Page 1

OBD 100

en

Original instructions

EOBD & CAN Scan Tool

Page 2

2 | OBD 100 | Symbols used | OBD 100 | 3

en

Content English

1. Symbols used 3

1.1 In the documentation 3

1.1.1 Warning notices - Structure and meaning 3

1.1.2 Symbols in this documentation 3

1.2 On the product 3

2. User information 3

2.1 Terms of warranty 3

2.2 Exemption from liability 3

2.3 Data and software 3

3. Product description 4

3.1 Intended use 4

3.2 Prerequisites 4

3.3 Scope of delivery 4

3.4 Description of device 4

3.4.1 Button panel 4

3.4.2 OBD diagnostic connector 4

3.5 Cleaning 4

4. All you need to know about OBD 5

4.1 What are OBD, OBD II, OBD-2 and EOBD 5

4.2 Is my vehicle provided with OBD 5

4.3 Where is the OBD diagnostic socket

located 5

4.4 Why and when does the malfunction

indicator light (MIL) come on 5

4.5 What are trouble codes 6

4.5.1 Trouble code structure 6

4.5.2 Stored trouble codes 6

4.5.3 Pending code (Pnd) 6

4.5.4 Confirmed code (Cnf) 6

4.5.5 Permanent code (Prm) 6

4.5.6 Erasing trouble codes 7

5. Operation 7

5.1 Safety information 7

5.2 Connection to vehicle 8

5.3 Functions in main menu 8

5.4 Codes (trouble codes) 9

5.4.1 Reading trouble codes 9

5.4.2 Erasing trouble codes 9

5.5 Live data (PID display) 10

5.6 MIL status (malfunction indicator light) 11

5.7 I/M monitors 11

5.8 Freeze frame (data) 12

5.9 VIN (vehicle identification number) 12

5.10 Faults 12

6. Decommissioning 13

6.1 Change of location 13

6.2 Disposal and scrapping 13

7. Technical data 13

7.1 Dimensions and weights 13

7.2 Temperature and humidity 13

7.2.1 Ambient temperature 13

7.2.2 Humidity 13

7.3 Electromagnetic compatibility (EMC) 13

8. Glossary 14

9. PID definitions 16

569624 Rev "A" 2013-12-19

|

Robert Bosch GmbH

Page 3

Symbols used | OBD 100 | 3 en

1. Symbols used

1.1 In the documentation

1.1.1 Warning notices -

Structure and meaning

Warning notices warn of dangers to the user

or people in the vicinity. Warning notices also

indicate the consequences of the hazard as well

as preventive action. Warning notices have the

following structure:

Warning

symbol

The key word indicates the likelihood of

occurrence and the severity of the hazard in the

event of non-observance:

1.1.2 Symbols in this documentation

Symbol Designation Explanation

KEY WORD – Nature and source of

hazard!

Consequences of hazard in the event

of failure to observe action and

information given.

¶ Hazard prevention action and

information.

Key word Probability of

DANGER Immediate

WARNING Possible

CAUTION Possible dangerous

!

i

1.

2.

e

"

occurrence

impending danger

impending danger

situation

Attention Warns about possible property

Information Practical hints and other

Multi-step

operation

One-step

operation

Intermediate

result

Final result There is a visible final

Severity of danger

if instructions not

observed

Death or severe

injury

Death or severe

injury

Minor injury

damage.

useful information.

Instruction consisting of

several steps.

Instruction consisting of one

step.

An instruction produces a

visible intermediate result.

result on completion of the

instruction.

2. User information

These operating instructions describe the

functions of the OBD 100 and contain step-bystep directions for use of the OBD 100. Study

and observe these operating instructions in full

before using the OBD 100. It is also essential

to heed all the vehicle manufacturer's safety

instructions and information.

2.1 Terms of warranty

The warranty is expressly restricted to the

first purchasers of Bosch electronic diagnostic

testers (referred to in the following as units). A

2-year (24-month) warranty against material and

manufacturing defects applies to Bosch units as

of the date of delivery. This warranty does not

apply to any units used incorrectly, modified or

employed for a purpose for which they are not

intended or which deviates from that described

in the usage instructions. The sole course of

action in the event of a defective unit is repair or

replacement by Bosch. Under no circumstances

is Bosch liable for direct, indirect, special and

exemplary damages or consequential damages

(including lost profits) whether this is based

on warranty, contract, tort or any other legal

theory.

2.2 Exemption from liability

The above warranty supersedes all other

guarantees made explicitly or implicitly,

including guarantees of marketability or

suitability for a particular area of application.

2.3 Data and software

The system software is protected by copyright.

Users have no rights or claims to the system

software other than a restricted right of use

which can be revoked by Bosch. The system

software must not be passed on or disclosed

without the written consent of Bosch. Copying

of the system software is not permissible.

1.2 On the product

! Observe all warning notices on products and

ensure they remain legible.

569624 Rev "A"

| Robert Bosch GmbH

2013-12-19

Page 4

4 | OBD 100 | Product description All you need to know about OBD | OBD 100 | 5

en

3. Product description

3.1 Intended use

The OBD 100 reads and displays emissionrelated diagnostic data via the OBD interface

of gasoline and diesel passenger vehicles. It is

also possible to erase or reset trouble codes

and to display additional electronic control unit

information. The diagnostic data can help to

establish the cause of problems in the vehicle.

! The OBD 100 is only to be used with the

vehicle stationary. Use whilst driving is

prohibited.

3.2 Prerequisites

OBD interface (OBD-2 or EOBD) in the vehicle

to be tested (refer also to Section "4.1 What are

OBD, OBD II, OBD-2 and EOBD").

3.3 Scope of delivery

Designation Order number

OBD 100 diagnostic tester SP02000002

Original operating instructions 569624 Rev "A"

