Bosch PL2632 Operating/safety Instructions Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Version Version française Versión en español

See page 2 Voir page 17 Ver la página 32

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

PL2632

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 1

-2-

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapt e r plugs with earth e d

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e co mmon sense w hen oper ating a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

sw itch is in the off-position before

connecting to power source and / or battery

pa ck, picking up or car rying the tool.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not for ce the powe r tool. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

!

WARNING

General Power Tool Safety Warnings

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 2

-3-

Disconnect the plug from the power source

a

nd/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of

parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

Keep cutting tools sharp and clean. Properly

m

aintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified

rep a i r per s o n usi n g only identi c al

replacement parts. This will ensure that the

safety of the power tool is maintained.

Safety Rules for Planers

Wait for the cutter to stop before setting the

tool down. An exposed rotating cutter may

engage the surface leading to possible loss of

control and serious injury.

Hold the power tool by insulated gripping

surfaces only, because the cutter may

contact its own cord. Cutting a "live" wire

may make exposed metal parts of the tool

"live" and could give the operator an electric

shock.

Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against the body leaves it unstable and may

lead to loss of control.

Always start the planer before blade is in

contact with the workpiece and allow the

blade to come to full speed. Tool can

vibrate or chatter if blade speed is too slow at

beginning of cut and possibly kickback.

Check the workpiece for nails, if there are

nai ls, eit her rem ove or set the m well

below intended finished surface. If the

planer blades strike objects like nails it may

cause the tool to kickback and serious

personal injury may result.

Unplug t h e planer b efore c h a n g i n g

accessories. Before plugging the tool in,

chec k that the t r igger lock is "OFF".

Accidental start-ups may occur if planer is

plugged in while changing an accessory.

After changing blades, rotate the blade

drum to make sure blades are not hitting

any part of the blade head housing and

the blade locking scr e w s a r e t i g h t.

Spinning blades could strike tool housing and

damage tool as well as possible injury.

Al ways hold the tool firmly w ith both

hands for maximum control.

Never pull the plane backward over the

workpiece. Loss of control may occur.

Do not put fingers or any objects into the

shavings exhaust port or clean out

shavings while tool is running. Contact

with blade drum will cause injury.

Rem ove plu g from power s ource i f it

becomes necessary to remove chips. The

blades are hidden from view and you may be

cut if blade is contacted.

Never use dull or damaged blades. Sharp

blades m u st b e handled with c a r e .

Damaged blades can snap during use. Dull

blades require more force to push the tool,

possibly causing the blade to break.

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 3

-4-

Additional Safety Warnings

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

th e tool since internal wire s may be

misplaced or pinched or safety guard return

sp ring s may be impro perl y mounted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

Risk of injury to user. The power cord must only

be serviced by a Bosch Factory Service Center

or Autho rized Bosch Service Station.

Some dust created by power

sanding, sawing, grinding,

drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

!

WARNING

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 4

-5-

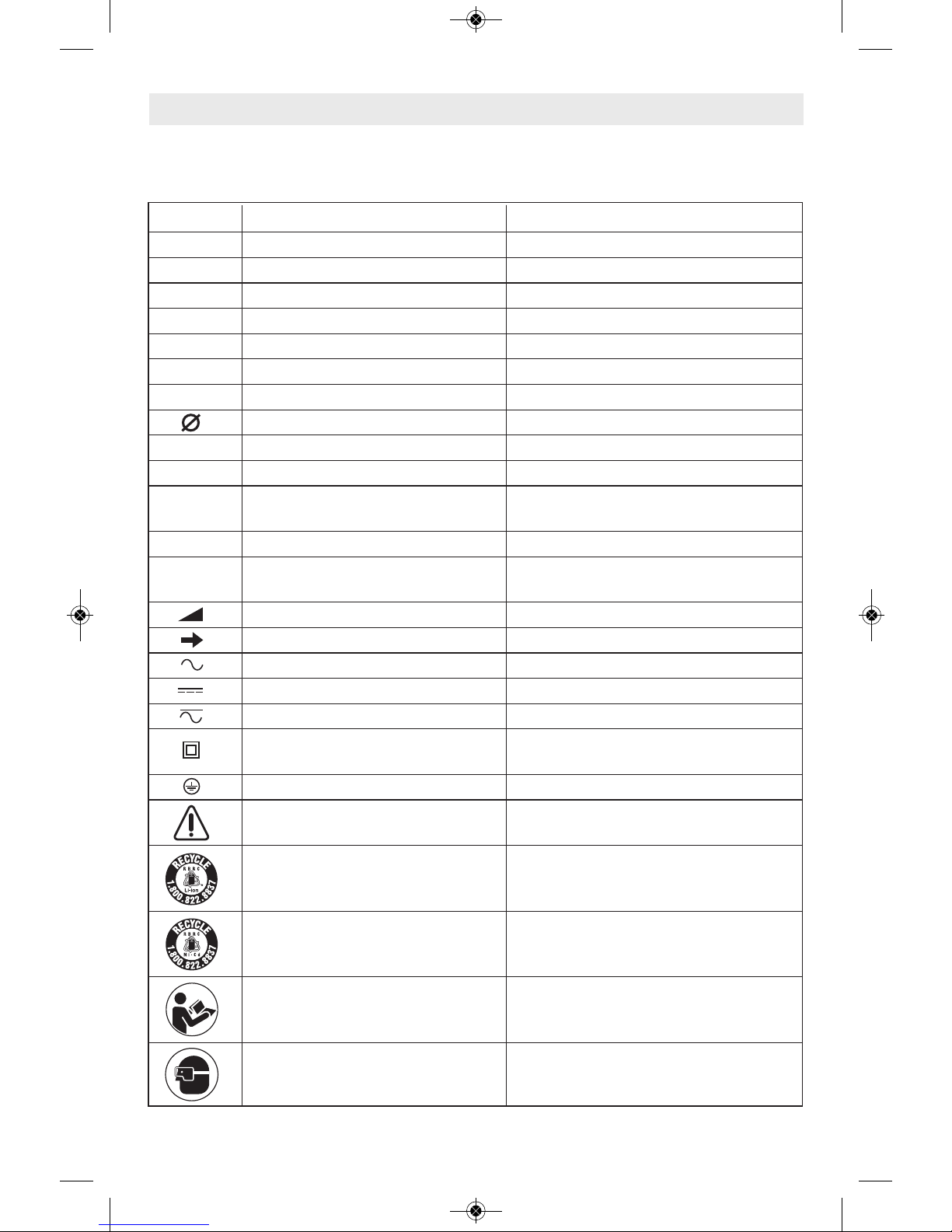

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

n Rated speed Maximum attainable speed

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

per minute orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling

program

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

Symbols

0

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 5

-6-

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

This symbol designates that this component is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 6

-7-

Functional Description and Specifications

Dis connect the p l ug from the p ower s ource b efore making any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

!

