Bosch Buderus SB625WS, Buderus SB745WS Installation Instructions Manual

Read these instructions carefully before installation and operation of the heating system.

Installation Instructions

Stainless Steel Condensing Boiler

Buderus SB625WS/Buderus SB745WS

6 720 805 220-00.1T

DANGER!

The installation instructions included in this Manual are intended solely for

use by a trained and certified installer, service company or the gas supply

company. If the information in this manual is not followed, a fire or explosion

may result causing property damage, personal injury, or death.

Have installation and service performed by a trained and certified

installer or service company, or the gas supply company.

Bosch recommends signing a service and maintenance contract with a

trained and certified installer or service company that covers annual

servicing and condition-based maintenance. Proper maintenance is a

fundamental requirement for safe and efficient operation and long

service life.

The boiler must be serviced annually including the main burner, ignition

burner, the entire venting system, and the combustion air supply. All

parts that show any signs of damage or corrosion must be replaced.

Improper installation, adjustment, alteration, service, or maintenance

can cause property damage, personal injury, or death. Refer to this

manual and consult a trained and certified installer or service company,

or the gas supply company before installation, service or maintenance.

The owner and operator is responsible for the operational safety and

regulatory compliance of the heating system.

THIS MANUAL SHOULD BE HANDED TO THE OWNER AND OPERATOR OF

THE APPLIANCE.

INSTALLER MUST REVIEW ALL SAFETY INSTRUCTIONS WITH THE

OWNER AND OPERATOR.

UPON COMPLETION OF THE INSTALLATION THE INSTALLER MUST

INSTRUCT THE OWNER AND OPERATOR ON THE FUNCTIONALITY AND

THE PROPER OPERATION OF THE BOILER AND THE HEATING SYSTEM

Low temperature condensing boilers for gas/oil fired power burners

6 720 805 218 (2013/02) en-us

2 | Contents

SB625WS/SB745WS6 720 805 218 (2013/02)

Contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 3

2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Certification and testing mark . . . . . . . . . . . . . . . . . . . . . 6

2.3 Regulations and Guidelines . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.1 National regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.2 Compliance with standards and regulations . . . . . . . . . . 6

2.3.3 Additional regulations for installations in the

Commonwealth of Massachusetts . . . . . . . . . . . . . . . . . 6

2.4 Suitable fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.7 Tools, materials and auxiliary equipment . . . . . . . . . . . . 8

2.8 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.9 Dimensions and specifications . . . . . . . . . . . . . . . . . . . . 9

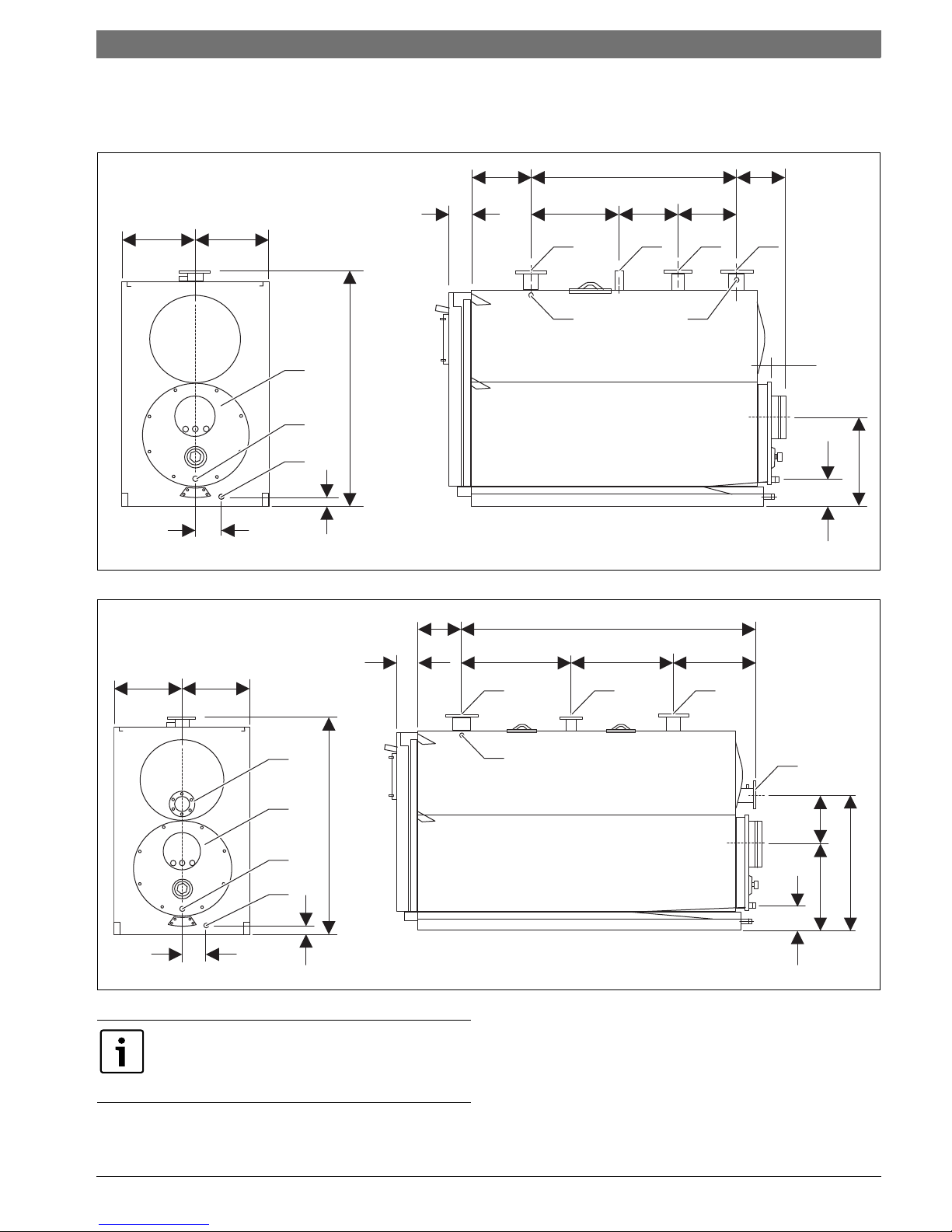

2.9.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.9.2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.9.3 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Chemical and physical characteristics . . . . . . . . . . . . . 13

3.2 Central heating system . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Limescale deposits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Deposit corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.3 Stray current corrosion . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.4 Diffused and localized acid corrosion . . . . . . . . . . . . . . 14

3.3 New central heating systems . . . . . . . . . . . . . . . . . . . . . 14

3.4 Reconditioning old heating systems . . . . . . . . . . . . . . . 14

3.5 Elimination air and gas from central heating system . . 14

3.6 Use of Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Boiler Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Assembling the paneling . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Refitting the door hinges . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.1 Changing the direction of door opening . . . . . . . . . . . . 20

5.3.2 Removing the hinge assembly “B” . . . . . . . . . . . . . . . . . 23

5.4 Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5 Combustion gas exhaust . . . . . . . . . . . . . . . . . . . . . . . . 24

5.6 Venting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.7 Code Required Vent Terminations . . . . . . . . . . . . . . . . 25

5.8 Combustion Air from outside the building . . . . . . . . . . 25

5.9 Combustion Air from an adjacent room . . . . . . . . . . . . 26

5.10 Condensate Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.11 Condensate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.11.1 Draining the condensate . . . . . . . . . . . . . . . . . . . . . . . . 26

5.11.2 Neutralizing the condensate . . . . . . . . . . . . . . . . . . . . . 26

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1 Control unit settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2 Hydraulic connection to the heating system . . . . . . . . 29

6.3 Hydraulic flow through boiler . . . . . . . . . . . . . . . . . . . . 29

6.4 Making the electrical connection . . . . . . . . . . . . . . . . . 30

6.5 Fitting temperature sensors . . . . . . . . . . . . . . . . . . . . . 31

6.6 Flushing the heating system . . . . . . . . . . . . . . . . . . . . . 31

6.7 Filling the heating system . . . . . . . . . . . . . . . . . . . . . . . 32

6.8 Preparing the heating system for operation . . . . . . . . . 32

6.9 Commissioning the control unit and burner . . . . . . . . . 32

6.10 Setting control unit parameters . . . . . . . . . . . . . . . . . . 32

6.11 Commissioning report . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 Shutting down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1 Shutting down the heating system . . . . . . . . . . . . . . . . 34

7.2 Shutting down the heating system in an emergency . . 34

8 Inspection and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.1 Why is regular maintenance important? . . . . . . . . . . . . 35

8.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2.1 Opening the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2.2 Adjusting the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.3 Cleaning the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.4 Checking and correcting the water pressure . . . . . . . . 37

8.4.1 When should you check the water pressure in the

heating system? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.4.2 Sealed unvented systems . . . . . . . . . . . . . . . . . . . . . . . 37

8.5 Inspection and maintenance reports . . . . . . . . . . . . . . 38

9 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11 Environmental protection/disposal . . . . . . . . . . . . . . . . . . . . 48

12 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Key to symbols and safety instructions | 3

6 720 805 218 (2013/02)SB625WS/SB745WS

1 Key to symbols and safety instructions

1.1 Explanation of symbols

Warnings

Keywords at the start of a warning indicate the type and seriousness of

the ensuing risk if measures to prevent the risk are not taken.

The following keywords are defined and can be used in this document:

• NOTE indicates that property damage may occur.

• CAUTION indicates that personal injury may occur.

• WARNING indicates that severe personal injury may occur.

• DANGER indicates that severe personal injury or death may occur.

Important information

Additional symbols

1.2 General safety instructions

If you hear gas leaking

▶ Leave the building immediately.

▶ Prevent others from entering the building.

▶ Notify the police and fire department from outside the building.

▶ From outside the building, call the gas supply company and a trained

and certified installer or service company.