Tab. 1: Scope of delivery

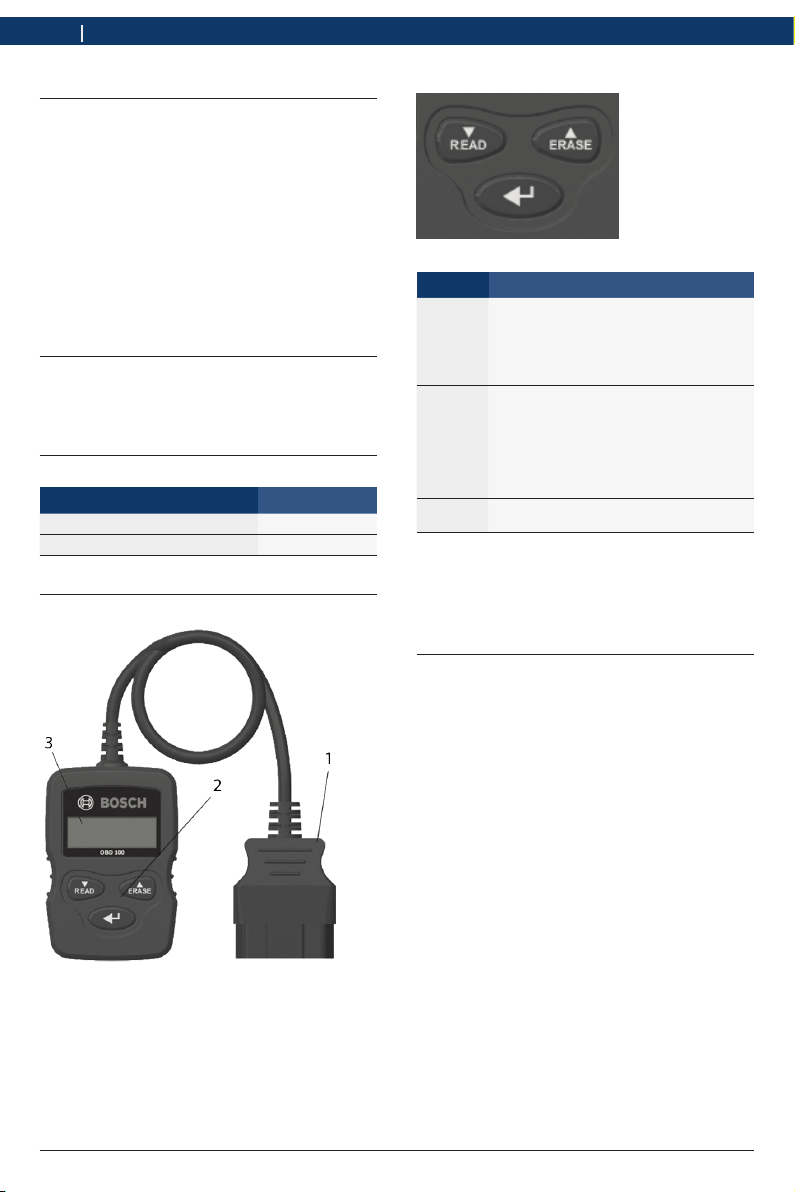

3.4 Description of device

3.4.1 Button panel

Fig. 2: OBD 100 buttons

Button Function

READ

ERASE

Tab. 2: Buttons and their functions

R Scrolls down through the screen dis-

play when ↓ or ↕ appears on the

screen.

R Reading of electronic control unit diag-

nostic data (press and hold for 2 seconds).

R Scrolls up through the screen display

when ↑ or ↕ appears on the screen.

R Erasing of trouble codes in electron-

ic control unit (press and hold for 3

seconds).

R Resetting of inspection and main-

tenance monitors in electronic control unit.

E

R Go to function selected.

R Return to main menu.

3.4.2 OBD diagnostic connector

This connects the OBD 100 to the OBD

diagnostic socket in the vehicle.

Fig. 1: OBD 100

1 OBD diagnostic connector

2 Button panel

3 LCD (two-line)

569624 Rev "A" 2013-12-19

|

3.5 Cleaning

! Do not use abrasive cleaning agents and

coarse workshop cloths.

¶ The housing is only to be cleaned with a soft

cloth and neutral cleaning agents.

Robert Bosch GmbH

Page 5

All you need to know about OBD | OBD 100 | 5 en

4. All you need to know

about OBD

4.1 What are OBD, OBD II, OBD-2

and EOBD

OBD (on-board diagnosis) means that

R Emission-related components and systems

are monitored by the vehicle whilst driving

R Any malfunctions are recorded and indicated

by a warning lamp (MIL)

R This information can be read by a diagnostic

tester

i A further purpose of OBD is to protect

vulnerable components such as catalytic

converters.

In these operating instructions, OBD is always

used to refer to the standard OBD-2 (OBD II).

OBD-2 has been obligatory in the USA for all

new vehicles since 1st January 1996. In the EU,

OBD-2 was introduced for new vehicles with

gasoline engine in January 2001 with the EURO3 standard and for diesel vehicles in January

2004. EOBD is the abbreviation for European

on-board diagnosis based on OBD-2.

The OBD diagnostic system is integrated into the

electronic control unit and constantly monitors

defined emission-related components in the

vehicle. The malfunction indicator light (MIL)

informs the driver of OBD faults reported by the

electronic control unit.

A minimum of five monitoring systems are

provided:

R Emission-related components

R Missing combustion

R Fuel system

R Upstream and downstream Lambda sensors

R Catalytic converter efficiency

R Exhaust gas recirculation

R Secondary air system

The following are monitored once per drive

cycle:

R Lambda sensor function

R Catalytic converter function

i Speed, temperature and Lambda sensor

values can also be read out by way of the

OBD diagnostic socket.

4.2 Is my vehicle provided with OBD

In the EU, OBD-2 was introduced for new vehicles

with gasoline engine in January 2001 with the

EURO-3 standard and for diesel vehicles in

January 2003.

i Vehicles manufactured before these dates

may however also be provided with OBD.

4.3 Where is the OBD diagnostic socket located

The OBD diagnostic socket is usually situated

in the driver's footwell in the area of the center

console or in the glove compartment.

i The installation location can also be looked

up in the owner's manual of the vehicle

concerned or found in the internet.

4.4 Why and when does the malfunction indicator light (MIL)

come on

The malfunction indicator light must come on

briefly when switching on the ignition. The

malfunction indicator light must go out at the

latest when the engine is started. The MIL status

(malfunction indicator light "On" or "Off") is

read from the vehicle electronic control unit.

If the vehicle has detected an emission-related

fault, the status is set to "faulty". It is then no

longer possible to pass the exhaust emission

test. In such cases the malfunction indicator

light is permanently lit to show the driver that

the vehicle should be taken to a workshop.

The following are permanently monitored:

R Missing combustion

R Fuel system (injection times)

R Circuits for emission-related components

569624 Rev "A"

| Robert Bosch GmbH

2013-12-19

Page 6

6 | OBD 100 | All you need to know about OBD All you need to know about OBD | OBD 100 | 7

en

4.5 What are trouble codes

The OBD trouble codes (DTC) are defined in

SAE J2012 and ISO 15031-6. Manufacturerspecific trouble codes can be defined by vehicle

manufacturers.

A trouble code is a 5-position code made up of

a letter and four digits. A distinction is made

between standard trouble codes which may

occur with all vehicle makes and manufacturerspecific trouble codes specified by vehicle

manufacturers for certain vehicle models.

i A plain language text outlining the cause of

the problem can be assigned to each trouble

code.

4.5.1 Trouble code structure

i The structure of the trouble codes is shown in

the following table. This information facilitates

trouble-shooting in situations for which no

trouble code description is provided.

Trouble codes are 5-position codes.