WARNING

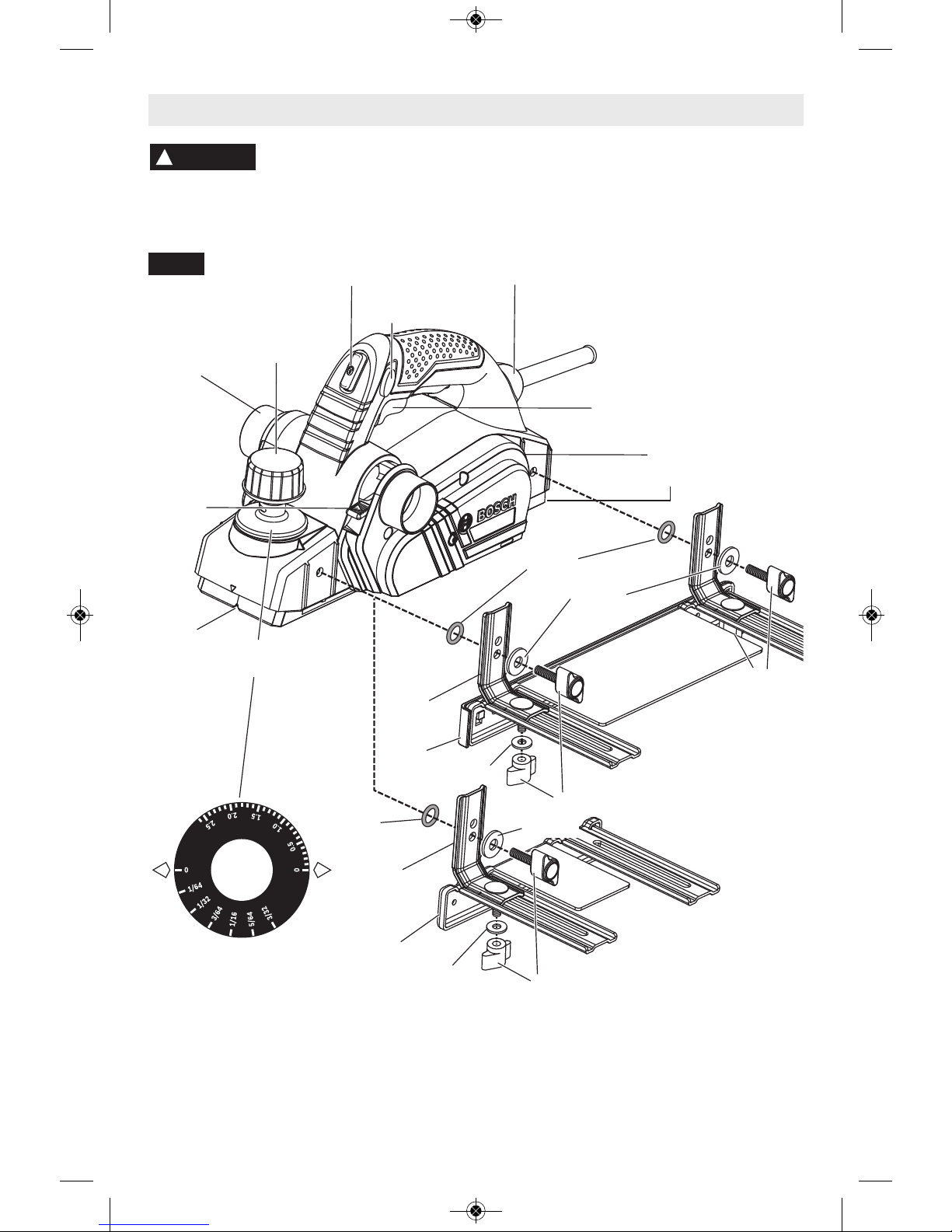

PL2632 Planer

PORT

SELECTOR

LEVER

Maximum Capacities

Planing depth 0 - 5/32" (0 - 2.6mm)

Rabbeting depth 0 - 5/16" (0 - 9mm)

Planing width 3-1/4" (82mm)

NOTE: For tool specifications refer to

the nameplate on your tool.

GUIDE

BRACKET

DEPTH

ADJUSTMENT

KNOB

SHAVINGS

EXHAUST

PORT

GUIDE

BRACKET

FENCE

CHAMFER

V-GROOVE

WASHER

WASHER

WASHER

WASHER

O-RING

O-RING

FIG. 1

TRIGGER SWITCH

W

R

EN

C

H

S

TO

R

A

G

E A

R

EA

“LOCK-ON”

BUTTON

“LOCK OFF”

BUTTON

BALL-JOINT

CORD SWIVEL

WING KNOBS

WING KNOBS

FENCE

PLANER STAND

DEPTH

SCALE

Dual-Mount

Guide Fence

PA1207

Basic Guide

Fence

WING KNOBS

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 7

Assembly

-8-

GUIDE FENCES

Purposes of Guide Fences

The Bosch planer guide fences all have a

protective shield that covers the unused

section of the blade. Therefore, we

recommend always attaching a planer guide

fence (except in situations when the planing

takes place farther in from the edge of a

workpiece than the width of the planer blade

and would interfere with the work).

All of the Bosch planer guide fences can be

used to control the width of the cut, such as

when creating rabbets (See page 14).

All of the Bosch planer guide fences also

provide added stability when planing materials

that are up to 3-1/4" wide.

The optional dual-mount guide fence is

especially helpful when planing a vertical edge,

such as when planing an un-mounted door

that is laid flat, such as on saw horses. (Fig. 2)

Positioning of Guide Fences

For right-handed use, the guide fence should

be installed on the left side of the tool. For lefthanded use, the guide fence should be

installed on the right side of the tool, except

when using the planer to create rabbets, which

requires the guide fence to be installed on the

left side of the tool.

