Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

GPL 2

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente, appelez

ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Version Version française Versión en español

See page 3 Voir page 12 Ver la página 21

Page 2

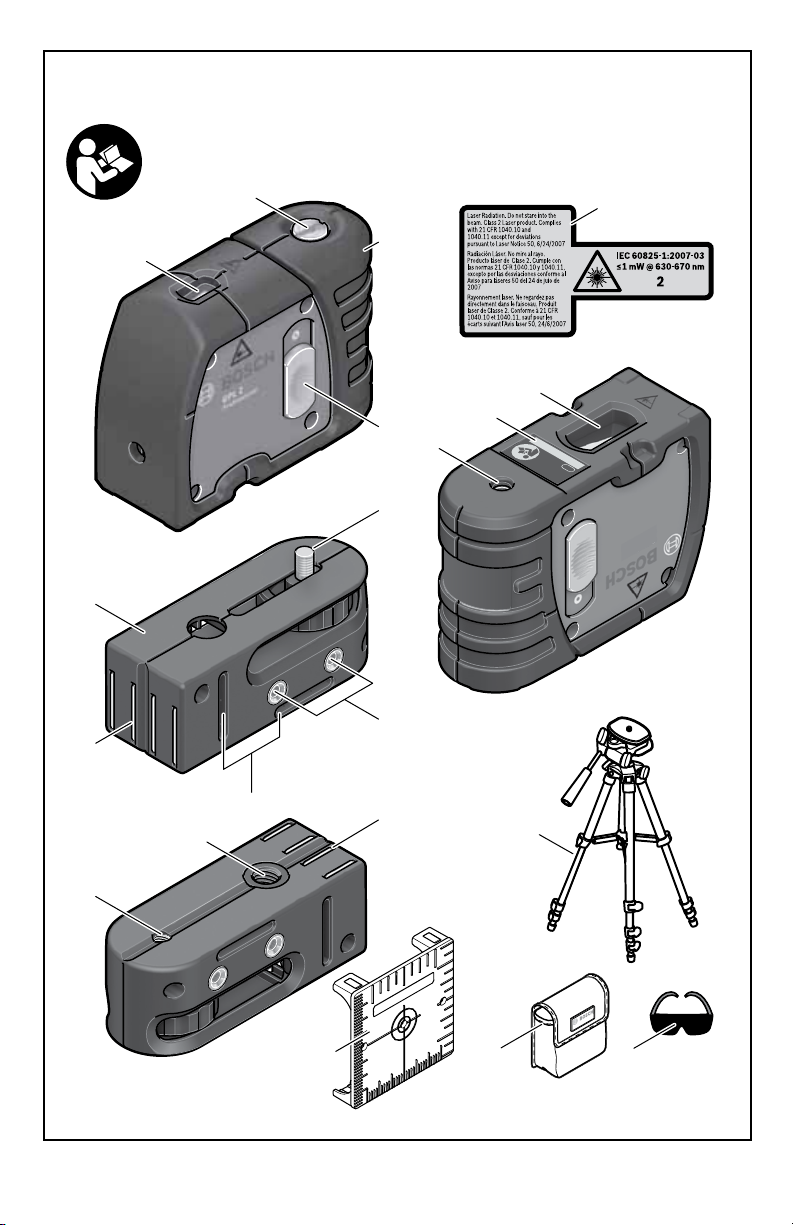

12

2

1

3

5

1

7

4

6

177

Made in China

Mount Prospect, IL

Robert Bosch Tool Corp.

GPL 2 3 601 K66 110

9

GPL 2

8

10

13

14

11

15

12

-2-

16

18

17

Page 3

General Safety Rules

!

WARNING

below may result in hazardous radiation

exposure, electric shock, fire and/or serious

injury. The term “tool” in all of the warnings listed

below refers to your mains-operated (corded) tool

or battery-operated (cordless) tool.

The following labels are on your laser tool for

your convenience and safety. They indicate

where the laser light is emitted by the tool.

ALWAYS BE AWARE of their location when

using the tool.

DO NOT remove or deface any warning or caution labels. Removing labels increases the risk

of exposure to laser radiation.

!

CAUTION

ALWAYS make sure that any bystanders in the vicinity of use are made aware of the

dangers of looking directly into the laser tool.

DO NOT place the laser tool in a position that may cause anyone to stare into the laser

beam intentionally or unintentionally. Serious eye injury could result.

ALWAYS position the laser tool securely. Damage to the laser tool and/or serious injury to the

user could result if the laser tool fails.

ALWAYS use only the accessories that are recommended by the manufacturer of your

laser tool. Use of accessories that have been designed for use with other laser tools could result in

serious injury.

DO NOT use this laser tool for any purpose other than those outlined in this manual. This

could result in serious injury.

DO NOT leave the laser tool “ON” unattended in any operating mode.

DO NOT disassemble the laser tool. There are no user serviceable parts inside. Do not modify

the product in any way. Modifying the laser tool may result in hazardous laser

radiation exposure.

DO NOT use the laser viewing glasses as safety goggles. The laser viewing glasses are used

for improved visualization of the laser beam, but they do not protect against laser radiation.

DO NOT use the laser viewing glasses as sun glasses or in traffic. The laser viewing glasses

do not afford complete UV protection and reduce color perception.

DO NOT use any optical tools such as, but not limited to, telescopes or transits to view the

laser beam. Serious eye injury could result.

DO NOT stare directly at the laser beam or project the laser beam directly into the eyes of

others. Serious eye injury could result.

Read all instructions. Failure

to follow all instructions listed

Do not direct the laser beam at persons or animals and do not stare into the

laser beam yourself. This tool produces laser class 2 laser radiation and

complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007. This can lead to persons being blinded.

Use of controls or adjustments or performance of procedures other than those

specified in this manual, may result in hazardous radiation exposure.

SAVE THESE INSTRUCTIONS

FCC Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

-3-

Page 4

!

WARNING

equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

- Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

DO NOT operate the laser tool around

children or allow children to operate the

laser tool. Serious eye injury could result.

Electrical safety

Batteries can explode or leak, cause injury

or fire. To reduce this risk, always follow all

instructions and warnings on the battery label

and package.

DO NOT short any battery terminals.

DO NOT charge alkaline batteries.

DO NOT mix old and new batteries.

Replace all of them at the same time with

new batteries of the same brand and type.

DO NOT mix battery chemistries.

Dispose of or recycle batteries per local

code.

DO NOT dispose of batteries in fire.

Keep batteries out of reach of children.

Remove batteries if the device will not be

used for several months.

Personal safety

Stay alert, watch what you are doing and

use common sense when operating a tool.

Do not use a tool while you are tired or

under the influence of drugs, alcohol or

medication. A moment of inattention while

operating a tool may result in serious personal

injury or incorrect measurement results.

Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

Multiple-Purpose Attachment

Keep the multiple-purpose

attachment 8 away from

cardiac pacemakers. The

magnets 12 generate a field

that can impair the function of

cardiac pacemakers.

• Keep the multiple-purpose attachment

8 away from magnetic data medium

and magnetically-sensitive equipment.

The effect of the magnets 12 can lead to

irreversible data loss.

Use and care

Use the correct tool for your application.

The correct tool will do the job better and safer.

Do not use the tool if the switch does not

turn it on and off. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Store idle tool out of the reach of children

and do not allow persons unfamiliar with

the tool or these instructions to operate

the tool. Tools are dangerous in the hands of

untrained users.

Maintain tools. Check for misalignment or

binding of moving parts, breakage of parts

and any other condition that may affect

the operation. If damaged, tool must be

repaired by the authorized Bosch service

center before further use. Many accidents are

caused by poorly maintained tools.

-4-

Page 5

Use the tool, accessories, etc., in

accordance with these instructions and in

the manner intended for the particular type

of tool, taking into account the working

conditions and the work to be performed.

Use of the tool for operations different from

those intended could result in a hazardous

situation.

Service

Have your tool serviced by a qualified repair

person using only identical replacement

parts. This will ensure that the safety of the tool

is maintained.

Intended Use

This tool is intended for accurate transfer of plumb point from floor to ceiling.

Preparation

Develop a periodic maintenance schedule

for tool. When cleaning a tool be careful not

to disassemble any portion of the tool since

internal wires may be misplaced or pinched

or may be improperly mounted. Certain

cleaning agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage

plastic parts.

Inserting/Replacing the Battery

Alkaline batteries are recommended for

the tool.

To open the battery compartment 3, turn the

latch 2 in clockwise direction to position and

pull off the battery lid. Insert the batteries

provided.

When inserting, pay attention to the correct

polarity according to the representation on the

inside of the battery compartment.

Position the battery lid to the bottom of the

housing and then push it upward. To lock the

battery lid, turn the latch 2 in counterclockwise

direction to the position.

Features

The numbering of the product features shown

refers to the illustration of the tool on the

graphic page.

1 Exit opening for laser beam

2 Latch of battery lid

3 Battery lid

4 On/Off switch

5 Laser warning label

6 Tripod mount 1/4”

7 Serial number

8 Multiple-Purpose Attachment

9 Locking screw for Multi-Purpose

Attachment

10 Screw holes of Multi-Purpose

Attachment

When the laser beams flash slowly during

operation,the batteries are low. When the

flashing begins, the tool can be operated for

approx. 8 h.

Always replace all batteries at the same time.

Only use batteries from one brand and with the

identical capacity.

!

WARNING

it for extended periods. When storing for

extended periods, the batteries can corrode and

discharge themselves.

11 Opening for strap attachment

12 Magnets

13 1/4” tripod mount on Multi-Purpose

Attachment

14 5/8” tripod mount on Multi-Purpose

Attachment

15 Laser Target*

16 Belt Pouch*

17 Laser viewing glasses*

18 Tripod*

*The accessories illustrated or described are

not included as standard delivery.

