Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

TS2000

Call Toll Free

for Consumer Information

& Service Locations

Pour tous renseignements

et pour obtenir la liste des

centres de service après-

vente, appelez le

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Parlez-vous français? ¿Habla español?

See page 2

Voir page 10

Ver página 18

Page 2

Safety Instructions

!

WARNING

follow all instructions listed below may result

in serious personal injury.

Fully assemble and tighten all the

fasteners required for this stand. Also

remember to occasionally check the

stand and make sure it is still tight.

loose stand is unstable and may shift in use

and cause serious injury.

Turn tool switch off and disconnect power

before mounting to the stand.

startup during assembly can cause injury.

Read and understand all

instructions.

Failure to

Unintended

Pre-Assembly

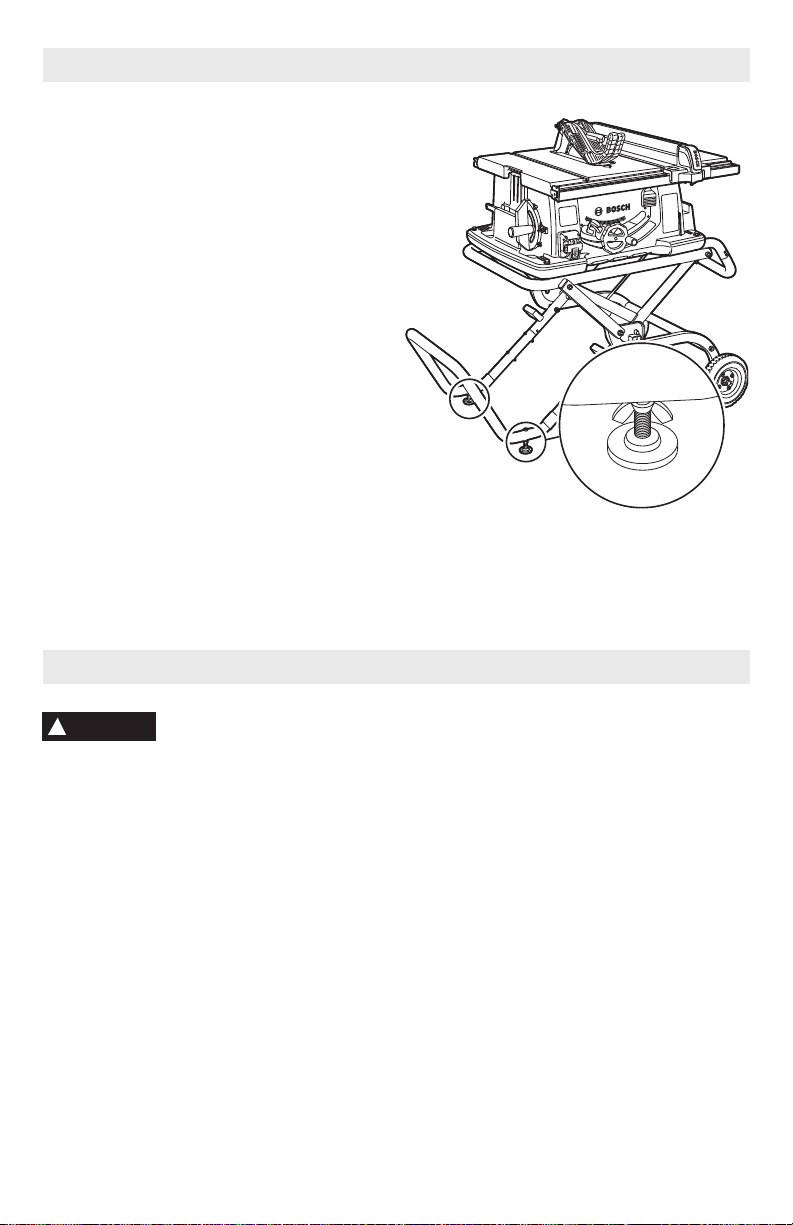

You have purchased a Bosch Table Saw

Stand TS2000. Designed for job site use, this

unit sets up and folds quickly, and is easily

loaded or unloaded by one person into a

truck.

For use with the following table saws:

Bosch 4100/4000, Dewalt DW744,

Craftsman 21830, and Makita 2704.

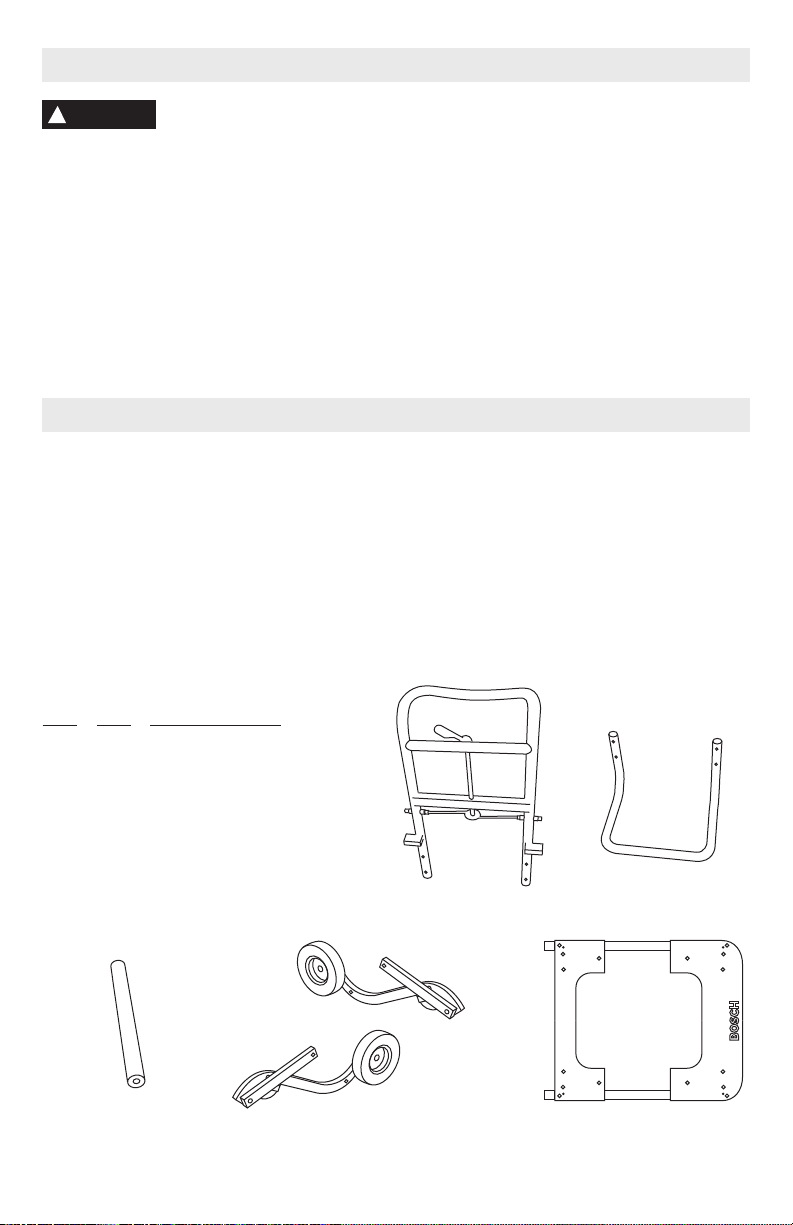

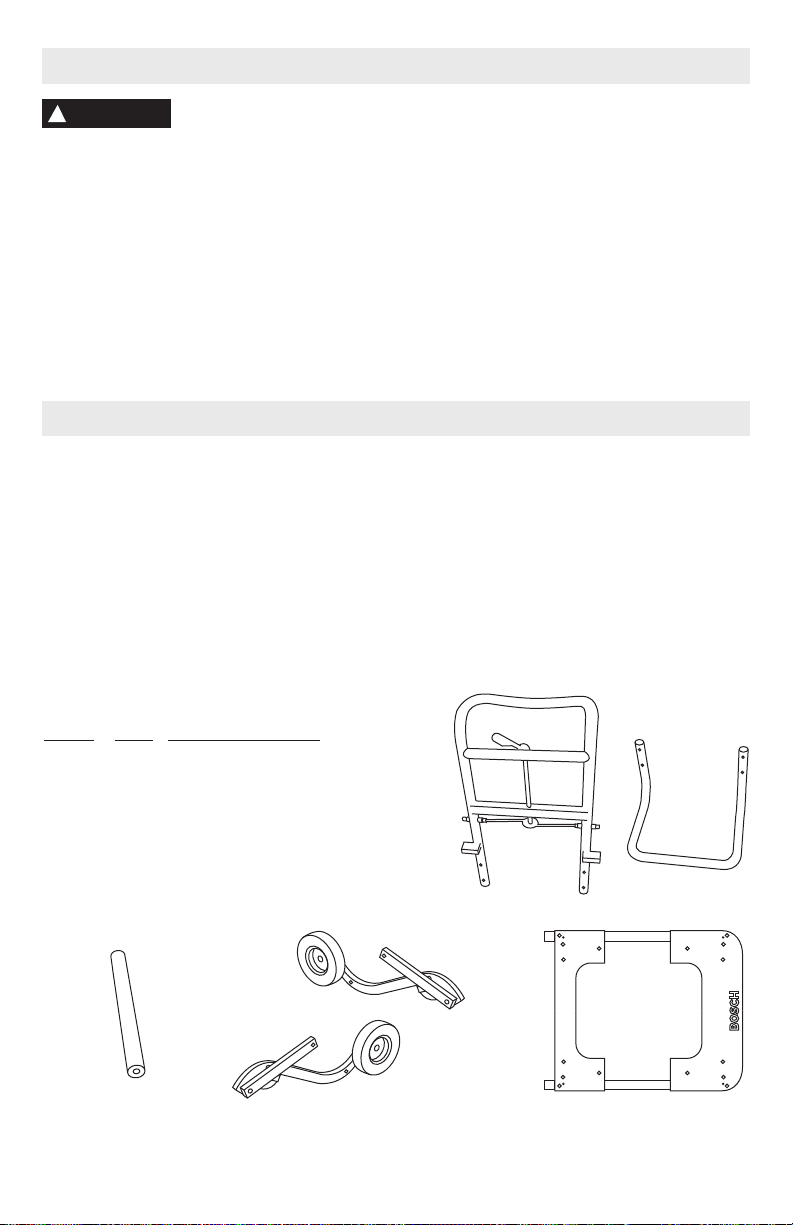

TS2000 TABLE SAW STAND

PACKAGE CONTENTS:

Qty. Part Description

Item

A (1) Upper Cross Bar

B (1) Lower Cross Bar

C (1) Kickback Bar

D (1) Right Leg/Wheel Assembly

E (1) Left Leg/Wheel Assembly

F (1) Table Top

Before operating make sure the entire unit

is placed on a solid, flat, level surface.

