Page 1

OBJ_BUCH-1466-004.book Page 1 Wednesday, December 16, 2015 2:04 PM

Robert Bosch Power Tools GmbH

70538 Stuttgart

GERMANY

www.bosch-pt.com

TSH 5000 Plus Professional

1 609 92A 2G8 (2014.10) O / 7

cn 正本使用说明书

Page 2

1

TSH 5000 Plus

4

5

5

2

3

6

6

OBJ_BUCH-1466-004.book Page 2 Wednesday, December 16, 2015 1:47 PM

2 |

1 609 92A 2G8 | (16.12.15) Bosch Power Tools

Page 3

B

A

2 608 684 884

Hex 17 mm

2 608 684 885

2

2

OBJ_BUCH-1466-004.book Page 3 Wednesday, December 16, 2015 1:47 PM

| 3

Bosch Power Tools 1 609 92A 2G8 | (16.12.15)

Page 4

OBJ_BUCH-1466-004.book Page 4 Wednesday, December 16, 2015 1:47 PM

4 | 中文

在电动工具接通之前,拿掉所有调节钥匙或扳手。

中文

安全规章

电动工具通用安全警告

阅读所有警告和所有说明 ! 不遵照以下警

警告!

告和说明会导致电击、着火和/或严重伤

害。

保存所有警告和说明书以备查阅。

在所有下列的警告中术语 " 电动工具 " 指市电驱动

(有线)电动工具或电池驱动 (无线)电动工具。

工作场地的安全

保持工作场地清洁和明亮。 混乱和黑暗的场地会引

发事故。

不要在易爆环境,如有易燃液体、气体或粉尘的环

境下操作电动工具。 电动工具产生的火花会点燃粉

尘或气体。

让儿童和旁观者离开后操作电动工具。 注意力不集

中会使操作者失去对工具的控制。

电气安全

电动工具插头必须与插座相配。绝不能以任何方式

改装插头。需接地的电动工具不能使用任何转换插

头。 未经改装的插头和相配的插座将减少电击危

