Bosch OBD 2220 INFO SCAN User Manual

OBD 2220 Info Scan

en User guide

en | 2 | User guide

| OBD 2220

Info Scan

Serial No: __________________________________

SW ID: _____________________________________

HW Ver: ____________________________________

Boot Ver: ___________________________________

Prod ID: ____________________________________

Board ID: ___________________________________

Burn Date: _________________________________

Record the above information about your tool. The information is available

at Main Menu --> System Setup --> Tool Information. Provide this information when contacting technical support.

If you have questions or concerns contact Technical Support:

Phone: 1300 783 031

Email: automotive.techsupport@au.bosch.com

The information, specifications, and illustrations in this guide are based on

the latest information available. Bosch reserves the right to make changes

at any time without notice.

580000 | REV. A | 04.2017

Bosch Automotive Service Solutions Inc.

OBD 2220 Info Scan | User guide | 3 | en

Table of Contents

1 Safety Precautions ....................... 5

1.1 Read All Instructions ................ 5

1.2 Safety Messages ...................5

2 Important Safety Warnings and Instructions .. 5

3 Getting Started .........................8

3.1 Introduction .......................8

3.2 Download Scanning Suite ............ 8

3.3 OBDII ............................8

3.4 SAE Publications ...................8

3.5 OBDII Data Link Connector (DLC) ...... 8

OBD II Data Link Connector (DLC) Pins .. 8

3.6 OBDII Diagnostic Trouble Codes (DTCs) . 9

Powertrain Codes ...................9

Chassis Codes ......................9

Body Codes ........................ 9

Network Communication Codes ........9

4 Using the Scan Tool ......................9

4.1 The Scan Tool ......................9

4.2 Specifications ..................... 10

Dimensions .......................10

4.3 Display ..........................10

Keypad ..........................10

4.4 Power ...........................10

Vehicle Power ..................... 10

USB Power .......................10

4.5 System Setup .....................10

Changing Measurement Units ......... 11

Language Setup ................... 11

Long PID Names ................... 11

Tool Information ...................12

Display Test ....................... 12

Keypad Test ....................... 13

Memory Test ......................13

Program Mode ....................14

4.6 Vehicle-Specific Features ............14

Review Data ......................14

Recording ........................ 14

4.7 Code Lookup ..................... 15

4.8 Locating Data Link Connector ........16

4.9 Connect the Tool ..................16

4.10 Vehicle Selection .................. 16

4.11 Acronyms ........................ 17

4.12 Component Locator ................18

5 Diagnostic Menu .......................19

5.1 I/M Monitors (Emissions) ........... 19

5.2 Read Codes ......................20

5.3 Erase Codes ...................... 21

5.4 MIL Status ....................... 22

5.5 State OBD Check ..................23

5.6 View Data ........................23

5.7 Record Data ...................... 24

5.8 View Freeze Data ..................25

5.9 Drive Cycle Monitor ................26

5.10 O2 Monitor Tests .................. 27

5.11 Diagnostic Monitor Tests ........... 28

5.12 On-Board Systems ................. 29

5.13 Charging System Monitor ........... 30

5.14 Vehicle Information ................ 31

6 Troubleshooting ........................ 32

6.1 Error Messages ...................32

6.2 Scan Tool Does Not Power Up ........ 32

6.3 Vehicle Communication Fault ........ 32

6.4 Operating Error or Erroneous Data .... 32

6.5 Tool Self-Tests .................... 33

6.6 Technical Support ................. 33

7 Appendix A—PID Definitions .............. 33

8 Appendix B—Glossary ................... 36

Declaration of Conformity ................... 41

Limited Warranty ..........................41

Bosch Automotive Service Solutions Inc.

580000 | REV. A | 04.2017

en | 4 | User guide

| OBD 2220

Info Scan

580000 | REV. A | 04.2017

Bosch Automotive Service Solutions Inc.

OBD 2220 Info Scan | User guide | 5 | en

1 Safety Precautions

For your safety, read this manual thoroughly before

operating your scan tool. Always refer to and follow

safety messages and test procedures provided by the

manufacturer of the vehicle or equipment being tested.

The safety messages presented below and throughout

this user’s manual are reminders to the operator to

exercise extreme care when using this test instrument.

1.1 Read All Instructions

Read and understand the user guide before operating the tool.

Read, understand, and follow all safety messages and

instructions in this manual and on the test equipment.

Safety messages in this section of the manual contain a

signal word with a three-part message and, in some

instances, an icon.

1.2 Safety Messages

Safety messages are provided to help prevent personal

injury and equipment damage. All safety messages are

introduced by a signal word. The signal word indicates

the level of the hazard in a situation. The types of safety

messages are.

DANGER

Indicates a possible hazardous situation

which, if not avoided, will result in death or

serious injury to operator or bystanders.

WARNING

Indicates a possible hazardous situation

which, if not avoided, could result in death

or serious injury to operator or bystanders.

CAUTION

Indicates a possible hazardous situation

which, if not avoided, may result in moderate

or minor injury to operator or bystanders.

IMPORTANT

Indicates a condition which, if not avoided, may

result in damage to test equipment or vehicle.

2 Important Safety Warnings

and Instructions

WARNING

Risk of electric shock.

• Do not exceed voltage limits between

inputs indicated in the Specifications.

• Use extreme caution when working

with circuits that have voltage greater

than 60 volts DC or 24 volts AC.

Electric shock can cause injury.

WARNING

Risk of poisoning.

• Safety goggles and protective clothing must

be worn by the operator and any bystanders.

– Even if everyday glasses have

impact resistant lenses, they are

NOT safety glasses, and may not

provide adequate protection.

• Do not use this scan tool in environments where explosive vapors may

collect. These areas include:

– below-ground pits.

– confined areas.

– areas that are less than 18 inches

above floor.

• Use this scan tool in locations with

mechanical ventilation providing at

least 4 air changes per hour.

• Flammable fuel and vapors can ignite.

• Do not smoke, strike a match, or cause

a spark in the vicinity of the battery.

Battery gases can ignite.

• Avoid making an accidental connection

between the battery terminals. Do not place

uninsulated metal tools on the battery.

• When removing battery cables, remove

the ground cable first.

• Avoid sparks when connecting or disconnecting power leads to the battery.

• Make sure ignition is off, headlights

and other accessories are off and

vehicle doors are closed before disconnecting the battery cables.

– This also helps prevent damage to

on-board computer systems.

• Always disconnect the battery ground

connections before servicing electrical system components.

Explosion can cause injury.

Bosch Automotive Service Solutions Inc.

