Page 1

INSTALLATION GUIDE

VB0185

1. T h e o n e a n d o n l y m a i n w a l l

2. These units have a new balancing

3. The terminal connectors for

IMPORTANT NOTES

control compatible with these

units is the VT9W wall control.

procedure, see Section 7.

these units are not in the

installation kit; they are already

mounted to their control board.

ERV200 ECM HRV200 ECM

ERV250 ECM HRV250 ECM

These products earned the ENERGY STAR® by meeting strict energy efficiency guidelines set by Natural

Resources Canada and the US EPA. They meet ENERGY STAR requirements only when used in Canada.

! !

RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

Broan-NuTone LLC; Hartford, Wisconsin www.broan.com 800-543-3055

REGISTER YOUR PRODUCT ONLINE AT: www.broan.com/register

For additional information - visit www.broan.com

21992 rev. 01

Page 2

ABOUT THIS GUIDE

!

Because of the large amount of models covered in this publication, the illustrations are typical ones. Some details of your unit may be

slightly different than the ones shown.

Please take note that this guide uses the following symbols to emphasize particular information:

WARNING

Identifies an instruction which, if not followed, might cause serious personal injuries including possibility of death.

CAUTION

Denotes an instruction which, if not followed, may severely damage the unit and/or its components.

NOTE: Indicates supplementary information needed to fully complete an instruction.

ABOUT THESE UNITS

LIMITATION

For residential (domestic) installation only. Installation work and electrical wiring must be done by a qualified person(s) in accordance with

all applicable codes and standards, including fire-rated construction codes and standards.

WARNING

!

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSON(S) OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. We recommend that your unit be inspected by a specialized technician once a year.

3. Before servicing or cleaning the unit, disconnect power cord from electrical outlet.

4. This unit is not designed to provide combustion and/or dilution air for fuel-burning appliances.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Do not use the units with any solid-state speed control device other than the corresponding ones listed below:

UNIT MAIN CONTROL AUXILIARY CONTROL

ERV200 ECM, ERV250 ECM,

HRV200 ECM, HRV250 ECM

VTW9 EXCLUSIVELY VB60W

7. This unit must be grounded. The power supply cord has a 3-prong grounding plug for your personal safety. It must be plugged into a

mating 3-prong grounding receptacle, grounded in accordance with the national electrical code and local codes and ordinances. Do

not remove the ground prong. Do not use an extension cord.

8. Do not install in a cooking area or connect directly to any appliances.

9. Do not use to exhaust hazardous or explosive materials and vapors.

10. When performing installation, servicing or cleaning these units, it is recommended to wear safety glasses and gloves.

11. Due to the weight of the unit, two installers are recommended to perform installation.

12. When applicable local regulations comprise more restrictive installation and/or certification requirements, the aforementioned

requirements prevail on those of this document and the installer agrees to conform to these at his own expenses.

CAUTION

1. To avoid prematurate clogged filters, turn OFF the unit during construction or renovation.

2. Please read specification label on product for further information and requirements.

3. Be sure to duct air outdoors – Do not intake/exhaust air into spaces within walls or ceiling or into attics, crawl spaces, or garage.

4. Intended for residential installation only in accordance with the requirements of NFPA 90B (for a unit installed in USA).

5. Do not run any air ducts directly above or closer than 2 ft (0.61 m) to any furnace or its supply plenum, boiler, or other heat producing

appliance. If a duct has to be connected to the furnace return plenum, it must be connected not closer than 9’ 10” from this plenum

connection to the furnace.

6. The ductwork is intended to be installed in compliance with all applicable codes.

7. When leaving the house for a long period of time (more than two weeks), a responsible person should regularly check if the unit

operates adequately.

8. If the ductwork passes through an unconditioned space (e.g.: attic), the ducts must be insulated, and the unit must operate continuously

except when performing maintenance and/or repair. Also, the ambient temperature of the house should never drop below 65°F.

TECHNICAL SUPPORT

F

OR ASSISTANCE, CALL ON WEEKDAYS, 8:30 AM TO 5:00 PM (EASTERN STANDARD TIME): 1-800-543-3055.

NOTE: T

HIS PHONE NUMBER IS STRICTLY RESERVED FOR INSTALLERS USE ONLY. Do not call this number for ordering parts.

2

Page 3

TABLE OF CONTENTS

1. S ERVICE PARTS ...............................................................................................................................................................4-5

2. AIR DISTRIBUTION ...............................................................................................................................................................6

3. I

NSTALLATION .................................................................................................................................................................6-12

3.1 INSPECT THE CONTENT OF THE BOX ............................................................................................................................................... 6

3.2 LOCATING THE UNIT ..................................................................................................................................................................6-7

3.3 PLANNING OF THE DUCTWORK ....................................................................................................................................................... 8

3.4 DUCT SIZE ................................................................................................................................................................................ 8

3.5 INSTALLING THE DUCTWORK AND REGISTERS ............................................................................................................................... 8-10

3.6 CONNECTING THE DUCTS TO THE UNIT ..........................................................................................................................................11

3.7 INSTALLING TWO EXTERIOR HOODS .............................................................................................................................................. 12

3.8 CONNECTING THE DRAIN ............................................................................................................................................................ 12

4. CONTROLS ..................................................................................................................................................................13-16

4.1 UNITS BOOTING SEQUENCE ........................................................................................................................................................ 13

4.2 WALL CONTROL(S) ELECTRICAL CONNECTION ........................................................................................................................... 13-15

4.3 SETTING UNIT OPERATION IN THE REMAINING 40 MINUTES ON 20 MIN/H MODE AND SETTING UNIT DEFROST CYCLE TYPE

USING VT9W MAIN WALL CONTROL ............................................................................................................................................ 16

5. ELECTRICAL CONNECTION TO THE FURNACE ..........................................................................................................................17

6. WIRING DIAGRAM .............................................................................................................................................................. 18

7. B ALANCING THE UNIT ....................................................................................................................................................19-24

7.1 WHAT Y OU NEED TO BALANCE THE UNIT ...................................................................................................................................... 19

7.2 PRELIMINARY STAGES TO BALANCE THE UNIT.................................................................................................................................. 19

7.3 USING MAGNEHELIC GAUGES ....................................................................................................................................................... 19

7.4 BALANCING CHART AND PRESET SPEEDS TABLE ........................................................................................................................ 19-20

7.5 BALANCING PROCEDURE ........................................................................................................................................................ 21-24

8. TROUBLESHOOTING .......................................................................................................................................................25-27

3

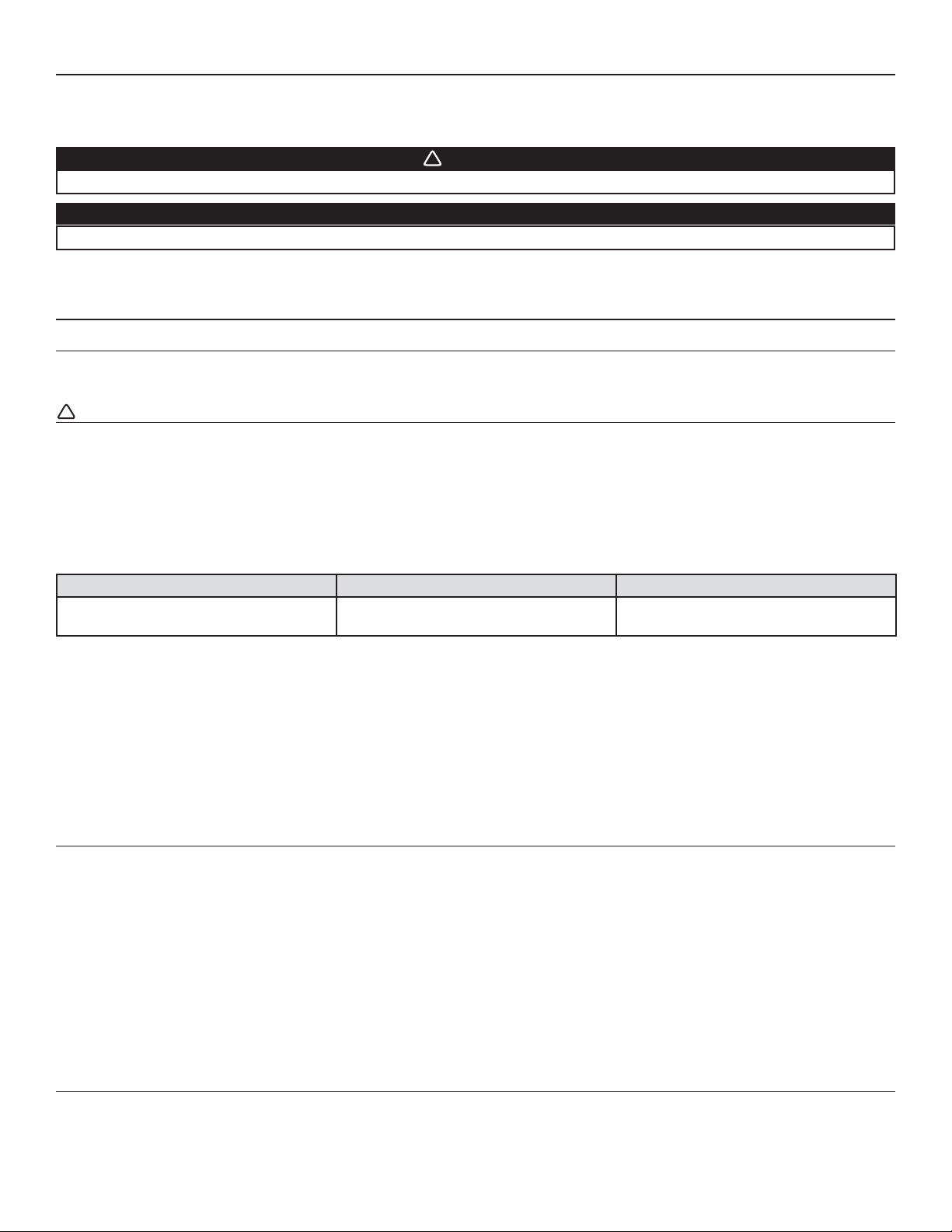

Page 4

O

D

N

B

M

L

K

J

D

F

I

C

1. SERVICE PARTS

E

H

G

VL0071

4

Page 5

1 SV63420 SV63420 SV63420 SV63420

2 SV63421 SV63421 SV63421 SV63421

1 SV63569 SV63569 SV63569 SV63569

1 SV63437 SV63437 SV63437 SV63437

1 SV63434 SV63434 SV63434 SV63434

1 SV63435 SV63435 SV63435 SV63435

1 SV63436 SV63441 SV63442 SV63443

ORE FILTER (PAIR) 1 SV63426 SV63426

1BRACKET KIT 1 SV63419 SV63419 SV63419 SV63419

NO.DESCRIPTION QTY. ERV200 ECM HRV200 ECM ERV250 ECM HRV250 ECM

ORE FILTER (PAIR) 1 SV63433

AMPER SYSTEM ASSEMBLY

LOWER ASSEMBLY

(INCLUDING 2 PLASTIC SCREWS)

D

2

(INCLUDING 3 PLASTIC SCREWS)

B

3

HRV C

4

ERV C

EAT RECOVERY CORE 1 SV63422 SV63423

NERGY RECOVERY CORE 1 SV63425

E

H

5

OOR ASSEMBLY

D

6

IGHT PANEL 1 SV63565 SV63566 SV63567 SV63568

(INCLUDING NO. 16)

7R

ORE FILTER (PAIR) 1 SV63427

NERGY RECOVERY CORE 1 SV63424

8 ERV C

9E

1. SERVICE PARTS (CONT’D)

AUGHTER BOARD

D

5

10

(INCLUDING INO. 11)

ONNECTOR

(MAIN CONTROL)

PCB C

11

ONNECTOR

(AUXILIARY CONTROL)

PCB C

12

INCLUDING NOS. 10 &12)

PCB

(

13

ARM SIDE THERMISTOR KIT* 1 SV62481 SV62481 SV62481 SV62481

RANSFORMER 1 SV63438 SV63438 SV63438 SV63438

14 T

15 W

OOR MAGNETIC SWITCH* 1 SV19060 SV19060 SV19060 SV19060

16 D

ARDWARE KIT* 1 SV22488 SV22488 SV22488 SV22488

LASTIC SCREW (SET OF 6)* 1 SV63439 SV63439 SV63439 SV63439

17 P

18 H

* Not shown.

REPLACEMENT PARTS AND REPAIR

In order to ensure your ventilation unit remains in good working condition, you must use the Broan-Nutone LLC genuine replacement parts only. The Broan-NuTone LLC genuine

replacement parts are specially designed for each unit and are manufactured to comply with all the applicable certification standards and maintain a high standard of safety. Any

third party replacement part used may cause serious damage and drastically reduce the performance level of your unit, which will result in premature failing. Broan-NuTone LLC

recommends to contact a BRoan-NuTOne LLC certified service depot for all replacement parts and repairs.

