Page 1

SERVICE

FOR

082-8797

082-8798

MANUAL

SINGLE NEEDLE ADJUSTABLE

BOTTOM

FEED

LOCK STITCH MACHNE

. .

~

TOP

·

'

AND

Page 2

CONTENTS

I

SPECIFICATIONS,........................................................

I

MECHANICAL

II)

Upper shaft and needle bar mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IZ]Lower shaft and rotary

~Upper

II]

Presser

I

STANDARD

DESCRIPTIONS

I·.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

hook

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . 4

feed mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . 5

foot

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . 6

ADJUSTMENT

I·.............................................. 7

1

IIJAdjusting feed

IZ]Adjusting

~Adjusting

IIJAdjusting feed

rn:JAdjusting

II)Synchronizer

[l]Replacing

'OTHER,

[!]Sewing

IZ1Sewing

~Attaching

IIJAttaching material end sensor . . . . . . . . . . . . . . . . . . . • . . . • . . . . . . . . . . 14

timing

timing

presser

dog

feeding

<Alternative

<Feeding

<Adjusting

<Adjusting

foot

feeding

feeding

{082-8798)

fixed and movable knives

between needle and rotary hook . . . . . . . . . . . . . . . . 7

foot

foot

up and

and presser

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

height

height

and presser

down

foot

foot

. . . . . . • . • . . . . . . . . . . . . . . . . . . . • . . . • . . . . . • 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

foot

movement

foot

height>

front

and rear

feed>

{082-8798)

. . . . . . . . . . . . . . . . . . . . . . . . . . 9

of

feeding and presser

. 0

0. 0 ••••••••

position>

....

0

••••

0 0

....... .-.......................................................

with

synthetic thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with

vi nylon thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

presser

foot

lifter

set . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . .

foot>

0

••

0. 0 0...

0

•••

0

•••••

••••••

0

•••

0

•••••

. . . . . . . . . . . . • . . . . .

9

9

0...