Remove the batteries from

the tool when not using

-5-

Page 6

Technical Data

Working range (typical) ......... 100 ft (30m)

Leveling Accuracy

Minimum Factory

Accuracy ...............up to 1/8-in at 30 ft

(up to 3 mm/10 m)

Typical Accuracy ........ up to 1/16-in at 30 ft

(up to 2 mm/10 m)

Self-leveling range (typical) alongside the:

– lateral axis ......................... ±3°

Leveling duration, typically ............. <3s

Operating temperature ........ 14 °F... 104 °F

(–10 °C ... +40 °C)

Storage temperature ......... -4 °F... 158 °F

( –20 °C ... +70 °C)

Relative air humidity, max. .............90 %

Operation

Initial Operation

!

WARNING

irradiation.

Do not subject the tool to extreme

temperatures or variations in temperature.

As an example, do not leave it in vehicles for

longer periods. In case of large variations in

temperature, allow the tool to adjust to the

ambient temperature before putting it into

operation. In case of extreme temperatures or

variations in temperature, the accuracy of the

tool can be impaired.

Avoid heavy impact or falling of the tool.

After heavy exterior impact on the tool, an

accuracy check should always be carried

out before continuing to work (see “Leveling

Accuracy”). Do not use the tool when the laser

emitting cover has been damaged after heavy

exterior impact on the tool. Many accidents are

caused by poorly maintained tools.

Switch the tool off during transport. When

switching off, the leveling unit, which can be

damaged in case of intense movement, is

locked.

To switch on the tool, slide the On/Off switch

4 upward so that “I” is indicated on the switch.

Immediately after switching on, the tool sends a

laser beam out of each exit opening 1.

Do not point the laser beam at persons or

animals and do not look into the laser beam

Protect the tool against

moisture and direct sun

Switching On and Off

Laser class ........................... 2

Laser type ................635 nm, <1 mW

Tripod mount ......................1/4-20

Batteries ................3 x 1.5 V LR6 (AA)

Operating lifetime, approx. ..............24 h

Weight .....................0.5lb (0.25kg)

Dimensions ...........4-1/8” x 3-1/8” x 1-5/8”

(105 x 80 x 42 mm)

Please observe the article number on the type

plate of your tool. The trade names of the

individual tools may vary.

The tool can be clearly identified with the serial

number 7 on the type plate.

yourself, not even from a large distance.

To switch off the tool, push the On/Off switch

4 downward so that “0” is indicated on the

switch. When switching off, the leveling unit is

locked.

Setting the Automatic Switch-off

By default, the tool automatically shuts off

20 minutes after being switched on. The

automatic switch-off can be set from 20 minutes

to 8 hours. For this, switch the tool on, then

immediately off, and then on again within 4

s. To confirm the change, all laser beams

will flash quickly for 2 s after switching on the

second time.

Do not leave the switched on tool

unattended and switch the tool off after

use. Other persons could be blinded by the

laser beam. When switching on the tool the

next time, the automatic switch-off is set to

20 minutes again.

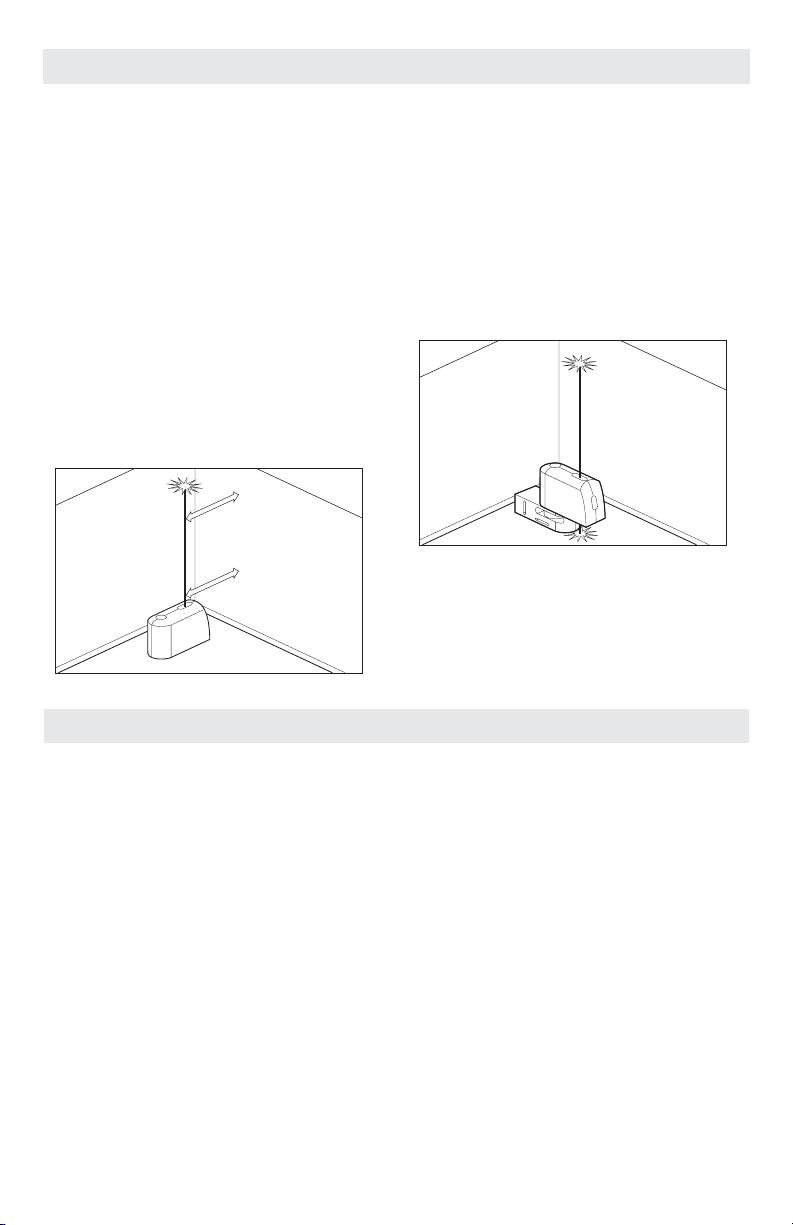

Working with Automatic Leveling

Position the tool on a level and firm support,

attach it to the holder 8 or to the tripod 18.

After switching on, the automatic leveling

function automatically compensates

irregularities within the self-leveling range from

±5° (longitudinal axis) and ±3° (lateral axis). The

leveling is finished as soon as the laser points

do not move any more.

If the automatic leveling function is not possible,

e.g. because the surface on which the tool

stands deviates by more than 5° (or 3° from the

horizontal plane) the laser beams flash rapidly.

-6-

Page 7

In this case, bring the tool to the level position

d

d

and wait for the self-leveling to take place. As

soon as the tool is within the self-leveling range

of ±5° or ±3° respectively, all laser beams light

up continuously again.

In case of ground vibrations or position changes

during operation, the tool is automatically

leveled in again. To avoid errors by moving the

tool, check the position of the laser beams with

regard to the reference points upon re-leveling.

Leveling Accuracy

Influences on Accuracy

The ambient temperature has the greatest

influence. Especially temperature differences

occurring from the ground upward can divert

the laser beam.

As thermal fluctuation is largest close to the

ground, the tool, if possible, should be mounted

on a commercially available tripod and placed in

the center of the working area.

Apart from exterior influences, device-specific

influences (such as heavy impact or falling

down) can lead to deviations. Therefore, check

the accuracy of the tool each time before

starting your work.

Should the tool exceed the maximum deviation

during one of the tests, see recalibration

procedure or have it recalibrated by a Bosch

after-sales service center.

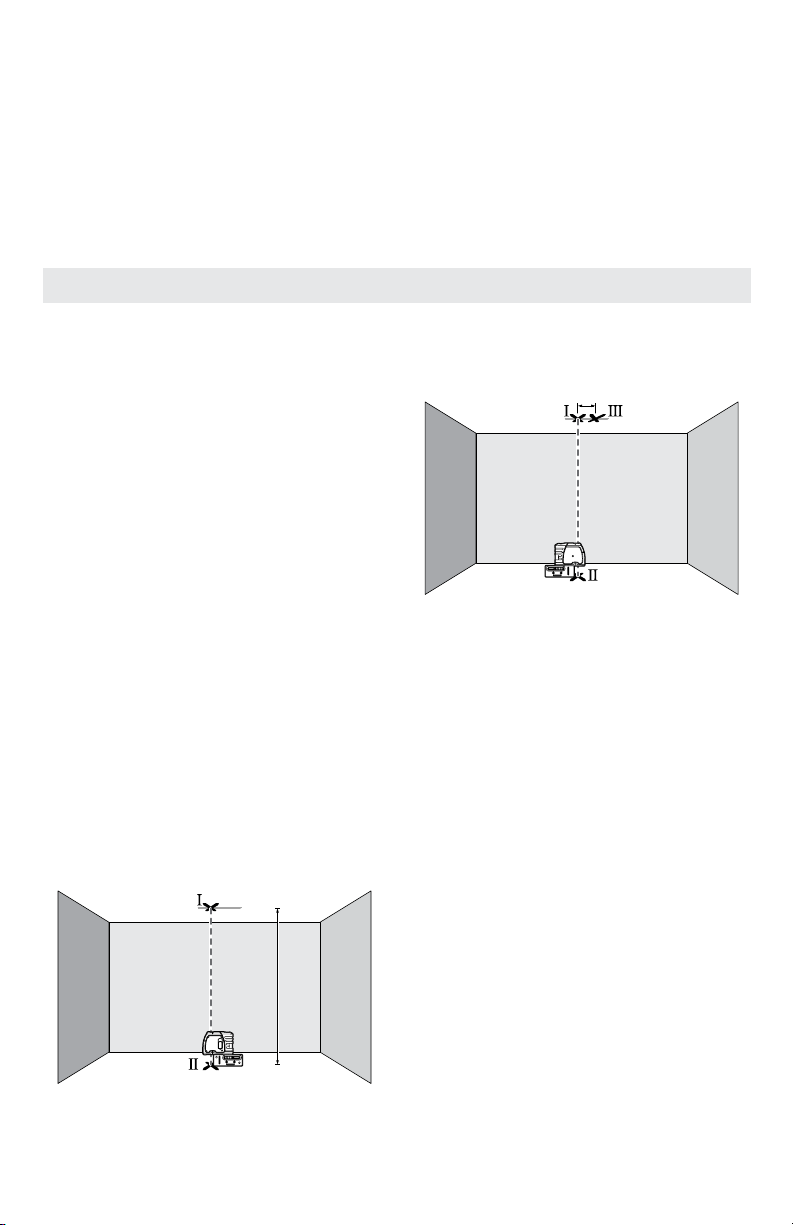

Checking the Vertical Leveling Accuracy

For this check, a free measuring distance of

approx. 13 ft between floor and ceiling on a firm

surface is required.

