Bosch RA1141 User Manual

Operating/Safety Instructions

Consignes de fonctionnement/

sécurité

Instrucciones de funcionamiento

y seguridad

IMPORTANT:

Read Before Using

IMPORTANT :

Lire avant usage

IMPORTANTE:

Leer antes de usar

For English

See page 2

Parlez-vous français?

Voir page 34

¿Habla español?

Ver página 67

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll-Free Number: Appel gratuit : Número de teléfono gratuito:

RA1141

1-877-BOSCH99 (1-877-267-2499) http://www.boschtools.com

Table of Contents

IMPORTANT SAFETY

INFORMATION . . . . . . . . . . . . . . . . . . . . . 2–6

Parts List . . . . . . . . . . . . . . . . . . . . . . . . 7–10

Router Table Setup . . . . . . . . . . . . . . . 11–19

Router Table Operation . . . . . . . . . . . 20–33

2

Power Tool Safety Rules

Read and understand the tool manual and these instructions for the

below may result in serious personal injury.

use of this table with your router. Failure to follow all instructions listed

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

Grounded tools must be plugged into an outlet

properly installed and grounded in accordance

with all codes and ordinances. Never remove

the grounding prong or modify the plug in any

way. Do not use any adaptor plugs. Check with

a qualified electrician if you are in doubt as to

whether the outlet is properly grounded. If the

tools should electrically malfunction or break down,

grounding provides a low resistance path to carry

electricity away from the user. Improper grounding

can shock, burn, or electrocute. Grounded tools

are equipped with three-conductor cord and threeprong-type plugs. Before plugging in the tool, be

certain the outlet voltage supplied is within the

voltage marked on the nameplate. Do not use

“AC only” rated tools with a DC power supply.

Double-insulated tools are equipped with a

polarized plug (one blade is wider than the

other). This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in any

way.

Double Insulation eliminates the need for the

three-wire grounded power cord and grounded

power supply system. Before plugging in the tool,

be certain the outlet voltage supplied is within the

voltage marked on the nameplate. Do not use “AC

only” rated tools with a DC power supply. Avoid

body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerators.

There is an increased risk of electric shock if your

body is grounded. If operating the power tool in

damp locations is unavoidable, a Ground Fault

Circuit Interrupter must be used to supply the

power to your tool. Electriciansʼ rubber gloves and

footwear will further enhance your personal safety.

Donʼt expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges, or

moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of

electric shock.

When operating a power tool outside, use an

outdoor extension cord marked “W-A” or “W.”

These cords are rated for outdoor use and reduce

the risk of electric shock. Refer to “Important

Information About Extension Cords” in your router

table manual.

3

Personal Safety

preventive safety measures reduce the risk

of starting the tool accidentally.

Keep guards in place. Maintain the guards

in working order and in proper adjustment and

alignment.

Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

Never leave tools running unattended.

Turn the power “OFF.” DO NOT leave tool

until it comes to a complete stop.

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools,

with sharp cutting edges, are less likely to

bind and are easier to control. Any alteration

or modification is a misuse and may result in

a dangerous condition.

Check for damaged guards or parts,

misalignment or binding of moving parts,

breakage of parts, and any other condition

that may affect the toolʼs operation. If

damaged, have the tool properly repaired

or replaced before using. Many accidents

are caused by poorly maintained tools.

Develop a periodic maintenance schedule

for your tool.

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be suitable

for one tool may become hazardous when

used on another tool.

Service

Tool service must be performed only

by qualified repair personnel. Service

or maintenance performed by unqualified

personnel could result in a risk of injury. For

example, internal wires may be misplaced or

pinched, or safety guard return springs may

be improperly mounted.

When servicing a tool, use only identical

replacement parts. Use of unauthorized parts

or failure to follow maintenance instructions

may create a risk of electric shock or injury.

Certain cleaning agents such as gasoline,

carbon tetrachloride, and ammonia may

damage plastic parts.

Additional Safety Warnings for Router Tables

Lift router table only by the table edges.

Lifting table by any other surface could cause

personal injury.

Always rotate leg assembly from end of leg

and keep fingers clear of joint. This avoids a

pinch point.

Never rotate leg assemblies until they are

in the unlocked position. This will prevent

possible damage to the legs or table housings.

Broken legs or table housings may allow the

table to collapse.

Do not use the router table until all

assembly and installation steps have been

completed. Prior to each use, verify that

fasteners and the router clamps are tight. A

loose table or router is unstable and may shift

in use, resulting in property damage or serious

personal injury.

Before operating the router in the router

table, ensure that the table legs are fully

extended, in the locked position, and the

entire unit (router table with router) is

placed on and secured to a solid, flat, level

surface that will not tip. Such precautionary

safety measures reduce the risk of the table

Stay alert, watch what you are doing, and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication.

A moment of inattention while operating power tools

may result in serious personal injury.

Avoid accidental starting. Be sure switch is

“OFF” before plugging in. Carrying tools with your

finger on the switch or plugging in tools that have

the switch “ON” invites accidents.

Remove adjusting keys or wrenches before

turning the tool “ON.” A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enable better control of the tool in unexpected

situations.

Use safety goggles (head protection). Wear

safety goggles (must comply with ANSI Standard

Z87.1) at all times. Wear nonslip footwear and a

hard hat, if appropriate. Also, use face or dust mask

if cutting operation is dusty and ear protectors

(plugs or muffs) during extended periods of

operation.

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body is unstable and may lead to

loss of control.

Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn

it “ON” or “OFF.” Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such

4

Additional Safety Warnings for Router Tables

shifting unexpectedly while in use, resulting in

property damage or serious personal injury.

Disconnect the router from the power

supply before installing router into the

table, making adjustments, changing

accessories, removing the router from the

table, performing maintenance, or storing

the tool. Such precautionary safety measures

reduce the risk of unintentional tool operation.

Do not plug router motor power cord into

standard wall outlet. Always plug router

cord into the router table switch box. Power

tool switches and controls need to be within

your reach in emergency situations.

Do not permit fingers to touch terminals on

the plug when inserting or removing plug

from the outlet.

Before connecting router or vacuum to

router table switch box, ensure that the

router or vacuum switch is off and that the

router table switch box is unplugged. Such

precautionary safety measures reduce the risk

of unintentional tool operation.

Before using the router table, verify that

the router is securely clamped in the router

table base. While working, periodically

check the router base fastener clamping

tightness. Vibrations from cutting operations

can cause router motor clamps to loosen and

the router motor may fall from the table.

Before starting to work, ensure that the

power cords from the router accessories,

the switch box, and the extension cord do

not and cannot come in contact with the

router or any moving parts of the router.

Such precautionary safety measures reduce

the risk of injury due to loss of control.

Do not use the router table without the

overhead guard unless required by a

particular cutting operation. Replace guard

immediately after completion of cutting

operation. Remove all dust, chips, and any

other foreign particles that can affect its

function. The guard will aid in keeping hands

from unintended contact with the rotating bit.

Do not use bits that have a cutting

diameter that exceeds the clearance hole

in the tabletop insert plate or insert rings.

Bit could contact insert plate or insert ring,

throwing fragments.

Never use dull or damaged bits. Damaged

bits can snap during use. Dull bits require

more force to push the workpiece, possibly

causing the bit to break or the material to

kick back.

Handle sharp bits with care. Such precautionary safety measures reduce risk of injury.

Do not alter insert ring or insert plate bit

hole. Match the cutting diameter of the

bit to the inner diameter of the insert ring

or insert plate bit hole such that the

difference is no less than 1/16" on a side.

Insert rings are meant to reduce the gap

between the cutting diameter of the bit and the

table so that workpieces maintain full support

of the table while routing.

Install bit in accordance with instructions

in the router manual. Securely clamp the

router bit in the collet chuck before making

any cuts. Securing the bit before cutting

reduces the risk of the bit becoming loose

during operation.

Never place your fingers near a spinning

bit or under the guard when the router is

plugged in. Such precautionary safety

measures reduce the risk of injury.

Never hold the workpiece on the outfeed

side of the bit. Pressing the workpiece

against the outfeed side of the fence may

cause material binding and possible kickback,

pulling your hand into the bit.

Guide the workpiece with the fence to

maintain control of the workpiece. Do not

place the workpiece between router bit

and fence while routing the edge. This

placement will cause the material to become

wedged, making kickback possible.

Only use routers for working with wood,

woodlike products, plastic, or laminates.

Do not use router and router table for

cutting or shaping metals. Be sure

workpiece does not contain nails or other

hard objects. Cutting nails may cause loss

of control of the tool or workpiece.

Never start the tool when the bit is

engaged in the material. The bit-cutting edge

may grab the material, causing loss of control

of the workpiece.

Feed the workpiece only against the

rotation of the bit. Do not “back feed” the

workpiece into the bit. The bit rotates

counterclockwise as viewed from the top of

the table. “Back feeding” will cause the

workpiece to “climb” up on the bit, pulling the

workpiece and possibly your hands into the

rotating bit.

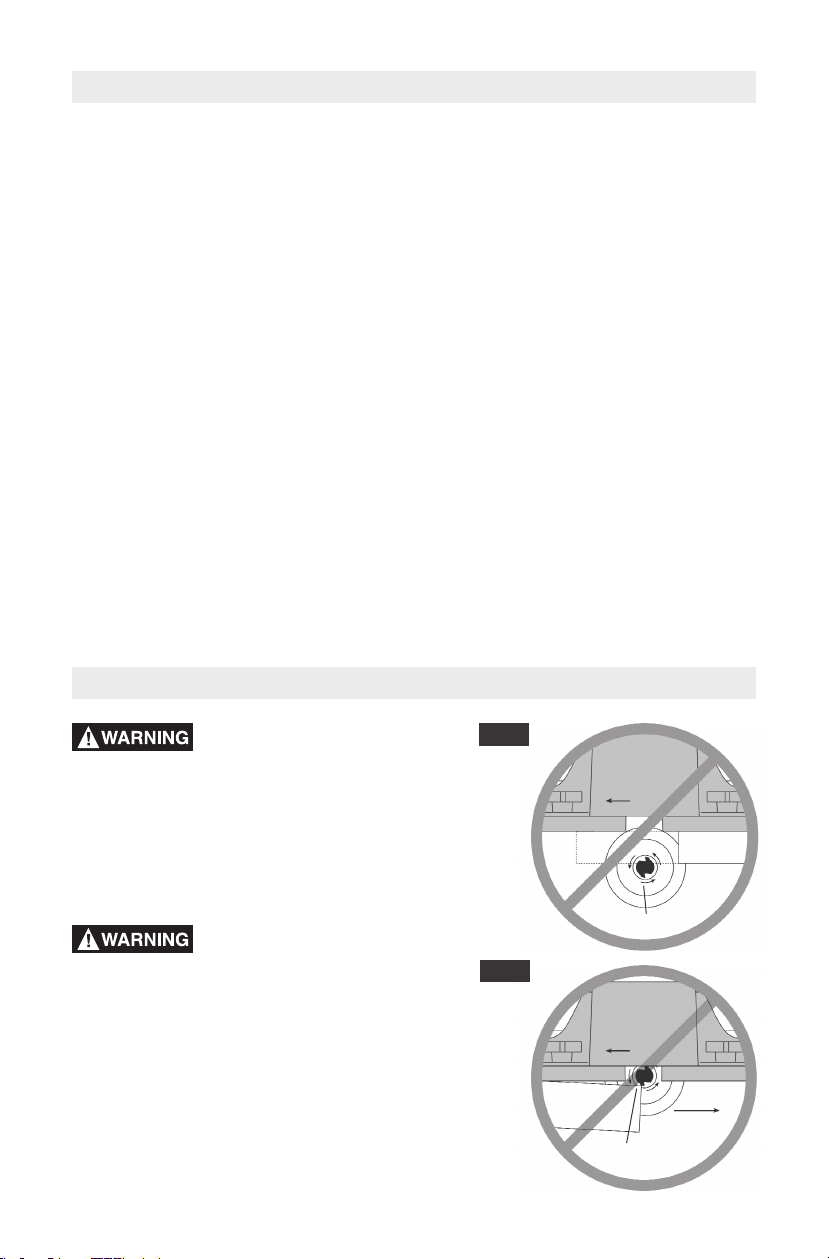

Do not feed the workpiece into the bit

where the majority of the workpiece is

between the fence and the bit. This creates

a “fence trap” which is a hazardous situation

due to the bit being exposed. This will cause

the work to “climb-cut” away from the tabletop

and may lead to loss of control during

operation.

Do not cut material that is warped, wobbly,

or otherwise unstable. The router table is

designed to cut flat, straight, and squared

materials. If the material is slightly curved

but otherwise stable, cut the material with

the concave side against the table or fence.

Cutting the material with the concave side up

or away from the table may cause the warped

or wobbly material to roll and kick back,

causing the user to lose control.

FIG. A

FIG. B

WORKPIECE

EXPOSED BIT

WORKPIECE

CLIMB-CUTTING

DIRECTION

OF FEED

CORRECT

DIRECTION

OF FEED

INCORRECT

DIRECTION

Use auxiliary infeed and outfeed supports

for long or wide workpieces. Oversize

workpieces without adequate support can flip

off the table or cause the table to tip.

Use push stick, vertically and horizontally

mounted featherboards (spring sticks), and

other jigs to hold down the workpiece.

Push sticks, featherboards, and jigs eliminate

the need to hold the workpiece near the

spinning bit.

Never let go of the workpiece when routing

until the cut has been completed and the

workpiece is completely clear of the bit.

Such precautionary safety measures reduce

the risk of injury and property damage.

Featherboards aid in holding the workpiece in

position when routing on a router table. They

are not intended to hold the workpiece in place

alone when the workpiece is in contact with

the bit, or at any other time when the bit is

turning.

Always hold the workpiece against the

router table fence when routing. Such

precautionary measures increase accuracy in

routing and improve control of the workpiece,

reducing the risk of injury.

Never leave the router unattended while it

is running or before it comes to a complete

stop. Such precautionary safety measures

reduce the risk of injury and property damage.

•

Lead from lead-based paints

•

Crystalline silica from bricks, cement,

and other masonry products

•

Arsenic and chromium from chemically

treated lumber

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals, work in a well-ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

Additional Safety Warnings for Router Tables

5

Improper Fence Location and Workpiece Feed

Do not use the table as a workbench or

work surface. Using it for purposes other

than routing may cause damage and make it

unsafe to use in routing.

Never stand on the table or use as a ladder

or scaffolding. The table could tip or the

cutting tool could be accidentally contacted.

When servicing the tool, use only

recommended Bosch replacement parts.

Follow instructions in the Maintenance

section of this manual. Use of unauthorized

parts or failure to follow maintenance

instructions can result in personal injury.

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals

known to cause cancer, birth defects, or

other reproductive harm. Some examples

of these chemicals are:

Do not feed the workpiece where

between the fence and the bit. This creates a “fence

trap” which is dangerous for two reasons:

The front of the bit is exposed during the cutting

•

operation (Fig. A).

The bit can “Climb-cut,” where the bit enters the

•

workpiece in the same direction as the feed

direction. This is likely to cause the workpiece to

“climb” away from the tabletop and may lead to loss

of control during operation (Fig. A).

“back feed” the work into the bit. The bit rotates

counterclockwise as viewed from the top of the table.

“Back feeding” the work is dangerous for two reasons:

It will cause climb-cutting where the workpiece can

•

“climb” off the tabletop in the direction of the bit

rotation, pulling the workpiece and possibly your

hands into the rotating bit (Fig. B).

It is difficult to keep the workpiece against the fence

•

face as the bit rotation will push the workpiece away

from the fence.

the majority of the workpiece is

Feed the workpiece only against

the rotation of the bit. Do not

An extension cord with

adequate size conductors

that is capable of carrying the current for

your tool must be used. This will prevent

excessive voltage drop, loss of power, or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles.

