Page 1

Cover Stitch Machine Operation Manual

Manual de instrucciones de la máquina de

puntada de recubierto

CONTENTS: ENGLISH

1. Names of parts and their functions

ii. Preparation before threading

iii. Threading.....................................................9

iV. Types of stitches.......................................11

Tri-cover stitch

Two needle three threads cover stitch

Chain stitch sewing

V. Sewing........................................................15

VI. Maintenance

VII. Machine specifications.............................19

.......................................

......

.......................................19

.............

.......................

................................

....

3

8

11

12

14

INDICE: ESPAÑOL

I. Nombres de las partes y sus funciones ....21

II. Preparación antes del enhebrado

III. Enhebrado

IV. Tipos de puntadas

Puntada de recubierto triple

Puntada de recubierto de

Costura de puntada de cadena..............32

V. Costura

Vi. Mantenimiento

Vil. Especificaciones de la máquina

.................................................

.....................................

dos agujas con tres hilos

.......................................................

...........................................

..............

...................

.............

...............

26

27

29

29

30

33

37

37

Page 2

"IMPORTANT SAFETY INSTRUCTIONS"

When using the sewing machine, basic safety precautions should always be followed,

including the following.

"Read all instructions before using."

DANGER “To reduce the risk of electric shock.

1. The sewing machine should never be left unattended when plugged in. Always unplug this sewing machine

from the electrical outlet immediately after using and before cleaning.

2. Always unplug before relamping. Replace bulb with same type rated 15 watts.

WARNING -

1.

Do not allow to be used as a toy. Close attention is necessary when the sewing machine is used by or near

children.

2.

Use this sewing machine only for its intended use as described in this manual. Use only accessories

recommended by the manufacturer as contained in this manual.

3.

Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer

or service center for examination, repair, electrical or mechanical adjustment.

Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing

machine and foot controller free from the accumulation of lint, dust, and loose cloth.

Never drop or insert any object into any openings.

Do not use outdoors.

Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

To disconnect, turn the main switch to the symbol “O” position which represents off, then remove plug from

outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch the sewing machine to the symbol “O” position when making any adjustments in the needle area, such

as threading needle, changing needle, or changing presser foot, and the like.

15. Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual.

16. This sewing machine is not intended for use by young children or infirm persons without supervision.

17. Young children should be supervised to ensure that they do not play with this sewing machine.

To reduce the risk of burns, fire, electric shock, or injury to persons.

CAUTION “ This appliance has a polarized plug (one blade wider than the other) to reduce the

risk of electric shock, this plug is intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit. Contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

When leaving this sewing machine unattended,

the main switch of the machine must be switched

off or the plug must be removed from the socketoutlet.

FOR USERS IN THE UK, EIRE, MALTA AND CYPRUS ONLY.

If your sewing machine is fitted with a 3 pin non rewireable BS plug then please read the following.

IMPORTANT

If the available socket outlet is not suitable for the

plug supplied with this equipment, it should be cut off

and an appropriate three pin plug fitted. With alterna

tive plugs an approved fuse must be fitted in the plug.

NOTE: The plug severed from the mains lead must

be destroyed as a plug with bared flexible cords is

hazardous if engaged in a live socket outlet. In the

event of replacing the plug fuse, use a fuse approved

by ASTAto BS 1362, i.e. carrying the mark, rating

as marked on plug.

Always replace the fuse cover, never use plugs with

the fuse cover omitted.

When servicing the sewing machine, or when

removing covers or changing lamps, the ma

chine or the electrical set must be disconnected

from the supply by removing the plug from the

socket-outlet.

The wires in this mains lead are coloured in accord

ance with the following code:

Blue

Brown

As the colours of the wiring in the mains lead of this

appliance may not correspond with the coloured

markings identifying the terminals in your plug, pro

ceed as follows.

The wire which is coloured blue must be connected

to the terminal which is marked with the letter ‘N’ or

coloured black or blue.

Neutral

Live

"SAVE THESE INSTRUCTIONS"

This sewing machine is intended for household."

WARNING: DO NOT CONNECT EITHER WIRE

TO THE EARTH TERMINAL WHICH IS MARKED

WITH THE LETTER ‘E’, BYTHE EARTH SYMBOL

OR COLOURED GREEN OR GREEN AND

YELLOW.

The wire which is coloured brown must be connected

to the terminal which is marked with the letter ‘L’ or

coloured red or brown.

1

Page 3

CONGRATULATIONS ON

CHOOSING THIS COMPACT COVER STITCH MACHINE

Your machine is a high quality, easy-to-use product. To fully enjoy all the features, we suggest that

you study this booklet.

if you need more information regarding the use of your machine, your nearest authorized dealer is

always happy to be of service.

Enjoy yourself!

CAUTION!

WHEN THREADING, REPLACING NEEDLE OR LIGHT BULB, BE SURE TO TURN OFF THE MAIN

POWER SWITCH OF THE MACHINE.

WHEN THE MACHINE IS NOT IN USE, IT IS RECOMMENDED THAT THE ELECTRIC SUPPLY PLUG

IS DISCONNECTED FROM THE WALL SOCKET TO AVOID ANY POSSIBLE HAZARDS.

Notes on the motor

The normal operating speed of this sewing machine is 1,000 stitches per minute, which is quite fast compared

to the normal operating speed of 300 to 800 stitches per minute forthe ordinary foot-operated sewing machine.

The bearings in the motor are made of a special sintered, oil-impregnated alloy mounted in oil-soaked felt to

withstand long hours of continuous operation.

Continuous operation of the sewing machine can cause heat to build in the motor area, but not enough to

adversely affect its performance.

It is important to keep fabric and paper away from the ventilating holes on the back and sides of the machine

so air can get to these holes.

When the motor is running, sparks can be seen through the ventilating hole in the motor bracket on the side

opposite the hand wheel. These sparks are produced by the carbon brushes and the commutator, and are

part of the machines normal operation.

CAUTION

WHEN THREADING THE MACHINE, REPLACING A NEEDLE, OR WHEN THE MACHINE IS NOT IN

USE, WE RECOMMEND DISCONNECTING THE ELECTRIC SUPPLY PLUG TO AVOID ANY POSSI

BLE HAZARDS.

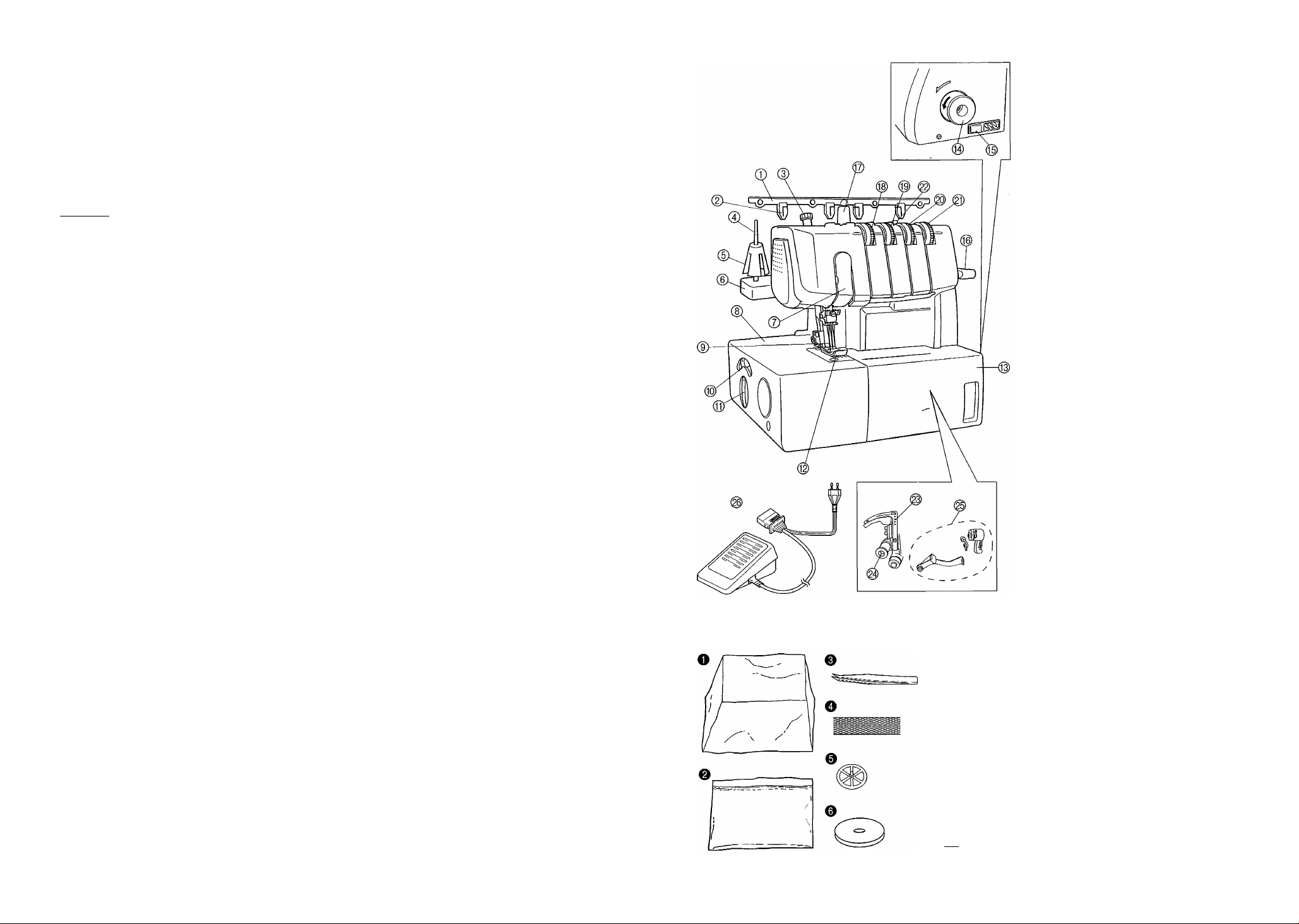

I. Names of parts and their functions

0 Thread tree

@ Thread plate

® Presser foot pressure adjustment screw

0 Spool pin

0 Spool cushion

0 Spool support

0 Thread take-up cover

0 Material plate cover

0 Needles

0 Differential feed raito adjustment dial

0 Stitch length adjustment dial

0 Presser foot

0 Front cover

0 Hand wheel

0 Main power switch and light switch

0 Presser foot lifting lever

© Spool stand

0 Left needle thread tension dial

0 Center needle thread tension dial

0 Right needle thread tension dial

0 Looper thread tension dial

0 Thread guide

0 Looper

0 Looper release lever

0 Lopper thread take up

0 Foot controller:

XC7359021 (110/120V Area)

XC7438321 (220/240V Area)

XC7456321 (U.K.)

