the

photosensitive drum.

At the end of the stage, negative charges remain in the unexposed ”dark” area. Charges are

absent from the ”light” areas, where the laser beam struck (exposed) the drum surface.

Since this image of negative charges on the drum is invisible to the eye, it is called an

”electrostatic latent image”.

3. Develop

ment

Cassette feed

Developing stage

Registration

Paper path

Direction of drum rotation

Multi-purpose tray feed

0

-100

-500

Primary

Surface potential (V)

charge

(step 1)

Exposed

area

Scanning

exposure

(step 2)

Figure 2.8

II - 6

Time (t)

Unexposed

area

Transfer

(step 4)

Primary

charge

(step 1)

Page 23

Step 1 Primary charge

,,

,

,

,,

,,

,

,

,

,,

,,

,,

,

,

,,

As preparation for latent image formation, a uniform negative potential is applied to the

photosensitive drum surface. The printer uses the charging method that directly charges the

drum for the primary charge.

The primary charging roller consists of conductive rubber. In addition to DC bias, AC bias is

applied to the primary charging roller to keep the potential on the drum surface uniform. This DC

bias is changed with the developing DC bias.

This charging method has advantages such as lower applied voltage, less ozone generation,

etc., compared with the corona charge system.

Primary charging roller

AC bias

Photosensitive drum

DC bias

Figure 2.9

Step 2 Scanning exposure

Unexposed area

When the laser beam scans the drum surface, it causes the charge to be neutralized in the areas

struck by the beam. Areas on the drum with no charge form the electrostatic latent image.

Laser beam

___

+++

Exposed area

Figure 2.10

II - 7

Page 24

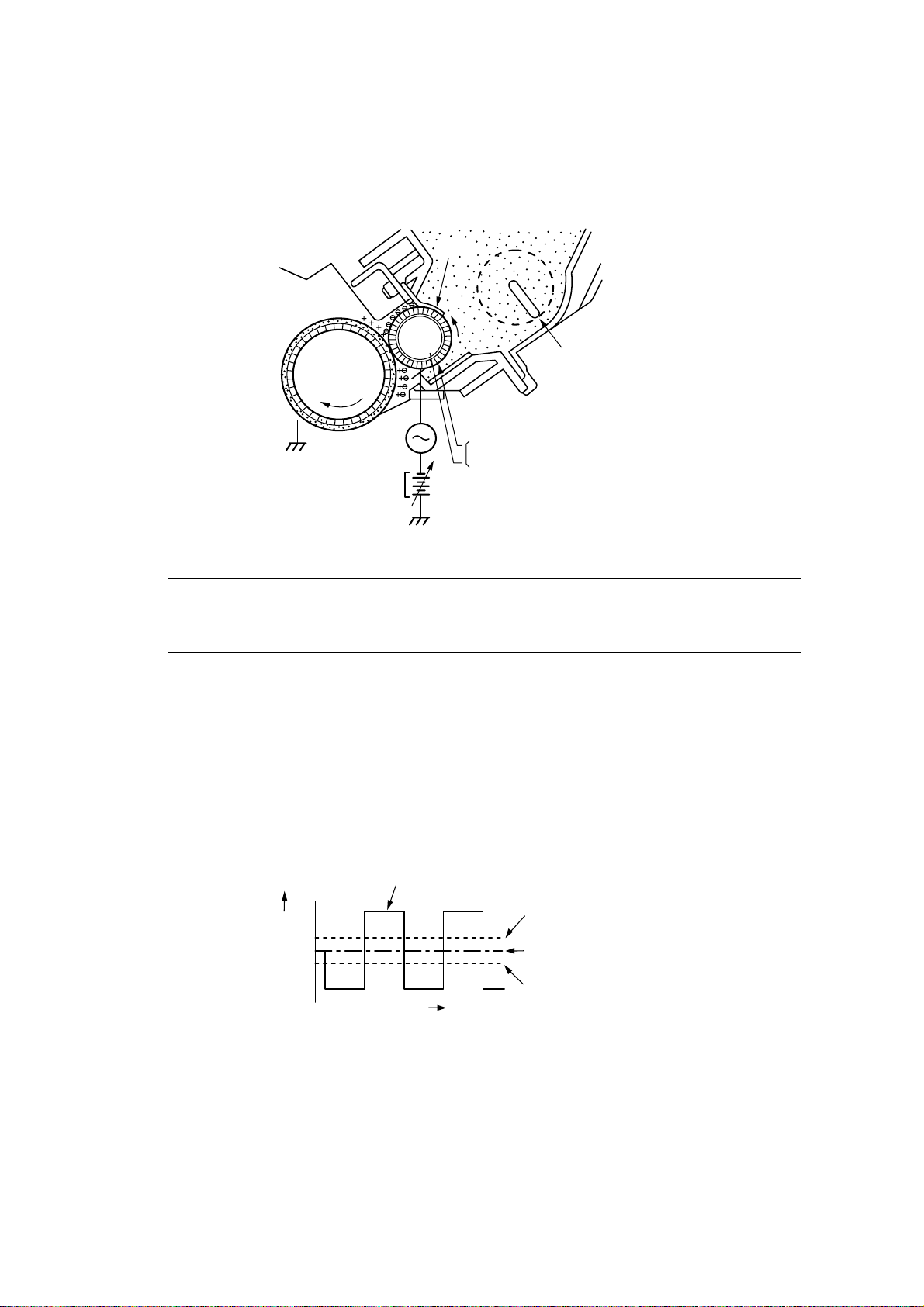

3.2.2 Developing stage

Development places particles of toner onto the areas of the drum that have been cleared of

charge by the laser beam. This makes a visible image. This printer uses the toner projection

development method with a single-component toner.

Step 3 Development

Blade

Photo-

sensitive

drum

AC bias

DC bias

Developing cylinder

Cylinder

Magnet

Stirrer

Figure 2.11

Note: The charges on the light areas on the photosensitive drum are shown as positive in this

figure. Actually they are negative, but they are more positive than the developing

cylinder and explanation is simplified by regarding them as positive.

As shown in Figure 2.11, the developing unit consists of a developing cylinder and rubber blade.

The developing cylinder rotates around a fixed internal magnet. The single-component toner

consists of magnetite and a resin binder, and is held to the cylinder by magnetic attraction. The

toner is an insulator, and acquires a negative charge by friction due to the rotation of the cylinder.

The areas on the drum that were exposed to the laser beam have a higher potential (are less

negative) than the negatively charged toner particles on the developing cylinder. When these

areas approach the cylinder, the potential difference projects the toner particles onto them. This

is called toner projection, and the latent image on the drum becomes visible.

Developing cylinder

surface potential

+V

0

-V

Voltage (V)

Time t

Drum surface

potential

(exposed area)

DC bias

Drum surface

potential

(unexposed area)

Figure 2.12

An AC bias is applied to the developing cylinder to help project the toner particles to the drum

surface and improve the contrast of the printed image. The center voltage of the AC bias (1600

Vp-p) varies with the DC bias voltage.

The IMAGE DENSITY ADJUSTMENT signal (sent from the Engine CPU to the high-voltage

power supply) changes the DC bias, and thus the potential difference between the cylinder and

drum. This changes the density of the print.

This printer has a stirring mechanism to supply toner in the cartridge smoothly to the cylinder.

