Page 1

Repair manual

C1

C1 200

BMW Motorrad

After Sales

Page 2

Published by BMW Motorrad

After Sales

UX-VS-2

All rights reserved. Reprints, translation and duplication allowed exclusively with prior written permission

from the publisher.

Errors and omissions excepted. We reserve the right to introduce technical modifications at any time.

Printed in Germany 03/01

Page 3

Preface

This Repair Manual is intended to assist you in performing all essential maintenance and repair operations

to a professional standard. In its role as a reference source for service personnel, it supplements and expands upon the theoretical and hands-on instruction provided at our training centres to enhance the quality

of our service.

A new edition of this manual will be issued in response to required revisions or the need to incorporate additional information (supplements).

The illustrations and descriptions contained in this manual apply exclusively to standard, unmodified BMW

Motorcycles and/or BMW Motorcycles equipped with factory-approved BMW accessories and options.

The Repair Manual's structure reflects the logical sequence in which the operations it describes will be

•

performed: removal, dismantling, repairs, assembly and installation.

The individual chapters in this manual correspond to the motorcycle's individual assembly groups.

•

11 10.

Chap. chapter page continued

A reference arrow with chapter and page calls your attention to additional information contained in another

section of the manual.

e.g. a ................ Refer to Assembly Group 46

Group "00" describes the operations carried out in the course of each Inspection. The various inspec-

•

tion routines are numbered I, II, III and IV. To help in maintaining a continuous, logical work sequence,

these same numerical designations are employed to identify the subsequent sections describing the actual repair operations.

Use of the BMW special tools needed for certain operations is described in the work instructions.

•

When the need arises, repair instructions are also issued in the form of Service Information Bulletins. This

information is then incorporated into subsequent editions of the repair manual. We also recommend the

lavishly illustrated Electronic Parts Catalogue as a supplementary source of information.

When individual steps within an overall operation only apply to motorcycles with specific accessories or

optional equipment, the options to which the steps refer are identified by brackets at the start of the line,

such as

Please devote your careful attention to the following pages with their explanations describing the symbols

used in the manual and their significance.

BMW Motorrad

After Sales

[with heated grips]

.

Published by BMW Motorrad

After Sales

UX-VS-2

80788 München

All rights reserved. Reprints, duplication and translation, in whole or part, are allowed exclusively with prior

written permission.

We reserve the right to introduce technical modifications at any time. Errors and omissions excepted.

Printed in Germany

Page 4

How to use this manual

Each chapter starts with a table of contents.

Following the table of contents is a table containing the techical data and specifications for the chapter's

subject.

Chapter 00 describes maintenance procedures and provides general information as well as the pre-delivery

inspection; it furnishes all torque specifications along with listings of fluids and lubricants.

Explanation of symbols

This repair manual for the C1 employs the following symbols; please refer to the table for their meanings.

Special notices for more efficient procedures

L

Note:

These special notices help technicians work more efficiently when operating, inspecting, adjusting and

maintaining motorcycles.

e

Attention:

Special information and precautionary notices to prevent damage to the motorcycle. Failure to observe

these mandatory precautions may invalidate the warranty.

d

Warning:

Precautions intended to protect the rider and/or other individuals against injury as well as potentially fatal

hazards.

Contents

The titles of the operations described in this chapter ............. together with the page numbers

Operations

Operations

•

A dot or period identifies individual procedures described under a title

•

– Previous operations

– The hyphen identifies procedures described in more detail under a different title or in another chapter

Remove means:

to completely unscrew a retaining component (such as a bolt or screw)

or

to detach a component (such as an injection rail) and move it enough to gain access to assemblies installed

behind it (such as a throttle-valve).

Loosen means:

to unscrew an attachment (such as a bolt or screw) without removing it entirely from its threaded socket or

retainer

X

Torque specifications:

These data are indicated whenever torques deviate from the standards defined in DIN EN 24 014 and

DIN 912 ISO.