险。

避免人体接触接地表面,如管道、散热片和冰箱。

如果你身体接地会增加电击危险。

不得将电动工具暴露在雨中或潮湿环境中。 水进入

电动工具将增加电击危险。

不得滥用电线。绝不能用电线搬运、拉动电动工具

或拔出其插头。使电线远离热源、油、锐边或运动

部件。 受损或缠绕的软线会增加电击危险。

当在户外使用电动工具时,使用适合户外使用的外

接软线。 适合户外使用的软线将减少电击危险。

如果在潮湿环境下操作电动工具是不可避免的,应

使用剩余电流动作保护器 (RCD)。 使用 RCD 可减

小电击危险。

人身安全

保持警觉,当操作电动工具时关注所从事的操作并

保持清醒。当你感到疲倦,或在有药物、酒精或治

疗反应时,不要操作电动工具。 在操作电动工具时

瞬间的疏忽会导致严重人身伤害。

使用个人防护装置。始终佩戴护目镜。 安全装置,

诸如适当条件下使用防尘面具、防滑安全鞋、安全

帽、听力防护等装置能减少人身伤害。

防止意外起动。确保开关在连接电源和 / 或电池

盒、拿起或搬运工具时处于关断位置。 手指放在已

接通电源的开关上或开关处于接通时插入插头可能

会导致危险。

1 609 92A 2G8 | (16.12.15) Bosch Power Tools

遗留在电动工具旋转零件上的扳手或钥匙会导致人

身伤害。

手不要伸展得太长。时刻注意立足点和身体平衡。

这样在意外情况下能很好地控制电动工具。

着装适当。不要穿宽松衣服或佩戴饰品。让衣服、

手套和头发远离运动部件。 宽松衣服、佩饰或长发

可能会卷入运动部件中。

如果提供了与排屑、集尘设备连接用的装置,要确

保他们连接完好且使用得当。 使用这些装置可减少

尘屑引起的危险。

电动工具使用和注意事项

不要滥用电动工具,根据用途使用适当的电动工

具。 选用适当设计的电动工具会使你工作更有效、

更安全。

如果开关不能接通或关断工具电源,则不能使用该

电动工具。 不能用开关来控制的电动工具是危险的

且必须进行修理。

在进行任何调节、更换附件或贮存电动工具之前,

必须从电源上拔掉插头和 / 或使电池盒与工具脱

开。 这种防护性措施将减少工具意外起动的危险。

将闲置不用的电动工具贮存在儿童所及范围之外,

并且不要让不熟悉电动工具或对这些说明不了解的

人操作电动工具。

是危险的。