Page 6

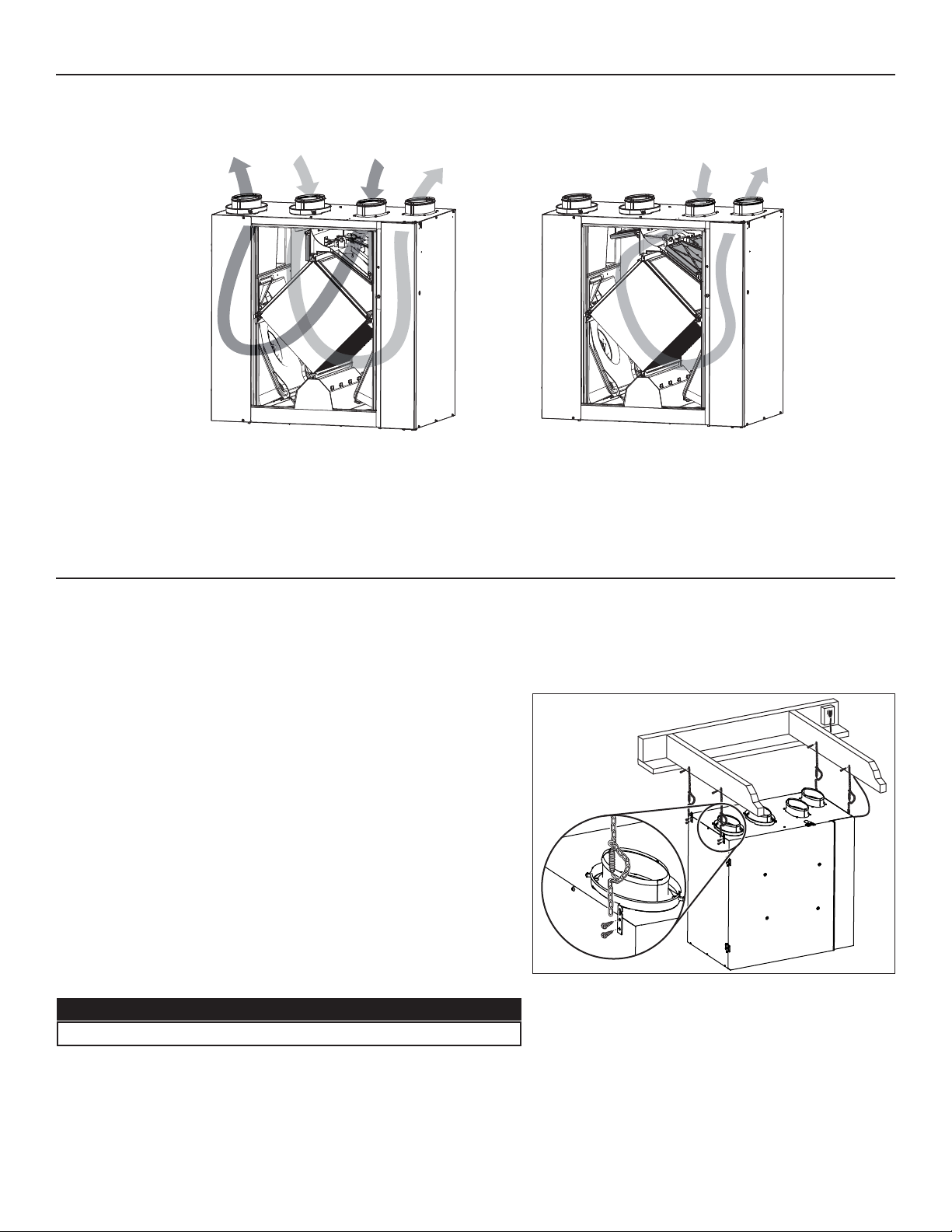

2. AIR DISTRIBUTION

STALE AIR

TO OUTDOORS

VF0063

NORMAL OPERATION DEFROST OR RECIRCULATION

FRESH AIR

FROM OUTDOORS

STALE AIR

FROM

BUILDING

FRESH AIR

BUILDING

TO

STALE AIR

FROM

BUILDING

FILTERED AIR

BUILDING

TO

3. INSTALLATION

3.1 INSPECT THE CONTENT OF THE BOX

Inspect the exterior of the unit for shipping damage. Ensure that there is no damage to the door, ports, power cord, etc.

3.2 LOCATING THE UNIT

Choose an appropriate location for the unit.

• Within an area of the house where the ambient temperature is kept

between 50°F and 104°F.

• Away from living areas (dining room, living room, bedroom), if possible.

• So as to provide easy access to the interior of the unit, for regular and

annual maintenance.

NOTE: There must be a 27” clearance in front of the unit to fully open

the door. In limited space, the door can be removed by lifting it

up, but there must be a 18” clearance in front of the unit to

remove the core.

• Close to an exterior wall, so as to limit the length of the insulated flexible

duct to and from the unit.

• Away from hot chimneys and other fire hazards.

• Allow for a power source (standard 3-prong grounding outlet).

• Close to a drain. If no drain is close by, use a pail to collect run-off.

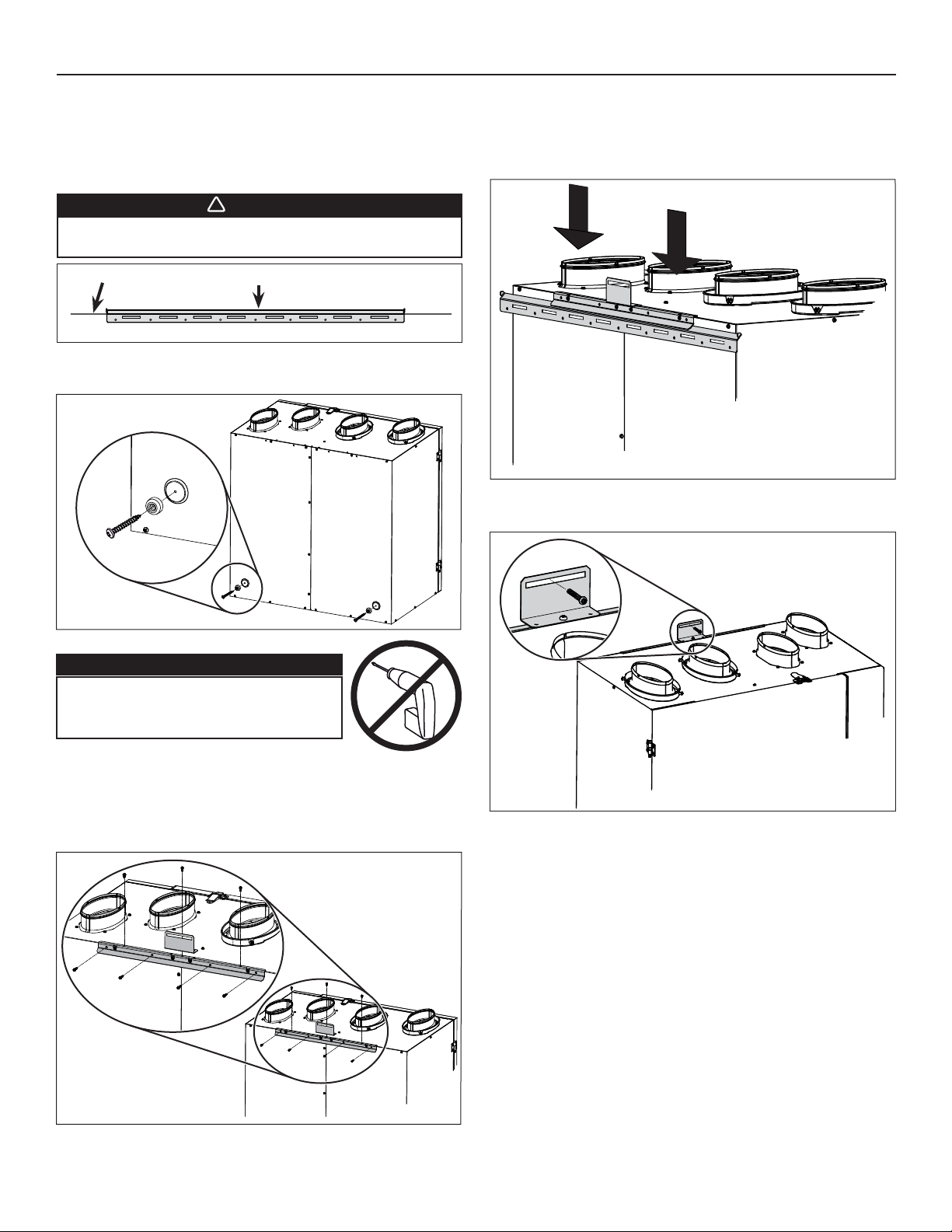

The unit can be hung using provided 4 chains and springs (see at right) or

hung to the wall using provided brackets (see next page).

CAUTION

In every case, make sure the unit is level.

VD0378

UNIT HUNG BY CHAINS AND SPRINGS

6

Page 7

3. INSTALLATION (CONT’D)

!

OCATING THE UNIT (CONT’D)

3.2 L

UNIT HUNG TO WALL BRACKET

Trace a level line on the wall; align the wall bracket (the longer

one) to the line and secure this bracket to the wall using 4 provided

screws (1½” long) and washers, if using the slots on bracket).

WARNING

Ensure the wall bracket is attached to all of the

available studs, not into the drywall alone.

LEVEL LINE WALL BRACKET

VD0379

Using 1½” long provided screws, assemble both spacers to left and

right back bottom corner of the unit.

Lift the unit and hang it to the wall bracket. Ensure the bracket

assembled on back of the unit rests on the wall bracket.

VO0271

Secure the unit to the wall using one 1½” long provided screw

through the small bracket.

VD0380

CAUTION

Never use an electric screwdriver or

drill to screw the brackets to the unit;

use a standard screwdriver.

VR0086

Using 3/8” long provided screws, mount the other bracket (A) to the

back of the unit; start with the 4 back screws, then 2 screws on top

left and right sides, then use the last center one to assemble the

last small bracket (B).

NOTE: These screws must be hand tightened.

B

A

VO0272

VD0392

7

Page 8

3. INSTALLATION (CONT’D)

!

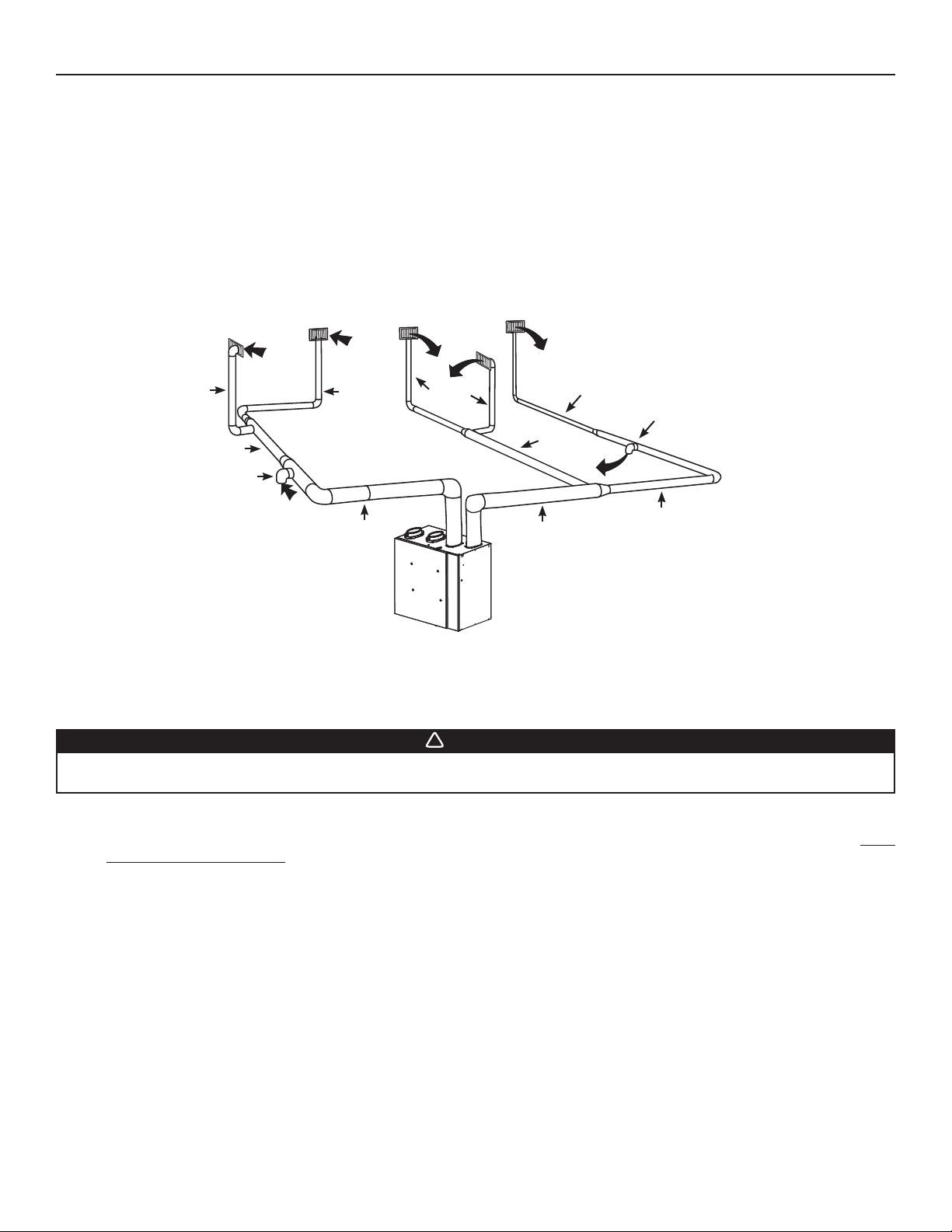

3.3 PLANNING OF THE DUCTWORK

• Keep it simple. Plan for a minimum of bends and joints.

• Keep the length of insulated and non-insulated ducts to a minimum, because the length of the ductwork impacts directly the unit

airflow performances.

• Do not ventilate crawl spaces or cold rooms. Do not attempt to recover the exhaust air from a dryer or a range hood. This would cause

clogging of the filters and recovery module.

• If the house has two floors or more, be sure to plan for at least one exhaust register on the highest lived-in level.

3.4 DUCT SIZE

To determine the appropriate duct size to be used, refer to the ASHRAE or HRAI HANDBOOK. Below is an example of a design

for a fully ducted system with a unit having a high speed performance of 160 cfm.

4" Ø, 47 CFM

5" Ø, 93 CFM

5" Ø, 67 CFM

4"

VI0019

4" 4"

4" Ø,

46 CFM

5"

6"

6" Ø, 160

4"

CFM

4"

4" Ø,

37 CFM

5"

4"

4" Ø, 24 CFM

5" Ø,

74 CFM

6"

6" Ø, 160 CFM

4"

5" Ø, 62 CFM

5"

5"

5" Ø, 86 CFM

3.5 INSTALLING THE DUCTWORK AND REGISTERS

3.5.1 FULLY DUCTED SYSTEM

WARNING

Never install a stale air exhaust register in a closed room where a combustion device operates, such as a gas

furnace, a gas water heater or a fireplace.

Stale air exhaust ductwork

• Install the stale air exhaust registers where the contaminants are produced: kitchen, living room, etc. Position the registers as far

from the stairway as possible and in such a way that the air circulates in all the lived-in spaces in the house.

• If a register is installed in the kitchen, it must be located at least 4 feet from the range.

• Install the registers 6 to 12 inches from the ceiling on an interior wall OR install them in the ceiling.

• If possible, measure the velocity of the air flowing through the registers. If the velocity is higher than 400 ft/min, then the register

type is too small. Replace with a larger one.

Fresh air distribution ductwork

• Install the fresh air distribution registers in bedrooms, dining rooms, living room and basement.

