Page 1

Repair Manual

F 650 CS

BMW Motorrad

After Sales

Page 2

Issued by © BMW Motorrad

After Sales

UX-VS-2

All rights reserved. Not to be reprinted, translated or duplicated either wholly or in part without prior written

permission.

Errors and omissions excepted; subject to technical amendment.

Printed in Germany 06/01

Page 3

Introduction

This Repair Manual will help you to perform all the main maintenance and repair work correctly and efficiently. If it is consulted regularly by workshop personnel it will form a useful addition to the theoretical and

practical knowledge acquired at the BMW Training Centre. It is a contribution toward achieving even higher

Service quality.

A new issue of this repair manual will be published if amendments or additions (supplements) are needed.

All information in both text and illustrations refers to motorcycles in standard condition or with genuine

BMW accessories installed, and not to motorcycles which have been modified in any way to depart from

the manufacturer’s specification.

The Repair Manual is structured in the logical sequence of the work to be performed: Removal, Disas-

•

sembling, Repair, Assembly, Installation.

The entire contents are divided into individual chapters, corresponding to the Construction Groups.

•

11 . 10

Chapter Page number within chapter

If a reference is needed to a different page or chapter, an arrow symbol is shown followed by the chapter

and page numbers, e. g. (

Work to be performed during an Inspection is described in Group “00”. The various inspection routines

•

are numbered I, II, III and IV. This numbering is repeated in the work descriptions which follow, so that

work can take place without interruption.

a 12.5).

Use of the BMW special tools needed for certain tasks is described in the work instructions.

•

If the need arises, repair instructions are also issued in the form of Service Information. This information is

of course incorporated into the next issue of the Repair Manual. We also recommend, as an additional

source of information, the Electronic Parts Catalogue (ETK), which contains clear and easy-to-follow illustrations.

If the work described here is restricted to a particular equipment specification, for instance if a specific optional extra (OE) is fitted, this is stated in square brackets at the start of the item concerned, e.g. [Heated

handlebar grips].

Please refer to the following pages as well for a description of other symbols used and how to work with

them.

BMW Motorrad

After Sales

Issued by BMW Motorrad

After Sales

UX-VS-2

D-80788 München

All rights reserved. Not to be reprinted, translated or duplicated either wholly or in part without prior written

permission.

Errors and omissions excepted; subject to technical amendment.

Produced in Germany

Page 4

Use

Each chapter starts with the list of contents.

The list of contents is followed by the technical data table.

Key to symbols

In this Repair Manual for the F 650 CS model, the following symbols are used; their meanings are explained

in the table.

Special instructions aimed at improving the work procedures

L Note:

Special information on operating and inspecting the motorcycle as well as maintenance and adjustment

procedures.

e Attention:

Instructions and precautions specifically intended to prevent damage to the motorcycle. Failure to comply

with them could invalidate the warranty.

d Warning:

This symbol stands for precautions and measures which are essential in order to protect the rider or other

persons from possibly severe or fatal injury.

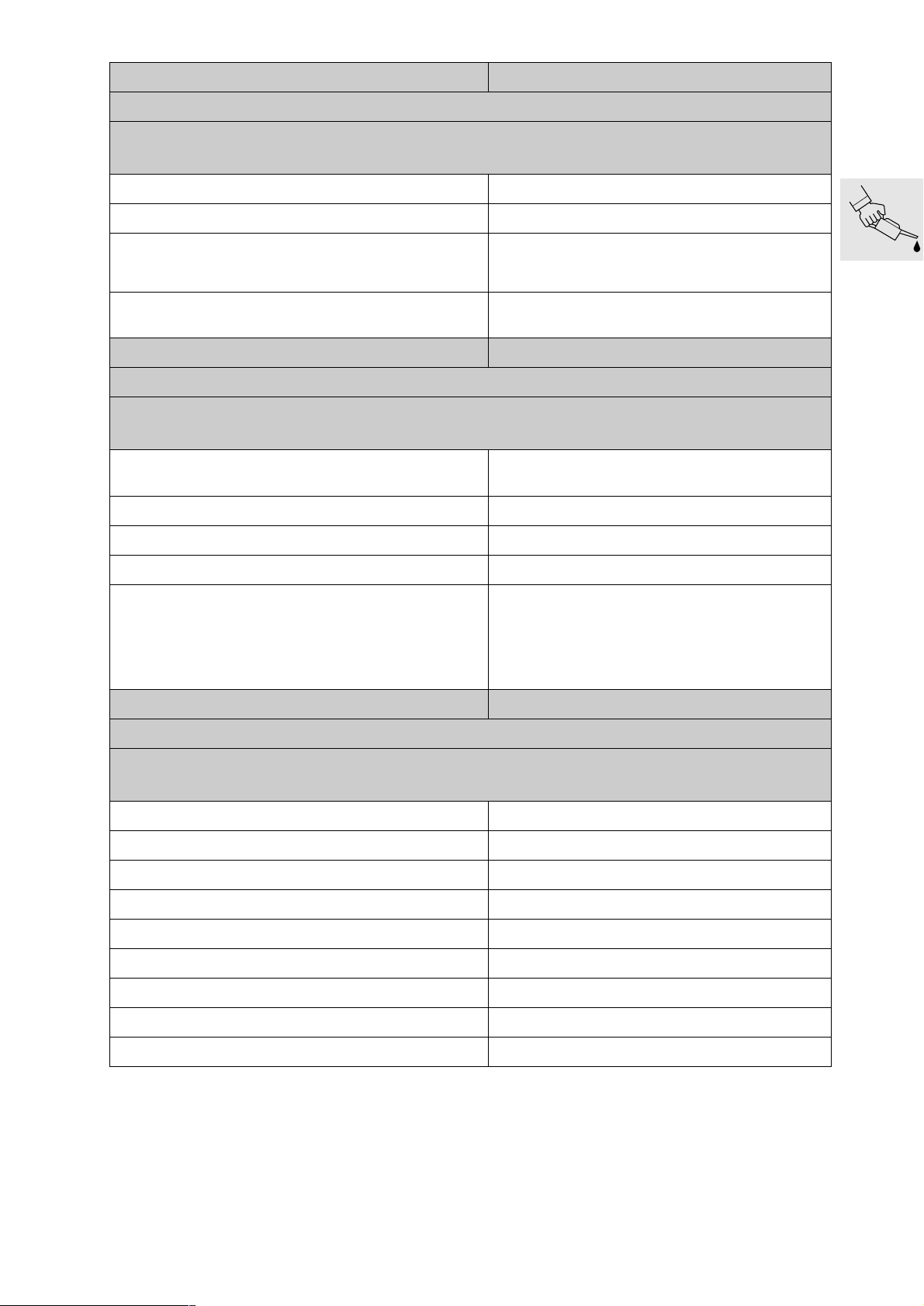

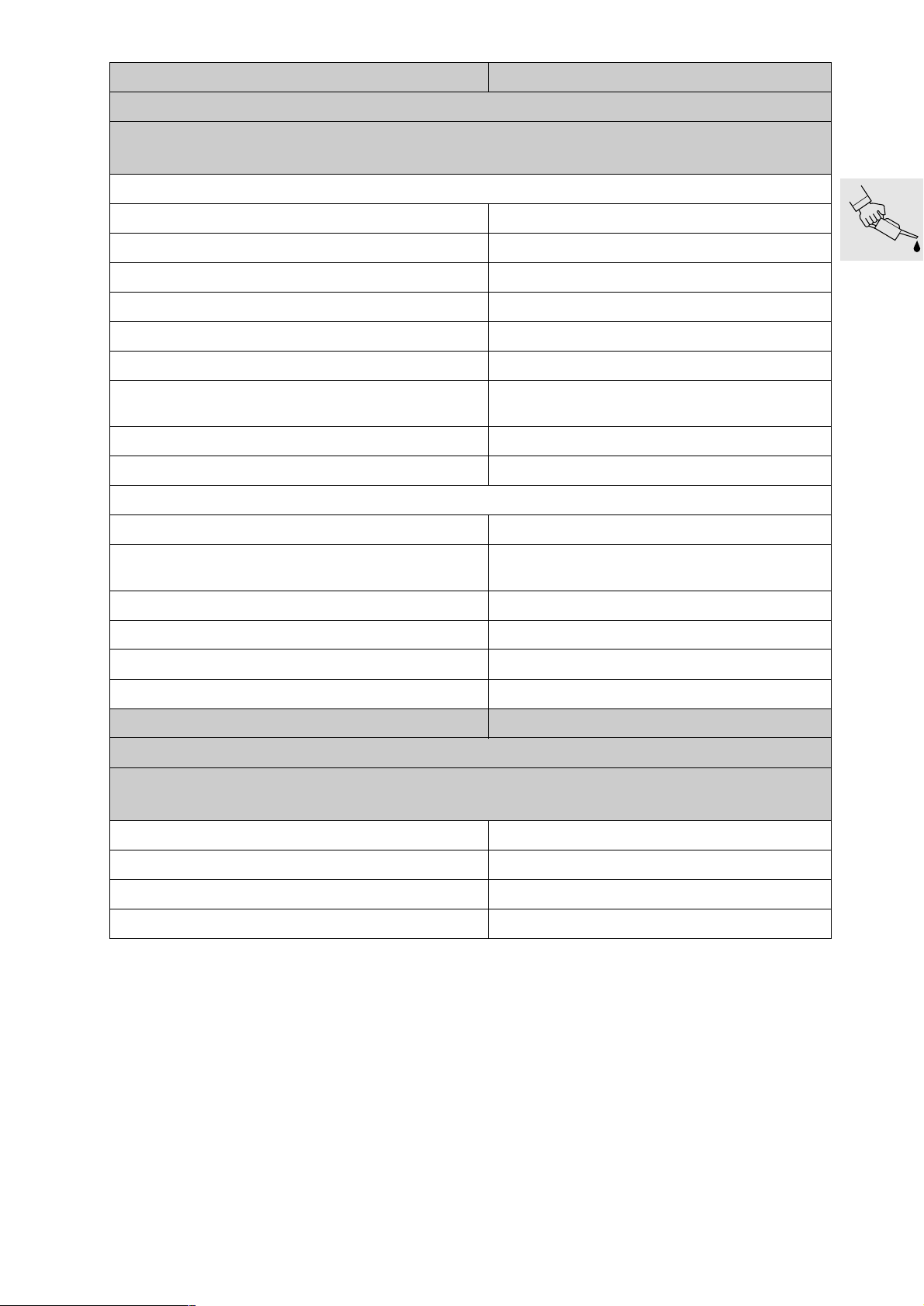

Contents

The titles of the tasks described in this chapter............. complete with page numbers

Activities

Activities

•

The bullet symbol indicates work steps that are described in greater detail under another headline

•

– Preceding activities

– A line indicates work steps that are described in greater detail under another headline or in another

chapter

The term "remove" means that:

the fastener (e.g. screw) must be backed off completely and removed

or

a component (e.g. injection rail) has to be removed to the extent that components behind it (e.g. throttle

valve rail) are rendered accessible

The term "loosen" or "slacken" means that:

the fastener (e.g. screw) must be backed off, but not removed

X Tightening torque:

Values are stated if they differ from DIN EN 24 014 or DIN 912 ISO industrial standards.