XE0629001 (Australia, New Zealand)

XC7438321 (Germany)

Accessories included

o

©

©

©

(0^

o Soft cover X77871001

O Accessory bag 122991002

0 Tweezers X75902001

O Thread net (4) X75904000

0

Thread spool cap (4) X77260000

©Spool mat (4) XB1218000

O Cleaning brush X75906001

0

Hexagonal wrench XB0393001

0

Needle set: SCHMETZ 130/705H

(90/#14):3pcs. XB1216001

® Special presser foot (LC1) XB1265001

The special presser foot is used when an

optional attachment is used.

Page 4

Powering the machine

Stitch length

NOTE: (For U.S.A. only)

This foot controller can be used for sewing machine

model 2340CV.

Turning direction of motor

Opening and ciosing the front cover

Preparation

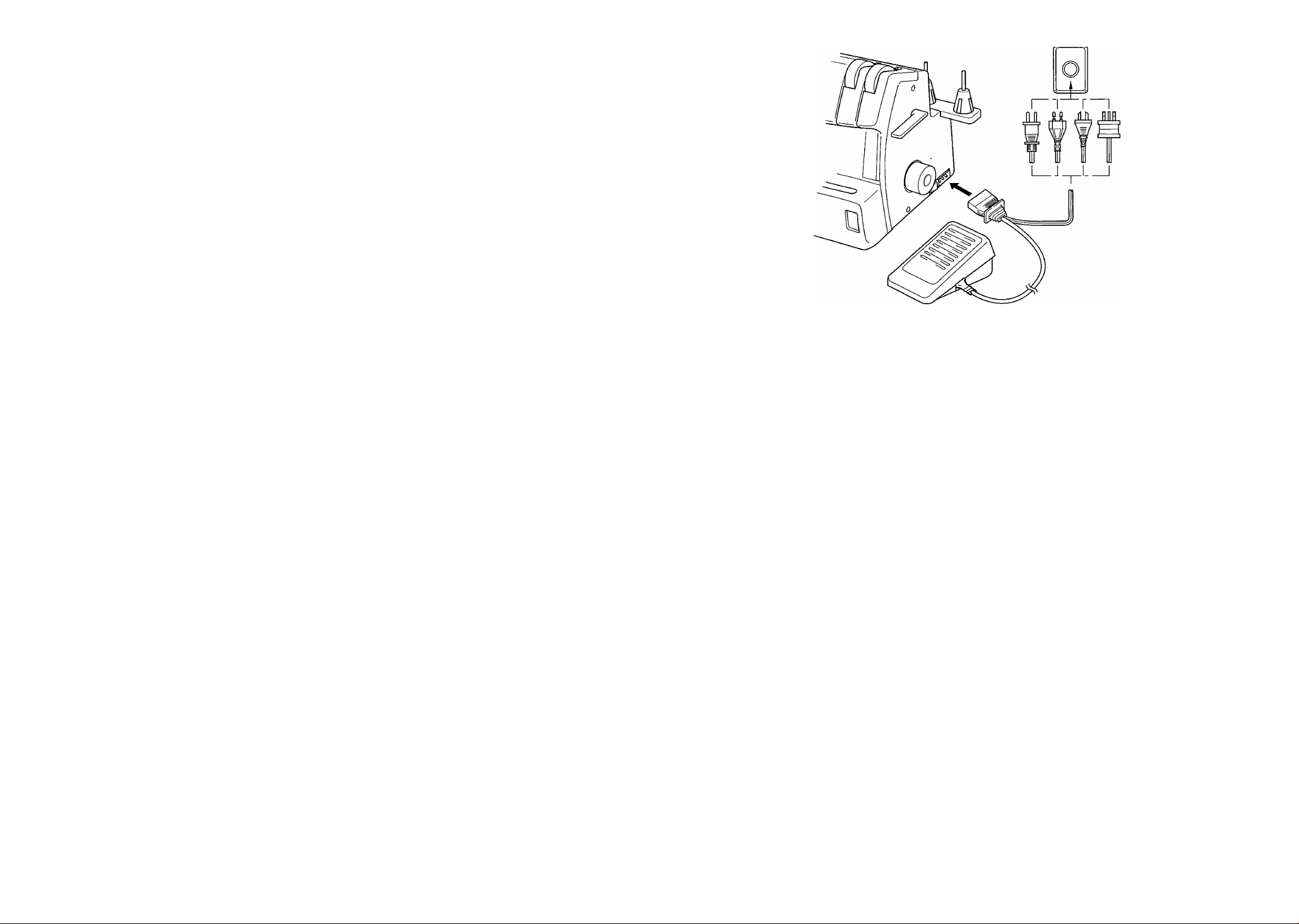

• Insert the three-pin plug into the socket on the bottom

right side of the machine. Insertthe power supply plug

into a power outlet.

Main Power and Sewing Light Switch

This switch turns the power and sewing light on or off. To turn

on push toward “ - ” mark. To turn off push toward “O ” mark.

® Main Power and Sewing Light Switch

Operation

When the pedal is pressed lightly, the machine runs at a

low speed. As the pedal is pressed further, the machine

will increase speed. When the pedal is released, the

machine stops.

©Foot Controller: Model KD-1902

The motor and hand wheel of this machine turn in a

counterclockwise direction (direction of arrow). This is

the same direction as an ordinary home sewing ma

chine.

©Hand wheel

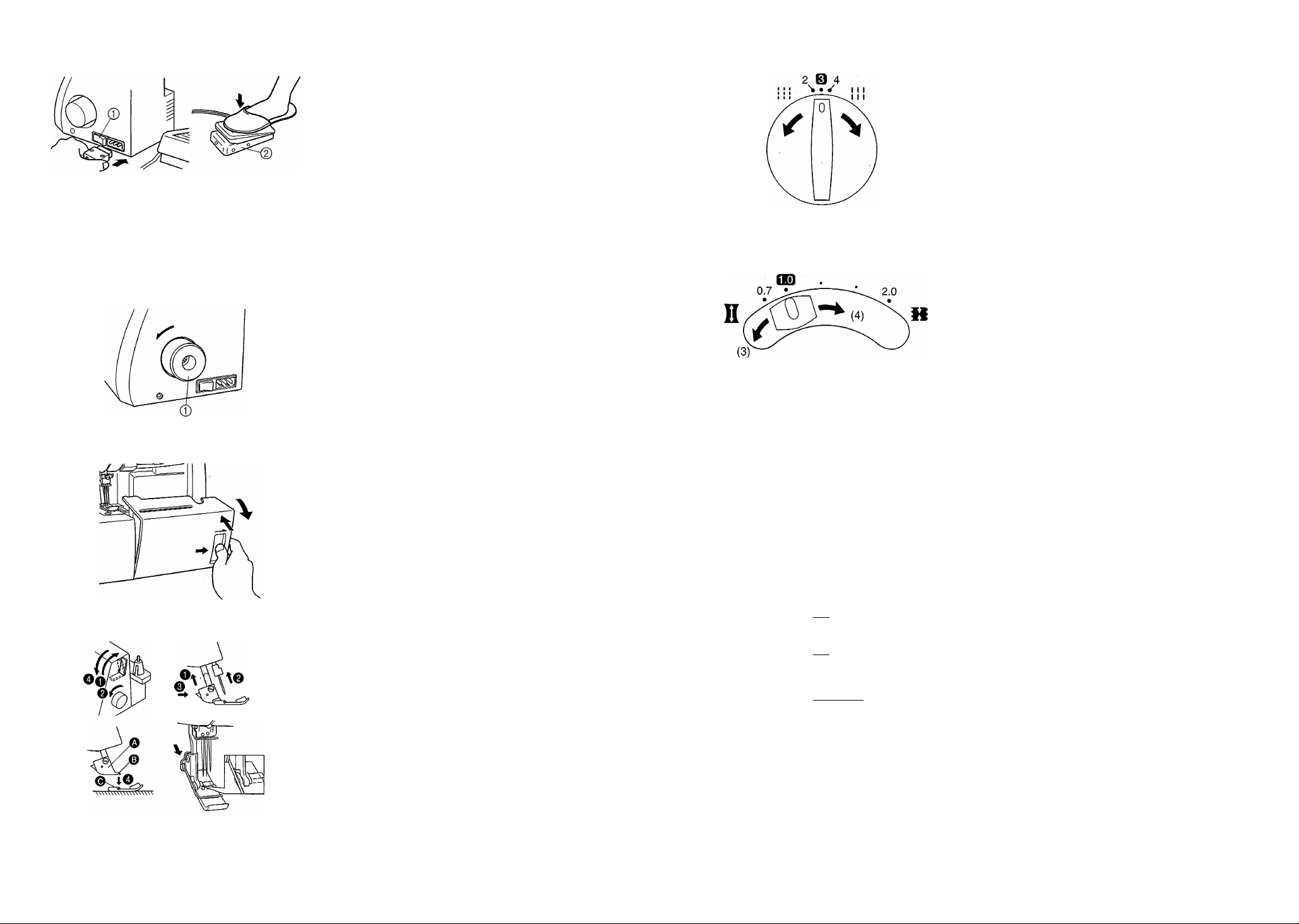

To change the stitch length, .

