Page 1

INSTRUCTION

FOR

BROTHER

SINGLE

ADJUSTABLE

LOCK

NEEDLE

STITCH

TOP

MACHINE

MANUAL

082-8792

AND

BOTTOM

FEED

Ill

Th

ank you very much

pur

cha

se

machine

The

se

wing machine depend s, a b

on

Be

followi

of a BROTH

.

full pe

correct op

sure to

ng ins

rform

eration.

care

tructions before use.

ance

of your

fully read

for your

ER sewing

new

ove

all,

the

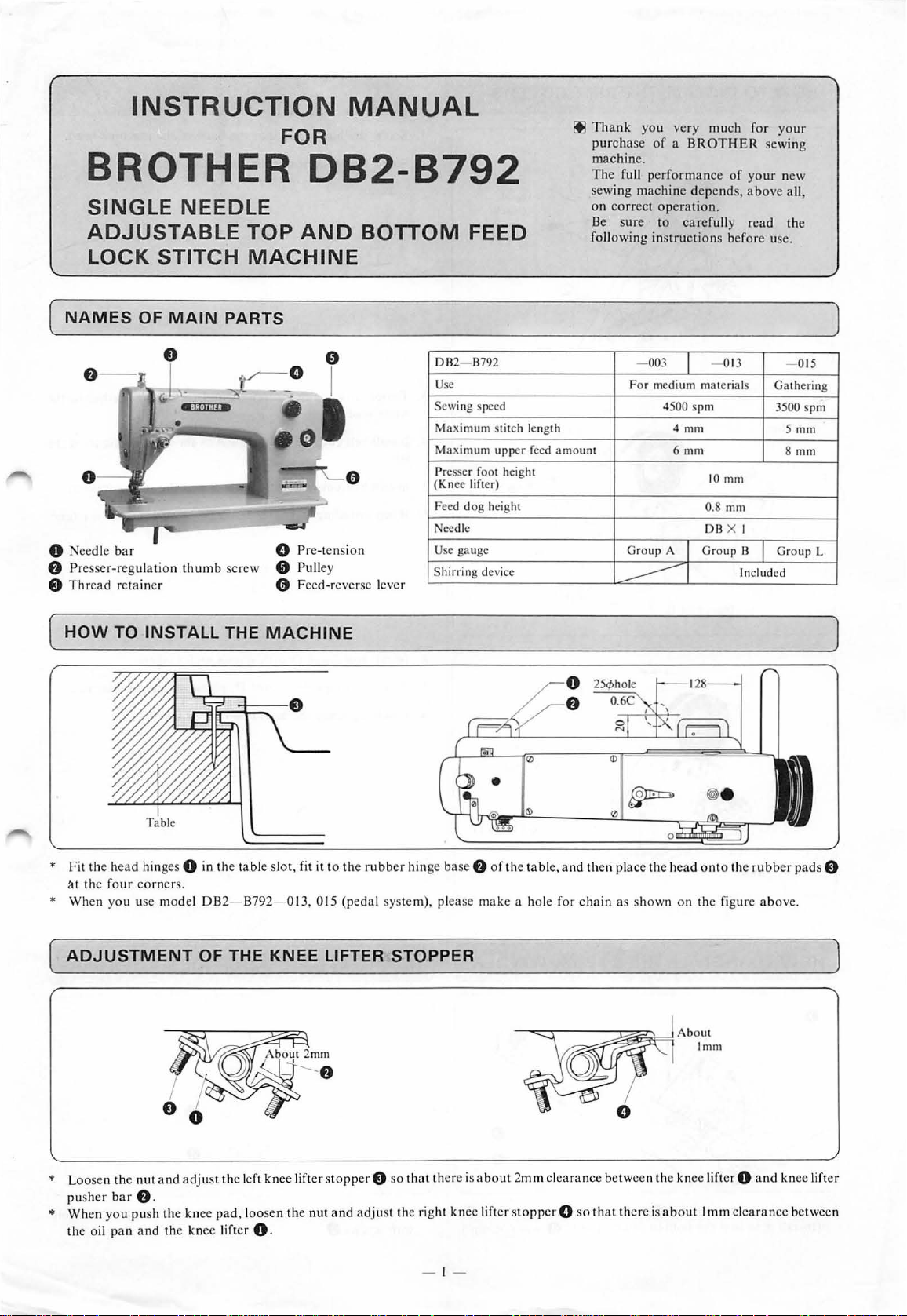

NAMES

0 Nee

dle bar

f)

Presser-regulati on

0

Thread retain

(

HOW

TO INSTALL THE

OF

er

MAIN

thumb

PARTS

0

scr

ew

0 Pulley

0 Fee

MACHINE

Pr

e-t

d-r

ens

ion

everse lever

DB2-

B792

Usc

Sewing speed

Maximum stitch length

Maximum upper

Presser foot heig

(Knee lifter)

Feed

dog

ccdlc

Usc gau

ge

Shirring device

feed

ht

height

amou

-

003

For medium materials

nt

Group A I

--------1

I

4500 spm

4

mm

6

mm

Group B

- 013

10

mm

0.8

mm

DB X I

In

cluded

- 015

Gathering

3500 spm

5

mm

8

mm

Group L

)

Table

* Fit the h

at the

* When yo u u

(

ADJUSTMENT

* L

pusher

*

Wh

the oil

ead

hinges 0 in the table slot, fit it to

four corners.

se mode

oosen th

e nut and a

bar

f)

en you push the knee pad, loosen the nut

pan

and

l DB2- 8792- 013, 015 (p

OF

THE

dju

st

the left knee lifter

.

the knee lifter 0 .