保养电动工具。检查运动件是否调整到位或卡住,

检查零件破损情况和影响电动工具运行的其他状

况。如有损坏,电动工具应在使用前修理好。 许多

事故由维护不良的电动工具引发。

保持切削刀具锋利和清洁。 保养良好的有锋利切削

刃的刀具不易卡住而且容易控制。

按照使用说明书,考虑作业条件和进行的作业来使

用电动工具、附件和工具的刀头等。 将电动工具用

于那些与其用途不符的操作可能会导致危险。

维修

将你的电动工具送交专业维修人员,使用同样的备

件进行修理。 这样将确保所维修的电动工具的安全

性。

电动工具在未经培训的用户手中

锤类工具的安全警告

戴好耳罩。 暴露在噪声中会引起听力损伤。

使用随工具提供的辅助手柄。 操作失手会引起人身

伤害。

在切削附件可能触及暗线或其自身软线之处进行操

作时,要通过绝缘握持面来握持工具。 切削附件碰

到带电导线会使工具外露的金属零件带电从而使操

作者受到电击。

Page 5

OBJ_BUCH-1466-004.book Page 5 Wednesday, December 16, 2015 1:47 PM

使用合适的侦测装置侦察隐藏的电线,或者向当地

的相关单位寻求支援。 接触电线可能引起火灾並让

操作者触电。损坏了瓦斯管会引起爆炸。凿穿水管

不仅会造成严重的财物损失,也可能导致触电。

工作时必须用双手握紧电动工具,並且要确保立足

稳固。 使用双手比较能够握稳电动工具。

固定好工件。 使用固定装置或老虎钳固定工件,会

比用手持握工件更牢固。

等待电动工具完全静止后才能够放下机器。 机器上

的工具可能在工作中被夹住,而令您无法控制电动

工具。

产品和功率描述

阅读所有的警告提示和指示。 如未确实

遵循警告提示和指示,可能导致电击,

火灾并且 / 或其他的严重伤害。

按照规定使用机器

本机器适合在混凝土、砖头、石材和沥青上凿削。安

装了合适的附件后,也可以使用机器进行挤压和捣实

作业。

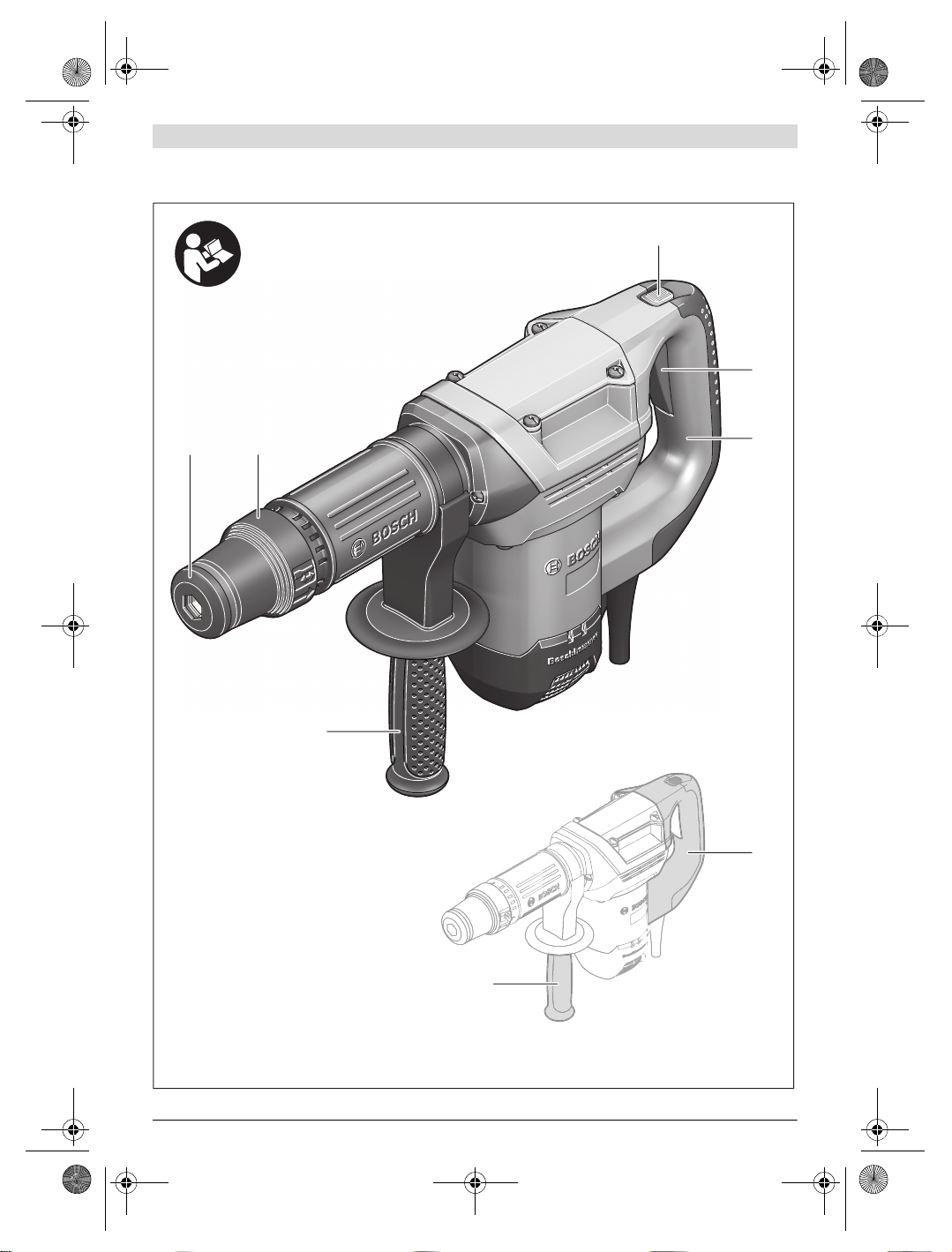

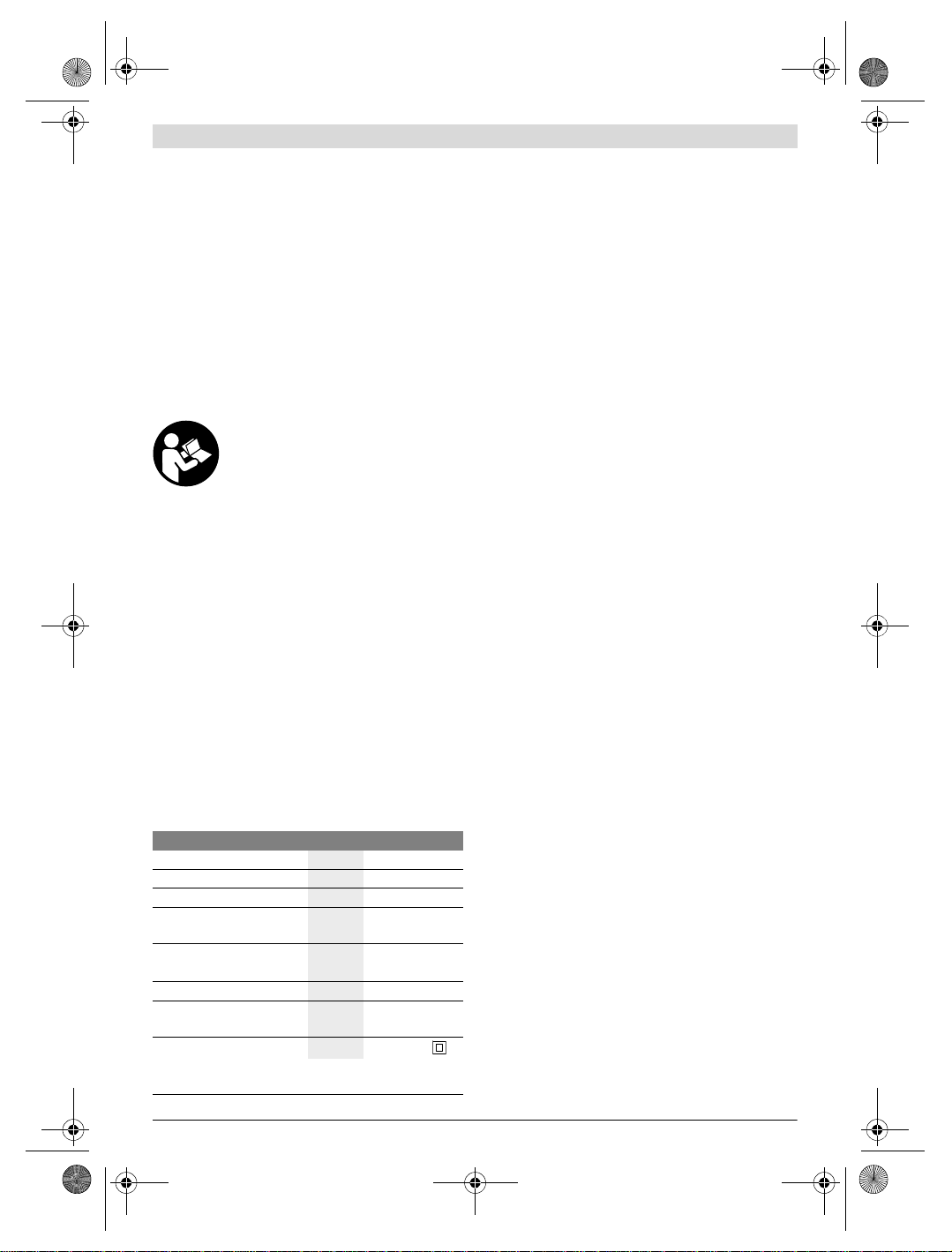

插图上的机件

机件的编号和电动工具详解图上的编号一致。

1 防尘盖

2 锁定套筒

3 起停开关的锁紧键

4 起停开关

5 手柄 (绝缘握柄)

6 辅助手柄 (绝缘握柄)

