Page 1

SP

79

Non contractual photograph

Use

The SP volumetric d ivider is a machine developed to divide

with precision softer types of dough or moderately leavened

dough into pieces of the desired size and weight as well as to

automatically feed the machines next in the production line.

Designe d for intensive workloads, the volumetric divider is

particularly suitable for bakeries and pastry workshops and

manufacturers for medium or high volume production.

Developed to be fed by mixers with self-tipping device or

bowl lifters and to feed in turn a wide range of machines

(rounders, moulders, long moulders), the SP divider can be

considered as the core of a well-conceived automatic

production line. Heavy gauge steel covering plates, the iron

and special alloy weighing group along with the high

resistance stainless steel dividing knife contribute to making

the divider a particularly trouble free and long-lasting

machine. Greasing takes place through an individually

programmable 6 delivery automatic pump. A practical preselection piece counting device sets the number of pieces to

be produced so that production stops automatically when the

desired output has been reached. Should the machine stop

before the final output has been produced, the number of

missing pieces is shown on the piece counter display.

Protection and safety devices were designed to comply with

the strictest safety standard. The electric system is connected

with safety devices either to the crankcase or to the hoppers,

which in turn come with either a mobile disk or grid safety

guard. Maintenance and cleaning are particularly easy at the

end of the work cycle. The machine noise level is particularly

low due to the use of carefully selected components and to

the mechanics conceived to lower the noise of the piece

suction and ejection process.

Version planned for single or double piece output

selection is made by means of a practical device installed on

the dividing piston. The divider is available with front or side

exit, both of which are height-adjustable, to allow the divider

to work in line with different machine types. Both versions

feature a conveyor with two belts whose speed can be set

separately so as to allow the most convenient speed for

double-piece production. Each belt speed can be adjusted by

a practical selector featuring two positions. The mechanical

stainless steel flour sifter adjusts the flour output through the

motion transmitted by the belt conveyor motor.

The

Automatic volumetric

dividers

Version planned for single piece output only

size bread production. The mechanical brush flour sifter has an independent

motor.

Version planned for double piece output only

exit conveyor whose speed can be set separately. The mechanical brush

flour sifter has an independent motor.

Construction

• Cast iron frame on castors, one of them self-locking

• Food-grade epoxy painted

• Cast iron weigh chamber

• Speed variable by hand-wheel

• Supply voltage : three phase 400 V 50 Hz

• Machine mounted on 2 fixed wheels and 1 rotating.

Combinations

SP 1 SP 1D SP 1DL SP 2 SP 2L SP 2D SP 2DL SP S2 SP3 SP S3

1 way 2 way 2 way 1 way 1 way 1-2 wa y 1-2 way 2 wat 1 way 2 way

UF UF UL UF UL UF UL UF UF UF

UF

= frontal exit

UL

= lateral exit

Hoppers

HLB

HLT

HLR

HPR

Above models have grid safety guard planned for the electric connection to the

Accessories

T/ARR

Machine complies with regulations

SP 1 & 2 SP 3

Round shaped s/s hopper. )0 kg dough cpty. Manual

loading.

Round shaped s/s hopper. 280 kg. dough cpy. M odel

suggested for lateral and back coupling with elevator

tipper mod. ESR.

Rectangualr shape s/s hopper. 220 kg. dough cpty.

Model sugg ested for late ral and back c oupling with

mixers mod. MONO-TWIN 200 and TNSE H

Rectangualr shape s/s hopper. 280 kg. dough cpty.

Model sugg ested for late ral and back c oupling with

mixer mod. ISE/300 FRA

Rounding belt installed on the exit conveyor (recommended to work

soft and sticky dough). This accessory may be applied only on

machines with front exit.

