Bosch Nexxt Gas Operating, Care And Installation Instructions Manual

!

en Operating, Care and

Installation instructions

fr Notice d'utilisation.

de maintenance et

d'installation

as ODeraci6n. cuidado

e mstrucciones para

la instalacion

le Co

Definitions ................................................................................. 3

iMPORTANT SAFETY iNSTRUCTiONS ........................................................ 4

GROUNDING INSTRUCTIONS .............................................................. 5

iNSTALLATION iNSTRUCTiONS .............................................................. 6

Introduction .............................................................................. 6

Information concerning waste disposal ....................................................... 6

Before installing the dryer ................................................................... 6

Electrical connection ....................................................................... 8

Gas connection .......................................................................... 8

Exhaust air connection ................................................................... 9

Accessories .............................................................................. 11

Installation step by step ................................................................... 12

Check tist before using the dryer ............................................................. 12

Preparing to transport the dryer step by step ................................................. 12

OPERATING INSTRUCTIONS ................................................................ 13

Your new dryer ............................................................................ 13

Panel .................................................................................... 14

Summary of instructions ..................................................................... 15

Safety information .......................................................................... 16

Before switching on the dryer ............................................................... 16

Using the dryer ........................................................................... 16

Protecting the dryer ........................................................................ 16

Protection of the environment ................................................................ 16

Before using the dryer for the first time ....................................................... 17

Temporary disconnection of the dryer ........................................................ 17

Laundry .................................................................................... 17

Identification of fabrics ..................................................................... 17

Drying tips ............................................................................... 17

Program selection .......................................................................... 18

Automatic programs ....................................................................... 18

Time programs ........................................................................... 18

Options .................................................................................. 18

Indicator of program sequence .............................................................. 18

Program selection tame ..................................................................... 19

Operation .................................................................................. 20

Using the dryer ........................................................................... 20

Using the dryer rack ....................................................................... 21

Cleaning and care .......................................................................... 23

Cleaning the dryer ......................................................................... 23

Cleaning the tint filter ....................................................................... 23

Cleaning the exhaust duct .................................................................. 23

Cleaning the moisture sensor ............................................................... 23

Cleaning the bearing shield ................................................................. 23

Change the tight bulb ...................................................................... 24

Troubleshooting ............................................................................ 24

SERVICE and REPAIR ..................................................................... 25

STATEMENT OF WARRANTIES BOSCH CLOTHES DRYERS .................................... 26

Exclusions ............................................................................... 26

Congratulationsonhavingselected

aBOSCHclothesdryer,thechoice

ofthosethatdemandexceptional

performancefromtheirclothes

dryer.

Thisdryercomplieswith

ANSIZ21.5.1/ CGA 7.1 2002

Clothes Dryers Vot. k

A distinctive feature of your dryer is

tow energy consumption.

An easy operation philosophy,

a variety of customized drying

programs and a solid touch and feet

make this appliance a user friendly

assistant in your household.

The BOSCH dryer offers the

following standard features:

High efficiency precision drying

system

Large 6.25 cu.ft. (177 t)

stainless steel drum with

a capacity up to 17.6 tbs (8 kg)

toad

Large port hole (18"/457 mm),

door lock with automatic drum

stop function

Exceptionally quiet operation

Sensor controlled auto cycles

Timed cycles from

20 to 60 minutes

Each dryer which leaves our factory

has undergone a thorough

performance test and is in full

working condition. If you have any

questions especially concerning

installation of the dryer our

customer service team will be

happy to advise you.

Further information and a selection

of our products can be found on

our web site:

www.bosch.appliances.com

Information

Please read and follow these

operating and installation

instructions and all other

information enclosed with the dryer,

CAUTION Please refer to the

rating plate to insure that your

dryer is designed for your fuel

source,

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

Definitions

WARNING This indicates that

death or serious injuries may

occur as a result of non

observance of this warning.

CAUTION This indicates that

minor to moderate injuries or

damage may occur as a result of

non observance of this warning.

CAUTION This indicates that

minor damage may occur as a

result of non observance of this

warning.

][]This symbol is used to draw the

user's attention to something in

particular.

WARNING: For your safety the information in this manual must be followed to minimize

the risk of fire or explosion or to prevent property damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

(3 Do not try to light any appliance.

(3 Do not touch any electrical switch. Do not use any phone in your building.

(3 Clear the room, building or area of all occupants.

(3 Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

(3 If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

1 T

1. Read all instructions before

using the dryer. Bosch dryers

are provided with Operating,

Care and Installation

Instructions.

2. Do not dry articles that have

been previously cleaned,

washed, soaked, or spotted

with gasoline, dry cleaning

solvents, other flammable, or

explosive substances as they

give off vapors that could ignite

or explode.

3. Do not allow children to play on

or with the appliance. Close

supervision of children is

necessary when the appliance

is used near children.

4. Do not reach into the appliance

if the drum is rotating.

5. Do not install or store this

appliance where it wilt be

exposed to the weather.

6. Do not tamper with the

controls.

7. Do not repair or replace any

part of the appliance or attempt

any service unless specificatly

recommended in the

user-maintenance instructions

or in published user repair

instructions that you

understand and have the skills

to carry out.

8. Do not use fabric softeners or

products to eliminate static

unless recommended by the

fabric manufacturer.

9. Do not use heat to dry articles

containing foam rubber or

similarly textured rubber like

materials. Foam rubber

materials can ignite when

heated.

10. Clean lint screen before or after

each toad.

11. Keep area around the exhaust

opening and adjacent

surrounding areas free from the

accumulation of tint, dust and

dirt. An obstructed port might

reduce the airflow and cause

over heating.

12. The interior of the machine and

exhaust duct should be

cleaned periodically by qualified

service personnel.

13. Removing any panel or cover,

including the light cover, may

expose live electrical circuits.

Always unplug the dryer from

the electrical supply before

attempting any service.

14. Store all laundry chemicals and

aids in a coot dry place

according to the manu-

facturer's instructions.

Make sure children cannot

reach them.

15. To reduce the risk of fire,

clothes, cleaning rags, mop

heads and the like which have

traces of any flammable

substance, such as vegetable

oit, cooking oit, petroleum

based oils or distillates, waxes,

fats, etc., must not be placed

in the dryer. These items may

contain some flammable

substance(s) even after

washing.

16. Combustible materials,

gasoline, and other flammable

vapors and liquids must not be

stored near the dryer.

17. Do not place items exposed to

cooking oils in your dryer. Items

contaminated with cooking oils

may contribute to a chemical

reaction that could cause

a toad to catch fire.

18. Do not climb or sit on top of

the dryer.

19. To reduce the risk of fire or

electrical shock, DO NOT use

an extension cord or an

adapter to connect the dryer to

the electrical power supply.

20. The dryer must only be used for

its intended purpose.

21. Always check pockets and

remove any objects. Cigarette

lighters are particularly

hazardous.

22. Do not operate until worn out

power cords and/or loose plugs

are replaced.

23. Do not operate the dryer if any

guards and/or panels have

been removed.

24. Do not operate the dryer if any

parts are missing or broken.

25. Do not bypass any safety

devices.

26. Do not use a plastic or

non metal flexible duct with this

dryer. Plastic or non metal

flexible duct are a potential fire

hazard.

27. Do not operate this dryer until

you are sure that the dryer

has been installed according

to the INSTALLATION

INSTRUCTIONS and that

installation and grounding are

in compliance with all local

regulations and/or other

applicable regulations and

requirements.

28. Failure to install, maintain

and/or operate the dryer

according to the manufac

turer's instructions may result

in injury and/or damage.

29. BEFORE THE APPLIANCE IS

REMOVED FROM SERVICE

OR DISCARDED, REMOVE

TNE DOOR TO THE DRYING

COMPARTMENT.

30. To avoid floor damage and

mold growth, do not let spills or

splashout cause standing

water around or under the

appliance.

31. No other fuel-burning

appliances shall be installed in

the same closet as the dryer.

4

Notes:

ACThe IMPORTANT

SAFEGUARDS and

WARNINGS presented in

this manual do not cover all

possible conditions that

may occur.

Common sense, caution

and care must be

exercised when installing,

maintaining or operating

the dryer.

Always contact your

dealer, distributor, service

agent or the manufacturer

about any problems or

conditions that you do not

understand.

Follow also the Safety

Information in the

INSTALLATION

INSTRUCTIONS and the

OPERATING

INSTRUCTIONS,

GROUNDING

INSTRUCTIONS

This appliance must be grounded.

In the event of malfunction or

breakdown, grounding will reduce

the risk of electric shock by

providing a path of least resistance

for the electric current. This

appliance is equipped with a cord

having an equipment grounding

conductor and a grounding plug.

The plug must be plugged into an

appropriate outlet that is properly

installed and grounded in

accordance with all local codes and

ordinances.

For the State of Massachusetts

Installations:

1. Installation must be performed b_/

a licensed plumber or gas fitter licen-

sed by the state, province or region

where this appliance is being instal

ed.

2. Shut off valve must be a "-

qandte gas cock.

3. Flexible gas connector must not

be longer than 36 inches.

Improper connection of the

equipment grounding conductor

can result in a risk of electric

shock,

Check with a qualified electrician

or service person if you are in

doubt as to whether the dryer is

properly grounded,

DO NOT modify the plug

provided with the appliance

if it will not fit the outlet have

a proper outlet installed by

a qualified electrician or

exchange the cord with an

appropriate one rated for the

dryer.

KEEP THESE

INSTRUCTIONS FOR

FUTURE REFERENCE.

In case of change of ownership,

manual should be conveyed with

the dryer.

SAVE THESE INSTRUCTIONS!

I

Introduction

Read these installation instructions

completely and carefully. They wilt

save you time and effort and help to

ensure optimum dryer performance.

Be sure to observe all listed

warnings and cautions.

These installation instructions are

intended for use by qualified

installers, in addition to these

instructions the dryer must be

installed:

In the U.S.A. in accordance

with the National Electric Code,

ANSI/NFPA70 latest

edition/State and Municipal

codes and/or local codes.

In Canada, in accordance with

the Canadian Electric Code

C22.1 latest edition/Provincial

and Municipal codes and/or

local codes.

The gas installation must conform

with locat codes, or in absence of

local codes, with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54

or the CAN/CSA B149.1,

Installation Codes.

Note:

This gas dryer has been UL and

C UL listed for safe operation up to

a height of 7,700 ft, without any

modifications to components for

natural or propane gas.

Information

concerning waste

disposal

Disposal of the packaging

Keep children away from

shipping carton and packaging

components. Danger of

suffocation from plastic foil and

folding cartons.

All packaging materials are

environmentally friendly and can be

reused. Please dispose of

packaging in an environmentally

friendly manner.

Please ask your deater or inquire at

your local authority about current

means of disposal.

Disposal of the appliance

If appliance is no longer usable,

pull out main plug, cut off power

cord and discard with main plug,

To prevent children from locking

themselves in the appliance,

remove the door,

Old appliances are not worthless

rubbish! Valuable raw materials can

be reclaimed from environmentally

friendly recycling,

Please ask your dealer or inquire at

your local authority about current

means of disposal,

Before installing

the dryer

Unpacking the appliance

The dryer is very heavy. Do not

lift it by yourself. Do not lift the

appliance by projecting

components (e.g. door) dueto

risk of breakage.

Remove the appliance

packaging carefully to prevent

damage to the surfaces.

Check the dryer for transportation

damage. Do not connect a dryer

which is visibly damaged. If in

doubt, contact your dealer.

Supplied components

After removing the packaging,

immediately remove any objects

from the drum.

The dryer is delivered as a complete

unit. The operating instructions and

supplied accessories can be found

in the drum.

6

installation location

Do not install the dryer:

outdoors,

in an environment with dripping

water,

near flammable materials,

in rooms which are at risk of

frost,

in rooms which may contain

gas or other fuels,

in cupboards with lockabte

doors or in alcoves.

with other fuel burning

appliance in the same closet,

The installation room must be welt

ventilated, otherwise the dryer will

operate below optimum

performance,

Do not operate the dryer at

temperatures above 104 °F (40 °C)

and below 41 °F (5 °C). Low

temperatures affect the automatic

program sequence and may

prolong the drying times.

The installation surface for the dryer

must be clean, level and firm. Do

not install the appliance on carpets!

Compensate for uneven floors with

the height adjustable feet.

Install the dryer and level side

to side and front to back.

Use a bubble level. Never remove

the height adjustable feet!

The size of the installation area

depends on the dimensions of the

dryer. Ensure that there is adequate

room for the swivel range of the

door!