– Draw a straight line on the ceiling.

– Mount the tool to the holder or a tripod.

Switch the tool on and rotate it in such a

manner that the bottom plumb beam can

be seen on the floor.

13 ft

– Position the tool in such a manner that the

upper plumb beam points against the line

on the ceiling. Allow the tool to level in.

Working Advice

Always use the center of the laser point for

marking. The size of the laser point changes

with the distance.

Mark the center of the upper laser point on

the line on the ceiling (point I). Also, mark

the center of the laser point on the floor

(point II).

– Rotate the tool by 180°. Position it in such a

manner that the center of the bottom laser

point is directed on the already marked

point II and the upper laser point is directed

against the line on the ceiling. Allow the

tool to level in. Mark the center of the upper

laser point on the line on the ceiling (point

III).

– The difference d of both marked points I

and III on the ceiling results in the actual

deviation of the tool to the plumb line.

On the measuring distance of 2 x 13 ft = 26 ft ,

the maximum allowable deviation is:

26 ft x ±0.0036 in/ft = ±3/16 in.

Thus, the difference d between points I and III

should not exceed 3/16 in (max.).

Recalibration Procedure (Up & Down

Beams)

All tools are calibrated when processed

through the Bosch quality control program. This

process assures that the customer receives a

superior product which conforms to the Product

Specifications. Although tools have been

calibrated before reaching our customers, it

contains many precision machined parts which

may be affected if the instrument is subjected to

abuse. Therefore, if the device is ever dropped

-7-

Page 8

or sustains significant impact, the user should

B

A

5

ʹ

50

ʹ

C

1/2

1 ecafruS2 ecafruS

check calibration by following these steps:

Calibrating the Top and Bottom Beams

1. Choose your recalibration site. To get the

most accurate calibration possible, it is best

to use a floor/ceiling distance greater than

10’ (the greater distance, the better the

accuracy). Floor/Ceiling (top of doorway)

distance of approximately 10’.

E

F

D

2. Turn the tool off.

3. Remove the calibration plug on the side of

tool with a flathead screw-driver. Set the

plug where it will not be lost.

4. Draw a straight line on the ceiling.

5. Turn the tool on.

6. Place the tool on the floor (on its accessory

so that you can see the down laser beam

on the floor).

7. Align the tool so that the top laser beam hits

the line on the ceiling.

8. Mark the down laser beam on the floor,

Mark D. Mark the up laser beam on the

ceiling, Mark E.

9. Rotate the tool 180 degrees and align the

down beam with the mark on the floor.

1

E

F

1/2

10. Mark the up beam on the ceiling, Mark F.

You should have two marks on the ceiling.

11. Compare the two marks on the ceiling.

If the two marks are on the same point,

the unit does not need to be calibrated. If

the two marks are not on the same point,

proceed to step 12.

12. Turn the tool off.

13. Insert the 2mm Allen wrench into the side

calibration port. The objective is to get

the laser beam halfway between the two

marks on the ceiling. Turn the Allen wrench

clockwise or counter clockwise to move the

laser beam.

14. Turn the tool on and check the position

of the beam to see if it is exactly halfway

between the marks on the ceiling. If the

beam is not correctly positioned, repeat

steps 12–14 until the beam is at the correct

position.

15. Plug the side calibration plug on the tool.

16. Calibration is complete.

-8-

Page 9

Applications

A

B

Plumbing a surface

1. Position tool close to the surface to

be plumbed.

2. Turn on tool.

3. Measure distance A at a point relatively

close to tool and make a note of the

distance.

4. Measure distance B at a point further away

from tool and make a note of the distance.

Note: The greater the distance between the two

points of measurement, the greater

the accuracy.

5. Compare distance A with distance B. If

distance A equals distance B, then the

surface is plumb. If distance A does not

equal distance B, then the surface is not

plumb and should be corrected.

Plumb

B

A

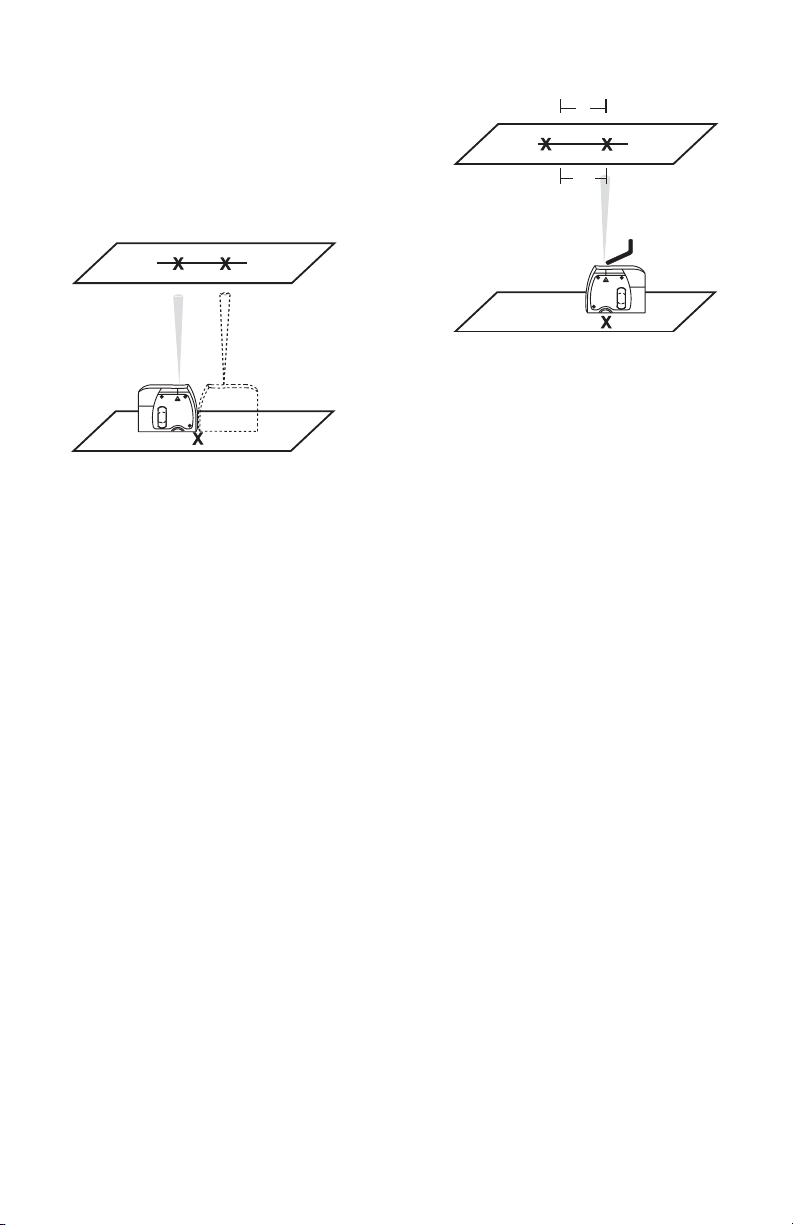

Transferring points with the plumb beam

1. Mark the point to be transferred (labeled

A in this illustration).

2. Use the Mounting accessory or a Tripod

to position the plumb down beam over

point A.

3. The plumb up beam will transfer this point

along a perfectly vertical axis to point B.

4. Mark point B.

Note: This process may be reversed.

Plumb Transfer

B

A

Use with Attachments

To fasten the tool on the Multiple-Purpose

Attachment 8, screw the locking screw 9 of

the Multiple-Purpose Attachment into the 1/4”

tripod mount 6 on the tool and tighten. To rotate

the tool on the Multiple-Purpose Attachment,

slightly loosen the screw 9.

– Rotate the tool on the Multiple-Purpose

Attachment 8 sideward or toward the rear

to make the bottom plumb beam visible.

– Rotate the tool on the Multiple-Purpose

Attachment 8 to project heights with the

horizontal laser beam.

With the Multiple-Purpose Attachment 8, the

tool can be attached as follows:

– Mount the Multiple-Purpose Attachment 8 to

a commercially available camera tripod

via the 1/4” tripod mount 13. For fastening

to a commercially available construction

tripod, use the 5/8” tripod mount 14.

– The Multiple-Purpose Attachment 8 can be

fastened to steel parts via the magnets 12.

– The Multiple-Purpose Attachment 8 can

be fastened to drywall or wood walls with

screws. For this, insert screws with a

minimum length of 2 in. into the screw holes

10 of the Multiple-Purpose Attachment.

– The Multiple-Purpose Attachment 8 can

also be fastened to pipes or similar beams

using a commercially available strap by

threading it through the opening 11 for

strap attachment.

Working with the Tripod

(Optional Accessory)

A tripod 18 offers a stable, height-adjustable

measuring support. Place the tool via the tripod

mount 6 onto the 1/4” male thread of the tripod

and screw the locking screw of the tripod tight.

-9-

Page 10

Working with the Measuring Plate

(Optional Accessory)

With the measuring plate 15, it is possible to

project the laser mark onto the floor or the laser

height onto a wall.

With the zero field and the scale, the offset or

drop to the required height can be measured

and projected at another location. This

eliminates the necessity of precisely adjusting

the tool to the height to be projected.

