Page 1

FACSIMILE EQUIPMENT

SERVICE MANUAL

MODELS: MFC620CN

MFC420CN/410CN

MFC210C

FAX2440C

DCP310CN/110C

Confidential

Page 2

© Copyright B r other 2004-2005

All rights reserved.

No part of this publi c ati on may be reproduced i n any

form or by any means without perm ission in wri ting

from the publi sher.

Specifications are subject to change wit hout notice.

Confidential

Page 3

Preface

This Service Manual is intended for use by service personnel and details the specifications,

const ruction, t heory of operat ion, and ma intenance for the Brother machines noted on the front cover.

It includes information required for troubleshooting and service--disassembly, reassembly, and

lubrication--so that service personnel will be able to understand equipment function, repair the

equipment in a timely manner a nd order s pare parts as neces sary.

To per for m app rop ria te maint enance s o tha t the mac hine is alwa ys in the bes t poss ible condit ion for

the cus tomer, service personnel must adequa tely unders tand and apply this manual .

How this manual is organized

This ma nual is ma de u p of nine chap ters and ap pendices.

CHAPTER 1 PARTS NAMES AND FUNCTIONS

Conta ins ext erna l views and na mes of components and desc ribes their fu nctions . Infor mation abou t

the keys on the control p anel is included to help you check op erat ion or make adjustments.

CHAPTER 2 SPECIFICATIONS

List s the sp ecif ic ations of each model, which enab les you to make a c omparison of different models.

CHAPTER 3 THEORY OF OPERATION

Gives a n overview of the s canning a nd print ing mechanisms a s well as the sensor s, a ctua tors, and

control electronics. It aids in understanding the basic principles of operation as well as locating

defects f or troubl es hooting.

CHAPTER 4 TRANSFER OF DATA LEFT IN THE M ACHINE TO BE SE NT FOR REP AIR

Descr ib es how to t r a nsf er da ta left in t he machine to b e sent f or r epa ir . T he s ervic e per sonnel s hould

inst ru ct end u s er s t o f oll ow t he t r ans fer pr o cedu re giv en in thi s ch a p t er if t he mac hi ne a t t he u s er s i t e

cannot print received dat a due t o the print ing mechanism defective. End us ers ca n tr ansfer r eceived

data to another machine to prevent data loss.

CHAPTER 5 DISASSEMBLY/REASSEMBLY AND LUBRICATION

Deta ils pr ocedur es for disa ss embling a nd rea ssembling t he machine t ogether wit h rela ted notes . The

disassembly order flow provided enables you to see at a glance the quickest way to get to

component(s ) involved.

At the star t of a disa ssembly job, you check a disa ssembly order flow that guides you through a

shortcut to the ob ject components .

This chapter also covers screw tightening torques and lubrication points to which the specified

lubricants shou ld be app lied du ring reassembly job s.

CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS RE QUIRED AFTER P ARTS

REPLACEMENT

Deta ils a dju st ments a nd up da t ing of s ett ings , which a r e r equir ed if t he head/ ca r r i a ge unit, ma in PC B

and some other part s have been replac ed.

CHAPTER 7 CLEANING

Provides cleaning pr ocedures not covered by the User's Manu al. Before starting any repair work,

clean t he mac hine as it ma y solve the pr oblem concerned.

i Confidential

Page 4

CHAPTER 8 MAINTENANCE MODE

Describes the maintenance mode which is exclusively designed for the purpose of checks, settings

and adjustments using the keys on the control panel.

In the maintenance mode, you can update memory (EEPROM: electrically erasable programmable

read-only memory) contents for optimizing the drive conditions of the head/carriage unit, paper

feed roller or paper ejection roller (if they have been replaced) or for setting the CIS scanner area,

for example. You can also customize the EEPROM according to the shipment destination of the

machine concerned. In addition, you can perform operational checks of the LCD, control panel

PCB or sensors, perform a print test, display the log information or error codes, and modify

firmware switches (WSW).

CHAPTER 9 ERROR INDICATION AND TROUBLESHOOTING

Details error messages and codes that the incorporated self-diagnostic functions display if any error

or malfunction occurs. If any error message appears, refer to this chapter to find which components

should be checked or replaced.

The latter half of this chapter provides sample problems that could occur in the main sections of the

machine and related troubleshooting procedures. This will help service personnel pinpoint and

repair defective components.

Appendix 1 Serial Numbering System

Shows the location of serial number labels put on some parts and lists the coding information

pertaining to the serial numbers.

Appendix 2 Firmware Installation

Provides instructions on how to update firmware stored in the flash ROM on the main PCB or load

firmware to a new main PCB from the host PC.

No hardware replacement is required for updating.

Appendix 3 Customizing Codes According to Shipping Destination

Provides instructions on how to set up the customizing codes for the various preferences

exclusively designed for each destination (e.g. language). Those codes are stored in the memory

(EEPROM) mounted on the main PCB. If the main PCB is replaced, therefore, you need to set up

the proper customizing code with the machine in the maintenance mode.

Customizing codes customize firmware for individual models, enabling the common firmware to

be used for various models. They come with the firmware data provided by Brother Industries.

Appendix 4 Firmware Switches (WSW)

Describes the functions of the firmware switches, which can be divided into two groups: one is for

customizing preferences designed for the shipping destination (as described in Appendix 3) and the

other is for modifying preferences that match the machine to the environmental conditions. Use the

latter group if the machine malfunctions due to mismatching.

Appendix 5 Wiring Diagram

Provides the wiring diagram that helps you understand the connections between PCBs.

Appendix 6 Circuit Diagrams

Provides the circuit diagrams of the MJ PCB and power supply PCB.

ii Confidential

Page 5

Appendix 7 Viewing the Event Log File

When insta lling the p rint er dr iver, t he insta ller logs events tha t occur dur ing the inst alla tion pr ocess

in the event log file. T his ap pendix views a sample of t he event log file. Selecting S ta rt | P rogr am |

Brot her | MF L-Pro Suite model name | Inst allation Diagnostics rea ds out the event log file.

This manual describes the models and their versions destined for major countries. The specifications and

functions are subject to change depending upon each destination.

iii Confidential

Page 6

SAFETY PRECAUTIONS

To use the machine safely

Please refer to these instructions for later reference and before attempting any maintenance.

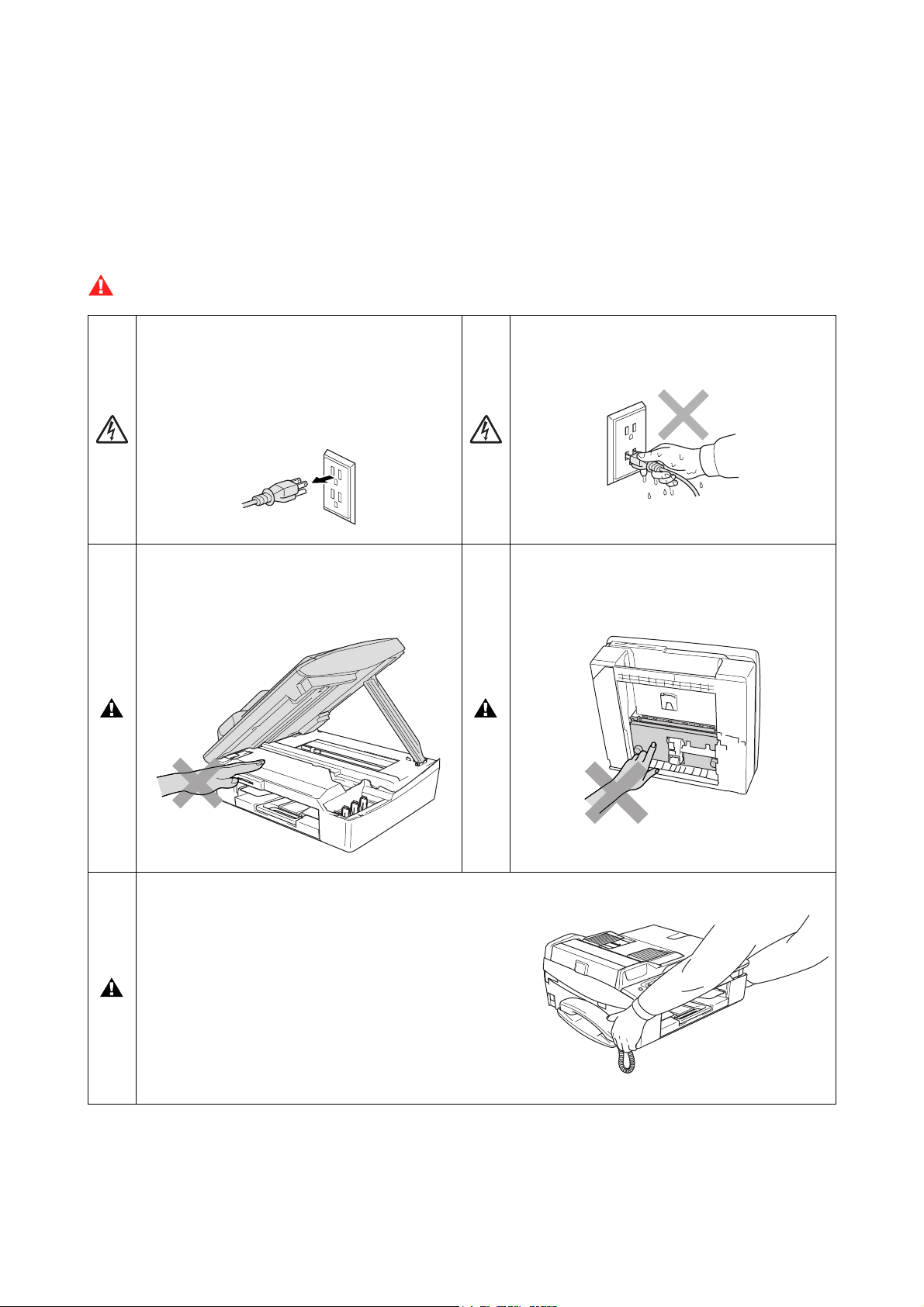

WARNING

There are high voltage electrodes inside the

machine. Before you clean the machine,

make sure you have unplugged t he

telephone line c or d fir st and then the power

cord from the AC power outlet .

To prevent injuries, be careful not to put your

hands on the edge of the machine under the

scanner cover.

Do not handle the plug with wet hands. Doing

this might cause an el ectr ic al shock.

To prevent injuries, be careful not to touch

the area shaded in the illustration.

When moving the machine you must lift it

from the base, by placing a hand at each side

of the unit as shown in the illustr ation. Do

NOT carry the machine by holding the

scanner cover.

iv Confidential

Page 7

WARNING

n Use caution when in stalling or modifyin g telephone line s. Neve r touch tele phone wi res o r termin als th at are

not insulated unless the telephone line has been disconnected at the wall jack. Never install telephone

wiring during a lightning storm. Never install a telephone wall jack in a wet location.

n This prod uct m ust be in stalled ne ar an A C powe r outlet that is e asily acc e ssible . In case of eme rgencie s, yo u

must disconnect the power cord from the AC power outlet in order to shut off power completely.

n To reduce the r isk of s hock or fire, use onl y a No. 26 AWG or larger telecommunication line cord.

Caution

n Lightning and power surges can damage this product! We recommend that you use a quality surge

protection device on the AC power line and on the telephone line, or unplug the cords during a lightning

storm.

n When lifting up the machine, hold it from the base. Holding the scanning cover (scanner unit) leaves the

machine body inclined, disengaging the scanner cover from the machine body or letting the machine body

fall.

IMPORTANT SAFETY INSTRUCTIONS

When using your telephone equipment, basic saf ety pr ec autions should always be followed to

reduce the risk of fi r e, electric shock and injury to persons, i ncluding the following:

1. Do not use this product near water, for example, near a bath tub, wash bowl, kitchen sink or

washing machine, in a wet basem ent or near a swimming pool.

2. Avoid using this product during an electrical storm . T her e m ay be a rem ote risk of elec tric shock

from lightning.

3. Do not use this product t o report a gas leak in t he vi ci nity of the leak.

4. Use only the power cord provi ded with the MFC.

SAVE THESE INSTRUCTIONS

v Confidential

Page 8

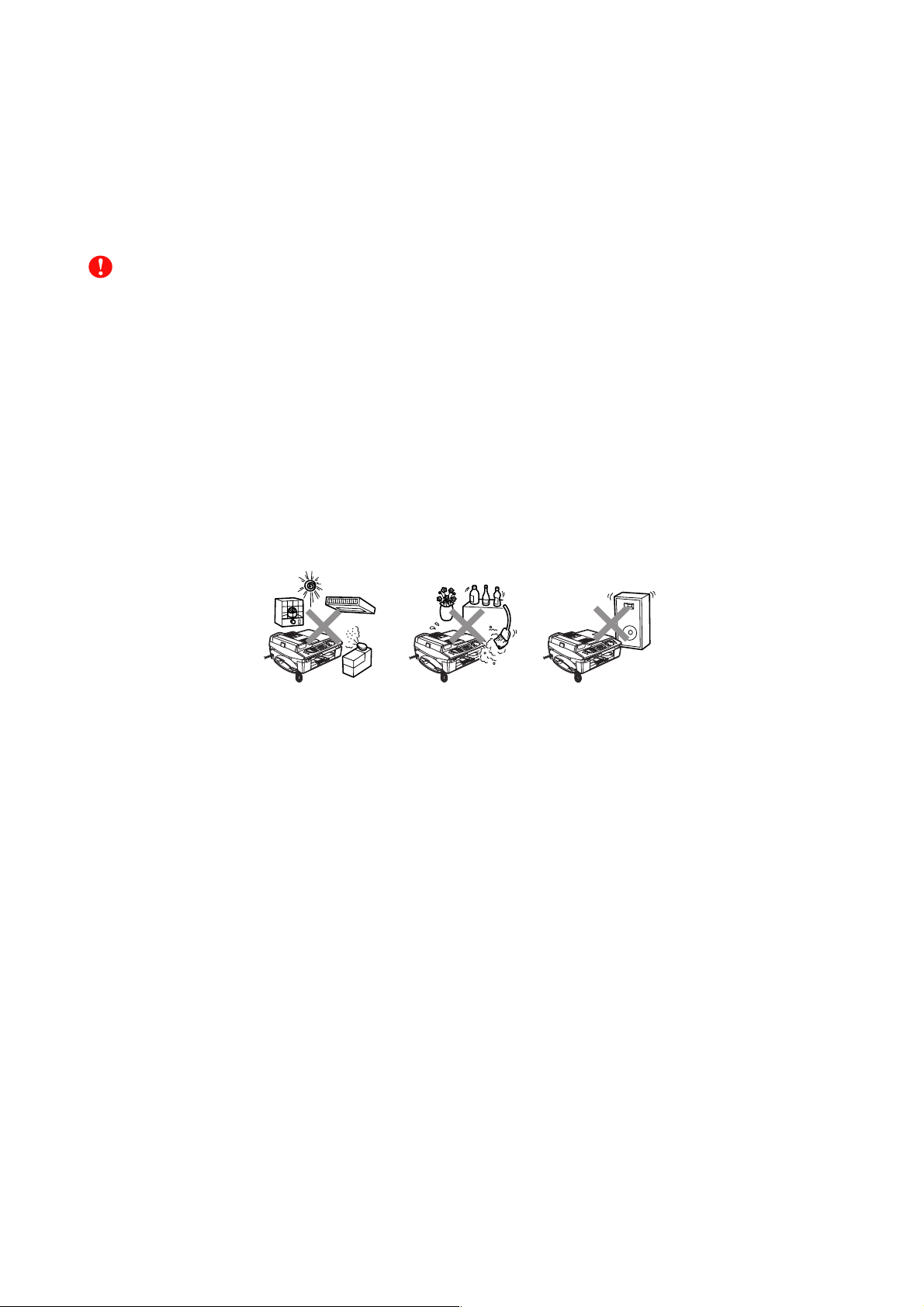

Choosing a location

Place your MFC on a flat, stable surface that is free of vibration and shocks, such as a desk. Put the MFC near

a telephone wall jack and a standard, grounded AC power outlet. Choose a location where the temperature

remains between 50°F and 95°F (10°C and 35°C).