Example:

P 0 1 22 Throttle position sensor signal too low

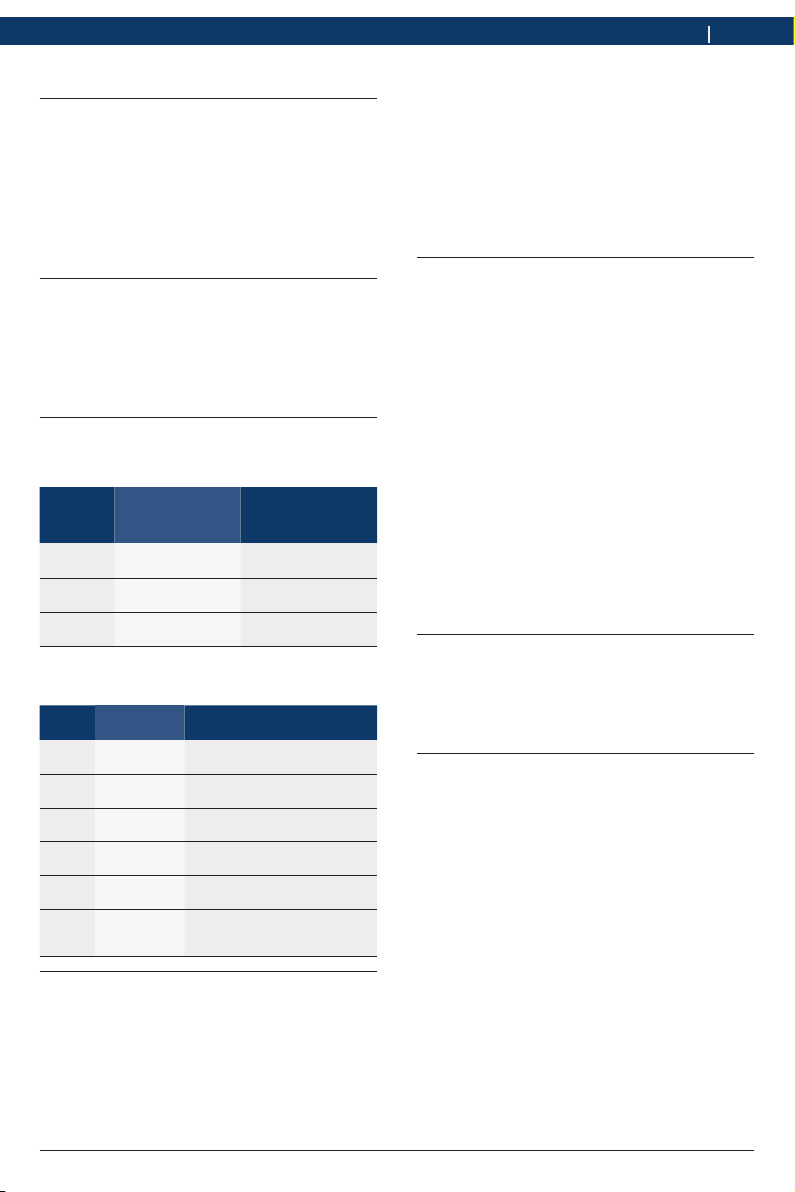

Pos. Value Description

1 B

2

Example

for P

3

Example

for P0

4, 5 00 – 99 Identification of individual

Tab. 3: Trouble code structure

Body

C

Chassis

P

Powertrain

U

Network

0, 2

Trouble code defined by ISO / SAE

1

Trouble code defined by

manufacturer

3

Trouble code defined by ISO / SAE

or by manufacturer

0 – F

Grouped by systems

0 – 2

Fuel air metering

3

Ignition system

4

Auxiliary emission controls

5

Vehicle speed and idle control

6

Computer and output signals

7 – 9

Transmission

A – C

Hybrid

D – F

Reserved for ISO / SAE

components

4.5.2 Stored trouble codes

Stored trouble codes (DTC) are trouble codes

which have been stored in the electronic control

unit (ECU). The description of the trouble

code and the number of the electronic control

unit with the designation of its origin are also

displayed.

i If a trouble code has been set which causes

the malfunction indicator light (MIL) to come

on, the electronic control unit stores the

current values of the sensors at the time at

which the fault occurred.

4.5.3 Pending code (Pnd)

The first time a fault occurs this is stored

as a pending code in the fault memory. If a

pending code is confirmed in the second drive

cycle, it becomes a confirmed code. A pending

code stored in the electronic control unit is

automatically erased after 40 drive cycles

if the prevailing operating conditions were

the same as when the trouble code was set.

Otherwise the pending code is erased after

80 engine cycles. Such trouble codes report

those faults which have occurred during a drive

cycle but which were not sufficient to cause a

trouble code to be stored, i.e. not causing the

malfunction indicator light to come on.

4.5.4 Confirmed code (Cnf)

If a pending code is confirmed in the second

drive cycle, it becomes a confirmed code and

the malfunction indicator light comes on.

4.5.5 Permanent code (Prm)

Permanent codes are a special form of confirmed

codes. Permanent codes have only been set by

vehicles since 2010, which means that they are

not supported by all vehicles.

i Permanent codes cannot be erased with a

diagnostic tester or by disconnecting the

battery voltage. The problem must have been

rectified and must not have occurred again for

the trouble code to be automatically deleted

from the fault memory by the electronic control

unit.

569624 Rev "A" 2013-12-19

|

i The presence of a permanent code will cause

the vehicle to fail an Inspection or exhaust

emission test.

Robert Bosch GmbH

Page 7

All you need to know about OBD | OBD 100 | 7 en

4.5.6 Erasing trouble codes

"Erase trouble codes" erases all pending and

confirmed codes from the fault memory.

! Before erasing trouble codes it must be

remembered that this procedure also resets

all the freeze frame data and the status of the

on-board monitoring (Readiness codes). As

a result, exhaust emission testing performed

directly after erasing the trouble codes may not

be passed by reading out the OBD diagnostic

data, as the vehicle has not yet completed its

internal tests. Additional testing (exhaust gas

measurement or sensor testing) is required in

such cases.

Erasing the trouble codes also deletes the

following information stored in the electronic

control unit:

R Number of trouble codes

R Freeze frame data

R Status of system monitoring tests

R Engine running time (in minutes) with activated

malfunction indicator light since trouble codes

were last erased.

5. Operation

5.1 Safety information

! The OBD 100 can only read and recognize

emission-related diagnostic data and

faults. It is not possible to read and display

information or faults relating to airbags, the

braking system, steering or other important

vehicle functions. The vehicle is therefore

to be taken to a workshop in the event of

any vehicle reports which are not emissionrelated.

¶ Pay attention to the warnings, instructions

and service procedures of the vehicle

manufacturer.

¶ The OBD 100 is not intended for use by

anyone (including children) with physical,

sensory or mental disabilities or without

the necessary experience and/or knowledge

unless they are supervised by a person

responsible for their safety or have received

instructions from this person on how to use

the OBD 100.

¶ Make sure the OBD 100 is always kept in a

safe place.

¶ Never expose the OBD 100 to direct sunlight.

¶ Keep oils, greases, moisture, rainwater and

the like away from the OBD 100. Avoid all

contact with water or other liquids. Water

could cause a short circuit and damage both

the vehicle to be tested and the OBD 100.