580000 | REV. A | 04.2017

en | 6 | User guide

| OBD 2220

Info Scan

WARNING

Risk of poisoning.

• Use this scan tool in locations with

mechanical ventilation providing at

least 4 air changes per hour. Engine

exhaust contains odorless gas which

can be lethal.

• Route the exhaust outside while

testing with the engine running.

Poisoning can result in death or serious injury.

WARNING

Battery acid is a highly corrosive sulfuric acid.

• Safety goggles and protective gloves must be

worn by the operator and any bystanders.

– Even if your everyday glasses

have impact resistant lenses, they

are NOT safety glasses, and may

not provide adequate protection.

• Make sure someone can hear you or is

close enough to provide aid when

working near a battery.

• Have plenty of fresh water and soap nearby.

– If battery acid contacts skin,

clothing, or eyes, flush exposed

area with soap and water for 10

minutes. Seek medical help.

• Do not touch eyes while working near battery.

Battery acid can burn eyes and skin.

WARNING

Risk of fire.

• Safety goggles and protective clothing must

be worn by the operator and any bystanders.

– Even if your everyday glasses

have impact resistant lenses, they

are NOT safety glasses, and may

not provide adequate protection.

• Do not position your head directly in

front of or over the throttle body.

• Do not pour gasoline down the throttle body when cranking or running the

engine, when working with fuel delivery systems or any open fuel line.

– Engine backfire can occur when

the air cleaner is out of position.

• Do not use fuel injector cleaning solvents

when performing diagnostic testing.

• Keep cigarettes, sparks, open flame

and other sources of ignition away

from vehicle.

• Keep a dry chemical (Class B) fire

extinguisher rated for gasoline, chemical and electrical fires in work area.

Fire can cause death or serious injury.

WARNING

Risk of flying particles.

• Safety goggles and protective gloves must

be worn by the operator and any bystanders while using electrical equipment.

– Electrical equipment or rotating

engine parts can cause flying particles.

– Even if your everyday glasses

have impact resistant lenses, they

are NOT safety glasses, and may

not provide adequate protection.

Flying particles can cause eye injury.

WARNING

Risk of burns.

• Batteries can produce a short-circuit

current high enough to weld jewelry

to metal.

– Remove jewelry such as rings,

bracelets and watches before

working near batteries.

Short circuits can cause injury.

WARNING

Risk of burns.

• Do not remove radiator cap unless

engine is cold.

– Pressurized engine coolant may

be hot.

• Do not touch hot exhaust systems, manifolds, engines, radiators, sample probe.

• Wear insulated gloves when handling

hot engine components.

• Tester leads can become hot after extended

testing in close proximity to manifolds.

Hot components can cause injury.

WARNING

Risk of expelling fuel, oil vapors, hot steam,

hot toxic exhaust gases, acid, refrigerant

and other debris.

• Safety goggles and protective clothing

must be worn by the operator and any

bystanders.

– Even if your everyday glasses

have impact resistant lenses, they

are NOT safety glasses, and may

not provide adequate protection.

• Engine systems can malfunction,

expelling fuel, oil vapors, hot steam,

hot toxic exhaust gases, acid, refrigerant and other debris.

Fuel, oil vapors, hot steam, hot toxic

exhaust gases, acid, refrigerant and other

debris can cause serious injury.

580000 | REV. A | 04.2017

Bosch Automotive Service Solutions Inc.

OBD 2220 Info Scan | User guide | 7 | en

P R N D L 2

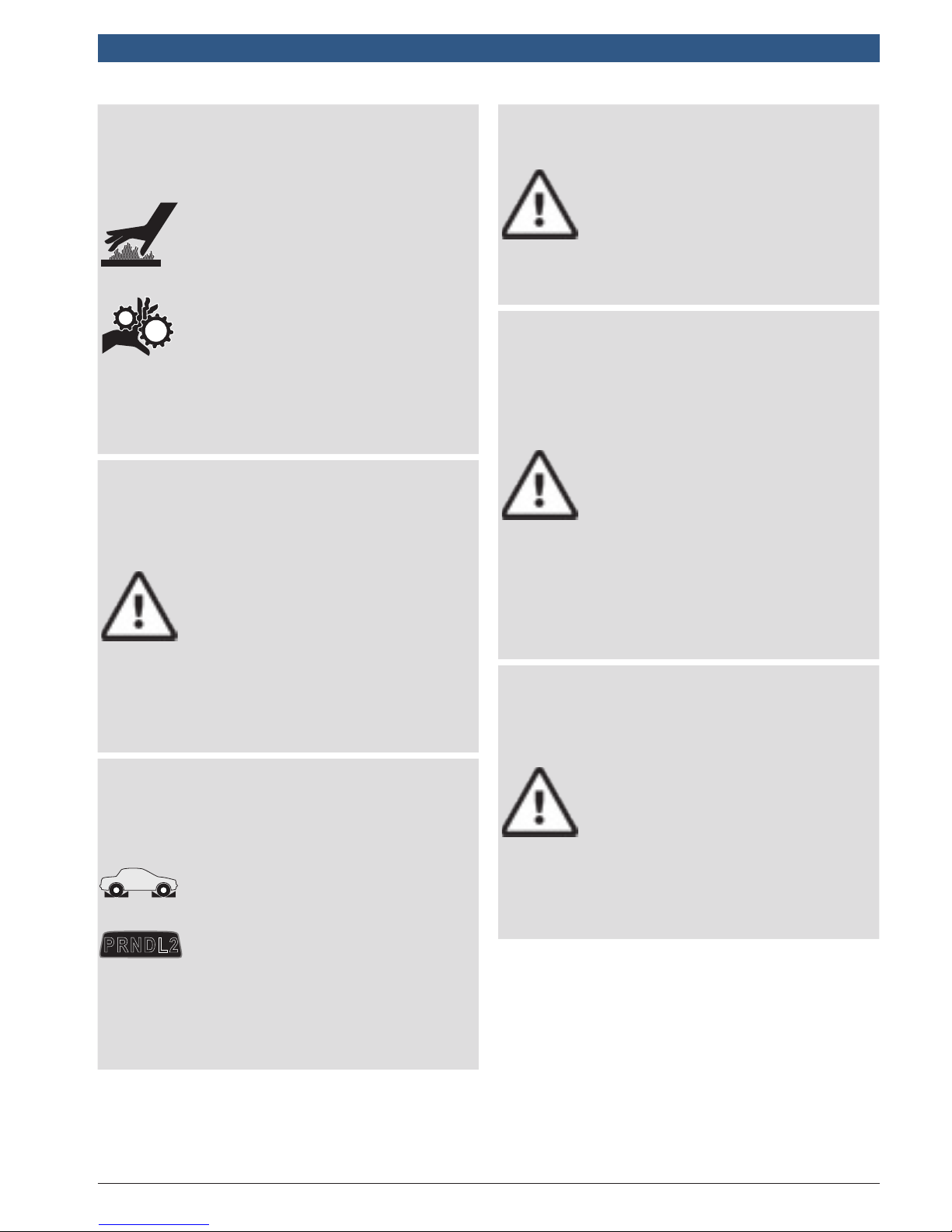

WARNING

Engine compartment contains electrical

connections and hot or moving parts.

