Page 1

INSTRUCTION

FOR

MANUAL

BROTHER

SINGLE NEEDLE ADJUSTABLE TOP

LOCK

[~=

M

=

A

=

~

=

H

=

*

Au

to thread trimming machine DB2- B792 h

$BROTHER

DB2 -

MADE

ODD

Thread trimmer Single needle lock stitch machine

Thr

ea

d wiper

Quick rever

P

resse

r foot

Shi

rr

ing devi

STITCH

~

=

N

~:=

s

=

P

=

E

INDUSTRIES

B792-

IN JAPAN

se

li

ft

ce

~

C

=

IF

=

IC

=A=

ODD

j-"'

------

MACHINE

T

=

I

=

O

=

N

=

S

LTD

I

103

--

-----

DB2-B792-100,-200,-500,-600

With

AND

AUTOMATIC

BOTTOM

THREAD

==========~==============================~

.

I

~

Soleno

--

as the followin

203

id (buil

g specifications.

503

t-in

face plate) I

I

Pn

eumatic

Pneumatic

60

3

FEED

TRIMMER

11

3 613

Pn

---------------

~

Pn

Included

eumat

ic

eumatic

]

[~=

N

=

A

=M=

E

==

O

=

F

=M=

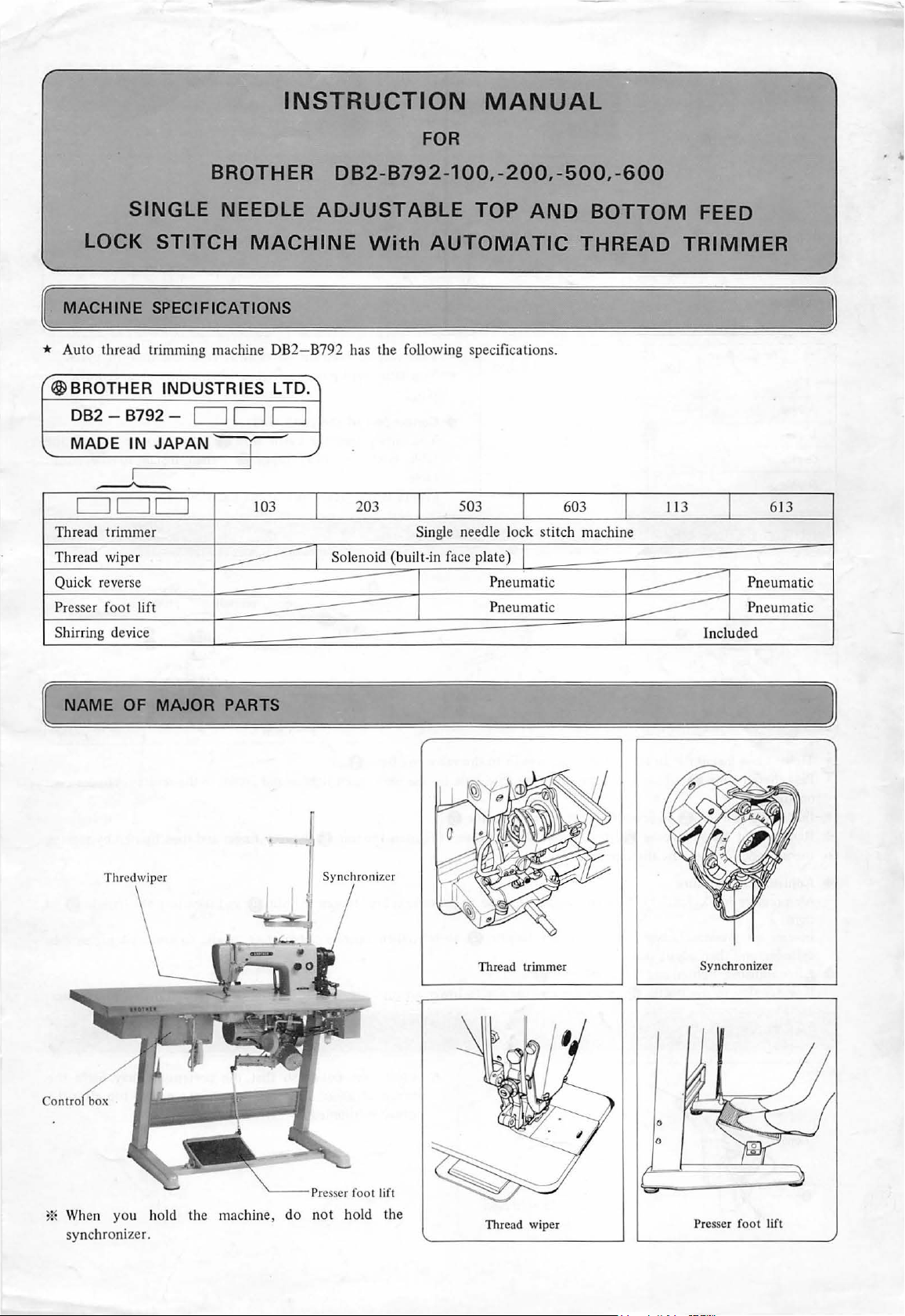

Thrcdwipcr

AJ

==

O

=

R

~

P

=

A

~

R

=

T

~

S

========~==============~~==~==========

Sy

nchronizer

Thread trimmer

Synchronizer

(}

6

~]

Presser foot lift

*

Wh

en you hold the

sy

nchronizer.

