Page 1

R

E

P

A

I

R

I

N

S

T

R

U

C

T

I

O

N

R

E

P

A

I

R

I

N

S

T

R

U

R

E

P

A

I

R

I

N

S

Fully-automatic coffeemaker

C

T

R

U

C

T

I

O

N

T

I

O

N

1 SAFETY........................................................2

1.1 Safety instructions..............................................................2

1.2 Repair instructions .............................................................2

2 INSTALLATION............................................3

2.1 Installation...........................................................................3

2.2 Scope of delivery................................................................ 3

3 OPERATION.................................................4

3.1 Starting the appliance.........................................................4

3.2 Controls...............................................................................5

3.3 Displays and operating logic........................................... 12

3.4 Adjusting water hardness................................................20

3.5 Reducing temperature......................................................21

3.6 Reset..................................................................................21

3.7 Manually cooling the heater.............................................22

3.8 Service programme .......................................................... 23

3.9 Maintenance and daily cleaning...................................... 28

4 COMPONENTS...........................................30

4.1 Flowmeter..........................................................................30

4.2 Heater and NTC-sensor.................................................... 31

4.3 Brewing unit...................................................................... 33

4.4 Gear unit............................................................................38

4.5 Steam valve and proximity switch................................... 42

4.6 Hot water / steam nozzle ..................................................43

4.7 Water filter.........................................................................44

5 FUNCTIONS ...............................................45

5.1 Construction......................................................................45

5.2 Fluid system......................................................................47

5.3 Temperature...................................................................... 48

6 REPAIR.......................................................49

6.1 Replacing the brewing unit.............................................. 49

6.2 General disassembly........................................................ 52

6.3 Replacing the pump ......................................................... 55

6.4 Replacing the thermal fuse.............................................. 56

6.5 Replacing the heating element and NTC sensor............ 59

6.6 Replacing the electronics board ..................................... 60

6.7 Replacing the power cord................................................ 61

6.8 Replacing the coffee outlet.............................................. 62

6.9 Replacing the front panel................................................. 63

6.10 Replacing steam valve and operating panel .................. 64

6.11 Appliance test................................................................... 65

7 FAULT DIAGNOSTICS...............................67

7.1 Incoming goods inspection............................................. 67

7.2 Incoming goods inspection............................................. 68

7.3 System and error messages............................................ 69

7.4 Measuring the coffee temperature.................................. 73

8 TECHNICAL SPECIFICATIONS.................74

8.1 Rating plate....................................................................... 74

8.2 Power................................................................................. 75

8.3 Temperatures.................................................................... 75

8.4 Consumption values (230 V/50 Hz models).................... 76

8.5 Dimensions and weight.................................................... 77

8.6 Filling amounts................................................................. 77

8.7 Components...................................................................... 78

58300000123125_ARA_en_d.doc – 09.10.09 Seite 1 von 78

Page 2

1 SAFETY

1.1 Safety instructions

Danger!

► Repairs may be carried out by a qualified electrician only!

► The user may be put at considerable risk and injured by

improper repairs!

► Electric shock may occur if live components are touched

inside the appliance!

► Do not touch components in the appliance. Even the modules

can be live!

► Before commencing repairs, ALWAYS disconnect the

appliance from the power supply!

► If tests have to be conducted while the appliance is live,

ALWAYS use a residual-current-operated circuit-breaker!

► The protective conductor connection must not exceed the

standardised values! This is essential for personal safety and

appliance function!

► When repairs are complete, perform a test in accordance with

VDE 0701 or the corresponding national regulations!

► Following each repair, conduct a leak and performance test.

1.2 Repair instructions

Caution!

► NEVER attempt repairs by randomly replacing components!

► ALWAYS proceed systematically and comply with the

technical documentation for the appliance!

► Components become hot during operation. Before

commencing repairs, leave the appliance to cool down.

► As a rule, printed-circuit boards are not repaired but are

completely replaced with original spare parts. Exceptions are

documented separately.

Risk of scalding!

Hot water / steam nozzle or auto-cappuccinatore frothing-up

nozzle (optional) become very hot. Take hold of the nozzles

by the plastic parts only, not by the metal parts. Keep body

parts away from the nozzles and do not aim it to yourself or

anyone else.

When steam or hot water is released, the nozzles may initially

sputter!

58300000123125_ARA_en_d.doc – 09.10.09 Seite 2 von 78

Page 3

2 INSTALLATION

2.1 Installation

► The installation location must be level and dry.

► Protect the appliance from splash water.

► There must be a minimum filling height of 410 mm.

► Connect and operate the appliance only in accordance with

the specifications on the rating plate.

► Operate the appliance indoors and at room temperature only.

► Do not place the appliance on a hot surface (e.g. heating

plate) and never use it close to an open flame.

2.2 Scope of delivery

Accessories included in packing without extra box:

► 2 Detergent-tablets

► Test strip for determining the local water hardness

► 2 Descaler-tablets (for 1 descaling process)

► Operating instructions in 7 languages

58300000123125_ARA_en_d.doc – 09.10.09 Seite 3 von 78

Page 4

3 OPERATION

3.1 Starting the appliance

Risk of damage!

Do not use coffee beans which have been glazed,

caramelised or treated with other additives containing

WARNING

► Pull the mains plug out of the cord store at the rear of the

appliance and connect according to the specifications on the

rating plate.

► Remove the water tank and fill with fresh, cold, non-

carbonated water. Observe “max” mark.

► Attach water tank straight and press all the way down.

► Fill the bean container with fresh coffee beans. Preferably

use espresso beans or bean mixtures for fully automatic

machines.

► Set the mains switch at the rear

of the appliance to I.

LED above stand-by button lights up

dim red.

► Ensure that the rotary knob for

drawing steam/hot water is set

to O.

► Press Standby button.

sugar. These will damage the grinding unit.

Note:

When the appliance is used for the first time or if the

appliance has not been used for a prolonged period, the

first cup of coffee still does not have the full aroma and

should therefore not be drunk.

3.1.1 Self-test

► Brewing module is initialised.

► Appliance heats up to operating temperature.

► Brewing module is moved to brewing position.

► Pump starts running and conveys approx. 50 ml water

through the coffee outlet.

Brewing module and coffee outlet are rinsed and heated.

► Brewing module drains and moves to home position

Appliance is ready for use when the LED above the stand-by button

is lit green.

3.1.2 Filling the system

When switching on the appliance for the first time and after a service

the water pipe system in the appliance must be filled.

LEDs above stand-by button and “Turn steam/hot water valve”

flash:

► Place a cup under the hot water/ steam nozzle.

► Set rotary knob for drawing steam/hot water to “Steam”.

A small amount of water is conveyed and the water pipe

system is filled.

► Set rotary knob for drawing steam/hot water to “O”.

LED above stand-by button flashes, appliance heats up and is

rinsed.

Appliance is ready for use when the LED above the stand-by

button is lit green.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 4 von 78

Page 5

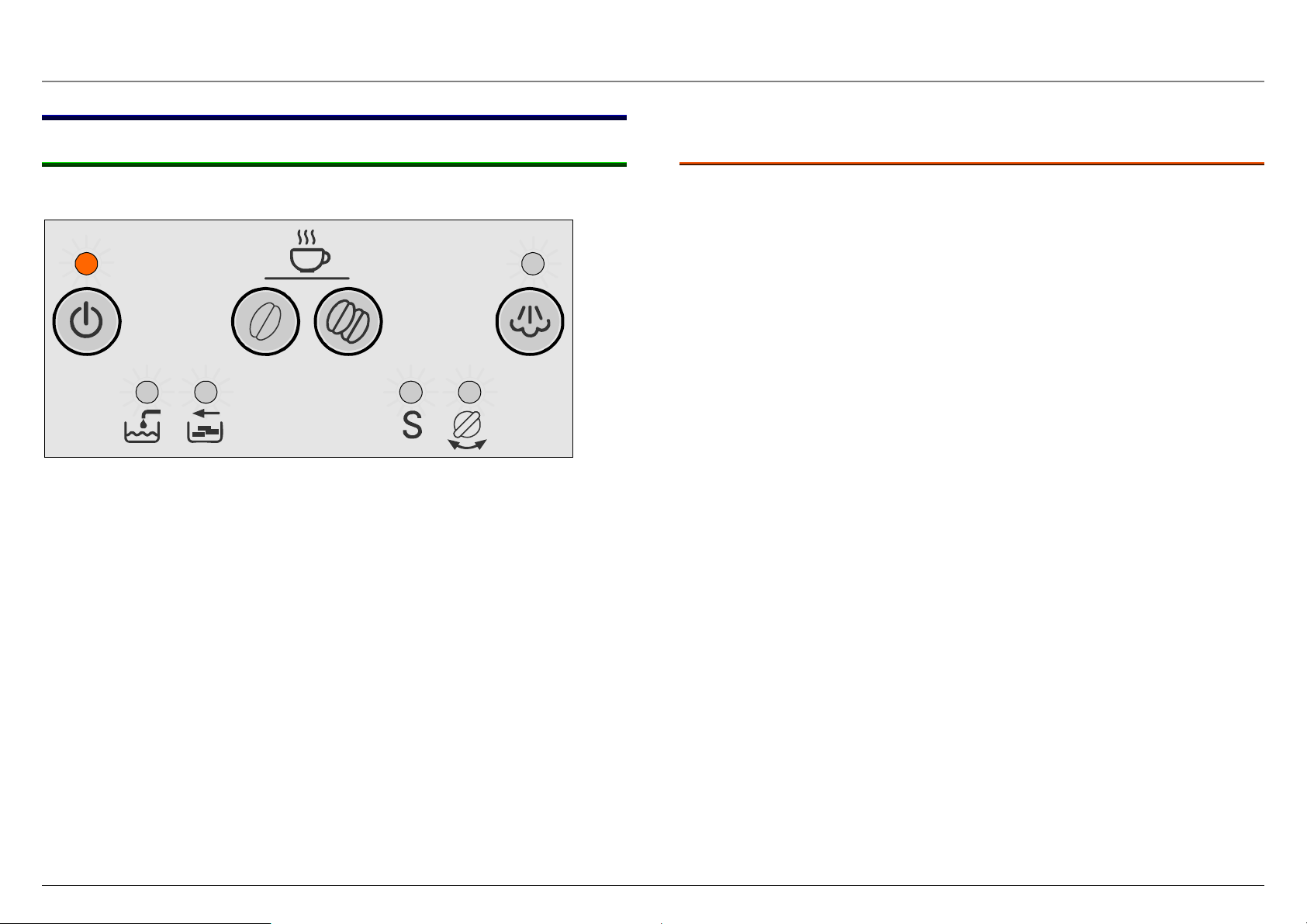

3.2 Controls

3.2.1 Overview of the controls 1

2

3

4

5

6

7

8

9

10

11

12

a

b

c

d

Mains switch I / O

Standby button

Coffee on button (mild)

Coffee on button (strong)

Steam button

Hot water/steam production knob

LED display

Fill water

Empty trays

Run Service programme

Turn steam/hot water valve

Steam pipe with frothing nozzle

Coffee outlet, height-adjustable

Cover, water tank

Water tank

Bean container with aroma protection cover

13

14

15

16–19

20

21

Slot for detergent tablets

Cup shelf with cup heater

Slide switch, degree of ground coffee

Drip tray

Store for power cord

Service flap (access to brewing module)

58300000123125_ARA_en_d.doc – 09.10.09 Seite 5 von 78

Page 6

3.2.2 Overview of the controls 16

17

18

19

Drip plate

Drawer for coffee dregs

Drip tray

Float for level indicator

Note!

The level of the drip tray is indicated via the float

through an opening in the drip plate. The level is not

monitored electronically!

16

17

18

19

58300000123125_ARA_en_d.doc – 09.10.09 Seite 6 von 78

Page 7

3.2.3 Controls

1. Mains switch

The mains switch on the rear of the appliance switches the power

supply on or off.

When the mains switch has been switched on, the Standby button

lights up dim red. The appliance is in standby mode.

Attention!

Risk of damage!

Do not actuate the mains switch during the brewing

process. When the appliance is switched on again,

malfunctions and damage may occur.

► Do not switch off the appliance with the mains

switch until it has been switched off with the

WARNING

Standby button.

2. Standby button

The Standby button switches on and starts the appliance or

switches it from brewing mode to standby.

When the Standby button has been pressed, a self-test runs: The

appliance is initialised, heats up and is rinsed. The LED of the

Standby button flashes during this process.

If the LED is lit green, the appliance is ready for use.

Switching on a cold appliance:

When the Standby button has been pressed, the appliance heats up

and is rinsed. The button flashes. Coffee cannot be brewed until the

button stops flashing.

Switching on a warm appliance:

If the appliance is switched on with the Standby button, a rinsing

process or self-test will not occur until the heater has reached the

operating temperature. The Standby button is lit constantly. Coffee

can be brewed immediately.

The appliance is not rinsed if:

► it was still warm when switched on

or

► there was no coffee from the last brew before the appliance

was switched off.

Automatic switch-off:

Appliance automatically switches to standby after 3 hours.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 7 von 78

Page 8

Controls

3. Coffee on button (mild)

If the coffee on button (mild) is pressed, a coffee brewing

process is started with a small amount of ground coffee.

Amount of ground coffee saved permanently: mild =

7.6 +/– 1g

► Press 1 x for a cup of mild coffee.

Coffee beans are ground, pre-brewed and conveyed into the cup.

4. Coffee on button (strong)

If the coffee on button (strong) is pressed, a coffee brewing

process is started with a large amount of ground coffee.

Amount of ground coffee saved permanently: strong =

12.3 +/– 1g

► Press 1 x for a cup of strong coffee.

Coffee beans are ground, pre-brewed and conveyed into the cup.

If the button is pressed again, the coffee brewing process can be

interrupted early. The grinding process is ended, the brewing process

is stopped, the brewing module is emptied.

The same amount of liquid can also be drawn:

► To do this, press the coffee on button (strong) again within

3 seconds after the end of the brewing process.

The already used ground coffee is brewed.

The factory preset amount of liquid (125 ml) can be changed.

► To do this, press the “on” button and hold down until the

required amount of coffee has run through.

Programming range 30–220 ml

Reset to factory setting ► Remove drip tray

► Simultaneously press Mild +

Strong “on” buttons and hold

down for 5 second

LEDs flash

► Re-insert drip tray

► Switch on appliance with

standby button

58300000123125_ARA_en_d.doc – 09.10.09 Seite 8 von 78

Page 9

Controls

5. Steam button

By pressing the button, steam is generated for frothing or

heating.