图表或说明上提到的附件,并不包含在基本的供货范围中。

本公司的附件清单中有完整的附件供应项目。

技术数据

电镐 TSH 5000 Plus

物品代码

额定输入功率

冲击次数 次 / 分 2750

单一冲击强度苻合 EPTAProcedure 05/2009 的规定

工具夹头

润滑

重量符合 EPTA-Procedure

01/2003

绝缘等级

本说明书提供的参数是以 230 V 为依据,于低电压地区,此数据

有可能不同。

3 611 C38 180

瓦

焦耳 6,8

17 毫米

油脂润滑

公斤

安装

维修电动工具或换装零、配件之前,务必从插座上

拔出插头。

辅助手柄

操作电动工具时务必使用辅助手柄 6。

您可以根据需要改变辅助手柄 6 的位置,以提高工作

安全和增加工作的舒适性。

– 朝著逆时针方向转动辅助手柄 6。把辅助手柄 6 摆

动到需要的位置。接著再朝顺时针方向转紧辅助手

柄 6。

更换工具

使用 Hex 工具接头,能够简便地更换凿具,无需借助

其它的辅助工具。

防尘盖 1 可以防止工作时凿削废尘侵入夹头中。安装

工具时必须小心,勿损坏防尘盖 1。

如果防尘盖坏损了必须马上更换。 最好委托本公司

的顾客服务处换装。