¶ Make sure the OBD 100 and the OBD

diagnostic connector are dry before

connecting the OBD 100 to the vehicle.

¶ Never connect the OBD 100 to a vehicle with

wet hands.

¶ Secure the vehicle to stop it rolling away.

¶ Prior to vehicle testing make sure the

transmission is set to PARK (automatic) or

NEUTRAL (manual) and that the handbrake

is applied.

¶ Unless otherwise stated, the ignition is

always to be set to OFF on connecting and

disconnecting electrical components.

¶ The OBD 100 is maintenance-free and has no

exchangeable replacement parts. It is thus

not necessary to open the OBD 100.

¶ Make sure the OBD 100 is not damaged in

any way before connecting the OBD 100 to

the vehicle.

569624 Rev "A"

| Robert Bosch GmbH

2013-12-19

Page 8

8 | OBD 100 | Operation Operation | OBD 100 | 9

en

¶ Never route the OBD diagnostic cable over

sharp edges or hot surfaces.

¶ Ensure adequate ventilation if the OBD 100 is

used with the engine running.

¶ In Germany and other EU countries it is not

permissible to operate the OBD 100 whilst

driving.

¶ Pull the OBD diagnostic connector and not

the cable to disconnect the OBD 100 from

the vehicle.

5.2 Connection to vehicle

i The OBD 100 is supplied with power solely by

way of the vehicle OBD interface.

1. Locate the OBD diagnostic socket in the

vehicle.

i The OBD diagnostic socket is usually situated

in the driver's footwell in the area of the

center console or in the glove compartment.

The installation location can also be looked

up in the maintenance manual of the vehicle

concerned or found in the internet.

5.3 Functions in main menu

2. Remove the cover over the OBD diagnostic

socket if necessary.

3. Switch on the ignition (position 2).

! Do not start the engine.

4. Insert the OBD diagnostic connector of the

OBD 100 in the OBD diagnostic socket of the

vehicle.

The OBD 100 is switched on.

The OBD diagnostic data are read out.

" The main menu appears.

i Use READ or ERASE to select the

corresponding main menu functions.

Main menu Description and function Notes Read Erase Reset

1) Codes Reading, erasing and

2) Live data Display of emission-

3) MIL STATUS Display of stored MIL

4) I/M monitor Display of current status

5) Freeze frame Display of PID data if a

6) VIN Display of the vehicle

Tab. 4: Functions in main menu

569624 Rev "A" 2013-12-19

resetting of stored vehicle

trouble codes.

related diagnostic data.

status of electronic

control unit.

of emission-related

Readiness codes.

trouble code has been

set.

identification number

stored in the electronic

control unit.

|

Different functions are available depending

on the trouble code (pending, confirmed

and permanent) and the vehicle connected.

The information (PID) displayed depends

on the vehicle.

Use whilst driving is prohibited.

The status of the malfunction indicator light

(MIL) is read from the electronic control

unit in the vehicle and can be compared

to the display of the malfunction indicator

light in the vehicle.

The Readiness codes are evaluated in the

exhaust emission test.

This menu item can be used to check

whether all emission-related tests have

been performed and passed.

If a trouble code has been set, the data

stored at the time of occurrence and

transmitted are displayed.

The VIN display can be used to check

whether the vehicle identification number

stored in the electronic control unit

matches the vehicle identification number

of the vehicle.

x x x

x – –

x – –

x – x

x x –

x – –

Robert Bosch GmbH

Page 9

Operation | OBD 100 | 9 en

5.4 Codes (trouble codes)

5.4.1 Reading trouble codes

1. Switch on the ignition (position 2).

2. Connect the OBD 100 to the vehicle.

Data are read.

3. In the main menu select "1) Codes" and

confirm with E.

i Alternatively, press and hold READ for

2seconds.

i If the vehicle does not have any DTCs, "No

Codes" will be displayed.

One or more trouble codes is/are displayed.

Fig. 3: Trouble code display - description from top left

to bottom right

1 Trouble code

2 Type of trouble code (see Tab. 5)

3 Trouble code number, continuously changing display

(see Tab. 6)

4 Note on scrolling (see Tab. 7)

5 Trouble code description (moving message with long

descriptions)

Type Function

Pnd Pending code

Cnf Confirmed code

Prm Permanent code

Tab. 5: Type of trouble code

Number Function

Mod ## Indicates the module (electronic control

#/# Indicates the sequence of the trouble code

Tab. 6: Trouble code number

Scroll Function

↑

↓

↕

Tab. 7: Scrolling

unit) which transmitted the trouble code.

## stands for consecutive numbering of

electronic control units

and the number (trouble code x of n).

Example: The display 2/9 means the 2nd of

9 trouble codes reported by the electronic

control unit.

Scrolling up possible.

Scrolling down possible.

Scrolling up and down possible.

5.4.2 Erasing trouble codes

! The function "Erase trouble codes" is not to

be performed until the systems have been

fully checked and the trouble codes written

down.

! Do not erase the trouble codes before

establishing whether repair is necessary.

Failure to perform essential repairs

could prove costly and dangerous. If the

malfunction indicator light (MIL) is reset

without the underlying problem having

been rectified, the indicator light will come

on again. If the underlying problem is of a

serious nature, further trouble codes may

be set or the fault may be aggravated if

appropriate action is not taken. It is not

sufficient to just erase the trouble codes and

reset the warning light. The underlying fault

must be rectified.

! Before erasing trouble codes it must be

remembered that this procedure also erases

all the freeze frame data and the status of

the on-board monitoring (status mask). As a

result, exhaust emission testing performed

immediately after erasing may not be

successful if the vehicle has not completed

its internal tests by then.

i Once the vehicle has been serviced any

trouble codes stored can be erased if so

desired. If a trouble code appears again, this

means that the problem has not yet been

rectified or other faults have occurred.

i All trouble codes are displayed with the

corresponding icon.

i Scroll through trouble codes using READ or

ERASE.

569624 Rev "A"

| Robert Bosch GmbH

2013-12-19

Page 10

10 | OBD 100 | Operation Operation | OBD 100 | 11

en

Implementation of the "Erase trouble code"

function results in the following:

R Confirmed and pending codes are erased.

i Permanent codes can only be erased by the

vehicle.

R Freeze frame data results are erased.

R I/M monitors are set to "Not ready".

1. Switch on the ignition (position 2).

2. Connect the OBD 100 to the vehicle

Data are read.

! Do not start the engine. The engine must not

be running when erasing the trouble codes.

3. Press ERASE for 3 seconds.

A confirmation message appears on the

screen.

i Cancel the operation and return to the main

menu by pressing E.

Cancel the operation and read data again

with READ.

4. Press the ERASE button for a further

3seconds to erase trouble codes.

i It may be necessary to drive the vehicle again.

5.5 Live data (PID display)

The Live data function enables parameters

(PID) of the vehicle electronic control unit to

be displayed in real time. A list of the PIDs

supported by the OBD 100 is given in Section 9.

i All values are displayed in metric units.

i Press E to return to the main menu.