KNEE

the

rubb

er hinge base

eda

l sys tem), please make a hole

LIFTER

stoppe

and

STOPPER

rO

so

that there

adjust the right knee lifter st

- 1-

is a

f)

of

bout

the tabl

2mm clea

oppe

e,

and then place

for

chain

rance betw

rO

so that

the head onto the

as show

n on the figure

een the knee lifter 0

there

is

about I

rubb

mm cleara

er

pad

above

.

and

knee lifter

nce between

s 0

)

Page 2

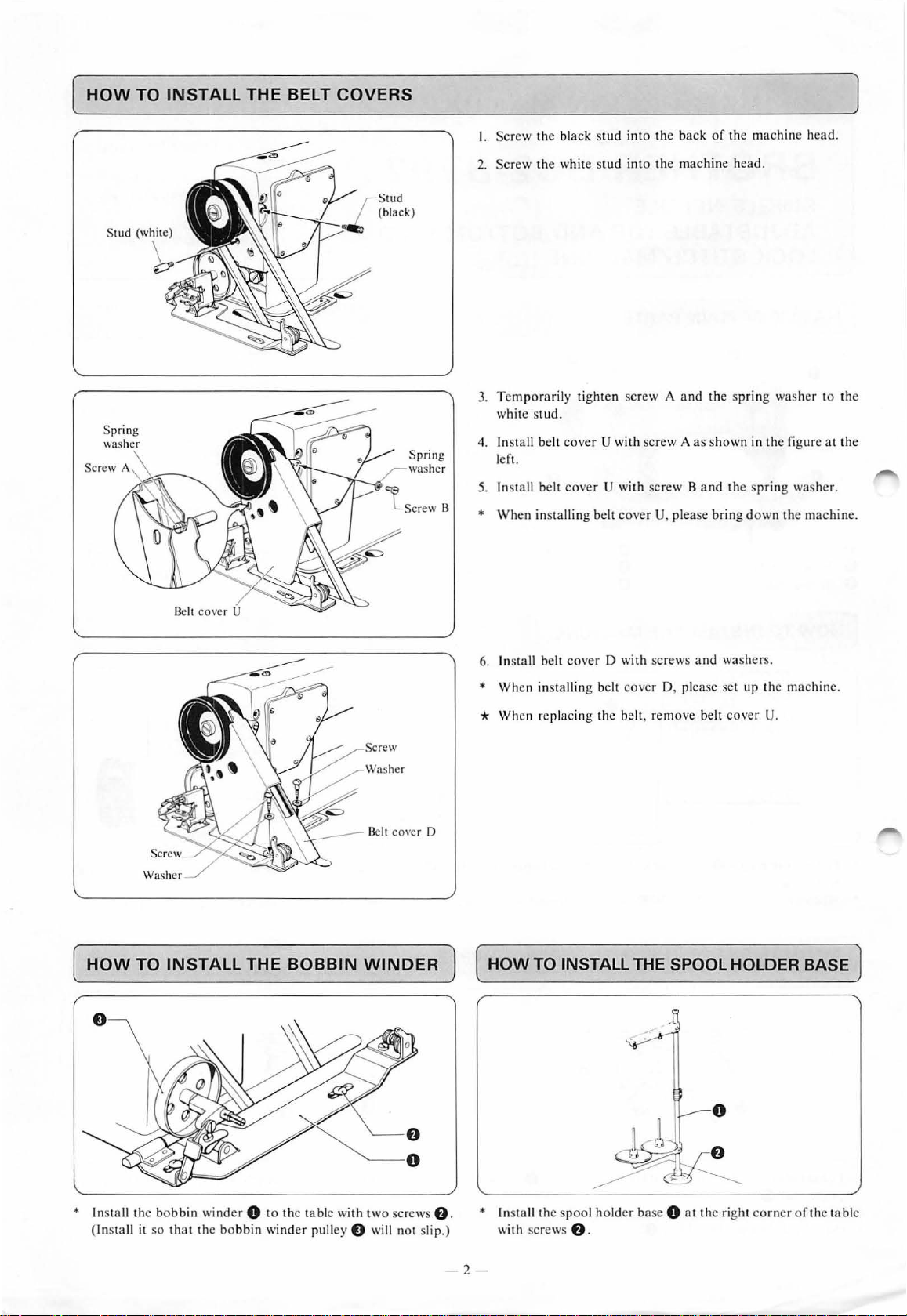

[

HOW

TO

INSTALL THE BELT

COVERS

Stud

(black)

Spring

wash

er

I. Scr

ew

2.

Screw

3.

Temporarily

white s

4.

Install belt

left.

5.

Install

•

When insta

the black

the

white stud

tighten

tud.

cove

belt

cover

lling belt

stud

r U

U with

with

cover

into

the

back

into

the

machine head.

screw A and

screw A as

screw B and

U, please

of

the

machine

the spring

shown

in

the

spr

bring

down

washer

the

figure

ing

the

head

to

at

washer.

machine.

.

the

the

HOW

TO

INSTALL THE BOBBIN

WINDER

6. Install belt

•

*

)

(

HOW

cover

When

installing belt

When replacing

D with screws

cover

the belt,

D, pl

rem

and

ease

ove belt

washers.

set up

the

cover

U.

TO INSTALL THE SPOOL HOLDER BASE )

machine.

* Install

the

(Ins tall it

bobbin wind

so

that

the

er 0 to

bobbin winder

the

tabl

e with

two

pulley 0 will

screws

not

slip.)

f)

.

• Install the

with screws

spool

- 2 -

f)

holder

.

base 0

at

the

right

corner of

the

table

Page 3

[ LUBRICATION

1 . Lubrication

( I) Supply oil slowly

If the o

il

level falls bel

oi

l.

to

the

ow

mark

the

at

the left ("HIG H").

mark

at the right

("LOW"), add

ADJUSTMENT

OF OIL SUPPLY

AMOUNT

(2) If the o

oil cover

(3) Wipe

* Use

2. Oiling

* Before using

o

TO

ARM

* Re

sh

Lower

*

hook

il

becomes

sc

away

th

e oil specified

il

to

the

SHAFT

mo

ve

the f

aft

by

turning

the head

by

turni

contaminated,

rew G.

contaminat

the

mach

point

ind

icated by th e

AND

ace plate, and

the scr

, and adju

ng the scr

ion fr

om

by

BROTHER:

ine,

be

sure to supply one

ROTATING

adju

ew

0 .

st the lubri

ew

G.

rem

ove

the

oil

cap

the magnet

arrow

f)

Hi-White 70.

or

.