Caution

n Avoid placing your MFC in a high-traffic area.

n Avoid placing your MFC on the carpet.

n Do not place near heaters, air conditioners, water, chemicals, or refrigerators.

n Do not expose the MFC to direct sunlight, excessive heat, moisture, or dust.

n Do not connect your MFC to electrical outlets controlled by wall switches or automatic timers.

n Disruption of power can wipe out information in the MFC’s memory.

n Do not connect your MFC to electrical outlets on the same circuit as large appliances or other equipment

that might disrupt the power supply.

n Avoid interference sources, such as speakers or the base units of cordless phones.

vi Confidential

Page 9

CHAPTER

PARTS NAMES & FUNCTIONS

Confidential

Page 10

CHAPTER 1 PARTS NAMES & FUNCTIONS

This chapter contains external views and names of components and describes their functions.

Information about the keys on the control panel is included to help you check operation or make

adjustments.

CONTENTS

1.1 OUTLINE .........................................................................................................................1-1

1.2 CONTROL PANEL .......................................................................................................... 1-3

1.3 COMPONENTS ............................................................................................................... 1-9

Confidential

Page 11

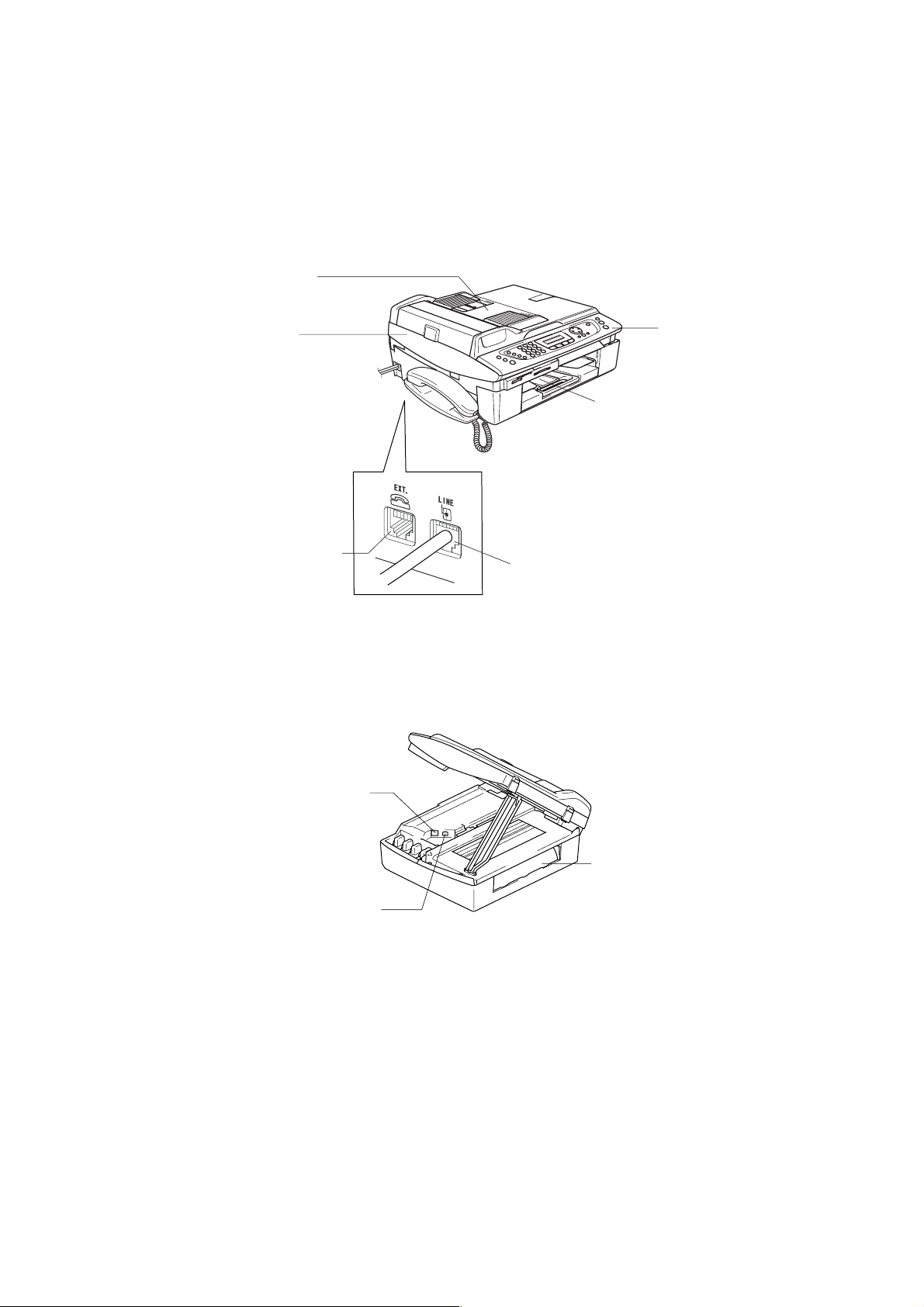

1.1 OUTLINE

Front view

(6) ADF & document

cover ASSY

(5) Scanner cover

(Scanner unit)

(4) External telephone line jack

Rear view

(1) Control panel

(2) Paper tray

(3) Telephone line jack

(8) LAN cable connector*

(7) USB interface connector

(9) Jam clear cover

*Provided on the MFC620CN/420CN/410CN and DCP310CN

1-1 Confidential

Page 12

No. Name Description

(1) Control panel

(2) Paper tray

Use the keys to operate the machine. The liquid crystal display

(LCD) shows the machine operation status.

Load paper here. Paper will be fed into the machine, sheet by

sheet.

(3) Telephone line jack Plug in the modular plug on the telephone line here.

(4) External telephone line jack Plug in the modular plug on the external telephone line here.

(5) Scanner cover (Scanner unit) Open to load ink cartridges or remove jammed paper.

ADF: Load documents (originals) here. Documents will be fed

ADF* & document cover ASSY

into the machine, page by page.

(6)

(*MFC620CN/420CN and FAX2440C)

Document cover: Open to place the document (original) on the

scanner glass.

(7) USB interface connector Connect the USB cable here.

LAN cable connector

(8)

(MFC620CN/420CN/410CN and

DCP310CN)

Connect the LAN cable here.

(9) Jam clear cover Open to remove paper jammed inside the machine.

1-2 Confidential

Page 13

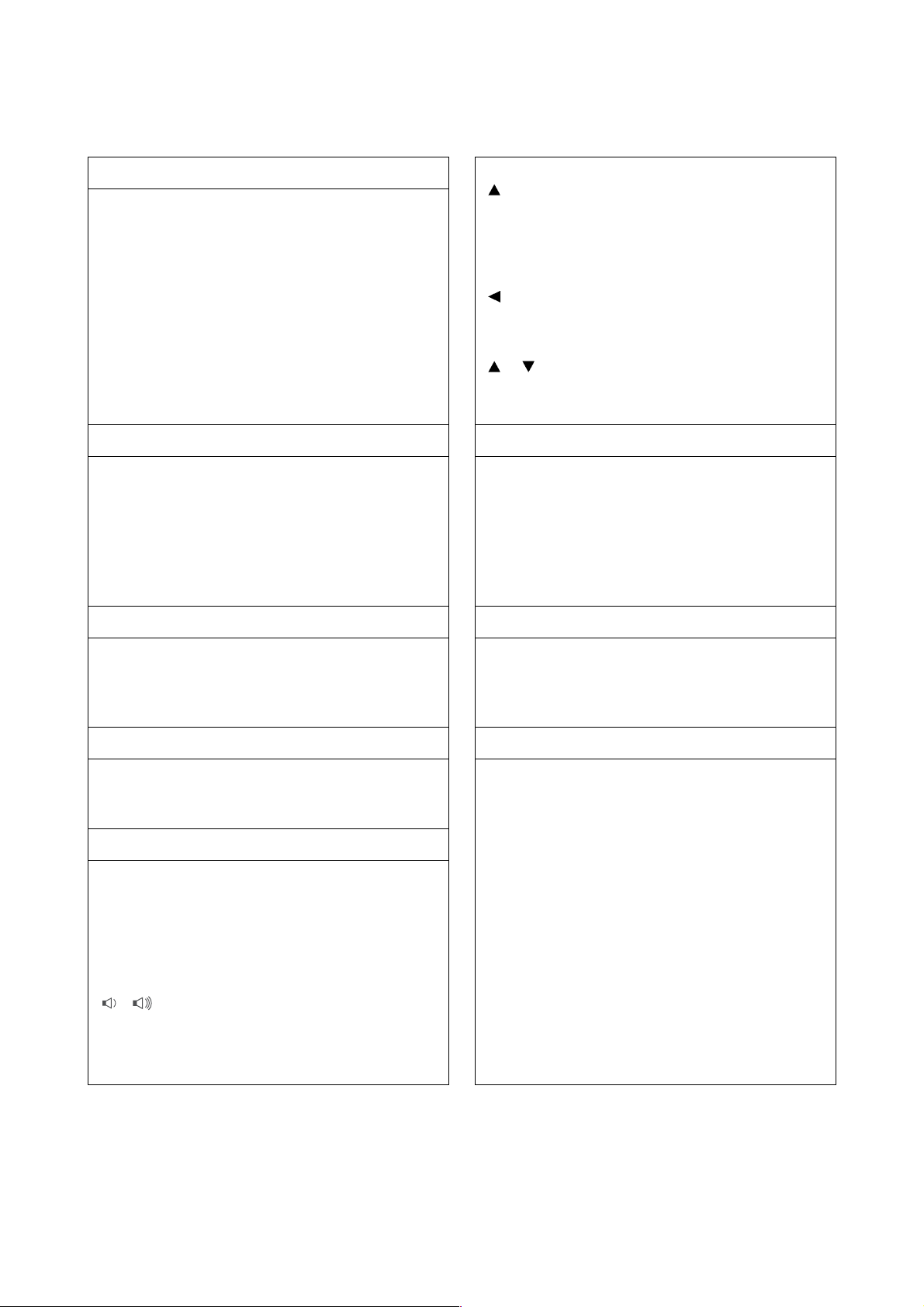

1.2 CONTROL PANEL

n MFC620CN

n FAX2440C

1-3 Confidential

Page 14

1. Message Center keys 3. Dial Pad

MC On/Off

Lets you activate the Message Center and will blink

if you have new messages.

Play/Record

Lets you listen to voice messages stored in memory.

Also, lets you record telephone calls.

Erase

Lets you delete voice messages, all fax messages or

all messages.

2. Telephone keys

Microphone

Picks up your voice when you speak to another party

using Speaker Phone.

Speaker Phone

Lets you speak to another party without lifting the

handset.

Use these keys to dial telephone and fax numbers

and as a keyboard for entering information into the

machine.

The # key lets you temporarily switch the dialing

mode during a telephone call from Pulse to Tone.

4. Mode keys

PhotoCapture (MFC620CN only)

Lets you access the PhotoCapture Center™ mode.

Copy

Lets you access Copy mode.

Fax

Lets you access Fax mode.

Scan (MFC620CN only)

Lets you access Scan mode.

Redial/Pause

Redials the last number you called. It also inserts a

pause in auto dial numbers.

Hold

Lets you place telephone calls on hold.

Ink

Lets you clean the print heads, check the print

quality, and check the available ink volume.

5. Copy Options

You can quickly and easily select temporary settings

for copying.

6. Fax Resolution

Adjusts the resolution when you send a fax.

1-4 Confidential

Page 15

7. Black Start

Lets you start sending faxes or making copies in

black and white.

Also for MFC620CN, lets you start a scanning

operation. (Color or mono, depending on the

scanning setting on your PC)

8. Color Start 12. Liquid Crystal Display (LCD)

Search/Speed Dial

Lets you look up numbers that are stored in the

dialing memory. It also lets you dial stored numbers

by pressing # and a two-digit number.

Press to scroll backward to a menu selection.

or

Press to scroll through the menus and options.

Lets you start sending faxes or making copies in full

color.

Also for MFC620CN, lets you start a scanning

operation. (Color or mono, depending on the

scanning setting on your PC)

Displays messages on the screen to help you set up

and use your machine.

The LCD examples are for models with a two-line

display. There may be slight differences between the

examples and models that have a one-line display.

9. Stop/Exit 13. One-Touch keys (FAX2440C only)

Stops an operation or exits from the menu. These keys give you instant access to previously

stored Quick-Dial numbers.

10. On/Off 14. Shift (FAX2440C only)

You can turn the machine on or off.

Lets you access memory locations 4 to 6 in the OneTouch keys.

11. Navigation keys

Menu/Set

The same key is used for Menu and Set operations.

Lets you access the Menu to program and store your

settings in the machine.

When using the speaker or during ringing in fax

mode, you can press these keys to adjust the volume.

1-5 Confidential

Page 16

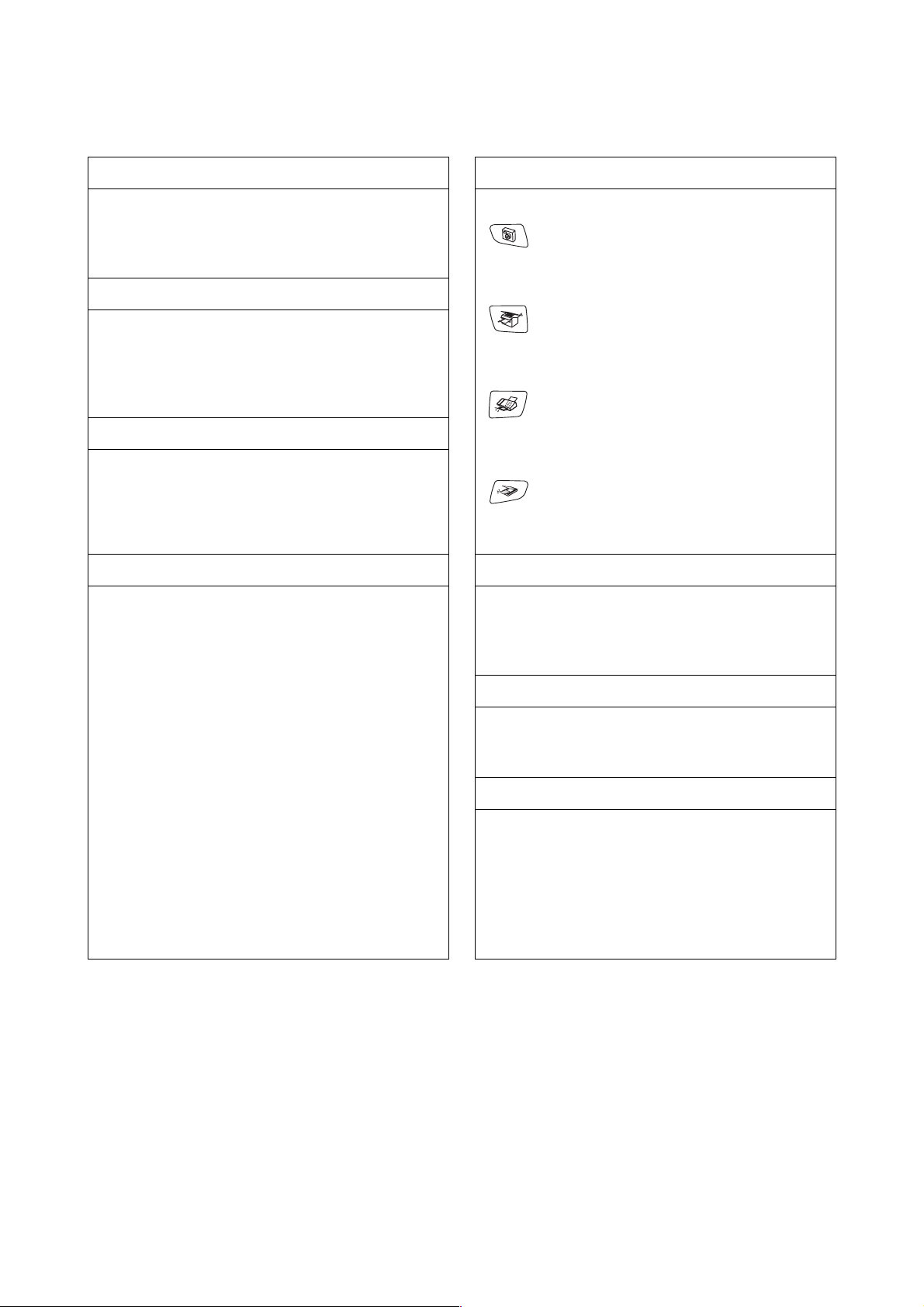

n MFC210C

1-6 Confidential

Page 17

1. Redial/Pause 5. Mode keys

Redials the last number you called. It also inserts a

pause in auto dial numbers.