II - 8

Page 25

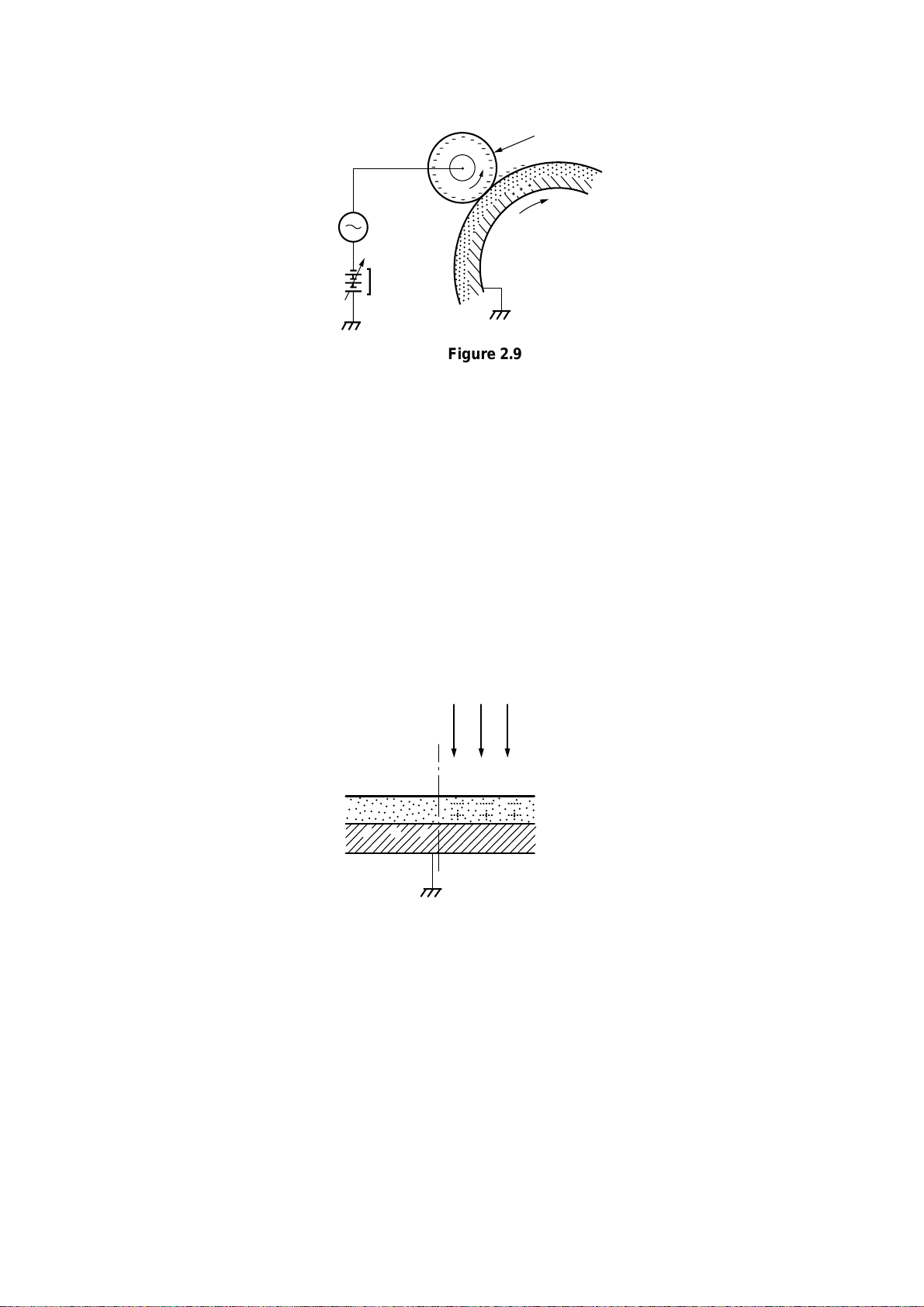

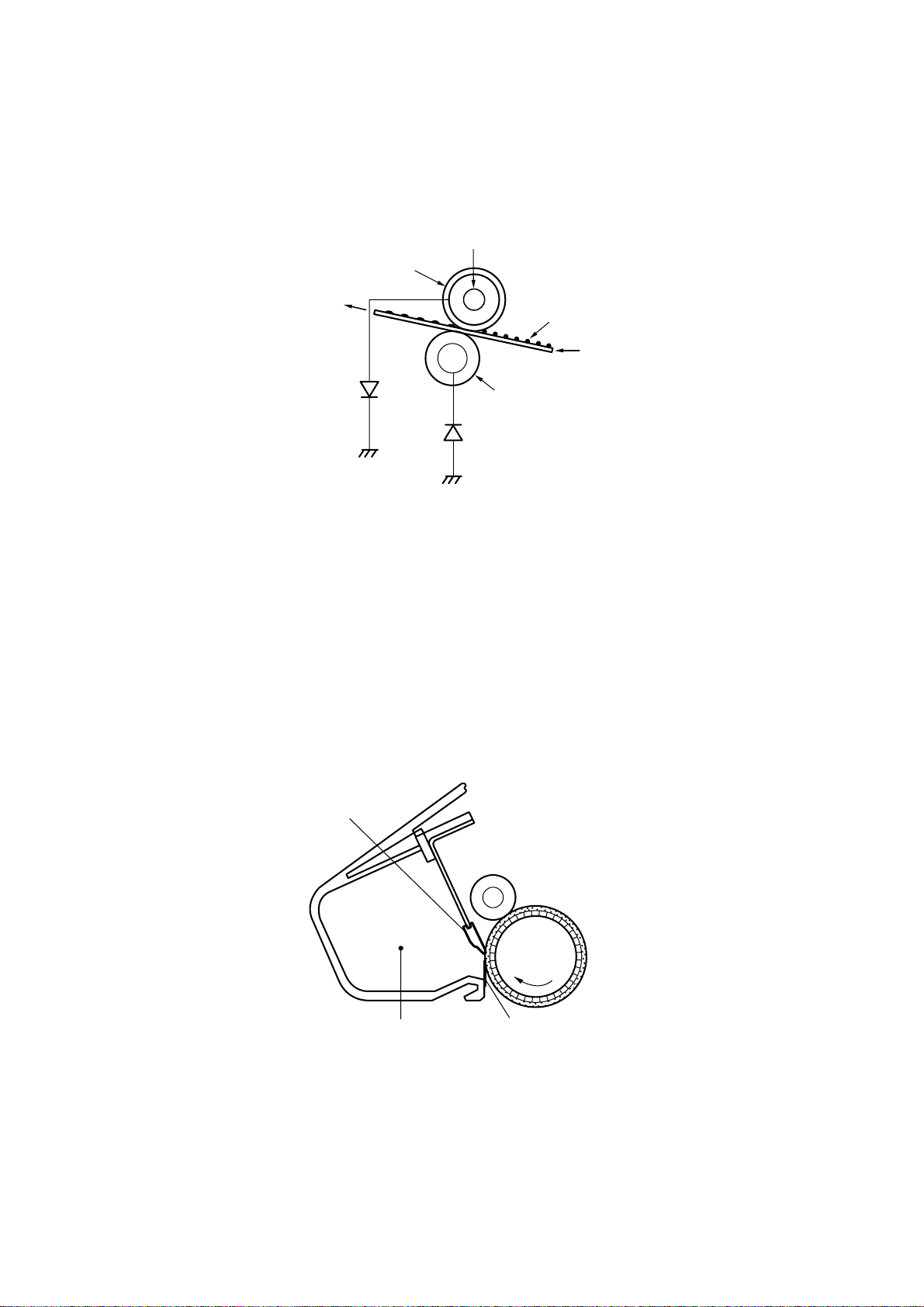

3.2.3 Transfer stage

In the transfer stage, the toner image is transferred from the drum surface to the paper.

