Page 1

)

)

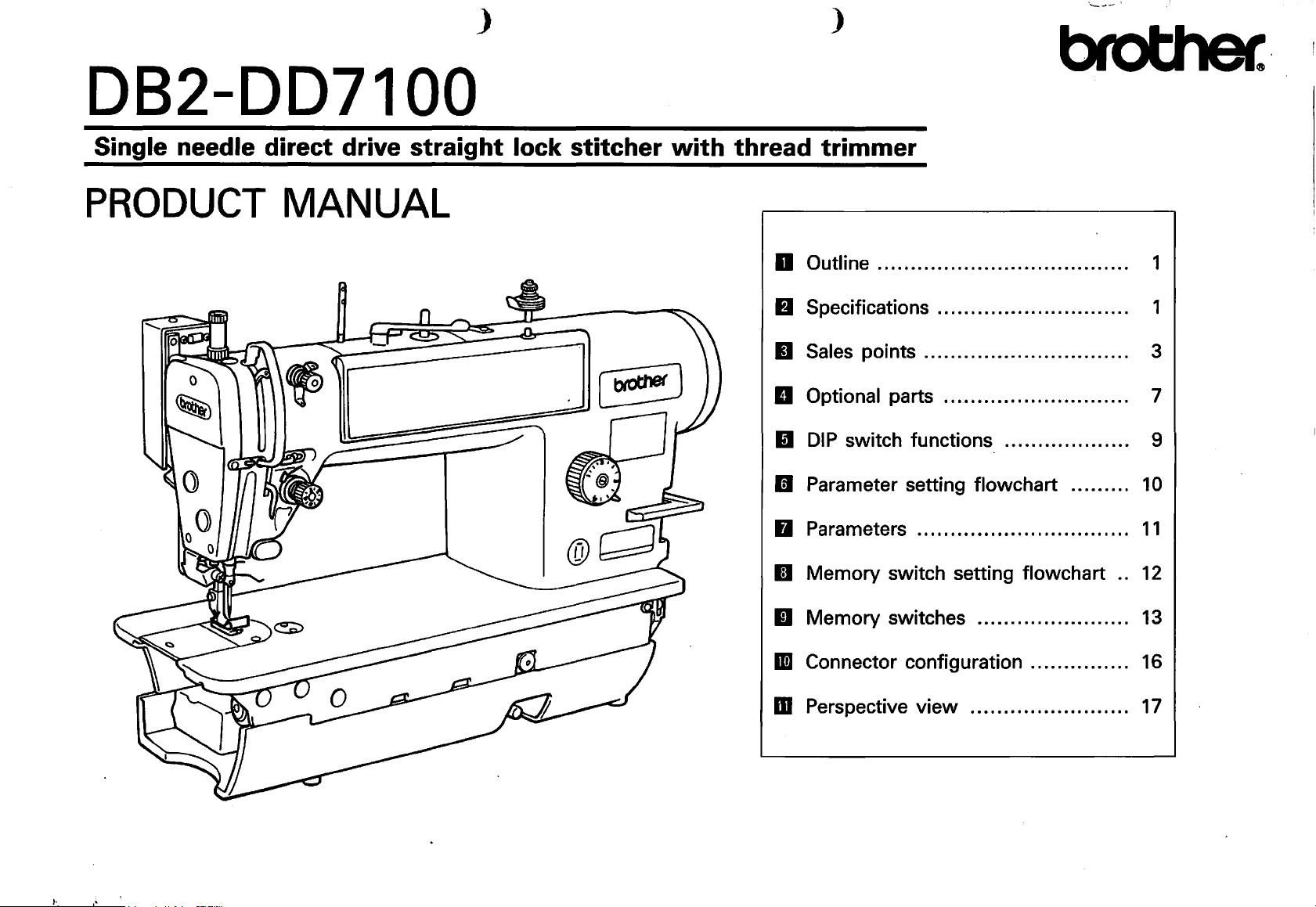

DB2-DD7100

Single needle direct drive straight lock stitcher with thread trimmer

,......_

____

'

PRODUCT

MANUAL

D Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

II

Specifications . . ... . . . . . ... . . . .. . . . .. .. .. .. 1

II

Sales points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

II

Optional parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

II

DIP

switch functions ...... ... . . ... . . . . . 9

II

Parameter setting flowchart . . . . . . . . .

II

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .

II

Memory switch setting flowchart ..

II Memory switches . . . . . . . . . . . . . . . . . . . . . . .

1m

Connector configuration

...............

10

11

12

13

16

m Perspective view . . . . . . . . . . . . . . . . . . . . . .. .