The measuring plate 15 has a reflective coating

that enhances the visibility of the laser beam

at greater distances or in intense sunlight. The

brightness intensification can be seen only

when viewing, parallel to the laser beam, onto

the measuring plate.

Maintenance and Service

Store and transport the tool only in the

supplied protective case.

Keep the tool clean at all times.

Do not immerse the tool into water or

other fluids.

Wipe off debris using a moist and soft cloth.

Do not use any cleaning agents or solvents.

Regularly clean the surfaces at the exit opening

of the laser in particular, and pay attention to

any fluff of fibers.

If the tool should fail despite the care taken in

manufacturing and testing procedures, repair

should be carried out by an authorized aftersales service center for Bosch power tools.

Laser Viewing Glasses

(Optional Accessory)

The laser viewing glasses filter out the ambient

light. This makes the red light of the laser

appear brighter for the eyes.

• Do not use the laser viewing glasses as

safety goggles. The laser viewing glasses

are used for improved visualization of the

laser beam, but they do not protect against

laser radiation.

• Do not use the laser viewing glasses

as sun glasses or in traffic. The laser

viewing glasses do not afford complete UV

protection and reduce color perception.

In all correspondence and spare parts orders,

please always include the 10-digit article

number given on the type plate of

the tool.

In case of repairs, send in the tool packed in its

protective case 16.

ENVIRONMENT PROTECTION

Recycle raw materials & batteries

instead of disposing of waste. The

unit, accessories, packaging & used batteries

should be sorted for environmentally friendly

recycling in accordance with the latest

regulations.

-10-

Page 11

LIMITED WARRANTY OF BOSCH LASER AND MEASURING TOOL PRODUCTS

Robert Bosch Tool Corporation (“Seller”) warrants to the original purchaser only, that all Bosch

lasers and measuring tools will be free from defects in material or workmanship for a period of one

(1) year from date of purchase. Bosch will extend warranty coverage to two (2) years when you

register your product within eight (8) weeks after date of purchase. Product registration card must

be complete and mailed to Bosch (postmarked within eight weeks after date of purchase), or you

may register on-line at www.boschtools.com/Service/ProductRegistration. If you choose not to

register your product, a one (1) year limited warranty will apply to your product.

30 Day Money Back Refund or Replacement -

If you are not completely satisfied with the performance of your laser and measuring tools, for

any reason, you can return it to your Bosch dealer within 30 days of the date of purchase for a

full refund or replacement. To obtain this 30-Day Refund or Replacement, your return must be

accompanied by the original receipt for purchase of the laser or optical instrument product. A

maximum of 2 returns per customer will be permitted.

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited Warranty

and, to the extent permitted by law, any warranty or condition implied by law, shall be the repair

or replacement of parts, without charge, which are defective in material or workmanship and

which have not been misused, carelessly handled, or misrepaired by persons other than Seller

or Authorized Service Center. To make a claim under this Limited Warranty, you must return the

complete Bosch laser or measuring tool, transportation prepaid, to any BOSCH Factory Service

Center or Authorized Service Center. Please include a dated proof of purchase with your tool. For

locations of nearby service centers, please use our on-line service locator or call 1-877-267-2499.

THIS WARRANTY PROGRAM DOES NOT APPLY TO TRIPODS AND RODS. Robert Bosch

Tool Corporation (“Seller”) warrants tripods and leveling rods for a period of one (1) year from date

of purchase.

THIS LIMITED WARRANTY DOES NOT APPLY TO OTHER ACCESSORY ITEMS AND

RELATED ITEMS. THESE ITEMS RECEIVE A 90 DAY LIMITED WARRANTY.

To make a claim under this Limited Warranty, you must return the complete product, transportation

prepaid. For details to make a claim under this Limited Warranty please visit www.boschtools.com

or call 1-877-267-2499.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO ONE YEAR FROM DATE

OF PURCHASE. SOME STATES IN THE U.S., AND SOME CANADIAN PROVINCES DO NOT

ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS) ARISING

FROM THE SALE OR USE OF THIS PRODUCT. SOME STATES IN THE U.S., AND SOME

CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., OR PROVINCE

TO PROVINCE IN CANADA AND FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO PRODUCTS SOLD WITHIN THE UNITED

STATES OF AMERICA, CANADA AND THE COMMONWEALTH OF PUERTO RICO. FOR

WARRANTY COVERAGE WITHIN OTHER COUNTRIES, CONTACT YOUR LOCAL BOSCH

DEALER OR IMPORTER.

-11-

Page 12

Consignes générales de sécurité

!

AVERTISSEMENT

instructions figurant ci-dessous risquerait de causer

une exposition dangereuse aux rayonnements, un choc

électrique, un incendie et/ou des blessures graves.

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES

CONSIGNES DE SÉCURITÉ POUR RÉFÉRENCE FUTURE.

L’expression « instrument de topologies » dans tous

les avertissements figurant plus bas fait référence à

votre instrument de mesure, de détection et de tracé de

topologies branché sur le secteur (avec cordon) ou à votre instrument de mesure, de détection et de tracé de

topologies à piles (sans fil).

Les étiquettes suivantes sont apposées sur votre instrument laser pour votre commodité et votre

sécurité. Elles indiquent où la lumière laser est émise par le instrument. IL FAUT TOUJOURS

CONNAÎTRE sa position lors de l’utilisation du instrument.Utilisez l’outil correct pour votre application.

Ne dirigez pas le faisceau laser en direction de personnes ou d’animaux, et ne regardez

pas directement le faisceau laser vous-même. Cet instrument produit des rayonnements

laser de classe 2 et est conforme aux normes 21 CFR 1040.10 et 1040.11, à l’exception

des déviations en vertu de l’Avis relatif au laser N° 50 daté du 24 juin 2007. Ceci risquerait

de causer l’aveuglement des personnes affectées.

!

MISE EN GARDE

étiquettes d’avertissement ou de mise en garde.

Le retrait de telles étiquettes augmente le risque

d’exposition aux rayonnements laser. L’emploi de

commandes ou de réglages autres que ceux qui sont

indiqués dans ce mode d’emploi risquerait de causer

une exposition dangereuse aux rayonnements.

ASSUREZ-VOUS TOUJOURS que les personnes

présentes aux environs de l’endroit où vous

employez cet instrument sont au courant des

dangers résultant de l’observation directe du

faisceau laser.

NE PLACEZ PAS l’instrument dans une

position telle que cela permettrait à quiconque

de regarder directement le faisceau laser

intentionnellement ou non. Ceci risquerait de

causer des blessures graves aux yeux.

POSITIONNEZ TOUJOURS l’instrument de façon

qu’il soit stable. La chute de l’instrument risquerait

d’endommager ce dernier et/ou de causer des

blessures graves à son utilisateur.

N’UTILISEZ TOUJOURS que les accessoires

qui sont recommandés par le fabricant de votre

instrument. L’emploi d’accessoires qui ont été

conçus pour emploi avec d’autres outils risquerait de

causer des blessures graves.

N’UTILISEZ PAS cet instrument dans un but

autre que ceux qui sont indiqués dans ce mode

d’emploi. Ceci risquerait de causer des blessures

graves.

Déclaration de la FCC

Cet appareil est conforme à la partie 15 des Règlements de la FCC. Son utilisation est autorisée moyennant

le respect des deux conditions suivantes : (1) Cet appareil ne doit pas causer d’interférences nuisibles et

(2) cet appareil doit accepter toute interférence reçue, y compris les interférences qui risquent de causer un

fonctionnement indésirable.

Lisez toutes les instructions.

Le non-respect de toutes les

NE RETIREZ PAS

et n’effacez pas des

NE LAISSEZ PAS l’instrument allumé («

ON ») sans surveillance dans un mode de

fonctionnement quelconque.

NE DÉMONTEZ PAS l’instrument. Il ne

contient aucune pièce pouvant être réparée

par l’utilisateur. Ne modifiez ce produit en

aucune façon. Toute modification de cet instrument

risquerait de causer une exposition dangereuse aux

rayonnements.

N’UTILISEZ PAS les verres de visionnement du

laser à la place de lunettes de protection. Les

verres de visionnement du laser sont utilisés pour

améliorer la visualisation du faisceau laser, mais ils ne

protègent pas contre les rayonnements laser.

N’UTILISEZ PAS pas les verres de visionnement

du laser en guise de lunette de soleil ou lorsque

vous conduisez un véhicule. Ces verres n’assurent

pas une protection complète contre les rayons UV et

ils réduisent la perception des couleurs.

N’UTILISEZ PAS d’instruments optiques tels,

que, entre autres, des télescopes ou des lunettes

d’astronome pour regarder le faisceau laser. Ceci

risquerait de causer des blessures graves aux yeux.

NE FIXEZ PAS directement des yeux le faisceau

laser et ne projetez pas la faisceau laser

directement dans les yeux d’autres personnes.

Ceci risquerait de causer des blessures graves aux

yeux.

CONSERVEZ CES INSTRUCTIONS.

-12-

Page 13

!

AVERTISSEMENT

de l’utilisateur de faire fonctionner l’équipement.

Remarque : Cet équipement a été testé et jugé conforme aux limites pour un équipement numérique de

Classe B en vertu de la Partie 15 des Règlements de la FCC. Ces limites sont conçues pour assurer une

protection raisonnable contre les interférences nuisibles dans une installation résidentielle. Cet équipement

émet, utilise et peut rayonner de l’énergie de fréquence radio et, s’il n’est pas installé et utilisé conformément

aux instructions, il pourrait causer des interférences nuisibles aux communications radio. Cependant, il n’existe

aucune garantie qu’aucune interférence ne se produira dans une installation particulière. Si cet équipement

cause des interférences nuisibles pour la réception de programmes à la radio ou à la télévision, ce qui peut

être déterminé en allumant et en éteignant à plusieurs reprises l’équipement en question, l’utilisateur est

encouragé à corriger l’interférence en prenant une ou plusieurs des mesures suivantes :

- Réorienter ou déplacer l’antenne de réception.