Step 4 Transfer

A positive charge applied to the back of the paper attracts the negatively charged toner particles

to the paper. The printer accomplishes transfer by using the charging roller method. Advantages

compared with the corona transfer method are as follows:

Photo-

sensitive

drum

Transfer charging roller

Figure 2.13

Paper

• Low transfer voltage that is less than half that for corona transfer.

• Less ozone generation.

• The paper is supported by the transfer charging roller and photosensitive drum, so feed is

more stable.

Reference:

If the image on the photosensitive drum is not completely transferred to the paper due to

jamming, etc., the toner may adhere to the transfer charging roller. The printer removes the toner

from the transfer charging roller by switching the transfer voltage between positive and negative

in sequence. During wait, initial rotation, and last rotation, the printer sets the primary DC voltage

to zero, and sets the charge on the drum to zero. In this case, the transfer voltage is made

negative to remove the negatively-charged toner on the transfer charging roller to the drum. The

transfer charging roller is thus cleaned.

Step 5 Separation

Photo-

sensitive

drum

Paper

Static charge

eliminator

Transfer char

ging roller

Figure 2.14

The stiffness of the paper causes it to separate from the drum. (Curvature separation)

To stabilize the paper feed and prevent small white circles from appearing in the printed image

at low temperature and humidity, the charge on the back of the paper is reduced by the static

charge eliminator after transfer.

II - 9

Page 26

3.2.4 Fixing stage

The toner image transferred to the paper in the transfer stage is held only by electrostatic

attraction and slight physical adhesion, so even a light touch will smear the image.

In the fixing stage, the toner image is fixed by heating the paper and applying pressure. This

fuses the toner particles to the paper to make a permanent image.

Step 6 Fixing

The upper roller surface is PFA-coated. The upper and lower roller surfaces are grounded via

a diode to prevent the negative potential of the upper roller becoming higher than that of the

lower roller, resulting in the toner being drawn to the lower roller, and adhering to the lower roller

surface.

3.2.5 Drum cleaning stage

Halogen heater

Upper fixing roller

Toner

Paper

Lower fixing roller

Figure 2.15

In the transfer stage, not all the toner is transferred to the paper. Some remains on the

photosensitive drum. This residual toner is cleaned off in the drum cleaning stage so that the

next print image will be clear.

Step 7 Drum cleaning

Prior to the next printing, the residual toner on the drum surface is scraped away by the cleaning

blade to clean the drum surface. The removed toner is collected in the cleaner container.

Cleaning blade

Cleaner container

Photo-

sensitive

drum

Sweeper strip

Figure 2.16

II - 10

Page 27

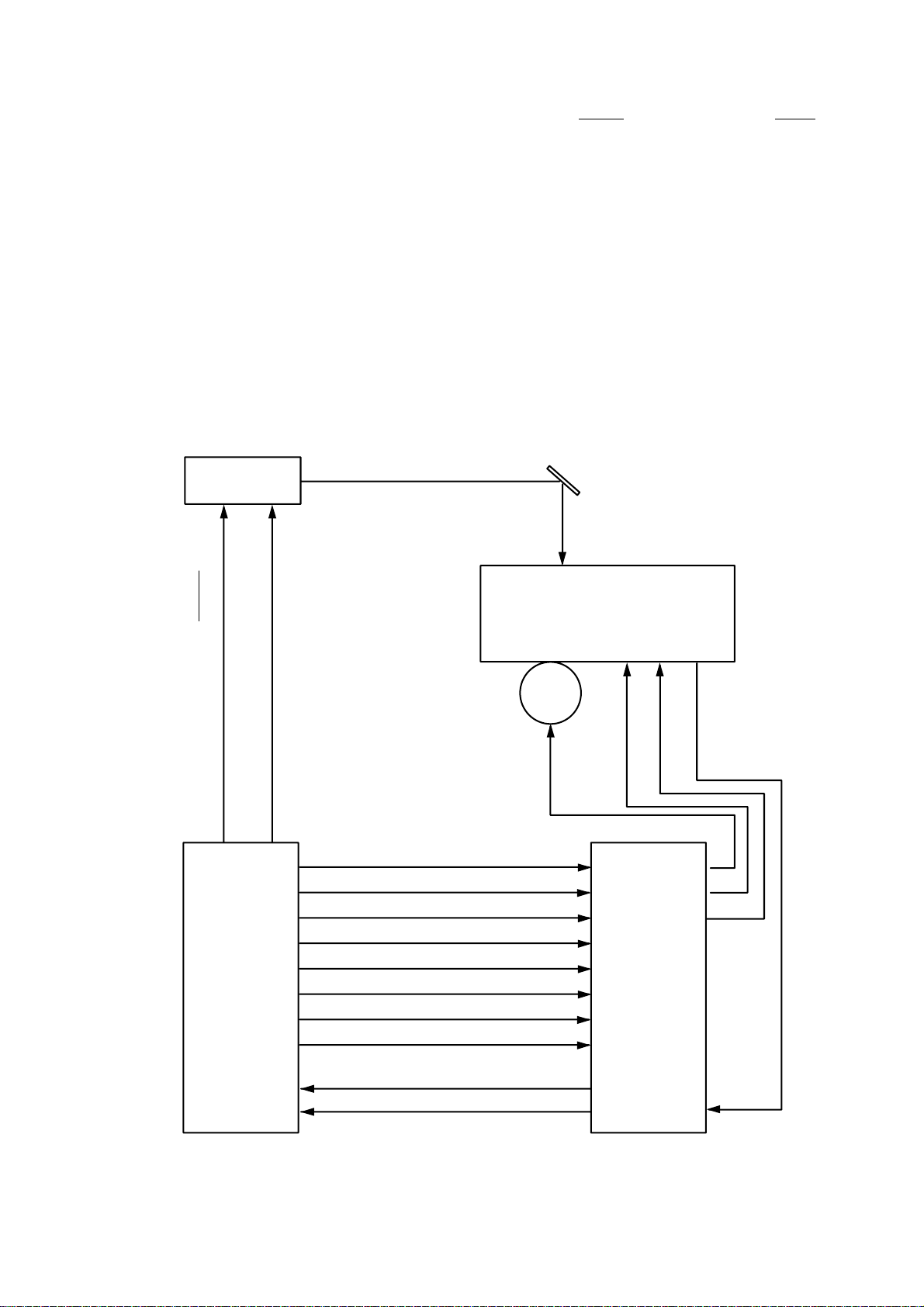

3.3 Operation

When the engine controller circuit receives a print signal (PRINT) or a pre-feed signal (PRFD)

from the video controller circuit, the engine controller circuit drives the main motor to rotate the

photosensitive drum.