17

Page 2

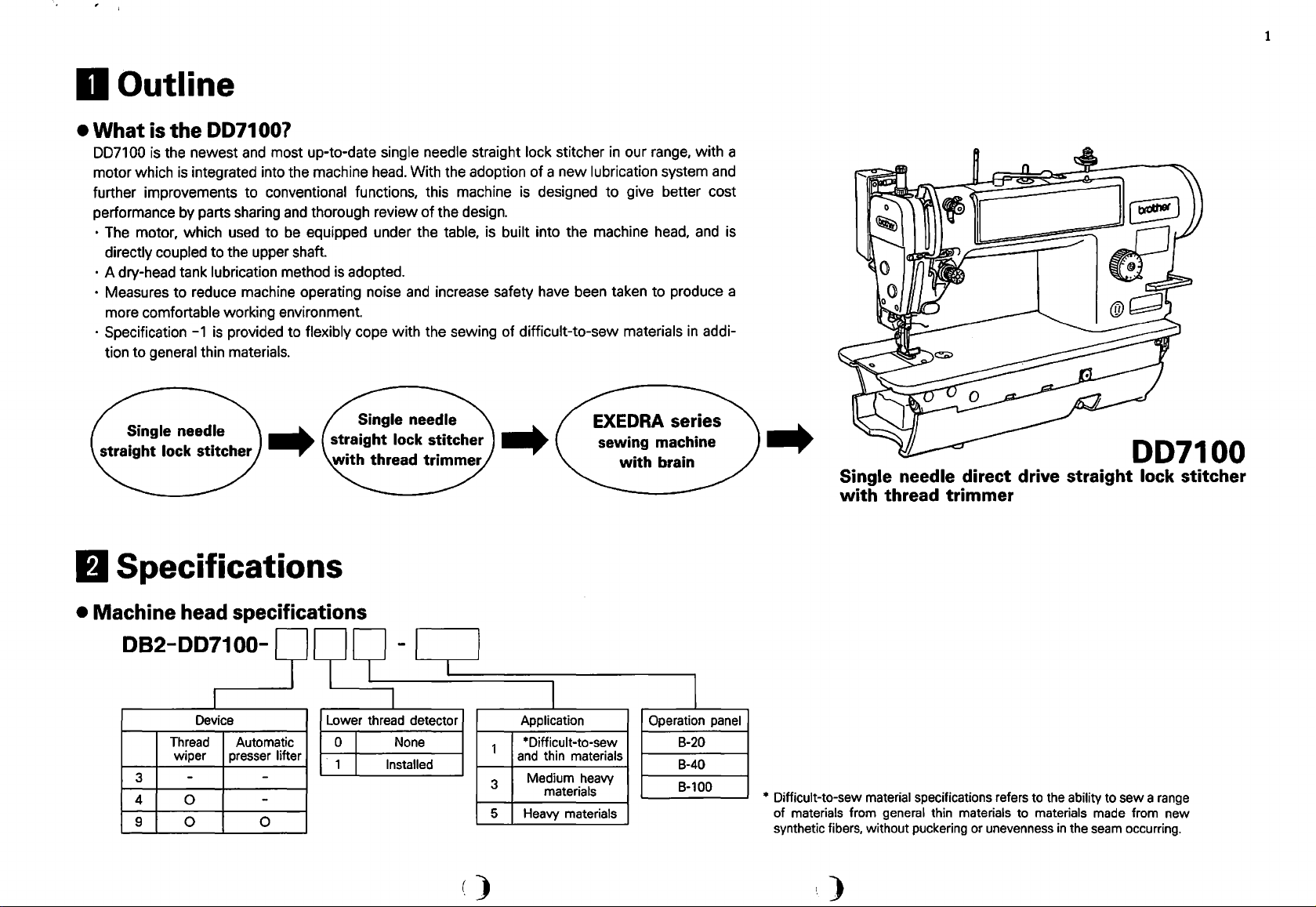

D Outline

•

What

007100

motor which

further improvements to

performance by parts sharing and thorough review

• The motor, which used to

• A dry-head tank lubrication method is adopted.

• Measures

• Specification

is

the

DD71 00?

is

the newest

is

integrated into the machine head. With the adoption

directly coupled to the upper shaft.

to

reduce machine operating noise and increase safety have been taken to produce a

comfortable working environment.

more

-1

general thin materials.

tion to

and

most up-to-date single needle straight lock stitcher

conventional functions, this machine

be

equipped under the table, is built into the machine head,

is

provided to flexibly cope with the sewing of difficult-to-sew materials

of

the design.

of a new

is

designed

in

our range, with a

lubrication system and

to

give better cost

and

is

in

addi-

1

..

fJ

Specifications

•

Machine

082-007100-

head specifications

I

Device

Thread

wiper

3 -

4

9

0

0 0

Automatic

presser

-

-

9

99-l

Lower thread detector

lifter

o I

. 1 I

1

I

None

Installed

..

I

1

3

5

)

I

Application

*Difficult-to-sew

and

thin materials

Medium heavy

materials

Heavy materials

I

Operation panel

B-20

8-40

B-100

..

Single needle direct drive straight lock stitcher

with thread trimmer

• Difficult-to-sew material specifications refers to the ability to

of

materials from general thin materials to materials made from new

synthetic fibers, without puckering or unevenness

in

the seam occurring.

()

sew

007100

a range

Page 3

)

)

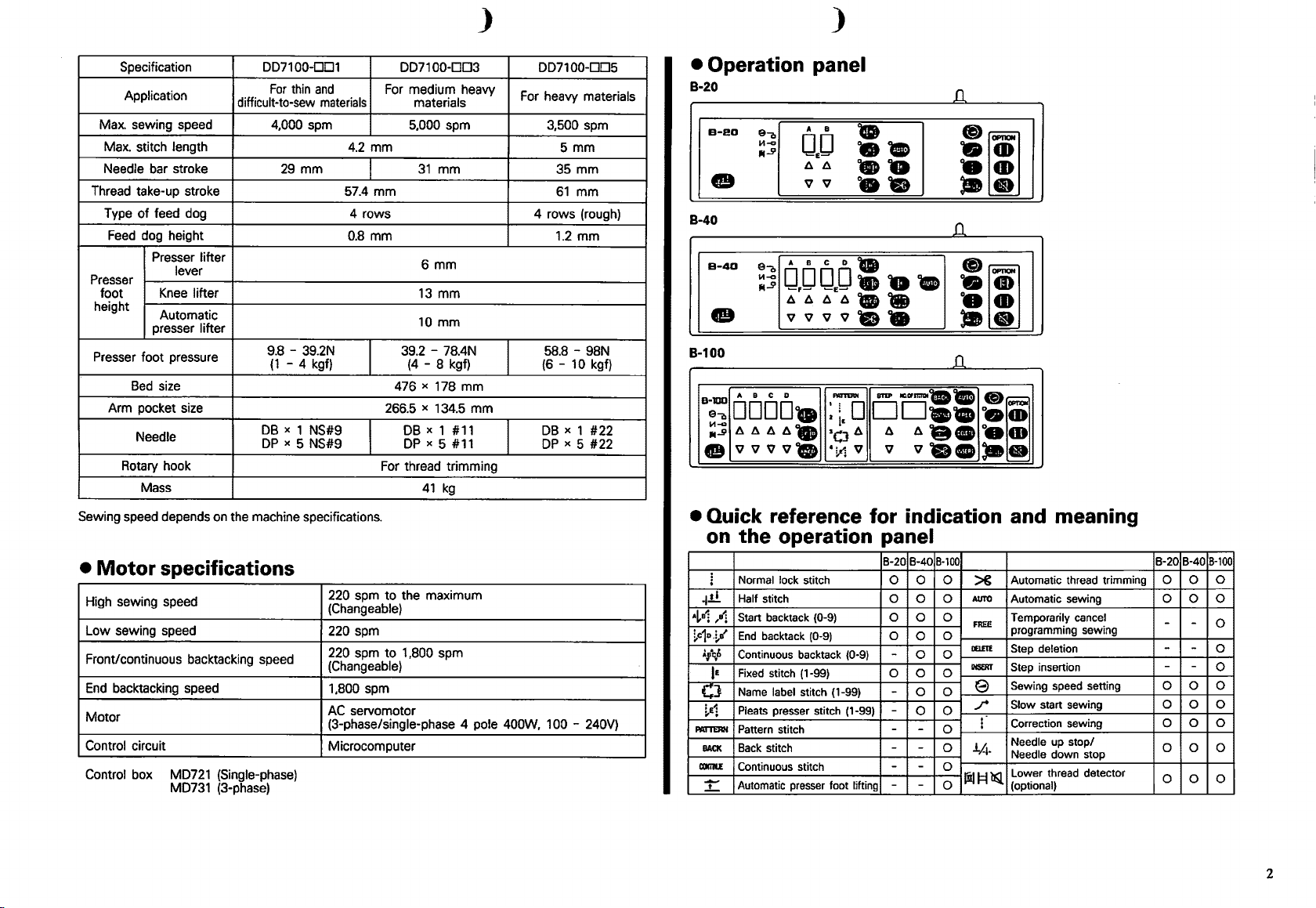

Specification DD7100-001

For

thin

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Thread take-up stroke

Type

of

feed dog

Feed dog height

Presser lifter

Presser

foot

height

Presser foot pressure

Arm pocket size

Rotary hook

Sewing speed depends on the machine specifications.