0 • • • • 9

9

11

12

12

12

13

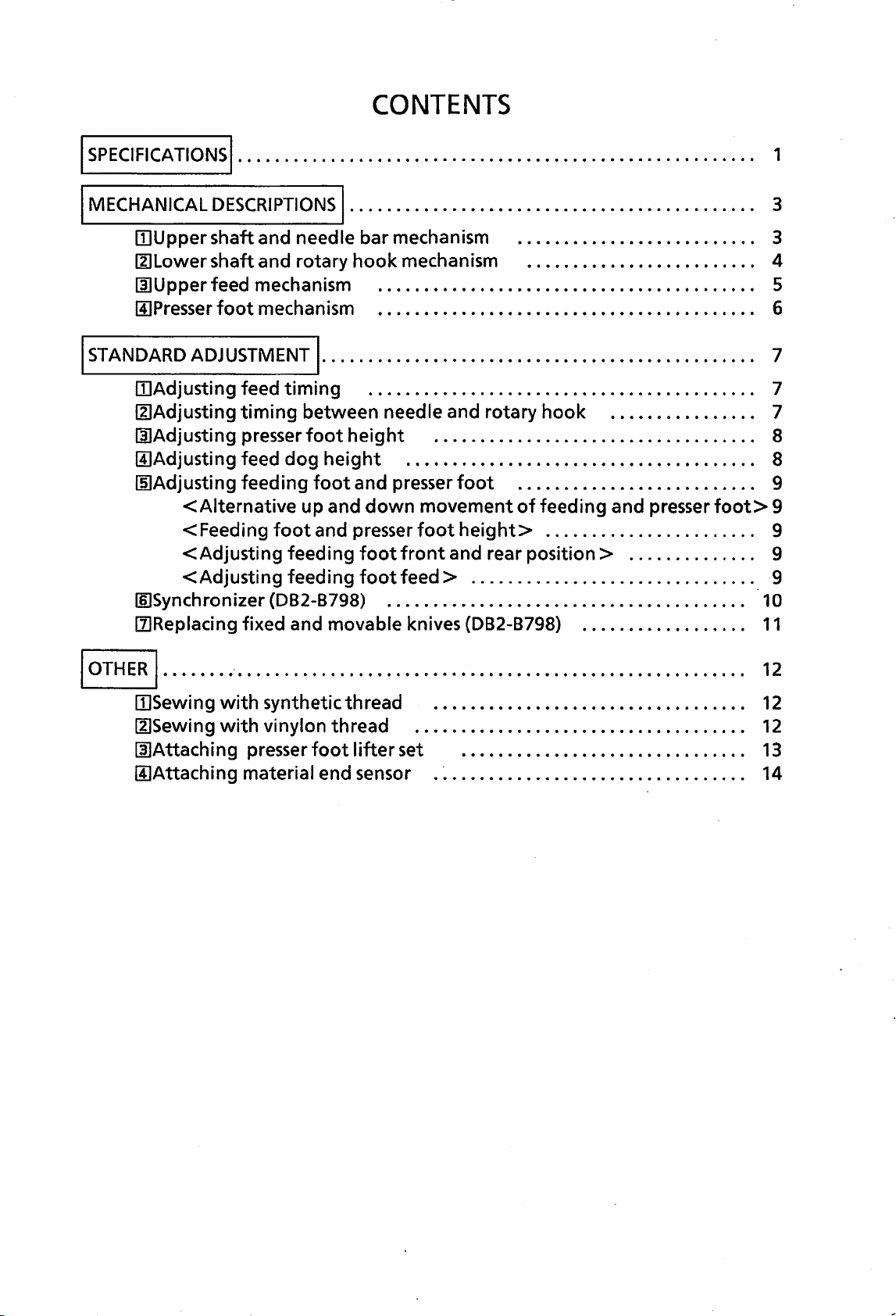

Page 3

I

SPECIFICATIONS

[B

797]

I

[B798]

Options are

Operation panel

E- 20

E-

40

E-20

E -

as

0

40

0

follows.

Production counter

@

brother

EJ

P.COUNTER

Material end sensor

SENSORll

E-

100

-1

-

Us

e one

of

the sensor t

the

operation

ogether

panels and

.