Page 5

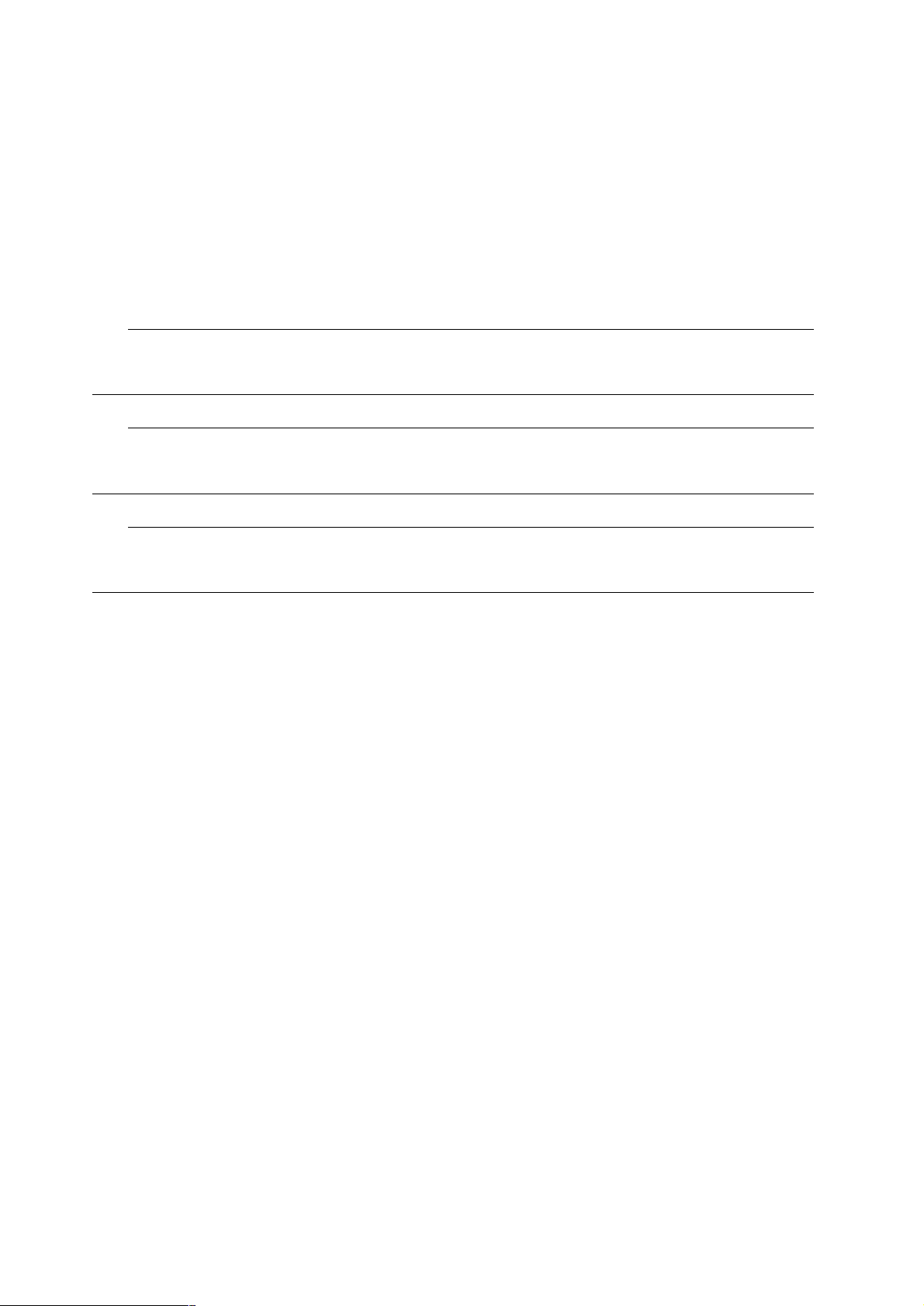

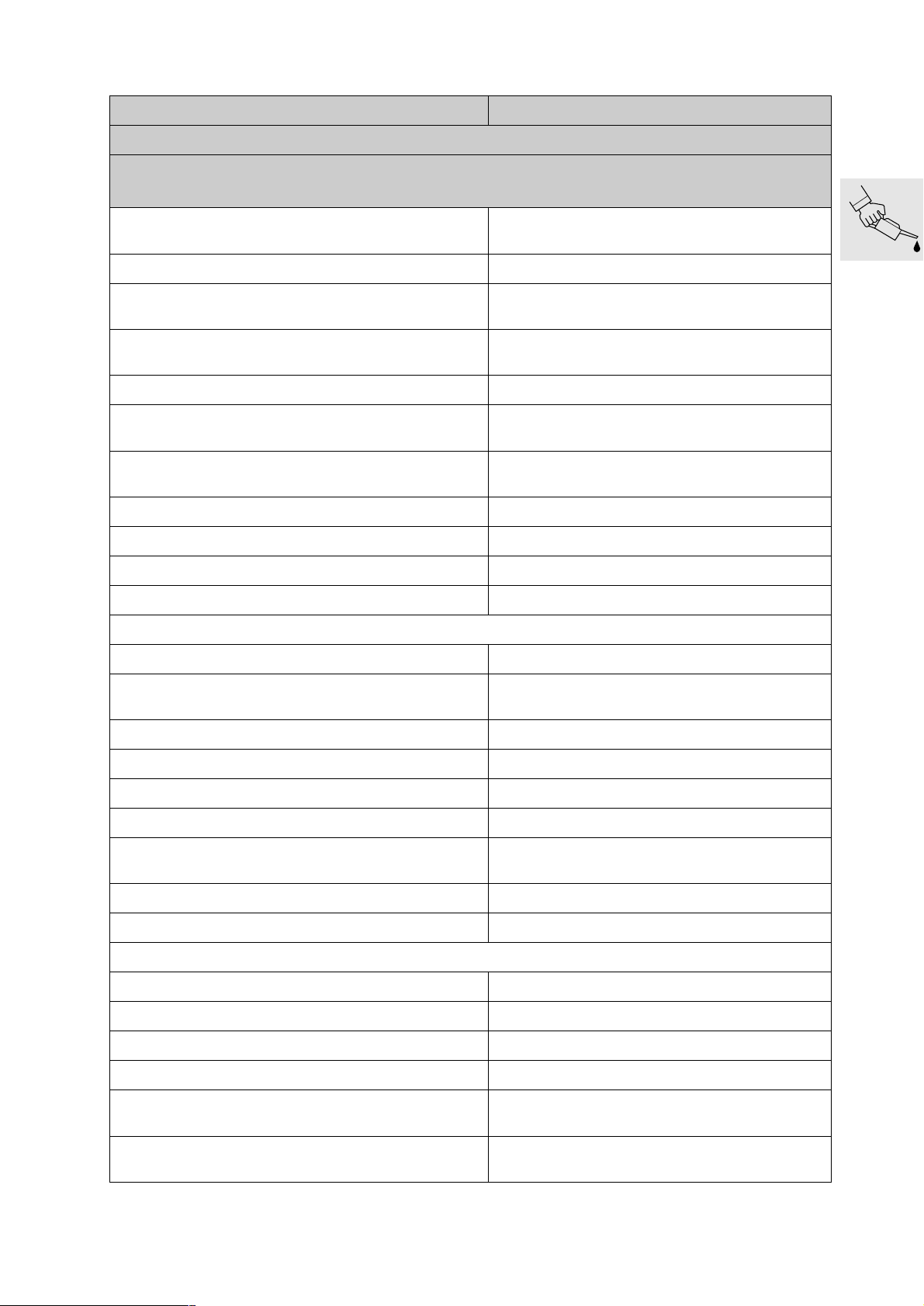

BMW Motorrad

Maintenance schedule

F 650 CS

Customer Licence No. Mileage

Job Order No. Date Mechanic’s signature

Read the fault code memory with the BMW MoDiTeC

Change the engine oil [engine only] while at regular operating temperature

and replace the oil filter element

Change the engine oil [engine and oil tank] while at regular operating temperature

and replace the oil filter element

if motorcycle is used only for short journeys or at outside temperatures below 0°C (32°F): every

3 months or at the latest after 3,000 km (1,800 miles)

Clean oil strainer in frame

once only at 10,000 km/6,000 miles

Check the coolant and restore to correct level if necessary

Grease rubber grommets for cover insert

Replace the coolant

every 2 years

Check valve clearances, adjust if necessary

Replace the spark plug

Drain the outlet hose from the air filter box

Replace intake air filter

If motorcycle is operated in very dirty or dusty conditions, clean or replace the intake air filter every

10,000 km (6,000 miles); check every 3,000 km (1,800 miles)

Replace fuel filter

every 40,000 km (24,000 miles)

Check clutch play, adjust if necessary

Examine brake pads and discs for wear, replace if necessary

Check front/rear circuit brake fluid

Check for operation of brake system and freedom from leaks; repair/replace if necessary

Renew brake fluid at least once a year

[ABS] Replace the primary front/rear brake master cylinder cup

every 40,000 km (24,000 miles)

Replace toothed belt

Check toothed belt and sprocket, replace if necessary

Check belt tension, adjust if necessary

Check battery acid level, add distilled water if necessary

Clean and grease the battery terminals, if necessary

Check steering head bearings and adjust *) or replace if necessary

Grease the side stand

Using a torque wrench, check that the screws and nuts of the engine mounts, manifold fastener, the frame threaded fasteners, the rear-frame threaded fasteners, and the eccentric

clamp are tightened to specified torque

Final inspection with road safety and functional check:

– Clutch, gearshift

– Steering

– Front and rear brakes

– Side stand contact switch

– Condition of tyres and wheels, tyre pressures

– Lights and signalling equipment, indicator and warning lights, instruments

– Optional equipment

– Test ride, if necessary

*) Write up on separate invoice; Not part of standard service procedure

*)

*)

*)

*)

*)

*)

*)

BMW Inspection

at 1,000 km/600 miles

BMW Maintenance

Service every

10,000 km/6,000 miles

BMW Inspection

every 20,000 km/

12,0 0 0 miles

BMW

Annual Service

*)