Page 5

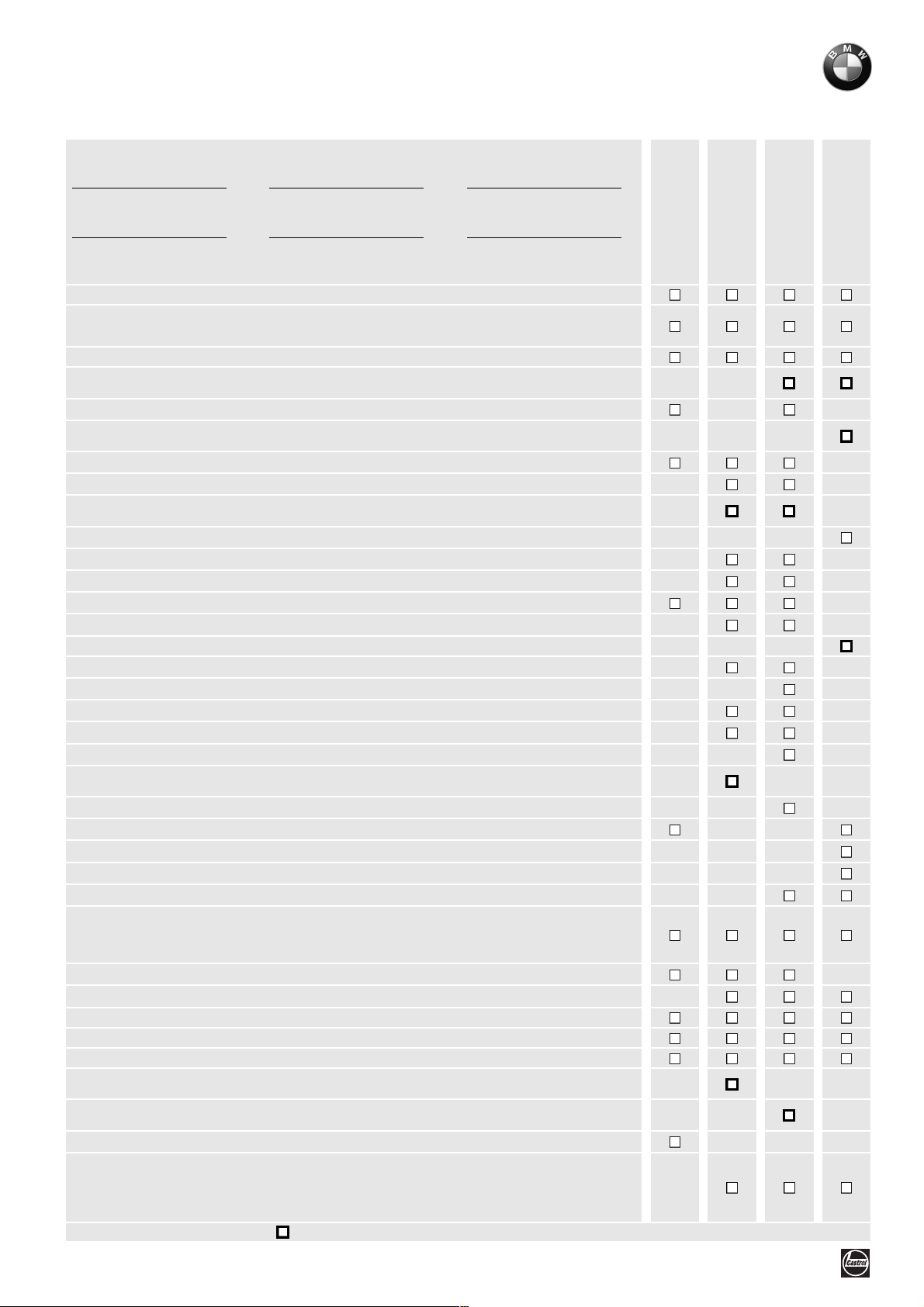

Contents

<< Back

Group / Chapter

00 Tightening torques operating fluids

00 Pre-delivery check

00 Maintenance

11 Engine

12 Engine electrics

13 Fuel preparation and control

16 Fuel tank and lines

17 Radiator

18 Exhaust system

21 Clutch

24 Gearbox

31 Front forks

32 Steering

>> Continuation

Page 6

Group / Chapter

33 Rear wheel drive

34 Brakes

36 Wheels and tyres

46 Frame

51 Equipment

>> Continuation

52 Seat

61 General electrical equipment

62 Instruments

63 Lights

65 Optional extras

72 Seat belts

<< Back

Page 7

BMW Motorrad

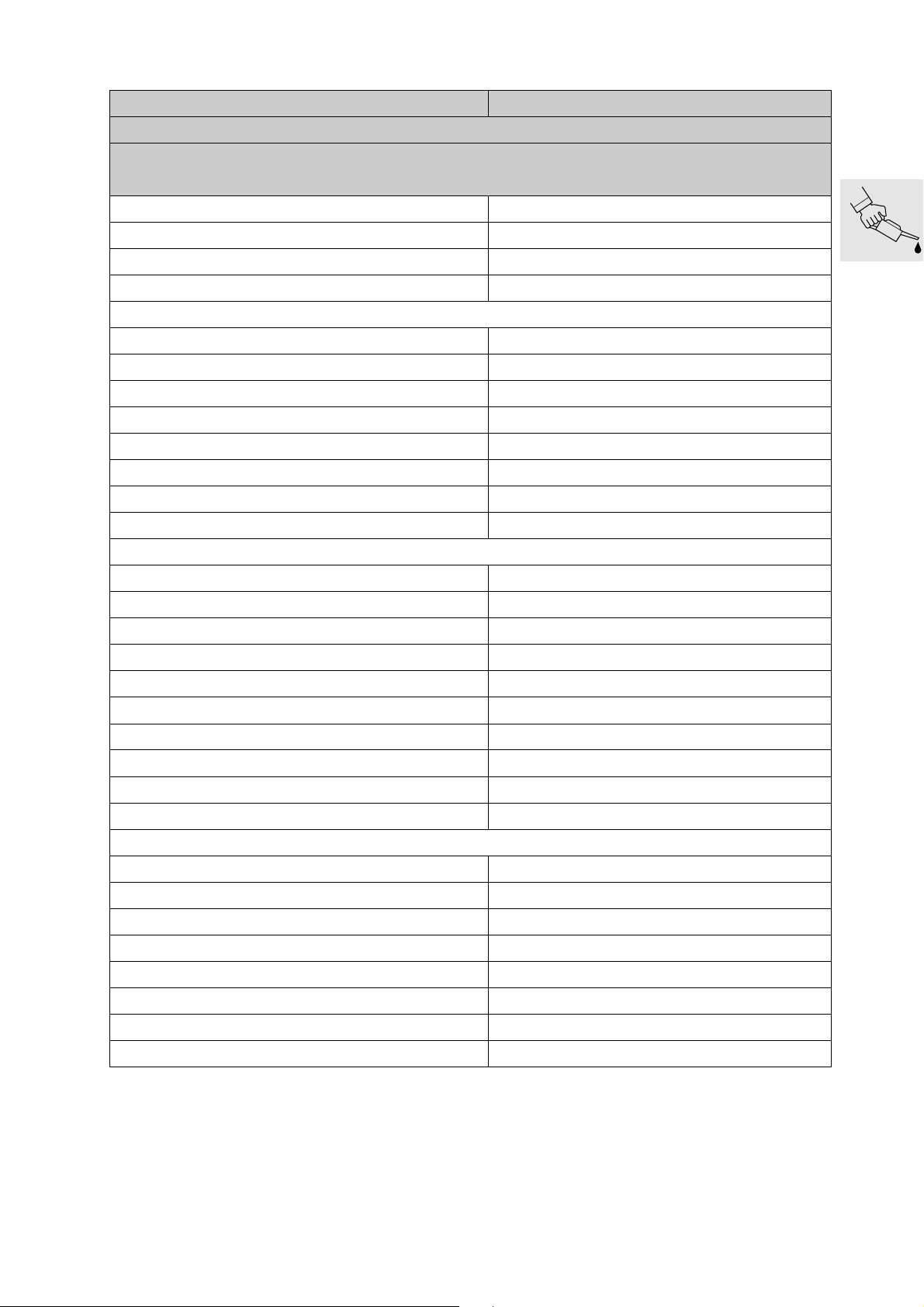

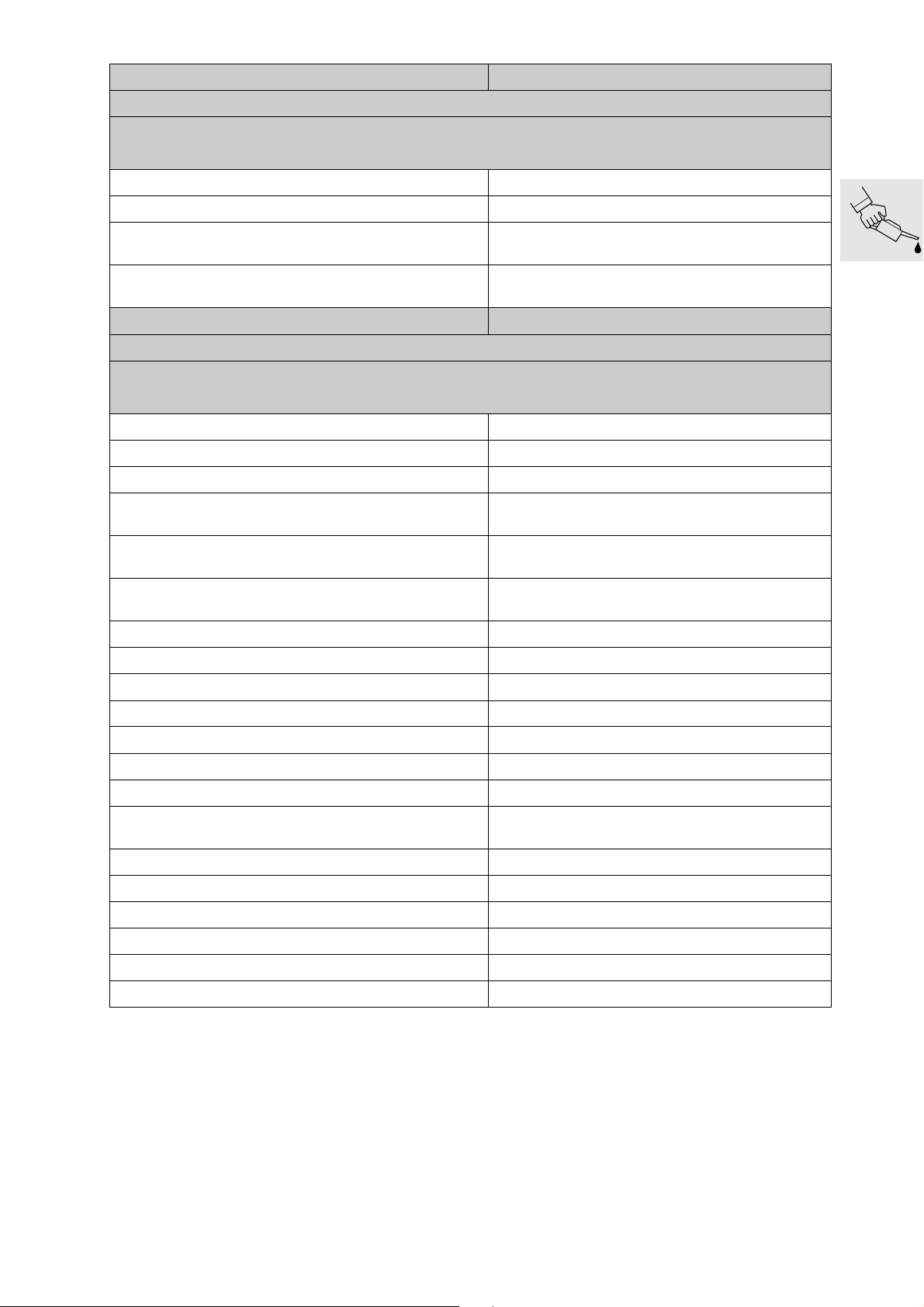

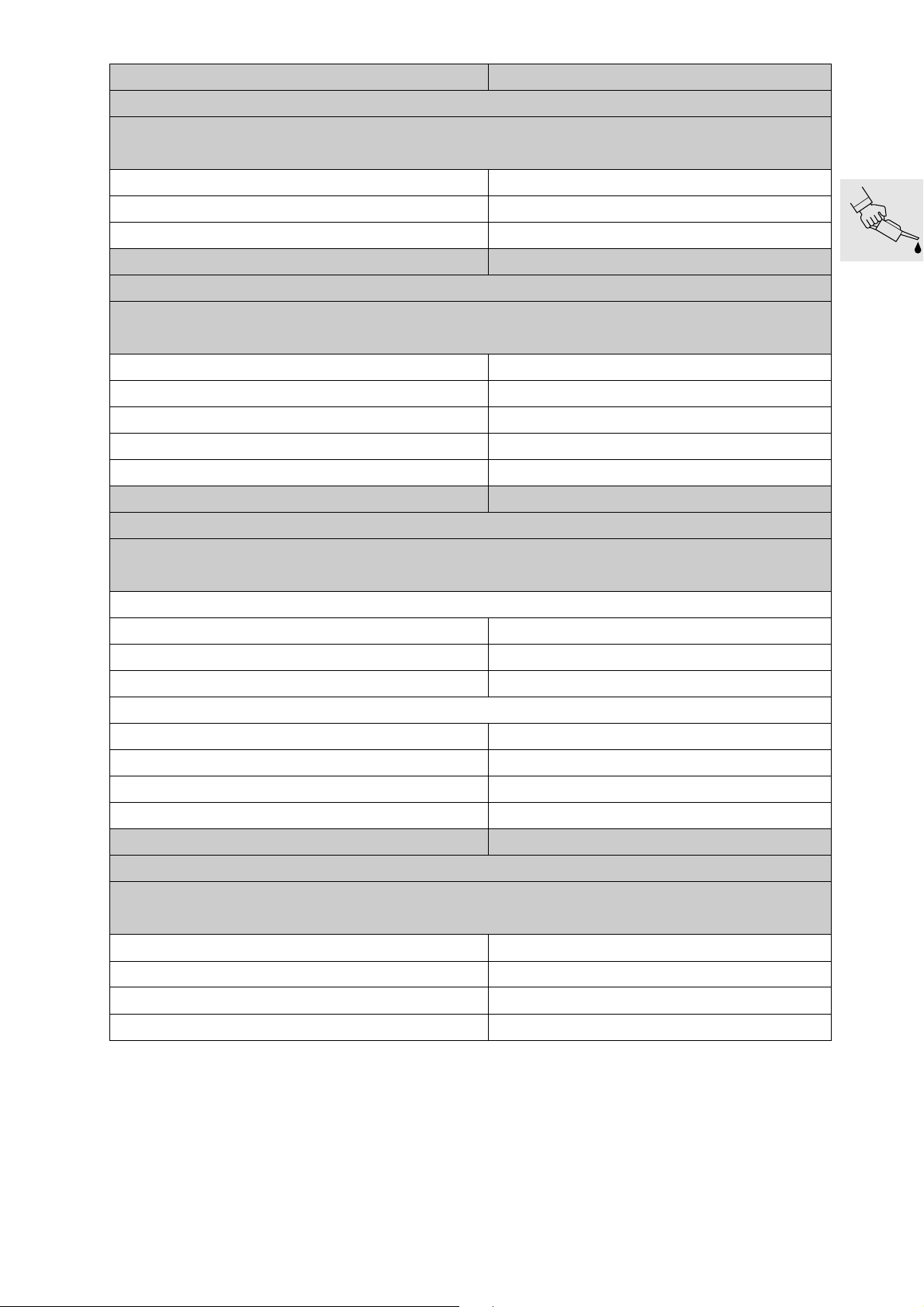

Maintenance schedule

C1, C1 200

Customer Licence No. Mileage

Job Order No. Date Mechanic's signature

MoDiTeC/DIS plus

Change the engine oil while at regular operating temperature and replace the oil filter element

If the vehicle is ridden for short distances only or at outside temperatures below 0° C (32° F): every 3 months or after

every 3,000 km (1,800 miles) at the latest

Clean oil strainer and magnetic plug

Change transmission fluid

every 30,000 km/18,000 miles or 3 years

Inspect coolant level, top up if necessary, inspect hoses for damage, chafing points

Change the coolant

every 2 years

Check valve clearances and adjust if necessary

Replacing spark plug

Replace air filter element

shorten change interval if severely dirty or dusty

Drain condensate drain hose from air manifold

Brake hoses and connections: check condition and routing

Check operation of brake system and check for leaks; repair/replace as necessary

Inspect brake fluid level at front/rear

Examine brake pads and discs for wear, renew if necessary

brake fluid

Renew

Replace variator belt

Check clutch liner, replace if necessary

Cleaning mesh filter of variator

Grease driving variator (greased version)

Check and clean driving variator (ungreased version, replace variator if necessary)

Replace complete driving variator

every 22,500 km/14,000 miles, greased version only

Check wheel bearings for play; replace if necessary

Checking that leading-link mounts are free of play

Battery: check battery acid level, if necessary add distilled water

Clean and grease the battery terminals, if necessary

Check freedom of movement of Bowden cables, check for abrasion and damage

Easy-lift mechanism:

– Check operation of mechanism and check freedom of movement

– Inspect Bowden cables for damage and signs of wear and chafing, ensuring that mechanism moves

freely without binding; check free travel and adjust as required

Check windscreen washer system; adjust nozzles if necessary and top up washer fluid in reservoir

Check windscreen wiper; replace wiper blade if necessary

Safety elements: check cable for release, belt buckles, belt strap, inertia reels, and belt locks

Check crash element for damage

Inspect shoulder bar for damage, replace deformation element if necessary

Replace fuel filter

every 37,50 0 km/22,500 miles

Only ABS: Replace seal in brake master cylinder

every 30,000 km/18,000 miles

Check tightness of bolts and nuts at engine mountings and quick-release axles

Final inspection with road safety and functional check:

– Clutch engagement, steering, front and rear brake

– Condition of tyres and wheels, tyre inflation pressure

– Lights and signalling equipment, telltale and warning lights, instruments

– If necessary, test ride

*) Write up on separate invoice; Not part of standard service procedure

, read fault code memory

*)

at least

*)

*)

once a year

*)

*)

*)

*)

*)

*)

*)

*)