• Keep yourself, test leads, clothing and

other objects clear of electrical connections and hot or moving engine parts.

• Do not wear watches, rings, or loose

fitting clothing when working in an

engine compartment.

• Do not place tools or test equipment

on fenders or other places in engine

compartment.

• Barriers are recommended to help

identify danger zones in test area.

• Prevent personnel from walking

through test area.

Contacting electrical connections and hot

or moving parts can cause injury.

WARNING

Risk of injury.

• The scan tool should be operated by

qualified personnel only.

• Use the scan tool only as described in

the user’s manual.

• Use only manufacturer’s recommended attachments.

• Do not operate the scan tool with

damaged cables.

• Do not operate the scan tool if it has

been dropped or damaged, until examined by a qualified service representative.

Operation of the scan tool by anyone other

than qualified personnel may result in injury.

WARNING

Risk of unexpected vehicle movement.

• Block drive wheels before performing

a test with engine running.

• Unless instructed otherwise:

– set parking brake

– put gear selector in neutral for

manual transmissions

– put gear selector in park for

automatic transmissions

– disconnect release mechanism on

the automatic parking brake

release for testing and reconnect

when testing is completed.

• Do not leave a running engine unattended.

A moving vehicle can cause injury.

CAUTION

Risk of equipment or circuit damage.

• Unless specifically directed by manufacturer, make sure ignition is off before

connecting or disconnecting connectors

or any vehicle electrical terminals.

• Do not create a short between battery

terminals with a jumper wire or tools.

Improper equipment use can cause equipment or circuit damage.

CAUTION

Misdiagnosis may lead to incorrect or

improper repair and/or adjustment.

• Do not rely on erratic, questionable,

or obviously erroneous test information or results.

– If test information or results are

erratic, questionable, or obviously

erroneous, make sure all connections and data entry information

are correct and test procedures

were performed correctly.

– If test information or results are

still suspicious, do not use them

for diagnosis.

Improper repair and/or adjustment may

cause vehicle or equipment damage or

unsafe operation.

DANGER

Some vehicles are equipped with air bags.

• Follow service manual warnings when

working around air bag components

or wiring.

– If service manual instructions are

not followed, an air bag may deploy

unexpectedly, resulting in injury.

– Note an air bag can still deploy

several minutes after ignition key

is off (or even if vehicle battery is

disconnected) because of a

special energy reserve module.

An air bag opening can cause injury.

Bosch Automotive Service Solutions Inc.

580000 | REV. A | 04.2017

en | 8 | User guide

9 16

| OBD 2220

Info Scan

3 Getting Started

3.1 Introduction

The scan tool was developed by experts in the automotive service industry to help diagnose vehicles and assist

in troubleshooting procedures.

The scan tool monitors vehicle events and retrieves

codes from the vehicle’s control modules to help pinpoint problem areas.

All information, illustrations and specifications contained

in this manual are based on the latest information available from industry sources at the time of publication.

No warranty (expressed or implied) can be made for its

accuracy or completeness, nor is any responsibility

assumed by the manufacturer or anyone connected with

it for loss or damages suffered through reliance on any

information contained in this manual or misuse of

accompanying product. The manufacturer reserves the

right to make changes at any time to this manual or

accompanying product without obligation to notify any

person or organization of such changes.

3.2 Download Scanning Suite

1. Go to www.boschdiytools.com.au to download the

Scanning Suite PC application. Scanning Suite is

NOT required to operate the scan tool.

2. Install the downloaded Scanning Suite application

before connecting the scan tool to the PC.

To be able to use Scanning Suite the PC must meet

the following minimum requirements:

• Microsoft Windows 7, 8, and 10

• Adobe Acrobat Reader

• Screen Resolution of 800 x 600

– If screen resolution is 800 x 600, in Display

Properties, Settings Tab, set Font Size to

Small Fonts.

3. Use Scanning Suite to determine if any updates are available for your tool by clicking Check for Update button.

4. Check for updates to Use Scanning Suite by clicking

on the Check For Scanning Suite Update button. This

should be done before checking for Tool Updates.

You can also configure the Scanning Suite Frequency (SS

Frequency) to automatically check every xx minutes. The

default frequency is 7 days.

Refer to instructions provided on www.boschdiytools.

com.au for how to install Scanning Suite and Tool

updates.

• A universal OBDII data link connector, called the

DLC, with dedicated pin assignments.

• A standard location for the DLC, visible under the

dash on driver’s side.

• A standard list of diagnostic trouble codes (DTCs)

used by all manufacturers.

• A standard list of parameter identification (PID) data

used by all manufacturers.

• Ability for vehicle systems to record operating conditions when a fault occurs.

• Expanded diagnostic capabilities that records a

code whenever a condition occurs that affects

vehicle emissions.

• Ability to clear stored codes from the vehicle’s

memory with a scan tool.

3.4 SAE Publications

SAE has published hundreds of pages of text defining a

standard communication protocol that establishes hardware, software, and circuit parameters of OBDII systems. Unfortunately, vehicle manufacturers have different interpretations of this standard communications

protocol. As a result, the generic OBDII communications

scheme varies, depending on the vehicle.