HOOK

st the lubrication

cation for the

0 and

.

two

for

drop

the

rotat

th

of

arm

ing

e

€1D

More oil

ROTATION

CID

Le

ss oil

DIRECTION

OF

THE

MACHINE

- 3 -

* The

*

* When

correct

co

unterclockwise as viewed

Press

th

e belt 0 ,

G so th at

the

the

mach

rota

and

belt

ine

can

runs id

ting direct

ion

from

the pulley side.

adjust the belt

be

pushed

le, be sure to raise the

ten

inward

of

the m

sion by

about

achine

turn

ing the nut

15 - 20mm.

presser foot.

)

is

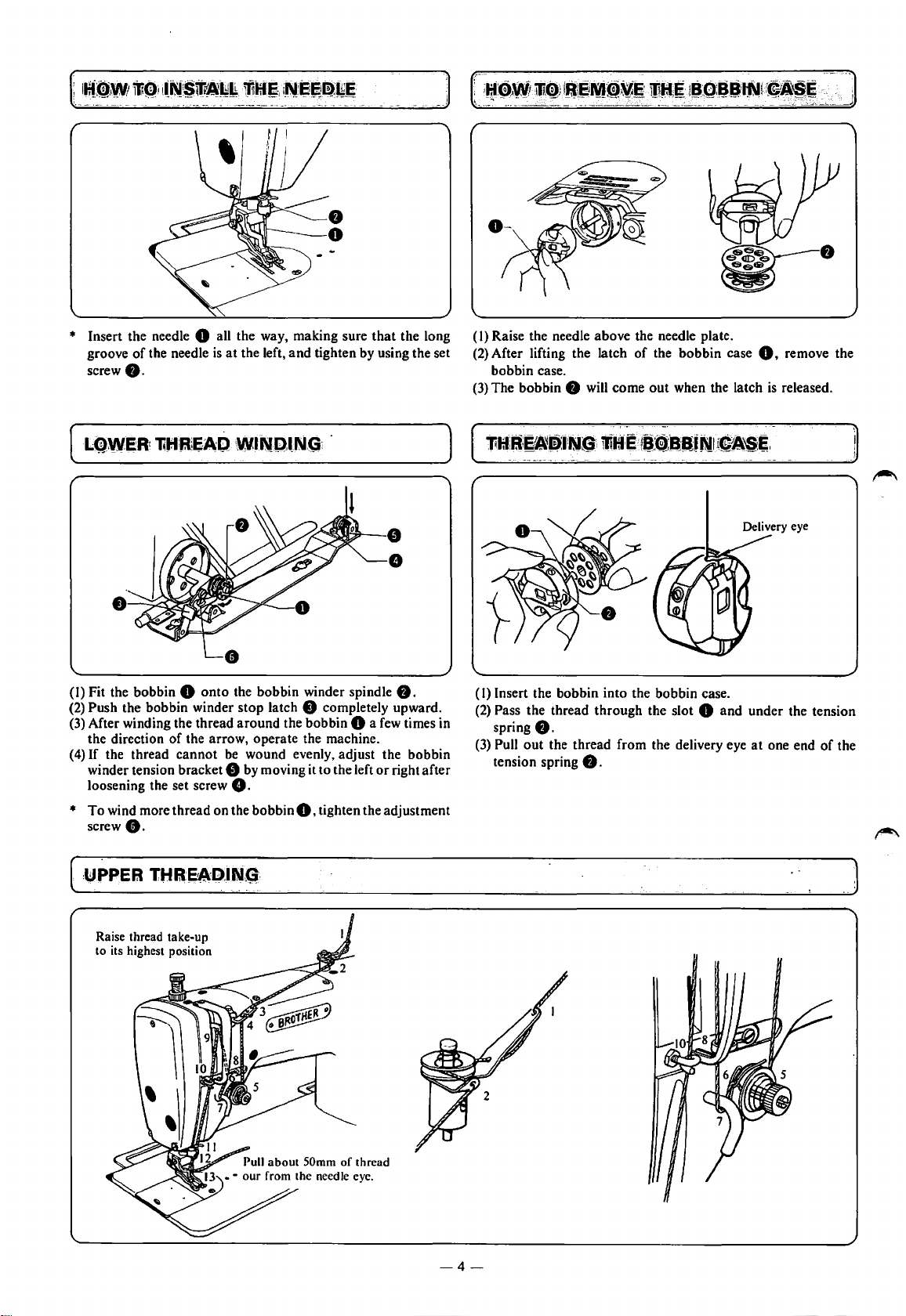

Page 4

* Insert the needle 0 all the way, making sure that the long

of

groove

screw

the needle

8.

is

at

the left, and tighten by using the set

iJif:f>wiliQJ•fB1~Jl\11§)._~fi

(I)

Raise the needle above the needle plate.

(2)

After lifting the latch of the bobbin case

bobbin case.

(3)

The bobbin 8 will come

m_f.liE:·-~a~o:~JIJ:t:Nc:~~~;

-

.....

_

---~

--"''

-.

- -

-·

·-· ·-·

0,

remove the

out

when the latch

is

released.

J

Delivery eye

(I)

Fit the bobbin 0 onto the bobbin winder spindle

(2)

Push the bobbin winder stop latch 8 completely upward.

(3)

After winding the thread around the bobbin 0 a

the direction

(4)

If

the thread cannot be wound evenly, adjust the bobbin

winder tension bracket

loosening the set screw

* To wind more thread on the bobbin

screw

Raise thread take-up

to its highest position

0.

of

the arrow, operate the machine.

8 by moving it to the left

0.

0,

tighten the adjustment

few

or

8.

times in

right after

(I) Insert the bobbin into the bobbin case.

