Bosch US9, US7 Installation Manual

Electric water heaters

TRONIC 3000C Pro

Models: US3, US6, US7 & US9

en Installation Manual and Operating Instructions 2

es Instrucciones de instalación y funcionamiento 18

fr Instructions d'installation et d'utilisation 33

IMPORTANT: This booklet should be given to the customer after installation and demonstration.

For Service & Installation contact:

BOSCH Thermotechnology Corp.

50 Wentworth Avenue, Londonderry

NH 03053

Phone 800-798-8161

www.bosch-climate.us

6 720 647 005 (2011/09) US

2 | Table of contents US

Table of contents

1 Explanation of Symbols and Important Safety

Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . . 3

1.2 Important Safety Instructions . . . . . . . . . . . 3

2 Information about the heater . . . . . . . . . . . . . . . . 4

2.1 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1.1 Approval number . . . . . . . . . . . . . . . . . . . . 4

2.2 Technical identification code . . . . . . . . . . . 4

2.3 Package contents . . . . . . . . . . . . . . . . . . . . 4

2.4 Model name and number identification . . . 4

2.5 General description . . . . . . . . . . . . . . . . . . 5

2.6 Electrical diagram . . . . . . . . . . . . . . . . . . . . 6

2.7 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Important information . . . . . . . . . . . . . . . . 9

4.1.1 Freeze prevention . . . . . . . . . . . . . . . . . . . . 9

4.2 Installing the Tronic 3000C Pro . . . . . . . . . 9

4.3 Water connections . . . . . . . . . . . . . . . . . . 10

4.3.1 Water quality . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Electrical connections . . . . . . . . . . . . . . . 10

4.5 Securing the unit to the wall . . . . . . . . . . 12

4.5.1 Deciding the position . . . . . . . . . . . . . . . . 12

4.5.2 Deciding the wiring route . . . . . . . . . . . . . 12

4.5.3 Mounting on the wall . . . . . . . . . . . . . . . . 12

5 Starting up the Tronic 3000C Pro . . . . . . . . . . . 14

5.1 Sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Adjusting the flow . . . . . . . . . . . . . . . . . . . 14

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 For the Installer . . . . . . . . . . . . . . . . . . . . 15

6.2 For the User . . . . . . . . . . . . . . . . . . . . . . . 16

7 Interior components and parts list . . . . . . . . . . 17

6 720 647 005 (2011/09)

Explanation of Symbols and Important Safety Instructions | 3US

1 Explanation of Symbols and Important Safety Instructions

1.1 Explanation of symbols

Warnings

Warnings are indicated in the text by a

warning triangle and a gray background.

In case of danger due to electric shock, the

exclamation point on the warning triangle is

replaced with a lightning symbol.

Signal words at the beginning of a warning are used to

indicate the type and seriousness of the ensuing risk if

measures for minimizing damage are not taken.

• NOTE indicates that minor damage to property may

occur.

• CAUTION indicates possible minor to medium

personal injury.

• WARNING indicates possible severe personal injury.

• DANGER indicates that severe personal injury may

occur.

Important information

Important information that presents no risk

to people or property is indicated with this

symbol. It is separated by horizontal lines

above and below the text.

Additional symbols

Symbol Meaning

B Sequence of steps

→

• Listing/list entry

– Listing/list entry (2nd level)

Table 1

Cross-reference to other points in this

document or to other documents

1.2 Important Safety Instructions

When using this electrical equipment, basic safety

precautions should always be followed, including the

following:

B Read and follow all instructions.

B This appliance must be grounded.

B Disconnect this product from the electrical supply

before cleaning, servicing or removing the cover.

B To reduce the risk of injury, close supervision is

necessary when the product is used near children or

elderly persons.

B Warning: Do not install the heater in a location where

it may be subject to freezing.

B Warning: Do not install a check valve or any other

types of back flow preventer within six feet of the cold

water inlet.

B The electrical installation must conform to current

National Electrical Codes.

B Warning: Do not switch the heater on if you suspect

that it may be frozen. Wait until you are sure that it

has completely thawed cut.

B The Tronic 3000C Pro is designed to heat potable cold

water for domestic purposes. Contact Bosch

Thermotechnology before specifying or installing the

appliance in any other application.