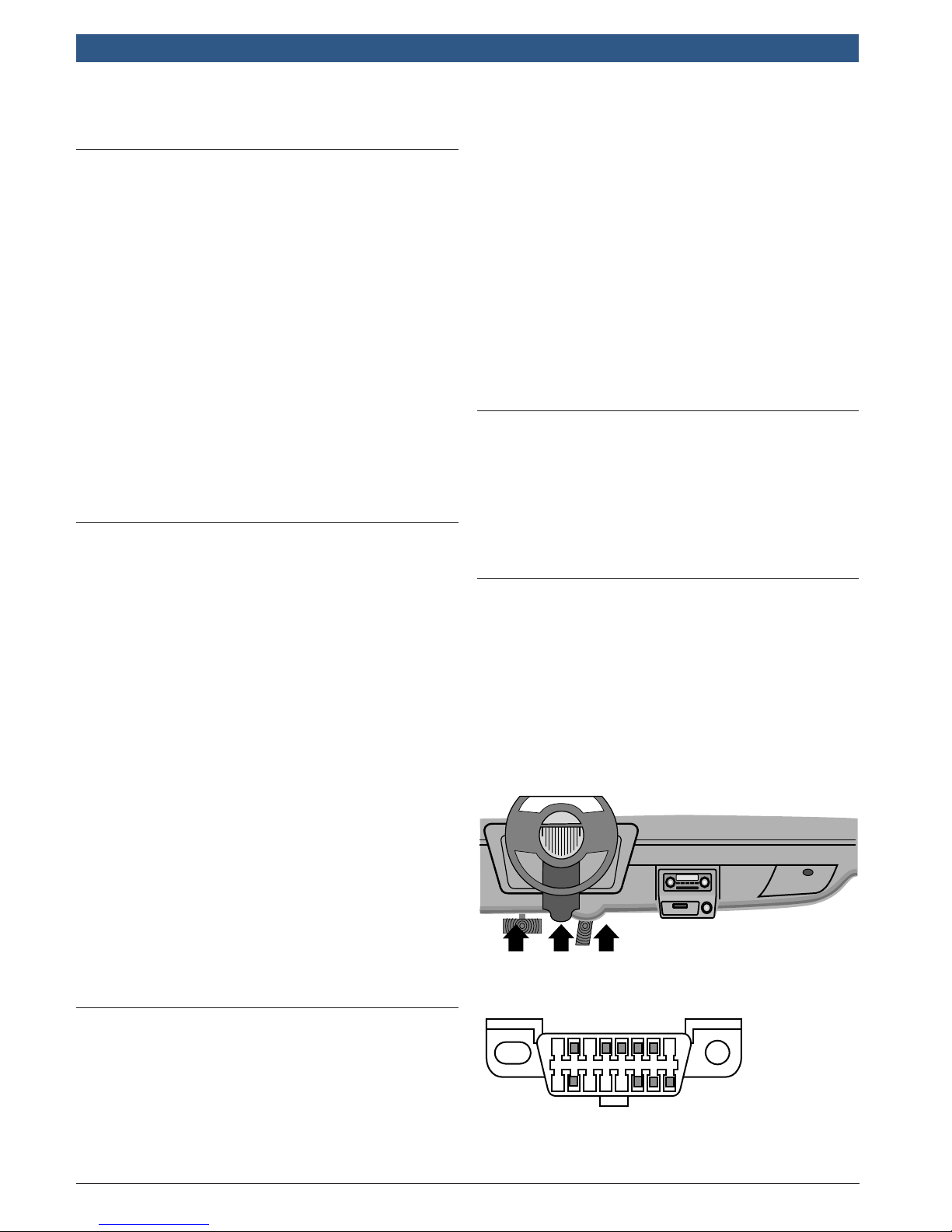

3.5 OBDII Data Link Connector (DLC)

The OBDII data link connector (DLC) allows the scan

tool to communicate with the vehicle’s computer(s).

Beginning in 1996, vehicles use the J1962 (OBDII) DLC,

a term taken from a physical and electrical specification

number assigned by the SAE (J1962). The DLC should

be located under the dashboard on the driver’s side of

the vehicle. If the DLC is not located under the dashboard as stated, a decal describing its location should

be attached to the dashboard in the area the DLC should

have been located.

OBD II Data Link Connector (DLC) Pins

3.3 OBDII

On-board diagnostics version II (OBDII) is a system that

the Society of Automotive Engineers (SAE) developed to

standardize automotive electronic diagnosis.

Beginning in 1996, most new vehicles sold in the United

States were fully OBDII compliant.

Technicians can now use the same tool to test any OBDII

compliant vehicle without special adapters. SAE established guidelines that provide:

580000 | REV. A | 04.2017

1 8

1. Manufacturer reserved

2. J1850 bus+

3. Manufacturer reserved

Bosch Automotive Service Solutions Inc.

OBD 2220 Info Scan | User guide | 9 | en

4. Chassis ground

5. Signal ground

6. CAN high, J-2284

7. K line, ISO 9141-2 & ISO/DIS 14230-4

8. Manufacturer reserved

9. Manufacturer reserved

10. J1850 Bus-

11. Manufacturer reserved

12. Manufacturer reserved

13. Manufacturer reserved

14. CAN low, J-2284

15. L line, ISO 9141-2 & ISO/DIS 14230-4

16. Battery power

3.6 OBDII Diagnostic Trouble Codes

(DTCs)

J2012 and ISO 15031-6 are standards for all DTCs,

established by the SAE, International Organization for

Standardization (ISO) and other governing bodies.

• Codes and definitions assigned by these specifications are known as Generic OBDII codes.

• Codes not reserved by the SAE are reserved for the

manufacturer and referred to as Manufacturer Specific Codes.

DTCs are used to help determine the cause of a problem

or problems with a vehicle.

• DTCs consist of a five-digit alphanumeric code.

• The DTC format and general code types are shown below.