(2)

Pass the thread through the slot 0 and under the tension

8.

spring

(3)

Pull

out

the thread from the delivery eye

tension spring

8.

at

one end

of

the

J

-4-

Page 5

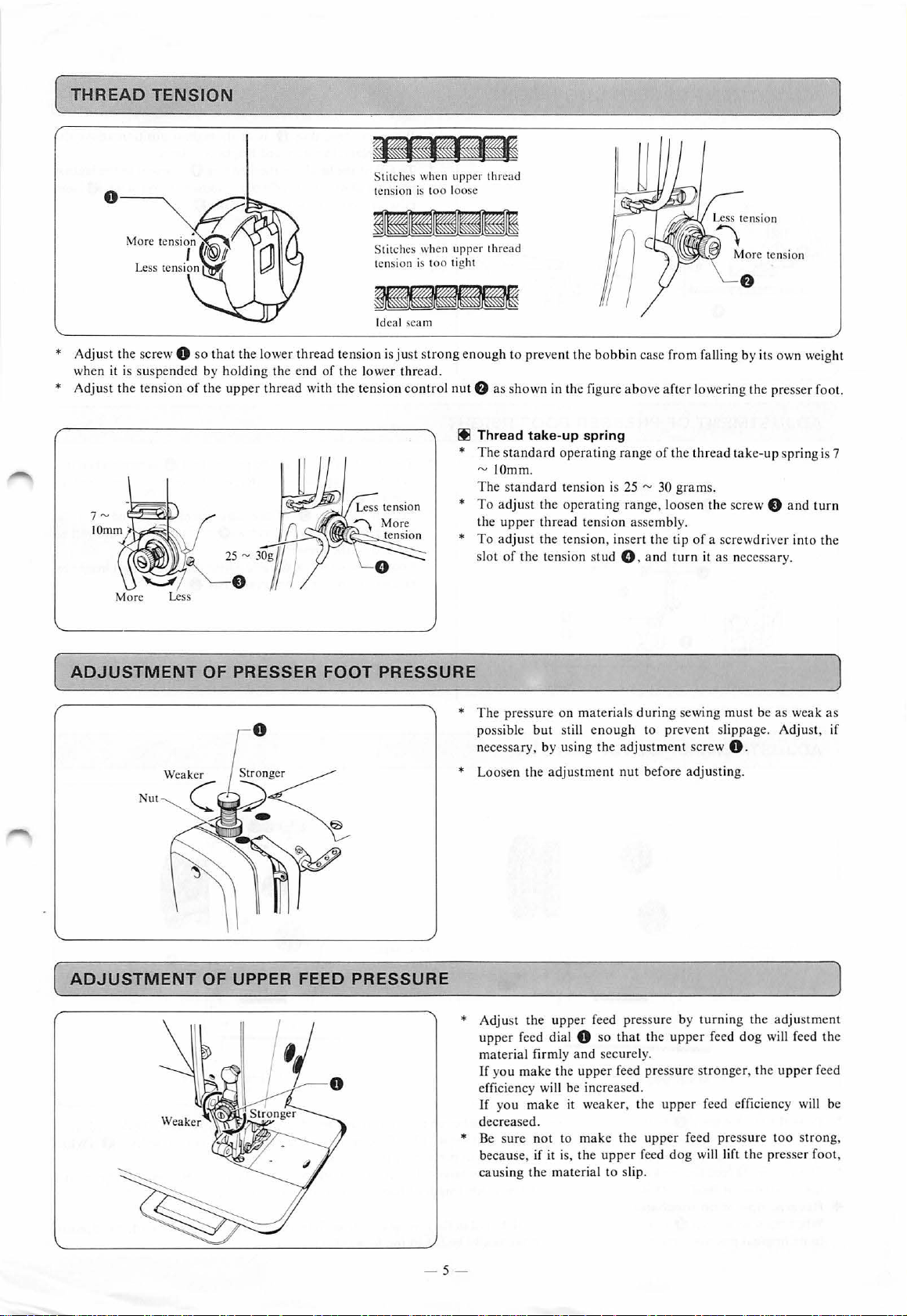

(

THREAD

o-

TENSION

~

* Adjust the screw 0

when it is suspe nd

*

Adjust the tensio n

so

that

the lower thread tension is

ed

by holding the

of

the

upper

end

of

thread with

Stitches

tension

Stitches

-

tension

I

deal seam

-

the lower

the tension

when

is

too

loose

when

is too

tight

just strong

thread.

control nut

upper thread

upper

thr

ead

enough to

f)

as shown

prevent the bo

in the figure

bbin

above

case

More

tension

from

falling by its

after

lowering the presser foot.

own

weig

J

ht

Ill Thread

*

The

~ lOmm.

The standard

*

To

the

*

To

sl

[

~_A_D_J_U_S_T_M_E_N_T_O

__

F_P_R_E_S_S_E_R

_F_O_O_T

__

PR

__

Es_s_u_R

__ E __

*

Th

possible

necessary,

* Loosen the

Nut

adju

upper

adjust

ot

sta

nda rd op

of

the

take-up

st the

spring

era

ting

range of

ten

sion

is 25 ~ 30

operat

ing range, loosen

thread

tension assembly.

the tension, in

tension stud 0 , and tu

sert

the tip

the

thread

grams.

of

rn

it

__________________________

e press

ure

on

materials

but

still

by

using the adjus t

adjustment

enough

nut

dur

ing sewing must be

to prevent slippage. Adjust,

ment

screw 0 .

before

adjusti

take-up

the

scr

ew

f)

a screwdriver

as

necessary.

as

ng.

spring is 7

and

turn

into

the

~

weak

as

)

if

(

ADJUSTMENT

OF

UPPER

FEED

PRESSURE

- 5 -

* Adjust the

upp

er

material fi

If

you

efficiency will be increased.

If

you

decrea

* Be s

because, if

causing

upper

feed dial 0 so

rmly

make

the u

make

it weaker,

se

d.

ure not

to

it

is,

th

e material

feed pressure by t

that

the

upp

and

securel

y.

pper

feed pressure stronger, the

the

upper

make

the

upper

the

upper

feed

dog will li

to

slip.

urning

the

adjustmen

er

feed

dog

will feed

upp

feed efficiency will be

feed pressure too st

ft

the

presser foot,

)

t

the

er feed

rong,

Page 6

ADJUSTMENT

(

'----·

----------

OF FEED

0.8mm

!

DOG

HEIGHT

*

When

needle pl

*

To adju

position

raise

the

feed

dog

0 is

ate, the

st the height

above

or lower the feed

standard

of

the

needle

the

lift

at

its highest

height

feed

plate,

ing

arm

dog

loose

is

0.8mm.