• Keep in mind that the fresh air registers must be located as far as possible from the stale air registers.

• Install the registers either in the ceiling or high on the walls with air flow directed towards the ceiling. (The cooler air will then cross

the upper part of the room and mix with room air, before descending to occupant’s level.)

• If a register must be floor installed, direct the airflow up the wall.

8

Page 9

3. INSTALLATION (CONT’D)

!

3.5 INSTALLING THE DUCTWORK AND REGISTERS (CONT’D)

3.5.2 CENTRAL DRAW POINT SYSTEM

Stale air exhaust ductwork

Same as for Fully Ducted System, described on point 3.5.1

WARNING

When performing duct connections, always use approved tools and materials. Respect all corresponding laws and

safety regulations. Please refer to your local building code.

CAUTION

When performing duct connections to the furnace supply duct, this duct must be sized to support the additional

airflow produced by the unit. Also, the use of metal duct is highly recommended.

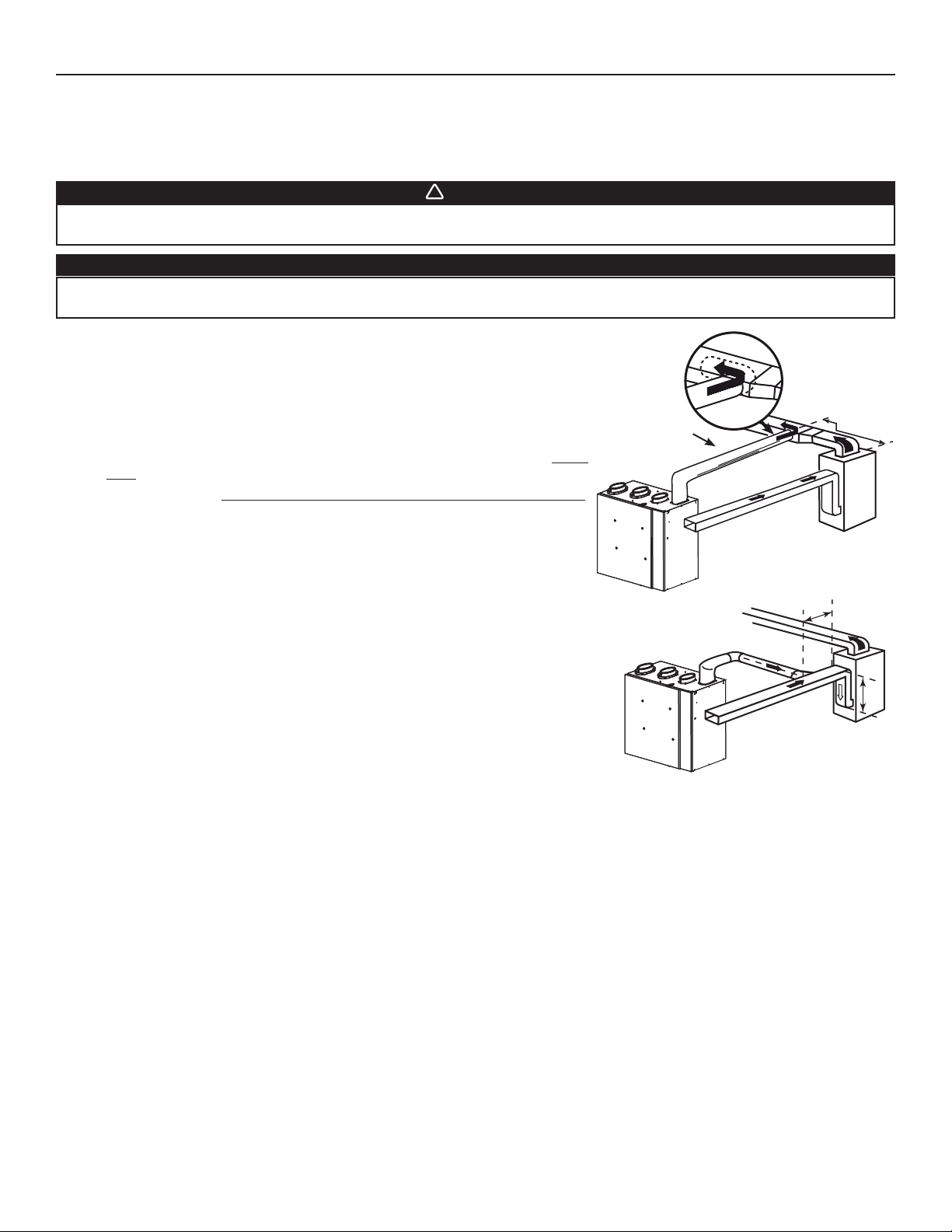

Fresh air distribution ductwork

• There are 2 methods for connecting the unit to the furnace/air handler:

Method 1: Supply side connection

• Cut an opening into the furnace supply duct at least 18 inches from the furnace/

air handler.

• Connect this opening to the Fresh air distribution port of the unit (use metal

duct, see figure at right).

• Make sure the unit duct forms an elbow inside the furnace/air handler ductwork.

• If desired, interlock (synchronize) the furnace/air handler blower operation (see

Section 5 ELECTRICAL CONNECTION TO THE FURNACE).

METAL DUCT

MINIMUM 18"

Method 2: Return side connection

• Cut an opening into the furnace return duct not less than 10 feet from the furnace/

air handler (A+B).

• Connect this opening to the Fresh air distribution port of the unit (see figure at

right).

NOTE: For Method 2, it is not essential that the furnace/air handler runs when the

unit is operation, but we recommend it. If desired, interlock (synchronize)

the furnace/air handler blower operation (see Section 5 ELECTRICAL

CONNECTION TO THE FURNACE).

VJ0128

A

B

A+B = NOT LESS

THAN 10’

VJ0129

9

Page 10

3. INSTALLATION (CONT’D)

!

3.5 INSTALLING THE DUCTWORK AND REGISTERS (CONT’D)

3.5.3 SIMPLIFIED INSTALLATION

WARNING

When performing duct connections, always use approved tools and materials. Respect all corresponding laws and

safety regulations. Please refer to your local building code.

CAUTION

When performing duct connections to the furnace supply duct (Method 1), this duct must be sized to support the

additional airflow produced by the unit. Also, the use of metal duct is highly recommended. For a Return-return

installation, the furnace blower must be in operation when the unit is in operation.

There are 2 methods for connecting the unit to the furnace/air handler:

Method 1: Supply-return connection Method 2: Return-return

A

MINIMUM 18"

METAL DUCT

B

MINIMUM 3'

B

VJ0131

A+B = NOT LESS

THAN 10’

A

A+B = NOT LESS

VJ0130

THAN 10’

Stale air intake

• Cut an opening into the furnace/air handler return duct not less than 10 feet from the furnace/air handler (A+B).

• Connect this opening to the Exhaust air from building port of the unit.

Fresh air distribution

• Same instructions as for Method 1 or Method 2, Section 3.5.2.

For Method 2 (Return-return), make sure there is a distance of at least 3 feet between the 2 connections to the furnace/air handler.

CAUTION

If using Method 2, make sure the furnace/air handler blower operation is synchronized with the unit operation!

See Section 5.

NOTE: For Method 1, it is not essential to synchronize the furnace blower operation with the unit operation, but we recommend it.

10

Page 11

3. INSTALLATION (CONT’D)

3.6 CONNECTING THE DUCTS TO THE UNIT

NOTE: All unit ports are were created to be connected to ducts having a minimum of 6” diameter, but if need be, they can be connected

to bigger sized ducts by using an appropriate transition (e.g.: 6” diameter to 7” diameter transition).

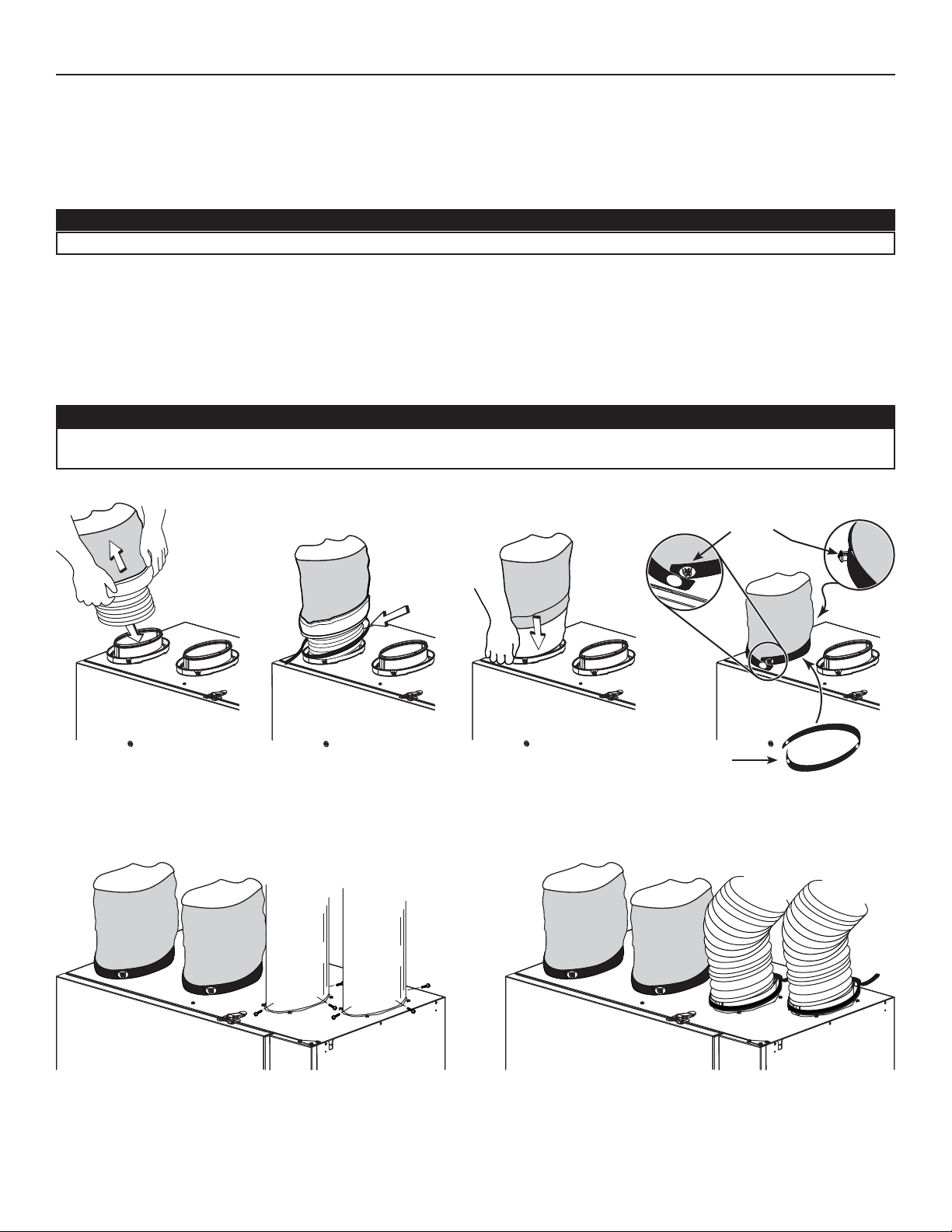

Insulated flexible ducts

Use the following procedure to connect the insulated flexible ducts to the ports of the unit (Exhaust air to outdoors and Fresh air

from outdoors ports).

CAUTION

If ducts have to go through an unconditioned space (e.g.: attic), always use insulated ducts.

Pull back the insulation to expose the flexible duct.

Attach the flexible duct to the port using tie wrap.

Pull the insulation over the joint and tuck in between the inner and outer rings of the double collar.

Pull down the vapor barrier (shaded part in illustrations below) over the outer ring to cover it completely. Fasten in place the vapor

barrier using the port strap (included in unit parts bag). To do so, insert one collar pin through vapor barrier and first strap hole,

then insert the other collar pin through vapor barrier and center strap hole and close the loop by inserting the first collar pin in the

last strap hole.

CAUTION

Make sure the vapor barrier on the insulated ducts does not tear during installation to avoid condensation within

the ducts.

12 3 4

VJ0132

Non-insulated rigid ducts

Use metal screws and duct tape to connect the rigid ducts to the

unit ports.

COLLAR PINS

STRAP

Non-insulated flexible ducts

Use tie wraps to connect the flexible ducts to the unit ports.

VJ0133

11

Page 12

3. INSTALLATION (CONT’D)

!

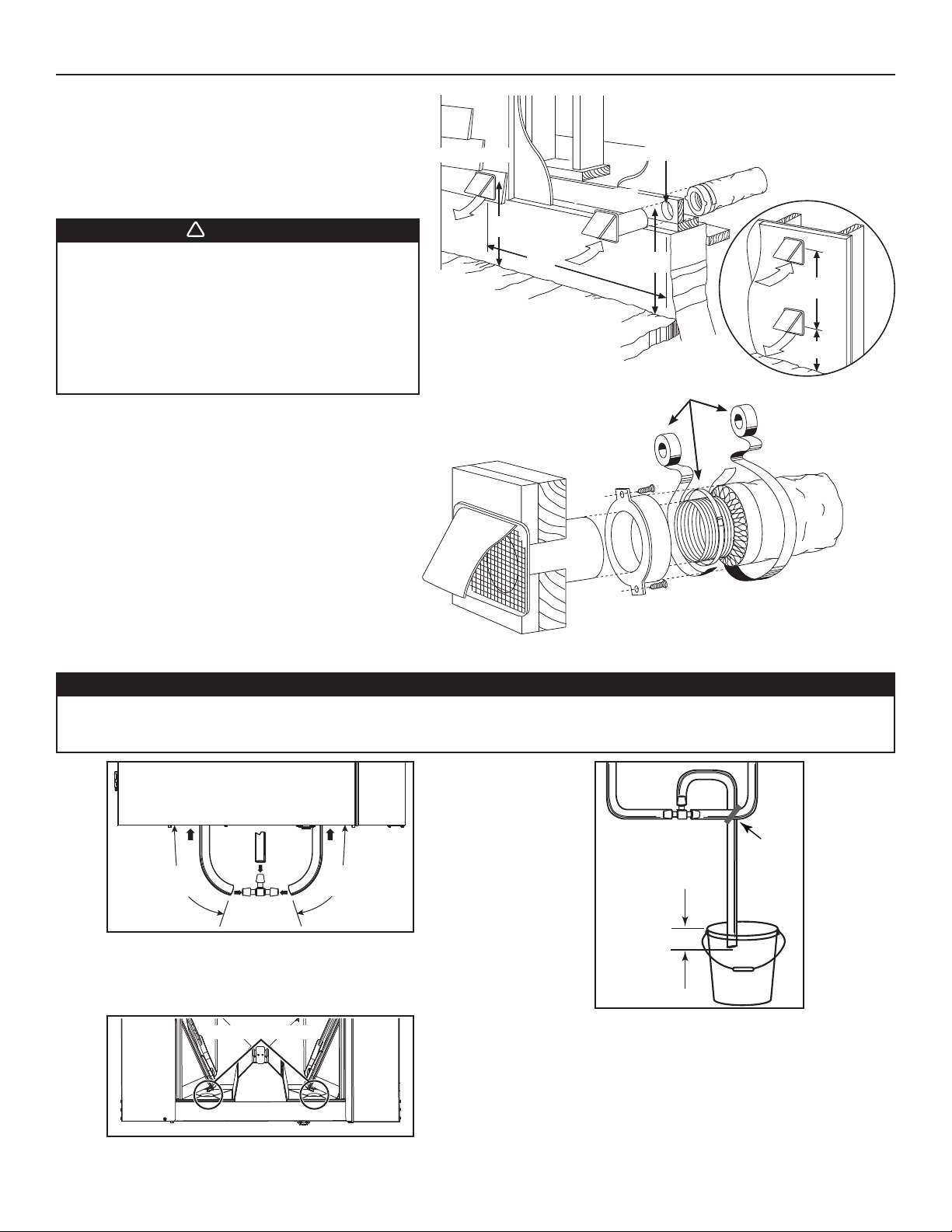

3.7 INSTALLING TWO EXTERIOR HOODS

Choose an appropriate location to install the exterior hoods:

• There must be a minimum distance of 6 feet between

the hoods to avoid cross-contamination.