Additional Canadian Safety Instructions

• A green terminal (or wire connector marked "G", "GR",

"GROUND", or "GROUNDING") is provided within the

control box. To reduce the risk of electric shock,

connect this terminal or connector to the grounding

terminal of the electric service of supply panel with a

continuous copper wire in accordance with the

Canadian Electrical Code, Part I.

• This product shall be protected by a Class A ground

fault circuit interrupter.

Safe these instructions

B Keep this guide in a safe place once your Tronic

3000C Pro unit has been installed.

B You may need to refer to it for general instructions or

future maintenance.

6 720 647 005 (2011/09)

4 | Information about the heater US

2 Information about the heater

2.1 Disclaimer

2.1.1

Commonwealth of Massachusetts

As a condition of installing this product in the

Commonwealth of Massachusetts a pressure relief valve

shall be installed on the cold water side, by a licensed

plumber MGL 142 Section 19.

(Approval number: P1-09-25).

Approval number

2.2 Technical identification code

US 3 - 1 M W I H B

US 6 - 1 M W I H B

US 7 - 1 M W I H B

US 9 - 1 M W I H B

Table 2

US Electronic Instantaneous

3 Maximum output (kW)

M Mechanical temperature control

W Wall hung

I Indoor

H Horizontal installation

B Water connections

2.3 Package contents

• Electric water heater

• 4 No. 8 wood screws

2.4 Model name and number

identification

Model Name Model Number

Tronic 3000C Pro US 3-1 Pro

Tronic 3000C Pro US 6-1 Pro

Tronic 3000C Pro

Tronic 3000C Pro US 9-1 Pro

Table 3

US 7-1 Pro

M W I H B

M W I H B

M W I H B

M W I H B

6 720 647 005 (2011/09)

2.5 General description

Outlet

Inlet

Information about the heater | 5US

Fig. 1

1 Mounting hole

2 Heat exchanger tube

3 Thermal cut-out (manual re-set)

4 Heating elements

5 Terminal block

6 Cable rear entry

7 Ground stud

8 Cable clamp

9 Filter and water pipe mounting

10 Cable side entry

11 Flow switch

12 Power selector

13 Cover fixing screw

14 Neon light

6 720 647 005 (2011/09)

6 | Information about the heater US

Heating elements

Electrical

supply

Manual reset Thermal cut-out

Neon

Power selector

and Flow switch

2.6 Electrical diagram

DANGER: Risk of electric shock!

B Always switch off the electrical supply to

the unit before removing cover or

performing any maintenance and service.

Fig. 2 Internal wiring plan

6 720 647 005 (2011/09)

2.7 Function

How the water heater works:

• Water comes in through the cold water inlet.

The heater is designed for cold water supply

only. Do not supply with pre-heated water.

• The flow switch senses how much water is passing

through the unit. If it detects more than the preset

level, the unit’s heating elements switch on. This is

shown by the neon light glowing.

• The water is heated instantly as it passes through the

copper heat exchanger tube.

The temperature of the water coming out of the unit

depends on:

• The voltage of the electrical supply,

• The temperature of the incoming water supply,

• The setting of the power selector,

• The flow rate,

• The power rating of the unit.

• Depending on the region of the country, the

temperature of the water supply can vary between

Information about the heater | 7US

40 °F in winter to 70 °F in summer, with an average of

50 °F.

Fig. 3

A Manual reset thermal cut out

The table below shows the rise in water temperature you

can expect from the unit:

Element

Model Volts Amps

US9 240 40 2x12 Ω 9,5kW - NA 84F 64F 42F 32F NA

US9 240 20 1x12 Ω - 4,75kW NA 42F 32F 21F 16F NA

US9 208 35 2x12 Ω 7,1kW - NA 64F 48F 32F 24F NA

US9 208 18 1x12 Ω - 3,5kW NA 32F 24F 16F 12F NA

US6 277 22 2x25 Ω 6,0kW - 81F 55F 42F 27F NA NA

US6 277 11 1x25 Ω - 3,0kW 41F 28F 21F 14F NA NA

US3 120-110 27 2x8 Ω 3,4-3,0kW - 41F 28F 20F NA NA NA

US7 240-220 30 2x16 Ω 7,2-6,1kW - NA 63F 48F 32F 24F NA

US7 240-220 15 1x16 Ω - 3,6- 3,05kW NA 32F 24F 16F 12F NA

Resistance

High

Setting Low Setting Temperature Rise (deg F) at Flow Rate (GPM)

0,5

GPM

0,75

GPM

1,0

GPM

1,5

GPM

2,0

GPM

Table 4

Manual reset thermal cut-out

The unit has a thermal cut-out (Fig. 1) which is mounted

circumstances (Fig. 3). Call your service person or Bosch

Water Heating if this happens frequently.

on the heat exchanger tube. This will switch off the

heater elements if the water temperature goes above

194 °F.