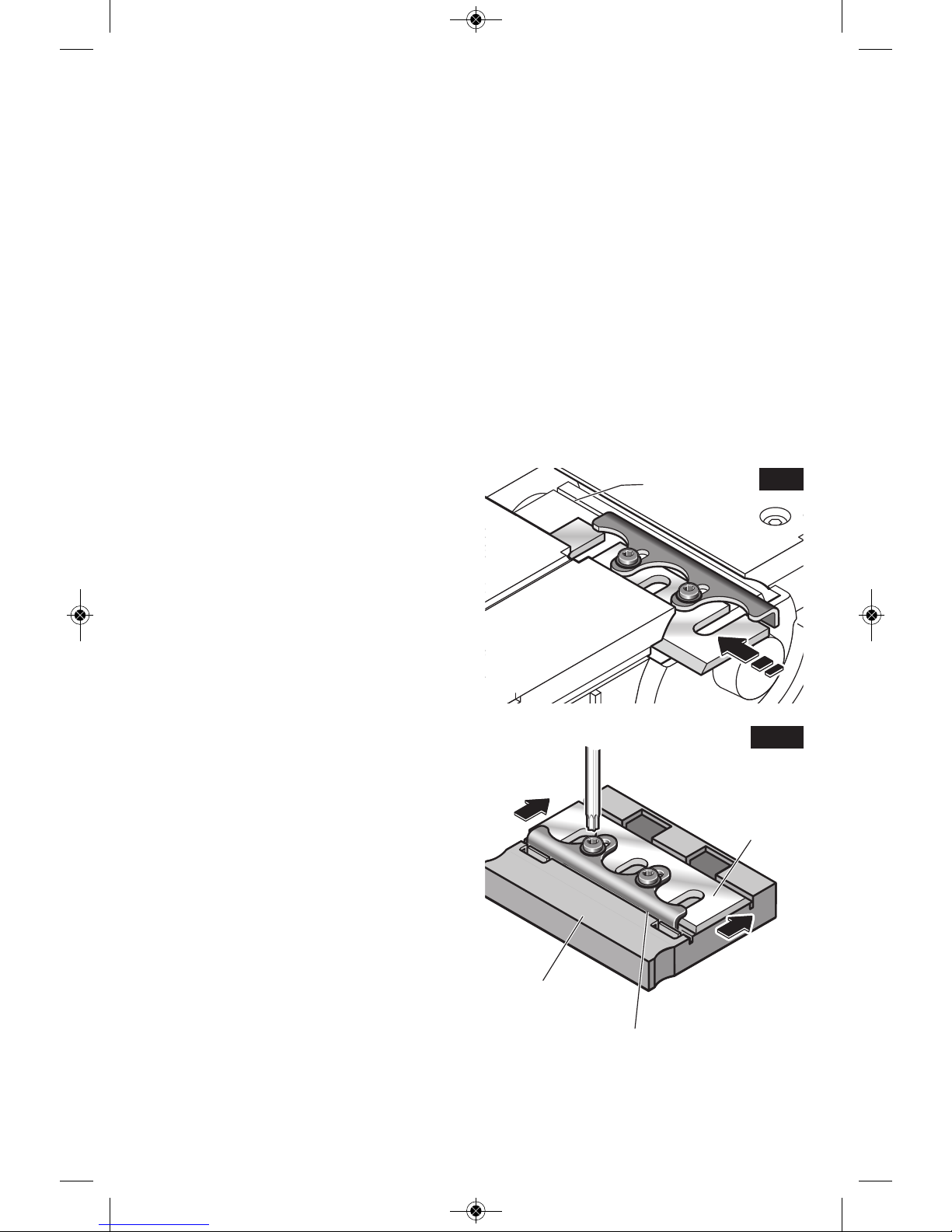

Installation of Basic Guide Fence

1. Place a wing screw through the bottom hole

in the long end of the bracket and screw into

the front mount on the appropriate side of

the planer and securely tighten wing knob.

(The O-ring should be on the backside of

the bracket and the flat washer between the

back of the knob and the front side of the

bracket.)

2. Place the bolt through the top of the hole on

the short end of the bracket and then

through the slot in the appropriate arm of the

fence. Place the flat washer on the bottom of

the bolt below the guide fence’s arm and

then install wing knob. If the washer is not

installed, the guide fence is likely to slip.

3. Securely tighten wing knob.

Installation of Dual-Mount Guide Fences

• This is the same as installing the Basic

Guide Fence, except that both brackets are

attached to the planer’s front mount area

and rear mount area (Fig. 1).

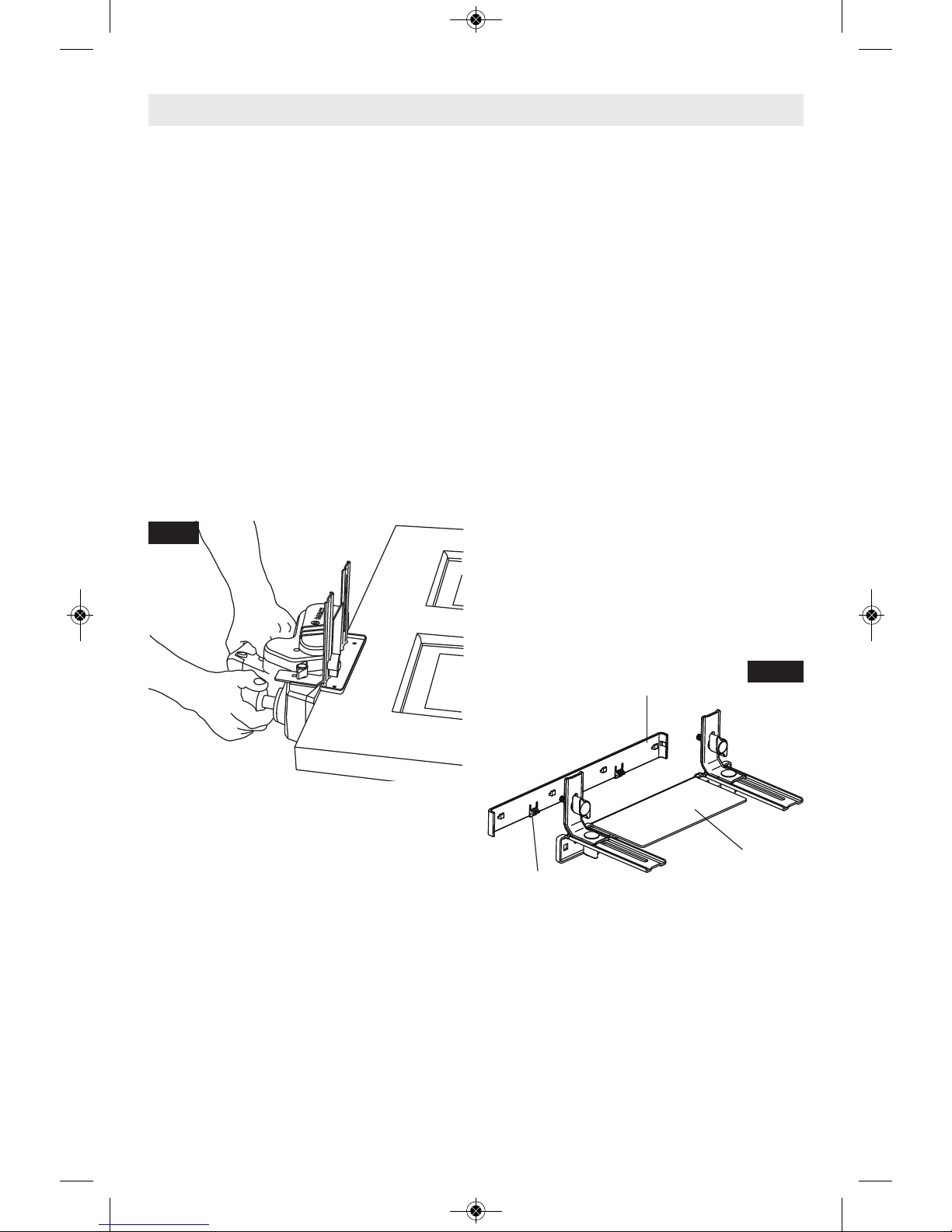

Attachment of Plastic Overshoe to Dual-

Mount Guide Fences

• There are two plastic overshoes that can be

used with the dual-mount fence, a straight

overshoe and 3-degree overshoe (sold

separately).