• There must be a minimum distance of 18 inches from

the ground.

EXHAUST HOOD

INTAKE HOOD

6" Ø

PTIONAL DUCT

O

LOCATION

WARNING

Make sure the intake hood is at least 6 feet away

from any of the following:

• Dryer exhaust, high efficiency furnace vent,

central vacuum vent

• Gas meter exhaust, gas barbecue-grill

• Any exhaust from a combustion source

• Garbage bin and any other source of

contamination.

Refer to figure at right for connecting insulated ducts to the

exterior hoods. An “Anti-gust intake hood’’ should be installed

in regions where a lot of snow is expected to fall.

3.8 CONNECTING THE DRAIN

VD0028

18"

6'

18"

6'

18"

TAPE AND DUCT TIE

CAUTION

A drain tubing (included) must be installed for all HRV units. For ERV units, it is not required, however, it is

recommended for climates where the outdoor temperature typically remains below -13°F, (over a 24-hour period)

for several days in a row, combined with an indoor humidity of 40% or higher.

TIE WRAP

16"

(406 mm)

VO0273A

16"

(406 mm)

± 1”

Cut 2 sections of the plastic tube, at least 16” long, and attach them

to each inner drain fitting, located under the unit.

Join both short sections to the “T” junction and main tube as shown.

DRAIN PLUG LOCATIONS

VD0387

NOTE: For ERV units installed in cold climate, remove both drain

plugs inside the unit prior to install tubing.

Make a water trap loop in the tube to prevent the unit from

drawing unpleasant odors from the drain source. Make sure this

loop is located OVER the “T” as shown. Run the tube to the floor

drain or to an alternative drain pipe or pail.

IMPORTANT

If using a pail to collect water, locate the tube end approximately

1” from the top of the pail in order to prevent water from being

drawn back up into the unit.

12

VD0337A

Page 13

4. CONTROLS

!

4.1 UNIT BOOTING SEQUENCE

The unit booting sequence is similar to a personnal computer boot sequence. Each time the unit is plugged after being unplugged, or after

a power failure, the unit will perform a 30-second booting sequence before starting to operate.

During the booting sequence, the unit is checking and resetting the motorized damper position.

Once the motorized damper position completely set, the booting sequence is done.

NOTE: No command will be taken until the unit is fully booted.

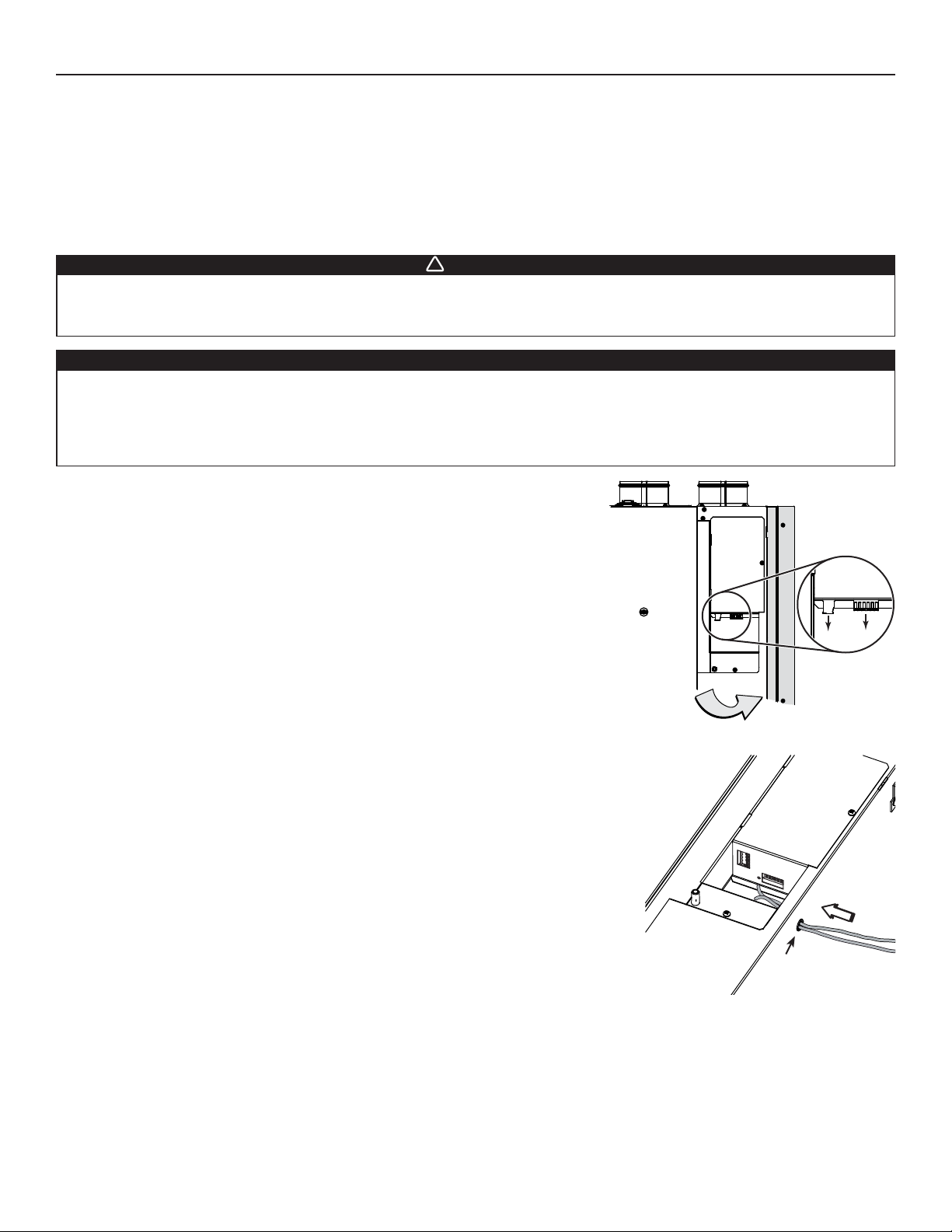

4.2 WALL CONTROL(S) ELECTRICAL CONNECTION

WARNING

The VT9W wall control is the only main wall control compatible to your unit. Never attempt to install another wall

control model. Always disconnect the unit before making any connections. Failure to disconnect power could

result in electric shock or damage to the wall control or electronic module inside the unit.

CAUTION

Failure to comply with the following can cause erratic operation of the unit and/or the wall control:

Never install more than one VT9W main wall control per unit. Make sure that the wires do not short-circuit between

themselves or by touching any other components on the wall control. Avoid poor wiring connections. To reduce

electrical interference (noise) potential, do not run wall control wiring next to control contactors or near light

dimming circuits, electrical motors, dwelling/building power or lighting wiring, or power distribution panel.

Unplug the unit from power source. Open the side panel to access terminal blocks

(A is the one for main control connection only and B is the one for auxiliary controls). Pull

out from the unit board the needed connector(s).

VE0351

Run the end of the control wire(s) through the grommet located on the unit wall. Refer to

illustration at right (side panel removed to ease understanding).

GROMMET

B

A

13

Page 14

4. CONTROLS (CONT’D)

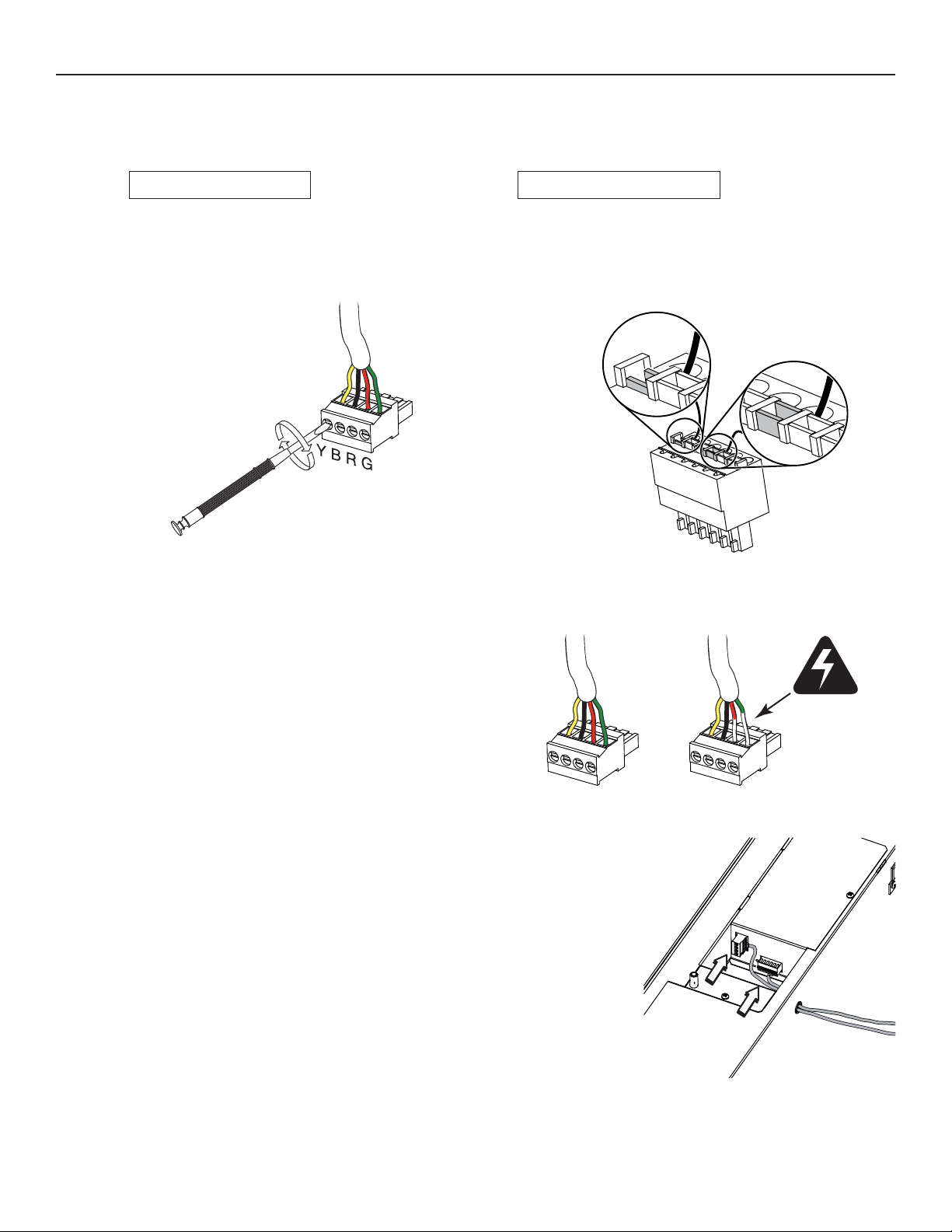

4.2 WALL CONTROL(S) ELECTRICAL CONNECTION (CONT’D)

4.2.1 TERMINAL BLOCK(S) CONNECTION

MAIN CONTROL TERMINAL BLOCK

Strip the end of the main control cable to access the 4 wires.

Strip the end of each wire. Using a small flat blade screwdriver,

connect each wire to its corresponding terminal, by referring

on the sticker affixed on the unit: YELLOW wire to “Y”, BLACK

wire to “B”, RED wire to “R” and GREEN wire to “G”.

VE0352

AUXILIARY CONTROL TERMINAL BLOCK

Strip the end of the auxiliary control cable to access the wires.

Strip the end of 3 wires. Check if all wires are correctly inserted in

their corresponding holes in the terminal block. (A wire is correctly

inserted when its orange receptacle is lower than another one

without wire. On illustration below, wire A is correctly inserted,

but wire B is not.)

A

B

VE0353

RIGHT WRONG

When stripping the wires, ensure to remove only the necessary

lenght of sheat in order to prevent short circuits.

VE0354

Once the terminal block(s) connections have been made, reinstall it (them)

on the unit PC board. Refer to illustration at right (side panel removed to ease

understanding). Close the side panel.

NOTE: For information about the operation of the wall controls, refer to their

installation sheet.