2. Hook

Press before dialing if you want to make sure a

machine will answer, and then press Black Start or

Color Start.

3. Ink

Lets you clean the print heads, check the print

quality, and check the available ink volume.

4. Dial Pad 6. Copy Options

Use these keys to dial telephone or fax numbers and

as a keyboard for entering information into the MFC.

The # key lets you temporarily switch the dialing

mode during a telephone call from Pulse to Tone.

PhotoCapture

Lets you access the PhotoCapture Center™ mode.

Copy

Lets you access Copy mode.

Fax

Lets you access Fax mode.

Scan

Lets you access Scan mode.

You can quickly and easily select temporary settings

for copying.

7. Fax Resolution

Sets the resolution when you send a fax.

8. Black Start

Lets you start sending faxes or making copies in

black and white.

Also lets you start a scanning operation. (Color or

mono, depending on the scanning setting on your

PC)

1-7 Confidential

Page 18

9. Color Start 12. Liquid Crystal Display (LCD)

Lets you start sending faxes or making copies in full

color.

Also lets you start a scanning operation. (Color or

mono, depending on the scanning setting on your

PC)

10. Stop/Exit 13. On/Off

Stops an operation or exits from the menu.

11. Navigation keys

Menu/Set

The same key is used for Menu and Set operations.

Lets you access the Menu to program and store your

settings in the MFC.

When using the speaker or during ringing in fax

mode, you can press these keys to adjust the volume.

Displays messages on the screen to help you set up

and use your MFC. The LCD examples in this guide

are for models with a two-line display. There may be

slight differences between the examples provided

and models with a one-line display.

You can turn the MFC on or off.

Search/Speed Dial

Lets you look up numbers that are stored in the

dialing memory. It also lets you dial stored numbers

by pressing # and a two-digit number.

Press to scroll backward to a menu selection.

or

Press to scroll through the menus and options.

1-8 Confidential

Page 19

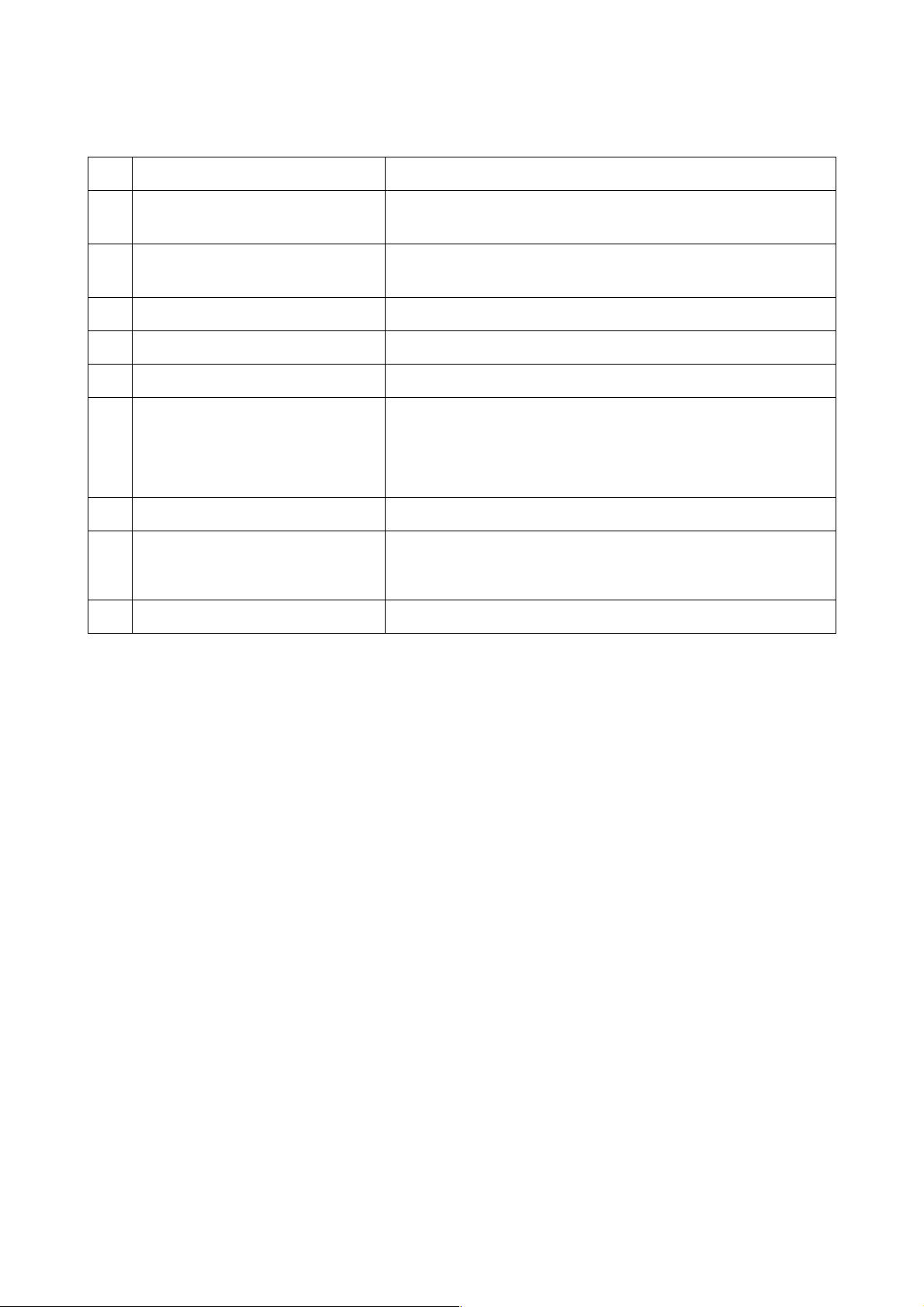

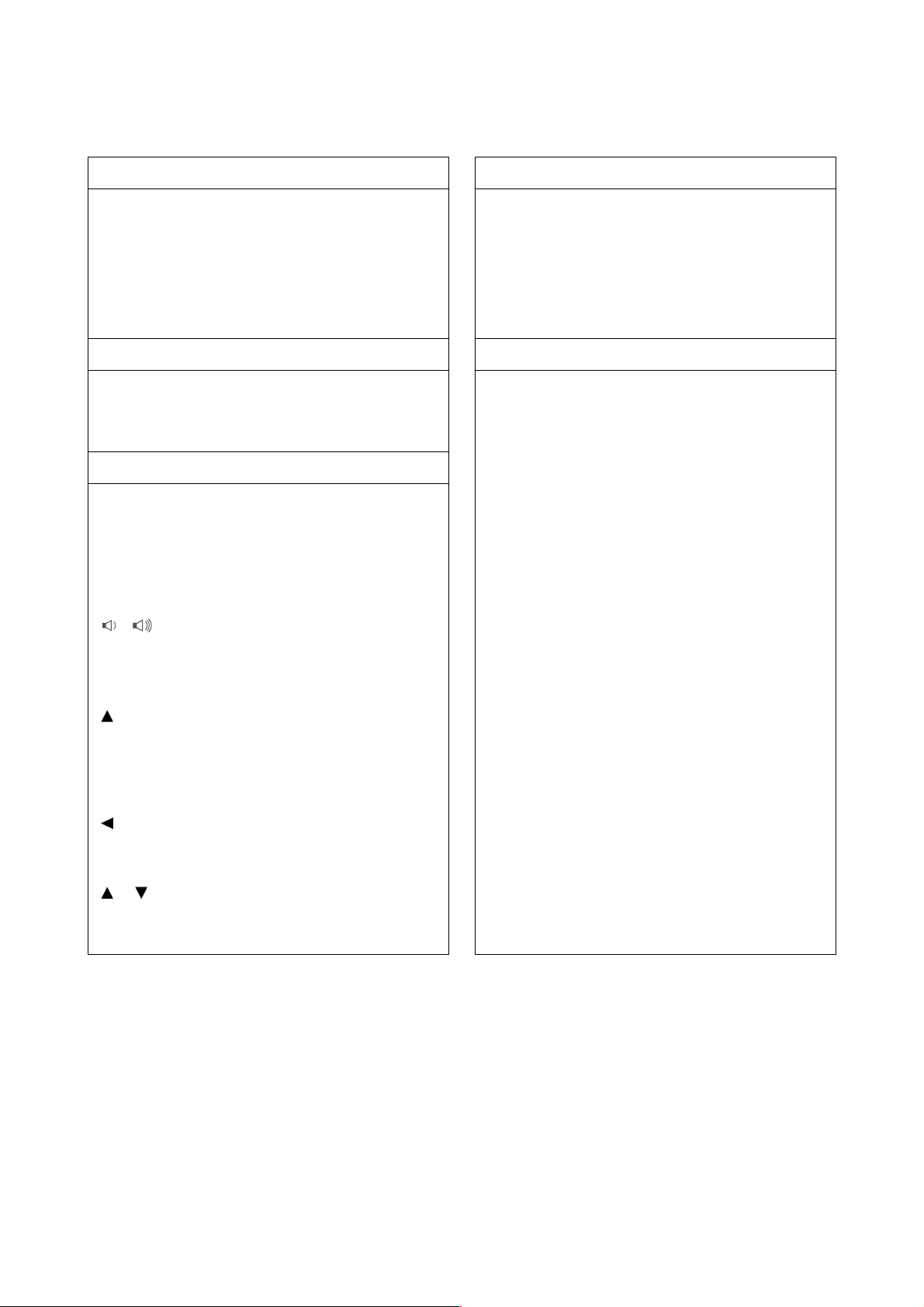

1.3 COMPONENTS

The machine consists of the following major components:

Scanner cover

(Scanner unit)

Scanner cover

damper

Scanner cover

stopper

Upper cover

Ink absorber box

Document cover***

ADF & document

cover ASSY**

Control panel

ASSY

Head/carriage unit

Maintenance unit

Engine unit

Ink refill

ASSY

Lower cover

Hook switch

PCB*

Handset

mount*

Handset*

MJ/PS shield

box

Power supply

PCB

* MFC620CN U.S.A./Canadian models and FAX2440C

** MFC620CN/420CN and FAX2440C

*** MFC410CN/210C and DCP310CN/110C

1-9 Confidential

Main PCB

ASSY

Paper tray

MJ PCB

Page 20

CHAPTER

SPECIFICATIONS

Confidential

Page 21

CHAPTER 2 SPECIFICATIONS

This chapter lists the specifications of each model, which enables you to make a comparison of

different models.

CONTENTS

2.1 GENERAL........................................................................................................................2-1

2.1.1 General Specifications.........................................................................................2-1

2.1.2 Paper Specifications............................................................................................2-3

2.1.3 Printable Area......................................................................................................2-6

2.2 SPECIFICATIONS LIST .................................................................................................. 2-7

Confidential

Page 22

2.1 GENERAL

2.1.1 General Specifications

Memory Capacity

MFC620CN:

Automatic Document Feeder (ADF) Up to 10 sheets

MFC620CN/420CN and FAX2440C only)

(

Paper Tray 100 sheets (20 lb.)

Printer Type Ink Jet

Print Method Piezo with 74 nozzles for each of three colors + a pair of 74 nozzles

Liquid Crystal Display (LCD)

MFC620CN:

Operating Environment 50 to 95°F (10 to 35°C)

Best Print Quality 68 to 91°F (20 to 33°C)

Power Source 100 to 120 VAC, 50/60 Hz (U.S.A./Canada)

Power Consumption

MFC620CN U.S.A./Canadian models:

MFC620CN European/Asian models: Minimum: under 4.0 Wh

16 MB

for black

16 characters x 2 lines

230 VAC, 50/60 Hz (Europe/Asia)

Minimum: under 3.5 Wh

Standby: 9.5 Wh or less (25°C)

Peak: 27 Wh or less

Standby: 9.5 Wh or less (25°C)

Peak: 26 Wh or less

2-1 Confidential

Page 23

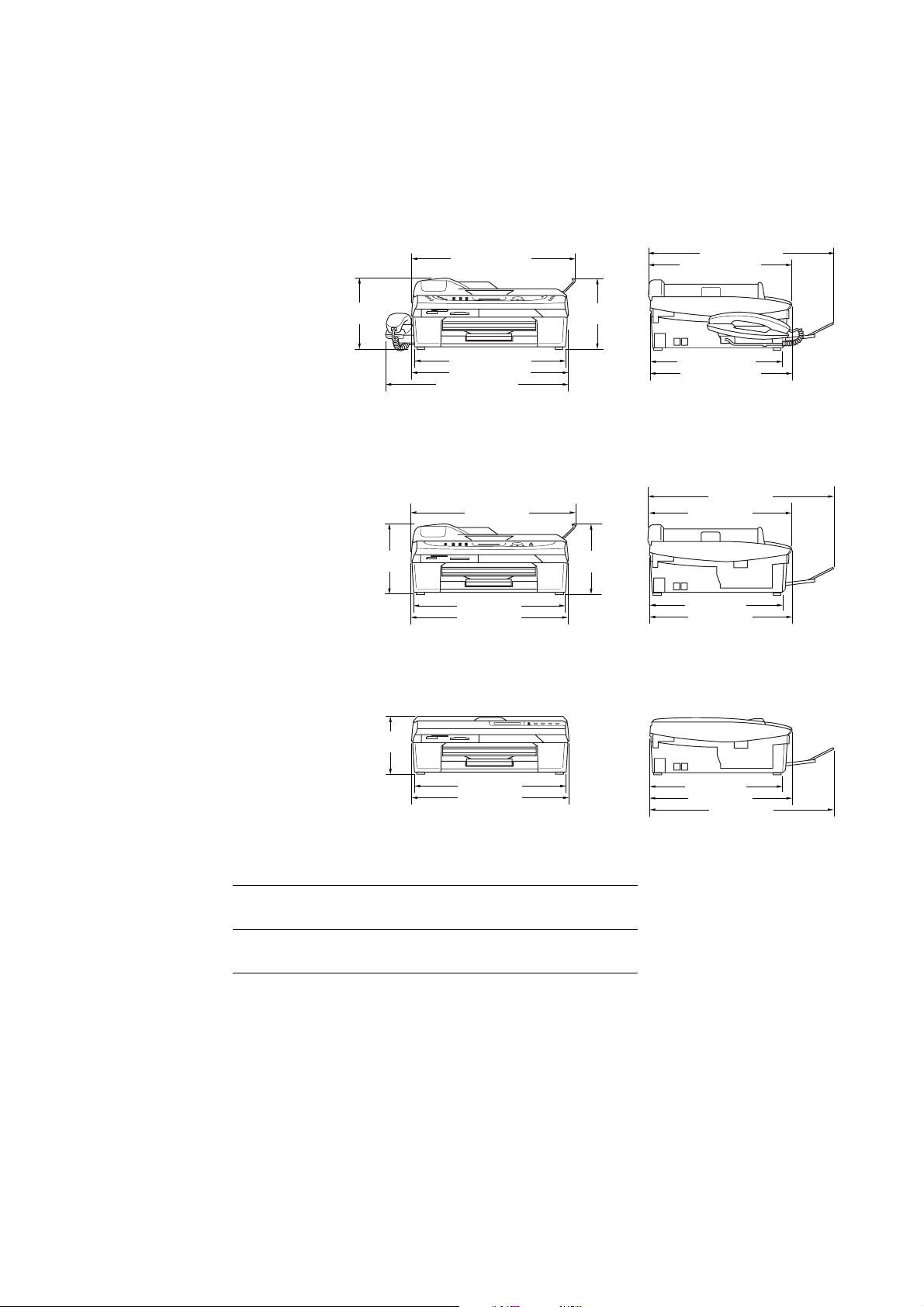

Dimensions (W x D x H)