(1) Locate the stitch length adjustment dial on the left side

of the machine.

(2) Turn the stitch length adjustment dial forward to

lengthen the stitch to a maximum of 4 mm (5/32 inch).

Turn the stitch length adjustment dial backwards to

shorten the stitch length to a minimum of 2 mm (5/64

inch).

(3) The normal stitch length setting is 3 mm to 4 mm

(1/8 to 5/32 inch)

Instructions for the differential feed mechanism

This machine is equipped with two sets of feed dogs

under the presser foot to move the fabric through the

machine. The differential feed controls the movement of

both the front and the rear feed dogs. When set at 1, the

feed dogs are moving at the same speed (ratio of 1).

When the differential feed ratio is set at less than 1, the

front feed dogs move slower than the rear feed dogs,

stretching the fabric as it is sewn. This is effective on

lightweight fabric that may pucker. When the differential

feed ratio is set at greater than 1, the front feed dogs

move faster than the back feed dogs, gathering the fabric

as it is sewn. This function assists in removing the rippling

when serging stretch fabrics.

It is necessary to open the front cover when threading this

machine.

• Open the front cover by sliding it to the right and

guiding the top toward you.

NOTE:

For your safety, make sure that the front cover is closed

when operating the machine.

How to attach and remove the presser foot

• Turn off the main power switch or disconnect the

electric supply plug.

(1) Raise the presser foot lever. ©

(2) Set the needle to its highest position by turning the

hand wheel (© counter clockwise.

(3) Push the button on the presser foot holder and the

standard foot will be released. (3) @

(4) Raise the presser foot farther by pushing the presser

foot lever upward. Then remove the presser foot and

store it in a safe location.

(5) Again, raise the presser foot farther by pushing the

presser foot lever upward. Then place a presser foot

CAUTION

Always be sure to turn off the power before

carrying out this operation.

just under the presser foot holder ® so that the

groove in the bottom of the presser foot holder (g) is

aligned and catches the bar on the top of the foot © .

Then lower the presser foot lever to attach the foot.

Feed ratio Main feed (rear)

0.7-1.0

1.0

1.0-2.0

r ; )

( ; )

c~~ ; 3

• To adjust the differential feed.

(1) Locate the differential feed adjustment lever on the left

side of the machine.

(2) The normal setting is 1.0 on the differential feed

adjustment lever.

(3) To set less than 1.0, move the lever back.

(4) To set greater than 1.0, move the lever forward.

Differentiai feed (front)

o

Effect

Material is pulled

tight.

Without differential

feed.

Material is gath

ered or pushed

together.

Appiication

Prevents thin mate

rials from puckering

Normal sewing

Prevents stretch ma

terials from stretch

ing or puckering

Page 5

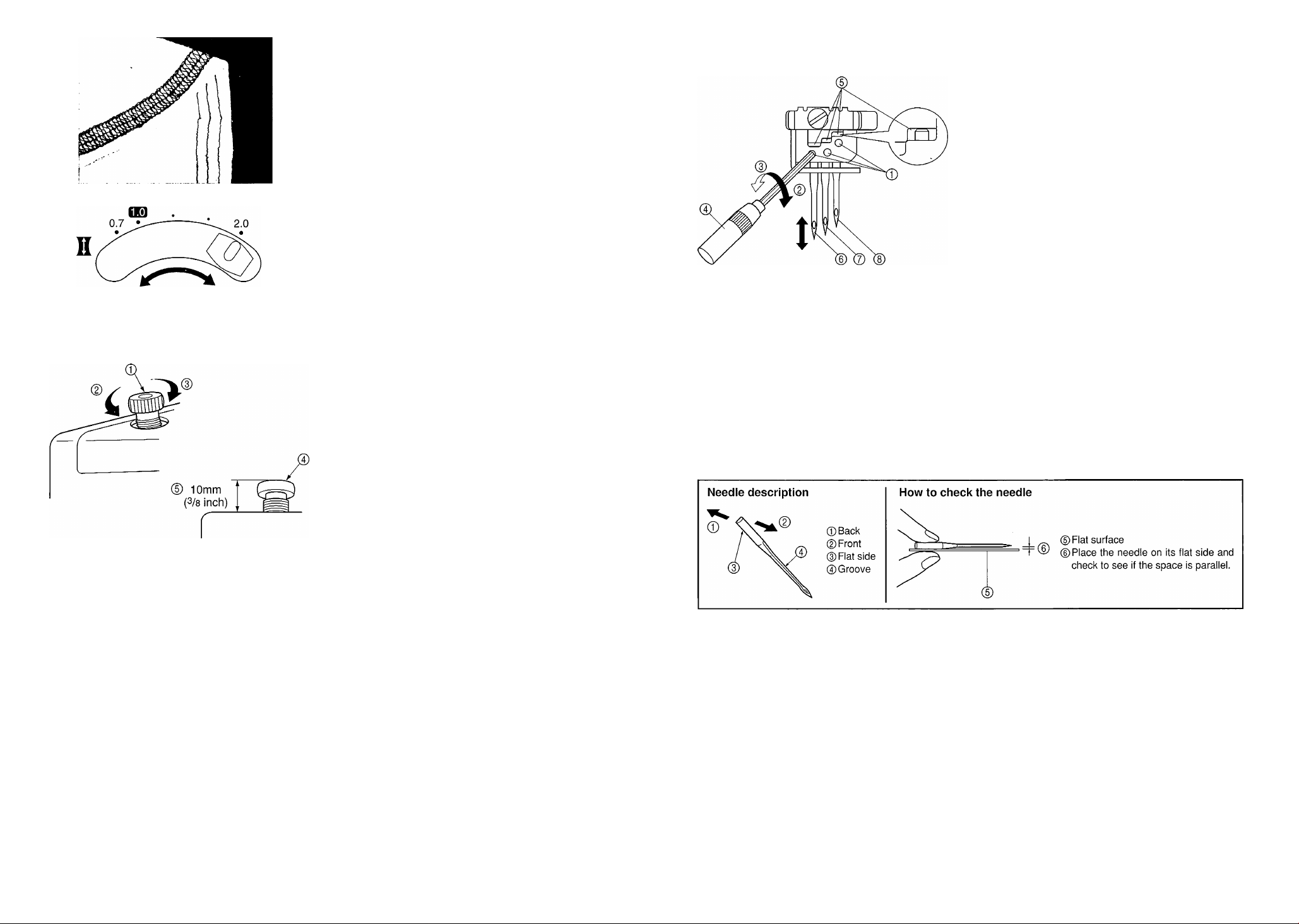

• An example where adjustment is required

When stretch material is sewn without using the differen

tial feed, the material will be wavy.

To make the material more smooth, adjust the feed ratio

from 1.0 toward 2.0.

(The feed ratio required depends on the elasticity of the

material.)

The more elastic the material, the further toward 2.0 the

differential feed ratio should be set. Test sew with a scrap

of the fabric to find the correct adjustment.

Needle

This machine uses a standard home sewing machine

needle.

The recommended needle is SCHMETZ 130/705H

(90/#14).

To remove the needle

(1) Turn the main power switch to the OFF position.

(2) Turn the hand wheel counter-clockwise by hand until

the needle is at its highest position.

(3) Loosen the needle set screw with hexagonal wrench

and remove the needle.

Presser foot pressure

H

CAUTION

When sewing thick non-stretchabie materiai such

as denim, do not use the differentiai feed as it

may damage the fabric.

The pressure of the presser foot can be adjusted by

turning the pressure adjustment screw at the top left

of this machine. Since this machine has already been

adjusted to a pressure suitable for light to medium

fabrics, no further adjustment is necessary except

when sewing on very heavy or very light materials.

Usually, when sewing on very light materials, the

presser foot pressure should be loosened. When

sewing very heavy materials, the presser foot pres

sure should be tightened.

©Pressure adjustment screw

©Less pressure

©More pressure

©Pressure adjustment screw

©(Standard height for medium material)

NOTE:

When front needles are inserted correctly you can

see the top of the needle in the window (®) above

each needle position.

----------------------------

CAUTION

UAUIIUN --------------------------------

Always be sure to turn off the power before

carrying out this operation.

------------------------ CAUTION

---------------------

^

Do not drop the needle and needle set screw

in the machine, otherwise it may be dam

aged.

To insert the needle

(1) Turn the main power switch to the OFF position.

(2) Turn the hand wheel until the needle bar is at its

highest position.

(3) Hold the needle with its flat side away from you and

insert it up as far as it will go.

(4) Tighten the needle set screw securely with the hex

agonal wrench.

©Needle set screw

©Tighten '

©Loosen

©Hexagonal wrench

©Window

©Left needle

©Center needle

©Right needle

NOTE:

Countermeasures for material breakage.

It can reduce the occurrence of material breakage by using SCHIMETZ 130/705H SUK (90/#14) BALL POINT.