Serious injury could occur if tool is unstable

and tips.

Never stand on tool or its stand or use as

ladder or scaffolding.

occur if the tool is tipped or the cutting tool is

accidentally contacted. Do not store

A

materials on or near the tool such that it is

necessary to stand on the tool or its stand to

reach them.

Use only Bosch replacement parts. Any

others may create a hazard.

Phillips screwdriver, 10 MM open end

wrench, 16 MM open end wrench, or

adjustable wrench.

Sort out and account for all parts to make

sure that you have all necessary materials to

assemble your stand. Do not discard packing

material until all parts are accounted for.

TOOLS REQUIRED:

BEFORE YOU ASSEMBLE THIS

TABLE SAW STAND:

A

Serious injury could

B

E

C

D

-

2

-

F

Page 3

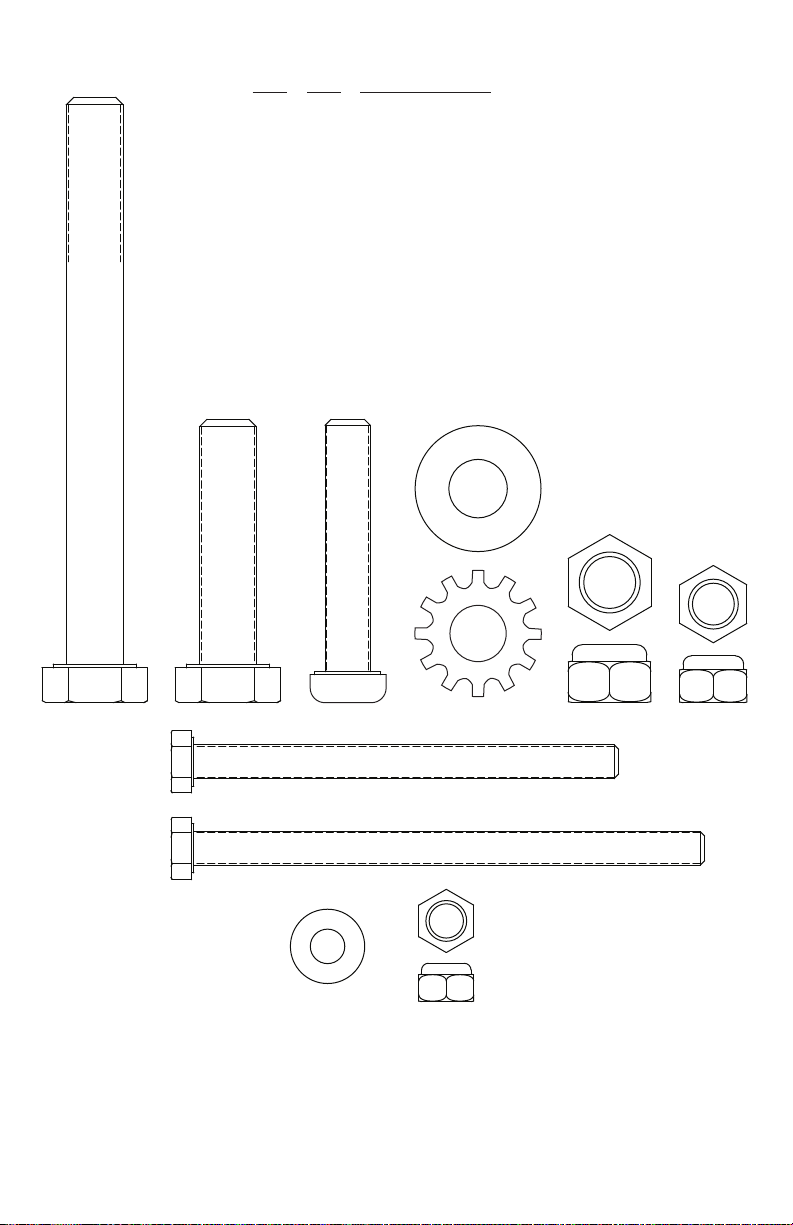

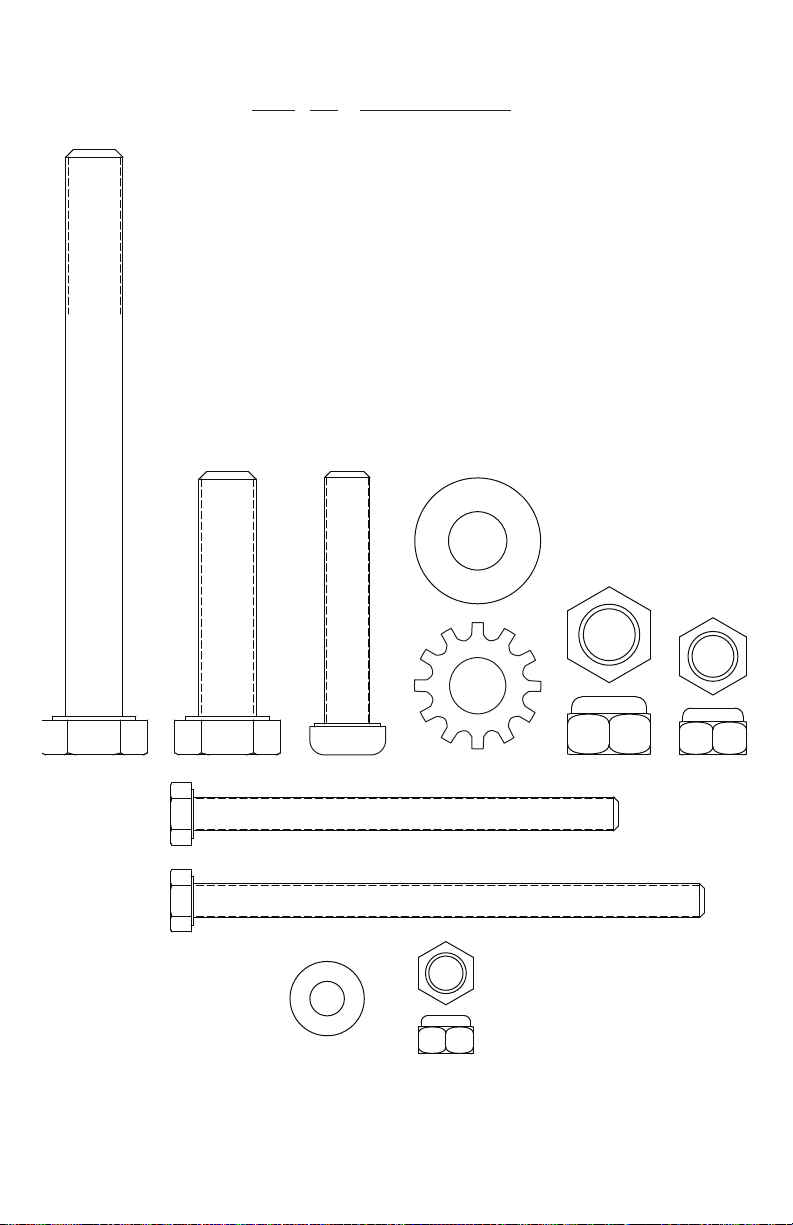

STAND ASSEMBLY HARDWARE

Qty. Part Description

Item

G 6 10mm x 100mm Hex Head Bolts

H 2 10mm x 50 mm Hex Head Bolts

I 6 8mm x 50 mm Phillips Head Screws

J 22 10mm Flat Washers

K 2 10mm Star Washers

L 8 10mm Lock Nuts

M 6 8mm Lock Nuts*

N 4 6mm x 75mm Hex Head Bolt (4000 Table Saw)

O 4 6mm x 90mm Hex Head Bolt (4100 Table Saw)

P 8 6mm Flat Washer

Q 4 6mm Lock Nuts

GHI

J

L

M

K

N

O

P

Q

*Note: There are two (2) 8mm x 50mm Phillips head screws and two (2) 8mm lock nuts to be

used only when attaching other branded table saws to the Bosch TS2000 stand. See page 7

for instructions.

-3-

Page 4

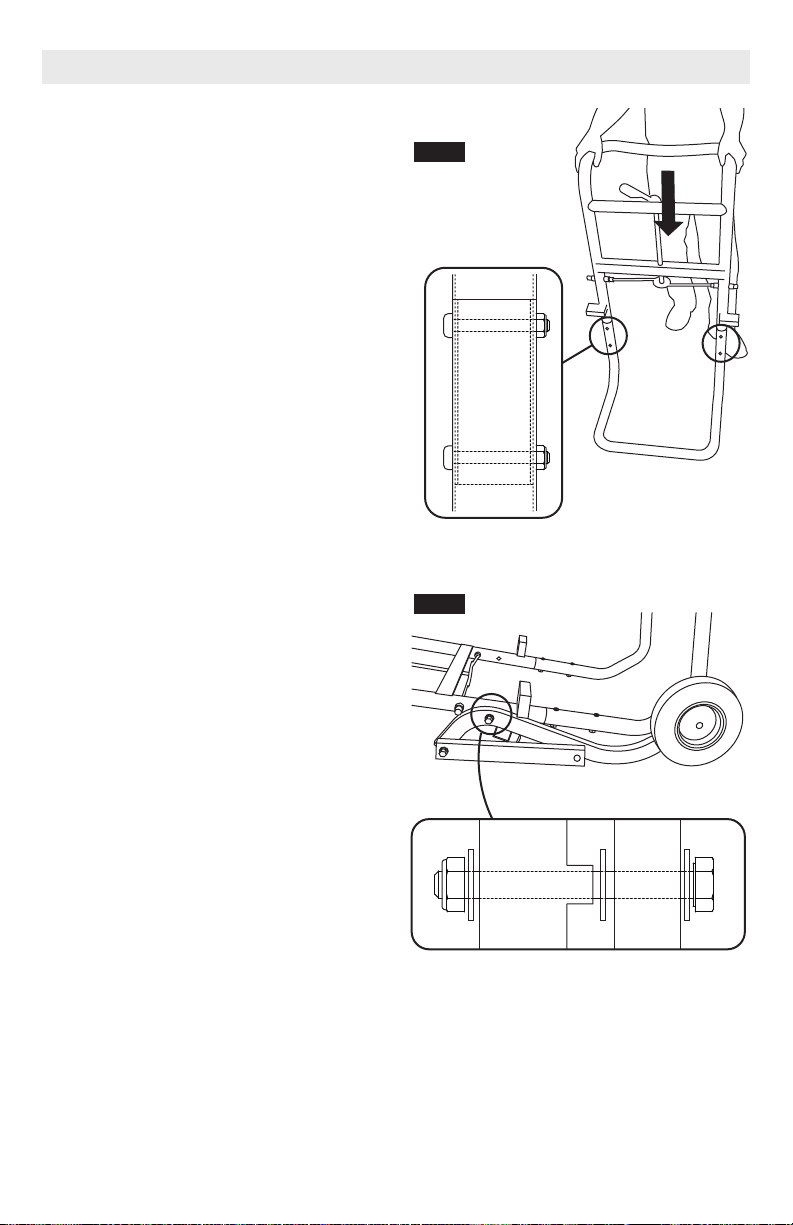

Assembly

Upper

Cross Bar

Leg/Wheel

Assembly

Washer WasherWasher

BoltLock Nut

Step 1

Attach Upper and Lower Cross Bars

1. Position lower cross bar on a flat surface

as shown in figure A.