MFC620CN U.S.A./Canadian models and FAX2440C:

17.3 x 13.7 x 6.5 inches (438 x 347 x 165 mm)

(with paper tray and document 17.9 x 17.9 x 6.5 inches (454 x 455 x 165 mm)

stopper opened)

14.8" (375 mm)

17.9" (455 mm)

13.7" (347 mm)

6.5"

(165 mm)

MFC620CN European/Asian models and MFC420CN:

14.7 x 13.6 x 6.5 inches (373 x 345 x 165 mm)

(with paper tray and document 14.8 x 17.9 x 6.9 inches (375 x 455 x 174 mm)

stopper opened)

6.5"

(165 mm)

MFC210C and DCP310CN/110C:

14.7 x 13.6 x 5.3 inches (373 x 345 x 135 mm)

(with paper tray opened) 14.7 x 17.8 x 5.3 inches (373 x 453 x 135 mm)

5.3"

(135 mm)

14.2" (361 mm)

14.7" (373 mm)

17.3" (438 mm)

14.8" (375 mm)

14.2" (361 mm)

14.7" (373 mm)

6.9"

(174 mm)

6.9"

(174 mm)

12.7" (322 mm)

13.6" (345 mm)

17.9" (455 mm)

13.7" (347 mm)

12.7" (322 mm)

13.6" (345 mm)

Weight

MFC620CN:

14.2" (361 mm)

14.7" (373 mm)

(Machine proper) 13.4 lb. (6.1 kg) U.S.A./Canadian models

13.2 lb. (6 kg) European/Asian models

(In package)

17.6 lb. (8 kg) U.S.A./Canadian models

18.9 lb. (8.6 kg) European/Asian models

2-2 Confidential

12.7" (322 mm)

13.6" (345 mm)

17.8" (453 mm)

Page 24

2.1.2 Paper Specifications

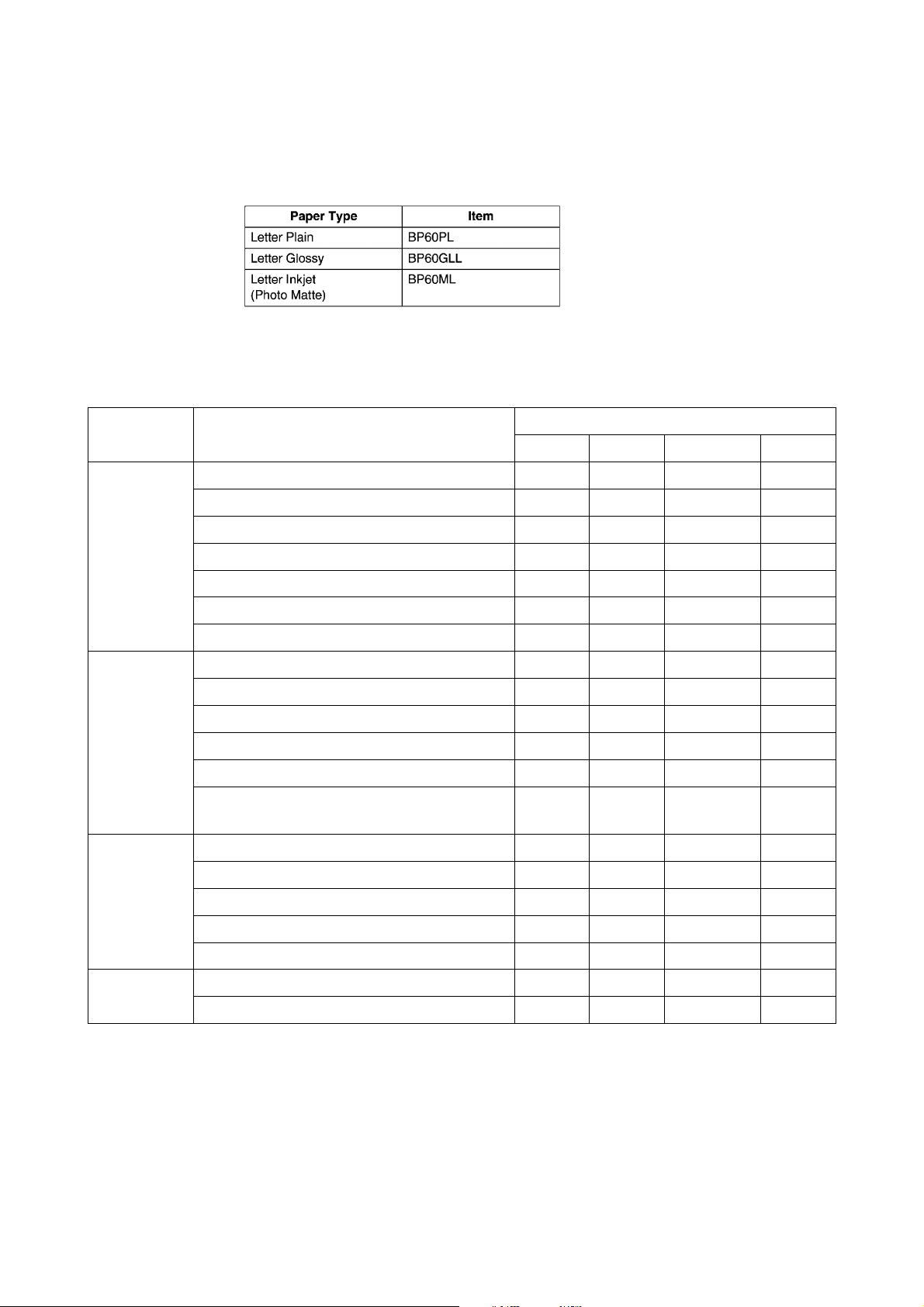

Recommended Paper

Brother Paper

Transparencies: 3M Transparency Film

Paper Type and Size for Each Operation

Paper Type Paper Size

Fax Copy PhotoCapture Printer

Cut Sheet Letter 8 1/2" x 11" (216 x 279 mm) Yes Yes Yes Yes

A4 8.3" x 11.7" (210 x 297 mm) Yes Yes Yes Yes

Legal 8 1/2" x 14" (216 x 356 mm) Yes Yes - Yes

Executive 7 1/4" x 10 1/2" (184 x 267 mm) - - - Yes

JIS B5 7.2" x 10.1" (182 x 257 mm) - - - Yes

A5 5.8" x 8.3" (148 x 210 mm) - Yes - Yes

A6 4.1" x 5.8" (105 x 148 mm) - - - Yes

Cards Photo 4" x 6" (102 x 152 mm) - Yes Yes Yes

Photo L 3 1/2" x 5" (89 x 127 mm) - - - Yes

Photo 2L 5" x 7" (127 x 178 mm) - - Yes Yes

Index Card 5" x 8" (127 x 203 mm) - - - Yes

Post Card 1 3.9" x 5.8" (100 x 148 mm) - - - Yes

Post Card 2

(Double)

Envelopes C5 Envelope 6.4" x 9" (162 x 229 mm) - - - Yes

5.8" x 7.9" (148 x 200 mm) - - - Yes

Usage

DL Envelope 4.3" x 8.7" (110 x 220 mm) - - - Yes

COM-10 4 1/8" x 9 1/2" (105 x 241 mm) - - - Yes

Monarch 3 7/8" x 7 1/2" (98 x 191 mm) - - - Yes

JE4 Envelope 4.1" x 9.3" (105 x 235 mm) - - - Yes

Transparencies Letter 8 1/2" x 11" (216 x 279 mm) - Yes - Yes

A4 8.3" x 11.7" (210 x 297 mm) - Yes - Yes

2-3 Confidential

Page 25

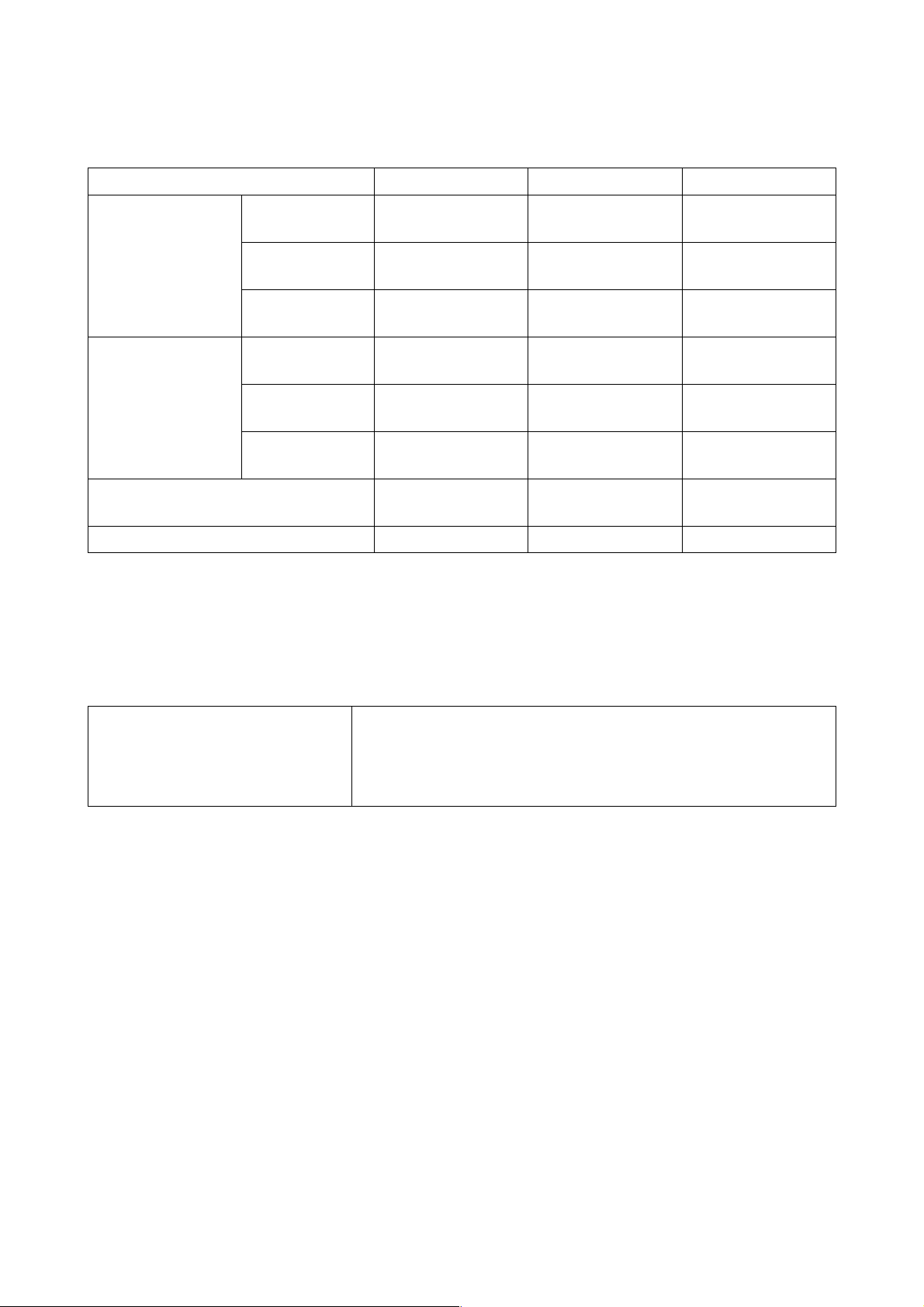

Paper Weight, Thickness and Capacity

Paper Type Weight Thickness No. of sheets

Cut Sheet Plain Paper 17 to 32 lb

(64 to 120 g/m

Inkjet Paper 17 to 53 lb

(64 to 200 g/m

Glossy Paper Up to 58 lb

(Up to 220 g/m

Cards Photo Card Up to 64 lb

(Up to 240 g/m

Index Card Up to 32 lb

(Up to 120 g/m

Post Card Up to 53 lb

(Up to 200 g/m

2

)

2

)

2

2

2

2

0.003" to 0.006"

(0.08 to 0.15 mm)

0.003" to 0.01"

(0.08 to 0.25 mm)

Up to 0.01"

)

(Up to 0.25 mm)

Up to 0.01"

)

(Up to 0.28 mm)

Up to 0.006"

)

(Up to 0.15 mm)

Up to 0.01"

)

(Up to 0.23 mm)

Envelopes - Up to 0.02"

(Up to 0.52 mm)

Transparencies - - 10

* Up to 50 sheets for Legal size paper (20 lb).

* Up to 100 sheets of 20 lb.

100

20

20

20

30

30

10

Paper Capacity of the Output Paper Support

Output Paper Support Up to 25 sheets of 20 lb (Letter)

n Transparencies or glossy paper must be picked up from the

output paper support one page at a time to avoid smudging.

n Legal paper cannot be stacked on the output paper support.

2-4 Confidential

Page 26

Do not use paper or envelopes:

n that are damaged, curled, wrinkled, or irregularly shaped

0.04 in.

or longer

0.04 in.

or longer

n that are extremely shiny or highly textured

n that were previously printed by a printer

n that cannot be arranged uniformly when stacked

n that are made with a short grain

Do not use envelopes:

n that are of a baggy construction

n that are embossed (have raised writing on them)

n that have clasps on them

n that are not sharply creased

n that are preprinted on the inside

2-5 Confidential

Page 27

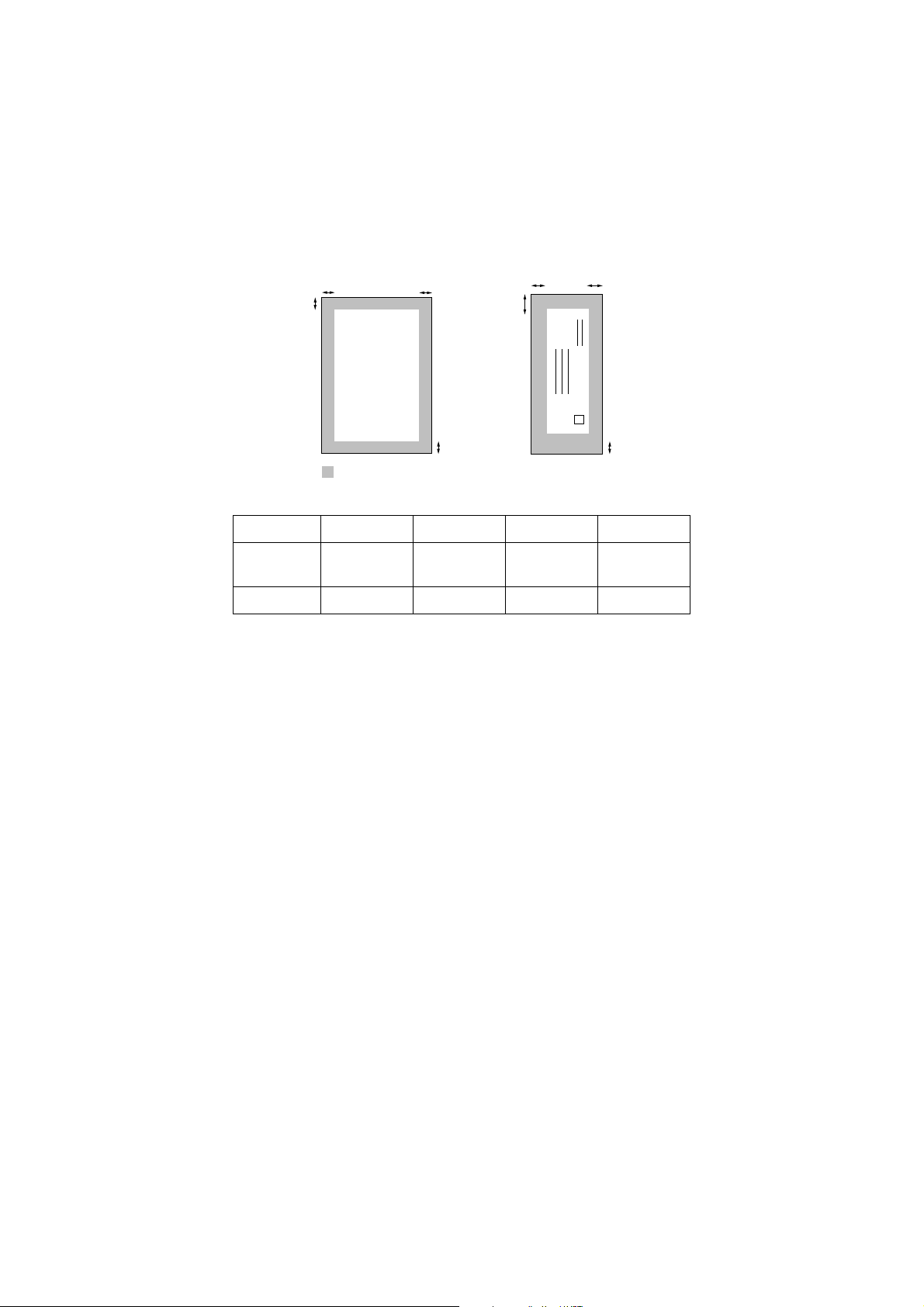

2.1.3 Printable Area

The printable area depends on the settings in the application you are using. The figures below show the

unprintable areas on cut sheet paper and envelopes.