Page 6

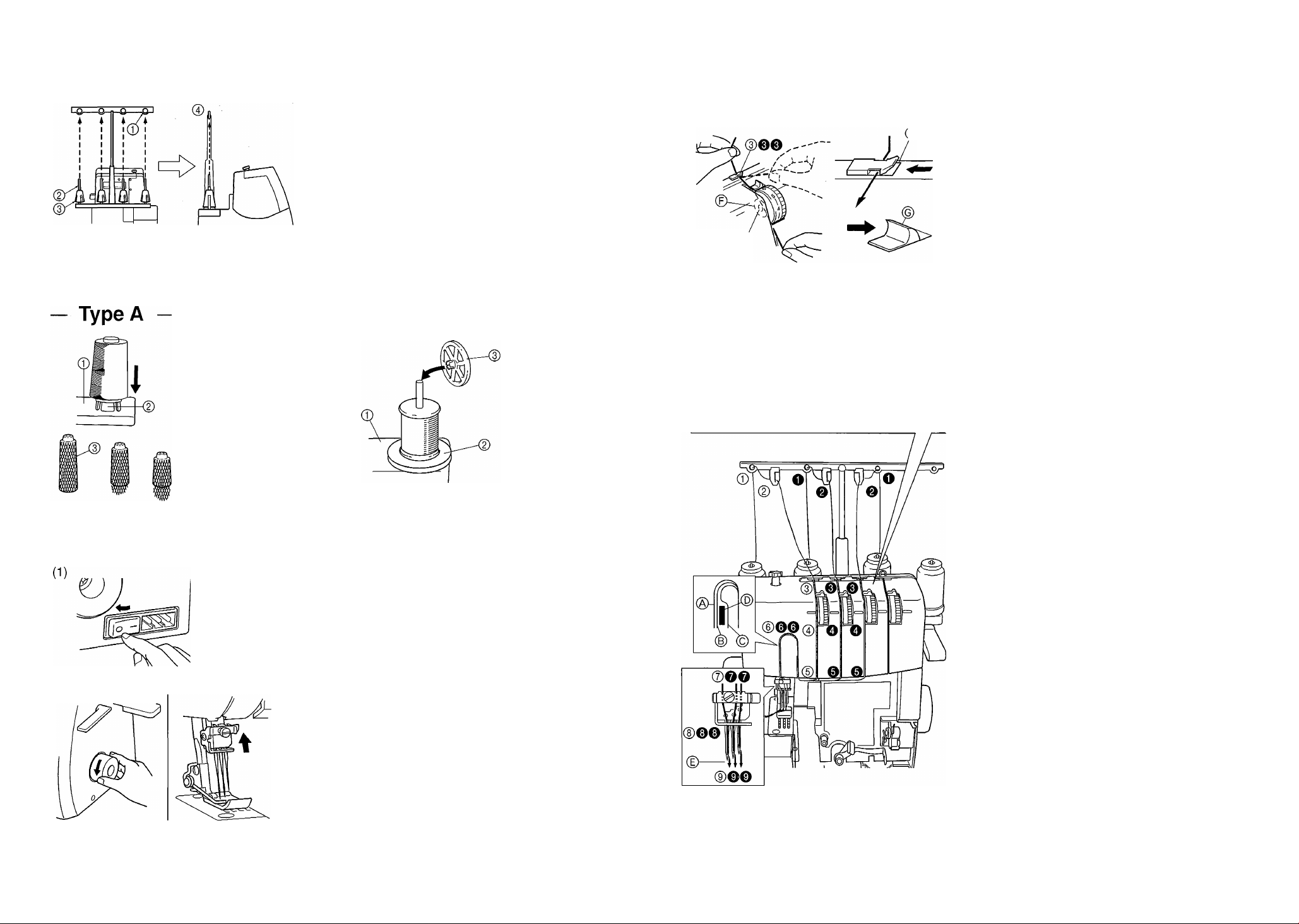

II. Preparation before threading

Thread tree

Raise the telescoping thread tree to its highest position.

Make sure that the thread holders are in alignment above

the spool pins as illustrated left.

©Thread holder on thread tree

©Spool pin

©Spool cushion

©Correct position

Thread spool

The procedure for placing the spool of thread on the spool pin differs according to the shape of the spool.

- Type B ---------------------

If you are sewing with loosely

spun nylon thread, we recom

mend that you cover the spool

with the net supplied to prevent

the thread from slipping off the

spool.

Adapt the net to the shape of the

spool.

©Spool support

©Spool cushion

©Net

Needle position

©Spool support

©Spool mat

©Spool cap

II. Threading

Needie threading

3)00

0OO

Pass each thread from (3)0© to @00 as

shown in this illustration.

Pass the thread through the proper thread

guide.

Slide and hold the thread tension release

button to the right, then pass the thread through

the tension disc which is in the channel next to

the tension adjustment dial. Release the but

ton.

©Tension disk

©Thread tension release button

CAUTION

Always be sure to turn off the power before carrying out the following operation.

(1) Follow the procedure described below to thread the needle.

Threading the left needle

• Run the thread in the sequence illustrated, following

the yellow color and the numbers next to each thread

ing point. ((©-©)

Threading the center needle

• Run the thread in the sequence illustrated, following

the pink color and the numbers next to each threading

point. (O'©)

Threading the right needle

• Run the thread in the sequence illustrated, following

the green color and the numbers next to each thread

ing point. (O-©)

CAUTION

When needle threading, always thread in this order:

Left needle, center needle and then right needle.

®To left needle

©To center needle

©To right needle

©Branching plate

©Pull about 6 cm (about 2-1/2 inches) of thread

through the eye of the needle.

®®0 Front to back

(2)

8

(1)Turn off the main power switch for safety.

(2) Set the needle bar in its highest position by turning the

handwheel toward you.

Turn the handwheel to find the easiest position for

threading.

Page 7

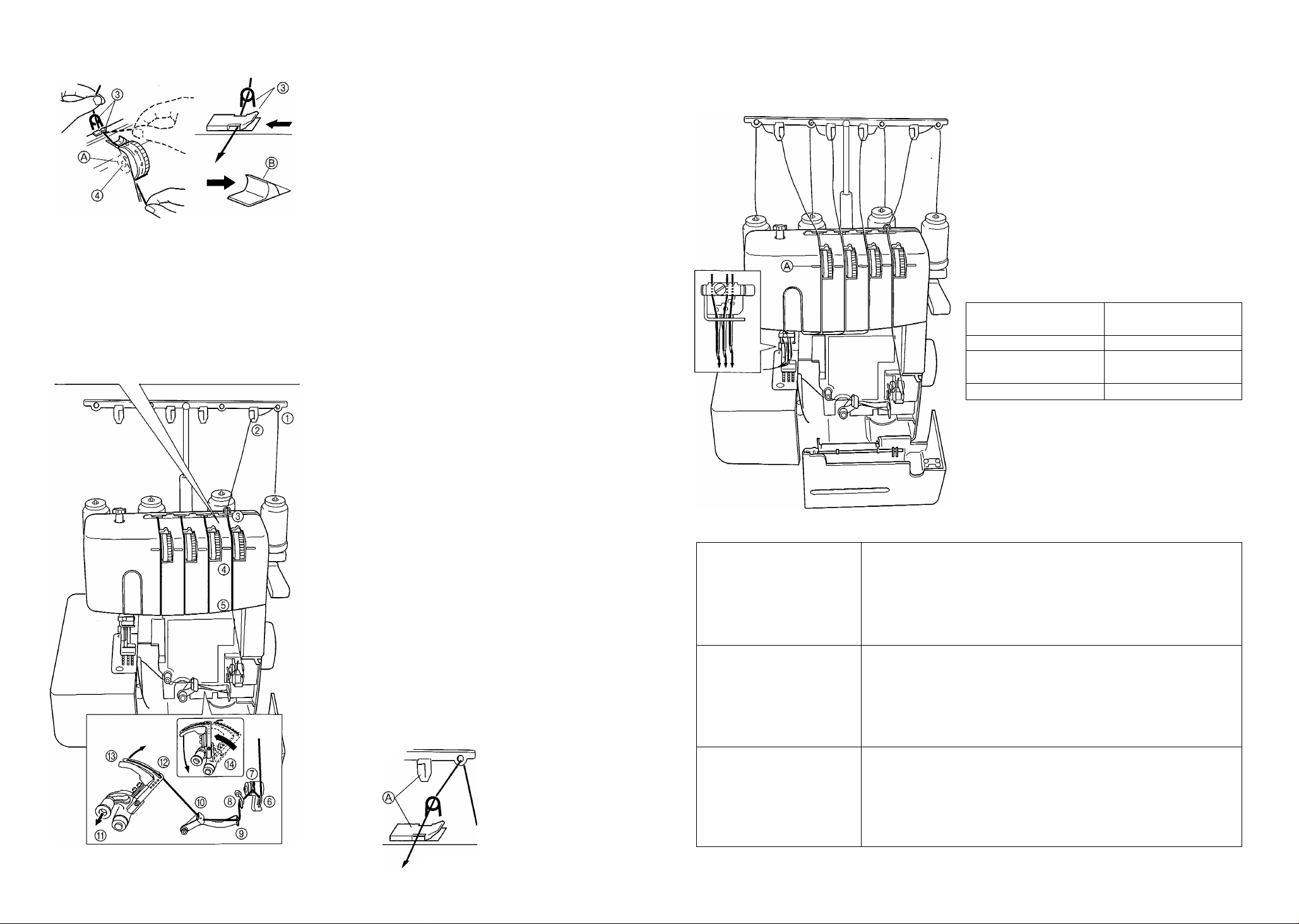

Looper threading

• Pass each thread from (3) to 0 as shown in

this illustration.

• Pass the thread through the proper thread

guide.