•

Motor

High sewing speed

Low sewing speed

Front/continuous backtacking speed

End

backtacking speed

Motor

Control circuit

Control box MD721 (Single-phase)

lever

Knee

Automatic

presser

Bed

size 476 x 178

Needle

Mass

specifications

MD731 (3-phase)

difficult-to-sew

lifter

lifter

9.8-

DB

DP

and

materials

4,000 spm

29

mm

39.2N

(1

- 4 kgf)

X 1 NS#9

X 5 NS#9

4.2

mm

57.4

4 rows 4 rows (rough)

0.8

mm

220 spm

(Changeable)

220 spm

220 spm

(Changeable)

1,800 spm

AC

servomotor

(3-phase/single-phase 4 pole 400W, 1 00 - 240V)

Microcomputer

DD7100-003

For medium heavy

materials

5,000 spm 3,500 spm

31

mm

mm

6

mm

13

mm

mm

10

39.2-

78.4N

(4

- 8 kgf)

mm

x 134.5

266.5

DB

DP

For thread trimming

41

to

the maximum

to

1 ,800 spm

mm

X 1 #11

X 5 #11

kg

For heavy materials

DD7100-005

5 mm

35

mm

61

mm

1.2

mm

58.8-

98N

(6

- 10 kgf)

DB

X 1

X 5

#22

#22

DP

• Operation panel

8·20

a-eo

e

e-a

Ill-<~

--...9

A B

OJJ

11 11

v v

•

••

••

••

B-40

B-40

e

B 100

-

A B C D FIGTEIIN

B-100

ea

DODD•

jll-cl

_....9

11111111.

vvvv.

e

• Quick reference

the

on

Normal lock stitch

!

.j.!.!.

Half stitch

A~B1

,a1

Start backtack (0-9)

~c1o,~a'

End

~,q,&

Continuous backtack (0-9)

Fixed

IE

Name label stitch (1-99)

CJ

Pleats presser stitch (1-99) -

!.e1

PlA1TERH

Pattern stitch -

BACK

Back

coma

Continuous stitch

Automatic presser foot lifting -

-

..!....

A B C D •

ea

jll-cl

_....9

O,OOEO•

11111111

v v

v

••

vee•

,.

D

2

~&

,o

11

.!.-1

v

operation

backtack (0-9)

stitch (1-99)

stitch -

••

STEP

IIUIFIIlliDI

oo

11

11

v

vcee

for

indication

panel

B-20 B-40

0 0 0

0 0 0

0 0 0

0

0

0 0

-

0 0 0

0 0

-

0 0

-

-

- -

-

D.

..,

·;

••

-·

D.

•m

-~

••

-·

D.

••

••

••

o•m

·;

••

--

and meaning

8-100

Automatic thread trimming

~

AUTO

Automatic sewing

Temporarily cancel

FJIEE

0

0

0

0

0

programming sewing

DELETE

Step deletion

II&Rf

Step insertion

Sewing speed setting

e

Slow start sewing

.r

Correction sewing

i

Needle up stop/

J.A.

Needle down stop

Lower thread detector

lill=t

lQ.

(optional)

B-20 B-40

0 0

0 0

- -

-

-

- -

0 0 0

0 0 0

0 0

0

0 0 0

0 0

0

B-100

0

0

0

0

0

2

Page 4

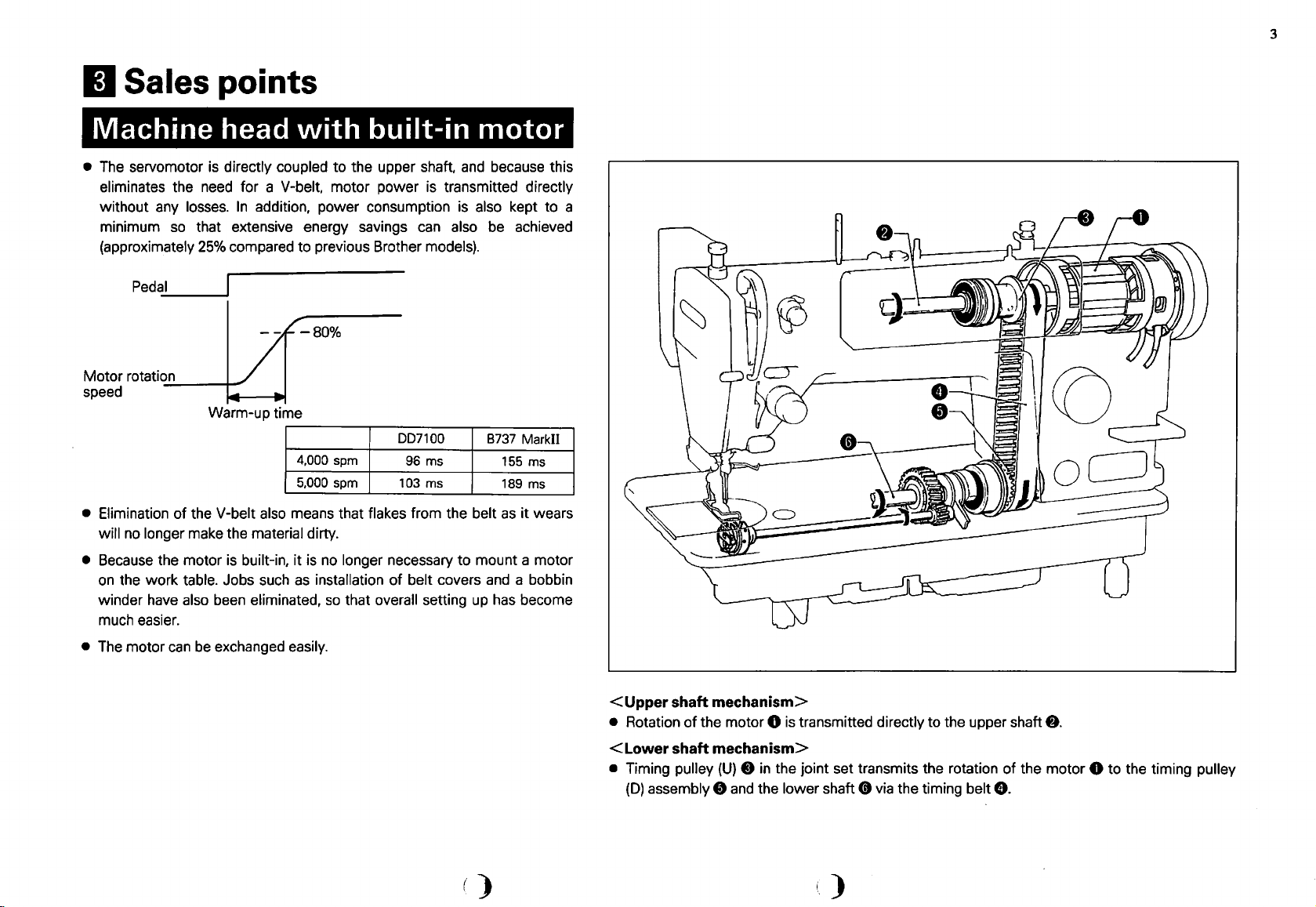

II

Sales points

3

Machine head

• The servomotor

eliminates the

without any losses.

minimum

(approximately

Pedal

---~

• Elimination of the V-belt also means that flakes from the belt

will

no

longer make the material dirty.

• Because the motor

on

the work table. Jobs such

winder have

much easier.

is

directly coupled to the upper shaft,

need

for a V-belt, motor power

In

so

that extensive energy savings

25%

compared to previous Brother models).

Warm-up time

is

built-in, it

also been eliminated,

with

addition, power consumption

4,000

5,000

is

no

as

installation

built-in

is

can

007100

spm

spm

longer necessary to mount a motor

so

that overall setting

96

ms

103 ms

of

belt covers

motor

and

transmitted directly

is

also kept to a

also be achieved

8737 Markll

and

up

because this

155

ms

189

ms

as

it

wears

a bobbin

has

become

•

The

motor

can

be

exchanged easily.