mac

hine, do not hold the

Threa d wi

per

Presser

foot

lift

Page 2

[~=

CO

=

N

=

N

=

E

=

C

=

TI

=

O

=

N

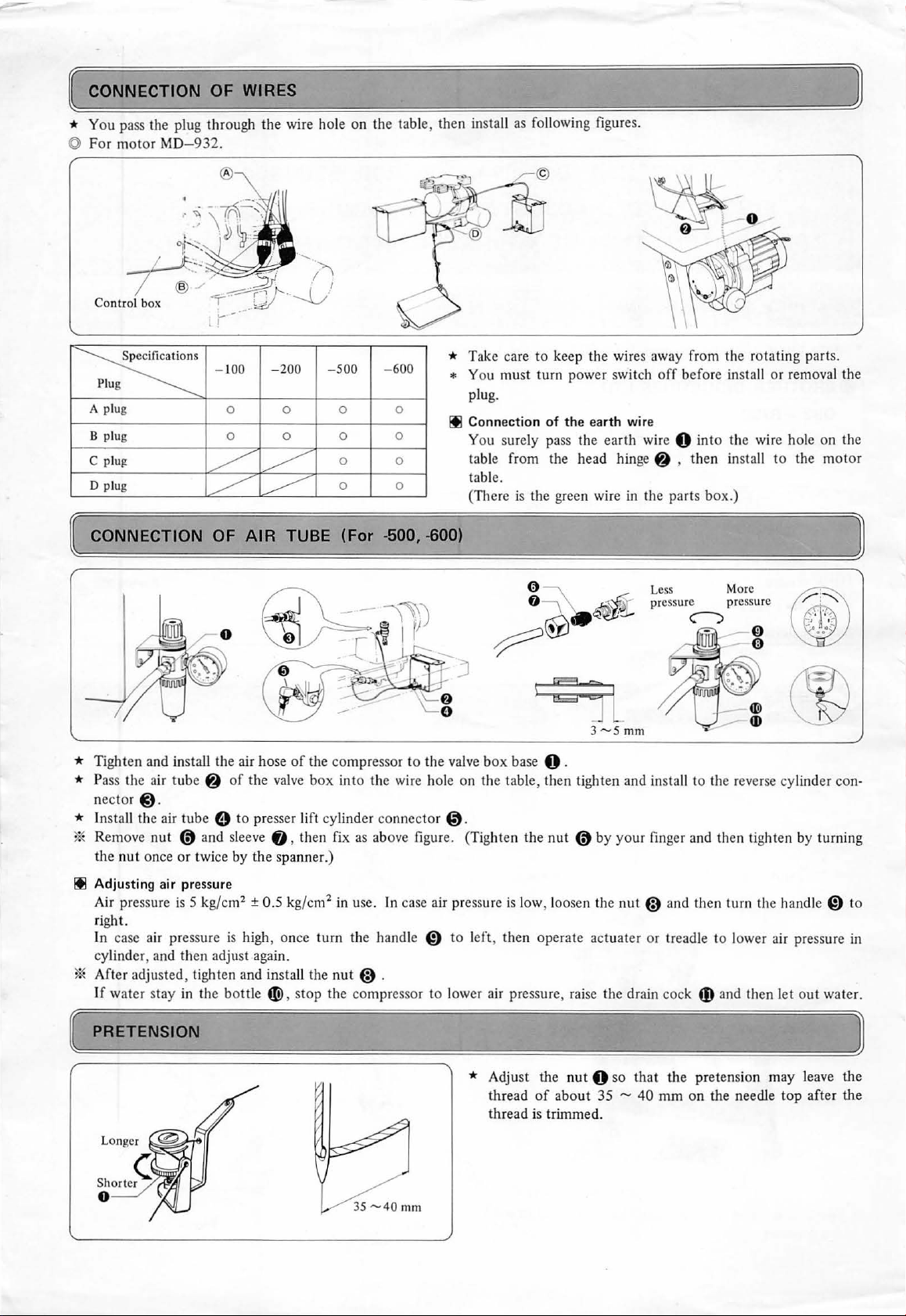

*

You

pas

s the plug th rough

©

For

motor

MD

-932.

=

O

=

F

==

W

®

=

IR

=

E

=

S

======~====~========~==============

the

wire hole

on

the

table,

then

install as following figures.

~]

g

~

A

plu

g

B plug

C plu!!

D plug

[~=

C

=

O

=

N

=

N

=

E

=

C

=

T

=

IO

* Tigh

* Pass the air

* Insta

* Remove

nec

the

ten

tor

ll

nut

@ .

the

and install

tube 8 of

air

nut

once

- 100

0 0

0 0

~

~

=

N

==

O

=

F

the

tube 9 to

(3

and sleeve

or

twice by

-2

00

-

500

0 0

0 0

~

~

=

A

=

I

=

R

==

T

air hose

of

the valve

presser lift cylinder co nnec

fj

, then fix as above

the

spanner.)

0

0

~

=

U

=

BE

==

(

the

compressor

box

into

=

Fo

=

r

- 600

0

0

=

-

=

5

=

00

the wire hole on

* Take care

* You must

ttl Conn

=

,

=~=

0

=

0)

====

to

the valve box

tor

@)

.

fi

gure. (Tighten

to

keep

the

wires away from the r

turn

power swit ch

plug.

ec

tion

of the

ear

th

Y

ou

surely pass

tab le from the

tab le.

(There is

the

th

~

~==========~~==========~]

base 0 .

table,

the

the

earth

head

e green wire in

3-S

then

tighten and insta

nut

(3

by

off

before

wire

wire 0 in to

hin

ge

8 ,

then insta

the

parts

box.)

Less M

pressure pressure

~

mm

ll

to the reverse cylinder con-

your

finger and then tighten by

insta

the

ore

- 0

otat

ing parts.

ll

or

removal the

wire hole

ll

to the

0

on

the

motor

turning

Ill

Adjusting air pressure

Air pressure is 5 kg/cm

righ

t.