- Augmenter la distance entre l’équipement et le récepteur.

- Connecter l’équipement à une prise de courant raccordée à un circuit différent de celui auquel le

récepteur est connecté.

- Consulter le détaillant ou un technicien radio ou télévision expérimenté pour lui demander conseil.

Sécurité sur le lieu de travail

Maintenez votre lieu de travail propre et bien

éclairé. Les lieux de travail encombrés ou sombres

invitent les accidents.

N’UTILISEZ PAS l’instrument laser à proximité

d’enfants, et ne laissez pas des enfants se servir

de l’instrument laser. Cela risquerait de produire

des blessures graves aux yeux.

Sécurité électrique

Les piles risquent d’exploser ou de fuir, et

de causer des blessures ou un incendie. Afin

de réduire ce risque, suivez toujours toutes les

instructions et tous les avertissements figurant sur

l’étiquette des piles et sur l’emballage.

NE COURT-CIRCUITEZ PAS de bornes des piles.

NE RECHARGEZ PAS des piles alcalines.

NE MÉLANGEZ PAS des piles neuves et des

piles usagées. Remplacez toutes les piles en

même temps par des piles neuves de la même

marque et du même type.

NE MÉLANGEZ PAS des piles ayant des

compositions chimiques différentes.

Jetez ou recyclez les piles conformément aux

règlements du code local.

NE JETEZ PAS des piles dans un feu.

Gardez les piles hors de la portée des enfants.

Retirez les piles si vous ne pensez pas utiliser cet

instrument pendant plusieurs mois.

Sécurité personnelle

Restez alerte, surveillez ce que vous źtes en train

de faire et faites preuve de bons sens lorsque

vous utilisez un quelconque outil. N’utilisez

pas un outil pendant que vous êtes fatigué(e)

ou sous l’influence de drogues, d’alcool ou de

médicaments. Un moment d’inattention pendant que

vous vous servez d’un outil risquerait de causer de

graves blessures personnelles ou de produire des

Les changements ou modifications à cette unité n’étant pas expressément

approuvé par la partie responsable de la conformité pourrait annuler l’autorité

résultats de mesures imprécis.

Utilisez des équipements de sécurité. Portez

toujours une protection des yeux. Des

équipements tels que des masques antipoussières,

des chaussures de sécurité antidérapantes, un

casque ou une protection des oreilles utilisés pour

les conditions appropriées réduiront les blessures

corporelles.

Fixation multifonctionelle

Ne pas mettre la fixation

multifonctionelle 8 dans la

proximité de stimulateurs

cardiaques. Les disques

magnétiques 12 génèrent un champ

qui peut entraver le fonction-nement

de stimulateurs cardiaques.

•

Maintenir la fixation éloignée des support

de données magnétiques et des appareils

réagissant aux sources magnétiques.

L’effet du disque magnétique 12 peut entraîner

des pertes de données irréversibles.

Utilisation et entretien

Utilisez l’outil correct pour votre application.

L’instrument de mesure, de détection et de tracé de

topologies correct vous permettra de faire un meilleur

travail et avec plus de sécurité à la vitesse pour

laquelle il a été conçu.

N’utilisez pas cet instrument si l’interrupteur ne

s’allume pas ou ne s’éteint pas. Un instrument qui

ne peut pas être contrôlé par son interrupteur est

dangereux et doit être réparé.

Rangez l’instrument hors de la portée des

enfants lorsque vous ne vous en servez pas,

et ne laissez pas de personnes ne connaissant

pas bien cet instrument ou n’ayant pas lu ce

mode d’emploi mettre l’outil en marche. De tels

instruments pourraient être dangereux entre les

mains d’utilisateurs n’ayant pas reçu la formation

nécessaire à leur utilisation.

-13-

Page 14

Entretenez vos instruments. Assurez-vous que

les pièces sont alignées correctement et que

les pièces mobiles ne se coincent pas, qu’il n’y

a pas de pièces brisées ou d’autres conditions

pouvant affecter le fonctionnement. Réparez tout

instrument endommagé avant de vous en servir.

Tout outil endommagé doit être réparé par le centre

de service après-vente agréé de Bosch avant d’être

employé à nouveau. De nombreux accidents par des

instruments de mesure, de détection et de tracé de

topologies mal entretenus.

Utilisez l’outil, les accessoires, etc. conformément

à ce mode d’emploi et de la manière prévue pour

le type particulier d’instrument, en tenant compte

des conditions de travail à réaliser. L’emploi de cet

instrument pour des opérations différentes de celles

qui sont indiqués dans le mode d’emploi risquerait de

causer une situation dangereuse.

Emploi prévu

L’appareil de mesure est utilisé pour transfert précis des plumb point du sol au plafond.

Préparation

Mise en place/changement des piles

Pour le fonctionnement de l’appareil de mesure,

nous recommandons d’utiliser des piles alcalines au

manganèse.

Pour ouvrir le couvercle du compartiment à piles 3,

tournez le blocage 2 en position dans le sens

des aiguilles d’une montre et retirez le couvercle du

compartiment à piles. Introduisez les piles fournies.

Veillez à la bonne position des pôles qui doit

correspondre à la figure se trouvant à l’intérieur du

compartiment à piles.

Montez le couvercle du compartiment à piles en

dessous sur le boîtier et poussez-le vers le haut.

Tournez le blocage 2 en position dans le sens

inverse des aiguilles d’une montre pour verrouiller le

Service après-vente

Faites réparer votre instrument par un

réparateur agréé n’utilisant que des pièces de

rechange identiques. Ceci assurera le respect des

prescriptions de sécurité pour l’instrument.

Préparez un calendrier de maintenance

périodique pour l’instrument. Lorsque vous

nettoyez un instrument, faites attention de

ne pas démonter une partie quelconque de

l’instrument étant donné que des fils internes

risqueraient d’être déplacés ou pincés, ou qu’ils

pourraient être remontés de façon incorrecte.

Certains produits de nettoyage tels que de l’essence,

du tétrachlorure de carbone, de l’ammoniac, etc.

risqueraient d’endommager les composants

en plastique.

CONSERVEZ CES INSTRUCTIONS.

couvercle du compartiment à piles. Si les faisceaux

laser clignotent à un rythme lent pendant le service,

c’est que les piles sont faibles.

Après le premier clignotement, il est possible de

continuer à utiliser l’appareil de mesure pendant

8 h env.

Toujours remplacer toutes les piles en même temps.

N’utiliser que des piles de la même marque avec la

même capacité.

• Sortir les piles de l’appareil de mesure au cas

oĚ l’appareil ne serait pas utilisé pour une

période assez longue. En cas de stockage

long, les piles peuvent corroder et se

décharger.

Features

La numérotation des éléments de l’appareil se réfère

à la représentation de l’appareil de mesure sur la

page graphique.

1 Orifice de sortie du faisceau laser

2 Blocage du couvercle du compartiment à piles

3 Couvercle du compartiment à piles

4 Interrupteur Marche/Arrêt

5 Plaque d’avertissement de laser

6 Raccord de trépied 1/4”

7 Numéro de série

8 Fixation multifonctionelle

9 Vis de serrage de la fixation multifonctionelle

10 Trous filetés de la fixation multifonctionelle

11 Guidage de la bande

12 Aimants

13 Raccord de trépied 1/4” de la fixation

14 Raccord de trépied 5/8” de la fixation

15 Marqueur d’objectif à laser*

16 Etui de protection*

17 Lunettes de vision du faisceau laser*

18 Trépied*

*Les accessoires décrits ou montrés ne sont pas

compris dans l’emballage standard.

-14-

Page 15

Données techniques

Zone de travail

– Standard .......................100 ft (30 m)

Précision de nivellement :

Précision minimale d’usine ....

Précision typique de nivellement .jusqu’á 2 mm á 10 m

Plage typique de nivellement

automatique le long de

– l’axe transversal ......................... ±3°

Temps typique de nivellement ............... <3 s

Température de service .........–10° C ... +40° C

Température de stockage .......–20° C ... +70° C

Humidité relative de l’air max ................90 %

Classe laser ................................2

jusqu’á 3 mm á 10 m

Consignes d’utilisation

Mise en service

• Protéger l’appareil de mesure contre

l’humidité, ne pas l’exposer aux rayons

directs du soleil.

• Ne pas exposer l’appareil de mesure ą

des températures extrźmes ou de forts

changements de température. Ne le laissez

pas traîner longtemps dans la voiture par ex. En

cas d’importants changements de température,

laissez l’appareil de mesure prendre la

température ambiante avant de le mettre en

service. Des températures extrêmes ou de forts

changement de température peuvent entraver la

précision de l’appareil de mesure.

• Eviter les chocs ou les chutes de l’appareil

de mesure. Lorsque l’appareil de mesure a

été soumis à de fortes influences extérieures,

toujours effectuer un contrôle de précision

avant de continuer à travailler (voir « Précision

de nivellement »). N’utilisez pas l’outil quand

le cache du point d’émission du laser a été

endommagé à la suite d’un choc important

ayant affecté l’extérieur de l’outil. De

nombreux accidents par des instruments de

mesure, de détection et de tracé de topologies

mal entretenus.

• Eteignez l’appareil de mesure quand

vous le transportez. Lorsque l’appareil est

éteint, l’unité pendulaire se verrouille afin

de prévenir son endommagement lors de

mouvements forts.

Mise en Marche/Arrźt

Pour mettre en marche l’appareil de mesure, glisser

l’interrupteur Marche/Arrêt 4 vers le haut de sorte que

« I » apparaisse sur l’interrupteur. Immédiatement

après avoir été mis en marche, l’appareil de mesure

Type de laser ...................635 nm, <1 mW

Raccord de trépied ......................1/4-20

Piles .......................3 x 1,5 V LR6 (AA)

Durée de service env ......................24 h

Poids .................................0,25 kg

Dimensions ..............4-1/8 x 3-1/8 x 1-5/8-in

(105 x 80 x 42 mm)

Faire attention au numéro d’article se trouvant sur

la plaque signalétique de l’appareil de mesure. Les

désignations commerciales des différents appareils

peuvent varier.