UX-VS-2, 07.2001

BMW recommends Castrol

Page 6

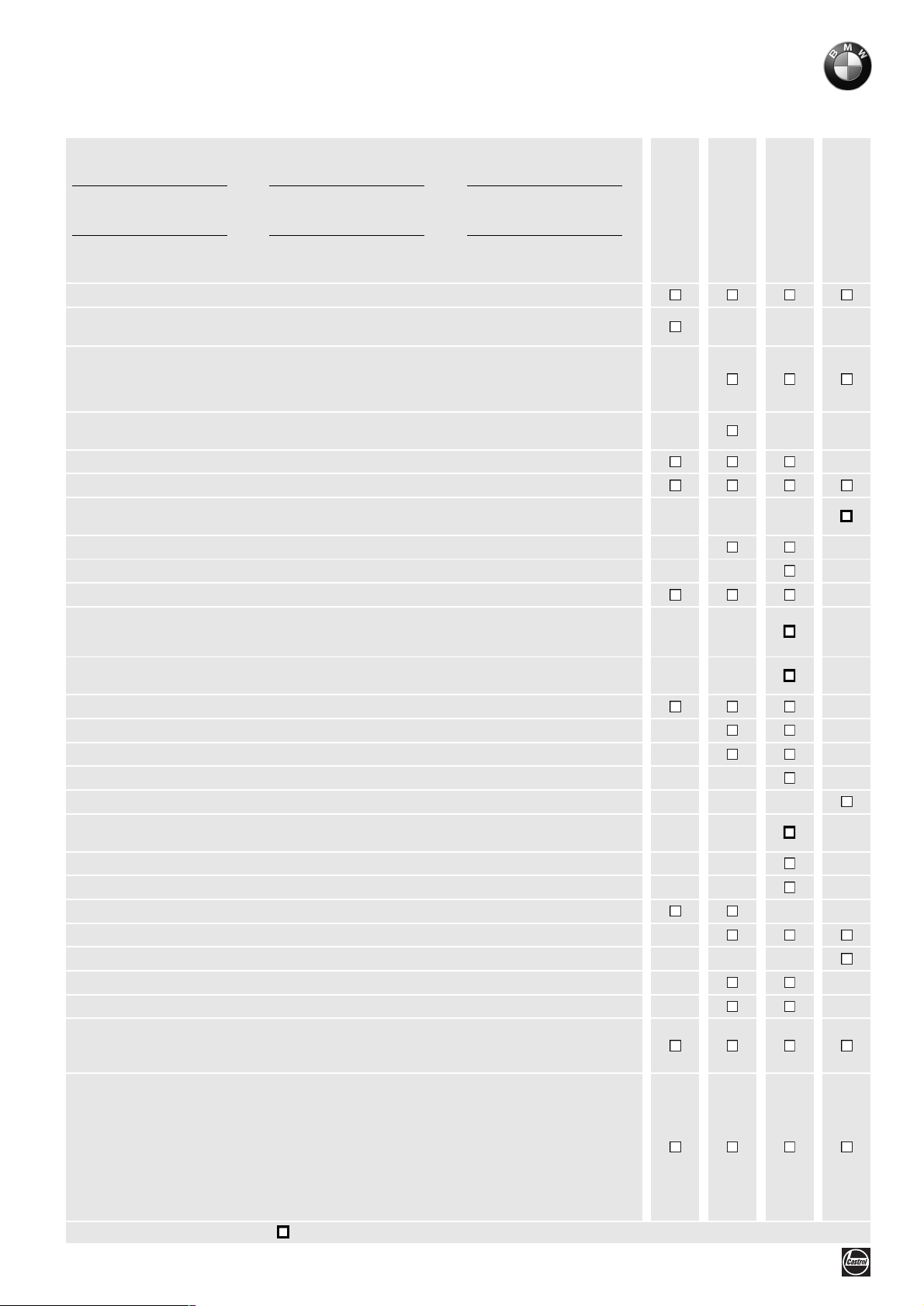

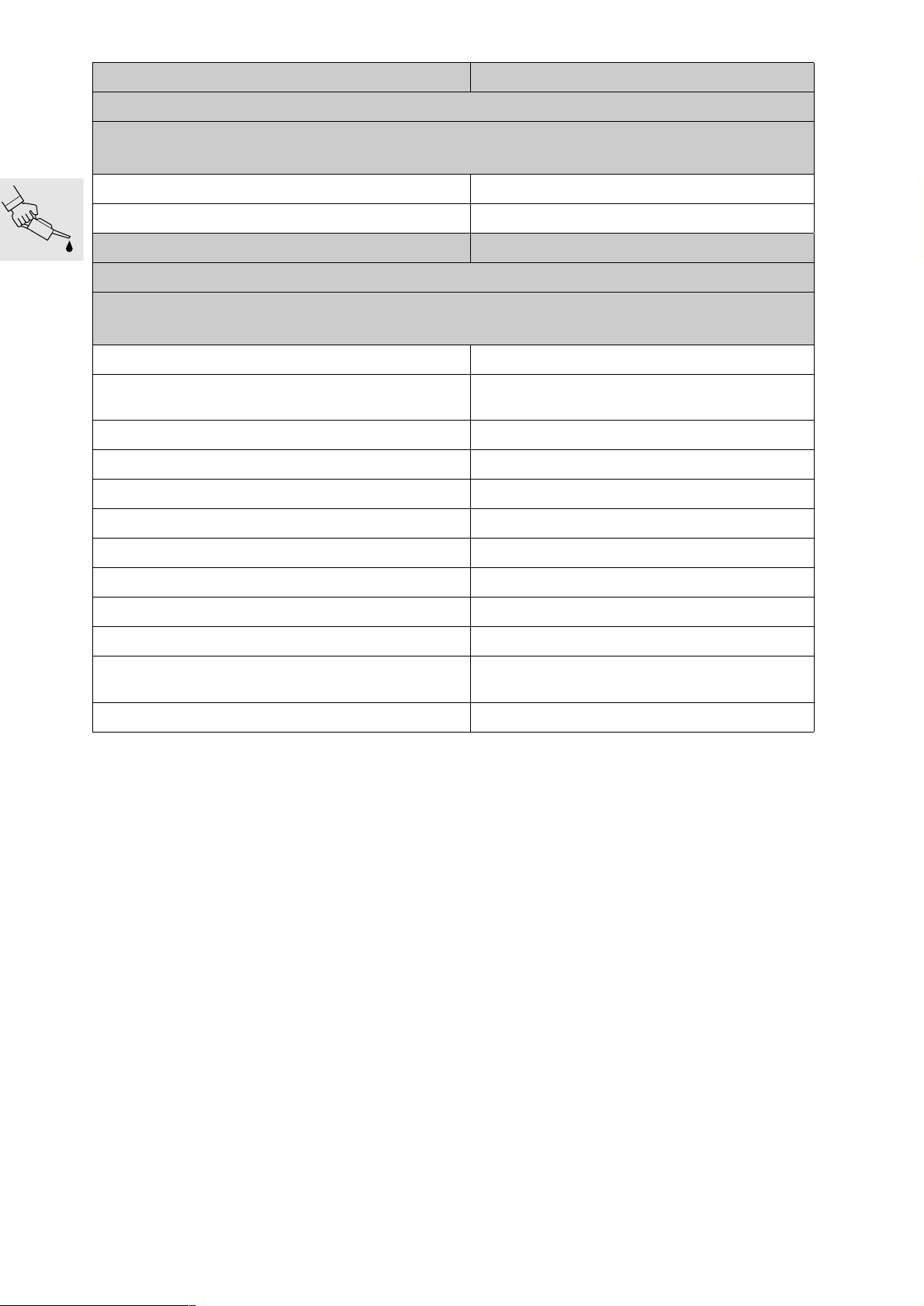

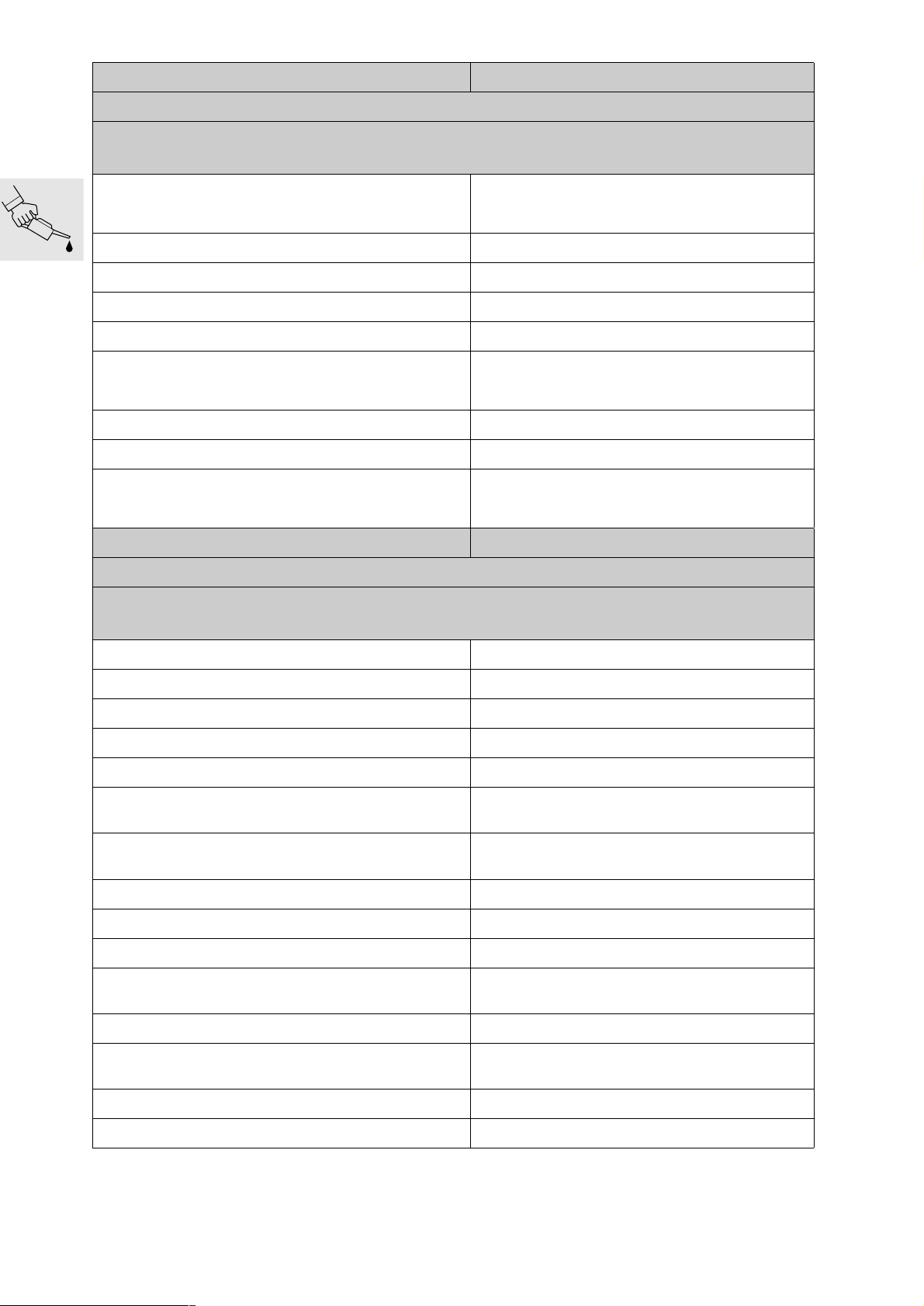

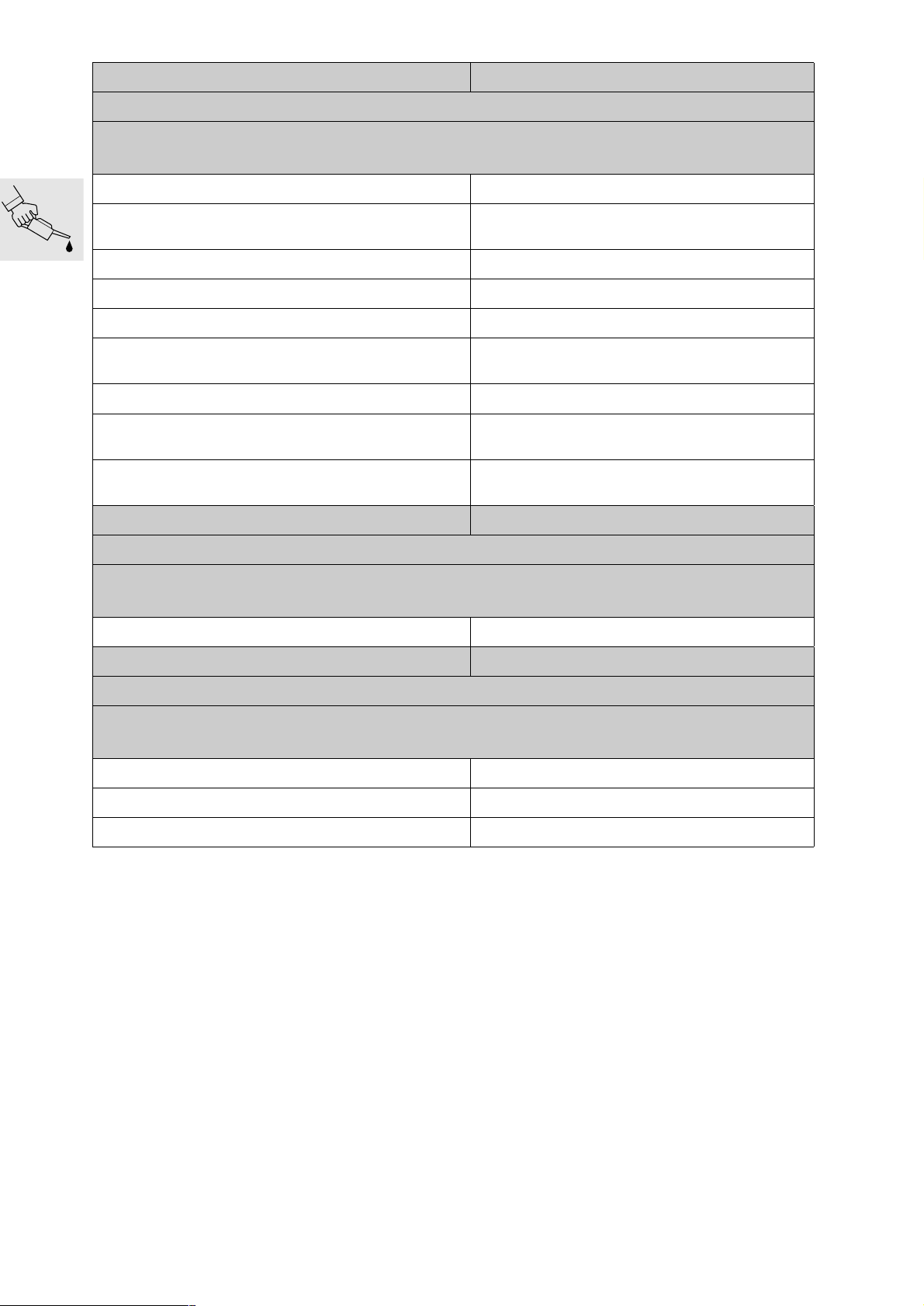

BMW Motorrad

Pre-delivery check

F 650 CS

Customer Licence No.

Job Order No. Mechanic’s signature

Check the shipping pallet for damage

Unpack the motorcycle

Inspect motorcycle for damage

Check complete specification delivery:

– tools

– handbooks and documents

– keys

– optional extras

Motorcycle complete

BMW

Pre-delivery check

Battery:

– remove

– add battery acid

– charge

– grease the terminal posts

– re-install (mark date)

Check tyre pressure

Fuel the motorcycle

Safety/operating check as final inspection:

– Oil inspection

– Clutch, gearshift

– Steering

– Hand brakes and foot brakes

– Check lights and signalling equipment, warning and indicator lights, instruments, ABS

– Test ride, if necessary

Confirm delivery inspection in “Maintenance Booklet“

Final cleaning

Vehicle delivered on:

UX-VS-2, 07.2001

BMW recommends Castrol

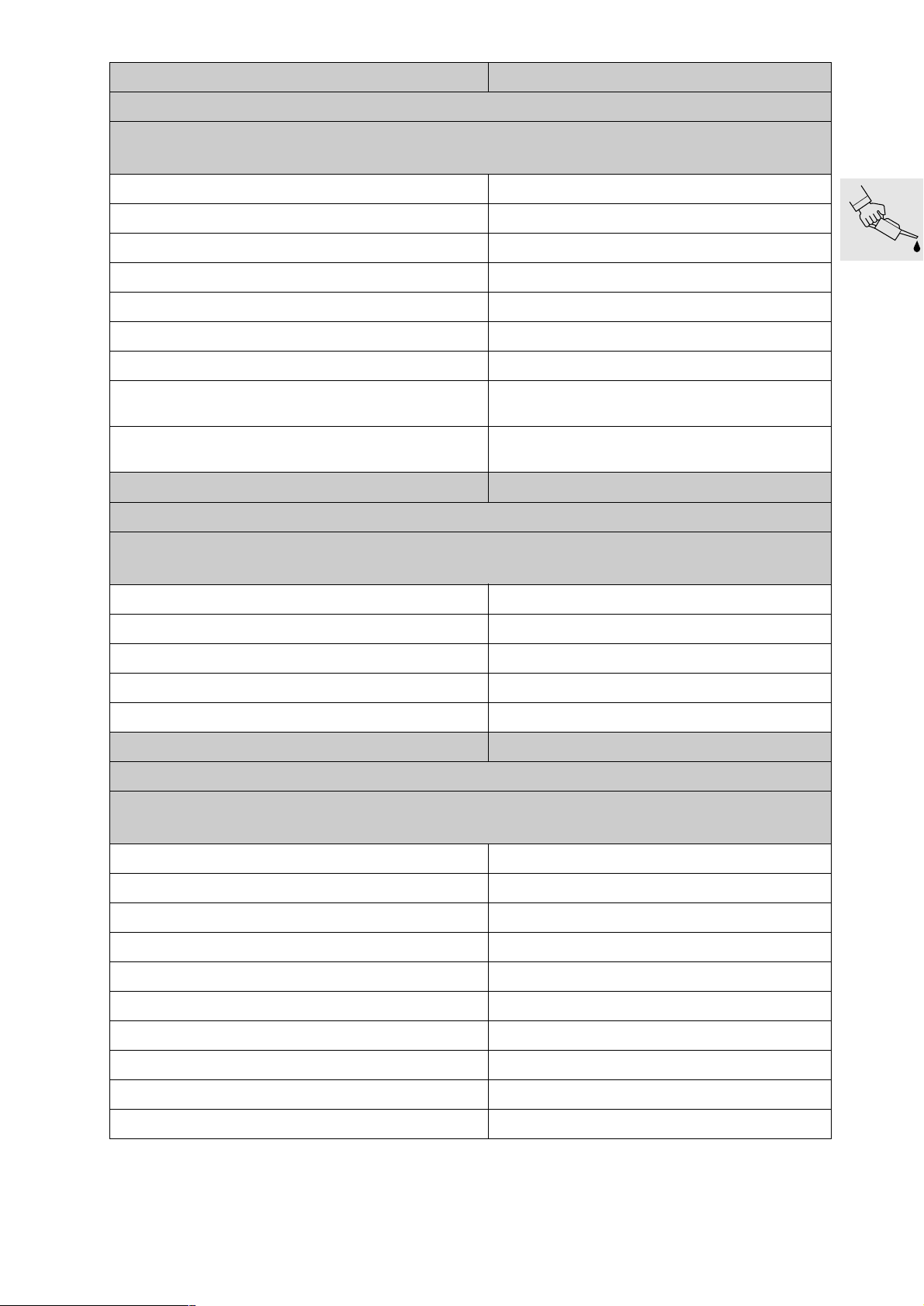

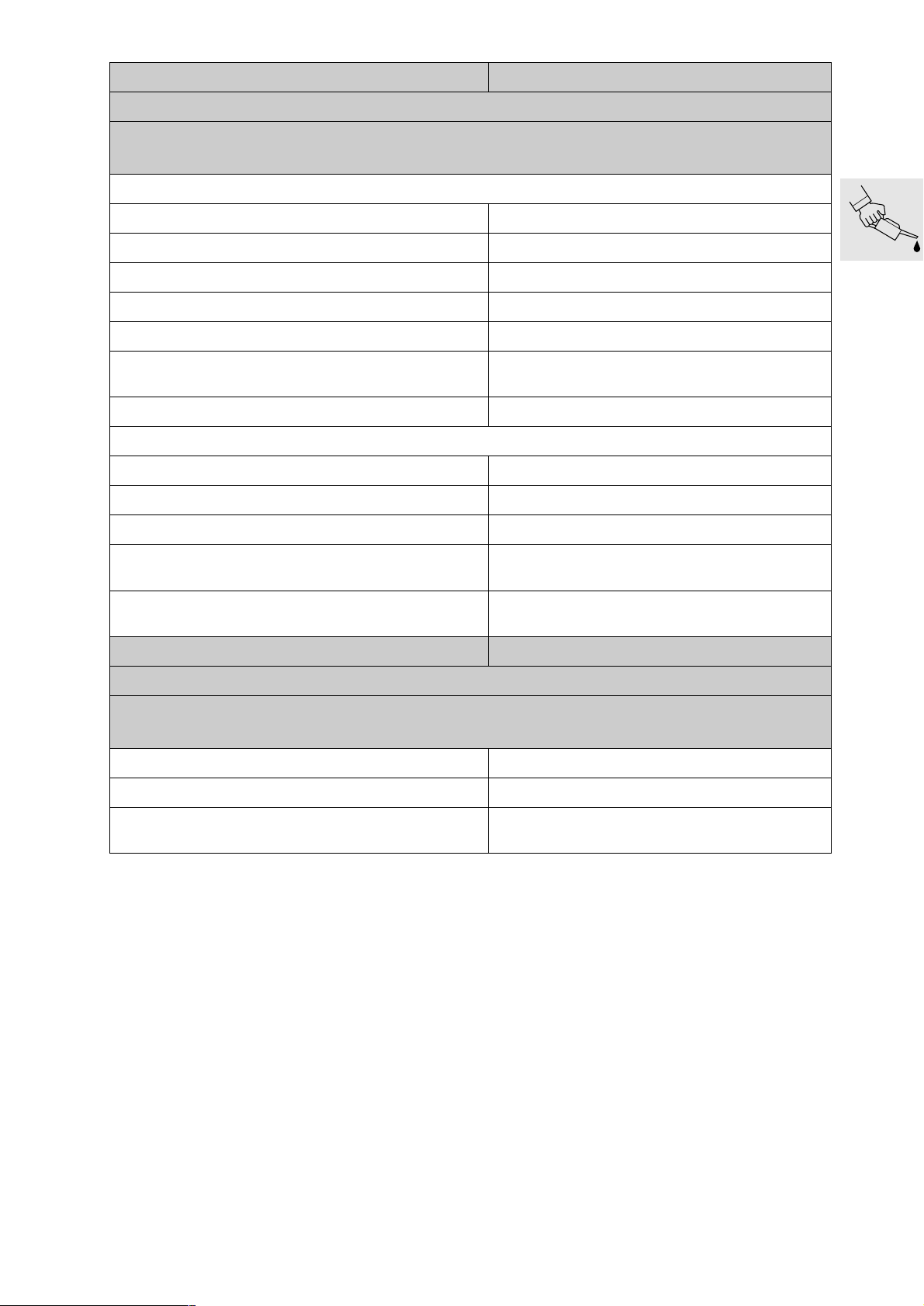

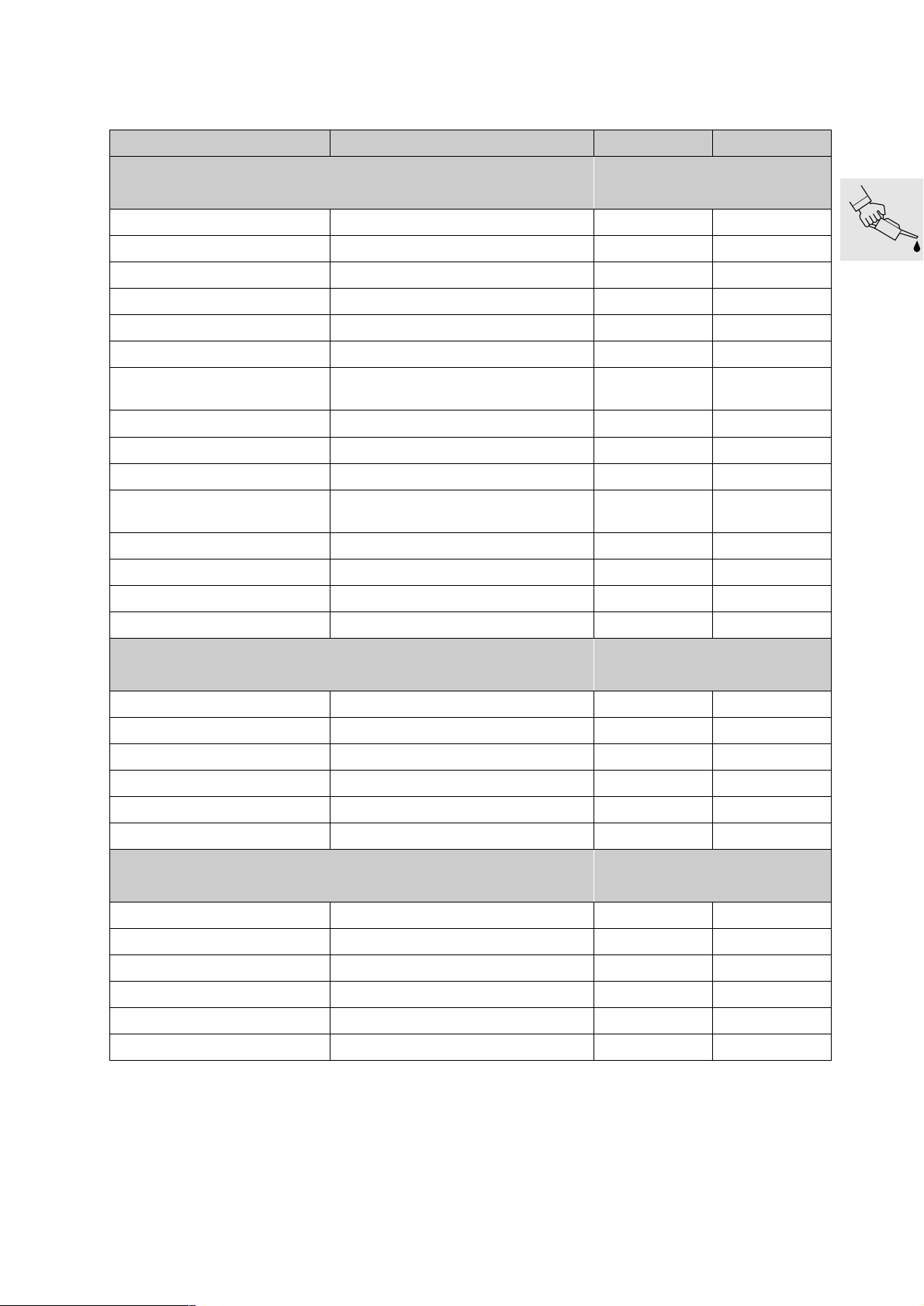

Page 7

BMW Motorrad

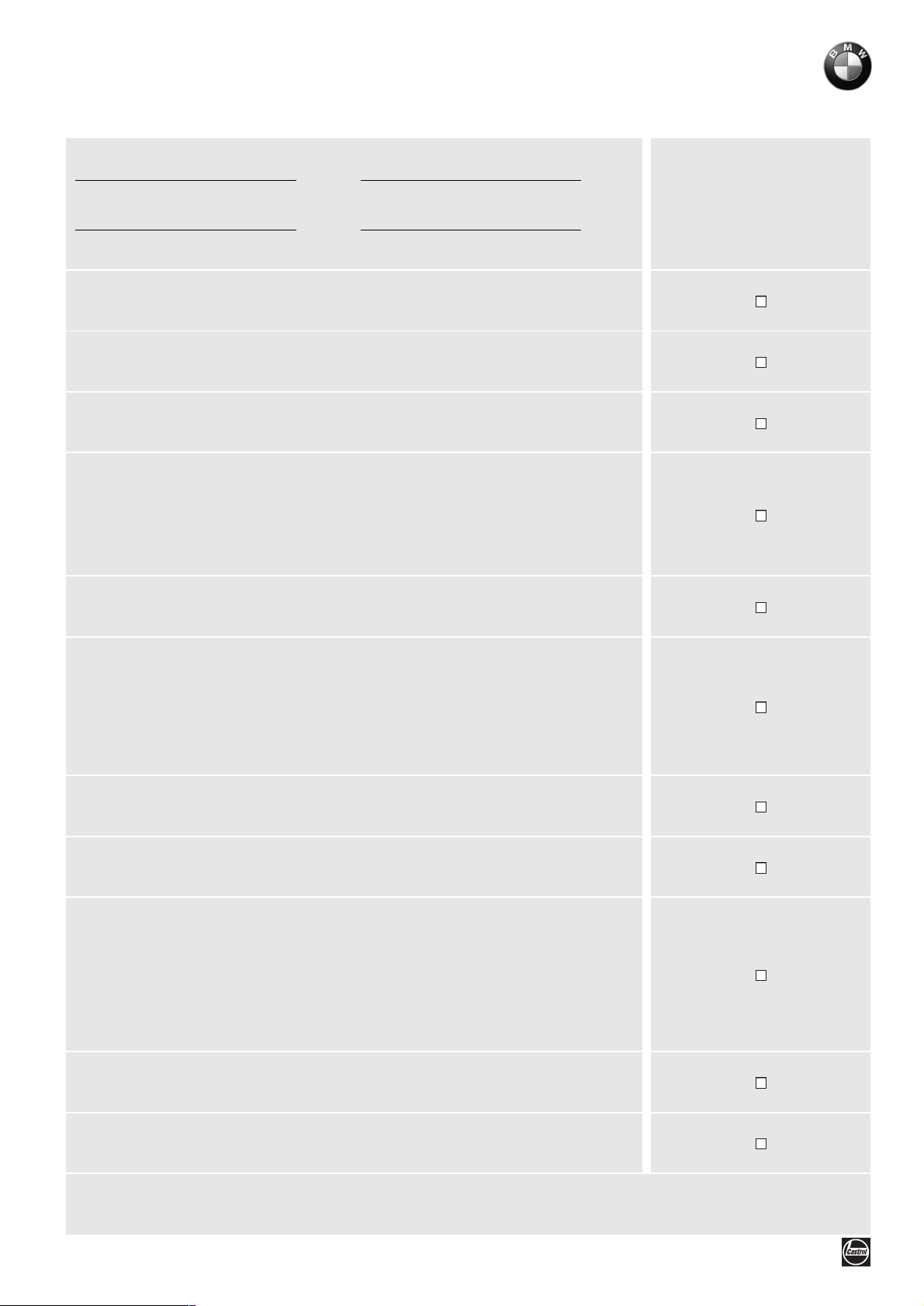

Service data

F 650 CS

Item Desired value Units / Specifications

Oil capacities

Engine (incl. filter) 0.5 (0.88/0.53)

Engine (incl. filter) and oil tank 2.5 (4.4/2.64)

Coolant

Cooling system 1.3 (2.29/1.37) Litres (Imp. pints/US quarts)

Reservoir 0.1 (0.18/0.11) Litres (Imp. pints/US quarts)

Brake Fluid DOT 4

Valve clearance

Inlet 0.03-0.11 (0.0012-0.004) mm (in)

Exhaust 0.25-0.33 (0.010-0.013) mm (in)

Spark plugs NGK DR8 EB

Electrode gap 0.6...0.7 (0.02...0.03) mm (in)

Engine idle speed 1,400 rpm

Clutch cable play

Cable at grip 1.0 - 2.0 (0.004 - 0.008) mm (in)

Tyre pressure

Solo front/rear 2.2/2.5 (31.91/36.26) bar (psi)

fully loaded front/rear 2.2/2.5 (31.91/36.26) bar (psi)

Tightening torques

Engine oil drain plug 40 Nm

Oil filter cover 10 Nm

Drain plug, on-frame oil tank 21 Nm

Oil lines to frame 42 Nm

Oil strainer to frame 80 Nm

Water pump drain screw 10 Nm

Vent screw 12 Nm

Expansion tank to radiator 9 Nm

Cylinder head cover 10 Nm

Spark plugs 20 Nm

Camshaft bearing cap 10 Nm

Chain guide 10 Nm (Loctite 243)

Fuel filter to stowage-compartment frame 9 Nm

Intake air pipe to intake air silencer 9 Nm

Suspension strut to angled lever 41 Nm

Eccentric clamp Initial tightening 10

Brake caliper to swinging arm 21 Nm

Struts to swinging arm 41 Nm

Swinging-fork pivot axle 100 Nm

Adjusting screw steering head bearing 25

Clamp screw for fork bridge steering head 23 Nm

Engine to frame at rear 50 Nm

Cylinder head to frame 41 Nm

Cylinder head to frame, locknut 100 Nm

Engine shell to engine 55 Nm

Engine shell to engine, bottom, with bottom truss 55 Nm

Engine shell to bracing tube 24 Nm

Rear frame to main frame 24 Nm (Loctite 2701)

Exhaust manifold to cylinder head 20 Nm

Silencer to exhaust manifold 55 Nm

50%

50%

21

Back off through

angle of rotation 60

Litres (Imp. pints/US quarts)

Specification: see latest

Service Information

Litres (Imp. pints/US quarts)

Specification: see latest

Service Information

Water

Anti-freeze

protection to –25 °C

measured cold (max. 35 °C/95 °F)

tyres cold

Nm

Nm

Nm

°

UX-VS-2, 07.2001

BMW recommends Castrol

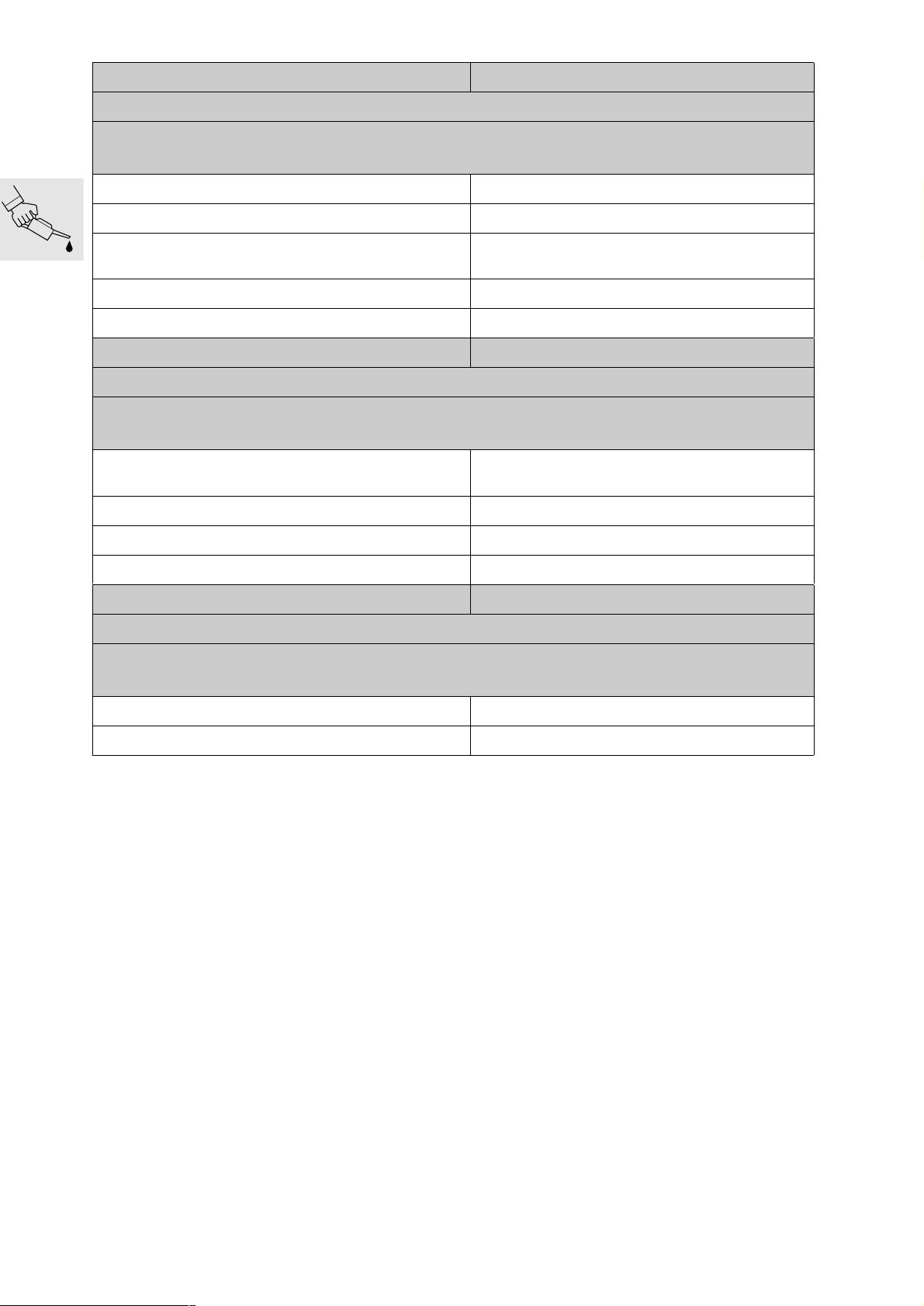

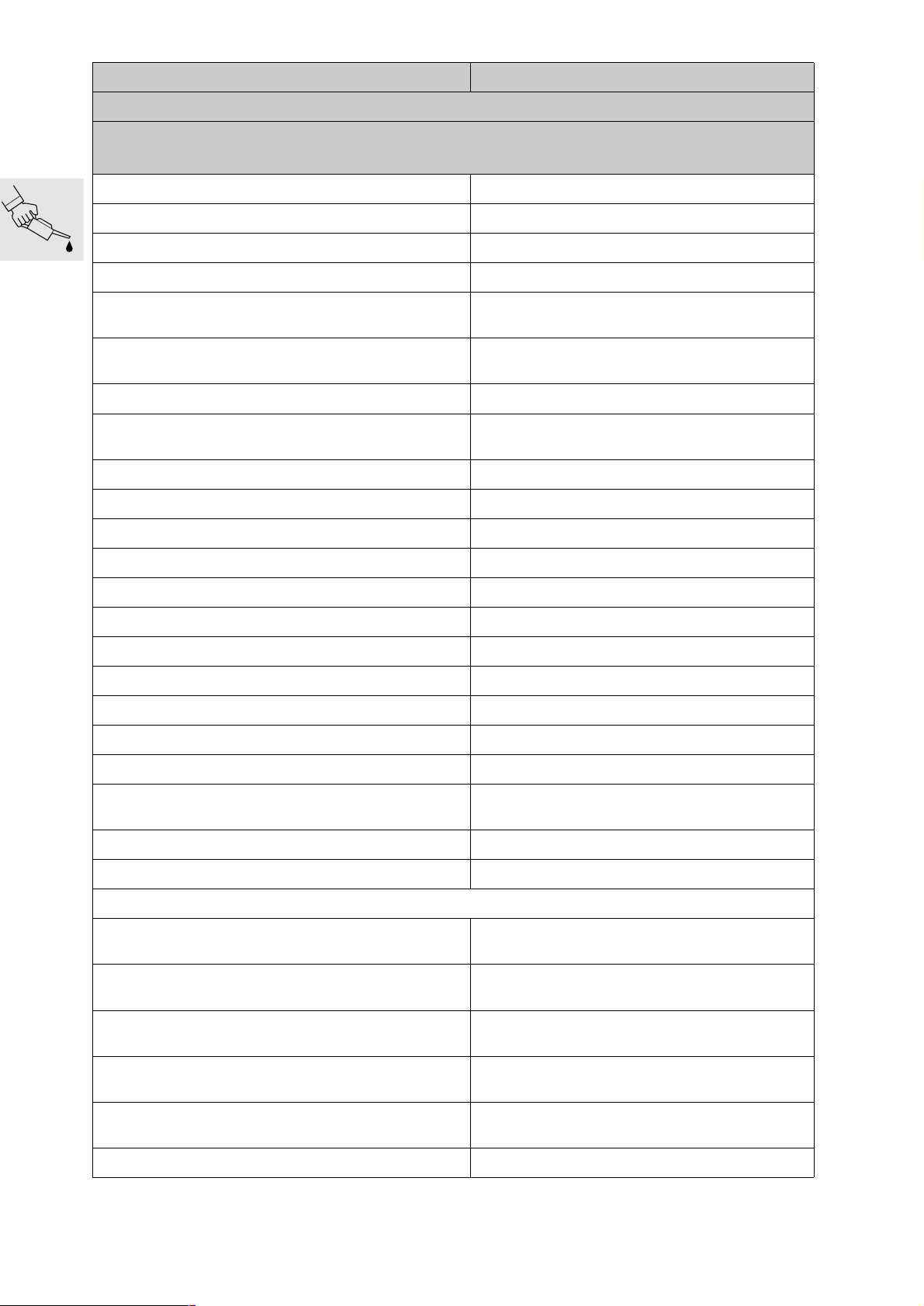

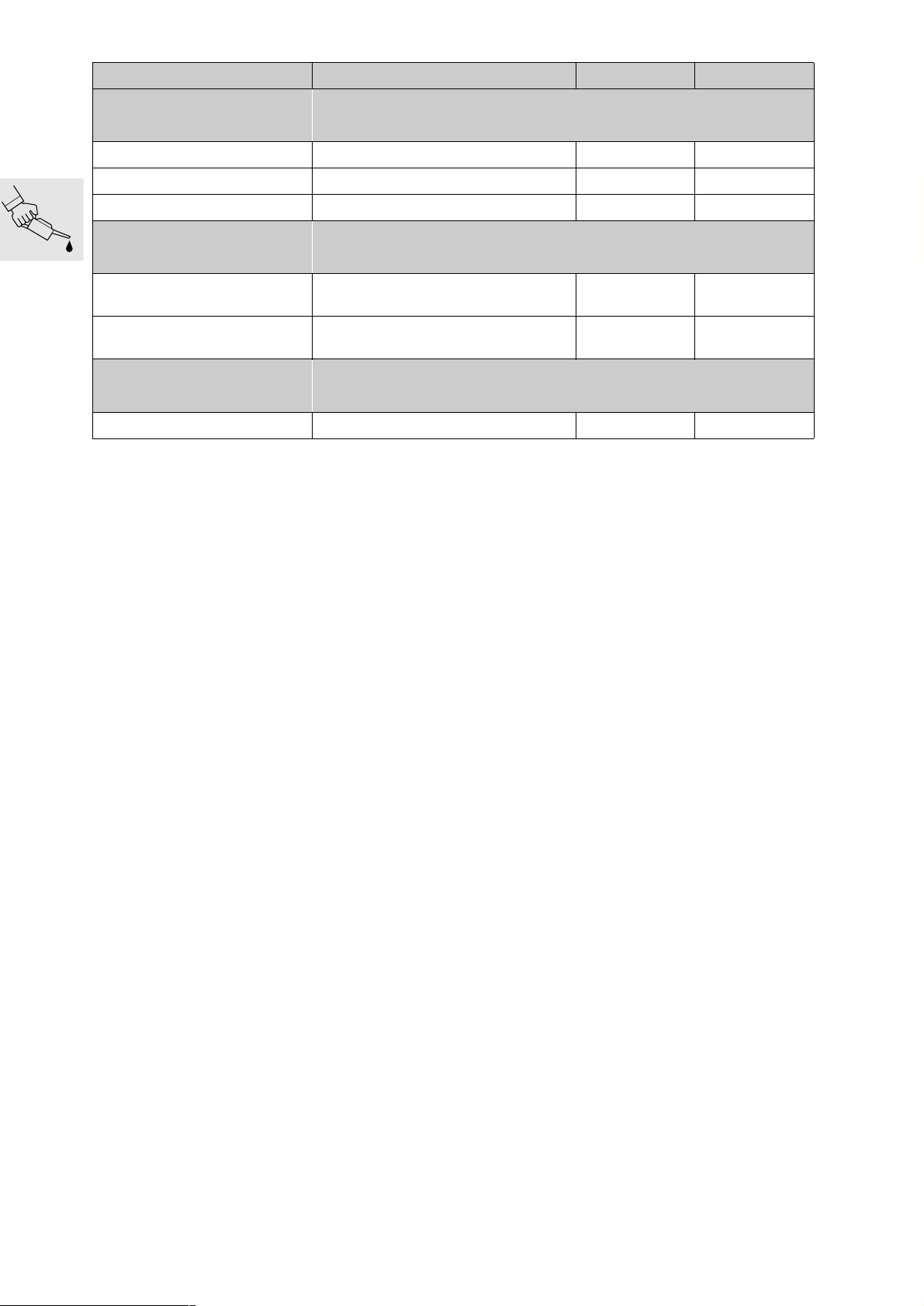

Page 8

Contents

<< Back

Group / Chapter

00 Tightening torques, Operating fluids

00 Pre-delivery check

00 Maintenance

11 Engine

12 Engine electrics

13 Fuel preparation and control

16 Fuel tank and lines

17 Radiator

18 Exhaust system

21 Clutch

23 Gearbox

27 Chain/belt drive

W

M

B

31 Front forks

>> Continuation

Page 9

Group / Chapter

32 Steering

33 Rear wheel drive

34 Brakes

36 Wheels and tyres

46 Frame

>> Continuation

51 Equipment

61 General electrical equipment

62 Instruments

63 Lights

<< Back

Page 10

00

00 Tightening torques,

Operating fluids

Contents Page

Tightening torques ......................................................................................................................3