In

case air pressure

cylinder, and

*

After

adjusted, tighten

If

water stay

[~

P

~

R

~

ET

~

th

in

EN

~

SI

=

ON

==

2

±

0.5

kg/cm2 in use. In case air pressu

is

high, once

en adjust again.

and

install the

the

bott

le

4D>

, s

top

turn

the handle 0

nut ~ .

the compre

ssor to lower air pressure, raise

==========~~

re

to left,

then

==

======~==

*

Adjust

thread

th

read is trimmed.

is

low

operate

the

of

, loosen

nut 0 so

abo

the

actuater

the

ut

35 -40

nut~

and then turn the handle 0

or tread le

drain cock

======

that

mm

the

pretension

on

to

lower air pressure in

4D

and

then

let o

==~]

may

the

needle

top

ut

leave

after

to

water.

the

the

Page 3

[ OPERATION OF TREADLE PEDAL

®

@1----~

Ill Trea

Ill Treadle

2. Make sure whether sl

3.

4. When the

5. In case

dl

e (- 100, - 200)

1. Make sure

Pressing

2. Make sure

(when

3.

In

case

the rear

1. Lightly depress the

Pressing

Make sure

(when

the rear

whether

the

treadle pedal 0 again

whether

you

release the treadle pedal 0 ) @

the

treadle pedal 0

end

@ ), thread trimmer is once t

(-

500, -600)

the

treadle pedal 0 again

whether

you

release

upper

the

tr

eadle pedal 0 is pressed at

end

@), thread trimmer is

~

~~

slow speed

the sewing machine stops

upper

ow

the sewing machine stops

the

treadle pedal 0 )@

plate 8

motor

to

is

pressed

plate

f}

of

speed

motor

to

of

the

treadle pedal 0 is positioned

once

~

runs

smoothly,

@ ,

then

after

at

the rear

urn

the

treadle pedal 0

runs smoothly, pressing

@ ,

then

after

the

turn

--

pressing the treadle pedal 0 lightly

high speed

at

the

pressing

and

the

high speed

at

the

pressing

rear

and the needl e is

motor

needle down position,

the

end

@(o

needle is

to

mot

needle down po sition,

the

end

@(o

runs.

the

treadle pedal 0 is positioned

treadle pedal 0

r back

at

up

and

position

the

or

treadle pedal 0

at

r back

@,

treadle pedal 0 lightly

runs.

® , pre sser foo t lifts up.

at

up

and

at

the front.

the

neutral @

then

the

machine is stop.

the presser foot come

the

treadle pedal 0 is positioned

at

the neutral @after

then the machine is

after

the front.

to

®.

at

the

treadle pedal 0

s down.

to®.

the

treadle pedal 0 is pressed at

sto

p.

is

at

@

the

neutral

pressed

the neutral

at

]

[ ADJUSTING SYNCHRONIZER

Adjusting

1)

Turn

2) Remove

3)

Turn the pulley towa

~

the t

In

moving the

(4)

Turn on the power switch a

the position of

If the needle bar

hole I.C @ .

(5)

Sto p the machine at the needle

above the

If th e needle

the ho

*

Ym.1

I.C

position

off

hr

ead trimming the

case

of

le

move the hole I.C @ ,

@ ,

f}

of

thr

ead

trimming

the power switch by all means. (In case

th

e cover

upp

I.C

of

the synchronizer.

rd you and place the need le bar lowes t position. At th

the magnet 0 is not in line with the th read t

thr

ead trimm ing the hole I.C.

I 8-22 mm above the upper face

is

er face

po

sition

f}

.

to the rever

ho

not stop

of

the needl e plate.

is

se

signal

le I.C 8 .

nd

stop the machine at th e needle down position.

at

the fixe

up

not s

top

f}

to the machine rotating direction, then the needle

direction, then the needle bar is raised.

at

Needle

down

pos

ition

1

8-22

mm

---

of

adjust each the hole l. C, turn off

ri

mming the hole

of

d position, loosen

position. At this tim

the fixed position, loosen clamp ing screw

the needle plate.

cl

amping screw 0 and adju

e,

the needle point should st

I.