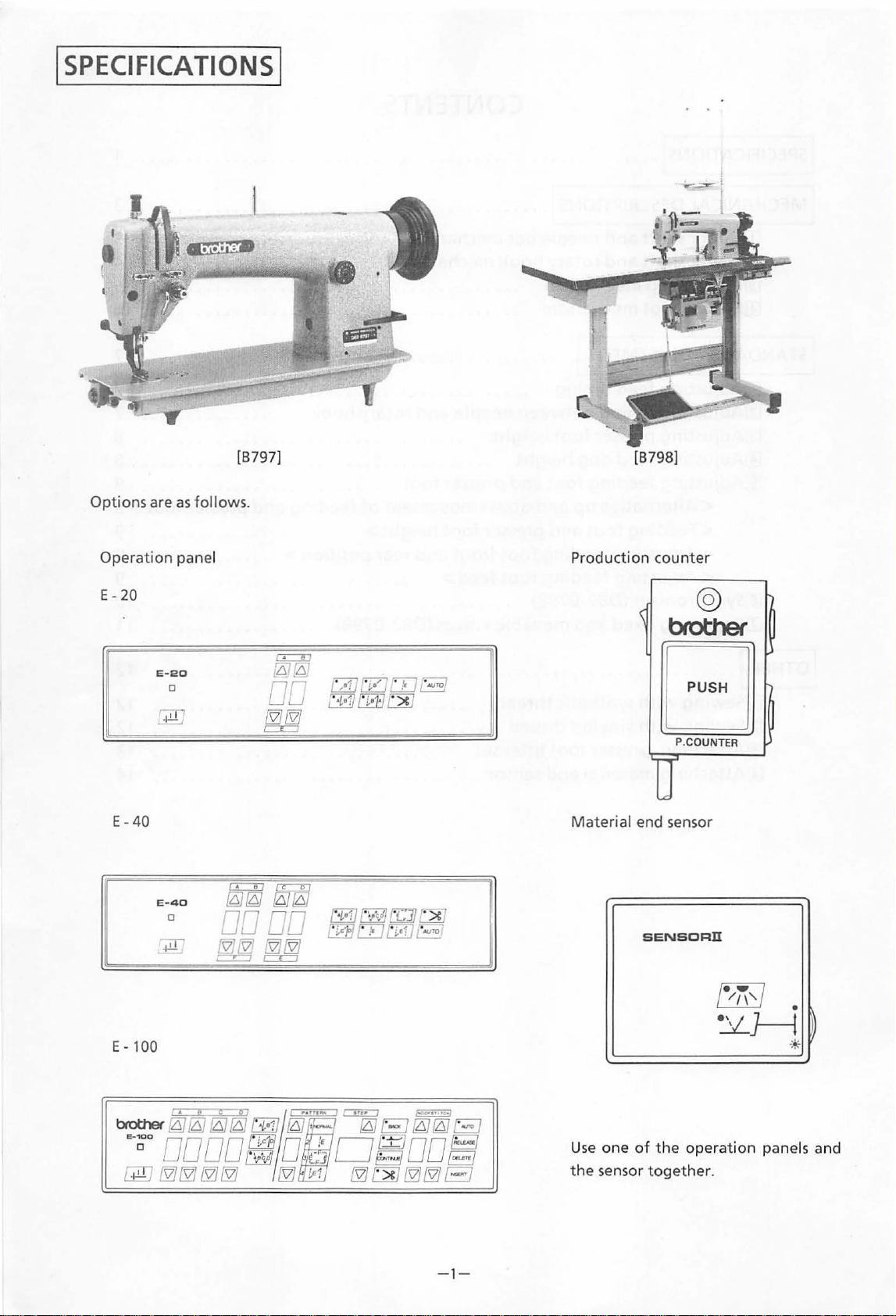

Page 4

DB2-B797

DB2-B798

Application

Sewing speed

Sewing

Height

(knee

Height

(presser bar

Rotary hook

Weight

Thread take-up stroke 73mm 73mm

Needle bar stroke

Presser

length

of

presser

of

presser

Lubrication

Needle

of

machine head 30kg 30kg

foot

foot

lifter)

foot

lifter

lever)

stroke 4.5mm 4.5mm

Thick material

2000spm

0-Smm

14mm

7.5mm

Double sized

Manual lubrication

DPx

17#23

(39mm)

34mm

Thick material

2000spm

0-9mm

15mm

Smm

Double sized

Manual lubrication

DPx

17#23

38mm

Feeding

Height

Durability

foot

of

feed dog

stroke

2-4.5mm

1.2mm

Thread take-up and needle

•

bar crank have bearings. bar crank

Upper feed rock lever

•

stud screws.

uses

Thread take-up and needle

•

bearings.

Upper feed rock lever

•

taper

2.2-4mm

1.2mm

do

threads.