Pour permettre une identification précise de votre

appareil de mesure, le numéro de série 7 est marqué

sur la plaque signalétique.

envoie un faisceau laser à travers chaque orifice de

sortie 1.

• Ne pas diriger le faisceau laser vers des

personnes ou des animaux et ne jamais

regarder ans le faisceau laser, même si vous

êtes à grande distance de ce dernier.

Pour éteindre l’appareil de mesure, glisser

l’interrupteur Marche/Arrêt 4 vers le bas de sorte que

« 0 » apparaisse sur l’interrupteur. Lorsque l’appareil

est éteint, l’unité pendulaire est verrouillée.

Réglage de la coupure automatique

L’appareil de mesure se met automatiquement hors

fonctionnement 20 min après sa mise en service.

Il est possible de modifier cette coupure automatique

de 20 min à 8 h. Pour ce faire, mettez l’appareil

de mesure en fonctionnement, éteignez-le

immédiatement et remettez-le en marche en l’espace

de 4 s. Pour confirmer la modification, tous les

faisceaux laser clignotent à un rythme rapide pendant

2 s après la deuxième mise en marche.

• Ne pas laisser sans surveillance l’appareil

de mesure allumé et éteindre l’appareil de

mesure aprŹs l’utilisation. D’autres personnes

pourraient être éblouies par le faisceau laser.

Lors de la prochaine mise en marche

de l’appareil de mesure, la coupure

automatique est ànouveau réglée sur 20

min.

Travailler avec nivellement automatique

Placez l’appareil de mesure sur un support

horizontale solide, montez-le sur la fixation

18

sur le trépied

.

Une fois l’appareil mis en marche, le

nivellement automatique compense

-15-

8

ou

Page 16

automatiquement les inégalités à l’intérieur de

d

la plage de nivellement automatique de ±5°

(axe longitudinal) ou ±3° (axe transversal).

Dès que les points laser ne bougent plus, le

nivellement est terminé.

Si un nivellement automatique n’est pas

possible, par ex. parce que la surface où

est posé l’appareil de mesure diffère de plus

de 5° ou de plus de 3° de l’horizontale, les

faisceaux laser clignotent au rythme rapide.

Dans un tel cas, placez l’appareil de mesure

horizontalement et attendez le nivellement

Précision de nivellement

Influences sur la précision

C’est la température ambiante qui exerce la

plus grande influence. Ce sont notamment les

différences de température entre le sol et la

hauteur de travail qui peuvent faire dévier le

faisceau laser.

Puisque la stratification de la température est à

son maximum à proximité du sol, l’appareil de

mesure devrait toujours être monté sur un trépied

disponible dans le commerce, si possible, et être

installé au centre le la zone de travail.

Outre les influences extérieures, des influences

spécifiques à l’appareil (par ex. chutes ou

chocs violents) peuvent entraîner de légères

divergences. Avant de commencer tout travail,

contrôler donc la précision de l’appareil de

mesure.

Si l’appareil de mesure dépasse la divergence

maximale de précision pour un des contrôles, le

faire réparer par un service après-vente Bosch.

Contrôler la précision du nivellement

vertical

Pour ce contrôle, on nécessite une distance

dégagée de 5 m sur un sol stable entre le sol et

le plafond.

– Dessinez une ligne droite sur le plafond.

– Montez l’appareil de mesure sur la fixation

ou un trépied. Mettez l’appareil de mesure

en fonctionnement et tournez-le de sorte

que le faisceau d’aplomb inférieur soit

visible sur le sol.

5 m

automatique. Dès que l’appareil de mesure se

trouve à l’intérieur de la plage de nivellement

automatique de ±5° ou ±3°, les faisceau laser

restent à nouveau allumés en permanence.

Dans le cas de secousses ou de modifications

pendant l’utilisation, l’appareil de mesure est

automatiquement nivelé à nouveau. Après le

nivellement, vérifiez la position des faisceaux

laser par rapport aux points de référence

afin d’éviter des erreurs causées par un

déplacement de l’appareil de mesure.

– Positionnez l’appareil de mesure de sorte

que le faisceau d’aplomb supérieur atteigne

la ligne sur le plafond. Laissez l’appareil

de mesure effectuer un nivellement

automatique. Marquez le milieu du point

laser supérieur sur la ligne du plafond (point

I). Marquez également le milieu du point

laser inférieur sur le sol (point II).

– Tournez l’appareil de mesure de 180°.

Positionnez- le de sorte que le milieu

du point laser inférieur se trouve sur

le point II déjà marqué et le point laser

supérieur sur la ligne du plafond. Laissez

l’appareil de mesure effectuer un

nivellement automatique. Marquez le milieu

du point laser supérieur sur la ligne du

plafond (point III).

– L’écart d entre les deux points I et III

marqués sur le plafond indique la divergence

réelle de l’appareil de mesure de la verticale.

Pour une distance à mesurer de 2 x 5 m = 10

m, la divergence de précision max. admissible

est de :

10 m x ±0,3 mm/m = ±3 mm.

Par conséquent, la différence d entre les points

I et III ne doit être que 3 mm max.

d

-16-

Page 17

Procédure d’Étalonnage

B

A

5

ʹ

50

ʹ

C

1/2

1 ecafruS2 ecafruS

D

Tous les niveaux laser GPL 2 sont étalonnés

par le fabricant lors du contrôle de la qualité

assuré par Bosch. Le contrôle de la qualité

garantit que l’utilisateur est possession d’un

instrument de qualité supérieure et conforme

aux spécifications du produit. Bien qu’il soit

étalonné avant de quitter l’usine, le niveau laser

GPL 2, doté de nombreuses pièces usinées

avec précision et pouvant être affectées en cas

de traitement abusif, doit de temps à autre être

étalonné pour assurer son bon fonctionnement.

Par conséquent, si l’unité est laissée tombée

ou subit un impact important, l’utilisateur doit

vérifier l’étalonnage en respectant les étapes

suivantes:

Étalonnage des faisceaux laser du haut

et du bas

1. Sélectionnez un site d’étalonnage. Pour

obtenir les meilleurs résultats possible, il est

conseillé d’utiliser un plancher ou un plafond

à une distance de plus de 10 pi (plus la

distance est importante, plus l’exactitude de

l’étalonnage est grande). Plancher/plafond

(le point le plus élevé d’une entrée de porte)

à une distance d’environ 10 pi.

E

F

2. Mettez le niveau laser GPL 2 en arrêt.

3. Utilisez un tournevis à tête plate pour retirer

le capuchon de l’orifice d’étalonnage sur le

côté du niveau. Rangez le capuchon dans

un endroit sûr.

4. Tracez une ligne droite sur le plafond.

5. Mettez le niveau laser GPL 2 en marche.

6. Posez le niveau laser GPL 2 laser sur le

plancher (sur son socle de montage afin

que le faisceau laser du bas soit visible sur

le sol).

7. Alignez le niveau laser GPL 2 de façon à ce

que le faisceau est braqué sur la ligne sur le

plafond.

8. Marquez l’emplacement du point que

produit le faisceau du bas sur le plancher

comme étant point D ; marquez le point

créé par le faisceau du haut sur le plafond

comme étant point E.

9. Faites pivoter le niveau laser GPL 2 de 180°

et alignez le faisceau du bas avec le point

sur le plancher.

1

E

F

1/2

10. Marque el haz superior sobre el cielorraso

como Marca F. Debe haber dos marcas en

el cielorraso.

11. Compare las dos marcas en el cielorraso.

Si ambas están en el mismo punto, no será

necesario calibrar la unidad. De lo contrario,

proceda hasta el paso 12.

12. Apague el dispositivo GPL 2.

13. Inserte la llave Allen de 2 mm en el puerto

de calibración lateral. El objetivo es hacer

que el haz láser quede a mitad de camino

entre ambas marcas del cielorraso. Gire la

llave Allen en sentido horario o antihorario

para mover el haz láser.

14. Encienda el dispositivo GPL 2 y verifique la

posición del haz para ver si se encuentra

exactamente a medio camino entre las

marcas del cielorraso. Si el haz no está

posicionado correctamente, repita los

pasos 12 a 14 hasta que se encuentre en la

posición correcta.

15. Coloque el botón de calibración lateral en el

dispositivo GPL 2.

16. Se acaba de completar la calibración.

-17-

Page 18

Applications

A

B

Mise d’aplomb d’une surface

1. Posez le niveau laser GPL 2 près de la

surface à mettre d’aplomb.

2. Mettez le niveau laser GPL 2 en marche.

3. Mesurez la distance A depuis un point

relativement rapproché du niveau et prenez

en note la valeur obtenue.

4. Mesurez la distance B depuis un point

relativement éloigné du niveau et prenez en

note la valeur obtenue.

Remarque: plus la distance entre les deux

points de mesure est importante, plus

l’exactitude des données est grande.

5. Comparez la distance A à la distance B.

Si A égale B, la surface est d’aplomb. Si A

n’égale pas B, la surface est hors d’aplomb

et doit être corrigée.

D’aplomb

B

A

Transfert de points ą l’aide du faisceau

de mise d’aplomb

1. Marquez le point à transférer (repéré par la

lettre A dans l’illustration).

2. Utilisez le socle de montage ou un trépied

pour diriger le faisceau de mise d’aplomb

du bas sur point A.

3. Le faisceau de mise d’aplomb du haut

va transférer ce point le long d’un axe

parfaitement vertical vers point B.

4. Marquez le point B.

Remarque: Il est possible d’inverser l’ordre de

cette procédure.

Transfert de la mise d’aplomb

B

A

Utiliser avec accessories

Pour fixer l’appareil de mesure sur la fixation

multifonctionelle 8, serrez la vis de blocage 9

de la fixation multifonctionelle dans le raccord

de trépied 1/4” 6 se trouvant sur l’appareil de

mesure. Pour tourner l’appareil de mesure

sur la fixation multifonctionelle, desserrez

légèrement la vis 9.