C 8 , loosen clamping screw

Needle

up

posi

tion

9-11

the

powe r switch

is

tim

e,

the magnet 0 must be in line with

At

this time, the needle bar should stop at

st

by

moving the needle down the

op

at the position

(3

and adjust

bar

is down. When you move the hole

by

all means.)

@)

and adjust by

of

9 - I I mm

by

moving the needle up

mm

*

For

prevent the bobbin run idle wh

is

the

there

*

Wh

en

0

by moving the bobbin presser 0 back

bo

thr

ead trimmed, loosen cla

0

bbin presser O.

en

thread trimmed,

mp

ing screw 8 and adju

or forth

.

st

Page 4

ADJUSTING

FOOT

LIFT

PRESSER

(-500

, -

600)

[~=

A

=

D

=

JU

=

S

=

T

=

IN

=

G

==

~

Lightly O

~::;

0

·

~

T

=

R

=

E

=

A

=

D

~

H

eavi

ly A 0 •

~..,~

=

L

=

E

=

P

=

E

=

D

=

A

~

. r.::

C:::J 9

Lightly 1 Heavily

L-

=

L

~=======~]

O

*

Turn

the

kn

ob 0 and adjust

presser fo

[~=

C

=

H

Abo

About0.5

=

A

=

N

=

"'

~

ot.

G

=

IN

=

G

==

08

mm

Rotary hook

T

=

H

=

E

==

K

The

the

=

N

=

IF

=

E

==

0

f)

ax

is

of the n eedle

TI1e

knife

lifting up speed

of

the

~==================

How

to

(1)

Turn

(2)

Turn

remove

Turn

(3)

(4) Tilt the machine head back .

(5)

Loo

cover 8 -

(6)

Push

pull

w

ith

(7) Remove the scr

3:!~

After

H

ow

to insta

*

Let the point

reversely with your hand and make sure

be positioned

scr

ew

knife ~ to be 3

* Make sure

finger

abo

*

Turn

so th

1. Adjusting its weight

Slow spee d sewing

the treadle pedal

you

press

the

the

nut

0 and adjus t by turning

2. Adju sting its weig

Loosen the

nut

====

remove the knife

off

the

power

switc

h.

the

pulley and place the needle

the

needle plate.

the pull

sen the clamping screw 0 and remove the

ey

ease.

ut

at

ey

and place the needle

the thread trimming

toward you until the position

ew

e I kni

fe

the knife ~ is

ll

the kni fe

changed, install

of

the

knife ~ m

at the axis

e for the clearance b

mm.

that

the

clearance between the knife ~ and lower

fj

and

that

between lower thread finge r

0.5

mm.

(Eno

ugh for usable thr

the pull

ey towa

the kn i

rd you and get the knife

fe ~ is not

touch

at slow

speed sewing

is

done

when

you

put

your

foot

and

slow speed sewing is

treadle pedal lightly. In such cases, loosen

the bo

ht

at back

@)

and a

dju

st

by

~==~

stopper

~

I

spacer

eet

of

the needle as figure.

et

wee n the lower thread

at

============~]

at

the

highest position and

at the lowest positi

@)

with

your finger and turn the

of

you

may

(3

and lower thread finger

them

reverse

with t

he

needle, turn the pulley

that

point

ead

to

pass

~

the needle.

not

done wh

lt 8 .

turning the bolt

on.

thr

ead trimming

remove the screw e

order.

of

the

knif

e ~ may

Then

tigh

ten

finger

fj

and

thr

fj

and the h

smoothly.)

at

it

s original position

ook

on

en

0 .

then

fj

the

the

ead

is

.

@ BROTHER

-

INDUSTRIES,

NAGOYA, JAPAN

LTD.

117-792-100,

192792-0-1

Pr

inted

- 200,- 500,-600

2

in

Japan

Loading...

Loading...