If you smell gas

▶ Turn off the gas shut-off valve.

▶ Open windows and doors

▶ Do not touch any electrical switch, telephone, and do not use outlets.

▶ Extinguish all open flames.

▶Do not smoke!

▶ Do not use lighters!

▶ Warn all occupants of the building that they need to leave the building.

▶ Do not ring doorbells!

▶ Notify the police and fire department from outside the building.

▶ From outside the building, call the gas supply company and a trained

and certified installer or service company.

If you smell flue gas

▶ Switch off the heating system by shutting off the emergency shut-off

switch.

▶ Open windows and doors.

▶ Call a trained and certified installer or service company.

DANGER: Risk of fatal injury from failing to consider your own

safety!

▶ Never risk your own life. Your own safety must always take the highest

priority

NOTICE: Risk of appliance damage from improper operation of the

boiler!

▶ Only use the boiler for its intended purpose.

▶ Only operate the boiler if it has been installed and maintained per the

instructions provided in the Installation Manual.

▶ Do not attempt to operate an appliance if any part of it is not in

working order or is damaged.

▶ Use only original spare parts! The use of parts not supplied by the

manufacturer may cause damage to the boiler, other property and

personal injury. Also, boiler damage caused by the use of

unauthorized parts is not covered by the warranty.

DANGER: Risk of fire when soldering and brazing!

▶ Take appropriate protective measures when soldering and brazing

around combustible and flammable material.

NOTICE:

▶ The installation must comply with all applicable national, state, and

local codes, rules, and regulations.

▶ The operator is responsible for the operational safety and regulatory

compliance of the heating system.

▶ In the Commonwealth of Massachusetts, the appliance must be

installed by a licensed plumber or gas fitter.

DANGER: Risk of personal injury or death from flue gas poisoning!

▶ Do not install a thermostatic flue gas damper downstream of the draft

hood.

▶ Do not tamper with, remove, or attempt to repair the blocked vent

switch.

▶ When replacing the blocked vent switch, install the new part in the

original location.

▶ A blocked vent switch tripping more than once indicates a problem

with the venting system or chimney which must be repaired

immediately.

▶ Ensure none of the vent pipes and chimneys are damaged or blocked.

▶ Connect only one appliance to each venting system or chimney.

▶ The venting system must not feed into or route through another air

extraction duct.

▶ The venting system must be inspected annually. All parts that show

any signs of damage or corrosion must be replaced.

▶ Never close off or reduce the size of the combustion air openings.

▶ The boiler must not be operated until any obstructions have been

removed.

Warnings in this document are identified by a warning

triangle printed against a grey background.

Important information for the proper use of the boiler is

also provided in this manual. You will find the

information with a symbol shown on the left and

bordered by horizontal lines above and below the text.

Symbol Meaning

▶ Sequence of steps

Cross-reference to other points in this document or to

other documents

• Listing/list entry

– Listing/list entry (2nd level)

Table 1

4 | Key to symbols and safety instructions

SB625WS/SB745WS6 720 805 218 (2013/02)

DANGER: Risk of personal injury or death from explosion!

▶ Work on gas components may only be carried out by a trained and

certified installer or service company.

▶ Appliance installation, the connection of gas and vent piping, initial

commissioning, electrical connections, and service and maintenance

must only be carried out by a trained and certified installer or service

company.

DANGER: Risk of personal injury or death from fire!

▶ Do not use flammable or combustible material in the boiler room.

▶ It is recommended not to store any items within 16 inches (415mm)

of the appliance

CAUTION: Appliance damage from contaminated combustion air!

▶ Keep the combustion air free of corrosive substances, e.g.

halogenated hydrocarbons from painting operations or beauty

salons.

▶ Keep combustion air free from dust and lint, e.g. from laundry or

agricultural operations.

▶ If clean room air is not available, fresh outdoor combustion air must be

provided

DANGER: Risk of personal injury or death from electric shock.

▶ Before removing the front panel, disconnect the heating system from

the electrical power supply by shutting off the emergency shutoff

switch or the heating system circuit breaker.

▶ It is not enough to switch off the control panel. Power to the panel

must be disconnected! Ensure that the power is not restored

unintentionally by following proper lock out/tag out procedures.

▶ Only qualified electricians are permitted to carry out electrical work.

DANGER: Safety devices!

▶ Never shut off safety valves!

▶ Hot water may escape from the safety valve at any time when the

appliance is running.

DANGER: Risk of personal injury or death after a flood!

▶ Do not attempt to operate an appliance if any part of it has been under

water.

▶ An appliance that was subject to flooding must be replaced.

NOTICE:

▶ Upon completion of the installation, these instructions should be

handed to the owner and operator of the appliance.

▶ The installer must instruct the owner and operator on the functionality

of the components and the proper operation of the boiler and the

heating system.

▶ The boiler must be serviced annually including the main burner,

ignition burner, the entire venting system, and the combustion air

supply. All parts that show any signs of damage or corrosion must be

replaced.

Product Description | 5

6 720 805 218 (2013/02)SB625WS/SB745WS

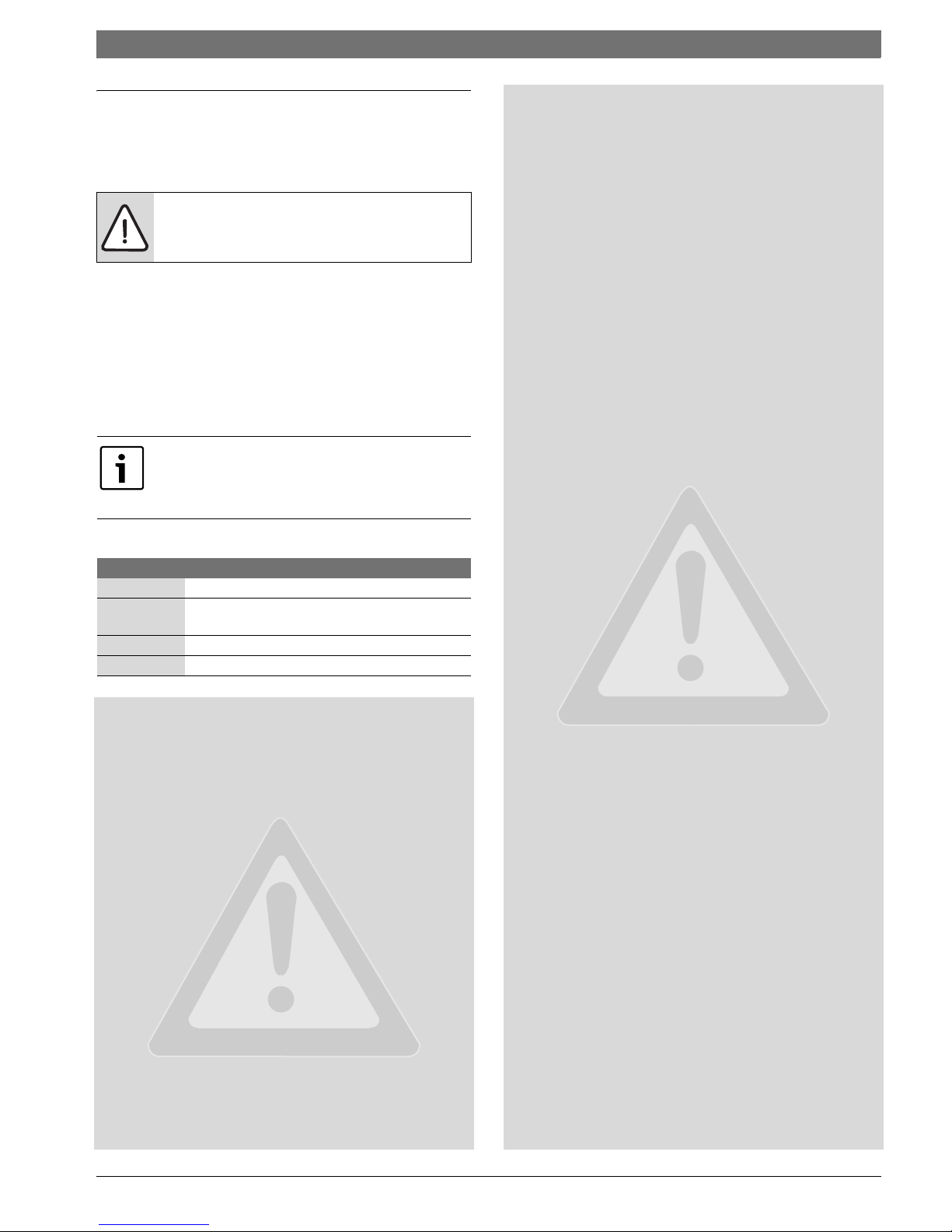

2 Product Description

The high efficiency SB Series boilers are designed to condense flue

gases through a unique three-pass construction for installation in a

mechanical room. While they are designed primarily for central heating

purposes, in conjunction with a suitable storage tank they can also be

used to produce domestic hot water.

All parts that come into contact with the combustion gases are made

from titanium stabilized stainless steel to ensure maximum resistance to

the corrosive action of acid condensation.

The boiler has been designed with the combustion chamber at the top

and the smooth pipe tube bundle at the bottom to optimize heat

exchange and to maximize the condensing effect.

The boiler has a high total water content which is differentially

distributed between its top and bottom sections. This hydraulic feature

allows outgoing water to reach the set temperature quickly while

maintaining the condensing effect and the water heating time around the

tube bundle for as long as possible.

The boilers feature lightly pressurized combustion chambers for a

smoother burner action, and high temperature resistant, stainless steel

turbulators inside the tube bundle for maximum burner efficiency.

The boiler body is thoroughly insulated with a layer of high density glass

wool.

The paint finished external paneling is also internally insulated with a

layer of high density glass wool.

The boiler’s front door and the flue gas chamber can be opened

completely to facilitate the inspection, maintenance and cleaning of

internal parts and to speed up servicing in general.