If installed in a garage, the dryer

must be installed on a

substantial platform at least 18

inches above the floor to reduce

the tiktihood of igniting

flammable vapors and be

located or protected so it cannot

be damaged by a moving vehicle

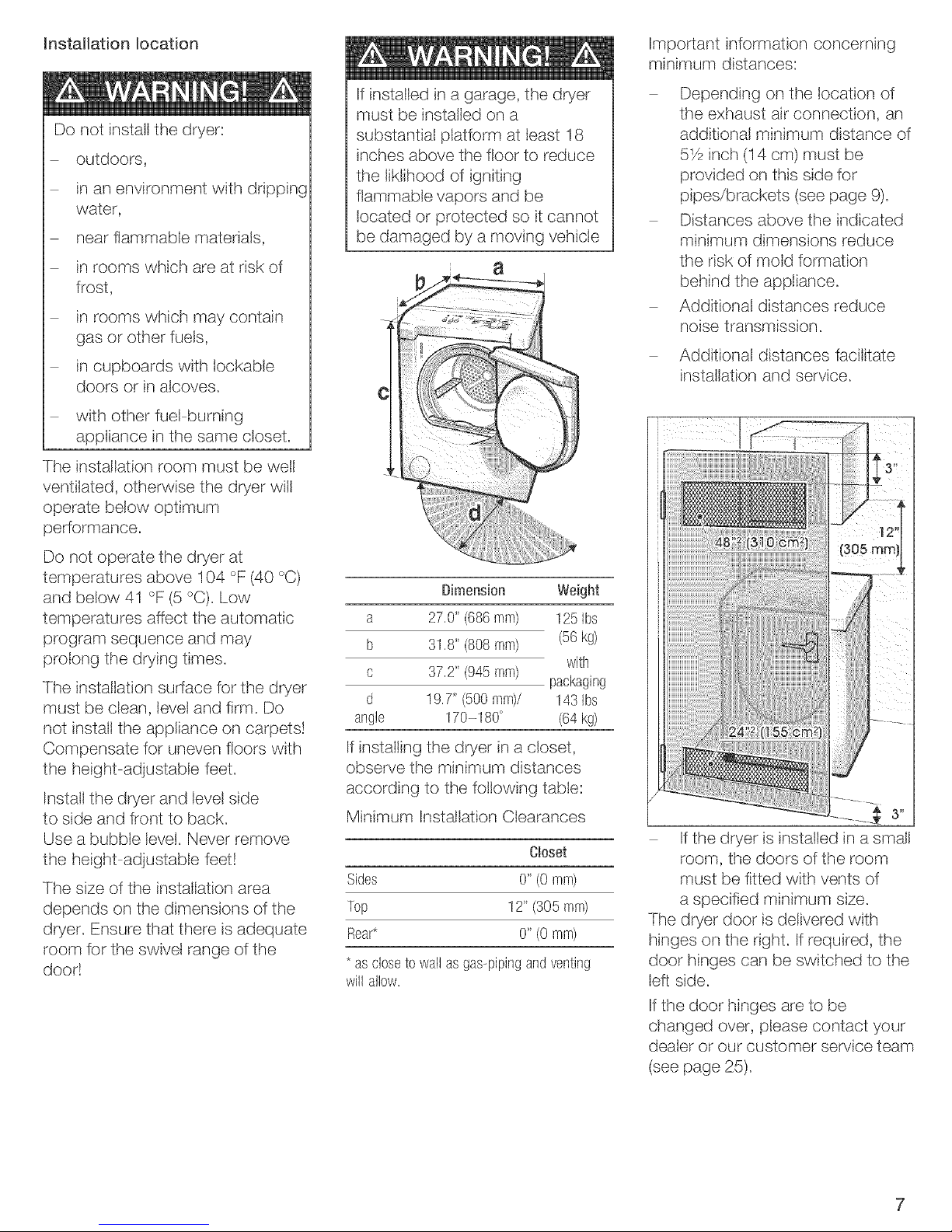

a

a

b

c

d

angle

Dimension Weight

27.0"(686mm) 125Ibs

31,8"(808ram) (56kg)

with

37,2"(945 ram) packaging

19,7" (500ram)/ 143Ibs

170-180 ° (64kg)

If installing the dryer in a closet,

observe the minimum distances

according to the following table:

Minimum Installation Clearances

Closet

Sides 0"(0 mm)

Top 12"(305 mm)

Rear* 0"(0mm)

* ascloseto wall asgas-pipingandventing

willallow.

Important information concerning

minimum distances:

Depending on the location of

the exhaust air connection, an

additional minimum distance of

5Y2 inch (I 4 ore) must be

provided on this side for

pipes/brackets (see page 9).

Distances above the indicated

minimum dimensions reduce

the risk of mold formation

behind the appliance.

Additional distances reduce

noise transmission.

Additional distances facilitate

installation and service.

If the dryer is installed in a small

room, the doors of the room

must be fitted with vents of

a specified minimum size.

The dryer door is delivered with

hinges on the right. Ifrequired, the

door hinges can be switched to the

left side,

If the door hinges are to be

changed over, please contact your

dealer or our customer service team

(see page 25).

Electrical connection

GROUNDING iNSTRUCTiONS

This appliance must be grounded.

In the event of a malfunction or

breakdown, grounding wilt reduce

the risk of electrical shock by

providing a path of least resistance

for the electric current.

This appliance features a cord with

an equipment-grounding conductor

and a grounding plug. The plug

must be plugged into an

appropriate outlet which has been

properly installed and grounded in

accordance with all tocal

regulations and ordinances.

Improper connection of the

equipment grounding conductor

may result in electric shock.

Have the appliance checked by

a qualified electrician or service

technician if you are in doubt as

to whether the dryer has been

properly grounded.

Do not modify the plug provided

with the appliance if it will not fit in

the outlet, have a proper outlet

installed by a qualified electrician or

exchange the cord with an

appropriate one rated for the dryer,

The dryer must only be

connected to an individual

branch circuit via a socket which

has been properly installed and

grounded.

The household electrical voltage

must correspond to the voltage

specification on the dryer (rating

plate),

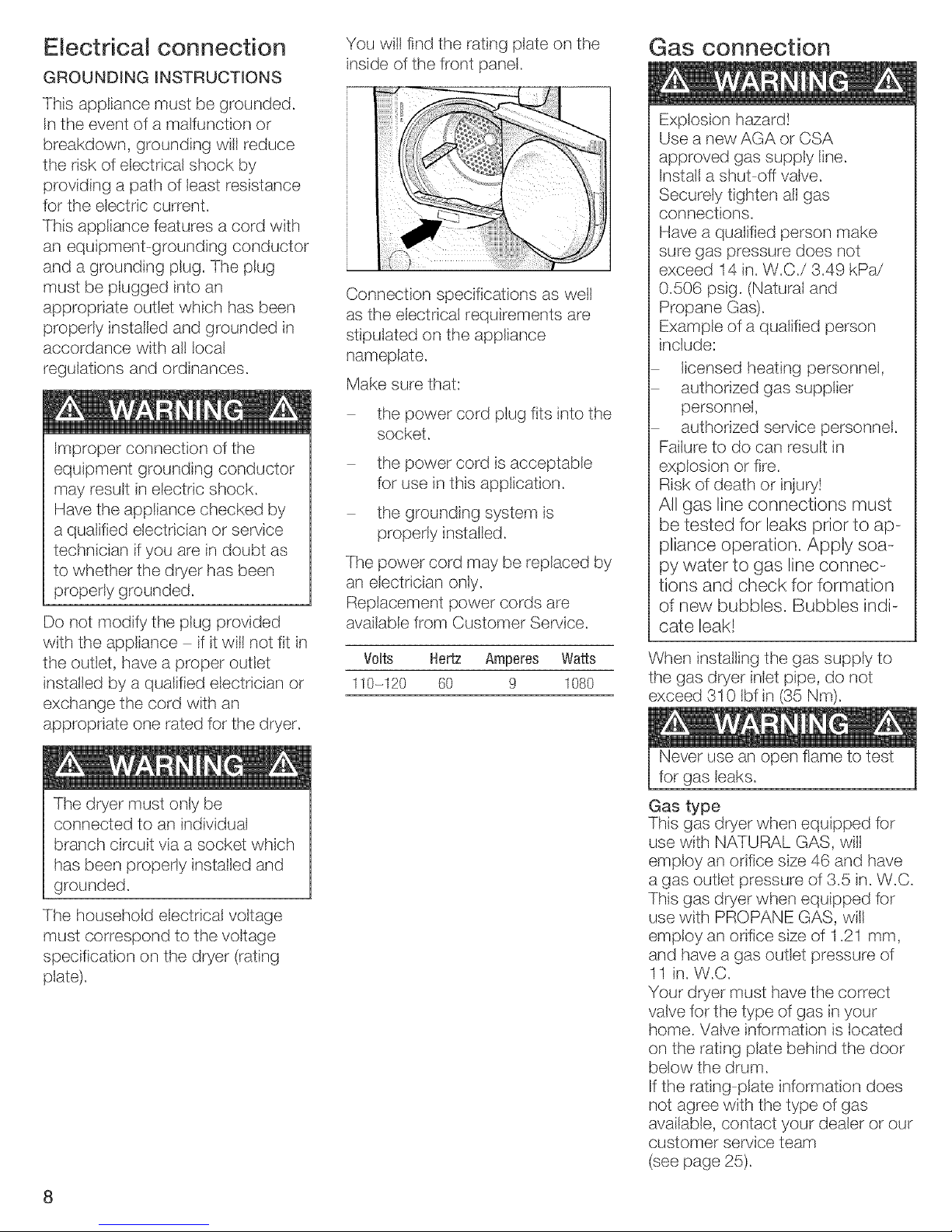

You wilI find the rating plate on the

inside of the front panel,

Connection specifications as well

as the electrical requirements are

stipulated on the appliance

nameplate.

Make sure that:

the power cord plug fits into the

socket,

the power cord is acceptable

for use in this application,

the grounding system is

properly installed.

The power cord may be replaced by

an electrician only.

Replacement power cords are

available from Customer Service.

Volts Hertz Amperes Watts

110-120 60 9 1080

Gas connection

Explosion hazard!

Use a new AGA or CSA

approved gas supply line.

Install a shut off valve.

Securely tighten all gas

connections.

Have a qualified person make

sure gas pressure does not

exceed 14 in. W.C./3.49 kPa/

0.506 psig. (Natural and

Propane Gas).

Example of a qualified person

include:

licensed heating personnel,

authorized gas supplier

personnel,

authorized service personnel.

Failure to do can result in

explosion or fire.

Risk of death or injury!

All gas line connections must

be tested for leaks prior to ap-

pliance operation. Apply soa-

py water to gas line connec-

tions and check for formation

of new bubbles. Bubbles indP

cate leak!

When installing the gas supply to

the gas dryer inlet pipe, do not

exceed 310 tbf in (35 Nm).

Never use an open flame to test

for gas leaks.

Gas type

This gas dryer when equipped for

use with NATURAL GAS, will

employ an orifice size 46 and have

a gas outlet pressure of 3.5 in. W.C.

This gas dryer when equipped for

use with PROPANE GAS, wilt

employ an orifice size of 1.21 mm,

and have a gas outlet pressure of

11 in. W.C.

Your dryer must have the correct

valve for the type of gas in your

home. Valve information is located

on the rating plate behind the door

below the drum.

If the rating plate information does

not agree with the type of gas

available, contact your dealer or our

customer service team

(see page 25).

8

Gas supply line

1/2" I.D. pipe is recommended.

3/s" approved tubing is acceptable

for lengths under 20 ft (6.1 m) if

local codes and gas supplier

aermit.

Must include 1/8" NPT plugged

tapping, immediately upstream of

the gas connection.

A shut off valve must be included:

USA:

An individual manual shut-off

valve must be installed within

6 ft (1.8 m) of the dryer in

accordance with the National

Fuel Gas Code, ANSI Z223.1.

Canada:

An individual manual shut off

valve must be installed in

accordance with the B149,

Installation Codes, CAN/CSA

B149.1 and CAN/CSA B149.2.

It is recommended that an

individual manual shut off valve

be installed within 6 ft (I .8 m) of

the dryer.

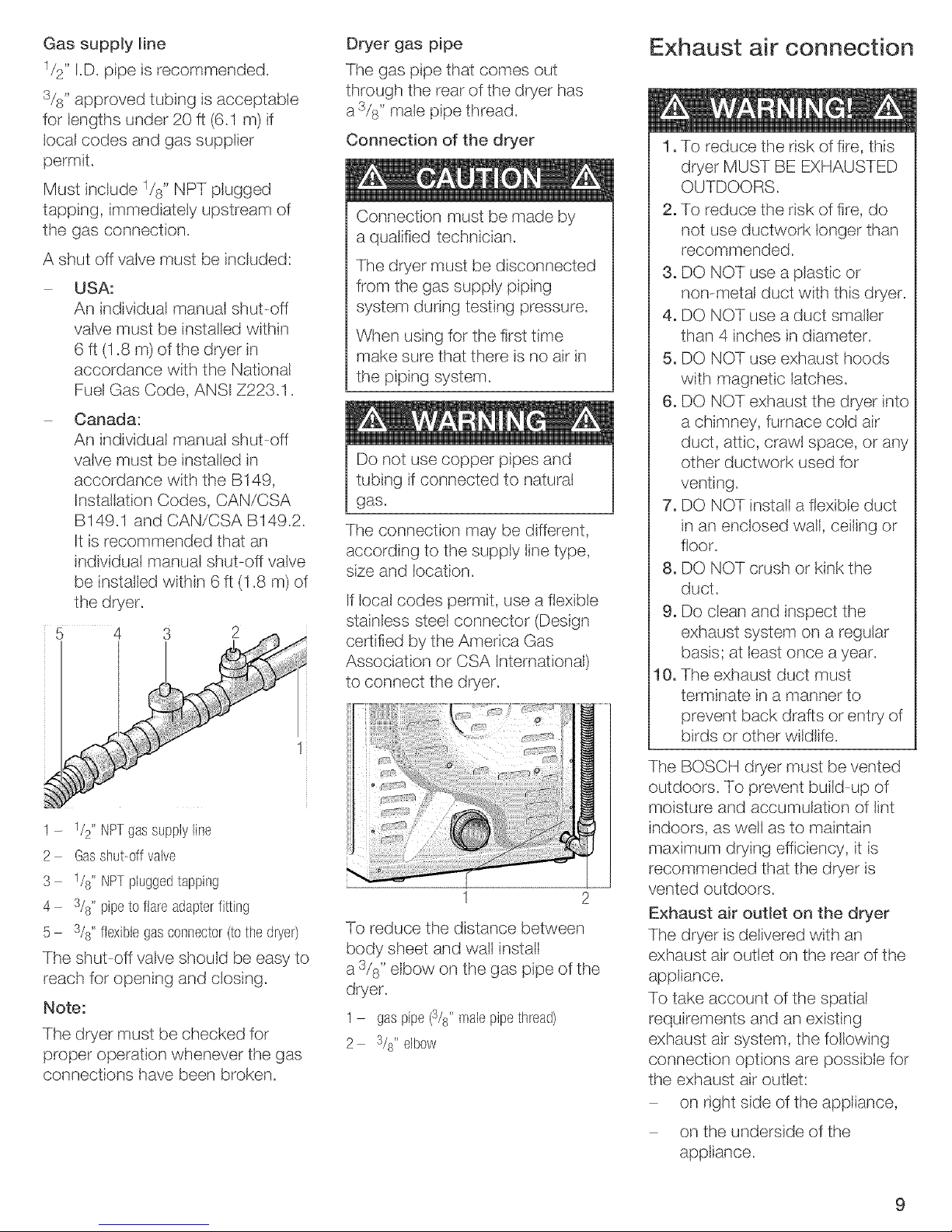

1 - 1/2" NPTgassupplyline

2- Gasshut-0ffvalve

3- 1/8"NPTpluggedtapping

4- 3/8"pipeto flareadapterfitting

5 - 3/8"flexiblegasconnector(tothe dryer)

The shut off valve should be easy to

reach for opening and closing.