2. Insert ends of upper cross bar into the

lower cross bar and push downward as far

as it will go.

3. Insert four (4) 8 mm x 50 mm Phillips Head

Screws through the holes of the upper and

lower cross bars, and securely tighten with

four (4) 8 mm lock nuts as shown.

FIG. A

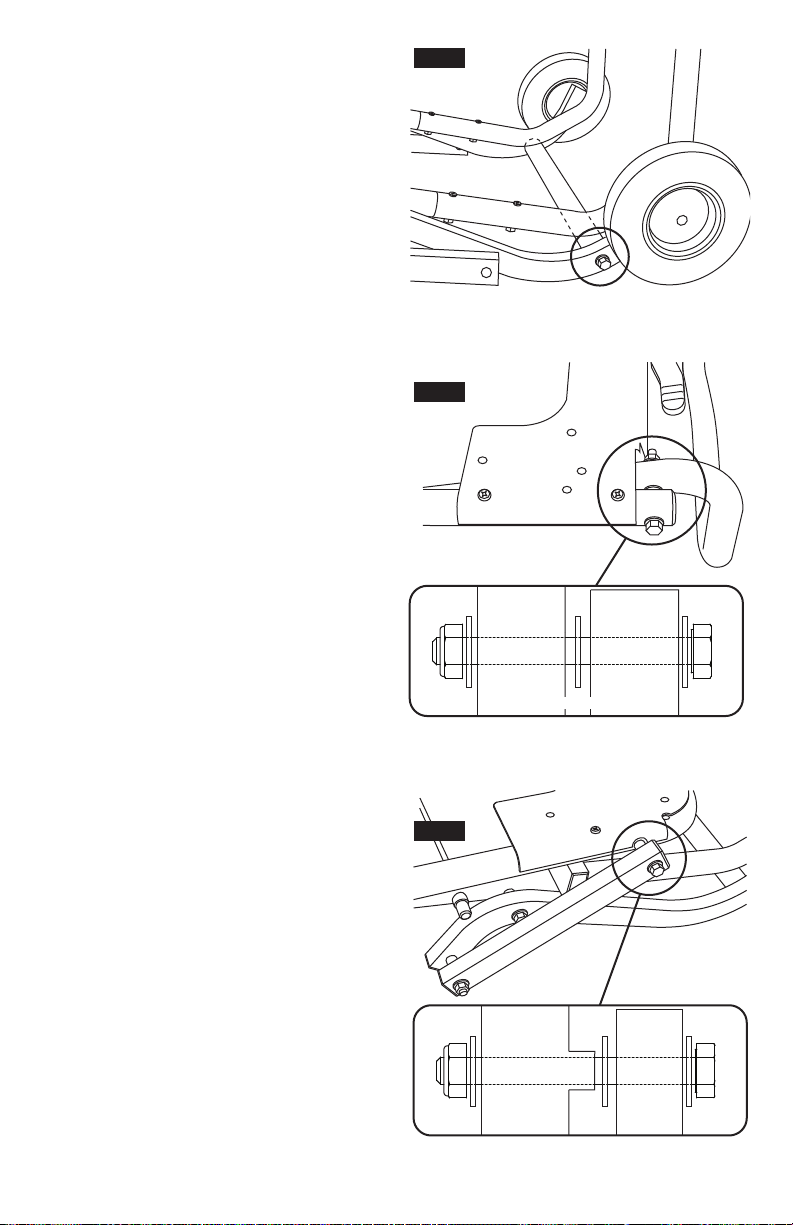

Step 2

Attach Leg/Wheel Assemblies

1. Locate the right leg/wheel assembly and

position on right side of upper/lower cross

bar assembly as shown in figure B.

2. Place one (1) flat washer onto one (1) 10

mm x 100 mm bolt and insert through right

leg/wheel assembly.

3. Place another (1) 10 mm flat washer on

bolt between leg/wheel assembly and

upper/lower cross bar assembly.

4. Insert bolt through upper/lower cross bar

assembly, place one (1) 10 mm flat

washer, and loosely tighten with one (1) 10

mm lock nut.

Note: Do not over-tighten lock nut - these

parts need to freely rotate for stand to

operate properly.

Repeat procedure on left side.

FIG. B

-4-

Page 5

Table TopUpper

Cross Bar

WasherWasher

BoltLock Nut

Washer

Table Top Linkage

Bar

Washer WasherWasher

BoltLock Nut

Step 3

Attach Kick Bar

1. Locate the kick bar and position it between

the left and right wheel assemblies as

shown in figure C.

2. Place one (1) 10 mm star washer onto one

(1) 10 mm x 50 mm hex head bolt. Insert

bolt through the leg/wheel assembly and

thread it into the the kick bar and securely

tighten.

Repeat this procedure on other side.

Step 4

Attach Table Top

1. Locate the table top and position holes in

end of table top with holes in upper cross

bar as shown in figure D.

2. Place one (1) flat washer onto one (1) 10

mm x 100 mm bolt.

3.Insert bolt through table top and place

another (1) flat washer on bolt between

table top and upper cross bar.

4. Insert bolt through upper cross bar, place

one (1) flat washer, and loosely tighten

with one (1) 10 mm lock nut.

Note: Do not over-tighten lock nut - these

parts need to freely rotate for stand to

operate properly.

Repeat this procedure on opposite side.

FIG. C

FIG. D

Step 5

Attach Linkage Bars

1. Align hole in upper linkage bar with hole in

table top as shown in figure E.

2. Place one (1) flat washer onto one (1) 10

mm x 100 mm bolt.

3. Insert bolt through linkage bar and place

another (1) flat washer on bolt between

table top and upper cross bar.

4. Insert bolt through table top, place one (1)

flat washer, and loosely tighten with one

(1) 10 mm lock nut.

Note: Do not over-tighten lock nut - these

parts need to freely rotate for stand to

operate properly.

Repeat this procedure on opposite side.

FIG. E

-5-

Page 6

Assembly

For Mounting Bosch 4100/4000

Table Saw to Stand

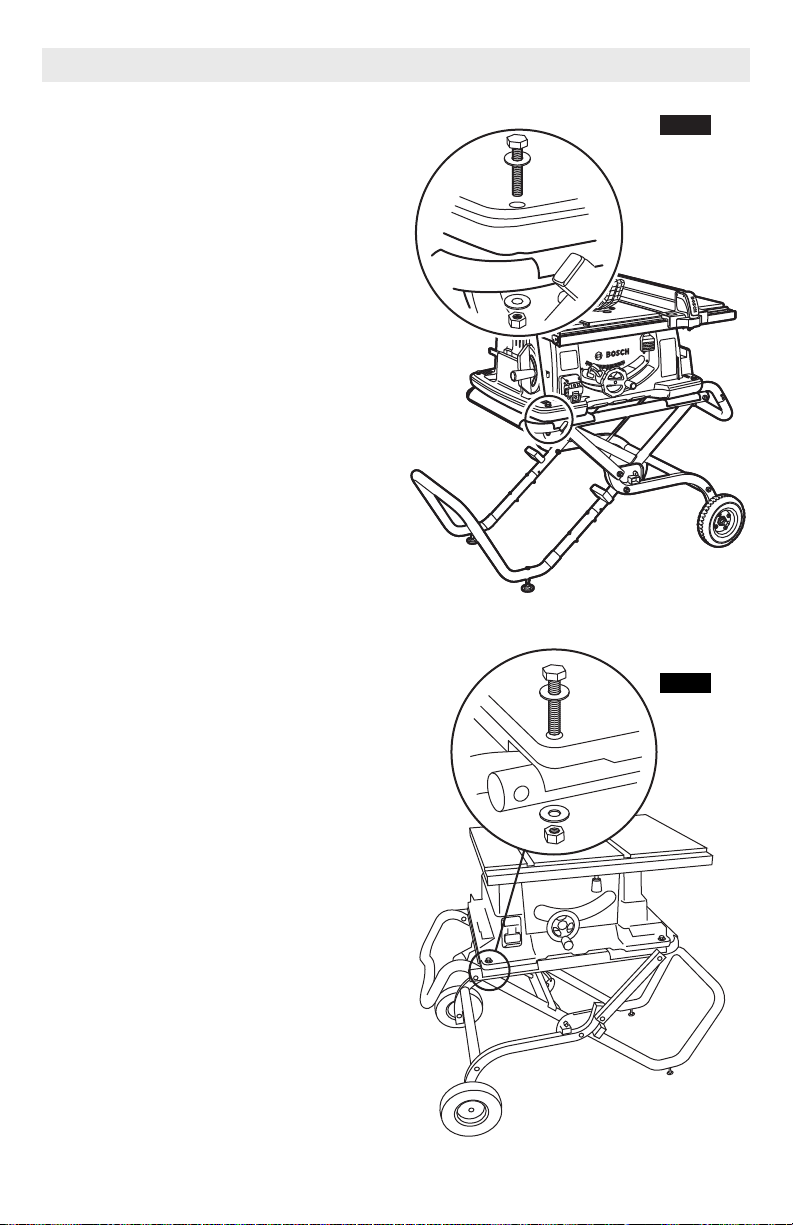

1. Using the diagram on page 7 (figure H),

locate the Bosch 4100/4000 mounting

holes and position saw on stand as shown

in figure G.

2.

To mount the 4100 Table Saw:

Align the saw as shown in figure F. Place

one (1) 6 mm flat washer onto one (1) 6

mm x 90 mm hex head bolt and insert bolt

through mounting hole in table saw and

through stand table top.

To mount the 4000 Table Saw:

Align the saw as shown in figure G. Place

one (1) 6 mm flat washer onto one (1) 6

mm x 75 mm hex head bolt and insert bolt

through mounting hole in table saw and

through stand table top.

3. Place one (1) 6 mm flat washer and

securely tighten with one (1) 6 mm lock

nut.

Repeat this procedure on the three remaining

mounting holes.