– Tournez l’appareil de mesure sur la fixation

multifonctionelle 8 vers le côté ou vers

l’arrière pour rendre visible le faisceau

d’aplomb inférieur.

– Tournez l’appareil de mesure sur la fixation

multifonctionelle 8 pour reporter des

hauteurs avec le faisceau laser horizontal.

A l’aide de la fixation multifonctionelle 8, vous

avez différentes possibilités de fixer l’appareil

de mesure, que voici :

– Montez la fixation multifonctionelle 8 à l’aide

du raccord detrépied 1/4” 13 sur le trépied

18 ou sur un trépied disponible dans le

commerce. Pour la fixation multifonctionelle

sur un trépied de chantier disponible dans

le commerce, utilisez le raccord de trépied

5/8” 14.

– Il est possible de fixer la fixation

multifonctionelle 8 à l’aide des aimants 12

sur des pièces métalliques.

– Il est possible de visser la fixation

multifonctionelle 8 au moyen de vis sur

les murs de construction sèche ou sur des

murs en bois. Pour ce faire, enfoncez des

vis d’une longueur d’au moins 50 mm à

travers les trous filetés 10 de la fixation

multifonctionelle.

– Il est possible d’attacher la fixation

multifonctionelle 8 sur des tuyaux ou des

éléments similaires au moyen d’une bande

disponible dans le commerce que l’on fait

passer à travers le guidage de la bande 11.

-18-

Page 19

Travailler avec le trépied (accessoire)

Un trépied 18 offre l’avantage d’être un support

de mesure stable à hauteur réglable. Placez

l’appareil de mesure avec le raccord du trépied

6 sur le filet 1/4” du trépied et serrez-le au

moyen de la vis de blocage du trépied.

Travailler avec la platine de mesure

(accessoire)

A l’aide de la platine de mesure 15, il est

possible de reporter le marquage du faisceau

laser sur le sol ou de reporter la hauteur du

laser sur le mur.

Le champ zéro et la graduation permettent

de mesurer l’écart par rapport à la hauteur

souhaitée et de la reporter sur un autre endroit.

Il n’est donc pas nécessaire d’ajuster l’appareil

de mesure précisément sur la hauteur à

reporter.

La platine de mesure 15 dispose d’un

revêtement réflecteur pour améliorer la

visibilité du faisceau laser à une distance plus

Maintenance et service

Nettoyage et entretien

Ne transporter et ranger l’appareil de mesure

que dans son étui de protection fourni avec

l’appareil.

Maintenir l’appareil de mesure propre.

Ne jamais plonger l’appareil de mesure dans

l’eau ou dans d’autres liquides.

Nettoyer l’appareil à l’aide d’un chiffon doux et

humide. Ne pas utiliser de détergents ou de

solvants.

Nettoyer régulièrement en particulier les

surfaces se trouvant près de l’ouverture

de sortie du laser en veillant à éliminer les

poussières.

Si, malgré tous les soins apportés à la

fabrication et au contrôle de l’appareil de

mesure, celui-ci devait avoir un défaut, la

réparation ne doit être confiée qu’à une station

de service après-vente agréée pour outillage

Bosch.

importante ou en cas d’un fort ensoleillement.

L’augmentation de la luminosité n’est visible

que lorsqu’on regarde en parallèle avec le

faisceau laser sur la platine de mesure.

Lunettes de vision du faisceau laser

(accessoire)

Les lunettes de vision du faisceau laser filtrent

la lumière ambiante. L’oeil perçoit ainsi la

lumière rouge du laser comme étant plus claire.

• Ne pas utiliser les lunettes de vision

du faisceau laser en tant que lunettes

de protection. Les lunettes de vision du

faisceau laser servent à mieux reconnaître

le faisceau laser, elles ne protègent

cependant pas du rayonnement laser.

• Ne pas utiliser les lunettes de vision

du faisceau laser en tant que lunettes

de soleil ou en circulation routière.

Les lunettes de vision du faisceau laser

ne protègent pas parfaitement contre

les rayons ultra-violets et réduisent la

perception des couleurs.

Pour toute demande de renseignement ou

commande de pièces de rechange, nous

préciser impérativement le numéro d’article à

dix chiffres de l’appareil de mesure indiqué sur

la plaque signalétique.

Au cas où l’appareil devrait être réparé,

l’envoyer dans son étui de protection 16.

PROTECTION DE L’ENVIRONNEMENT

ecyclez les matières premières et

les piles au lieu de les mettre au

rebut. L’instrument, ses accessoires,

son conditionnement et les piles

usées doivent être triés en vue d’un recyclage

écologique conforme aux lois les plus récentes.

-19-

Page 20

GARANTIE LIMITÉE DES PRODUITS LASER ET AUTRES

INSTRUMENTS DE MESURE BOSCH

Robert Bosch Tool Corporation (« Vendeur ») garantit, exclusivement à l’acheteur initial, que tous les outils laser et

de mesure de Bosch ne comporteront aucun défaut de matériau ou de fabrication pendant une période d’un (1) an à

compter de la date de l’achat. Bosch fournira une couverture de garantie portée à deux (2) ans si vous enregistrez votre

produit dans les huit (8) semaines suivant la date de l’achat. La carte d’enregistrement du produit doit être complète et

envoyée à Bosch (avec un cachet de la poste indiquant une date de moins de huit semaines après la date de l’achat), ou

vous pouvez vous inscrire en ligne à www.boschtools.com/Service/ProductRegistration. Si vous décidez de ne pas faire

enregistrer votre produit, une garantie limitée d’un (1) an s’appliquera à votre produit

Remboursement ou remplacement du produit jusqu’à 30 jours -

Si vous n’êtes pas complètement satisfait(e) par la performance de vos outils laser et de mesure pour quelque raison

que ce soit, vous pouvez les rapporter à votre détaillant Bosch dans les 30 jours suivant la date de l’achat pour obtenir

un remboursement intégral ou un remplacement. Pour obtenir ce remboursement du prix ou ce remplacement du produit

jusqu’à 30 jours après l’achat, votre retour doit être accompagné par l’original du reçu correspondant à l’achat du produit

laser ou de l’instrument optique. Un maximum de deux retours par client sera autorisé

LA SEULE OBLIGATION DU VENDEUR ET VOTRE SEUL REMÈDE en vertu de cette Garantie limitée et, dans

la mesure où la loi le permet, de toute autre garantie ou condition légalement implicite, seront la réparation ou le

remplacement à titre gratuit des pièces qui seront jugées défectueuses pour cause de vice de matériau ou de fabrication

et qui n’auront pas été utilisées de façon abusive, manipulées sans précautions ou réparées incorrectement par des

personnes autres que le Vendeur ou un Centre de service après-vente agréé. Pour vous prévaloir de la présente

Garantie limitée, vous devez retourner la totalité de l’outil laser ou de l’outil de mesure Bosch, en port payé, à un Centre

de service après-vente usine ou à un centre de service après-vente agréé de BOSCH. Veuillez inclure un justificatif

d’achat dûment daté avec votre outil. Pour trouver les adresses des centres de service après-vente, veuillez utiliser notre

guide en ligne service locator. ou téléphoner au 1-877-267-2499.

CE PROGRAMME DE GARANTIE NE S’APPLIQUE PAS AUX TRÉPIEDS OU AUX MIRES DE NIVELLEMENT.

Robert Bosch Tool Corporation (« Vendeur ») garantit les trépieds et les mires de nivellement pendant une période d’un

(1) an à compter de la date de l’achat.

CETTE GARANTIE LIMITÉE NE S’APPLIQUE PAS À D’AUTRES ACCESSOIRES ET ARTICLES

COMPLÉMENTAIRES. CES DERNIERS BÉNÉFICIENT D’UNE GARANTIE LIMITÉE DE 90 JOURS.

Pour vous prévaloir de la présente Garantie limitée, vous devez retournez la totalité du produit en port payé. Pour plus

de détails sur le recours à la présente Garantie limitée, veuillez visiter www.boschtools.com ou téléphoner au 1-877-267-

2499.

LA DURÉE DE TOUTE GARANTIE IMPLICITE SERA LIMITÉE À UN AN À COMPTER DE LA DATE DE L’ACHAT.

COMME CERTAINS ÉTATS AUX ÉTATS-UNIS ET CERTAINES PROVINCES AU CANADA NE PERMETTENT PAS

DE LIMITATIONS SUR LA DURÉE D’UNE GARANTIE IMPLICITE, LA LIMITATION CI-DESSUS NE S’APPLIQUE

PEUT-ÊTRE PAS À VOUS.

LE VENDEUR NE SERA EN AUCUN CAS RESPONSABLE POUR TOUS DOMMAGES INDIRECTS OU

SECONDAIRES (Y COMPRIS, MAIS SANS LIMITATION, LA RESPONSABILITÉ AU TITRE DE LA PERTE DE

BÉNÉFICES) RÉSULTANT DE LA VENTE OU DE L’EMPLOI DE CE PRODUIT. COMME CERTAINS ÉTATS AUX

ÉTATS-UNIS ET CERTAINES PROVINCES AU CANADA NE PERMETTENT PAS L’EXCLUSION OU LA LIMITATION

DE LA RESPONSABILITÉ POUR DOMMAGES INDIRECTS OU SECONDAIRES, LA LIMITATION CI-DESSUS NE

S’APPLIQUE PEUT-ÊTRE PAS À VOUS.

CETTE GARANTIE LIMITÉE VOUS CONFÈRE DES GARANTIES JURIDIQUES PARTICULIÈRES, ET VOUS

POUVEZ AUSSI AVOIR D’AUTRES DROITS, QUI VARIENT D’UN ÉTAT À L’AUTRE AUX ÉTATS-UNIS, D’UNE

PROVINCE À L’AUTRE AU CANADA OU D’UN PAYS À L’AUTRE.