<Upper

• Rotation

<Lower

• Timing pulley

shaft mechanism>

of

the motor 0

shaft mechanism>

(D)

assembly 8

(U) 8 in

the joint set transmits the rotation

and

the lower shaft 0

is

transmitted directly to the upper shaft

of

via

the timing belt

8.

I,)

8.

the motor 0 to the timing pulley

Page 5

)

)

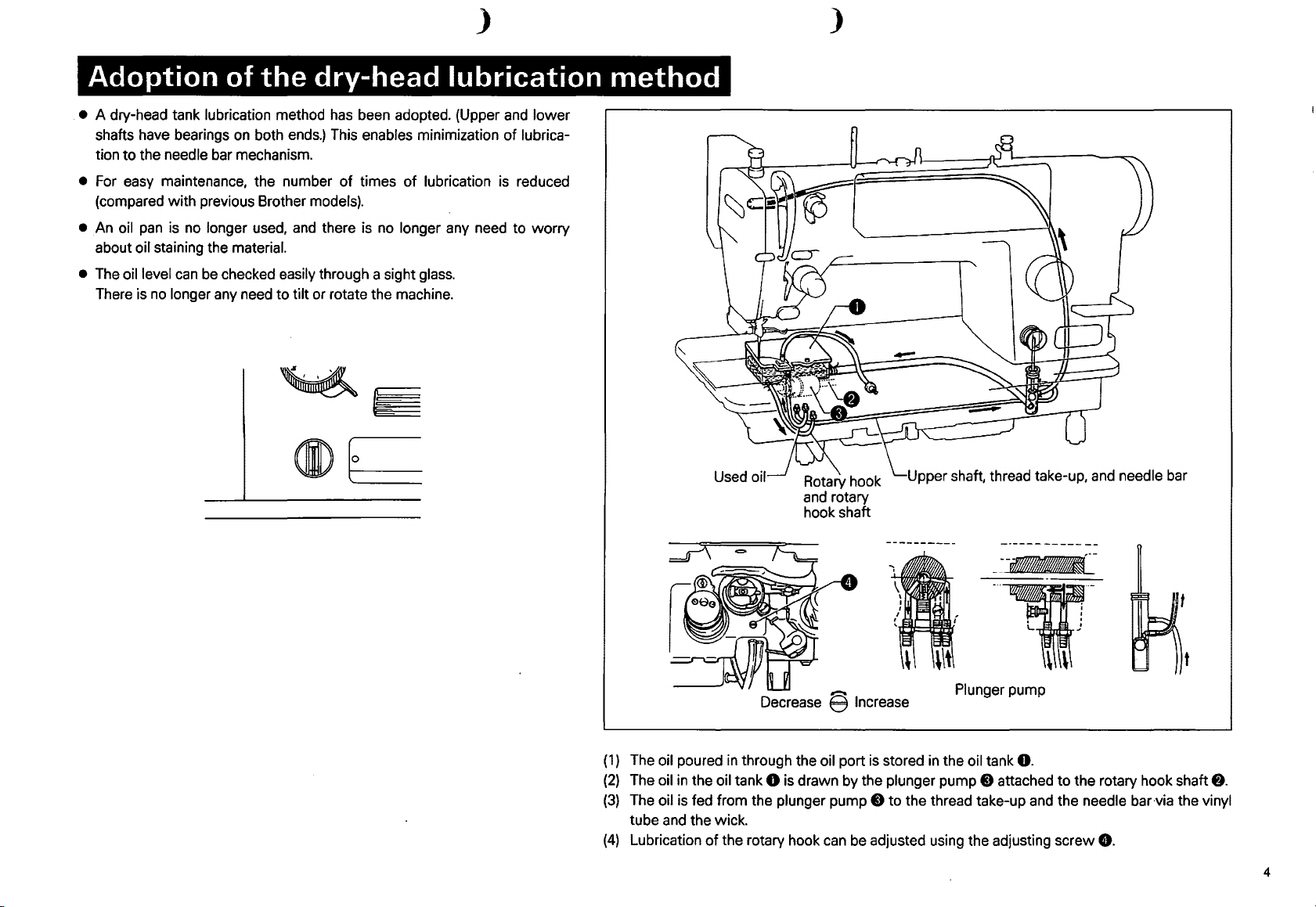

Adoption of

• A dry-head tank lubrication method has been adopted. (Upper and lower

shafts have bearings

tion

to

the needle bar mechanism.

• For easy maintenance, the number

(compared with previous Brother models).

•

An

oil

pan

is no longer used, and there is no longer any need to worry

about oil staining the material.

• The oil level

There is

can

be checked easily through a sight glass.

no

longer any need to tilt or rotate the machine.

the

on

both ends.) This enables minimization

dry-head lubrication

of

times

of

lubrication is reduced

of

lubrica-

method

Upper shaft, thread take-up, and needle bar

--~-

-·-1fi··-

. .

L J

\ \

Decrease § Increase

(1)

The oil poured

(2)

The oil

(3)

The oil is fed from the plunger pump 0 to the thread take-up and the needle bar via the vinyl

tube and the wick.

(4)

Lubrication

in

in

through the oil port is stored

the oil tank 0 is drawn by the plunger pump 0 attached

of

the rotary hook

can

be adjusted using the adjusting screw

Plunger pump

in

the oil tank

0.

to

the rotary hook shaft

0.

t

8.