11 Engine ...........................................................................................................................................3

12 Engine electrics ........................................................................................................................4

13 Fuel preparation and control ...............................................................................................5

16 Fuel tank and lines ...................................................................................................................5

17 Radiator ........................................................................................................................................5

18 Exhaust system .........................................................................................................................6

21 Clutch ............................................................................................................................................6

23 Transmission ..............................................................................................................................6

27 Chain/belt drive .........................................................................................................................7

31 Front fork ......................................................................................................................................7

32 Steering ........................................................................................................................................7

33 Rear wheel drive .......................................................................................................................8

34 Brakes ...........................................................................................................................................8

36 Wheels and tyres ......................................................................................................................9

46 Frame ..........................................................................................................................................10

51 Equipment .................................................................................................................................11

61 General electrical equipment ............................................................................................12

62 Instruments ...............................................................................................................................12

63 Lights ...........................................................................................................................................12

Table of operating fluids .........................................................................................................13

00.1

Page 11

00.2

Page 12

00

Tightening torques

Model F 650 CS

Connection

11 Engine

Freewheel housing and freewheel Nm 35

(clean thread + Loctite 648)

Engine block Nm 10

Double drive gear on crankshaft Nm 180

(clean thread + Loctite 243)

Driver to countershaft Nm 140

(clean thread + Loctite 243)

Pressure plate Nm 10

Magnetic hub to crankshaft Nm 180

(clean thread + Loctite 243)

Chainwheel to main shaft Nm 140

(clean thread + Loctite 243)

Signal transmitter Nm 8

Ignition cover Nm 10

Cylinder base Nm 10

Fastener for chain tensioner Nm 40

Oil circuit

Oil filter cover Nm 10

Oil pressure switch Nm 12

(clean thread + Loctite 243)

Strainer cover to housing half Nm 8

Drain plug, on-frame oil tank Nm 21

Engine oil drain plug Nm 40

Oil supply/oil return lines to engine Nm 42

Oil pump cover Nm 6

(clean thread + Loctite 243)

Oil pressure valve Nm 24

Oil retaining valve Nm 24

Cylinder head

Collar nuts for cylinder head Nm 60

Collar screws for cylinder head Nm 33

Machine screws (chaincase) Nm 10

Camshaft bearing cap Nm 10

Chain sprockets to camshafts Nm 60

threads oiled

Chain guide to camshaft bearing cap Nm 10

(clean thread + Loctite 243)

00.3

Page 13

Model F 650 CS

Connection

11 Engine

Cylinder head cover Nm 10

Machine screw (hole for locating screw) Nm 25

Model F 650 CS

Connection

12 Engine electrics

Spark plug Nm 20

Magnetic hub to crankshaft Nm 180

(clean thread + Loctite 243)

Signal transmitter Nm 8

Engine block cover, left/right Nm 10

Starter to clutch cover Nm 10

Positive lead to starter motor Nm 9

Positive contact to starter motor Nm 4

Necked-down bolt, starter housing Nm 6

Cable cover to engine block Nm 9

Cable holder to ignition cover Nm 8

Stator to ignition cover Nm 10

(clean thread + Loctite 243)

Ignition coil bracket to cylinder head cover Nm 9

00.4

Page 14

Model F 650 CS

Connection

13 Fuel preparation and control

Air intake pipe to cylinder head Nm 21

Fuel filter to stowage-compartment frame Nm 9

Injector holder to throttle valve Nm 5

Fuel hose to injection nozzle holder Nm 3

Fuel return hose to pump unit Nm 3

Intake air pipe to intake air silencer Nm 9

Throttle flap to intake stub Nm 1

Throttle-valve potentiometer to throttle

valve stub

Throttle valve actuator to throttle-valve

stub

Model F 650 CS

Connection

16 Fuel tank and lines

Fuel tank to rear frame (M 8 stud) Nm 21

Fuel filler cap to fuel tank Nm 3

Roll-over valve to fuel tank Nm 2

Clamps, activated charcoal filter bracket Nm 9

Fuel pump to fuel tank Nm 30

Model F 650 CS

Connection

17 Radiator

Nm 3

Nm 5

(clean thread + Loctite 243)

Expansion tank to radiator Nm 9

Radiator to main frame at top Nm 9

Fan to fan shroud Nm 3

Water pump drain screw Nm 10

Coolant hoses to radiator/engine/frame Nm 3

Breather hose to expansion tank Nm 2

Left engine block cover to engine block Nm 10

Water pump cover Nm 10

Temperature sensor in cylinder head Nm 15

Vent screw Nm 12

00.5

Page 15

Model F 650 CS

Connection

18 Exhaust system

Oxygen sensor to exhaust elbow Nm 45

Exhaust manifold to cylinder head Nm 20

Silencer to exhaust manifold

(Torca clamp)

Silencer to rear frame Nm 41

Guards to silencer Nm 5

Model F 650 CS

Connection

21 Clutch

Driver Nm 140

Pressure plate Nm 10

Engine block cover, left Nm 10

Release lever to release shaft Nm 10

Model F 650 CS

Connection

23 Transmission

Nm 55

(clean thread + Loctite 243)

Gear pedal to frame Nm 21

Shaft lever to selector shaft Nm 9

00.6

Page 16

Model F 650 CS

Connection

27 Chain/belt drive

Drive sprocket cover to engine Nm 2

Belt cover to swinging arm Nm 9

Eccentric clamp Nm 21

Initial tightening Nm 10

Belt sprocket to gearbox output shaft Nm 180

(clean thread + Loctite 638)

Model F 650 CS

Connection

31 Front fork

Clamp screws, upper fork bridge and

steering head clamp

Clamp screws at lower fork bridge Nm 23

Bracket to fork leg Nm 5

Damper retaining screw Nm 20

Adjusting screw

Preload Nm 25

Back off through angle of

rotation

Model F 650 CS

Connection

32 Steering

Handlebars to fork bridge Nm 23

Handlebar weight to handlebar Nm 9

Handlebar fitting to handlebar Nm 9

Cover of multi-function switch Nm 1

Nm 23

° 60

Pivot pin of clutch lever Nm 3

Locknut for pivot pin of clutch lever Nm 5

Pivot pin of handbrake lever Nm 7

Locknut of handbrake lever Nm 7

Guide to fork bridge Nm 5

00.7

Page 17

Model F 650 CS

Connection

33 Rear wheel drive

Suspension strut to frame Nm 58

Wrench angle ° 45 ± 15

Suspension strut to angled lever Nm 41

Swinging-fork pivot axle Nm 100

Struts to swinging arm Nm 41

Struts to angled lever Nm 41

Angled lever to frame Nm 58

Wrench angle ° 45 ± 15

Belt pulley to damper housing Nm 28

Damper fastener Nm 160

Eccentric clamp Nm 21

Initial tightening Nm 10

Model F 650 CS

Connection

34 Brakes

Bleed screw to brake caliper front/rear Nm 7

Brake caliper to fork slider tube Nm 41

Brake light switch to handlebar fitting Nm 3

Handlebar fitting to handlebar Nm 9

Brake light switch to frame Nm 5

Brake disc to front wheel Nm 10

(clean thread + Loctite 2701)

Brake disc to rear wheel drive shaft Nm 11

(clean thread + Loctite 2701)

Brake caliper to swinging arm Nm 21

Brake master cylinder to main frame Nm 10

Locknut for fork end to pushrod Nm 9

Bracket, rear, to main frame Nm 9

(clean thread + Loctite 2701)

Shroud to frame Nm 6

Brake fluid reservoir for rear brake to rear

frame

Brake pedal to frame Nm 21

Brake line distributor to main frame Nm 9

00.8

Nm 4

Page 18

Model F 650 CS

Connection

34 Brakes

Brake lines/hoses

Brake hose to brake caliper Nm 18

Brake hose to rear brake caliper Nm 18

Brake hose to brake lever fitting Nm 18

Brake hoses to distributor Nm 18

Brake hose to bracket, rear Nm 18

Brake line to master brake cylinder, rear

wheel

Banjo bolts, brake line Nm 18

ABS

ABS sensor front/rear Nm 9

ABS control unit to holder Nm 21

Brake lines to ABS control unit Nm 18

Brake disc and sensor ring to front wheel Nm 10

Locknut for adjustable stop, brake-light

switch

Model F 650 CS

Connection

36 Wheels and tyres

Clamp nut, front quick-release axle Nm 23

Front quick-release axle to fork leg Nm 30

Nm 18

(clean thread + Loctite 2701)

Nm 4

Wheel nut to drive shaft (wheel side) Nm 160

Lightly coat the thread with Optimoly TA

00.9

Page 19

Model F 650 CS

Connection

46 Frame

Covers, right and left, to main frame Nm 2

Covers, right and left, to air guide Nm 3

Cover, front, to covers, right and left Nm 1

Cover, front to main frame Nm 2

Cover, rear, to covers left and right and to

stowage-compartment frame

Stowage-compartment rail to stowagecompartment frame

Stowage-compartment frame to main frame Nm 9

Turn indicators, left and right, to fairing

bracket

Instrument cover to fairing holder Nm 2

Windscreen to windscreen bracket Nm 2

Windscreen bracket to fairing bracket Nm 9

Rear trim panels, left and right, to rear frame Nm 2

Rear trim panels, left and right, to seat lock Nm 2

Bracket for seat lock to rear frame Nm 3

Turn indicator, rear, to rear finisher Nm 3

Rear finisher to rear frame Nm 9

Number-plate carrier to rear finisher Nm 9

Spray guard to number-plate carrier Nm 3

Nm 2

Nm 9

Nm 3

Number-plate carrier to rear mudguard Nm 3

Cover of number-plate light to numberplate carrier

Grip to rear frame Nm 9

Luggage carrier to grab handle Nm 3

Mudguards/wheel guards

Front mudguard, front section, to front

mudguard, rear section

Front mudguard, front section, to slider

tube

Front mudguard, rear section, to slider

tube

Rear mudguard, front section, to rear

frame, front and side

Rear mudguard, front section, to rear

frame, rear and centre

Belt cover to swinging arm Nm 9

Nm 1

Nm 3

Nm 3

Nm 3

Nm 3

Nm 3

00.10

Page 20

Model F 650 CS

Connection

46 Frame

Frame

Drain plug, on-frame oil tank Nm 21

Oil strainer to frame Nm 80

Oil feed and return lines to main frame Nm 42

Oil tank cover to frame Nm 5

Footrest rubber to rear footrest Nm 5

Fairing bracket to main frame Nm 21

Rear frame to main frame Nm 24

(clean thread + Loctite 2701)

Engine shell to bracing tube Nm 25

Side stand to bottom truss Nm 41

Engine mounts

Engine shell to engine Nm 55

Engine shell to engine, bottom, with bottom truss

Engine to frame at rear Nm 50

Cylinder head to frame Nm 41

Cylinder head to frame, adjusting sleeve Nm zero play, max. 5

Cylinder head to frame, locknut Nm 100

Model F 650 CS

Connection

51 Equipment

Ignition/steering lock to fork bridge, top Nm 20

Mirror to clamp element Nm 18

Clamp element to handlebar fitting Nm 21

Seat hook to rear frame Nm 9

Nm 55

00.11

Page 21

Model F 650 CS

Connection

61 General electrical equipment

Cable to idle-indicator switch Nm 1

Idle-indicator switch Nm 3

(clean thread + Loctite 243)

Cover for hazard warning flasher switch Nm 5

Clutch switch to handlebar fitting Nm 5

Positive/ground leads, battery Nm 7

Ignition/light switch with cap to ignition/

handlebar lock

Voltage regulator to engine shell Nm 9

Horn to fork bridge Nm 18

Ground terminal, wiring harness to engine

block, right

Model F 650 CS

Connection

62 Instruments

Instrument cover to instrument cluster Nm 2

Model F 650 CS

Connection

63 Lights

Headlight to fairing bracket Nm 7

Nm 1

(clean thread + Loctite 243)

Nm 8

Number-plate light to number-plate carrier Nm 1

Rear light cluster to rear frame Nm 9

00.12

Page 22

Table of operating fluids

Item Use Order number Quantity

Lubricant

Staburags NBU 30 PTM High-performance lubricating grease 07 55 9 056 992 75 g tube