The front door can open in either direction and can be opened without

removing the burner. The door is factory fitted with hinges on the left,

but these can be reversed if necessary to suit individual installations.

Fig. 1 Main components

[1] Paneling

[2] Heating flow outlet

[3] Safety device fitting

1)

[4] Heating return (high temperature)

[5] Heating return (low temperature)

2)

[6] Instrument for bulb/probe socket

[7] Combustion chamber

[8] Flue connection

[9] Flue gas box

[10] Inspection port

[11] Condensate drain

[12] Boiler drain

[13] Turbulators

[14] Flue pipes

[15] Second flue pass

[16] Burner

[17] Flame inspection window with pressure measurement point

[18] Door

1 2 3 4 5

6

7

8

9

10

11

12

13

14

15

17

18

16

6 720 805 218-01.1T

1) On the 1550WS model the low temperature heating return is located at the rear

of the boiler.

2) On the 745WS models (800-1550) the safety device fitting is flanged.

6 | Product Description

SB625WS/SB745WS6 720 805 218 (2013/02)

2.1 Intended use

This boiler must only be used for the purpose specified by the

manufacturer and for which it is designed.

The SB625WS/SB745WS can be operated with gas, oil, and

combination burners. For a list of the approved burners, please contact

Bosch Thermotechnology Corp.

The boiler can be operated with an aquastat, the Logamatic 4000, and

other control systems.

The manufacturer declines all responsibility, contractual or other, for

damage to property or injury to persons or animals caused by improper

installation, adjustment, maintenance or use.

2.2 Certification and testing mark

This appliance has been tested and certified and meets all applicable

standards for the US and Canadian markets:

• CSA-AM 3.1 Industrial and commercial gas-fired package boilers

• CSA B140.0 General requirements for oil burning equipment

• CSA B140.2.1-10 Atomizing-type oil burners

• CSA B140.7-05 Oil-burning equipment - steam and hot water boilers

• UL 296 Standard for oil burners

• UL 726 Standard for oil-fired boiler assemblies

• UL 795 Standard for commercial industrial gas heating equipment

2.3 Regulations and Guidelines

2.3.1 National regulation

The heating system must comply with the requirements of the relevant

regulatory authorities or otherwise of the National Fuel Gas Code, ANSI

Z 223.1 In Canada, the requirements of CAN/CGA-B.149.1 and 2, or

CAN/CGA-B.139 must be observed.

If specified by the relevant regulatory authorities, the heating system

must comply with the regulations of the Standard for Controls and

Safety Devices for Automatically Fired Boilers, ANSI/ASME CSD-1.

Carbon monoxide detectors must be installed as specified by the local

regulations. The boiler must be serviced annually.

2.3.2 Compliance with standards and regulations

Installation of the boiler must comply with all applicable codes and

regulations imposed by the national, Federal or local authorities and

bodies. If no specific requirements are defined, in the USA, the latest

edition of the National Fuel Gas Code ANSI Z223.1/NFPA 54 must be

complied with.

In Canada, installation must comply in all respects with the latest edition

of the Natural Gas and Propane Installation Code, CAN/CGA-B. 149, the

Installation Code for Oil Burning Equipment, CAN/CGA-B. 139 and the

applicable local regulations and requirements for the appliance

category. The relevant authorities and regulatory bodies must be

informed before installation starts.

Where required by local regulations, the system must comply with the

American Society of Mechanical Engineers Safety Code for Controls and

Safety Devices for Automatically Fired Boilers (ASME CSD-1).

The local regulations regarding minimum pressure detectors and lowwater safety cutouts must be observed. Installation and operation must

comply with the device manufacturer‘s technical documentation.

We recommend fitting an 80 mesh dirt filter externally to the boiler

return to prevent contamination of the boiler by the water source.

Leak test

A leak test must be carried out. The testing pressure is based on the

normal operating pressure of the heating system and should be 1.3

times that pressure, and in any case no less than 14 psi (1 bar).

Safety limits

2.3.3 Additional regulations for installations in the

Commonwealth of Massachusetts

(a) For all side wall horizontally vented gas fueled equipment installed in

every dwelling, building or structure used in whole or in part for

residential purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust vent termination is less

than seven (7) feet above finished grade in the area of the venting,

including but not limited to decks and porches, the following

requirements shall be satisfied:

• INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of

installation of the side wall horizontal vented gas fueled equipment,

the installing plumber or gasfitter shall observe that a hard wired

carbon monoxide detector with an alarm and battery back-up is

installed on the floor level where the gas equipment is to be installed.

In addition, the installing plumber or gasfitter shall observe that a

battery operated or hard wired carbon monoxide detector with an

alarm is installed on each additional level of the dwelling, building or

structure served by the side wall horizontal vented gas fueled

equipment. It shall be the responsibility of the property owner to

WARNING: Risk of fatal Injury from explosion of

flammable gases!

▶ Installation, connection of the fuel supply and flue

pipe, commissioning, connection of the electrical

power supply, servicing and repair may only be

carried out by an authorized heating engineer.

▶ Any work on gas-carrying components may only be

carried out by an authorized gas installer.

The details on the boiler rating plate are definitive and

must be observed.

Safety limits

Maximum allowable temperature: 230 °F

(110 °C)

Maximum operating temperature 210 °F

(98.8 °C)

Permissible operating pressure: 80 psi

(5.5 bar)

Maximum cycle time for:

Safety temperature limiter: 40 s

Temperature control: 40 s

Table 2 Safety limits

Product Description | 7

6 720 805 218 (2013/02)SB625WS/SB745WS

secure the services of qualified licensed professionals for the

installation of hard wired carbon monoxide detectors.

– In the event that the side wall horizontally vented gas fueled

equipment is installed in a crawl space or an attic, the hard wired

carbon monoxide detector with alarm and battery back-up may be

installed on the next adjacent floor level.

– In the event that the requirements of this subdivision cannot be met

at the time of completion of installation, the owner shall have a

period of thirty (30) days to comply with the above requirements;

provided, however, that during said thirty (30) day period, a

battery operated carbon monoxide detector with an alarm shall be

installed.

• APPROVED CARBON MONOXIDE DETECTORS. Each carbon

monoxide detector as required in accordance with the above

provisions shall comply with NPA 720 and be ANSI/UL 2034 listed

and IAS certified.

• SIGNAGE. A metal or plastic identification plate shall be permanently

mounted to the exterior of the building at a minimum height of eight

(8) feet above grade directly in line with the exhaust vent terminal for

the horizontally vented gas fueled heating appliance or equipment.

The sign shall read, in print size no less than one-half (½) inch in size,

“GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS”.

• INSPECTION. The state or local gas inspector of the side wall

horizontally vented gas fueled equipment shall not approve the

installation unless, upon inspections, the inspector observes carbon

monoxide detectors and signage installed in accordance with the

provisions of 248 CRM 5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CRM

5.08(2)(a) 1 through 4:

• The equipment listed in Section 10 entitled “Equipment Not Required

To Be Vented” in the most current edition of NFPA 54 as adopted by

the board; and

• Product Approved side wall horizontally vented gas fueled equipment

installed in a room or structure separate from the dwelling, building or

structure used in whole or in part for residential purposes.

(c) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT VENTING

SYSTEM REQUIRED. When the manufacturer of Product Approved side

wall horizontally mounted gas equipment provides a venting system

design or venting system components with the equipment, the

instructions provided by the manufacturer for the installation of the

equipment and venting shall include:

• Detailed instructions for the installation of the venting system or the

venting system components; and

• A complete parts list for the venting system design or venting system.

(d) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT VENTING

SYSTEM NOT PROVIDED. When the manufacturer of Product Approved

side wall horizontally vented gas fueled equipment does not provide the

parts for the venting of flue gases, but identifies “special venting

systems”, the following requirements shall be satisfied by the

manufacturer:

• The referenced “special venting systems” shall be included with the

appliance or equipment installation instructions; and

• The “special venting systems” shall be Product Approved by the

Board, and the instructions for that system shall include a parts list

and detailed installation instructions.

(e) A copy of all instructions for all Product Approved side wall

horizontally vented gas fueled equipment, all venting instructions, all

parts lists for venting instructions, and/or venting design instructions

shall remain with the appliance or equipment at the completion of the

installation.

2.4 Suitable fuels

Permissible fuels

• Natural gas from the public gas supply in accordance with national

regulations with a total sulphur content < 15ppm.

• LP in accordance with national regulations with a content of

elementary sulphur < 1.5 ppm and volatile sulphur < 50 ppm.

• Ultra Low Sulphur Diesel in accordance with national regulations with

a content of elementary sulphur < 15 ppm (for use as back-up fuel in

condensing operation).

• Heating oil type 2 when boiler return temperature is not lower than

140 degrees Fahrenheit; non-condensing operation (for use as backup fuel only). See the warranty statement for additional details.

NOTICE:

▶ Do not use gasoline, crankcase drainings, or any oil

containing gasoline.

The boiler must only be operated with the specified

fuels.

Only burners that are suitable for the specified fuels may

be used.

Observe the manufacturer's burner selection list and the

burner manufacturer's instructions.