• The 3-degree bevel plastic overshoe is

especially useful when planing the long

edges of typical doors.

• The overshoes clip onto the steel fence.

• To remove either overshoe, gently pull tabs

on overshoe away from the fence and then

move overshoe upward (Fig. 2a).

Setting The Desired Planing Width

1. Loosen the wing knob(s) that hold the fence

onto the brackets guide bracket(s).

2. Slide the fence along the guide bracket(s) to

the desired planing width. (When using the

dual-mount fence, it may be necessary to

raise the planer stand before the desired

width can be reached.)

3. Securely tighten wing knobs.

FIG. 2

PLASTIC

OVERSHOE

DUAL-MOUNT

GUIDE FENCE

TABS (3x)

FIG. 2a

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 8

Assembly

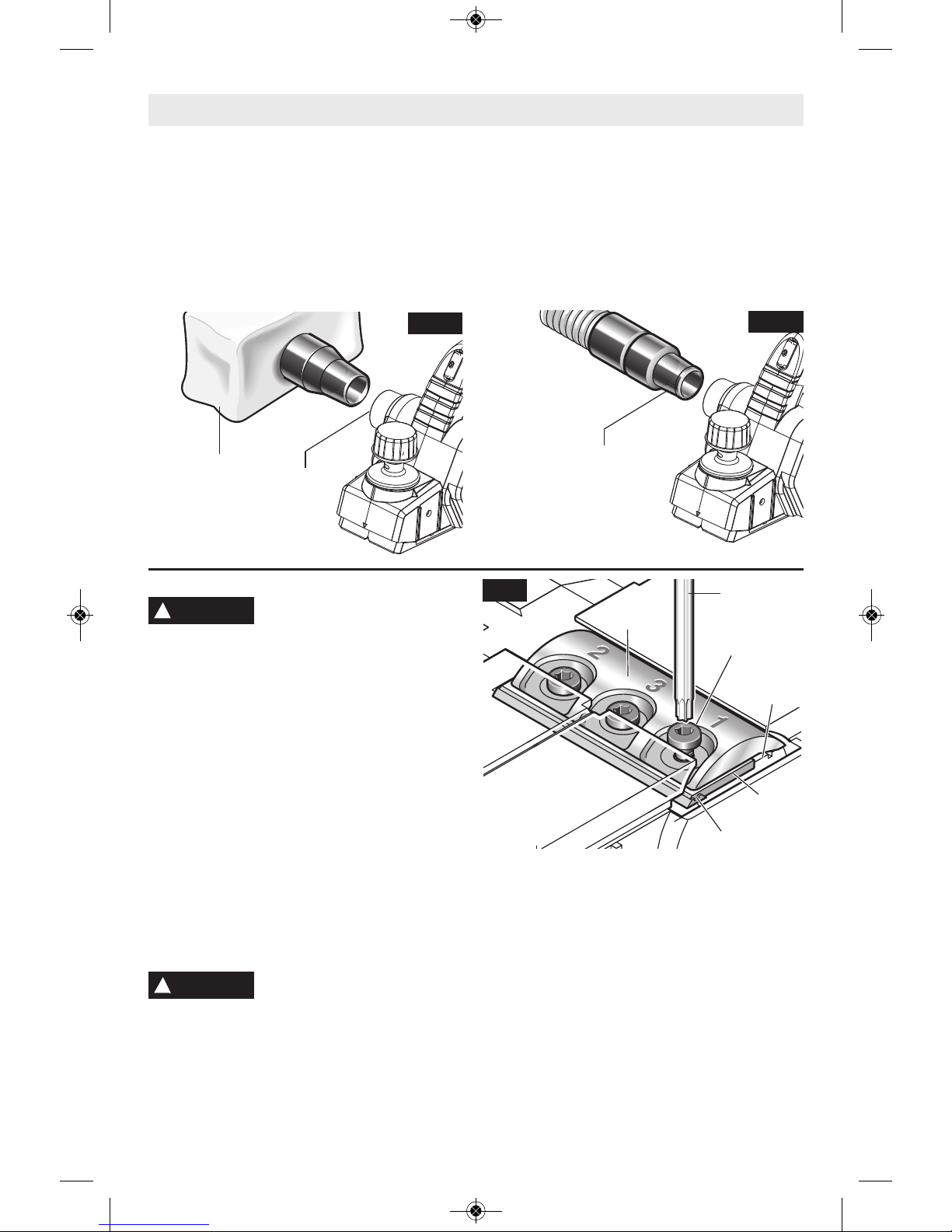

FIG. 3a

SHAVINGS

BAG

SHAVINGS

EXHAUST

PORT

SH

A

VI

N

G

S

EXT

R

A

C

T

I

O

N

T

he P

L2632

pl

aner c

om

es

w

i

t

h

t

w

o

s

hav

i

ngs

ex

haus

t

por

t

s

.

M

ov

i

ng

t

he

por

t

s

el

ec

t

or

l

ev

er

t

o

p

o

si

ti

o

n

1

(

to

w

a

r

d

s

fr

o

n

t

o

f

to

o

l

)

d

i

sch

a

r

g

e

s

s

hav

i

ngs

t

o t

he

l

ef

t

,

w

hi

l

e

pos

i

t

i

on 2 (t

ow

ards

re

a

r o

f

t

o

o

l

)

d

i

s

c

h

a

rg

e

s

s

h

a

v

i

n

g

s

t

o

t

h

e

ri

g

h

t

.

(

F

i

g.

1)

.

T

he

pl

aner

s

hav

i

ngs

ex

haus

t

por

t

m

ay

be

us

ed

wi

t

h

an opt

i

onal

shavi

ngs

bag

(

Fi

g.

3a)

or

a

s

hop

v

ac

uum

and

v

ac

uum

c

onnec

t

or

(

F

i

g.

3b)

t

o

k

eep

y

our

w

or

k

env

i

r

onm

ent

c

l

eaner

.

B

o

s

c

h

o

f

f

e

r

s

s

e

v

e

r

a

l

d

if

f

e

r

e

n

t

v

a

c

u

u

m h

o

s

e

s

t

hat

w

i

l

l

c

onnec

t

t

hes

e t

ool

s

t

o Bos

c

h v

ac

uum

c

l

e

a

n

e

r

s

. T

h

e

o

p

ti

o

n

a

l

B

o

s

c

h

V

A

C

0

0

2

o

r

V

A

C

0

2

4

a

d

a

p

te

r

s

w

i

l

l

co

n

n

e

ct

th

e

p

l

a

n

e

r

to

1

-

1

/4

”

a

n

d

1

-

1

/2

”

va

cu

u

m

h

o

se

s,

a

n

d

th

e

opt

i

onal

VAC

020

w

i

l

l

c

onnec

t

t

he

pl

aner

t

o

2

-

1/

2"

hoses.

FIG. 3b

VACUUM

HOSE ADAPTER

(OPTIONAL)

PLANER BLADES

The planer blades are sharp

and frag ile a nd m ust b e

handled carefully to avoid injury to the user

or damage to the blades.