Note:

The dryer must be checked for

proper operation whenever the gas

connections have been broken.

Dryer gas pipe

The gas pipe that comes out

through the rear of the dryer has

a 3/8" male pipe thread.

Connection of the dryer

Connection must be made by

a qualified technician.

The dryer must be disconnected

from the gas supply piping

system during testing pressure.

When using for the first time

make sure that there is no air in

the piping system.

Do not use copper pipes and

tubing if connected to natural

gas.

The connection may be different,

according to the supply line type,

size and location.

If local codes permit, use a flexible

stainless steel connector (Design

certified by the America Gas

Association or CSA International)

to connect the dryer.

1 2

To reduce the distance between

body sheet and wall install

a 3/8" elbow on the gas pipe of the

dryer.

1 - gaspipe(3/8"malepipethread)

2- s/8"elbow

Exhaust air connection

1. To reduce the risk of fire, this

dryer MUST BE EXHAUSTED

OUTDOORS.

2. To reduce the risk of fire, do

not use ductwork longer than

recommended.

3. DO NOT use a plastic or

non-metal duct with this dryer.

4. DO NOT use a duct smaller

than 4 inches in diameter.

5. DO NOT use exhaust hoods

with magnetic latches.

6. DO NOT exhaust the dryer into

a chimney, furnace cold air

duct, attic, crawl space, or any

other ductwork used for

venting.

7. DO NOT install a flexible duct

in an enclosed watt, ceiling or

floor.

8. DO NOT crush or kink the

duct.

9. Do clean and inspect the

exhaust system on a regular

basis; at least once a year.

10. The exhaust duct must

terminate in a manner to

prevent back drafts or entry of

birds or other wildlife.

The BOSCH dryer must be vented

outdoors. To prevent build up of

moisture and accumulation of lint

indoors, as well as to maintain

maximum drying efficiency, it is

recommended that the dryer is

vented outdoors.

Exhaust air outlet on the dryer

The dryer is delivered with an

exhaust air outlet on the rear of the

appliance.

To take account of the spatial

requirements and an existing

exhaust air system, the following

connection options are possible for

the exhaust air outlet:

on right side of the appliance,

on the underside of the

appliance.

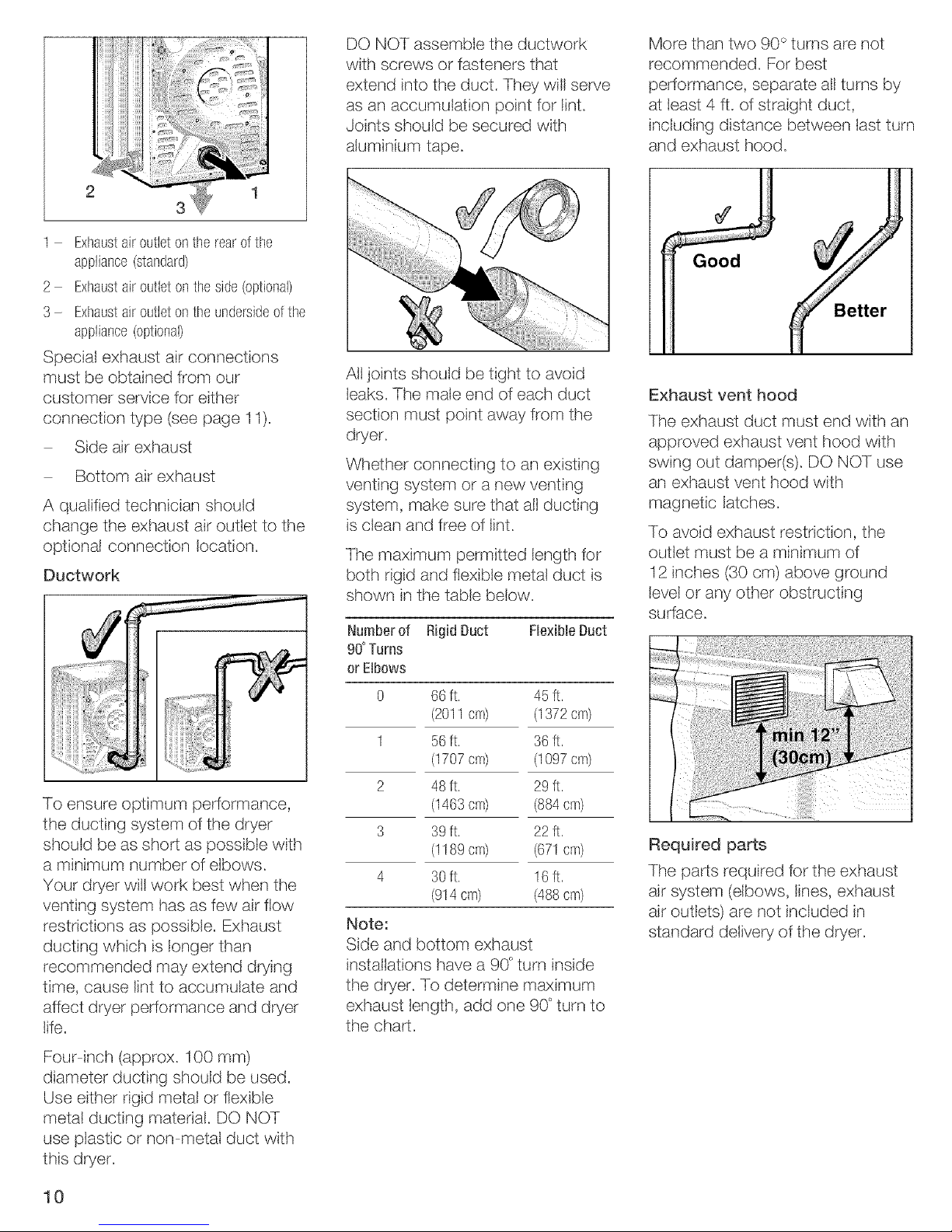

2 1

3

1 - Exhaustair outletontherearofthe

appliance(standard)

2- Exhaustair outleton theside(optional)

3 - Exhaustair outletonthe undersideof the

appliance(optional)

Special exhaust air connections

must be obtained from our

customer service for either

connection type (see page 11).

Side air exhaust

Bottom air exhaust

A qualified technician should

change the exhaust air outlet to the

optional connection location.

Ductwork

To ensure optimum pedormance,

the ducting system of the dryer

should be as short as possible with

a minimum number of elbows.

Your dryer witl work best when the

venting system has as few air flow

restrictions as possible. Exhaust

ducting which is longer than

recommended may extend drying

time, cause tint to accumulate and

affect dryer performance and dryer

tife.

Four inch (approx. 100 ram)

diameter ducting should be used.

Use either rigid metal or flexible

metal ducting material. DO NOT

use plastic or non metal duct with

this dryer.

DO NOT assemble the ductwork

with screws or fasteners that

extend into the duct. They will serve

as an accumulation point for tint.

Joints should be secured with

atuminium tape.

All joints should be tight to avoid

leaks. The mate end of each duct

section must point away from the

dryer.

Whether connecting to an existing

venting system or a new venting

system, make sure that all ducting

is clean and free of tint.

The maximum permitted length for

both rigid and flexible metal duct is

shown in the table below.

Numberof RigidDuct FlexibleDuct

90°Turns

or EJbows

0 66 ft. 45 ft,

(2011cm) (1372cm)

1 56 ft. 36ft,

(1707cm) (1097cm)

2 48 ft, 29ft,

(1463cm) (884cm)

3 39 ft, 22ft.

(1189cm) (671cm)

4 30ft, 16ft,

(914cm) (488cm)

Note:

Side and bottom exhaust

installations have a 90 °turn inside

the dryer. To determine maximum

exhaust length, add one 90 °turn to

the chart.

More than two 90 ° turns are not

recommended. For best

performance, separate all turns by

at least 4 ft. of straight duct,

including distance between last turn

and exhaust hood.

Good

Better

Exhaust vent hood

The exhaust duct must end with an

approved exhaust vent hood with

swing out damper(s). DO NOT use

an exhaust vent hood with

magnetic latches.

To avoid exhaust restriction, the

outlet must be a minimum of

12 inches (30 cm) above ground

level or any other obstructing

surface.

...............

Required parts

The parts required for the exhaust

air system (elbows, lines, exhaust

air outlets) are not included in

standard delivery of the dryer.

10

Accessories

The parts required for the exhaust

air system can be obtained from

customer service or your local

dealer. Please follow the installation

instructions supplied by the

appropriate manufacturer!

}ide exhaust kit

"\\O

part no. WTZ 1265

Note:

The maximum permitted number of

90 ° elbows (including this side

exhaust kit) is four!

[_3 Speciat toot for cutting the hole

in prepared side panel is

required. Contact local dealer!

LP - Gas Kit

part no. WTZ1280

The parts required for the LP

version can be obtained from your

local dealer. Please follow the

installation instructions supplied by

the appropriate manufacturer!

If you have a propane gas dryer and

need to convert it to natural gas,

(Service Kit 496297) please consult

your customer service agent for

assistance.

Note:

Dryer must be checked for proper

operation whenever the gas

connections have been broken.

Bottom exhaust kit

part no. WTZ1270

Note:

The maximum permitted number of

90 °elbows (including this side

exhaust kit) is four!

Left hinge kit

part no. WZ 1260

The door catch can be reversed if

necessary. The door is hinged on

the right at the factory.

Pedestal Mounting Kit

part no. WTZ 1295

If mounting the dryer on the

pedestal follow the instructions

supplied with the pedestal.

Mobile home kit

part no. WTZ 1 275

Note:

Please check with the Authority

Having Jurisdiction in your area to

verify if a gas dryer can be installed

in your mobile home. Once that has

been verified, installation of the

dryer shall conform to the

Manufactured Home Construction

and Safety Standard, Title 24 CFR,

Part 3280 {formerly the Federal

Standard for Mobile Home

Construction and Safety, Title 24,

HUD (Part 280)}, and/or Standard

CAN/CSA Z240 MH.

Please use mobile home kit number

WTZ 1275 for means to secure the

dryer to the structure.

See page 9 "Exhaust Air

Connection" for the exhaust duct

installation instructions.

The exhaust duct must be securely

fastened to a noncombustible

portion of the mobile home

structure and must not terminate

beneath the mobile home.

An opening to the outside must be

provided during installation, Insure

that the free area of the opening for

the introduction of outside air is not

tess than twice the area of the dryer

exhaust outlet or use at least a

5 inch diameter exhaust or at least

a 25 in2 square exhaust duct for the

opening.

11

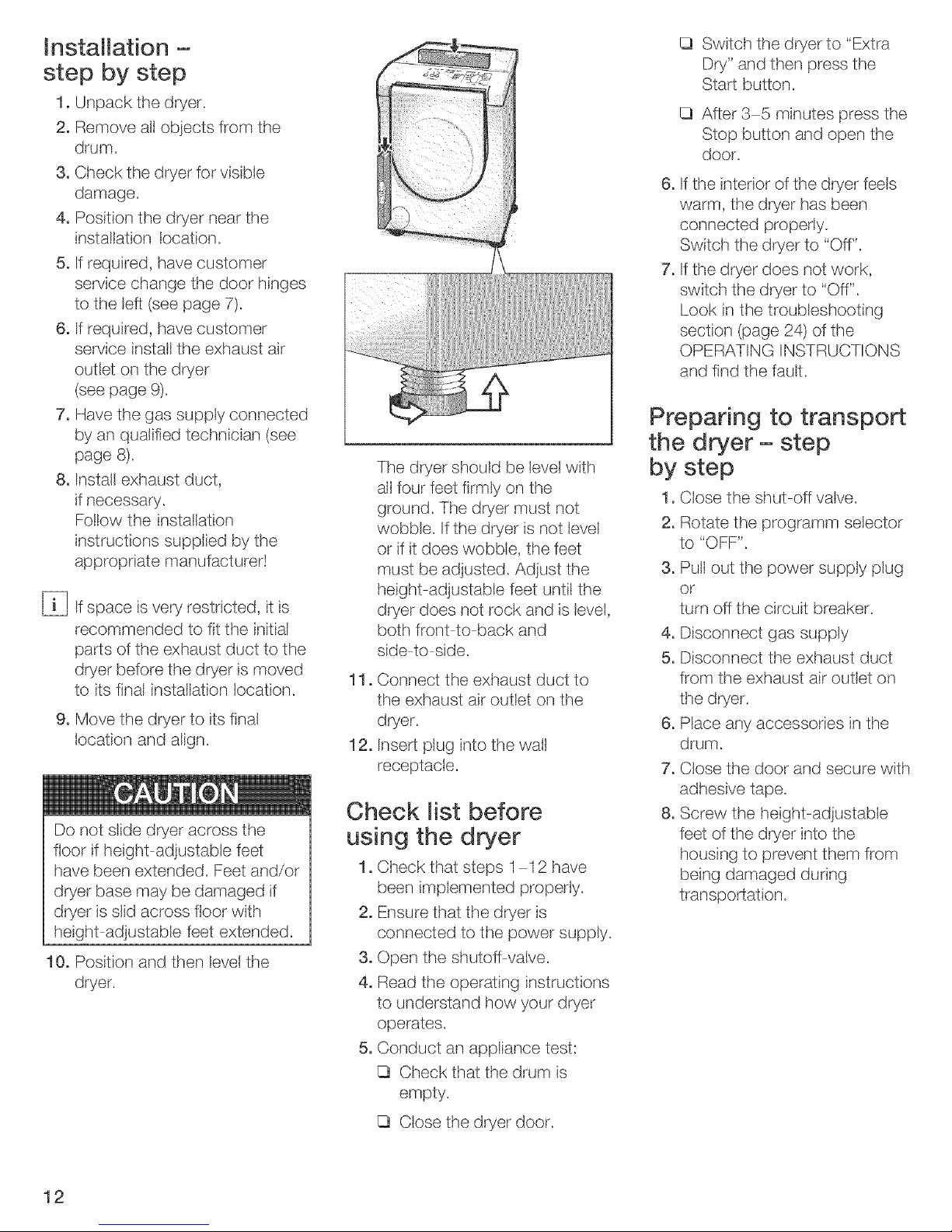

Installation -

step by step

1. Unpack the dryer.

2. Remove all objects from the

drum.