After the drum surface is charged negatively by the primary charge roller, the laser beam

modulated by a DATA signal scans the drum surface to from a latent image on the drum.

The latent image formed on the drum surface is converted into a visible image by the toner on

the developing cylinder and then image is transferred onto the paper by the transfer roller unit.

Then the residual toner is removed from the drum surface with the cleaner blade.

The cartridge also has a toner sensor. When the output from this sensor falls below a certain

level, it warns that the EP-ED cartridge will be out of toner with an alarm.

Scanner unit

Reflection mirror

Laser beam

Laser diode drive signal (DATA)

Scanner motor drive signal (SDRIVE)

Primary charge (AC) drive (HV1AC)

Main

PCB

Primary charge (DC) drive (HV1DC)

Developing bias (AC) drive (DBAC)

Developing bias (DC) drive (DBDC)

Transfer charger 1 drive (HVT1)

Transfer charger 2 drive (HVT2)

Transfer charger 3 drive (HVT3)

Transfer charger 4 drive (HVT4)

EP-ED cartridge

Transfer

roller

High-voltage

power supply

PCB

Toner sensor signal 1 (TONER 1)

Toner sensor signal 2 (TONER 2)

Figure 2.17

II - 11

Page 28

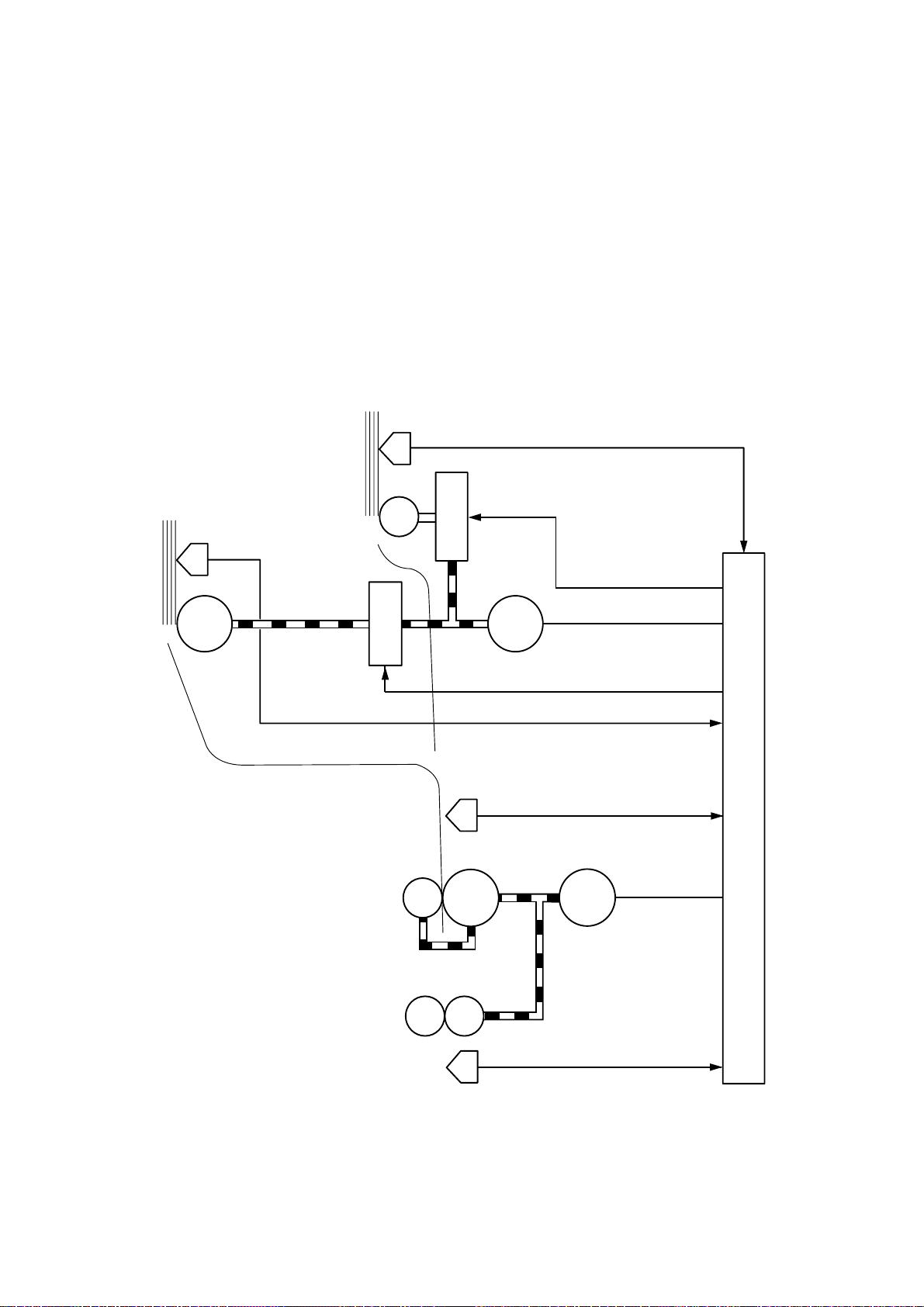

4. PAPER PICK-UP/FEED SYSTEM

4.1 Outline

If a tray1 paper pick-up roller solenoid drive signal (PUCL1) is input to the circuit while the paper

feed motor is rotating, the paper pick-up solenoid comes on and the paper pick-up roller solenoid

is engaged. As a result, the paper pick-up roller rotates to feed paper down to the photosensitive

drum.

The paper position is controlled by the registration sensor so that the leading edge of the paper

is aligned with the leading edge of the image on the photosensitive drum. After this operation,

the paper is deliveried to the face down tray via the fixing unit. Paper ejection is detected by the

paper ejection sensor; if printed paper has not reached or not cleared the paper ejection sensor

in a specified time, the printer judges that a paper jam has occurred. In this case a paper jam

is noticed to the external devise by a status signal.

MP tray

paper empty sensor

MP tray paper empty sensor signal (PEMP)

Tray paper

empty sensor

Tray1 Pick-up

roller solenoid

Transfer roller

MP tray Pick-up

roller solenoid

Tray1 pick-up roller solenoid drive signal (PUCL1)

Tray1 paper empty sensor signal (PETRAY1)

Registration

Photosensitive

MP tray pick-up roller

solenoid drive signal (MPSOL)

Paper feed motor drive signal

Paper-

feed

motor

Registration sensor signal (REGIST)

sensor

drum

Main motor drive

signal (MDRIVE)

Main motor

Main PCB

Fixing rollers

Paper ejection sensor

Figure 2.18

II - 12

Paper ejection sensor signal (EJECT)

Page 29

4.2 Cassette Feed

When the fixing rollers reach the specified temperature while a cassette with paper is in the

printer, the READY lamp changes from flashing to lighting.

When the engine controller circuit receives PRNT or PRFD signal from the video controller

circuit, the paper feed motor starts rotation. About 0.2 seconds later, the printer actuates the

tray1 pick-up roller solenoid and the pick-up roller makes one rotation. This feeds paper to the

photosensitive drum.