• There are three types of blades that can be

used with the Bosch PL2632 planer; standard

mini tungsten carbide blades, Bosch

Woodrazor micrograin mini tungsten carbide

blades (standard equipment with the Bosch

PL2632 planer), and large HSS blades.

• While the Bosch PL2632 mini tungsten

carbide blades are sharper and more durable

than standard mini tungsten carbide blades,

the assembly and adjustment of both of

Woodrazor and standard tungsten carbide

blades are the same. Henceforth, all

references in this manual to “mini TC blades”

refer to both Woodrazor blades and standard

mini tungsten carbide blades.

• To use large HSS blades with the PL2632 it

is necessary to purchase optional accessories.

Wear prote ctive g loves

when chang ing plan er

blades. Edges are sharp and may cause

injury.

REMOVING MINI TUNGSTEN CARBIDE

BLADES

Mini TC planer blades have two cutting edges,

and may be reversed when one of the cutting

edges becomes dull or chipped. (Fig. 6) Before

any work on the machine itself, pull the power

plug.

Always change both blades at the same time.

Otherwise, imbalance can cause vibration and

reduce the useful service life of the tool. Use

only blades designated for use with this model,

because other blades can cause vibration,

decrease performance and may not clamp

securely in blade holder. Do not attempt to

sharpen or use re-sharpened any TC blades.

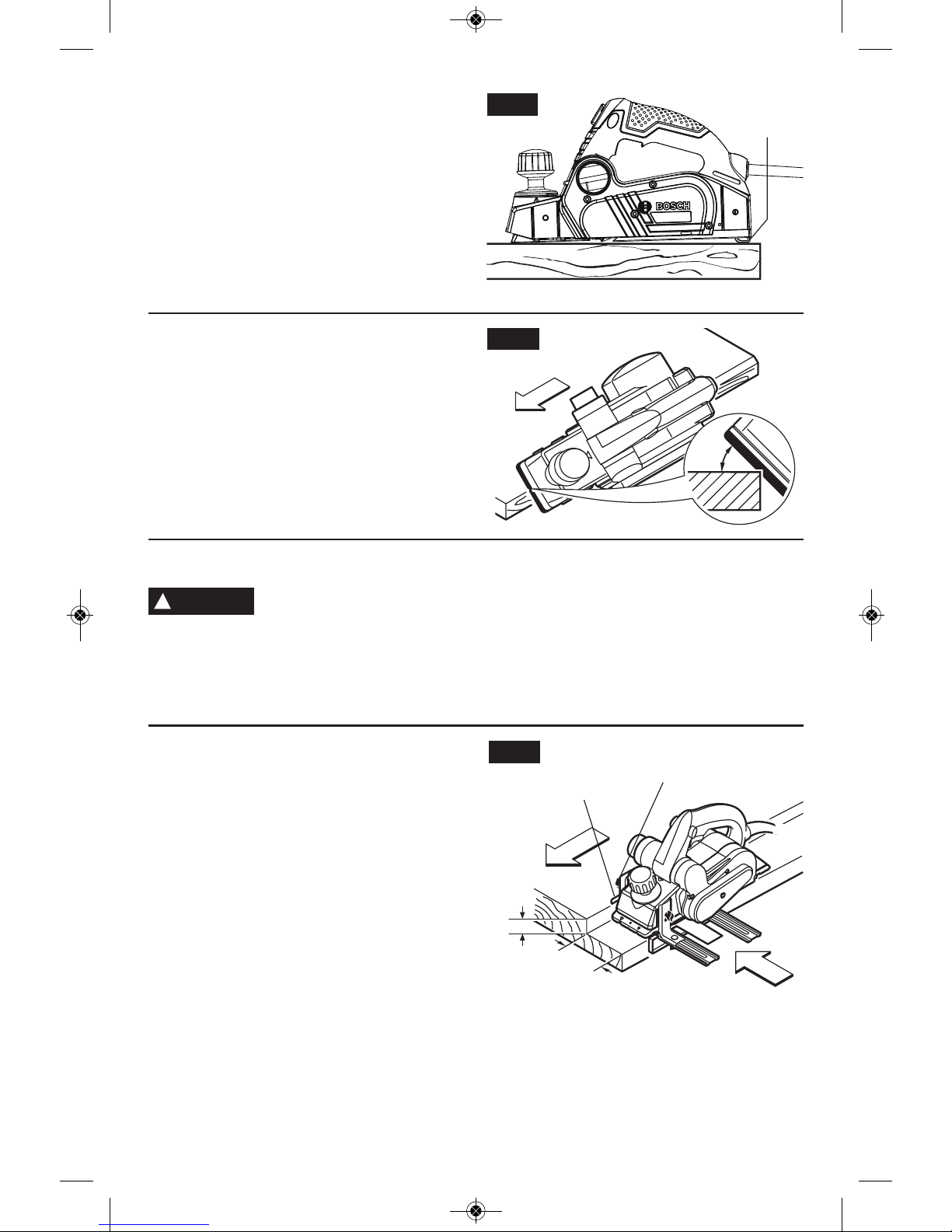

To remove the blades:

1. Rotate the blade drum until the clamping jaw

is parallel to the planer shoe.

!

WARNING

!

WARNING

FIG. 4

CLAMPING

SCREW

FRONT

SHOE

BLADE

HOLDER

RIDGE

CLAMPING

JAW

BLADE

DRUM

BLADE

WRENCH

-9-

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 9

-10-

2. Loosen the three clamp screws by about

one revolution each. (It is not necessary to

remove the clamping jaw.) (Fig. 4)

3. Slightly rotate the blade drum and use a

piece of wood to push the blade sideways and

out from under the clamping jaw. Make sure to

keep your fingers away from the sharp edges

of the blade. If the blade is gummed and

difficult to remove, you may clean the blade

and clamp with mineral spirits, lacquer thinner

or alcohol. (Fig. 5)

4. Rotate the blade drum 180° and repeat the

procedure to remove the second blade. Before

inserting a new or sharpened blade, clean all

surfaces (blades, retainer and drum) with

mineral spirits; lacquer thinner or alcohol, as

this will ensure an accurate blade setting and

proper tool performance.

INSTALLING AND ADJUSTING MINI

CARBIDE BLADES

If the blades and/or holder are gummed and

difficult to remove, remove the clamping jaws

and screws and clean all surfaces with mineral

spirits; lacquer thinner or alcohol, as this will

ensure an accurate blade setting and proper

tool performance. (See REMOVAL OF MINI

TC BLADE HOLDERS AND RETAINERS)

To install, carefully slide the blades onto ridges

on the blade holders.

To ensure proper operation and an even cut,

the blades must be positioned so that they are:

• Centered relative to the front and rear shoes.

• Aligned with each other.

• Positioned so that they will not touch against

any part of the planer when rotated.

• Evenly pressed back toward the holder to

ensure that they are level.