not

have

uses

-2-

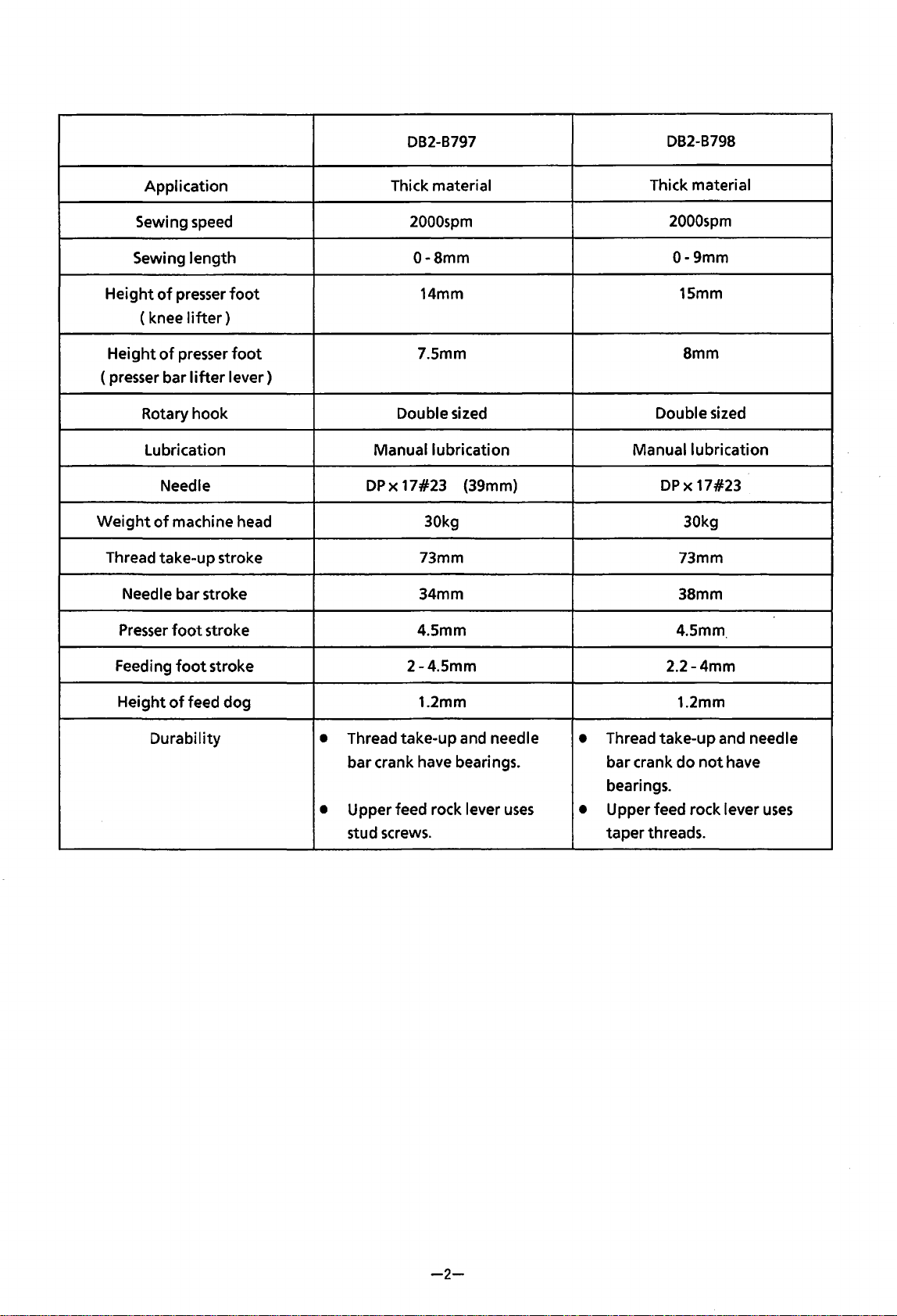

Page 5

I MECHANICAL

[II

Upper shaft and needle bar mechanism

DESCRIPTIONS!

1)

When

2)

The

3)

The counter

4)

The needle bar crank e

5)

The thread

6)

The needle bar

the

pulley 0 rotates

upper

shaft@

weight@

take-up

then

rotates

in

then

lever 0 moves

f)

is

guided by

in

turn

the

direction

the

counter

rotates

rotates

the

the

needle bar bushings, (U) @ and

ofthe

the

attached needle bar crank e.

the

thread take-

needle

arrow,

weight@.

bar

f),

up

attached

the

lever

upper

0.

to

the

shaft@

needle bar clamp

(D)

rotates.

@.

0,

up

and

down.