4

Page 6

5

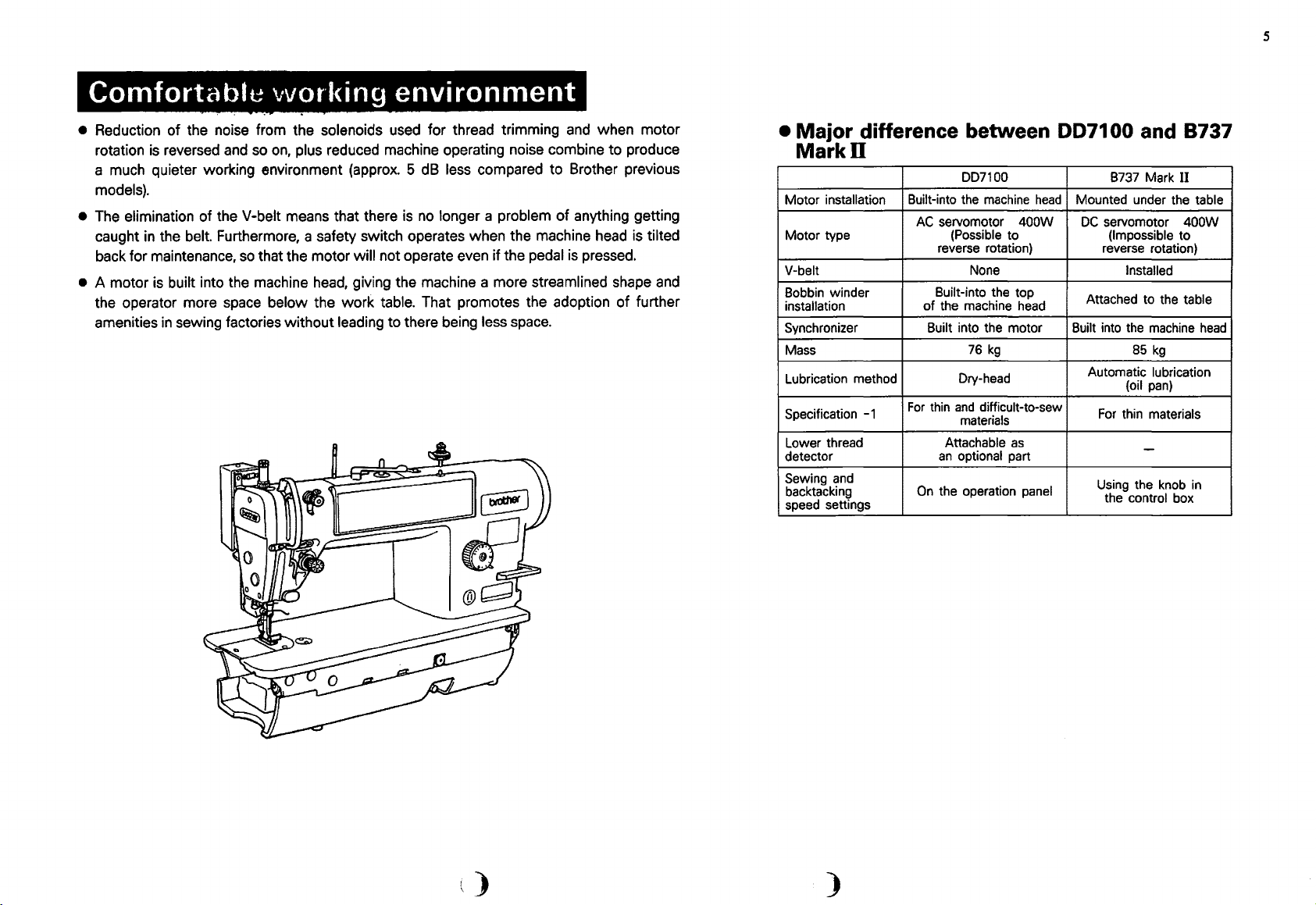

Comfortable

• Reduction of the noise from the solenoids used for thread trimming

rotation

a much quieter working environment (approx. 5 dB

is

reversed

and

vvorking

environment

and

so

on,

plus reduced machine operating noise combine to produce

less compared to Brother previous

when motor

models).

• The elimination of the V-belt means that there

caught

back for maintenance,

• A motor

in

the belt. Furthermore, a safety switch operates when the machine head is tilted

so

that the motor will not operate even if the pedal

is

built into the machine

head,

giving the machine a more streamlined shape

is

no

longer a problem

of

anything getting

is

pressed.

the operator more space below the work table. That promotes the adoption of further

amenities

in

sewing factories without leading to there being less space.

and

• Major difference between

Markll

DD7100

Motor

installation

Motor

type

V-belt

Bobbin winder

installation

Synchronizer

Mass

Lubrication method

Specification -1

Lower thread

detector

Sewing and

backtacking

speed settings

Built-into the machine

AC

servomotor

(Possible to

reverse rotation) reverse rotation)

None

Built-into the top

of

the machine head

Built into the motor Built into the machine

kg

76

Dry-head

For

thin

and

difficult-to-sew

materials

Attachable

an

optional part

On

the operation panel

head

400W

as

DD71

00 and 8737

B737 Mark

Mounted under the table

DC

servomotor 400W

(Impossible

Installed

Attached to the

85

kg

Automatic

For

lubrication

(oil

pan)

thin materials

-

Using the knob

the control box

II

to

table

head

in

)

)

Page 7

}

)

Flexible handling of even previously

• The focus

mechanisms such

high speed.

Needle bar stroke

Needle

Rotary hook For thin material Plastic race (lubrication not required)

Maximum sewing speed

*It is possible to attach a plastic race (lubrication not required).

• The special tool for measuring the presser foot pressure is no longer needed. A tension gauge set enabling easy measurement

and

of

machines with -1 specification is

as

the needle

(See

page

7.)

lower thread tensions is provided

bar,

DD71

on

sewing materials which are thin and difficult-to-sew. As a result

thread take-up, and rotary hook, materials which were previously difficult-to-sew

page

For

8.)

00-1 * for

materials specification

DB

as

difficult-to-sew

29.0

mm

X 1

#9

NS

4,000 spm 3,500 spm 4,000 spm

(In

this case, the maximum sewing speed is 3,500 spm.)

an

optional part.

(See

difficult-to-sew

new

synthetic materials specification

on the B737

31.0

mm

DB

X 1

#10

NS

materials

of

modification

can

be sewn at

B737-1 for thin materials

31.0

mm

DB

X 1

#11

For thin materials

of

Others

• The switches for

and check the current settings easily.

•

After thread trimming, the machine can be stopped with the needle at its highest position by reversing the motor. This is useful when

changing the

slow

start, correction stitch, and needle up/down stop position are provided

materials to be sewn, thick materials

in

particular.

(See

page

9.)

on

the operation panel so that you can

of

upper

s~t

• Gauge parts for the 8737

• A lower thread detector (optional part) is provided to indicate the remaining lower thread. This is useful when sewing a product that

allows

no

overlapping or incomplete stitching.

and

those for other manufacturer's

(See

page

7.)

can

be used.

6

Page 8

II

Optional parts

• Lower thread detector (183955-001)

The

lower

thread remaining will be displayed

thread detector will warn you that the thread has been all used up according

in

amount you set

issuing beep.

This is

Use the bobbin case

•

Set

*When the following part set is used on the machine, regularly set the sewing speed

useful when sewing a product that allows no overlapping or incomplete stitch-

ing.

for

new

advance by making the

assembly (525780-001) exclusive

synthetic fabric (for specification

as

% on the operation panel. The

lower

thread remaining indicator blink and a

to

the

DD71

00.

-3)

(18391 0-001)

lower

to

the

to

2,800 spm. (Max. 3,500 spm)

7

Adjusting

(S35781-001) li

Spring~

(S35783-001) m

Presser bar

pressure gauge

(S35782-001)

Presser

regulating

spring

(S35780-001)

Spring----~

(14751-001)

[For

screw~

ri

:--1

low

tension)

r--

Presser regulating

screw assembly

(S35779-001)

[with presser foot pressure indication]

Needle

DB

(S35775-31

[Plastic race:---..........._

lubrication

not required] r::'

Rotary hook

box assembly l }l 1

(535784-901)

r-------------------,

I

~Spring

I [For

: Spring (115188-001) :

1

I • I

L----

X 1 NS#10

0)

I

~

RP

~

C

~p:~.:~n

(S35788-001)

low

[For

""'->,,

..........

~

l

......

,}i\.'\Voef)V~.~~1

:...

..,

''

:~

I

.........

l,.,.,..,.'

......