The appliance heats up for approx. 20 seconds. Then steam can be

drawn by rotating hot water/steam production knob.

When the knob has been turned back to O, the steam button must be

pressed again before more steam can be drawn.

6. Hot water/steam production knob

Valve with 2 positions

O

When the hot water/steam production knob has been turned, hot

water or steam can be drawn via the steam pipe.

Before steam can be drawn, the steam button must also be pressed.

When the knob has been turned back to O, the steam button must be

pressed again before more steam can be drawn.

Coffee brewing process (valve closed)

Hot water/steam production (valve open)

7. LED display

Lit and flashing LEDs indicate the following:

lit Water tank is empty and must be filled.

lit Trays are full: Empty trays and re-insert.

flashes No trays: Re-insert trays.

S

S

8. Steam pipe with frothing nozzle

Steam pipe can be swivelled 30° to the side.

Standard frothing nozzle for drawing hot water and for drawing steam

to heat drinks and froth milk.

lit Service programme must be run:

flashes Service programme is running

flashes

lit

Knob must be turned to hot water/steam

production.

Knob must be turned to O.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 9 von 78

Page 10

Controls

9. Coffee outlet, height-adjustable

Adjustment range 80 mm–120 mm

10. Cover, water tank

Hinged, connected to upper section of appliance.

11. Water tank

Can be removed at side, 1.8 litre capacity up to “ max” mark.

Holder for screw-on water filter (mat. no. 46 1732) available.

12. Bean container with aroma protection cover

Transparent, capacity approx. 700 ml (equivalent to approx. 250

beans)

13. Slot for cleaning tablet

No sensor for cover monitor

14. Cup shelf with cup pre-heater

15. Slide switch – degree of ground coffee, 3-stage

Risk of damage!

Beans may become jammed in the grinding unit.

► Adjust degree of grinding only while the grinding

WARNING

unit is running

Irrespective of the degree of roasting and the oil content of the coffee

beans used, the coffee mill’s degree of grinding must be changed:

► Light roasting, low oil content finer grinding result

► Dark roasting, high oil content coarser grinding result

If beans are very oily, a very fine grinding unit setting

in conjunction with a large amount of ground coffee

may impair the operating sequence!

The new setting does not become noticeable until the second or third

cup of coffee.

Passively heated by the waste heat from the coffee heater

Temperature > 37 °C after 20 minutes

58300000123125_ARA_en_d.doc – 09.10.09 Seite 10 von 78

Page 11

Controls

16. Drip plate

Stainless steel, with opening for float

17. Drawer for coffee dregs

Capacity 12–14 coffee dregs at medium strength

18. Drip tray

Volume until float indicates limit, approx. 0.7 litres

The presence of the drip tray is monitored by a microswitch.

This also occurs in standby.

19. Float for level indicator

The level of the drip tray is indicated via the float through an opening

in the drip plate.

The level is not monitored electronically.

20. Store for power cord

Pull out power cord to required length.

21. Service flap

The service flap is locked in position on the right side of the appliance.

To open:

► Take hold of the recessed grip and

► pull the service flap outwards.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 11 von 78

Page 12

3.3 Displays and operating logic

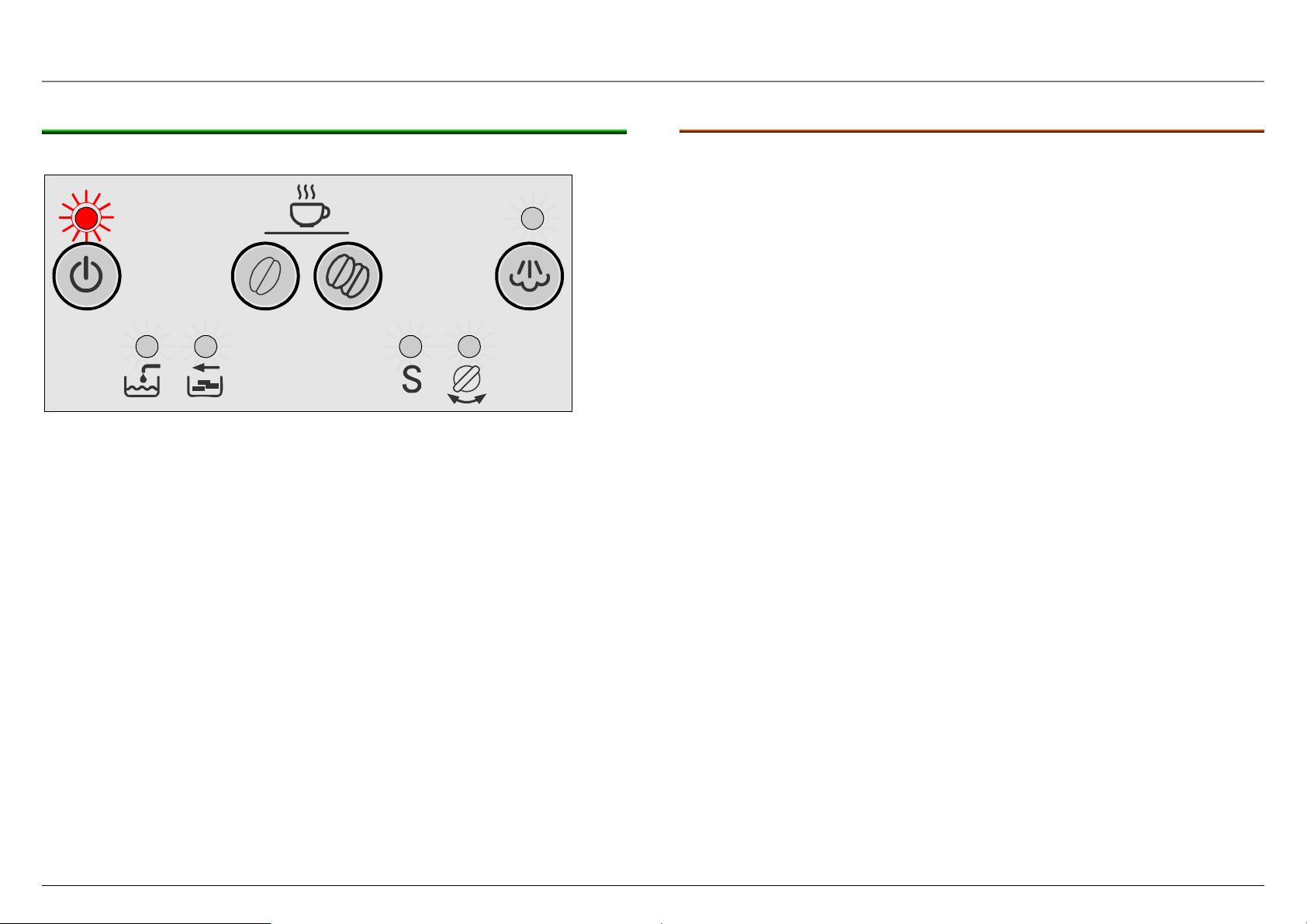

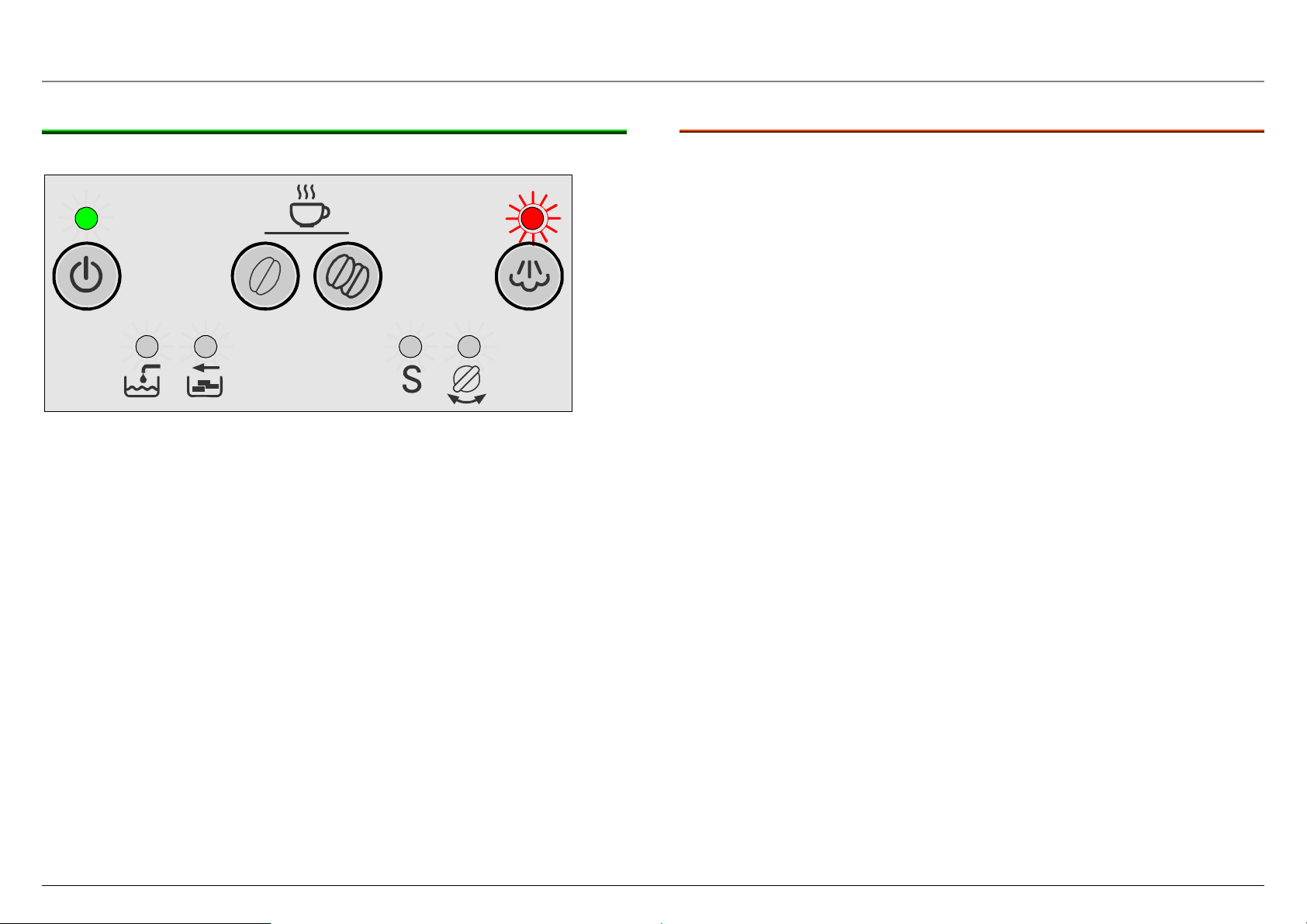

3.3.1 Standby

Set mains switch to I

LED button:

LED display:

Standby is lit dim red

No display

3.3.1.1 Options

Press Standby button: The appliance is initialised, heats up

and is rinsed

Press Coffee mild button: No response, appliance is off

Press Coffee mild button for

Service programme starts

5 seconds:

Press Coffee strong button: No response, appliance is off

Press the “Steam” button No response, appliance is off

Press Steam button for 5 sec.: Water hardness setting starts

Setting corresponds to the number

of lit LEDs

Press Coffee strong + Steam

buttons for 5 sec.:

Temperature reduction by 4°

Normal temperature = “Add water”

and “Empty trays” LEDs are lit. Pr ess

Coffee strong button = - 4°/ normal

Open hot water/steam valve: No response, appliance is off

Open hot water/steam valve,

Start appliance test

press Coffee mild + Steam

buttons for 5 sec.:

Remove trays: No response, appliance is off

Remove trays, Press Coffee

mild + strong buttons for 5 sec.:

Works reset for amount of coffee,

temperature and water hardness

Release brewing unit: No response, appliance is off

Service LED flashes alternately with

Standby LED buttons (dim red)

Press Coffee mild + strong +

Steam buttons for 5 sec.:

Set software bit for initial

operation: = Fill system +1.

Grinding unit running time +6 sec.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 12 von 78