NOTE: The smaller the gauge number, the

heavier the cord.

RECOMMENDED SIZES OF EXTENSION

CORDS FOR 120-VOLT ALTERNATING

CURRENT TOOLS

6

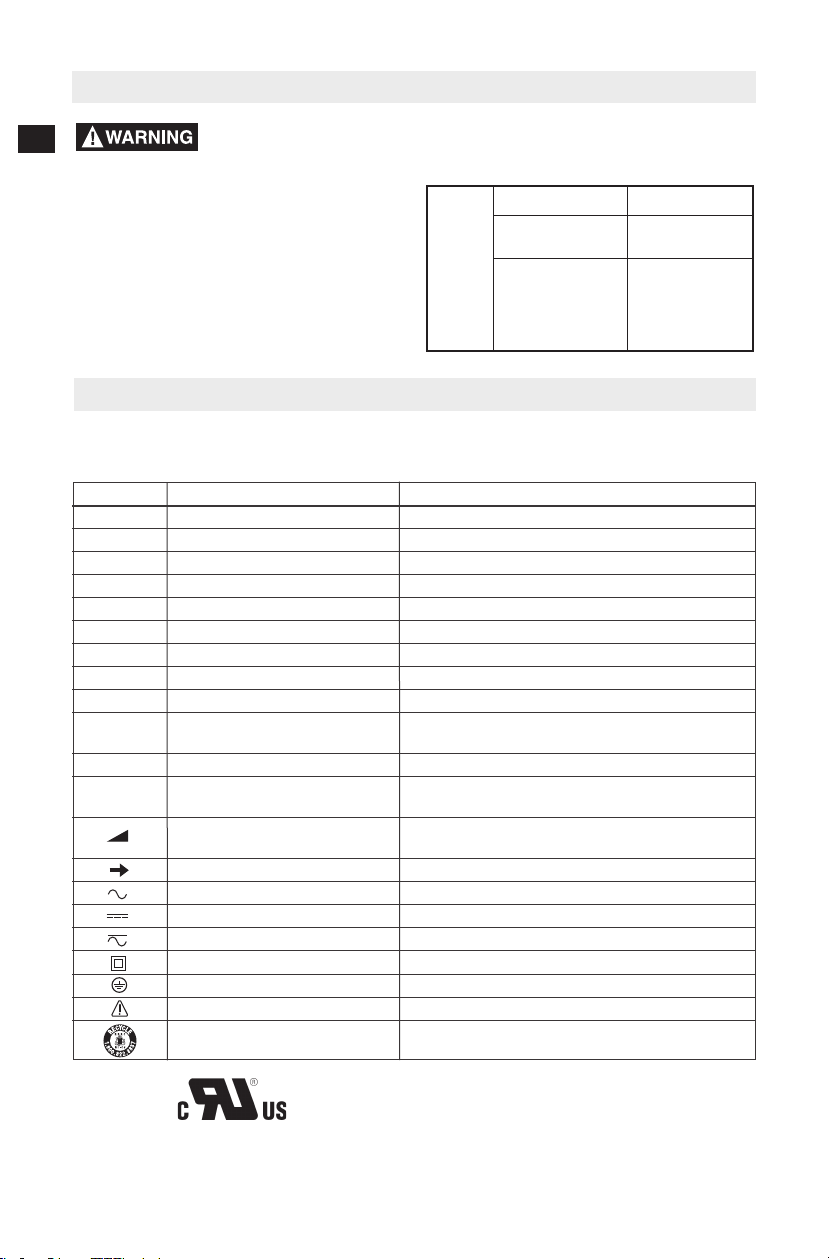

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and

learn their meaning. Proper interpretation of these symbols will allow you to operate the tool

better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Ø Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

.../min Revolutions or reciprocation Revolutions, strokes, surface speed, orbits,

per minute etc., per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque, or position settings

I, II, III, Higher number means greater speed

Infinitely variable selector Speed is increasing from 0 setting

with off

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates double-insulated construction tools

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling program

Symbols

0

This symbol designates that components of this tool are

recognized by Underwriters Laboratories and recognized

to Canadian Standards by Underwriters Laboratories.

Tool’s

Ampere

Rating

Cord Size in A.W.G.

Wire Sizes in mm

2

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Cord Length in Feet Cord Length in Meters

Important Information About Extension Cords

7

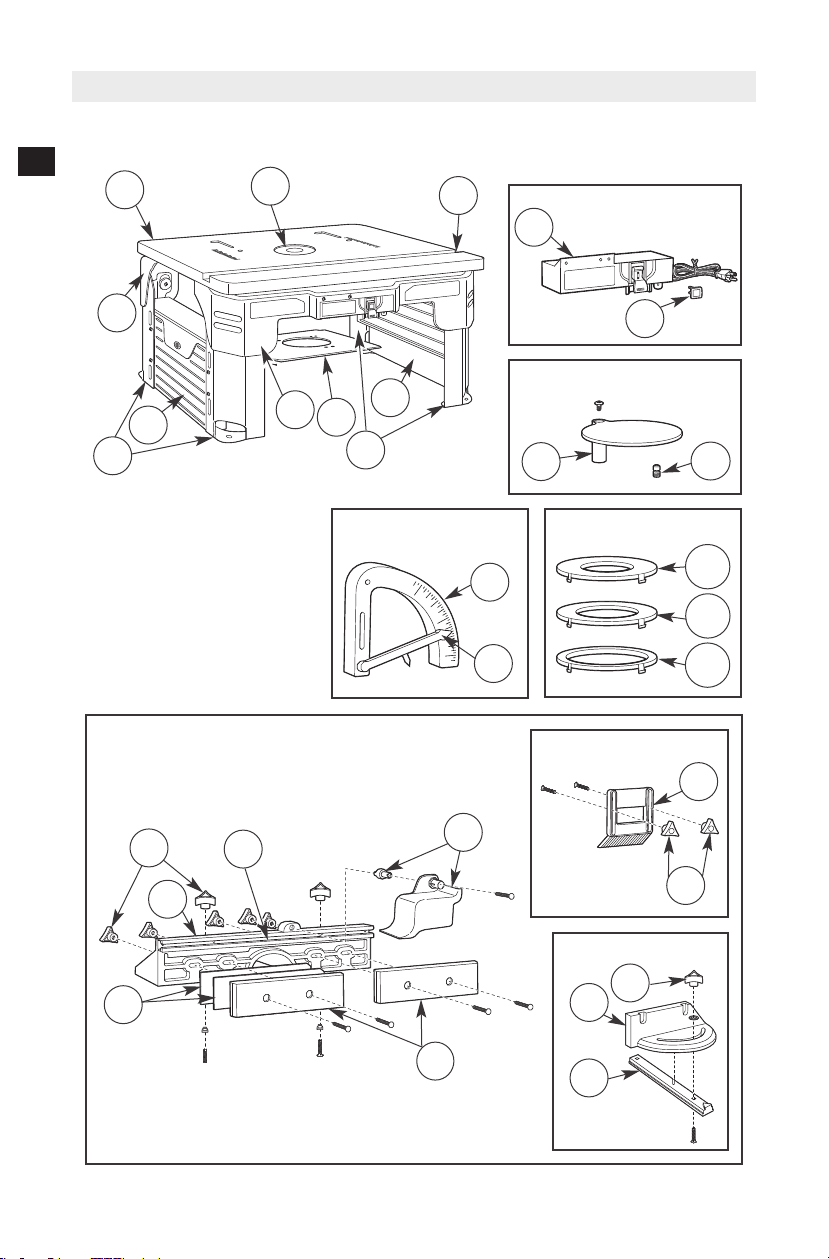

Parts List

Key No. Description Quantity

A ROUTER TABLE ASSEMBLY COMPONENTS

(shipped preassembled)

1

Router Tabletop, 1"

1

2 Insert Plate 1

3 Miter Channel (includes 3 #10-32 x 7/8" screws, item 41) 1

4

1

5 Router Release Mechanism (not shown) 1

6 Front Table Housing 1

7 Rear Table Housing 1

8 Left Folding Steel Legs 2

9 Tool Box w/ Hinged Cover 2

10 Right Folding Steel Legs 2

11 Insert Ring Set (3 rings per set) 1

11A Insert Ring w/ 1¼" dia. hole 1

11B Insert Ring w/ 17⁄8" dia. hole 1

11C Insert Ring w/ 21⁄8" dia. hole 1

12 Fence Retaining Bracket (not shown) 2

13 Small Star Clamping Knob (not shown) 2

B SWITCH BOX ASSEMBLY COMPONENTS

14 Switch Box Assembly (with lockout key) 1

15 Lockout Key 1

C FENCE ASSEMBLY COMPONENTS

(shipped preassembled)

16 Router Table Fence 1

17

Featherboard Mounting Rail

1

18

Overhead Guard Assembly (includes spacer)

1

19 Faceplate 2

20 Outfeed Shim Plate (may be attached to outfeed side of fence) 2

21 Clamping Knob 11

22 Featherboard 2

– Spacer (see item 31) 2

D MITER GAUGE ASSEMBLY COMPONENTS

23 Miter Bar 1

24 Protractor Head 1

– Flat Washer (see item 33) 1

25 Small Clamping Knob 1

E STARTER PIN COMPONENTS

26 Starter Pin 1

27 Starter Pin Guard 1

– Guard Screw (see item 38) 1

F BIT HEIGHT GAUGE ASSEMBLY (shipped preassembled)

28 Gauge Body 1

29 Gauge Pointer 1

•

If ANY of the parts are

missing, DO NOT attempt

to assemble, install, or use your router table

until the missing parts have been found or

replaced and your router table has been

properly and correctly assembled per this

manual.

•

In order to simplify handling and to minimize

any damage that may occur during shipping,

your router table comes mostly assembled.

Repositioning of some parts will be required.

•

Separate all parts from the packaging

materials and check each part against the

illustrations and the parts lists to make sure

that all parts have been included. Do this

before discarding any of the packaging

material.

Refer to Parts List below and on pages 8–10.

• For missing parts or technical

assistance, call 1-877-BOSCH99

(877-267-2499).

Easy Click Router Mounting Plate

8

Parts List

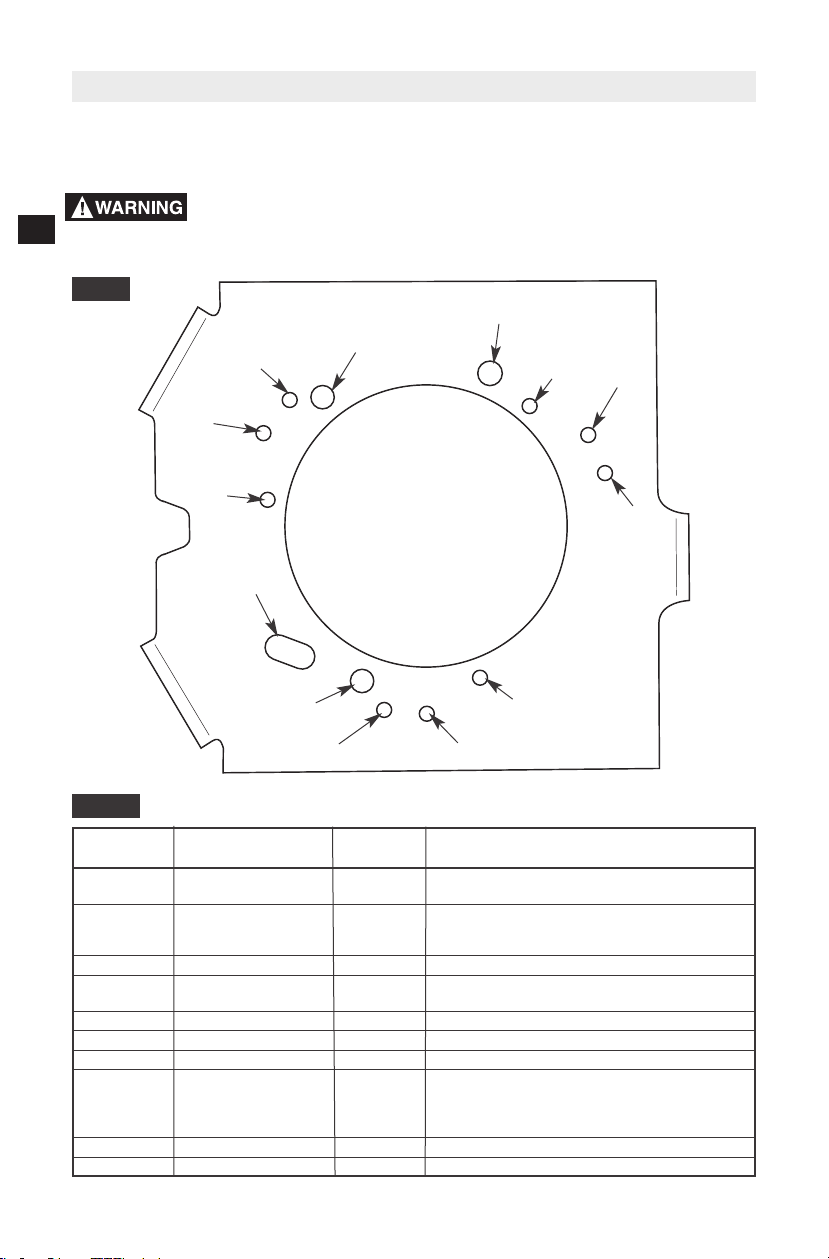

Table Assembly Components

Featherboard

22

21

Fence ComponentsFence Components

24

23

Miter Gauge

25

15

14

Switch Assembly

Tabletop Inserts

11C

11B

11A

26

Guide Pin Components

27

Bit Height Gauge

28

29

1

7

3

6

8

10

9

9

21

19

18

17

20

16

2

4

9

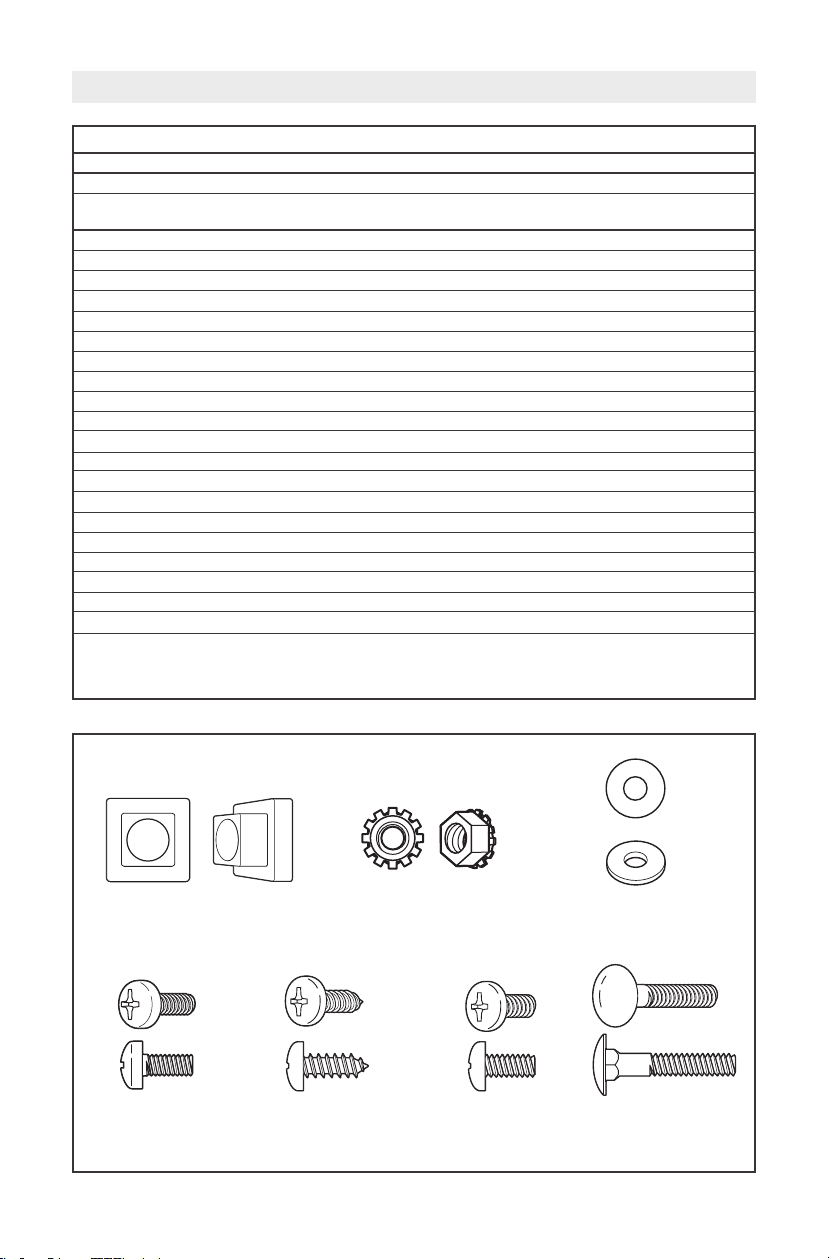

Parts List

Key No. Description Quantity

ITEMS NOT ILLUSTRATED

30 Operating/Safety Instructions 1

MISCELLANEOUS FASTENERS

(installed or bagged)