VE0355

14

Page 15

4. CONTROLS (CONT’D)

4.2 WALL CONTROL(S) ELECTRICAL CONNECTION (CONT’D)

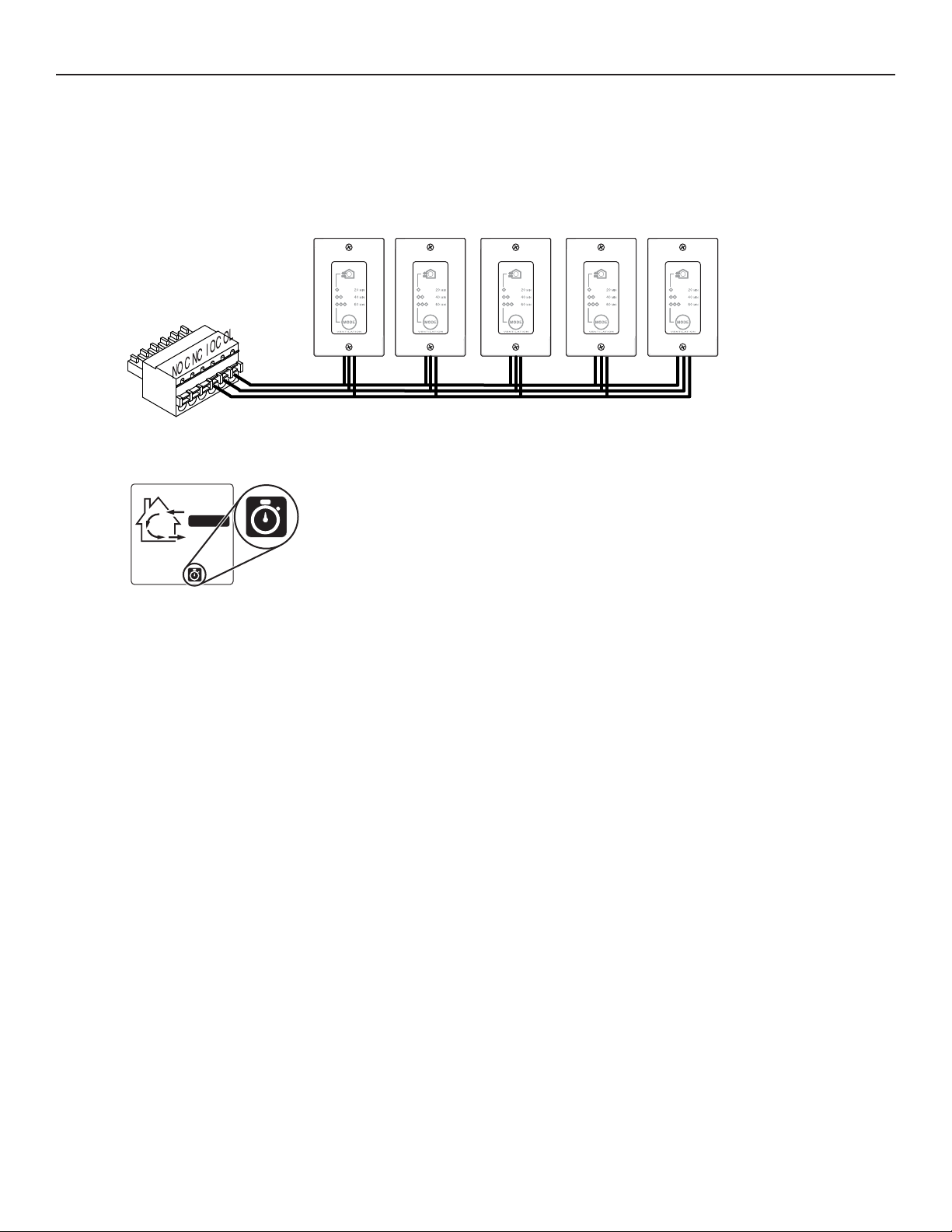

4.2.2 E

LECTRICAL CONNECTION TO VB60W OPTIONAL AUXILIARY CONTROL(S)

Up to five (5) VB60W auxiliary controls can be installed.

VE0349

When used, the VB60W activation will override the main control operation, as well as the unit

CONT

defrost cycle. On example shown on the left, the unit was in CONT mode when the auxiliary

control was activated; so the actual operation mode stays on VT9W main wall control screen,

but the chronometer icon appears as long as the VB60W is activated.

NOTE: In colder regions, the chronometer icon may stay after the end of the VB60W cycle,

due to defrost cycle.

15

Page 16

4. CONTROLS (CONT’D)

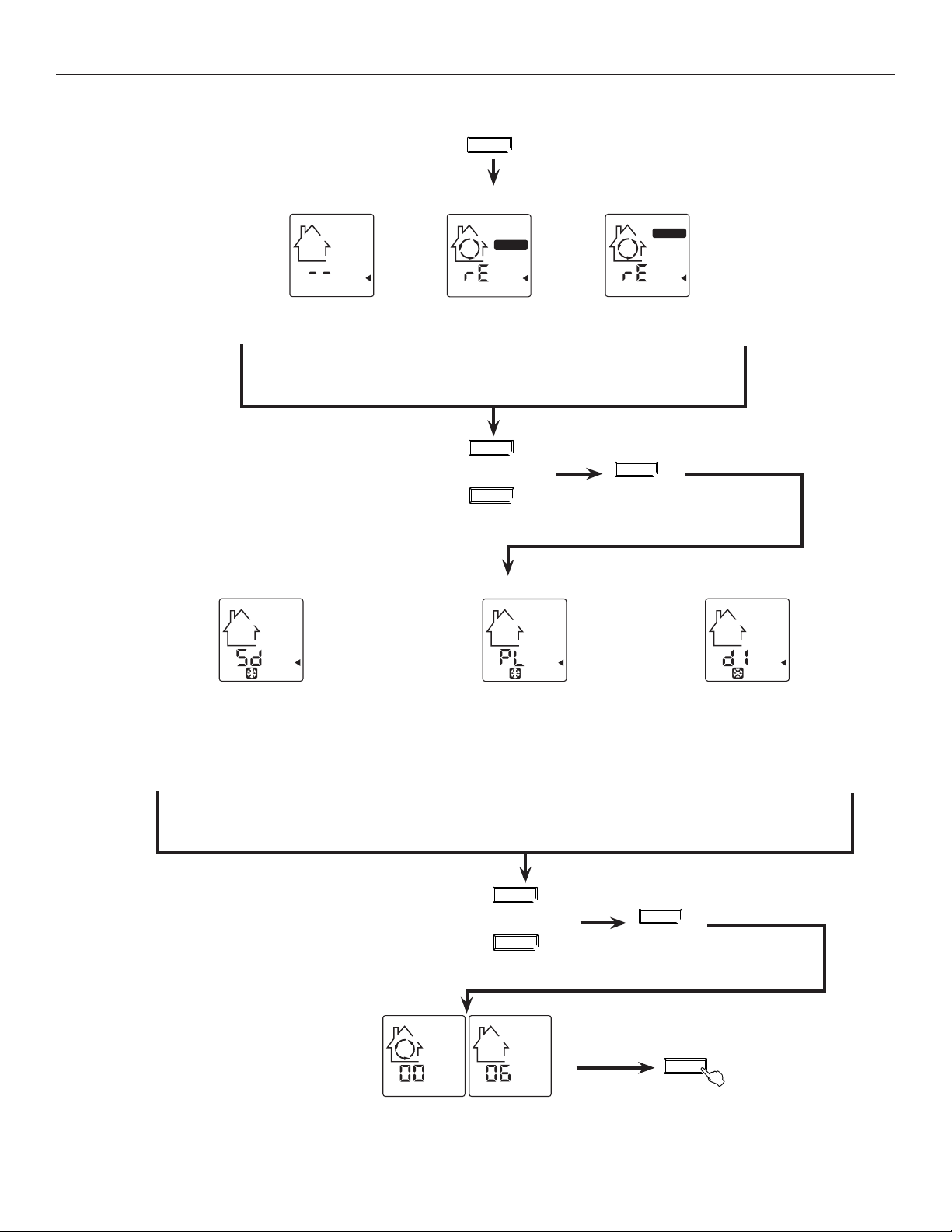

4.3 SETTING UNIT OPERATION IN THE REMAINING 40 MINUTES ON 20 MIN/H MODE AND SETTING UNIT DEFROST CYCLE TYPE

USING VT9W MAIN WALL CONTROL

Press and hold the

MODE key for 3 seconds.

The LCD screen will show one of these configurations:

MODE

3 sec.

OR

Two lines are flashing

to show Standby

(default configuration

setting).

Use MODE or TURBO key to

see all 3 configurations.

The LCD screen will show one of these defrost cycle types:

Recirculation arrows

flashes and CONT

label appears to show

RECIRCULATION on

OR

CONT

are turning, rE

low speed.

MODE

!

OR

TURBO

TURBO

OR

Recirculation arrows

are turning, rE

flashes and TURBO

label appears to show

RECIRCULATION on

high speed.

% HUM

Press % HUM key to accept chosen

configuration and go to setting defrost

cycle type.

OR

Sd (Standard)

(factory defrost cycle setting).

When needed, the unit will

perform defrost cycle on high

speed.

NOTE: This is the defrost type

used for the data published by

HVI and ENERGY STAR®.

Use MODE or TURBO key

to see all 3 defrost cycle type.

LCD screen alternates between the

house with circled arrows and the house

without arrow. The numbers under the

house are the software version number.

PL (Plus)

Use this cycle in cold region

(outdoor temperature -17°F and

lower). When needed, the unit

will perform defrost cycle on

high speed on a longer period

of time.

MODE

!

OR

TURBO

16

Press % HUM key to accept

chosen defrost cycle type and

go to software version display

dI (Discretion)

When needed, the defrost cycle

will be performed on the same

speed than the unit ventilation

speed. (e.g.: if the unit is set on

TURBO, the defrost cycle will

be done on high speed, and

if the unit is set on CONT, the

defrost cycle will be done on

low speed.

% HUM

% HUM

Press % HUM key OR

wait 10 seconds to exit

user setting menu.

Page 17

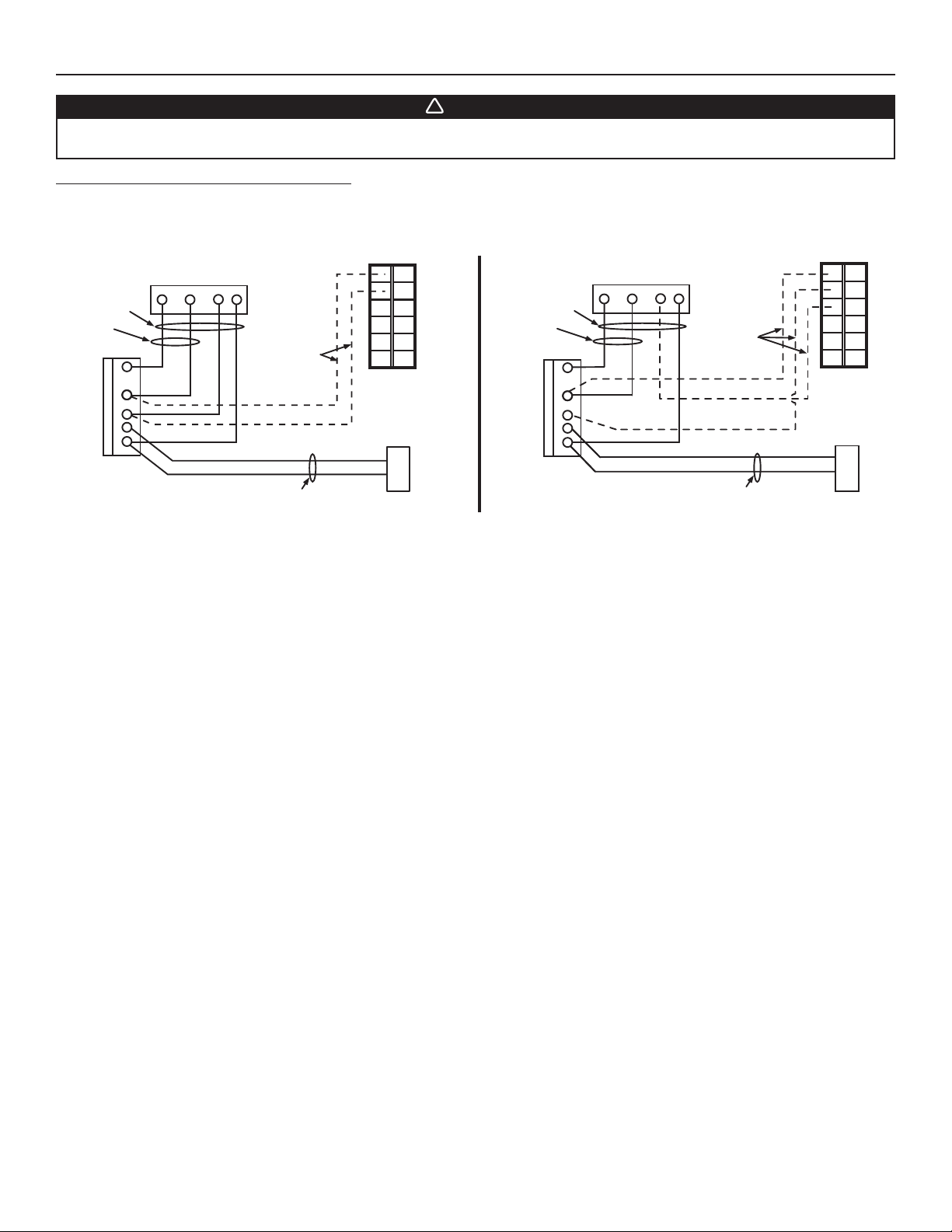

5. ELECTRICAL CONNECTION TO THE FURNACE

!

WARNING

Never connect a 120-volt AC circuit to the terminals of the furnace interlock (standard wiring). Only use the low

voltage class 2 circuit of the furnace blower control.

For a furnace connected to a cooling system:

On some older thermostats, energizing the “R” and “G” terminals at the furnace has the effect of energizing “Y” at the thermostat and

thereby turning on the cooling system. If you identify this type of thermostat, you must use the

STANDARD FURNACE INTERLOCK WIRING ALTERNATE FURNACE INTERLOCK WIRING

UNIT TERMINAL CONNECTOR

NO C NC I OC OL

ALTERNATE FURNACE INTERLOCK WIRING.

NO C NC I OC OL

UNIT TERMINAL CONNECTOR

4 WIRES

2 WIRES

heating only

FURNACE

24-VOLT

TERMINAL BLOCK

VE0350A

WRGY

W

R

G

C

Y

Y

THERMOSTAT

TERMINALS

LOW VOLTAGE

CLASS 2

2 WIRES

COOLING SYSTEM

4 WIRES

2 WIRES

heating only

W

R

G

C

Y

FURNACE

24-VOLT

TERMINAL BLOCK

WRGY

R

Y

THERMOSTAT

TERMINAL

LOW VOLTAGE

CLASS 2

NO

NC

C

2 WIRES

COOLING SYSTEM

17

Page 18

6. WIRING DIAGRAM

r

!