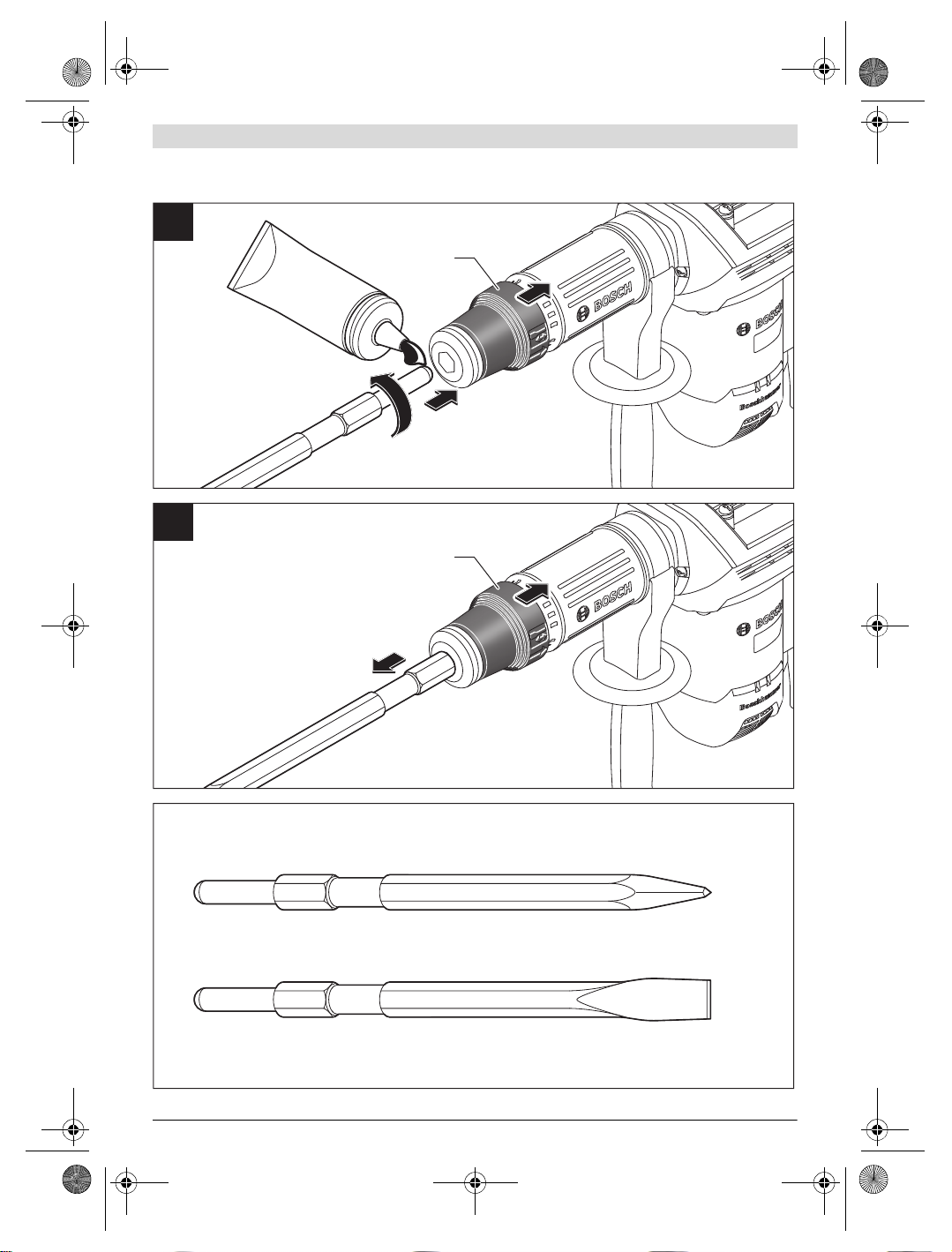

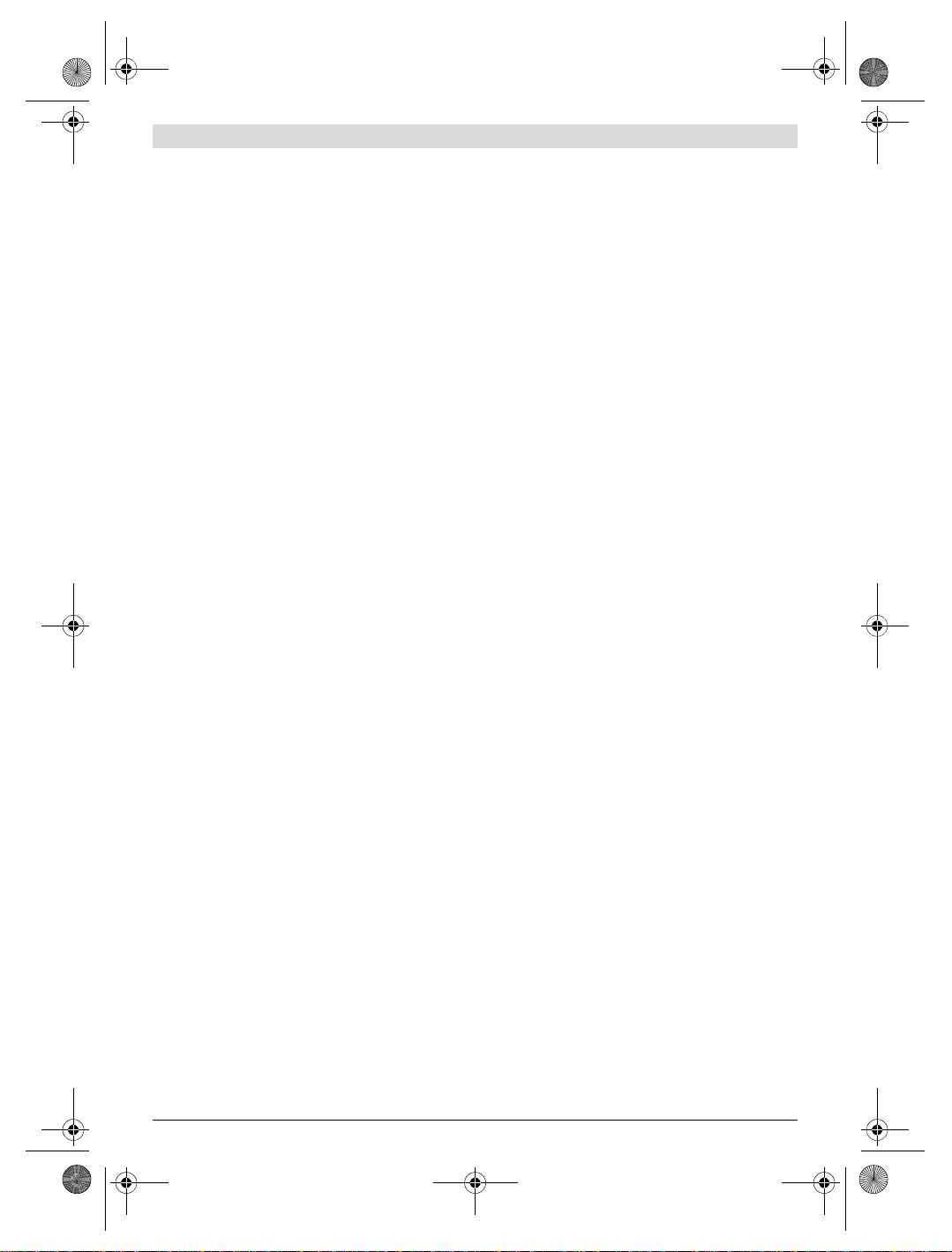

安装工具 (参考插图 A)

– 清洁工具柄並在柄上塗少许润滑脂。

– 向后推移锁定套筒 2,把工具拧入工具夹头中。 放

开锁定套筒 2 以便锁牢工具。

– 抽拉工具以确定它是否正确锁紧了。

拆卸工具 (参考插图 B)

– 向后推移锁定套筒 2 並取出工具。

吸锯尘 / 吸锯屑

含铅的颜料以及某些木材、矿物和金属的加工废尘

有害健康。机器操作者或者工地附近的人如果接

触、吸入这些废尘,可能会有过敏反应或者感染呼

吸道疾病。

某些尘埃 (例如加工橡木或山毛榉的废尘)可能致

癌,特别是和处理木材的添加剂 (例如木材的防腐

剂等)结合之后。只有经过专业训练的人才能够加

工含石棉的物料。

1025

– 工作场所要保持空气流通。

– 最好佩戴 P2 滤网等级的口罩。

请留心并遵守贵国和加工物料有关的法规。

操作

Hex

操作机器

注意电源的电压!电源的电压必须和电动工具铭牌

5,5

/II

上标示的电压一致。

为了节约能源,只在当您要使用机器时,才开动电动

工具。

中文 | 5

Bosch Power Tools 1 609 92A 2G8 | (16.12.15)