31 Spacer 2

32 #10-32 KEPS Nut 15

33 #10-32 Flat Washer 3

34 #8-32 x 1/2 Pan-Head Machine Screw (router mounting) 3

35 #10-16 x 1/2" Pan-Head Screw 4

36 #10-24 x 1/2" Pan-Head Machine Screw (router mounting) 3

37 #10-24 x 1" Carriage Bolt 1

38 #10-32 x 3/8" Truss-Head Screw 1

39 #10-32 x 1/2" Pan-Head Machine Screw (router mounting) 3

40 #10-32 x 5/8" Truss-Head Screw 20

41 #10-32 x 7/8" Countersunk-Head Screw 3

42 5/16-18 x 1/2" Pan-Head Machine Screw (router mounting) 3

43 B3 x 5/8" Washer-Head Tapping Screw 3

44 #10-32 x 2½" Truss-Head Screw 2

45 1/4-20 x 1¼" Carriage Bolt 4

46 1/4-20 x 1½" Carriage Bolt 4

47 1/4-20 x 2¼" Square-Head Bolt 2

48 1/4-20 x 2½" Carriage Bolt 1

49 Upper Table Slide (used in miter channel) 1

50 Lower Table Slide (used in miter channel) 1

NOTE: The hardware bag contains fasteners for mounting several models of routers. Some

fasteners may not be used in the setup of this model. Refer to the parts list above for the

correct sizes and quantities used with this table.

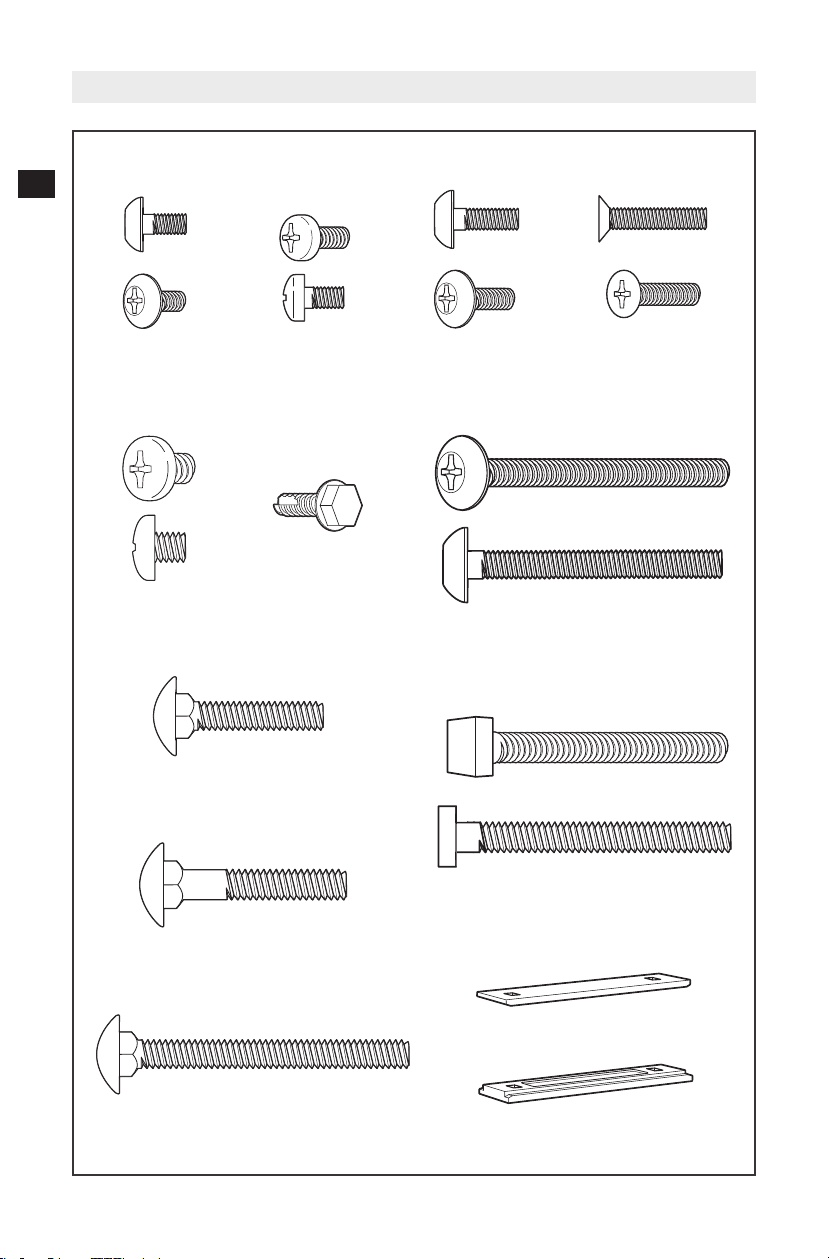

Miscellaneous Fasteners

(32) #10-32 KEPS Nut

(for Switch Box)

(33) #10-32 Flat Washer

(for Miter Gauge)

(31) Spacer

(for Square-Head Bolts)

(35) #10-16 x 1/2"

Pan-Head Tapping Screw

(for Leg Caps)

(37) #10-24 x 1"

Carriage Bolt

(for Miter Gauge)

(36) #10-24 x 1/2″

Pan-Head Machine

Screw (for Router)

(34) #8-32 x 1/2″

Pan-Head Machine

Screw (for Router)

10

Miscellaneous Fasteners (cont.)

(43) B3 x 5/8”

Washer-Head Screw

(for Insert Plate)

(47) 1/4-20 x 2¼" Square-Head Bolt

(for Fence Base)

(41) #10-32 x 7/8"

Countersunk-Head Screw

(for Miter Channel)

(44) #10-32 x 2½" Truss-Head Screw

(for Fence Retaining Brackets)

(45) 1/4-20 x 1¼" Carriage Bolt

(for Faceplate)

Parts List

(48) 1/4-20 x 2½" Carriage Bolt

(for Overhead Guard)

(50) Lower Slide Plate

(for Tabletop Featherboard Mounting)

(49) Upper Slide Plate

(40) #10-32 x 5/8"

Truss-Head Screw

(for Switch Box)

(38) #10-32 x 3/8"

Truss-Head Screw

(for Guide Pin Guard)

(39) #10-32 x 1/2″

Pan-Head Machine

Screw (for Router)

(42) 5/16-18x 1/2

″

Pan-Head Machine

Screw (for Router)

(46) 1/4-20 x 1½" Carriage Bolt

(for Featherboards)

11

PREPARING THE ROUTER TABLE FOR USE

HELPFUL TOOLS TO HAVE ON HAND

•

#1 and #2 Phillips screwdrivers

(not included)

•

3/8" wrench or nut driver (not included)