BMW Inspection

at 10,00 km/600 miles

BMW Maintenance

Service every

7,500 km/4,500 miles

BMW Inspection

every 15,000 km/

9,000 miles

BMW

Annual Service

UX-VS-2, 10.2001

BMW recommends Castrol

Page 8

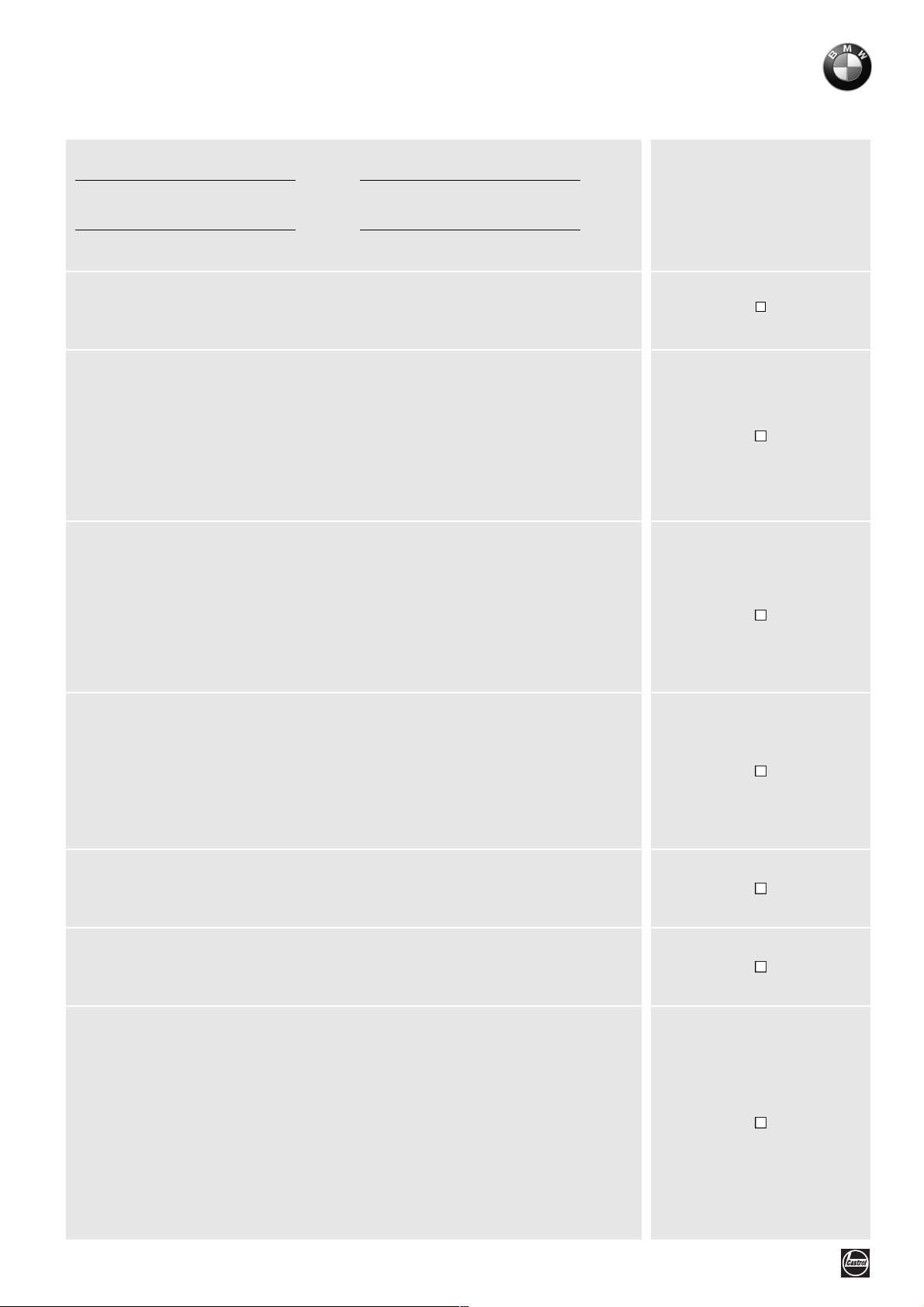

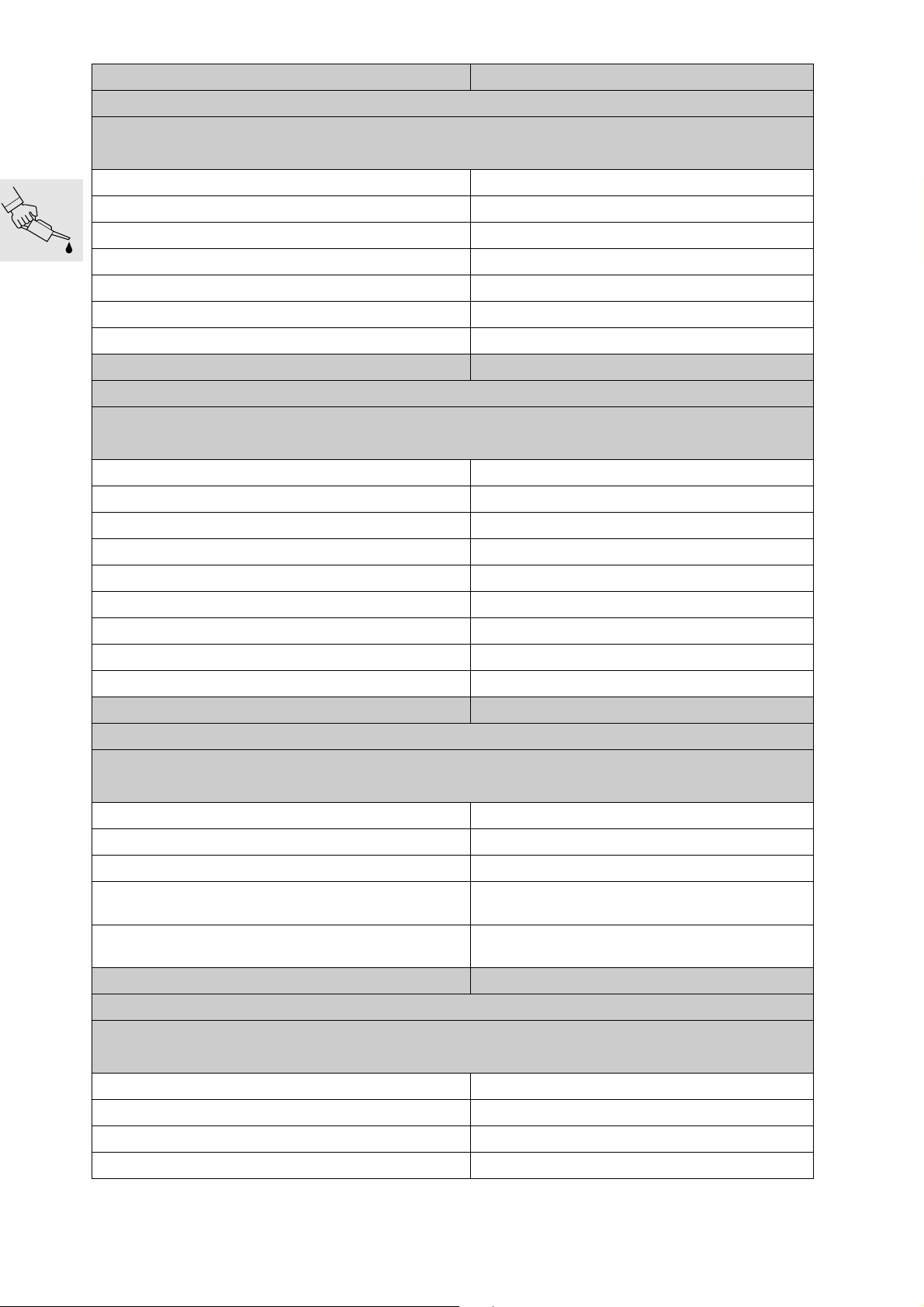

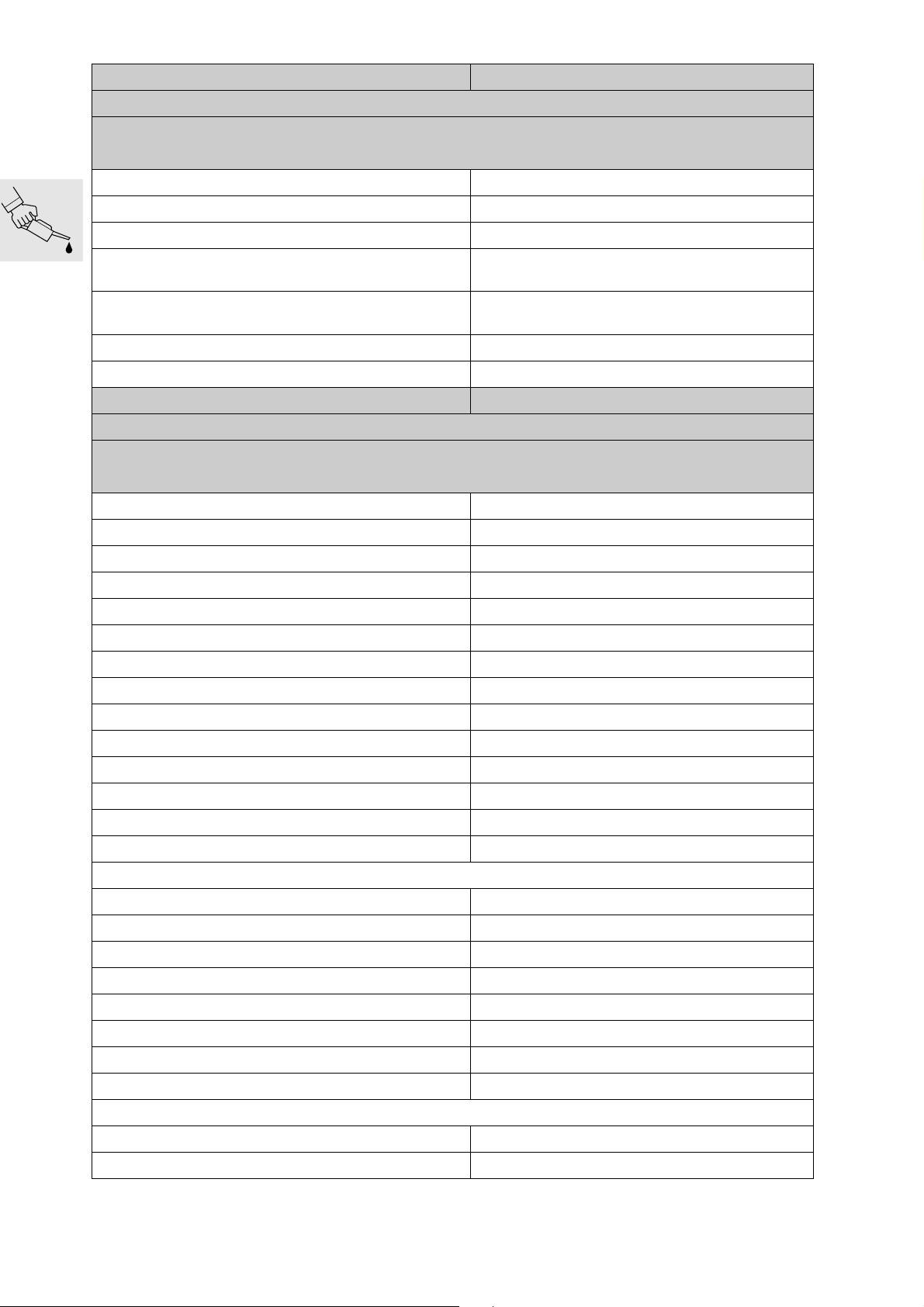

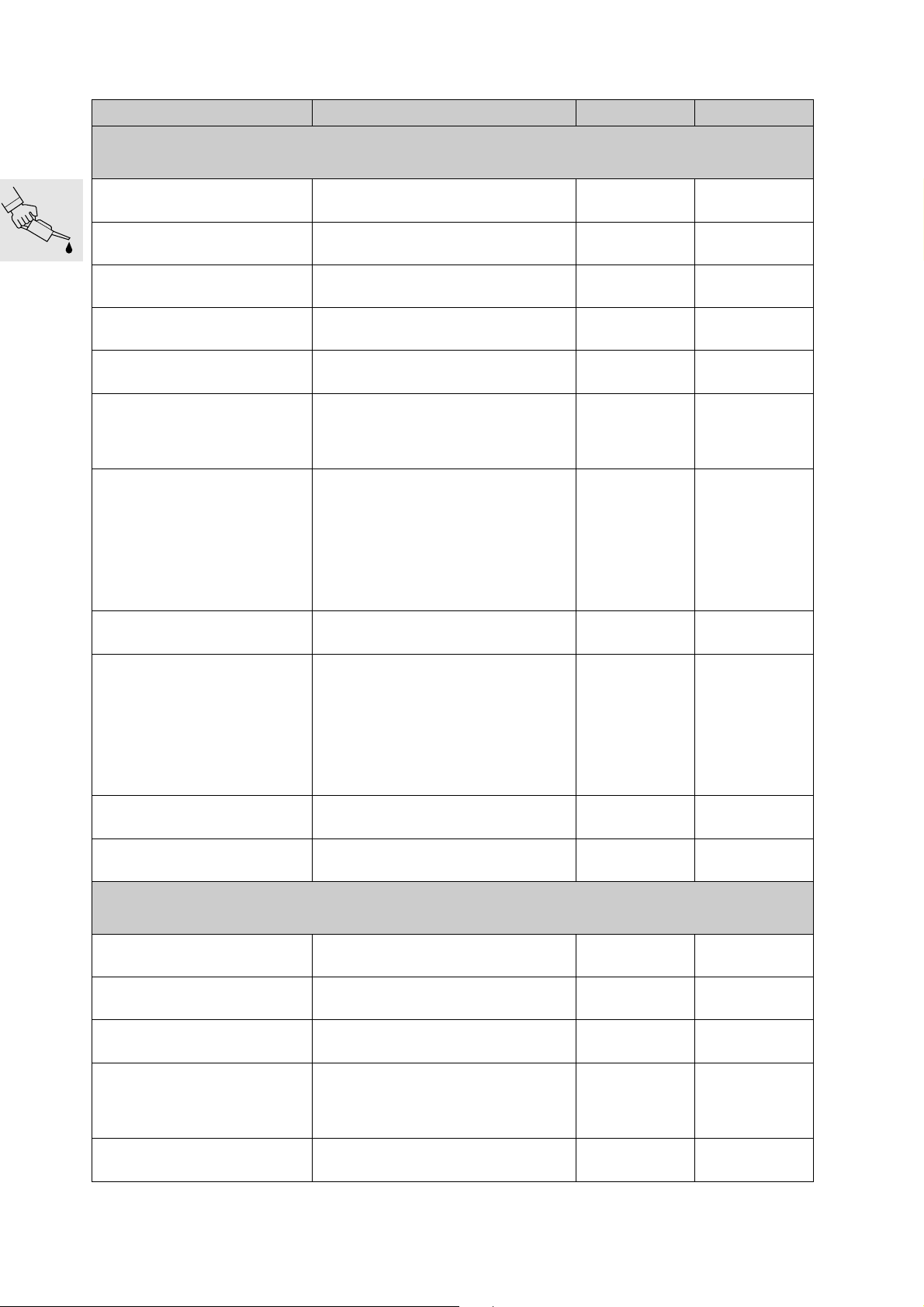

BMW Motorrad

Pre-delivery Check

C1, C1 200

Customer Registration number

Order no. Signature of mechanic

Inspect transportation packaging for damage

C1:

–Unpack

– Inspect for damage

–Attach parts

–Clean

Battery:

–Remove

– Pour in electrolyte

–Charge

–Grease terminals

– Install (mark date of installation)

BMW

Pre-delivery Check

Inspect complete scope of supply:

– Toolkit

– Documentation

–Keys

– Scope of optional equipment

Inspect tyre inflation pressure

Pour in fuel

Operational check as final inspection:

– Engine idling

– Clutch, clutch engagement

–Steering

–Seat belt

– Easy-lift mechanism

– Brakes, front and rear

– Lights and signalling equipment, telltale and warning lights, instruments

–Set headlight

– If necessary, test ride

UX-VS-2, 10.2001

BMW recommends Castrol

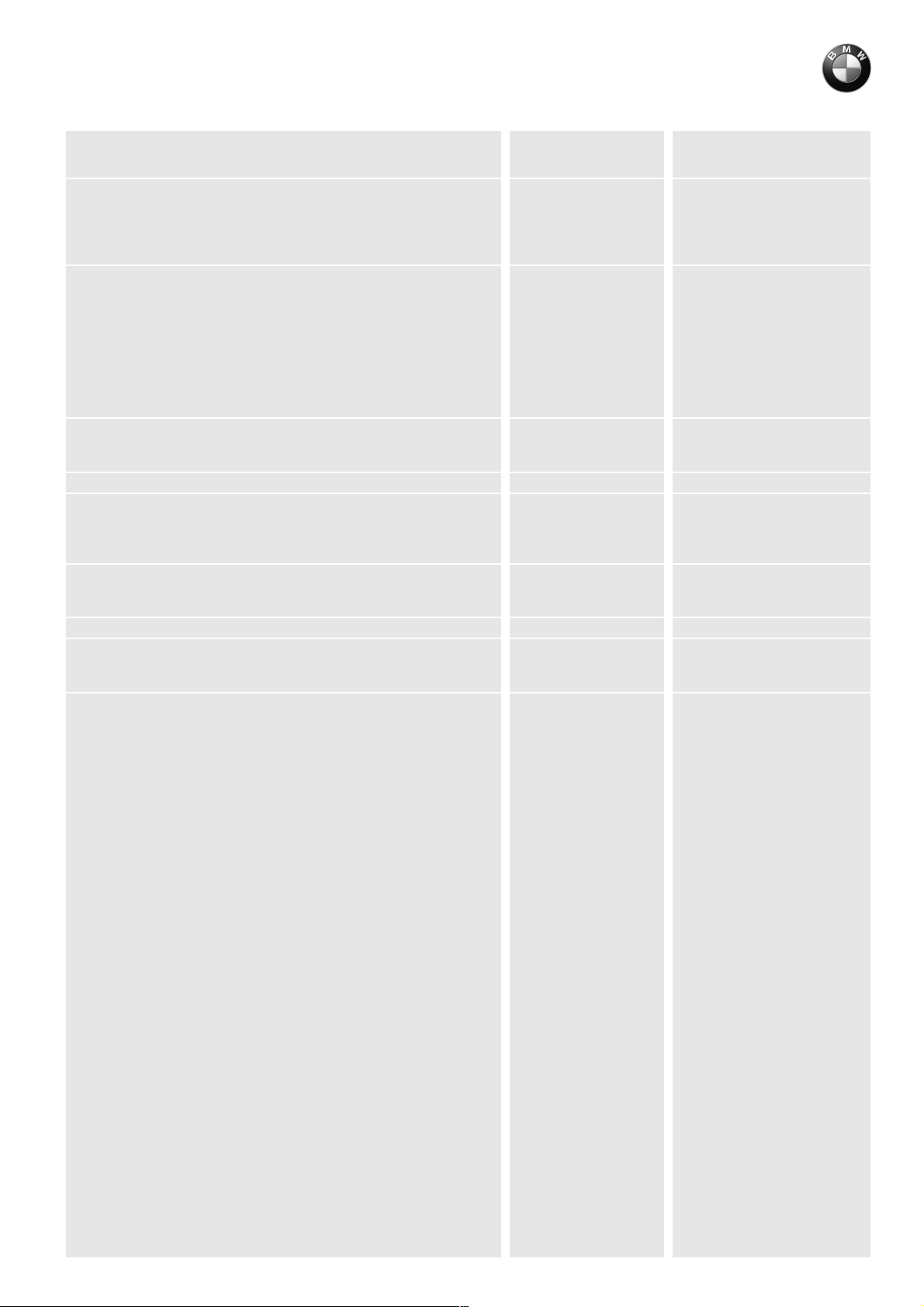

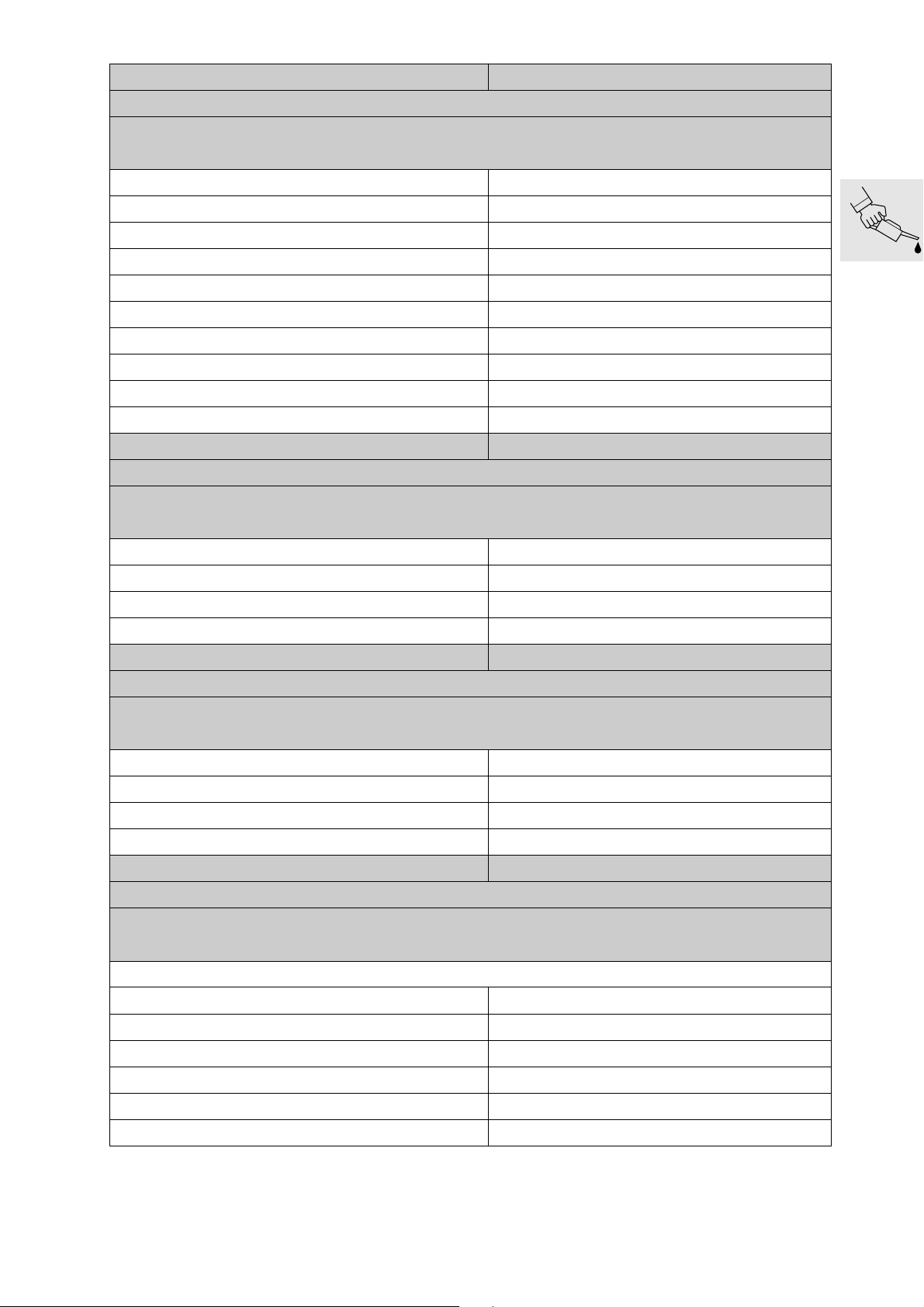

Page 9

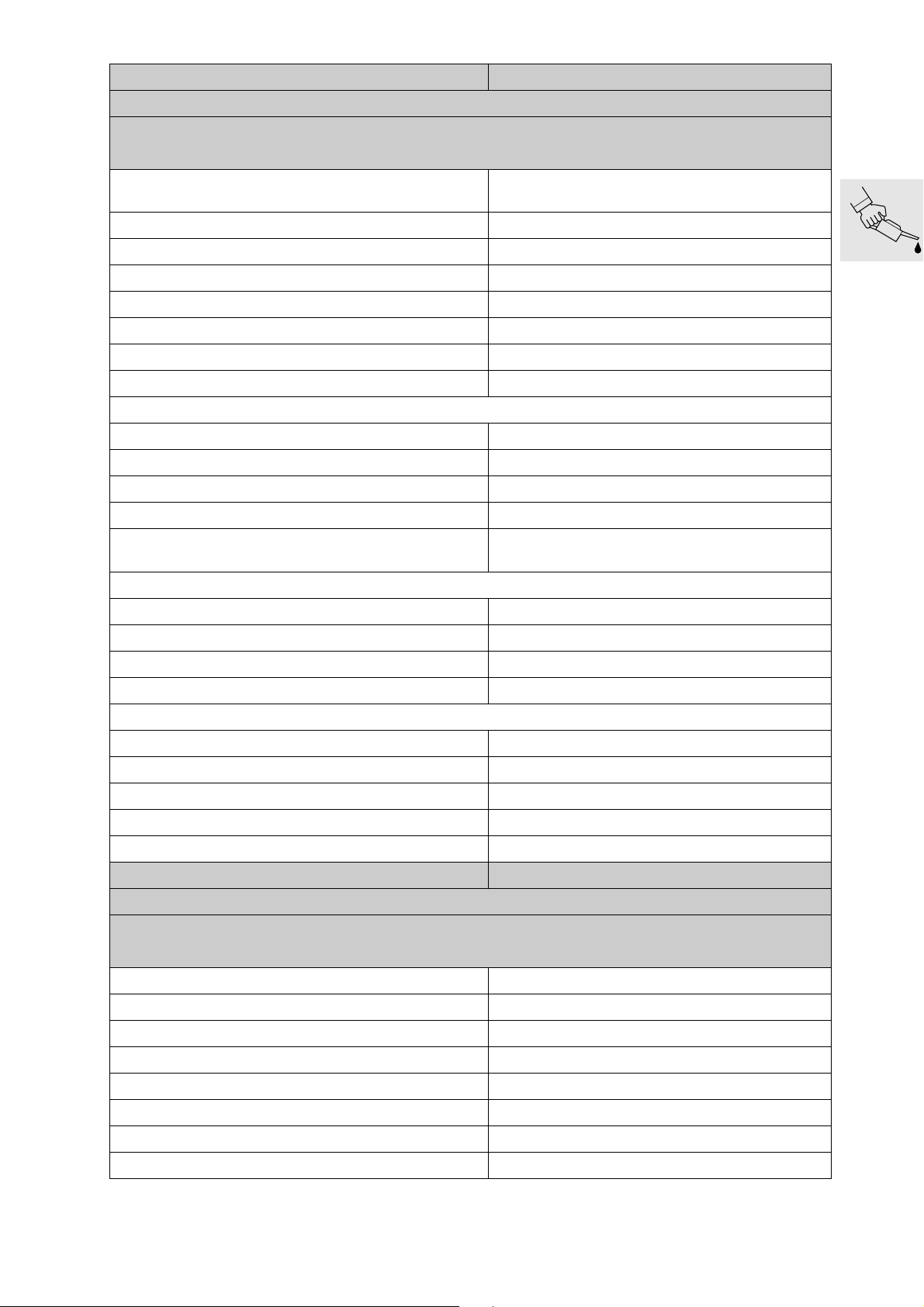

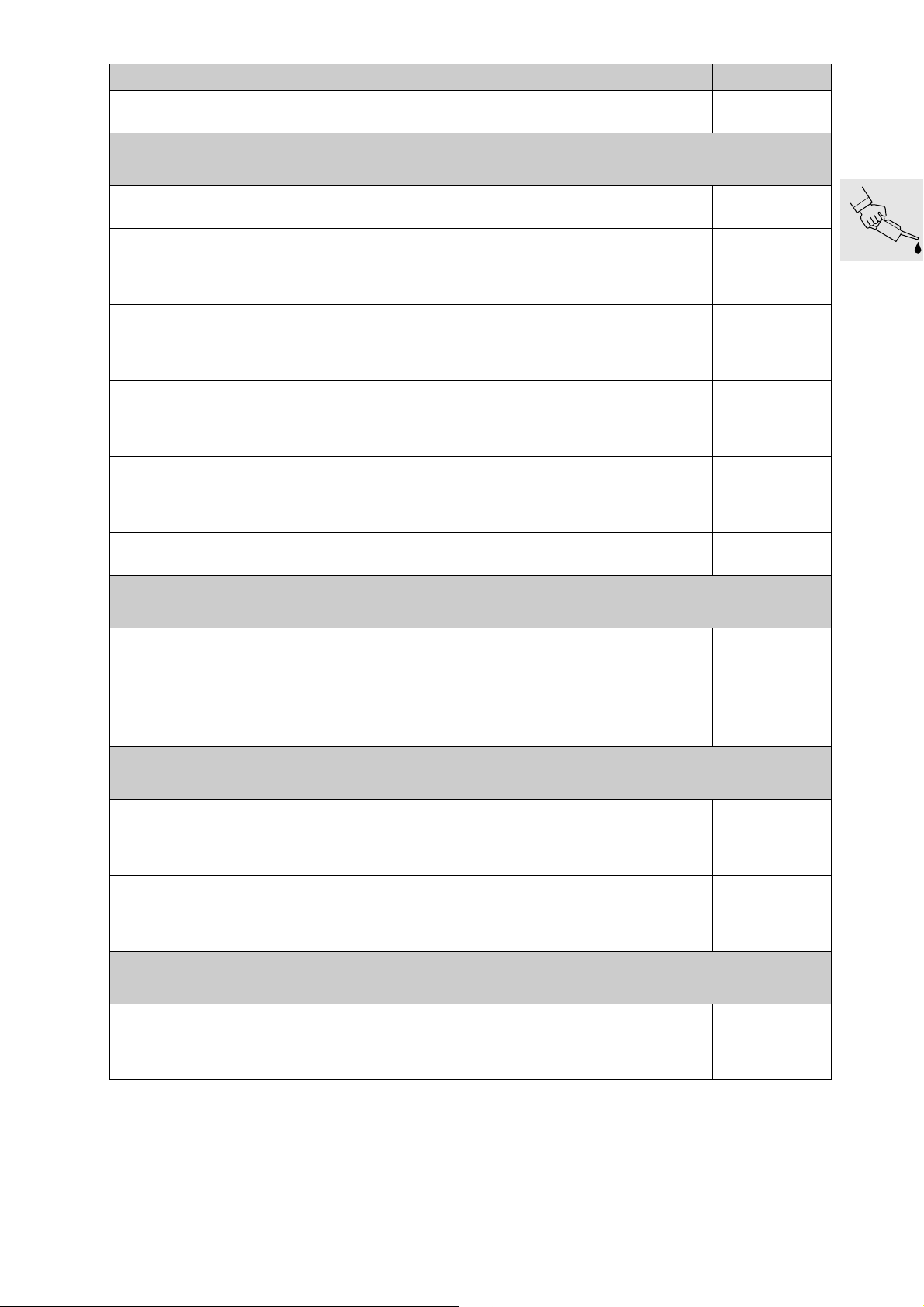

BMW Motorrad

Service data

C1, C1 200

Item Specified

value

Oil capacities

Engine (with filter)

Gearbox

Coolant

Cooling system

Expansion tank

Windshield washer fluid

Brake fluid

Valve clearances

Measured cold, maximum 35 °C (95 °F)

Spark plugs

Electrode gap 0.8…0.9

Idle speed

Tyre pressures (tyres cold)

Solo

Full load

Tightening torques:

Engine oil drain plug

Oil strainer to engine

Engine water drain plug

Oil filter cover

Camshaft gears to camshaft

Guide rail to camshaft support

Chain tensioner plug

Camshaft bearing bridge

Valve cover

Machine bolt TDC setting

Spark plug

Driving variator

Driving variator cover

Driven variator

Locknut of clutch to driven variator

Variator cover to power train link

Ventilation cover for variator

Front stub axle

Clamping bolts for front stub axle

Brake calliper at fork slider tube

Bleed screw in brake calliper

Cover of handbrake control

Rear stub axle,

Exhaust to cylinder head

Auxiliary link to power train link M8

Auxiliary link to power train link M10

Silencer to auxiliary link

Suspension strut to power train link/brake calliper holder

Link mounting to power train link

Tubular link to frame

Stand to frame

Rubber element to tubular link

Cladding bolts

Order no. 01 71 0 136 450 UX-VS-2, 03.2001 Printed in Germany

use nut only once

1.0 (0.22)

0.090 (0.020)

1.25 (2.2)

0.2 (0.35)

1.0 (1.8) litres (Imp pints)

Inlet: 0.05…0.14

(0.002…0.006)

Exhaust: 0.20…0.29

(0.009…0.010)

(0.031…0.035)

1900 rpm

Front/rear

1.9/2.1 (27.6/30.5)

1.9/2.4 (27.6/34.8)

20

30

10

10

30

10

35

10

10

15

15

60

4

60

50

10

9

30

21

41

14

Hand-tight

130

15

21

60

21

21

73

73

41

42

2.8

Unit of measure or

specification

litres (Imp pints)

15W40

litres (Imp pints)

API GL 4

litres (Imp pints)

litres (Imp pints)

Mixing ratio:

Water: 50%

Antifreeze: 50%

Protection down to

–25 °C (-13 °F)

Water and cleaning prod-

uct, antifreeze as required

DOT 4

mm

(in)

mm

(in)

NGK CR8 EB

mm

(in)

bar (psi)

bar (psi)

Nm

Nm

Nm

Nm

Nm (Loctite 243)

Nm (Loctite 243)

Nm

Nm

Nm

Nm

Nm

Nm (Loctite 243)

Nm

Nm

Nm (Loctite 243)

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm (Loctite 243)