8 | Product Description

SB625WS/SB745WS6 720 805 218 (2013/02)

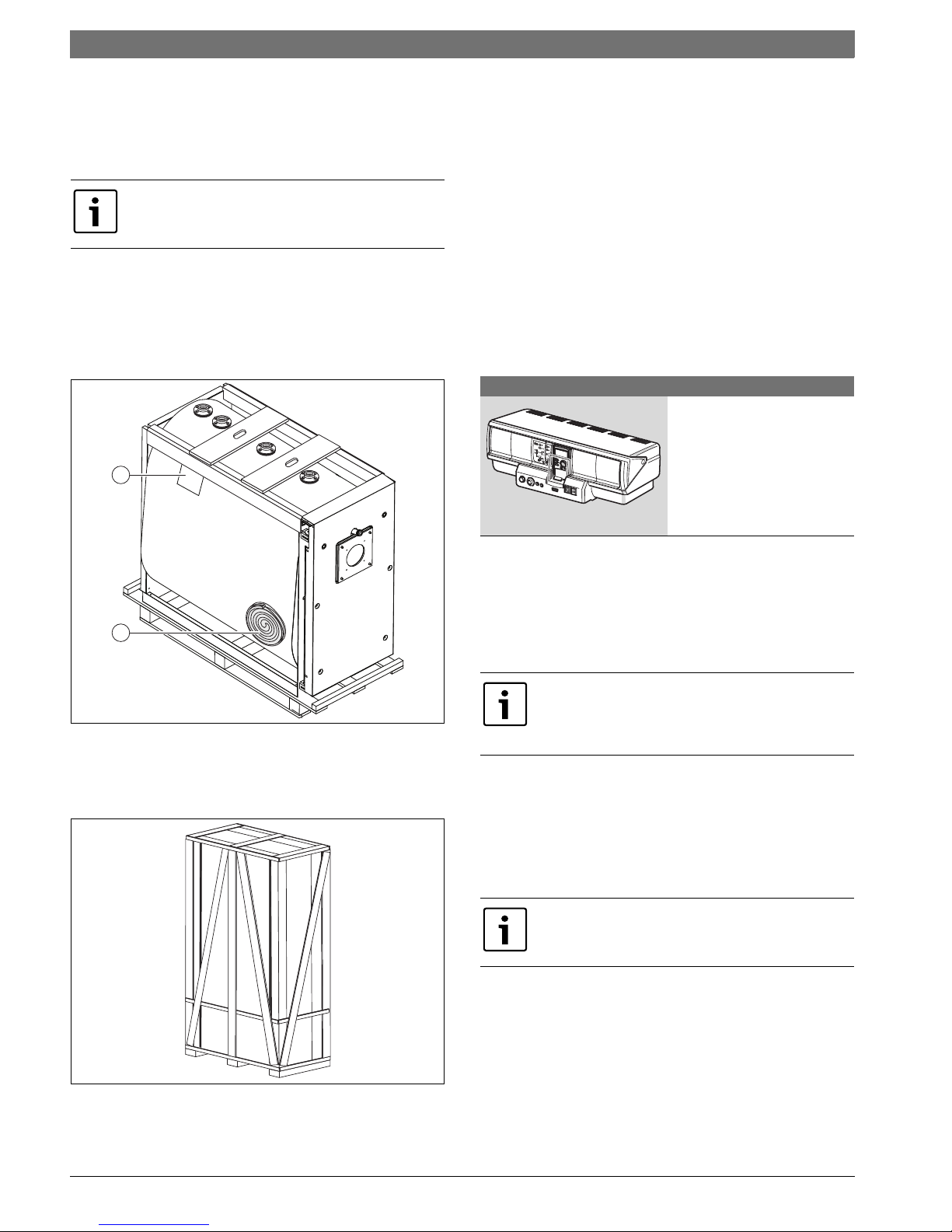

2.5 Scope of delivery

The boilers SB625WS / SB745WS comes in two separate crates and

one additional box.

Boiler body crate:

The boiler body crate bears the documentation envelope [1] and

contains:

• Instruction manual

• Certificate of Warranty

• Bar code labels

• Ceramic insulation [2]

Fig. 2 Boiler body crate

Paneling crate:

The paneling crate, complete with assembly accessories, protected by

cardboard packaging and a wooden crate.

Fig. 3 Paneling crate

Accessory box:

The boiler accessory box contains

• Manifold

• Pressure relief valve

• Pressure/temperature gauge

Checking the delivery for completeness

▶ After delivery, check all packaging is in perfect condition.

▶ Check the delivery for completeness.

▶ Dispose of packaging in an environmentally responsible manner.

2.6 Accessories

Control panels

The control panels listed below may be supplied by the manufacturer for

use with the SB625WS / SB745WS boilers.

2.7 Tools, materials and auxiliary equipment

For the installation and maintenance of the boiler, standard tools are

required, as used for heating, gas, water and electrical installations.

2.8 Data plate

Serial number plate

The serial number plate is located on the rear of the boiler block and

specifies the serial number and model.

Data plate

This lists the appliance’s technical specifications and performance. The

data plate will be factory installed on the boiler side panel.

The instruction manual is an integral part of the boiler.

Once located, read it thoroughly and keep it safe.

6 720 805 218-11.2T

1

2

6 720 805 218-12.1T

Model Description

The Logamatic 4321 control unit

is designed for low temperature

and condensing operation in

single or multiple boiler systems.

Additional possible functions

include DHW, mixed heating zones

and solar thermal integration.

Table 3 Control panels

If you contact the manufacturer with any questions about

this product, always provide the details on the data plate

and serial number plate. These details enable us to assist

you specifically and quickly.

If these plates or any other means of clearly identifying

the product are defaced, removed or lost, proper

installation and servicing may be difficult.

Product Description | 9

6 720 805 218 (2013/02)SB625WS/SB745WS

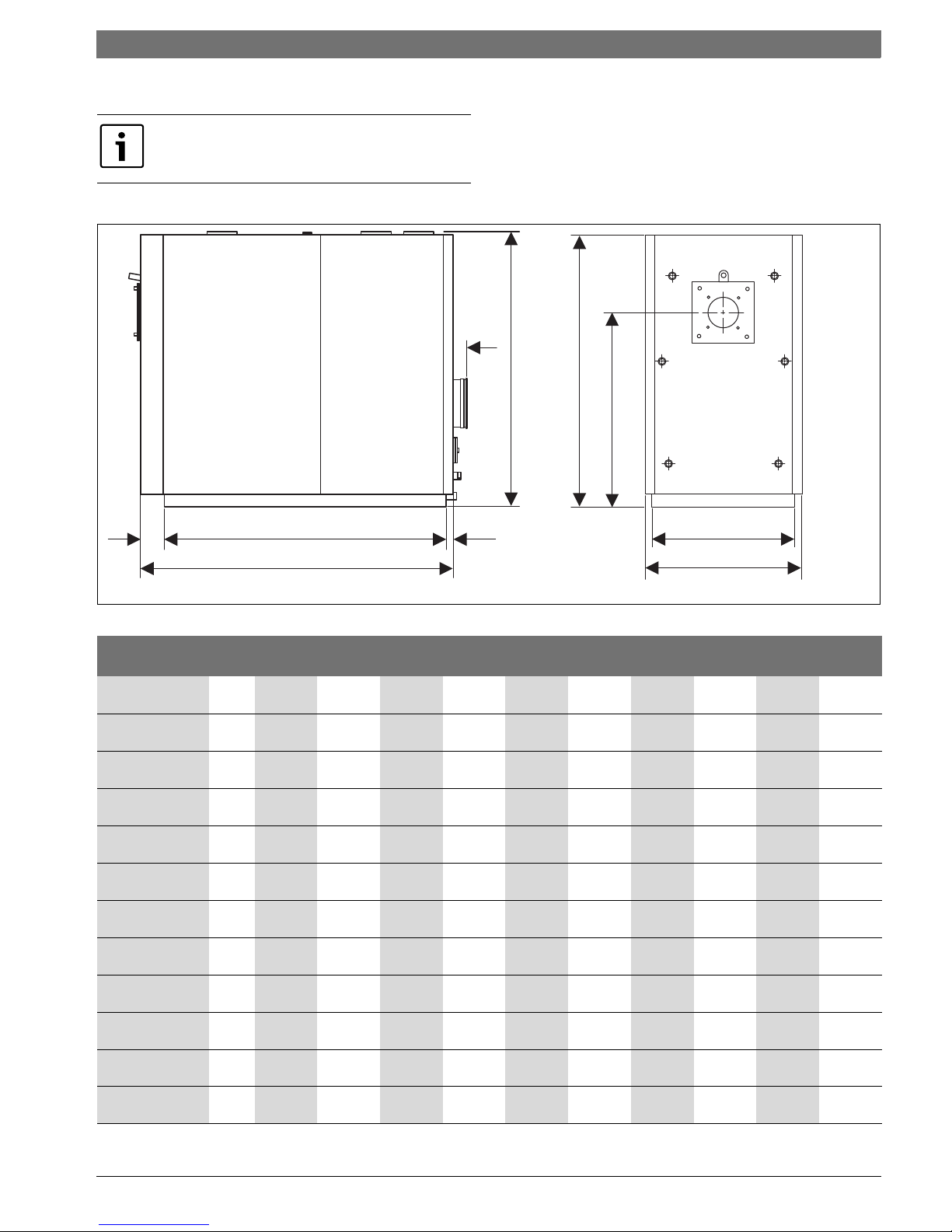

2.9 Dimensions and specifications

2.9.1 Dimensions

Fig. 4 Dimensions

Values obtained with RS.../M-burners.