' :

(100399-001) I

low

[For

low

~.::~

tension)

,.

l

..J

tension] I

tension]

1

I

•=m~y_j

Presser foot assembly

(S35777-001)

[For

low

friction]

~Screw

(S35786-001)

[without

lubrication hole)

When you change specifications -1 so

able

to

handle

following parts:

· Rotary hook

·Screw

(535786-001)

new

synthetic fabrics, use the

RP

box assembly (535784-901)

as

to

be

',)

)

Page 9

)

• Tension gauge set (183922-001)

This

is

a device designated for easy measurement

production is required, or the same thread tension is required on different machines.

of

upper and lower thread tensions. This is useful

when

frequent changing

)

of

threads and materials

to

be used for small-lot

Upper thread tension measurement

• Thread

wiper

set (183956-001)

• Presser foot lifting solenoid set

Presser foot lifting solenoid set A (with knee lifter) (183959-001)

Presser foot lifting solenoid set 8 (without knee lifter) (183960-001)

Lower thread tension measurement

8

Page 10

II

DIP switch functions

See

page

16,

"1!1

Connector configuration" for the

Presser foot position when the foot pedal

is

returned to the neutral position after

1

thread trimming

Setting of a delay from the time the

presser foot is turned

2

3

4

starts

Needle

rotation

(See

NOTE

up

stop position due to reverse

2.)

OFF

until the motor

5

Limited speed setting 1

6

7 Limited speed setting 2

8

DIP

switch position.

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Presser foot

Presser foot is kept raised. (Japanese specification only)

(See

With delay

Without delay

The machine stops with the needle at its highest position

due to reverse rotation.

The machine stops with the needle at its highest position

without reverse rotation.

N.C

Maximum sewing speed (during high-speed sewing) that

can

Always set to off.

is

lowered. (Export specification)

NOTE

1.)

be

set through the operation

(See

NOTE

4.)

panel

(See

NOTE

3.)

(NOTE

(NOTE

(NOTE

(NOTE

1)

Once the knee lifter switch

the foot

the machine

to raise

2)

For

automatic presser foot lifter), be sure to set

3)

Limited sewing speeds depend

and 7 as

sewing speed

panel, it

If the setting

sewing speed

DIP

switch 6

OFF

ON

OFF

ON

4)

If

pedal

can

not

is

stopped; at this time, only the knee lifter is able

and

lower the presser foot.

-900 series specification machines (machines with

shown

in

is

is

actually limited to 4,700 spm.

DIP

switch 8 is set to

Be

sure to set it to off.

specified

of

memory switch 04 is changed to

is

not limited to

DIP

is

be

used to raise the presser foot while

the following table. When the maximum

as

4,

switch 7

OFF

OFF

ON

ON

on,

all

pedal operations are deactivated.

used to lower the presser foot,

an

on.

the set

on

settings for

5,000 spm

700 spm.

DIP

switch 2 to

DIP

switches 6

on

the operation

on.

Limited speed

3,500 spm

4,000 spm

4,500 spm

5,000 spm

9

Page 11

Parameter

setting

Start

flowchart

Set memory switch 01 to

Turn

off

ail

For

Leave the machine

* Press the thread trimming and AUTO keys. (The

LED of

LEDs.

the

B-1C0operation panel,

the

thread trimming key will blink, and a

parameter number

•

Select

the

and V keys below

Press

desired

other parameter setting

the

thread trimming key. (The value corre

ON.

*1

stopped

will

parameter

the

Change

r finish

select

after thread trimming.

appear on the ABdisplays.)

number

Bdisplay.

settina?

Change

pattern 1.

using

the

Finish

spending to the currently set parameter number

will

blink.)

Change

the

value

using

theAand7keys

below

theABdisplays.

*1: Refer to

A

the

memory

switch

setting

flowchart

The

data

currently

set

for

the

parameter

can be

checked only while the A key below the A dis

play is kept pressed. *2

*2:As to the data related to backtacking, press the A key to indicate the timing

angle

(*15*)

*3

Indicate

parameter

and V keys

Changing completely?

Further

number99using

below

the

B display.

changes

the

and v keyto

No

more

A

indicate

changes

a plusor

Indicate

minus

parameter

symbol.

number

90.

Related

will

blink.)

using

I'

to

theAkey

below

theBdisplay.

(Parameter

num

M

=

*3:As to backtacking information,the timing angle

*4:Select a plus < -/ > or minus symbol < — > for the value determined in

♦3.

backtacking?

Press the thread trimming key.(The plus or minus sym

bol

currently

Select

Press

ber

selected

the

plusorminus

the

thread

will reappear.)

symbol

trimming key.

Press

the

thread

trimming key.

End

("15*)

willappear.

10

Page 12

fi

Parameters

11

Parameter

10

11

13

14

15

16 12

17

18

20

21

22

23

24

26

27.

30

31

32

33

*

*

~

No.

15

05

30

36

00

10

40

02

05

50

10

07

03

05

-04

00

+02

-04

Default value

(150

ms)

(50

ms)

(300

ms)

(3

min.)

(30

ms)

(10s)

(40

stitches)

(20

ms)

(50

ms)

(50

ms)

(10

ms)

(7

ms)

(30

ms)

(0.5s)

(-60°)

(0°)

(30°)

(-60°)

Data

value setting range

00 -25

03

10

00 -60

00

10 -12

05

00 -99

01 -07

04

40 -70

05 -25

01 -15

00 -05

02 -50

-23

(On

plus are

-23

(On

plus

-23

(On

plus

-23 to

(On

plus are

(x1Q]

(0 -250

- 10 (x10]

- 90

- 60 (x2.5]

- 30

- 10

to

the

to +23

the

are

to

the

are

the panel, indications for minus

(30

(x1Q]

(100

(x5]

(5

sec.

(0

(5 -30s)

(0 -99

(x10]

(10 -70

(x1Q]

(40

(x10]

(40 -70

(x1]

(5 -25

(x1]

(1 -15

(x10]

(0 -50

(x0.1]

(0.2 -5.0s)

+23

(in

15°

panel,

indications for minus

" - "

and

(in

15°

panel,

indications for minus

" - "

and

+23

(in

15°

panel,

indications for minus

..

- "

and

+23

(in

15°

" -

II

and

ms)

- 100

- 900

- 5

- 150

ms)

stitches)

ms)

- 100

ms)

ms)

ms)

ms)

increments).

" -{

,.

increments)

II

-{

" respectively.)

increments)

II

-{

" respectively.)

increments)

II

-{

II

ms)

ms)

min.)

ms)

respectively.)

respectively.)

Function

Time delay from the time the machine starts to operate with the automatic presser foot raised to the time the motor

operates.

Time delay from the time the thread wiper turns

Time to keep the automatic presser foot lifter raised

The

presser foot signal will be automatically off after the set time

foot signal

Time from the presser foot lowering command to the presser foot

Constant voltage required to turn

Puller continuous

The

Time delay from the time the machine stops after thread trimming to the time the thread wiper operates

Thread wiper

Lower thread detecting

The

The

Time delay from the thread wiper

Time delay from the time when the machine stops with the needle at its highest/lowest position to the lower thread

detecting

and

Quick reverse device ON-timing

and

Quick reverse device OFF-timing

and

Quick reverse device OFF-timing upon

and

The

is

not automatically off.

on

the presser foot after the presser foot lowering command

ON

time

number of stitches to

ON

time

first

ON

time of the lower thread detecting

first

OFF

time of the lower thread detecting pin

pin

ON

(Lower thread detection function at the needle up/down stop with the foot pedal

second ON-timing for the quick reverse device upon double

be

produced from the start of sewing until the puller lowers

pin

ON

control time

OFF

to the lower thread detecting

upon

start or continuous backtacking

upon

start

end

OFF

until the automatic presser foot turns

(in

all

blocks)

pin

and

continuous backtacking

backtacking

passes.