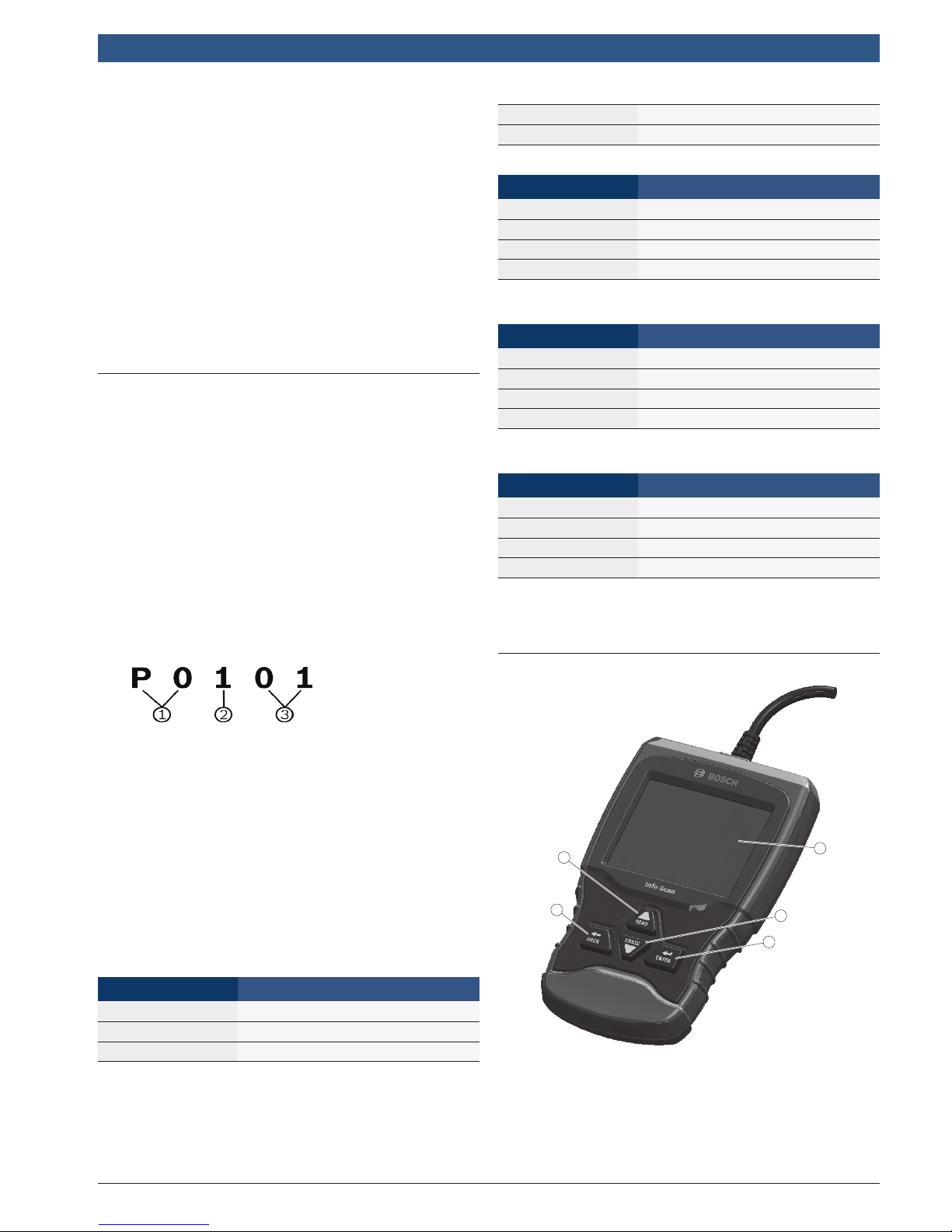

P30xx–P33xx Manufacturer specific

P34xx–P39xx Generic (SAE)

Chassis Codes

Code Type

C0xxx Generic (SAE)

C1xxx Manufacturer specific

C2xxx Manufacturer specific

C3xxx Generic (SAE)

Body Codes

Code Type

B0xxx Generic (SAE)

B1xxx Manufacturer specific

B2xxx Manufacturer specific

B3xxx Generic (SAE)

Network Communication Codes

Code Type

U0xxx Generic (SAE)

U1xxx Manufacturer specific

U2xxx Manufacturer specific

U3xxx Generic (SAE)

4 Using the Scan Tool

4.1 The Scan Tool

1. Bx = Body

Cx = Chassis

Px = Powertrain

Ux = Network communication

x - 0, 1, 2, or 3

2. Vehicle specific system

3. Specific fault designation

Example:

P0101 = Mass or volume air flow cir cuit range/perfor-

mance problem

Powertrain Codes

Code Type

P0xxx Generic (SAE)

P1xxx Manufacturer specific

P2xxx Generic (SAE)

Bosch Automotive Service Solutions Inc.

2

4

5

1

3

580000 | REV. A | 04.2017

en | 10 | User guide

| OBD 2220

Info Scan

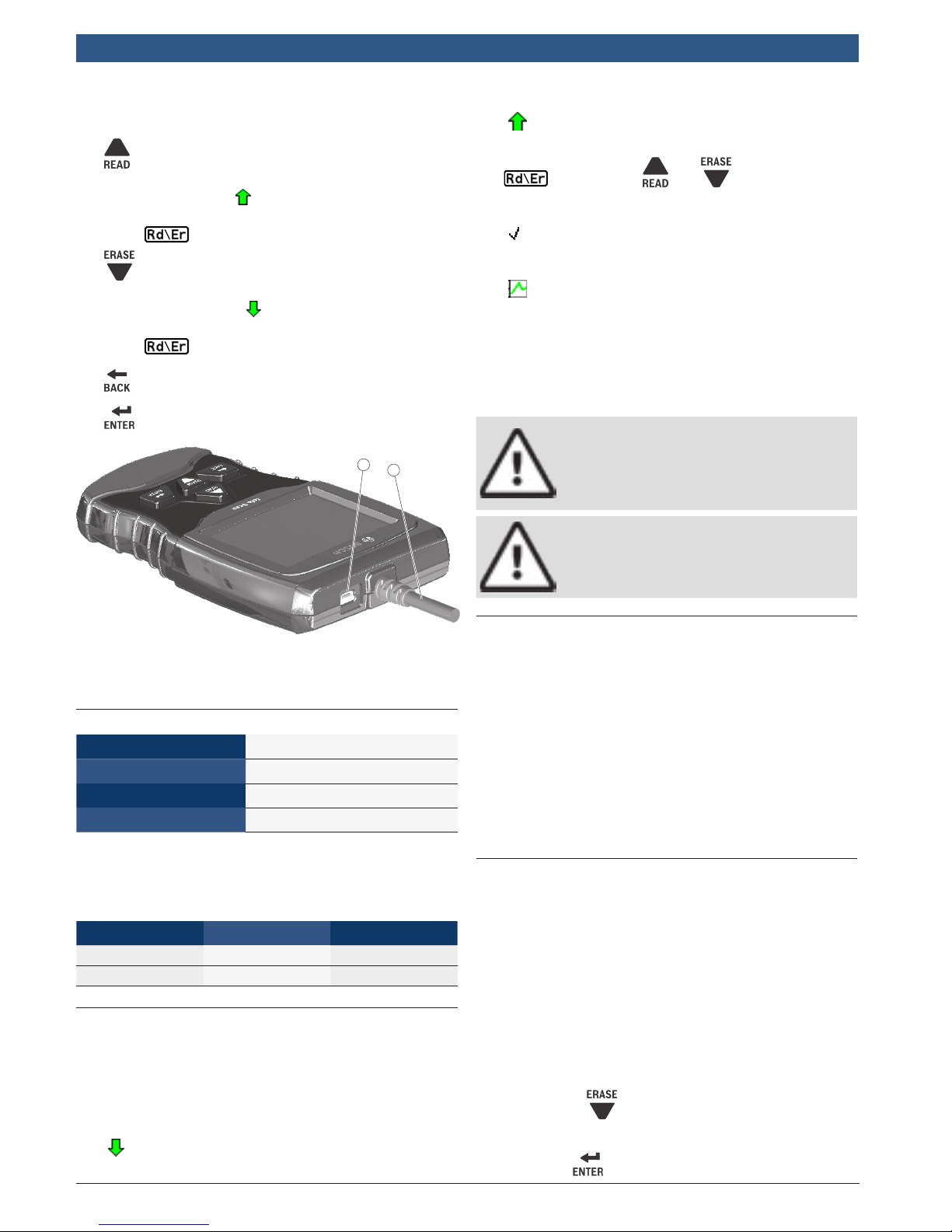

1. LCD display (color, backlit, QVGA resolution)

2. key performs the Read Codes function and

scrolls back through the screens. Press this key

when an up arrow ( ) appears on the display to

scroll backwards, or press and hold for 2 seconds

when appears on the display to read codes.

