Page 1

Installation and Maintenance Instructions

DHW Tank

QWST120 O

6 720 648 100-00.1ITL

6 720 648 071 (2012/03) US

Page 2

Table of Contents

Table of Contents

1 Key to symbols and safety instructions . . . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . 3

1.2 Safety instructions . . . . . . . . . . . . . . . . . . 3

2 General points . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Delivered condition . . . . . . . . . . . . . . . . . . 5

2.2 Tank installation . . . . . . . . . . . . . . . . . . . . 5

3 Moving the tank . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Dimensions and connections . . . . . . . . . . . . . . . 7

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Safety limits . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Connections and fittings . . . . . . . . . . . . . . 8

5.3 Temperature monitoring control options. . 9

5.3.1 Installing the temperature sensor . . . . . . . 9

5.3.2 Installing the Aquastat . . . . . . . . . . . . . . 10

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Maintenance and cleaning . . . . . . . . . . . . . . . . 12

7.1 Checking the magnesium anode . . . . . . . 12

7.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.3 Recommissioning after cleaning . . . . . . . 13

8 Spare parts for QWST120 O . . . . . . . . . . . . . . . 14

2

6 720 648 071 (2012/03)

Page 3

1 Key to symbols and safety instructions

Key to symbols and safety instructions

1.1 Explanation of symbols

Warnings

Warnings are indicated in the text by a

warning triangle and a gray background.

In case of danger from electric shock, the

exclamation point on the warning triangle is

replaced with a lightning symbol.

Signal words at the beginning of a warning are used to

indicate the type and seriousness of the ensuing risk if

measures for minimizing damage are not taken.

• NOTICE indicates that minor damage to property may

occur.

• CAUTION indicates possible minor to medium

personal injury.

• WARNING indicates possible severe personal injury.

• DANGER indicates that fatal injury may occur.

Important information

Important information that presents no risk

to people or property is indicated with this

symbol. It is separated by horizontal lines

above and below the text.

Additional symbols

Symbol Function

B Sequence of steps

1.2 Safety instructions

Safety instructions

Failure to observe the safety instructions can result in

serious injury and a risk of fatal injury as well as damage

to property and the environment.

B Read the safety instructions carefully prior to

commissioning the system.

B Ensure that only a trained and certified contractor

carries out installation, commissioning, maintenance

and service.

B Ensure that the system is approved by the local

jurisdiction.

B Clean and perform maintenance at least once a year.

Check that the entire system functions properly at the

same time. Immediately remedy faults.

Danger from failing to consider your own safety in an

emergency such as a fire

B Never put yourself at risk of fatal injury. Your own

safety must always take the highest priority.

Risk of damage from operator error

Operator errors can lead to injuries and/or damage to

property.

B Ensure that only individuals who can operate this

appliance correctly have access to it.

B Installation and commissioning as well as servicing

and maintenance must be carried out only by a

trained and certified contractor.

Æ Cross-reference to other points in this

document or to other documents

• Listing/list entry

– Listing/list entry (2nd level)

Table 1

6 720 648 071 (2012/03)

3

Page 4

Key to symbols and safety instructions

Installation and operation

B Have the appliance installed only by a qualified

contractor.

B Ensure that the hot water tank is completely full prior

to start up.

B To prevent damage from excess pressure, never

disable the safety valves.

B Water may escape from the safety valve when water is

being heated. Ensure that the safety valve is piped to

within 6 inches of the ground in an area where

property damage will not occur.

B Install the unit only in a frost-free room.

B Never store or place combustible material or liquids

near the appliance.

B Maintain safe clearances in accordance with local/

national regulations.

Risk of fatal injury from electric shock

B If an aquastat is used with line voltage, it must be

connected by a licensed electrician. The terminal

wiring diagram must be followed.

B Before carrying out any work, isolate all phases of the

electrical power using the emergency shut-off switch

or by disengaging the heating system circuit breaker.

Secure against unintentional reconnection.

B Do not install this device in rooms with a high

moisture level (e.g. bathrooms, saunas).

Instructing the owner/operator

B Instruct the owner/operator in the functionality and

operation of the appliance.

B Inform the owner/operator that they must never carry

out any modifications or repairs.

B Inform the owner/operator that children

unsupervised by adul ts should never be in the vicinit y

of the heating system.

B Complete the commissioning report in this document

and hand it over to the owner/operator.

B Give the technical documentation to the owner/

operator.

Disposal

B Dispose of packaging in an environmentally

responsible manner.

B Dispose of the appliance correctly at an authorized

disposal site.

Cleaning

B Clean the outside of the appliance with a damp cloth.