ON

pin

end

backtacking

When the data

once

ON

is

ON

set to

00,

in

the presser

neutral)

The

parameter numbers appear

(NOTES)

*:

The

timer-off function for the presser foot is activated only when memory switch 36 is set to off.

*:

This parameter is available only when memory switch 35

+:The

lower thread detection function for the needle up/down stop when the pedal

~:

This parameter is available only when memory switch

on

the

panel.

22

is

set to

is set to

on.

on.

is

positioned at neutral

is

activated only when memory switch

51

is set to

on.

Page 13

)

II

Memory switch setting flowchart

• Leave the machine stopped after thread trimming.

• Turn

off

all

LEOs

(For the

· Press the needle up/down stop key while pressing the thread trimming key.

(A

needle

8-1

8-1

memory switch number will appear on the

up/down

00 operation panel, the setting will be indicated

(except for the

00 operation panel, select pattern

stop key will be lit to indicate the direction

LED

of

the needle

1.)

A8

up/down

displays,

on

the D display.)

stop

and

of

either

movement.

key).

of

the

two

On

LEOs

of

the 8-40

)

the

---------· ............................... ------------,

or

·----------··------------Y

• Select

•

~------------------------------------------------------------~------------------------------------------------------------~

Change

the desired memory switch number using the

Press the needle up/down stop key

of

the

two

LEOs

of

(Either

operation panel, the

the needle

1::..

and

v keys below the D display can be used instead.)

to

1::..

change the setting

up/down

stop key will be

and v keys below the

of

the memory switch.

lit

On

the 8-40

A8

displays.

or

8-100

...............

Indication when memory switch

is

set

to

off

~

~@

~

Indication when memory switch

is set to on

....................... .

D

and

I

@I

.aD

D

~@and

'V

~

· Keep pressing the thread trimming key at least for 1 second

(All

LEOs

(NOTE)

except for the

If the power is turned

renewed.

LED

of

the needle up/down stop key will be turned off.)

off

before the end operation, memory switch settings are not

to

cause a beep to be issued.

12

Page 14

II

Memory switches

13

Memory switches

01

Parameter setting

Interlocking along with

02

forward step

Power supply drop

03

check

04

Limited sewing speed

Needle penetration force

05

06

07

08

(NOTE

1)

When the power

is

01

turned

- 08

Parameter setting

ON

OFF

Parameter setting change

Forward step

ON

(for thread trimming).

Forward step

OFF

(for thread trimming).

Power supply drop check (reset detection)

ON

function

OFF

Without the above-mentioned function

The

ON

(See

Maximum sewing speed

OFF

Needle penetration force

ON

OFF

Needle penetration force

ON

OFF

ON

OFF

ON

OFF

on

again,

is

same

NOTE

sewing speed

can

be

is

possible during backward step

is

impossible during backward step

activated.

as

settings of

1.)

can

DIP

is

is

is

be set

changed.

is

prohibited.

switches 6

limited to 4,700 spm.

strong.

ordinary.

up

to 5,000 spm.

and

7.

Memory switches

Thread trimming

11

thread wiper output

Presser foot position

after thread trimming

12

(See

NOTE

Presser foot position

after the machine stops

13

with the pedal

14 Actuator switch

15 Slowdown stop control

Lower thread remaining

16

detection

17

Half-stitch correction

Reverse stitch correction

18

2.)

and

in

neutral

11

- 18

ON

Without thread trimming

OFF

With thread trimming

Presser foot

ON

neutral.

Presser foot is lowered when the foot pedal is in

OFF

neutral.

ON

Presser foot

Presser foot is at its lowest position.

OFF

It

is

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

used

It

is

used

Ordinary slowdown stop

Slowdown

tion

Unable to

Able to be

A forward stitch or half stitch

(See

A forward stitch

cannot

A forward stitch or reverse stitch

rected.

A forward stitch

cannot

is

raised when the foot pedal

is

at its highest position.

as

the thread trimming switch.

as

the reverse

and

stop control with 1

be

used.

used.

NOTE

3.)

be

(See

be

can

corrected.

NOTE

can

corrected.

and

thread wiper

and

thread wiper

and

correction switches.

and

control

can

be

corrected. A half stitch

(See

NOTE

3.)

3.)

be

corrected. A reverse stitch

(See

NOTE

3.)

is

stitch elimina-

be

corrected.

can

be

cor-

in

(NOTE

2)

It

(NOTE

3) A forward stitch

stitch or reverse stitch

lit.

is

activated when

()

DIP

switch 1

can

be

corrected when the

can

be corrected when the

is

set to

on.

LED

of the correction switch

LED

of the correction switch is not

is

lit. A half

Page 15

)

)

Memory switches

Double start backtacking

21

Double end backtacking

22

Number

start backtacking plus 1 0

23

stitches

Number of stitches for

end backtacking plus 1

24

stitches

Feed

start backtacking is com-

25

pleted

Start end backtacking

26

Continuous backtacking

27

setting

Number

continuous backtacking

28

plus 1 0 stitches

of

stitches for

direction when the

of

stitches for

0

21

- 28

Start backtacking

ON

lengths A,

Start backtacking

OFF

lengths A and

End

backtacking is performed

lengths

ON

B-20 operation panel).

End

lengths C and D

OFF

panel).

Extra

ON

stitches set for both lengths A

No extra stitches are added.

OFF

Extra 1

stitches set for both lengths C

ON

on

No

OFF

The

ON

remaining

The machine

OFF

normal.

End

ON

down.

The machine

to start low speed sewing, then shift to end back-

OFF

tacking.

Forward stitching for the number of stitches set

in

number

ON

performed repeatedly for the number

set

Continuous stitching will be performed for lengths

OFF

A,

Extra

ON

C,

No

OFF

C,

backtacking

1 0 stitches are added to the number

0 stitches are added to the number

the B-20 operation panel).

extra stitches are added.

machine will stop with the reverse feed

backtacking will start without speed slowing

the A display, and backward stitching for the

of

in

the D display.

B,

C,

and D

1 0 stitches are added

and

D.

extra stitches are added.

is

B,

D,

on.

stitches set

performed

A,

then

B.

is

performed

B.

C,

and D

is

performed

(B

and A

will stop after feed

will slow the sewing speed gradually

(The

as

specified

in

the order

in

the order

in

(B,

in

the order

A,

B,

and A

in

the order

on

the B-20 operation

and

and D (B

is

the 8 display will

C display will

in

the

to

each lengths A,

on

the

B.

and

returned to

of

times

be

ABCD

displays.

of

of

of

of

of

of

A

be

blank.)

B,

Memory switches

Start backtacking suspensian by foot pedal being

placed

in

31

backtacking speed

change during the start

backtacking

The number

32

stitches

B-40 operation panel

Pleats presser stitching

33

direction

-

34

Presser foot soft drop

35

function

Presser foot timer-off

36

function

37

38

(NOTE

4)

(NOTE

5)

(NOTE

6)

(NOTE

7)

neutral or

of

backtack

on

the B-20 or

For

the B-40 operation panel, the number

fixed stitching or pleats presser sewing.