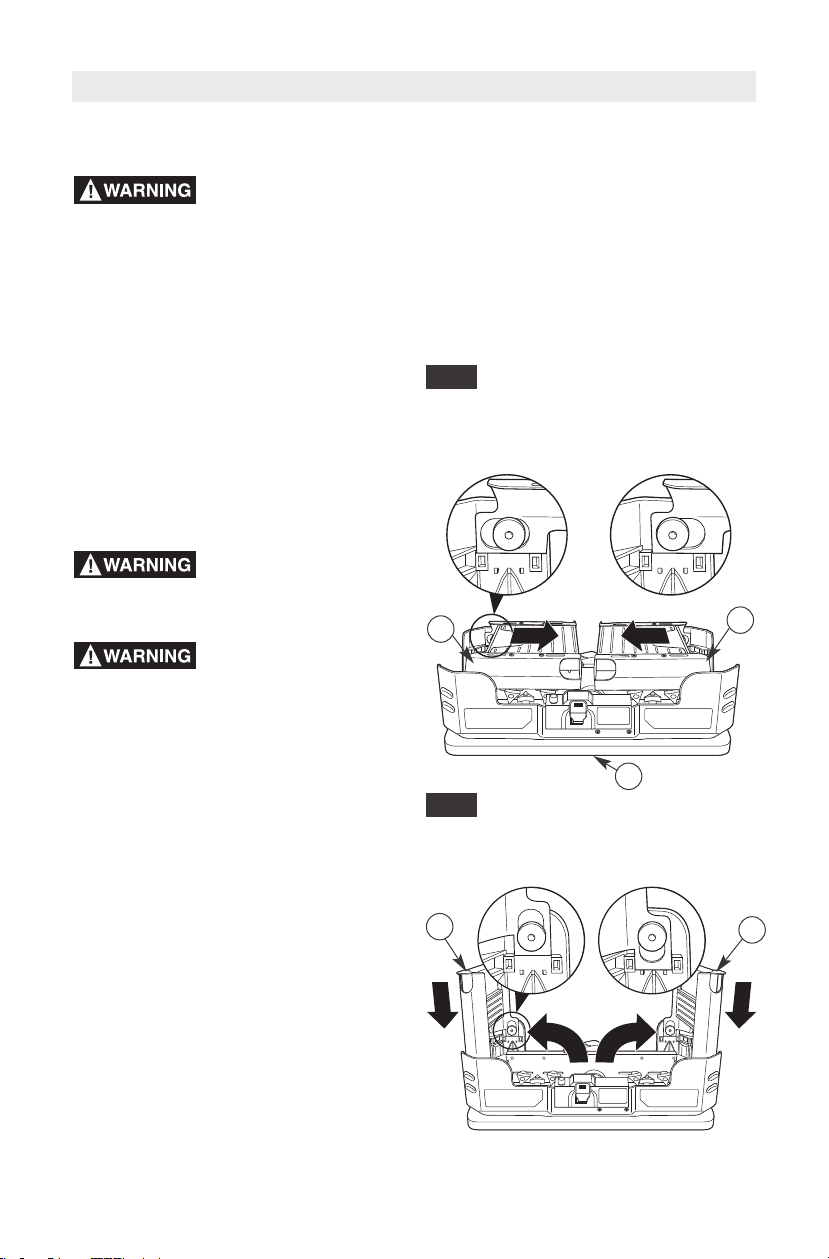

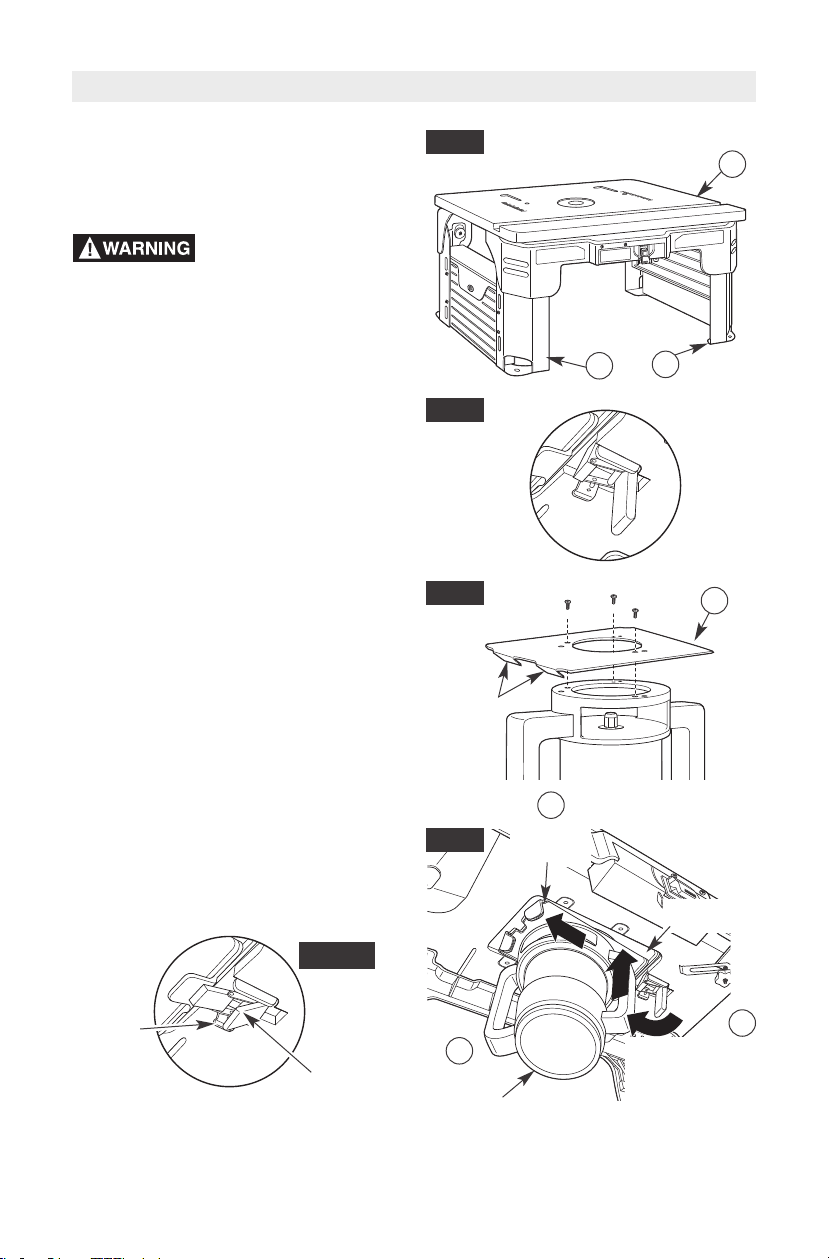

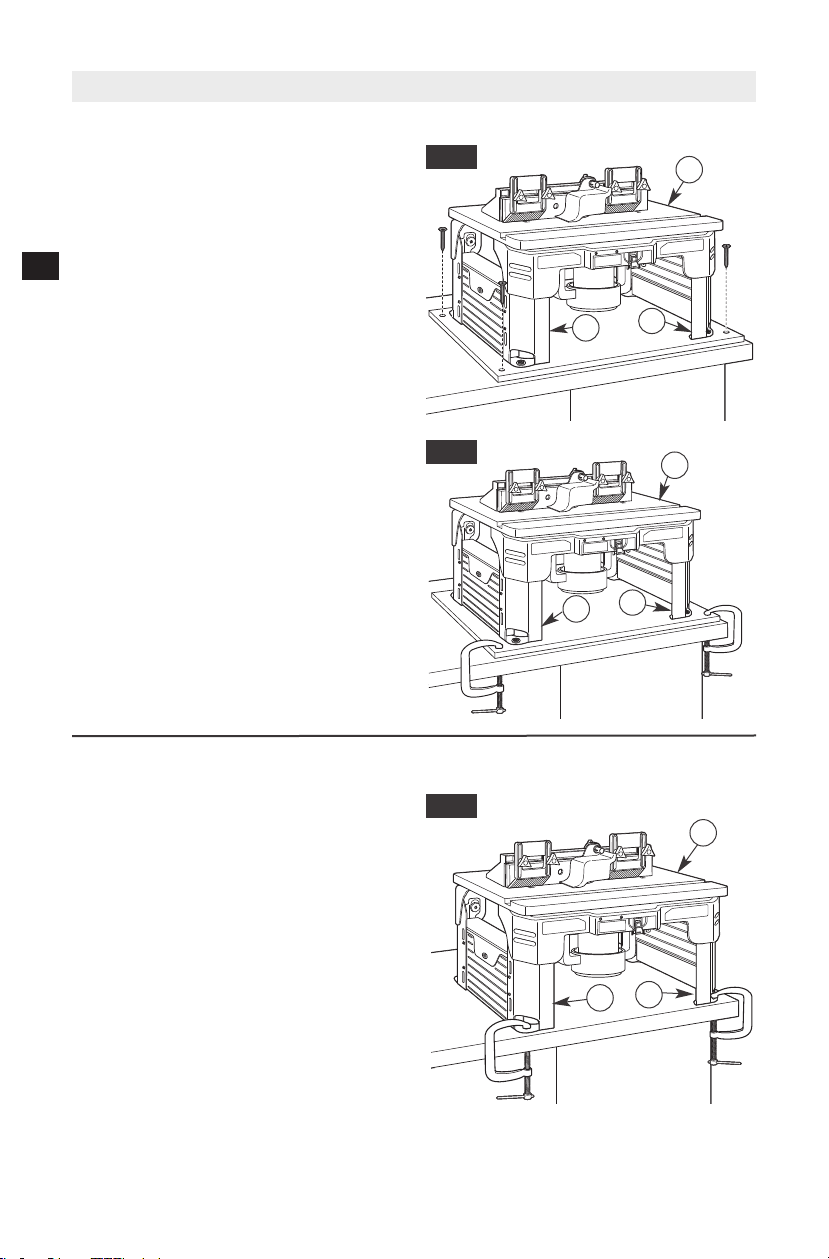

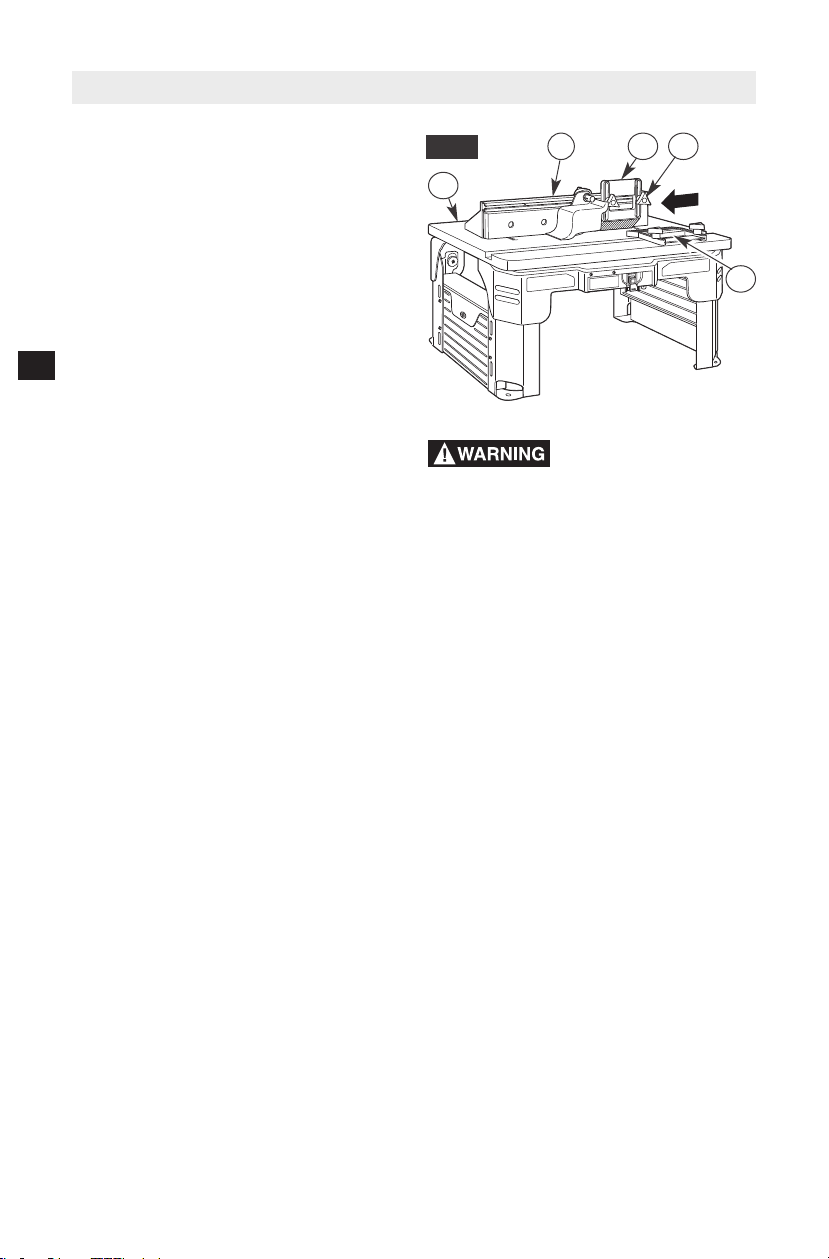

UNFOLDING AND LOCKING LEGS

(Figs. 1 and 2)

1. Gently lift and place the router table

assembly upside down on the tabletop (1).

2. Gently pull both leg assemblies (8 and 10)

inward towards center of the table until the

leg assemblies are in the unlocked position

as shown in Fig. 1.

Always rotate leg

assembly from end of leg

and keep fingers clear of joint. This avoids a

pinch point.

Never rotate leg

assemblies until the

locking tabs have been completely

disengaged. This will prevent possible

damage to the locking tabs or table housings.

3. After the leg assemblies (8 and 10) are

unlocked, rotate both leg assemblies to

the fully upright and extended position.

(See Fig. 2.)

4. Gently press down on both leg assemblies

(8 and 10) to secure and lock the left and

right leg assemblies in the upright position

as shown in Fig. 2.

Lift router table only by

the table edges. Lifting

table by any other surface could cause

personal injury.

Router Table Setup

LOCKED

(LEGS SLID

TOWARDS

OUTSIDE)

UNLOCKED

(LEGS SLID

TOWARDS

CENTER)

LOCKEDLOCKED

(LEGS SLID DOWN

TOWARDS TABLE)

UNLOCKED

(LEGS SLID UP

AWAY FROM TABLE)

8

10

1

FIG. 1

FIG. 2

8

10

12

Router Table Setup

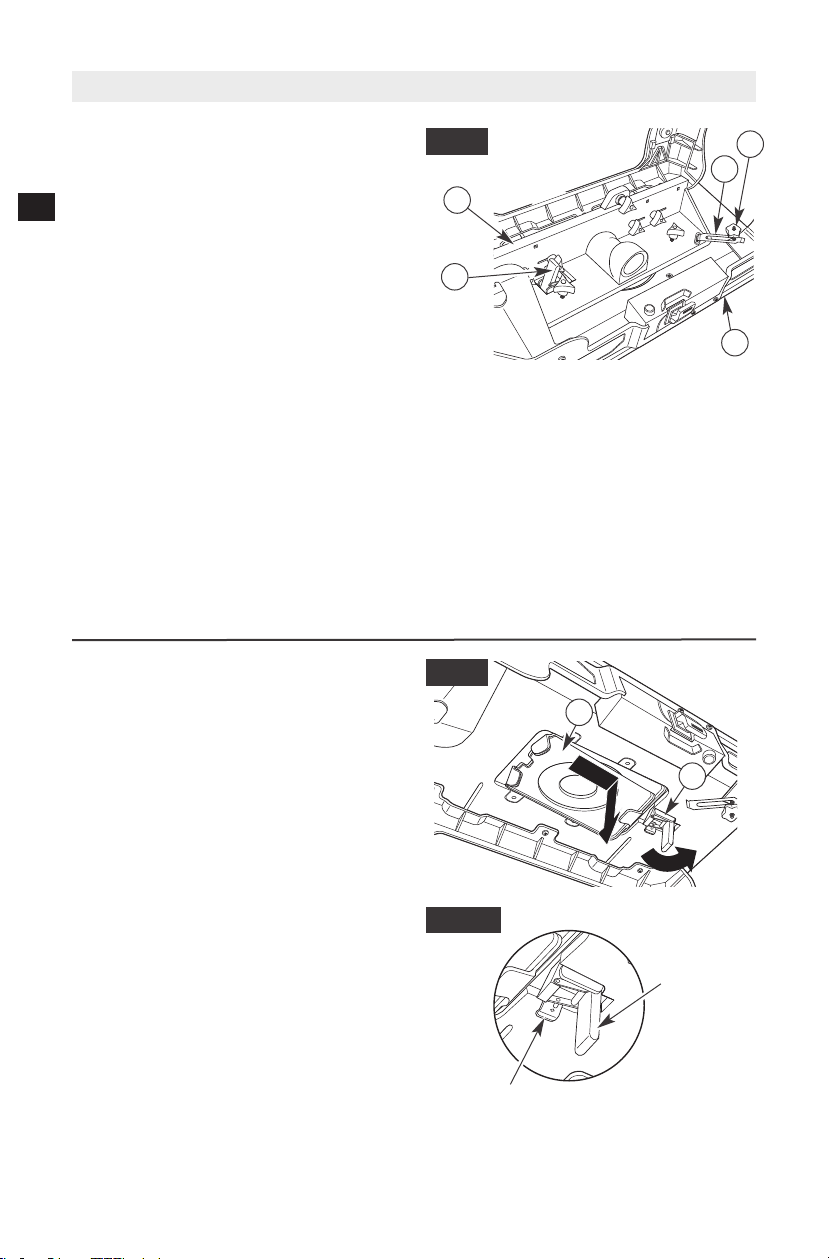

REMOVING THE FENCE ASSEMBLY

(Fig. 3)

The fence for your router table comes fully

assembled with the adjustable jointing fence

and overhead guard already in place. The fence

assembly is secured to the bottom of the table for

shipment and storage. The handle for the router

release mechanism passes through a square hole

in the base of the fence assembly when it is in its

stored position.

1. Loosen two small star clamping knobs (13)

and fence retaining brackets (12) securing

fence assembly (C) to bottom of router table

(1). Remove fence assembly (C) from the

storage position under the router table (1) and

set it to one side. (See Fig. 3.)

2. Tighten the small star clamping knobs (13)

and fence retaining brackets (12) to secure

the brackets to the bottom of the table (1).

To reinstall the fence assembly for storage:

1. Make sure the two faceplates are positioned

so they are completely together.

13

C

1

FIG. 3

5

12

FIG. 4

5

4

DETAIL 4

CLAMP

HANDLE

LATCH

SPRING

2. Position the fence assembly (C) so the square

hole is on the same side as the router release

mechanism (5). Slide the fence under the tool

box so that the square hole fits over the handle

of the router release mechanism and position

the fence assembly flat on the underside of the

table (1).

3. Position the two fence retaining brackets (12)

over the corners of the fence assembly and

tighten the small star clamping knobs (13) to

secure.

NOTE: Shim plates can be stored on outfeed side

of the fence assembly.

REMOVING THE EASY CLICK

ROUTER MOUNTING PLATE FROM

THE BASE PLATE (Fig. 4 and Detail 4)

This router table is provided with a Easy Click

router mounting system. The utilization of this

system requires the installation of a router

mounting plate to the router base. The mounting

plate has predrilled holes in it that will match up

with the mounting holes in most standard

routers.

1. Push latch spring away from clamp handle to

release the handle. (See Detail 4.)

2. Push clamp handle away from Easy Click

Base to open the router release mechanism (5).

3. Pull the tab on the router mounting plate (4),

closest to the clamp handle, towards the

handle and down to remove the mounting

plate from the base plate. (See Fig. 4.)

Router Table Setup

REMOVE

SUBBASE

FIG. 5

FIG. 6

4

13

Before using the router

table, verify that the router

is securely clamped in the router table

base. While working, periodically check the

router base fasteners clamping tightness.

Router motor vibration can loosen fasteners

during use, causing the router to fall from the

table.

NOTE: Mounting plate must be mounted with the

bent tabs towards the router. Plate must also be

mounted so no router parts interfere with the table

or the router mounting mechanism.

ATTACHING THE EASY CLICK

ROUTER MOUNTING PLATE TO

THE ROUTER (Figs. 5–7)

The router mounting plate included with this

router table is designed to fit the routers in

Chart 1 on page 14. The router mounting plate

also features access holes to allow use of the

over-table height adjustment (OTA) feature on

certain router models. See Fig. 7 for OTA access

hole. Refer to your router manual for additional

information on using this feature.

Disconnect the router

before installing router into the table,

making adjustments, changing accessories, removing the router from the table,

performing maintenance, or storing the

tool. Such precautionary s

reduce the risk of unintentional tool operation.

1. Remove the plastic subbase from your router.

(See Fig. 5.)

•

If you wish to mount the router with the

subbase, you may need to purchase longer

fasteners. Using the subbase reduces the

range of the cutting depth.

2. If your router has its own dust extraction hood

that mounts to the top of the router base and

you want to use it under the router table, this is

a convenient time to install it.

3.

Using Chart 1 on page 14, determine the

hardware and hole pattern type for your

router.

•

The screws are driven into threaded holes in

the routerʼs base.

• Other manufacturersʼ

Bosch's control. Changes made to these

routers may affect the compatibility to the

fasteners specified and/or supplied with this

table.

•

Always make sure the screw is fully seated

on the mounting plate and that the router

base is firmly against the mounting plate to

ensure secure mounting. If the router, plate,

and fasteners do not seat together properly,

you may need to purchase new fasteners of

a different length or size.

from the power supply

afety measures

routers are outside of

4. Refer to the mounting plate guide (Fig. 7) on

page 14 and align the appropriate mounting

plate holes for your router to the router base

holes. Before you mount the router, be sure

that the router position does not interfere with

the table switch and Easy Click router

mounting system.

When mounting your router to the mounting

plate, there may be numerous possible ways

to orient the router to the plate. Please

consider all orientations to see which one will

work best when the plate is mounted to the

table.

5. Securely mount the Easy Click mounting

plate (4) to your router. (See Fig. 6.)