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Page 10

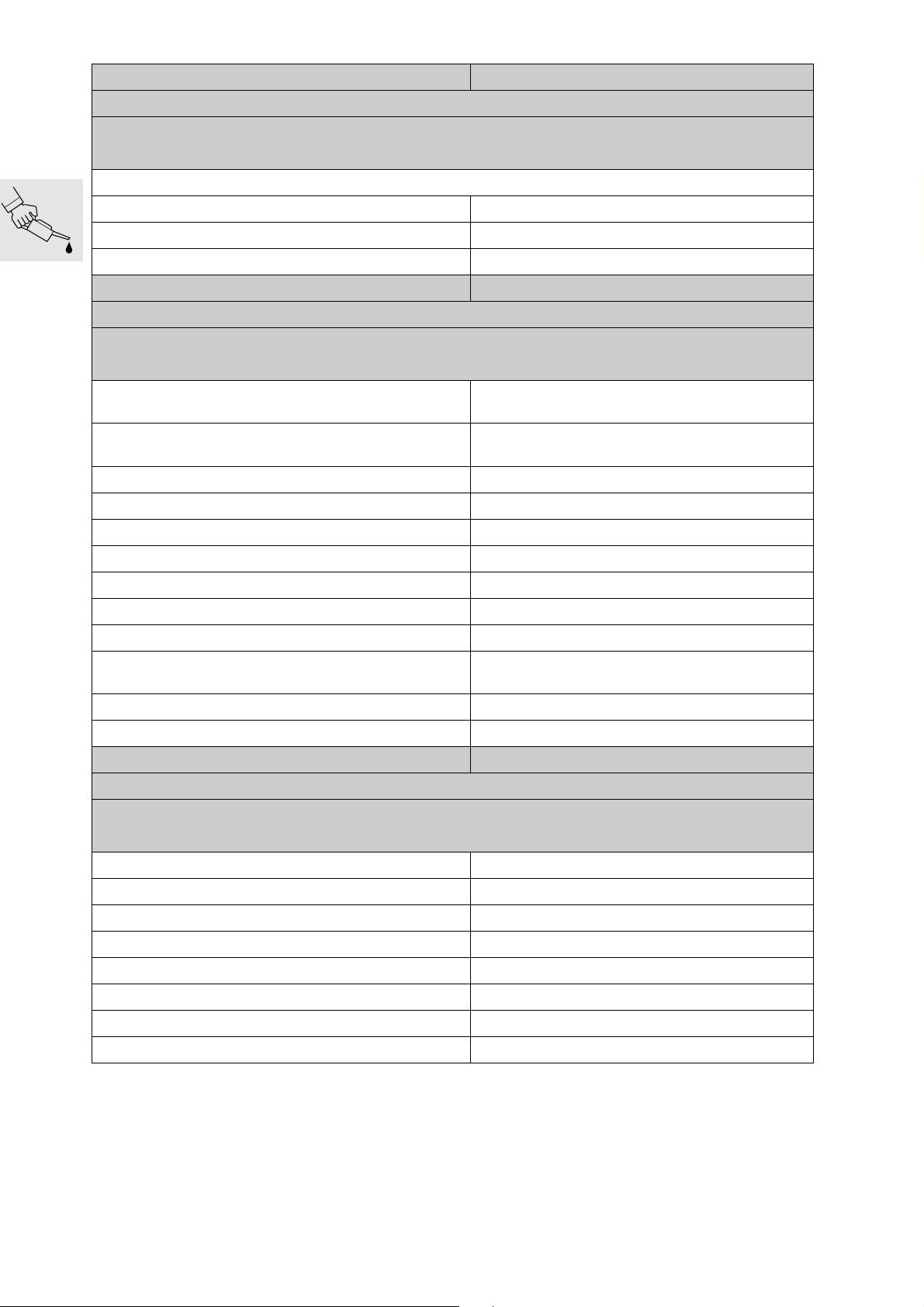

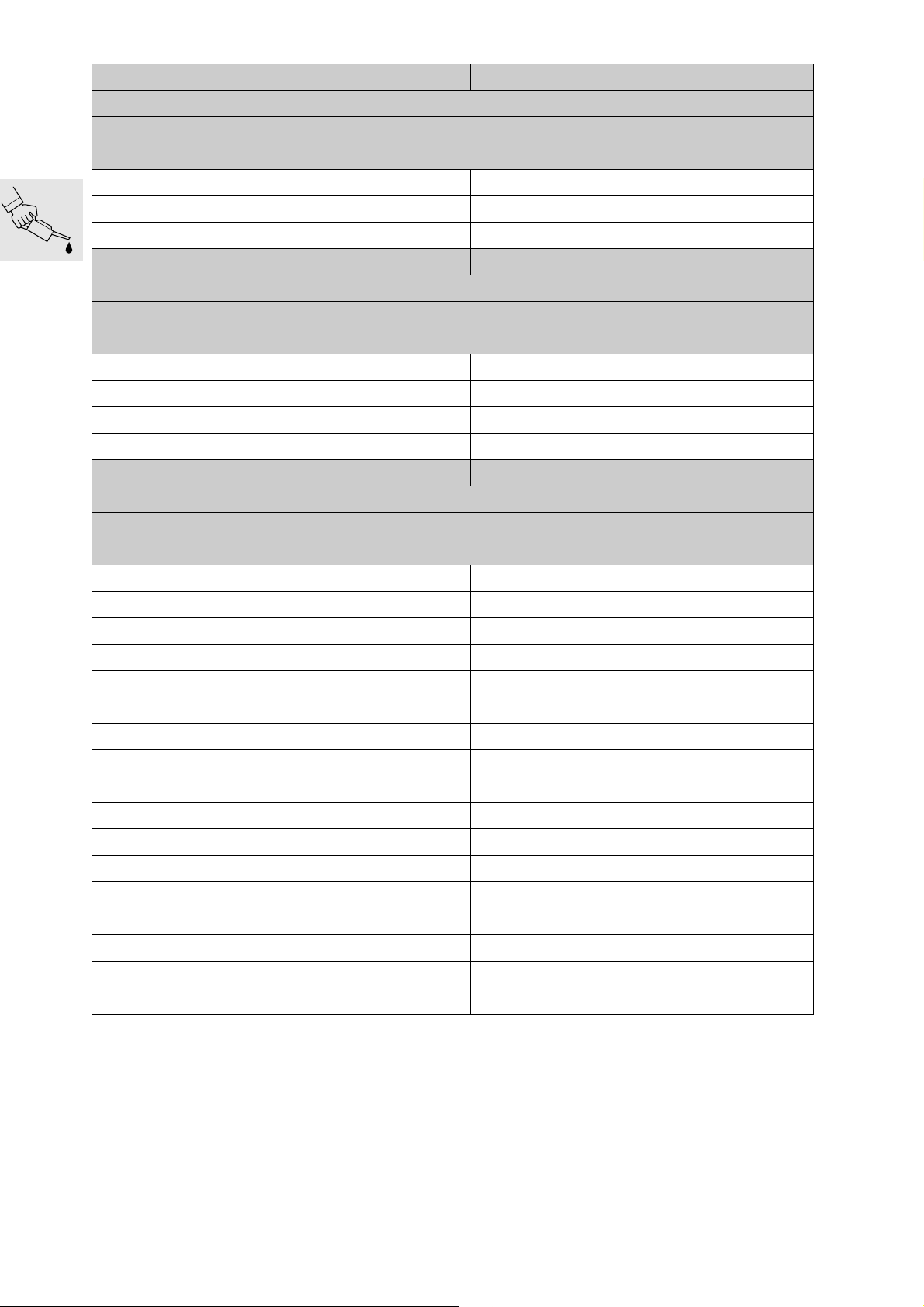

Page 11

00

00 Tightening torques

operating fluids

Contents

Torque specifications

11 Engine

...........................................................................................................................................3

12 Engine electrical system

13 Fuel injection system

16 Fuel tank

.......................................................................................................................................4

17 Cooling system

18 Silencer (muffler)

21 Clutch

24 Gearbox

31 Front forks

32 Steering

............................................................................................................................................5

........................................................................................................................................5

...................................................................................................................................6

........................................................................................................................................6

33 Final-drive unit

34 Brakes

36 Wheels

46 Frame

51 Equipment

52 Seats

...........................................................................................................................................7

..........................................................................................................................................8

............................................................................................................................................8

...................................................................................................................................9

............................................................................................................................................ 10

61 Electrical equipment

62 Instruments

63 Lights

........................................................................................................................................... 11

............................................................................................................................... 11

65 Optional extras

72 Seat belts

................................................................................................................................... 11

.................................................................................................................3

..............................................................................................................4

.........................................................................................................................4

.......................................................................................................................5

...........................................................................................................................7

............................................................................................................. 10

........................................................................................................................ 11

Page

.......................................................................................................4

Table of service products

....................................................................................................... 12

00.1

Page 12

00.2

Page 13

00

Torque specifications

Model C1

Connection

11 Engine

Oil drain plug, magnetic Nm 20

Threaded plug, oil strainer Nm 30

Oil filter cover Nm 10

Threaded TDC set plug Nm 15

Alternator

Alternator cover up to engine no.: 745 594 Nm 10

Alternator cover from engine no.: 745 595 Nm 12

Ignition trigger, Tapite screw Nm 6 LOCTITE 243

Holder for alternator cable, Tapite screw Nm 6 LOCTITE 243

Reluctor to crankshaft, locking fluid Nm 30 LOCTITE 243

One-way clutch, locking fluid Nm 30 LOCTITE 243

Alternator to cover Nm 10

Chain tensioning rail, locking fluid Nm 10 LOCTITE 243

Cylinder head

Cylinder head cover Nm 10

Collar nut Nm 30 ±1

Securing screw Nm 10

Spark plug Nm 15

Camshaft sprockets, locking fluid Nm 30 LOCTITE 243

Bearing cap Nm 10

Chain guide, locking fluid Nm 10 LOCTITE 243

Plug for chain tensioner Nm 35

Vent screw Nm 9

Dual temperature sensor, locking fluid Nm 15 LOCTITE 243

Housing

Starter motor Nm 10

Oil pressure switch, locking fluid Nm 12 LOCTITE 243

Oil pressure valve Nm 30

Stud (tie bolt) Nm 10

Housing screws Nm 10

Oil pump, Tapite screw Nm 6 LOCTITE 243

Water-pump housing, Tapite screw Nm 6 LOCTITE 243

Spring strut at bottom Nm 21

00.3

Page 14

Model C1

Connection

12 Engine electrical system

Spark plug Nm 15

Ignition coil to frame Nm 5

Ignition trigger, Tapite screw Nm 6 LOCTITE 243

Reluctor to crankshaft, locking fluid Nm 30 LOCTITE 243

One-way clutch, locking fluid Nm 30 LOCTITE 243

Alternator to cover Nm 10

Starter motor Nm 10

Model C1

Connection

13 Fuel injection system

Fuel filter clamp Nm 5

Holder for injection nozzle (self-tapping) Nm 4 LOCTITE 243

Pressure regulator clamp Nm 9

BMS control unit Nm 5

Intake manifold Nm 9

Air plenum clamp Nm Hand-tight

Air filter housing (inner/outer) Nm 9

Throttle cable Nm 8

Spring strut at bottom Nm 21

Model C1

Connection

16 Fuel tank

Fuel filter clamp Nm 5

Bracket, fuel tank to frame Nm 9

Union nut (fuel-pump unit) Nm 20

Baseplate to frame

Bracket for washer fluid reservoir on frame

Bracket for washer fluid reservoir/ABS control unit on frame

Model C1

Connection

Nm 9

Nm 9

17 Cooling system

Drain plug Nm 10

Vent screw Nm 9

Bracket for seat latch, right, to frame Nm 42

Bracket for seat latch, left, to frame Nm 5

00.4

Page 15

Model C1

Connection

17 Cooling system

Expansion tank to frame upright Nm 3

Front frame to cross brace Nm 14

Air duct to fan shroud Nm 9

Radiator to front frame Nm 9

Fan shroud to radiator Nm 9

Air duct to front frame Nm 9

Filler bowl to front frame Nm 9

Coolant pipe clamp to frame Nm 9

Screw clamp on engine Nm Hand-tight

Bleeder screw to engine Nm 9

Model C1

Connection

18 Silencer (muffler)

Shield to holder Nm 5

Exhaust pipe to cylinder head Nm 15

Silencer to auxiliary swing arm Nm 21

Oxygen sensor to silencer Nm 23

Model C1

Connection

21 Clutch

Vent cover for variator Nm 9

Variator cover Nm 10

Driven variator (clutch drum) Nm 60

Locknut on driven variator, locking fluid Nm 50 LOCTITE 243

Model C1

Connection

24 Gearbox

Variator

Vent cover for variator Nm 9

Variator cover Nm 10

Drive variator, locking fluid Nm 60 LOCTITE 243

Cover, drive variator Nm 4

Driven variator (clutch drum) Nm 60

Locknut of driven variator, locking fluid Nm 50 LOCTITE 243

00.5

Page 16

Model C1

Connection

24 Gearbox

Gearbox

Gearbox cover Nm 11

Gearbox drain plug Nm 20

Gearbox filler plug Nm 5

Model C1

Connection

31 Front forks

Fork cross brace to frame (screw stud) locking fluid

Leading link to telescopic tube cross brace

locking fluid

Brake line bracket on fork cross brace Nm 5

Fork stanchion to fork cross brace Nm 52

Handlebar to fork cross brace Nm 21

Leading-link joints Nm 41

Clamp screws for leading-link joints Nm 9

Spring strut to leading link Nm 41

Ball joint to telescopic fork cross brace Nm 230

Clamp of telescopic tube to telescopic tube

cross brace

Eyebolts Nm 8

Lock to easy-lift mechanism Nm 4

Model C1

Connection

32 Steering

Nm 83 LOCTITE 243

Nm 127 LOCTITE 2701

Nm 25

ABS sensor to telescopic tube Nm 9

Combination switch Nm 4

Brake light switch Nm Hand-tight

Throttle cable Nm 8

Clamp screw for brake lever fitting Nm 9

Brake line to brake lever fitting Nm 18

Handlebar to fork cross brace Nm 21

Locknut for handlebar lever pivot pin Nm 3

00.6

Page 17

Model C1

Connection

33 Final-drive unit

Top suspension strut Nm 41

Spring strut at bottom Nm 21

Auxiliary swing arm to brake caliper holder

M, screw locking fluid10

Auxiliary swing arm to brake caliper mount

M8

Model C1

Connection

34 Brakes

Brake caliper at telescopic tube Nm 41

Banjo bolt to brake caliper Nm 18

Bleed screw in brake caliper Nm 14

6-point nut to final-drive shaft

(rear wheel),

Auxiliary swing arm to brake caliper holder,

M10 bolt, with locking fluid

Auxiliary swing arm to brake caliper mount,

M8

Auxiliary swing arm to powertrain cradle Nm 21

Expansion tank cap Nm 1

use only once

Nm 60 LOCTITE 243

Nm 21

Nm 130

Nm 60 LOCTITE 243

Nm 21

Suspension strut to brake caliper carrier Nm 21

ABS sensor to brake caliper carrier Nm 9

ABS sensor to telescopic tube Nm 9

Brake disc Nm 21

ABS reluctor ring Nm 5

Baseplate to frame

Bracket for washer fluid reservoir on frame

Brake lines to ABS control unit, M12x1 Nm 18

Brake lines to ABS control unit, M10x1 Nm 18

Union, brake hose/brake line Nm 18

Bracket on frame joint Nm 5

Brake line to brake lever fitting Nm 18

All fasteners, brake line to frame Nm 5

Nm 9

00.7

Page 18

Model C1

Connection

36 Wheels

Stub axle, locking fluid Nm 30

Quick-release axle clamp screws Nm 21

Brake caliper at telescopic tube Nm 41

6-point nut to final-drive shaft (rear wheel),

use only once

Nm 130

Auxiliary swing arm to brake caliper holder,

locking fluid, M10

Auxiliary swing arm to powertrain cradle, M8 Nm 21

Spring strut at bottom Nm 21

Model C1

Connection

46 Frame

Body panels to body panels Nm 2,8

Body panels to frame Nm 2,8

Lightweight foam element to frame Nm 5

Foam part to cross member Nm 5

Air plenum to rear wheel mudguard Nm 12

Roof/windscreen to cross bar Nm 5

Windscreen to bracket Nm 5

Bracket, wiper motor to roof frame Nm 5

Rear mudguard to powertrain cradle Nm 12

Air filter housing to powertrain cradle Nm 12

Nm 60 LOCTITE 243

Crash element shoulder bar to frame Nm 9

Holder, crash element to frame Nm 9

Rear frame to frame Nm 21

Suspension strut to rear frame Nm 41

Joint

Nut to frame, front left, M28 Nm 105

Screw to frame, front left, M28 Stage 1 20

Screw to frame, front left, M28 Stage 2 Back off 1/2 turn

Screw to frame, front right Nm 73

Rubber bush to frame Nm 42

Rubber bush to joint Nm 42

Powertrain cradle to joint Nm 73

Joint swinging arms to each other Nm 73

Easy-lift mechanism

Spring strut to leading link Nm 41

Articulated-lever mechanism to frame Nm 21

00.8

Page 19

Model C1

Connection

46 Frame

Attachment of control cam of large hand lever, locking fluid

Stand to frame Nm 41

Switch (easy-lift mechanism) stand to frame Nm 8

Spring holder (easy-lift mechanism) to frame Nm 21

Bowden cable retaining bracket to frame Nm 21

Lock of Bowden cable Nm 8

Auxiliary swing arm to powertrain cradle Nm 21

Eyebolt to frame Nm 8

Shoulder bar

Seat to frame Nm 21

Head restraint to frame Nm 21

Shoulder bar, top, to frame M10 Nm 41

Shoulder bar, top, to frame M8 Nm 21

Shoulder bar, bottom, to frame M6 (clamping screw)