WARNING

• Risk of electric shocks. Before performing any maintenance or servicing, always disconnect the unit from its power source.

• This product is equipped with an overload protection (fuse). A blown fuse indicates an overload or a short-circuit situation.

If the fuse blows, unplug the product and check the polarity and voltage output from the outlet. Replace the fuse as per the

servicing instructions (refer to wiring diagram for proper fuse rating) and verify the product. If the replaced fuse blows, it may

be a short-circuit and the product must be discarded or returned to an authorized service center for examination and/or repair.

From

supply motor

From

Neutral

120V, 60Hz

LOGIC DIAGRAM

Line

120 V, 60Hz

J10-1J10-2

321

HI MED

J5-2

Exhaust

fan motor

J5-1

A1

K1

JU1

K2

F1

J9-2

J9-1

B

J5-3

J9-3

to A1-J17

J7-2

J9-4

J7-1

Supply

fan motor

K3

J4-1

J4-2

J4-3

to A1-J15

J6-2

J6-1

A2

J2-5

J12-5

J2-4

J12-4

Damper motor

J2-3

J12-3

K4

J3-2

J2-2

J12-2

J8-1

120 V

J3-1

J2-1

J12-1

J8-2

24 V

J8-4

class 2

Door interlock switch

J11-2

J8-5

9.5 V

class 2

J11-1

neutral

Furnace

blower

interlock

J14-3

J14-1

K5

K2K4K5

(optional; see

J14-2

K1

notes 3 & 5)

J15

12345

K3

nc

J17

12345

exhaust moto

nc

CPU

J16

J2

A3

Override

switch

(optional; see

J14-4

J14-5

notes 3 & 4)

J14-6

J3-4

J3-3

J3-2

J3-1

Field wiring

remote control

(see notes 3 & 4)

WIRING DIAGRAM

B

Damper motor

DAMPER

A2

1234512

J3

12

B

M3

ELECTRONIC ASSEMBLY

J1

J2

S1

reed switch)

Door interlock switch

(magnetically actuated

Defrost

temperature sensor

Class 2

to A1-J12

W W

T1

120 V

B

R1

t˚

low voltage

24 V

class 2

factory wiring

9.5 V

From

exhaust motor

From

supply motor

class 2

W

neutral

control cable

control cable

BR

BR

Y

Y

Override

R2

Thermistor

t˚

J17

nc

W

R

BL

Y

12345

nc

W

R

BL

Y

12345

J15

12

J11

12345

J8

123

J5

BL

BR

G

Power cable

switch

notes 3 & 4)

(optional; see

65432

J20

12345

to

A2-J2

123

MED HI

JU1

M1

Exhaust fan motor

18

J14-1: NO

Furnace blower interlock

J14

1

2

1

J13

J12

A1

12

1234

J9

See note 1

123

Control cable

W

R

BL

Y

to A1-J17

Power cable

J14-2: COM

J14-3: nc

(optional; see notes 3 & 5)

BDM

J2

J16

ASSEMBLY

ELECTRONIC

W

B

J10

F1

J4

BL

BR

M2

Supply fan motor

G

Field wiring

remote control

(see notes 3 & 4)

Y

R

B

G

J3

432

1

A3

W1

120 V, 60 Hz

Control cable

W

R

BL

Y

to A1-J15

Line voltage factory wiring

Class 2 low voltage factory wiring

Class 2 low voltage field wiring

G

Critical characteristic.

WHITE

COLOR CODE

BBLACK

BL BLUE

BR BROWN

GGREEN

RRED

Y YELLOW

W

nc no connection

NOTES

codes, ordinances and regulations.

be replaced, use the same equivalent wire.

(3A, 3AG Type).

1. Use specified UL listed/CSA Certified line fuse

2. If any of the original wire, as supplied, must

3. Field wiring must comply with applicable

4. Remote controls (class 2 circuit) available,

see instruction manual.

5. Furnace fan circuit must be class 2 circuit only.

VE0346A

Page 19

7. BALANCING THE UNIT

7.1 WHAT YOU NEED TO BALANCE THE UNIT

• One VT9W main wall control close to the unit.

• A magnehelic gauge capable of measuring 0 to 0.5 inch of water (0 to 125 Pa) and 2 plastic

tubes.

• The balancing chart of the unit.

VP0009

7.2 PRELIMINARY STAGES TO BALANCE THE UNIT

• Seal all the unit ductwork with tape. Close all windows and doors.

• Turn off all exhaust devices such as range hood, dryer and bathroom fans.

• Make sure all filters are clean (if it is not the first time the unit is balanced).

NOTE: Make sure that the furnace/air handler blower is ON if the installation is in any way connected to the ductwork of the cold air

return. If not, leave furnace/air handler blower OFF.

7.3 USING MAGNEHELIC GAUGES

HIGH

1. Place the magnehelic gauge on a level surface and adjust it to zero.

2. According to the airflow to be measured, connect tubing from gauge

to STALE air flow or FRESH air flow pressure taps (see illustration at

right).

Be sure to connect the tubes to their appropriate high/low fittings. If

the gauge drops below zero, reverse the tubing connections.

VP0027A

7.4 BALANCING CHART AND PRESET SPEEDS TABLE

The unit balancing chart and the unit preset speed table are affixed on the unit, behind the

right panel (circled area on illustration at right).

LOW

FRESH AIR FLOW

HIGH

LOW

STALE AIR FLOW

19

VD0388

Page 20

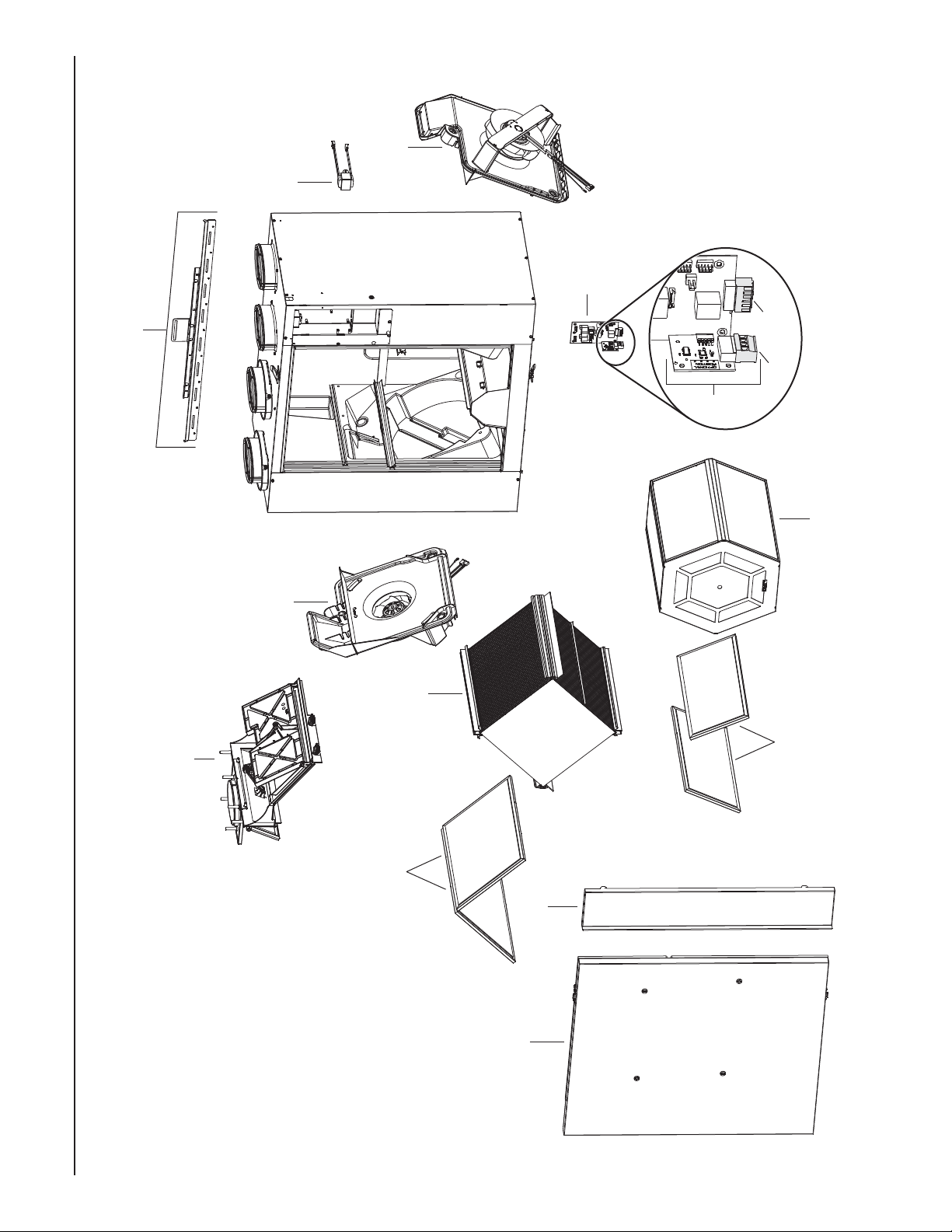

7. BALANCING THE UNIT (CONT’D)

7.4 BALANCING CHART AND PRESET SPEEDS TABLE (CONT’D)

Use the balancing chart to convert pressure (in. w.g.) values read from magnehelic gauge to airflow (CFM) values. While balancing,

the VT9W wall control screen shows which pressure taps have to be used. See example below.

UNIT BALANCING CHART

Plug magnehelic gauge

tubing to STALE airflow.

Plug magnehelic gauge

tubing to FRESH airflow.

NOTE: The unit is considered balanced even if there is a difference of ± 10 CFM (or ± 5 L/s or 17 m³/h) between the two airflows.

The special design of these units, combined with the VT9W main wall control, offer many preset speeds ranges according

to the unit models.

See preset speeds table example below.

PRESET SPEEDS TABLE

FLOW FRESH STALE

CFM IN. W.G. IN. W.G.

120 0.71 0.73

125 0.67 0.70

130 0.63 0.67

135 0.59 0.64

140 0.55 0.61

145 0.51 0.58

150 0.47 0.55

FRESH reading value with

its corresponding CFM

STALE reading value with

its corresponding CFM

UNIT MODEL

P

RESET

SPEEDS NO.

__

01 250 125 250 250

02 225 110 250 225

03 200 100 250 200

04 175 85 225 175

05 150 75 200 150

06 125 60 175 125

07 100 50 150 100

08 This speed must be used for HVI testing at 64 CFM @ 13°F (-25°C)

09 This speed must be used for HVI testing at 98 CFM @ 13°F (-25°C)

TURBO

IGH SPEED

H

(CFM@ 0.4 IN. W.G.)

From 60 to 250

CONT

LOW SPEED

(CFM@ 0.2 IN. W.G.)

From 30 CFM to

75% of adjusted

TURBO speed

R

20/40/60

ONTROL STALE AIR

C

(CFM@ 0.4 IN. W.G.)

From 60 to 250 From 60 to 250

MIN.

ECIRCULATION SPEED

(CFM@ 0.4 IN. W.G.)

20

Page 21

7. BALANCING THE UNIT (CONT’D)

7.5 BALANCING PROCEDURE

B Connect an VT9W main wall control nearby the unit.

ENERAL INFORMATION ABOUT VT9W WALL CONTROL USAGE IN UNIT BALANCING PROCEDURE

G

MODE

% HUM

TURBO

PROG flashes on screen as long as you

are in Program Mode Setting menus (preset

speeds or custom speeds). It disappears

from screen when all settings are done or

when there is no change after 60 seconds.

Enter Program Mode.

C

% HUM

AND

TURBO

Press and hold both

% HUM and TURBO

keys for 10 seconds.

Press on MODE key to raise the value.

Press on % HUM key to accept.

Press on TURBO key to lower the value.

10 sec.

!

PROG start flashing.

A 10-second

countdown appears.

TURBO

MODE

!

% HUM

TURBO

Press any key to enter

program mode. If there

is no key pressed before

the end of the countdown,

the unit will go back to its

previous mode.

!

OR

OR

This label section shows which speed is

being set (e.g.: TURBO).

Arrow shows where to install the

magnehelic gauge tubing

(e.g.: EXHAUST).

Motor speed indicator.

Choose between two options: • 01, 02, etc.: Preset speeds (balance the unit only, faster option)

•

VB60W control and RECIRC speeds).

Select the Preset speeds or Custom speeds.

D

01 speed value

(preset value) will

appear on screen.

NOTE: From 01 value, pressing on TURBO key will access to custom speed settings (see page 23).

E Connect the magnehelic tubings to the unit (see 7.3).

_ _: Custom speeds (adjust TURBO speed and balance the unit, then set CONT,

MODE

!

OR

TURBO

Press on MODE key to

raise the value.

Press on TURBO key to

lower the value.

Write selected

preset speed

on label affixed

on the unit for

future reference.

% HUM

Press % HUM key

to accept chosen

preset speed.

21

Page 22

7. BALANCING THE UNIT (CONT’D)

7.5 BALANCING PROCEDURE (CONT’D)

F

If the unit speed is set close to its highest speed, we recommend to first measure and note both airflows.

Refer to the unit balancing chart to find the corresponding CFMs.

G

H

Determine which airflow should be adjusted (the higher airflow must be lowered to equalize the lower one).

See example below.

Pressure

in. w.g.

0.31 152 155

0.32 156 159

0.33 159 162

0.34 162 166

0.35 165 169

0.36 168 172

0.37 171 176

0.38 174 179

0.39 177 183

0.40 180 186

0.41 183 189

0.42 186 193

0.43 189 196

0.44 193 200

0.45 196 203

0.46 199 206

0.47 202 210

0.48 205 213

0.49 208 217

0.50 211 220

0.51 214 223

0.52 217 227

0.53 220 230

0.54 223 234

0.55 226 237

Fresh

CFM

Stale

CFM

STALE reading

value with its

corresponding

CFM

FRESH reading

value with its

corresponding

CFM

NOTE: At first airflow readings, for speed value 01, both stale and fresh airflow

values displayed on control screen are 100%.