Timing chart for the pick-up one sheet

PRNT or PRFD

STBY PRINT STBY

Main motor

Paper empty

sensor

Paper feed

motor

Registration

sensor

Paper ejection

sensor

Pick-up roller

solenoid

0.2 sec

2.3 sec 4.24 sec

2.90 sec

0.2 sec

Figure 2.19

II - 13

Page 30

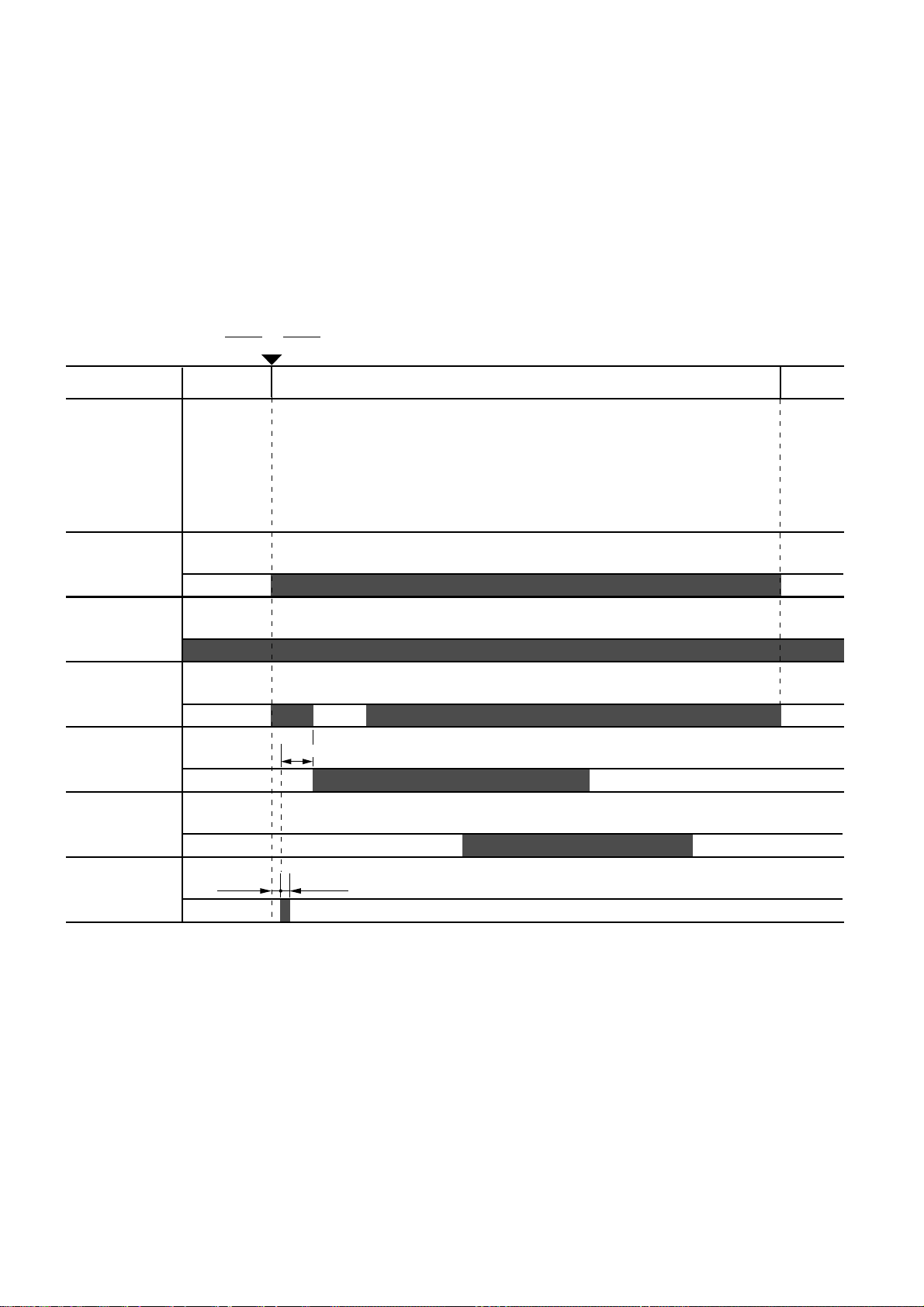

4.3 MP Tray Feed

The timing of the MP tray feed is identical to the timing of the cassette paper feed except for

the following points:

(1) The paper empty sensors are different.

Cassette feed : Tray1 paper empty sensor

MP tray feed

(2) The pick-up roller solenoids are different.

Cassette feed : Tray1 pick-up roller solenoid

MP tray feed

PRNT or PRFD

STBY PRINT STBY

: MP tray paper empty sensor

: MP tray pick-up roller solenoid

Main motor

Paper empty

sensor

Paper feed

motor

Registration

sensor

Paper ejection

sensor

Pick-up roller

solenoid

1.12 sec

0.2 sec 0.2 sec

Figure 2.20

II - 14

Page 31

4.4 Paper Jam Detection

The printer has a registration sensor and a paper eject sensor at the paper outlet to detect

whether the printed paper has been fed correctly. A paper jam is detected by whether the paper

is present at the sensor at the check periods programmed in the engine CPU memory. If the

engine CPU detects a paper jam, the main motor, paper feed motor and scanner motor is turned

off immediately and the jam status is transmitted to the video controller circuit.

A paper jam is detected in any of following conditions:

1) Paper exists at the paper ejection sensor or the registration sensor when power is

switched on. (JAM REAR or JAM INSIDE)

2) Paper has not reached the registration sensor within a specified time (JAM TRAYS).

3) Printed paper has not passed through the registration sensor within a specified time (JAM

INSIDE (1) ).

4) Printed paper has not reached the paper ejection sensor within a specified time (JAM

INSIDE (2) ).

5) Printed paper has not passed through the paper ejection sensor within a specified time

(JAM REAR).

Jam tray

STBY PRINT

Main motor

Pick-up

solenoid

Registration

sensor

Jam check

Main motor

Paper feed

motor

Jam inside (1)

STBY PRINT

5 sec5 sec

Figure 2.21

JamNormal

Registration

sensor

Jam check

Figure 2.22

II - 15

Normal

4.9 sec4.9 sec

Jam

Page 32

Jam inside (2)

Main motor

Paper feed

motor

Paper ejection

sensor

STBY PRINT

Jam check

Jam rear

Main motor

Paper feed

motor

Paper ejection

sensor

Figure 2.23

STBY PRINT

2.5 sec2.5 sec

JamNormal

9.56 sec

Jam check

9.56 sec

Figure 2.24

II - 16

JamNormal

Page 33

CHAPTER III ELECTRICAL SYSTEM

Electric signal levels are expressed by ”High” (approximate the supply voltage) or ”Low”

(approximate 0V). Signals with hyphen or slash, such as -FSRD or FSRD/, are low-active and

signals without hyphen or slash, such as FSRD, are high-active signals.

1. MAIN PCB

1.1 Outline

The Main PCB consists of the Video Controller Circuit and the Engine Controller Circuit.

The Video Controller Circuit performs the following functions.

(1) Converts data received from an external device, such as a personal computer, through

Centronics parallel interface or RS-232C serial interface into video data and transfers it

to the Engine controller circuit.

(2) Displays the current printer status in LED and LCD, and enables settings from the control

panel.

The operation sequence of the printer controlled by a microprocessor in the Engine Controller

Circuit. The Engine Controller Circuit outputs signals to drive the various loads on the laser

diode, scanner motor, main motor, etc. according to the print commands and image data from

the external device.