0 ,

0 .

position

move

n the set

above

the

it to the highest

sc

rew 8 ,

and

]

ADJUSTMENT

(

ADJUSTMENT

OF PRESSER

e

0

0

OF STITCH LENGTH

-·

FOOT

6mm

HEIGHT

*

The

sta

raised by using

topper

s

*

Loo

sen

presser

app

lied

sen the

Loo

ng

raisi

ndard

height of

the

f)

.

the

nut 0 of

foot

adjustment

to

the presser foot.

set

screw 0 ,

or lowering

the presser

knee lifter, an

the

adjustment

scr

ew e so

and

adjust

the presse r

foot

0 is

d locked by th e

screw

that

no

the

presser

bar

0 .

6mm

when

presser

and

pressure

foot

heig

then

will be

it is

foot

ht

the

by

Feed adjustment

dial assembly

*

Pr

ess

th

leng

se

tting the

*

The

amo

the maximum

Ill

Reve

When

to

its original posi

the

reverse l

(I - 4 on

unt

rse-operation

the

reverse le

ever 0 to

mode

reverse l

of

feed becomes

of

model 01

tion, and

_.......

Model

ls 003

ever

mec

ver

0 is

082-

8792- 003

the

center

and

013,

and

in

the

cent

er

greater

5 is 5 mm. The

hanism

pr

essed,

the

material will

position,

position,

as the

the

set the

I - 5 on model 0 15)

be certain

number

maxim

ma terial will be fed in

becomes l

um

automaticall

numb

er

to

the"

to press it a

arger.

stitch leng

the

y be fed

Feed adjustment

dial assembly

on the feed

12

th

reverse direction. Wh

adjustment

o'clock" position,

ll

the way into position.)

The

ma xi

mum

of bac

ktack

in

the

forward

Model

sewing, however, is

-6-

013

2- 8792-

dial which corresponds to

and then release

stitch lengt h

en

the

direction

.

013.0

of

mode

approximate

reve rse lever is released, it will

0

15

the

the

reverse lever 0 .

ls 003

and 013 is 4 mm , and

ly 2 mm.

desired stitch

(When

return

Page 7

(~_

A_D_J_U_S_T_M_E_N_

T

__

O_F_U_P_P_E_R

__

F_E_

ED

__

A_M

__

O_U_N_T

__________

____________

__________

~)

Upper feed adjustment dial asse mbly

\

--

Feed

a d

justmen~·

dial assembly

Model 0 82- 8792- 003 Model 082-8792-013.015

© Model

*

Pr

assembly to th e

*

Th

Ma

© Mod el

* Align the nu

Pr

the i

*

Th

© Model

* Align the

Press the reverse lever 0 to the cent

pin, a nd then rel

*

The

082-8792-00

ess the reve rse l

e upper feed

ximum feed amo

082-8792-013

mber

ess the reverse l

ndi

cation

pin

e up

per

feed a mou nt b

082-8792-015

number 8 on the upper-f

amo

unt

of upper feed be

eve

r 0 to

" 12 o'clock" position, release the r

amo

unt becomes larger

unt

= 6

6 (on the

ever

0 to the center pos ition,

, release the rever

eco

ease

the reverse l

@

~

,______,

3

th

e center positio n, and after settin

mm

upp

er feed stopper dial) wi

mes gre

eed

ever

comes

as

se

lever.

ate

r as th e n

stoppe

er positio

0 .

greater

0

eve

the

numb

and

afte r aligning the

umb

r dial with the indi

n, align th e desired

as the number

Upper feed stopper dial

g the desi

rse lev

er

O.

er becomes la rg

th th

e i

ndicati

er b

eco

mes larger.

catio

num

beco

mes l

er.

on

numb

n pin .

ber (I-

arge

red numb

pin

.

er (I ~ 6)

8) of the u

r.

Indication pin

er

( I ~ 6)

of

the u ppe r feed

pper

-feed

Upper feed adjustment dial asse mbly

on

the uppe r feed adj ust

adj

ustme

nt

adju

stme

nt

dia

l with the in

d ial assembly wi

men

t dial

dication

th

[~_

A_D_J_U_S_T_M_E_N_

Upper feed adjustme

dial assembly

Feed adjustme

dl

ol mombly

nt

1

Mo

* If the lowe r mat

nt

adjust me

* If th e

adjust me

* If the

u

pp

er feed

*

Turn the upper

lag.

dial assembl y to a l

upper

materia

nt

dia l assembly

uppe

r feed

adjustment

T

__

O_F_S_E_W

nt

\\ .

\

r-

del 082- 8792- 003

er

ial is long when sewing is finished , set th e u

l is l

adjustment

feed a djust me

__ IN_G

(~

arger

ong when sewi

to

a small

dial

is

dial.

nt

dial

__

LA

__ G ____

Fe

ed adjustment

dial

ass

embt

Model

num

ber.

ng is finished, set the u

er num

ber.

to be turned , first

assemb ly and the feed adjust me

____________________________________

feed

Upper

dia l assem

y

082

- 8792- 0 13.015

ppe

pper

turn the

adjustment

bl

y

~

~~

r f

eed adjustmen

feed adjust ment dial assembly

upper feed s

nt

dial

t di

topp

er

assem

bly little by little

al

dial

ass

to

The lower material is long.

Th

e upper ma terial is long.

emb

ly to a smaller num

to a larg

the

maximum numbe

to the plac

ber, or se t the feed

er numbe

r, and t

e wh

en

r,

or

there

set the feed

hen

turn

is

no

sewing

~)

the

-

7-

Page 8

(

GATHER

---

Model

* Use

the gather

* Use gr

The

tuck separato

SEWING

- ·---...

oup B or

Upper

feed a

assembly

for

es

djustment

gather

beautifu

sewing.

l tuck sewing.

dial

type

gauge

group L replacement parts

r e nsur

Model DB2

for

tuck

sewin

8792

g.

Upper

assembly

013.015

feed

adjustment

)

0

INSTALLING

Gath

er sewing

THE

GATHERING-SEPARATOR

Ill Sew ing me

I.

Turn the feed

2.

Set

the

amoun

3. B

ecause

of

material

factors, the

sing

by u

©

Partial

and

- 015

I.

Set the

Set

the

2.

3. Use the

lag.