FIG. F

FIG. G

-6-

Page 7

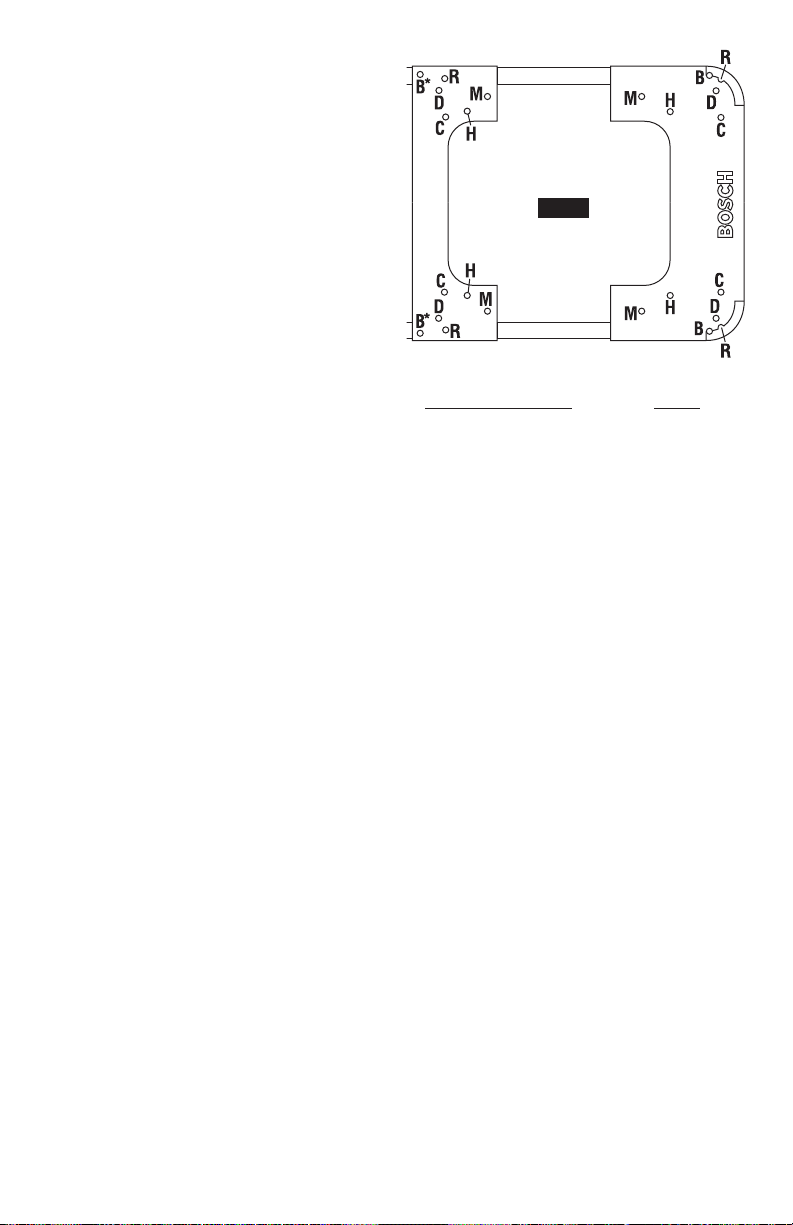

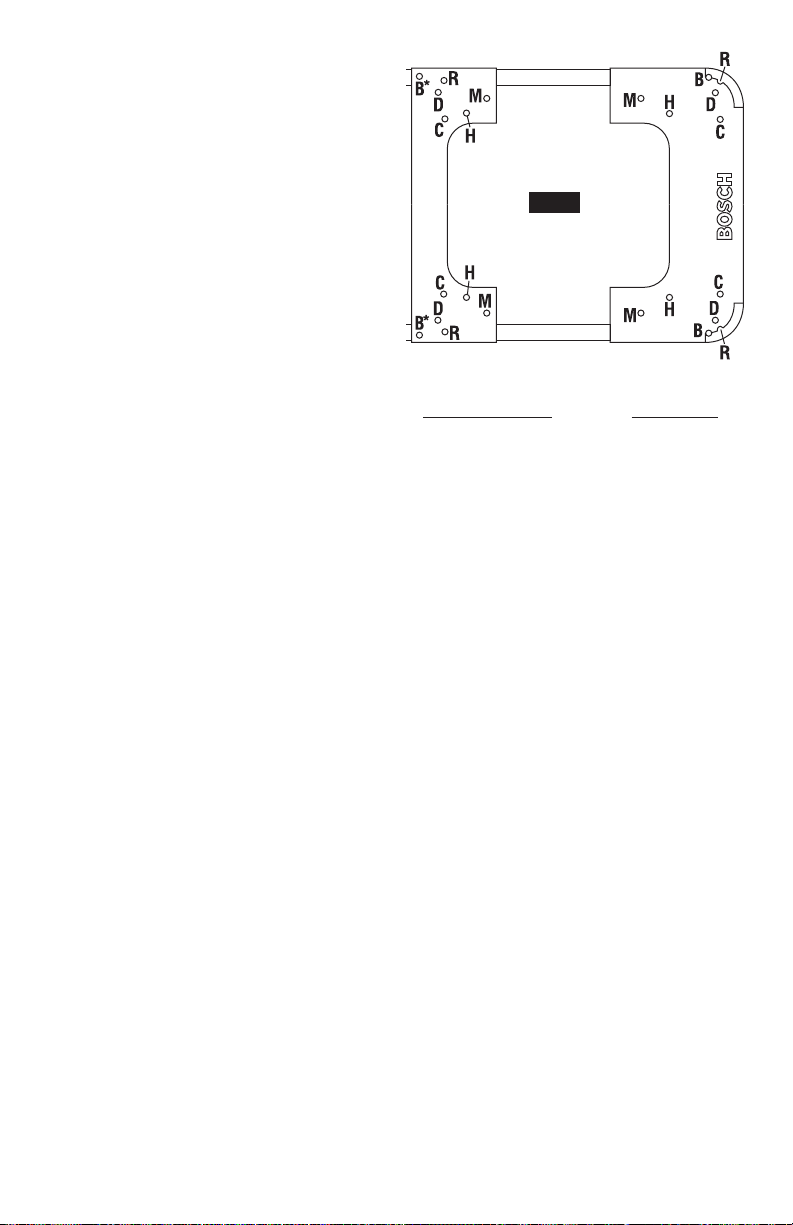

For Mounting Other Table Saws

Important: Before mounting a DeWalt,

Craftsman, Makita, Hitachi, or Ridgid table

saw, insert two (2) 8mm x 50mm Phillips

head screws through “B*” hole locations and

tighten using 8mm lock nuts.

1. Using the diagram below, locate the

correct mounting holes for the table saw

being used and position saw on stand

accordingly.

For use with Hitachi Table Saw:

If your TS2000 stand does not have "H"

holes, you will need to drill holes. Place

the saw over the center of the opening and

make pencil marks (through the L-shaped

bracket holes) on the table top mounting

plates. Remove saw and drill four (4) 5/16"

diameter holes through the mounting

plates.

For use with Ridgid Table Saw:

Locate the four “R” holes in the two

mounting plates and drill four (4) 3/8”

diameter holes completely through the

stand’s frame.

2. Mount the table saw using the appropriate

mounting hardware for your table saw

model.

FIG. H

Mounting

Table Saw Models

Holes

Bosch 4100/4000 B

Dewalt DW744 D

Craftsman 21830 C

Makita 2704 M

Hitachi C10RA2** H

Ridgid TS2400LS** R

**See instructions.

-7-

Page 8

Operating Instructions

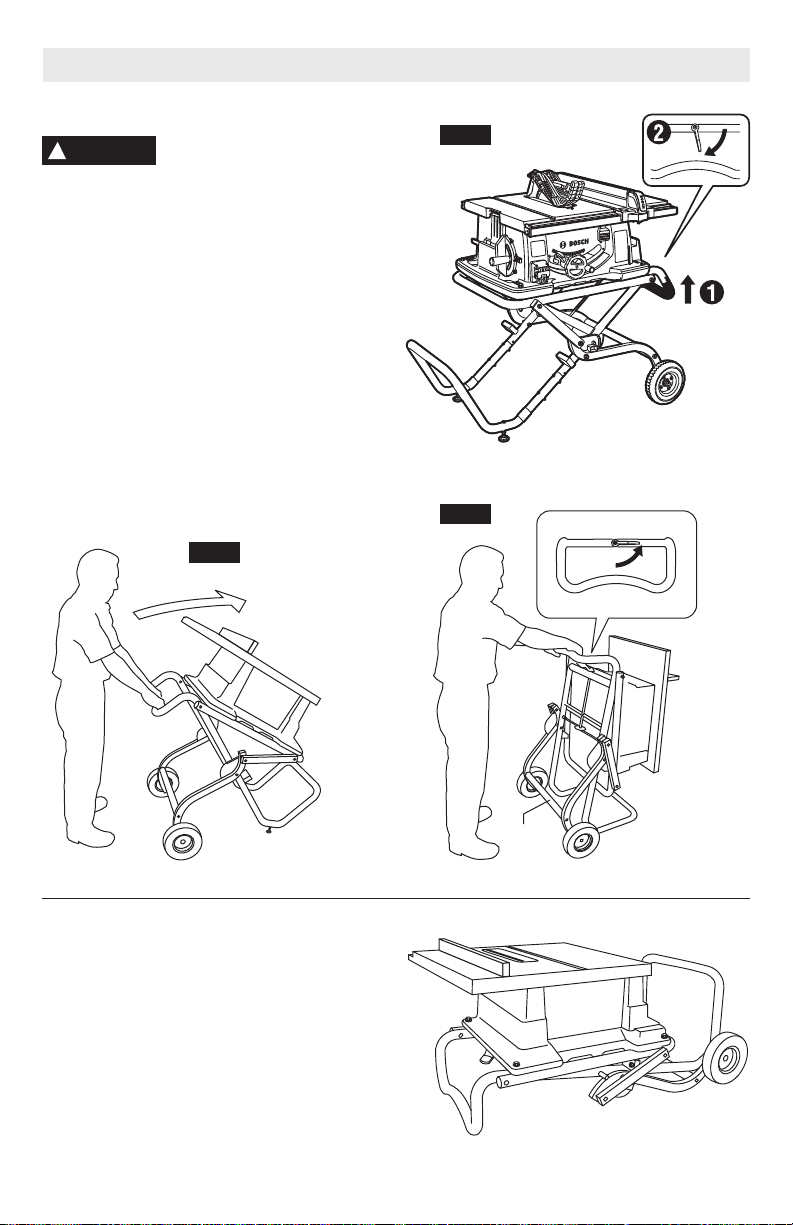

Fold Stand Upright

!