Page 13

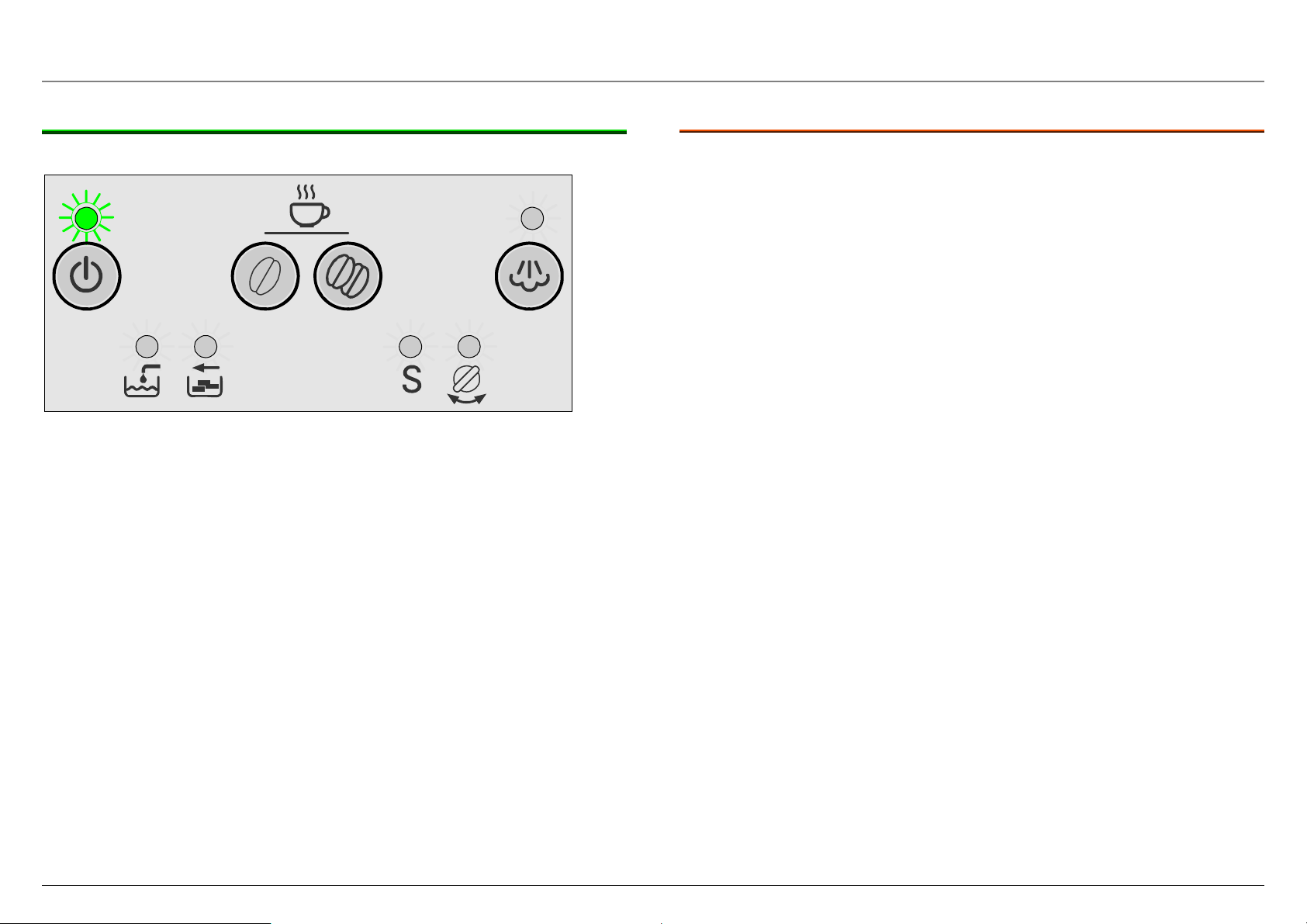

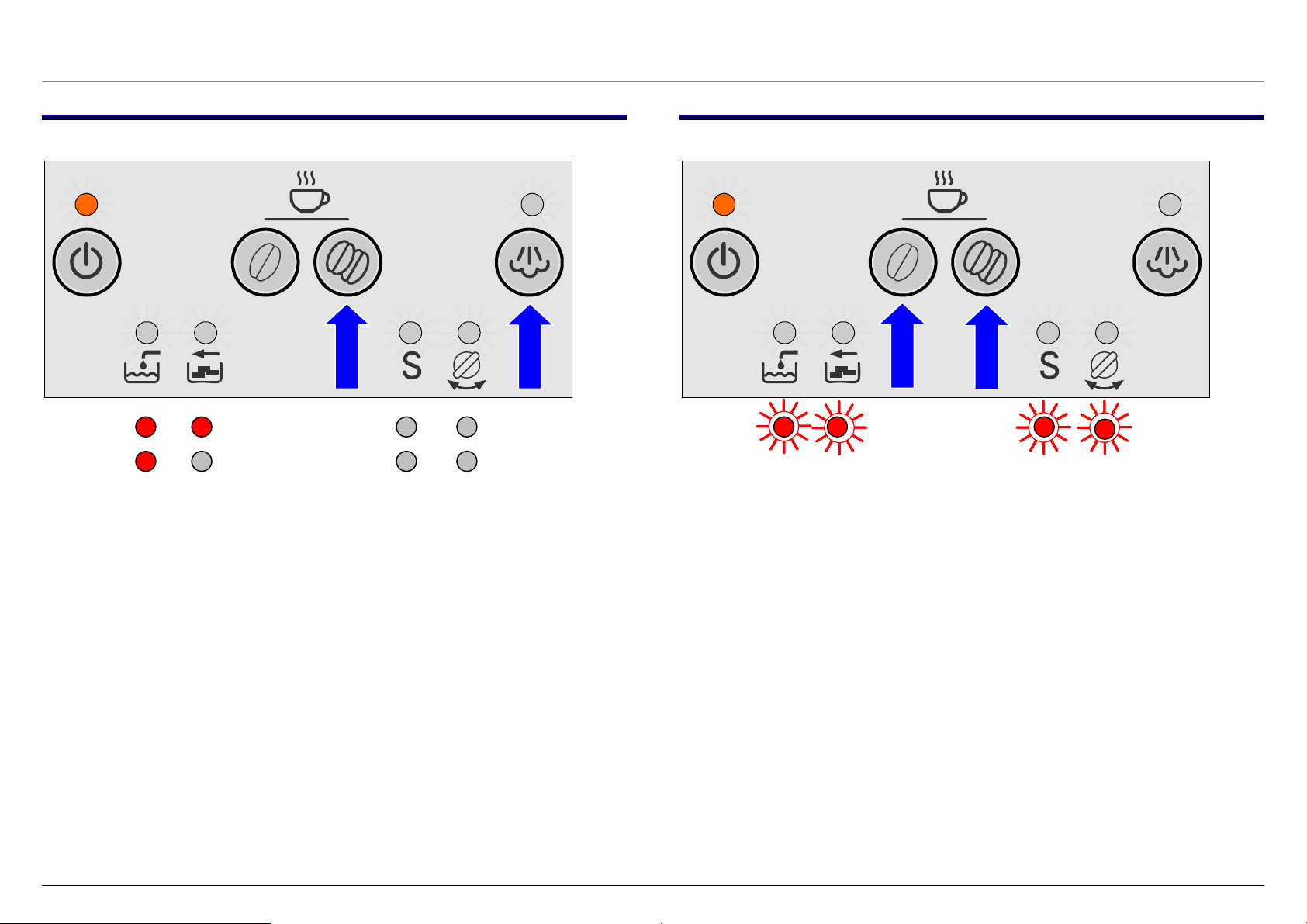

3.3.2 Switching on the appliance

Press Standby button

LED button:

LED display:

Appliance:

Standby flashes red

No display

The appliance is initialised, heats up and is rinsed

3.3.2.1 Options

Press Standby button: Appliance switches to standby

Press Coffee mild button: No response

Press Coffee strong button: No response

Press the “Steam” button: No response

Open hot water/steam valve: Close steam valve LED is lit

Remove trays: “Trays missing” LED flashes,

heating up is interrupted,

brewing unit does not move

Release brewing unit: Heating up ends.

Service LED flashes alternating

with Standby LED buttons (dim

red)

Lock brewing unit: Appliance switches to standby

58300000123125_ARA_en_d.doc – 09.10.09 Seite 13 von 78

Page 14

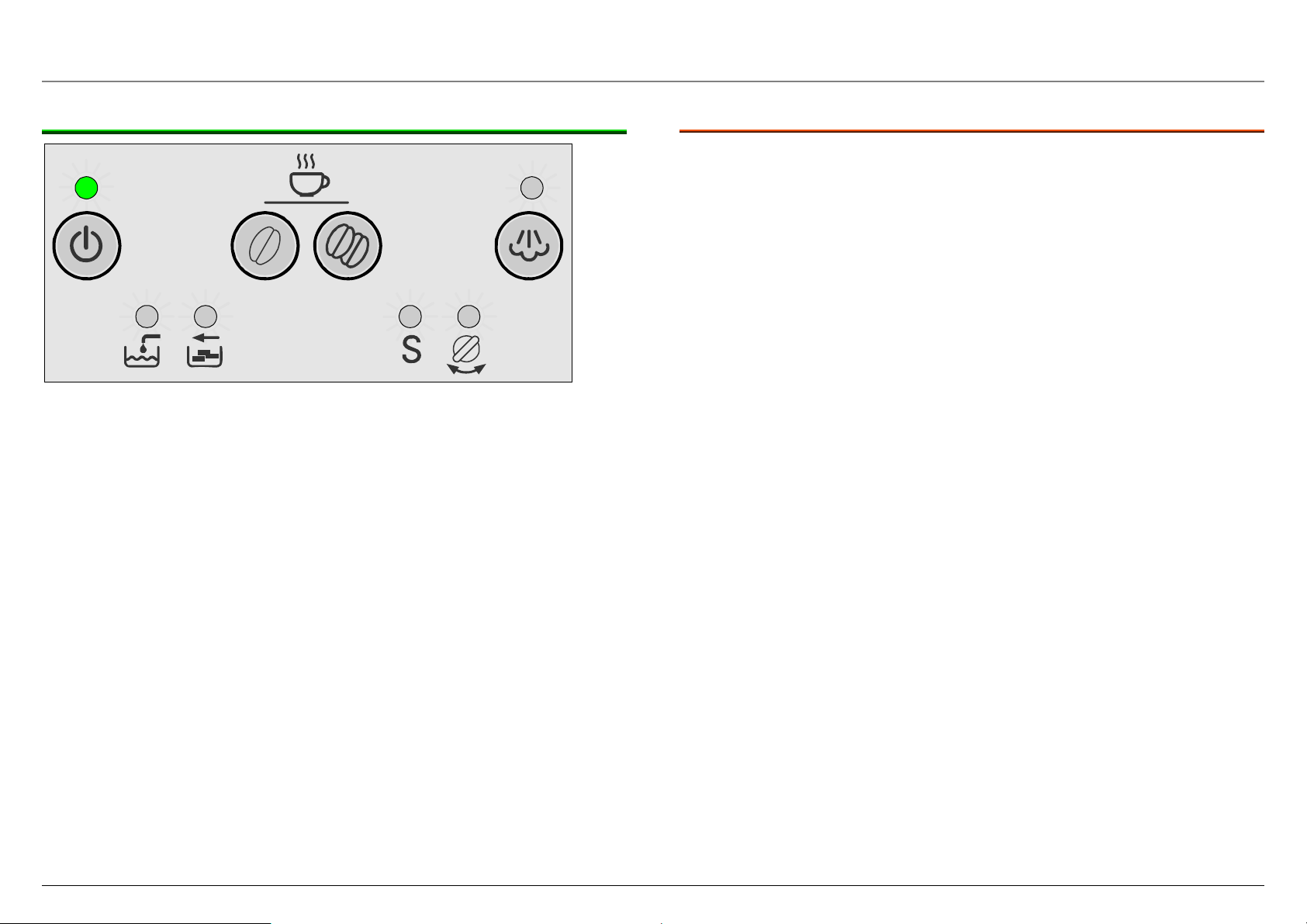

3.3.3 Appliance ready to use

LED button:

LED display:

Appliance:

Standby is lit green

No display

Ready to use

3.3.3.1 Options

Press Standby button: Appliance switches to standby

Press Coffee mild button: Brew coffee

Press Coffee strong button: Brew coffee

If the Coffee mild or Coffee

strong button is pressed again

within 3 seconds after the end of

the brewing cycle, the same

amount of liquid is brewed

through the ground coffee

already used.

Press the “Steam” button: Heat up to steam temperature

Open hot water/steam valve: Draw hot water

Remove trays: Standby button LED is lit, “Trays

missing” LED flashes

Release brewing unit: Service LED flashes alternating

with Standby LED buttons (dim

red)

Lock brewing unit: Appliance switches to standby

58300000123125_ARA_en_d.doc – 09.10.09 Seite 14 von 78

Page 15

3.3.4 Brewing coffee

Press the Coffee mild or Coffee strong button

LED button:

LED display:

Appliance:

Standby flashes green

No display

Brew coffee

3.3.4.1 Options

Press Standby button: The current coffee brewing process

is stopped, switches to standby.

Press Coffee mild button: The current coffee brewing process

is stopped, switches to standby.

Press Coffee strong button: The current coffee brewing process

is stopped, switches to standby.

If the Coffee mild or Coffee strong

button is pressed again within

3 seconds after the end of the

brewing cycle, the same amount of

liquid is brewed through the ground

coffee already used.

Press the “Steam” button: The current coffee brewing process

is stopped, switches to standby.

Open hot water/steam valve: The current coffee brewing process

is interrupted, Close steam valve

LED is lit, grinding is not

interrupted.

Remove trays: The current coffee brewing process

is interrupted, “Trays missing” LED

flashes, grinding is not interrupted.

Remove water tank: Coffee brewing process is stopped

after approx. 10 seconds, “Add

water” LED is lit, Open hot water/

steam valve LED flashes.

Adjust filling quantity: Active is accepted.

Beans running out: Current coffee brewing process is

completed.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 15 von 78

Page 16

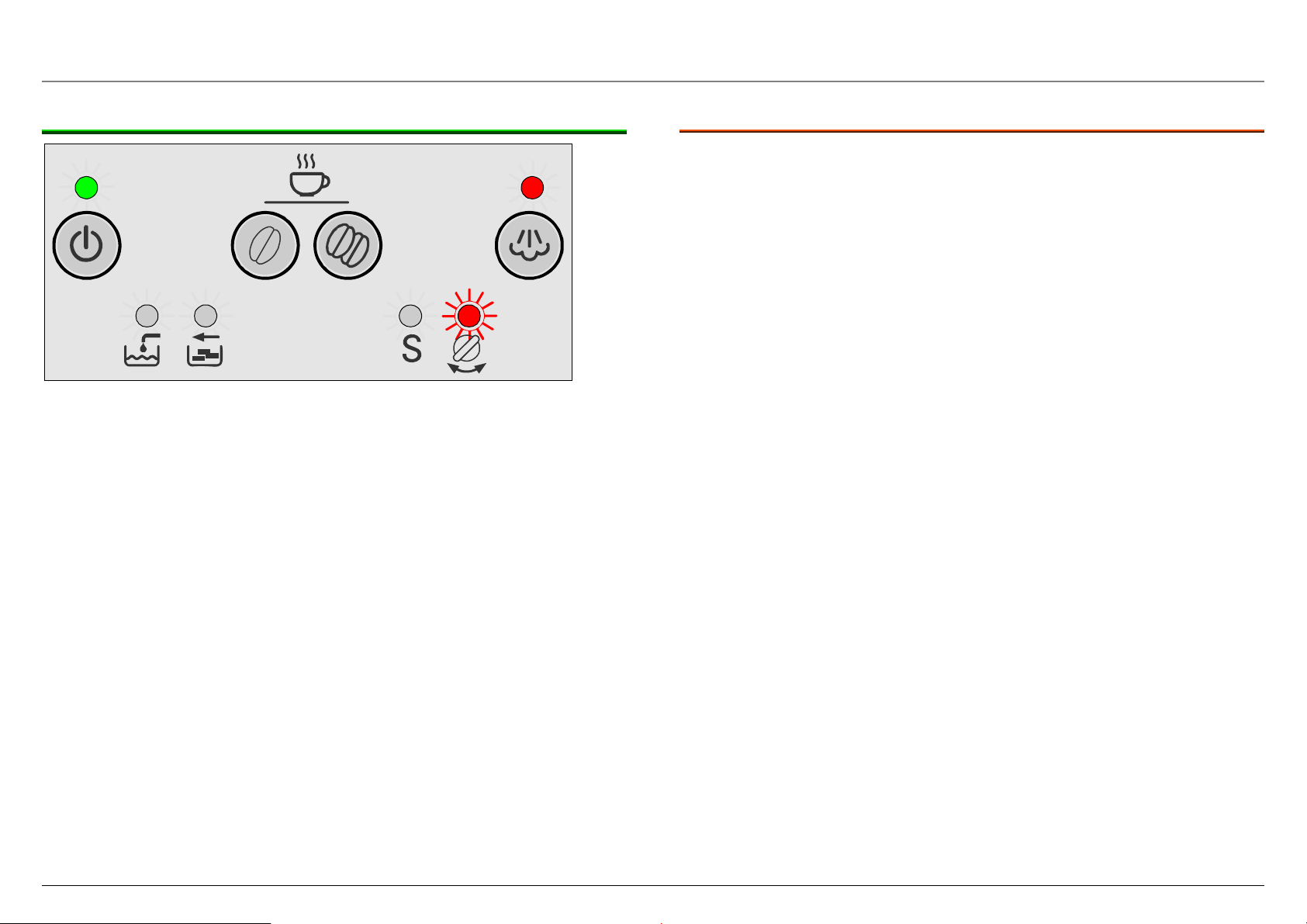

3.3.5 Drawing hot water

Open hot water/steam valve

LED button:

LED display:

Appliance:

Standby flashes green

Hot water/steam valve is lit

Pump is running, heating on

Convey hot water

3.3.5.1 Options

Press Standby button: Appliance switches to standby

Press Coffee on button: Brewing is stopped, “Close hot

water/steam valve” LED is lit

Press coffee strength button: Brewing is stopped, “Close hot

water/steam valve” LED is lit

Press the “Steam” button: Brewing is stopped, “Close hot

water/steam valve” LED is lit

Remove trays: Brewing is stopped, “Close hot

water/steam valve” LED is lit,

“Trays missing” LED flashes

Remove water tank: Brewing is stopped after approx.