• Slide and hold the thread tension release

button to the right, then pass the thread

through the tension disc which is in the

channel next to the tension adjustment dial.

Release the button.

©Tension disk

©Thread tension release button

CAUTION

Always be sure to turn off the power before carrying out the following operation.

(1) Follow the procedure described below to thread the

looper.

1 Open the front cover by sliding to the right and guiding

the top toward you.

2 Run the thread in the sequence illustrated, following

the blue color and the numbers next to each threading

point. (©-©)

3 After running the thread to pull the release lever ©,

and then run the thread through ® and 0.

4 With about 10 cm (4 inch) of thread pulled through the

eye of the needle, as shown by ® in the illustration,

move the looper back in the direction of the arrow to

lock it.

5 Close the front cover.

IV. Types of stitches

Tri-cover stitch (Three needies four threads cover stitch)

Use four threads, three front needles and the looper

thread to sew a 6 mm (15/64 inch) cover stitch.

Use: Ideal for hemming and for decorative stitching.

Threading

• For details on threading the machine, refer to “III.

Threading” on page 9 to 10.

< Threading the left, center and right needle >

< Threading the looper >

Tension adjustments

(1) First, set each thread tension dial to the number

shown below.

©Tension selection mark

Left needle dial

(yellow)

4

Right needle dial

(green)

4 4

CAUTION

Make sure that the thread is properly seated in

the tension discs by holding the tension release

button to the right while passing the thread

through the tension discs.

(2) Sew a test stitch. (Refer to “V. Sewing” on page 15.)

(3) Adjust the tension of each thread according to the

condition of the stitch.

Balanced tension

▲ The needle thread sews a straight seam on the top

1 side and the looper thread forms loops on the under

Stitching direction side of the fabric.

Center needle dial

(pink)

4

Looper needle dial

(blue)

10

NOTE:

When using thick thread, such as decorative thread,

as the looper thread, run the thread as shown in the

illustration.

Do not run the thread through ®.

1 1

^ 1 1 1

^ 1 1 1-

Needle thread is too loose

Turn the needle thread adjusting dial to a higher

number. Or turn the looper adjusting dial to a lower

number for looser tension.

Needle thread is too tight

Turn the needle thread adjusting dial to a lower

number. Or turn the looper adjusting dial to a higher

number for tighter tension.

11

Page 8

Two needles three threads cover stitch

6 mm (15/64 inch) (Wide)

Use three threads, two front needles and the looper

thread to sew a 6 mm (15/64 inch) or 3 mm (1/8 inch)

cover stitch.

Use: Ideal for hemming and for decorative stitching.

Needles and threading

• For details on installing and removing the needle,

Lightly tighten the screw at the unused needle

position, so it does not fall out while sewing.

Threading” on page 9 to 10.

< Threading the left and right needle >

< Threading the looper >

refer to “Needle” on page 7.

©Left needle

©Right needle

IMPORTANT!!

For details on threading the machine, refer to “I

Tension adjustments

(1) First, set each thread tension dial to the number

shown below.

©Tension selection mark

6 mm (15/64 inch) (Wide)

Left needle dial

(yellow)

4 -

Right needle dial

(green)

4

3 mm (1/8 inch) (Narrow)

Left needle dial

(yellow)

4 4

Right needle dial

(green)

-

---------------------------

Make sure that the thread is properly seated in

the tension discs by holding the tension release

button to the right while passing the thread

through the tension discs.

CAUTION

Center needle dial

(pink)

Looper needle dial

(blue)

4

Center needle dial

(pink)

Looper needle dial

(blue)

4

------------------------------

3 mm (1/8 inch) (Narrow)

Needles and threading

• For details on installing and removing the needle,

refer to “Needle” on page 7.

©Left needle

©Center needle

IMPORTANT!!

Lightly tighten the screw at the unused needle

position, so it does not fall out while sewing.

For details on threading the machine, refer to

Threading” on page 9 to 10.

< Threading the left and center needle >

< Threading the looper >

Stitching direction

(2) Sew a test stitch. (Refer to “V. Sewing” on page 15.)

(3) Adjust the tension of each thread according to the

condition of the stitch.

Balanced tension

The needle thread sews a straight seam on the top

side and the looper thread forms loops on the under

side of the fabric.

Needle thread is too loose

Turn the needle thread adjusting dial to a higher

number. Or turn the looper adjusting dial to a lower

number for looser tension.

Needle thread is too tight

Turn the needle thread adjusting dial to a lower

number. Or turn the looper adjusting dial to a higher

number for tighter tension.

12

13

Page 9

Chain stitch sewing (One needie two threads doubie chain stitch)

Use two threads. The center needle thread and looper

thread.

Use: For straight stitching, basting and decorative chain stitch.

Needle and threading

• For details on installing and removing the needle,

refer to “Needle” on page 7.

©Center needle

---------------------Lightly tighten the screw at the unused needle

position, so it does not fall out while sewing.

• For details on threading the machine, refer to “III.

Threading” on page 9 to 10.

< Threading the center needle >

< Threading the looper >

Tension adjustments

(1) First, set each thread tension dial to the number

shown below.

Left needle dial

(yellow)

Right needle dial

(green)

----------------------------CAUTION

Make sure that the thread is properly seated in

the tension discs by holding the tension release

button to the right while passing the thread

through the tension discs.

(2) Sew a test stitch. (Refer to “V. Sewing” on page 15.)

(3) Adjust the tension of each thread according to the

condition of the stitch.

IMPORTANT!!

©Tension selection mark

-

-

--------------------------

Center needle dial

(pink)

2

Looper needle dial

(blue)

5

------------------------------

V. Sewing

Sewing flat fabric (for example, trial sewing)

(1) Raise the presser foot, and then place the fabric at the

needle drop position.

(2) Lowerthe presserfoot, turn the handwheel toward you

a few times by hand, and then lightly step on the foot

controller to start sewing.

NOTE:

When starting to sew or after changing the thread, in order

for the needle thread to be on top of the presser foot, sew

with it positioned under the presser foot when you begin

sewing. If necessary, turn the handwheel toward you a few

times by hand, and then cut the thread as shown in the

illustration.

NOTE

14

^ 1

A The needle thread sews a straight seam on the top

1 side and the looper thread forms loops on the under

Stitching direction side of the fabric.

/ 1

Balanced tension

Needle thread is too loose

Turn the needle thread adjusting dial to a higher

number. Or turn the looper adjusting dial to a lower

number for looser tension.

Needle thread is too tight

Turn the needle thread adjusting dial to a lower

number. Or turn the looper adjusting dial to a higher

number for tighter tension.

Removing the fabric from the machine

(1)By hand, turn the handwheel toward you until the

needle is at its highest position.

\— r-^

(2) Raise the presser foot.

©This is where the needle is at its highest position.

15

Page 10

(3) While firmly taking the fabric with your hand, push the

thread release button to the right for the needle thread

currently being used to open the thread tension disc.

NOTE:

Do not take the seam.

CAUTION

Be careful when taking the fabric since the light

bulb is very hot.

(4) Slowly pull the fabric in the direction of the arrow with (3).

NOTE:

Be sure to pull the fabric to the back.

(5) Cut the needle thread which comes out on the upside

of the fabric.

Sewing a cover stitch

(1) Determine how much of the fabric will be folded up.

(2) Fold up the fabric the desired amount, and then iron it

in place.

(3) Use a ruler to measure, and then use a fabric marker

to mark the top of the fabric to see where the edge of

the folded fabric is positioned.

(4) Place the bottom of the presser foot onto the top of

fabric, and then check that the drawn mark is just

barely to the right of the left needle.

(5) Sew exactly on the mark.

(6) After sewing is finished, refer to “Removing the fabric

from the machine” in “V. Sewing” on page 15 for

details on taking care of the thread.

©Fabric (surface)

©Mark drawn with fabric marker

© Left needle (just barely on the left side of the mark)

©Right needle

©Fabric

©Needle

Sewing tubular garments (for example, cuffs)

(1) Raise the presser foot, insert the fabric as shown in

the illustration, lower the presser foot, and then begin

sewing.

(6) Again, slowly pull the fabric in the direction of the

arrow, so that the end of the needle threads are pulled

out behind the fabric.

(8) All threads are pulled at the back.

Tie all threads together and cut.

(2) Finish sewing by overlapping about 4 cm (1 -1 /2 inch)

of the beginning and end of the stitching.

NOTE:

When sewing tubular garments, overlapping the begin

ning and end of the stitching by about 4 cm (1 -1 /2 inch)

will prevent the seam from tearing.

(3) Remove the fabric as explained in “Removing the

fabric from the machine” in “V. Sewing” on page 15.

16

17

Page 11

Actual examples of two needles three threads cover stitch sewing

1) Hems of T-shirts

(Simple stitch)

3) Attaching tape

(edges of collars, etc) (Binding)

2) Stitches . ,

(Top stitched seams/Ribbing/Yokes)

4) Decorative stitching

(Decorative stitching)

VI. Maintenance

Change the light bulb

CAUTION

Always be sure to turn off the power before

carrying out the following operation. The glass

plate over the light bulb will be hot immediately

after using the machine, therefore it is advisable

to wait until the light bulb has had a chance to cool

down before changing bulbs.

Changing the light bulb.

• Remove the lamp cover as shown in the illustration.

• Loosen the lightbulb cover set screw pull up the light

bulb cover and remove it.

• Take out the light bulb and replace it with a new one.