WARNING

or unfolding the stand.

1. Slightly lift stand by the black handle.

2. Rotate release lever down to clear locking pins.

3. With both hands on the handle, pull up and

push forward on the stand, figure B, until it

locks in the upright position, figure C.

Keep fingers clear of

hinge points when folding

Lower Stand

1. Rotate the release lever, then pull back on

the stand slightly to disengage.

2. With both hands on the handle, pull back

and lower the stand until it locks in position.

FIG. B

FIG. A

FIG. C

Lowering Stand to its Lowest Position

Begin with the stand in the locked upright

position, as shown above in figure C.

Firmly grip the handle with both hands and

place one foot against the kick bar. Pull back

on the handle and lower the stand to the

ground, as shown.

Kickbar

-8-

Page 9

Operating Instructions

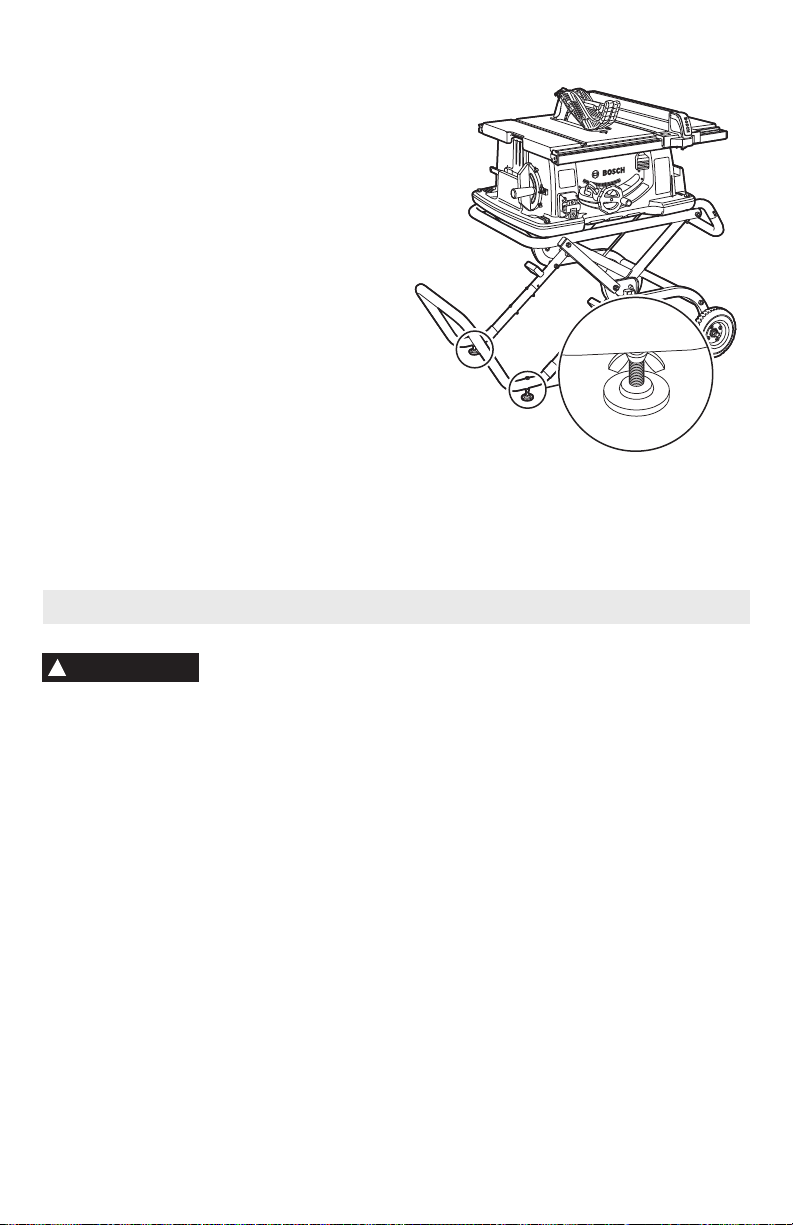

To Level Stand

The stand is equipped with two adjustable

feet for leveling the stand.

To adjust: loosen wing nut and adjust the

height of the foot by screwing the threaded

shaft clockwise to raise foot or counterclockwise to lower foot. Retighten wing

nut securely.

Maintenance

!

WARNING

fasteners are attached and adjusted

according to the assembly instructions

included in this manual.

To reduce the risk of injury,

periodically check that all

Tire Pressure

The TS2000 tires are shipped with an air

pressure of 25 to 30 P.S.I. — an adequate

pressure for most working conditions. If you

wish to increase the tire pressure for a

slightly firmer support, you may inflate the

tires to a maximum of 50 P.S.I. It is

recommended that a hand pump is used.

-9-

Page 10

Instructions relatives à la sécurité

!

AVERTISSEMENT

d’emploi. Le fait de ne pas respecter la totalité des

instructions contenues dans ce mode d’emploi peut

résulter en des blessures graves.

Assemblez et serrez complètement tous les

dispositifs de fixation nécessaires au montage de

cette plateforme de support. Souvenez-vous

également d’inspecter la plateforme de support de

temps à autre et de vérifier que toutes les

connexions sont restées bien serrées. Une plateforme

de support dont les dispositifs de fixation sont

desserrés sera instable et risquera de se déplacer

pendant l’emploi et de causer des blessures graves.

Mettez l’interrupteur de l’outil dans la position

d’arrêt et débranchez-le avant d’assembler la

plateforme de support. Une mise en marche

accidentelle qui se produirait pendant l’assemblage

pourrait entraîner des blessures.

Veuillez lire et bien

comprendre tout le mode

Pré-assemblage

Vous êtes maintenant en possession d’une plateforme

de support pour scie à table Bosch TS2000. Conçu

pour utilisation sur les chantiers, cet appareil s’installe

et se plie rapidement, et il peut être facilement chargé

sur un camion par une seule personne.

Pour utilisation avec les scies à table suivantes :

Bosch 4100/4000, Dewalt DW744, Craftsman 21830

et Makita 2704.

Un tournevis cruciforme Phillips, une clé à fourche de

10 mm, une clé à fourche de 16 mm ou une clé à

ouverture variable.

OUTILS NÉCESSAIRES

Avant de faire fonctionner cet appareil, veillez à ce

qu’il soit placé entièrement sur une surface plate,

solide et de niveau. Si l’outil était instable et se

renversait, cela pourrait entraîner des blessures graves.

Ne montez jamais sur l’outil ou sur sa plateforme de

support et ne les utilisez jamais comme une échelle

ou un échafaudage. De graves blessures pourraient

être encourues si l’outil se renversait ou si vous entriez

accidentellement en contact avec l’outil de coupe. Ne

rangez pas de matériaux sur l’outil ou à proximité de

celui-ci de telle façon qu’il serait nécessaire de se tenir

sur l’outil ou sur sa plateforme de support pour les

atteindre.

Utilisez uniquement des pièces de rechange Bosch.

L’utilisation de pièces de toute autre marque pourrait

présenter un danger.

AVANT D’ASSEMBLER CETTE PLATEFORME DE

SUPPORT POUR SCIE À TABLE :

Séparez toutes les pièces avant de faire un inventaire

afin de vous assurer que vous êtes en possession de

tous les éléments nécessaires à l’assemblage de votre

plateforme de support. Ne jetez pas le matériau de

conditionnement tant que vous n’avez pas confirmé la

présence de toutes les pièces nécessaires.

PLATEFORME DE SUPPORT POUR SCIE À TABLE

TS2000 CONTENU DU PAQUET :

Article Qté.

A (1) Barre transversale supérieure

B (1) Barre transversale inférieure

C (1) Barre anti-recul

D (1) Pied droit / ensemble de roue

E (1) Pied gauche / ensemble de roue

F (1) Plateau de table

C

Description de la pièce

D

B

A

E

F

-10-

Page 11

ÉLÉMENTS DE QUINCAILLERIE POUR L’ASSEMBLAGE

DE LA PLATEFORME DE SUPPORT

Article Qté. Description de la pièce

G (6) Boulons à tête hexagonale (10 mm x 100 mm)

H (2) Boulons à tête hexagonale (10 mm x 50 mm)

I (6) Vis à tête cruciforme Phillips (8 mm x 50 mm)

J (22) Rondelles plates de 10 mm

K (2) Rondelles étoile de 10 mm

L (8) Contre-écrous de 10 mm

M (6) Contre-écrous de 8 mm

N (4) Boulons à tête hexagonale (6 mm x 75 mm)

O (2) Boulons à tête hexagonale (6 mm x 90 mm)

P (8) Rondelles plates de 6 mm

Q (4) Contre-écrous de 6 mm

GHI

J

L

M

K

N

O

P

Q

*Remarque : deux (2) vis à tête cruciforme de 8 mm x 50 mm et deux (2) contre-écrous de 8

mm sont fournis mais ne doivent être utilisés que pour monter des scies à table d'autres

marques sur la plate-forme Bosch TS2000. Cf. instructions à la page 15.

-11-

Page 12

Assemblage

Upper

Cross Bar

Leg/Wheel

Assembly

Washer WasherWasher

BoltLock Nut

Étape 1

Fixation de la barre transversale supérieure et

de la barre transversale inférieure

1. Positionnez la barre transversale inférieure sur une

surface plate tel que cela est illustré à la figure A.

2. Insérez les extrémités de la barre transversale

supérieure dans la barre transversale inférieure et

enfoncez-les aussi loin que possible.

3. Insérez quatre (4) vis à tête cruciforme Phillips de 8

mm x 50 mm dans les trous de la barre

transversale supérieure et de la barre transversale

inférieure, et serrez fermement à l’aide des quatre

(4) contre-écrous de 8 mm, tel que cela est illustré.

Étape 2

Fixation des ensembles de pied/roue

1. Localisez l’ensemble de pied/roue de droite et

placez-le sur le côté droit de l’ensemble de barre

transversale supérieure/ barre transversale

inférieure, tel que cela est illustré à la figure B.

2. Placez une (1) rondelle plate sur un (1) boulon de

10 mm x 100 mm et insérez-les dans l’ensemble

de pied/roue de droite.

3. Placez une (1) autre rondelle plate de 10 mm sur

un boulon entre l’ensemble de pied/roue et

l’ensemble de barre transversale supérieure/ barre

transversale inférieure.

4. Insérez un boulon à travers l’ensemble de barre

transversale supérieure/ barre transversale

inférieure, placez une (1) rondelle plate de 10 mm

et serrez légèrement avec un (1) contre-écrou de

10 mm.

Remarque : ne serrez pas trop le contre-écrou – ce

type de pièce doit pouvoir tourner librement pour

que la plateforme de support puisse fonctionner

correctement.