10 sec., “Add water” and “Close

hot water/steam valve” LEDs are

lit

Release brewing unit: Brewing is stopped, Service LED

flashes alternating with Standby

LED buttons (dim red)

Lock brewing unit: Appliance switches to standby

58300000123125_ARA_en_d.doc – 09.10.09 Seite 16 von 78

Page 17

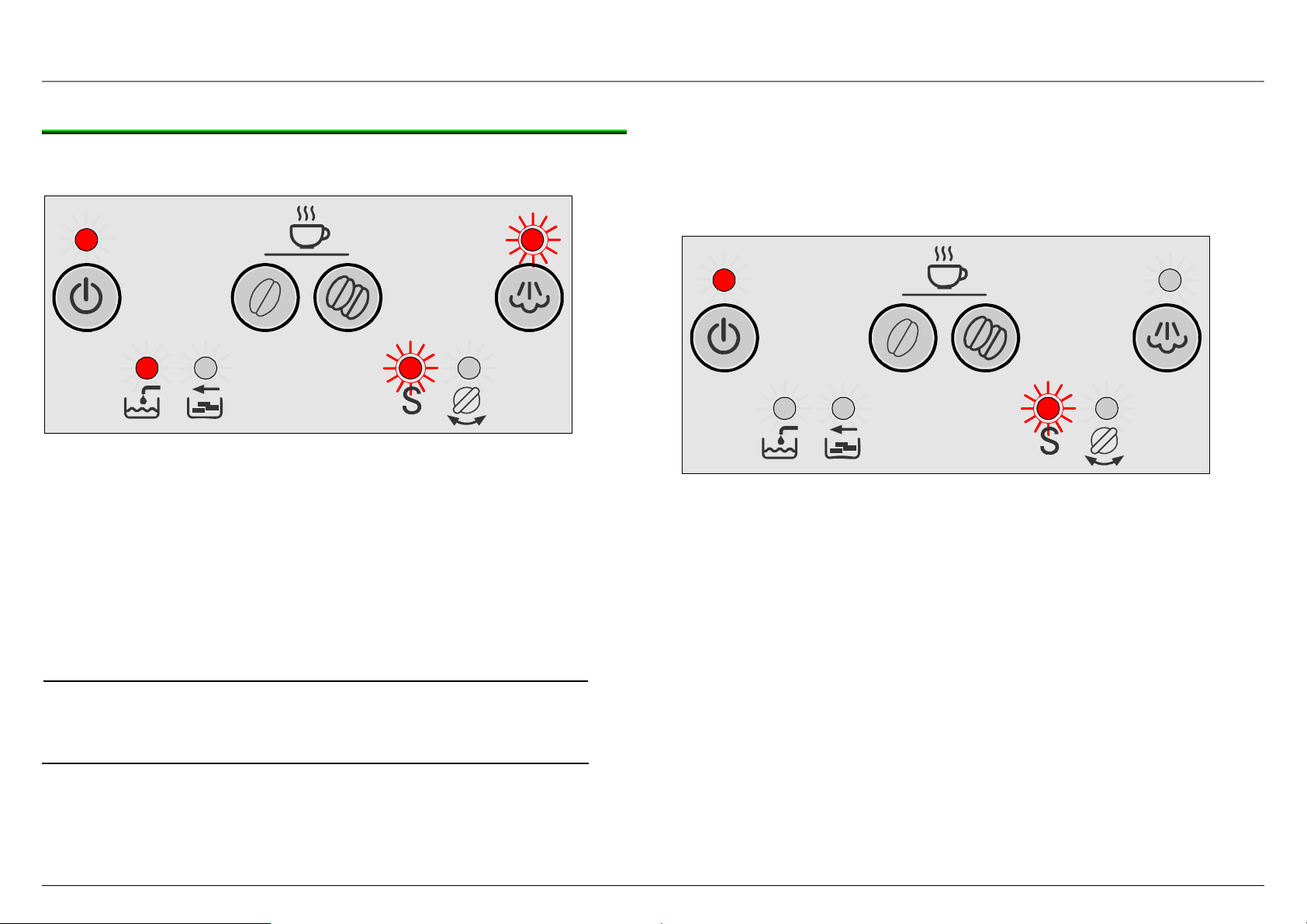

3.3.6 Heating up to steam

Press the “Steam” button

LED button:

LED display:

Appliance:

Standby is lit green, Steam flashes

No display

Heat up to steam temperature

3.3.6.1 Options

Press Standby button: Heating up is stopped, appliance

switches to standby

Press Coffee mild button: Heating up is stopped, appliance

switches to standby

Press Coffee strong button: Heating up is stopped, appliance

switches to standby

Press the “Steam” button: Heating up is stopped, appliance

switches to standby

Open hot water/steam valve: Wait until steam temperature has

been reached, then draw steam

Remove trays: Continues heating, “Trays

missing” LED flashes

Remove water tank: No response

Release brewing unit: Heating up is stopped, Service

LED flashes alternating with

Standby LED buttons (dim red)

Lock brewing unit: Appliance switches to standby

58300000123125_ARA_en_d.doc – 09.10.09 Seite 17 von 78

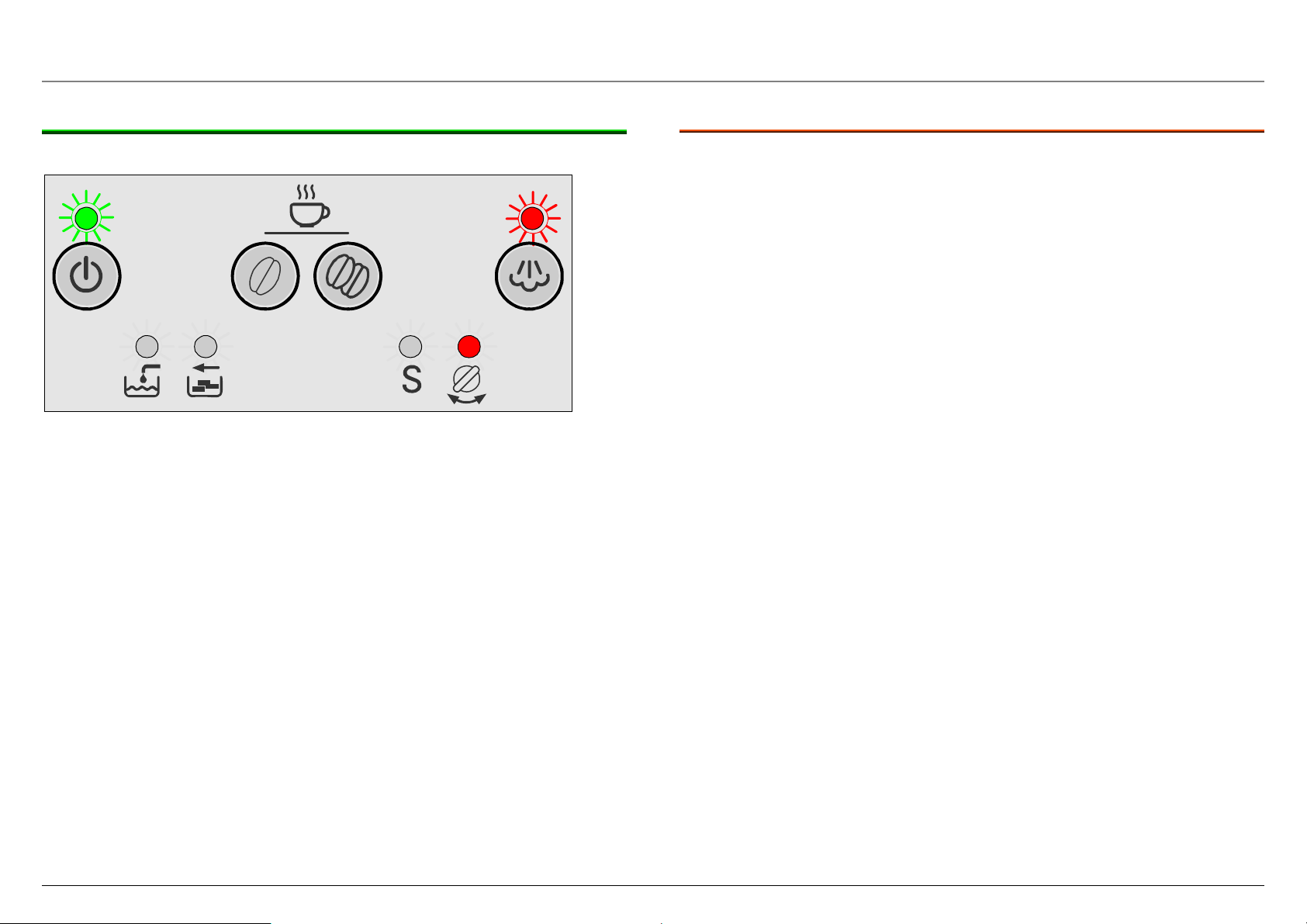

Page 18

3.3.7 Steam ready

LED button:

LED display:

Appliance:

Standby is lit green, Steam is lit

“Open steam valve” flashes

At steam temperature for approx. 1 minute

3.3.7.1 Options

Press Standby button: Stopped, appliance s witches to

standby

Press Coffee mild button: Stopped, appliance switches to

ready to use

Press Coffee strong button: Stopped, appliance switches to

ready to use

Press the “Steam” button: Stopped, appliance switches to

ready to use

Open hot water/steam valve: Steam is generated, “Close hot

water/steam valve” LED is lit

Close hot water/steam valve is lit Steam ready ends

Remove trays: Steam ready continues for

approx. 1 minute, “Close hot

water/steam valve” and “Trays

missing” LEDs flash

Release brewing unit: Steam ready is stopped, Service

LED flashes alternating with

Standby LED buttons (dim red)

Lock brewing unit: Appliance switches to standby

58300000123125_ARA_en_d.doc – 09.10.09 Seite 18 von 78

Page 19

3.3.8 Drawing steam

Open hot water/steam valve

LED button:

LED display:

Appliance:

Standby flashes green, Steam flashes

Open steam valve is lit

Pump is running, heating on

Convey steam

3.3.8.1 Options

Press Standby button: Stopped, appliance switches to

standby

Press Coffee mild button: Brewing is stopped, “Close hot

water/steam valve” LED is lit

Press Coffee strong button: Brewing is stopped, “Close hot

water/steam valve” LED is lit

Press the “Steam” button: Brewing is stopped, “Close hot

water/steam valve” LED is lit

Close hot water/steam valve is lit Stopped, appliance switches to

ready to use

Remove trays: Brewing is stopped, “Close hot

water/steam valve” LED is lit

Remove water tank: Brewing is stopped after approx.