Inspection/maintenance

B Recommendation: sign a maintenance and inspection

contract with a qualified heating contractor and have

the appliance serviced annually.

B The owner/operator is responsible for the safety and

environmental compatibility of the system.

B Read and follow the safety instructions in the

"Cleaning and maintenance" chapter.

Original spare parts

Damage caused by spare parts not supplied by the

manufacturer are excluded from our warranty.

B Use only original spare parts and accessories from

the manufacturer.

Frost damage

B When there is a risk of frost, drain the water from the

DHW tank and the heating system's pipework. The

system is protected from frost only if it is completely

dry.

4

6 720 648 071 (2012/03)

Page 5

2 General points

2.1 Delivered condition

The DHW tank QWST120 O Is delivered as a fully

assembled unit.

Additional components supplied with the tank:

1 125 psi P and T valve

3 3/4" brass couplings

1 3/4" brass tee

1 Honeywell L4006 adjustable differential tank

aquastat

1 Aquastat mounting bracket and 4 mounting screws

3 Adjustable tank leg leveling bolts

1 Roll of high quality Teflon tape

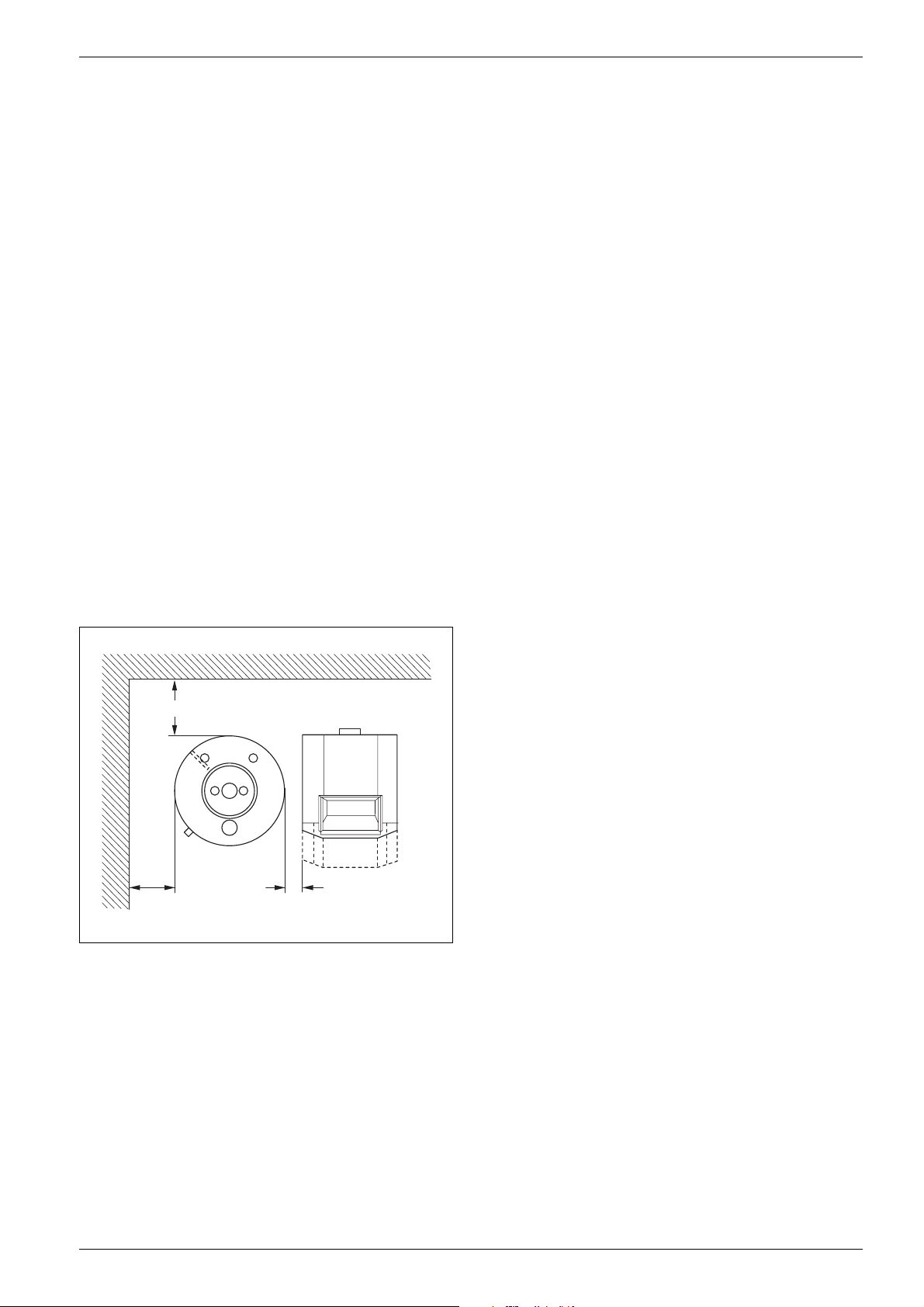

2.2 Tank installation

Select a dry, frost free room for installation. The tank

must not be allowed to freeze, or it must be drained or

protected appropriately when not in operation. The floor

must be level and able to carry the weight of the unit.