PC

PC

CDCC (bolse) IF

RS-232C IF

FONT

CARTRIDGE

IC CARD

(PCMCIA)

Video controller

ASIC

M65243FP

+24V

MIO BOARD

Engine controller

Regurator

MIO RELAY

(CONNECTOR)

PCB

Main PCB

Main CPU

79R3041

MASK ROM

16M mask 2 4MB

8M mask 2 2MB

DRAM

4M 4 2MB

DRAM (SIMM 3 slots)

24MBmax.

EEPROM

24CO4 4Kbit

ASIC

M65340FP (HRC/GSC)

Gate Array

µPD65626GF-176-3BA

(IO PORT. ENGINE)

Engine CPU

M38063

+24V

+5V

GND

CONTROL PANEL

Low-voltage

Power Supply

Figure 3.1 Main PCB Block Diagram

III - 1

Page 34

1.2 Video Controller Circuit

(1) CPU block

CPU(#26) IDT79R3041-20J manufactured by Integrated Device Technology

RISC chip

Clock speed: 19.6608 MHz

Appearance: 84-pin PLCC

(2) ASIC/Gate Array Block

• #32 M65243FP(Mitsubishi) - 208-pin QFP

Controls the address decoder, timers and interfaces (Centronics and RS-232C).

• #6 M65340FP(Mitsubishi) 80-pin QFP

Controls HRC(High Resolution Control), GSC(Gray Scale Control) and economy mode.

• #3 µPD65626GF-176-3BA(NEC) - 100-pin QFP

Controls the I/O ports and others.

(3) Font Cartridge/Card Block

• Font cartridge (option)

The font cartridge has a 32MB memory area and is controlled by the 16-bit bus.

The address bus a buffer LS244 and the data bus, a buffer LS245.

• Font Card (option)

The font card has a 32MB memory area and is controlled by the 16-bit bus.

The card is supplied with 12V power because the flash card requires 12V power supply when

writing or erasing data.

The address bus is buffered by LS244 and the data bus, is buffered by LS245.

(4) Centronics/RS-232C interface block

• Centronics parallel interface

Data transmission and reception are controlled by the M65243FP (#32).

• RS-232C

Data transmission and reception are controlled by the M65243FP (#32).

The ADM202JRN (#38) serves as driver/receiver.

(5) SIMM block

• SIMM (Single-Inline-Memory-Module) allows memory extension up to 26MB

• 3 SIMM sockets are available.

• SIMM should be of 72-pin type and its access time should be less than 70 ns.

• 4 types of SIMM (1MB, 2MB, 4MB and 8MB) can be combined:

1MB MH25632BJ-7 (MITSUBISHI), HB56D25632B-7A (HITACHI)

2MB MH51232BJ-7 (MITSUBISHI), HB56D51232B-7A (HITACHI)

4MB MH1M32EJ-7 (MITSUBISHI), HB56A132BT-7A (HITACHI)

8MB MH2M32EJ-7 (MITSUBISHI), HB56A232BT-7A (HITACHI)

1) The SIMMs have its printed marking on the PCB by silk screen: SLOT1, SLOT2 and

SLOT3, respectively. The SIMMs should be set in the order of SLOT1 - SLOT3.

2) SIMMs should be set in the order of its memory size and in the order of SLOT No.

Example: 3 SIMMs: 1MB, 2MB and 4MB

SLOT1 - 4MB

SLOT2 - 2MB

SLOT3 - 1MB

III - 2

Page 35

3) The attached Printer SIMM map shows the memory map for 4 SIMMs combined.

(6) ROM block

ROMs store the CPU control program and font data. ROMs are two 16Mbit masked ROMs and

two 8Mbit masked ROMs.

Optional sockets are available for two 8Mbit EPROM (µPD27C8000DZ-120 - NEC or equivalent) for expansion.

ROM access time should be less than 120nsec.

8Mbit EPROMs can be used instead of a 16Mbit masked ROM. To allow this substitution, the

soldering points SP5, SP6 and SP7 should be soldered and the cutting points CP2, CP3 and

CP4 should be cut.

(7) DRAM block

DRAMs are used for receiving buffer or working area of the CPU. The DRAM block contains

four 4Mbit DRAMs, thus having 2MB memory capacity in total.

The refreshing method is CBR (Cas Before Ras).

DRAM access time should be less than 80nsec.

III - 3

Page 36

0000_0000

0040_0000

0080_0000

0100_0000

0200_0000

ROM

(8MB)

Not used

(8MB)

Not used

(16MB)

0000_0000

0020_0000

0040_0000

0060_0000

0080_0000

Program ROM

(4MB)

Font ROM

(2MB)

Optional ROM

(2MB)

0400_0000

0600_0000

0800_0000

0B00_0000

0C00_0000

0E00_0000

0FC0_0000

0FD0_0000

(256MB)

MIO

(32MB)

Font card

(32MB)

Font cartridge

(32MB)

RAM

(MAX 48MB)

Not used

(16MB)

Peripheral I/O and

internal register

(32MB)

Not used

(approx. 32MB)

Boot ROM

0800_0000

0820_0000

09A0_0000

0B00_0000

0C00_0000

0C10_0000

0C20_0000

0C30_0000

0C40_0000

0C50_0000

0C60_0000

0C70_0000

0C80_0000

0C90_0000

0CA0_0000

0CB0_0000

0CC0_0000

0CD0_0000

0CE0_0000

Internal RAM

(2MB)

Expansion RAM

SIMM

(24MB max)

Not used

(22MB)

Inside M65243

µPD65626-176

Inside M65243

Inside M65243

Inside M65243

Inside M65243

M65340-0001FP

Not used

Not used

Inside M65243

Inside M65243

Inside M65243

Inside M65243

Not used

Figure 3.2 Memory map

III - 4

Page 37

ADDRESS

0820 0000

0830 0000

0840 0000

0850 0000

0860 0000

0870 0000

0880 0000

0890 0000

08A0 0000

123456789101112131415161718192021

NONE

1MB

2MB 2MB 2MB

1MB

1MB

1MB

2MB 2MB

1MB

1MB 1MB

4MB 4MB 4MB 4MB 4MB 4MB

8MB 8MB 8MB 8MB 8MB 8MB 8MB 8MB 8MB

2MB 2MB 2MB

1MB

4MB 4MB 4MB

1MB

2MB

08B0 0000

08C0 0000

08D0 0000

08E0 0000

08F0 0000

0900 0000

0910 0000

0920 0000

0930 0000

0940 0000

0950 0000

1MB

2MB

4MB

1MB

2MB 2MB

1MB

4MB 4MB 4MB

1MB

2MB

8MB 8MB 8MB 8MB

1MB

2MB

4MB

1MB

2MB

4MB

0960 0000

0970 0000

0980 0000

0990 0000

09A0 0000

8MB

Figure 3.3 SIMM map

III - 5

Page 38

DRAM block

SIMM block

Option I/F connector

ROM block

RS-232C serial I/F connector

Centronics parallel I/F connector

ASIC M65243FP

CPU(VIDEO)