AL1 E

L

D

H1

H

F

B

6 720 805 218-13.1T

C

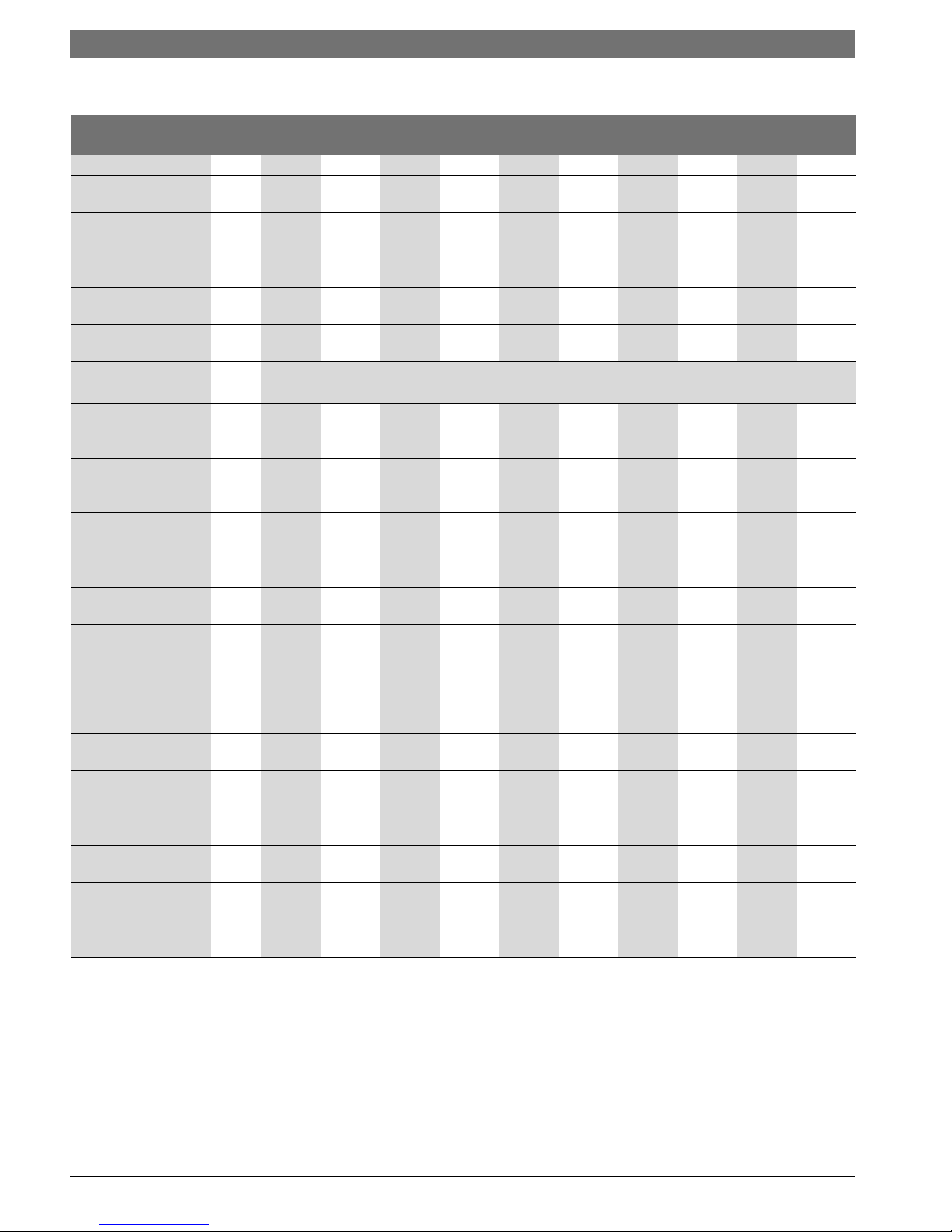

Description Unit SB625WS SB745WS

160 220 290 370 480 640 800 1050 1300 1550

A: Base width inch

(mm)

27 3/16

(690)

27 3/16

(690)

29 1/2

(750)

29 1/2

(750)

31 1/8

(790)

31 1/8

(790)

37 7/16

(950)

37 7/16

(950)

42 1/8

(1070)

44 1/2

(1130)

B: Overall width inch

(mm)

29 1/8

(740)

29 1/8

(740)

33 1/2

(850)

33 1/2

(850)

35 7/16

(900)

35 7/16

(900)

41 3/4

(1060)

41 3/4

(1060)

46 7/16

(1180)

48 1/4

(1225)

C: Length base to

front

inch

(mm)

4 3/4

(120)

4 3/4

(120)

4 3/4

(120)

4 3/4

(120)

4 3/4

(120)

4 3/4

(120)

4 3/4

(120)

4 3/4

(120)

4 3/4

(120)

4 3/4

(120)

D: Height of burner

plate

inch

(mm)

36 7/16

(925)

36 7/16

(925)

40 9/16

(1030)

40 9/16

(1030)

48 5/8

(1235)

48 5/8

(1235)

54 3/4

(1390)

54 3/4

(1390)

58 7/8

(1495)

62 5/8

(1590)

E: Length base to

rear

inch

(mm)

1 9/16

(40)

1 9/16

(40)

1 9/16

(40)

1 9/16

(40)

1 9/16

(40)

1 9/16

(40)

1 9/16

(40)

1 9/16

(40)

1 9/16

(40)

1 9/16

(40)

F: Flue connection

depth

inch

(mm)

2 3/4

(70)

2 3/4

(70)

2 3/4

(70)

2 3/4

(70)

2 3/4

(70)

2 3/4

(70)

2 3/4

(70)

2 3/4

(70)

2 3/4

(70)

2 3/4

(70)

H – Height o f water

fittings

inch

(mm)

52 3/4

(1340)

52 3/4

(1340)

57 1/16

(1450)

57 1/16

(1450)

66 3/4

(1695)

66 3/4

(1695)

75

(1905)

75

(1905)

80 5/16

(2040)

85 13/16

(2180)

H1 – Boiler height inch

(mm)

52 3/16

(1325)

52 3/16

(1325)

56 9/16

(1435)

56 9/16

(1435)

66 1/8

(1680)

66 1/8

(1680)

74 7/16

(1890)

74 7/16

(1890)

79 3/4

(2025)

85 1/4

(2165)

L – Length inch

(mm)

57 5/16

(1455)

57 5/16

(1455)

64 3/16

(1630)

72 1/16

(1830)

80 1/8

(2035)88(2235)

100 3/4

(2560)

110 5/8

(2810)

118 1/2

(3010)

121 1/4

(3080)

L1 – Base length inch

(mm)60(1295)60(1295)

57 7/8

(1470)

65 3/4

(1670)

73 13/16

(1875)

81 11/16

(2075)

94 1/2

(2400)

104 5/16

(2650)

112 3/16

(2850)

112 3/16

(2850)

Weight of boiler lbs

(kg)

1122

(510)

1168

(530)

1492

(677)

1660

(753)

2414

(1095)

2755

(1250)

4122

(1870)

4596

(2085)

5544

(2515)

6724

(3050)

Weight of paneling lbs

(kg)

110

(50)

110

(50)

132

(60)

154

(70)

198

(90)

264

(120)

308

(140)

352

(160)

473

(215)

506

(230)

Table 4 Technical Data

10 | Product Description

SB625WS/SB745WS6 720 805 218 (2013/02)

2.9.2 Technical Data

Description SB625WS SB745WS

160 220 290 370 480 640 800 1050 1300 1550

Fuel Gas Gas Gas Gas Gas Gas Gas Gas Gas Gas

Rated input (Nat. Gas) MBH

(kW)

563

(164.9)

788

(230.9)

1014

(297.1)

1314

(385.0)

1689

(494.9)

2200

(644.7)

3003

(880.0)

3754

(1100.0)

4692

(1375.0)

5443

(1595.0)

Rated input (#2 Oil) GPH

(LPH)

4.0

(15.1)

5.6

(21.2)

7.2

(27.3)

9.3

(35.2)

12.0

(45.4)

15.7

(59.4)

21.4

(81.0)

26.8

(101.4)

33.5

(126.8)

38.8

(146.9)

Gross output MBH

(kW)

544

(159.7)

762

(223.6)

990

(290.2)

1280

(375.2)

1642

(481.5)

2190

(642.0)

2738

(802.4)

3650

(1070.0)

4563

(1337.4)

5293

(1551.4)

Sensible losses from

stack

% 1.7 1.7 1.5 1.5 1.9 1.9 1.9 1.9 1.9 1.9

Jacket losses with burner

mounted

% 0.3 0.3 0.5 0.6 0.6 0.6 0.6 0.6 0.6 0.6

Flue gas temperature

(T)

°F

(°C)

< 113 - 167

(< 45 - 75)

< 113 - 167

(< 45 - 75)

< 113 - 167

(< 45 - 75)

< 113 - 167

(< 45 - 75)

< 113 - 167

(< 45 - 75)

Flue gas mass flow rate1lbs/sec

(kg/

sec)

0.15

(0.07)

0.19

(0.09)

0.26

(0.12)

0.33

(0.15)

0.44

(0.20)

0.57

(0.26)

0.72

(0.33)

0.94

(0.43)

1.19

(0.54)

1.38

(0.63)

Fireside pressure drop2Inch

W.C

(mbar)

0.802

(2.0)

1.083

(2.7)

1.284

(3.2)

1.846

(4.6)

2.007

(5.0)

2.208

(5.5)

2.288

(5.7)

2.529

(6.3)

2.729

(6.8)

2.970

(7.4)

Firebox volume Ft3

(dm3)

6.07

(172)

6.07

(172)

8.51

(241)

9.85

(279)

15.61

(442)

17.51

(496)

26.59

(753)

30.15

(854)

36.62

(1037)

44.10

(1249)

Total volume of flue gas

side

Ft3

(dm3)

8.93

(253)

9.78

(277)

14.58

(413)

17.02

(482)

26.03

(737)

30.37

(860)

45.55

(1290)

51.34

(1454)

62.25

(1763)

74.05

(2097)

Heat exchanger surface

area

Ft2

(m2)

65.65

(6.1)

94.72

(8.8)

139.93

(13.0)

175.45

(16.3)

234.65

(21.8)

310.00

(28.8)

426.25

(39.6)

500.52

(46.5)

604.93

(56.2)

670.37

(62.2)

Specific heat load MBH/

ft2

(kw/

m2)

8.28

(26.18)

8.04

(25.40)

7.07

(22.32)

7.29

(23.01)

6.99

(22.08)

7.06

(22.29)

6.42

(20.26)

7.29

(23.01)

7.54

(23.79)

7.89

(24.94)

Maximum condensate

production

Gal/h

(l/h)

4.86

(18.4)

7.23

(27.4)

8.42

(31.9)

10.80

(40.9)

13.78

(52.2)

19.49

(73.8)

23.24

(88.0)

29.42

(111.4)

35.05

(132.7)

42.13

(159.5)

Maximum working

pressure

PSI

(bar)80(5.5)

80

(5.5)80(5.5)

80

(5.5)

80

(5.5)

80

(5.5)

80

(5.5)80(5.5)80(5.5)

80

(5.5)

Maximum admissible

temperature

°F

(°C)

230

(110)

230

(110)

230

(110)

230

(110)

230

(110)

230

(110)

230

(110)

230

(110)

230

(110)

230

(110)

Maximum working

temperature

°F

(°C)

210

(98.8)

210

(98.8)

210

(98.8)

210

(98.8)

210

(98.8)

210

(98.8)

210

(98.8)

210

(98.8)

210

(98.8)

210

(98.8)

Pressure drop T

50 °F (10 °C)

Ft. Hd.