2,5

GPM

If the cut-out trips it will need to be reset manually inside

the unit. This cut-out will only operate in exceptional

6 720 647 005 (2011/09)

8 | Regulations US

3 Regulations

Any local by-laws and regulations pertaining to

installation and use of electric water heater appliances

must be observed. Please refer to the laws that should

be attended in your country.

• The electrical installation must conform to current

National Electrical Codes.

• To reduce the risk of electrical shock, connect this

terminal or connector to the grounding terminal of the

electrical service of supply panel with a continuous

copper wire in accordance with the Canadian

Electrical Code, Part I.

• This product shall be protected by a Class A ground

fault circuit interrupter.

• In the Commonwealth of Massachusetts a licensed

plumber or electrician must perform the installation.

(Approval number: P1-09-25).

• In the Commonwealth of Massachusetts a pressure

relief valve shall be installed on the cold water side by

a licensed plumber. (MGL 142 Section 19, Approval

number P1-09-25).

• The unit must be wired by a qualified electrician, in

accordance with the current version of the National

Electrical Code US) or Canadian Electric Code

(Canada).

• When the heater is not within sight of the electrical

circuit breakers, a circuit breaker lockout or

additional local means of disconnection for all nongrounded conductors must be provided that is within

sight of the appliance. (Ref NEC 422.31.).

• The power cable size and the installation must be in

accordance with the Canadian Electrical Code,

C22.1-02.

WARNING:

California Proposition 65 lists chemical

substances known to the state to cause

cancer, birth defects, death, serious illness

or other reproductive harm. This product

may contain such substances, be their

origin from fuel combustion (gas, oil) or

components of the product itself.

6 720 647 005 (2011/09)

4 Installation

Installation | 9US

DANGER: Risk of electric shock!

B For safety reasons, disconnect the power

supply to the heater before any service or

testing is performed.

WARNING:

B This heater must be electrically grounded

in accordance with the most recent

edition of the National Electrical Code.

NFPA 70. In Canada, all electrical wiring

to the heater must be in accordance with

local codes and the Canadian Electrical

Code, CSA C22.1 Part 1.

4.1 Important information

DANGER:

B The installation must only be performed

by a qualified person in accordance with

these instructions.

B Bosch Thermotechnology Corp. is not

responsible for improperly installed

appliances.

WARNING:

B The heater must only be wall mounted

and positioned with the water

connections located either at bottom or

the right side of the unit see Fig. 6. Under

no circumstances should the heater be

mounted differently.

Introduction

Please note that the installation manual states that the

water heater must not be installed in a location where it

may be exposed to freezing temperatures. If the heater

must be left in a space that is likely to experience

freezing temperatures, all water must be drained from

the heater.

Freeze damage is not covered under the warranty.

Use of agents like anti-freeze are not

allowed as they may cause damage to the

water heater’s internal components.

Draining the heater

Due to the shape of the heat exchangers and connecting

pipe, it is extremely difficult to get all of the water out of

the heater. Follow the procedure below to best minimize

the chance of freezing:

B Disconnect electric supply.

B Disconnect cold and hot water pipes from fittings on

bottom of heater. Allow water to drain out (have a

catch basin ready).

B After allowing all water to drain out, the heater should

be blown out with low pressure compressed air to

remove as much water as possible from water heater

modules. Bursts of air work better than continuous

flow.

Remember, these suggestions are only made to help

minimize the potential for freeze damage and are not to

be construed as the guaranteed method for dealing with

freeze possibilities.

Please follow these instructions. Failure to follow

instructions may result in:

• Damage or injury.

• Improper installation/operation.

• Loss of warranty.

4.1.1 Freeze prevention

WARNING:

B ELECTRICITY IS EXTREMELY

DANGEROUS. TAKE EXTRA

PRECAUTIONS AND ENSURE ALL

CIRCUIT BREAKERS ARE OFF BEFORE

PERFORMING ANY WORK TO THE

HEATER.

4.2 Installing the Tronic 3000C Pro

WARNING:

B Do not install the Tronic 3000C Pro in a

room where there is a chance of freezing.