Répétez la même procédure sur le côté gauche.

FIG. A

FIG. B

Contre-

écrou

Rondelle Rondelle

Barre

transversale

Ensemble

de

pied/roue

Boulon

Rondelle

-12-

Page 13

Étape 3

Table TopUpper

Cross Bar

WasherWasher

BoltLock Nut

Washer

Table Top Linkage

Bar

Washer WasherWasher

BoltLock Nut

Fixation de la barre anti-recul

1. Localisez la barre anti-recul et placez-la entre

l’ensemble de roue de droite et celui de gauche, tel

que cela est illustré à la figure C.

2. Placez une (1) rondelle de blocage de 10 mm sur

un (1) boulon à tête hexagonale de 10 mm x 50

mm. Insérez le boulon à travers l’ensemble de

pied/roue, enfilez-le dans la barre anti-recul et

serrez fermement.

Répétez la même procédure de l’autre côté.

Étape 4

Fixation du plateau de table

1. Localisez le plateau de table et alignez les trous

dans l’extrémité du plateau de table avec les trous

de la barre transversale supérieure, tel que cela est

illustré à la figure D.

2. Placez une (1) rondelle plate sur un (1) boulon de

10 mm x 100 mm.

3. Insérez le boulon à travers le plateau de table et

placez une (1) autre rondelle plate sur le boulon

entre le plateau de table et la barre transversale

supérieure.

4. Insérez le boulon à travers la barre transversale

supérieure, placez une (1) rondelle plate et serrez

légèrement à l’aide d’un (1) contre-écrou de 10 mm.

Remarque : ne serrez pas trop le contre-écrou – ce

type de pièce doit pouvoir tourner librement pour

que la plateforme de support puisse fonctionner

correctement.

Répétez la même procédure de l’autre côté.

FIG. C

FIG. D

Contre-

écrou

Rondelle Rondelle

Barre

transversale

Plateau de

table

Boulon

Rondelle

Étape 5

Fixation des barres de raccordement

1. Alignez le trou dans la barre de raccordement

supérieure avec le trou dans le plateau de table, tel

que cela est illustré dans la figure E.

2. Placez une (1) rondelle plate sur un (1) boulon de

10 mm x 100 mm.

3. Insérez le boulon à travers le plateau de table et

placez une (1) autre rondelle plate sur le boulon

entre le plateau de table et la barre transversale

supérieure.

4. Insérez le boulon à travers le plateau de table,

placez une (1) rondelle plate et serrez légèrement à

l’aide d’un (1) contre-écrou de 10 mm.

Remarque : ne serrez pas trop le contre-écrou – ce

type de pièce doit pouvoir tourner librement pour

que la plateforme de support puisse fonctionner

correctement.

Répétez la même procédure de l’autre côté.

FIG. E

Contre-

écrou

Rondelle Rondelle

-

13

-

Plateau de

table

Barre de

raccordem

ent

Boulon

Rondelle

Page 14

Assemblage

Pour le montage de la scie à table Bosch 4100

sur la plateforme de support

1. En utilisant le schéma de la page 15 (Figure H),

localisez les trous de montage Bosch 4100/4000 et

positionnez la scie sur le support comme illustré à

la Figure G.

2. Montage de la scie à table 4100 :

Alignez la scie comme illustré à la Figure F. Placez

une (1) rondelle plate de 6 mm sur un (1) boulon à

tête hexagonale de 6 mm x 90 mm et insérez le

boulon à travers le trou de montage dans la scie à

table et à travers le dessus de la table de support.

Montage de la scie à table 4000 :

Alignez la scie comme illustré à la Figure G. Placez

une (1) rondelle plate de 6 mm sur un (1) boulon à

tête hexagonale de 6 mm x 75 mm et insérez le

boulon à travers le trou de montage dans la scie à

table et à travers le dessus de la table de support.

3. Placez une (1) rondelle plate de 6 mm et serrez

fermement à l’aide d’un (1) contre-écrou de 6 mm.

Répétez la même procédure sur les trois autres trous

de montage.

FIG. F

FIG. G

-14-

Page 15

Pour le montage d’autres scies à table

Important : avant de monter une scie à table DeWalt,

Craftsman, Makita, ou Hitachi, insérez les vis à tête

cruciforme de 8 mm x 50 mm dans chaque

emplacement de trou « B » (« * » indiqué sur

l'illustration) et serrez en utilisant les contre-écrous

de 8 mm.

1. En vous servant du diagramme ci-dessous,

localisez les trous de montage appropriés pour la

scie à table que vous souhaitez utiliser et

positionnez la scie sur la plateforme de support en

conséquence.

Pour emploi avec une scie à table Hitachi :

Si votre plate-forme TS2000 n'a pas de trous « H

», vous devrez percer des trous. Placez la scie audessus du centre de l'ouverture et dessinez des

repères au crayon (à travers les trous des pattes de

fixation en forme de L sur les plaques de montage

du dessus de table. Retirez la scie et percez quatre

(4) trous de 5/16 po de diamètre à travers les

plaques de montage.

Pour utilisation avec la scie à table Ridgid :

Localisez les quatre trous « R » dans les deux

plaques de montage et percez quatre (4) trous de

3/8 po de diamètre traversant complètement le

châssis de la plateforme.

2. Utilisez les éléments de quincaillerie appropriés

pour votre modèle de scie à table.

FIG. H

MODÈLES DE TROUS DE

SCIES À TABLE

MONTAGE

Bosch 4100/4000 B

Dewalt DW744 D

Craftsman 21830 C

Makita 2704 M

Hitachi C10RAZ** H

Ridgid TS2400LS** R

**Cf. les instructions particulières

-15-

Page 16

Notice technique d’utilisation

Pliage de la plateforme de support dans la

position verticale

!

AVERTISSEMENT

d’articulation quand vous pliez ou dépliez la

plateforme de support.

1. Soulevez légèrement la plateforme par la

poignée noire.

2. Déplacez le levier de libération vers le bas en le

faisant tourner pour dégager les goupilles

de verrouillage.

3. Ensuite, tirez la plateforme de support vers le haut

et poussez-la vers l’avant à deux mains, tel que

cela est illustré à la figure B, jusqu’à ce qu’elle se

verrouille dans la position verticale (figure C).

Gardez vos doigts à

distance des points

Abaissement de la plateforme de support

1. Faites tourner le levier de dégagement, puis tirez

légèrement sur la plate-forme pour la dégager.

2. Ensuite, tirez la plateforme de support vers l’arrière

et abaissez-la à deux mains jusqu’à ce qu’elle se

verrouille en position.

FIG. B

FIG. A

FIG. C

Abaissement de la plateforme de support

jusqu’à sa position la plus basse

Commencez avec la plateforme de support verrouillée

dans la position verticale, tel que cela est illustré dans

la figure C ci-dessus.

Saisissez fermement la poignée à deux mains et

placez un pied contre la barre anti-recul. Tirez la

poignée vers l’arrière et abaissez la plateforme de

support jusqu’au sol, tel que cela est illustré.

Barre anti-

recul

-16-

Page 17

Mise de niveau de la plateforme de support

La plateforme de support est munie de deux pieds de

nivellement réglables.

Réglage : desserrez l'écrou à oreilles et ajustez la hauteur

du pied en vissant la tige filetée dans le sens des aiguilles

d'une montre pour relever le pied ou dans le sens

inverse des aiguilles d'une montre pour l'abaisser.

Serrez à nouveau fermement l'écrou à oreilles.

Entretien

!

AVERTISSEMENT

diquement que tous les dispositifs de fixation sont

attachés et ajustés conformément aux instructions

d’assemblage contenues dans ce mode d’emploi.

Pour réduire le risque de

blessures, vérifiez pério-

Pression de gonflage

Les pneus de la table TS2000 sont expédiés avec une

pression de 25 à 30 psi - une pression adéquate pour

la plupart des conditions de travail. Si vous désirez

augmenter la pression des pneus pour avoir un

support un peu plus ferme, vous pouvez gonfler les

pneus jusqu'à 50 psi. Il est recommandé d'utiliser une

pompe à bras.

-17-

Page 18

Instrucciones de seguridad

!

ADVERTENCIA

todas las instrucciones que aparecen a continuación,

el resultado podría ser lesiones corporales graves.

Ensamble y apriete completamente todos los

elementos de sujeción requeridos para esta base de

soporte. Recuerde también comprobar

ocasionalmente la base de soporte y asegurarse de

que siga estando apretada. Una base de soporte floja

es inestable y podría desplazarse durante el uso y

causar lesiones graves.

Ponga el interruptor de la herramienta en la

posición de apagado y desconecte la alimentación

eléctrica antes de realizar el montaje en la base de

soporte. Un arranque accidental durante el ensamblaje

puede causar lesiones.

Lea y entienda todas las

instrucciones.

Si no se siguen

Preensamblaje

Usted ha comprado una base de soporte para sierras

de mesa Bosch TS2000. Esta base de soporte está

diseñada para utilizarse en el lugar de la obra. Esta

unidad se despliega y pliega rápidamente y es fácil de

cargar o descargar de un camión por una persona.

Para utilizarse con las sierras de mesa siguientes:

Bosch 4100/4000, Dewalt DW744, Craftsman 21830 y

Makita 2704.

Antes de utilizar la herramienta, asegúrese de que

toda la unidad esté colocada sobre una superficie

sólida, plana y nivelada. Podrían producirse lesiones

graves si la herramienta es inestable y vuelca.

No se suba nunca a la herramienta ni a su base de

soporte, ni use la herramienta o la base de soporte

como una escalera de mano o un andamio. Se

podrían producir lesiones graves si la herramienta

vuelca o si se entra en contacto accidentalmente con la

herramienta de corte. No almacene materiales en la

herramienta ni cerca de ella de modo que sea

necesario subirse a la herramienta o a su base de

soporte para llegar a dichos materiales.

Utilice únicamente piezas de repuesto Bosch.

Cualquier otra pieza podría crear un peligro.

HERRAMIENTAS NECESARIAS:

Destornillador Phillips, llave de tuerca de boca de 10

mm, llave de tuerca de boca de 16 mm o llave de

tuerca ajustable.

ANTES DE ENSAMBLAR ESTA BASE DE SOPORTE

PARA SIERRAS DE MESA:

Organice todas las piezas y compruebe que no falte

ninguna pieza, para asegurarse de que tiene todos los

materiales necesarios para ensamblar la base de

soporte. No tire el material de empaquetamiento hasta

que se haya asegurado de que no falta ninguna pieza.