30 sec., “Add water” and “Close

hot water/steam valve” LEDs are

lit

Release brewing unit: Steam on is stopped, Service

LED flashes alternating with

Standby LED buttons (dim red)

Lock brewing unit: Appliance switches to standby

58300000123125_ARA_en_d.doc – 09.10.09 Seite 19 von 78

Page 20

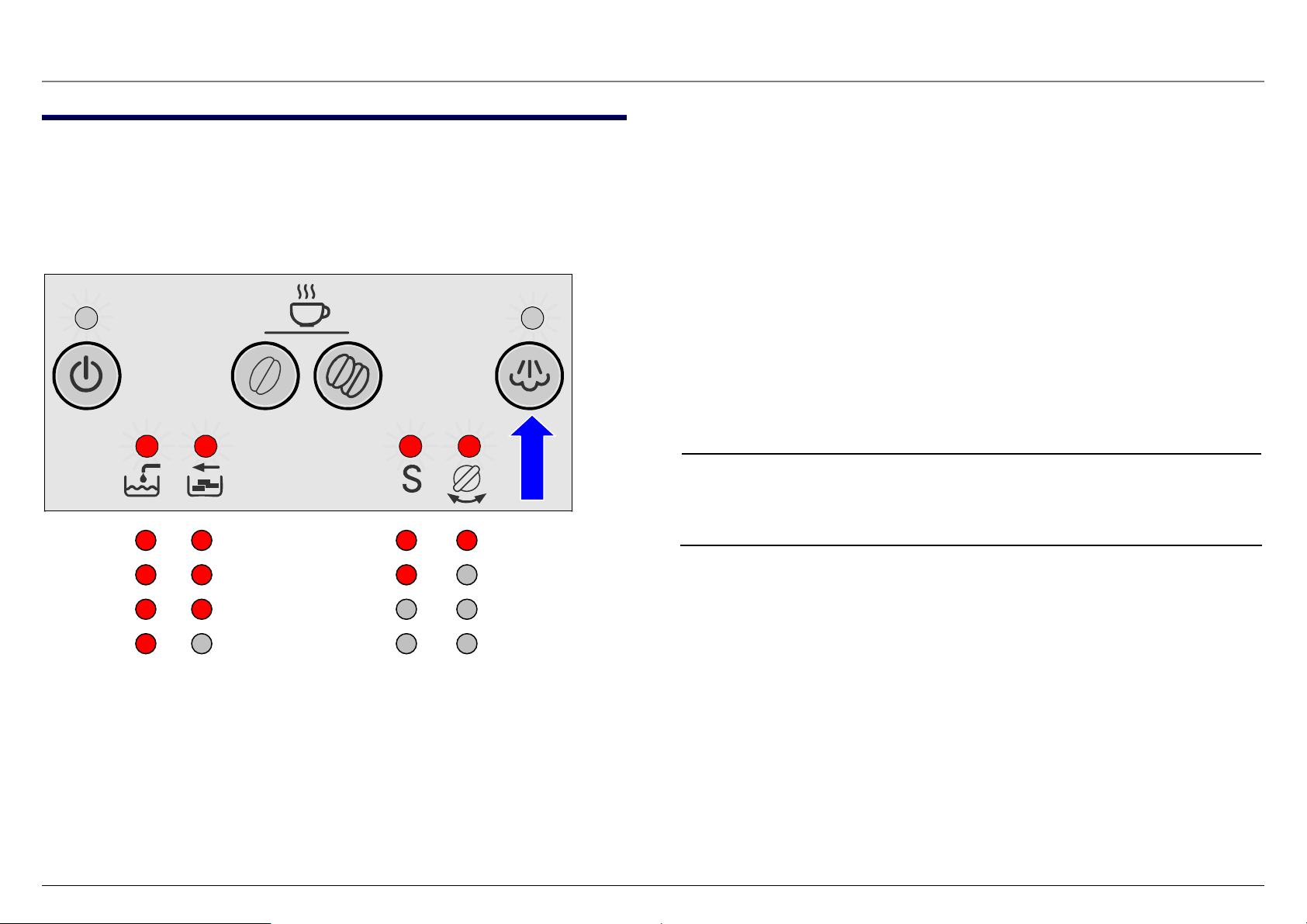

3.4 Adjusting water hardness

It is important that the water hardness is set correctly so that the

appliance indicates in good time when it requires descaling.

Water hardness 4 has been preset

Determine the water hardness with the enclosed test strip or ask your

local water supplier.

5 s

Hardness 4

Hardness 3

► Switch on the appliance with the mains switch.

Appliance is in standby

► Press Steam button for 5 seconds:

Number of lit LEDs indicates the currently set water hardness.

► Keep pressing Steam button until the buttons for the

required water hardness light up.

If no button is pressed within 90 seconds, the appliance switches back

to coffee ready without saving the water hardness. The previously set

water hardness is retained.

► Press Standby button once.

The set LEDs flash 3 times, the selected water hardness is saved.

Note:

If a water filter is used, water hardness 1 must

be set!

Hardness 2

Hardness 1

58300000123125_ARA_en_d.doc – 09.10.09 Seite 20 von 78

Page 21

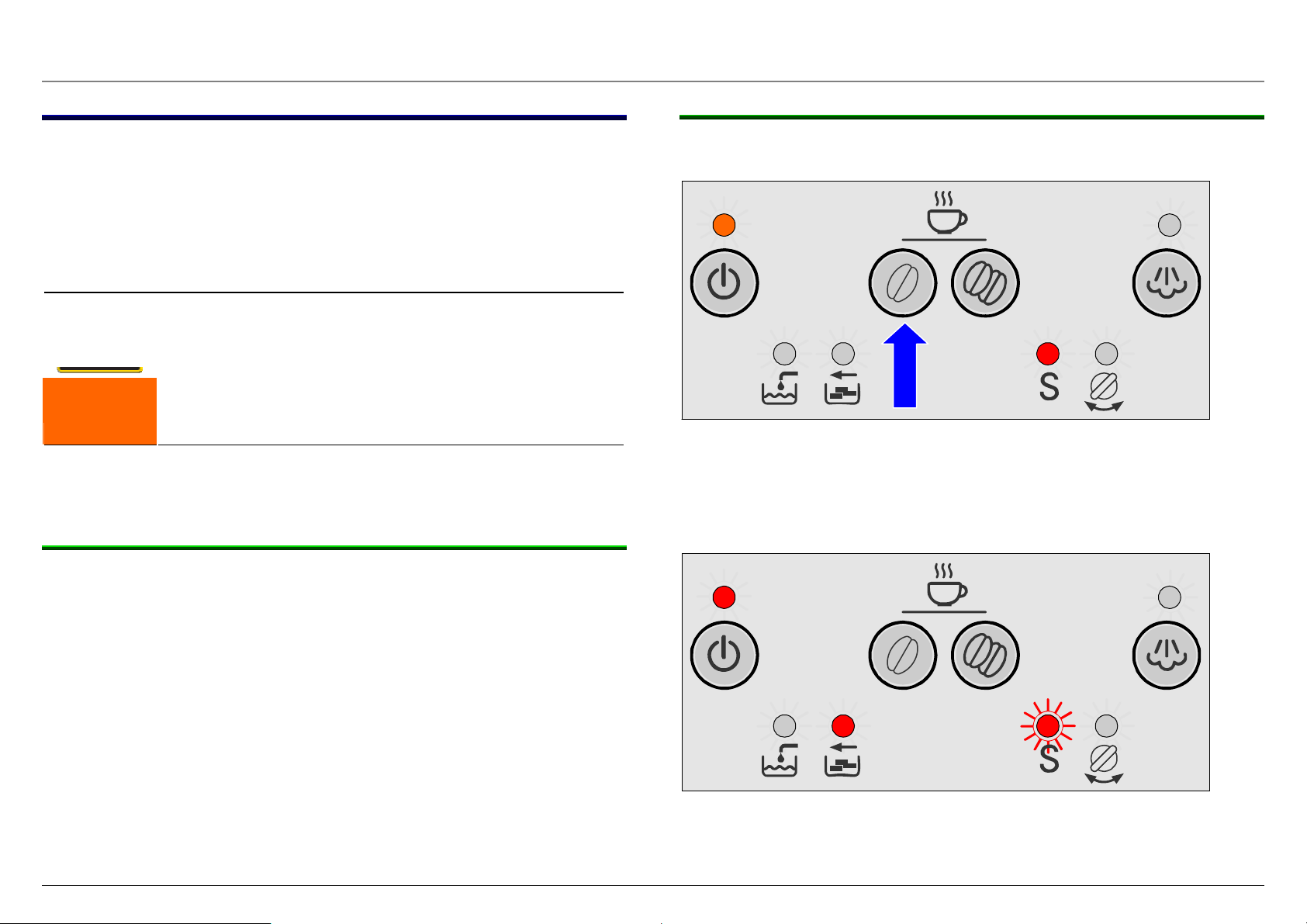

3.5 Reducing temperature

Temperature reduction by 4°

5 s

► Switch on the appliance with the mains switch.

Appliance is in standby

► Press Coffee strong and Steam buttons for 5 seconds:

Normal temperature: Add water and Trays missing LEDs are lit

► Press Coffee strong button to reduce the temperature

by 4°

–4°: Add water LED is lit

► Press Standby button once

The set LEDs flash 3 times, the selected water hardness is saved.

If no button is pressed within 90 seconds, the appliance switches back

to coffee ready without saving the water hardness. The previously set

water hardness is retained.

Normal

- 4°

3.6 Reset

► Switch on the appliance with the mains switch.

Appliance is in standby

► Remove drip tray

► Press Coffee mild and Coffee strong buttons for 5

The following values are reset to the factory settings:

– Amount of liquid coffee (set to 125 ml)

– Temperature (set to normal)

– Water hardness (set to hardness 4)

All 4 LEDs flash 3 times. Appliance switches back to standby

seconds:

3 x

5 s

58300000123125_ARA_en_d.doc – 09.10.09 Seite 21 von 78

Page 22

3.7 Manually cooling the heater

Heater and parts of the tube system become hot during operation. For

service activities heater and tube system can be cooled down

manually.

► Provide a 0.5 litre collecting vessel

3.7.1 Procedure

► Insert mains plug and set mains switch to “I”

Appliance is in standby. The standby button LED is lit dimly red.

► Place collecting vessel under steam nozzle.

► Simultaneously press coffee on MILD and steam

buttons for 5 seconds.

LED above Open steam tap symbol flashes for 5 seconds.

► Open steam tap: (if the steam tap is not opened during this

time, the appliance switches back to standby).

Cold water (maximum 0.5 litres) is conveyed out of the steam pipe.

It is not reheated, heater is cooled manually.

► Close steam tap.

Pump stops. Appliance switches back to standby. The standby button

LED is lit dimly red.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 22 von 78

Page 23

3.8 Service programme

The service programme combines the descaling and cleaning

process in one cycle.

If S lights up on the display when the appliance is switched on, the

service programme must be started.

Use liquid descaling agent, mat. no. 310451, and detergent tablets,

mat. no. 310575!

Risk of damage!

► Never interrupt the service programme!

► Never descale the appliance with vinegar or vinegar-

based substances.

► Before starting the service programme, remove

WARNING

While the Service programme is running (approx. 40 min.), the S LED

flashes.

3.8.1 Service alarm

water filter from the water tank!