1. Switch on the ignition (position 2).

2. Connect the OBD 100 to the vehicle.

Data are read.

3. In the main menu select "2) Live data" with

READ or ERASE and confirm with E.

i If there is more than one electronic control

unit in the vehicle, the OBD 100 displays a

menu for selecting the electronic control unit

for which the Live data are to be displayed.

" PID data are displayed.

Fig. 4: Live data display - description from top left to

bottom right

1 PID

2 Note on scrolling

3 Value, status or note

Symbol Function

Scroll down to the next PID with READ.

↓

Scroll up to the next PID with ERASE.

↑

Scroll down or up to the next PID with

↕

READ or ERASE.

Tab. 8: Scrolling symbols

569624 Rev "A" 2013-12-19

|

i Scrolling through PIDs with READ or

ERASE.

i Section 9 provides an alphabetical list of PIDs

and what they mean.

Robert Bosch GmbH

Page 11

Operation | OBD 100 | 11 en

5.6 MIL status (malfunction indica-

tor light)

The status of the malfunction indicator light

(MIL status) provides an indication of the

status reported ("On" or "Off") by the electronic

control unit with the engine running. This

information can be used to check correct

operation of the malfunction indicator light.

1. Switch on the ignition (position 2).

2. Connect the OBD 100 to the vehicle.

Data are read.

3. Start the engine.

4. In the main menu select "3) MIL-Status" with

READ or ERASE.

" The status ON or OFF is displayed.

i If the malfunction indicator does not light

with the engine running in MIL ON status,

there is a problem in the malfunction

indicator circuit in the vehicle.

5.7 I/M monitors

The I/M monitor function is used for inspection

and maintenance monitoring of the emissionrelated functions.

The OBD 100 supports the following monitoring

functions (Readiness codes):

Function Description

Misfire Monitor

Fuel System

Comprehen Comp

Catalyst

Htd Catalyst

Evaporative Sys

Second Air Sys

A/C Sys Refrig

Oxygen Sensor

Htd 02 Sensor

EGR/VVT

NMHC Catalyst

NOX Treatment

Boost Pressure

Exhaust Gas Sen

PM Filter

Tab. 9: I/M monitors

Misfire Monitor

Fuel System Monitor

Comprehensive Components

Monitor

Catalyst Monitor

Heated Catalyst Monitor

Evaporative System Monitor

Secondary Air System Monitor

Air Conditioning Refrigerant

Monitor

Oxygen Sensor Monitor

Oxygen Sensor Heater Monitor

Exhaust Gas Recirculation or

variable valve timing monitor

Non-Methane Hydrocarbon

Catalyst

Nitrogen Oxide Treatment

Boost Pressure

Exhaust Gas Sensor

Particulate Matter Filter

i This is a complete list of the inspection and

maintenance monitors supported by the

OBD 100. The number of monitors depends

on the vehicle. Vehicles with diesel engine

have no oxygen sensor monitors for example.

1. Switch on the ignition (position 2).

2. Connect the OBD 100 to the vehicle

Data are read in.

3. In the main menu select "4) I/M Monitor"

with READ or ERASE and confirm with E.

" Inspection and maintenance monitors for

emission-related functions are displayed.

Fig. 5: I/M monitor display - description from top left

to bottom right

1 I/M monitor (see table 9)

2 Note on scrolling (see table 7)

3 Report on test performed (see table 10)

Report Function

Ready Test has completed

Not ready Test has not completed

N. A. Test not possible for this vehicle

Tab. 10: I/M monitor - reports and function

i Display emission-related tests performed with

READ or ERASE.

i Taking Germany as an example:

To pass an OBD exhaust emission test, all

monitors must be listed as "Ready" or "N. A.".

569624 Rev "A"

| Robert Bosch GmbH

2013-12-19

Page 12

12 | OBD 100 | Operation Decommissioning | OBD 100 | 13

en

5.8 Freeze frame (data)

This provides an image of the operating and

ambient conditions at the moment in time at

which the trouble code was first generated.

Freeze frames are not stored and displayed for

all PIDs. A list of the PID numbers (parameter

IDs) supported by the OBD 100 is given in

Section 9.

1. Switch on the ignition (position 2).

2. Connect the OBD 100 to the vehicle

Data are read in.

3. In the main menu select "5) Freeze Frame" with

READ or ERASE and confirm with E.

Trouble codes are displayed

4. Select the trouble code and confirm with E.

" Freeze frame data are displayed.

i Scroll through the corresponding freeze

frame data using READ or ERASE.

5.9 VIN (vehicle identification

number)

i The VIN function is not supported by all

vehicles.

1. Switch on the ignition (position 2).

2. Connect the OBD 100 to the vehicle.

Data is read.

3. In the main menu select "6) VIN" with

READ or ERASE and confirm with E.

" The vehicle identification number appears as a

moving message.

5.10 Faults

Fault Remedy

LINK ERROR During reading

MIL status

Tab. 11: Faults

Turn the ignition key to the OFF

position for 10 seconds; then

return to the ON position and

press the <READ> button.

Make sure the ignition key is set

to ON (position 2) and not to

ACCESSORIES (position 1).

During erasing

Turn the ignition key to the

OFF position for 10 seconds;

then return to the ON position

and press one of the following

buttons with the ignition key set

to ON (position 2) and not to

ACCESSORIES (position 1):

R Continue erasing operation

with ERASE.

R Cancel erasing operation with

READ (read codes again) or

E (return to main menu).

A trouble code will appear again if

the cause of the problem has not

yet been rectified.

If the MIL status is ON and the

warning light does not come on

with the engine running, there

is a problem in the circuit of

the malfunction indicator light.

It is then advisable to consult a

workshop.

569624 Rev "A" 2013-12-19

|

Robert Bosch GmbH

Page 13

Decommissioning | OBD 100 | 13 en

6. Decommissioning

6.1 Change of location

¶ If the OBD 100 is passed on, all the

documentation included in the scope of

delivery must be handed over together with

the unit.

6.2 Disposal and scrapping

The OBD 100 is subject to the

European directive 2002/96/EC

(WEEE).

Dispose of used electrical and

electronic devices, including

cables, accessories and batteries,

separately from household waste.

¶ Make use of the local return and

collection systems for disposal.

¶ Proper disposal of the OBD 100

prevents environmental pollution

and possible health hazards.

7. Technical data

7.1 Dimensions and weights

Properties Value/Range

Dimensions (H x W x D) 83 x 56 x 19 mm

Weight (without accessories) 0,1 kg

7.2 Temperature and humidity

7.2.1 Ambient temperature

Properties Value/Range

Storage and transportation -25 °C – 60 °C

Function 0 °C – 45 °C

7.2.2 Humidity

Properties Value/Range

Storage and transportation 20 % – 80 %

Function 20 % – 80 %

7.3 Electromagnetic compatibility (EMC)

The OBD 100 is a class B product as per

EN 61 326-1.