14

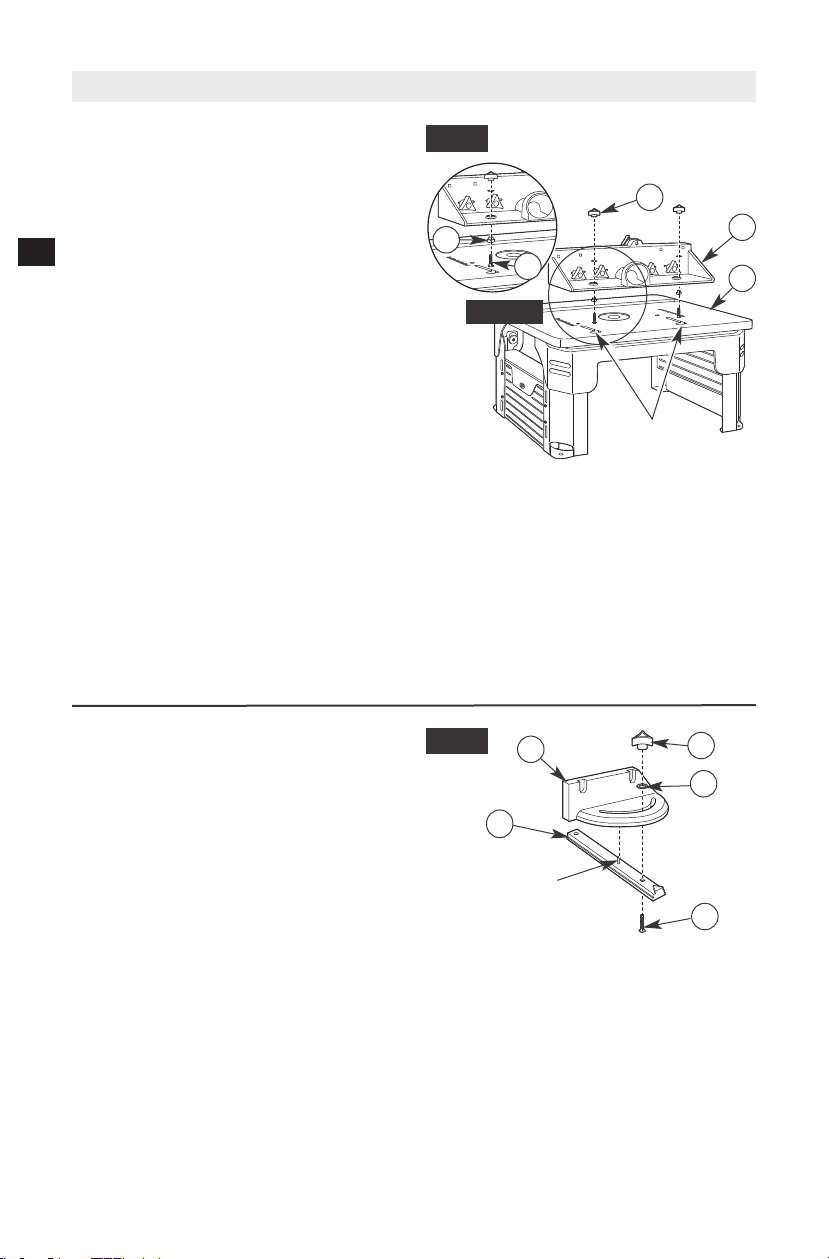

Router Table Setup

Router Router Hole Fasteners

Brand Model Pattern Required

Bosch 1617 series (fixed B #10-24 x 1/2"Pan-head Phillips machine screws (36)

base models only)

Craftsman 17508, 17542, 26620, A #10-32 x 1/2

"

Pan-head Phillips machine screws (39)

17533, 17528, 17511,

Craftsman 17541 C #10-32 x 1/2"Pan-head Phillips machine screws (39)

DeWalt DW616, DW618 B #8-32 x 1/2

"

Pan-head Phillips machine screws (34)

(fixed base only)

Hitachi M12VC B #10-32 x 1/2"Pan-head Phillips machine screws (39)

Makita RF1100, RF1101 B #10-24 x 1/2"Pan-head Phillips machine screws (36)

Milwaukee 5615, 5616 B #10-24 x 1/2"Pan-head Phillips machine screws (36)

Porter Cable 690 series, B #10-24 x 1/2

"

Pan-head Phillips machine screws (36)

7529 plunge router,

and 892–895 series

(fixed base only)

Ryobi 163K D 5/16-18 x 1/2"Pan-head Phillips machine screws (42)

Skil 1810, 1815, 1820, 1825 A #10-32 x 1/2

"

Pan-head Phillips machine screws (39)

CHART 1

FIG. 7

OTA1 = Over-table height adjustment 1

TOP FRONT OF PLATE

OTA1

B

B

B

A

A

A

C

C

C

D

D

D

ATTACHING THE EASY CLICK ROUTER MOUNTING PLATE

TO THE ROUTER (Figs. 5–7) (cont.)

Before using the router table, verify that the router is securely clamped in

fasteners clamping tightness.

the router to fall from the table.

the router table base. While working, periodically check the router base

Router motor vibration can loosen fasteners during use, causing

26834, 28190, 73277

15

1. Make sure the table (A) is upright and on its

legs (8 and 10). (See Fig. 8.)

2. Check the clamp handle to make sure it is

open and released. (See Fig. 9.)

3. Position the router mounting plate (4) on

the router so the angled tabs on the

mounting plate are facing down and

towards the router. (See Fig. 10.)

4. While supporting the router, slide the two

angled tabs on the mounting plate into the

left tabs on the base plate. Rotate the

router and the mounting plate up until the

mounting plate is flush against the base

plate; then secure the mounting plate by

pushing the clamp handle towards the

router. The latch spring will snap in place to

lock when the clamp handle is locked. (See

Fig. 11 and Detail 11.)

Router Table Setup

FIG. 10

FIG. 11

ANGLED

TABS

PUSH CLAMP

HANDLE TOWARDS

ROUTER

ROTATE

ROUTER UP

A

8

10

DETAIL 11

4

LATCH

SPRING

OPENED

CLAMP

HANDLE

CLOSED

CLAMP

HANDLE

FIG. 9

FIG. 8

INSERT

TABS

BASE PLATE

A

B

C

INSTALLING THE EASY CLICK

MOUNTING PLATE AND ROUTER TO

THE ROUTER TABLE (Figs. 8–11 and

Detail 11)

Before using the router

router is securely clamped in the router

table base. While working, periodically

check the router base fasteners clamping

tightness. Router motor vibration can loosen

fasteners during use, causing the router to fall

from the table.

NOTE: Mounting plate must be mounted so

no router parts interfere with the table or the

router mounting mechanism. If there are any

interferences which do not allow the plate to

sit fully into the mounting mechanism, please

try to reorient your router in one of the other

possible orientations on the mounting plate.

table, verify that the

16

Router Table Setup

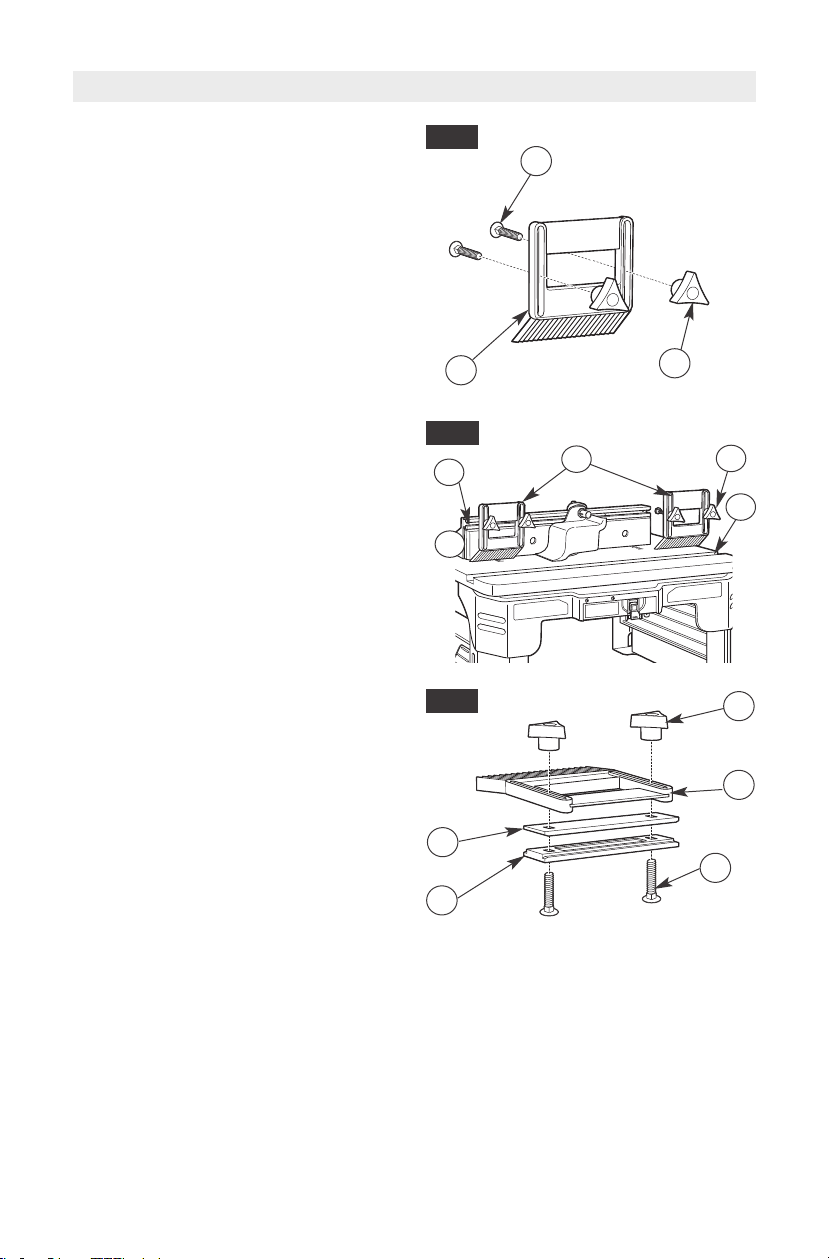

MITER GAUGE ASSEMBLY (Fig. 13)

The miter gauge assembly comes fully

assembled. If not, use the following instructions

to assemble it.

1. Insert tab on top of the miter bar (23) in the

hole in the bottom of the protractor head

(24).

2. Insert the #10-24 x 1" carriage bolt (37)

through the square hole in the miter bar

(23) and slot in the miter gauge and secure

with the flat washer (33) and the small

clamping knob (25).

INSTALLING THE FENCE ASSEMBLY

(Fig. 12 and Detail 12)

The fence comes assembled. Step 1 refers to

reassembly, if necessary; otherwise, go to Step 2

if already assembled.

1. Install spacers (31) on square-head bolts

(47) (Detail 12).

2. From underneath the fence, slide two 1/4-20 x

2

1

⁄4" square-head bolts (47) with spacers (31)

up through the holes in the bottom of the

fence assembly (C). Loosely attach a large

clamping knob (21) onto each bolt. (See

Fig. 12.)

3. Insert the square-head bolts (47) with

spacers (31) through the holes of the J-slots

on the tabletop (1), making sure the bolt

heads and spacers are below the inside

surface of the tabletop and can slide freely in

the J-slot.

4. From the rear of the table assembly, slide

the fence assembly (C) right and into the

J-slot and make sure that it slides smoothly

from front to back.

5. Tighten the large clamping knobs (21) to

secure the fence assembly (C) to a desired

position.

NOTE: Use the scale on the tabletop as a guide

when aligning the fence for routing operations.

Once the fence is positioned and aligned

correctly, tighten the clamping knobs SECURELY.

A

C

FIG. 12

37

33

25

23

FIG. 13

TAB

21

47

31

DETAIL 12

24

J-SLOTS

Router removed for clarity

Router Table Setup

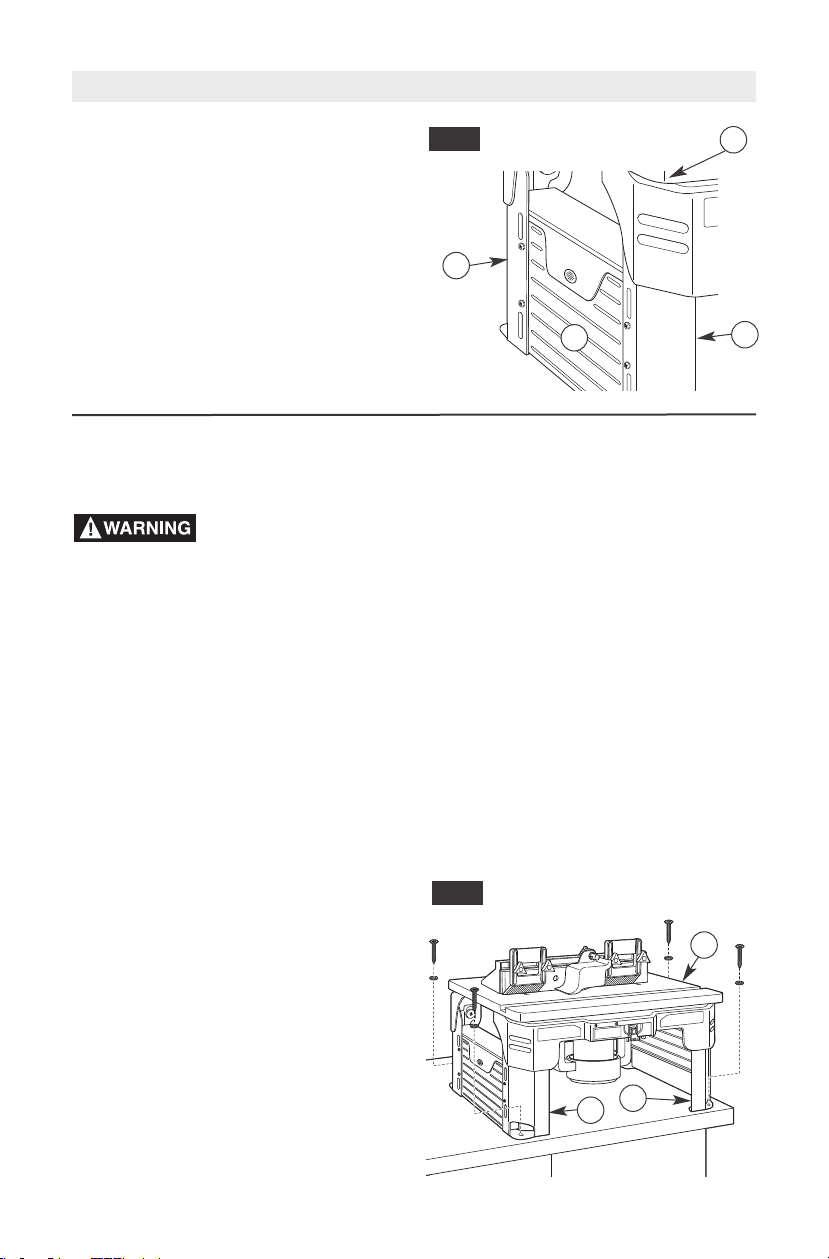

TOOL BOXES (Fig. 14)

Your router table (A) comes with two tool boxes

(9) with hinged covers. The tool boxes are

permanently mounted to the left and right leg

assemblies (8 and 10). Both tool boxes have

hinged covers with latching tabs on the front.

Please note the tool boxes are an integral part of

the leg assemblies and should not be removed.