particularly suitable for big

equipped with two belts

150318 150377

150326 150378

150335 150369

150336 150370

Page 2

SP

volumetric divider

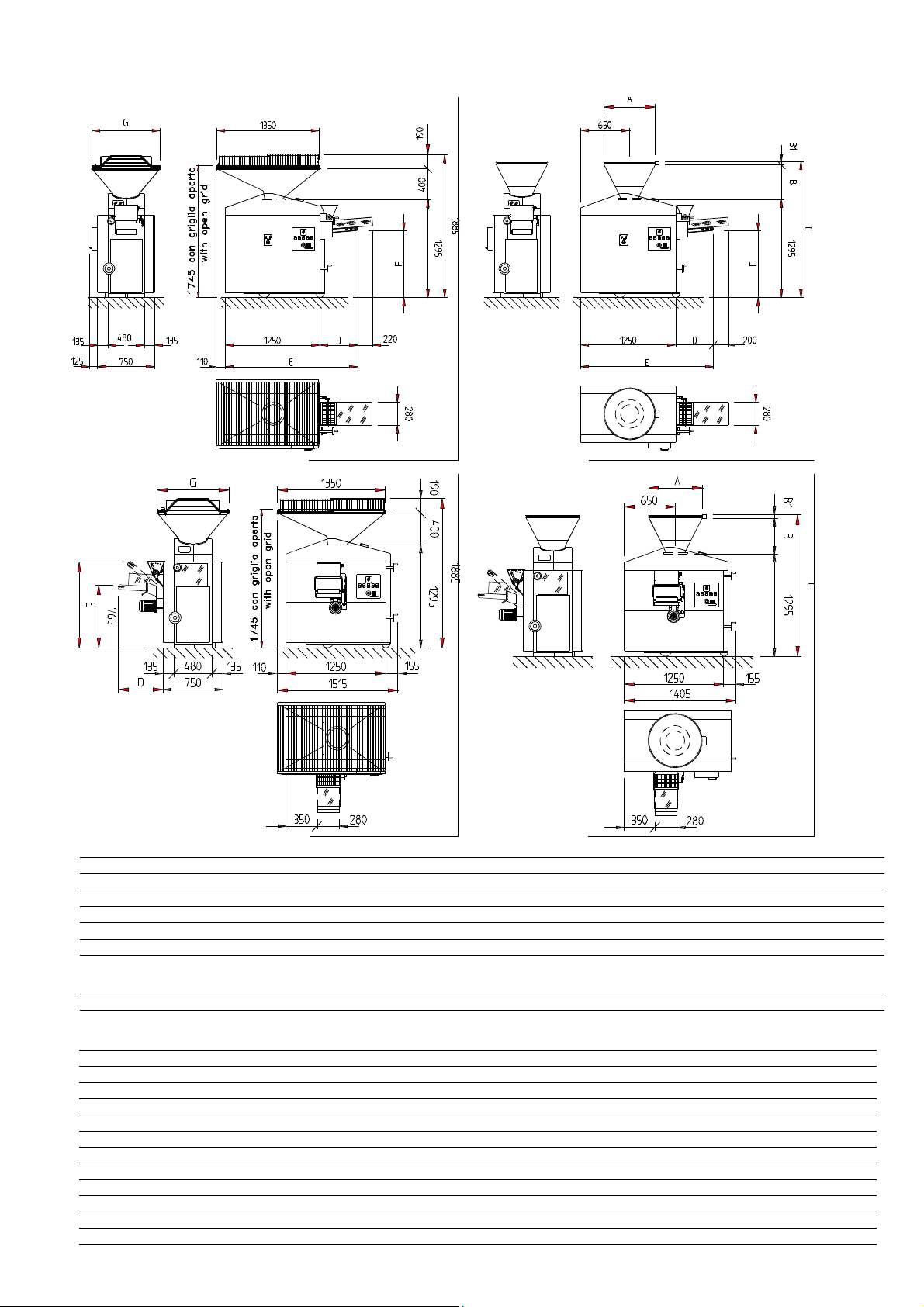

Lateral exit

Frontal exit

General features

Model

SINGLE division (1 way)

Dough piece (gr. min-max) 200-1700 200-1500 200-1500 400-2650 400-2650 400-2200 400-2200 - 500-3000 -

DOUBLE division (2 ways)

Dough piece (gr. min-max) - 40-500 40-500 - - 100-800 100-800 100-600 - 170-1300

Type of exit

Avalable lenghts (mm)

Power

working rythm (adjustable strockes/

hour)

Models and references SP 1 SP 1D SP 1DL SP 2 SP 2L SP 2D SP 2DL SP S2 SP 3 SP S3

FRONTAL EXIT - - - - - - - 02264402 - 02266002

FRONTAL EXIT Short - - - - - - - - - -

FRONTAL EXIT Medium 02251102 02250002 - 02264602 - 02260002 - - 02265002 -

FRONTAL EXIT Long 02251202 02251002 - 02264622 - 02261002 - - 02265102 -

FRONTAL EXIT Medium - Controls on Right 02251112 02250102 - 02264612 - 02260102 - - - -

FRONTAL EXIT Long - Controls on Right 02251212 02250202 - 02264632 - 02261102 - - - -

LATERAL EXIT Short - - 02252002 - 02264712 - 02262002 - - -

LATERAL EXIT Medium - - 02252102 - 02264812 - 02263002 - - -

LATERAL EXIT Long - - 02252202 - 02264912 - 02264002 - - -

LATERAL EXIT Short - Controls on Right - - - - 02264702 - 02262012 - - -

LATERAL EXIT Medium - Controls on Right - - 02252402 - 02264802 - - - - -

LATERAL EXIT Long - Controls on Right - - 02252502 - 02264902 - - - - -

1,1 1,1 1,47 1,1 1,47 1,1 1,47 1,1 1,1 1,1

650-1800 650-1800 650-1800 650-1800 650-1800 650-1800 650-1800 650-1800 650-1300 650-1300

SP 1 SP 1D SP 1DL SP 2 SP 2L SP 2D SP 2DL S P S2 SP 3 SP S3

frontal frontal lateral frontal lateral frontal lateral frontal frontal frontal

500

700

500

700

574

1344

1540

500

700

574

1344

1540

500

700

574

1344

1540

500

500

700

500

80

Loading...

Loading...