Optimoly MP 3 High-performance lubricating grease 07 55 9 062 476 100 g tube

Optimoly TA High-temperature assembly grease 18 21 9 062 599 100 g tube

Silicone grease 300, heavy Damping grease 07 58 9 058 193 10 g tube

Retinax EP2 Grease 83 22 9 407 845 100 g tube

Contact spray Contact spray 81 22 9 400 208 300 ml spray

Chain spray Lubricant

Shell HDX2 Lubricant 11 00 7 660 830 400 g tube

Klüberpaste 46 MR 401 High-temperature lubricant 11 00 7 660 831 60 g tube

MOLYKOTE 111 Silicon grease 11 00 7 660 832 100 g tube

Tyre mounting paste Assembly paste

Never Seez compound Lubricating paste 83 23 9 407 830 100 g tube

Grease for lock cylinders Grease 81 22 9 407 421

Rubber care product Rubber care 82 14 9 407 015 60 g tube

Long-life lubricant Lubricant 81 22 9 407 629 250 ml spray

Sealants

3-Bond 1110 B Surface sealant 07 58 9 056 998 5 g tube

3-Bond 1209 Surface sealant 07 58 9 062 376 30 g tube

OMNI VISC 1002 Surface sealant 07 58 1 465 170 90 g tube

Loctite 574 Surface sealant 81 22 9 407 301 50 ml tube

Loctite 577 Thread locking compound 33 11 2 328 736 5 g tube

72 60 2 316 676

72 60 2 316 667

36 32 1 239 263

36 32 1 239 264

50 ml spray

300 ml spray

2.5 kg

100 g

Curil K 2 Heat-conductive sealant 81 22 9 400 243 250 g can

Adhesives and retaining

agents

Loctite 648 Joint adhesive (narrow gap) 07 58 9 067 732 5 g bottle

Loctite 638 Joint adhesive (wide gap) 07 58 9 056 030 10 ml bottle

Loctite 243 Thread retainer, medium-strength 07 58 9 056 031 10 ml bottle

Loctite 270 Thread retainer, strong 81 22 9 400 086 10 ml bottle

Loctite 2701 Thread retainer, strong 33 17 2 331 095 10 ml bottle

Loctite 454 Cyanacrylate adhesive (gel) 07 58 9 062 157 20 g tube

00.13

Page 23

Item Use Order number Quantity

Cleaners

Brake cleaner Cleaners 83 11 9 407 848 600 ml spray

Normal dilution Cleaners 51 91 9 057 940 1 l bottle

Metal Polish Polish for chrome-plated parts 82 14 9 400 890 100 g tube

Testing agents

Penetrant MR 68

Developer MR 70

Installation aid

BMW chilling spray Cooling spray 83 19 9 407 762 300 ml spray

Crack testing agent for aluminium

housings

Crack testing agent for aluminium

housings

83 19 9 407 855 500 ml spray

81 22 9 407 495 500 ml spray

00.14

Page 24

00

00 Pre-delivery check

Contents Page

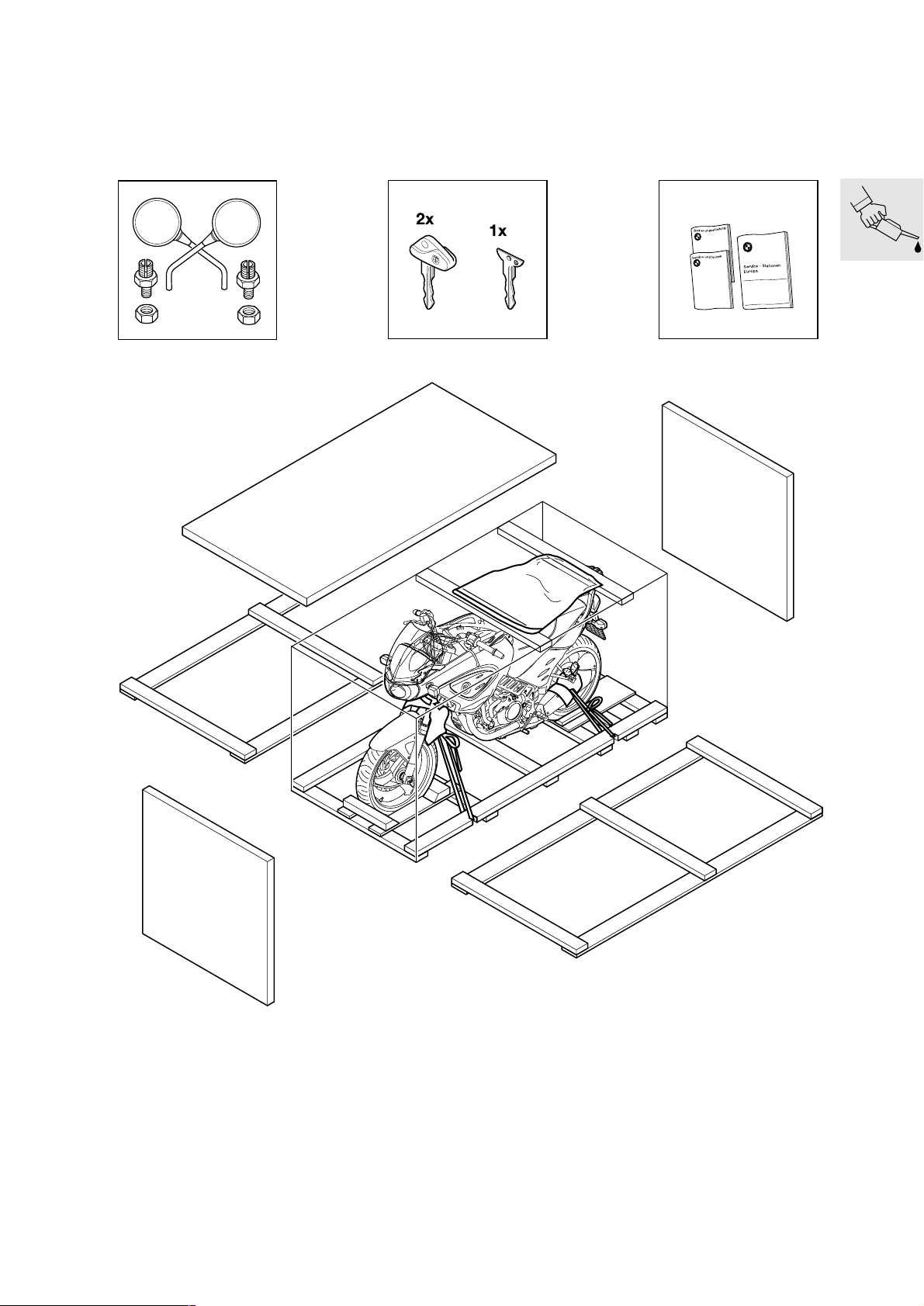

General view of crated motorcycle ...................................................................................17

Checking the shipping crate for damage ......................................................................18

In case of damage in Germany ...............................................................................................18

In case of damage in importer markets ..............................................................................18

Unpack the motorcycle ...........................................................................................................18

Inspecting motorcycle for damage ...................................................................................19

Checking that delivery is complete ..................................................................................19

Installing remaining items on motorcycle .....................................................................19

Filling and charging the battery .........................................................................................20

Removing the battery ..................................................................................................................20

Filling and charging the battery ...............................................................................................21

Checking engine oil level .......................................................................................................22

Checking tyre pressures .........................................................................................................22

Final inspection and function check ................................................................................23

Final cleaning ................................................................................................................................23

Handover .........................................................................................................................................23

00.15

Page 25

00.16

Page 26

00

General view of crated motorcycle

K14009440

00.17

Page 27

Checking the shipping crate for damage

When the motorcycle arrives, check the crate im-

•

mediately for damage and if necessary examine

the contents for consequential damage.

00 11

Unpack the motorcycle

Lever off the cover.

•

Take out the separate pack of items.

•

Force off cross-struts with a suitable lever.

•

In case of damage in Germany

Note the damage on the delivery slip.

•

Read the information sheet on damage in transit.

•

Notify the supplier without delay (e.g. freight

•

company or DB) and also

Bavaria Wirtschaftsagentur GmbH

Abteilung ZW - 12

D-80788 München

Tel. +49 89/14327-632

Fax. + 49 89/14327-709

In case of damage in importer markets

Note the damage on the delivery slip.

•

Comply with specific national market proce-

•

dures.

In case of doubt, please submit enquiries to:

Bavaria Wirtschaftsagentur GmbH

Abteilung ZW - 12

D-80788 München

Tel. +49 89/14327-632

Fax. +49 89 14327-709

Notify the supplier (e.g. freight company) without

•

delay.

e Attention:

Do not knock the cross-struts out or the motorcycle

may be damaged.

Remove the end-walls.

•

Remove the side-walls.

•

e Attention:

Make sure that the motorcycle cannot topple.

Remove the straps at front and rear.

•

e Attention:

Remove any nails projecting from the base of the

packing or lying on the base or on the floor.

Push the motorcycle forward off the pallet.

•

Remove the set of keys from the left rear footrest.

•

Dispose of the packing materials in an environ-

•

mentally responsible manner as described in Circular No. 23/91 - Sales.

Check the contents of the enclosed pack of

•

items:

– Mirrors with clamping screws and nuts

– Rider's Manual

– Maintenance Instructions

– Booklet listing service centres in Europe

– BMW emergency service sticker

– Handling instructions for batteries

00.18

Page 28

00 11 Inspecting motorcycle for dam-

age

Check for damage.

•

Use the “express handling service” to notify

•

BMW Motorrad,

UX-VS-1

Fax:+ 49 89-382-33220

Rectify the fault.

•

If parts are needed, order them through the usual

•

channel.

Costs are to be processed by the warranty claim

•

system (stage 4). Defect codes:

– Parts missing 10 01 00 00 00

– Parts damaged 10 02 00 00 00

– Incorrect parts delivered 10 03 00 00 00

00 11

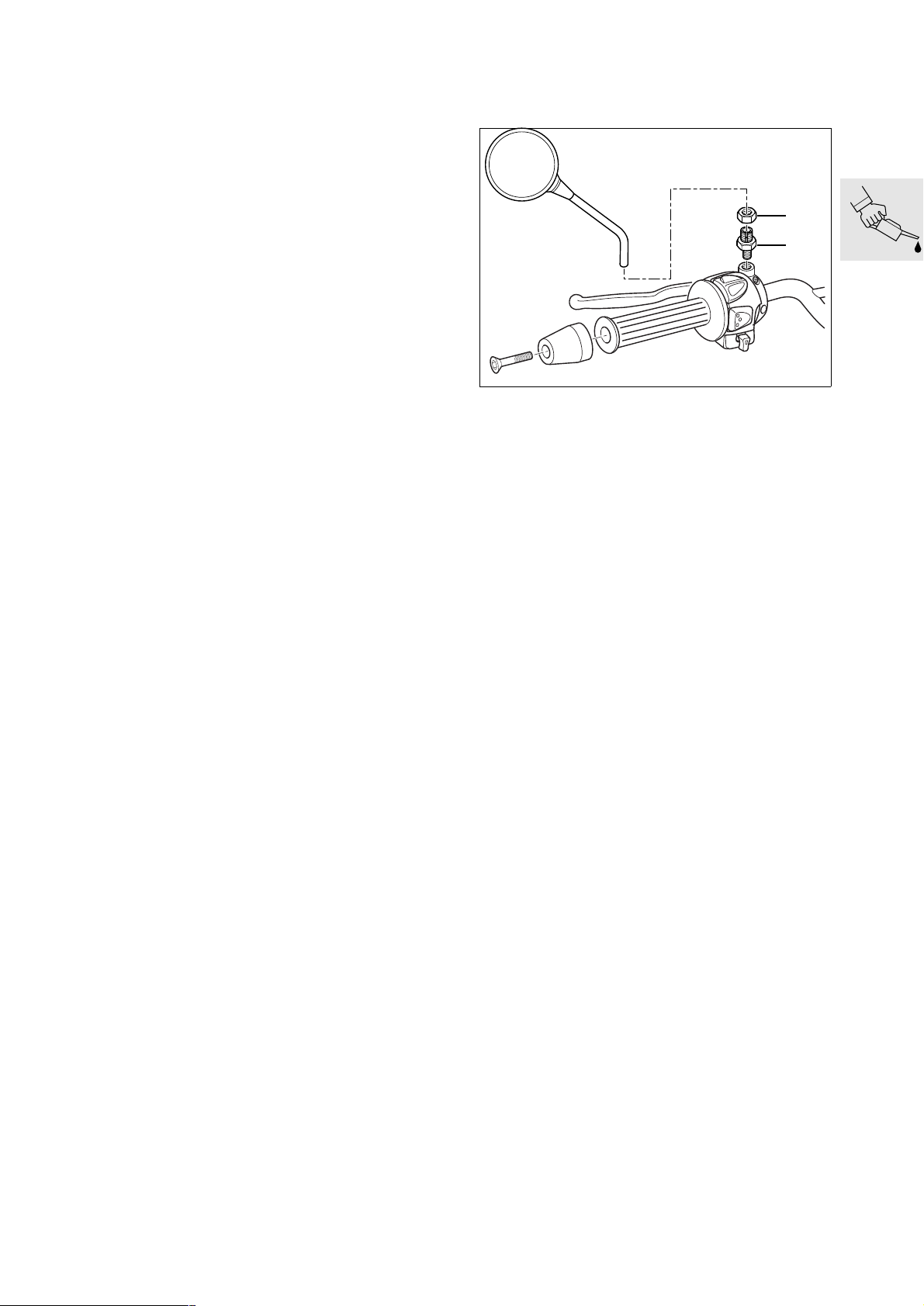

Installing remaining items on

motorcycle

1

2

Checking that delivery is complete

All optional extras

•

Toolkit:

•

– screwdriver, reversible blade

– crosshead screwdriver, small

– 3 open-end wrenches

w/f 8×10, 14, 15

– spark plug wrench

– 3 Allen keys

Torx T15, T25, T30

– 4 fuses

7.5 A, 10 A, 15 A, 20 A

– Breakdown kit

Documentation

•

Vehicle keys, 3 of

•

E000310

Fit clamp screw (2) to handlebar fitting.

•

Install mirror and secure by tightening nut (1).

•

X Tightening torque:

Clamp screw to handlebar fitting.................. 21 Nm

Union nut for mirror ...................................... 18 Nm

00.19

Page 29

1 2

3

5

4

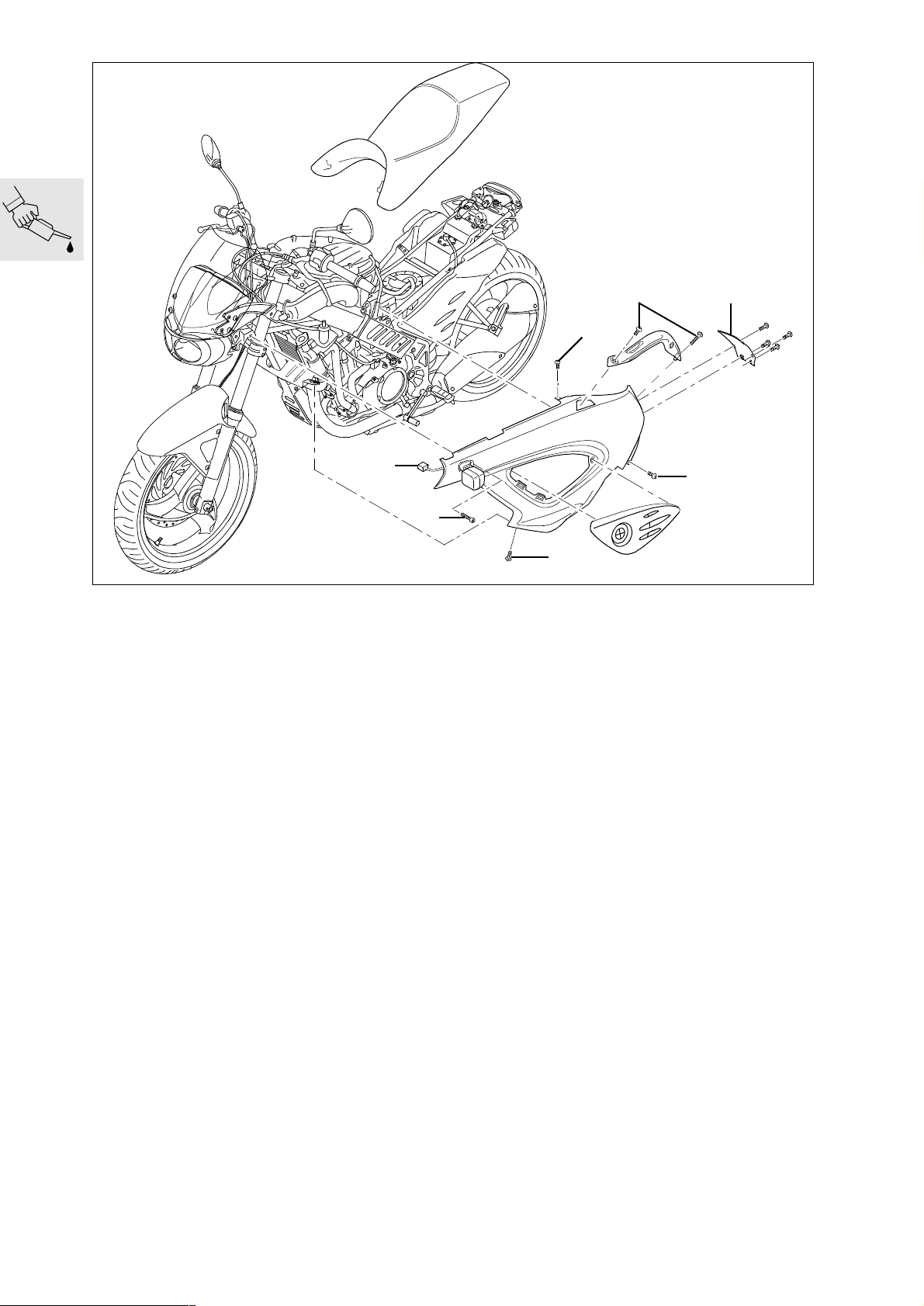

61 21 Filling and charging the battery 61 21 010 Removing the battery

– Place the motorcycle on the auxiliary stand,

BMW No. 00 1 620.