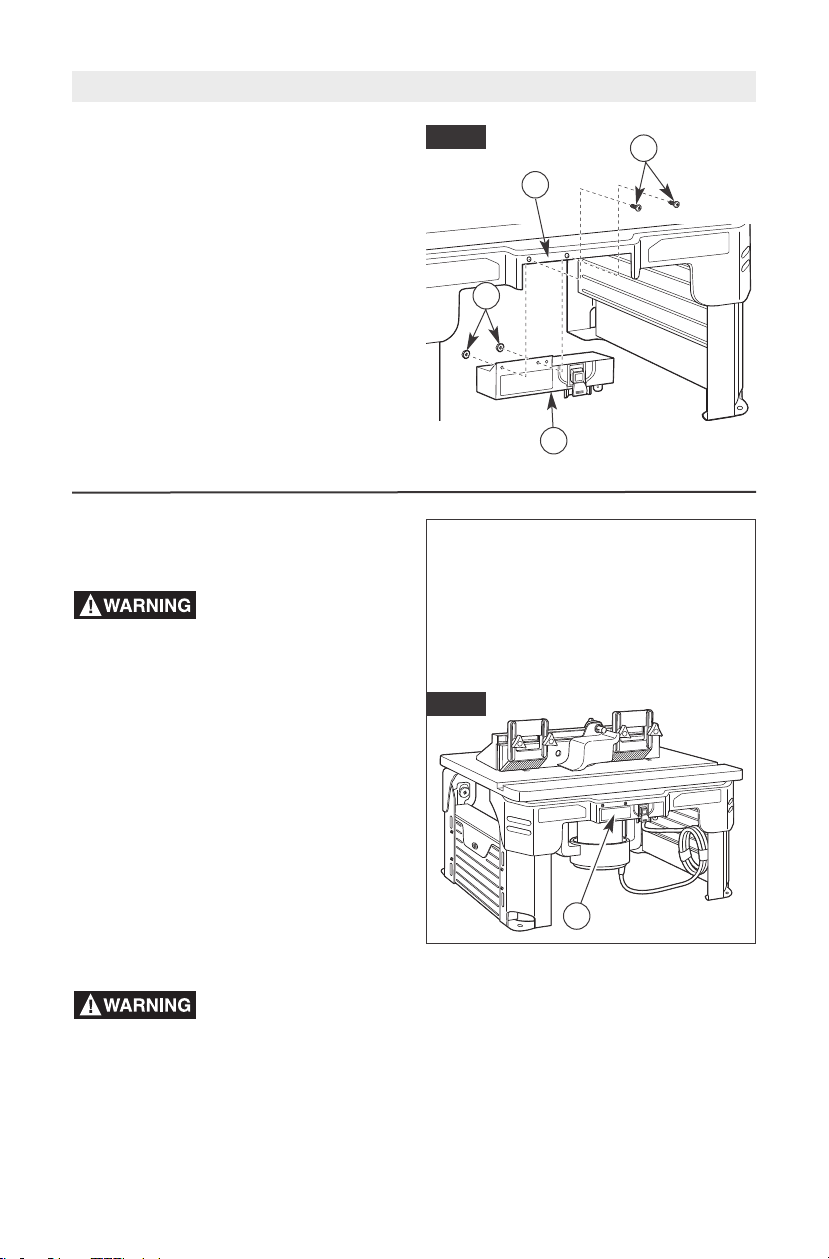

MOUNTING THE ROUTER TABLE TO A

WORK SURFACE OR WORKBENCH

•

C-clamps

•

Phillips screwdrivers

•

Small adjustable wrench

•

Electric or hand drill with drill bits

(depending on mounting method used)

•

Fasteners

— 4 #10-16 x 3/4" pan-head wood screws

and 4 washers (for solid wood surfaces

or workbenches)

OR

— 4 3/16" pan-head machine screws,

8 washers, and 4 hex nuts

FIG. 14

8

A

Before operating the

ensure that the table legs are fully extended

and in the locked position. The entire unit

(router table with router) is placed on and

secured to a solid, flat, level surface that will

not tip. Such precautionary measures reduce

the risk of table shifting unexpectedly while in

use resulting in property damage or serious

personal injury.

HELPFUL TOOLS AND PARTS

(not included)

NOTE: Method 1 and Alternate Method

1 will provide the best support for

the router table.

METHOD 1 (Fig. 15)

1. Set the router table (A) on a workbench or

other stable and sturdy surface with the

FRONT (switch side) of the router table

facing towards you.

router in the router table,

9

2.

While holding the router table in the desired

position, mark the location of the four

mounting holes (one in each leg [8 and 10]).

Remove the router table (A) from the

3.

workbench and set it aside.

Drill suitable pilot holes (for wood screws) or

4.

through-holes (for machine screws) at the

marked locations.

Place the router table (A) on the workbench

5.

and align the mounting holes in the router

table legs (8 and 10) with the holes drilled in

the workbench.

Secure the router table (A) in place using the

6.

wood screws and washers (not provided). If

using wood screws, applying a thin coat of

soap or wax to the screw threads will make it

easier to thread the screws into the pilot

holes.

TIGHTEN all screws SECURELY.

7.

FIG. 15

10

8

17

8

A

18

Router Table Setup

ALTERNATE METHOD 1

(Figs. 16 and 17)

1. Cut a board 18¼" wide x 23" long from a

piece of 3/4"-thick wood or plywood.

2. Center the router table (A) on the board and

mark the location of the four mounting holes

(one in each leg [8 and 10]).

3. Remove the router table (A) from the

workbench and set it aside.

4. Drill suitable pilot holes (for wood screws)

or through-holes (for machine screws) at

the marked locations.

5. Place the router table (A) on the board and

align the mounting holes in the router table

legs (8 and 10) with the holes drilled in the

board.

6. Secure the router table (A) in place using

the wood screws and washers (not

provided). Applying a thin coat of soap or

wax to the screw threads will make it easier

to thread the screws into the pilot holes.

7. Secure the board to a workbench or other

sturdy surface with screws (Fig. 17) or

clamps (Fig. 18) during use.

IMPORTANT: Be sure the placement of

the clamps will not interfere with operation

of the router table.

FIG. 16

FIG. 17

A

8

8

10

A

10

METHOD 2 (Fig. 18)

1. Set the router table (A) on a workbench

or other stable surface with the FRONT

(switch side) of the router table facing

towards you.

2. Using the clamping bosses on the router

table legs (8 and 10), secure the router

table legs to the workbench with clamps.

Be sure to tighten them securely.

IMPORTANT: Be sure the placement of

the clamps will not interfere with the

operation of the router table.

FIG. 18

A

10

8

19

Router Table Setup

FIG. 20

11B

11C

11A

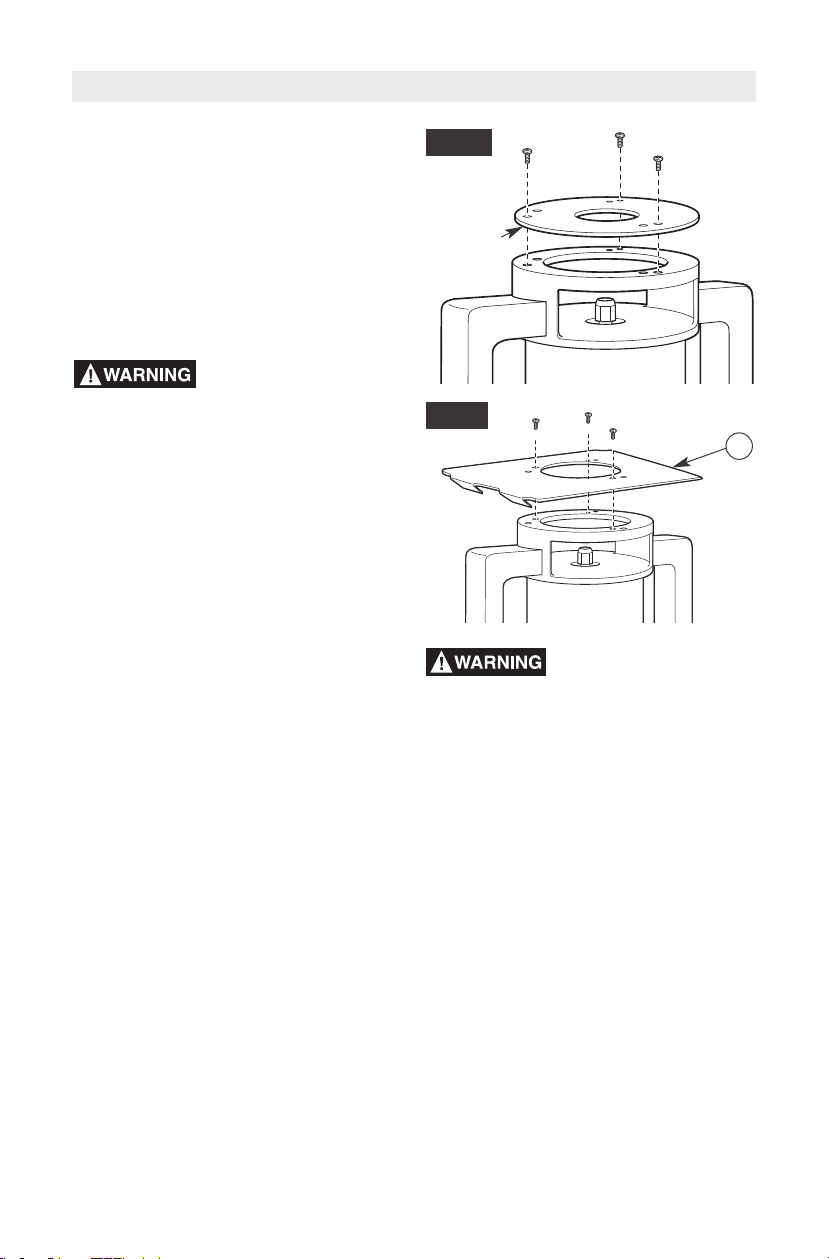

OVERHEAD GUARD ASSEMBLY

(Fig. 19)

The overhead guard assembly (18) comes

preinstalled on the fence assembly. Some

routing applications will require you to remove

this guard.

1. Loosen and remove clamping knob (21) on

the top back of the fence assembly (C).

2. Remove the 1/4-20 x 2½" carriage bolt (48),

overhead guard (18), and spacer from

the fence assembly (C).

3. Reinstall the overhead guard assembly (18)

by following these steps in reverse.

FIG. 19

21

C

18

48

Spacer

less than 1/16" on a side. Insert rings are

meant to reduce the gap between the cutting

diameter of the bit and table so that

workpieces maintain full support of the table

while routing.

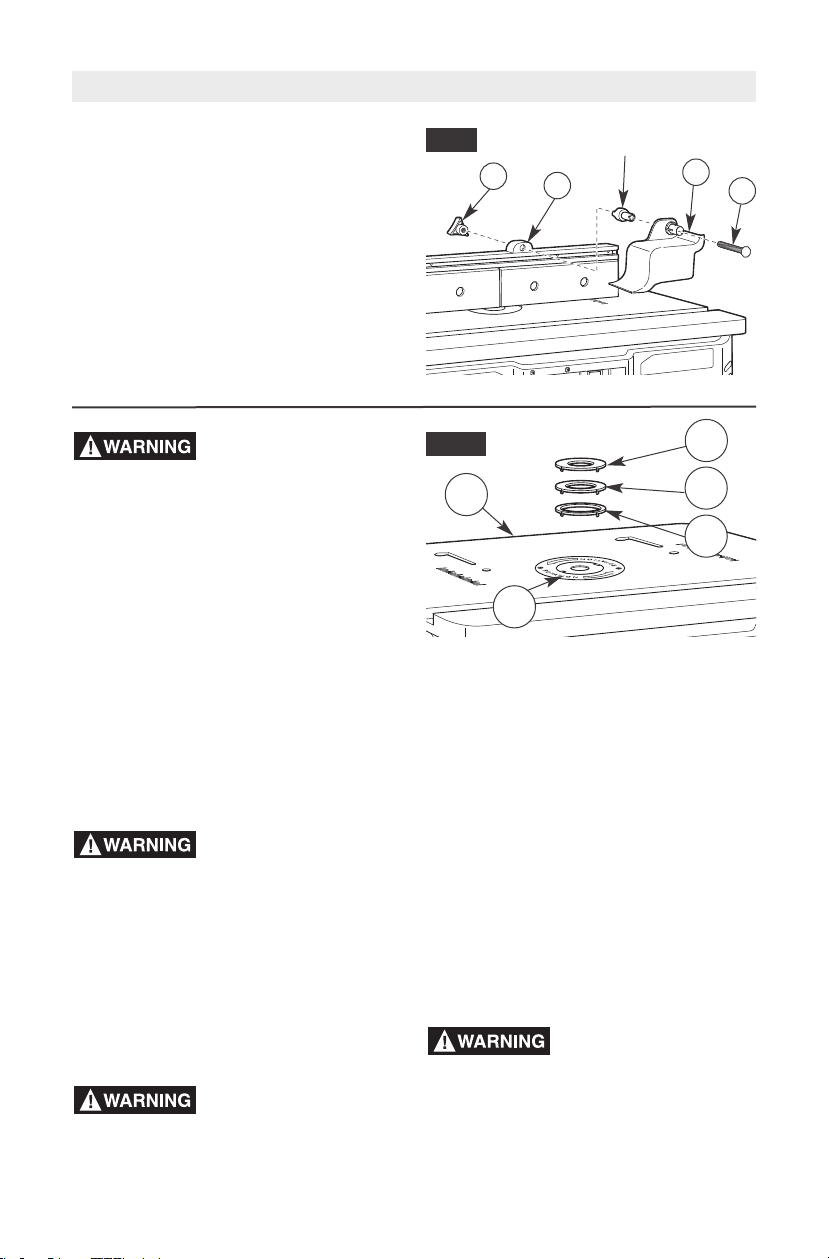

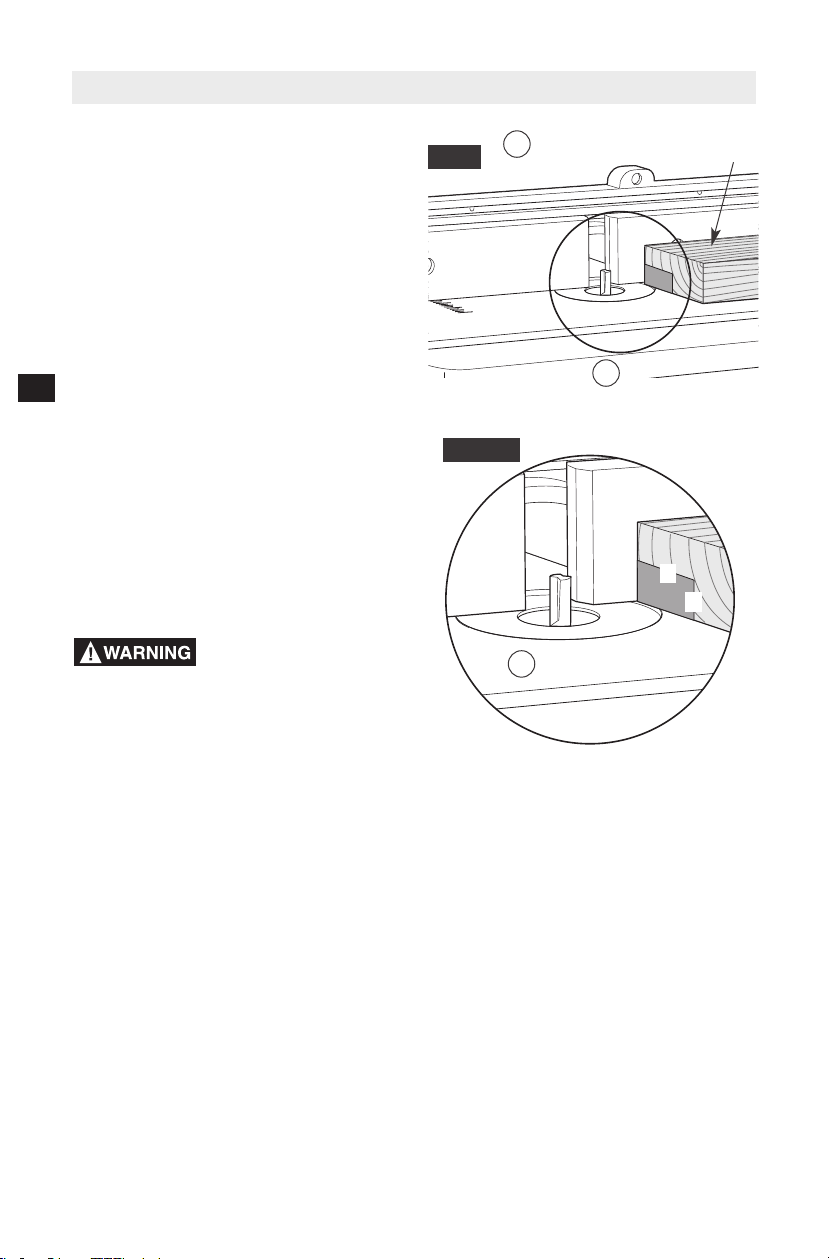

INSTALL TABLETOP

INSERT RINGS (Fig. 20)

1. Select the insert ring (11A–11C) that best

accommodates the router bit to be used.