- 3-

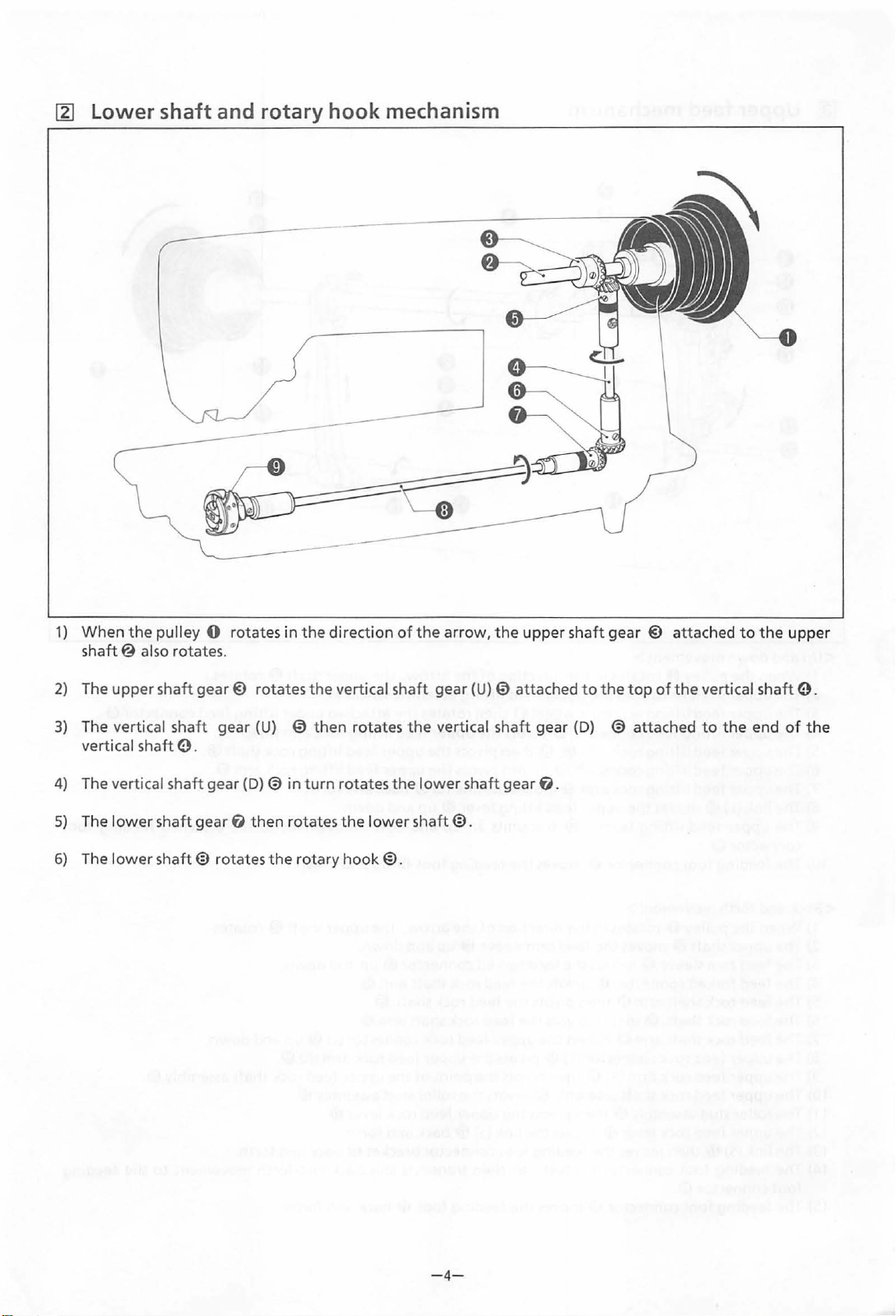

Page 6

~

lower

shaft and rotary hook mechanism

1)

When

shaft@

2)

The

upper

3)

The vertical sha

vertical

4)

The vertical

5)

The

lower

6)

The l

ower

the

also

shaft

pulley 0

rotates

shaft

gear@

ft

e.

shaft

gear

shaft

gear

shaft@

rotates

.

rotates

gear

(U)

(D)@ in

f)

then rotates

rotates

the

in

the

0

turn

rotary

direction

the

vertical sha

then

rotates

the

hook@.

rotates

the

lower

of

the

ft

the

lower

shaft@.

arrow,

gear

vertical

the

(U) 0 attached

shaft

shaft

upper

gear

gear

f).

shaft

gear @ attached

to

the

top

(D)

@

attached

of

the

to

vertical

to

the

the

shaft

end

upper

e.

of

the

-4-

Page 7

@]

Upper

feed

mechanism

<Up

and

down

movement>

1)

When

the

pulley 0 rotates in

2)

The upper

3)

The upper feed

4)

The upper

5)

The upper feed

6)

The upper feed

7)

The upper feed

8)

The

9)

The upper feed

connector®.