© Screw

©Lamp cover

©Screw

©Light bulb cover

©Light bulb

5) Attaching elastic

(Hem with sewn-in elastic)

Actual examples of three-needles four-threads cover stitch sewing

1) Plain stitching 2) Hem stitching

4) Circular hemming

6) Attaching lace

(Flat joining seam)

5) Elastic lace attaching

7) Belt loop sewing

(Belt loop sewing)

3) Tape attaching

VII. Machine specifications

Stitch

One needle two thread double chain stitch Presser foot

Two needles three thread cover stitch (Wide 6 mm Free presser type

(15/64 inch)/Narrow 3 mm(1/8 inch))

Three needles four thread cover stitch (6 mm (15/64

inch))

Sewing speed

1,000 stitches per minute

Stitch length (pitch)

2 mm to 4 mm (5/64 to 5/32 inch)

Presser foot lift

5 mm to 6 mm (3/16 to 15/64 inch)

Needle

SCHMETZ 130/705H (90/#14)

Machine net weight

7.0 kgs.

18

19

Page 12

FELICITACIONES POR HABER ELEGIDO ESTA

COMPACTA MÁQUINA DE PUNTADA DE RECUBIERTO

Su máquina es de una eficacia y calidad excelentes; así pues, a fin de disfrutar completamente de

todas las características incorporadas, le sugerimo estudie el manual.

Si se necesitara mayor información sobre el uso de esta máquina, el proveedor autorizado más

cercano estará encantado de ofrecerle sus servicios.

¡PRECAUCION!

ASEGURARSE DE QUE EL INTERRUPTOR GENERAL DE LA MAQUINA ESTE APAGADO CUANDO SE

ENHEBRE, REEMPLACE LA AGUJA O CAMBIE LA LAMPARITA.

CUANDO NO SE UTILICE LA MAQUINA, SE RECOMIENDA QUE EL ENCHUFE ESTE DESCONECTA

DO DE LA RED DE LA CORRIENTE, A FIN DE EVITAR CUALQUIER PELIGRO.

NOTAS SOBRE EL MOTOR

La velocidad normal de funcionamiento de esta máquina de coser es de 1.000 puntadas por minuto, lo que

resulta bastante rápido comparado con la velocidad normal de 300 a 800 puntadas por minuto de las

máquinas de coser normales que funcionan con pedal.

Los cojinetes del motor están hechos de una aleación especial impregnada en aceite sintético y montada en

un fieltro impregnado en aceite, para poder funcionar continuamente durante muchas horas.

Un funcionamiento continuo de la máquina puede contribuir a calentar algo la máquina en la zona del motor,

pero no lo suficiente como para alterar su rendimiento y funcionamiento.

Sin embargo, es menester mantener los orificios de ventilación de la parte trasera y en los lados de la máquina

sin tapar con tejido o papel durante el uso, para que el aire pueda circular por los orificios.

Durante el funcionamiento del motor, se pueden ver chispas a través del orificio de ventilación de la

abrazadera del motor, en el lado contrario a la ruedecilla. Estas chispas son producidas por las escobillas

de carbón que entran en contacto con el conmutador, y forman parte del funcionamiento normal de la

máquina.

PRECAUCION

Al enhebrar la máquina, cambiar una aguja o al dejar la máquina sin usar, le recomendamos

desenchufar la máquina para evitar cualquier peligro de corto circuito.

I. Nombres de las partes y sus funciones

Ф Arbol del hilo

® Placa del hilo

(3) Tornillo de ajuste de la presión del prénsatelas

Ф Portabobina

(5) Protector del carrete

(D Soporte de la bobina

® Tapa de toma de hilo

(8) Tapa de tejido

(9) Agujas

® Palanca diferencial de ajuste de la velo

cidad de alimentación

® Disco de ajuste del largo de las puntadas

© Prénsatelas

© Tapa delantera

@ Ruedecilla

© Interruptor de alimentación principal e

interruptor de luz

© Palanca de levantamiento del prénsatelas

© Filete para la canilla

© Disco de tensión del hilo de la aguja izquierda

© Disco de tensión del hilo de la aguja central

© Disco de tensión del hilo de la aguja derecha

© Disco de tensión del hilo del áncora

© Guía de enhebrado

© Áncora

© Palanca de liberación del áncora

© Toma de hilo del áncora

© Pedal:

XC7359021 (zona con 110/120V)

XC7438321 (zona con 220/240V)

XC7456321 (Reino Unido)

XE0629001 (Australia, Nueva Zelanda)

XC7438321 (Alemania)

Accesorios incluidos

20

o Funda X77871001

O Bolsa de accesorios 122991002

® Pinzas X75902001

O Malla (4) X75904000

Tope del carrete (4) X77260000

© Alfombrilla del carrete (4) XB1218000

© Cepillo limpiador X75906001

© Llave de tuerca hexagonal

XB0393001

© Juego de agujas: SCHMETZ130/705M

(90/#14): 3 unidades XB1216001

® Prénsatelas especial (LC1) XB1265001

El prénsatelas especial se emplea cuando

se utiliza un accesorio opcional.

21

Page 13

Encendido de la máquina

Largo de puntada

Preparación de la máquina

• Introduzca el zócalo de tres puntas en el enchufe que se

Interruptor principal y de luz

Este interruptor permite apagar y encender la máquina

así como la luz. Para encender, empuje hacia la marca

Funcionamiento

Al oprimir ligeramente el pedal, la máquina funcionará a

baja velocidad. A medida que se apriete más, la máquina

incrementará su velocidad. La máquina se parará tan

pronto como se suelte el pedal.

Para cambiar la dirección del motor

Abre y cierre de la tapa delantera

Es necesario abrir la tapa delantera para enhebrar la

máquina.

• Abra la tapa delantera moviéndola hacia la derecha y

NOTA:

Para su propia seguridad, averigüe siempre que la tapa

delantera esté bien cerrada antes de hacer funcionar la

máquina.

Cómo colocar y retirar el prénsatelas

• Apague el interruptor principal o desconecte el en

(1) Levante la palanca del prénsatelas. ©

(2) Ponga la aguja en su posición más alta, girando la

(3) Apriete el botón en el eje del prénsatelas, lo que

(4) Levante aún más el prénsatelas al apretar la palanca

(5) Otra vez, levante aún más el prénsatelas presionan

--------------------PRECAUCION

Asegúrese siempre de desconectar la ali

mentación antes de realizar esta operación.

---------------------

encuentra abajo, en el lado derecho de la máquina e

inserte el zócalo de alimentación en una toma de corriente.

para apagar, póngalo en la marca “O”.

©Interruptor principal y de luz

El motor y la ruedecilla de esta máquina funcionan en

el sentido contrario al de las manecillas del reloj

(dirección de la flecha), como es el caso con la

mayoría de las máquinas de coser domésticas.

©Ruedecilla

dirigiendo la parte superior hacia usted.

chufe de la toma de corriente.

ruedecilla (2) con la mano en el sentido contrario al de

las manecillas de un reloj.

liberará el prénsatelas colocado. (3) ©

correspondiente hacia arriba. Luego, retire el

prénsatelas y guárdelo en un lugar seguro.

do la palanca del prénsatelas hacia arriba. A conti

nuación, coloque el prénsatelas justo debajo del eje

del prénsatelas ® a fin de que la ranura que se

encuentra abajo del eje (§) se alinee y enganche la

barra en la parte superior del prénsatelas ©. Luego

baje la palanca del prénsatelas para sujetarlo.

Para cambiar el largo de las puntada:

(1 ) Busque el disco de ajuste del largo de las puntadas en

al lado izquierdo de la máquina.

(2) Gire el disco de ajuste del largo de las puntadas hacia

adelante para alargar la puntada a un máximo de 4 mm.

Gire el disco de ajuste del largo de las puntadas hacia

atrás para acortar la longitud de puntada a un mínimo

de 2 mm.

(3) Un ajuste normal para el largo de las puntadas se

sitúa entre 3 y 4 mm.

Instrucciones para el mecanismo de alimentación con diferencial

Esta máquina está provista de dos series de

alimentadores debajo del prénsatelas para guiar el tejido

por la máquina. El alimentador con diferencial controla

los movimientos de los alimentadores delanteros y trase

ros. Al ajustarlo en 1, los alimentadores se desplazarán

a una velocidad idéntica (relación de 1). Al ajustar la

relación del alimentado|' con diferencial en menos de 1,

los alimentadores delanteros van a moverse más despa

cio que los traseros, estirando el tejido a medida que se

cuese. Esta operación resulta muy eficiente al coser

materiales finos que pueden arrugarse.

Cuando el alimentador con diferencial esté ajustado en

un valor superior a 1, los alimentadores delanteros van

a moverse más rápido que los alimentadores

traseros, juntando el tejido al coserlo. Esta función per

mite quitar las arrugas al coser tejidos que se estiran.

• Para ajustar el alimentador diferencial.

(1 ) Busque la palanca de ajuste del alimentador diferen

cial en al lado izquierdo de la máquina.

(2) El ajuste normal es de 1,0 en la palanca de ajuste del

alimentador diferencial.

(3) Para ajustar menos de 1,0, mueva la palanca hacia

atrás.

(4) Para ajustar más de 1,0, mueva la palanca hacia

adelante.

Velocidad de

alimentación

0,7-1,0

1,0

1,0-2,0

Alimentador

principal (detrás)

C

C

J

3

Alimentador con

diferencial (delante)

o

Efecto Aplicación

El tejido se estira

Sin alimentación con

diferencial.

El tejido se contrae

o se junta.

dos finos frunzan.

Costura normal.

Impide que los teji

dos extensibles se

estiren o frunzan.

Impide que los teji

22

23

Page 14

• Ejemplo en que se requiere ajuste

Al coser tejidos elásticos sin utilizar una alimentación con

diferencial, el tejido va a ser oleado.