(mbar)

5.0

(150.1)

3.3

(100.4)

4.1

(121.5)

4.3

(128.7)

1.0

(30.2)

1.1

(33.8)

1.5

(46.4)

1.8

(54.0)

1.2

(36.0)

1.4

(43.2)

Pressure drop T

68 °F (20 °C)

Ft. Hd.

(mbar)

1.2

(36.3)

0.9

(28.4)

1.0

(30.6)

0.9

(28.7)

0.3

(8.5)

0.3

(9.0)

0.4

(13.4)

0.5

(16.3)

0.3

(10.2)

0.4

(11.3)

Water capacity Gal

(l)

85.3

(323)

95.1

(360)

130.7

(495)

146.6

(555)

196.2

(743)

203.4

(770)

348.7

(1320)

368.5

(1395)

482.1

(1825)

501.9

(1900)

Table 5 Technical Data

1. Depends on return temperature 86-140 °F (30-60 °C)

2. At maximum output with water temps supply/return of 176/140 °F (80/60 °C) and CO2 = 9.7 %

Product Description | 11

6 720 805 218 (2013/02)SB625WS/SB745WS

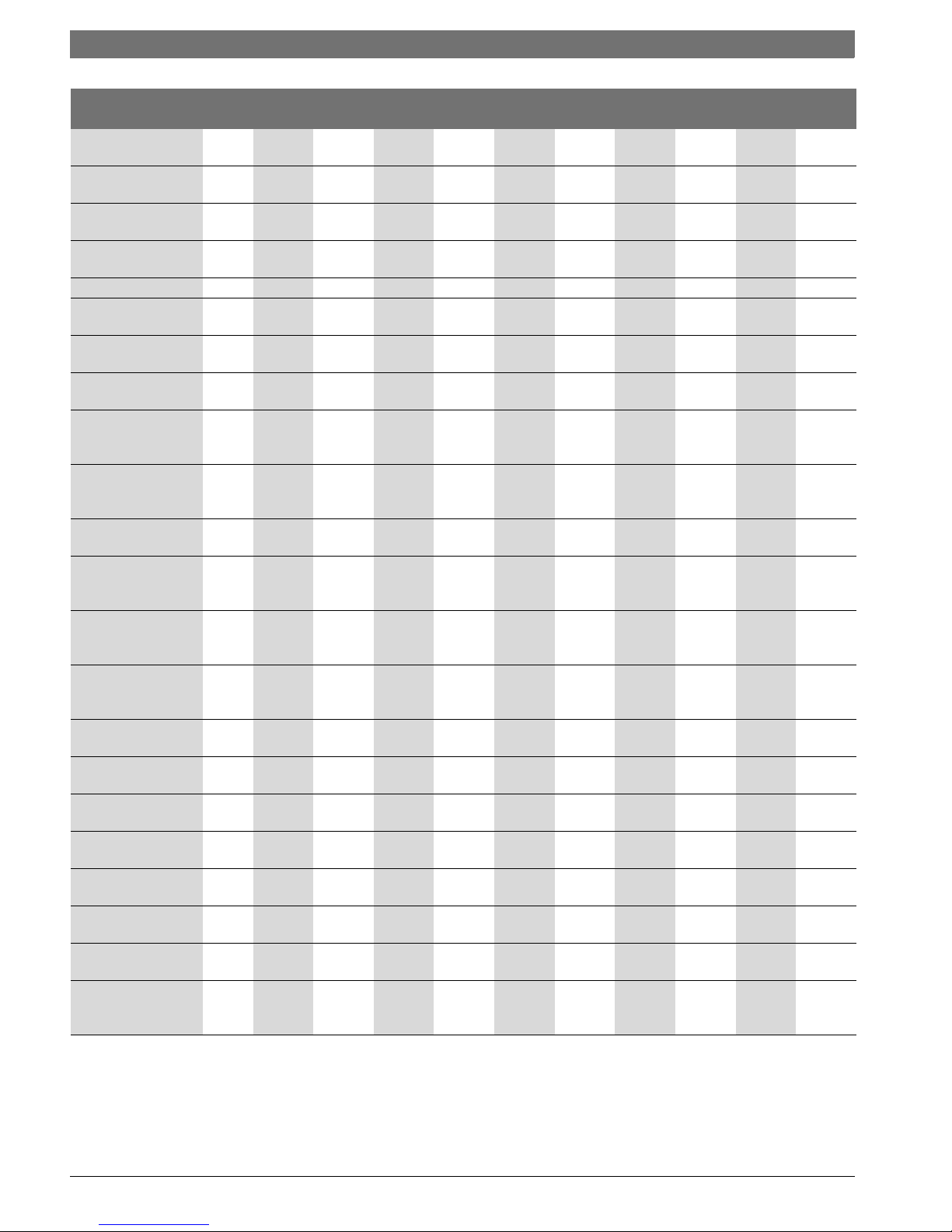

2.9.3 Water connections

The boilers are designed and made for use in central heating

installations, but can also be used for domestic hot water production if

connected to suitable sub-systems. Water fittings are as specified in the

following table.

Fig. 5 Water connections - SB625WS/160-640 and SB745/800-1300

Fig. 6 Water connections - SB745WS/1550

M

M

7

6

5

H

A

N

B

8

F

EDC

2

3

4

1

2 3/4”

(70 mm)

I

G

L

O

8

6 720 805 218-18.1T

M

M

7

2

6

5

H

I

F

G

L

O

A

N

B

EDC

2

8

3

4

1

6 720 805 218-19.1T

P

The choice of system components and the method of

their installation are left up to the installer. Installers

must use their expertise to ensure proper installation

and functioning in compliance with all applicable codes.

12 | Product Description

SB625WS/SB745WS6 720 805 218 (2013/02)

Description SB625WS SB745WS

160 220 290 370 480 640 800 1050 1300 1550

1 – Heating supply inch

(DN)

2 1/2

(65)

2 1/2

(65)

2 1/2

(65)

3

(80)

4

(100)4(100)5(125)5(125)6(150)6(150)

2 – Heating return 1

(Low Temperature)

inch

(DN)

2 1/2

(65)

2 1/2

(65)

2 1/2

(65)

3

(80)

4

(100)4(100)5(125)5(125)6(150)6(150)

3 – Heating return 2

(High Temperature)

inch

(DN)2(50)

2

(50)

2

(50)

2 1/2

(65)

3

(80)

3

(80)

3

(80)

3

(80)

4

(100)4(100)

4 – Safety device

fitting

Ø- inch 1 1/4 1 1/4 1 1/4 1 1/4 1 1/2 1 1/2 3333

5 – Boiler drain fitting Ø - inch 1111111 1/4 1 1/4 1 1/4 1 1/4

6 – Condensate drain

fitting

Ø- inch 11111 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4

7 – Flue gas exhaust

fitting

Ømm 200 200 250 250 300 300 350 350 400 450

8– Instrument bulb/

probe sockets

n° x Ø ‘’ 3 x 1/2 3 x 1/2 3 x 1/2 3 x 1/2 3 x 1/2 3 x 1/2 3 x 1/2 3 x 1/2 3 x 1/2 3 x 1/2

A– Distance from

burner head to heating

supply

inch

(mm)

11 7/8

(302)

11 7/8

(302)

11 13/16

(300)

12 5/8

(321)

12 1/4

(311)

12 1/4

(311)

16 1/8

(410)

16 1/8

(410)

17 5/16

(440)

17 3/8

(442)

B– Distance from

heating flow outlet to

return 1

inch

(mm)

34 7/8

(885)

34 7/8

(885)

41 3/8

(1050)

48 5/16

(1235)

55 5/16

(1405)

63 3/16

(1605)

70 7/8

(1800)

80 11/16

(2050)

86 5/8

(2200)

101 3/4

(2582)

C – Distance between

heating returns 1 & 2

inch

(mm)

7 7/8

(200)

7 7/8

(200)

11 13/16

(300)

9 7/8

(250)

10 1/8

(255)

11 13/16

(300)

13 13/16

(350)

13 13/16

(350)

13 13/16

(350)

28 13/16

(732)

D – Distance between

heating return 2 and

safety device fitting

inch

(mm)

11 1/4

(285)

11 1/4

(285)

11 13/16

(300)

17 3/4

(450)

23 5/8

(600)

27 9/16

(700)

29 1/2

(750)

33 1/2

(850)

33 1/2

(850)

33 1/2

(850)

E – Distance between

heating flow outlet and

safety device fitting

inch

(mm)

15 3/4

(400)

15 3/4

(400)

17 3/4

(450)

21 1/16

(535)

21 11/16

(550)

23 13/16

(605)

27 9/16

(700)

33 1/2

(850)

39 3/8

(1000)

39 3/8

(1000)

F – Distance between

heating return 1 and

flue gas outlet

inch

(mm)

10 5/8

(270)

10 5/8

(270)

10 5/8

(270)

10 5/8

(270)