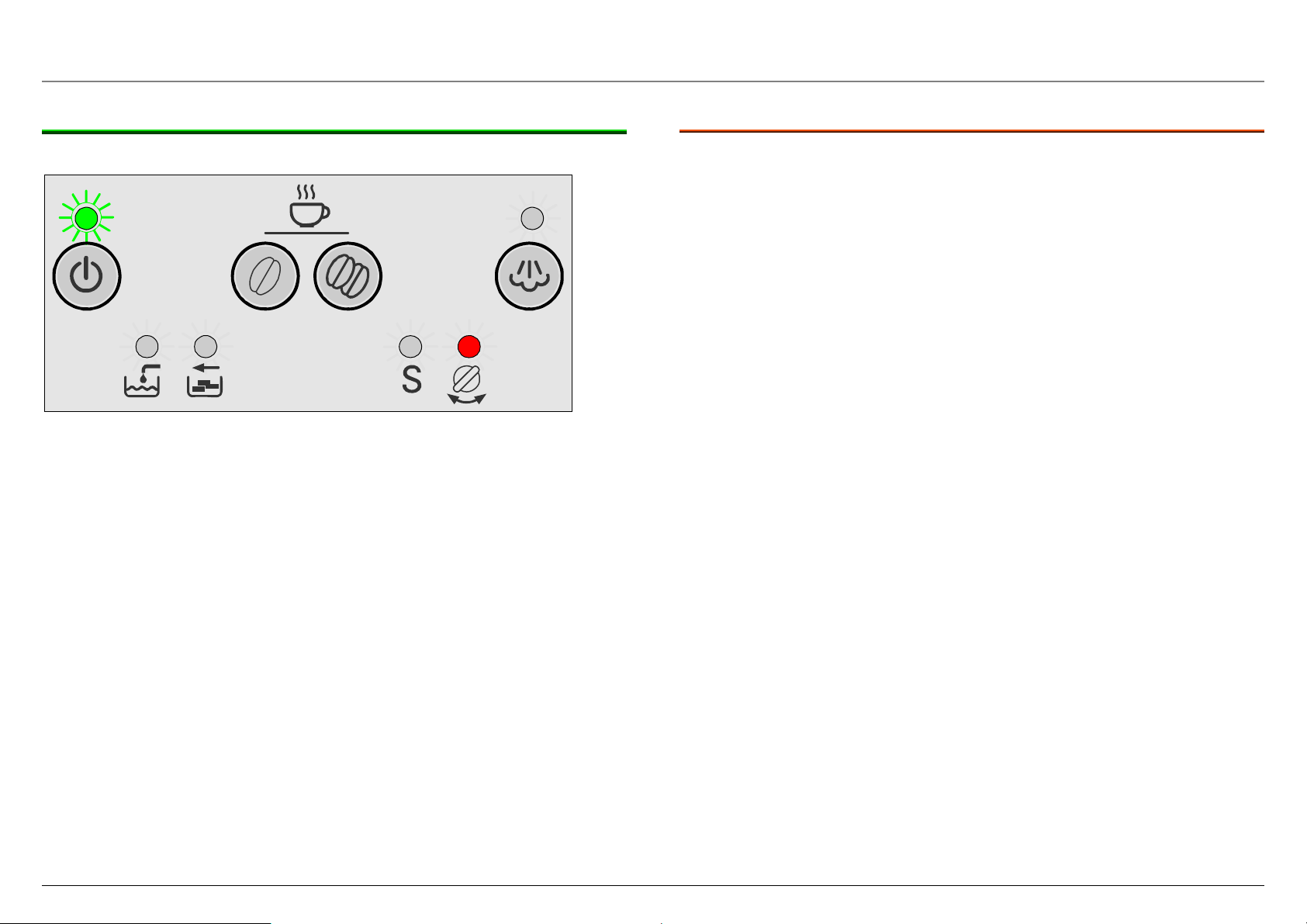

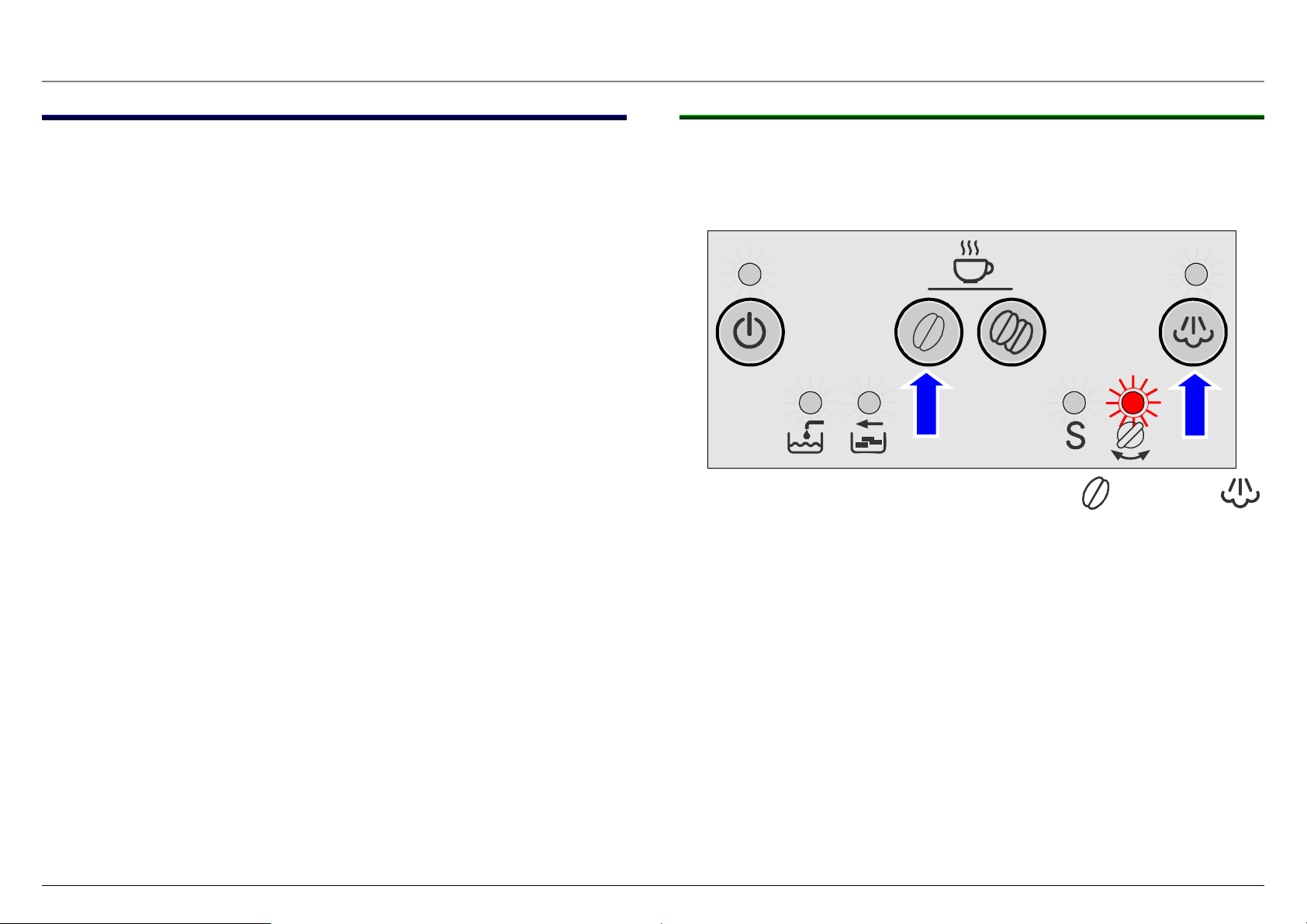

3.8.2 Starting the service programme

► To start the Service programme, switch the appliance to

standby.

5 S

LED button:

LED display:

Standby is lit dim red

S is lit

► Press Coffee mild button for 5 seconds

The appliance is initialised, heats up and is rinsed.

The Service alarm is displayed after

► 180 coffee brewing processes; irrespective of the coffee

strength and cup size (Cleaning alarm)

or

► 120 l water flow at a water hardness setting of 1

90 l water flow at a water hardness setting of 2

60 l water flow at a water hardness setting of 3

30 l water flow at a water hardness setting of 4

For steam the calculation is as follows: 6.4 seconds of steam

production correspond to 1 dl of hot water production.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 23 von 78

LED button:

LED display:

Standby is lit red

S flashes, Empty trays is lit

Page 24

3.8.3 Sequence of the Service programme (descaling)

► Remove drip tray with dregs drawer, empty and re-insert (time

window > 6 seconds).

LED button:

LED display:

Standby is lit red, Fill water is lit

S flashes, Steam flashes

► Place one cleaning tablet in the slot

► Fill water tank with lukewarm water, add descaling agent and

dissolve completely in water (total amount of liquid = 0.5

litres).

or

► Fill water tank with 0.5 l of ready mixed descaling solution.

► Press the steam button

Appliance starts the descaling cycle. Duration approx. 10 minutes.

Service marker is set

LED button:

LED display:

Standby is lit red

S flashes

Liquid outlet via drainage valve: 1 x 60 ml

16 x 15 ml

Total: 300 ml

Descaling via drainage valve ended.

If using descaling tablets, add two tablets.

Observe the dissolving time of the tablets

58300000123125_ARA_en_d.doc – 09.10.09 Seite 24 von 78

(approx. 4–6 minutes)!

Page 25

Sequence of the Service programme (descaling)

LED button:

LED display:

Standby is lit red

S flashes, Turn hot water/steam valve flashes

► Place an adequately large receptacle (approx. 0.5 litres) under

the steam pipe.

► Turn hot water/steam valve to hot water production

Sequence of the Service programme (rinsing)

LED button:

LED display:

Standby is lit red

S flashes, Empty trays is lit

► Remove drip tray with dregs drawer, empty and re-insert

(time window > 6 seconds).

Appliance continues descaling cycle. Duration approx. 5 minutes.

Liquid outlet via steam pipe: 15 x 20 ml

Total: 300 ml

Descaling ended

LED button:

LED display:

Standby is lit red, Steam is lit

S flashes, Fill water is lit

► Empty and clean water tank, fill with fresh water up to the

“max” mark and re-insert.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 25 von 78

Page 26

Sequence of the Service programme (rinsing)

► Place an adequately large receptacle (approx. 0.5 litres) under

the steam pipe.

► Press the “Steam” button.

Appliance starts rinsing. 100 ml of water are conveyed.

LED button:

LED display:

Standby is lit red

S flashes

Rinse cycle via steam pipe has ended when Turn hot water/steam

valve LED is also lit.

LED button:

LED display:

Standby is lit red

S flashes, Turn hot water/steam valve is lit

► Turn hot water/steam valve to O

Appliance starts the cleaning process. 100 ml of water are conveyed

via the drainage valve.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 26 von 78

Page 27

3.8.4 Sequence of the Service programme (cleaning)

Brewing module is moved to brewing position (drainage position)

LED button:

LED display:

Standby is lit red

S flashes

Liquid outlet via drainage valve: 1 x 80 ml

8 x 15 ml

Total: 200 ml

Brewing module is moved back to the home position, then to the

brewing position again

Liquid outlet via coffee outlet: 6 x 20 ml

Total: 120 ml

Cleaning cycle has ended when the Empty trays LED flashes

► Remove drip tray with dregs drawer, empty and re-insert (time

window > 6 seconds).

3.8.4.1 Manual rinsing after interruption If the Service programme was interrupted, e.g. by a

power failure, always rinse the appliance before

switching it on again.

► Press Standby button

LED button:

Standby and Steam flash

► Rinse water tank and fill with fresh water

► Press the “Steam” button

Appliance is rinsed via drainage valve

LED display:

Turn hot water/steam valve flashes

► Place cup under steam pipe, open hot water/steam valve

Appliance is rinsed via hot water/steam valve.

LED display:

Turn hot water/steam valve is lit

Service marker is deleted

Appliance heats up and is ready for use again when the Standby LED

is lit green.

► Turn hot water/steam valve to O

Service marker is deleted

Appliance is rinsed and is ready for use again.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 27 von 78

Page 28

3.9 Maintenance and daily cleaning

Risk of electric shock!

► Unplug the appliance before cleaning it.

► Never immerse the appliance in water.

► Do not use a steam cleaner.

Risk of damage!

► Do not use scouring agents.

3.9.1 Daily cleaning

► Wipe the outside of the appliance with a damp cloth. Do not

use scouring agents.

► Rinse out the water tank with water only.

► Remove, empty and clean the trays for residual water (21)

and coffee grounds (20).

Wash all removable parts by hand only.

► Wipe out or vacuum the inside of the appliance (tray holders)

Note!

If the appliance is cold when switched on with the

standby-button, or if it is set to standby after brewing

coffee, it is automatically rinsed, i.e. the system cleans

itself.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 28 von 78

Page 29

3.9.2 Cleaning the brewing unit

The brewing unit can be removed for cleaning.

► Turn off the appliance with the standby-button.

► Turn the mains switch to off.

► Open the service flap on the right hand side of the appliance.

► Press and hold the red button (1) down and push the handle

up until you hear it engage.

► Grasp the brewing unit by the handle.

► Rinse the brewing unit under running hot water. Do not use

cleaning agents.

Risk of damage!

Do not place the brewing unit in the dishwasher!

► Vacuum the inside of the appliance or clean it with damp

cloth.

► Dry and reinsert the brewing unit all the way into the

appliance.

► Press and hold the red button (1) down and push the handle

down until you hear it engage. The brewing unit is now

secure.

► Reinsert and close the service flap.

If the appliance is cold when switched on again is automatically

rinsed, i.e. the system cleans itself.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 29 von 78

Page 30

4 COMPONENTS

4.1 Flowmeter

The composition of the coffee

mixture is a well guarded secret of

the coffee roasting

establishments. To ensure that an

excellent coffee can be produced

from this secret, the coffee beans

must be roasted carefully and the

coffee machine controlled

precisely – unless the dosage is

constant, the quality of the coffee

cannot be maintained.

The flowmeter (A) is installed on the suction side between the water

tank (B) and pump (C). To ensure a precise measurement result, the

flowmeter must be operated in a horizontal position.

4.1.1 Design and function

Water is pumped in from the water

tank and flows through the

flowmeter.

Water is supplied via the

connection pipe in the lower

section of the housing (D).

Water is discharged via the

connection pipe in the upper

section of the housing (A).

The two halves of the housing are

sealed with a silicone seal (B).

The fan impeller (C) with the two

attached magnets is rotated by the

water flow.

The Hall-IC in the upper section of

the housing (A) generates square

pulses which measure the actually

required amount of water.

When installing the flowmeter, ensure that the

direction of flow is correct. An arrow on the

flowmeter housing indicates the direction of flow.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 30 von 78

Page 31

4.1.2 Connection diagram

The flowmeter itself does not supply an output voltage but simply

switches the signal connection to 0 volt earth (actuated) or leaves it

open (unactuated). Square pulses are generated in the upper

section of the housing via the Hall-IC.

Wrong connection of + voltage, signal and earth destroys the

flowmeter.

4.2 Heater and NTC-sensor

4.2.1 Heater (Instantaneous water heater)

In the instantaneous water heater the water for coffee production or

hot water/steam purchase is heated up.

Prevent inductive faults via the cable!

Do not lay the cable together with supply cables to

consumers.

Therefore the water is pumped in a stainless-steel pipe (A), which is

cast in together with a heating resistor (B) in an aluminum block.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 31 von 78

Page 32

4.2.2 Characteristic of NTC-sensor

Temperature R min R nom R max

25 °C 93.801k

100k

106.199k

95 °C 6.414k 6.624k 6.834k

140 °C 1.696k 1.771k 1.845k

58300000123125_ARA_en_d.doc – 09.10.09 Seite 32 von 78

Page 33

4.3 Brewing unit

The brewing unit forms the central element in the espresso machine.

The brewing unit extracts the aroma, flavour and bitter agents from the

ground coffee and forms the crema.

4.3.1 Operating principle

Ground coffee pours through the filling shaft (2) into the brewing

chamber and is compressed. Hot water is introduced under pressure

via the water supply (4) and forced through the ground coffee. The

coffee which is produced is conveyed to the coffee outlet (10). To

optimise crema formation, the crema valve, which is situated above

the brewing head, opens when the pressure reaches 4.5 bar.

At the end of the brewing process the used coffee dregs are emptied

into the dregs drawer via the discharge chute (7).

4.3.1.1 Variable brewing chamber

The brewing unit consists primarily of the brewing chamber (A), into

which the ground coffee (7 g – 14 g) is metered, and the springmounted brewing head (B) which moves upwards to seal the brewing

chamber.

Control lever, filling amount

1

Filling shaft

2

Locking lever

3

Water inlet

4

Clutch, drive shaft

5

58300000123125_ARA_en_d.doc – 09.10.09 Seite 33 von 78

Catch

6

Discharge chute

7

Stripping handle

8

Brewing head

9

Coffee outlet

10

The ground coffee is compacted and compressed in the brewing

chamber. When hot water is pumped into the brewing chamber, the

rising water pressure pushes up the brewing head, increasing the

volume in the brewing chamber. This improves extraction of the

flavours and formation of the crema.

Page 34

4.3.2 Sequence of the brewing cycle

4.3.2.1 Grinding and metering

4.3.2.2 Compression

Coffee beans are ground in the grinding unit (A). The ground coffee is

conveyed into the open brewing chamber via the funnel (B). The

amount of ground coffee generated depends on the running time of

the grinding unit. The brewing unit can process from 7 g to 14 g of

ground coffee.

Alternatively ground coffee can be poured in via the powder slot.

The grinding unit stops. The gears control the brewing unit to the

upper end position. In doing so, the ground coffee is compressed in

the brewing chamber (C). The pressure applied to the ground coffee

causes the spring-mounted brewing head (D) to move up. The more

powder there is in the brewing chamber, the higher the brewing head

is pushed upwards during compression. The actual amount of powder

is measured by a slide which is connected mechanically to the

brewing head and, if required, corrects the amount during the next

brewing process.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 34 von 78

Page 35

4.3.2.3 Brewing

4.3.2.4 Emptying

The brewing process starts. The pressure pump conveys the water

into the brewing unit. The brewing head (D) is moved up by the water

pressure, thereby increasing the volume in the brewing chamber. The

hot water is mixed with the ground coffee longer and more intensively,

thereby improving extraction of the flavours and formation of the

crema. If the pressure inside the brewing chamber increases above

When the programmed amount of water is reached, the pump stops.

The pressure in the brewing chamber drops and the coffee dregs are

compressed into a solid cake. The drainage valve opens, pressure

and residual water are released into the drip tray. When the brewing

unit descends, the brewing chamber moves back to the initial position

(G) and the coffee dregs are emptied into the dregs drawer.

4.5 bar, the crema valve (E) opens and the coffee can flow to the

coffee outlet (F).

58300000123125_ARA_en_d.doc – 09.10.09 Seite 35 von 78

Page 36

4.3.3 Removing the brewing unit

The brewing unit is accessed by opening the service flap on the righthand side of the appliance. Once released, the brewing unit can be

taken out of the appliance for cleaning.

4.3.3.1 Basic position

The brewing unit can only be replaced in the basic position.