3. Check the dryer for visible

damage.

4. Position the dryer near the

installation location.

5. If required, have customer

service change the door hinges

to the left (see page 7).

6. If required, have customer

service install the exhaust air

outlet on the dryer

(see page 9).

7. Have the gas supply connected

by an qualified technician (see

page 8).

8. Install exhaust duct,

if necessary.

Follow the installation

instructions supplied by the

appropriate manufacturer!

[_lf space is very restricted, it is

recommended to fit the initial

parts of the exhaust duct to the

dryer before the dryer is moved

to its final instatlation location.

9. Move the dryer to its final

location and afign.

Do not slide dryer across the

floor if height-adjustable feet

have been extended. Feet and/or

dryer base may be damaged if

dryer is slid across floor with

height adjustable feet extended.

0. Position and then level the

dryer,

The dryer should be level with

all four feet firmly on the

ground. The dryer must not

wobble. If the dryer is not level

or if it does wobble, the feet

must be adjusted. Adjust the

height adjustable feet until the

dryer does not rock and is level,

both front to back and

side to side.

11. Connect the exhaust duct to

the exhaust air outlet on the

dryer.

12. Insert plug into the wail

receptacle.

Check List before

using the dryer

1. Check that steps 1 12 have

been implemented properly.

2. Ensure that the dryer is

connected to the power supply.

3. Open the shutoff valve.

4. Read the operating instructions

to understand how your dryer

operates.

5. Conduct an appliance test:

(3 Check that the drum is

empty.

(3 Close the dryer door.

6.

7.

(3 Switch the dryer to "Extra

Dry" and then press the

Star button,

(3 After 3 5 minutes press the

Stop button and open the

door.

If the interior of the dryer feels

warm, the dryer has been

connected properly.

Switch the dryer to "Off".

If the dryer does not work,

switch the dryer to "Off".

Look in the troubleshooting

section (page 24) of the

OPERATING INSTRUCTIONS

and find the fault.

Preparing to transport

the dryer - step

by step

1. Close the shut off valve.

2. Rotate the programm selector

to "OFF".

3. Pull out the power supply plug

or

turn off the circuit breaker.

4. Disconnect gas supply

5. Disconnect the exhaust duct

from the exhaust air outlet on

the dryer.

6. Place any accessories in the

drum.

7. Close the door and secure with

adhesive tape.

8. Screw the height adjustable

feet of the dryer into the

housing to prevent them from

being damaged during

transportation.

12

OP NG

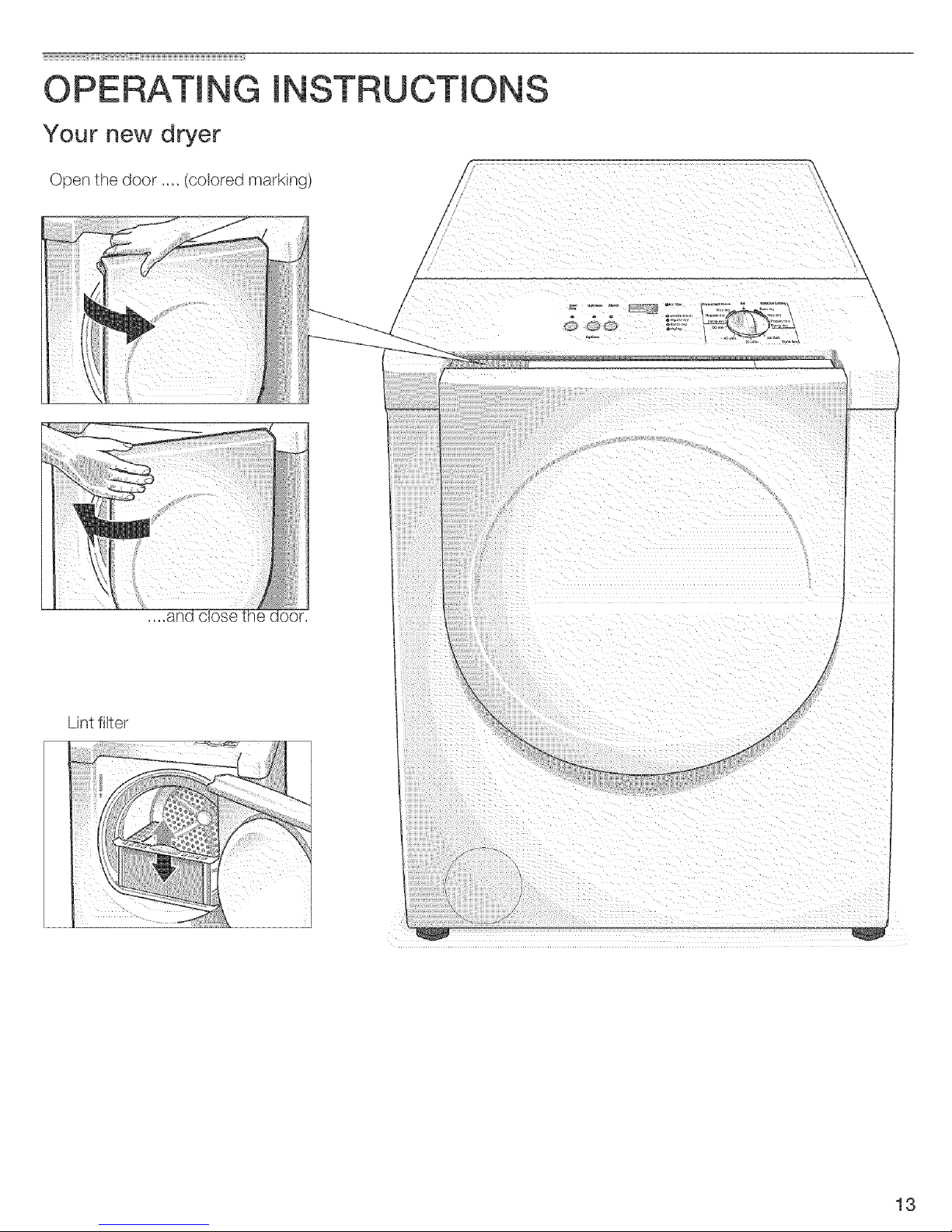

Your new dryer

Open the door .... (colored marking)

oor.

Lint filter

I?

I

/

/

/

S

/

/

/

t

/

/

!

/

!

/

#

/

-"_ Z

\

\

\

\

\

13

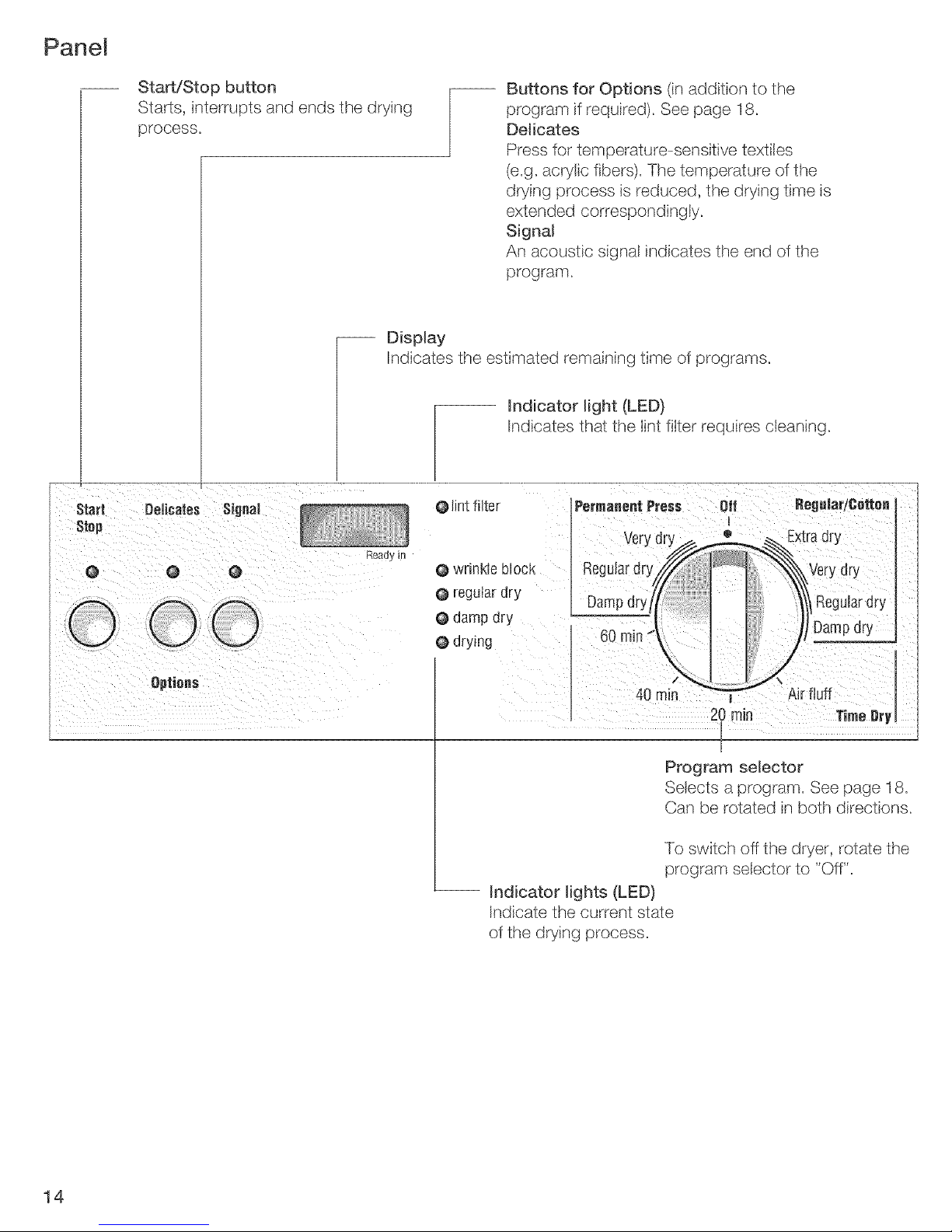

Panel

Start/Stop button

Starts, interrupts and ends the drying

process.

-- Buttons for Options (in addition to the

program if required). See page 18.

Delicates

Press for temperature-sensitive textiles

(e.g. acrylic fibers). The temperature of the

drying process is reduced, the drying time is

extended correspondingly.

Signal

An acoustic signal indicates the end of the

program.

-- Display

Indicates the estimated remaining time of programs.

S,aady _n

Indicator light (LED)

Indicates that the tint filter requires cleaning.

Start

Stop

0

0eli_ale$ Signal

@lint filter

Options

Permanent Press Off Regular/Cotton j

Program selector

Selects a program. See page 18.

Can be rotated in both directions.

To switch off the dryer, rotate the

program selector to "Off".

-- Indicator lights (LED)

Indicate the current state

of the drying process.

14

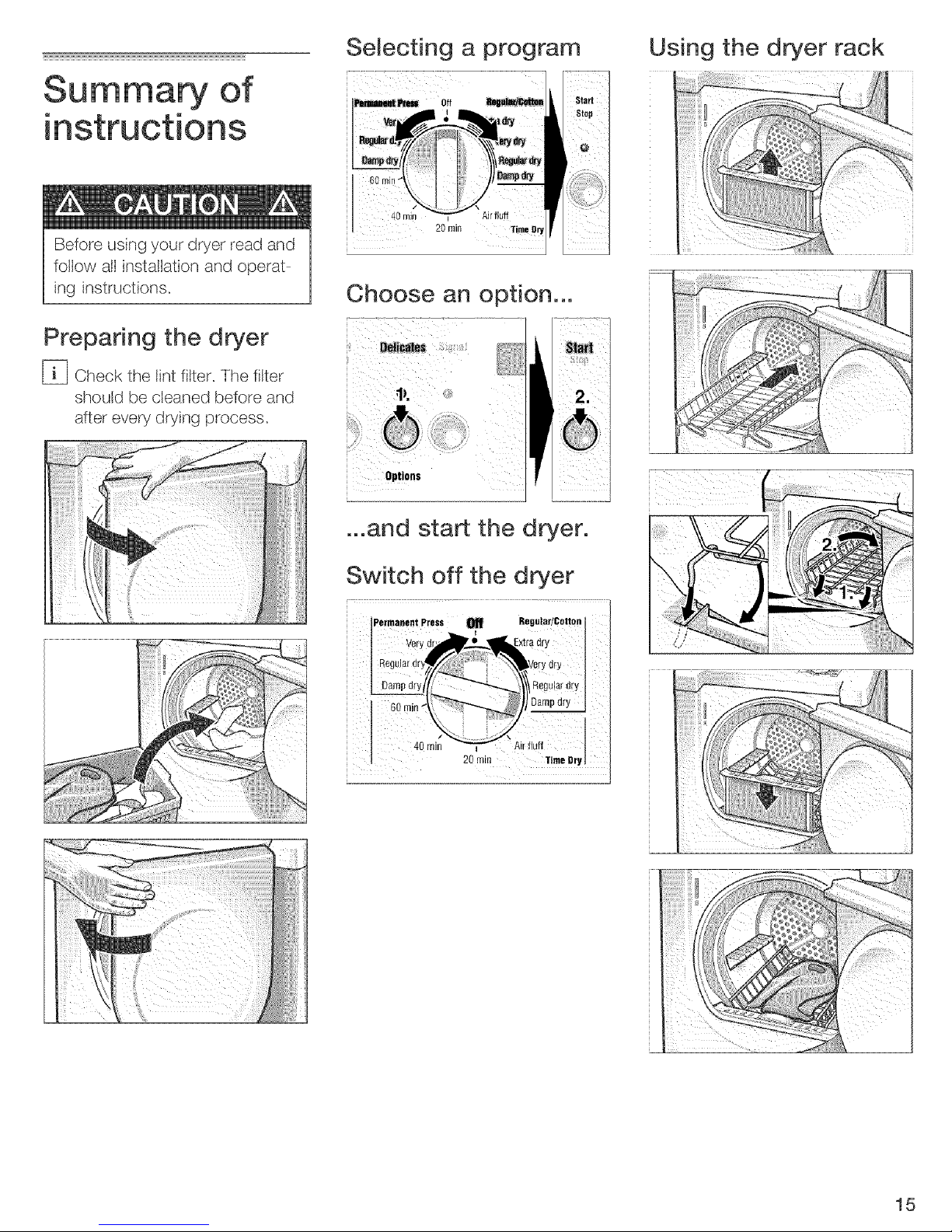

Before using your dryer read and

follow all installation and operat

ing instructions,

Preparing the dryer

[_ Check the lint filter, The filter

should be cleaned before and

after every drying process,

Selecting a program

20 rain

Choose an option...