Before airflow adjustment

STALE airflow

reading:

0.41 in. w.g.,

189 CFM

FRESH airflow

reading:

0.50 in. w.g.,

211 CFM

TURBO

TURBO

After airflow adjustment

TURBO

STALE airflow

reading:

0.41 in. w.g.,

189 CFM

TURBO

FRESH airflow

reading:

0.43 in. w.g.,

189 CFM

In that case, the FRESH

airflow must be lowered

to reach the STALE

airflow value.

I

Adjust stale air TURBO speed (or press % HUM key to keep it as is).

NOTE: The following shown values are example. The real values vary according to the preset speed chosen, the unit

installation, etc.

TURBO

TURBO

Take the reading

from stale airflow

pressure taps.

MODE

!

OR

TURBO

Press on MODE key to

raise the value.

Press on TURBO key to

lower the value.

TURBO

Check the magnehelic

Write selected

airflow percentage

on label affixed on

the unit for future

reference.

% HUM

Press % HUM key

to accept chosen

percentage.

gauge along with the unit

balancing chart until the

desired airflow is reached.

22

Page 23

7. BALANCING THE UNIT (CONT’D)

7.5 BALANCING PROCEDURE (CONT’D)

J

Adjust fresh air TURBO speed (or press % HUM key to keep it as is).

TURBO

TURBO

Install tubing on fresh

airflow pressure taps

and take the reading.

Press on MODE key to raise

Press on TURBO key to lower

Ajust the airflow until the

reading on magnehelic gauge

reaches the stale airflow value.

MODE

!

OR

TURBO

the value.

the value.

TURBO

Check the magnehelic

gauge along with the unit

balancing chart until the

desired airflow is reached.

If you have selected the preset speed balancing at H, the balancing procedure is completed.

If you have selected the custom speed balancing, continue with the following:

K

Set CONT speed.

CONT

CONT

MODE

!

OR

TURBO

Press on MODE key to raise

CONT

Write selected

airflow percentage

on label affixed on

the unit for future

the value.

Press on TURBO key to lower

the value.

Ajust the airflow until the

reading on magnehelic gauge

reaches the desired CFM value.

Check the magnehelic

gauge along with the unit

balancing chart until the

desired airflow is reached.

Write selected

airflow percentage

on label affixed on

the unit for future

reference.

reference.

% HUM

Press % HUM key

to accept chosen

percentage.

% HUM

Press % HUM key

to accept chosen

percentage.

23

Page 24

7. BALANCING THE UNIT (CONT’D)

7.5 BALANCING PROCEDURE (CONT’D)

Set VB60W control speed.

L

NOTE: According to the installation, the magnehelic gauge tubing can be

connected to exhaust OR supply air flow. The arrow on screen will

shown which airflow will have to be set.

Plug magnehelic gauge

tubing to STALE airflow.

Plug magnehelic gauge

tubing to FRESH airflow.

Set RECIRC speed.

M

Connect the

magnehelic gauge to

Fresh airflow taps.

MODE

!

OR

TURBO

Press on MODE key to raise

the value.

Press on TURBO key to lower

the value.

Ajust the airflow until the

reading on magnehelic gauge

reaches the desired CFM value.

MODE

!

OR

TURBO

Press on MODE key to raise

the value.

Press on TURBO key to lower

the value.

Ajust the airflow until the

reading on magnehelic gauge

reaches the desired CFM value.

Check the magnehelic

gauge along with the unit

balancing chart until the

desired airflow is reached

Check the magnehelic

gauge along with the unit

balancing chart until the

desired airflow is reached

Write selected

airflow percentage

on label affixed on

the unit for future

reference

Write selected

airflow percentage

on label affixed on

the unit for future

reference

% HUM

Press % HUM key

to accept chosen

percentage.

% HUM

Press % HUM key to

accept chosen percentage

and exit the menu OR

wait 60 seconds.

The balancing procedure is completed.

NOTE: The adjusted airflow values are stored within the unit, so, if needed, any VT9W main control can be used to adjust

the unit speeds and balance the unit again. If a power failure occurs, the unit will keep these setting values. To change the

setting values, go to step G and follow the procedure, the new values will replace the previous ones.

24

Page 25

8. TROUBLESHOOTING

If the unit does not work properly, reset the unit by unplugging and then replug it. If it is still not working properly, refer to the

table below.

If the LED of the unit is flashing, this means the unit sensors have detected a problem. See the table below to know where the problem

occurs on the unit.

LED SIGNAL

ON UNIT

LED flashes

GREEN

(double blink

every

2 seconds).

LED flashes

GREEN

(2 blinks per

second; faster

blink).

LED flashes

AMBER.

LED flashes

RED

(one blink

every

2 seconds).

LED flashes

RED

(2 blinks per

second; faster

blink).

ERROR CODE ON

CONTROL SCREEN

E21 Cold side thermistor

E22 Warm side

E23 Damper system

E25 and E26

alternately

E25 Cold side motor

E26 Warm side motor

ERROR TYPE ACTION UNIT STATUS

error.

thermistor error.

error.

Open door while the

unit is in function or

magnetic switch bad

contact.

error.

error.

Unit is on protection

mode.

• Ensure J12 connector is properly connected

and its wires are not damaged. If they are

correct:

• Replace the damper system assembly.

• Ensure J20 connector is properly connected

and its wires are not damaged. If they are

correct:

• Replace the warm side thermistor.

• Go to point 6 in next table. Unit does not work.

• Reset the VT9W wall control by pressing on

MODE and %HUM keys for 10 seconds.

• Check if the unit door is properly closed and for

the door magnet to be properly seated onto the

door. If not, correct the situation, close the door

and reset the VT9W wall control by pressing

on MODE and %HUM keys for 10 seconds.

• Ensure J11 connector is properly connected

and its wires are not damaged. If not, correct the

situation, close the door and reset the VT9W

wall control by pressing on MODE and %HUM

keys for 10 seconds.

• Using a flat blade screwdriver, jump J11, reset

the VT9W wall control by pressing on MODE

and %HUM keys for 10 seconds and set the

unit on CONT.

If the LED is still flashing, go to point 8 in next

table for motor diagnosis.

• Go to point 8 in next table.

• Go to point 8 in next table.

• If outside temperature is colder than -25°C, it

could be normal for the unit to enter in

protection mode. There is no action to be taken.

• If the snowflake icon appears frequently, the

airflows of the unit may be not balanced or the

damper system may be damaged. See point 7

in next table.

Unit works but will

defrost frequently.

Unit does not work.

Unit does not work.

Unit perform a special

defrost and go back to

its previous mode when

completed.

25

Page 26

8. TROUBLESHOOTING (CONT’D)

PROBLEMS POSSIBLE CAUSES YOU SOULD TRY THIS

The error code E01 is

1

displayed on VT9W wall

control screen.

The VT9W wall control

2

screen alternates between

normal display and E03.

The VT9W wall control

3

does not work.

4 Unit does not work.

The VB60W push-button

timer does not work (unit

5

LED lit, no matter the

color).

Unit is always on high

6

speed.

• The wires may be in reverse position.

• The wires may be misconnected.

• The wires may be broken.

• The VT9W wall control may be

defective.

• Wrong main control.

• The wires may be in reverse position.

• The wires may be misconnected.

• The wires may be broke.

• Defective wall control.

• Unit is unplugged.

• No power to power outlet.

• The fuse may be defective.

• J10, J9, or J8 connector(s) may be

unplugged.

• The transformer may be defective

(no 9.5 VAC between J8-4 and J8-5).

The main PCB may be defective.

•

• The wires may be in reverse postion.

• The wires may be misconnected.

• The wires may be broken.

• The push button may be defective.

• The VB60W push-button timer wires

may be shorted.

• Ensure that the color coded wires have been connected to

their appropriate places.

• Ensure the wires are correctly connected.

• Inspect every wire and replace any damaged ones. If wires

are hidden into walls, test the control using a shorter wire.

• Replace the VT9W wall control.

• Ensure the main control is an VT9W.

• Ensure that the color coded wires have been connected to

their appropriate places.

• Ensure the wires are correctly connected.

• Inspect every wire and replace any damaged ones. If wires

are hidden into walls, test the control using a shorter wire.

• Replace the wall control.

• Make sure the unit is plugged.

• Test the power outlet with another electrical device (e.g.: a

lamp). If it does not work, call an electrician.

• Check if fuse F1 (located on the PCB) is blown. In that case,

replace fuse F1 as per product nameplate.

• Check the connection of J10, J9, and J8 connectors.

• With unit powered on and J9 connected, check if there is

about 9.5 VAC between J8-4 and J8-5 (YELLOW wires)

transformer connector. If not, change the transformer.

• Replace the main PCB.

• Ensure that the color coded wires have been connected to

their appropriate places.

• Ensure the wires are correctly connected.

• Inspect every wire and replace any damaged ones. If wires

are hidden into walls, test the control using a shorter wire.

• Jump the OL and OC terminals. If the unit

switches to high speed, remove the push

button and test it right beside the unit

using another shorter wire. If it works here,

change the wire. If it doesn’t, change the

push button.

• Ensure OC and OL wires do not touch each others.

• Unplug wires from the auxiliary control terminal block and

measure the resistance between cables (there should be

no resistance). If resistance has been detected, ensure the

wires are correctly connected, then inspect every wire and

replace damaged ones.

VE0356

26

Page 27

8. TROUBLESHOOTING (CONT’D)

PROBLEMS POSSIBLE CAUSES YOU SOULD TRY THIS

The damper system

does not work

(LED flashes AMBER,

error code E23).

7

A. The supply motor does

not work, but exhaust

motor works.

(LED flashes RED, error

code E25)

8

B. The exhaust motor does

not work, but supply

motor works.

(LED flashes RED, error

code E26)

Unit works on CONT and

TURBO modes, but not in

RECIRC mode.

9

At power up, no RED LED. • See point 4.

At power up, LED lights RED and

there is a clicking sound coming

from electrical compartment, but

damper does not move:

• Ice or other things hindering the

• Remove ice or hindering elements.

damper movement.

• J12 unconnected or bad contact.

• Wrong connection of J8.

• The transformer may be defective

(no 24 VAC between J8-1 and J8-2).

• Check J12 connection (both harness side and board side).

• Check J8 connection.

• With unit powered and J9 connected, check if there is about

20-24 VAC between J8-1 and J8-2 (BROWN wires)

transformer connector. If no, change the transformer.

• Erase the error code by pressing on MODE and %HUM

keys for 10 sec., then set the unit in CONT and check if the

error code is displayed again.

• The damper actuator

• If the error code is back, replace the damper system.

may be defective.

Damper moves but does not stop

when supposed to:

• Bad connection of J12 connector.

• Damper system PCB defective or

• Check J12 connection (both harness side and board side).

• Replace the damper system.

damper motor stripped gear.

• The main PCB is defective.

• The supply motor may be defective.

• Replace the main PCB.

• Check the connection of J4 and J15 connectors.

• Jump the OL and OC terminals and plug

supply motor to J5 connector and exhaust

motor to J4 connector. If the supply motor

works but the exhaust motor does not,

replace the main PCB. If the supply motor is

still not working, plug back supply motor to J4 connector and

exhaust motor to J5 connector and continue to investigate.

• Swap both motor control cable connections on PCB:

connect supply control cable to J17 connector and exhaust

control cable to J15 connector. If the supply motor works

but the exhaust motor does not, replace the main PCB. If

the supply motor is still not working, plug back the exhaust

control cable to J17 connector and replace the supply motor.

• The exhaust motor may be defective.

• Check the connection of J5 and J17 connectors.

• Jump the OL and OC terminals and plug

exhaust motor to J4 connector and supply

motor to J5 connector. If the exhaust motor

works but the supply motor does not,

replace the main PCB. If the exhaust motor

is still not working, plug back exhaust motor to J5 connector

and supply motor to J4 connector and continue to investigate.

• Swap both motor control cable connections on PCB: connect

exhaust control cable to J15 connector and supply control

cable to J17 connector. If the exhaust motor works but the

supply motor does not, replace the main PCB. If the exhaust

motor is still not working, plug back the supply control cable

to J15 connector and replace the exhaust motor.

• Reversed motor connections. • Swap both motor power cable connections J4 and J5 on

PCB. Check for the supply motor (on right side of the unit)

operation in RECIRC mode.

• If the exhaust motor is still running in RECIRC mode instead

of supply, connect back in place power cable connections

J4 and J5 on PCB and swap control cables J15 and J17 on

PCB.

• If the problem is not solved, change the PCB.

VE0356

VE0356

27

Page 28

NOTES

28

Page 29

VB0185

MANUAL DE INSTALACIÓN

1. El único control mural compatible

con estas unidades es el control

mural VT9W.

2. Estas unidades están sujetas

a un nuevo procedimiento de

equilibrado. Véase la Sección 7.

3. Los conectores de terminales de

estas unidades no vienen con el

kit para la instalación; ya están

montados en su placa de control

electrónico.

NOTAS IMPORTANTES

ERV200 ECM HRV200 ECM

ERV250 ECM HRV250 ECM

Estos productos han sido distinguidos con el logotipo ENERGY STAR® al cumplir las directrices de

eficiencia energética establecidas por el Ministerio de Recursos Naturales de Canadá y la Agencia Federal

de Protección Ambiental (EPA) de Estados Unidos. Los productos cumplen las exigencias del programa

ENERGY STAR únicamente cuando se emplean en Canadá.

! !

SÓLO PARA USO RESIDENCIAL

LEA Y CONSERVE ESTAS INSTRUCCIONES

Broan-NuTone LLC; Hartford, Wisconsin www.broan.com 800-543-3055

REGISTRE SU PRODUCTO EN LÍNEA EN: www.broan.com/register

Para obtener más información, visitar nuestro sitio www.broan.com

21992 rev. 01

Page 30

ACERCA DE ESTE MANUAL

!

Dado el gran número de modelos de los que trata este manual, las ilustraciones son de carácter general. Algunos detalles de su aparato

pueden ser ligeramente distinos de los que se muestran aquí.

Con el fin de hacer hincapié en determinada información, en este manual se emplean los siguientes símbolos:

ADVERTENCIA

Se refiere a una instrucción que, de no siguirse podría causar heridas corporales graves e incluso la muerte.

PRECAUCIÓN

Se refiere a una instrucción que, si no seguirse, podría dañar gravemente el aparato o sus piezas.

NOTA : Da información complementaria para realizar una instrucción.