C153

1

71

REV

8

7

72

C152

2

#21

C49

SLOT1

18

2

1

0P

P15

71

72

71

72

C151

SLOT2

C63C64

C62

2

1

1

R52R51 RA25 RA24

74F04

74F04

#20

R38

B48K158-3

C27

RA13 RA12 RA11

R17

C24

(25)

A25

B25

(50)

C150

SLOT3

2

74F04

C46C47

C61

GND VCC

CN4

12

C154

72

71

#41 #39

RA52

R88

1034

1034

RA44

PST591DMT

C143

C126

74ALS

C122

C116

74ALS

R92

R90

#42

R110

SP11

CP6

C121

R98

C113

C110

R89

#32

HM514800

HM514800

#30

HM514800

#27

CN3

C141

C120

14

1

ROM2H ROM1H

R121

R114

R120

R115

C140

R112

C139

R113

SP12

C123

C125

C127

R111

C124

ADM202JRN ADM202JRN

#36#37

42

(EVEN) (EVEN)

1

1

#35

42

1

#40

C112

C114

C109

#38

C98 C82

22

21

C91

42

1

C73

22

21 1

21 1

C90

42

SLOT4

R44

74LS244

RA15

CARTRIDGE

R29

C30

RA14

C65

R28

RA22

74LS244

R22

21

21

22

R50

C58

#26

#15

#16

R42

CP3

SP6

CP4

SP7

C32

C57

#25

R43

#14

SP5

CP2

21

22

#10

RA19

R123

74LS245 74LS245

C25

#6#7

ABCDEFGHJKL

0123456789

C13

94 96

M

R21

RA9

8MX6

SOLDER OUT

SP5

SP6

SP7

CP2

CP3

CP4

(1)

P5

A1

B1

(26)

LS08

#2

1

2

35

C2

36

HM514800

#22

2

1

74F04

#19

#17

C44

#11

74LS244

#12

R23

C29

RA18

RA10

C28

RA16

RA17

ROM0H

(EVEN)

C92

ROM0LROM1LROM2L

(ODD)(ODD)(ODD)

X24C04F

R3

CP1

LS74

25

13

19

P14

RS232C

RA39

1

CDCC

P13

RA55 RA54

R103

74F245D

74F245D

RA51

R106

RA48

RA45

RA42

#31

C106

Y1

RA58

RA57

RA56

C103 C101

49.3576MHz

RA41

42

RA53

R109

R97

RA50

RA49

#34

RA47

RA46

RA43

22 42

RA40

RA38

#29

C85

74F245D 74F245D

RA35

RA36RA34

RA33

C76

RA30 RA28

RA31 RA27

#23

C66

C16

(48)

C59

B16

22

(32)

A16

(16)

RA64

RA60

C142

C137

C138

R108

R107

R104

R102

104

105

C115

#33

C108

C104

R87

R84

156

R83

C96

157

R78

C95

R76

R73

C84

R64

SP8

R63

53

54

RA37 RA32

C78

C74

RA29

RA26

C70

74

75

#28

#24

R37

C42

R35

C43

C39

C38

C36

R34

1

80 65

64

C18

µPD65626

C6

R2

IC CARD

XT1

5.0MHZ

81

50

RA23

25

R24

40

C26

R20

R124

80

C12

R11

C9

51

RA21

RA20

SP4

C33

24

25

M65340FP

40

41

#8

R14

100

1

#4

C11

R10

#5

Q3

Q2

R4

R8

30

31

R7

R6 Q1

SP2

AN78N12

#3

13

C5

D1

C4

#1

C3

RA1

R1

SP1

P2

RA63

RA59

C134

C135

C136

C119

R69

R65

C68

#13

LS07

24

M38063E6FP

41

C23

C22

C21

C20

C19

C16

C15

C14

C10

R9

RA3

RA2

R119

C131

C132

C133

R105

C86

P8

C37

R19

R16

C17

RA4

P.FEED

P3

33

34

67

68

RA62

C130

R68

R3041

OPT IO

C45

C50

R30

R15

1

19

C1

RA61

C147

C148

C149

R118

C146

SP10

C118

M65243FP

C93C94

R67

R72

R62

C67

C41

R36

R33

R18

2

R13

2

1

C129

R75

D3

R32

L1

C7

+24B

+5B

20

+5V

+24V

C144

C145

/RESET

53

208

C89

R70

R71

33

R46

R41

R26

1

64

R79

D2

Q5R12

R100

C117

C87

R66

11

R45

R40

Q6

C128

1

R122

R116

R117

R99

52

R94

R86

R85

C97

R77

R74

32

C79 R57

R53

C71

12

#18

UPC

358

R39

Q14

80

#9

65

8

SP3

+24VRET

1

P1

SP9

C107

C88

R31

R27

C34

FLOCK

GND

GND

+24V

HEAT

Q4

R125

R59

R56

C75

C48

+5V

+5V

7

C105

C102

C99

C53

R25

C31

PANEL

C100

R55

36

18

CN2

1

R101

D7

CP5

R58

R48

C56

1

D8

R95

R93

R96

R91

C111

R81

Q18

Q19 Q17

3

D6

1

D4

4

C81

C83

R61

C80

R60

1

C77

4

C72

R54

C69

Q15

1

6

P9

(33)

C1

C60

(17)

2

B1

A1

(1)

4

R49

C55

R47

C54

C52

1

C51

15

C40

P6

H.VOL

C35

Q12

Q13 Q10

Q11 Q9

Q8 Q7

1

BZ1

3

CN1

RC

1

Y2

39.3216MHZ

R82

R80

Q16

FAN

P12(WHITE)

D5

(WHITE)

P11

FUSER

SCNMTR

P10

SCNLSR

1

(RED)

P7

MTR

16

2

CPU(ENGINE)

P4

POWER

C8

S1

20

21

Font cartridge connector

Control panel connector

Font card connector

ASIC µPD65626

ASIC M65340 FP

Figure 3.4 Main PCB

III - 6

Page 39

1.3 Engine Controller Circuit

Scanner Unit

Primary charging roller

Engine

Controller

Circuit

High-Voltage

Power Supply

Assy

Paper Feeder

PCB

Detectors

Main Motor

Low-Voltage

Power Supply

Assy

Transfer roller

Developing cylinder

Toner sensor

Pick-up Solenoid

MP Tray Pick-up Solenoid

Pick-up Motor

Fixing Unit

Figure 3.5 Engine Controller Block Diagram

Components in the Circuit (refer to the next page)

A. Engine Control CPU

B. Low-Voltage Power Supply Connector

C. Fuser Unit Control

C-1. Heater Drive Circuit

C-2. Heater Temperature Input Signal

C-3. Paper Eject Input Signal

D. Paper Feeder PCB Control Signals and Connector

E. Option Interface Circuit and Connector

F. High-Voltage Power Supply Control Circuit and Connector

G. Scanner Unit Control

G-1. Scanner Motor Control Circuit

G-2. Laser Diode Drive PCB Control Circuit

H. Fan Motor Drive Circuit

I. Main Motor Control Circuit

J. Cover Open Detect Circuit

K. Safety Door Switch Circuit

III - 7

Page 40

F

D

C-2

C-3

E

A

J

C

C-1

K

B

Figure 3.6 Main PCB Circuit

III - 8

I

H

G

G-1

G-2

Page 41

2. PAPER FEED DRIVE CIRCUIT

A. Connector to Main PCB

B. Pick-up Motor Drive Circuit and Connector

C. Pick-up Solenoid Drive Circuit and Connector

D. Multi Purpose Tray Pick-up Solenoid Drive Circuit and Connector

E. Sensors

E-1. Tray1 Paper Empty Sensor

E-2. Multi Purpose Tray Paper Empty Sensor

E-3. Regist Sensor

E-4. Pre-Regist Sensor

E-5. Paper Detect Sensor in Duplex Unit

F. Tray1 Paper Size Detect Switches

Refer to the next page.