Options

...and start the dryer.

Switch off the dryer

PermanentPress

Using the dryer rack

ii

40 rain

15

Y

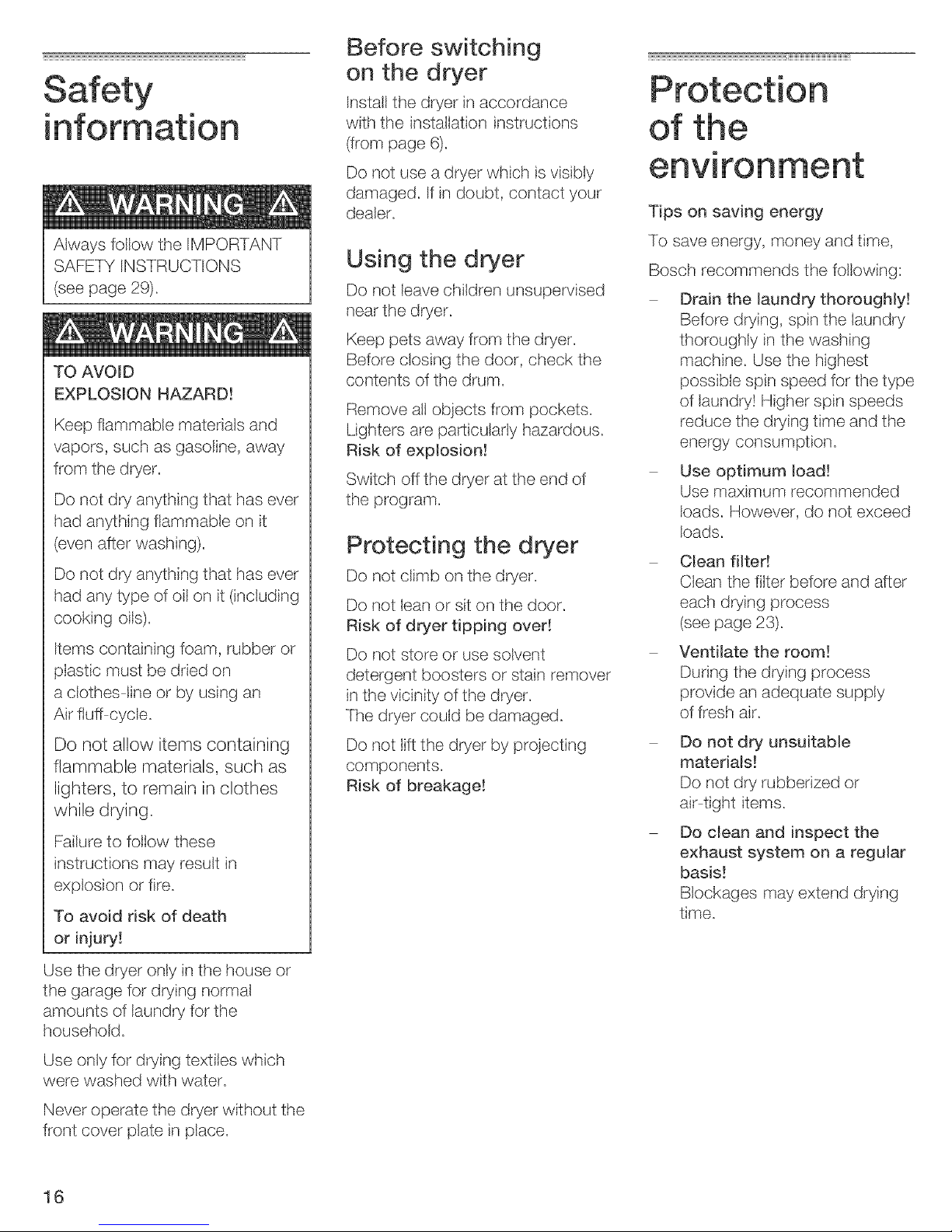

information

Always follow the IMPORTANT

SAFETY INSTRUCTIONS

(see page 29).

TO AVOID

EXPLOSION HAZARD!

Keep flammable materials and

vapors, such as gasoline, away

from the dryer.

Do not dry anything that has ever

had anything flammable on it

(even after washing).

Do not dry anything that has ever

had any type of oil on it (including

cooking oils),

Items containing foam, rubber or

plastic must be dried on

a clothes line or by using an

Air fluff cycle.

Do not allow items containing

flammable materials, such as

lighters, to remain in clothes

while drying,

Failure to follow these

instructions may result in

explosion or fire,

To avoid risk of death

or injury!

Use the dryer only in the house or

the garage for drying normal

amounts of laundry for the

household.

Use only for drying textiles which

were washed with water,

Never operate the dryer without the

front cover plate in place,

Before switching

on the dryer

Install the dryer in accordance

with the installation instructions

(from page 6).

Do not use a dryer which is visibly

damaged. If in doubt, contact your

dealer.

Using the dryer

Do not leave children unsupervised

near the dryer.

Keep pets away from the dryer.

Before closing the door, check the

contents of the drum.

Remove all objects from pockets.

Lighters are particularly hazardous.

Risk of explosion!

Switch off the dryer at the end of

the program.

Protecting the dryer

Do not climb on the dryer.

Do not lean or sit on the door.

Risk of dryer tipping over!

Do not store or use solvent

detergent boosters or stain remover

in the vicinity of the dryer.

The dryer could be damaged.

Do not lift the dryer by projecting

components.

Risk of breakage!

.....................................................................................................................................................iiiii[_

of the

environment

Tips on saving energy

To save energy, money and time,

Bosch recommends the following:

Drain the laundry thoroughly!

Before drying, spin the laundry

thoroughly in the washing

machine. Use the highest

possible spin speed for the type

of laundry! Higher spin speeds

reduce the drying time and the

energy consumption.

Use optimum load!

Use maximum recommended

loads. However, do not exceed

loads.

Clean filter!

Clean the filter before and after

each drying process

(see page 23).

Ventilate the room!

During the drying process

provide an adequate supply

of fresh air.

Do not dry unsuitable

materials!

Do not dry rubberized or

air tight items.

Do clean and inspect the

exhaust system on a regular

basis!

Blockages may extend drying

time.

16

dryer for

first time

Before you use the dryer for the first

time:

1. Read these operating

instructions carefully.

2. Check that the supply voltage

corresponds with the voltage

specifications on the rating

plate of the dryer, see picture

page 25

3. Check that the gas type

corresponds with specifications

on the rating plate of the dryer,

see picture page 25.

4. Have a qualified person make

sure gas pressure does not

exceed 14 in. WC/3.49 kPa /

0.506 psig (Natural and

Propane Gas).

5. Remove atI objects from the

drum.

6. Check the dryer for visible

damage. If damages found

contact your dealer.

7. Wipe the inside of the drum

with a damp cloth.

8. Conduct an appliance test see

page 12.

9. If the dryer does not work,

switch the dryer to "OFF".

Look in the troubleshooting

section (page 24) of the

operating instructions and find

the fault.

disconnection

of the dryer

Operate your dryer only when you

are at home. If you intend going on

vacation or are not using your dryer

for an extended period of time, you

should:

1. Turn off the circuit breaker.

2. Close the shut off valve.

3. Pull out the power supply plug

if possible.

4. Clean the tint filter.

au

Identification

of fabrics

Observe the treatment symbols on

the textile labels. They provide

valuable information as well as

limitations about the drying

process.

Do not dry the following textiles in

the dryer:

Air tight textiles

(e.g. rubberized)

Delicate fabrics (silk, synthetic

curtains)

E]

E]

Dry woolen or wool rich textiles

with dryer rack only!

Use the time program "Air fluff"

to dry articles containing foam

rubber or similarly textured

rubber like materials.

Drying tips

In principle, the following applies to

all drying programs:

To ensure a uniform drying

result, sort the laundry

according to fabric type and

drying program.

Fasten zippers, hooks and

eyes. Fasten loose belts,

apron strings, etc..

Do not overdry easy care

laundry risk of wrinkling!

Leave laundry to dry in the air.

Do not iron laundry immediately

after drying. Place the laundry

in a pile for a short while.

Residual moisture will then be

distributed uniformly.

Knitted textiles (e.g. T-shirts,

cotton jersey laundry) often

shrink when dried for the first

time. Do not use the "Very

dry/Extra dry" program.

17

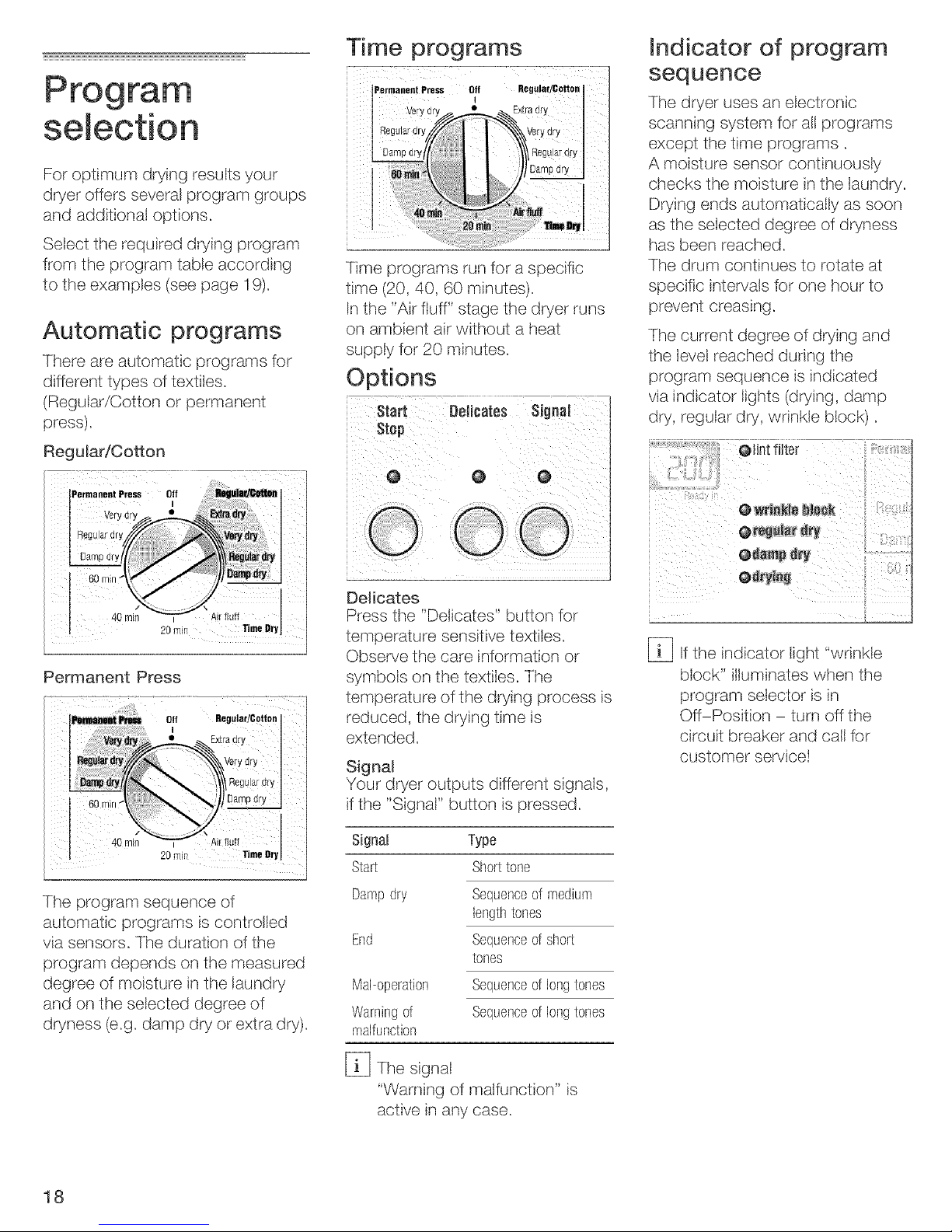

Program

on

For optimum drying results your

dryer offers several program groups

and additional options.

Select the required drying program

from the program table according

to the examples (see page 19).

Automatic programs

There are automatic programs for

different types of textiles.

(Regular/Cotton or permanent

press).