3. key performs the Erase Codes function and

scrolls forward through the screens. Press this key

when a down arrow ( ) appears on the display to

scroll forward, or press and hold for 2 seconds

when appears on the display to erase codes.

4. key returns to previous screen.

5. key selects item.

6

7

• Indicates additional information is available by

scrolling up.

• Indicates the and hot keys are

active.

• Indicates data is available for items on the

Review Data Menu.

• Indicates graphical viewing of data items is

available in View Data.

Keypad

The keypad is used to move through the different menus

of the scan tool. The scan tool’s software is designed for

ease in operating and navigating through menus.

CAUTION

Do not use solvents such as alcohol to clean

keypad or display. Use a mild nonabrasive

detergent and a soft, cotton cloth.

CAUTION

Do not soak keypad as water might find its

way inside the scan tool.

6. USB port provides USB connection for the computer.

7. DLC cable provides connection for vehicle interface.

8. Serial number plate (on back; not shown).

4.2 Specifications

Display Color, backlit, QVGA resolution

Operating Temperature 0 to 50°C (32 to 122°F)

Storage Temperature -20 to 70°C (-4 to 158°F)

External Power 7 to 16 Volts

A minimum of 8.0 V is required for most control modules

to operate properly in a vehicle.

Dimensions

Height Width Depth

5.6 inches 3.5 inches 0.9 inches

142 mm 89 mm 23 mm

4.3 Display

The display has a large viewing area for displaying messages, instructions, and diagnostic information.

The back-lit liquid crystal display (LCD) is a QVGA pixel

display. Characters used to help operate the scan tool

are:

• Indicates additional information is available by

scrolling down.

580000 | REV. A | 04.2017

4.4 Power

Vehicle Power

When the scan tool is connected to the vehicle’s DLC,

the tool is powered by the vehicle and will automatically

turn on once connected.

USB Power

When the tool is connected to a PC via the USB cable

(not provided), the tool will automatically power up.

Refer to “6.2 Scan Tool Does Not Power Up” on page

32 if there are problems.

4.5 System Setup

System Setup allows:

• Measurement units to be changed.

• Scan tool information to be viewed.

• Display to be checked.

• Operation of the keypad to be checked.

• Memory of the tool to be checked.

• Scan tool to be upgraded.

• Language to be changed.

• Long PID names to be turned ON or OFF.

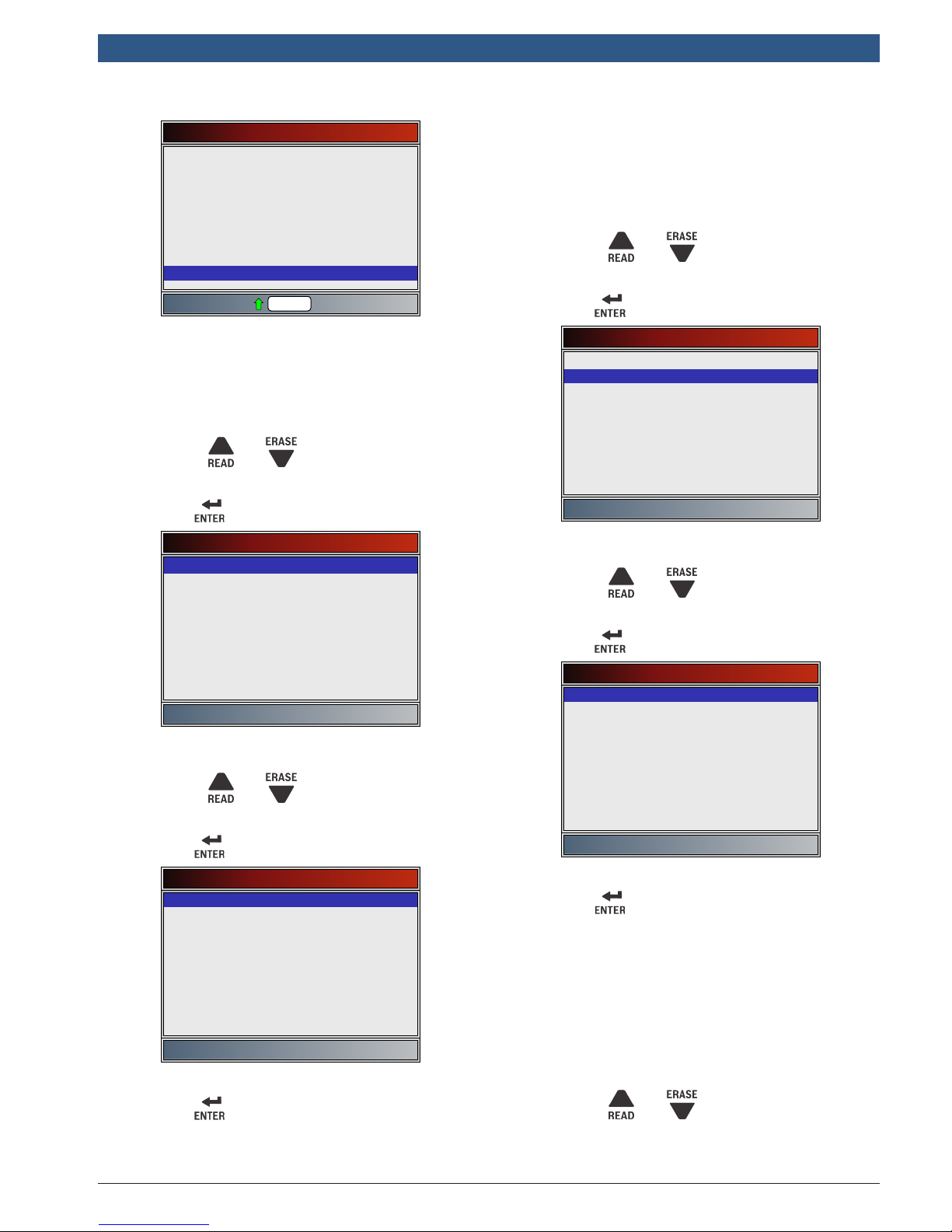

From the Diagnostic Menu:

1. Select System Setup.

• Use the key until System Setup is high-

lighted.