Cut Sheet Paper Envelopes

(3) (4)

(1) (1)

(2) (2)

unprintable area

Paper (1) Top (2) Bottom (3) Left (4) Right

(3) (4)

Cut sheet

Envelopes 0.47 in. 0.94 in. 0.12 in. 0.12 in.

0.12 in.

(0 in.)*

0.12 in.

(0 in.)*

0.12 in.

(0 in.)*

0.12 in.

(0 in.)*

* When you set the Borderless feature to On.

Printable area depends on the Printer driver settings.

The figures above are approximate and the printable area may

vary depending on the type of cut sheet paper you are using.

2-6 Confidential

Page 28

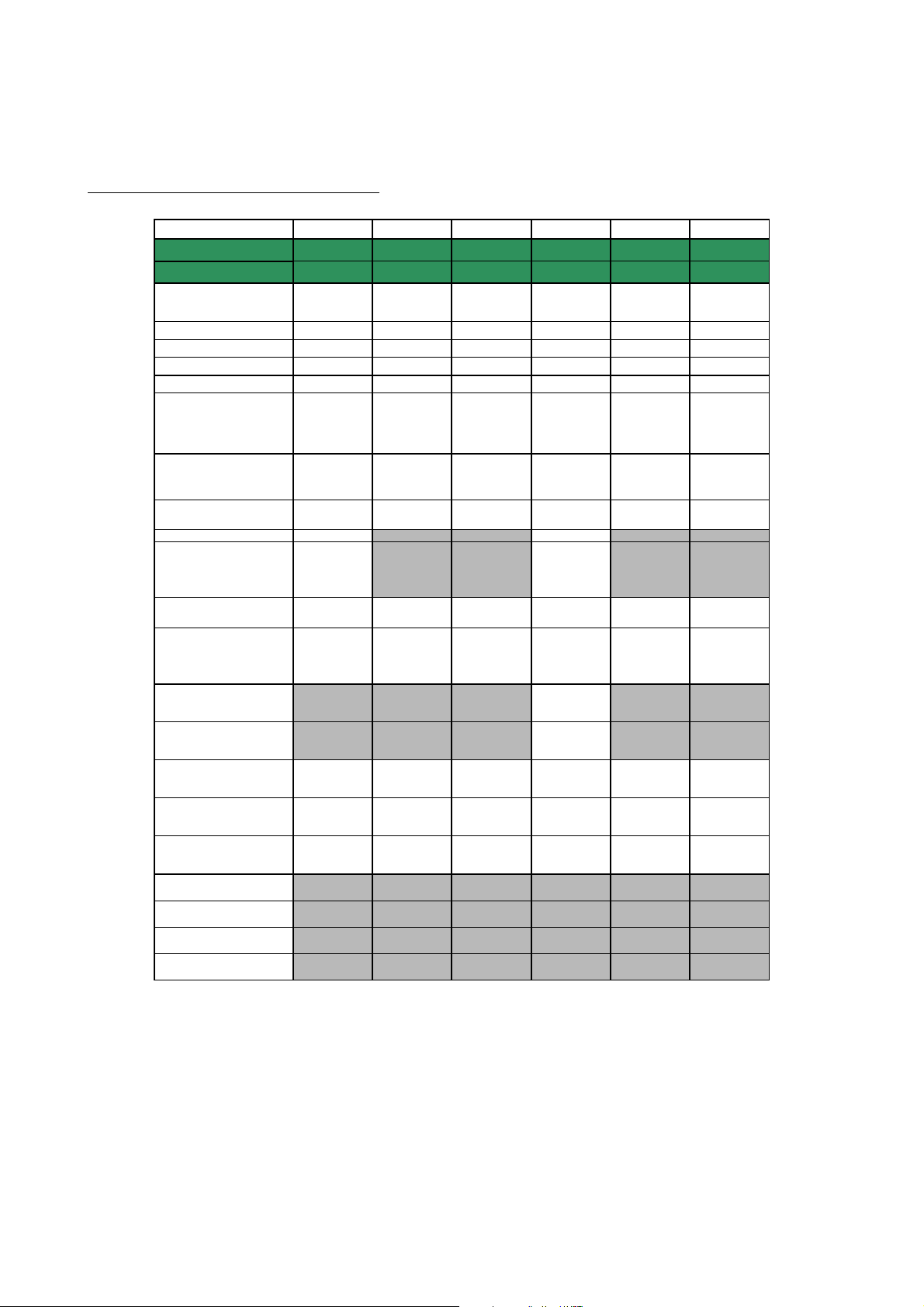

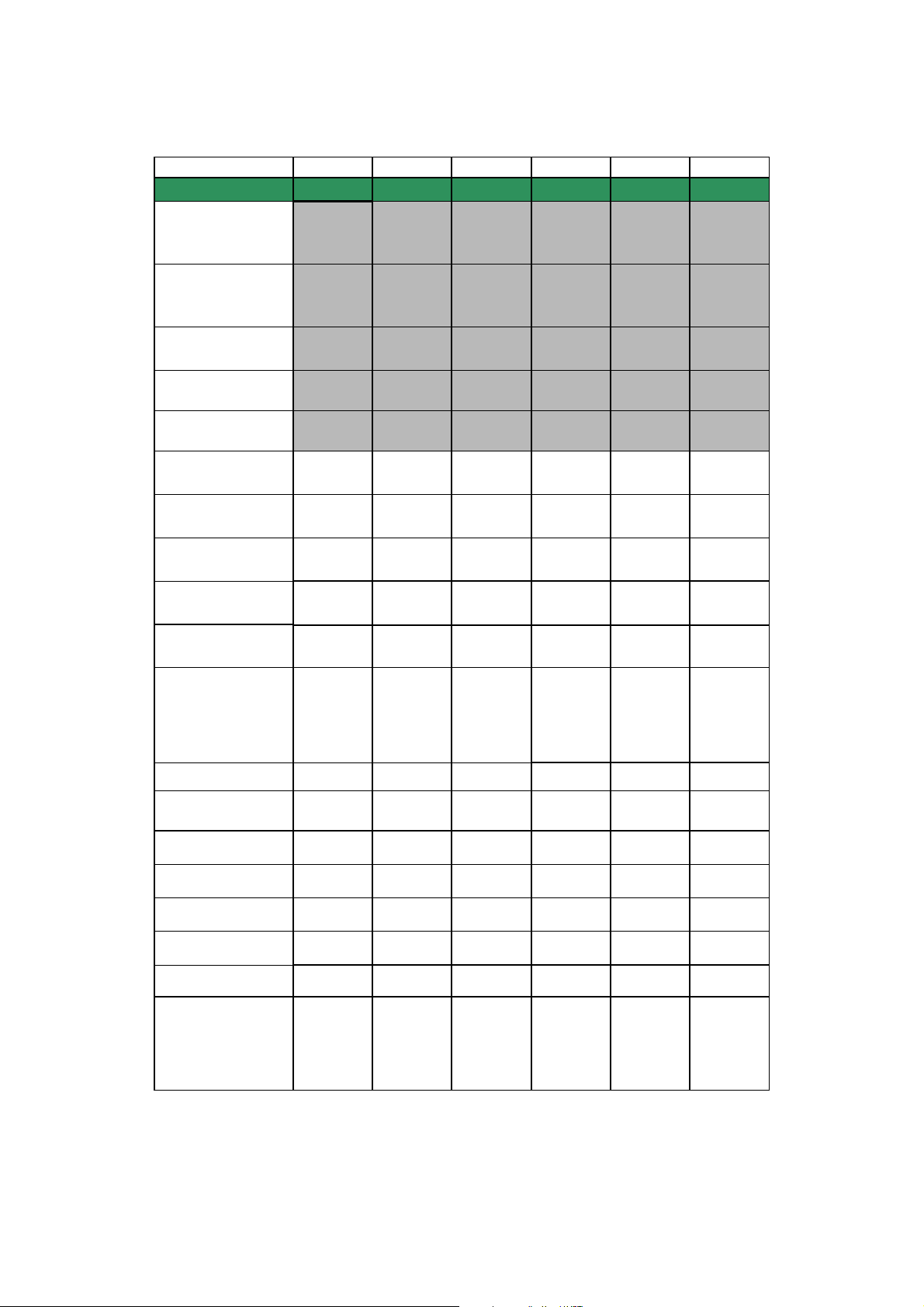

2.2 SPECIFICATIONS LIST

(

)

(

)

(

)

(

)

p

p

MFC210C/MFC420CN/MFC410CN

USA EUR ASIA/OCE/C H N USA EUR ASIA/OCE/CHN

Model name

GENERAL

Print Engine

Technology

Scanning Method

CPU Speed

Back up Clock

Operating Environment

Temperature

(BestPrintQu a lity)

Humidity

On/Off Switch

Demo Model

Panel Key for demo sheet

Simultaneous Operation

Test Sheet

Min. Input of ADF

( Width/Height)

Max. Input of ADF

( Width/Height)

Max. Input of Glass

( Width/Height)

Min. Output of Auto Cut

sheet

Feeder

Width/Height

Max. Output o f Au to C ut

sheet

Feeder

Width/Height

Min. Output of Manual

Feed Slot

Width/Height

Max. Output of Manual

Feed Slot

Width/Height

Min. Output of Multi-

ose

Pur

Max. Output of Multi-

ose

Pur

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

BH3 (KKCMY)

74 nozzles/line

Inkjet Inkjet Inkjet Inkjet Inkjet Inkjet

CISCISCISCISCISCIS

RISC 128MHz RISC 128MHz RISC 128MHz RISC 128MHz RISC 128MHz RISC 128MHz

1 hour 1 hour 1 hour 1 hour 1 hour 1 hour

5 - 35 (20-33)

degrees

Centigrade

20 - 80 %

(without

condensation)

Yes Yes Yes Yes Yes Yes

Yes - - Yes - -

Press[Copy]

&[Fax] mode

key at the

same time.

Yes Yes Yes Yes Yes Yes

Yes:Print

Quality/Alignm

ent (in Ink

Key)

8.5"/11.7",

216/297mm

3.5"/5.0",

89/127mm

8.5"/14.0",

216/356mm

BH3 (KKCMY)

74 nozzles/line

5 - 35 (20-33)

degrees

Centigrade

20 - 80 %

(without

condensation)

Yes:Print

Quality/Alignm

ent (in Ink

Key)

---

---

8.5"/11.7",

216/297mm

3.5"/5.0",

89/127mm

8.5"/14.0",

216/356mm

BH3 (KKCMY)

74 nozzles/line

5 - 35 (20-33)

degrees

Centigrade

20 - 80 %

(without

condensation)

--

Yes:Print

Quality/Alignm

ent (in Ink

8.5"/11.7",

216/297mm

3.5"/5.0",

89/127mm

8.5"/14.0",

216/356mm

------

------

------

------

Key)

BH3 (KKCMY)

74 nozzles/line

5 - 35 (20-33)

degrees

Centigrade

20 - 80 %

(without

condensation)

Press[Copy]

&[Fax] mode

key at the

same time.

Yes:Print

Quality/Alignm

ent (in Ink

Key)

5.8"/5.8"(147/1

47mm)

8.5"/14"

(216/356mm)

8.5"/11.7",

216/297mm

3.5"/5.0",

89/127mm

8.5"/14.0",

216/356mm

BH3 (KKCMY)

74 nozzles/line

5 - 35 (20-33)

degrees

Centigrade

20 - 80 %

(without

condensation)

Yes:Print

Quality/Alignm

ent (in Ink

Key)

8.5"/11.7",

216/297mm

3.5"/5.0",

89/127mm

8.5"/14.0",

216/356mm

BH3 (KKCMY)

74 nozzles/line

5 - 35 (20-33)

degrees

Centigrade

20 - 80 %

(without

condensation)

--

Yes:Print

Quality/Alignm

ent (in Ink

Key)

--

--

8.5"/11.7",

216/297mm

3.5"/5.0",

89/127mm

8.5"/14.0",

216/356mm

(1/14)

2-7 Confidential

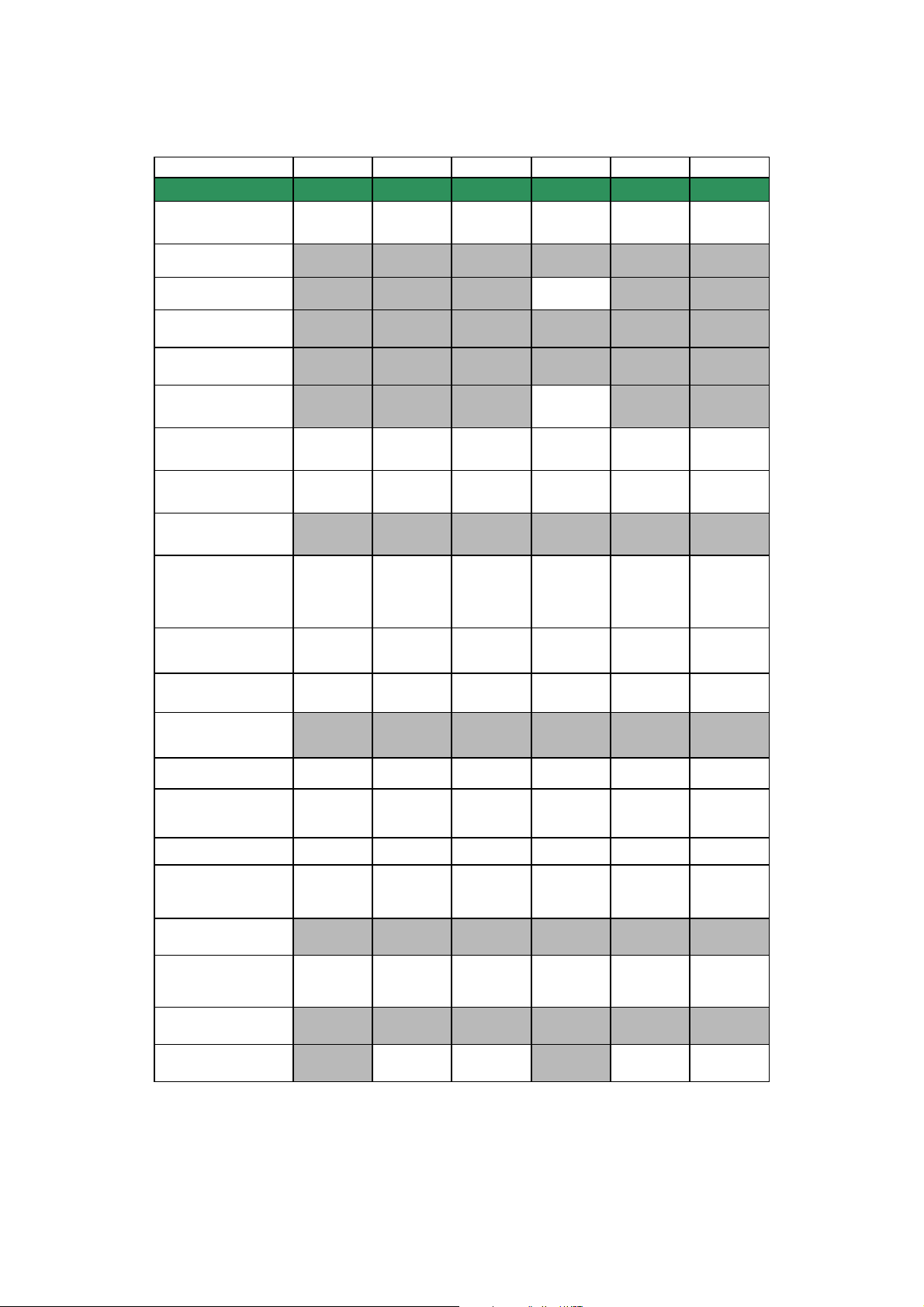

Page 29

Model name

/

/

/

/

Sheet Weight (Paper tray)

Sheet Weight

(2nd Paper tray)

Sheet Weight (ADF)

Sheet Weight (Manual

Feed Slot)

Sheet Weight (MP Tray)

ADF (pages)

(2/14)

USA EUR ASIA/OCE/CHN USA EUR ASIA/OCE/CHN

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

64 -220 g/m2

( 17 - 58 lb. )

------

---

------

------

---

64 -220 g/m2

( 17 - 58 lb. )

64 -220 g/m2

( 17 - 58 lb. )

64 -220 g/m2

( 17 - 58 lb. )

64-90g/mm2

(17-24lb.)