– Remove seat.

Remove securing screws for stowage-compart-

•

ment rail (1) and remove left stowage-compartment rail; use wrench from toolkit if necessary.

Remove fasteners of rear cover and remove rear

•

cover (2).

Disconnect the plug for flashing turn indicator (5).

•

Remove securing screw for flashing turn indica-

•

tor (4).

Remove screws securing left cover (3).

•

Remove the left cover.

•

3

3

K14000450

00.20

Page 30

- UPPER LEVEL-

- LOWER LEVEL-

K14000460

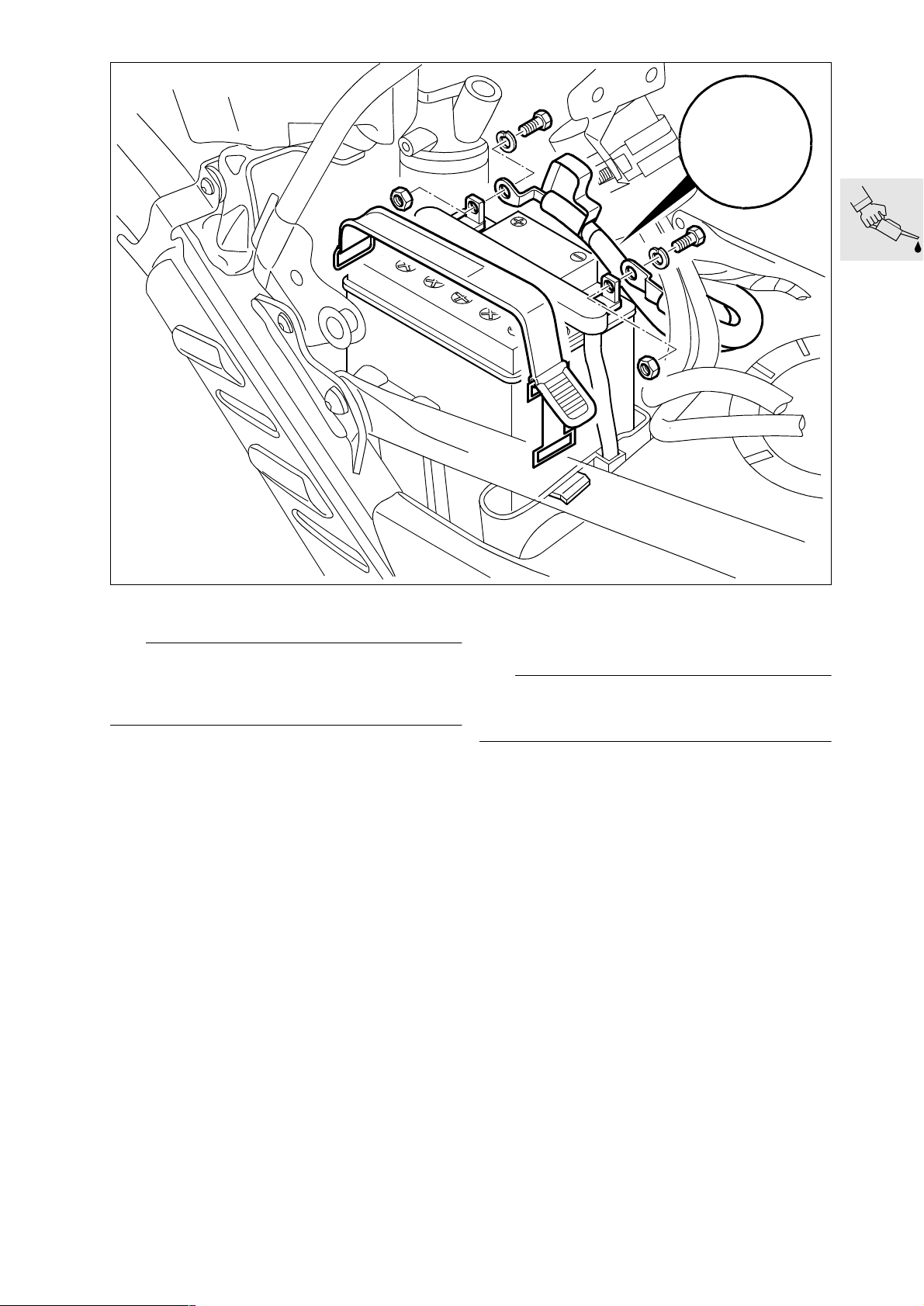

61 21 Filling and charging the battery

d Warning:

Battery acid is highly caustic.

Protect your eyes, face, hands, clothing and the

paintwork.

Disengage the rubber strap holding the battery.

•

Disconnect the battery breather hose.

•

Remove the battery.

•

Fill all the cells with pure battery acid of

•

density 1.28 to the Upper Level mark.

Allow the battery to stand for approximately

•

30 minutes.

The battery does not achieve full charge capacity

•

from being filled, so it has to be charged with a

battery charger.

L Note:

Follow the instructions for use supplied with the battery charger.

Charge current (A)

.........................10 % of rated battery capacity (Ah)

Charging time

..............................................................5-10 hours

Battery charge can be measured by checking

•

the density of the battery acid.

Acid density

Battery fully charged

............1.26-1.30 at a temperature of 20 °C (68 °F)

Shake the battery slightly to allow the gas bub-

•

bles to escape.

Wait until the battery acid has settled, check that

•

no more bubbles rise and if necessary, top up

the acid to the max. mark.

Reinstall the plugs.

•

Make a note of the charging date on the battery.

•

00.21

Page 31

e Attention:

Connect the positive battery terminal first, then the

negative terminal.

Install the battery.

•

L Note:

When connecting the battery lead, always make

sure that the spring washer is between the screw

head and the battery lead.

Checking engine oil level

00 00

Check whether there is oil in the tank (e.g. dip-

•

stick wetted).

e Attention:

Top up the level if there is no engine oil in the tank.

Checking tyre pressures

Apply acid-proof grease to the battery terminal

•

posts.

Connect the battery breather hose.

•

Install the left cover.

•

Install the rear cover.

•

Install the stowage-compartment rail.

•

Install the seat.

•

X Tightening torque:

Positive and negative leads to battery ............ 7 Nm

Cover, rear, to covers left and right and

to stowage-compartment frame .....................2 Nm

Cover, front, to left and right covers ............... 1 Nm

Left and right covers to main frame ................ 2 Nm

Left and right covers to air duct...................... 3 Nm

Turn indicators, left and right, to fairing bracket... 3 Nm

Stowage-compartment railing to stowage-

compartment frame........................................ 9 Nm

Check/correct tyre pressures.

•

Tyre pressures:

one-up ...............................front 2.2 bar (31.91 psi)

........................................... rear 2.5 bar (36.26 psi)

two-up ............................... front 2.2 bar (31.91 psi)

........................................... rear 2.5 bar (36.26 psi)

two-up + luggage............... front 2.2 bar (31.91 psi)

........................................... rear 2.5 bar (36.26 psi)

00.22

BMW recommends Castrol

Page 32

Final inspection and function check

Handover

Clutch

•

Check gear shift action.

•

Steering

•

Handbrake and footbrake

•

Check lights and signalling equipment:

•

– Front and rear parking lights

– Instrument lighting

– Low and high headlight beams, headlight flasher

– Brake light (operate brake at front and rear)

– Turn signals left/right

– Horn

– Telltale and warning lights

– Instruments

Where necessary, check function of optional ex-

•

tras:

ABS: perform starting test. The ABS warning

•

light comes on if there is a fault in the system and

the vehicle is ridden for at least 10 seconds at a

speed in excess of 30 km/h (18.64 miles).

If necessary, take the motorcycle for a test ride.

•

Confirm pre-delivery check in “Maintenance In-

•

structions”

See “Checking motorcycle for damage” if any-

•

thing is unsatisfactory.

00 11 459

Clean the motorcycle.

•

Final cleaning

This is the ideal opportunity to familiarise the customer with the motorcycle in order to ensure the

customer’s satisfaction and safety.

The following points must be demonstrated and

•

explained to the customer:

– Documentation and stowage space

– Toolkit and stowage space

– Suspension preload adjustment to suit total

weight

– How to check the brake fluid

– How to adjust the mirrors

– Controls

– instruments and telltale lights

– Optional equipment and accessories fitted

The user must be given the following information:

•

– Running-in recommendations and inspection in-

tervals

– Safety check

– How to check the oil level in accordance with the

vehicle documentation

L Note:

Do not use a steam or high-pressure water jet. The

high steam or water pressure could damage seals,

the hydraulic system or electrical components.

BMW recommends Castrol

00.23

Page 33

00.24

Page 34

00

00 Maintenance

Contents Page

Key to maintenance intervals ..............................................................................................29

Reading the fault code memory with the MoDiTeC .................................................30

(Inspections I, II, III and IV) .................................................................................................................30

Changing the engine oil [engine only] and oil filter element .............................30

(Inspection I) ......................................................................................................................................30

Preparatory work ...........................................................................................................................30

Draining engine oil ........................................................................................................................30

Replacing oil filter element ........................................................................................................31

Filling with engine oil ....................................................................................................................31

Changing the engine oil [engine and oil tank] and oil filter element .............32

(Inspections II, III and IV) ....................................................................................................................32

Preparatory work ...........................................................................................................................32

Draining engine oil ........................................................................................................................32

Replacing oil filter element ........................................................................................................33

Filling with engine oil ....................................................................................................................33

Cleaning oil strainer in frame ...............................................................................................34

(Inspection II, once only) ....................................................................................................................34

Greasing rubber grommets for cover insert ................................................................34

(Inspections I, II, III and IV) .................................................................................................................34

Checking coolant, topping up if necessary .................................................................35

(Inspections I, II and III) ......................................................................................................................35

Checking coolant ..........................................................................................................................35

Adding coolant ...............................................................................................................................35

Changing coolant .......................................................................................................................36

(Inspection IV, every 2 years) .............................................................................................................36

Checking and adjusting valve clearances ....................................................................38

(Inspections II and III) .........................................................................................................................38

Checking valve clearances .......................................................................................................38

Preparatory work ...............................................................................................................................38

Remove the intake air silencer together with the intake air pipe. ........................................................38

Exposing the radiator ........................................................................................................................38

Exposing cylinder head .....................................................................................................................39

Turning crankshaft to TDC position ....................................................................................................39

Checking valve clearance ..................................................................................................................40

00.25

Page 35

Contents Page

Adjusting valve clearances ........................................................................................................40

Installing cylinder head cover ............................................................................................................41

Replacing spark plug ...............................................................................................................42

(Inspection III) ....................................................................................................................................42

Emptying drain from intake air silencer .........................................................................42

(Inspections I, II and III) ......................................................................................................................42

Replacing air cleaner element ............................................................................................43

(Inspection III) ....................................................................................................................................43

Replacing fuel filter ...................................................................................................................44

(Inspection III, every 40,000 km/24,000 miles) ...................................................................................44

Checking clutch play, adjusting if necessary ..............................................................45

(Inspections I, II and III) ......................................................................................................................45

Checking brake pads and discs for wear, replacing if necessary ...................45

(Inspections II and III) .........................................................................................................................45

Checking brake pads for wear ................................................................................................45

Brake pads, front brake .....................................................................................................................45

Brake pads, rear brake ......................................................................................................................45

Replacing brake pads .................................................................................................................46

Brake pads, front brake .....................................................................................................................46

Brake pads, rear brake ......................................................................................................................47

Checking the brake discs ..........................................................................................................47

Checking brake fluid level at front and rear ................................................................48

(Inspections II and III) .........................................................................................................................48

Brake fluid level (front brake) ....................................................................................................48

Checking brake fluid level (front brake) ..............................................................................................48

Brake fluid level (rear brake) .....................................................................................................48

Checking brake fluid level (rear brake) ...............................................................................................48

Checking operation of brake system and checking for leaks; repairing/

replacing as necessary ...........................................................................................................49

(Inspection III) ....................................................................................................................................49

Changing brake fluid and bleeding brake system ....................................................49

(Inspection IV) ....................................................................................................................................49

Changing brake fluid and bleeding brake system (front brakes) ..............................49

Changing brake fluid and bleeding brake system (rear brakes) ...............................50

Replacing primary sealing boot, front brake master cylinder ...........................52

(Inspection III, every 40,000 km/24,000 miles for motorcycles with ABS) ..........................................52

Replacing primary sealing boot, rear brake master cylinder .............................53

(Inspection III, every 40,000 km/24,000 miles for motorcycles with ABS) ..........................................53

Checking toothed belt pulley and sprocket, replacing if necessary .............54

(Inspection III) ....................................................................................................................................54

00.26

Page 36

Contents Page

Replacing toothed belt ............................................................................................................54

(Inspection III) ....................................................................................................................................54

Checking belt tension, adjusting if necessary ...........................................................56

(Inspections I, II and III) ......................................................................................................................56

Checking belt tension .................................................................................................................56

Adjusting belt tension ..................................................................................................................57

Used belt, new belt ...........................................................................................................................57

Checking battery acid level, adding distilled water if necessary ....................59

(Inspections II, III and IV) ....................................................................................................................59

Checking battery acid level ......................................................................................................59

Adding distilled water ..................................................................................................................59

Cleaning and greasing battery terminals, if necessary .........................................59

(Inspection IV) ....................................................................................................................................59

Checking and adjusting steering head bearing play,

replacing if necessary ..............................................................................................................60

(Inspections II and III) .........................................................................................................................60

Checking steering head bearing play ..................................................................................60

Adjusting steering head bearing play ...................................................................................60

Greasing side stand ..................................................................................................................61

(Inspections II and III) .........................................................................................................................61

Side stand ........................................................................................................................................61

Checking specified torque of threaded fasteners with torque wrench .......61

(Inspections I, II, III and IV) .................................................................................................................61

Final inspection with road safety and functional check .......................................62

(Inspections I, II, III and IV) .................................................................................................................62

Road safety check .............................................................................................................................62

Tyre tread depth (recommended minimum value) ...............................................................................62

Tyre pressures (tyres cold) .................................................................................................................62

Roadworthiness check ......................................................................................................................62

00.27

Page 37

00.28

Page 38

00

Key to maintenance intervals

Maintenance tasks consist of the first Inspection (after the first 1,000 km/600 miles), the BMW Service,

BMW Inspection and BMW Annual Service.

Inspection 1,000 km (600 miles)

BMW Running-in Check after the

first 1,000 km (600 miles).

BMW Service

After the first 10,000 km (6,000 miles) and each additional 20,000 km (12,000 miles)

(at 30,000 km ... 50,000 km ... 70,000 km)

(at 18,000 miles ... 30,000 miles ... 42,000 miles).

BMW Inspection

After the first 20,000 km (12,000 miles) and each

additional 20,000 km (12,000 miles)

(at 40,000 km ... 60,000 km ... 80,000 km)

(at 24,000 miles ... 36,000 miles ... 48,000 miles).

BMW Annual Service

Certain maintenance tasks depend on elapsed time

as well as the distance the motorcycle has covered.

They should therefore be carried out at least once a

year (e. g. changing brake fluid).

If these tasks cannot be carried out during a Service

or an Inspection, a BMW Annual Service must be

performed.

In this Repair Manual, the individual maintenance intervals are shown by the following codes:

— Inspection at 1,000 km (600 miles)......................I

— BMW Service at 10,000 km (6,000 miles)...........II

— BMW Inspection at 20,000 km (12,000 miles) .. III

— BMW Annual Service........................................ IV

00.29

Page 39

00 13 624 Reading the fault code mem-

ory with the MoDiTeC

00 11 209

Changing the engine oil

[engine only] and oil filter element

(Inspections I, II, III and IV)

K14000010

– Place the motorcycle on the auxiliary stand,

BMW No. 00 1 620.

Unclip diagnosis plug (arrow) behind cover on

•

right.

Connect the diagnosis unit to the diagnosis plug.

•

Read out the fault memory.

•

Perform any repair work indicated.

•

(Inspection I)

L Note:

If an engine failure occurs, the oil tank and feed line

must be flushed with thin oil, and then blown

through with compressed air (a 11.17).

00 11 209

– Remove cover for belt sprocket from engine.

– Place the motorcycle on the auxiliary stand,

BMW No. 00 1 620.

00 11 209

Preparatory work

Draining engine oil

d Warning:

Observe the hazard avoidance instructions for running internal combustion engines in enclosed spaces.