10)

The feeding

<Back

and

1)

When

2)

The upper

3)

The feed cam sleeve@ moves

4)

The feed

5)

The feed rock

6)

The feed roc k

7)

The feed rock

8)

The upper feed rock connector

9)

The upper feed rock arm

1

0)

The upper feed rock shaft

11)

The

12)

The

13)

The

14)

The

foot

15)

The feeding

shaft@

lifting

link

{L)@ moves

foot

forth

movement>

the

pulley

shaft@

forked

shaft

shaft @ in

shaft

roller

stud assembly@

upperfeed

link

(S)@

then

feeding

connector®.

foot

foot

rotates

lifting

feed connector 0 pivots

lifting

lifting

lifting

lifting

connector®

0 rotates in

moves

connector

arm

arm®

rock lev

moves

connector bracket

connector®

the

direction

the

upper feed li

eccentric

rock arm

rock

rock arm

the

upper

lever @ transmits an up-and-down

ill

turn

(R)

er@

wheel@

(R) 0 then

shaft@

the

ill

then

moves

®then

assembly®

then

moves

the

in

f)

moves

feed

moves

the

direction

feed

cam

the

feed

pivots

pivots

pivots

the

{L)

(f) pivots

pivots

the

feeding

moves

lifting

the

the

pivots

of

the

arrow,

fting

eccentric

then

rotates

the

upper

pivots

turn

pivots

the

link

lever@

the

feeding

ofthe

sleeve@ up and

forked

the

upper feed rock connector

pivots

the

lin

foot

a>

the

connector

feed rock shaft arm ill.

feed rock shaft

feed rock shaft arm

the

upper

the

point

the

upper feed rock

k {S)@ back and

connector bracket

then

transmits this back-and-f

feeding

the

feed

the

upper feed

the

upper feed

(L)@ back and

up

and

foot

ID

arrow,

feed rock arm

of

the

roller

stud assembly@.

foot

ID

the

upper

wheel@.

attached

lifting

down.

up and

the

upper

down.

ill

up

@.

®.

upper

lever@.

forth.

a>

back and

shaft@

upper

lift

rock arm

lifting

lifting

forth.

movement

down.

and down.

{L)

feed rock shaft

back and

rock

rock arm

shaft@

(f)

up

and

{R)

®.

orth

forth.

(R)

rotates.

ing feed connector 0 .

0.

shaft@.

f).

to

the

attached

rotates.

down.

assembly®.

forth.

movement

feeding

to

the

foot

feeding

-5-

Page 8

[!]

Presser

foot

mechanism

1)

When

the

2)

The

upper

3)

The

upp

er feed

4)

The

upper

5)

The

upper

6)

The

upper

7) The

8)

9)

1 0) The presser

11)

upper

The

link

(L)@

The

upper

The presser bar

pulley 0 rotates

shaft@

liftin

feed

feed

feed

feed

foot

rotates the

lifting

g feed connector e pivots

lifting

lifting

lifting

then

moves

lifting

bar

bracket®

ID

moves

in

the

eccentric

rock arm

rock

shaft@

rock arm

the

lever@

the

presser

upper

direction

wheel@

(R) 0 then

in

f)

moves

upper feed

in

turn

then transmits this back-and-

feed

turn

moves

foot

of

the

lifting

the

@ up and

eccentric

then

rotates

the

upper

pivots

the

pivots

the

link

lifting

lever@ back and

the

presser

arrow,

(L)@ back and

it rotat

the

feed

upper feed

upper feed li

foot

down

es

wheel@.

attached

lifting

.

forth.

bar

forth

rock arm

lifting

bracket®

the

upper

upper

(R)

rock

fting

rock arm

forth.

movement

shaft@.

lifting

feed connector e.

0.

shaft@

f).

back and

to

the

.

forth.

presser bar

ID.

-

6-

Page 9

I

STANDARD

ADJUSTMENT

lil Adjusting feed timing

I

penetration

1.

4

........

Smm

5.