Regular/Cotton

Permanent Press Off

I

60 mn"

40 rain Air 11dl

20 ill] rl Time Dry I

Permanent Press

Off

I

Regular/Cotton

Extradry

60 mir,"

40rain t

20 mn TAmeDryJ

The program sequence of

automatic programs is controlled

via sensors. The duration of the

program depends on the measured

degree of moisture in the laundry

and on the selected degree of

dryness (e.g. damp dry or extra dry).

Time programs

I

Time programs run for a specific

time (20, 40, 60 minutes).

In the "Air fluff" stage the dryer runs

on ambient air without a heat

supply for 20 minutes.

Options

Start DeHcates Signal

Stop

e e e

Delicates

Press the "Deticates" button for

temperature sensitive textiles.

Observe the care information or

symbols on the textiles. The

temperature of the drying process is

reduced, the drying time is

extended.

Signal

Your dryer outputs different signals,

if the "Signal" button is pressed.

Signal Type

Start Shorttone

Dampdry

End

Sequenceof medium

lengthtones

Sequenced short

tones

Sequencedl0ng tones

Sequencedl0ng tones

MaFoperation

Warningof

malfunction

[_The signat

"Warning of malfunction" is

active in any case.

Indicator of program

sequence

The dryer uses an electronic

scanning system for all programs

except the time programs.

A moisture sensor continuously

checks the moisture in the laundry.

Drying ends automatically as soon

as the selected degree of dryness

has been reached.

The drum continues to rotate at

specific intervals for one hour to

prevent creasing.

The current degree of drying and

the level reached during the

program sequence is indicated

via indicator lights (drying, damp

dry, regular dry, wrinkle btock).

[_lf the indicator light "wrinkle

block" illuminates when the

program selector is in

Off Position turn off the

circuit breaker and call for

customer service!

18

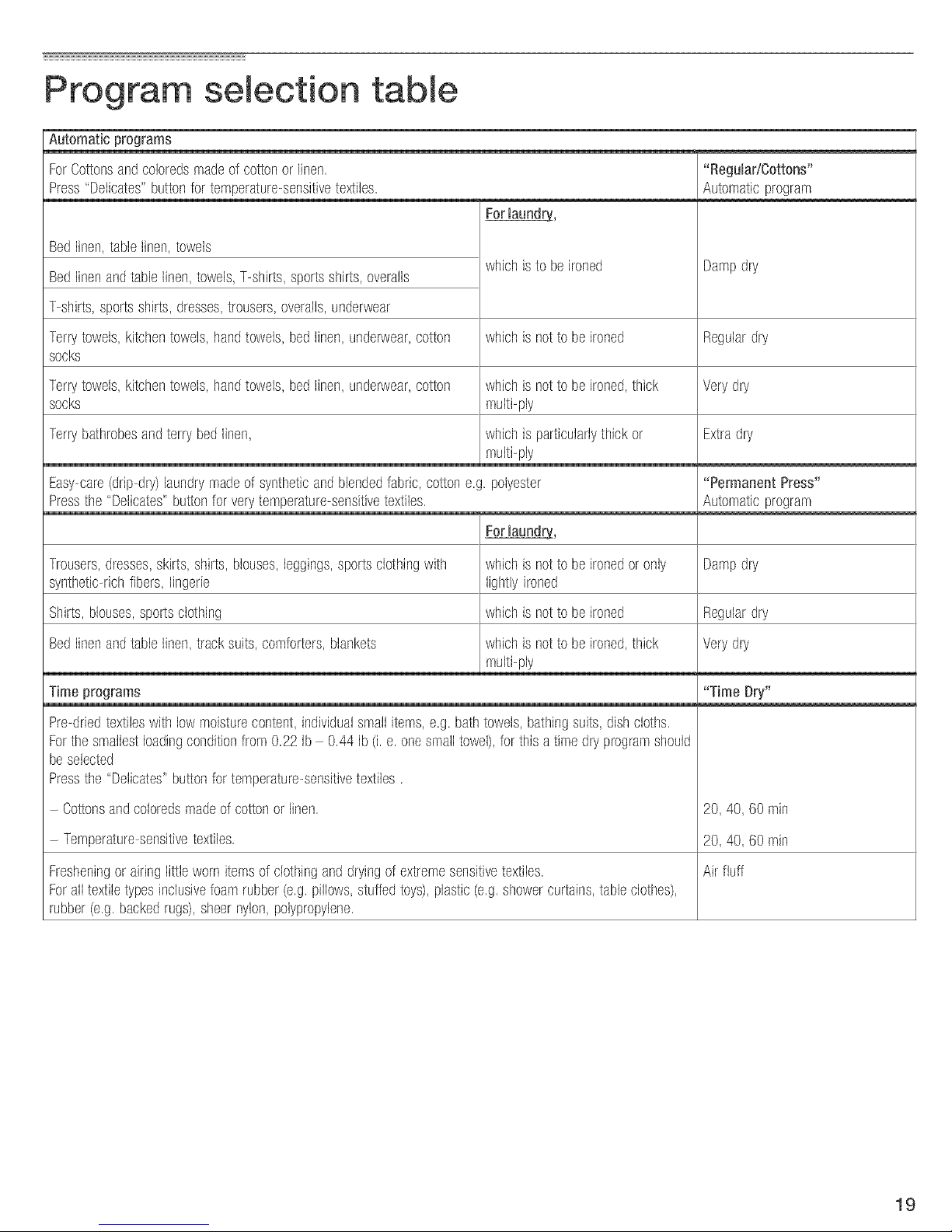

Program

Automatic programs

ForCottonsandcoloredsmadeof cottonorlinen, "Regular/Cottons"

Press"Delicates"buttonfortemperature-sensitivetextiles, Automaticprogram

Bedlinen,tablelinen,towels

Bedlinenandtablelinen,towels,T-shirts,sportsshirts,overalls

T-shirts,sportsshirts,dresses,trousers,overalls,underwear

Terrytowels,kitchentowels,handtowels,bedlinen,underwear,cotton

socks

Terrytowels,kitchentowels,handtowels,bedlinen,underwear,cotton

socks

Terrybathrobesandterrybedlinen,

whichisto be ironed

whichisnotto beironed

whichisnotto beironed,thick

multi-ply

whichisparticularlythickor

multi-ply

Easy-care(drip-dry)laundrymadeof syntheticandblendedfabric,cottone,g, polyester

Pressthe "Delicates"buttonfor verytemperature-sensitivetextiles.

Trousers,dresses,skirts,shirts,blouses,leggings,sportscWthingwith whichis notto beironedoronly

synthetic-richfibers,lingerie lightlyironed

Shirts,blouses,sportsclothing whichisnotto beironed

Bedlinenandtablelinen,tracksuits,comforters,blankets

Time programs

whichisnotto beironed,thick

multi-ply

Pre-drbdtextileswithlowmoisturecontent,individualsmallitems,e,g. bathtowels,bathingsuits,dishcloths.

Forthe smallestloadingconditionfrom022 Ib- 0,44Ib (i,e,onesmalltowel),forthis atimedry programshould

be selected

Pressthe "Delicates"buttonfor temperature-sensitivetextiles,

- Cottonsandcoloredsmadeofcottonorlinen,

- Temperature-sensitivetextiles,

Fresheningor airinglittlewornitemsof clothinganddryingof extremesensitivetextiles,

Foralltextiletypesinclusivefoamrubber(e,g.pillows,stuffedtoys),plastic(e,g,showercurtains,tableclothes),

rubber(e,g,backedrugs),sheernylon,polypropylene,

Dampdry

Regulardry

Verydry

Extradry

"PermanentPress"

Automaticprogram

Dampdry

Regulardry

Verydry

"Time Dry"

20,40,60 min

20,40,60 min

Airfiuff

19

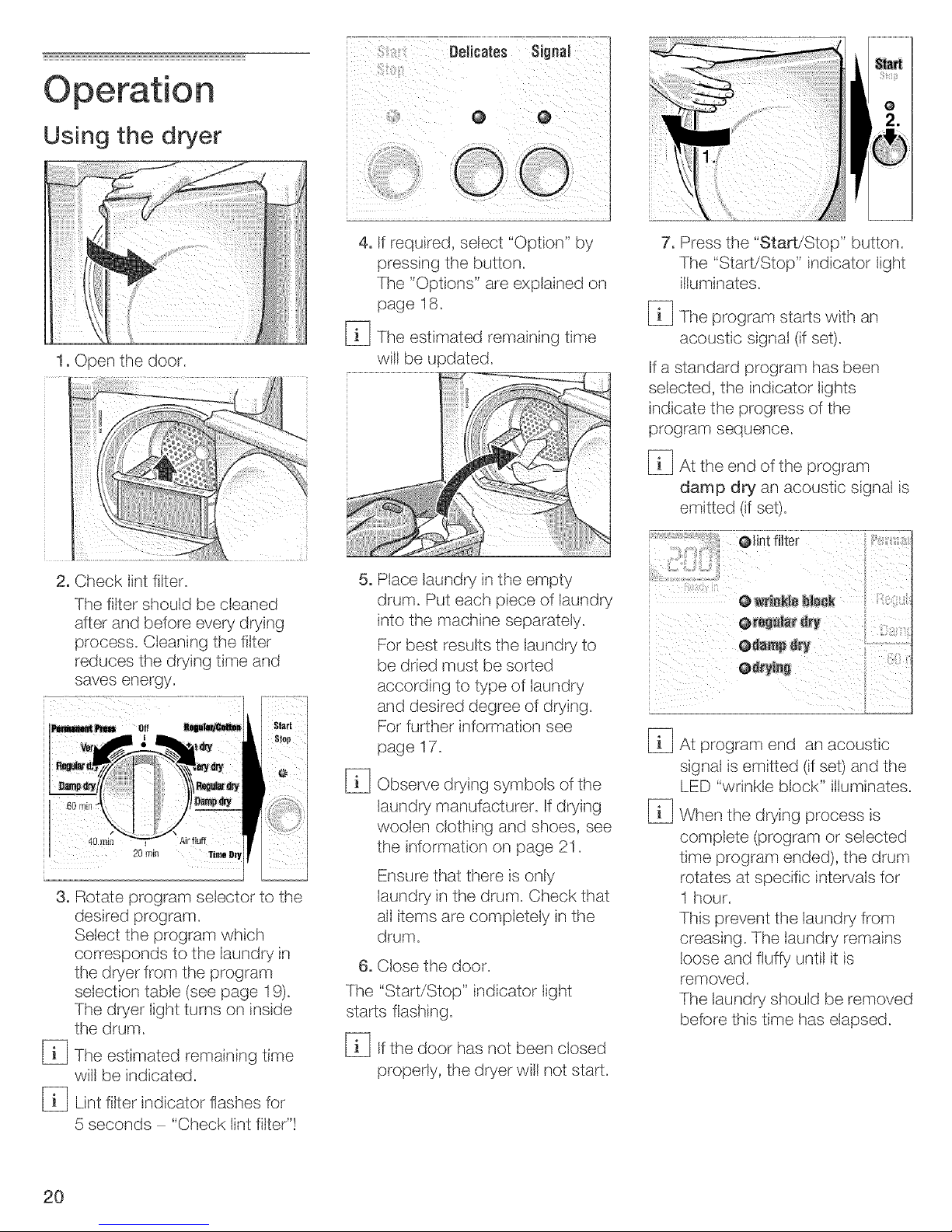

Operation

Vsing the dryer

!. Open the door,

2. Check tint filter.

The filter should be cleaned

after and before every drying

process. Cleaning the filter

reduces the drying time and

saves energy.

3. Rotate program selector to the

desired program.

Select the program which

corresponds to the laundry in

the dryer from the program

selection table (see page 19).

The dryer light turns on inside

the drum.

[_3 The estimated remaining time

will be indicated.

[_3 Lint filter indicator flashes for

5 seconds "Checktint fitter"!

} : Delicates Signal

4. If required, select "Option" by

pressing the button.

The "Options" are explained on

page 18.

E_The estimated remaining time

will be updated.

5.

E]

Place laundry in the empty

drum. Put each piece of laundry

into the machine separately.

For best results the laundry to

be dried must be sorted

according to type of laundry

and desired degree of drying.

For further information see

page 17.

Observe drying symbols of the

laundry manufacturer. If drying

woolen clothing and shoes, see

the information on page 21.

Ensure that there is only

laundry in the drum. Check that

all items are completely in the

drum.

6. Close the door.

The "Start/Stop" indicator light

starts flashing.

[_lf the door has not been closed

properly, the dryer will not start.

7. Press the "Start/Stop" button.

The "Start/Stop" indicator light

illuminates.

E_The program starts with an

acoustic signal (if set).

If a standard program has been

selected, the indicator lights

indicate the progress of the

program sequence.

E_At the end of the program

damp dry an acoustic signal is

emitted (if set).

@lintfilter :::?

i ill

@w_lnkleblnck

cry

o ry .g

E]

E]

At program end an acoustic

signal is emitted (if set) and the

LED "wrinkle block" illuminates.

When the drying process is

complete (program or selected

time program ended), the drum

rotates at specific intervals for

1 hour.

This prevent the laundry from

creasing. The laundry remains

loose and fluffy until it is

removed.

The laundry should be removed

before this time has elapsed.

2O

8. Open the door.

9. Take the laundry out of the

dryer.

40rain ! Airfluff

20 rnir_ TimeDry

10. Rotate the program selector

to "Off".

The dryer light goes out.

11. Clean the filter.

The filter should be cleaned

after each drying process.

Cteaning the filter reduces the

drying time and saves energy.