Warm up the engine to operating temperature.

•

Place a suitable container in position to catch the

•

oil.

Remove the oil drain plug from the engine and

•

fully drain the oil from the engine.

00.30

Page 40

00 11 215 Replacing oil filter element

1

3

00 11 215

Install the oil drain plug in the engine with a new

•

sealing ring and tighten.

Fill the oil tank with 0.5 l

•

(0.88 Imp. pints/0.53 US quarts) of engine oil and

install the filler cap.

2

L Note:

The requisite quantity of oil is 0.5 (0.88 Imp. pints/

0.53 US quarts) to 1,5 l (2.64 Imp. pints/1.59 US

quarts), depending on operating status.

Filling with engine oil

11 7 511

K14000160

Remove the left-hand screw (3) securing the oil-

•

filter cover (1).

Remove the cable for the neutral-indicator

•

switch from its guide.

Engage the oil drain guide, BMWNo.117511,

•

on the pins (arrows) on the engine block.

Position a drip tray beneath the engine.

•

Remove the screws (2) and remove the oil-filter

•

cover.

Remove the filter element.

•

Fully drain the oil and clean the oil-filter housing.

•

e Attention:

Dispose of the used oil and oil filter in an environmentally compatible manner.

Fit a new filter element onto the oil-filter cover.

•

Coat the O-ring of the filter element lightly with

•

oil.

Check the O-ring of the oil-filter cover for dam-

•

age and replace if necessary.

Install the oil-filter cover complete with filter ele-

•

ment.

Installation is the reverse of the removal proce-

•

dure: pay particular attention to the following.

d Warning:

Observe the hazard avoidance instructions for running internal combustion engines in enclosed spaces.

Installation is the reverse of the removal proce-

•

dure: pay particular attention to the following.

d Warning:

Observe the hazard avoidance instructions for running internal combustion engines in enclosed spaces.

Check the oil level with the engine at operating

•

temperature, proceeding as follows:

L Note:

Lower the dipstick into the oil filler neck, but do not

engage the threads.

1. Make sure the engine is at operating temperature, and allow it to idle for 1 minute.

2. Switch off the engine and check the oil level with

the dipstick.

L Note:

Do not reinstall the belt sprocket cover at this stage,

if other maintenance work has to be performed on

assemblies normally concealed by this component.

X Tightening torque:

Oil filter cover............................................... 10 Nm

Sprocket cover to engine ............................... 2 Nm

K14000170

3. Top up the engine oil if necessary, but no higher

than the midway mark (arrow) and repeat

steps 1) to 3).

BMW recommends Castrol

00.31

Page 41

e Attention:

Do not use synthetic oils.

Operating fluids:

Brand-name HD oil, API classification SF, SG or SH;

suffix letters CD or CE are permitted; alternatively,

brand-name HD oil of CCMC classification G4 or

G5; suffix PD2 is permitted.

Capacity, engine:

with filter replacement ......................................0.5 l

.............................(0.88 Imp. pints/0.53 US quarts)

X Tightening torque:

Oil drain plug, engine ................................... 40 Nm

00 11 215

Changing the engine oil [engine and oil tank] and oil filter element

(Inspections II, III and IV)

L Note:

If an engine failure occurs, the oil tank and feed line

must be flushed with thin oil, and then blown

through with compressed air (a 11.17).

00 11 215

– Place motorcycle on side stand.

– Remove cover for belt sprocket from engine.

00 11 215

Preparatory work

Draining engine oil

d Warning:

Observe the hazard avoidance instructions for running internal combustion engines in enclosed spaces.

Warm up the engine to operating temperature.

•

Place a suitable container in position to catch the

•

oil.

1

K14000150

Remove the filler cap from the oil tank.

•

Remove the oil drain plug from the frame (1).

•

Fully drain the oil.

•

– Place the motorcycle on the auxiliary stand,

BMW No. 00 1 620.

Remove the oil drain plug from the engine and

•

fully drain the oil from the engine.

00.32

Page 42

00 11 215 Replacing oil filter element

1

00 11 215

Install the oil drain plug in the frame with a new

•

sealing ring and tighten.

Install the oil drain plug in the engine with a new

•

sealing ring and tighten.

Fill the oil tank with 2 l (3.52 Imp. pints/2.11 US quarts)

•

of engine oil and install the filler cap.

Filling with engine oil

2

3

11 7 511

K14000160

Remove the left-hand screw (3) securing the oil-

•

filter cover (1).

Remove the cable for the neutral-indicator

•

switch from its guide.

Engage the oil drain guide, BMWNo.117511,

•

on the pins (arrows) on the engine block.

Position a drip tray beneath the engine.

•

Remove the screws (2) and remove the oil-filter

•

cover.

Remove the filter element.

•

Fully drain the oil and clean the oil-filter housing.

•

e Attention:

Dispose of the used oil and oil filter in an environmentally compatible manner.

d Warning:

Observe the hazard avoidance instructions for running internal combustion engines in enclosed spaces.

Run the engine for thirty seconds.

•

Add another 0.5 l (0.88 Imp. pints/0.53 US quarts)

•

of engine oil to the oil tank.

Installation is the reverse of the removal proce-

•

dure: pay particular attention to the following.

Check the oil level with the engine at operating

•

temperature, proceeding as follows:

L Note:

Lower the dipstick into the oil filler neck, but do not

engage the threads.

1. Make sure the engine is at operating temperature, and allow it to idle for 1 minute.

2. Switch off the engine and check the oil level with

the dipstick.

Fit a new filter element onto the oil-filter cover.

•

Coat the O-ring of the filter element lightly with

•

oil.

Check the O-ring of the oil-filter cover for dam-

•

age and replace if necessary.

Install the oil-filter cover complete with filter ele-

•

ment.

Installation is the reverse of the removal proce-

•

dure: pay particular attention to the following.

L Note:

Do not reinstall the belt sprocket cover at this stage,

if other maintenance work has to be performed on

assemblies normally concealed by this component.

X Tightening torque:

Oil filter cover............................................... 10 Nm

Sprocket cover to engine ............................... 2 Nm

K14000170

3. Top up the engine oil if necessary, but no higher

than the midway mark (arrow) and repeat steps

1) to 3).

BMW recommends Castrol

00.33

Page 43

e Attention:

Do not use synthetic oils.

Operating fluids:

Brand-name HD oil, API classification SF, SG or SH;

suffix letters CD or CE are permitted; alternatively,

brand-name HD oil of CCMC classification G4 or G5;

suffix PD2 is permitted.

Capacities, engine and oil tank:

with filter replacement ......................................2.5 l

.............................(4.40 Imp. pints/2.64 US quarts)

X Tightening torque:

Oil drain plug, engine ................................... 40 Nm

Drain plug, frame oil tank.............................. 21 Nm

Cleaning oil strainer in frame

(Inspection II, once only)

– Drain engine oil (

– Remove left cover (

a 00.32).

a 46.6).

X Tightening torque:

Oil drain plug, engine ................................... 40 Nm

Oil drain plug, frame oil tank......................... 21 Nm

Oil line to frame............................................ 42 Nm

Oil strainer to frame...................................... 80 Nm

Oil tank cover to frame................................... 5 Nm

Right and left covers to main frame................ 2 Nm

Right and left covers to air duct ..................... 3 Nm

Right and left covers to cover, front ............... 1 Nm

Right and left turn indicators to fairing

bracket........................................................... 3 Nm

Cover, rear, to right and left covers and

stowage-compartment frame ......................... 2 Nm

Stowage-compartment rail to stowage-compart-

ment frame..................................................... 9 Nm

Release lever to release shaft....................... 10 Nm

Greasing rubber grommets for cover insert

(Inspections I, II, III and IV)

– Remove cover inserts.

1

2

4

3

K14000350

Remove oil-tank cover (1).

•

Disengage clutch cable (arrow).

•

Remove release lever (3).

•

Disconnect oil line (4).

•

Remove oil strainer (2) and clean it with com-

•

pressed air.

Installation is the reverse of the removal proce-

•

dure: pay particular attention to the following.

Always install new seals for the oil line and oil

•

strainer.

Adjust clutch play (a 00.45).

•

6

5

K14000380

Coat pin (5) and hook (6) with rubber care prod-

•

uct.

Install cover insert.

•

00.34

Page 44

Checking coolant, topping up if necessary

(Inspections I, II and III)

e Attention:

Check coolant level only when the engine is cold.

Do not refill the coolant expansion tank if valve clearance still has to be checked/adjusted.

Check antifreeze concentration in the expansion

•

tank, top up antifreeze if necessary.

L Note:

Mix the coolant to a ratio of 50 % antifreeze,

50 % water.

Check coolant level in expansion tank.

•

If the coolant level is below the MIN mark, top up

•

coolant to the MIN mark.

Checking coolant

– Place the motorcycle on the auxiliary stand,

BMWNo.001620.

Check coolant level through the slot in the insert

•

in the left cover.

Top up the coolant if the level is below the MIN

•

mark.

Adding coolant

– Remove cover insert from left cover.

A

B

Maximum level ..................................................... A

Minimum level...................................................... B

Installation is the reverse of the removal proce-

•

dure.

K14000100

e Attention:

Anti-freeze protection must be guaranteed to at

least -30 °C (-22 °F). Use only nitrite-free long-term

antifreeze and corrosion inhibitor.

When the engine is cold, do not top up expansion

tank past the MIN mark (B).

00.35

Page 45

17 00 035 Changing coolant

(Inspection IV, every 2 years)

– Remove left cover (a 46.6).

– Place motorcycle on side stand.

Position a drip tray beneath the engine.

•

2

1

K14000110

Remove drain plug (1) from water pump.

•

Hold a funnel below the drain and open the radi-

•

ator cap.

Drain off all the coolant.

•

K14000130

Remove fastener (2), lift out the expansion tank

•

and drain off all coolant.

e Attention:

Dispose of old coolant in an environmentally compatible manner.

L Note:

Do not install and refill the coolant expansion tank if

valve clearance still has to be checked.

Install the expansion tank.

•

Install the drain plug with a new sealing ring and

•

tighten.

Tighten hose clamp securing coolant hose.

•

– Place the motorcycle on the auxiliary stand,

BMW No. 00 1 620.

K14000120

Disconnect the coolant hose (arrow) at the frame

•

on the left and drain the radiator.

00.36

Page 46

1

K14000140

Slacken bleed screw (1) in cylinder head.

•

Connect a hose to the bleed screw.

•

Fill the radiator until coolant escapes at the bleed

•

screw; repeatedly squeeze the coolant hoses to

expel the air.

Tighten bleed screw (1).

•

K14000130

Filling capacity

Cooling system ................................................1.3 l

.............................(2.29 Imp. pints/1.37 US quarts)

In expansion tank.............................................0.1 l

.............................(0.18 Imp. pints/0.11 US quarts)

Antifreeze

Use only nitrite-free long-term antifreeze and corrosion inhibitor.

Concentration

Antifreeze.........................................................50%

Water ...............................................................50%

Run the engine for a short time, then switch it off.

•

Check coolant level and top up if necessary.

•

Installation is the reverse of the removal proce-

•

dure: pay particular attention to the following.

L Note:

Do not reinstall the cover at this stage, if other maintenance work has to be performed.

X Tightening torque:

Stowage-compartment rail to stowage-compart-

ment frame..................................................... 9 Nm

Cover, rear, to left and right covers and

stowage-compartment frame ......................... 2 Nm

Right and left covers to air duct ..................... 3 Nm

Right and left covers to main frame................ 2 Nm

Right and left covers to cover, front ............... 1 Nm

Right and left turn indicators to fairing bracket3 Nm

Drain plug, water pump................................ 10 Nm

Expansion tank to radiator ............................. 9 Nm

Bleed screw................................................. 12 Nm

Coolant hose to frame.................................... 3 Nm

Top up coolant until the level reaches the top of

•

the filler neck (arrow).

Top up expansion tank to the MIN mark.

•

00.37

Page 47

00 11 602 Checking and adjusting

valve clearances

(Inspections II and III)

0011601

Preparatory work

– Place the motorcycle on the auxiliary stand,

– Remove the left, right and front covers (

Remove the intake air silencer together with the intake air pipe.

•

•

Checking valve clearances

BMW No. 00 1 620.

a 46.6).

Push up the tab to pull the fuse box from the

holder.

Remove the fuel filter from the stowage-compartment frame.

1

K14000030

Disengage the clamp (arrow) securing the

•

breather hose and disconnect the hose from the

intake air silencer.

Carefully disconnect the intake air silencer from

•

the throttle flap stub.

Disengage the intake air pipe with rubber grom-

•

met from the link.

Pull the intake air silencer with intake air pipe to

•

the rear to remove, disconnecting the plug for

the intake-air temperature sensor.

Cover/seal the throttle flap stub.

•

Exposing the radiator

K14000020

Remove fasteners securing stowage-compart-

•

ment frame to main frame (arrows).

Remove stowage-compartment frame (1).

•

K14000040

L Note:

When temporarily securing the expansion tank,

make sure that the cap is above the level of the coolant.

Disconnect the expansion tank from the radiator,

•

pull it to one side and temporarily secure it to the

handlebar with a cable tie or similar.

Protect the interior of the radiator with cardboard

•

or similar.

00.38

Page 48

Exposing cylinder head

1

4

2

3

6

Remove fasteners securing bracket (1) of ignition

•

coil, pull bracket complete with ignition coil (2)

forward and lay it down.

Remove rubber cap (arrow).

•

Release knurled nut (3).

•

Disengage throttle cable from adapter.

•

Use pliers, BMW No. 17 5 500, to release hose

•

clip (5) and disconnect cylinder-head breather

hose (6).

Remove spark plug.

•

5

K14000050

L Note:

Note the position of the two anchorages for ignition

coil (1) on the cylinder-head cover.

Remove 8 fasteners (4) and remove the cylinder-

•

head cover with gasket.

Turning crankshaft to TDC position

Remove the central threaded plug in the magnet

•

housing.

E110410

L Note:

TDC position: Marks on the timing-chain

sprockets (arrows) must be parallel with the cylinder

head, the bores in the timing-chain sprockets are at

the top.

Use an Allen key to turn the crankshaft clockwise

•

to the TDC position.

00.39

Page 49

Checking valve clearance

1

11 1 810

E000160

Use feeler gauges, BMWNo.111810, to meas-

•

ure valve clearances.

Make a note of the valve clearances, or adjust

•

them if necessary.

Valve clearances:

Inlet valve ........ 0.03...0.11 mm (0.0012...0.0043 in)

Exhaust valve .. 0.25...0.33 mm (0.0098...0.0130 in)

00 11 602 Adjusting valve clearances

11 6 570

K14000070

Remove the fasteners securing the chain

•

guide (arrows) and remove chain guide (1).

E000370

Use cable ties (arrow) to secure the timing chain

•

to both sprockets.

Remove the upper section of the camshaft carri-

•

er.

K14000060

L Note:

Watch out for escaping oil and catch it in a suitable

container.

Remove the screw at the oil feed stub pipe and

•

insert locating screw, BMW No. 11 6 570, to

lock the crankshaft at TDC.

e Attention:

Oil the camshafts to facilitate their removal and installation.

Carefully remove the inlet camshaft and lay it

•

aside.

Carefully remove the exhaust camshaft and lay it

•

aside.

00.40

Page 50

E000380

Turn the bucket tappet until the shim (arrow) can

•

be levered out at the groove in the bucket tappet.

Before installing new shims, check thickness

•

with a micrometer.

Position the shim in the bucket tappet.

•

e Attention:

Check that the shim is correctly seated in the bucket

tappet.

Installation is the reverse of the removal proce-

•

dure: pay particular attention to the following.

When installing the inlet camshaft, press the

•

chain rail back against the chain tensioner if necessary.

L Note:

TDC position: Marks on the timing-chain sprockets

must be parallel with the cylinder head, the bores in

the timing-chain sprockets are at the top.

Before installing the chain guide, remove the lo-

•

cating screw and install the screw plug, fitted

with a new sealing ring.

Turn the engine over once and bring it to TDC.

•

Check the TDC positions of the camshaft

•

sprockets.

Check valve clearances.

•

Clean the threads of the securing screws for the

•

chain guide, coat threads with Loctite 243 and

install the screws.

Installing cylinder head cover

Before installing the cylinder head cover, remove

•

all traces of the gasket and clean the sealing face