Yes (10)

64 -220 g/m2

( 17 - 58 lb. )

64 -220 g/m2

( 17 - 58 lb. )

--

--

Paper Capacity (sheets)

100 (80 gsm) 100 (80 gsm) 100 (80 gsm) 100 (80 gsm) 100 (80 gsm) 100 (80 gsm)

Output Paper Capacity

(sheets) 25 25 25 25 25 25

Optional Paper Tray

(sheets)

------

Brother Paper

(for Plain,Glossy and

Inkjet)

Recommended Paper

(Only for Transparency)

LCD Size

LTR Plain /

LTR Glossy/

LTR Inkjet

3M 3410

Transparency

film

Standard 16

x 1 line

A4 Plain /

A4 Glossy/

A4 Inkjet

3M 3410

Transparency

film

Standard 16

x 1 line

A4 Plain /

A4 Glossy/

A4 Inkjet

3M 3410

Transparency

film

Standard 16

x 1 line

LTR Plain /

LTR Glossy/

LTR Inkjet

3M 3410

Transparency

film

Standard 16

x 2 lines

A4 Plain /

A4 Glossy/

A4 Inkjet

3M 3410

Transparency

film

Standard 16

x 2 lines

A4 Plain /

A4 Glossy/

A4 Inkjet

3M 3410

Transparency

film

Standard 16

x 2 lines

LCD Back Light & Color

------

On-Screen Programming

LCD Language

Illuminated Mode Key

Memory Capacity

(physical: Mbytes)

Yes Yes Yes Yes Yes Yes

English

(+French for

CAN model)

PCC/Copy/Fax

/Scan

RAM 8MB

ROM 2MB

Depending on

countries

PCC/Copy/Fax

Scan

RAM 8MB

ROM 2MB

English

PCC/Copy/Fax

Scan

RAM 8MB

ROM 2MB

English

(+French for

CAN model)

PCC/Copy/Fax

Scan

RAM 16MB

ROM 8MB*

Depending on

countries

PCC/Copy/Fax

Scan

RAM 16MB

ROM 8MB

English

PCC/Copy/Fax

/Scan

RAM 16MB

ROM 8MB

Memory Backup (with

battery 24hour)

Back Up Print: ON/OFF

Feature (in function Menu)

Memory Security

Transmission Lock

------

Yes Yes Yes Yes Yes Yes

------

- Yes Yes - Yes Yes

*4MB (w/o demonstration program)

2-8 Confidential

Page 30

(3/14)

g

p

g)

USA EUR ASIA/OCE/CHN USA EUR ASIA/OCE/CHN

Model name

Dimensions w/ Carton

(WxDxH)=>Please refer to

"Logistic Information" on

Sales Data Bank.

Dimensions w/o Carton

(WxDxH) * tray is not

opened )=>Please refer

to "Logistic Information"

Dimensions w/o Carton

with tray is opend

=>refer to "Logistic

Weight w/ Carton

Please refer to "Logistic

Information"

Weight w/o Carton

w/o tray Please refer to

istic Information"

"Lo

Body Color = Top Cover

Body Color = Pane l cover Black Black Black Metallic Blue Metallic Blue Metallic Blue

Body Color = Bottom

Cover

Body Color = Bottom

Cover (Engine unit)

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

W 420 x

D 200 x H 380

W 373 x

D 345 x H 135

W 373 x

D 453 x H 135

6.6kg 7kg 7kg 7.5kg 6.5kg 6.5kg

5.5kg 5.5kg 5.5kg 6kg 5.5kg 5.5kg

BHmini Silver BHmini Silver BHmini Silver Metallic Blue Metallic Blue Metallic Blue

Dark gray Dark gray Dark gray Dark gray Dark gray Dark gray

Dark gray Dark gray Dark gray Dark gray Dark gray Dark gray

W 500 x

D 200 x H 450

W 373 x

D 345 x H 135

W 373 x

D 453 x H 135

W 500 x

D 200 x H 450

W 373 x

D 345 x H 135

W 373 x

D 453 x H 135

W 420 x

D 200 x H 380

W 373 x

D 347 x H 165

W 375 x

D 455 x H 165

W 500 x

D 200 x H 450

W 373 x

D 347 x H 165

W 373 x

D 453 x H 135

W 500 x

D 200 x H 450

W 373 x

D 347 x H 165

W 373 x

D 453 x H 135

Power Source

Power

Consumption(Power OFF/

Power Save(CPU Sleep)/

Standby/ Peak)

Energy Star Compliant

( USA Only )

Machine Noise

(Standby/Peak ex. In

rintin

Total print pages

Copy pages

PC print pages

Fax RX pages

PCC pages

Ink Gauge Indication

AC 120 V

50/60Hz

(3.0Wh / - /

7.0Wh /

20.0Wh)

Yes Yes Yes Yes Yes Yes

better than

35dBA/45dBA

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

Yes (in Ink

Key/ Status

Monitor)

AC 220-240 V

50/60Hz

(3.0Wh / - /

7.0Wh /

20.0Wh)

better than

35dBA/45dBA

Yes (in Ink

Key/ Status

Monitor)

AC 220-240 V

50/60Hz

(3.0Wh / - /

7.0Wh /

20.0Wh)

better than

35dBA/45dBA

Yes (in Ink

Key/ Status

Monitor)

AC 120 V

50/60Hz

(3.5Wh / - /

8.0Wh /

25.0Wh)

better than

35dBA/45dBA

Yes (in Ink

Key/ Status

Monitor)

AC 220-240 V

50/60Hz

(4.0Wh / - /

9.0Wh /

19.0Wh)

better than

35dBA/45dBA

Yes (in Ink

Key/ Status

Monitor)

AC 220-240 V

50/60Hz

(4.0Wh / - /

9.0Wh /

19.0Wh)

better than

35dBA/45dBA

Yes (in Ink

Key/ Status

Monitor)

2-9 Confidential

Page 31

Model name

LIST/REPORT

Activity Report/Jour-l

Report

Transmission Verification

Report

Cover page

Help List

(4/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

Yes (up to

200)

Yes (in Menu

Table)

------

Yes (in

Reports menu)

Yes (up to

200)

Yes (in Menu

Table)

Yes (in

Reports menu)

Yes (up to

200)

Yes (in Menu

Table)

Yes (in

Reports menu)

Yes (up to

200)

Yes (in Menu

Table)

Yes (in

Reports menu)

Yes (up to

200)

Yes (in Menu

Table)

Yes (in

Reports menu)

ASIA/OCE/CHN

Yes (up to

200)

Yes (in Menu

Table)

Yes (in

Reports menu)

Call Back Message

Caller ID List

Quick Dial List

Quick Dial List ( New )

New =>Empty box is not

printed out.

Tel Index List

Memory Status List

System Setup(User

Setting) List

Order Form

INTERFACE

Exter-l TAD Interface

Host Interface

LAN

Cable included

PictBridge

------

Yes(in

CallerID

Menu)

------

Yes (in

Reports menu)

------

------

---

------

Yes Yes Yes Yes Yes Yes

USB1.1/2.0(@

FULL-

SPEEED)

- - - Yes Yes Yes

------

------

--

Yes (in

Reports menu)

USB1.1/2.0(@

FULL-

SPEEED)

Yes (in

Reports menu)

USB1.1/2.0(@

FULL-

SPEEED)

Yes(in

CallerID

Menu)

Yes (in

Reports menu)

Yes (in

Reports Menu)

USB1.1/2.0(@

FULL-

SPEEED)

--

Yes (in

Reports menu)

Yes (in

Reports Menu)

USB1.1/2.0(@

FULL-

SPEEED)

Yes (in

Reports menu)

Yes (in

Reports Menu)

USB1.1/2.0(@

FULL-

SPEEED)

Acceptable Media Card

CF/MS/SD/SM

/xD

CF/MS/SD/SM

/xD

CF/MS/SD/SM

/xD

CF/MS/SD/SM

/xD

CF/MS/SD/SM

/xD

CF/MS/SD/SM

/xD

2-10 Confidential

Page 32

Model name

S

pag

y

y

y

y

y

y

;

)

p

)

SUPPLIES/ OPTION

Bundled Ink (Life / Yield)

(5/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

BK:500pages

(Normal 5%)

BK:500pages

(Normal 5%)

BK:500pages

(Normal 5%)

BK:500pages

(Normal 5%)

BK:500pages

(Normal 5%)

ASIA/OCE/CHN

BK:500pages

(Normal 5%)

Supply Ink Cartridge (Life

/ Yield)

Supply Ink Cartridge (Life

/ Yield) *HighCapacity

Options

SERVICE

INFORMATION

Monthly Volume

Machine Life (year)

Periodical Replacement

Parts for Laser

Fixing Unit

Separation Pad Assy

Paper Pick-up Roller Assy

Scanner Unit

MTBF (Mean Time

Between Failures

MTTR (Mean Time To BE

Re

aired

Ozone Emission;

Printer

Scanner (Mono/Color)

TELEPHONE

Handset

Hook

Off Hook Alarm

Duplex Speaker Phone

Power Failure Phone

Power Failure Dialing

Chain Dialing

Automatic Redial

Recall (For ASIA)

PBX Feature

( EUR&ASIA )

C/M/Y:400pag

es(Normal 5%)

BK:500pages

(Normal 5%)

C/M/Y:400pag

es(Normal 5%)

2500

30,000 pages

(print)/50,000

pages (scan)

or 5

4,000 hours 4,000 hours 4,000 hours 4,000 hours 4,000 hours 4,000 hours

30 min. 30 min. 30 min. 30 min. 30 min. 30 min.

Yes - Yes Yes - Yes

Yes Yes Yes Yes Yes Yes

Yes

(1time/5min)

C/M/Y:400pag

es(Normal 5%)

BK:500pages

(Normal 5%)

C/M/Y:400pag

es(Normal 5%)

------

------

es 2500 pages 2500 pages 2500 pages 2500 pages 2500 pages

30,000 pages

(print)/50,000

pages (scan)

ears

------

------

------

------

------

------

------

------

------

------

------

------

------

------

-Yes

or 5

Yes

(3time/5min)

ears

C/M/Y:400pag

es(Normal 5%)

BK:500pages

(Normal 5%)

C/M/Y:400pag

es(Normal 5%)

30,000 pages

(print)/50,000

pages (scan)

or 5

ears

Yes

(3times/5min)

-

C/M/Y:400pag

es(Normal 5%)

BK:500pages

(Normal 5%)

C/M/Y:400pag

es(Normal 5%)

30,000 pages

(print)/50,000

pages (scan)

or 5

Yes

(1time/5min)

C/M/Y:400pag

es(Normal 5%)

BK:500pages

(Normal 5%)

C/M/Y:400pag

es(Normal 5%)

30,000 pages

(print)/50,000

pages (scan)

ears

-Yes

or 5

Yes

(3time/5min)

ears

C/M/Y:400pag

es(Normal 5%)

BK:500pages

(Normal 5%)

C/M/Y:400pag

es(Normal 5%)

30,000 pages

(print)/50,000

pages (scan)

or 5

Yes

(3times/5min)

-

ears

2-11 Confidential

Page 33

Model name

y)

y)

y )

y )

y )

y )

y )

y )

(

)

Handset Volume

Speaker Volume

Ring Volume

Hold/Mute Key

(6/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

- - - - - -

Yes (3 steps +

OFF)

Yes (3 steps +

OFF)

Yes (3 steps +

OFF)

Yes (3 steps +

OFF)

- - - - - -

Yes (3 steps +

OFF)

Yes (3 steps +

OFF)

Yes (3 steps +

OFF)

Yes (3 steps +

OFF)

Yes (3 steps +

OFF)

Yes (3 steps +

OFF)

ASIA/OCE/CHN

Yes (3 steps +

OFF)

Yes (3 steps +

OFF)

Music on Hold

Monitoring the Line on

Hold with Music

One-Touch Dial

Speed Dial

Figures of One-Touch &

Speed Dial 20 digits 20 digits 20 digits 20 digits 20 digits 20 digits

Resisterable Number Of

Characters

Group Dial ( Up to X

groups )

Telephone Index

( Search/Speed dial key )

Caller ID

Call Waiting Caller ID

Call waiting Ready ( Only

for USA )

Distinctive Ringing

- - - - - -

- - - - - -

------

20 20 20 80 80 80

15 characters 15 charact ers 15 characters 15 charact ers 15 characters 15 characters

Yes (6) Yes (6) Yes (6) Yes (6) Yes (6) Yes (6)

Yes Yes Yes Yes Yes Yes

Yes -

------

- - -- - -

Yes

Yes (UK,DE N

only)

Yes

(ARL/NZ/SIN/

HK only)

Yes

(ARL/NZ/SIN/

HK onl

Yes -

Yes

Yes (UK,DE N

only)

Yes

(ARL/NZ/SIN/

HK only)

Yes

(ARL/NZ/SIN/

HK onl

COLOR FAX

Modem Speed(bps)

Transmission Speed(sec.)

ITU-T Group

Coding Method

Fax/Tel Switch

Super Fine

Gray Scale

Contrast

(Auto/S.Light/S.Dark)

Dual Access

Enhanced Remote

Activate

Station ID

20digits/20characters

14,400(Fax) 14,400(Fax) 14,400(Fax) 14,400(Fax) 14,400(Fax) 14,400(Fax)

Approx.6

(Brother#1,MM

R)

G3 G3 G3 G3 G3 G3

Mono:MH/MR/

MMR,

Color:JPEG

Yes (Hook

key)

Yes ( TX &

RX:B&W onl

Mono:64,

Color:256

Yes Yes Yes Yes Yes Yes

Yes (B&W

only)

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

Approx.6

(Brother#1,MM

R)

Mono:MH/MR/

MMR,

Color:JPEG

Yes (Tel key)

Yes ( TX &

RX:B&W onl

Mono:64,

Color:256

Yes (B&W

only)

Approx.6

(Brother#1,MM

R)

Mono:MH/MR/

MMR,

Color:JPEG

Yes (Hook

key)

Yes ( TX &

RX:B&W onl

Mono:64,

Color:256

Yes (B&W

only)

Approx.6

(Brother#1,MM

R)

Mono:MH/MR/

MMR,

Color:JPEG

Yes (Hook

key)

Yes ( TX &

RX:B&W onl

Mono:64,

Color:256

Yes (B&W

only)

Approx.6

(Brother#1,MM

R)

Mono:MH/MR/

MMR,

Color:JPEG

Yes (Tel key)

Yes ( TX &

RX:B&W onl

Mono:64,

Color:256

Yes (B&W

only)

Approx.6

(Brother#1,MM

R)

Mono:MH/MR/

MMR,

Color:JPEG

Yes (Hook

key)

Yes ( TX &

RX:B&W onl

Mono:64,

Color:256

Yes (B&W

only)

2-12 Confidential

Page 34

Model name

)

(

g

(

)

g

)

)

)

)

)

)

)

)

)

)

Remote Maintenance

RX Mode Indication

Resolution Indication

Paper Handling Size

Ducument Scanning Width

Delayed Timer

(up to 50:B&W only)

Polled Sending (type)

*B&W only

Next-Fax Reservation

Batch Transmission

Quick-Scan(Memory

transmission)

Memory Transmission

ITU-T Test Chart

Memory Transmission

Brother Chart/ MMR

ECM (Error Correction

Mode)

Error Re-Transmission

Broadcasting (Speed+

OneTouch+Manual

Manual Broadcasting

Easy Rece ive /F a x D e te c t

Polling Receiving (type)

*B&W only

Auto Reduction

Out-of-Paper Reception

(ITU-T Test Chart

#1/MMR

Out-of-Paper Reception

(Brother Chart/ MMR)

Remote Access

Fax Retrieval

Fax Forwarding

Paging

Color FAX (Document

Send/Receive)

Color FAX (Memory

Send/Receive)

(7/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

- - - Yes Yes Yes

LCD LCD LCD LCD LCD LCD

LCD LCD LCD LCD LCD LCD

LTR, A4 LTR, A4 LTR, A4

208mm 208mm 208mm 208mm 208mm 208mm

- - - Yes Yes Yes

- - - Yes(Std.)