Smm

6

mm

1)

Turn the pulley

2)

Loosen

3)

Loosen

turning the feed

~

<Needle bar rise>

the screw and detach the rear plate.

the

Adjusting timing between needle and rotary hook

to

make the feed dog even

two

screws

cam

0.

@ in the direction

with

the needle plate

Adjust the needle penetration

of

the arrow.

Rotate the pulley toward yourself and align

rotary hook point 0

the needle

or

I 0. I

mm

less

•

•

NOTE: When using

Loosen

point

At

this time,

the gap between the rotary hook

the

needle@

top

surface.

to

4-6mm shown in the figure above by

with

needle center @ when

is

raised

the screw

0

with

2.2

mm

from its lowest position.

@).

Align the rotary hook

the needle center@.

secure

the rotary hook 0

is

less

than

0.1

vi

nylon thread,

mm.

see

point

P.12.

the

so

that

0 and

-7-

Page 10

<Needle bar

height>

0.5--l.Smm

~

Adjusting presser

foot

height

Adjust

and rotary hook

rotary hook

center@.

•

The

raised using the presser

1)

2)

3)

the

gap between the

point 0 to

point

Loosen

up and

standard presser 0 rise

Loosen

the

@.

Put a 7.5 mm gauge

the presser

Loosen

0 up and

the screw

down

the presser adjusting screw

presser

the screw 0 and move the presser

down

0

to

adjust

foot

0 using the presser

foot

0.

to

top

of

the needle

0.5-1.5 mm when the

is

aligned

@).

Move the needle bar 0

the

foot

lifter@.

or

something similar under

adjust.

with

the

gap.

is

7.5 mm when

@)

foot

eye

needle

it

is

and raise

lifter

foot

[!]

Adjusting feed dog height

-8-

The

standard feed dog 0 height from the needle

plate

top

at

its maximum.

•

Loosen

@)

up and

surface

the

screw@.

down

is

1.2

mm when the stitch length

Move

the

feed ·lifting arm

to

adjust.

is

Page 11

~

Adjusting feeding

foot

and presser

foot

<Alternative

up and

down

movement

left

JMJ'l

<Feeding

-------=-==--

same

height

foot

and presser

foot

height>

of

feeding and presser

foot>

The

feeding

and down

The

feeding

equal or slightly lower than

highest position.

1)

Lower the presser

thread take-up

2)

Loosen

lifting

When moved

When moved

The

standard height range

• Loosen

appropriate

upper

down.

Maximum height . . . . . 4.5

Minimum height . . . . . 2 mm

foot

0 and presser

alternately.

foot

the

rock arm 0

the

lifting

0 height position should be

is

screw 0 .Move

right

left

nut

to

the

feed connector shaft 6 up and

foot

at

its highest position.

right

and left.

. . . .

. . . . .

is

2-4.5

@)

and adjust

material by

mm

foot

@ move up

the

presser

lifter

Presser

to

Presser

@)

while

the

upper feed

foot

rises

the feeding foot.

foot

descends.

mm.

the

moving

foot

the

even

heights

the

@

2-4.5mm

<Adjusting

<Adjusting

feeding

feeding

foot

foot

front

feed>

and rear

position>

The

feeding

feed

dog@

•

Loosen

shaft

The

feeding

feed dog 0 feed.

•

The

conditions.

•

Loosen

and down

foot 0 end

end.

the screw

assembly«!)

foot

feeding

the

nut

to

should

@).

to

adjust.

@ feed should

foot

feed

Q). Move the roller stud

adjust it.

be

aligned

Turn the upper feed rock

be

can

be

changed

with

equal

to

to

4D

the

the

suit

up

-9-

Page 12

[§]

Synchronizer (082-8798)

21--23mm

.The

synchronizer detects

ICs.

Also,the synchronizer controls needle lowest

position signal and thread

one hole

The

and screw bottom

needle

between the

needle

stopped

Be

IC.

distance between the needle plate

should

is

at

its lowest position. Also,the distance

needle plate

tip

is

12-13

mm when

at

the needle highest position.

sure

to

turn

off

the

the

needle

trimming

be

21-23

top

surface and

the

power when adjusting.

with

top

mm

when the

machine

two

signal

surface

the

is

hole

with

<Adjusting needle thread trimming signal sensor

position>

1)

2)

NOTE:

Turn

the

pulley

operation

from its

If

the hole

@ bottom, loosen the screw e and move

hole

Move the hole

operation

position.