INSTALLATION PROCEDURE

1. Align the groove on top of the blade with the

ridge of the blade holder and carefully slide the

blade onto the blade holder, as shown in

Figure 6.

2. Using a block of wood push the TC blade

back towards the blade holder so that the inner

side of the blade is pressed against the sloping

part of the blade holder. (This will ensure that

the blades are level.)

3. Then tighten the Torx clamping screws

using the correct tightening sequence (1,2,3),

as shown in Figure 4, and your planer is ready

for use.

Blade Retainer Screws - Under normal

circumstances, the position of the retainer on

the mini TC blade holders does not require

readjustment. If fact, the screws that attach the

retainer to the blade holder are factory sealed

with a yellow fastening compound that should

not be disturbed. However, if you believe that

adjustments must be made, proper adjustment

is critical, and it is best performed by a Bosch

Factory Service or Bosch Authorized Service

Center.

CONVERSION TO HIGH-SPEED STEEL

BLADES

The PL2632 Planer can be converted to

accept large HSS blades. The conversion

requires the optional PA1204 HSS Blades with

Retainers (pair). (Fig. 7) Additional pairs of

HSS blade, the PA1205 large HSS blades, can

also be purchased separately.

FIG. 7

HSS

BLADE

BLADE

RETAINER

F

I

G.

6

BLADE

HOLDER

FIG. 5

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 10

REMOVAL OF MINI TC BLADE HOLDERS

AND RETAINERS

1. Rotate the blade drum until the clamping jaw

is parallel to the planer shoe.

2. Loosen the three clamp screws completely

and remove the screws and clamping jaw.

3. Slightly rotate the blade drum and use a

piece of wood to push the blade, holder and

retainer off of the blade drum. Make sure to

keep your fingers away from the sharp edges

of the blade. If the blade is gummed and

difficult to remove, you may clean the blade

and clamp with mineral spirits, lacquer thinner

or alcohol.

4. Rotate the blade drum 180° and repeat the

procedure to remove the second blade.

INSTALLING AND ADJUSTING HSS

BLADES AND RETAINERS

Before inserting a new or sharpened blade,

clean all surfaces (blades, retainer and drum)

with mineral spirits; lacquer thinner or alcohol,

as this will ensure an accurate blade setting

and proper tool performance.

New or re-sharpened plane blades must be

properly leveled before installation using the

optional PA1206 HSS Blade Leveling Fixture.

(The PA1204 HSS Blades with Retainers are

leveled at the factory.)

To ensure proper operation and an even cut,

the blades must be positioned so that they are:

• Centered relative to the front and rear shoes.

• Aligned with each other.

• Positioned so that they will not touch against

any part of the planer when rotated.

Procedure:

1. To install the blades, carefully slide the

blade/retainer assembly sideways to over one

of the two clamping areas on the blade drum.

The retainer must engage in the groove. (Fig.

8)

2. Place a properly-oriented clamping jaw over

the blade. (Fig. 4)

3. Tighten the three clamp screws with the

Torx key using the correct tightening sequence

(1,2,3). (Fig. 4)

4. Rotate the blade drum 180° and repeat the

procedure for the second blade clamp.

REMOVING LARGE HSS BLADES

To remove the blades:

1. Rotate the blade drum until the clamping jaw

is parallel to the planer shoe.

2. Loosen and remove the three clamp screws

with the Torx key.

3. Also remove the clamping jaw.

4. Slightly rotate the blade drum and use a

piece of wood to push the blade and retainer

sideways and out of the blade drum. Make

sure to keep your fingers away from the sharp

edges of the blade. If the blade is gummed and

difficult to remove, you may clean the blade

and clamp with mineral spirits, lacquer thinner

or alcohol.

Rotate the blade drum 180° and repeat the

procedure to remove the second blade.

RESHARPENING HSS BLADES

Worn or dull HSS plane blades can be

resharpened. The optimal blade angle of 50°

should be maintained when sharpening. Once

a total of 6 mm of steel has been removed

from tips of the blades, both blades must be

replaced because the minimum HSS blade

height is 23 mm from back to tip.

FIG. 8

GROOVE

FIG. 9

HSS

BLADE

BLADE

RETAINER

BLADE

LEVELING

FIXTURE

-11-

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 11

Operating Instructions

TRIGGER "ON/OFF" SWITCH

Hold the tool with bo th

hands while starting the

tool, since torque from the motor can

cause the tool to twist.

If the “Lock-ON” button is

continuously being

depressed, the trigger cannot b e

released.

Never l e a ve t h e tr i g g er

locked "ON". Before

plugging the tool in, check that the trigger

lock is "OFF". Accidental start-ups could

cause injury.

Be aware of the location

and setting of the switch

"Lock-ON" button. If the switch is locked

"ON" during the use, be ready for emergency

situations to switch it "OFF".

TO TURN THE TOOL “ON”: Depress the

“Lock-OFF” button on either side of the tool

and squeeze the trigger switch.

TO TURN THE TOOL “OFF”: Simply release

the trigger switch.

Your planer is also equipped with a “Lock-ON”

button located on the front of the handle that

allows continuous operation without squeezing

the trigger.

TO LOCK THE SWITCH ON: Squeeze trigger

switch fully, depress the “Lock-ON” button and

release trigger.

TO UNLOCK THE SWITCH: Squeeze trigger

switch and release it without depressing the

“Lock-ON” button.

CORD SWIVEL

The swiveling ball joint on the power cord

makes it easy to position the cord in a way that

makes it easier to use the tool (Fig. 1).