2. Press the insert ring (11A–11C) into the

large hole in the plastic insert plate (2).

3. Press down evenly over the tabs until the

insert ring locks into place.

4. To remove, pull up gently until the tabs

disengage. When not in use, store insert

rings (11A–11C) in one of the tool boxes (9)

or a convenient place.

1

2

Disconnect the router

from the power supply

before installing router into the table,

making adjustments, changing accessories, removing the router from the table,

performing maintenance, or storing the

tool. Such precautionary safety measures

reduce the risk of unintentional tool operation.

INSERT RINGS (Fig. 20)

This router table includes three tabletop insert

rings with the following hole sizes:

(11A) 1¼" diameter, for use with bits up to

11⁄8" diameter

(11B) 17⁄8" diameter, for use with bits larger

than 11⁄8" and up to 1¾" diameter

(11C) 21⁄8" diameter, for use with bits larger

than 1¾" and up to 2" diameter

No insert ring is required for bits with

diameters between 2" and 2½".

Do not use the router

table with bits over 2½"

in diameter. Bits larger than 2½" exceed

the clearance hole in the tabletop insert

rings. Bits larger than 2½" can contact insert

plate or insert ring, throwing fragments.

These three insert rings are supplied

individually and can be found in one of the

storage boxes. The insert ring should fit into

the tabletop hole completely. Use a fine file

or emery board to remove excess plastic or

rough edges that may cause the insert ring

to protrude above the table surface.

Do not alter insert ring or

insert plate bit hole.

Match the cutting diameter of the bit to the

inner diameter of the insert ring or insert

plate bit hole such that the difference is no

Do not use, attempt to

tabletop insert rings from the tabletop

unless the router is off and unplugged.

Such precautionary safety measures reduce

the risk of unintentional tool operation.

change, or remove

20

Router Table Operation

SWITCH CONTROL BOX

Improper connection of the equipmentgrounding conductor can result in risk

of an electrical shock. The conductor with

insulation that has a green outer surface,

with or without yellow stripes, is the

equipment-grounding conductor.

DO NOT CONNECT THE EQUIPMENTGROUNDING CONDUCTOR TO A LIVE

TERMINAL.

Check with a licensed electrician if the

grounding instructions are not completely

understood or if there is doubt as to whether

the electrical outlet or extension cord is

properly grounded.

Do not permit fingers to

touch terminals of the

plug when inserting or removing the plug

from the outlet.

Use the switch box only

when properly assembled

to the router table. Use only with a router

that has also been properly installed on a

properly assembled router table. Such

precautionary safety measures reduce the risk

of injury due to loss of control.

Do not exceed a total

combined rating of 15

amps when connecting the router and any

accessories such as a light or wet/dry

vacuum. The switch has a rating of 15 amps.

Do not plug router motor

wall outlet. It must be plugged into the

router table switch. Power tool switches and

controls need to be within your reach in

emergency situations.

GENERAL INFORMATION

The power switch is designed for use with

most BOSCH Router Tables. It provides the

convenience of an ON (RESET)/OFF switch

at the front of the table, thus eliminating the

need to reach underneath the table to turn

the router ON and OFF.

The power switch also provides an optional

simultaneous ON/OFF control of an additional

accessory, such as a light or a wet/dry vacuum.

The switch has an internal, resettable circuit

breaker to provide overload protection.

ELECTRICAL REQUIREMENTS

The switch box cord should only be plugged

into a 14-gauge (or heavier), three-wire

extension cord with a three-hole grounding

receptacle and three-prong grounding plug.

The extension cord must be plugged into a

matching outlet that has been installed by a

licensed electrician and grounded in

accordance with all local codes and

ordinances.

DAMAGED OR WORN EXTENSION CORDS

ARE NOT TO BE USED AND ARE TO BE

REPLACED IMMEDIATELY.

The electrical outlet at the back of the switch

will accept three-hole extension cords.

The electrical receptacles at the back of

the switch will accept either three-prong or

two-prong plugs from a router or accessory.

In the event of a malfunction or breakdown,

grounding provides the path of least resistance

for electrical current in order to reduce the risk

of electrical shock. This switch box is equipped

with an electrical cord that has an equipmentgrounding connector and a grounding plug.

DO NOT modify the plug from the switch if it

does not plug into the extension cord. Obtain

an extension cord with the proper outlet.

power cord into standard

21

Router Table Operation

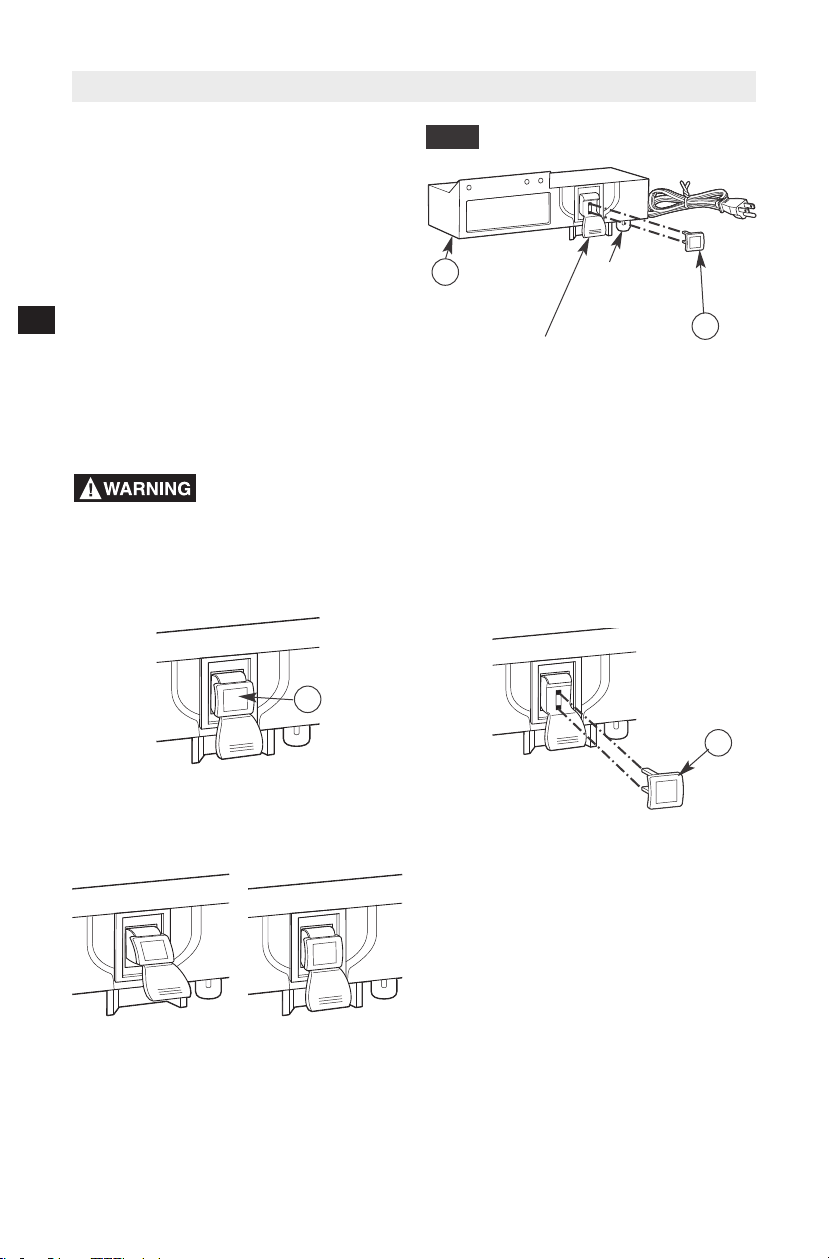

CONNECTING THE ROUTER

POWER CORD TO THE SWITCH

(Fig. 22)

Before connecting router

to router table switch

box, ensure that the router switch is OFF,

and that the router table switch box is

unplugged. Such precautionary safety

measures reduce the risk of unintentional tool

operation.

1. Plug the router power cord into one of the

electrical outlets on the back of the switch

box (14).

2. Form the excess power cord into a coil.

3. Wrap two pieces of electrical tape or cable

ties around the coiled cord at opposite sides

of the coil.

4. Allow some slack so that the cord does not

become stretched when it is plugged into

the switch box outlets.

5. If desired at this time, plug the power cord

from an accessory, such as a wet/dry

vacuum or light, into the other outlet.

Before starting to work

ensure that the power

cords from the router, accessories, the

switch case, and the extension cord do not

and cannot come in contact with the router

or any moving parts of the router. Such

precautionary safety measures reduce the risk

of injury due to loss of control.

Cord Positioning

Position the switch cord and any accessory

power cords down the inside of the legs,

then out the rear base of the router table to

an electrical outlet. Secure cord(s) to leg(s)

with electrical tape or tie straps. This will

prevent cord(s) from coming in contact with

any moving parts.

FIG. 22

14

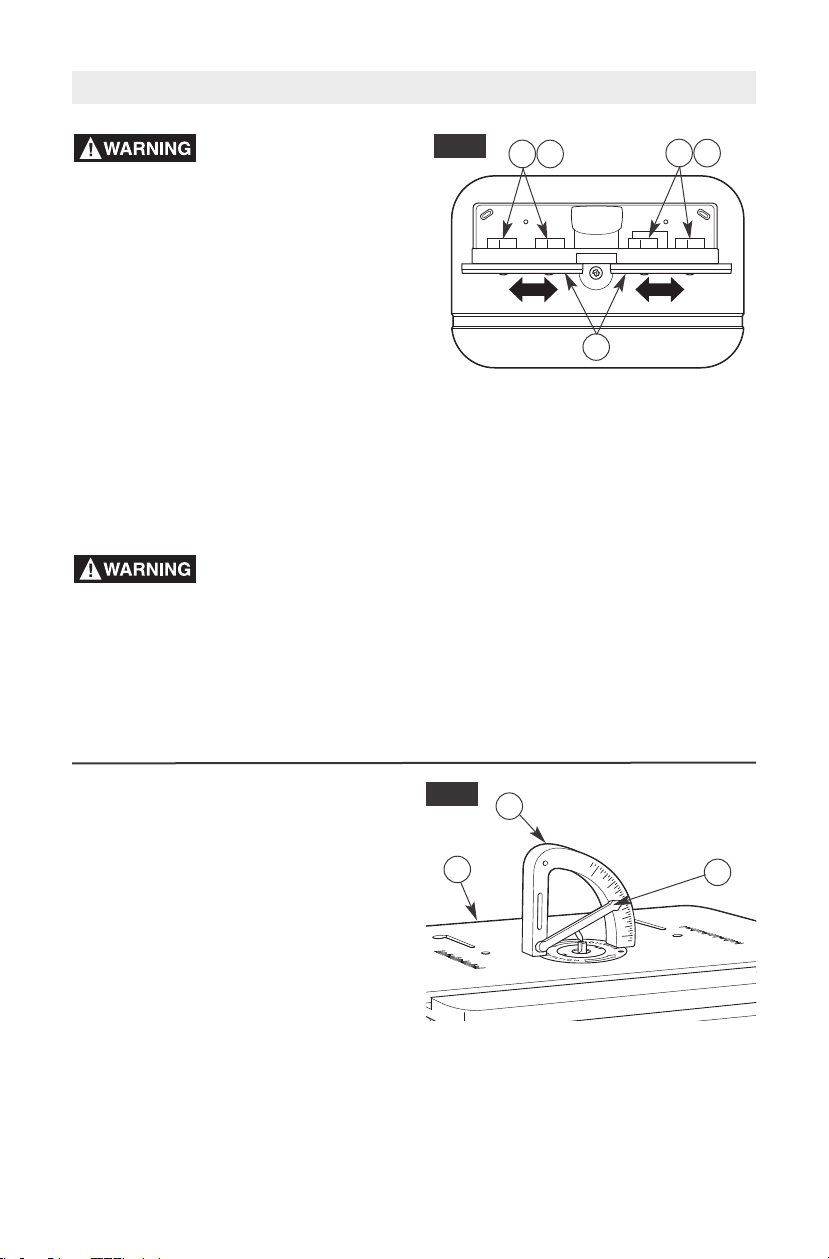

INSTALLING THE SWITCH BOX

(Fig. 21)

If the switch box assembly (14) does not come

preinstalled to the front table housing (6), use the

following instructions to attach the switch box.

1. Place two #10-32 x 5/8" truss-head screws

(40) in the holes in the front table housing

opening. NOTE: The screw heads should

face the front of the table.

2. While holding the screws in place, slide on

the switch box (14) and start the KEPS nuts

(32) on the screws. NOTE: The switch box

should be behind the housing opening, and

the washer side of the nuts should be

against the switch box.

3. Hold the KEPS nuts (32) while tightening

the two #10-32 x 5/8" screws (40) to secure

the switch box (14).

FIG. 21

40

14

32

6

22

SWITCH OPERATION (Fig. 23)

This section explains the operation and features

of the switch box assembly prior to plugging the

power cord into a power outlet. The intent is to

familiarize the user with the switch operation

without actually turning ON the router.

The switch box (14) (Fig. 23) incorporates a

lockout key (15) to help prevent unauthorized

use by others.

• The lockout key (15) is the yellow part in

the top of the red plastic paddle. The yellow

lockout key must be completely inserted

into the top of the red plastic paddle and

switch box (14) before the paddle can be

turned ON.

• The circuit reset button for the switch box

(14) is on the bottom right side of the box.

Make sure that the

extension cord is not

plugged into an electrical outlet before

proceeding any further.

1. Make sure the yellow lockout key (15) is

completely inserted in the top of the red

plastic paddle.

Yellow

lockout key

Switch box

assembly

Red

plastic paddle

(ON/OFF switch)

FIG. 23

Router Table Operation

4. To prevent unauthorized use, the switch can

be disabled by removing the yellow lockout

key (15) completely from the top of the red

plastic paddle.

2. To turn the router ON, lift the red plastic

paddle up to the ON position.

3. To turn the router OFF, press the red plastic

paddle to the OFF position.

Circuit

reset button

14

15

15

15

OFF

(DOWN)

ON

(UP)

23

Before proceeding any

further, make sure the

switch on the router is in the OFF position

and the switch lever is in the OFF position.

Never leave the router

unattended while it is

running or before it comes to a complete

stop.

Before starting to work

ensure that the power

cords from the router, accessories, the

switch case, and the extension cord do not

and cannot come in contact with the router

or any moving parts ob the router. Such

precautionary safety measures reduce the risk

of injury due to loss of control

The switch power cord can now be

plugged into the extension cord.

ROUTER AND SWITCH OPERATION

This section explains operation of the switch

with the power cord plugged into the extension

cord.

The router will turn ON when the red

paddle on the switch box is pulled up

to the ON position.

1. Position the ON/OFF switch on the router in

the ON position. On certain routers this will

require the use of the switch trigger and

“LOCK-ON” button. (Consult router ownerʼs

manual.) Make sure the switch on the

switch box is in the OFF position when

doing this.

2. To turn the router ON, pull up the red

paddle to the ON position. See page 22.

3. To turn the router OFF, press the red paddle

to the OFF position. See page 22.

CIRCUIT RESET BUTTON

NOTE: In the event of an overload, the

internal switch circuit breaker will trip the

switch box assembly OFF. This will interrupt

power to the router and any accessory

plugged into the switch itself. If this occurs,

proceed as follows:

1. Push the red plastic paddle to the OFF

position and unplug the switch cord from the

wall outlet or extension cord.