10 5/8

(270)

10 5/8

(270)

12 13/16

(325)

12 13/16

(325)

13 5/8

(345)

22 1/4

(565)

G – Height of

condensate drain

inch

(mm)

6 5/16

(160)

6 5/16

(160)

6 1/2

(165)

6 1/2

(165)

8 1/2

(215)

8 1/2

(215)

7 11/16

(195)

7 11/16

(195)

8 7/8

(225)

9 1/4

(235)

H – Height of boiler

flanges

inch

(mm)

52 3/4

(1340)

52 3/4

(1340)

57 1/16

(1450)

57 1/16

(1450)

66 3/4

(1695)

66 3/4

(1695)75(1905)75(1905)

80 5/16

(2040)

85 13/16

(2180)

I – Height of flue gas

outlet

inch

(mm)

20 1/4

(515)

20 1/4

(515)

21 1/2

(545)

21 1/2

(545)

25 3/8

(645)

25 3/8

(645)

26 3/4

(680)

26 3/4

(680)

28 3/8

(720)

31 11/16

(805)

L – Height of boiler

drain fitting

inch

(mm)

2 3/8

(60)

2 3/8

(60)

2 7/16

(61)

2 7/16

(61)

3 1/4

(82)

3 1/4

(82)

3 3/8

(86)

3 3/8

(86)

3 1/2

(90)

3 3/8

(86)

M – Boiler centerline inch

(mm)

13 9/16

(345)

13 9/16

(345)

14 9/16

(375)

14 9/16

(375)

15 9/16

(395)

15 9/16

(395)

19 5/16

(490)

19 5/16

(490)

21 1/16

(535)

22 1/4

(565)

N– Distance from

burner head to door

inch

(mm)

4 5/16

(110)

4 5/16

(110)

4 3/4

(120)

4 3/4

(120)

4 15/16

(125)

4 15/16

(125)

4 15/16

(125)

4 15/16

(125)

5 1/2

(140)6(150)

O – Distance from

Boiler drain fitting

inch

(mm)

5 3/16

(132)

5 3/16

(132)

5 3/8

(137)

5 3/8

(137)

4 15/16

(125)

4 15/16

(125)

6 7/8

(175)

6 7/8

(175)

7 1/8

(181)7(178)

P – Height of heating

return 1

(Low Temperature)

inch

(mm)

– – – – – – – – – 53 7/8

(1370)

Table 6 Technical Data

Water treatment | 13

6 720 805 218 (2013/02)SB625WS/SB745WS

3 Water treatment

The quality of the fill and top-up water is an essential factor for increased

efficiency, functional reliability, long service life and for maintaining the

constant operational condition of a heating system. If the system is filled

with water that has a high calcium hardness, this will be deposited on the

heat exchanger surfaces and will obstruct the transfer of heat to the

heating water.

As a result, the wall temperatures of the stainless steel heat exchanger

surfaces will increase and the thermal stress (loads on the boiler body)

will increase. Water treatment is an essential factor in ensuring trouble

free operation, availability, a long service life and the efficiency of the

heating system.

3.1 Chemical and physical characteristics

The chemical and physical characteristics of heating system water must

be similar to those of drinking water.

A chemical water treatment device is recommended in order to protect

system components as well as an inlet filter to prevent solid particles

from entering the system in suspension and causing corrosion or sludge.

Typical layouts of water treatment systems

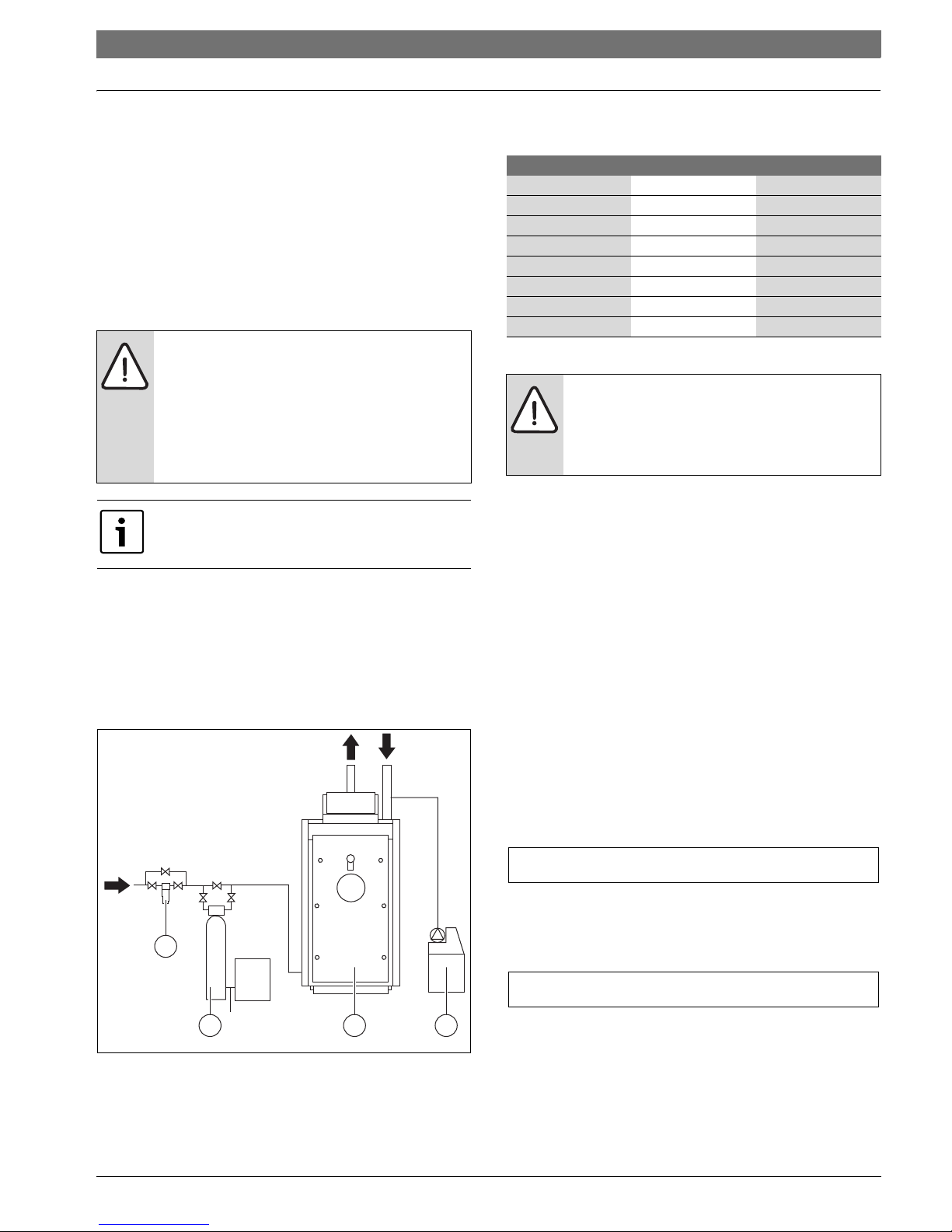

Fig. 7 Water treatment for heating installations

[1] Filter

[2] Water softener

[3] Boiler

[4] Chemical treatment unit

Chemical and physical requirements of heating system water

3.2 Central heating system

Possible causes for corrosion and limescale

Typical problems encountered in central heating systems include:

• the breakage of heated surfaces through overheating caused by the

thermal insulation of limescale deposits on the water side

• oxygen corrosion

• deposit corrosion

• stray current corrosion

• diffused and localized acid corrosion.

3.2.1 Limescale deposits

Limescale forms when the calcium and magnesium bicarbonates that

are dissolved in the water at ambient temperature become chemically

transformed when the water is heated.

Calcium bicarbonate forms calcium carbonate, water and carbon

dioxide, while magnesium bicarbonate transforms into magnesium

hydroxide and carbon dioxide.

Calcium bicarbonate Ca(HCO

3)2

when temperature is increased:

Form. 1 Calcium bicarbonate changes when temperature is increased

Magnesium bicarbonate Mg(HCO3)

2

when temperature is increased:

Form. 2 Magnesium bicarbonate changes when temperature is

increased

Calcium carbonate and magnesium hydroxide precipitate to form

insoluble deposits that adhere and compact on surfaces to form

limescale, a substance with a high thermal insulating power.

Inside a boiler, limescale forms mainly in areas subj ect to direct heat and

high temperatures. It is so common to find deposits localized in a few

NOTICE:

If it proves impossible to treat the heating system water

supply properly because the water charging system is

automatic and uncontrolled, if there are no barriers

installed to prevent water oxygenation, and if the

heating system includes an open expansion vessel, then

the boiler itself must be separated from the heating

system by means of a heat exchanger.

Installation must conform to any and all national, fed eral,

state and local standards and codes.

Y

6 720 805 218-17.1T

1

32 4

Parameters Unit of measure Heating water

pH 7.5- 9,5

Hardness ppm <50

Electrical conductivity s/cm < 100

Chlorides mg/l <10

Sulphides mg/l <10

Nitrides mg/l <10

Oxygen in solution mg/l –

Iron (Fe) mg/l <0.5

Table 7 Requirements of heating system water

NOTICE:

Chemical products used for water treatment must be

compatible with applicable water pollution laws.

Provided they are properly applied, these laws

guarantee the safe functioning of the heating system.

CaCO3H2OCO

2

++

Mg OH22CO

2

+

14 | Water treatment

SB625WS/SB745WS6 720 805 218 (2013/02)

specific areas, where temperature is the highest. A coating of limescale

of only 1 mm can cause severe overheating in metal parts and

consequent damage through thermal stress. It is continuous topping up

(automatic fill from incoming water) that causes thick deposits to form,

leading to boiler breakdown.

3.2.2 Deposit corrosion

Deposit corrosion is an electro-chemical phenomenon caused by the

presence of foreign bodies (sand, rust, etc.) in the water mass. These

solid substances generally form deposits (sludge) in the bottom of the

boiler.