► The brewing chamber is located completely underneath the

filling funnel.

► The unlocking lever is engaged in the "locking mechanism

open" position (1).

► The mark on the input shaft is next to the tip of the marking

arrow (2).

4.3.3.2 Locking mechanism

When locked, the brewing chamber is prevented from moving. Only

when placed in the appliance is the locking mechanism released by

two cams (1) in the brewing unit compartment. Lock bolt (2) releases

unlocking lever (3). The unlocking lever is released by pressing knob

(4). The unlocking lever can be turned downwards, where it engages

in recess (5). The brewing unit is locked. A microswitch on the

transmission housing monitors the locked status.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 36 von 78

Page 37

4.3.4 Compensation of the grinding unit running time

The amount of ground coffee which is generated by the grinding unit

depends on the running time of the grinding unit.

To ensure that the required amount of coffee is always ground, both

with different types of coffee, at different grinding settings and possibly

with worn grinding tools, the amount of ground coffee which was

actually conveyed to the brewing module (B) is measured.

The electronics module measures the number of the voltage changes

(connection A) caused by the switching processes which occur

immediately before the pressure pump switches on and can therefore

detect whether and how much ground coffee has been metered. This

value can be compared with the nominal value for the aroma setting.

Differences are adjusted by changing the running times of the grinding

unit.

The more powder there is in the brewing chamber, the higher the

spring-mounted brewing head is pushed upwards during compression.

A microswitch (µ) closes and opens as it moves past via a slide which

is connected mechanically to the brewing head.

4.3.4.1 Switching states

If there is a minimum amount of coffee (<7 g), the brewing head

does not move. The switch is not actuated. = Not enough coffee

beans. ADD BEANS is displayed

(I)

(II)

(III)

(IV)

Special cases:

Too hot and too little

powder before brewing

Too little powder during 1st

brewing process

Amount of powder >7 g – <10 g

Amount of powder 10 g

Amount of powder >10 g – <13 g

Amount of powder >14 g = Too many coffee beans. The

running time of the grinding unit must be reduced.

Brewing is ended (dry discharge),

there is no pumping. The brewing

module moves to the grinding

position. Auto cooling starts (several

ml of water are conveyed) and

SYSTEM TOO HOT is displayed

ADD BEANS is displayed and an

additional time of 1.3 sec. is given.

Compensation is not active during

this and the next brewing process.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 37 von 78

Page 38

4.4 Gear unit

The gear unit is the drive for the brewing unit.

The gear motor is actuated at +/– 16 V DC and transfers its power via

gears to a drive shaft which is connected to the brewing unit.

4.4.1 Front housing

Microswitches (S1 and S2) are attached to the front housing of the

gear unit. These microswitches measure the position of the gears and

the brewing unit via a cam (B) connected to the drive shaft.

4.4.2 Rear housing

On the rear housing section of the gear unit the drainage valve (B) is

attached to the expansion chamber (C). This valve controls the

passage of water from and to the brewing unit. The microswitch (D) is

actuated by the lock on the brewing unit. The drive shaft (E) is the

connection to the brewing unit.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 38 von 78

Page 39

4.4.3 Cam on the gear unit

The position of the brewing unit is detected with two microswitches S1

and S2. These two switches are able to define three positions.

When the appliance is switched on, the switch status of the

microswitches is checked and transmitted to the control module. The

brewing unit is moved to the basic position (= initialising).

Home position

Brewing position Drainage position

The brewing unit

is in the grinding

position and can

be filled.

Switch S1 is

activated by

switch cam (A).

Switch S2

remains open.

The transmission

turns clockwise

until switch S2 is

closed by switch

cam (A) and

switch S1 is open.

The brewing unit

is in the brew

position. The

transmission

motor stops.

Water can be

supplied and

coffee can be

brewed.

Once the brewing

process is complete,

the system is

drained.

For this, the motor

turns the cam disc

back by about 8°, so

that the drainage

valve is opened

again and the

remaining water can

run into the drip tray.

Switches S1 and S2

are closed.

S1 ON

S2 OFF

58300000123125_ARA_en_d.doc – 09.10.09 Seite 39 von 78

S1 OFF

S2 ON

S1 ON

S2 ON

Page 40

4.4.4 Drainage valve

The drainage valve (B) connects the water inlet (A) to the brewing unit

and drains the system at the end of the brewing cycle.

4.4.4.1 Home position

When the gears are in the home position, the drainage valve is open.

The cam (E) of the actuator must then be in the illustrated position.

Warning!

Malfunction

The position of the actuator and therefore the cam (E)

is not specified permanently on the drive shaft.

The actuator may be in the wrong position. The

function sequence may malfunction.

When installing the gears, ensure that actuator is

in the correct position, as indicated under “Home

position”!

58300000123125_ARA_en_d.doc – 09.10.09 Seite 40 von 78

Page 41

4.4.4.2 Brewing position

When the gears move into the brewing position, the drive shaft rotates

with the actuator (D) in an anti-clockwise direction.

4.4.4.3 Drainage position

Once the brewing process is complete, the water pump switches off.

The brewing unit is moved upwards. The connection to the drainage

valve is closed with the water

coupling in the brewing unit. The switch cam on tripping device (D)

reaches into the drainage valve control line and closes it. Water can

flow from inlet (A) through drainage valve (B) to outlet (C).

The transmission motor turns the input shaft with tripping device (D)

back through about 8° and opens the drainage valve.

The pressure is relieved and the water can drain into the expansion

chamber and then into the drip tray. To prevent underpressure, air can

flow back through valve (B).

Then the transmission turns back in a clockwise direction until it is in

the basic position again.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 41 von 78

Page 42

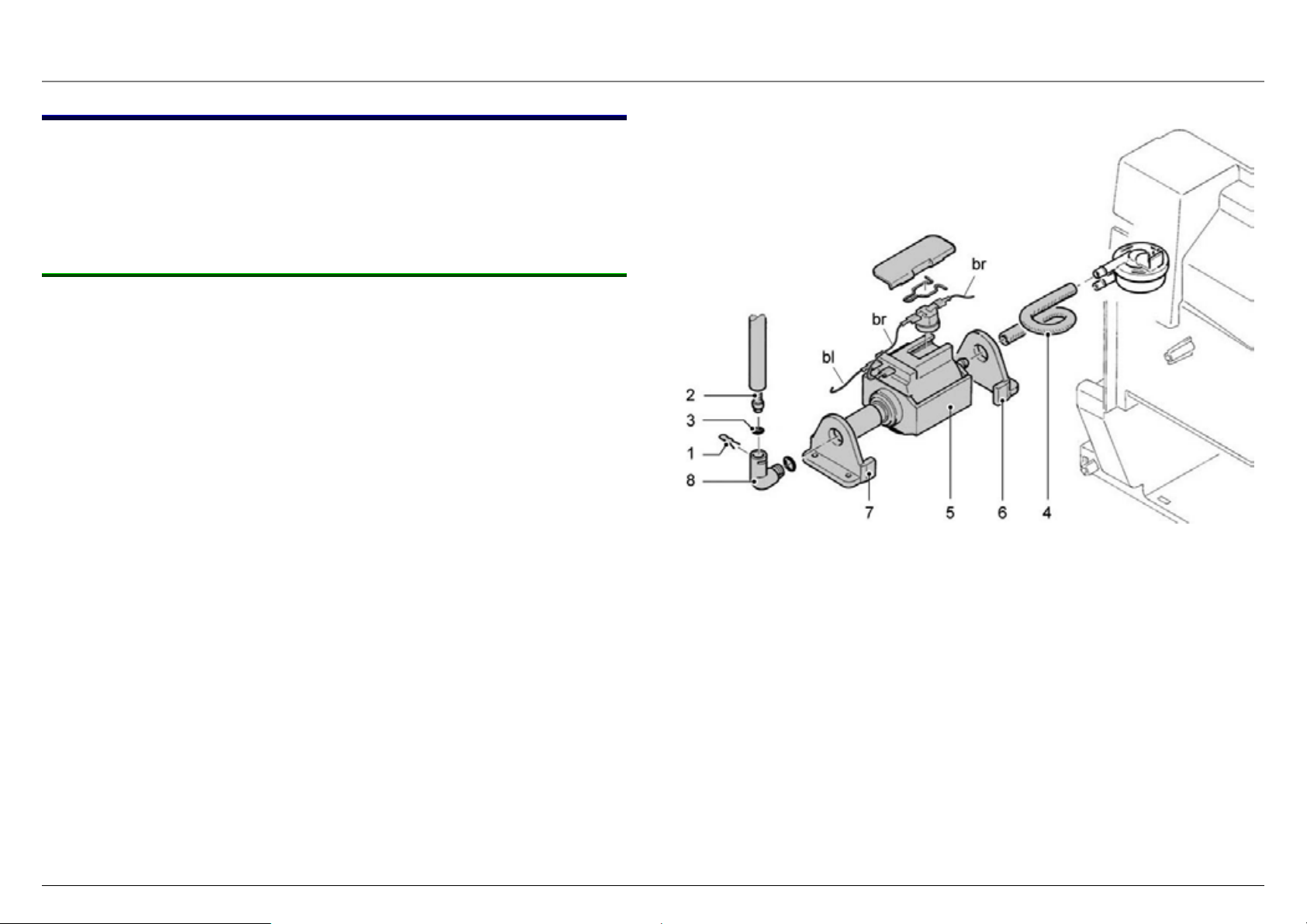

4.5 Steam valve and proximity switch

In order for hot water or steam to be dispensed, steam valve (1) must

be turned open.

The pump must not start supplying until the steam valve is open.

For this, there is a lever with a magnet (2) on the steam valve which is

guided by reed switch (3) in the control board when opening.

Hot water or steam is guided into the steam valve via pressure hose

(4) and then on to steam pipe (5).

To dispense steam, first press the steam button and wait for the

heat up phase.

Dispense coffee

Dispense

Steam

Hot water

58300000123125_ARA_en_d.doc – 09.10.09 Seite 42 von 78

Page 43

4.6 Hot water / steam nozzle

Risk of burns!

The nozzle gets very hot.

► Do not touch the metal parts!

DANGER

(1) Sleeve with plastic grip

To dispense hot water or to froth

milk, move the sleeve downward

by the plastic grip.

To warm drinks with steam, slide

the sleeve upwards by the plastic

grip.

(2) Tip of nozzle with inlet

Sucks in milk and mixes with air

to make milk froth.

Note:

Every time you froth milk, clean the nozzle immediately

afterwards by dispensing hot water. Dried on milk

residues are difficult to remove.

4.6.1 Function

The steam flows through steam pipe

(A) and the connected steam nozzle,

thereby creating underpressure

inside the steam nozzle.

This underpressure is balanced out

by fresh air flowing in through

opening (B) on the nozzle holder

and (C) on the tip of the nozzle.

If the nozzle is immersed in cold milk

to above side opening (C) and steam

is dispensed, fresh air flows in

through opening (B) on the nozzle

holder. At the same time, milk is

sucked into this air flow through

opening (C), mixed with the flow of

steam and emitted at the tip of the

steam nozzle.

The resulting circulation of sucked

in, mixed and emitted milk, warms

the milk up. The milk froth is created

by the mixing of the milk proteins

with air. The proteins are stable up

to approximately 76 °C.

They are destroyed by higher

temperatures and froth formation is

not possible then.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 43 von 78

Page 44

4.7 Water filter

The filter cartridge is screwed directly into the water tank. The filter

cartridges can be used for all appliances belonging to this series.

Carbon hardness, contents (e.g. chlorine) which impair taste and

odour, heavy metals and other substances are reduced to protect the

machine. Important minerals and fluoride are retained.

4.7.1 Filtration when drawing water

The water required for the preparation of coffee is filtered directly

before use. The water is drawn in by fins in the lower area of the filter

cartridge, filtered by the granulate and conveyed out through the

centre of the water tank valve. (= Up flow principle)

4.7.2 Filter specifications

The filter capacity at 27° dH is approx. 50 litres (400 brews) or

2 months.

The filter filling consists of approx. 100 ml ion exchange resin and

silvered activated carbon in the ratio 4:1.

Filter diameter:

27–42 mm

Filter length:

Filling volume:

Filter effect:

(Reduction if

following

substances

are in the

water)

175 mm

95–100 ml

Carbon

hardness

Chlorine

Lead

Copper

Aluminium

up to

up to

up to

up to

up to

► Follow the information in the operating

instructions for inserting or replacing the water

filter!

► Do not insert filter if the descaling display lights

up! First descale the appliance!

► If the appliance is always operated with the

water filter inserted, descale as a precaution

once or twice a year!

58300000123125_ARA_en_d.doc – 09.10.09 Seite 44 von 78

Page 45

5 FUNCTIONS

5.1 Construction

5.1.1 Overview, left side

1

2

3

4

5

6

7

8

9

10

11

Pump with temperature monitoring and angle

for flow reduction

Transmission position microswitch

Transmission position microswitch

Flow meter

Transformer

Electronic main board

Mains switch

Control panel

Steam valve

Grinding compensation microswitch

Pressure valve 4 bar

12

13

14

15

NTC

Heating element

Transmission cam disc

Grinder with temperature sensor

58300000123125_ARA_en_d.doc – 09.10.09 Seite 45 von 78

Page 46

5.1.2 Overview, right side

Once the brewing unit has been removed, the following components

are visible:

Centring for the brewing unit Part of the component

1

bracket

Input shaft for the brewing unit Part of the transmission

2

unit

Cams for releasing the brewing unit Part of the component

3

bracket

Coupling for coffee outlet Screwed to the

4

component bracket

Switch for grinder compensation Screwed to the

5

component bracket

Brewing unit inserted switch On transmission

6

housing

Filling duct Screwed to grinder

7

58300000123125_ARA_en_d.doc – 09.10.09 Seite 46 von 78

Page 47

5.2 Fluid system

The pump (c) sucks the water out of the water tank (a)

via flow meter (b). The water flows through the flow

meter thereby causing the impeller inside to rotate. This

generates electrical pulses which are used to determine

the actual volume of water required.

The pump generates a pressure of 5 - 8 bar. The water

is conveyed through a reduction angle and pressure

hose to the heating element. The NTC (e) records the

temperature at the outlet of the heating element.

After the heating element, the fluid system is divided into

a pressure line to steam valve (g) and a pressure line to

valve (f) and then to the brewing unit. Valve (f) has an

opening pressure of 4 bar and closes off the brewing

system when hot water/steam is being dispensed.