When installing the heating boiler and DHW tank,

observe the minimum clearance requirements for

assembly and service (Æ Fig. 1).

General points

(406 mm)

16"

(406 mm)

16"

min. 4"

Fig. 1 Minimum space requirements for installation

and maintenance

(102 mm)

6 720 648 100-14.1ITL

6 720 648 071 (2012/03)

5

Page 6

Moving the tank

3 Moving the tank

NOTICE: Take care not to damage the tank

when moving it.

B Observe the handling instructions on the

packaging.

B Use suitable means of transportation,

e.g. a hand truck with strap, to handle

this product.

B Move this product upright.

B Prevent impact and shock.

The DHW tank can be moved by means of a hand truck

(accessory, Æ Fig. 2) while still packaged or after

removal of the packaging.

B Position the tank on the hand truck, secure with a

strap if necessary, and transport safely to the

installation location.

B Remove the strap.

B Lay the polystyrene cover [1] on the ground and

carefully lay the DHW tank [2] on its side.

B Remove bottom polystyrene pad and pallet. Install the

adjustable feet M10 x 30 [3].

2 3

3/4 - 1"

(19 - 25 mm)

ca. 0.78"

1

Fig. 3 DHW tank on polystyrene cover pad (illustrative)

6 720 648 100-15.1ITL

6 720 648 100-02.1ITL

Fig. 2 Hand truck (illustrative)

B Remove the plastic wrapping.

B Remove the polystyrene cover pad and 4 wooden

boards.

1 Polystyrene cover pad

2 DHW Tank

3 Adjustable feet

B Place the DHW tank upright.

B Dispose of the DHW tank packaging in an

environmentally responsible manner.

6

6 720 648 071 (2012/03)

Page 7

4 Dimensions and connections

Dimensions and connections

37"

37"

(940 mm)

EL

3/4" - 1"

3/4" - 1"

(19 - 25 mm)

Fig. 4 Dimensions and connections

1 Magnesium anode

AB Hot water outlet

EK Cold water inlet

VS Tank coil supply

RS Tank coil return

MB Hot water temperature sensor or Aquastat

EL Drain

MB

1

EKRSVS

MB

AB

EL

20"

20"

(508 mm)

6 720 648 100-13.1ITL

Type VS RS EK/AB Sacrificial

anode

120 NPT ¾ " NPT ¾ " NPT ¾ " G 1" 158 (72)

Table 2 Dimensions and connections

Weight (empty)

Lbs (kg)

6 720 648 071 (2012/03)

7

Page 8

Installation

5 Installation

B Level the DHW tank by adjusting the feet (Æ Fig. 5).

6 720 648 100-05.1ITL

Fig. 5 Adjusting the feet (illustrative)

5.1 Safety limits

WARNING: Risk of damage to property and

personal injury if temperature / pressure

limits exceeded.

B For safety reasons, never exceed the

following limits.

5.2 Connections and fittings

It is the installer's responsibility to follow national and

local code when installing this tank (Æ Fig. 6).

B Connect all piping to the DHW tank by means of

threaded fittings. For easy service and maintenance,

each connection should be equipped with a shutoff

valve. Install a drain valve [2] in the hot water pipe

upstream and downstream of the shut-off valve [3].

Attach a tag with the following statement to the safety

valve [4]: "Do not close drain line. During heating,

water may be released for safety reasons."

2

3

4

11 10 9 8 6

1

5

6 7 6

Maximum Temperature:

• Heating water (boiler) 230 °F (110 °C)

• Domestic water (DHW tank) 203 °F (95 °C)

Operating pressure:

• Heating water (boiler) 87 psi

1

• Domestic water (DHW tank) 145 psi (10 bar)

12

6 720 648 100-06.1ITL

Fig. 6 Installation (illustrative)

1 Storage tank

2 Purge valve

3 Shut-off valve with drain

4 Pressure and temperature safety valve

5 Flow check valve

6 Shut-off valve

7 DHW recirculation pump (optional)

8 Pressure reducer (if required)

9 Purge valve

10 Backflow preventer

11 Pressure gauge connection

12 Drain

AB Hot water outlet

EK Cold water inlet

EZ Recirculation inlet

EL Drain

1. From the heating system, individual safety equipment

required (safety valve, expansion vessel).