When

4.

will begin

mach

(Use

desired

*

When

be

se wn wi

dial.

the amount

th

od

adjustment

upp

er feed

adjustment

t of

upper

feed

is

larger

the

amount

appropriate

the

gathering

feed

upp

er

upper

the gath

gather sewing, When the pe

ine will

the

upper-feed stopper

amount.)

the

gathe

th the amount

When

the

of feed

of gath

being used,

amount must be

adjustment

adjustment

feed s

feed

er

resume normal sewing

r-sewing

peda

dial.

is possible

dial to

topper

adjustment

sewing

pedal

pedal

of

l is relea s

set

by

dial

ering

the length

dial

feed

the

[Standard equipment on

to

set the

desired stitch

dia l

to a position

than

that

of the

differs

according

of the stit

with

model

the

desired s

to the maximum

dial

to e

0 is

depressed.

dal 0 is

.

dial

to

adjust

is

depr

essed, the

set

by the

ed,

the

material will

upper-feed adjustment

ch

determined

s

082

- 8792- 013

titc

limin

ate any s

the

gather

upp

er feed st

082-8792-015]

length

in which

lower

to

the

and oth

and set

h le

ngth

number.

the

machin

releas

ed.

material

be

sewn

dial.

the

feed.

type

er

.

ewing

the

to

th

will

oppe

with

.

e

e

r

/

Separator-p

I. Insta

ll

the guide

(I

nstall the guide b

2. Fit the se

3.

Adjust the

* R

efer to

figure A

(Install the sepa r

bar 0 by

ar 0 so

parator-plate assemb

sew

ing

mar

for the alig

ator-plate

using the

gi n by us

so

screw

that

it is in

dire

ly 0

on

to

the guide

ing the

grip scr

nment

of

the

that the needle wi

f)

and the wash

ct

contact with the

bar.

ew

0.

and then ti

front end

of the se

ll

not come

er

and

then

parator-plate.

into

0 .

proj

ecting

temporari

ghten the

con

tact

part.)

grip

with

ly

tight

it.)

8 -

0

late

en with the

sc

rew 0 firmly.

Fig. A

grip scr

Separator-plate

ew

0 .

Page 9

Model

082-8792-003

I. Turn the upper feed adjustment dial assembly to set the upper feed amount to maximum.

2.

Turn the machine pulley slowly.

3.

The minimum clearance between the upper feed dog and the presser foot should be approximately

is

type upper feed dog

~

4. Loosen the screw

0.

used, and

and

2.5

mm when the gathering type upper feed dog

adjust the clearance by moving the upper feed

Model

082-8792-013,

015

arm

1. Needle bar lift amoung

0

f)

is

used.

forward

1.0

or

backward.

mm when the forward-pulling

i :

I '

• j

I /

* Turn the machine pulley toward you. When the need

and adjust so that the rotating hook point 0

2.2mm

is

at

leO

is

at

·the center

the position

of

the needle

2.2mmabove

0.

* Adjust so that the clearance between the rotating hook point 0 and the needle 0

2.

Needle bar height

0

•

* Loosen the set screw

rotating hook point

* Refer to figure A for the lowest position of the needle bar

8.

and raise

0

is

about 0.5 mm when the rotating hook point coincides with the center line

or

lower the needle bar 0 so that the clearance between the upper edge

0.

and to figure B to raise the needle

Reference line

the lowest position, loosen

is

0.05

"'

0.1

mm.

Reference line

of

of

the needle

bar

0 by 2.2 mm.

Fig. A

thesetscrewf),

Fig. B

the needle hole and

0.

-9-

Page 10

~~·1i~*

~..;.:.:;__;~~-

1.

How

me~

:~i~~-~·~t~~tse

. i '

to remove the presser foot, upper feed dog, needle plate and feed dog

-'"---~·

~~*a~s:

· · · -

2.

(I) Loosen the set screw

(2)

Remove the set

(3)

Remove the hexagonal bolt

feed dog

(4)

Remove the cap screw

•

•

How

to attach the presser foot, upper feed dog, needle plate and feed

0

•

-----

•

..

---:~--

r----

I

• •

(5)

Remove the set screw

* For model

and then remove the upper feed dog

(I) Temporarily tighten the

(2)

Attach the needle plate 0 by using the cap screw

* Turn the machine pulley to move the feed

secure it

front/back and left/right margins

0.

plate

* Confirm the height

(3)

Attach the upper feed dog 0 by using the hexagonal bolt

(4)

Attach the presser foot 8

* Confirm the height

-~jii

Jl,

~

~

'-8

__

F.

* Confirm the clearance between the upper feed dog 0 and the

presser foot

(5)

Attach the needle 8 by using the set screw

0,

and then remove the needle

screw8,and

0.

DB2-B792-015,

in

place, by using the set screw

of

of

G. Refer to page

then remove the

0,

8,

and then remove the needle plate

f),

and then remove the

loosen the hexagonal bolt

dog

feed

dog(!)

the feed dog. Refer to page 6 .

by

using the set screw

the presser foot

8.

8.

presserfootG.

and then remove the upper

feed

dog(!).

0,

0.

by

using the set screw

dog(!),

f),

so that there are

in

the grooves

8.

Refer to page

0.

ofthe

f).

8.

and then

needle

0.

8.

6.

Slide plate

•

•

6mm

-10-

Page 11

3. Gauge parts

* Select the gauge

*

Group A of

with model

the replacement

OB2- B792- 015.

parts

(presser foot,

upp

er

feed dog, feed dog, needle plate) from

parts

is included with model

OB2

- B792

-003, group

tho

se

B with

show

n below.

model OB2

- B

792-0

13,

and

group

L

Replacement

parts code

Replacement parts

Group

A ·

1

83

041

- 0- 01

For str

etching

Men

's

jacket

Model

OB2- B792-003

Presser

151277- 0- 0 1 15 1383- 0-

e

Th

ese parts arc used to prevent sewing l

mater

e

The use

must

e

Th

ese

there will be no

* These

(Examples)

foot

ial as well

of

be

are

par

as

these

matched. ·

forward -pulling type parts. Becau

bu

ts

arc

not suitable for ga

For

sleeve caps,

clothes

Upper feed dog

parti

cularly s

parts

is especially effective when decorative sti tching is desired,

nchin g even when sew ing togeth er materials

01

ag

and puckeri ng whe n sewing

mooth materials which tend

ther

sewing.