Yes (Dual

Access)

Yes (Dual

Access)

Yes (Dual

Access)

---

Approx.4.72se

c/page@LTR

Approx. 5.02

sec./page@A4

Up to 170

Pa

UP to 200

Pa

Yes Yes Yes Yes Yes Yes

Yes (70

locations

Yes(50

locations )

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

Up to 170

Page

UP to 200

Pages

Yes/Yes (ITU-

color FAX)

No / Yes (ITU-

color FAX)

Approx.4.72se

c/page@LTR

Approx. 5.02

sec./page@A4

Up to 170

e

Pages

UP to 200

es

------

---Yes (Std/Seq)

- - - Yes Yes Yes

---

---

---Yes--

Pages

Yes (70

locations

Yes(50

locations )

Up to 170

Pages

UP to 200

Pages

Yes/Yes (ITU-

color FAX)

No / Yes (ITU-

color FAX)

Approx.4.72se

c/page@LTR

Approx. 5.02

sec./page@A4

Up to 170

Pages

UP to 200

Pages

Yes (70

locations

Yes(50

locations )

Up to 170

Pages

UP to 200

Pages

Yes/Yes (ITU-

color FAX)

No / Yes (ITU-

color FAX)

LTR,

A4+LEGAL(wit

hADF

Yes (Dual

Access)

Yes (B&W

only /not color)

Approx.4.72se

c/page@LTR

Approx. 5.02

sec./page@A4

Up to 400

Pages

UP to 480

Pages

Yes (130

locations

Yes(50

locations )

Up to 400

Pages

UP to 480

Pages

Yes (B&W

only)

Yes (B&W

only)

Yes/Yes (ITU-

color FAX)

No / Yes (ITU-

color FAX)

LTR, A4 LTR, A4

Yes

(Std/Secure)

Yes (Dual

Access)

Yes (B&W

only /not color)

Approx.4.72se

c/page@LTR

Approx. 5.02

sec./page@A4

Up to 400

Pages

UP to 480

Pages

Yes (130

locations

Yes(50

locations )

Yes

(Std/Seq/Sec u

re/Timer

Up to 400

Pages

UP to 480

Pages

Yes (B&W

only)

Yes (B&W

only)

Yes/Yes (ITU-

color FAX)

No / Yes (ITU-

color FAX)

ASIA/OCE/CHN

Yes

(Std/Secure)

Yes (Dual

Access)

Yes (B&W

only /not color)

Approx.4.72se

c/page@LTR

Approx. 5.02

sec./page@A4

Up to 400

Pages

UP to 480

Pages

Yes (130

locations

Yes(50

locations )

Yes

(Std/Seq/Sec u

re/Timer

Up to 400

Pages

UP to 480

Pages

Yes (B&W

only)

Yes (B&W

only)

Yes/Yes (ITU-

color FAX)

No / Yes (ITU-

color FAX)

2-13 Confidential

Page 35

Model name

)

(

)

COLOR PRINTER

Color/Mono

Resolution(dpi)

Speed(ppm) Simple

First print out time (from

READY mode *2

Warm up Time ( from

SLEEP mode )

Emulation

Resident Fonts

Fonts Disk Based

Paper Handling Size

(Paper Tray)

Paper Handling Size

(2nd Tray)

(8/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

Color Color Color Color Color Color

up to

1200x6000 dpi

20/15ppm

(Mono/Color:

600x150 dpi)

------

------

------

------

Yes (35

TrueType)

A4, LTR, LGL,

EXE, JISB5, A5,

A6,

Photo(4x6"/102x

152mm),

Indexcard(5x8"/1

27x203mm),

Photo L

(3.5x5"/89x127m

m),

Photo2L(5x7"/12

7x178mm), Post

Card

1(3.9x5.8"/100x1

48mm), Post

Card 2

(Double)(5.8x7.8"

/148x200mm),

C5 Envelope,

Com-10, DL

Envelope, Morch, JE4

Envelope.

- - - - - -

up to

1200x6000 dpi

20/15ppm

(Mono/Color:

600x150 dpi)

Yes (35

TrueType)

A4, LTR,

LGL, EXE,

JISB5, A5, A6,

Photo(4x6"/102x

152mm),

Indexcard(5x8"/1

27x203mm),

Photo L

(3.5x5"/89x127m

m),

Photo2L(5x7"/12

7x178mm), Post

Card

1(3.9x5.8"/100x1

48mm),

Post Card 2

(Double)(5.8x7.8"

/148x200mm),

C5 Envelope,

Com-10,

DL Envelope,

Mo-rch,

JE4 Envelope.

up to

1200x6000 dpi

20/15ppm

(Mono/Color:

600x150 dpi)

Yes (35

TrueType)

A4, LTR,

LGL, EXE,

JISB5, A5, A6,

Photo(4x6"/102x

152mm),

Indexcard(5x8"/1

27x203mm),

Photo L

(3.5x5"/89x127m

m),

Photo2L(5x7"/12

7x178mm), Post

Card

1(3.9x5.8"/100x1

48mm),

Post Card 2

(Double)(5.8x7.8"

/148x200mm),

C5 Envelope,

Com-10,

DL Envelope,

Mo-rch,

JE4 Envelope.

up to

1200x6000 dpi

20/15ppm

(Mono/Color:

600x150 dpi)

Yes (35

TrueType)

A4, LTR,

LGL, EXE,

JISB5, A5, A6,

Photo(4x6"/102x

152mm),

Indexcard(5x8"/1

27x203mm),

Photo L

(3.5x5"/89x127m

m),

Photo2L(5x7"/12

7x178mm), Post

Card

1(3.9x5.8"/100x1

48mm),

Post Card 2

(Double)(5.8x7.8"

/148x200mm),

C5 Envelope,

Com-10,

DL Envelope,

Mo-rch,

JE4 Envelope.

up to

1200x6000 dpi

20/15ppm

(Mono/Color:

600x150 dpi)

Yes (35

TrueType)

A4, LTR,

LGL, EXE,

JISB5, A5, A6,

Photo(4x6"/102x

152mm),

Indexcard(5x8"/1

27x203mm),

Photo L

(3.5x5"/89x127m

m),

Photo2L(5x7"/12

7x178mm), Post

Card

1(3.9x5.8"/100x1

48mm),

Post Card 2

(Double)(5.8x7.8"

/148x200mm),

C5 Envelope,

Com-10,

DL Envelope,

Mo-rch,

JE4 Envelope.

ASIA/OCE/CHN

up to

1200x6000 dpi

20/15ppm

(Mono/Color:

600x150 dpi)

Yes (35

TrueType)

A4, LTR,

LGL, EXE,

JISB5, A5, A6,

Photo(4x6"/102x

152mm),

Indexcard(5x8"/1

27x203mm),

Photo L

(3.5x5"/89x127m

m),

Photo2L(5x7"/12

7x178mm), Post

Card

1(3.9x5.8"/100x1

48mm),

Post Card 2

(Double)(5.8x7.8"

/148x200mm),

C5 Envelope,

Com-10,

DL Envelope,

Mo-rch,

JE4 Envelope.

Paper Handling Size

Manual Slots

- - - - - -

Paper Handling Size (MP)

- - - - - -

Media Type (Paper Tray)

Media Type (2 nd Paper

Tray)

Media Type

(Manual Slots)

Media Type (MP Tray)

Plain, Inkjet,

Glossy,

Transparency

Plain, Inkjet,

Glossy,

Transparency

Plain, Inkjet,

Glossy,

Transparency

Plain, Inkjet,

Glossy,

Transparency

Plain, Inkjet,

Glossy,

Transparency

Plain, Inkjet,

Glossy,

Transparency

- - - - - -

- - - - - -

- - - - - -

2-14 Confidential

Page 36

Model name

y)

y)

y)

Print Paper Margin (upper,

lower, left, right)

Variable Dot Print

Minimum Droplet Size

Shingling Print

Color Enhancement

COLOR COPY

Color/Mono

Speed (cpm) *time

culcurated excluding

paper feeding

**EU's defult is culcurated

by "nomal mode"speed.

Warm up Time (from

SLEEP mode)

Multi Copy (Stack)

Multi Copy (Sort)

Reduction/Enlargement

(%)

Resolution (dpi)

N in 1

Poster

Image Enhancement

(9/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

Borderless

ON:0, 0, 0,0*

OFF:0.12, 0.12,

0.12,

0,12"/3,3,3,3mm**

* Borderless For

A4

/LTR/A6/Photo(4x6

"/102x152mm),

Indexcard(5x8"/12

7x203mm), Photo

L

(3.5x5"/89x127mm

), Photo

2L(5x7"/127x178m

m), Post Card

1(3.9x5.8"/100x14

8mm), Post Card 2

(Double)(5.8x7.8"/

148x200mm) only

**

0.47x0.95x0.12x0.

12"/12,24,3,3mm

for Envelops

Yes (3 sizes) Yes (3 sizes) Yes (3 sizes) Yes (3 sizes) Yes (3 sizes) Yes (3 sizes)

3 pl 3 pl 3 pl 3 pl 3 pl 3 pl

YesYesYesYesYesYes

Color Color Color Color Color Color

17/11cpm 17/11cpm 17/11cpm 17/11cpm 17/11cpm 17/11cpm

Yes (Up to 99) Yes (Up to 99) Yes (Up to 99) Yes (Up to 99) Yes (Up to 99) Yes (Up to 99)

25 -- 400 in

1% increments

Print: Max.

600x1200 dpi

Scan: Max.

600x1200 dpi

Borderless

ON:0, 0, 0,0*

OFF:0.12, 0.12,

0.12,

0,12"/3,3,3,3mm**

* Borderless For

A4

/LTR/A6/Photo(4x6

"/102x152mm),

Indexcard(5x8"/12

7x203mm), Photo

L

(3.5x5"/89x127mm

), Photo

2L(5x7"/127x178m

m), Post Card

1(3.9x5.8"/100x14

8mm), Post Card 2

(Double)(5.8x7.8"/

148x200mm) only

**

0.47x0.95x0.12x0.

12"/12,24,3,3mm

for Envelops

Borderless

ON:0, 0, 0,0*

OFF:0.12, 0.12,

0.12,

0,12"/3,3,3,3mm**

* Borderless For

A4

/LTR/A6/Photo(4x6

"/102x152mm),

Indexcard(5x8"/12

7x203mm), Photo

L

(3.5x5"/89x127mm

), Photo

2L(5x7"/127x178m

m), Post Card

1(3.9x5.8"/100x14

8mm), Post Card 2

(Double)(5.8x7.8"/

148x200mm) only

**

0.47x0.95x0.12x0.

12"/12,24,3,3mm

for Envelops

Borderless

ON:0, 0, 0,0*

OFF:0.12, 0.12,

0.12,

0,12"/3,3,3,3mm**

* Borderless For

A4

/LTR/A6/Photo(4x6

"/102x152mm),

Indexcard(5x8"/12

7x203mm), Photo

L

(3.5x5"/89x127mm

), Photo

2L(5x7"/127x178m

m), Post Card

1(3.9x5.8"/100x14

8mm), Post Card 2

(Double)(5.8x7.8"/

148x200mm) only

**

0.47x0.95x0.12x0.

12"/12,24,3,3mm

for Envelops

Borderless

ON:0, 0, 0,0*

OFF:0.12, 0.12,

0.12,

0,12"/3,3,3,3mm**

* Borderless For

A4

/LTR/A6/Photo(4x6

"/102x152mm),

Indexcard(5x8"/12

7x203mm), Photo

L

(3.5x5"/89x127mm

), Photo

2L(5x7"/127x178m

m), Post Card

1(3.9x5.8"/100x14

8mm), Post Card 2

(Double)(5.8x7.8"/

148x200mm) only

**

0.47x0.95x0.12x0.

12"/12,24,3,3mm

for Envelops

------

------

---Yes-25 -- 400 in

1% increments

Print: Max.

600x1200 dpi

Scan: Max.

600x1200 dpi

---

25 -- 400 in

1% increments

Print: Max.

600x1200 dpi

Scan: Max.

600x1200 dpi

25 -- 400 in

1% increments

Print: Max.

600x1200 dpi

Scan: Max.

600x1200 dpi

2in1,

4in1(Mono/Col

or, A4/LTR

onl

25 -- 400 in

1% increments

Print: Max.

600x1200 dpi

Scan: Max.

600x1200 dpi

2in1,

4in1(Mono/Col

or, A4/LTR

onl

- - - Yes (3x3) Yes (3x3) Yes (3x3)

------

ASIA/OCE/CHN

Borderless

ON:0, 0, 0,0*

OFF:0.12, 0.12,

0.12,

0,12"/3,3,3,3mm**

* Borderless For

A4

/LTR/A6/Photo(4x6

"/102x152mm),

Indexcard(5x8"/12

7x203mm), Photo

L

(3.5x5"/89x127mm

), Photo

2L(5x7"/127x178m

m), Post Card

1(3.9x5.8"/100x14

8mm), Post Card 2

(Double)(5.8x7.8"/

148x200mm) only

**

0.47x0.95x0.12x0.

12"/12,24,3,3mm

for Envelops

25 -- 400 in

1% increments

Print: Max.

600x1200 dpi

Scan: Max.

600x1200 dpi

2in1,

4in1(Mono/Col

or, A4/LTR

onl

2-15 Confidential

Page 37

Model name

p

)

p

)

g

Paper Handling Size

(Paper Tray)

Paper Handling Size

(2nd Tray)

Paper Handling Size

(Manual Slots)

(10/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

Letter/Legal/A

4/A5/4"x6"(10(

W)x15(H)cm)

- - - - - -

- - - - - -

Letter/Legal/A

4/A5/4"x6"(10(

W)x15(H)cm)

Letter/Legal/A

4/A5/4"x6"(10(

W)x15(H)cm)

Letter/Legal/A

4/A5/4"x6"(10(

W)x15(H)cm)

Letter/Legal/A

4/A5/4"x6"(10(

W)x15(H)cm)

ASIA/OCE/CHN

Letter/Legal/A

4/A5/4"x6"(10(

W)x15(H)cm)

Paper Handling Size (MP)

Media Type (Paper Tray)

Media Type (2nd Tray)

Media Type (Manual

Slots)

Media Type (MP Tray)

Print Paper Margin (upper,

lower, left, right)

Duplex Copy

Resolution Indication

COLOR SCANNER

Color/Mono

Optical Resolution (dpi)

Interpolated Resolution

(dpi)

- - - - - -

Plain, Inkjet,

Glossy,

Transparency

- - - - - -

- - - - - -

- - - - - -

0.12, 0.12,

0.12, 0,12"

(3,3,3,3mm)

------

LCD LCD LCD LCD LCD LCD

Color Color Color Color Color Color

600x2400 dpi 600x2400 dpi 600x2400 dpi 600x2400 dpi 600x2400 dpi 600x2400 dpi

up to

19200x19200

dpi (For XP,

with special

tool.