3.3 x 2.2 x 0.7 inch

0.2 lb

-13 °F – 140 °F

32 °F – 113 °F

569624 Rev "A"

| Robert Bosch GmbH

2013-12-19

Page 14

14 | OBD 100 | Glossary Glossary | OBD 100 | 15

en

8. Glossary

Cnf Confirmed code

If a pending code is confirmed in the second

drive cycle, it becomes a confirmed code and

the malfunction indicator light (MIL) comes on.

DTC Diagnostic trouble code

A trouble code is a 5-position code made up of

a letter and four digits. A distinction is made

between standard trouble codes which may

occur with all vehicle makes and manufacturerspecific trouble codes specified by vehicle

manufacturers for certain vehicle models.

Aplain language text outlining the cause of the

problem can be assigned to each trouble code.

ECU Electronic control unit

EOBD European On-Board diagnosis

EOBD is not an official term but is often used to

refer to OBD-2 in conjunction with EU vehicles.

For further information refer to Section 4.1.

Drive cycle

A drive cycle commences on starting the engine

(warm or cold) and ends on switching off the

engine.

Freeze frame data (FFD)

The following data (freeze frame data) are

stored in connection with the first pending

code:

R Vehicle speed

R Coolant temperature

R Intake manifold pressure

R Engine load

R Mixture formation adaptation value

R Lambda control status (control loop)

R Time since trouble first recorded

The data represent a sort of snapshot of the

prevailing operating and ambient conditions at

the moment in time at which the trouble was

detected. A freeze frame data set remains stored

in the memory even if another emission-related

trouble code is stored (this does not however

apply to trouble codes resulting from misfiring

or faults in the fuel system). Freeze frame data

stored for a trouble code arising from misfiring

or a fuel system fault overwrite all previously

stored data and cannot be overwritten

themselves.

I/M monitors

The Readiness code is used in OBD to refer

to the testing of emission-related functions.

Since the introduction of OBD-2 all electrical

components have been continuously checked for

proper operation. In addition, complete systems

(e.g. exhaust gas recirculation) are checked

by way of diagnostic routines which are not

constantly active. The Readiness code is set as

a means of checking whether these diagnostic

routines have been performed.

The Readiness code gives an indication of

whether a diagnosis result has been supplied

for all individual systems since the fault memory

was last erased or the electronic control unit

was replaced.

The following are permanently monitored:

R Missing combustion

R Fuel system (injection times)

R Circuits for emission-related components

The following are monitored once per drive

cycle:

R Lambda sensor function

R Catalytic converter function

If the functions of systems and components

are tied to certain operating conditions, these

are only checked on passing the corresponding

operating points (speed, load or temperature

thresholds).

569624 Rev "A" 2013-12-19

|

i The Readiness code was introduced as a

means of revealing manipulation. It makes

it possible to see whether the fault memory

was erased by disconnecting the battery for

example.

Robert Bosch GmbH

Page 15

Glossary | OBD 100 | 15 en

MIL Malfunction indicator light

The malfunction indicator light (also called

malfunction lamp or engine warning lamp) comes

on:

R If the ignition key is in position II (bulb check

function).

R If a fault occurs during the electronic control

unit self-test.

R If an emission-related fault occurs in two

consecutive drive cycles.

R If a fault (misfiring) occurs which results

in cylinder deactivation, i.e. for catalytic

converter protection (the MIL flashes in this

case).

i The malfunction indicator light goes out

automatically in the fourth drive cycle if

the fault has no longer occurred in three

consecutive drive cycles.

OBD On-Board diagnosis

In these operating instructions, OBD is always

used to refer to the standard OBD-2. In the EU,

OBD-2 (EOBD) was introduced for new vehicles

with gasoline engine in January 2001 with the

EURO-3 standard and for diesel passenger

vehicles in January 2003.

i Vehicles marketed before these dates may

however also be provided with OBD.

Prm Permanent code

Permanent codes are a special form of

confirmed codes. Permanent codes were first

set by vehicles around 2010, which means that

they are not supported by all vehicles. Whereas

confirmed codes can be erased by way of the

diagnostic tester, this is not possible in the

case of permanent codes. Permanent codes are

erased by the vehicle if the electronic control

unit has decided that the fault no longer exists.

Readiness code Refer to I/M monitors

VIN Vehicle identification number

The vehicle identification number is the serial

number assigned to a vehicle at the factory.

The vehicle identification number is marked

on the driver side of the dashboard and can

be seen from outside the vehicle. The vehicle

identification number contains information

on the vehicle, as well as the body and engine

code numbers for example. Provided that the

electronic control unit has not been replaced,

the vehicle identification number displayed in

the OBD 100 must coincide with the vehicle

identification number of the vehicle. Matching

numbers ensure that the correct diagnostic data

are being displayed. It is advisable to consult a

workshop if the vehicle identification numbers

do not match.

OBD-2 Refer to OBD

PID Parameter identification

Status information, actual values and electronic

control unit values calculated by the system are

output by way of PID (refer also to Section 9).

Pnd Pending code

The first time a fault occurs this is stored as a

pending code in the fault memory. This fault

appeared during a drive cycle but was not

sufficient to set the MIL status to ON.