underarms,backs,

15

se

the uppe r feed

shou

lders

Feed dog

1324- 0- 0 I

to

slip.

dog

of

and

side seams

Needle

151261- 0-

thin

or medium thickness

or

when

is located behind

different thic knesses.

of

men's

the

and

plate

01

patt

erns

needle,

women's

Replaceme

Gro

up B

183042- 0-

For

shirring

Attachment

Attachment

Girl's dress

Model

DB2- B792

nt

part

01

of rufncs

-0

of

13

s

e These

e These

cuffs

e If these pa rts

(Examples)

151281

- 0-

01

parts are

parts

materials (linings,

should be used togeth

an

adver

and

used in

are effective for the prevention

leather

are

used especially for gathering,

se effect on the bottom material (when the material

Attachment of

(Effective in preventing sewing lag when sewing different materia ls together).

151384- 0-

order

to

gat

and cloth,

er

with them.

yokes, gathered cuffs

01

her or tuck materia ls

knitted material

By

using the

151325- 0- 0 I

of

sewing lag.

the

gathering attachment (gathe ring se p

se

pa rts, th e

or

of

thin

or

medium thickness.

They

are also useful when differe

and

cloth, etc.)

amou

facing to children's

are

nt

of

ga thering can be increased,

is

thin)

151262- 0- 0 I

sewn together.

can

be prevented.

or

women's clothing

nt

arator)

11

-

-

Page 12

Replacement parts

Group C

183043-0-01

For

tucking prevention

Plain belt seam

Plain waist-lining seam

Presser

foot

Decorative stitches

pocket openings

Men's slacks

Replacement parts

Group D

183044-0-0

For

materials which

need large feeding

capacity

Attachment

of

Plain collar seam

sleeve

151286-0-01 151384-0-01

151326-0-01

151263-0-01

e These parts are used for gathering, decorative stitching and preventing sewing lag in medium

that

thickness materials. The fact

for partial gathering

of

bias materials as well.

(Examples)

of

Sewing princess lines on women's blazers, underarm seams of two-layered sleeves,

decorative stitches

waist-lining seams.

and for the prevention of puckering. They are very effective for the attachment

the area pressed by these parts

of

pocket openings on men's slacks, plain belt seams and plain

I

151324-0-01

Side

seam

151288-0-01

e A large feed dog

of

151385-0-01

the same length as the presser foot operates on both sides

e Materials that are difficult to feed, such as quilting materials, polyurethane, materials containing

elastic, vinyl, and bonded material, can be sewn easily without uneven feed

is

very large also makes them ideal

151261-0-01

of

the needle.

or

sewing lag.

Sewing underarm seam

Leather jacket

Replacement parts

GroupE

183045-1-0

For

hemming

I

(Examples)

151290-0-01

Underarm seams, shoulder seams, sleeves,

raincoats, etc.

151386-0-01

or

side seams

153200-0-01

of

e These parts are used for sewing a double-folded hem on lining materials

e Adjustment

e A double-fold wrapper

of

the amount

of

upper feed eliminates twisting even in the sewing of flared skirts.

is

necessary for this operation.

ski wear, leather jackets,

153199-0-0

of

skirts, dresses, etc.

I

-12-

Page 13

Replacement

parts

code

Presser

foot

Upper

feed

dog

Feed

dog

Needle

plate

Replacement

Group

F

183046

- 1- 0 I

For

top

stitching

uff stitches

C

Repl

aceme

Group

FD

1

83108

- 0- 0 I

part

nt pa rts

s

151387

- 0-

151292

e T h

e If

and

e

The

(Examp

153983

e A s

e

Co

- 1-

01

ese

parts are

the

stitch

the n use a file

se

parts are also

le)

used for s

widt

Collar and

- 0- 01 151

tep

presser is

nsiste nt stit

ch

titchin

h is less

than 7 mm

to

decrease

used for

attached

widths can be o

hem

cuff stit

to the righ t side

g wit h a

, m

easure the width

the

width

stit ch

es

ches

on

387

- 0- 01

btained when

01

width

of

on

dre

silk

ss shirts.

of

151

327

- 0- 01

of 7 mm.

from

the

the right

portion

cotton material, etc. ,

15132

7- 0-

the F-group pre sse r

sew

ing

patches

point

of

the presser f

as

01

foo

or hems.

where

well

t.

as

151264-0- 0

the needle

oot

for

151

descen

accordingl

general

264

- 0- 0 I

stitches.

I

ds,

y.

C

uff stitches

Replacement

Group

G R

183047

- 0- 01

For

attachment

ri

ght zipp

er

!

Re

placem

ent

Gro

up

GL

183048

- 0 01

For

attachme

left z

ipp

er

part

of

parts

nt

of

s

(Example)

151

293

e T he se

ee

th of the z

t

e Su

ita

ble for sewi

e

Th

is

group ca

(Ex

ampl

es)

Colla

- 0-

01

parts arc

ipp

Rea r zi

Front zippe

r a

nd cuff stitch

151

used

for

sewi ng

er

facing

rig

ng

bias

materials (when a free-pr

n a lso be used f

ppers

of skirts a nd one-piece d resses.

rs

of slacks an

es

on dress s

388

- 0- 01

medium

ht

and the material

or

sewing extremely

d pa nts.

hirt

s.

151

thickness mat

to

be s

esser

close

328

- 0- 01

erial

on

the

left s

ewn

facing left, a nd then

is used).

to

the

edges

1

51265

ide

of

zippe

of material s.

- 0-01

rs. Pl

ace

sew them.

the

151

296

.

I

.

.

.

l

e

Th

ese

teeth of the zi

e S

uitabl

e T his g

(Example}

- 0- 01

part

s a rc used f

pper

e fo r sewing

roup can al

Sid e z

so

ipp

151389

or

sewing

facing left

bias material

be used

ers

of skirts and one-

- 0- 0 I

medium

and

for

thickness m

the material to be sewn faci ng ri

s when a fr

sew

ing extr

ee-presser

emely

piece

dre

- 13 -

1

51329

ate

rial on the right

is used.

close

to the

sses .