This setting depends

to

00,

the machine response will

This setting depends

to 1

0,

the machine response will

Timer-off function

is

31

- 38

Sewing can be suspended by returning the foot

pedal to neutral. During start backtacking, sewing

ON

speed depends

Sewing

foot pedal to neutral. During start backtacking,

OFF

sewing speed is fixed regardless

pedal stroke.

The number

ing, label attaching, or pleats presser sewing can

ON

be

The

(for fixed stitching, label attaching, and pleats

OFF

presser sewing).

Without reverse stitching (Fixed stitching will be

ON

called

With reverse stitching (Ordinary pleats presser

OFF

stitching)

-

ON

-

OFF

Manual soft drop function

ON

Automatic soft drop function

OFF

Timer-off function

ON

will not be lowered by timer.)

Timer-off function

OFF

ON

OFF

ON

OFF

on

the setting

on

not activated when parameter No.14 is set to

be

the setting

be

can

changed.

number

back.)

of

parameter No.15. When parameter No.15

the fastest but with noisy operating sounds.

of

parameter No.16. When parameter No.16

the fastest but with noisy operating sounds.

on

the foot pedal stroke.

not

be

suspended by returning the

of

backtack stitches for fixed stitch-

of

backtack stitches

(See

NOTE

4.)

(See

is

not activated. (Presser foot

is

activated.

of

end backtack stitches

NOTE

(See

(See

00.

of

is

NOTE

can

the foot

fixed to 4

5.)

6.)

NOTE

7.)

be changed for

is

set

is

set

14

Page 16

15

Memory switches

Mode after lower thread

41

alarm

Rotary hook

42 the lower thread

detector

43

(See

44

(See

Delayed start of standing

45

operation

Emergency stop

presser lifter pedal

46

during standing

operation

Emergency stop using

variable speed pedal

47

during standing

operation

Lifting the presser foot

using thread trimming

48

pedal during standing

operation

Memory switch

Puller output selection

61

(lifting/lowering the

I I

NOTE

NOTE

used

8.)

8.)

with

by

61

puller)

41

- 48

Foot pedal

ON

After lower thread alarm, the foot pedal operation

OFF

is deactivated until the cancel key is pressed.

1.7-time rotary hook

ON

Standard rotary hook

OFF

-

ON

Be

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

1--0-F-F-+-P-u-lle_r_o_u_t_pu-t---------------11

sure to set to off.

-

Be

sure to set to off.

Without any delay.

With a delay (for 80

Impossible to make

presser lifter pedal

During automatic sewing, emergency stop

performed using presser lifter

Impossible to make

variable speed pedal

During automatic sewing, emergency stop

performed using variable speed

It

is

pedal is used.

It

is

Synchronizer signal output I

can

be used after lower thread alarm.

ms).

an

emergency stop using

pedal.

an

emergency stop using

pedal.

always deactivated after the presser lifter

activated.

can

can

be

be

Memory switches

Lower thread detection

after the machine

stopped by putting foot

51

52

53

54

55

56

57

58

(NOTE

(NOTE

in

pedal

(See

Needle up/down stop

key operation

8)

9)

neutral

NOTE

Do

not change these settings.

The

time for delay

ward within the time, lower thread

This function

is

9.)

can

is

available for sewing process without thread trimming.

51

OFF

be

- 58

is

Lower thread

stopped by putting foot pedal

ON

specified time.

Lower thread is not detected after the machine

OFF

stopped

Needle up/down stop key operation

ON

(Needle stop position cannot

OFF

Needle up/down stop key operation is activated.

ON

OFF

ON

OFF

ON

OFF

ON

ON

OFF

ON

OFF

changed

in

parameter

will not detected.

detected while the machine is

by

putting foot pedal

be

No.

27.

If the foot pedal

The

default delay

in

in

neutral for the

neutral.

is

deactivated.

changed.)

is

pushed for-

is

0.5

seconds.

is

Page 17

1m

Connector configuration

)

)

CN7

6j@oooo§Jj1

z 0

Nrn

0

~

...,.

~~

z

~

0 0

~m

0

0

r-..

z 0

wm

0

~

...,.

~~~~ansformer

seconda~

co11

11

CNS

DSW

1

8

~ooooooooo§Jj

FVR

1

~1!!!!!!!!1

CN9

ljo

o ol3

(I

I

FUSE2

ToCNS

l.liii

[]

IJML7

1

AC201V[]D.

D:f-1{

/NOD

AC20V

ID

AC20V

0

20

AC

~L_

______

1.

Connectors

2.

Connector

are

illustratec:t

positions

as

are

different from

CNS

0000000000

19

0000000000

20

(X)-

...,.

-

z

Lt')

0

-CD

FUSE1

11o

(Power)

SA

o o

o14

CNM

Ground

u

v

w

...,. N

CN1

(Motor)

g

SA

ToCN7

6

~

I

0

0

z

,\

.,..

....

'*"

(/)

6V20W

TMI

2 1

- 0

z 0

om

0 :

CND

1

Ground

1XXV

2

3

1XXV

4

2XXV

2XXV

5

2XXV

6

I

-411

r---......::<=::::5~

CJ.......!:Q=~;;;;:>

viewed from the

actual

To

the transformer primary

pin

side.

ones.

CND

coil

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

CN1

(Transformer) (Forward step)

AC10V

AC10V

AC30V

AC30V

CN10 CN12

External

power

supply

DC+12V

DC+5V

sov

ov

+40V

(E1)

CN2

DC+8V

DC+5V

Forward

sov

(Presser

ov

Presser

Presser

Presser

step

power

switch

output

input

foot)

CN3 CN4 CN5

(Standing

DC+8V

High

speed

Thread

trimming

sov

Low

speed

Presser

Variable

operation)

switch

switch

foot

speed

switch

switch

input

(Detector)

F.

G

N.C

N.

C

N.C

sov

ENCA

ENCB

u B

v

w D

Needle

down E

Needle

up

DC+5V

N.

C

N.

C

N.C

CN13 CN14

(Machine)

F.

G

N.

C

Thread

trimmer

Thread

wiper

Quick

reverse

ov

OV

N.·c

N.C

Tlvead

trirming

Thread

wiper

Quick

reverse

Quick

reverse

Safety switch

power

power

power

output

output

output

swi1ch

(lower

thread)

F.

G Puller output

N.

C

Sensor

input

Lower

thread

power

DC+8V

sov

DC+5V

Lower

thread

output

(Panel)

DC+5V

sov

KEYO

KEY1

KEY2

oc

A

c

(LEDO)

F

(LED1)

G

(LED2)

PLED

DC+8V

SEN

BUZZ

N.

C

N.C

N.

C

CN15

(Puller)

N.

C

N.

C

N.C

N.

C

Puller

N.

C

N.

C

N.

C

N.

C

(STB)

power

CN6

(VR/Bobbin

DC+5V

VR

(Bobbin

Bobbin

output

sov

TM1

(lamp)

AC6V

AC6V

changer)

input)

CN9

(Transformer)

AC6V

N.

C

AC6V

16

Page 18

1D

Perspective

view

17

Page 19

r

""(:---

r.

I

(

r----

----

-

·~·

.,

,

......

.

()

.....

·,

:-·:

~

BROTHER

~rinteci

INDUSTRIES,

in Japan

LTD.

NAGOYA,

JAPAN

117-510

160506888

1996. 05.

<D

Loading...

Loading...