569624 Rev "A"

| Robert Bosch GmbH

2013-12-19

Page 16

16 | OBD 100 | PID definitions PID definitions | OBD 100 | 17

en

9. PID definitions

PID PID description

ABS FRP Absolute Fuel Rail Pressure

ABS LOAD Absolute Load Value

ABS TPS B, C Throttle Position B, C

ABSLT TPS Absolute Throttle Position

ACC POS D Accelerator Pedal D, E, F

ACC POS REL

AECD1_TIME1,

TIME 2

AECD10_TIME1,

TIME 2

AECD11_TIME1,

TIME 2

AECD12_TIME1,

TIME 2

AECD13_TIME1,

TIME 2

AECD14_TIME1,

TIME 2

AECD15_TIME1,

TIME 2

AECD16_TIME1,

TIME 2

AECD17_TIME1,

TIME 2

AECD18_TIME1,

TIME 2

AECD19_TIME1,

TIME 2

AECD2_TIME1,

TIME 2

AECD20_TIME1,

TIME 2

AECD3_TIME1,

TIME 2

AECD4_TIME1,

TIME 2

AECD5_TIME1,

TIME 2

AECD6_TIME1,

TIME 2

AECD7_TIME1,

TIME 2

AECD8_TIME1,

TIME 2

AECD9_TIME1,

TIME 2

ALCOHOL Alcohol Fuel Percent

BARO PRS Barometric Pressure

BAT_PWR

Relative Accelerator Pedal

Position

Total Run Time with EI-AECD #1

Timer 1 Active, #2 Timer Active

Total Run Time with EI-AECD #10

Timer 1 Active, #2 Timer Active

Total Run Time with EI-AECD #11

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #12

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #13

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #14

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #15

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #16

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #17

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #18

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #19

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #2

Timer 1 Active, #2 Timer Active

Total Run Time with EI-AECD #20

Timer 1 active, #2 Timer Active

Total Run Time with EI-AECD #3

Timer 1 Active, #2 Timer Active

Total Run Time with EI-AECD #4

Timer 1 Active, #2 Timer Active

Total Run Time with EI-AECD #5

Timer 1 Active, #2 Timer Active

Total Run Time with EI-AECD #6

Timer 1 Active, #2 Timer Active

Total Run Time with EI-AECD #7

Timer 1 Active, #2 Timer Active

Total Run Time with EI-AECD #8

Timer 1 Active, #2 Timer Active

Total Run Time with EI-AECD #9

Timer 1 Active, #2 Timer Active

Hybrid Battery Pack Remaining

Life

PID PID description

BP_A_ACT, B_ACT

BP_A_CMD, B_CMD

BP_A_STAT, B_STAT

CACT 11, 12

CACT 21,22

CALC LOAD Calculated Engine Load

CAT TEMP11,

TEMP12

CAT TEMP21,

TEMP22

CLR DIST Distance since erase

CLR TIME Minutes Run since Erase

CLR TRPS Warmups Since Erase

CMD EQ RAT Commanded Equivalence Ratio

COOLANT Engine Coolant Temp

DPF_REG_AVGD

DPF_REG_AVGT

DPF_REG_STAT

DPF_REG_TYP

DPF_REGEN_PCT

DPF1_DP, DPF2_DP

DPF1_INP, DPF2_

INP

DPF1_INT, DPF2_

INT

DPF1_OUTP, DPF2_

OUTP

DPF1_OUTT, DPF2_

OUTT

ECT 1, 2

EGR CMD Comanded EGR

EGR ERR Exhaust Gas Recirculation Error

EGR_A_ACT, B_ACT

EGR_A_CMD, B_

CMD

EGR_A_ERR, B_ERR EGR A Error, B Error

Boost Pressure Sensor A,

Sensor B

Commanded Boost Pressure A,

Pressure B

Boost Pressure A Control Status,

B Control Status

Charge Air Cooler Temperature

Bank 1 Sensor 1 supported,

Sensor 2 supported

Charge Air Cooler Temperature

Bank 2 Sensor 1 supported,

Sensor 2 supported

Cataltic Converter Temp Bank1,

Temp Bank 3

Cataltic Converter Temp Bank2,

Temp Bank 4

Average Distance Between DPF

Regen

Average Time Between DPF

Regen

Diesel Particulate Filter (DPF)

Regen Status

Diesel Particulate Filter (DPF)

Regen Type

Normalized Trigger for DPF

Regen

Diesel Particulate Filter (DPF)

Bank 1 Delta Pressure Ban,k 2

Delta Pressure

Diesel Particulate Filter (DPF)

Bank 1 Inlet Pressure, Bank 2

Inlet Pressure

DPF Bank 1 Inlet Temperature

Sensor, Bank 2 Inlet

Temperature Sensor

Diesel Particulate Filter (DPF)