Roof frame

Front roof bar (clamp) Nm 21

Rear roof bar (clamp) Nm 21

Nm 2 LOCTITE 243

Nm 9

Roof frame cross brace Nm 21

Mirror brackets Nm 5

Luggage system

Top bracket to frame Nm 8

Bracket to rear frame Nm 21

Top bracket to bracket Nm 21

Lock carrier Nm 5

Head restraint to frame Nm 21

Model C1

Connection

51 Equipment

Ignition lock to frame Nm 9

Seat latch Nm 9

Seat bench lock to left rear side panel Nm 3

Striker on rear storage compartment Nm 3

Lock cylinder on rear storage compartment Nm 7

Striker of storage compartment Nm 3

Lock cylinder on storage compartment Nm 7

Lock bolt for luggage rail Nm 3

00.9

Page 20

Model C1

Connection

51 Equipment

Mirror bracket to frame Nm 5

Mirror to mirror bracket Nm 4

Cover on mirror arm Nm 3

Model C1

Connection

52 Seats

Seat to frame Nm 21

Seat lock Nm 9

Backrest Nm Hand-tight

Head restraint to frame Nm 21

Model C1

Connection

61 Electrical equipment

Combination switch Nm 4

Battery cable to battery Nm 3

Battery cable to starter relay Nm 3

Control current cables to starter relay Nm 0,4

Voltage regulator to frame Nm 12

BMS control unit to frame Nm 5

Wipe/wash sensor to frame Nm 3

Earth cable to frame Nm 5

Wiper arms Nm 9

Clamp, cable harness to frame Nm 5

Horn to frame Nm 8

Windscreen wiper motor to bracket Nm 5

Wiper motor bracket to roof frame Nm 5

Stationary shaft, wiper motor Nm 9

Cable to starter Nm 5

Bracket of starter relay to frame Nm 5

Bracket of wiring harness to frame Nm 5

00.10

Page 21

Model C1

Connection

62 Instruments

Instrument cluster to instrument panel Nm 3

Cable clamp to instrument cluster Nm 1

Cable terminal to instrument cluster Nm 0.5

Model C1

Connection

63 Lights

Front/rear turn signal lens Nm 2

Front turn signal to fairing Nm 2

Rear turn signal to license plate holder Nm 3

Headlight subframe Nm 9

Taillamp cluster Nm 5

Model C1

Connection

65 Optional extras

Alarm system

Control unit Nm Hand-tight

Motion sensor Nm Hand-tight

Bracket/ignition coil Nm 5

Fun audio system

Volume control Nm Hand-tight

Amplifier Nm 2

Speaker front trim panel Nm 2

Speaker bracket Nm 4

Model C1

Connection

72 Seat belts

Seat belt inertia reel to frame Nm 42

Belt buckle to belt-buckle mount Nm 42

Belt-buckle mount to frame Nm 42

Secondary mudguard Nm 5

00.11

Page 22

Table of service products

Item Use Order number Quantity

Lubricant

StaburagsNBU30PTM High-performance lubricating paste 07 55 9 056 992

Optimoly MP 3 High-performance lubricating paste 07 55 9 062 476

Optimoly TA High-temperature assembly paste 18 21 9 062 599

Silicone grease 300, heavy Insulation grease 07 58 9 058 193

Retinax EP2

Contact spray Contact spray 81 22 9 400 208

Chain spray Drive chain

Shell HDX2

Klüber paste 46 MR 401

Wheel, steering head and taper roller

bearing grease

Variator rollers

driven variator (pins and bearing)

against fretting corrosion

spacer, variator shaft spline, clutch

drum

crankshaft and outer disc

Shaft seal seats

Ball-bearing seats, shaft journals,

bearing shells, outer ø

Small-end bore, piston pin

83 22 9 407 845

72 60 2 316 676

72 60 2 316 667

11 00 7 660 830

11 00 7 660 831

75 g (2.65 oz)

tube

100 g (3.53 oz)

tube

100 g (3.53 oz)

tube

10 g (0.35 oz)

tube

100 g (3.53 oz)

tube

300 ml

(0.53 Imp pint/

0.32 US quart)

spray

50 ml

(0.088 Imp pint/

0.053 US quart)

spray

300 ml

(0.53 Imp pint/

0.32 US quart)

spray

400 g (14.12 oz)

tube

60 g (2.12 oz)

tube

MOLYKOTE 111

Never Seez Compound Oxygen sensor 83 23 9 407 830

Sealants

3-Bond 1110 B Surface sealant 07 58 9 056 998

3-Bond 1209 Surface sealant 07 58 9 062 376

omni VISC 1002 Surface sealant (max. 200 °C/392 °F) 07 58 1 465 170

Loctite 574 Surface sealant 81 22 9 407 301

Curil K 2 Heat-conductive sealant 81 22 9 400 243

00.12

Water pump, water pump chamber,

shaft seals

11 00 7 660 832

100 g (3.53 oz)

tube

100 g (3.53 oz)

tube

5 g (0.18 oz)

tube

30 g (1.06 oz)

tube

90 g (3.18 oz)

tube

50 ml

(0.088 Imp pint/

0.053 US quart)

tube

250 g (8.83 oz)

can

Page 23

Item Use Order number Quantity

Hylomar SQ 32 M Permanently elastic sealant 81 22 9 400 339

Adhesives and retainers

100 g (3.53 oz)

tube

Loctite 648 Joint adhesive (low clearance) 07 58 9 067 732

Loctite 638 Joint adhesive (greater clearance) 07 58 9 056 030

Loctite 243 Thread retainer, medium-strength 07 58 9 056 031

Loctite 270 Thread retainer, strong 81 22 9 400 086

Loctite 2701 Thread retainer, strong 33 17 2 331 095

Loctite 454 Cyanacrylate adhesive (gel) 07 58 9 062 157

Cleaners

Brake cleaner Brake cleaner 83 11 9 407 848

Metal Polish Polish for chrome-plated parts 82 14 9 400 890

5 g (0.18 oz)

bottle

10 ml

(0.018 Imp pint/

0.010 US quart)

bottle

10 ml

(0.018 Imp pint/

0.010 US quart)

bottle

10 ml

(0.018 Imp pint/

0.010 US quart)

bottle

10 ml

(0.018 Imp pint/

0.010 US quart)

bottle

20 g (0.71 oz)

tube

600 ml

(1.056 Imp pint/

0.634 US quart)

spray

100 g (3.53 oz)

tube

Testing agents

Penetrant MR 68

Developer MR 70

Installation aids

BMW cooling spray

Crack testing agent for aluminium

housings

Crack testing agent for aluminium

housings

Cooling components before assembly

83 19 9 407 855

81 22 9 407 495

83 19 9 407 762

500 ml

(0.880 Imp pint/

0.528 US quart)

spray

500 ml

(0.880 Imp pint/

0.528 US quart)

spray

300 ml

(0.53 Imp pint/

0.32 US quart)

spray

00.13

Page 24

00.14

Page 25

00

00 Pre-delivery check

Contents

Check transport container for damage

Damage in Germany

Damage in export markets

Unpack C1

Place C1 on stand ............................................................................................................................ 19

Take the C1 from the stand ..............................................................................................................21

...................................................................................................................................... 18

Check C1 for damage

.................................................................................................................... 17

....................................................................................................... 17

..............................................................................................................23

..........................................................................17

Page

Check package contents to determine whether consignment is complete

23

Fill and charge the battery

Use BMW MoDiTeC/DIS plus to access stored error codes

Check tyre inflation pressures

Add fuel

............................................................................................................................................ 25

....................................................................................................24

..............................25

............................................................................................25

.

Operation check as final inspection

Final cleaning

Vehicle delivery

............................................................................................................................... 26

............................................................................................................................ 26

................................................................................25

00.15

Page 26

00.16

Page 27

00

Check transport container for damage

Inspect the transport container immediately for

•

damage as soon as the C1 is delivered, remembering to check for collateral damage if indicated

Damage in Germany

Record the damage on the consignment waybill

•

Read transport damage information sheet

•

Inform supplier (freight expediter, rail, etc.) and

•

Bavaria Wirtschaftsagentur GmbH

Abteilung ZW - 12

80788 München

Tel. 089/143 276 32

Fax. 089/143 276 39

immediately

Damage in export markets

Record damage on the consignment waybill

•

National response arrangements apply

•

Submit questions to:

Bavaria Wirtschaftsagentur GmbH

Abteilung ZW - 12

80788 München

Tel. +49 89 143 276 32

Fax. +49 89 143 276 39

Inform supplier (freight expediter, etc.) immedi-

•

ately

00.17

Page 28

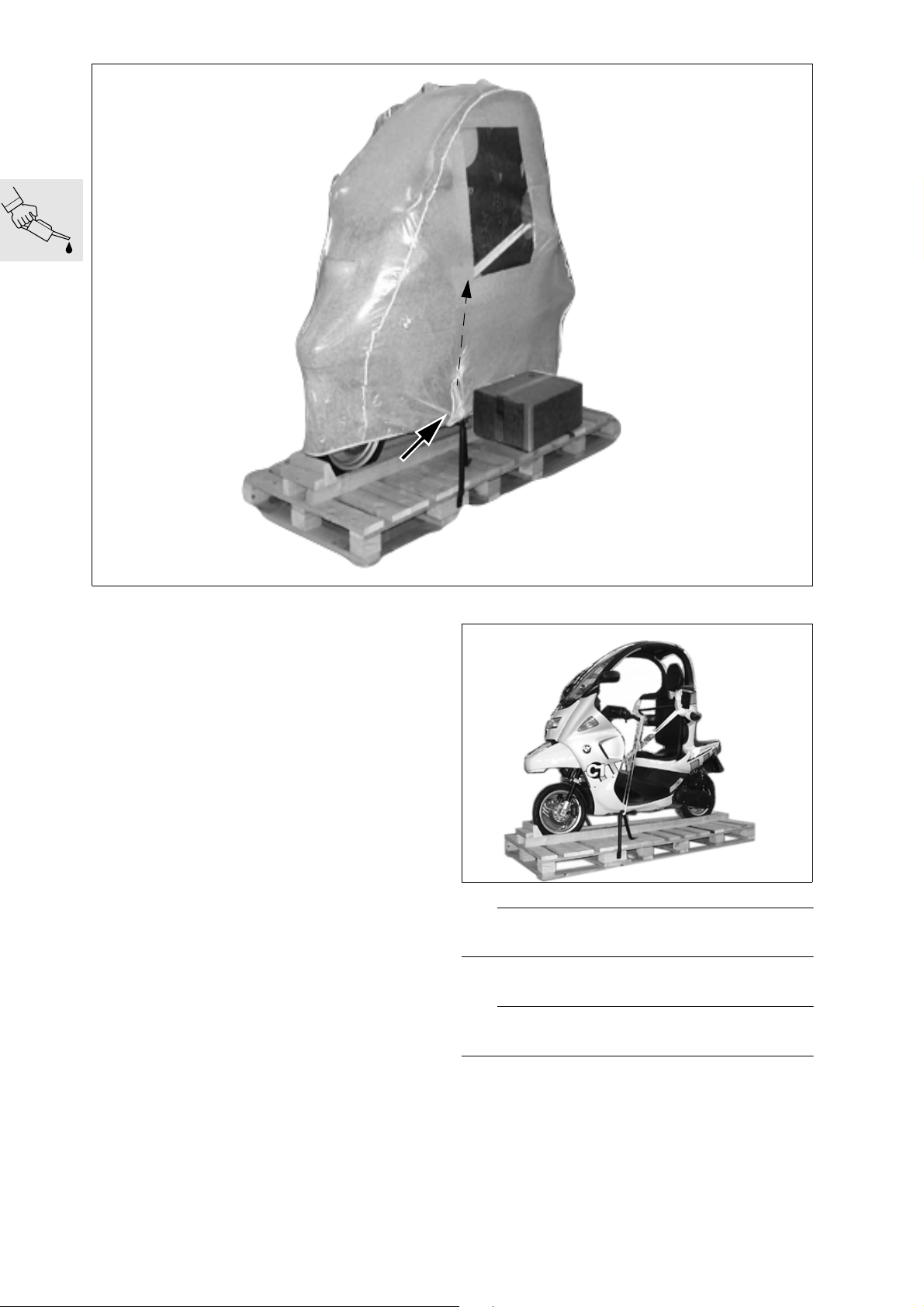

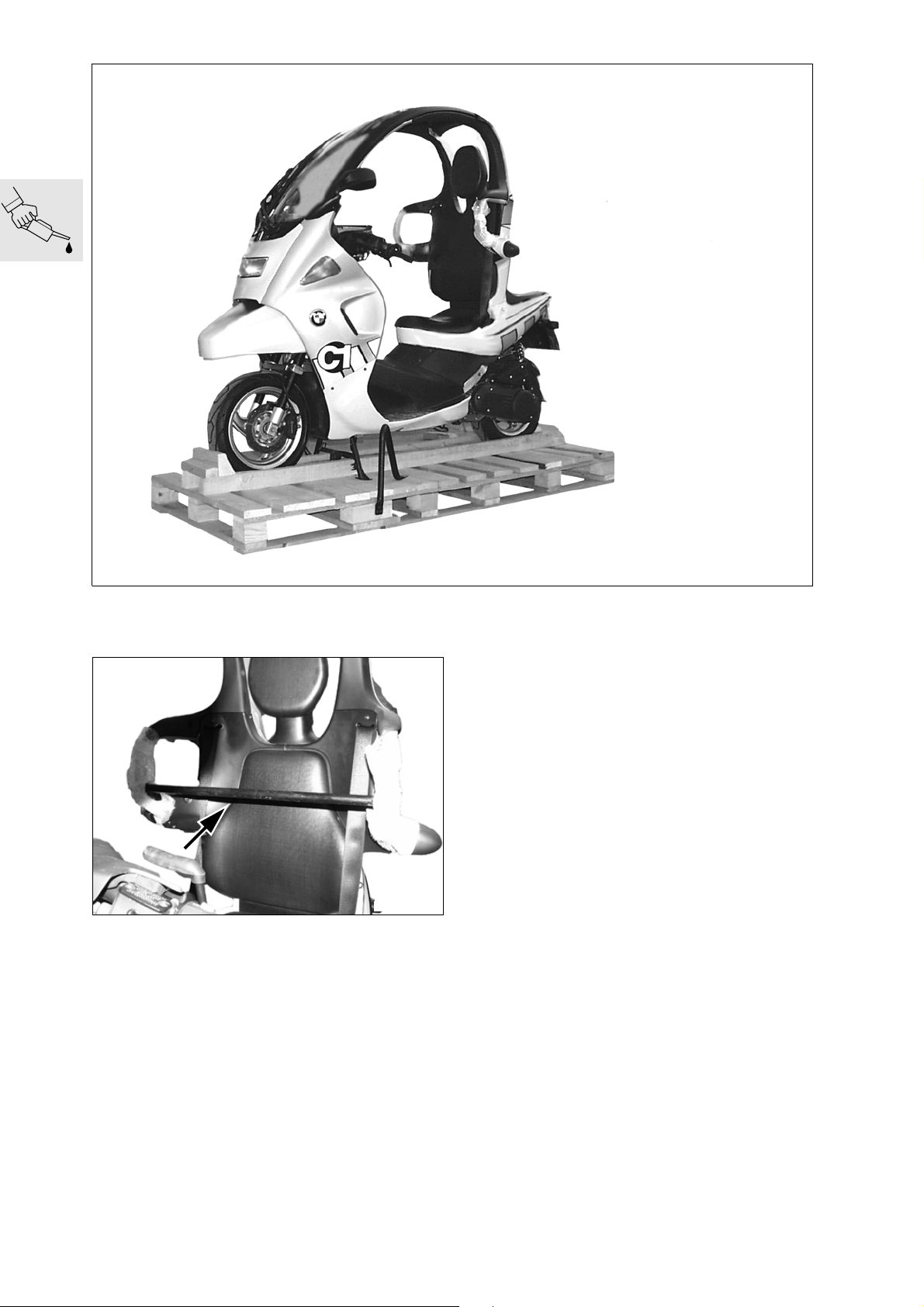

Unpack C1

Open shipping container at strap holes (enlarged

•

openings) on left and right sides

Remove any enclosed packages

•

–Luggage rack

Cut open along the line indicated (follows path of

•

strap)

Dismantle shipping container

•

e

Attention:

Loosen straps without yet removing!