CETTE GARANTIE LIMITÉE NE S’APPLIQUE QU’AUX PRODUITS VENDUS AUX ÉTATS-UNIS D’AMÉRIQUE, AU

CANADA ET À PORTO RICO. CONTACTEZ VOTRE DISTRIBUTEUR OU IMPORTATEUR BOSCH POUR OBTENIR

DES INFORMATIONS SUR LA COUVERTURE DE LA GARANTIE DANS LES AUTRES PAYS.

-20-

Page 21

Nomas generales de seguridad

!

ADVERTENCIA

continuación, el resultado podría ser exposición a

radiación peligrosa, descargas eléctricas, incendio

y/o lesiones graves.

GUARDE TODAS LAS ADVERTENCIAS E

INSTRUCCIONES PARA REFERENCIA FUTURA

La expresión “herramienta de medición, detección y

disposición” en todas las advertencias que aparecen a

continuación se refiere a su herramienta de medición,

detección y disposición alimentada por la red eléctrica

(alámbrica) o su herramienta de medición, detección y disposición alimentada por baterías (inalámbrica).

Las siguientes etiquetas están colocadas en su herramienta láser para brindarle conveniencia y

seguridad. Indican el lugar donde la luz láser es emitida por el nivel. CONOZCA SIEMPRE su ubicación

cuando utilice el nivel.

!

PRECAUCIÓN

advertencia o de precaución. Si se retiran las

etiquetas, se aumenta el riesgo de exposición a

radiación láser.

La utilización de controles o ajustes, o la

realización de procedimientos que no sean los

especificados en este manual, puede causar

exposición a radiación peligrosa.

Asegúrese SIEMPRE de que todas las personas

que se encuentren en la vecindad del lugar de

uso conozcan los peligros de mirar directamente

al láser.

NO coloque la herramienta en una posición que

pueda hacer que alguien mire al rayo láser de

manera intencional o accidental. El resultado

podría ser lesiones graves en los ojos.

Posicione SIEMPRE la herramienta de manera

segura.

Si la herramienta falla, el resultado

podría ser daños a la misma y/o lesiones

graves al usuario.

Utilice SIEMPRE sólo los accesorios que

estén recomendados por el fabricante de su

herramienta.

sido diseñados para utilizarse con otras

herramientas podría causar lesiones graves.

NO utilice esta herramienta para propósitos

que no sean los indicados en este manual.

hace, el resultado podría ser lesiones graves.

El uso de accesorios que hayan

Lea todas las instrucciones. Si no se siguen todas las

instrucciones que aparecen a

No dirija el rayo láser hacia personas o animales y no mire al rayo láser usted mismo.

Esta herramienta produce radiación láser de clase 2 y cumple con las normas 21 CFR

1040.10 y 1040.11, excepto por las desviaciones conformes al Aviso sobre láser No. 50,

de fecha 24 de junio de 2007. Esto puede causar ceguera en las personas.

NO retire ni desfigure

ninguna etiqueta de

NO deje la herramienta láser “ENCENDIDA”

desatendida en ningún modo de funcionamiento.

NO desarme la herramienta.

hay piezas reparables ni reemplazables por el

usuario. No modifique el producto de ninguna

manera. Si se modifica la herramienta, el

resultado podría ser exposición a radiación

láser peligrosa.

NO utilice los anteojos de visión láser como

anteojos de seguridad.

láser se utilizan para mejorar la visualización

del rayo láser, pero no protegen contra la

radiación láser.

NO utilice los anteojos de visión láser como

lentes de sol o en tráfico.

láser no ofrecen protección completa contra

los rayos UV y reducen la percepción de los

colores.

NO use herramientas ópticas, tales como,

pero no limitadas a, telescopios o telescopios

meridianos, para ver el rayo láser.

podría ser lesiones graves en los ojos.

NO mire directamente al rayo láser ni proyecte

el rayo láser directamente a los ojos de otras

personas.

graves en los ojos.

El resultado podría ser lesiones

En su interior no

Los anteojos de visión

Los anteojos de visión

El resultado

GUARDE ESTAS INSTRUCCIONES

Si lo

Declaración de FCC

Este dispositivo cumple con la parte 15 de las reglas de la FCC. Su operación está sujeta a las dos

condiciones siguientes: (1) Este dispositivo no puede causar interferencia perjudicial y (2) este dispositivo debe

aceptar cualquier interferencia recibida, incluyendo la interferencia que puede causar un funcionamiento no

deseado.

-21-

Page 22

!

ADVERTENCIA

operar el equipo.

Nota: Este equipo ha sido sometido a prueba y se ha comprobado que cumple con los límites para un

dispositivo digital de Clase B, conforme a la parte 15 de las reglas de la FCC. Estos límites están diseñados

para ofrecer una protección razonable contra la interferencia perjudicial en una instalación residencial. Este

equipo genera, utiliza y puede irradiar energía de radiofrecuencia y, si no se instala y utiliza de acuerdo con

las instrucciones, puede causar interferencia perjudicial para las radiocomunicaciones. Sin embargo, no hay

garantía de que no ocurrirá interferencia en una instalación específica. Si este equipo causa interferencia

perjudicial para la recepción de radio o televisión, lo cual se puede determinar apagando y encendiendo el

equipo, se recomienda al usuario que intente corregir la interferencia mediante una o más de las siguientes

medidas:

Los cambios o modificaciones a esta unidad no aprobados expresamente por la

parte responsable del cumplimiento podrían anular la autoridad del usuario para

- Reoriente o reubique la antena receptora.

- Aumente la separación entre el equipo y el receptor.

- Conecte el equipo a un tomacorriente de un circuito diferente al circuito al cual el receptor está

conectado.

- Consulte al distribuidor o a un técnico experto en radio y televisión para obtener ayuda.

Seguridad en el área de trabajo

Mantenga el área de trabajo limpia y bien iluminada.

Las áreas desordenadas u oscuras invitan a que se

produzcan accidentes.

NO utilice la herramienta láser cerca de niéos ni

deje que los niéos utilicen la herramienta láser. El

resultado podría ser lesiones graves en los ojos.

Seguridad eléctrica

!

ADVERTENCIA

causar lesiones o incendios. Para reducir este

riesgo, siga siempre todas las instrucciones y

advertencias que están en la etiqueta y en el paquete

de las baterías.

NO haga cortocircuito en los terminales de las

baterías.

NO cargue baterías alcalinas.

NO mezcle baterías viejas y nuevas. Reemplace

todas las baterías al mismo tiempo con baterías

nuevas de la misma marca y el mismo tipo.

NO mezcle las químicas de las baterías.

Deseche o recicle las baterías de acuerdo con el

código local.

NO deseche las baterías en un fuego.

Mantenga las baterías fuera del alcance de los

niños.

Retire las baterías si el dispositivo no se va a usar

durante varios meses.

Las baterías pueden

explotar o tener fugas y

Seguridad personal

Manténgase alerta, fíjese en lo que está haciendo

y use el sentido común cuando utilice una

herramienta. No utilice una herramienta mientras

esté cansado o bajo la influencia de drogas,

alcohol o medicamentos. Un momento de descuido

mientras se utiliza una herramienta puede causar

lesiones personales graves o resultados de medición

incorrectos.

Use equipo de seguridad. Use siempre

protección de los ojos. El equipo de seguridad, tal

como una máscara antipolvo, zapatos de seguridad

antideslizantes, casco o protección de la audición,

utilizado para las condiciones apropiadas, reducirá

las lesiones corporales.

Base multifuncional

No coloque la base multifuncional

8 cerca de personas que utilicen

un marcapasos. El campo

magnético que produce la base

multifuncional 12 puede perturbar el

funcionamiento de los marcapasos.

• Mantenga la base multifuncional 8 alejado de

soportes de datos magnéticos y de aparatos

sensibles a los campos magnéticos. La base

multifuncional 12 puedes provocar una pérdida

de datos irreversible.

Uso y cuidado

Use la herramienta correcta para la aplicación

que vaya a realizar. La herramienta correcta de

medición, detección y disposición hará el trabajo

mejor y de manera más segura a la capacidad

nominal para la que fue diseñada.

No utilice la herramienta si el interruptor no la

enciende y apaga. Cualquier herramienta que no se

pueda controlar con el interruptor es peligrosa y debe

ser reparada.

Cuando no esté utilizando la herramienta,

almacénela fuera del alcance de los niĖos

y no deje que las personas que no estén

familiarizadas con ella o con estas instrucciones

utilicen la herramienta. Las herramientas son

peligrosas en las manos de los usuarios que no

hayan recibido capacitación.

Mantenga las herramientas. Compruebe si hay

piezas desalineadas o que se atoren, si hay

piezas rotas y si existe cualquier otra situación

que pueda afectar al funcionamiento. Si la

-22-

Page 23

herramienta está daĖada, se debe reparar antes

de utilizarla. Si la herramienta está dañada, debe ser

reparada por el centro de servicio Bosch autorizado

antes de seguir usándola. Muchos accidentes son

causados por herramientas de medición, detección y

disposición mal mantenidas.

Utilice la herramienta, los accesorios, etc., de

acuerdo con estas instrucciones y de la manera

prevista para el tipo específico de herramienta,

teniendo en cuenta las condiciones de trabajo

y el trabajo que se vaya a realizar. El uso de la

herramienta para realizar operaciones distintas a las

previstas podría causar una situación peligrosa.

Haga que su herramienta reciba servicio de ajustes

y reparaciones por un técnico de reparaciones

calificado, utilizando únicamente piezas de repuesto

idénticas. Esto asegurará que se mantenga la

seguridad de la herramienta.

Desarrolle un programa de mantenimiento

periódico para su herramienta. Cuando limpie

una herramienta, tenga cuidado de no desarmar

ninguna parte de la herramienta, ya que los

cables internos se pueden descolocar o

pellizcar, o se pueden montar incorrectamente.

Ciertos agentes de limpieza, tales como gasolina,

tetracloruro de carbono, amoniaco, etc., pueden

dañar las piezas de plástico.

Servicio

Uso previsto