ACERCA DE ESTOS APARATOS

LIMITACIÓN

Sólo para instalaciones residenciales. El trabajo de instalación y el cableado eléctrico han de ser efectuados por personal cualificado

conforme a todos los códigos y normas aplicables, incluso los relativos a lugares con alto riesgo de incendo.

!

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA ELÉCTRICA O LESIÓN CORPORAL, RESPETE LAS SIGUIENTES

INDICACIONES:

1. Utilice este aparato únicamente de la forma en que indica el fabricante. Si tiene cualquier pregunta, comunique con el fabricante en

la dirección o el teléfono que aparecen en la garantía.

2. Le aconsejamos que un técnico especializado examine el aparato una vez por año.

3. Antes de reparar o limpiar el aparato, desenchufe el cable de alimentación de la toma.

4. Este aparato no se ha concebido para proporcionar aire de combustón o de dilución a otros aparatos de combustión.

5. Al cortar o perforar la pared o el techo, procure no dañar el cableado eléctrico ni otras instalaciones de servicios públicos.

6. No utlice este aparato con un dispositivo de control de velocidad con semiconductores distito al control siguientes:

UNIDAD CONTROL PRINCIPAL CONTROL AUXILIAR

ERV200 ECM, ERV250 ECM,

HRV200 ECM, HRV250 ECM

7. Este aparato debe conectarse a tierra. El cable de alimentación tiene un enchufe de tres pastillas para su seguridad personal. Este

enchufe debe enchufarse en una toma tres pastillas, conectada a tierra según el código nacional de electricidad y los códigos y

ordeneza locales. No quite la pastilla de tierra ni utilice un cable prolongador.

8. No instale este aparato en una zona donde se cocine ni lo conecte directamente a ningún tipo de aparato.

9. No utilice este aparato para extraer materiales y vapores peligrosos o explosivos.

10. Al instalar, reparar o limpiar estos aparatos, se aconseja llevar anteojos y guantes de seguridad.

11. Teniendo en cuenta el peso del aparato, se aconseja que lo instalen dos personas.

12. Cuando una reglamentación local esta en vigor y conlleva exigencias de instalación y/o de certificación mas estrictas, susodichas

exigencias prevalecen sobre aquellas en este documento y el instalador acepta somerterse a estas exigencias a sus gastos.

VT9W EXCLUSIVAMENTE VB60W

PRECAUCIÓN

1. Para evitar que los filtros se obtruyan prematuramente, apague el aparato cuando realice obras de construción o renovación.

2. Para mayor información y conocer mejor los requisitos del aparato, lea la etiqueta con las caracrerístocas téchnicas del producto.

3. Comprobe que el aire va fuera. No introduzca ni saque el aire de espacios situados entre paredes, techos o altillos, sótanos ococheras.

4. Aparato previsto únicamente para instalaciones residenciales con arreglo a los requisitos NFPA 90B.

5. No ponga ningún tubo de aire diractamente sobre (o a menos de 2 pies) una caldera o de su cámara de alimentación, de una cámara

de combustión o de cualquier otro aparato que produzca calor. Si hay que conectar un tubo a la cámara de retorno de una caldera,

la conexión debe acerse a 9’10’’ o más de la conexión de dicha cámara con la caldera.

6. Los tubos deben instalarse con arreglo a los códigos locales y nacionales aplicables.

7. Si no va a estar en la casa durante un largo periodo (más de dos semanas), un responsable debería verificar regularmente que el

aparato funciona debidamente.

8. Si las tuberías pasa a través de un espacio do acondicionado (p. ej., un altillo), el aparato debería funcionar constantemente, menos

cuando se repare o se limpie. Asimismo, la temperatura ambiente de la casa nunca debería bajar de 65°F.

ASISTENCIA TÉCNICA

P

ARA OBTENER ASSISTANCIA, LLAME DURANTE DíAS LABORABLE, ENTRE LAS 8:30 AM Y LAS 5:00 PM (HORA ESTÁNDAR DEL ESTE): 1-800-543-3055.

NOTA: ÉSTE NÚMERO ESTA SÓLO PARA INSTALADORES. No llame a éste número para ordenar piezas.

2

Page 31

ÍNDICE

1. P IEZAS ..........................................................................................................................................................................4-5

2. DISTRIBUCIón DEL AIRE ........................................................................................................................................................6

3. I

NSTALACIóN ..................................................................................................................................................................6-12

3.1 EXAMEN DEL CONTENIDO DE LA CAJA .............................................................................................................................................. 6

3.2 UBICACIóN DEL APARATO ............................................................................................................................................................ 6-7

3.3 PLANIFICACIóN DE LOS TUBOS ....................................................................................................................................................... 8

3.4 TAMAÑO DE LOS CONDUCTOS ........................................................................................................................................................8

3.5 INSTALACIóN DE LOS TUBIOS Y REGISTROS .................................................................................................................................. 8-10

3.6 CONEXIÓN DE LOS TUBULOS AL APARATO ........................................................................................................................................11

3.7 INSTALACIóN DE 2 BOCAS EXTERIORES ........................................................................................................................................... 12

3.8 CONEXIóN DEL DESAGüE ............................................................................................................................................................ 12

4. CONTROLES ................................................................................................................................................................13-16

4.1 SECUENCIA DE PUESTA EN MARCHA .............................................................................................................................................. 13

4.2 CONEXIÓN ELÉCTRICA DEL CONTROL O CONTROLES MURALES ........................................................................................................ 13-15

4.3 CONFIGURACIÓN DEL FUNCIONAMIENTO DE LA UNIDAD EN LOS 40 MINUTOS RESTANTES EN EL MODO 20 MIN/H

Y CONFIGURACIÓN DEL TIPO DE CICLO DE DESHIELO DE LA UNIDAD MEDIANTE EL CONTROL MURAL PRINCIPAL VT9W. ..................................... 16

5. CONEXIóN ELÉCTRICA CON LA CALDERA ................................................................................................................................. 17

6. DIAGRAMA DE CABLEADO ....................................................................................................................................................18

7. E QUILIBRADO DEL APARATO ............................................................................................................................................19-24

7.1 ELEMENTOS NECESARIOS PARA EQUILIBRAR EL APARATO ................................................................................................................... 19

7.2 ETAPAS PRELIMINARES PARA EQUILIBRAR EL APARATO ........................................................................................................................ 19

7.3 USO DE CAUDALÍMETROS DE HÉLICE ............................................................................................................................................... 19

7.4 CUADRO DE EQUILIBRADO Y TABLA DE VELOCIDADES PRESELECCIONADAS ......................................................................................... 19-20

7.5 PROCEDIMIENTO DE EQUILIBRADO ............................................................................................................................................. 21-24

8. SOLUCIÓN DE PROBLEMAS ..............................................................................................................................................25-27

3

Page 32

O

D

N

B

M

L

K

J

D

F

I

C

E

H

G

VL0071

1. PIEZAS

4

Page 33

1 SV63420 SV63420 SV63420 SV63420

2 SV63421 SV63421 SV63421 SV63421

1 SV63434 SV63434 SV63434 SV63434

1 SV63435 SV63435 SV63435 SV63435

1 SV63436 SV63441 SV63442 SV63443

ONJUNTO DEL SISTEMA DE LA CLAPETA

IT DE SOPORTES 1 SV63419 SV63419 SV63419 SV63419

C

1K

N.o DESCRIPCIóN CTD ERV200 ECM HRV200 ECM ERV250 ECM HRV250 ECM

(INCLUYE 2 TORNILLOS DE PLÁSTICO)

2

ONJUNTO DEL VENTILADOR IMPELENTE

C

(INCLUYE 3 TORNILLOS DE PLÁSTICO)

3

CLEO DE RECUPERACIóN DE CALOR 1 SV63422 SV63423NúCLEO DE RECUPERACIóN DE ENERGíA 1 SV63425

ILTRO DEL NúCLEO RECUPERADOR DE CALOR HRV (PAR) 1 SV63426 SV63426FILTRO DEL NúCLEO RECUPERADOR DE ENERGíA ERV (PAR) 1 SV63433

Nú

F

5

4

ONJUNTO DE LA PUERTA (INCLUYE EL íTEM 16) 1 SV63569 SV63569 SV63569 SV63569

6C

1. PIEZAS (CONTINUACIÓN)

CLEO DE RECUPERACIóN DE ENERGíA 1 SV63424

ANEL DE DERECHA 1 SV63565 SV63566 SV63567 SV63568

ILTRO DEL NúCLEO RECUPERADOR DE ENERGíA ERV (PAR) 1 SV63427

8F

9 Nú

7P

ONECTOR DE LA PLACA DE CIRCUITOS IMPRESOS (PCB)

LACA SECUNDARIA (INCLUYE íTEM 11) 1 SV63437 SV63437 SV63437 SV63437

C

11

10 P

5

(CONTROL PRINCIPAL)

ONECTOR DE LA PLACA DE CIRCUITOS IMPRESOS (PCB)

C

(CONTROL AUXILIAR)

12

ONECTOR DE LA PLACA DE CIRCUITOS IMPRESOS (PCB)

C

(INCLUYE LOS ÍTEMS 10 Y 12)

13

IT DEL TERMISTOR DEL LADO CALIENTE* 1 SV62481 SV62481 SV62481 SV62481

RANSFORMADOR 1 SV63438 SV63438 SV63438 SV63438

14 T

15 K

NTERRUPTOR MAGNÉTICO DE PUERTA* 1 SV19060 SV19060 SV19060 SV19060

16 I

IT DE PIEZAS* 1 SV22488 SV22488 SV22488 SV22488

ORNILLO DE PLÁSTICO (JUEGO DE 6)* 1 SV63439 SV63439 SV63439 SV63439

17 T

18 K

Sin illustración*

SUSTICTUCIón de piezas y reparación

Para que la unidad se conserve en buen estado, debe usar repuestos genuinos Broan-NuTone LLC únicamente. Estas piezas se han diseñado especialmente para cada unidad y

se han fabricado conforme a las normas de certificación aplicables y un elevado nivel de seguridad. El uso de repuestos de otros fabricantes podría causar daños graves y reducir

radicalmente el desempeño de la unidad, causando así fallas prematuras. Broan-NuTone LLC también aconseja ponerse en contacto con un taller de reparación homologado por

Broan-NuTone LLC para todos los repuestos y reparaciones.

Page 34

2. DISTRIBUCIÓN DEL AIRE

FUNCIONAMIENTO NORMAL DESHIELO O RECIRCULACIóN

AIRE

AIRE VICIADO

HACIA EL

EXTERIOR

VF0063

DESDE EL

EXTERIOR

FRESCO

AIRE DE SALIDA

DEL EDIFICIO

AIRE PURO DE

ENTRADA EN EL

EDIFICIO

AIRE DE SALIDA

DEL EDIFICIO

AIRE

FILTRADO

DE ENTRADA EN

EL EDIFICIO

3. INSTALACIÓN

3.1 EXAMEN DEL CONTENIDO DE LA CAJA

Examine el exterior del aparato para ver si hay daños debidos al envío. Compruebe que la puerta, los pestillos, el cable de alimentación,

etc., no estén dañados.

3.2 UBICACIóN DEL APARATO

Elija un lugar apropriado para el aparato.

• En una zona de la casa donde la temperatura ambiente se sitúe entre

50°F y 104°F.

• Lejos de las zonas habitables (comedor, sala de estar, dormitorio) de

ser posible.

• De manera que se tenga acceso fácilmente al interior del aparato para

las tareas de mantenimiento semestrales y anuales.

NOTA: Es necesario que haya un espacio de 27’’ delante de la unidad

para poder abrir la puerta completamente. En espacios limitados,

la puerta se puede retirar levantántola, pero se necesita un

espacio de 18” adelante de la unidad para retirar el núcleo.

• Cerca de una pared exterior para limitar la longitud del tubo flexible

aislado que va del aparato al exterior.

• Lejos de las chimenea calientes y otros peligros relacionados con el fuego.

• Cerca de una fuente de alimentación (toma con puesta a tierra

de 3 patillas).

• Cerca de un desagüe. Si no hay un desagüe, utilice un balde para

recoger los residuos líquidos.

VD0378

UNIDAD COLGADA CON CADENAS Y MUELLES

La unidad puede colgarse con las 4 cadenas y muelles provistos (véase la ilustración a la derecha) o colgarse de la pared con les

soportes provistos (véase la página siguiente).

PRECAUCIÓN

En cualquiera de los casos, verifique que la unidad esté a nivel.

6

Page 35

3. INSTALACIÓN (CONTINUACIÓN)

!

3.2 UBICACIóN DEL APARATO (CONTINUACIóN)

UNIDAD COLGADA AL SOPORTE MURAL

Trace una línea a nivel en la pared; alinee el soporte mural (el

más largo) con la línea y fije el soporte a la pared con los

4 tornillos (1½’’ de largo) y las arandelas provistos, si se usan los

huecos del soporte).

ADVERTENCIA

Compruebe que el soporte mural esté fijado a todos

los montantes disponibles y no sólo al panel mural.

LINEA AL NIVEL SOPORTE MURAL

VD0379

Utilice los tornillos largos de 1½” provistos, ensamble los dos

espaciadores en las esquinas inferiores izquierda y derecha de

la unidad.

Levante la unidad y cuélguela al soporte mural. Compruebe que

el soporte instalado en la parte trasera de la unidad reposa en el

soporte mural.

VO0271

Sujete la unidad a la pared con el tornillo largo de 1½’’ provisto

haciéndolo pasar a través del soporte mural.

VD0380

PRECAUCIÓN

No use nunca un destornillador

o una taladradora eléctricos para

atornillar los soportes a la unidad;

use un destornillador normal.

Utilice los tornillos largos de 3/8” provistos; instale el otro soporte

(A) en la parte trasera de la unidad; empiece con los 4 tornillos

traseros y continúe con los 2 tornillos en la parte superior izquierda

y derecha. A continuación, use el último tornillo central para sujetar

el último soporte pequeño (B).

NOTA: Estos tornillos deben apretarse manualmente.

VR0086

B

A

VO0272

VD0392

7

Page 36

!

3. INSTALACIÓN (CONTINUACIÓN)

3.3 PLANIFICACIóN DE LOS TUBOS

• Intente hacer una instalación sencilla. Prevea la menor cantitad posible de tubos curvados y juntas.

• Utilice conductos aislados de una longitud mínima ya que dicha longitud influye directamente en el rendimiento

de las corrientes de aire de la unidad.