12. Close the door.

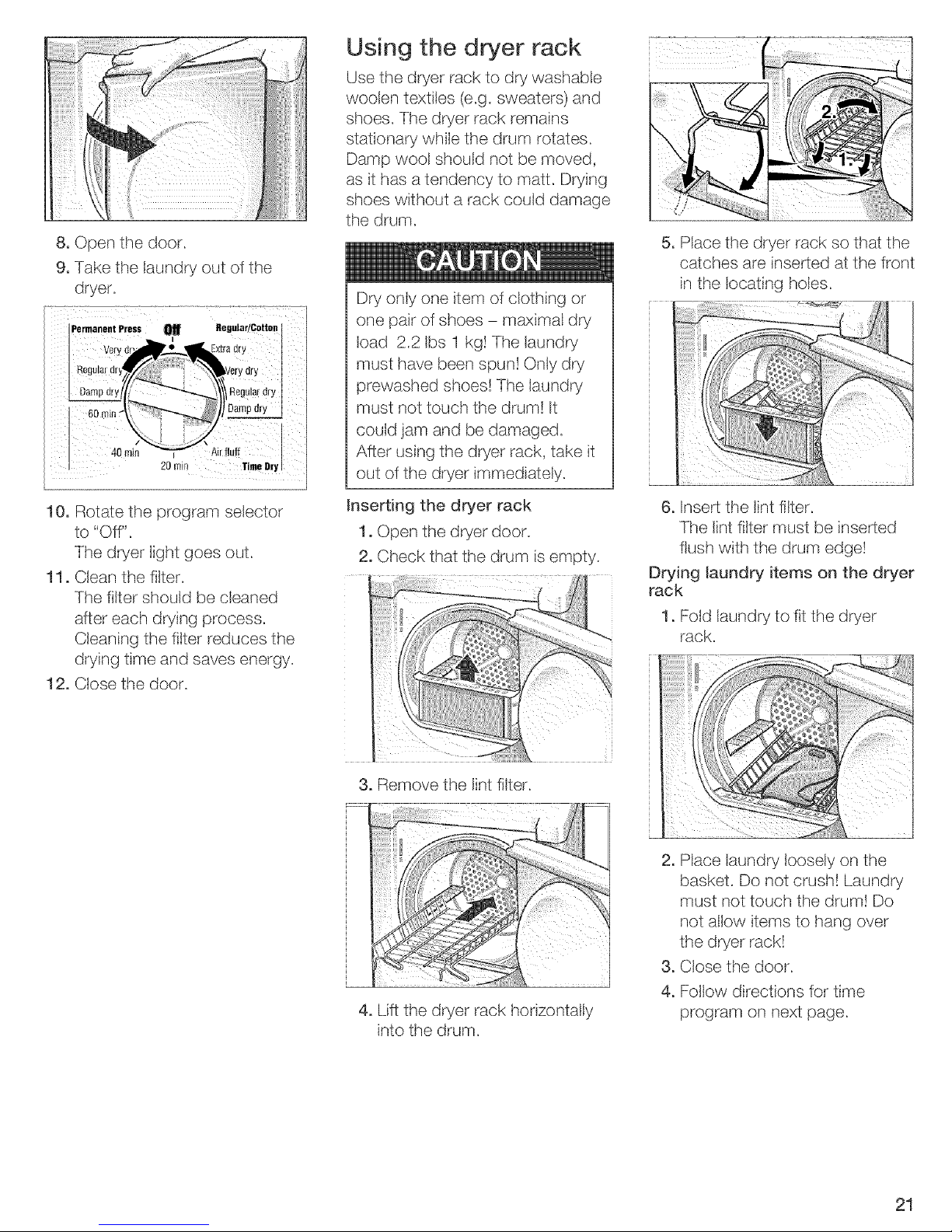

Using the dryer rack

Use the dryer rack to dry washable

woolen textiles (e.g. sweaters) and

shoes. The dryer rack remains

stationary while the drum rotates.

Damp woot should not be moved,

as it has a tendency to matt. Drying

shoes without a rack could damage

the drum.

Dry onty one item of clothing or

one pair of shoes maximat dry

toad 2.2 Ibs 1 kg! The laundry

must have been spun! Only dry

prewashed shoes! The laundry

must not touch the drum! It

could jam and be damaged.

After using the dryer rack, take it

out of the dryer immediately.

Inserting the dryer rack

1. Open the dryer door.

2. Check that the drum is empty.

3. Remove the tint filter.

6. Insert the tint filter.

The lint filter must be inserted

flush with the drum edge!

Drying laundry items on the dryer

rack

1. Fold laundry to fit the dryer

rack.

4. Lift the dryer rack horizontally

into the drum.

2. Place laundry toosety on the

basket. Do not crush! Laundry

must not touch the drum! Do

not atlow items to hang over

the dryer rack!

3. Close the door.

4. Fotlow directions for time

program on next page.

21

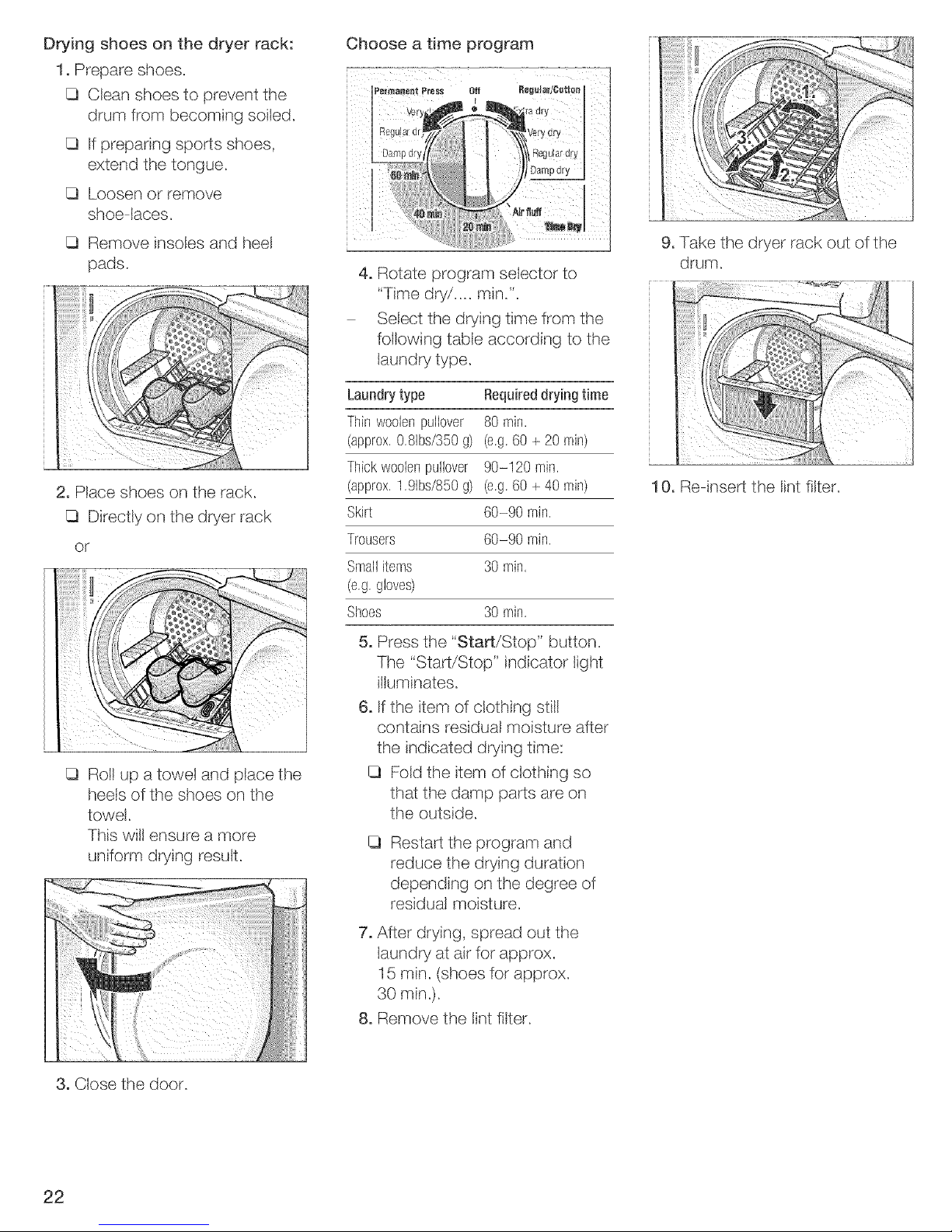

Drying shoes on the dryer rack:

1. Prepare shoes.

Clean shoes to prevent the

drum from becoming soiled.

If preparing sports shoes,

extend the tongue.

Loosen or remove

shoe laces.

Remove insoles and heel

pads.

2. Place shoes on the rack.

Directly on the dryer rack

OF

Roll up a towel and place the

heels of the shoes on the

towel.

This will ensure a more

uniform drying result.

Choose a time program

4. Rotate program selector to

"Time dry/ .... rain.".

Select the drying time from the

following table according to the

laundry type.

Laundrytype Requireddryingtime

Thinwoolenpullover 80 min,

(approx.0.81bs/350g) (e.g.60+ 20 min)

Thickwoolenpullover 90-120 min.

(approx.1.91bs/850g) (e.g.60+ 40 min)

Skirt 60-90 min.

Trousers 60-90 rain.

Smallitems 30 min.

(e.g.gloves)

Shoes 30 min.

5. Press the "Start/Stop" button.

The "Start/Stop" indicator light

illuminates.

6. If the item of clothing still

contains residual moisture after

the indicated drying time:

Fold the item of clothing so

that the damp parts are on

the outside.

Restart the program and

reduce the drying duration

depending on the degree of

residual moisture.

7. After drying, spread out the

laundry at air for approx.

15 min. (shoes for approx.

30 rain.).

8. Remove the tint filter.

9. Take the dryer rack out of the

drum.

10. Re insert the tint filter,

3. Close the door.

22

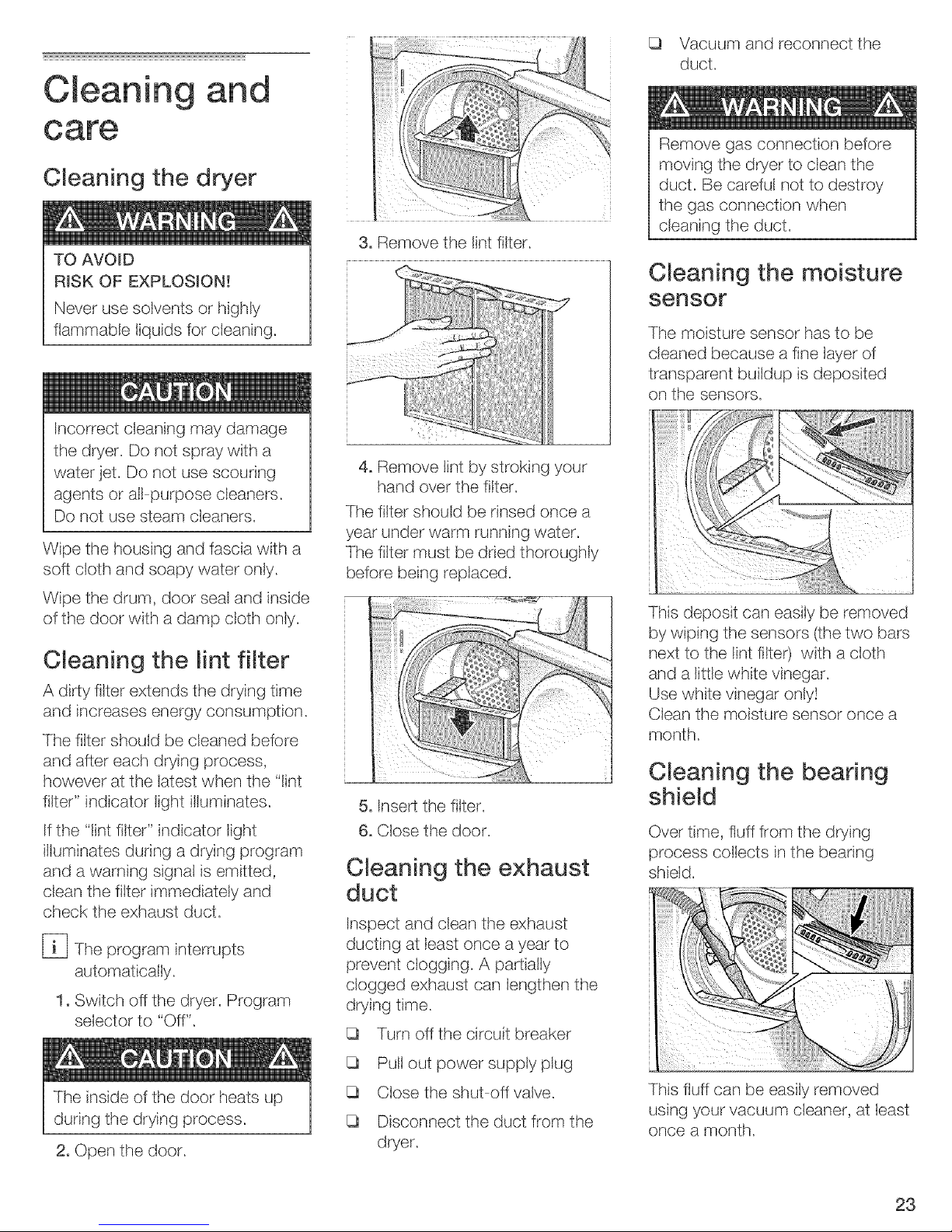

Cleaning

Cleaning the dryer

TO AVOID

RISK OF EXPLOSION!

Never use solvents or highly

flammable liquids for cleaning.

Incorrect cleaning may damage

the dryer. Do not spray with a

water jet. Do not use scouring

agents or all purpose cleaners.

Do not use steam cleaners.

Wipe the housing and fascia with a

soft cloth and soapy water only.

Wipe the drum, door seat and inside

of the door with a damp cloth only.

Cleaning the lint filter

A dirty filter extends the drying time

and increases energy consumption.

The filter should be cleaned before

and after each drying process,

however at the latest when the "tint

filter" indicator light illuminates.

If the "tint filter" indicator light

illuminates during a drying program

and a warning signal is emitted,

clean the filter immediately and

check the exhaust duct.

[_The program interrupts

automatically.

1. Switch off the dryer. Program

selector to "Off".

The inside of the door heats up

during the drying process.