2. Turn router switch to OFF position.

3. Remove the workpiece from the router

table.

4. Correct the cause of the overload situation.

For example, if too many accessories are

plugged into the switch, or combined

amperage exceeds the switch rating,

remove the accessory. Other causes

include the removal of too much stock

or use of too high a feed rate.

5. Press the circuit reset button on the bottom

of the switch box.

6. Plug the switch power cord into the wall

outlet or extension cord.

7. Restart the router as described in

the section ROUTER AND SWITCH

OPERATION on this page.

IIf the switch case does

not work and you have

tried to RESET the circuit reset button as

described above:

WHEN THE ROUTER TABLE IS NOT

IN USE

1. Make sure the switch is in the OFF position.

2. Remove the lockout key (15). See page 22.

3. Store the lockout key in a safe location

where it is not available to children and

other unauthorized persons.

4. Unplug the switch power cord from the wall

outlet or extension cord.

5. Remove the router bit from the router.

6. Position the router collet assembly below

the top of the router table.

Router Table Operation

• Unplug ALL electrical connections.

• Remove the switch from the router

table and obtain a replacement switch

by calling BOSCH customer service at

1-877-BOSCH99.

NOTE: If the key should become lost or

damaged, replacement keys are

available by calling BOSCH customer

service at 1-877-267-2499.

24

ATTACHING AND USING A

WET/DRY VACUUM

Before connecting vacuum

to router table switch box,

ensure that the vacuum switch is OFF, and

that the router table switch box is unplugged.

Such precautionary safety measures reduce the

risk of unintentional tool operation.

Do not exceed a total

combined rating of 15

amps when connecting the router and any

accessories such as a light or wet/dry

vacuum. The switch has a rating of 15 amps.

The fence assembly has a port for connecting

a wet/dry vacuum hose with a 2½" nozzle. To

attach, simply push the nozzle into the port

while holding the fence assembly in place.

The vacuum can be plugged into the router

table switch box. Be sure the cord does not

interfere with router operation.

Operating the router table

without a wet/dry vacuum

can result in an excessive buildup of sawdust

and wood chips under the fence assembly and

guard, reducing the performance of the router

table and fence assembly.

RECOMMENDATION: To maximize

performance, regardless of whether a wet/dry

vacuum is being used, remove the sawdust

and wood chips from under the fence

assembly and guard as needed.

RECOMMENDATION: It is always a good

practice to keep the work area clean. As

necessary, remove any accumulated sawdust

and wood chips from the top of the router table, as

well as from the surrounding work area and floor.

Never place your fingers

near a spinning bit or

under the guard when the router is

plugged in. Such precautionary safety

measures reduce the risk of personal injury.

INSTALLING THE ROUTER BIT

(CUTTER)

Disconnect the router

from the power supply

before making adjustments or changing

accessories. Such precautionary safety

measures reduce the risk of unintentional tool

operation.

Install the router bit according to the instructions

included with your router. Because of the large

variation of router bits, certain router bits may

not always operate in the desired manner with

this router table.

USING THE ROUTER TABLE

Router Table Operation

To ensure that the most popular bits will perform

satisfactorily, install the bit so that the router

collet engages 3/4" of the router bit shank. If the

shank of the router bit bottoms out in the collet,

back out the router bit approximately 1/16" to

allow for proper tightening.

NEVER INSTALL ROUTER BITS WITH

LESS THAN 3/4" OF SHANK

ENGAGEMENT IN THE COLLET.

25

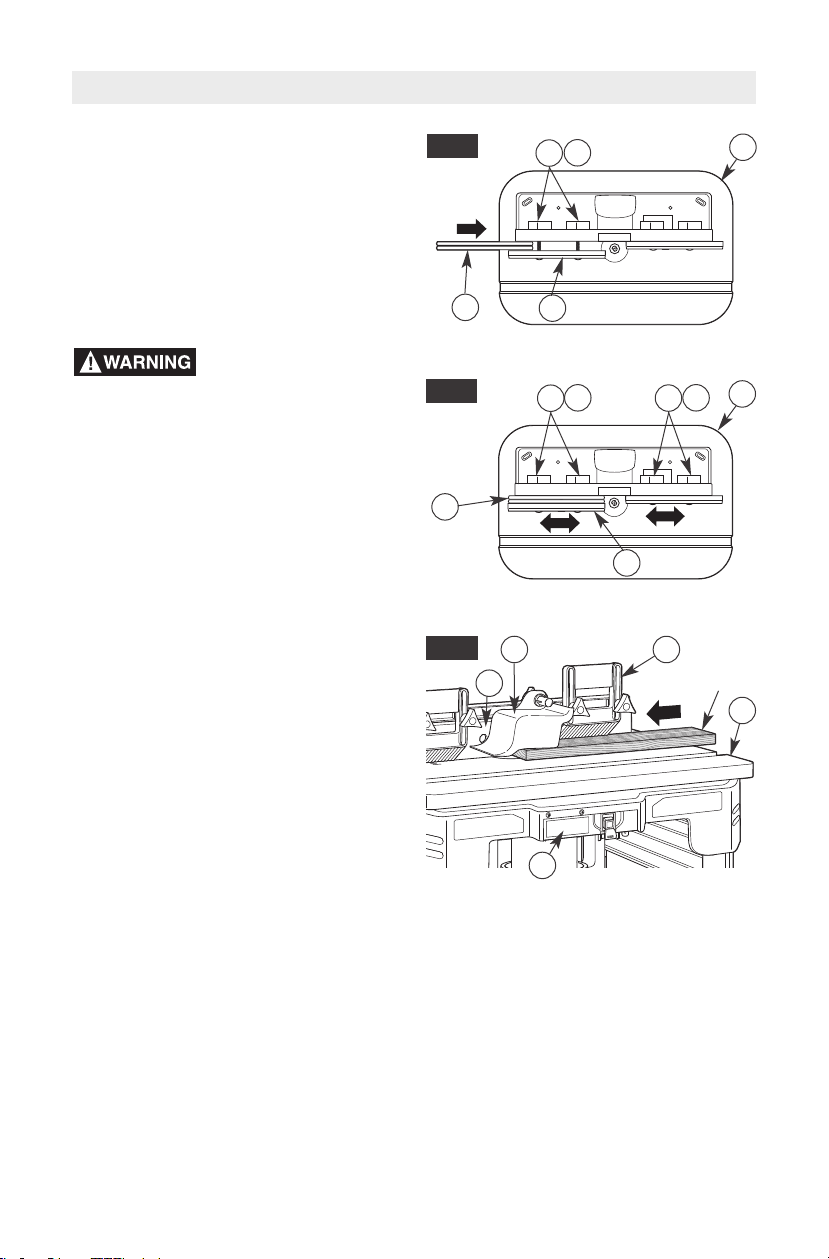

ASSEMBLING THE

FEATHERBOARDS (Figs. 24–26)

NOTE: The top/front side of each featherboard

is marked to indicate proper feed direction.

Fence Featherboard (Fig. 24 and 25)

1. Insert two 1/4-20 x 1½" carriage

bolts (46) through the slotted holes in

each featherboard (22). (See Fig. 24.)

2. Thread clamping knobs (21) three or four

turns onto each carriage bolt (46).

3. To install on fence, slide the head of each

carriage bolt (46) into the end of the T-slot

in the featherboard mounting rail (17). (See

Fig. 25.)

4. Secure the featherboard(s) (22) to fence

assembly (C) by tightening the small

clamping knobs (21). (See Fig. 25.)

Tabletop Featherboard (Fig. 26)

NOTE: The featherboard slide plate assembly

is T-shaped for use in the miter channel and

has round indentations on the bottom for the

carriage bolt heads.

1. Insert two 1/4-20 x 1¾" carriage bolts (46)

through the holes in both the lower and

upper featherboard slide plates (50 and 49)

and the slotted holes in the featherboard

(22) as shown in Fig. 26.

2. Thread a small clamping knob (21) three

or four turns onto each carriage bolt (46).

3. To install the featherboard (22) in the miter

channel (3), insert the upper and lower

featherboard slide plates (49 and 50)

into the miter channel. Then slide the

featherboard to the desired location on the

miter channel and tighten the clamping

knobs (21).

Router Table Operation

21

22

17

C

FIG. 26

21

46

22

50

49

3

FIG. 24

46

22

21

FIG. 25

26

Router Table Operation

ROUTING USING FEATHERBOARDS

(Fig. 27)

Featherboards are helpful in controlling the

workpiece while routing and assisting in

keeping the workpiece flat on the tabletop.

The tabletop featherboard combined with the

fence featherboard helps keep the workpiece

pressed against the fence and tabletop. The

best location for the featherboards varies

according to your application, workpiece size,

and other factors.

1. Loosen clamping knobs (21) on

featherboard(s) (22) until featherboard(s)

are adjustable.

2. Place the workpiece on the router table (1)

so that it is squarely against the fence

assembly (C).

3. Position the featherboard(s) (22) snugly

against the workpiece and tighten the

clamping knobs (21).

4. The workpiece should move with some

resistance but without requiring a great

effort.

5. For wider workpieces, the tabletop

featherboard cannot be used. The second

featherboard may also be positioned on the

fence, if desired.

Never let go of the

workpiece when routing

until the cut has been completed and the

workpiece is completely clear of the bit.

Such precautionary safety measures reduce

the risk of personal injury and/or property

damage.

•

Featherboards aid in holding the workpiece

in position when routing on a router table.

•

They are NOT intended to hold the

workpiece in place alone when the

workpiece is in contact with the bit, or

at any other time when the bit is turning.

FIG. 27

22C 21

1

DIRECTION

OF FEED

22

27

Router Table Operation

For accuracy in routing

and improved control, the

workpiece should be held against the

router table fence when routing.

ADJUSTING THE FENCE

FACEPLATES (Fig. 28)

The right and left fence faceplates are

attached to the front face of the router table

fence and can be adjusted inward or outward

from the router bit to allow proper clearance

for different-sized bits. To provide the best

support during routing operations, the fence

faceplates should be as close to the bit as

possible without being able to come in contact

with the bit (typically about 1/4" from the bit is

a suitable distance).

1. Loosen the clamping knobs (21) and

carriage bolts (45) securing each fence

faceplate (19) and slide the faceplates

inward or outward from the router bit as

needed.

Always hold the

workpiece against the

router table fence when routing. Such

precautionary safety measures increase the

accuracy in routing and improve the control of

the workpiece reducing the risk of personal

injury.

2. Once the fence faceplates (19) are in

the desired position, tighten the clamping

knobs (21) and carriage bolts (45)

SECURELY.

USING THE BIT HEIGHT GAUGE

(Fig. 29)

The bit height gauge allows you to measure

the depth of the cut the bit will make in the

workpiece. Use the following steps to adjust

and set a predetermined cutting depth of

the bit.

1. Position the bit height gauge (28) flat on the

tabletop (1) over the router bit. The top of

the bit should be in contact with the gauge

pointer (29) on the bit height gauge.

2. Adjust the bit height to the desired cutting

depth of the bit. The bit height will be shown

on the outside edge of the bit height gauge.

3. Secure the bit at the desired cutting depth,

remove the bit height gauge, and prepare

the workpiece for cutting.

NOTE: Be sure fence and overhead guard

are in place before routing.

FIG. 28

21

19

21

Guard not shown for clarity

FIG. 29

28

29

1

45

45

ADJUSTING DEPTH AND HEIGHT OF

CUT (Fig. 30 and Detail 30)

1. Select a board that is smooth and straight,

with good square edges.

2. Mark lines “A” and “B” on the end of the

board, as shown in Detail 30.

•

Line “A” indicates the desired height of cut.

•

Line “B” indicates the desired final depth

of cut.

•

The area outlined by “A,” “B,” and the edge

of the board is the area that will be cut away.

3. If the desired depth of cut can be cut in a

single pass, loosen the fence clamping

knobs (21) and move the fence forward or

backward until the outermost cutting edge of

the router bit is aligned with line “B.”

NOTE: For deeper cuts, DO NOT attempt to

make the cut in a single pass. Make multiple

shallower cuts, progressively moving the

fence backward until the desired depth of cut

is reached.

4. Use the scales on the tabletop (1) as a guide

to align the fence; then SECURELY tighten

both fence clamping knobs (21).

Always make sure that the

fence and guard cannot

come in contact with the router bit. Failure to

do so will result in damage to the router table

and can cause personal injury.

5. Following the instructions that came with your

router, adjust the router height of cut until the

top of the router bit lines up with line “A.”

6. Once all adjustments have been made,

double-check that:

•

The router is SECURELY tightened in

the router base.

•

The router bit is SECURELY tightened in

the router collet, with at least 3/4" shank

engagement.

•

The router base is SECURELY tightened to

the bottom of the router table.

AREA OF

DETAIL 30

SCRAP WOOD

A

B

FIG. 30

DETAIL 30

1

21

Behind fence

on base

1

28

Router Table Operation

7. Remove the board from the table.

NOTE: When making adjustments, use

a piece of scrap wood to make trial cuts

before making the cut with the actual

workpiece.

8. Turn the router on and make desired cut in

the workpiece.

Guard not shown for clarity

29

Router Table Operation

FULL EDGE CUTTING OR JOINTING

(Figs. 31–33)

For maximum strength and accuracy, boards

that are to be joined together should be

smooth and true. The edges should be true to

the workpiece surface. You can true the edges

using the router table with a straight bit.

NOTE: Use the outfeed shim plate(s) to

provide continuous support for the workpiece

as it is fed past the router bit.

Always make sure that

the fence and guard

cannot come in contact with the router bit.

Failure to do so will result in damage to the

router table and can cause personal injury.

If you are using a wet/dry vac, it should be

connected to the vacuum port on the back of

the fence assembly.

1. Loosen the clamping knobs (21) on the

back of the outfeed fence faceplate (19).

2. Align the slot in the outfeed shim plate(s) (20)

with the holes in the outfeed fence faceplate

(19), and slide the outfeed shim plate(s) (20)

between the fence assembly (C) and the

outfeed faceplate (19) (Fig. 31).

Use one outfeed shim plate for a 1/16" offset,

or both shim plates for a1/8" offset.

3. Install a straight bit in the router.

4. Position both fence faceplates so that

they clear the bit by 1/4" (Fig. 32).

5. Tighten the clamping knobs (21) and

carriage bolts (45) while holding both

faceplates (19) in place.

6. Place a straight edge or a straight piece

of wood on the table (1) so that it rests

against the outfeed fence faceplate (19).

7. Move the fence back until the straight edge

lines up with the cutting edge of the bit and is

still in contact with the outfeed faceplate (19).

8. Tighten the clamping knobs (21) and the

carriage bolts (45).

9. Remove the straight edge or board.

13. Make sure that both the router and switch

box are OFF; then plug the router into the

switch box (14).

14. While firmly holding a piece of scrap

wood against the fence and down against

the router table, feed a piece of scrap

wood toward the bit in the direction

shown by the arrow in Fig. 33.

15. Using the switch box (14), turn the router

OFF. If any adjustments are needed,

unplug the power cord and repeat steps

6–11 until all adjustments are correct.

Once you are satisfied with all settings,

make the cut with the actual workpiece.

10. Adjust the height of the bit so that it will cut

the complete thickness of the workpiece.

11. Position the featherboard(s) (22), if desired.

See ROUTING USING FEATHERBOARDS

on page 26.

12. Remove the board from the table (1) and

make sure the overhead guard (18) is

securely in place.

NOTE: When making adjustments, use a

piece of scrap wood to make trial cuts before

making the cut with the actual workpiece.

WORKPIECE

FIG. 31

FIG. 33

FIG. 32

21

19

C

20

19

20

21

C

19

18

22

14

1

21

45

45

45

Guard not shown for clarity

Guard not shown for clarity

Loading...

Loading...