Para remediar el problema y mejorar la apariencia del

tejido, ajuste la velocidad de alimentación de 1,0 hacia 2,0.

(El ajuste de la velocidad de alimentación depende de la

elasticidad del material.)

Cuanto más elástico el tejido, más hacia 2,0 se debe

poner el ajuste de la velocidad de alimentación con

diferencial. Haga una prueba con un poco de tejido para

encontrar el ajuste correcto.

Aguja

Está máquina funciona con una aguja normal para má

quinas domésticas.

Así mismo, se recomiendael uso de una aguja SCHMETZ

130/705H (90/#14).

Para sacar la aguja

(1) Apague el interruptor principal (posición OFF).

(2) Gire la ruedecilla a mano, en contra de las manecillas

del reloj hasta que la aguja alcance la posición más

elevada.

(3) Afloje el tornillo de instalación de la aguja con la llave

hexagonal y saque la aguja.

Presión del prénsatelas

PRECAUCION

Si debe coser tejidos gruesos que no son elás

ticos, tales como el tejano, no trabaje con el

alimentador diferencial, para no deteriorar el

material.

La presión del prénsatelas puede ajustarse al girar el

tornillo de ajuste de presión, en la parte superior

izquierda de la máquina. Dado que la máquina ya ha

sido ajustada para tener una presión conveniente

para los tejidos finos y medios, no requiere ningún

ajuste suplementario si no es para coser tejidos muy

gruesos o muy delgados. En general, al coser tejidos

muy finos, la presión del prénsatelas debe ser floja y,

al contrario, debe ser más fuerte para coser tejidos

gruesos.

©Tornillo de ajuste de la presión

©Menos presión

©Más presión

©Tornillo de ajuste de la presión

©(altura estandard para tejidos medios)

NOTA:

Una vez introducidas correctamente las agujas

delanteras, puede ver la parte superior de la aguja

en la ventana ((©) encima de la posición de cada

aguja.

PRECAUCION

Asegúrese siempre de desconectar la ali

mentación antes de realizar esta operación.

PRECAUCION

No deje caer la aguja y el tornillo de instala

ción de la aguja en la máquina; de lo contra

rio, podría dañarse.

Para introducir la aguja

(1) Apague el interruptor principal (póngalo en OFF).

(2) Gire la ruedecilla hasta que la barra de la aguja

alcance la posición más alta.

(3) Sujete la aguja con la parte curvada de cara a Vd. e

insértela hacia arriba hasta el tope.

(4) Vuelva a apretar firmemente el tornillo de instalación

de la aguja con la llave hexagonal.

©Tornillo de instalación de las agujas

©Apretar

©Aflojar

©Llave de tuerca hexagonal

©Ventana

©Aguja izquierda

©Aguja central

©Aguja derecha

24

NOTA:

Medidas preventivas contra la rotura de material.

La utilización de SCHIMETZ 130/705H SUK (90/#14) BALL POINT permite reducir la rotura de material.

25

Page 15

II. Preparación antes del enhebrado

Arbol del hilo

Levante el árbol telescópico del hilo hasta su posición

más alta. Compruebe que los corchetes de hilos quedan

alineados sobre los portabobinas como se ilustra a

continuación.

©Portahilos en el árbol del hilo

©Portabobina

©En los modelos de dos agujas

© Posición correcta

Carrete de hilo

II. Enhebrado

Enhebrado de la aguja

3)00

PRECAUCION

Asegúrese siempre de desconectar la alimenta

ción antes de realizar la operación siguiente.

(1)Siga el procedimiento que se describe más abajo

para enhebrar la aguja.

Enhebrado de la aguja izquierda

• Enhebre la aguja tal como ilustrado en la secuencia,

respetando el color amarillo y los números inscritos al

lado de cada punto de enhebrado. (®-@)

El procedimiento de colocación del carrete de hilo en el portabobina varía según sea la forma del carrete.

|— Tipo A

Si está cosiendo con un hilo de

hilvanar, le recomendamos cu

brir el carrete con la malla provis

ta para que el hilo no se deslice

del carrete.

Adapte la malla a la forma del

carrete.

©Soporte de la bobina

© Protector del carrete

©Malla

Tipo B

-<3)

©Soporte de la bobina

©Alfombrilla del carrete

©Tope del carrete

Posición de la aguja

(1) Apagar el interruptor principal por seguridad.

Pase cada hilo de @0© a 0O© tal como se

muestra en la ilustración.

Pase el hilo por la guía de hilo correspondiente.

Deslice y retenga el botón de liberación de la

tensión del hilo hacia la derecha y pase el hilo

por el disco de tensión, que es el canal situado

al lado del disco de ajuste de la tensión. Suelte

el botón.

©Disco de tensión

© Botón de liberación de la tensión del hilo

Enhebrado de la aguja central

• Enhebre el hilo teniendo en cuenta el orden Indicado en

la ilustración, siguiendo el color rosado y los números

inscritos al lado de cada punto de enhebrado. (0-0)

Enhebrado de la aguja derecha

• Enhebre el hilo según ilustrado en la secuencia,

siguiendo el color verde y los números inscritos al lado

de cada punto de enhebrado. (0-0)

-----------------------

Al enhebrar agujas, siga siempre este orden:

aguja izquierda, aguja central y luego aguja

derecha.

PRECAUCIÓN---------------------------

® A la aguja izquierda

©A la aguja central

©A la aguja derecha

©Placa de bifurcación

©Tire del hilo unos 6 cm por el ojo de la aguja

@0© De delante hacia atrás

(2)

26

(2) Colocar la aguja en la posición más alta, girando la

polea hacia afuera.

Girar la perilla hasta encontrar la posición más fácil

para enhebrar.

27

Page 16

Enhebrado del áncora

Pase cada hilo de (D a 0 tal como se

muestra en la ilustración.

Pase el hilo por la guía de hilo correspondiente.

Deslice y retenga el botón de liberación de la

tensión del hilo hacia la derecha y pase el

hilo por el disco de tensión, que es el canal

situado al lado del disco de ajuste de la

tensión. Suelte el botón.

©Disco de tensión

® Botón de liberación de Intensión del hilo

PRECAUCION

Asegúrese siempre de desconectar la alimenta

ción antes de realizar la operación siguiente.

(1)Siga el procedimiento que se describe más abajo

para enhebrar el áncora.

1 Abra la tapa delantera deslizándola hacia la derecha

y guiando la parte superior hacia usted.

2 Enhebre el hilo según lo ilustrado en la secuencia,

observando el color azul y los números inscritos al

lado de cada punto de enhebrado. (®-@)

3 Después de enhebrar la aguja a tire de la palanca

de liberación 0 y, a continuación, enhebre el hilo por

©y®.

4 Pasando unos 10 cm de hilo por el ojo de la aguja,

según se muestra en la ilustración (g), mueva el

áncora hacia atrás en la dirección de la flecha para

cerrarlo.

5 Cierre la tapa delantera.

IV. Tipos de puntadas

Puntada de recubierto triple (puntada de recubierto de cuatro hilos y tres agujas)

utilice tres agujas delanteras con cuatro hilos y el hilo del

áncora para coser una puntada de recubierto de 6 mm.

Uso: ideal para dobladillos y costura decorativa.

Enhebrado

• Si desea más información, véase “III. Enhebrado” en

las páginas 27 y 28.

< Enhebrado de la aguja izquierda, central y derecha >

< Enhebrado del áncora >

Ajustes de tensión

(1) En primer lugar, ajuste cada disco de tensión del hilo

en el número indicado más abajo.

©Marca de selección de tención

Disco de la aguja

izquierda (amarillo)

4 4

Disco de la aguja'

derecha (verde)

4 4

PRECAUCION

Asegúrese de que el hilo esté bien coiocado en

los discos de tensión reteniendo el botón de

liberación de ia tensión a la derecha mientras

pasa ei hilo por los discos de tensión.

(2) Cosa una puntada de prueba. (Véase “V. Costura” en

la página 33.)

(3) Ajuste la tensión de cada hilo según el tipo de puntada.

Tensión ajustada

▲ El hilo de la aguja realiza costuras rectas en el

1 derecho del tejido y el hilo del áncora forma ondas en

Dirección de la puntada el revés del tejido.

Disco de la aguja central

(rosado)

Disco de la aguja del

áncora (azul)

28

NOTA:

Al utilizar hilos gruesos (por ejemplo, hilos decorati

vos) como hilos del áncora, enhebre el hilo según se

muestra en la ilustración.

El hilo de la aguja está suelto

Gire el disco de ajuste del hilo de la aguja a un número

superior. 0 bien, gire ei disco de ajuste del áncora a

un número inferior para disminuir la tensión.

El hilo de la aguja está demasiado tendido

Gire el disco de ajuste del hilo de la aguja a un número

inferior. 0 bien, gire el disco de ajuste del áncora a un

número superior para aumentar la tensión.

29

Page 17

Puntada de recubierto de dos agujas con tres hilos

6 mm (Ancha) Utilice tres hilos, dos agujas delanteras y el hilo del

áncora para coser una puntada de recubierto de 6 mm o

de 3 mm.

Uso: ideal para dobladillos y costura decorativa.

Agujas y enhebrado

• Para información más detallada sobre cómo colocar

y sacar la aguja, véase “Aguja” en la página 25.

® Aguja izquierda

©Aguja derecha

Ajustes de tensión

(1 ) En primer lugar, ajuste cada disco de tensión del hilo

en el número indicado más abajo.

©Marca de selección de tención

6 mm (Ancha)

Disco de la aguja

izquierda (amarillo)

4

Disco de la aguja

derecha (verde)

4

Disco de la aguja central

(rosado)

-

Disco de la aguja del

áncora (azul)

4

rrfejin

W

I

©n®

3 mm (Estrecha)

(§>-

IMPORTANTE!!