CONTENIDO DEL PAQUETE DE LA BASE DE SOPORTE

PARA SIERRAS DE MESA TS2000:

Artículo Cant. Descripción de la pieza

A (1) Barra transversal superior

B (1) Barra transversal inferior

C (1) Barra antirretroceso

D (1) Ensamblaje derecho de pata y rueda

E (1) Ensamblaje izquierdo de pata y rueda

F (1) Tablero de la mesa

E

C

D

B

A

F

-18-

Page 19

HERRAJES DE ENSAMBLAJE DE LA BASE DE SOPORTE

Artículo Cant. Descripción de la pieza

G (6) Pernos de cabeza hexagonal de 10 mm x 100 mm

H (2) Pernos de cabeza hexagonal de 10 mm x 50 mm

I (6) Pernos de cabeza Phillips de 8 mm x 50 mm*

J (22) Arandelas planas de 10 mm

K (2) Arandela de estrella de 10 mm

L (8) Tuercas de fijación de 10 mm

M (6) Tuercas de fijación de 8 mm*

N (4) Perno de cabeza hexagonal de 6 mm x 75 mm

O (2) Pernos de cabeza hexagonal de 6 mm x 90 mm

P (8) Arandela plana de 6 mm

Q (4) Tuercas de fijación de 6 mm

GHI

J

L

M

K

N

O

P

Q

*Nota: Hay dos (2) tornillos de cabeza Phillips de 8 mm x 50 mm y dos (2) tuercas de fijación

de 8 mm para usarlos solamente cuando se instalen sierras de mesa de otras marcas en la

base de soporte Bosch TS2000. Consulte la página 23 para obtener instrucciones.

-19-

Page 20

Ensamblaje

Upper

Cross Bar

Leg/Wheel

Assembly

Washer WasherWasher

BoltLock Nut

Paso 1

Acople las barras transversales superior e

inferior

1. Posicione la barra transversal inferior sobre una

superficie plana de la manera que se muestra en la

figura A.

2. Introduzca los extremos de la barra transversal

superior en la barra transversal inferior y empuje

hacia abajo la barra superior para que los extremos

entren tanto como sea posible.

3. Introduzca cuatro (4) tornillos de cabeza Phillips de

8 mm x 50 mm a través de los agujeros de las

barras transversales superior e inferior, y

apriételos firmemente con cuatro (4) tuercas de

fijación de 8 mm de la manera que se muestra en

la ilustración.

Paso 2

Coloque los ensamblajes de pata y rueda

1. Localice el ensamblaje derecho de pata y rueda y

posiciónelo sobre el lado derecho del ensamblaje

de las barras transversales superior e inferior de la

manera que se muestra en la figura B.

2. Coloque una (1) arandela plana en un (1) perno de

10 mm x 100 mm e introduzca el perno a través

del ensamblaje derecho de pata y rueda.

3. Coloque otra (1) arandela plana de 10 mm en el

perno entre el ensamblaje de pata y rueda y el

ensamblaje de las barras transversales superior e

inferior.

4. Introduzca el perno a través del ensamblaje de las

barras transversales superior e inferior, coloque

una (1) arandela plana de 10 mm y apriete

flojamente el perno con una (1) tuerca de fijación

de 10 mm.

Nota: No apriete excesivamente la tuerca de

fijación. Estas piezas necesitan girar libremente

para que la base de soporte funcione

correctamente.

Repita este procedimiento en el lado izquierdo.

FIG. A

FIG. B

Tuerca de

fijación

Arandela Arandela

Barra

transversal

Ensamblaje

de pata y

rueda

Perno

Arandela

-20-

Page 21

Paso 3

Table TopUpper

Cross Bar

WasherWasher

BoltLock Nut

Washer

Table Top Linkage

Bar

Washer WasherWasher

BoltLock Nut

Coloque la barra antirretroceso

1. Localice la barra antirretroceso y posiciónela entre

los ensamblajes de rueda izquierdo y derecho de la

manera que se muestra en la figura C.

2. Coloque una (1) arandela de seguridad de 10 mm

en un (1) perno de cabeza hexagonal de 10 mm x

50 mm. Introduzca el perno a través del

ensamblaje de pata y rueda, enrósquelo en la barra

antirretroceso y apriételo firmemente.

Repita este procedimiento en el otro lado.

Paso 4

Coloque el tablero de la mesa

1. Localice el tablero de la mesa y posicione los

agujeros ubicados en el extremo del tablero de la

mesa de modo que coincidan con los agujeros

ubicados en la barra transversal superior, de la

manera que se muestra en la figura D.

2. Coloque una (1) arandela plana en un (1) perno de

10 mm x 100 mm.

3. Introduzca el perno a través del tablero de la mesa y

coloque otra (1) arandela plana en el perno entre el

tablero de la mesa y la barra transversal superior.

4. Introduzca el perno a través de la barra transversal

superior, coloque una (1) arandela plana y apriete el

perno firmemente con una (1) tuerca de fijación de

10 mm.

Nota: No apriete excesivamente la tuerca de fijación.

Estas piezas necesitan girar libremente para que la

base de soporte funcione correctamente.

Repita este procedimiento en el lado opuesto.

FIG. C

FIG. D

Tuerca de

fijación

Arandela Arandela

Barra

transversal

Tablero de la

mesa

Perno

Arandela

Paso 5

Coloque las barras de articulación

1. Alinee el agujero ubicado en la barra de articulación

superior con el agujero ubicado en el tablero de la

mesa de la manera que se muestra en la figura E.

2. Coloque una (1) arandela plana en un (1) perno de

10 mm x 100 mm.

3. Introduzca el perno a través del tablero de la mesa

y coloque otra (1) arandela plana en el perno entre

el tablero de la mesa y la barra transversal

superior.

4. Introduzca el perno a través del tablero de la mesa,

coloque una (1) arandela plana y apriete flojamente

el perno con una (1) tuerca de fijación de 10 mm.

Nota: No apriete excesivamente la tuerca de

fijación. Estas piezas necesitan girar libremente

para que la base de soporte funcione

correctamente.

Repita este procedimiento en el lado opuesto.

-21-

FIG. E

Tuerca de

fijación

Tablero

de la mesa

Barra de

articulación

Perno

Page 22

Ensamblaje

Para montar la sierra de mesa Bosch 4100

en la base de soporte

1. Utilizando el diagrama de la página 23 (figura H),

localice los agujeros de montaje de la sierra de

mesa Bosch 4100/4000 y posicione la sierra sobre

la base de soporte de la manera que se muestra en

la figura G.

2. Para montar la sierra de mesa 4100:

Alinee la sierra de la manera que se muestra en la

figura F. Coloque una (1) arandela plana de 6 mm

en un (1) perno de cabeza hexagonal de 6 mm x 90

mm e inserte el perno a través del agujero de

montaje ubicado en la sierra de mesa y a través del

tablero de mesa de la base de soporte.

Para montar la sierra de mesa 4000:

Alinee la sierra de la manera que se muestra en la

figura G. Coloque una (1) arandela plana de 6 mm

en un (1) perno de cabeza hexagonal de 6 mm x 75

mm e inserte el perno a través del agujero de

montaje ubicado en la sierra de mesa y a través del

tablero de mesa de la base de soporte.

3. Coloque una (1) arandela plana de 6 mm y apriete

firmemente el perno con una (1) tuerca de fijación

de 6 mm.

Repita este procedimiento en los tres agujeros de

montaje restantes.

FIG. E

FIG. F

-22-

Page 23

Para montar otras mesas de sierra

Importante: Antes de montar una sierra de mesa

DeWalt, Craftsman o Makita, introduzca los tornillos

de cabeza Phillips de 8 mm x 50 mm a través de cada

ubicación de agujero “B” (marcada con un “*”en la

ilustración) y apriételos usando las tuercas de fijación

de 8 mm.

1. Utilizando el diagrama que aparece más adelante,

localice los agujeros de montaje correctos para la

sierra de mesa que se vaya a utilizar y posicione la

sierra sobre la base de soporte según corresponda.

Para utilizarse con la sierra de mesa Hitachi :

Si su base de soporte TS2000 no tiene los agujeros

"H", tendrá que taladrarla para hacer los agujeros.

Coloque la sierra sobre el centro de la abertura y

haga marcas con un lápiz (a través de los agujeros

de los soportes con forma de L) en las placas de

montaje del tablero de mesa. Retire la sierra y haga

cuatro (4) agujeros de 5/16" de diámetro a través

de las placas de montaje.

Para uso con la sierra de mesa Ridgid:

Localice los cuatro agujeros “R” ubicados en las

dos placas de montaje y haga cuatro (4) agujeros

de 3/8” de diámetro que atraviesen completamente

el armazón de la base de soporte.

2. Utilice los herrajes de montaje apropiados para su

modelo de sierra de mesa.

FIG. H

MODELOS DE AGUJEROS

SIERRA DE MESA

DE MONTAJE

Bosch 4100/4000 B

Dewalt DW744 D

Craftsman 21830 C

Makita 2704 M

Hitachi C10RAZ** H

Ridgid TS2400LS** R

**Consulte las instrucciones especiales.

-23-

Page 24

Instrucciones de utilización

Pliegue la base de soporte en posición

vertical

!

ADVERTENCIA

cuando pliegue o despliegue la base de soporte.

1. Levante ligeramente la base de soporte por el

mango negro.

2. Gire la palanca de liberación hacia abajo para que

no toque los pasadores de fijación.

3. Ahora, con las dos manos en el asa, tire hacia

arriba del asa y empuje hacia delante sobre la base

de soporte, figura B, hasta que se bloquee en la

posición vertical, figura C.

Mantenga los dedos alejados

de los puntos de bisagra

Baje la base de soporte

1. Gire la palanca de liberación y luego tire

ligeramente hacia atrás de la base de soporte para

desacoplarla.

2. Ahora, con las dos manos en el asa, tire hacia atrás

del asa y baje la base de soporte hasta que se

bloquee en la posición correcta.

FIG. B

FIG. A

FIG. C

Bajada de la base de soporte hasta

su posición más baja

Comience con la base de soporte en la posición

vertical bloqueada de la manera que se muestra en la

figura C.

Agarre firmemente el asa con las dos manos y

coloque un pie contra la barra antirretroceso. Tire

hacia atrás del asa y baje la base de soporte hasta el

piso de la manera que se muestra en la ilustración.

-24-

Barra

antirretroceso

Page 25

Instrucciones de utilización

Para nivelar la base de soporte

La base de soporte está equipada con dos pies

ajustables para nivelarla.

Para ajustar los pies: Afloje la tuerca de mariposa y

ajuste la altura del pie enroscando el eje roscado en el

sentido de las agujas del reloj para subir el pie y en

sentido contrario al de las agujas del reloj para

bajarlo. Reapriete firmemente la tuerca de mariposa.

Mantenimiento

!

ADVERTENCIA

periódicamente que todos los elementos de sujeción

estén sujetos y ajustados de acuerdo con las

instrucciones de ensamblaje incluidas en este manual.