• Press .

Bosch Automotive Service Solutions Inc.

OBD 2220 Info Scan | User guide | 11 | en

Diagnostic Menu

Diagnostic Monitor Tests

On-Board Systems

Charging System Monitor

Vehicle Information

Component Locator

Acronyms

Review Data

Code Lookup

System Setup

Rd\Er

Changing Measurement Units

English is the default measurement unit. Measurement

units can be changed in View and Record Data.

From System Setup screen:

1. Select English/Metric.

• Use the and keys until English/Metric

is highlighted.

• Press .

System Setup

English/Metric

Language Setup

Long PID Names

Tool Information

Display Test

Keypad Test

Memory Test

Program Mode

Language Setup

Language Setup selection allows the user to change the

language used by the Tool. English is the default language.

From System Setup screen:

1. Select Language Setup.

• Use the and keys until Language Setup

is highlighted.

• Press .

System Setup

English/Metric

Language Setup

Long PID Names

Tool Information

Display Test

Keypad Test

Memory Test

Program Mode

2. Select desired measurement unit.

• Use the and keys until the desired

language is highlighted.

• Press .

Language Setup

English

Español

Francais

2. Select desired measurement unit.

• Use the and keys until the desired unit

is highlighted.

• Press .

Measurement Units

English

Metric

3. Save measurement setting.

• Press .

Bosch Automotive Service Solutions Inc.

3. Save language setting.

• Press .

NOTE: When Spanish or French translation is not known,

English will be shown.

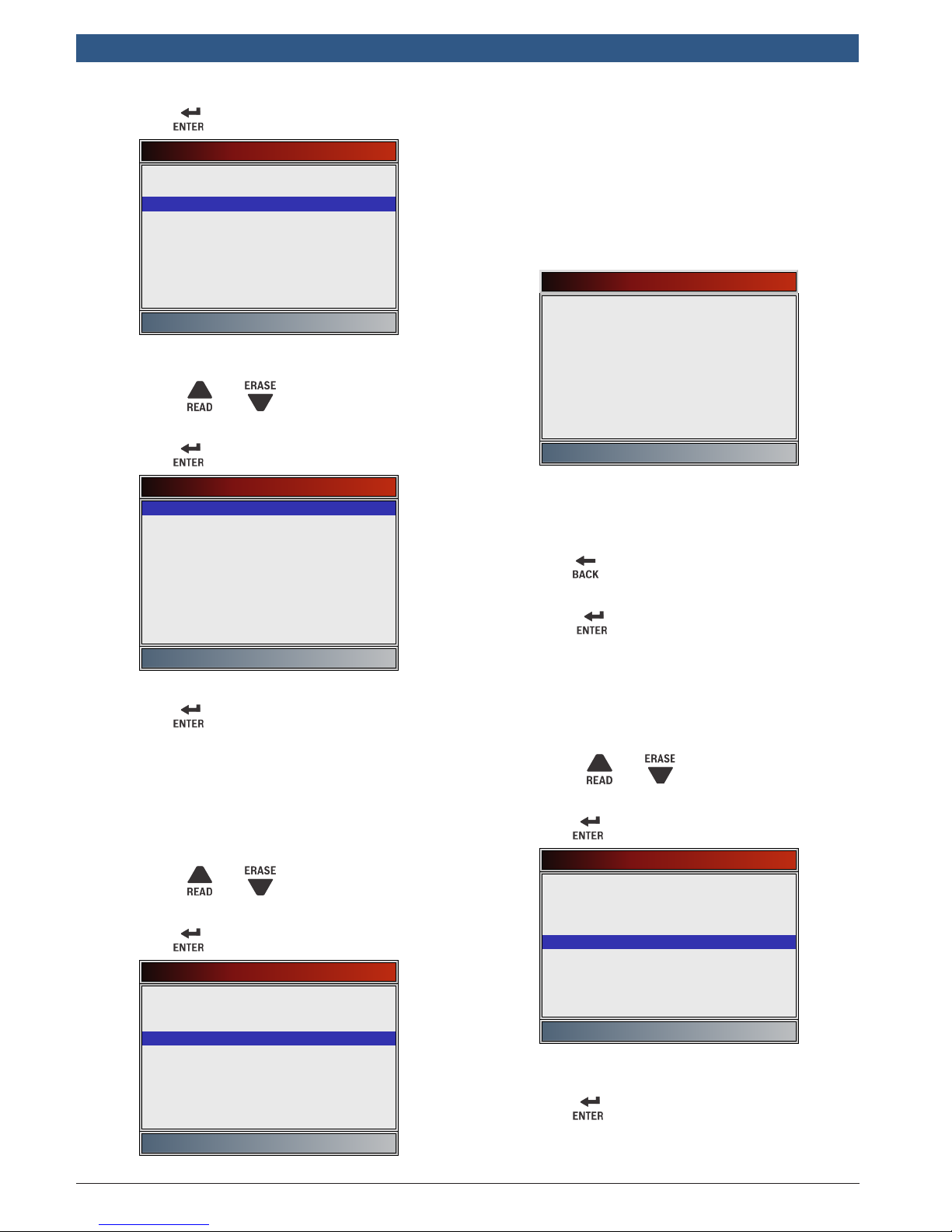

Long PID Names

Long PID Names allows the user to enable/disable the tool

scrolling the complete PID name on the bottom line of the

display while viewing Live Data or viewing Freeze Data.

From System Setup screen:

1. Select Long PID Names.

• Use the and keys until Long PID

Names is highlighted.

580000 | REV. A | 04.2017

en | 12 | User guide

| OBD 2220

Info Scan

• Press .

System Setup

English/Metric

Language Setup

Long PID Names

Tool Information

Display Test

Keypad Test

Memory Test

Program Mode

2. Select ON or OFF.

• Use the and keys until the desired

option is highlighted.

• Press .