Page 6

OBJ_BUCH-1466-004.book Page 6 Wednesday, December 16, 2015 1:47 PM

6 | 中文

开动 / 关闭

– 操作电动工具时先按下电动工具的起停开关 4,并

持续按着。

– 按下锁紧键 3 即可锁定被按住的起停开关 4。

– 放开起停开关 4 即可关闭电动工具。如果起停开关

被锁紧键 3 固定了,先按下起停开关 4 並随即将

其放开。

在低温的工作环境中,必须经过短暂的暖机,电动工

具才能够发挥最大的冲击功率。

把安装在电动工具上的凿头轻撞地面,可缩短暖机的

起动时间。

有关操作方式的指点

维修电动工具或换装零、配件之前,务必从插座上

拔出插头。

磨利凿具

使用锋利的凿具才能够达到好的工作效果,务必及时

研磨凿具,如此才能够延长凿具的使用寿命,加强工

作效果。

补磨

在磨片 (例如白刚玉)上研磨凿具,并使用均匀的水

流 冲刷。注意,刀刃上不可以出现回火色;如此会影

响凿具的硬度。

锻造,先将凿头加热至摄氏 850 度与 1050 度之间

(淡红至黄色)。

硬化 过程,先把凿头加热至摄氏 900 度,再将凿头

放入油中淬火,紧接著把凿头放入火炉中以摄氏

320 度回火一个小时 (回火色为淡蓝)。

维修和服务

维修和清洁

维修电动工具或换装零、配件之前,务必从插座上

拔出插头。

电动工具和通风间隙都必须保持清洁,这样才能够

提高工作品质和安全性。

如果防尘盖坏损了必须马上更换。 最好委托本公司

的顾客服务处换装。

如果必须更换连接线,务必把这项工作交给博世或者

经授权的博世电动工具顾客服务执行,以避免危害机

器的安全性能。

润滑电动工具

本电动工具是采用油脂润滑。更换润滑油脂只能在维

护或修理机器时进行,而且必须交给经过授权的博世

电动工具顾客服务中心执行。只能使用针对本机器的

博世润滑油脂。

顾客服务处和顾客咨询中心

询问和订购备件时,务必提供机器铭牌上标示的

10 位数物品代码。

本公司顾客服务处负责回答有关本公司产品的修理,

维护和备件的问题。以下的网页中有爆炸图和备件的

资料 :

www.bosch-pt.com

博世顾客咨询团队非常乐意为您解答有关本公司产品

及附件的问题。

有关保证,维修或更换零件事宜,请向合格的经销商

查询。

中国大陆

博世电动工具 (中国)有限公司

中国 浙江省 杭州市

滨江区滨康路 567 号

邮政编码:310052

免费服务热线: 4008268484

传真:(0571) 87774502

电邮:contact.ptcn@cn.bosch.com

www.bosch-pt.com.cn

羅伯特 博世有限公司

香港北角英皇道 625 號 21 樓

客戶服務熱線:+852 2101 0235

傳真:+852 2590 9762

電郵:info@hk.bosch.com

網站:www.bosch-pt.com.hk

制造商地址:

Robert Bosch Power Tools GmbH

罗伯特 · 博世电动工具有限公司

70538 Stuttgart / GERMANY

70538 斯图加特 / 德国

处理废弃物

必须以符合环保的方式,回收再利用损坏的机器、附

件和废弃的包装材料。

不可以把电动工具丢入家庭垃圾中 !

保留修改权。

1 609 92A 2G8 | (16.12.15) Bosch Power Tools

Page 7

OBJ_BUCH-1466-004.book Page 1 Wednesday, December 16, 2015 1:47 PM

| 1

Bosch Power Tools 1 609 92A 2G8 | (16.12.15)

Page 8

WARNING

OBJ_BUCH-1466-004.book Page 2 Wednesday, December 16, 2015 1:47 PM

2 | English

Prevent unintentional starting. Ensure the switch is in

English

Safety Notes

General Power Tool Safety Warnings

Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-opera ted (cordless)

power tool.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ig nite the dust

or fumes.

Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges and moving parts. Damaged

or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord s uitable

for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoid-

able, use a residual current device (RCD) protected

supply. Use of an RCD reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while op-

erating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

1 609 92A 2G8 | (16.12.15) Bosch Power Tools

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a ro-

tating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

Dress properly. Do not wear loose clothing or jewel-

lery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-

duce dust-related hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the

job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation.

If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power

tools.

Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

Use the power tool, accessories and tool bits etc. in ac-

cordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified repair per-

son using only identical replacement parts. This will en-

sure that the safety of the power tool is maintained.

Page 9

OBJ_BUCH-1466-004.book Page 3 Wednesday, December 16, 2015 1:47 PM

Hammer Safety Warnings

Wear ear protectors. Exposure to noise can cause hear-

ing loss.

Use auxiliary handle(s), if supplied with the tool. Loss

of control can cause personal injury.

Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting ac-

cessory contacting a “live” wire may make exposed metal

parts of the power tool “live” and could give the operator an

electric shock.

Use suitable detectors to determine if utility lines are

hid den in th e wo rk ar ea o r call the local utility company

for assistance. Contact with electric lines can lead to fire

and electric shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property damage or

may cause an electric shock.

When working with the machine, always hold it firmly

with both hands and provide for a secure stance. The

power tool is guided more secure with both hands.

Secure the workpiece. A workpiece clamped with clamp-

ing devices or in a vice is held more secure than by hand.

Always wait until the machine has come to a complete

stop before placing it down. The tool insert can jam and

lead to loss of control over the power tool.

Products sold in GB only: Your product is fitted with a

BS 1363/A approved electric plug with internal fuse (ASTA

approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug should

have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains socket elsewhere.

Products sold in AUS and NZ only: Use a residual current device (RCD) with a rated residual current of 30 mA or less.

Product Description and Specifications

Read all safety warnings and all instructions. Failure to follow the warnings and in-

structions may result in electric shock, fire

and/or serious injury.

Intended Use

The machine is intended for chiselling work in concrete, brick,

masonry and asphalt as well as for driving in and compacting,

when using the respective accessories.

Product Features

The numbering of the product features refers to the illustration of the machine on the graphics page.

1 Dust protection cap

2 Locking sleeve

3 Lock-on button for On/Off switch

4 On/Off switch

5 Handle (insulated gripping surface)

6 Auxiliary handle (insulated gripping surface)

Accessories shown or described are not part of the st andard delivery scope of the product. A complete overview of accessories can

be found in our accessories program.

Technical Data

Demolition Hammer TSH 5000 Plus

Article number

Rated power input

Impact rate

Impact energy per stroke

according to EPTA-Procedure

05/2009

Tool holder

Lubrication

Weight according to

EPTA-Procedure 01/2003 kg 5.5

Protection class

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

Assembly

Before any work on the machine itself, pull the mains

plug.

Auxiliary Handle

Operate your machine only with the auxiliary handle 6.

The auxiliary handle 6 can be set to any position for a secure

and low-fatigue working posture.

– Turn the bottom part of the auxiliary handle 6 in counter-

clockwise direction and swivel the auxiliary handle 6 to the

desired position. Then retighten the bottom part of the

auxiliary handle 6 by turning in clockwise direction.

Changing the Tool

The Hex tool holder allows for simple and convenient tool-free

changing of the application tool.

The dust protection cap 1 largely prevents the entry of drilling

dust into the tool holder during operation. When inserting the

tool, take care that the dust protection cap 1 is not damaged.

A damaged dust protection cap should be changed im-

mediately. We recommend having this carried out by

an after-sales service.

Inserting (see figure A)

– Clean and lightly grease the shank end of the tool.

– Push back the locking sleeve 2 and insert the tool in a twist-

ing manner into the tool holder. Release the locking sleeve

2 again in order to lock the tool.

– Check the latching by pulling the tool.

English | 3

3 611 C38 180

W1025

-1

min

J6.8

Grease lubrication

2750

17 mm

Hex

/II

Bosch Power Tools 1 609 92A 2G8 | (16.12.15)

Page 10

OBJ_BUCH-1466-004.book Page 4 Wednesday, December 16, 2015 1:47 PM

4 | English

Removing (see figure B)

– Push back the locking sleeve 2 and remove the tool.

Dust/Chip Extraction

Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treatment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the materials to be worked.

Operation

Starting Operation

Observe correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

To save energy, only switch the power tool on when using it.

Switching On and Off

–To start the machine, press the On/Off switch 4 and keep

it pressed.

– To lock the pressed On/Off switch 4, press the lock-on

button 3.

–To switch off the machine, release the On/Off switch 4 or

when it is locked with the lock-on button 3, briefly press

the On/Off switch 4 and then release it.

For low temperatures, the machine reaches the full impact

rate only after a certain time.

This start-up time can be shortened by striking the chisel in

the machine against the floor one time.

Working Advice

Before any work on the machine itself, pull the mains

plug.

Sharpening Chisels

Good results are only achieved with sharp chisels; therefore,

sharpen the chiselling tools in good time. This ensures a long

service life of the tools and good working performance.

Re-sharpening

Sharpen chiselling tools using grinding wheels (e. g. ceramic

bonded corundum wheel) with a steady supply of water. Take

care that no annealing coloration appears on the cutting edges; this impairs the hardness of the chiselling tools.