Bank 1 Outlet Pressure, Bank 2

Outlet Pressure

DPF Bank 1 Outlet Temperature

Sensor, Bank 2 Outlet

Temperature Sensor

Engine Coolant Temperature 1,

Temperature 2

Actual EGR A Duty Cycle/

Position, B Duty Cycle/Position

Commanded EGR A Duty Cycle/

Position, B Duty Cycle/Position

569624 Rev "A" 2013-12-19

|

Robert Bosch GmbH

Page 17

PID definitions | OBD 100 | 17 en

PID PID description

EGRT 11, 21

EGRT 12, 22

EGT 11, 21

EGT 12, 22

EGT 13, 23

EGT 14, 24

EMIS_SUP

ENG RUN Time Since Engine Start

ENG SPEED Engine RPM

EOT Engine Oil Temperature

EP_1, 2

EQ RATIO Equivalence Ratio

EVAP PURGE Commanded EVAP Purge

EVAP VP EVAP Vapor Pressure

EVAP VPA Absolute EVAP Vapor Pressure

FRP_A, B Fuel Rail Pressure A, B

FRP_A_CMD, B_

CMD

FRT_A, B Fuel Rail Temperature A, B

FUEL LEVEL Fuel Level Input

FUEL PRES Fuel Rail Pressure

FUEL SYS 1, 2

FUEL TYPE Fuel Type

FUEL_RATE Engine Fuel Rate

Exhaust Gas Recirculation

Temperature Bank 1 Sensor 1,

Bank 2 Sensor 1

Exhaust Gas Recirculation

Temperature Bank 1 Sensor 2,

Bank 2 Sensor 2

Exhaust Gas Temperature

(EGT) Bank 1 Sensor 1, Bank 2

Sensor 1

Exhaust Gas Temperature

(EGT) Bank 1 Sensor 2, Bank 2

Sensor 2

Exhaust Gas Temperature

(EGT) Bank 1 Sensor 3, Bank 2

Sensor 3

Exhaust Gas Temperature

(EGT) Bank 1 Sensor 4, Bank 2

Sensor 4

Emission requirements to which

vehicle is designed

Exhaust Pressure Sensor Bank

1, Bank 2

Commanded Fuel Rail Pressure

A, B

Fuel System 1 Loop Status,

System 2 Loop Status

PID PID description

FUEL_TIMING Fueling Injection Timing

GPL_STAT Glow Plug Lamp Status

IAF_A_CMD, B_CMD

IAF_A_REL, B_REL

IAT Intake Air Temp

IAT 11, 21

IAT 12, 22

IAT 13, 23

ICP_A, B Injection Control Pressure A, B

ICP_A_CMD, B_

CMD

IDLE_TIME Total Idle Run Time

IGN ADV Timing Advance

LAMBDA11, 21

LAMBDA12, 22

LT FTRM1 Long Term Fuel Trim 1 or 3

LT FTRM2 Long Term Fuel Trim 2 or 4

LT SEC FT1, 2, 3, 4

MAF, A, B Mass Air Flow, A, B

MAP, A, B Manifold Absolute Pressure, A, B

MIL DIST MIL_DIST

MIL STATUS Malfunction Indicator Lamp

MIL TIME Minutes Run by MIL activated

MST Manifold Surface Temperature

N/D_STAT Auto Trans Neutral Drive Status

N/G_STAT

NNTE_Stat NOx NTE control area status

NOX 11, 21

NOX 12,22

Commanded Intake Air Flow A

Control, B Control

Relative Intake Air Flow A

Position, B Position

Intake Air Temperature Sensor

Bank 1 Sensor 1, Bank 2 Sensor

1

Intake Air Temperature Sensor

Bank 1 Sensor 2, Bank 2 Sensor

2

Intake Air Temperature Sensor

Bank 1 Sensor 3, Bank 2 Sensor

3

Commanded Injection Control

Pressure A, B

02 Sensor Lambda Bank 1

Sensor 1, Bank 2 Sensor 1

02 Sensor Lambda Bank 1

Sensor 2, Bank 2 Sensor 2

Long Term Secondary O2 Sensor

Fuel Trim 1, 2, 3, 4

Manual Trans Neutral Gear

Status

NOx Sensor Concentration Bank

1 Sensor 1, Bank 2 Sensor 1

NOx Sensor Concentration Bank

1 Sensor 2, Bank 2 Sensor 2

569624 Rev "A"

| Robert Bosch GmbH

2013-12-19

Page 18

18 | OBD 100 | PID definitions PID definitions | OBD 100 | 19

en

PID PID description

SCR inducement system actual

state 10K history HI1 (0-10000

NOX LEVEL HI, HI1,

HI2, HI3, HI4

NOX_ADS_DESUL

NOX_ADS_REGEN NOx Adsorber Regen Status

NWI_TIME

O2S

O2S11_PCT,

O2S21_PCT

O2S12_PCT,

O2S22_PCT

OBD2 STAT OBD Status

OUT TEMP Ambient Air Temp

PM 11, PM 21

PNTE_Stat PM NTE control area status

PTO STATUS PTO Status

PTO_STAT Power Take Off (PTO) Status

PTO_TIME Total Run Time With PTO Active

REAG_DEMD

REAG_LVL Reagent Tank Level

REAG_RATE Average Reagent Consumption

REL FRP Relative Fuel Rail Pressure

REL TPS Relative Throttle Position

RUN_TIME Total Engine Run Time

SCR REAG DEV,

DEV1, DEV2, DEV3,

DEV4

SCR REAG LOW,

LOW1, LOW2,

LOW3, LOW4

km), 10K history HI2 (1000020000 km), 10K history HI3

20000-30000 km), 10K history

HI4 (30000-40000 km): NOx

emission too high

NOx Adsorber Desulfurization

Status

Total Run Time by the Engien

whicle NOx warning mode is

activated

O2 Voltage or Current indicates

Bank/Sensor

02 Sensor Concentration Bank 1

Sensor 1, Bank 2 Sensor 1

02 Sensor Concentration Bank 1

Sensor 2, Bank 2 Sensor 2

PM Sensor Mass Concentration

Bank 1 Sensor 1, Bank 2 Sensor 1

Average Demanded Reagent

Consumption

SCR inducement system actual

state 10K history DEV1 (0 10000 km), 10K history DEV2

(10000 - 20000 km), 10K history

DEV3 (20000 - 30000 km), 10K

history DEV4 (30000 - 40000

km): deviation of reagent

consumption

SCR inducement system actual

state 10K history LOW1 (0 10000 km), 10K history LOW2

(10000 - 20000 km), 10K history

LOW3 (20000 - 30000 km), 10K

history LOW4 (30000 - 40000

km): reagent level too low

PID PID description

SCR inducement system actual

SCR REAG

WRONG, WRONG1,

WRONG2,

WRONG3,

WRONG4

SCR SYS ACTIVE

SCR_DIST_1D

SCR_DIST_1N, 2N,

3N, 4N

SECOND AIR Secondary Air Status

ST FTRM Fuel Trim Bank/Sensor

ST FTRM1, 3 Short Term Fuel Trim1 or 3

ST FTRM2, 4 Short Term Fuel Trim2 or 4

ST SEC

FT1, 2, 3, 4

TAC_A_CMD, B_

CMD

TAC_A_REL, B_REL

TCA_CINP, TCB_

CINP

TCA_CINT, TCB_

CINT

TCA_COUT, TCB_

COUT

TCA_RPM, TCB_

RPM

TCA_TCOUT, TCB_

TCOUT

TCA_TINT, TCB_

TINT

THROT CMD

TP G Absolute Throttle Position G

TQ_ACT Actual Engine - Percent Torque

TQ_DD

TQ_MAX1, 2, 3, 4, 5

TQ_REF Engine Reference Torque

TROUB CODE Code causing the Freeze Frame

VEH SPEED Vehicle Speed

state 10K history WRONG1

(0 - 10000 km), 10K history

WRONG2 (10000 - 20000 km),

10K history WRONG3 (20000

- 30000 km), 10K history

WRONG4 (30000 - 40000 km):

incorrect reagent

SCR inducement system actual

state: inducement system active

Distance travelled in current 10K

block (0 - 10000 km)

Distance travelled while

inducement system active in

current 10K block 1N (0 - 10000

km), 20K block 2N (10 - 20000

km), 30K block 3N (20 - 30000

km), 40K block 4N (30 - 40000

km)

Short Term Secondary O2

Sensor Fuel Trim 1, 2, 3, 4

Commanded Throttle Actuator A

Control, B Control

Relative Throttle A Position, B

Position

Turbocharger Compressor Inlet

Pressure Sensor A, Pressure

Sensor B

Turbocharger A Compressor Inlet

Temperature, Turbocharger B

Turbocharger A Compressor

Outlet Temperature,

Turbocharger B

Turbocharger A RPM, B RPM

Turbocharger A Turbine Outlet

Temperature, Turbocharger B

Turbocharger A Turbine Inlet

Temperature, Turbocharger B

Commanded Throttle Actuator

Control

Driver's Demand Engine Percent Torque

Engine Percent Torque At Point

1 (Idle), Point 2, 3, 4, 5

569624 Rev "A" 2013-12-19

|

Robert Bosch GmbH

Page 19

PID PID description

VGT_A_ACT, B_ACT

VGT_A_CMD, B_

CMD

VGT_A_STAT, B_

STAT

VPWR Control Module Voltage

WG_A_ACT, B_ACT Wastegate A Position, B Position

WG_A_CMD, B_

CMD

TQ_DD Driver's demand engine percent

TQ_ACT Actual engine percent torque

TQ_MAX1,

MAX2, MAX3,

MAX4, MAX5

TQ_REF Engine reference torque

VGT_A_ACT Variable geometry turbo A

VGT_A_CMD Commanded variable geometry

VGT_A_STAT Variable geometry turbo A

VGT_B_ACT Variable geometry turbo B

VGT_B_CMD Commanded variable geometry

VGT_B_STAT Variable geometry turbo B

VPWR Control module voltage

WG_A_ACT Wastegate A position

WG_A_CMD Commanded wastegate A

WG_B_ACT Wastegate B position

WG_B_CMD Commanded wastegate B

Tab. 12: PID definitions

Variable Geometry Turbo A

Position, Turbo B

Commanded Variable Geometry

Turbo A Position, Turbo B

Variable Geometry Turbo A

Control Status, Turbo B

Commanded Wastegate A

Control, B Control

torque

Engine percent torque at

idle point 1, 2, 3, 4, 5

position

turbo A position

control status

position

turbo B position

control status

control

control

PID definitions | OBD 100 | 19 en

569624 Rev "A"

| Robert Bosch GmbH

2013-12-19

Page 20

Robert Bosch GmbH

Diagnostics

Franz-Oechsle-Straße 4

73207 Plochingen

DEUTSCHLAND

www.bosch.com

bosch.prueftechnik@bosch.com

569624 Rev "A" | 2013-12-19

Loading...

Loading...