Move the

direction

to

lowest position.

IC@

IC@

to

adjust it.

to

in

the

direction

raise the needle bar 0

is

not

aligned

IC@

to

raise the needle bar 0 highest

hole

IC@

lower it.

in

in

with

the

direction

the

opposite

the

magnet

of

of

7.5

the

the

mm

the

<Adjusting needle highest

•

Loosen

NOTE:

the screw@

Move

the

the

Move

hole

hole

position>

to

move the hole

IC

€)

in

the

IC@

in

the

IC@

and adjust it.

direction

opposite direction

of

the operation

to

-10-

to

raise it.

lower the needle bar 0 highest position.

Page 13

(1]

Replacing fixed and movable knives

Be

sure

to

turn

off

the power when replacement.

fixed

<Replacing

knife>

lower

thread

finger

(082-8798)

1)

Tilt the sewing machine head.

2)

3)

Remove

case

Remove

knife0.

the screw

holder position bracket

the screw

0,

and remove the bobbin

@.

@)

then remove the fixed

<Replacing movable

knife>

fig.

A

NOTE:

1)

2)

3)

4)

5)

If

the fixed knife 0

an

oil stone

Raise

the

lever.

Remove

plate@>.

Turn the sewing machine pulley until the needle

bar reached its highest position.

Press

manually in

position

reached then stop.

Remove

movable knife

the

the

at

the

to

presser

screws

thread

the

which

screws

@).

has

lost its sharpness,

sharpen it,

foot

@)

cutter

direction

the

screws

as

shown in Fig.A.

by using the presser

then remove the needle

connecting

of

the

@)

can

@)

and then remove

rod 6

arrow

be

foot

until

seen

use

is

the

NOTE:

NOTE:

-11-

When removing the needle plate @)and the

movable knife

needle.

Reassembly can be

reversing the above procedure.

@),

be

sure

performed

to

first remove the

by simply

Page 14

!OTHER

I

[]] Sewing

When sewing

[082-

8797]

with

with

synthetic thread

synthetic thread, thread

as

in the figure below.

[082-

8798]

~ Sewing

with

vinylon thread

2.8-3.0mm

When sewing

machine pulley towards you

hook

point 0 is

needle

mm above its lowest position.

@ when the needle

with

aligned

vinylon

with

thread,

so

that

the

the center

is

raised

turn

rotary

of

2.8-

the

the

3.0

-12-

Page 15

@1

Attaching presser

foot

lifter set

Attach

<Measuremen~s,

the

presser foot lifter set

top

view>

machine

table

edge

to

the

underside

46mm

107mm

of

the

table as shown

in

the

58mm

62mm

figure below.

<The

underside of

the

table>

-13-

Page 16

[!]

:>.<:

Make

sensor

Attaching material end sensor

sure

the

power

is

off

when

attaching

the

material end sensor.

D

1)

Change

shown

2)

Remove

operation

Plug

the

in

the

the

panel.

the

connector of

posi

tion

figure

rubber

of

on

the left.

cap

the

the

on

sensor

operat

the

into

ion

side

the

panel

of

panel.

as

the

SE

NSORU

3)

Be

careful

connector and attach

two

screws.

not

<Thread

to

catch

ing

the

the

the

flat

sensor

cord>

cable

II

with

of

the

the

Put

the

reflect

ion

plate

direct

ly

under

the sensor.

-

14-

Page 17

...

. ;

...

. -,.:·

.;

BROTHER

HEAD

OFFICE:

HORITA-OORI,

CABLE:

BROTHER

TELEX:

4473696

1990.01.

INDUSTRIES,

No.

35,

9-CHOME,

MIZUHO-KU,

NAGOYA,

BROS

Printed in Japan I

NAGOYA,

J

LTD.

JAPAN

0010418H

467

Loading...

Loading...