NOTE:

B Read entire instructions.

B Check the pressure of the main water

supply.

To operate correctly the unit needs the following

running pressures:

Sink

• Min: 10 psi (0,7 bar)

• Max: 150 psi (10,3 bar)

6 720 647 005 (2011/09)

10 | Installation US

4.3 Water connections

B The unit should be connected directly to the main

cold water supply and not to pre- heated water. The

unit should be installed with service valves on both

the inlet and outlet. These valves can be used to turn

off the water supply to the unit if it needs servicing, or

to reduce the water flow if it is too high.

B We recommend that you use ½" copper or high

pressure flex connections.

B Use Teflon tape for sealing pipe threads. Do NOT use

pipe dope.

B Remember to keep the hot water pipe runs as short

as possible. In some cases it may be worth fitting a

second unit to serve an additional fixture.

B The inlet and outlet are clearly marked on the unit.

They each have a ½" NPT connector.

B If the unit is to supply a sink, we recommend that you

use aerators, which you can get from your local

distributor/dealer.

B If the unit is to supply more than one sink, the aerator

should be the same at each tap if they are to be used

at the same time. If not, one outlet will take all the

water.

B After the unit has been plumbed in, and before you

wire it, flush it with water to remove any debris or

loose particles. Failure to do so may make the unit

inoperable.

As a condition of installing this product in

the Commonwealth of Massachusetts a

pressure relief valve must be installed on

the cold water side by a licensed plumber.

MGL 42 Section 19.

Approval number: P1-09-25

4.3.1 Water quality

Water quality can have an impact on appliance longevity

and may not be covered under the manufacturer's

warranty.