1200x1200dpi

for XP w/o

special tool)

Plain, Inkjet,

Glossy,

Transparency

0.12, 0.12,

0.12, 0,12"

(3,3,3,3mm)

up to

19200x19200

dpi (For XP,

with special

tool.

1200x1200dpi

for XP w/o

special tool)

Plain, Inkjet,

Glossy,

Transparency

0.12, 0.12,

0.12, 0,12"

(3,3,3,3mm)

up to

19200x19200

dpi (For XP,

with special

tool.

1200x1200dpi

for XP w/o

special tool)

Plain, Inkjet,

Glossy,

Transparency

0.12, 0.12,

0.12, 0,12"

(3,3,3,3mm)

up to

19200x19200

dpi (For XP,

with special

tool.

1200x1200dpi

for XP w/o

special tool)

Plain, Inkjet,

Glossy,

Transparency

0.12, 0.12,

0.12, 0,12"

(3,3,3,3mm)

up to

19200x19200

dpi (For XP,

with special

tool.

1200x1200dpi

for XP w/o

special tool)

Plain, Inkjet,

Glossy,

Transparency

0.12, 0.12,

0.12, 0,12"

(3,3,3,3mm)

up to

19200x19200

dpi (For XP,

with special

tool.

1200x1200dpi

for XP w/o

special tool)

Warm up Time (from

Scanner Lam

Warm up Time

Scanner Lam

Gray Scale

Ducument Scannin

Scan Image

Scan / OCR

Scan to E-mail

Scan to File

Scan to Card

OFF

(from

OFF: Color

------

------

256 256 256 256 256 256

Max. 210mm Max. 210mm Max. 210mm Max. 210mm Max. 210mm Max. 210mm

width

Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key)

Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key)

Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key)

Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key) Yes (scan key)

- - - Yes (scan key) Yes (scan key) Yes (scan key)

2-16 Confidential

Page 38

Model name

Scan speed (Mono/Color)

*@100dpi

(11/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

Max. 3.54/5.58

sec

@Letter_size

Max. 3.76/5.93

sec @A4_size

Max. 3.54/5.58

sec

@Letter_size

Max. 3.76/5.93

sec @A4_size

Max. 3.54/5.58

sec

@Letter_size

Max. 3.76/5.93

sec @A4_size

Max. 3.54/5.58

sec

@Letter_size

Max. 3.76/5.93

sec @A4_size

Max. 3.54/5.58

sec

@Letter_size

Max. 3.76/5.93

sec @A4_size

ASIA/OCE/CHN

Max. 3.54/5.58

sec

@Letter_size

Max. 3.76/5.93

sec @A4_size

Scanner Lamp Switch

(CIS doesn't require switch)

Color Depth (Input/Output)

MESSAGE CENTER

TAD

ICM Recording Time

Toll Saver

Memo/Recording

Conversation

OGM (MC/TAD,F/T)

User Recording OGM

TIME( MC/TAD, F/T )

PC FAX

Supplier

Color/Mono

Sending

Receiving

Protocol Compliance

Broadcasting

Support OS Version

(Refer

to"Application&OS"

sheet)

- - - - - -

36/24 bit color

processing

Brother Brother Brother Brother Brother Brother

Mono Mono Mono Mono Mono Mono

Yes Yes Yes Yes Yes Yes

up to 50 up to 50 up to 50 up to 50 up to 50 up to 50

36/24 bit color

processing

------

------

------

------

------

------

- - - Yes Yes Yes

------

36/24 bit color

processing

36/24 bit color

processing

36/24 bit color

processing

36/24 bit color

processing

Others

------

2-17 Confidential

Page 39

Model name

PHOTO CAPTURE

CENTER

Acceptable Media Card &

Size

(12/14)

USA EUR

ASIA/OCE/CHN

USA EUR

ASIA/OCE/CHN

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

SmartMedia

(3.3V):4MB-

128MB

Compact Flash

(Type-1, excl.

Type2/MicroDrive):4MB-2GB

Memory

Stick:16MB-

128MB (Duo with

Adopter)

Memory Stick

Pro:256MB-1GB

(MagicGate:Yes

if not use MG

function)

Secure

Digital

:16MB512MB (MiniSD

with Adopter)

xD Picture

Card:16-512MB

SmarMedia

(3.3V):4MB-

128MB

Compact Flash

(Type-1, excl.

Type2/MicroDrive):4MB-2GB

Memory

Stick:16MB-

128MB (Duo with

Adopter)

Memory Stick

Pro:256MB-1GB

(MagicGate:Yes

if not use MG

function)

Secure

Digital

:16MB512MB (MiniSD

with Adopter)

xD Picture

Card:16-512MB

SmartMedia

(3.3V):4MB-

128MB

Compact Flash

(Type-1, excl.

Type2/MicroDrive):4MB-2GB

Memory

Stick:16MB-

128MB (Duo with

Adopter)

Memory Stick

Pro:256MB-1GB

(MagicGate:Yes

if not use MG

function)

Secure

Digital

:16MB512MB (MiniSD

with Adopter)

xD Picture

Card:16-512MB

SmartMedia

(3.3V):4MB-

128MB

Compact Flash

(Type-1, excl.

Type2/MicroDrive):4MB-2GB

Memory

Stick:16MB-

128MB (Duo with

Adopter)

Memory Stick

Pro:256MB-1GB

(MagicGate:Yes

if not use MG

function)

Secure

Digital

:16MB512MB (MiniSD

with Adopter)

xD Picture

Card:16-512MB

SmartMedia

(3.3V):4MB-

128MB

Compact Flash

(Type-1, excl.

Type2/MicroDrive):4MB-2GB

Memory

Stick:16MB-

128MB (Duo with

Adopter)

Memory Stick

Pro:256MB-1GB

(MagicGate:Yes

if not use MG

function)

Secure

Digital

:16MB512MB (MiniSD

with Adopter)

xD Picture

Card:16-512MB

SmartMedia

(3.3V):4MB-

128MB

Compact Flash

(Type-1, excl.

Type2/MicroDrive):4MB-2GB

Memory

Stick:16MB-

128MB (Duo with

Adopter)

Memory Stick

Pro:256MB-1GB

(MagicGate:Yes

if not use MG

function)

Secure

Digital

:16MB512MB (MiniSD

with Adopter)

xD Picture

Card:16-512MB

Paper Handling Size &

Type (Paper Tray)

Paper Handling Size &

Type (Manual Slots)

Paper Handling Size &

Type (MP)

Print Paper Margin (upper,

lower, left, right)

Available paper size for

full (Max) size printing

Direct Print Size for

A4/LTR

Borderless / Cropping

(Full Auto)

Letter

Glossy/4"x6"(1

0x15cm)

Glossy/5"x7"(1

3x18cm)

Glossy /A4

Glossy/Letter

Plai-4

Plain/Letter

Inkjet/A4

Inkjet/4"x6"(10

x15cm) Inkjet

Letter

Glossy/4"x6"(1

0x15cm)

Glossy/5"x7"(1

3x18cm)

Glossy /A4

Glossy/Letter

Plai-4

Plain/Letter

Inkjet/A4

Inkjet/4"x6"(10

x15cm) Inkjet

Letter

Glossy/4"x6"(1

0x15cm)

Glossy/5"x7"(1

3x18cm)

Glossy /A4

Glossy/Letter

Plai-4

Plain/Letter

Inkjet/A4

Inkjet/4"x6"(10

x15cm) Inkjet

Letter

Glossy/4"x6"(1

0x15cm)

Glossy/5"x7"(1

3x18cm)

Glossy /A4

Glossy/Letter

Plai-4

Plain/Letter

Inkjet/A4

Inkjet/4"x6"(10

x15cm) Inkjet

Letter

Glossy/4"x6"(1

0x15cm)

Glossy/5"x7"(1

3x18cm)

Glossy /A4

Glossy/Letter

Plai-4

Plain/Letter

Inkjet/A4

Inkjet/4"x6"(10

x15cm) Inkjet

Letter

Glossy/4"x6"(1

0x15cm)

Glossy/5"x7"(1

3x18cm)

Glossy /A4

Glossy/Letter

Plai-4

Plain/Letter

Inkjet/A4

Inkjet/4"x6"(10

x15cm) Inkjet

------

------

Borderless

(For all size)

ON:0, 0, 0,0

OFF:0.12,

0.12, 0.12,

0,12"/3,3,3,3m

m

4x6"(10x15cm)

/

5x7"(13x18cm)

only

4x3"(10x8cm)/

5x3.5"(13x9cm

)/

6x4"(15x10cm)

/

7x5"(18x13cm)

/

8"x6"(20x15c

m)

Borderless

(For all size)

ON:0, 0, 0,0

OFF:0.12,

0.12, 0.12,

0,12"/3,3,3,3m

m

4x6"(10x15cm)

/

5x7"(13x18cm)

only

4x3"(10x8cm)/

5x3.5"(13x9cm

)/

6x4"(15x10cm)

/

7x5"(18x13cm)

/

8"x6"(20x15c

m)

Borderless

(For all size)

ON:0, 0, 0,0

OFF:0.12,

0.12, 0.12,

0,12"/3,3,3,3m

m

4x6"(10x15cm)

/

5x7"(13x18cm)

only

4x3"(10x8cm)/

5x3.5"(13x9cm

)/

6x4"(15x10cm)

/

7x5"(18x13cm)

/

8"x6"(20x15c

m)

Borderless

(For all size)

ON:0, 0, 0,0

OFF:0.12,

0.12, 0.12,

0,12"/3,3,3,3m

m

Borderless

(For all size)

ON:0, 0, 0,0

OFF:0.12,

0.12, 0.12,

0,12"/3,3,3,3m

m

Borderless

(For all size)

ON:0, 0, 0,0

OFF:0.12,

0.12, 0.12,

0,12"/3,3,3,3m

m

All size All size All size

4x3"(10x8cm)/

5x3.5"(13x9cm

)/

6x4"(15x10cm)

/

7x5"(18x13cm)

/

8"x6"(20x15c

m)/

Max.Size

4x3"(10x8cm)/

5x3.5"(13x9cm

)/

6x4"(15x10cm)

/

7x5"(18x13cm)

/

8"x6"(20x15c

m)/

Max.Size

4x3"(10x8cm)/

5x3.5"(13x9cm

)/

6x4"(15x10cm)

/

7x5"(18x13cm)

/

8"x6"(20x15c

m)/

Max.Size

Yes/Yes Yes/Yes Yes/Yes Yes/Yes Yes/Yes Yes/Yes

2-18 Confidential

Page 40

Model name

K

p

)

Media Format

(13/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

DPOF, Exif,

DCF

DPOF, Exif,

DCF

DPOF, Exif,

DCF

DPOF, Exif,

DCF

DPOF, Exif,

DCF

ASIA/OCE/CHN

DPOF, Exif,

DCF

Image Format

Print by PCC

Scan to Card

Color Enhancement - - - Yes Yes Yes

Removable Disk Yes

Scan to Card - - - Yes Yes Yes

Network PCC - - - Yes DL only

Photo Print:

JPEG

Scan to Card:

JPEG/PDF

(Color),

TIFF/PDF

(B&W)

(Read/Write)

Photo Print:

JPEG

Scan to Card:

JPEG/PDF

(Color),

TIFF/PDF

(B&W)

Yes

(Read/Write)

Photo Print:

JPEG

Scan to Card:

JPEG/PDF

(Color),

TIFF/PDF

(B&W)

Yes

(Read/Write)

Photo Print:

JPEG

Scan to Card:

JPEG/PDF

(Color),

TIFF/PDF

(B&W)

Yes

(Read/Write)

(FTP browser)

Photo Print:

JPEG

Scan to Card:

JPEG/PDF

(Color),

TIFF/PDF

(B&W)

Yes

(Read/Write)

Yes DL only

(FTP browser)

Photo Print:

JPEG

Scan to Card:

JPEG/PDF

(Color),

TIFF/PDF

(B&W)

Yes

(Read/Write)

Yes DL only

(FTP browser)

NETWOR

Standard/Option( User

tion or Dealer Option

O

Model name

Printer

Scanner

PC FAX

Internet FAX (Firmware)

---

---

---

---

---

------

Yes:Standard Yes:Standard Yes:Standard

Embedded

(NC-110h)

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Embedded

(NC-110h)

Embedded

(NC-110h)

Forrmat ( Scan to E-mail

server )

ITU SUB Addressing

Support OS version

Support OS version

Support OS version

Network connection

------

------

---

---

---

---

Win98(SE)/Me

/2K/XP

PC-Print/Fax:

Mac OS 8.6-

10.2.4(greater)

Scan: Mac

10.2.4(greater)

- (Novell

NetWare)

Ethernet

10/100BASE-

TX Auto

Negotiation

9.2,

Win98(SE)/Me

/2K/XP

PC-Print/Fax:

Mac OS 8.6-

9.2,

10.2.4(greater)

Scan: Mac

10.2.4(greater)

- (Novell

NetWare)

Ethernet

10/100BASE-

TX Auto

Negotiation

Win98(SE)/Me

/2K/XP

PC-Print/Fax:

Mac OS 8.6-

9.2,

10.2.4(greater)

Scan: Mac

10.2.4(greater)

- (Novell

NetWare)

Ethernet

10/100BASE-

TX Auto

Negotiation

2-19 Confidential

Page 41

Model name

Support Protocols

Protocols

Protocols

Protocols

Protocols

(14/14)

USA EUR

ASIA/OCE/CHN

USA EUR

MFC-210C MFC-210C MFC-210C MFC-420CN MFC-410CN MFC-410CN

- - - TCP/IP TCP/IP TCP/IP

RARP,

---

---

---

---

BOOTP,

DHCP, APIPA,

NetBIOS,

LPR/LPD,

Port9100

(SMTP/POP3

available with

web DL opt)

(SMB(NetBIO

S/ IP), IPP,

IPX/DLC)

mDNS, FTP,

TELNET,

SNMP, TFTP,

Scanner port

-

RARP,

BOOTP,

DHCP, APIPA,

NetBIOS,

LPR/LPD,

Port9100

(SMTP/POP3

available with

web DL opt)

(SMB(NetBIO

S/ IP), IPP,

IPX/DLC)

mDNS, FTP,

TELNET,

SNMP, TFTP,

Scanner port

-

ASIA/OCE/CHN

RARP,

BOOTP,

DHCP, APIPA,

NetBIOS,

LPR/LPD,

Port9100

(SMTP/POP3

available with

web DL opt)

-

(SMB(NetBIO

S/ IP), IPP,

IPX/DLC)

mDNS, FTP,

TELNET,

SNMP, TFTP,

Scanner port

Network Management

Network Management

Network Management

Network reset

Others

Optional I/F

---

---

---

Wireless OPT

*via USB

Wireless OPT

*via USB

Wireless OPT

*via USB

BRAdmin

Professio-l

- (Network

Remote

Setup)

- (MIB-II as

well as Brother

private MIB)

Yes

(in LAN Menu)

Wireless OPT

*via USB

BRAdmin

Professio-l

- (Network

Remote

Setup)

- (MIB-II as

well as Brother

private MIB)

Yes

(in LAN Menu)

Wireless OPT

*via USB

BRAdmin

Professio-l

- (Network

Remote

Setup)

- (MIB-II as

well as Brother

private MIB)

Yes

(in LAN Menu)

Wireless OPT

*via USB

2-20 Confidential

Page 42

MFC620CN/DCP110C/DCP310CN

(

)

(

)

(

)

(

)

p

p

USA EUR

Model name

GENERAL

Print Engine

Technology

Scanning Method

CPU Speed

Back up Clock

Operating Environment

Temperature

(BestPrintQuality)

Humidity

On/Off Switch

Demo Model

Panel Key for demo sheet

MFC-620CN MFC-620CN MFC-620CN DCP-110C DCP-110C DCP-310CN

BH3 (KKCMY)

74 nozzles/line

Inkjet Inkjet Inkjet Inkjet Inkjet Inkjet

CISCISCISCISCISCIS

RISC 128MHz RISC 128MHz RISC 128MHz RISC 128MHz RISC 128MHz RISC 128MHz

1 hour 1 hour 1 hour 1 hour 1 hour 1 hour

5 - 35 (20-33)

degrees

Centigrade

20 - 80 %

(without

condensation)

Yes Yes Yes Yes Yes Yes