Para reducir el riesgo de

lesiones, compruebe

Presión de las llantas

Las llantas de la base de soporte TS2000 se envían

con una presión de aire de 25 a 30 P.S.I., que es una

presión adecuada para la mayoría de las condiciones

de trabajo. Si desea aumentar la presión de las llantas

para obtener un soporte ligeramente más firme,

puede inflar las llantas hasta un máximo de 50 P.S.I.

Se recomienda usar una bomba de mano.

-25-

Page 26

-26-

Page 27

-27-

Page 28

Robert Bosch Tool Corporation (“Seller”) warrants to the original purchaser only, that all BOSCH portable and benchtop power tools will be free from

defects in material or workmanship for a period of one year from date of purchase. SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY

under this Limited Warranty and, to the extent permitted by law, any warranty or condition implied by law, shall be the repair or replacement of parts,

without charge, which are defective in material or workmanship and which have not been misused, carelessly handled, or misrepaired by persons

other than Seller or Authorized Service Station. To make a claim under this Limited Warranty, you must return the complete portable or benchtop

power tool product, transportation prepaid, to any BOSCH Factory Service Center or Authorized Service Station. For Authorized BOSCH Power Tool

Service Stations, please refer to your phone directory.

THIS LIMITED WARRANTY DOES NOT APPLY TO ACCESSORY ITEMS SUCH AS CIRCULAR SAW BLADES, DRILL BITS, ROUTER BITS, JIGSAW

BLADES, SANDING BELTS, GRINDING WHEELS AND OTHER RELATED ITEMS.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO ONE YEAR FROM DATE OF PURCHASE. SOME STATES IN THE U.S., SOME

CANADIAN PROVINCES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY

FOR LOSS OF PROFITS) ARISING FROM THE SALE OR USE OF THIS PRODUCT. SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES

DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIO N OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO

STATE IN THE U.S., PROVINCE TO PROVINCE IN CANADA AND FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO PORTABLE AND BENCHTOP ELECTRIC TOOLS SOLD WITHIN THE UNITED STATES OF AMERICA,

CANADA AND THE COMMONWEALTH OF PUERTO RICO. FOR WARRANTY COVERAGE WITHIN OTHER COUNTRIES, CONTACT YOUR LOCAL

BOSCH DEALER OR IMPORTER.

Robert Bosch Tool Corporation (le « vendeur ») garantit à l'acheteur initial seulement que tous les outils électriques portatifs et d'établi BOSCH

seront exempts de vices de matériaux ou d'exécution pendant une période d'un an depuis la date d'achat. LA SEULE OBLIGATION DU VENDEUR ET

LE SEUL RECOURS DE L’ACHETEUR sous la présente garantie limitée, et en autant que la loi le permette sous toute garantie ou condition implicite

qui en découlerait, sera l’obligation de remplacer ou réparer gratuitement les pièces défectueuses matériellement ou comme fabrication, pourvu que

lesdites défectuosités ne soient pas attribuables à un usage abusif ou à quelque réparation bricolée par quelqu’un d’autre que le vendeur ou le

personnel d’une station-service agréée. Pour présenter une réclamation en vertu de cette garantie limitée, vous devez renvoyer l'outil électrique

portatif ou d'établi complet, port payé, à tout centre de service agréé ou centre de service usine. Veuillez consulter votre annuaire téléphonique

pour les adresses.

LA PRÉSENTE GARANTIE NE S’APPLIQUE PAS AUX ACCESSOIRES TELS QUE LAMES DE SCIES CIRCULAIRES, MÈCHES DE PERCEUSES, FERS

DE TOUPIES, LAMES DE SCIES SAUTEUSES, COURROIES DE PONÇAGE, MEULES ET AUTRES ARTICLES DU GENRE.

TOUTE GARANTIE IMPLICITE SERA LIMITÉE COMME DURÉE À UN AN À COMPTER DE LA DATE D’ACHAT. CERTAINS ÉTATS AMÉRICAINS,

CERTAINES PROVINCES CANADIENNES N’ADMETTANT PAS LE PRINCIPE DE LA LIMITATION DE LA DURÉE DES GARANTIES IMPLICITES, IL

EST POSSIBLE QUE LES LIMITATIONS CI-DESSUS NE S’APPLIQUENT PAS À VOTRE CAS.

EN AUCUN CAS LE VENDEUR NE SAURAIT ÊTRE TENU POUR RESPONSABLE DES INCIDENTS OU DOMMAGES INDIRECTS (INCLUANT, MAIS NE

SE LIMITANT PAS AUX PERTES DE PROFITS) CONSÉCUTIFS À LA VENTE OU L’USAGE DE CE PRODUIT. CERTAINS ÉTATS AMÉRICAINS ET

CERTAINES PROVINCES CANADIENNES N’ADMETTANT PAS LE PRINCIPE DE LA LIMITATION NI L’EXCLUSION DES DOMMAGES INDIRECTS ET

CONSÉQUENTIELS, IL EST POSSIBLE QUE LES LIMITATIONS OU EXCLUSIONS CI-DESSUS NE S’APPLIQUENT PAS À VOTRE CAS.

LA PRÉSENTE GARANTIE VOUS ACCORDE DES DROITS BIEN DÉTERMINÉS, Y COMPRIS POSSIBLEMENT CERTAINS DROITS VARIABLES DANS

LES DIFFÉRENTS ÉTATS AMÉRICAINS, PROVINCES CANADIENNES.

CETTE GARANTIE LIMITÉE NE S'APPLIQUE QU'AUX OUTILS ÉLECTRIQUES PORTATIFS ET D'ÉTABLI VENDUS AUX ÉTATS-UNIS D'AMÉRIQUE,

AU CANADA ET AU COMMONWEALTH DE PORTO RICO.POUR COUVERTURE DE GARANTIE DANS LES AUTRES PAYS, CONTACTEZ VOTRE

IMPORTATEUR OU REVENDEUR BOSCH LOCAL.

GARANTIA LIMITADA PARA HERRAMIENTAS MECANICAS PORTATILES Y PARA TABLERO DE BANCO BOSCH

Robert Bosch Tool Corporation ("el Vendedor") garantiza, únicamente al comprador original, que todas las herramientas mecánicas portátiles y

para tablero de banco BOSCH estarán libres de defectos de material o de fabricación durante un período de un año a partir de la fecha de compra.

LA UNICA OBLIGACION DEL VENDEDOR Y EL RECURSO EXCLUSIVO QUE USTED TIENE bajo esta Garantía Limitada y, hasta donde la ley lo

permita, bajo cualquier garantía o condición implícita por ley, consistirá en la reparación o sustitución sin costo de las piezas que presenten

defectos de material o de fabricación y que no hayan sido utilizadas incorrectamente, manejadas descuidadamente o reparadas incorrectamente

por personas que no sean el Vendedor o una Estación de servicio autorizada. Para efectuar una reclamación bajo esta Garantía Limitada, usted

debe devolver el producto, que consiste en la herramienta mecánica portátil o para tablero de banco completa, con el transporte pagado, a

cualquier Centro de servicio de fábrica o Estación de servicio autorizada BOSCH. Para Estaciones de servicio autorizadas de herramientas

mecánicas BOSCH, por favor, consulte el directorio telefónico.

ESTA GARANTIA LIMITADA NO SE APLICA A ARTICULOS ACCESORIOS TALES COMO HOJAS PARA SIERRAS CIRCULARES, BROCAS PARA

TALADROS, BROCAS PARA FRESADORAS, HOJAS PARA SIERRAS DE VAIVEN, CORREAS PARA LIJAR, RUEDAS DE AMOLAR Y OTROS

ARTICULOS RELACIONADOS.

TODAS LAS GARANTIAS IMPLICITAS TENDRAN UNA DURACION LIMITADA A UN AÑO A PARTIR DE LA FECHA DE COMPRA. ALGUNOS

ESTADOS DE LOS EE.UU., ALGUNAS PROVINCIAS CANADIENSES NO PERMITEN LIMITACIONES EN CUANTO A LA DURACION DE UNA

GARANTIA IMPLICITA, POR LO QUE ES POSIBLE QUE LA LIMITACION ANTERIOR NO SEA APLICABLE EN EL CASO DE USTED.

EL VENDEDOR NO SERA RESPONSABLE EN NINGUN CASO DE NINGUN DAÑO INCIDENTAL O EMERGENTE (INCLUYENDO PERO NO LIMITADO

A RESPONSABILIDAD POR PERDIDA DE BENEFICIOS) QUE SE PRODUZCA COMO CONSECUENCIA DE LA VENTA O UTILIZACION DE ESTE

PRODUCTO. ALGUNOS ESTADOS DE LOS EE.UU. Y ALGUNAS PROVINCIAS CANADIENSES NO PERMITEN LA EXCLUSION O LIMITACION DE

LOS DAÑOS INCIDENTALES O EMERGENTES, POR LO QUE ES POSIBLE QUE LA LIMITACION O EXCLUSION ANTERIOR NO SEA APLICABLE EN

EL CASO DE USTED.

ESTA GARANTIA LIMITADA LE CONFIERE A USTED DERECHOS LEGALES ESPECIFICOS Y ES POSIBLE QUE USTED TAMBIEN TENGA OTROS

DERECHOS QUE VARIAN DE ESTADO A ESTADO EN LOS EE.UU., DE PROVINCIA A PROVINCIA EN CANADA.

ESTA GARANTIA LIMITADA SE APLICA SOLAMENTE A HERRAMIENTAS ELECTRICAS PORTATILES Y PARA TABLERO DE BANCO VENDIDAS EN

LOS ESTADOS UNIDOS DE AMERICA, CANADA Y EL ESTADO LIBRE ASOCIADO DE PUERTO RICO. PARA COBERTURA DE GARANTIA EN OTROS

PAISES, PONGASE EN CONTACTO CON SU DISTRIBUIDOR O IMPORTADOR LOCAL DE BOSCH.

LIMITED WARRANTY OF BOSCH PORTABLE AND BENCHTOP POWER TOOLS

GARANTIE LIMITÉE DES OUTILS ÉLECTRIQUES PORTATIFS ET D'ÉTABLI BOSCH

© Robert Bosch Tool Corporation 1800 W. Central Road Mt. Prospect, IL 60056 -2230

Exportado por: Robert Bosch Tool Corporation Mt. Prospect, IL 60056 -2230, E.U.A.

Importado a México por: Robert Bosch, S.A. de C.V., Calle Robert Bosch No. 405, Zona Industrial,

Toluca, Edo. de México, C.P. 50070, Tel. (722) 2792300

2610923971 10/07 Printed in Taiwan

Loading...

Loading...