2. Open the door.

3. Remove the lint filter,

4. Remove tint by stroking your

hand over the filter.

The filter should be rinsed once a

year under warm running water.

The filter must be dried thoroughly

before being replaced.

5. Insert the filter.

6. Close the door.

Cleaning the exhaust

duct

Inspect and clean the exhaust

ducting at least once a year to

prevent clogging. A partially

clogged exhaust can lengthen the

drying time.

13 Turn off the circuit breaker

13 Pull out power supply plug

13 Close the shut off valve.

13 Disconnect the duct from the

dryer.

13 Vacuum and reconnect the

duct.

Remove gas connection before

moving the dryer to clean the

duct. Be careful not to destroy

the gas connection when

cleaning the duct.

Cleaning the moisture

sensor

The moisture sensor has to be

cleaned because a fine layer of

transparent buildup is deposited

on the sensors.

This deposit can easily be removed

by wiping the sensors (the two bars

next to the tint filter) with a cloth

and a little white vinegar.

Use white vinegar only!

Clean the moisture sensor once a

month.

Cleaning the bearing

shield

Over time, fluff from the drying

process collects in the bearing

shield.

This fluff can be easily removed

using your vacuum cleaner, at least

once a month.

23

Change the Light bulb

The dryer light turns on inside the

drum when you open the door,

To change the light bulb:

[_ Set program selector to "Off",

[_ Turn off the circuit breaker,

[_ Pull out power supply plug,

[_ Open the door and locate the

tight bulb on the upper left side

of the seaI,

Loosen the screw of the cover

and open the cover.

Turn bulb counterclockwise.

Replace the bulb with a new

appliance bulb only (obtainable

through parts department).

Replace the cover and secure

with the screw.

Plug in dryer or reconnect

power supply.

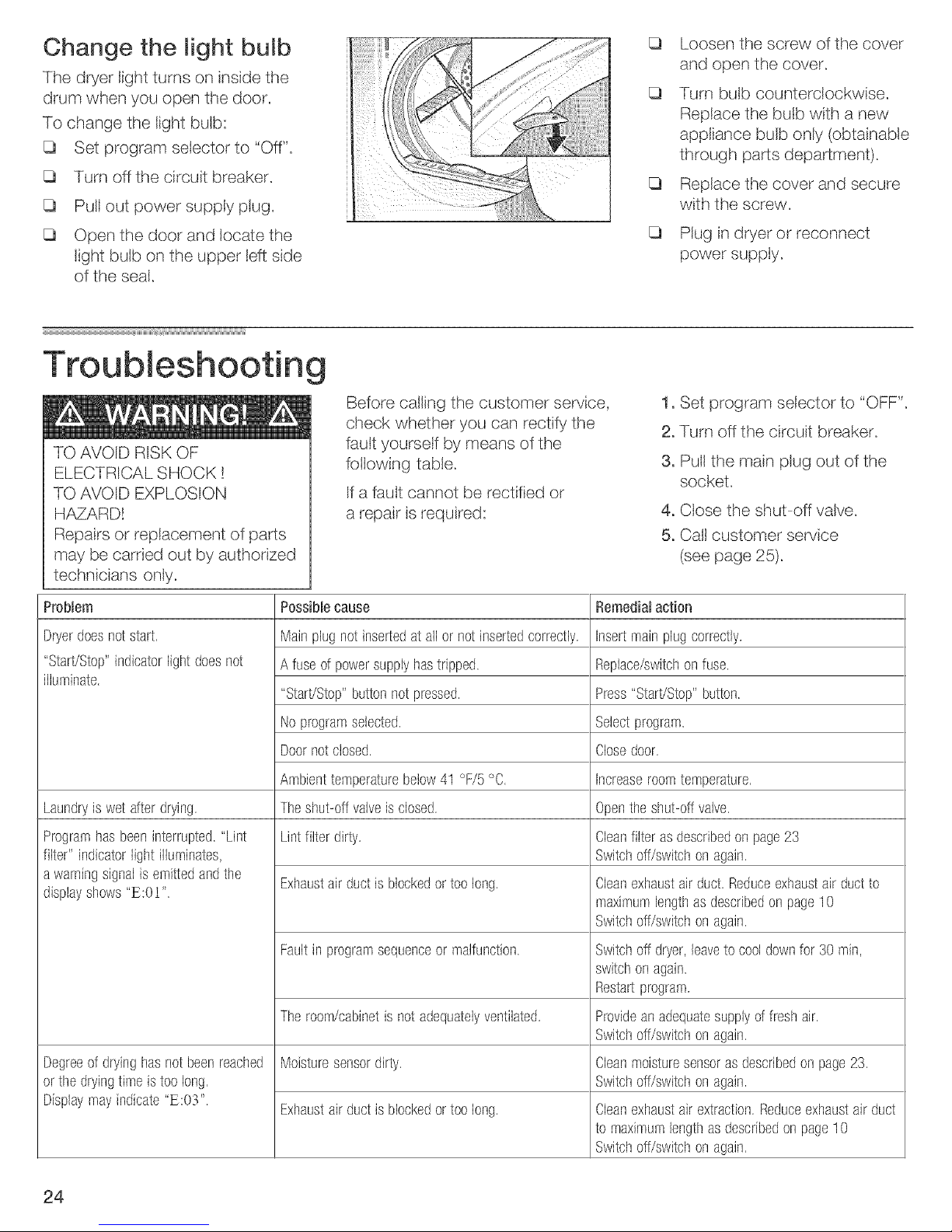

TO AVOID RISK OF

ELECTRICAL SHOOK !

TO AVOID EXPLOSION

HAZARD!

Repairs or replacement of parts

may be carried out by authorized

technicians onty.

Problem

Dryerdoesnotstart.

"Start/Stop"indicatorlightdoesnot

illuminate.

Laundryiswet afterdrying.

Programhasbeeninterrupted."Lint

filter" indicatorlightilluminates,

a warningsignalisemittedandthe

displayshows"]E:0i".

Degreeofdryinghasnotbeenreached

or thedryingtimeistoo long.

Displaymayindicate"]E:03".

Before calling the customer service,

check whether you can rectify the

fault yourself by means of the

following table.

If a fault cannot be rectified or

a repair is required:

Possiblecause

Mainplugnot insertedatallor not insertedcorrectly.

A fuseofpowersupplyhastripped.

"Start/Stop"buttonnotpressed.

Noprogramselected.

Doornot closed.

Ambienttemperaturebelow41 °F/5°C.

Theshut-offvalveisclosed.

Lintfilterdirty.

Exhaustair ductis blockedortoolong.

Faultin programsequenceor malfunction,

Theroom/cabinetis notadequatelyventilated.

Moisturesensordirty.

Exhaustairductisblockedortoo long.

1. Set program selector to "OFF".

2. Turn off the circuit breaker.

3. Pull the main plug out of the

socket.

4. Close the shut off valve.

5. Call customer service

(see page 25).

Remedialaction

Insertmainplugcorrectly.

Replace/switchon fuse.

Press"Start/Stop"button.

Selectprogram.

Closedoor.

Increaseroomtemperature.

Opentheshut-offvalve.

Cleanfilterasdescribedonpage23

Switchoff/switchonagain.

Cleanexhaustairduct,Reduceexhaustairductto

maximumlengthasdescribedonpage10

Switchoff/switchonagain.

Switchoffdryer,leaveto cooldownfor 30 min,

switchon again.

Restartprogram.

Provideanadequatesupplyoffreshair.

Switchoff/switchonagain.

Cleanmoisturesensorasdescribedon page23.

Switchoff/switchonagain.

Cleanexhaustair extraction.Reduceexhaustair duct

to maximumlengthasdescribedon page10

Switchoff/switchonagain.

24

Problem

Degreeof dryinghasnotbeenreached

or thedryingtimeistoo long.

Displaymayindicate"]E:03".

Drumlightdoesnotfunction.

"Start/Stop"indicatorlightdoesnot

illuminate,"Lintfilter" indicatorlight

flashes."wrinkleblock"indicatorlights.

Thedisplayshows"000".

PossibJecause

Lintfilterdirty.

Unsuitableprogramselected.

Maximumdryingtimewasexceeded.

Motorlimittemperaturewasexceeded.

Noprogramselected.

Lightbulbdefective,lightbulbburnedout.

Nopowersupply.

Faultin programsequenceor malfunction.

Remedialaction

Cleanfilter asdescribedonpage23.

Switchoff/switchonagain.

Spinlaundryat higherspeedinthewashing

machine.Switchoff/switchonagain.

Selectprogramwithaid d theprogramselection

table(seepage19).Switchoff/switchonagain.

Cleanlintfilter (seepage23).

Checkexhaustair extraction.

Spinlaundryat a higherspeedinyourwasher.

Switchoffdryer,leaveto cooldownfor 30 min.

Switchonagain.Startprogram.

Selectprogram.

Changelight bulb,seepage24.

Guaranteepowersupply.

Switchoffdryer,leaveto cooldownfor 30 min,

switchon again,

Restartprogram.

SERVICE and REPAIR

CAUTION Label all wires prior

to disconnection when servicing

controls, Wiring errors can cause

improper and dangerous

operation, verify proper

operation after servicing,

The Bosch dryers require no special

care other than the care and

cleaning noted above.

j_] If you are having a problem with

your dryer, before calling for

service please refer to Table on

page 24, following.

If service becomes necessary,

contact your dealer or installer or an

authorized service center. Do not

attempt to repair the appliance

yourself. Any work performed by

unauthorized personnel may void

the warranty.

If you are having a problem with

your Bosch dryer and are not

pleased with the service you have

received:

First, please contact your

installer or the Bosch

Authorized Service Contractor

in your area and explain to

them why you are not satisfied.

This will usually correct the

problem.

If after working with your

installer or service person the

problem still has not been

resolved to your satisfaction,

please let us know by either

writing to us at,

BSH Home Appliances

5551 McFadden Avenue

Huntington Beach, CA 92649

or, calling us at

1-800-944-2904.

Please be sure to include, if writing,

or have available, if calling, the

following information:

Model Number

Serial Number

Date of Original Purchase

Date Problem Originated

Explanation of Problem

Also, if writing, please be sure to

include a daytime telephone

number and a copy of the sales

invoice,

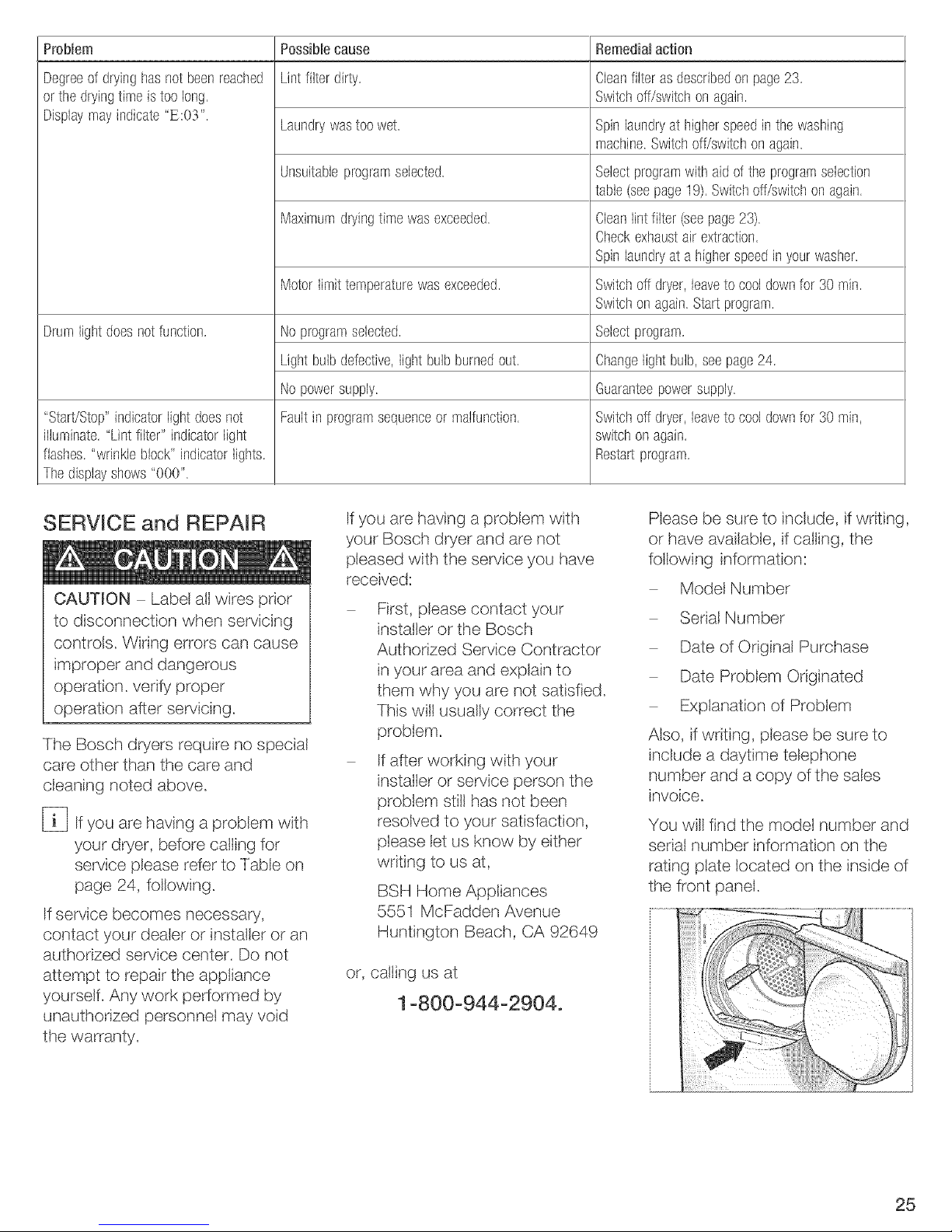

You wilt find the model number and

serial number information on the

rating plate located on the inside of

the front panel,

;!/

j--

25

Loading...

Loading...