Loosen straps

•

C1000340

C1000350

00.18

e

Attention:

Ensure that it will be possible to fold out the stand!

Page 29

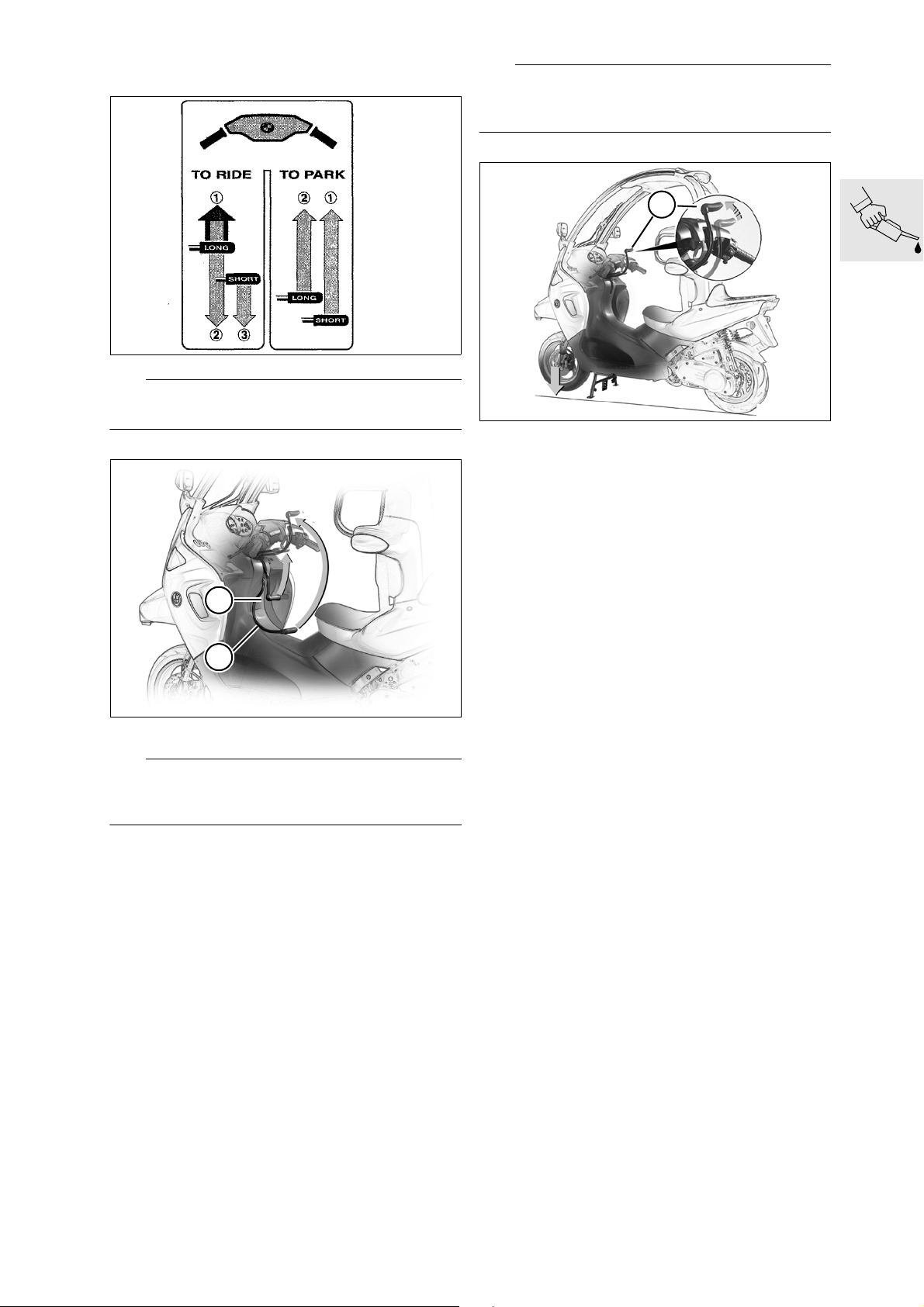

Place C1 on stand

L

Note:

Note instruction plate on instrument trim!

C1000360

L

Note:

The easy-lift mechanism has overload protection.

Fold out the stand with foot if necessary!

1

C1000370

Push up long lever (1) on easy-lift mechanism

•

until it reaches the end of its travel

– The front wheel lifts clear of the ground

– Keep a firm grip on the lever

Slowly move the long lever (1) back until the de-

•

tent engages

Check to verify that the C1 is standing securely

•

2

1

C100BA56

e

Attention:

Excessive strain can damage the easy-lift mechanism!

Hold C1 vertical

•

Centre the handlebar

•

Pull up short lever (2) on easy-lift mechanism

•

– The stand extends

00.19

Page 30

Release and remove straps

•

C1000390

Remove cross member (arrow, shipping brace)

•

C1000380

00.20

Page 31

e

Attention:

Use ramp to avoid damage.

Use ramp from motorcycle hoist, etc.

•

e

Attention:

Clear away any nails lying on the bottom of the shipping container or the shop floor.

C1000400

Take the C1 from the stand

e

Attention:

The stand must be folded all the way back before

the vehicle is rolled down!

Excessive strain can damage the easy-lift mechanism!

00.21

Page 32

Check that the stand is fully retracted

•

L

1

Note:

The easy-lift mechanism has overload protection. If

necessary, use your foot to retract the stand.

Push C1 off the pallet backwards

•

e

Attention:

Make sure the surface under the vehicle is level and

firm!

Do not park the C1 on slopes of more than 6°/12%,

as the stand may fail to provide secure support.

C1000370

Remove weight from vehicle

•

Release long lever (1) from the detent mecha-

•

nism by

– first moving the lever (1) on the easy-lift mecha-

nism all the way forward and up, and then slowly

pushing it downward

– Keep a firm grip on the lever

– The front wheel is lowered to the ground

2

1

C1000410

Hold C1 vertical

•

Push short lever (2) on easy-lift mechanism

•

downward

– The stand retracts

En sure t hat the lo ng lev er (1) is locked at the bot-

•

tom

Place C1 on stand (a 00.19)

•

e

Attention:

Do not cut adhesive tape - can damage shoulder

bar!

C1000420

Remove protective wrap from shoulder bar

•

Dispose of the shipping materials through eco-

•

logically sound channels, refer to bikebox

00.22

Page 33

Check C1 for damage

Record and problems

•

"Early warning card" to

•

BMW Motorrad, UX-VS-1

Fax number 089/382 332 20

+49 89 382 332 20

Rectify problems

•

Order any necessary parts via the electronic

•

parts catalogue

Submit expense claims through GW system

•

(Stage 4) Diagnosis codes:

– Missing parts 10 01 00 00 00

– Damaged parts 10 02 00 00 00

– Incorrect parts delivery 10 03 00 00 00

If required components are not available through the

electronic parts catalogue, please contact the

C1 support staff at UX-VS-2

Phone: 089/382 375 82

+49 89 382 375 82

Check package contents to determine whether consignment is complete

Optional equipment

•

Open rear storage compartment

•

Check contents of enclosed package:

•

On-board tool kit:

•

– Screwdriver with dual insert

– Pair of universal pliers

– Spark plug spanner

–1 angled Allen wrench

Torx T25

– Roadside assistance kit

Vehicle documentation

•

– Rider's Manual

– Service and technology manual

– Remove directory of European dealers from the

factory equipment package and enclose

– BMW roadside assistance service sticker (do-

mestic only)

Vehicle keys, 2

•

Please submit urgent queries and questions concerning technical issues to the C1 support staff at

UX-VS-2

Phone: 089/382 375 82

+49 89 382 375 82

00.23

Page 34

C1000430

Fill and charge the battery

Open cover of rear storage compartment

•

– Remove battery cover

– Remove the battery

a

....................................................See Group 61

d

Warning:

Battery acid is extremely caustic.

Protect your eyes, face, hands, clothing and the

paintwork!

Pull off battery vent hose

•

Remove battery

•

Fill battery with electrolyte, continuing until it

•

reaches upper graduation (arrow)

Allow the battery to stand for at least an hour

•

Shake the battery slightly to allow the remaining

•

air bubbles to escape

Refill to upper graduation as necessary

•

Recharge the battery or allow to stand for

•

24 hours

Charge current (amps)

.....................................10 % of rated capacity (Ah)

Use distilled water to top up the electrolyte, con-

•

tinuing until it reaches the upper graduation

Make a note of the charging date on the battery

•

e

Attention:

Start by tightening the battery' positive terminal,

then proceed to the negative side!

Apply acid-resistant grease to the bettary termi-

•

nals

Installing the battery

•

Install battery cover

•

Close rear storage compartment

•

Fluids and lubricants:

Acid-resistant grease ............................from Bosch

X

Torque specification:

Battery cable to battery terminals................... 3 Nm

00.24

Page 35

Use BMW MoDiTeC/DIS plus to access stored error codes

C1000010

Open seat by inserting ignition key in lock at the

•

left rear

Release backrest mount and remove backrest

•

Connect diagnosis unit to diagnosis plug

•

Access stored error codes

•

Carry out any repair operations indicated

•

Install backrest

•

Check tyre inflation pressures

Check/correct tyre inflation pressures

•

Tyre inflation pressures:

One-up.............................. Front 1.9 bar (27.56 psi)

.......................................... Rear 2.1 bar (30.46 psi)

Full load ............................ Front 2.1 bar (30.46 psi)

.......................................... Rear 2.4 bar (34.81 psi)

Add fuel

Open the seat

•

Pour in fuel

•

Operation check as final inspection

C1000040

Check engine oil

•

Safety belt release mechanism

•

Clutch engagement speed

•

Steering

•

Front and rear brakes

•

Check lights and signalling equipment:

•

– Front and rear parking lamps

– Instrument illumination

– Headlamp, high beam, headlamp flasher

– Brake lamp (actuation of front and rear brakes)

– Left/right turn signals

–Horn

– Indicator and warning lights

– Instruments

Check any optional equipment to confirm that it

•

is operational, check ABS, carry out driving test.

When vehicle is ridden for at least 10 seconds at

over 30 km/h (19 miles/h) the ABS warning lamp

will come on if there any problems in the ABS

Conduct road test as required

•

Confirm delivery in service and technology man-

•

ual

Respond to problems by refering to "Checking

•

C1 for defects"

00.25

Page 36

Final cleaning

Vehicle delivery

Cleaning the C1

•

L

Note:

Do not use steam cleaners or high-pressure spray

wands. High water pressure can lead to damage affecting seals as well as the hydraulic and electrical

systems.

L

Note:

To ensure optimal orientation of every licence plate,

the licence plate holder is not equipped with sockets!

To promote optimal levels of safety and foster satisfaction, the customer should be acquainted with the

C1 as part of the delivery process.

Show/explain the following to the customer:

•

– On-board literature and its storage location

– Owner's manual for description of functions

– Service and technology for service activities on

the C1

– On-board tools and their location

– Operation of the easy-lift mechanism

– Safety belt use - starting lockout

– Central belt release mechanism

– Starting with rear brake engaged - clutch en-

gagement speed

– Windscreen wiper and washer fluid refill cap lo-

cation

– Oil and brake fluid level checks

– Mirror adjustment

– Controls

– Instruments and warning lamps

– Any optional equipment

The customer must be informed of the following:

•

– Break-in information and service intervals

–Helmet laws

–Safety check

00.26

Page 37

00

00 Maintenance

Contents

Maintenance intervals

1,000 km/600 miles Inspection .........................................................................................................31

BMW Service ...................................................................................................................................31

BMW Inspection ...............................................................................................................................31

BMW Annual Service ........................................................................................................................31

Reading out BMW MoDiTeC/DIS and error codes stored in ECU

(Inspections I, II, III and IV) ................................................................................................................31

Engine oil change

(Inspections I, II, III and IV) ................................................................................................................32

Drain engine oil and clean magnetic plug .........................................................................................32

Clean oil filter screen ........................................................................................................................32

Replace oil filter element .................................................................................................................. 32

Refill engine with oil ..........................................................................................................................33

Gearbox oil change

(Inspection III, IV) every 30,000 km/18,000 miles or every 3 years .................................................... 33

Checking coolant

(Inspections I and III) ........................................................................................................................34

Adding coolant .................................................................................................................................34

.............................................................................................................31

...................31

....................................................................................................................... 32

...................................................................................................................33

....................................................................................................................... 34

Page

Change coolant

(Inspection IV, every 2 years) .............................................................................................................35

Drain coolant ....................................................................................................................................35

Draining expansion tank ...................................................................................................................35

Adding coolant .................................................................................................................................35

Checking valve clearances

(Inspections I, II and III) .....................................................................................................................36

Swivel out powertrain cradle

Checking valve clearances

Adjusting valve clearances

Replace spark plug

(Inspections II and III) ........................................................................................................................42

Replacing air cleaner element

(Inspections II and III) ........................................................................................................................43

Empty drain pipe from intake-air plenum chamber

(Inspection IV) ................................................................................................................................... 43

Checking brake lines

(Inspections II and III) ........................................................................................................................44

Checking brake lines ........................................................................................................................ 44

........................................................................................................................... 35

...................................................................................................36

....................................................................................................36

.......................................................................................................38

.......................................................................................................39

...................................................................................................................42

............................................................................................43

................................................. 43

................................................................................................................44

Checking brake system operation and inspect for leaks

(Inspections II and III) ........................................................................................................................ 44

.....................................44

00.27

Page 38

Contents

Page

Checking brake fluid level

(Inspections I, II and III) .....................................................................................................................44

Checking fluid level in the closed brake fluid reservoir

Checking fluid level in the open brake fluid reservoir

Checking brake pads and discs for wear/replacing

(Inspections II and III) ........................................................................................................................46

Checking brake pads for wear

Front brake pads .............................................................................................................................. 46

Rear brake pads ...............................................................................................................................46

Replacing brake pads

Front brake .......................................................................................................................................47

Rear brake ........................................................................................................................................48

.................................................................................................................47

Checking the brake discs

Replacing brake fluid

(Inspection IV) ................................................................................................................................... 50

Front brake

Drawing off brake fluid/forcing back brake pistons ...........................................................................50

Bleed the front brake circuit .............................................................................................................51

....................................................................................................................................... 50

.....................................................................................................44

................................................ 44

................................................... 45

............................................... 46

................................................................................................46

.........................................................................................................49

...............................................................................................................50

Rear brake

Drawing off brake fluid/forcing back brake pistons ...........................................................................51

Bleeding rear brake circuit ................................................................................................................ 52

Variator drive belt replacement

(Inspections II and III) ........................................................................................................................52

Check belt

Checking clutch lining

(Inspection III) ...................................................................................................................................54

Clean variator filter screen

(Inspections II and III) ........................................................................................................................54

Drive variator

Remove drive variator

Check, clean and grease drive variator (lubricated version)

(Inspection II, III) (lubricated version) .................................................................................................55

Check and clean drive variator (unlubricated version)

(Inspection II, III) (unlubricated version) ............................................................................................. 57

........................................................................................................................................ 51

..........................................................................................52

........................................................................................................................................ 53

.............................................................................................................54

....................................................................................................54