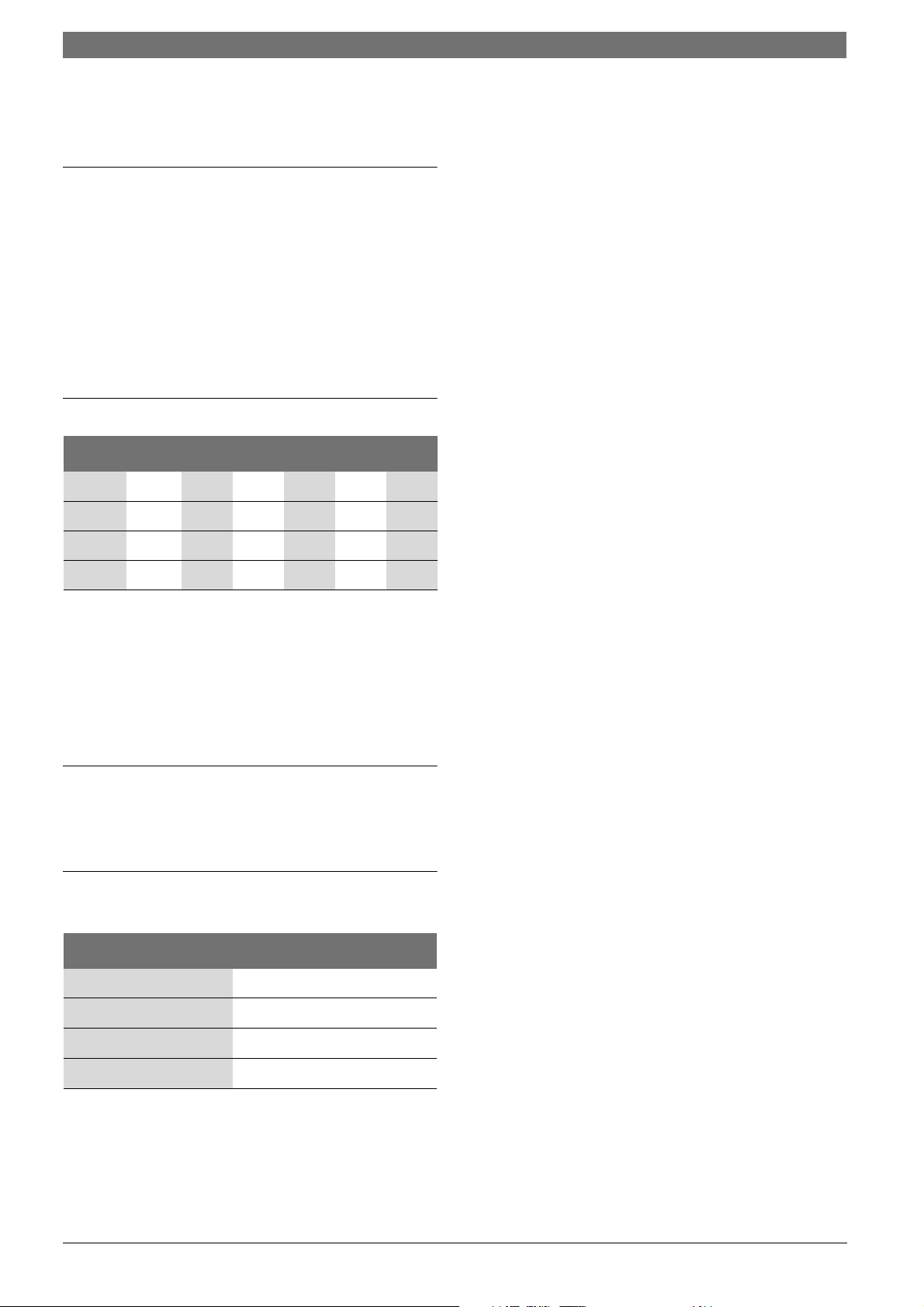

Description

Max. Levels

pH pH 6.5 - 8.5

TDS (total Dissolved

Solids)

Total hardness mg/l or ppm

mg/l or ppm 500

100

Aluminum mg/l or ppm 2.0

Chlorides mg/l or ppm 250

Copper mg/l or ppm 1.0

Iron mg/l or ppm 0.3

Manganese mg/l or ppm 0.05

Zinc mg/l or ppm 5.0

Table 5

4.4 Electrical connections

WARNING:

B The unit must be installed by a qualified

electrician.

B The unit must be grounded.

B Connect the unit to power.

Rated

Voltage

Model

US3 110 30 10

US6 277 25 10

US7 240 30 10

US9 208 35 8

US9 240 40 8

Table 6

(V)

Rated

Current

(A)

Recommen

d Wire Size

(AWG)

B For water analysis data call your local water

department, or if on a well, have well water analyzed

periodically.

If water quality exceeds one or more of the values

specified below, Bosch recommends consulting a

local water treatment professional for water

softening/conditioning options.

6 720 647 005 (2011/09)

NOTE:

When the Tronic 3000C Pro is not within

sight of the electrical circuit breakers, a

circuit breaker lockout or additional local

means of disconnection for all non

grounded conductors must be provided that

is within sight of the appliance. (REF NEC

422.31)

Installation | 11US

Rubber

Sleeve

Ground

Connecting the unit to power

B Strip back the insulation on the power wires about

3/8". Any insulation on the ground should be stripped

back about 3/4".

B Feed the cable through the cover bottom or backplate

rear entry grommets, as appropriate.

B Connect the cables to the terminal block and ground

stud (Fig. 4):

B Set the Power Selector Screw (Fig. 5) on the desired

setting. If it is set to LO, only one heating element will

operate and the output will be half power. See the

Table 4 on page 7 for temperature rise at various flow

rates. If the element is set on HI, both heating

elements will operate and the output will be full

power. When setting the Power Selector Screw, it is

important that the screw be adjusted all the way to

the end of the slot and that it be well tightened.

Fig. 4 Cable termination

B Make sure that all the terminal block screws are

tightened securely. Loose connections can cause

wires to heat up.

B Make sure that the ground wire is wrapped around its

terminal stud and into the saddle washer. The nut

should be tightened securely.

Fig. 5 Power selector screw

B Attach the front cover and tighten the retaining

screws.

6 720 647 005 (2011/09)

12 | Installation US

Cold

Hot

Hot

Front view

Hot

Cold

Cold

1

2

6720646914-07.1V

4.5 Securing the unit to the wall

4.5.1 Deciding the position

B If being used in a public place, position the unit out of

reach to discourage vandalism.

B Mount the unit onto a flat section of wall, well away

from any potential splashes of water or spray.

B Mount only as shown in Fig. 6 with the water

connections located either at bottom or the right side

of the unit.

Remember to keep the lengths of hot water pipe to a

minimum in order to save energy.

B If the unit is to supply a sink, you can fit it either above

or below the sink.