Long PID Names

ON

OFF

• Serial Number (Serial No:)

• Software ID (SW ID:)

• Hardware Version (HW Ver:)

• Boot Version (Boot Ver:)

• Product ID (Prod ID:)

• Board ID (Board ID:)

• Burn Date (Burn Date:)

• Burn Location (Burn Loc:)

a

Serial No

SW ID

HW Ver

Boot Ver

Prod ID

Board ID

Burn Date

Burn Loc

Tool Information

--

773B

01

01

23

35

--/--/--

--

3. Record Tool Information.

• Space is provided inside the front cover of this

manual to write down the scan tool information.

4. Return to System Setup menu.

• Press

or

3. Save Long PID Names setting.

• Press .

Tool Information

Tool Information allows the user to view specific tool

information that may be needed when contacting customer service.

From System Setup screen:

1. Select Tool Information.

• Use the and keys until Tool Informa-

tion is highlighted.

• Press .

System Setup

English/Metric

Language Setup

Long PID Names

Tool Information

Display Test

Keypad Test

Memory Test

Program Mode

2. View information.

580000 | REV. A | 04.2017

• press .

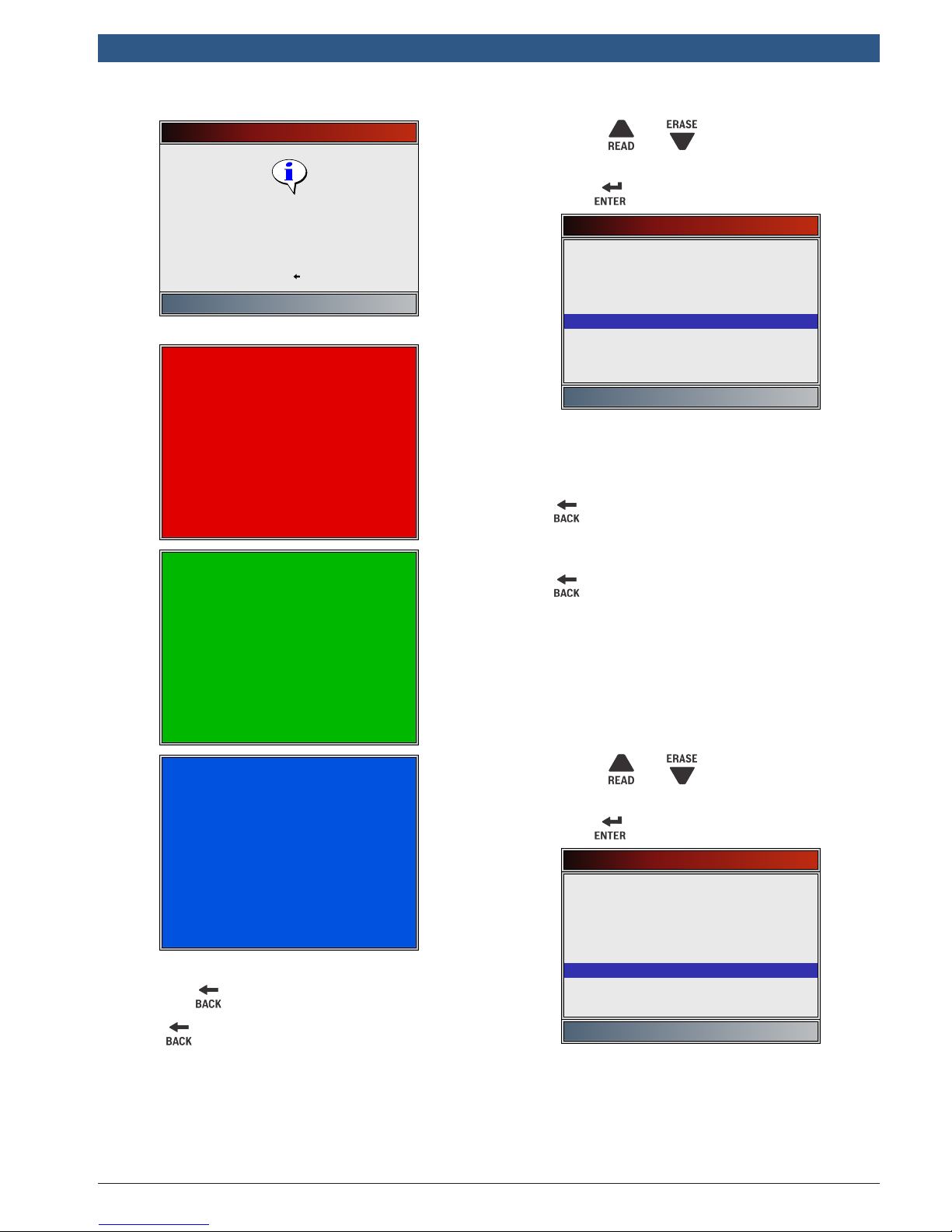

Display Test

The Display Test is used to check the display. The test

fills every pixel of the display with a solid color.

From System Setup screen:

1. Select Display Test.

• Use the and keys until Display Test is

highlighted.

• Press .

System Setup

English/Metric

Language Setup

Long PID Names

Tool Information

Display Test

Keypad Test

Memory Test

Program Mode

2. Start Display Test.

• Press .

3. Look for missing spots.

• The first screen displayed says, “Check for

missing spots in the display.”

Bosch Automotive Service Solutions Inc.

OBD 2220 Info Scan | User guide | 13 | en

Display Test

Check for missing spots in

the display

Press BACK to exit

• Solid red, green, and blue screens are displayed.

• Use the and keys until Keypad Test is

highlighted.

• Press .

System Setup

English/Metric

Language Setup

Long PID Names

Tool Information

Display Test

Keypad Test

Memory Test

Program Mode

2. Press a key.

• The on-screen key will appear depressed, and

the key name will appear bold.

• will return the tool to the System Setup

screen.

• If the System Setup menu does not return, the

• These four screens will continue in succession

until is pressed.

4. Press to exit the test and return to the System

Setup menu.

Keypad Test

The Keypad Test is used to verify that the keys are work-

ing correctly.

From System Setup screen:

1. Select Keypad Test.

key is not functioning correctly.

Memory Test

The Memory Test will test RAM and flash ROM. Run the

Memory Test if the tool has trouble:

• Playing back recorded data.

• Displaying trouble code definitions.

From System Setup screen:

1. Select Memory Test.

• Use the and keys until Memory Test is

highlighted.

• Press .

System Setup

English/Metric

Language Setup

Long PID Names

Tool Information

Display Test

Keypad Test

Memory Test

Program Mode

• Memory Test may take several minutes to complete.

• Memory Test results display:

– If no problems were detected, then

“Passed” is displayed.

– If RAM fails, an error message is shown.

Bosch Automotive Service Solutions Inc.

580000 | REV. A | 04.2017

Loading...

Loading...