................................................................................................................................. 55

.................................................................................................................55

......................................55

................................................. 57

Replacing complete drive variator

(Inspection II) every 22,500 km (13,500 miles) – lubricated version only ...........................................58

Checking wheel bearing float

(Inspection III) ...................................................................................................................................59

00.28

....................................................................................58

..............................................................................................59

Page 39

Contents

Page

Check to ensure that leading link bearing has zero play

(Inspection I, IV) ................................................................................................................................60

Checking steering bearing play ........................................................................................................60

Check battery electrolyte level - add distilled water if necessary

(Inspection IV) ................................................................................................................................... 60

Checking battery electrolyte level

Adding distilled water .......................................................................................................................61

Clean/grease battery terminals if necessary

(Inspection IV) ................................................................................................................................... 61

Checking Bowden cables

(Inspections III and IV) ......................................................................................................................61

......................................................................................................61

Checking windscreen washer

(Inspections I, II and III) .....................................................................................................................62

Check windscreen wiper

(Inspections II, III and IV) ...................................................................................................................62

Checking safety elements

(Inspections I, II, III and IV) ................................................................................................................62

.......................................................................................................62

.....................................................................................................62

Check Bowden cable for central seat-belt release

..........................................................................................60

.............................................................. 61

.............................................................................................62

........................................................ 62

.....................................60

..................60

Check belt straps and belt buckles

Check inertia reels

....................................................................................................................... 62

......................................................................................62

Check inertia-reel's detent mechanism to ensure that it engages correctly

Examine crash elements

(Inspections I, II, III and IV) ................................................................................................................63

Check shoulder bar and deformation element

(Inspections I, II, III and IV) ................................................................................................................63

Measure shoulder bar

Replacing fuel filter

(Inspection II) every 37,500 km (22,500 miles) .................................................................................. 63

...................................................................................................................63

........................................................................................................63

.......................................................... 63

.................................................................................................................63

Replacing boot in brake-control assembly (master cylinder), only

with optional ABS

(Inspection III) every 30,000 km (18,000 miles ) ................................................................................. 64

Check mounts

(Inspection I) .....................................................................................................................................65

Final inspection with road safety and operation check

(Inspections II, III and IV) ................................................................................................................... 65

Tyre tread depth (recommended minimum) .......................................................................................65

Tyre pressures (tyres cold) ................................................................................................................65

Roadworthiness check .....................................................................................................................65

....................................................................................................................... 64

.............................................................................................................................. 65

........................................ 65

......62

00.29

Page 40

00.30

Page 41

00

Maintenance intervals

1,000 km/600 miles Inspection

BMW Break-in Inspection after the initial 1,000 km/

600 miles

BMW Service

At the end of the first 7,500 km/4,500 miles

and then at intervals of 15,000 km/9,000 miles,(at

22,500 km, 37,500 km…/13,500 miles,

22,500 miles… )

BMW Inspection

At the end of the first 15,000 km/9,000 miles

and then at intervals of additional 15,000 km/

9,000 miles,(at 30,000 km, 45,000 km…/18,000 miles,

27,000 miles…)

BMW Annual Service

Although many service operations are scheduled

according to milage, many procedures (such as

brake fluid changes) should be carried out at least

once a year, regardless of elapsed milage.

If these operations are not performed in the course

of a standard, milage-based Service or Inspection,

an extra visit for an Annual Service will be required.

The codes for service and maintenance intervals in

this repair manual are as follows:

Reading out BMW MoDiTeC/DIS and error codes stored in ECU

(Inspections I, II, III and IV)

Open the seat

•

Remove the backrest

•

C1000010

Connect

•

ble to diagnostic interface (arrow)

L

Note:

Follow the instructions in the diagnosis program.

MoDiTeC/DIS plus diagnosis ca-

BMW

– BMW Inspection at 1,000 km/600 miles ............

– BMW Maintenance Service every

7,500 km/4,500 miles .......................................

– BMW Inspection every 15,000 km/9,000 miles

– BMW Annual Service ......................................

Operations specified for extended-milage vehicles:

a

Replacement of complete drive variator (

a

............................. Refer to Assembly Group 24

.......................................... for more information

Vehicles with ABS: replace handbrake fittings (rubber diaphragm on brake master cylinder) (

a

............................. Refer to Assembly Group 32

.......................................... for more information

Replace fuel filter (a00.63)

a

............................. Refer to Assembly Group 16

.......................................... for more information

00.58)

a

00.64)

I

II

III

IV

00.31

Page 42

Engine oil change

(Inspections I, II, III and IV)

Drain engine oil and clean magnetic plug

Clean oil filter screen

L

Note:

Drain the engine oil only after the engine has

warmed to normal operating temperature!

e

Attention:

Observe all safety precautions when allowing an internal-combustion engine to run in an enclosed area!

1

Unscrew oil filter screen bolt (2)

•

Clean oil filter screen

•

Replace oil filter element

2

C1000022

11 7 661

Unscrew magentic oil drain plug (1)

•

Clean magnet

•

C1000022

Secure oil guard

•

haust

Unscrew oil filter cover bolts (arrows)

•

BMW No. 11 7 661

C1000330

to the ex-

00.32

BMW recommends Castrol

Page 43

Fluids and lubricants:

Engine oil ................................ 1.0 l/1.76 Imp pints

Brand- name HD oi l, AP I cl a ssi fica tion SF, S G or S H;

suffix letters CD or CE are approved; alternatively,

brand-name HD oil with CCMC classification G4 or

G5; suffix PD2 is permitted.

X

Tightening torque:

Oil filter cover ............................................... 10 Nm

Magnetic oil drain plug ................................. 20 Nm

Oil filter screen attachment bolt.................... 30 Nm

Replace oil filter element

•

Refill engine with oil

L

Note:

Replace drain plug seal rings!

C1000030

C1000040

Gearbox oil change

(Inspection III, IV) every 30,000 km/18,000 miles

or every 3 years

1

Unscrew oil drain plug (1)

•

Pour gearbox oil in filler opening (2)

•

Fluids and lubricants:

GL 4 gear lubricant ................ 0.09 l/0.16 Imp pints

2

C1000500

Add engine oil through oil filler neck

•

Add oil up to the MAX mark on the dipstick

•

Run the engine briefly, then switch it off and

•

check oil level again: add oil if necessary

Check coolant level and top up as required

•

00.33

Page 44

Checking coolant

Adding coolant

(Inspections I and III)

max

min

C1000050

L

Note:

Check coolant level only with the engine cold!

Open the seat and check the coolant level

•

Maximum level ............................................

Minimum level ..............................................

"max"

"min"

– Remove the backrest

1

2

C1000060

Remove cap (1) from expansion tank (2)

•

e

Attention:

Add or refill coolant only when engine is cold. Add

coolant to expansion tank only if a small quantity has

been lost. Otherwise refill with coolant (a17.15).

Reinstall cap (1)

•

00.34

Page 45

Change coolant

(Inspection IV, every 2 years)

Drain coolant

– Remove front fairing panel

– Loosen radiator cap

C1000071

Adding coolant

Pour coolant into filler neck

•

C1170290

Slip hose (arrow) over screw head

•

Remove drain plug

•

Drain coolant

•

L

Note:

Replace drain plug seal!

Tighten drain plug

•

X

Torque specification:

Drain plug..................................................... 10 Nm

Draining expansion tank

L

Note:

If powerplant cradle is pivoted expansion tank may

be accessed under lock fitting. Alternatively, draw

off coolant with a syringe or similar.

1

C1000080

Open vent screw (1) in cylinder head to bleed air

•

from system, reclosing only after coolant starts

to emerge

To top up coolant in expansion tank

•

Run the engine briefly, then stop it, recheck cool-

•

ant level and top up if necessary

Capacities:

Cooling system ...................... 1.25 l/2.20 Imp pints

Expansion tank ........................ 0.2 l/0.35 Imp pints

e

Attention:

Use only nitrite-free extended-duty antifreeze with

corrosion inhibitor!

Mixture ratio:

Water .............................................................. 50%

Antifreeze.........................................................50%

Protection down to .............................—25 °C/77 °F

00.35

Page 46

Checking valve clearances

(Inspections I, II and III)

Swivel out powertrain cradle

Secure front wheel

•

Remove wiring from clip (arrow):

•

- Alternator

- Ignition unit

C1000090

Remove wiring from clip:

•

- Injector

- Air temperature sensor

- Idle actuator

- Coolant temperature sensor in cylinder head

C1000110

Open the seat

•

C1000100

Release clip and disconnect plug from oxygen

•

sensor (arrow)

C1000120

Release coolant hose from clamp at injector and

•

on variator cover bracket (arrow)

00.36

Page 47

C1000130

e

Attention:

To avoid stretching hoses and lines, do not swivel

the powertrain cradle more than 20°!

Lift C1 no further than stop: powertrain cradle

•

swivels down

When installing:

Install the cylinder head cover before swiveling

•

the powertrain cradle back into place

e

Attention:

Ensure that gasket and cover are free of oil!

Remove hose from bracket on intake-air plenum

•

chamber (arrow)

33 1 531

00 1 580

00 1 570

C1000140

Position vehicle jack

•

tachment

Raise the vehicle slightly

•

Install fixture,

•

spring strut and powertrain cradle

Remove lower end of right spring strut from

•

brake caliper holder

BMW No. 00 1 580

BMW No. 33 1 531,

BMW No. 00 1 570

at separation point

between left

with at-

Installing cylinder head cover

•

e

Attention:

When lowering note positions of struts and intakeair plenum chamber!

L

Note:

Ensure that the detent engages to secure the long

lever on the easy-lift mechanism. If necessary, move

the lever to the drive position first, and then move it

to the park position.

X

Tightening torque:

Cylinder head cover ..................................... 10 Nm

Strut, lower .................................................. 21 Nm

00.37

Page 48

Checking valve clearances

– Remove left and right service covers

– Swivel out powerplant cradle

17 5 500

1

Open hose clamp (arrow) with pliers

•

BMW No. 17 5 500

Unscrew cylinder head cover bolts (1)

•

C1000150

C1111001C1000170

Measure valve clearance using single feeler

•

gauge blade

Record the valve clearances

•

and adjust valve clearance as indicated (replace

•

valve lifters)

Specified clearances:

C1000160

Watch throttle (arrow)

•

Remove spark plug

•

Use camshafts to rotate engine until the lobes

•

are pointing outward

IV left

mm (in)

0.05

Spec.

clearance

Clearance,

measured

(used)

Difference

Inlet valve clearance........................0.05…0.09 mm

............................................ (0.00197…0.00354 in)

Exhaust valve clearance..................0.20…0.29 mm

............................................ (0.00787…0.01147 in)

(0.00197)

0.09

(0.00354)

0.15

(0.00590)

0.01

(0.00039)

IV right

mm (in)

0.05

(0.00197)

0.09

(0.00354)

EV left

mm (in)

0.20

(0.00787)

0.29

(0.01147)

0.15

(0.00590)

-0.05

(-0.00197)

EV right

mm (in)

0.20

(0.00787)

0.29

(0.01147)

00.38

Page 49

Adjusting valve clearances

To foster enhanced clarity, some of the illustrations

show components with the powerplant cradle removed

– Swivel out powerplant cradle

– Checking valve clearances

C1130010

Loosen hose clamp (arrow) on intake-air plenum

•

chamber

11 7 651

C1000220

Remove Allen bolt adjacent to starter and use

•

special bolt,

L

Note:

Because the round cover plate can rotate against

the gear, the TDC mark should always be made on

the gear itself - not on the cover plate

BMW No. 11 7 651,

to lock at TDC

C1000200

L

Note:

Watch for dirt and contamination around the starter/

threaded plug (arrow) - no contamination in engine!

C1000180

Use a coloured marker to mark TDC (arrow) on

•

the inlet camshaft's sprocket

00.39

Page 50

Release chain tensioner bolt (arrow)

•

C1000231

L

Note:

Watch bolt length and take care to install in correct

positions,

lettering is to the outside, use coloured marker to

identify end as necessary!

C1000190

Detach mounts (arrows) from chain guide and re-

•

move

C1110910

Press chain tensioner to the outside using chain

•

tensioning rail

L

Note:

The bolts on the chain guide mechanism are secured with thread-locking compound!

L

Note:

The camshafts can also be removed and installed

with the sprockets in place!

L

Note:

The camshaft sprocket is secured with locking compound!

Undo bolts and remove camshaft sprokets

•

L

Note:

Make sure that the timing chain does not drop into

the housing. Use a retainer to keep timing chain tensioned at all times!

Secure the timing chain to prevent it from falling

•

00.40

Page 51

L

Note:

Note the length of the bolts used to attach the camshaft bearing cap!

C1000232

Subtract negative difference of bucket (old)

•

Add positive difference of bucket (old)

•

Note sizes of available bucket tappets

•

L

Note:

The bucket tappets are available in sizes ranging

from 2.50 mm (0.09842 in) to 3.20 mm (0.12598 in)

in 5/100ths graduations.

Should it prove impossible to adjust the valve clearance with the smallest bucket tappet (2.50 mm/

0.09842 in) the cylinder head will have to be re-

a

placed (

If it is not possible to adjust the valve clearance with

the largest bucket tappet (3.20 mm/0.12598 in) the

valve seat will have to be reground (a11.30).

When installing:

While installation is basically a reversal of the re-

•

moval process, careful attention should be directed toward the following operations:

11.40).

Remove 8 bolts

•

Remove camshaft bearing cap

•

Removing camshafts

•

Remove camshaft bearing seat

•

Remove the tappet

•

Record the figures on the bottoms of the tappets

•

Sample calculation:

Spec.

clearance

Clearance,

measured

(used)

Difference

Bucket,

measured

(used)

Bucket

specification (new)

Bucket,

measured

(new)

Clearance

specification (new)

IV left

mm (in)

0.05

(0.00197)

0.14

(0.00551)

0.15

(0.00590)

0.01

(0.00039)

2.80

(0.11023)

2.81

(0.11062)

2.85

(0.11220)

0.10

(0.00394)

IV right

mm (in)

0.05

(0.00197)

0.14

(0.00551)

EV left

mm (in)

0.20

(0.00787)

0.29

(0.01147)

0.15

(0.00590)

-0.05

(-0.00197)

2.80

(0.11023)

2.75

(0.10826)

2.75

(0.10826)

0.20

(0.00787)

EV right

mm (in)

0.20

(0.00787)

0.29

(0.01147)

e

Attention:

The grooves in the bearing caps are oil passages!

Note the lengths of the camshaft bearing cap bolts!

C1110111

e

Attention:

Align bearing caps, make sure that bearing caps

and bearing seats are correctly aligned. Run a finger

along the joint to check alignment!

Remove traces of Loctite from threads of cam-

•

shafts and chain guide

Coat threads of fasteners for chain guide and

•

camshaft gear with Loctite

The inlet camshaft bears a punch mark (arrow) as

•

identification

Make sure that the camshafts turn easily and

•

smoothly

Clearance,

measured

(new)

00.41

Page 52

L

Note:

Always renew the screw plug's sealing ring!

Install chain tensioner (a11.33)

•

e

Attention:

Remove TDC set bolt,

BMW No. 11 7 651.