Fig. 6 Examples of installations

4.5.2 Deciding the wiring route

You have a choice of whether to feed the electric cable

through the cover bottom or through the back of the

unit,

B If it is going to be through the cover bottom, cut out

the plastic lug to expose the rubber sleeve (Fig. 7):

Fig. 7 Cover lug cut out

B If it is going through the back of the unit, cut through

the grommet on the backplate with a sharp knife.

Make sure that you do not remove the grommet from

the backplate (Fig. 8):

Fig. 8 Back of unit

1 Grommet

2 Fixing holes

B Feed the cable through the grommet before you

mount the unit to the wall. If you are using an

approved cable fitting, remove the grommet.

4.5.3 Mounting on the wall

B Undo the retaining screws on the cover and take the

cover of the unit. Hold the backdate in position

against the wall while you mark the four mounting

holes.

6 720 647 005 (2011/09)

B Drill the holes and secure the unit to the wall using

the four no. 8 wood screws supplied.

WARNING:

B Do not install a non-return check valve

within 6 feet of the inlet.

Installation | 13US

6 720 647 005 (2011/09)

14 | Starting up the Tronic 3000C Pro US

5 Starting up the Tronic 3000C Pro

WARNING:

B Do not use the unit if you think it may be

frozen, as this could result in serious

damage to the unit. Wait until you are

sure it has completely thawed out before

you switch it on.

5.1 Sink

WARNING:

Before turning on power:

B Open cold water shutoff valve to the unit

and turn on all hot water taps supplied by

the unit. Flow water out the tap(s) until

all air has purged from the unit and

plumbing.

B Check that the power is switched on at the circuit

breaker panel.

B Turn on the hot tap FULLY.

If you do not turn the tap full on, you will find that the

temperature of the water may vary. The hot water

temperature can then be set by adjusting the flow.

B The inlet service valve should not be used to regulate

temperature.

When using the hot water at a fixture, open

tap fully. To regulate hot water temperature,

adjust water flow accordingly as directed in

Section 5.2.

NOTE:

If the unit is servicing a single lever faucet

you may need to restrict the cold water

supply to the faucet to balance water

pressure and improve performance.

NOTE:

B Before leaving the site, the installer

should demonstrate the unit to the user

and give him/her this guide.

If the unit has been used recently:

B run the water through for a few seconds to let the

temperature settle down.

If the unit has been used recently, You may initially get

a short burst of very hot water from the unit.

If a second tap connected to the unit is also turned on,

the hot water will be shared between the two, therefore

the flow and/or the temperature of the water will

decrease.

5.2 Adjusting the flow

Checking for leaks

B Ensure the service valves are open and check that no

pipe joints leak.

B Turn on the hot tap fully at the sink.

B Adjust the outlet service valve until the water comes

out of the tap at the required temperature, (increase

flow for cooler, decrease for hotter). Refer to Table 4,

page 7 for expected temperature rise at given flow

rates.

B Check that the unit works correctly when the sink tap

is closed and then opened again; if not adjust the

service valve slightly.

6 720 647 005 (2011/09)

Troubleshooting | 15US

6 Troubleshooting

WARNING: Always switch off the electricity

supply to the unit before you remove the

cover.

If the problem persists:

The person who initially installed the unit is probably the best one to contact for help. You can also call Bosch

Thermotechnology Corporation at 800-798-8161 or visit www.bosch-climate.us. Please have this guide with you when

you call.

6.1 For the Installer

Symptom Cause What do do

Cold water only -neon light

off.

Water too cold -neon light

on.

Water flow too low, or

temperature too high.

Electricity not on. Check electrical supply.

The water supply is connected to

the OUTLET of the unit.

The high temperature thermal cut

out has tripped.

The flow switch is not working. Turn off the power and observe if the flow

Water flow too high. Adjust water flow (see Table 4).

The power selector screw not all

the way to “HI”.

One element is not working. Switch off the electricity and check the

The power supply voltage has

dropped.

There are restrictions in the

plumbing.

Reconnect the water supply to the INLET

(marked in blue).

Reset it by opening the unit and pushing the

button on the cut out (Fig. 3). Before you do

this you must find the cause of the problem.

switch activates when the water is turned on.

If not contact Bosch Thermotechnology 800798-8161 www.bosch-climate.us

Change the power select screw to “HI”, see

Fig. 5.

resistance of the elements (see Table 4).

Check the supply voltage to the heater (see

Table 4).

Check the plumbing. Only use Teflon tape for

sealing pipe joints.

Table 7

6 720 647 005 (2011/09)

Loading...

Loading...