The lower parts of the boiler can therefore be affected by a chemical

reaction of micro-corrosion caused by the electrochemical potential

difference created between the metal (steel) and the impurities around

it.

3.2.3 Stray current corrosion

Stray current corrosion is not common, but can be caused by the

different electrical potentials of the boiler water and the metal body of

the boiler or piping creating a cathode/anode effect.

All metal parts of the boiler should therefore be connected to an efficient

ground (earth) point, even though this form of corrosion is actually

caused by the passage of DC current, no longer used for domestic

power. Stray current corrosion is easily identified by the regular tiny

conical holes it leaves.

3.2.4 Diffused and localized acid corrosion

Other forms of corrosion exist that are harder to see but nonetheless

dangerous because they affect the entire heating system and not just the

boiler.

These forms of corrosion are generally due to the water becoming acidic

(pH < 7), and are caused by:

• Incorrect water softening and the presence of carbon dioxide (which

lowers the water’s pH). Carbon dioxide is released more easily in

softened water and also forms during the limescale formation

process. Acid corrosion is diffused and attacks the entire system

more or less uniformly

• Incorrect acid washing (e.g. washing done without a passivating

agent). Acid introduced into the system can cause localized

perforation if it is not properly removed from all parts of the system.

The formation of corrosion can easily be detected by analyzing the

chemical composition of the water. Even a minimal iron content is a

clear sign that corrosion is occurring.

3.3 New central heating systems

Mistakes to avoid and precautions.

To eliminate contact between system water and the air, the following is

required:

• ensure that the expansion vessel is a closed vessel, and of the correct

size and pre-charge pressure (the pressure should be checked

periodically)

• ensure that the system is always kept at a pressure higher than

atmospheric pressure at all points (including the pump suction side)

and at all operating conditions (precisely because the seals, gaskets

and joints in a water circuit are designed to resist pressure from

within, but not to resist a vacuum within)

• ensure that no part of the system is made from materials that are

permeable to gases (e.g. plastic pipes with no oxygen barrier used in

floor heating systems).

The heating system should not need any further topping up once it is

filled and bled of all air.

Any top-ups need to be monitored (by a meter), treated and recorded in

the heating system’s technical log. The presence of a water softener in

conjunction with an automatic filling system is not sufficient to ensure

proper performance.

If more than one boiler is installed in a large system, all boilers must be

switched on at the same time to ensure that any possible limescale

formation is uniformly distributed.

3.4 Reconditioning old heating systems

Frequent mistakes and necessary precautions.

If a boiler must be replaced, do not refill the entire central heating circuit

if the quality of water in it conforms to requirements.

If the quality of water fails to conform to requirements, either

recondition the old water or separate the water circuits (water in the

boiler circuit must conform to requirements).

Conclusions

Never forget that proper water conditioning and proper heating system

design not only guarantee safety and security but also ensures

significant savings in maintenance costs and overall thermal efficiency.

3.5 Elimination air and gas from central heating system

When designing new heating systems, it is necessary to eliminate the air

and other gases that form in the system.

Recently added fill or top-up water loses much of its volume in the first

few days because it releases gases. With new systems you should

therefore initially check the heating water pressure on a daily basis, and

then at gradually longer intervals. Air and gas in the water system not

only causes the corrosion problems listed above, but also reduces

thermal efficiency, causing pump failure and noise and vibration

throughout the heating system. Air bubbles and gas inevitably form in

heating circuits during normal functioning, especially if the precautions

listed above are not fully respected.

The technical details provided in this section refer

specifically to domestic and industrial hot water heating

systems with working temperatures up to 210 °F

(98,8 °C).

NOTICE:

The original system filling water and any topping up

water must always be filtered (using synthetic or metal

mesh filters with a filtration rating of no less than 50

microns) to prevent sludge from forming and triggering

deposit induced corrosion.

NOTICE:

Loss of water from the system, and the consequential

need to add water, can be caused not only by leaks from

the circuit, but also from the incorrect sizing of the

expansion vessel or precharge pressure. (If normal

thermal expansion causes pressure in the system to

increase beyond the setting of the safety valve, that

safety valve will open continuously.)

The expansion vessel size should be corrected to

prevent unnecessary safety valve blow-off.

Water treatment | 15

6 720 805 218 (2013/02)SB625WS/SB745WS

In particular:

• as temperature increases, oxygen becomes less watersoluble and

bubbles begin to form.

• CO2 (carbon dioxide) is generated as the carbonates of calcium and

magnesium precipitate out.

• the chemical oxidation of the metals in the system also generates

hydrogen.

These gases must be eliminated as they are formed. The system needs

to be designed and installed so that all gases can be vented quickly,

easily, and effectively.

3.6 Use of Antifreeze

In areas where freezing may occur, an antifreeze may be added to the

system water as protection. Please adhere to the specifications

provided by the antifreeze manufacturer.

▶ Use the anti-freeze manufacturer’s data to determine the anti-freeze

ratio for the desired freeze protection temperature.

▶ Do not exceed 50% antifreeze mix ratio and do not use antifreeze

other than specifically made for hot water heating systems.

Do not use automotive silicate-based antifreeze in the

heating system.

16 | Transport

SB625WS/SB745WS6 720 805 218 (2013/02)

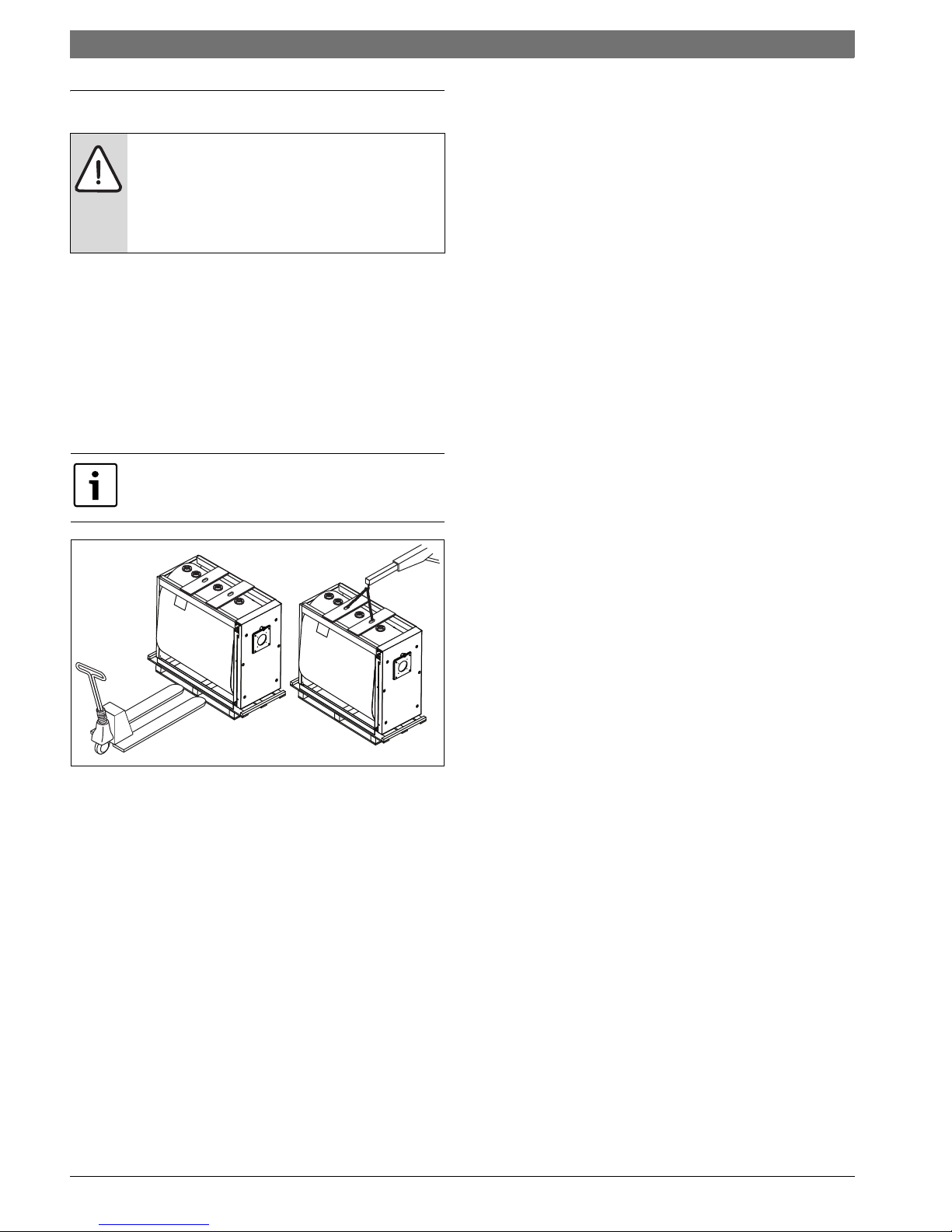

4 Transport

▶ Only use lifting equipment of adequate capacity.

▶ Remove the transport straps and the wooden pallet before

positioning the boiler.

▶ For lifting using a rigging crane, use only the lifting provisions

supplied.

▶ When lifting the boiler using chains, make sure that at least two chains

are load-bearing. Lift up very carefully.

▶ Maintain less than a 45 degree angle with the vertical when lifting the

boiler with chains or cables.

▶ The rigging crane must be operated by trained personnel.

Fig. 8 Transport

WARNING: Risk of injury from carrying heavy loads and

inadequately securing loads for transport.

▶ Use suitable means of transportation, e.g. several

pallet trucks, a forklift truck, crane or heavy duty

rollers.

▶ Secure the load against falling.

Never pull retaining straps (fixing straps, chains) over

the boiler insulation.

6 720 805 218-14.1T

Loading...

Loading...