For forging, heat the chisel to between 850 and 1050 °C

(bright red to yellow).

For hardening, heat the chisel to approx. 900 ° C and quench

in oil. Then anneal in an oven for approx. one hour at 320 ° C

(annealing colour = light blue).

Maintenance and Service

Maintenance and Cleaning

Before any work on the machine itself, pull the mains

plug.

For safe and proper working, always keep the machine

and ventilation slots clean.

A damaged dust protection cap should be changed im-

mediately. We recommend having this carried out by

an after-sales service.

If the replacement of the supply cord is nece ssary, this has to

be done by Bosch or an authorized Bosch service agent in order to avoid a safety hazard.

Power Tool Lubrication

The power tool is grease-lubricated. Replacement of the lubricating grease is required only during maintenance or repair

through an authorised customer services agent for Bosch

power tools. Here, it is essential that the specified Bosch lubricating grease is used.

After-sales Service and Application Service

In all correspondence and spare parts order, please always include the 10-digit article number given on the type plate of

the machine.

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can also be found under:

www.bosch-pt.com

Bosch’s application service team will gladly answer questions

concerning our products and their accessories.

People’s Republic of China

China Mainland

Bosch Power Tools (China) Co., Ltd.

567, Bin Kang Road

Bin Jiang District 310052

Hangzhou, P.R. China

Service Hotline: 4008268484

Fax: (0571) 87774502

E-Mail: contact.ptcn@cn.bosch.com

www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Hong Kong Co. Ltd.

21st Floor, 625 King’s Road

North Point, Hong Kong

Customer Service Hotline: +852 2101 0235

Fax: +852 2590 9762

E-Mail: info@hk.bosch.com

www.bosch-pt.com.hk

1 609 92A 2G8 | (16.12.15) Bosch Power Tools

Page 11

OBJ_BUCH-1466-004.book Page 5 Wednesday, December 16, 2015 1:47 PM

Indonesia

PT Robert Bosch

Palma Tower 9

th

& 10th Floor

Jl. Let. Jend. TB Simatupang II S/06

Jakarta Selatan 12960

Indonesia

Tel.: (021) 3005 6565

Fax: (021) 30 05 5801

E-Mail: boschpowertools@id.bosch.com

www.bosch-pt.co.id

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers,

3rd Avenue corner 31st Street,

Fort Bonifacio Global City,

1634 Taguig City, Philippines

Tel.: (02) 8703871

Fax: (02) 8703870

matheus.contiero@ph.bosch.com

www.bosch-pt.com.ph

Bosch Service Center:

9725-27 Kamagong Street

San Antonio Village

Makati City, Philippines

Tel.: (02) 8999091

Fax: (02) 8976432

rosalie.dagdagan@ph.bosch.com

Malaysia

Robert Bosch (S.E.A.) Sdn. Bhd.

No. 8A, Jalan 13/6

G.P.O. Box 10818

46200 Petaling Jaya

Selangor, Malaysia

Tel.: (03) 79663194

Fax: (03) 79583838

cheehoe.on@my.bosch.com

Toll-Free: 1800 880188

www.bosch-pt.com.my

Thailand

Robert Bosch Ltd.

Liberty Square Building

No. 287, 11 Floor

Silom Road, Bangrak

Bangkok 10500

Tel.: 02 6393111, 02 6393118

Fax: 02 2384783

Robert Bosch Ltd., P. O. Box 2054

Bangkok 10501, Thailand

www.bosch.co.th

Bosch Service – Training Centre

La Salle Tower Ground Floor Unit No.2

10/11 La Salle Moo 16

Srinakharin Road

Bangkaew, Bang Plee

Samutprakarn 10540

Thailand

Tel.: 02 7587555

Fax: 02 7587525

Singapore

Robert Bosch (SEA) Pte. Ltd.

11 Bishan Street 21

Singapore 573943

Tel.: 6571 2772

Fax: 6350 5315

leongheng.leow@sg.bosch.com

Toll-Free: 1800 3338333

www.bosch-pt.com.sg

Vietnam

Robert Bosch Vietnam Co. Ltd

10/F, 194 Golden Building

473 Dien Bien Phu Street

Ward 25, Binh Thanh District

84 Ho Chi Minh City

Vietnam

Tel.: (08) 6258 3690 ext. 413

Fax: (08) 6258 3692

hieu.lagia@vn.bosch.com

www.bosch-pt.com

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: (01300) 307044

Fax: (01300) 307045

Inside New Zealand:

Phone: (0800) 543353

Fax: (0800) 428570

Outside AU and NZ:

Phone: +61 3 95415555

www.bosch.com.au

Disposal

The machine, accessories and packaging should be sor ted for

environmental-friendly recycling.

Do not dispose of power tools into household waste!

Subject to change without notice.

English | 5

Bosch Power Tools 1 609 92A 2G8 | (16.12.15)

Loading...

Loading...