8

6 720 648 071 (2012/03)

Page 9

Installation

WARNING: Precautions must be taken prior

to manually operating the relief valve to

avoid contact with hot water being released

and to prevent water damage.

WARNING: If a relief valve discharges

periodically, this may be due to thermal

expansion in a closed water supply system.

Contact the installer to correct this

situation. Do not plug the relief valve.

B A listed pressure and temperature relief valve (PTRV)

must be installed at the time of installation. No valve

is to be placed between the PTRV and the heater. No

reducing coupling or other restriction may be

installed in the discharge line. The discharge line must

be a minimum of 6" (153 mm) above a drain and

installed such that it allows complete drainage of

both the PTRV and the line. The discharge line must

be placed where it will not cause any water damage.

The location of the PTRV must be readily accessible

for servicing or replacement, and be mounted as close

to the water heater as possible.

B Manually activate the TPRV annually to ensure proper

operation. If the TPRV does not activate it must be

replaced.

B Make sure that the installed pipework and

connections are free of stress.

B Check all connections for leaks! Do not kink or twist

hoses.

Safety valve

Only use approved and listed pressure and temperature

relief valves of the proper size for the output of the tank.

5.3 Temperature monitoring control

options

Install a temperature sensor or an Aquastat on the DHW

tank to measure and monitor the hot water temperature.

5.3.1 Installing the temperature sensor

B Feed the temperature sensor [2] with the spring [1]

into the sensor well [3].

Ensure that the sensor surface has contact

with the sensor well surface over its full

length, and that it cannot accidentally be

pulled out.

3

2

1

6 720 648 100-07.1ITL

Fig. 7 Installing the temperature sensor

1 Spring clip

2 Temperature sensor

3 Sensor well

Minimum

connection

diameter

3/4" 32 (120 liters) 255

Table 3 Safety valve

6 720 648 071 (2012/03)

Nominal capacity

of the water

chamber (gal)

Max. heating

capacity

[kBtu/hr]

9

Page 10

Installation

5.3.2 Installing the Aquastat

DANGER: Risk of fatal injury from electric

shock.

B Disconnect all electrical power before

working on the system.

B Remove cover from the Aquastat.

B If necessary, remove any unnecessary attachments.

Attach bracket [3] to Aquastat [2] by means of 2 selftapping screws [1].

2

3

1

B Feed the temperature probe [4] with the spring [5]

into the sensor well [3]. Ensure that the probe makes

contact with the well wall over its entire length.

B Attach Aquastat [2] to the DHW tank by means of

2 self-tapping screws [1].

2

3

1

4

5

6 720 648 100-09.1ITL

6 720 648 100-08.1ITL

Fig. 8 Attaching the Aquastat to the bracket

1 Self-tapping screws C-ST 4.2x13 mm

2 Aquastat

3 Bracket

Fig. 9 Installing the Aquastat

1 Self-tapping screws C-ST 4.2x13 mm

2 Aquastat

3 Sensor well

4 Temperature sensor

5 Spring

Connect the electrical power and set the

temperature as shown in the manual

supplied with the Aquastat.

B Replace the cover of the Aquastat.

10

6 720 648 071 (2012/03)

Page 11

6 Commissioning

NOTICE: Risk of property damage in the

event of improper operation!

Commissioning with a partially filled tank

can destroy the appliance.

B Check that the DHW tank is completely

filled and that fresh water can enter the

tank.

Prior to commissioning, check for the following and

ensure that systems are connected and operating

properly:

• Absence of leaks in the heating system

• Absence of leaks in the pipework

• Verify all electrical connections

• Consult the operating instructions supplied with the

control unit or boiler (standard delivery - control unit

or boiler) for operating information.

• The system should be commissioned by the installer

in the presence of the owner/operator.

Commissioning

6 720 648 071 (2012/03)

11

Page 12

Maintenance and cleaning

7 Maintenance and cleaning

DANGER: Risk of fatal injury from electric

shock.

B Only trained and certified electricians are

permitted to carry out electrical work.

B Isolate the DHW tank electrically by using

the emergency shut-off switch or by

disengaging the heating system circuit

breaker.

B Secure the DHW tank against

unintentional reconnection.

B Please observe all installation

instructions.

WARNING: Risk of equipment damage from

improper maintenance!