0 01

edges

side

of zipp

ght. and th

of mate ria ls .

151266

en

sew them.

- 0-

01

ers. Place

the

Page 14

Replacement

parts code

Repl

ace

ment

part

Gro

up

H

Fo r p

oc

ket welting

"S

uisei" LOT o.A 10

Presser

s

foot

Upper feed dog

Feed dog

Needle plate

L{J LIJ

Wrapped hem

/

L_f=!

Double-fol

hem

Piping

Rep

Group

183064- 0- 0 I

For

C

ollar stitch

Folded hem

//

j

~

ded

Bin

/ fold ed hems, bi nd ing he m

laceme

nt

J

stretch

ing

,...:'

/ e

Th

e C o

ding hem e By

part

s

e

Th

e

Th

is used .

e

If the stitch wi

and then use a

e

(Ex

Th

amp

es

151299

- 0- 01 151

ese

par

ts a rc used

mm

ercially sold needle plat

com

bi ni

ng

diff

151622- 0- 01

ese parts a rc used

ere is no

ese

le)

part

bun

chin g eve n when layered edges are sewn becau

dth

fi

le

s arc a l

Co

llar

"S

uis

s.

as well

kir

ei"(LOT

1

5132

of 10 mm.

idth

ht

portio n o f the presser foot accord ingly.

ts.

383

- 0-

01

for

sewing w

erent wrappers, the following hem stitc hes a re possibl e: folded he ms, do

s,

for

sewing stitches w

is less t

han

to

decrea se the wi

so

used for sewing h

and cuff stitches on dress s

rapp

ed

hem

es a nd feed dogs

pipin g (groove processing necessary), etc.

5162

1- 0- 01

1

ith a width

10

mm

, measu re the w

dth

of the rig

em

stitches on silk cotton. etc. as we

o. A 1

0)

"Suis

ei'

as wrappers can be used.

4- 0- 0 I

se

the forwa rd-

from the po

int

15126

pulling upp

where the needle descends,

ll

as for gener

'(L

OT No. A

1- 0-01

er feed dog

al stitches.

ubl

10

)

e-

Repl

aceme

nt

Group

J O

183109- 0- 01

C

ollar

stit ches

eplace

3065

r s

hirring

nd

era rm seam

U

me nt

- 0- 0 I

R

Group K

18

Fo

part

part

s

e A ste p presser is

e

Examp

(

s

e

e

e T he upper f

s

153984- 0- 01 151621- 0- 01

attached to the right side

Co

nsistent stitch widt hs ca n be obtain ed by using these part

Collar

and c

uff

le)

153170- 0- 0 I

Attaching z

Th

ese parts arc used for a tt ac hing the type of z

pla

ce

ipp

ers to thi ck materials such

ee

d d

og

has te

d o n the left side of the needle.

stitches o n dr

153171- 0- 01 151329- 0-

eth

only on the right s

of

ess

as

151

the

F-g

skirts.

jersey,

quiltin

ipp

er that can be separa ted .

ide

of the needl

32

4- 0- 01

roup presser foot.

s when sewing pa tches

01

g,

etc.

e.

The teeth

151

26

1- 0- 01

or

hem

s.

151266- 0- 0 I

of the zipper should be

- 14 -

Page 15

Replacement

parts code

Presser foot Upper feed dog

Feed dog

Needle plate

Replacement

Group

L

1

83085

- 0-

For

shi

rring

Attachmcm

Gir

l's

dre

Model

D

B2-B

792-0 15

Replaceme

Group

M

183107

- 0- 01

nt

ss

01

part

of

part

s

cuffs

s

1

e

These part

e

The

diffe

e If

s

hould

and

e

There

s

ewn.

(Examp

53575

se

rent

the

se

an

is

les)

- 0- 0 I

s a rc used fo r

parts arc

materia

parts arc

be used t

adverse

no

groove

Attaching yoke

diff

effective

ls t

oget

used

ogethe

effect

on

ere

nt

mate

1

5358

1- 0-

gathering or tucking

for the preven

her (l

inings. leather

especially for

r with

them

. By us

on

the bott

the

om

presser

s.

gathered cuff

rials

arc sewn

mater

foot

01

tion

of sewin g

and

gathering.

ing

the

ial

to

prevent the

s,

togethe

thin

or medium

cloth.

the gatheri

se

part

(when

or

insi

r).

1

53577

s. the

the

bunching of

0- 01

lag

and

knitted

ng

amount

mater

de

linings (sewing l

151

263-0-0

thickness

arc part

mat

attachment (gathering separator)

ial is thin) can be preve

icular

erial and

of gat

materia

materials.

ly useful for sewin g

cloth

, etc .).

hering

can

be

l when

thin material

ag

is

prevent

1

increased,

nted

.

ed

when

is

I

I I

I

I

I

GATHERING

SEPARATOR

183084- 0- 0 I

I

I

I

1

e

The

the edges

e Slide

e T wists in the

dog.

e Both

153978- 0 01

se

parts ar

c used

of

materials.

th

e presse r

ma

thin

mat

erial

[Standard

e T he

bct

e The usc

whe n

e

!\

stitc h g uide is

e

To be.:

1539

for stitching do

foot

to t

he

teria l are

s. such

prevent

as

equipment

amount of gath

wco.:n

the

top

of

the gathering separa to r prevents the bott

thin materia

used with

82

- 0- 01 151324 0 01 1

uble z

ippers and

left

and

righ t in

ed

by

these

crepe.

and

medi

on

8792-015

erin g can be incr

and bottom material s.

ls

arc gath

attached.

type B o r type L

ere

order

part

um

d.

arc also

to

s beca u

thickne

eased

gauge

eff

ective

opera te.

se

the needle moves be

ss

mat

erial s

typ

e]

by inserting

om material fro m puckering

part

>.

5126

fo r sewing extr

hind

can

be se wn.

the

gath

eri ng se

1- 0-

eme

the

upper

01

ly close to

feed

parator

15 -

Page 16

$ BROTHER

INDUSTRIES,

NAGOYA,JAPAN

LTD.

117-792

192792-1-02

Printed in Japan 1

I

l

Loading...

Loading...