At the end of a brewing cycle, the remaining water is

drained from the brewing unit into the drip tray via

drainage valve (h). The rest of the system remains full

of water.

Warning:

The appliance must be emptied if there

is a risk of frost (e.g. on the way to or

from customer services). The heater or

the piping may be damaged if the water

in the fluid system freezes.

Emptying the fluid system: see

appliance test

58300000123125_ARA_en_d.doc – 09.10.09 Seite 47 von 78

Page 48

5.3 Temperature

5.3.1 Temperature pattern

The temperature graph indicates the temperature pattern on the

heater during operation.

! After coffee has been drawn,

the appliance may be briefly

disabled from re-heating.

As soon as steam has been

drawn, coffee can be brewed

again without waiting for the

appliance to cool down.

Coffee cannot be drawn after

steam has been drawn if there

is too little ground coffee in the

brewing unit. The brewing

process is terminated, there is

no pumping. The brewing unit

moves to the grinding

position.

I

II

III

IV

V

VI

VII

VIII

IX

58300000123125_ARA_en_d.doc – 09.10.09 Seite 48 von 78

Heating up

Ready to use

Draw coffee (91 °C) / draw hot water (95 °C)

Re-heating

Ready to use

Heating up to draw steam (140 °C)

Steam ready

Drawing steam

Cooling down after drawing steam

A

B

C

D

E

F

Switch on, press Standby button. Heating up process begins

Press coffee dispensing button or draw hot water

Stop drawing coffee / hot water

Press steam button, heating up process begins

Open steam valve for steam production.

Close steam valve to stop steam production, cooling down

process begins

Page 49

6 REPAIR

6.1 Replacing the brewing unit

6.1.1 Removing the brewing unit

The brewing unit is not permanently installed in the appliance and can

be removed once it has been unlocked.

The service flap on the right-hand side of the appliance give access to

the brewing unit.

6.1.1.1 Opening the service flap

The service flap is clipped into the right-hand side of the appliance.

To open:

► Reach into the upper recessed handle and

► pull the service flap outwards.

6.1.1.2 Removing the brewing unit:

1. Press the red knob on the handle and

2. Turn the handle clockwise until you hear it engage.

► Pull the brewing unit out of the guide by the handle.

Symbols on the brewing unit indicate whether the lock is open or

closed.

Lock closed Lock open

58300000123125_ARA_en_d.doc – 09.10.09 Seite 49 von 78

Page 50

6.1.2 Installation of the brewing unit

6.1.2.1 Basic position

The brewing unit can only be inserted in basic position.

► The brewing chamber is totally located underneath the filling

duct.

► Handle is engaged in position „Lock open“ (1).

► Mark on the drive shaft is opposite the peak of the marking

arrow (2).

6.1.2.2 Inserting the brewing unit

Slide the brewing unit into the appliance in the basic position and lock

in place:

1. Press the red knob on the handle and

2. Turn the handle anti-clockwise until you hear it engage.

► First insert the service flap into the lower guide and then press

it in at the top.

Symbols on the brewing unit indicate whether the lock is open or

closed.

Lock closed Lock open

58300000123125_ARA_en_d.doc – 09.10.09 Seite 50 von 78

Page 51

6.1.3 Greasing the brewing unit

During a service, the O-ring for the coffee outlet (A), the lip seal

surrounding the brewing head (B), the O-ring for the water inlet (C)

and the coupling for the input shaft (D) must be thinly greased with

food-safe special lubricating grease PARALIQ® GTE 703 Mat.-no.:

31 0574.

Note:

After replacing the O-ring for the coffee outlet (A) or for

the water inlet (C) they must be thinly greased with foodsafe special lubricating grease PARALIQ® GTE 703

Mat.-no.: 31 0574.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 51 von 78

Page 52

6.2 General disassembly

Risk of electric shock!

Pull out mains plug before disassembly.

Appliance must not be live!

DANGER!

Tools:

► Torx screwdriver T10

► Slotted screwdriver

6.2.1 Preparation

1.

2.

3.

Remove water tank, drip tray with drip plate and dregs

drawer.

Open service flap on the right side of the appliance and

remove.

Release and remove brewing module.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 52 von 78

Page 53

6.2.2 Opening the housing – step 1

1.

2.

3.

4.

Loosen two Torx T10 screws on the cup shelf.

Loosen three Torx T10 screws on the rear panels.

Carefully press in the three locking hooks with a flat screw-

driver and loosen upper housing section.

Lift off upper housing section; disengage on front panel

remove upwards.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 53 von 78

Page 54

6.2.3 Opening the housing – step 2

1.

Loosen two (6) Torx T10 screws on the left (7) and right (8)

sides of the housing.

2.

Pull the left (7) and right (8) sides of the housing to the rear,

disengage from the guides of the base group and remove. If

required, disengage mains switch (9) or remove supply hose

(10) from the flow meter.

3.

Assemble in reverse sequence

58300000123125_ARA_en_d.doc – 09.10.09 Seite 54 von 78

Page 55

6.3 Replacing the pump

Tools:

► Pliers

► Slotted screwdriver

6.3.1 Procedure:

1.

2.

3.

4.

5.

6.

7.

Disassemble the appliance as described in the "General

disassembly" section.

Remove the retaining clip (1), hose (2) and O-ring (3).

Remove inlet hose (4) from the pump.

First, pull the pump (5) out of the rubber holder (6) on the side

of the inlet hose.

Release the angled hose mount fitting (8) from the pump and

pull the pump out of the second rubber holder (7).

Unplug electrical connections from the pump.

Replace the faulty pump.

8.

To reassemble, proceed in the reverse order of disassembly.

Note the pin assignment of the pump in the wiring diagram.

The O-ring must be replaced with a new one every

time a fluid connection is opened!

58300000123125_ARA_en_d.doc – 09.10.09 Seite 55 von 78

Page 56

6.4 Replacing the thermal fuse

The thermo cut off element (TCO) is a safety element

which is used to prevent damage caused by the heater

overheating. To ensure correct function, it is essential to

install the thermal fuse properly.

► Whenever the appliance is repaired, check as a

precaution that the thermal fuse is in perfect

condition and is correctly installed!

6.4.1 Checking an installed thermo cut off element: The following points must be checked:

► Position and attachment of Teflon hose (must be firmly

anchored)

► Position of thermo cut off element (centred under installation

bracket)

► Quality of the cable connections

► Bend correct

6.4.3 Installation location 1 Screw with circlip

2 Installation bracket

3 Heater

► Installation bracket is firmly attached

6.4.2 Component

The thermo cut off element is supplied as a pre-assembled

component. (Wire colour and type may deviate in reality).

58300000123125_ARA_en_d.doc – 09.10.09 Seite 56 von 78

Page 57

6.4.4 Generally

The thermo cut off (TCO) element is a safety element, which will

protect the appliance and its surrounding against serious damaging

based on an overheating of the heater.

If a thermo cut off element will be defect, please take special care

during the repair to eliminate also the root cause of the overheating.

The assembling and exchange of the thermo cut off element must be

done accordingly to the following instructions.

6.4.5 How to proceed in repair case

The following listed parts of the heater must be exchanged in any

case before the failure analysis will be continued:

► Both thermo cut off elements (complete with wires)

► Temperature sensor (NTC)

► Plastic fluid connectors (including seal ring) at heater inlet and

outlet

The heater itself must not be exchanged in any case. But you have to

ensure, that the heating element will not be damaged.

The control of the heating element must be done by measuring the

power consumption during operation. The respective rated values of

the power consumption and voltage must be taken from the

declaration on the heater itself.

Heater will become hot during measurement!

► Never touch the heater during measurement!

► Cool down the heater manually before repair!

DANGER

The measured power consumption must be within a tolerance of +/5% to the nominal power consumption (measured at nominal voltage).

Maximum acceptable temperature of 300°C on heating element must

not be exceeded during measurement!

58300000123125_ARA_en_d.doc – 09.10.09 Seite 57 von 78

Page 58

6.4.6 Installing / replacing the thermal fuse:

7. Insert installation bracket into the designated guide. (Ensure

that the bracket is inserted according to the picture)

► After removing the defective thermal fuse,

comply with the following new steps to ensure

correct installation:

1. Check installation position for heater (no dirt or projecting

edges permitted).

2. Check installation bracket (no dirt or sharp edges permitted).

3. Check whether it is the correct type of thermal fuse (according

to wiring / circuit diagram).

4. Position Teflon hose over the thermal fuse, ensuring that none

of the electrically conductive parts remains uncovered (same

as the illustrated example of the thermal fuse, slight kinking is

used to fix the hose).

5. Before installation, bend connections of the new thermal fuse

according to the thermal fuse to be replaced. This must be

done with a suitable pair of flat nose pliers. In doing so,

comply with the following points:

► Bend must be at least 5 mm from the housing of the thermal

fuse.

8. Attach installation bracket with the corresponding screw and

circlip.

9. Following installation, check that the installation bracket on the

side of the thermal fuse is not situated on the heater

(according to following picture).

10. Connect thermal fuse wires to the correct terminals in the

appliance.

► Teflon hose and thermal fuse must not be damaged.

► Connections may be bent 1 x only.

6. Position thermal fuse on the mounting surface of the heater,

ensuring that the installation bracket is in the centre of the

thermal fuse housing (attention: note original position).

Important!

Installation bracket must not be situated on the

heater

58300000123125_ARA_en_d.doc – 09.10.09 Seite 58 von 78

Page 59

6.5 Replacing the heating element and NTC sensor

Tools:

► Open-ended wrench WAF 8 mm

► Torx screwdriver T20

► Allen key WAF 4 mm

6.5.1 Procedure:

Note: Heating element may still be hot. Cool the heating

element manually!

1.

2.

3.

4.

5.

6.

7.

Disassemble the appliance as described in the "General

disassembly" section.

Undo Torx T20 screw (4) and remove the earthed conductor

connection from the heating element.

Undo two screws (5), remove thermal fuses (6) and retaining

clips (7) from the heating element.

Undo screws M6 x 25 (2) and pull the heating element out of

the retainer.

Remove the electrical connections from the heating element.

Remove the retaining clip (10) and hose connections (11) and

(12) from the heating element.

Disconnect the NTC plug from the electronic circuit board.

Only lightly tighten NTC temperature sensor until the

spring washer is flat.

O-rings must be replaced with a new one every time a

fluid connection is opened.

8.

Unscrew the NTC sensor (8) from the heating element and

replace it if necessary.

9.

10.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 59 von 78

Replace the faulty heating element.

To reassemble, proceed in the reverse order of disassembly.

Page 60

6.6 Replacing the electronics board

Tools:

► Torx screwdriver T10

► Long-nosed pliers

Risk of damage!

Static voltage may destroy components on the

electronics module!

WARNING

Procedure:

Disassemble appliance as described in the chapter “General

1.

disassembly”, Steps 1 and 2.

Place earthing strap around your wrist and connect to the earth

2.

cable of the unplugged machine! This will prevent a potential

difference.

► Use earthing strap!

Loosen fastening screws (1), Torx T10. Detach housing

3.

together with electronics board from the catch and pull out.

Disconnect all plugs and plug-in connections on the electronics

4.

board (A).

Replace the electronics board.

5.

Assemble in reverse sequence.

6.

(See “Wiring and connecting diagram”)

58300000123125_ARA_en_d.doc – 09.10.09 Seite 60 von 78

Page 61

6.7 Replacing the power cord

Tools:

► Slotted screwdriver 5.5 mm

► Long-nosed pliers

Procedure:

When installing the power cord:

Install power cord according to the following

Disassemble appliance as described in the chapter “General

1.

disassembly”, Steps 1 and 2.

Disconnect plug-and-socket connections on the power cord

2.

from the electronics board and the mains switch.

Detach cord grip (1) with a flat screwdriver.

3.

installation instructions!

This ensures that the protective conductor is interrupted last if the power cord is torn off.

Pull power cord out of the guide and replace.

4.

Insert new power cord and pull through until the insulated end

5.

projects 75–80 mm over the left edge of the housing. Press in

cord grip (1).

Feed power cord upwards. Pull brown wire (2) for the mains

6.

switch between housing and electronics board.

Connect plugs to the electronics board and mains switch. (See

7.

“Wiring and connecting diagram”)

Insert power cord over lower fixing plate (3) on the electronics

8.

board and install as illustrated.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 61 von 78

Page 62

6.8 Replacing the coffee outlet

Tools:

► Torx-screwdriver T10

6.8.1 Procedure:

1.

2.

3.

4.

5.

6.

7.

Pull coffee outlet (1) down completely.

Reach between coffee outlet (1) and cover panel (2) from

below and pull the cover panel forwards.

Reach into outlet cover (3) from above and pull off forwards.

Undo two Torx T10 screws (4) and remove coffee distributor

(5). Carefully pull silicone hose (6) with anti-kink spring from

the coffee distributor.

Replace coffee distributor (5) if necessary.

To release outlet slider (7), push this up completely, undo two

Torx T10 screws (8) and remove the outlet slider.

To reassemble, proceed in the reverse order of disassembly.

Make sure that the silicone hose is routed such that

there are no kinks.

Pull the anti-kink spring as far forward as possible so

that the silicone hose does not kink when the outlet

slider is right at the top. If necessary, push the silicone

hose further back into the appliance.

58300000123125_ARA_en_d.doc – 09.10.09 Seite 62 von 78

Page 63

r

6.9 Replacing the front panel

Tools:

► Torx screwdriver T10

► Long-nosed pliers

6.9.1 Procedure:

1.

Disassemble appliance as described in the chapter entitled

“General disassembly”.

2.

Remove coffee outlet as described in the chapter entitled

“Replacing the coffee distributor”, Points 1.–4.

3.

4.

Loosen two Torx T10 screws (1) on the front panel.

Pull outlet slide all the way down and loosen two Torx T10

screws (2).

5.

Disconnect electric plug-and-socket connection for operating

panel (3) on electronics board.

6.

Loosen retaining clip on pressure hose (4) on the steam valve

and remove pressure hose.

7.

Remove front panel with operating panel and steam valve

from the chassis and, if required, replace.

8.

Assemble in reverse sequence.

Replacing O-ring on the pressure hose!

Ensure that the hose system is installed without

kinks!

Pull the anti-kink spring in the coffee outlet as fa

forwards as necessary until the silicone hose does not

kink when the outlet slide is at the very top. If required,