Lack of maintenance or improper

maintenance can result in damage or

destruction of the DHW tank and voiding the

warranty.

B Arrange for regular, thorough, and

professional maintenance of the DHW

tank.

B Protect electrical components and

control units from water and moisture.

7.1 Checking the magnesium anode

The anode rod must be inspected annually

and replaced if compromised. Failure to

operate the tank without a properly

maintained anode rod may void the

warranty.

DANGER: Risk of fatal injury from electric

shock.

B Before working on the system,

disconnect the electrical power.

B Close the cold water inlet (EK); open the tank's drain.

To allow air into the system, open a fixture at a higher

elevation than the drain valve.

B Remove the plastic plugs [1] from the magnesium

anode [2] and inspection port.

B Unscrew the magnesium anode [2].

1

1

2

Use only original spare parts from the

manufacturer or parts approved by the

manufacturer.

Damage caused by spare parts not supplied

by the manufacturer is excluded from our

warranty.

• If not agreed to otherwise in writing, the DHW tank

may be filled only with potable water.

• It is recommended that a qualified installer inspect

and clean the DHW tank at regular intervals of not

more than 2 years.

• In the event of poor water quality (hard to very hard

water) in combination with high temperatures,

inspection and cleaning should be carried out at

shorter intervals.

3

6 720 648 100-10.1ITL

Fig. 10 Installing / removing the magnesium anode

1 Plug (24 mm socket)

2 Magnesium anode (27 mm wrench required)

3 Inspection port (plug, 24 mm socket)

Never bring the magnesium anode surface in

contact with oil or grease. Ensure

cleanliness.

B Check the diameter of the magnesium anode.

B If the diameter is reduced to about 1/2" (13 mm), the

anode rod must be replaced.

12

6 720 648 071 (2012/03)

Page 13

Maintenance and cleaning

7.2 Cleaning

B Unscrew the plug [1] from the inspection port.

1

6 720 648 100-11.1ITL

Fig. 11 Unscrewing the plug

1 Plug (24 mm socket)

2 Inspection port

NOTICE: Risk of physical damage to the

DHW tank if limescale is broken up with

sharp implements.

B Never break up limescale deposits with

hard or sharp implements as this may

damage the surface coating on the inside

of the tank.

7.3 Recommissioning after cleaning

B Seal the magnesium anode [2] back into place.

B Seal the plug [3] back into the inspection port.

1

1

2

2

3

6 720 648 100-10.1ITL

Fig. 12 Installing / removing the magnesium anode

1 Plastic plugs

2 Magnesium anode (27 mm wrench required)

3 Inspection port (plug, 24 mm socket)

B Start up the system again.

B Check all threaded connections for leaks.

B Install the plastic plugs [1] at the magnesium anode

and inspection port.

B Inspect and clean the interior of the tank.

B To clean the coil run the boiler to heat the coil, then

spray down with cold water.

B Drain all debris from the tank.

6 720 648 071 (2012/03)

13

Page 14

Spare parts for QWST120 O

8 Spare parts for QWST120 O

50

5

80

50

10

80

100

70

20

40

90

110

60

30

6 720 648 100-12.1ITL

Fig. 13 Spare parts for QWST120 O

Item no. Article description Product No. Number

5 DHW tank QWST120 O, complete 8 718 543 265 1

10 Magnesium anode D26 × 505 mm, G1" 87 185 713 470 1

20 Plug 63 004 276 1

30 Bracket for Aquastat 63 032 088 1

40 Casing lid, white 77 470 110 240 1

50 Self-tapping screw DIN 7981-C-ST6.3 × 19 - A3T 73 986 10

60 Spring clip 87 182 240 810 1

70 Fill & drain valve 87 185 433 400 1

80 Plastic plug, white 87 185 433 390 2

90 Hex-head bolt ISO 4017- M10 × 30 - 8.8 - A3K 7 747 022 050 1

100 Immersion pipe, 1-1/4" (31 mm) long 7 747 020 191 1

110 Immersion pipe, 32" (813 mm) long 7 747 020 190 1

Table 4 Spare parts available for the QWST120 O from Bosch

14

6 720 648 071 (2012/03)

Page 15

Notes

6 720 648 071 (2012/03)

15

Page 16

United States and Canada

Bosch Thermotechnology Corp.

50 Wentworth Avenue

Londonderry, NH 03053

U.S.A.

Tel. 03-552-1100

Fax 603-584-1681

www.bosch-climate.us

Bosch Thermotechnology Corp. reserves the right

to make changes without notice due to continuing

engineering and technological advances.

Loading...

Loading...