III - 9

Page 42

F

B48K140-1

MT B

MT A

2

5

P1(FEED MOTOR)

#1

SW1

4

P1(SIZE)

MT D

MT C

6

1

8181117

OUTA

INA

SLA7027M

6175162

SW2

3

PSIZE1

+24VB

OUTB

OUTAN

INB

INAN

SW3

2

PSIZE2

+24VB

3

+24VB

VSSA

OUTBN

INBN

TDA

±0V

SW4

1

PSIZE3

PSIZE4

+24VB

4

C1

100µ-35V

+

C2

103

0V

12314415

VSSB

GNDA

GNDB

TDB

RSA

13910

5

0V

REFA

RSB

+5V

REFB

+24VRET

R10

MP-SOL

1

2

P4 (MP SOL)

R11

27

R12

82

±0V

1K

R6

1-1W

C5

222

R7

2.2K

R4

C4

222

2.2K

R5

1-1W

Q1

+24VRET+24VRET

DTC114ES

(* -02D) HLD

±0V

Q2

2SC5060

CA-SOL

1

2

P3 (CA SOL)

+24V +24V

+24V +24V

D

R15

4.7K

+24VRET

+24VRET

B

B48K139-1

P5(ENGINE)

796820

ABC

D

FE-MT

FE-MT

FE-MT

FE-MT

+5V

19

CA SOL

+5V

R2

3

PF-PE

MP SOL

470

PH2

R3

47K

R8

47K

E-1

±0V

±0V

R14

14

+5V

470

PH5

MP-PE

C3

C6

E-2

R1

±0V

±0V

471

471

+5V

5

REGIST

470

PH1

E-3

±0V

±0V

+5V

R13

470

13

PREREG

E-4

±0V

PH4

±0V

Q3

2SC5060

0V

C

R16

4.7K

PSIZE1

PSIZE2

PSIZE3

SIZE1

SIZE2

243

171516

SIZE3

PSIZE4

1

18

SIZE4

5

±0V 0V

F

HLD (* -05D)

+24VB

11410

HOLD

+24VB

+24VRET

+5V

12

+5V

+24VRET

±0V

1

0V

R9

2

+5V

DUPE

E-5

470

PH3

P2(SIZE)

±0V

±0V

Figure 3.7 Paper Feed/Size-SW PCB Circuit

A

III - 10

Page 43

3. DISPLAY CIRCUIT

3.1 Outline

The control panel of this printer has four LED lamps, one LCD display, and eight switches.

The control panel is connected to the Main PCB and its functions are as follows:

(1) The LCD shows the printer status and error message in alpha-numeric characters.

(2) The LED lamps indicate the operating conditions of the printer.

(3) The printing mode and LCD brightness can be changed by switches.

LCD

LED1

LED2

SW8 SW7 SW6 SW5 SW4 SW3 SW2 SW1

LED3

LED4

)

PAD4-PAD7

LED2 (READY)

3.2 Operation

Indicators on the control panel (LED lamps and LCD) are controlled by the video controller

circuit.

All the switch signals are input to the video controller circuit.

Signals Descriptions:

LED1 - LED4 On-off control for the respective LED lamps.

PAD4 - PAD7 LCD control signal.

LCDRS A signal to distinguish PAD4 - PAD7 into command and data.

LCDE A signal to start the operation.

SW1 - SW8 Input signals from the switches.

LED3 (DATA)

LED4 (ALARM)

FORM FEED

LCDE, LCDRS

LED1 (ONLINE)

SW8 (SEL)

Main PCB

SW7 (MODE)

SW6 (FONT)

SW5 (

Figure 3.8 Display Circuit

Illuminating when Low and extinguished when High.

Going Low when each switch is pressed.

SW4 (SET)

SW3 (CONTINUE)

SW2 (DOWN)

SW1 (UP)

III - 11

Page 44

4. LOW-VOLTAGE POWER SUPPLY ASSY

4.1 Outline

The low-voltage power supply assy consists of the low-voltage generating block (hereinafter the

DC block) and the heater drive circuit block to turn the heater on (hereinafter the AC block).

When the power switch (SW1) is turned on, AC power is supplied to the low-voltage power supply

assy.

The DC block generates +5 VDC, and +24 VDC.

When the heater is turned on, AC power is supplied to the AC block under control of the heater

on-off signal from the engine controller.

+24V output is reserved in the DC block, for the cooling fan for the low-voltage power supply

assy.

4.2 Protection Functions

Each of the power supply circuits, +5V, and +24V, has a protection function to prevent the circuit

from accident by automatically cutting off the power supply in the case of a over-voltage or overcurrent of the load.

When the cooling fan stops to rotating, an over-voltage protection or a short-circuit protection

function is activated, and all the DC power supplies are cutoff.

In this case check and clear the cause on the load after turning the power switch (SW1) off, and

then switch the power on again at least one minute after the power shut-down.

III - 12

Page 45

P3

HEAT/

1

+24V

4

Rectfier

Transformer

+5V

+5V

2

3

Chopper

±0V

+24VRET

6

5

±0V

7

Over

FANLOCK/

8

Voltage

Detector

Feedback Control

AC IN

H1TH1

Lamp

Thermal

Fuse

Heater

21

To Heater Circuit

P1

F101

L

Control

N

Inlet

F102

L

Rectfier

Noise

Filter

Power

Switch

N

(SW1)

Figure 3.9 Low-Voltage Power Supply PCB Block Diagram

III - 13

Page 46

5. HIGH-VOLTAGE POWER SUPPLY ASSY

5.1 Outline

The High-Voltage Power Supply Assy supplies the high-voltage for the charging roller, the

developer cylinder and the transfer roller according to the engine CPU’s control signals.

The block diagrams are shown Fig 3.10 and 3.11.

5.2 Operation of the Components of the High-Voltage Power Supply Assy

(1) Primary charging

When input signal/HV1AC gets the Low level, the primary high-voltage AC is applied to the

primary charging roller. And when input signal/HV1DC gets the Low level, the primary highvoltage DC is applied to the primary charging roller. The primary high-voltage DC changes with

developer bias DC according to values of the input signal DNSTY which is for print density

adjustment.

(2) Developer bias

When input signal/DBAC gets the Low level, the developer bias AC is applied to the developer

cylinder. And when input signal/DBDC gets the Low level, the developer bias DC is applied to

the developer cylinder. The developer bias DC changes according to values of the input signal

DNSTY which is for print density adjustment, like the primary high-voltage DC.

(3) Transfer charging

Transfer bias is controlled by the input signals HVT1 - 4 and HVTFB. When the input signal/

HVT1 gets the Low level, negative high-voltage is applied to the transfer roller. When the input

signal/HVT2 gets the Low level, positive high-voltage is applied to the transfer roller. When the