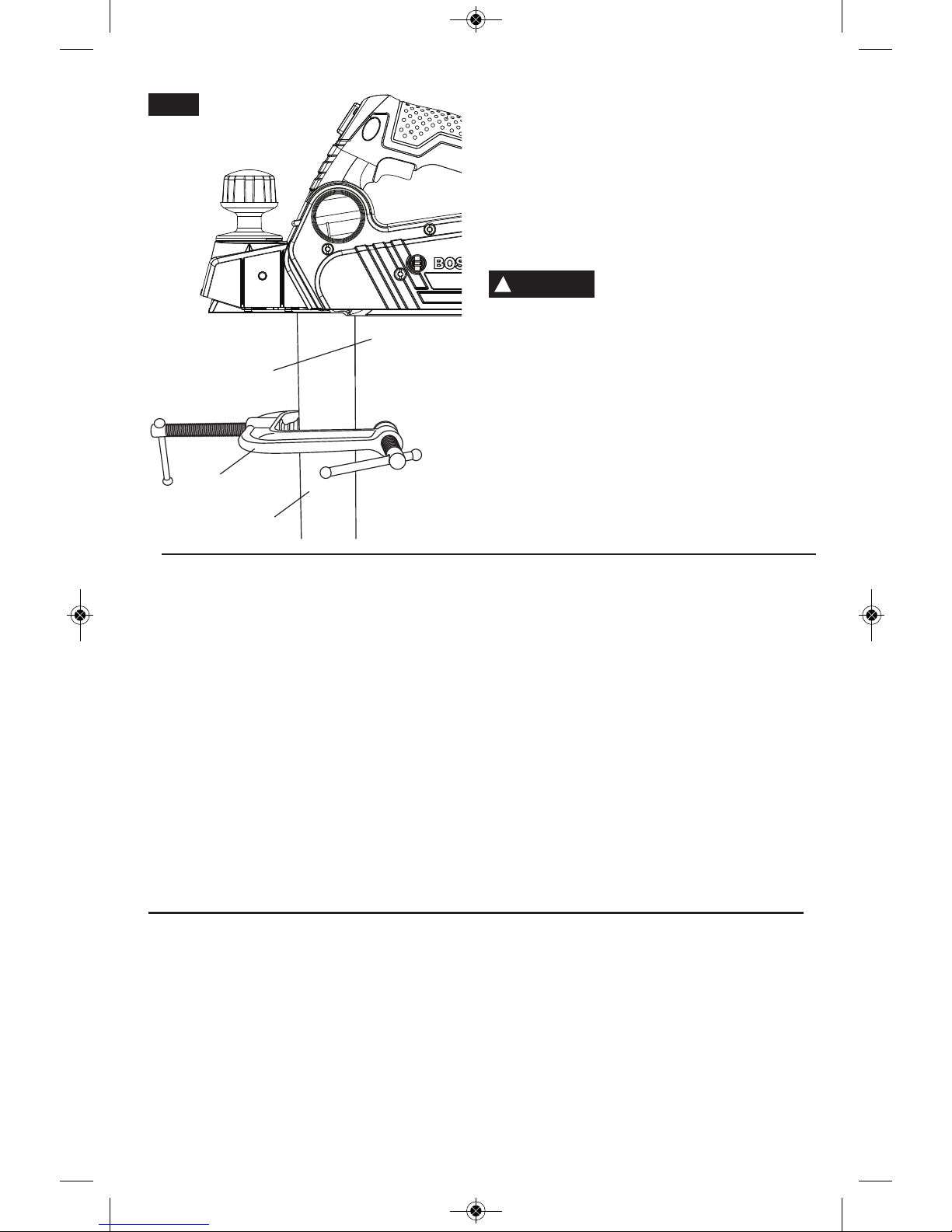

PLANING ACTION

Proper planing action helps to achieve the

desired result. With practice and experience, it

will become second nature. Make sure that the

workpiece is held in place securely on your

work surface, and standing comfortably, hold

the planer firmly with both hands.

1. With the planer fully adjusted, place the front

shoe on the workpiece, (be certain that the

blade drum is not in contact with the work)

and start the planer as described earlier.

2. With pressure on the front shoe, and the

fence against the side of the work (to control

the width or angle,) feed the planer steadily

until the full length of the rear shoe passes

over the edge of the workpiece. (Fig. 10)

3. Then gradually transfer pressure to the rear

shoe, and continue planing to the end of the

cut.

4. If pressure is not maintained over the rear

shoe through the end of the cut, a divot may

be created in the workpiece once the front

shoe clear the end of the workpiece. To

minimize this possibility, use a 3-way edge

clamp to hold a piece of scrap wood (at

least 1-1/2" (38 mm) thick) on the end of the

workpiece, aligned with the surface to be

planed (Fig. 11). Doing this moves the

location of a potential divot off the workpiece

-12-

LEVELING OF HSS BLADES

A PA1206 HSS Blade Leveling Fixture

(optional accessory) is required to level new or

resharpened HSS blades. (Not necessary with

the PA1204 HSS Blades and Retainers, which

are leveled at the factory.)

1. Place the blade and blade retainer on the

leveling fixture and make sure that the blade

retainer engages in the grooves intended for

this purpose. (Fig. 9)

2. Press the plane blade against the stop in

front of the cutting edge to achieve the proper

depth and evenness (levelness) and with the

blade retainer in this position and tighten it with

t

he locking screws. This will automatically

adjust the blade to the correct height and

levelness.

3. Tighten the retainer screws.

4. Remove blade and retainer assembly from

the leveling fixture.

5. Repeat the procedure for the second blade.

!

WARNING

!

WARNING

!

WARNING

!

WARNING

PLANER

STAND

SHOE

FIG. 10

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 12

-13-

and on to the piece of scrap wood.

5. Feed the planer at a uniform and reasonable

rate that does not put excessive strain on

the motor or blades, (do not pull the planer

back over the surface already cut.)

6. Use progressive cuts until you are near the

desired depth, and then re-adjust to a thin

cut for the final pass to obtain a good

surface finish.

The motor may stall if

improperly used or

overloaded. Reduce the pressure (feed rate)

or depth of cut to prevent possible damage to

the tool if the motor labors.

!

CAUTION

FIG. 11

EDGE

CLAMP

WOOD SCRAP

WORK PIECE

DEPTH OF CUT AND FEED RATE

The cutting depth (planing depth) is

determined by the difference in height between

the adjustable front shoe and the fixed rear

shoe of the planer. The depth knob adjusts the

front shoe, which retracts and exposes the

blade and determines the amount of material

removed from the workpiece. The cutting

depth range is from 0 to 3/32" (2.6 mm) per

pass. (Fig. 1)

The appropriate depth of cut and feed rate

depends on the workpiece material:

To avoid clogging and/or damage to the motor,

a thinner cut and/or a slower feed rate may be

needed if the material has any of these

characteristics: hardness; gumminess,

sappiness, moisture, paint, varnish and/or

knots. Also, when planing against the grain or

across the grain rather than with the grain, a

shallower cut and/or slower feed rate is

required. Whenever possible, test by planing a

similar piece of scrap material.

Use multiple, progressive cuts to achieve the

total desired depth.

Start with a thin cut. If the plane moves freely

through the workpiece with no excessive load

on the motor, the depth setting can be

increased before the next cut.

When near the desired total depth, re-adjust

the planing depth to a thin setting for the final

cut to obtain a good surface finish.

Adjusting the Depth of Cut: Rotate depth

adjustment knob until the indicator is aligned

with the desired cutting depth on the depth

scale (Fig. 1).

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 13

BEVELING EDGES

The V-groove in the front planer base plate

allow quick and easy beveling of workpiece

edges. (Fig. 13).

RABBETING

Although all of the compatible Bosch planer

guide fences can be used with the PL2632 for

rabbeting (sometimes called "shiplapping"), the

best fence for this purpose is the optional dualmount fence.

The PL2632 can create rabbets up to 82 mm /

3-1/2" wide. (Fig. 14). Keep in mind that it

takes steady sideways pressure and many

passes to create rabbets using a planer.

RABBETING DEPTH STOP

The optional rabbeting depth stop (Fig. 14)

allows the user to set any rabbeting depth from

0 to 5/16" (9 mm). For best results, it is

important that the blade be properly aligned

(See "BLADE ALIGNMENT").

Setting the rabbet depth: Loosen wing knob

and using the depth scale on the rabbeting

depth stop, set the desired rabbet depth.

Securely tighten wing knob (Fig. 14).

FIG. 14

9mm

max.

82mm

ma

x

.