Apriete ligeramente el tornillo en la posición de

la aguja no utilizada para que no se caiga al

coser.

Si desea más información, véase “III. Enhebrado” en

las páginas 27 y 28.

< Enhebrado de la aguja izquierda y derecha >

< Enhebrado del áncora >

Agujas y enhebrado

• Para información más detallada sobre cómo colocar

y sacar la aguja, véase “Aguja” en la página 25.

©Aguja izquierda

©Aguja central

IMPORTANTE!!

Apriete ligeramente el tornillo en la posición de

la aguja no utilizada para que no se caiga al

coser.

Si desea más información, véase “III. Enhebrado” en

las páginas 27 y 28.

< Enhebrado de la aguja izquierda y central >

< Enhebrado del áncora >

3 mm (Estrecha)

Disco de la aguja

izquierda (amarillo)

Disco de la aguja

derecha (verde)

------------------------

Asegúrese de que el hilo esté bien colocado en

los discos de tensión reteniendo el botón de

liberación de la tensión a la derecha mientras

pasa el hilo por los discos de tensión.

(2) Cosa una puntada de prueba. (Véase “V. Costura” en

la página 33.)

(3) Ajuste la tensión de cada hilo según el tipo de puntada.

Tensión ajustada

EI hilo de la aguja realiza costuras rectas en el

Dirección de la puntada revés del tejido.

t

derecho del tejido y el hilo del áncora forma ondas en

El hilo de la aguja está suelto

Gire el disco de ajuste del hilo de la aguja a un número

superior. O bien, gire el disco de ajuste del áncora a

un número Inferior para disminuir la tensión.

El hilo de la aguja está demasiado tendido

Gire el disco de ajuste del hilo de la aguja a un número

inferior. O bien, gire el disco de ajuste del áncora a un

número superior para aumentar la tensión.

Disco de la aguja central

(rosado)

4

Disco de la aguja del

áncora (azul)

PRECAUCION----------------------------

4

4

30

31

Page 18

Costura de puntada de cadena (puntada de cadena doble de una aguja y dos hilos)

Utilice dos hilos: el hilo de la aguja central y el hilo del áncora.

Uso: para costura recta, costura de hilvanado y costura

de cadena decorativa.

Agujas y enhebrado

• Para información más detallada sobre cómo colocar

y sacar la aguja, véase “Aguja” en la página 25.

©Aguja central

----------------------

Apriete ligeramente el tornillo en la posición de

la aguja no utilizada para que no se caiga al

coser.

• Si desea más información, véase “III. Enhebrado” en

las páginas 27 y 28.

< Enhebrado de la aguja central >

< Enhebrado del áncora >

Ajustes de tensión

(1 ) En primer lugar, ajuste cada disco de tensión del hilo

en el número indicado más abajo.

Disco de la aguja

izquierda (amarillo)

Disco de la aguja

derecha (verde)

Asegúrese de que el hilo esté bien colocado en

los discos de tensión reteniendo el botón de

liberación de la tensión a la derecha mientras

pasa el hilo por los discos de tensión.

(2) Cosa una puntada de prueba. (Véase “V. Costura” en

la página 33.)

(3) Ajuste la tensión de cada hilo según el tipo de puntada.

IMPORTANTE!!

©Marca de selección de tención

-

PRECAUCION

--------------------------

Disco de la aguja central

(rosado)

Disco de la aguja del

áncora (azul)

2

5

V. Costura

Costura de tejido plano (por ejemplo, costura de prueba)

(1) Levante el prénsatelas y, a continuación, coloque el

tejido en la posición de entrada de la aguja.

(2) Baje el prénsatelas, gire un poco hacia usted la polea

con la mano y luego pise ligeramente el pedal para

comenzar a coser.

NOTA:

Al empezar a coser o después de cambiar el hilo, para que

el hilo de la aguja esté en la parte superior del prénsatelas,

cosa con el hilo colocado debajo del prénsatelas antes de

empezar la costura. Si es necesario, gire un poco la polea

con la mano hacia usted y, a continuación, corte el hilo

según se muestra en la ilustración.

NOTA

32

Tensión ajustada

A El hilo de la aguja realiza costuras rectas en el

1 derecho del tejido y el hilo del áncora forma ondas en

Dirección de la puntada revés del tejido.

El hilo de la aguja está suelto

Gire el disco de ajuste del hilo de la aguja a un número

superior. 0 bien, gire el disco de ajuste del áncora a

un número inferior para disminuir la tensión.

El hilo de la aguja está demasiado tendido

Gire el disco de ajuste del hilo de la aguja a un número

inferior. 0 bien, gire el disco de ajuste del áncora a un

número superior para aumentar la tensión.

Retirada del tejido de la máquina

(1)Con la mano, gire la polea hacia usted hasta que la

aguja esté en la posición más alta.

©Éste es el punto en el que la aguja está en la

posición más alta.

(2) Suba el prénsatelas.

33

Page 19

(3) Mientras sujeta firmemente el tejido con la mano,

presione hacia la derecha el botón de liberación del

hilo de la aguja que está utilizando actualmente para

abrir el disco de tensión del hilo.

NOTA:

No retire la costura.

----------------------Tenga cuidado al retirar el tejido ya que la

lamparita está muy caliente.

(4) Tire del tejido lentamente en la dirección de la flecha

con (3).

NOTA:

Asegúrese de tirar del tejido hacia atrás.

(5) Corte el hilo de la aguja que sobresale del derecho del

tejido.

PRECAUCIÓN

--------------------------

Costura de puntada de recubierto

(1 ) Determine cuánto tejido se va a doblar.

(2) Doble el tejido que desee y, a continuación, plánchelo.

(3) Utilice una regla para medirlo y después utilice un

marcador para tela para marcar el derecho del tejido

y ver dónde está colocado el borde del tejido doblado.

(4) Coloque la parte inferior del prénsatelas en el derecho

del tejido y, a continuación, compruebe que la marca

dibujada está casi a la derecha de la aguja izquierda.

(5) Cosa exactamente en la marca.

(6) Tras finalizar la costura, véase “Retirada del tejido de

la máquina” en “V. Costura” en la página 33 para

obtener información sobre el manejo del hilo.

©Tejido (superficie)

©Marca dibujada con el marcador para tela

©Aguja izquierda (casi a la izquierda de la marca)

©Aguja derecha

©Tejido

©Aguja

Costura de prendas tubulares (por ejemplo, puños)

(1 ) Suba el prénsatelas, inserte el tejido según se mues

tra en la ilustración, baje el prénsatelas y, por último,

comience a coser.

(6) Tire otra vez del tejido lentamente en la dirección de

la flecha para que los extremos de los hilos de la aguja

sobresalgan por detrás del tejido.

(8)Todos los hilos sobresalen por detrás.

Ate los hilos y córtelos.

(2) Termine la costura solapando unos 4 cm del principio

y del final de la costura.

NOTA:

Al coser prendas tubulares, la acción de solapar el

principio y el final de la costura unos 4 cm evitará que se

rasgue el tejido.

(3) Retire el tejido como se explica en “Retirada del tejido

de la máquina” en “V. Costura” en la página 33.

35

Page 20

Ejemplos reales de puntada de recubierto de tres hilos y dos agujas

VI. Mantenimiento

1) Dobladillo dé camisetas

(puntada simple)

3) Colocación de cintas

(bordes de cuellos, etc.) (juntas)

5) Colocación de gomas 6) Colocación de lazos

(dobladillo con costura de goma) (costura de junta plana)

2) Puntadas • .

(costuras sobrepuestas/cintas/canesús)

4) Costura decorativa

(costura decorativa)

7) Costura de cinturón de vuelta

(Costura de cinturón de vuelta)

Cambio de la bombilla de luz

PRECAUCION

Asegúrese siempre de desconectar la alimenta

ción antes de realizar la operación siguiente. La

placa de cristal encima de la bombilla se calen

tará inmediatamente después de utilizar la má

quina; por tanto, antes de cambiar la bombilla,

es aconsejable esperar hasta que se enfríe.

Cambio de la bombilla de luz.

• Extraiga la tapa de la lámpara como se muestra en la

ilustración.

• Afloje el tornillo de fijación de la tapa de la lámpara,

empuje la tapa de la bombilla de luz hacia arriba y

extráigala.

• Saque la bombilla de luz y reemplácela por otra

nueva.

©Tornillo

(2)Tapa de la,lámpara

©Tornillo

©Tapa de la bombilla de luz

©Bombilla de luz

©Tapa de la bombilla de luz

Ejemplos reales de puntada de recubierto de cuatro hilos y tres agujas

1) Puntada básica 2) Puntada de dobladillo

4) Dobladillo circular

5) Colocación de lazos elásticos

3) Colocación de cintas

Vil. Especificaciones de la máquina

Puntada

Puntada de cadena doble de un aguja y dos hilos

Puntada de recubierto de dos agujas y tres hilos

(Ancha 6 mm/Estrecha 3 mm)

Puntada de recubierto de tres agujas y cuatro hilos

(6 mm)

Velocidad de costura

1.000 puntadas por minuto

Largo de las puntadas (altura)

2 a 4 mm

Prénsatelas

Tipo prénsatelas libre

Movimiento del prénsatelas

5 mm a 6 mm

Aguja

SCHMETZ 130/705H (90/#14)

Peso neto de la máquina

7,0 kgs

36

37

Page 21

ENGLISH / ESPAÑOL

884-500

XB1148-001®

0308

Printed in Taiwan

Loading...

Loading...