RABBETING

DEPTH STOP

WING

KNOB

-14-

P

LANER STAND

The planer stand automatically springs down

to help keep the blade from coming in

contact with the work surface when planer is

not in use (Fig. 12). The planer stand is

designed to swing up and out of the way by it

itself when the back of the plane crosses the

leading edge of the workpiece (Fig. 10). It will

also swing up when planing begins in the

middle of the work piece (in from the edge of

the work piece).

45°

FIG. 13

FIG. 12

PLANER

STAND

UNCLOGGING THE SHAVINGS

EXHAUST SYSTEM

Remove plug from power

source if it becom es

necessary to manually remove shavings.

The blades are hidden from view and you may

be cut if contacted.

To minimize the possibility of clogging, make

sure:

1. The depth of cut is reasonable for the

material.

2. The feed rate is reasonable for the material.

(See DEPTH OF CUT AND FEED RATE)

3. Unplug the planer and carefully insert a

screwdriver or similar object into the

exhaust port to break up the clog.

!

WARNING

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 14

Service

Pre ventive main t enance

performed by unauthorized

personnel may result in misplacing of

internal wires a nd comp onents whic h

cou l d cause ser i o us hazard. We

recommend that all tool service be performed

by a Bosch Factory Service Center or Autho rized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated

and is ready to use. It is recommended that

tools with gears be regreased with a special

gear lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your tool

have been engineered for many hours of

dependable service. To maintain peak

efficiency of the motor, we recommend every

two to six months the brush es be examined.

Only genuine Bosch replace ment brushes

specially designed for your tool should be

used.

BEARINGS

Bearings which become noisy (due to heavy

load or very abrasive material cut ting) should

be replaced at once to avoid overheating or

motor failure.

Cleaning

To avoid accidents always

dis connect the tool from

the power suppl y befor e cleani n g o r

performing any main tenance. The tool may

be cleaned most effectively with compressed

dry air. Always wear safety gog gles when

cleaning tools with compressed air.

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not at tempt to clean by inserting pointed

objects through openings.

Ce rtain clea ning agent s

and solvent s damag e

plastic parts. Some of these are: gasoline,

carbon tetrachlo ride, chlo rinated cleaning

solvents, ammonia and house hold detergents

that contain ammonia.

Clean the planer stand regularly and ensure

that it springs back freely.

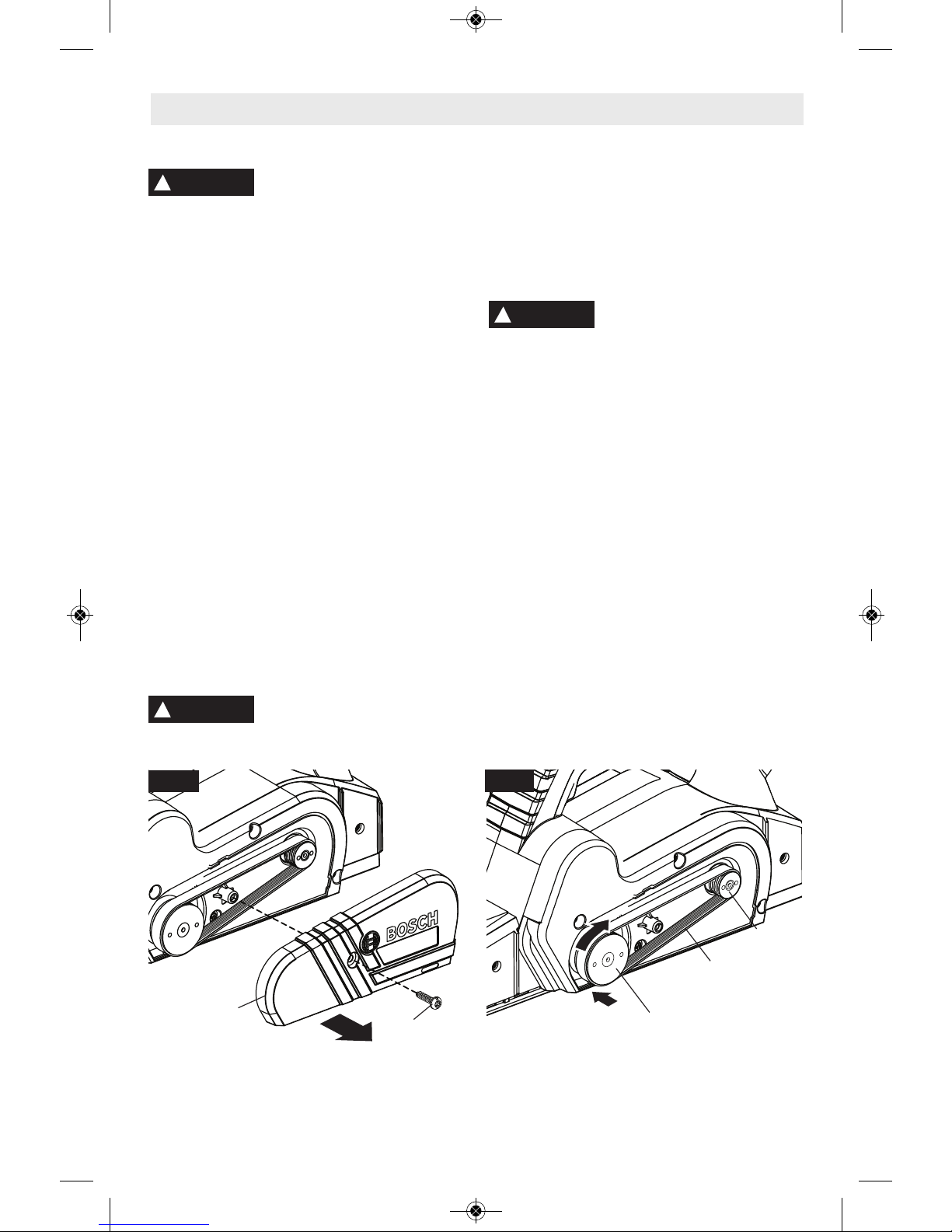

DRIVE BELT

The drive belt is a normal maintenance part

and should be inspected periodically for wear.

If the drive belt shows signs of drying out,

cracking or tearing, it should be replaced. If the

drive belt will not track properly or comes off

the pulleys, it should be replaced.

Installing new drive belt: Loosen screw and

remove the drive belt cover (Fig. 15). Cut and

remove the worn drive belt. Before installing the

new drive belt, clean both pulleys thoroughly.

First place the new drive belt onto the drive

pulley then rotate clockwise while pushing the

belt onto the driven pulley (Fig. 16). Reinstall

the drive belt cover and securely tighten screw

(Fig. 15).

!

WARNING

Maintenance

!

WARNING

!

CAUTION

-15-

FIG. 15

FIG. 16

SCREW

DRIVE BELT

COVER

DRIVEN

PULLEY

DRIVE

PULLEY

DRIVE

BELT

2610035786 PL2632 01-15.qxp_PL2632 1/14/15 9:33 AM Page 15

Loading...

Loading...