Page 1

MT3870

CONVEYOR OVEN

SERVICE AND REPAIR MANUAL

BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (802) 658Ć6600 Fax: (802)864Ć0183

PN M7489 Rev B (6/01)

Duplication of the information in this manual is prohibited without the consent of the Blodgett Service Department.

1996 - G.S. Blodgett Corporation All rights reserved.

Page 2

TABLE OF CONTENTS

1. INTRODUCTION

Oven Specifications 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation Requirements 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Specifications 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Illustrated Parts Lists 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. ASSEMBLY

Oven Assembly Procedures 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Air Diverters 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Nozzles 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conveyor Rack Assemblies 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire Conveyor Belt 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Chain 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Plates 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End Plugs 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conveyor Belt Tensioners 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crumb Pans 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mount Remote Control 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

False Front (If Applicable) 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. OPERATION

Computer Controller 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Description 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Procedures 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Information 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequence of Operation 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Domestic and General Export Ovens 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Ovens 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oven Adjustments for Cooking 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conveyor Speed Time vs. Temperature 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Flow Adjustments 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. CALIBRATION AND ADJUSTMENT

Convection Blower Motors 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To check motor rotation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To check lowĆlimit 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulated Gas Pressure 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Computer Control Configuration 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Calibration 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 3

TABLE OF CONTENTS

Belt Speed Calibration 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closed Loop System 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open Loop System - Single belt 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open Loop System - Twin Belt 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

motor control Board Adjustment 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rerating the Appliance 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Firing Rate 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. TROUBLESHOOTING

DC Drive System 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Computer Control System 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heating System 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Convection System 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. TECHNICAL APPENDIX

Intermittent Ignition System 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Principles of Operation 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Procedures 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing the Invent Hood 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Illustrated Parts List 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Maintenance 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing Access 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Conversion 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conversion Factors 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooking Computer - Temperature vs Resistance 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 4

Literature Addendum

Operation - Cooking Computer without Conveyor Control

NOTE: This addendum applies to tandem ovens only.

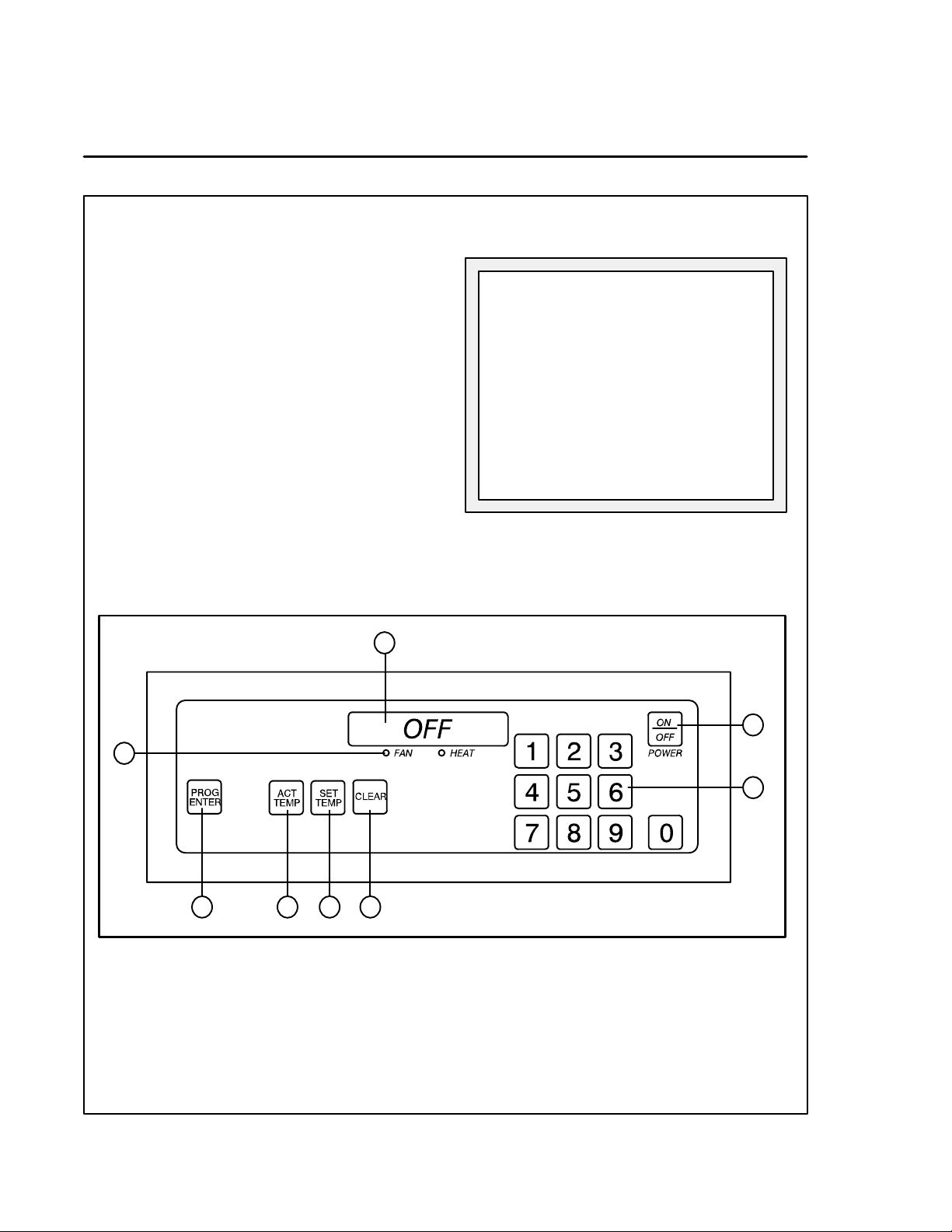

CONTROL DESCRIPTION

1. DIGITAL DISPLAY - Displays the time, temĆ

perature and controller related information.

2. OVEN ON/OFF - Controls power to the

oven.

3. NUMERIC KEYS - Used to enter numerical

data in the programming mode.

4. CLEAR KEY - Used to clear the display if an

error is made in the programming mode.

5. SET TEMP KEY - Used to view or program

the temperature setpoint.

6. ACT TEMP KEY - Used to view the current

oven temperature.

7. PROG/ENTER KEY - Used to enter and exit

the programming mode. Also used to lock

in programmed settings.

8. STATUS LAMPS - When lit indicate that the

fan or burners are operating.

This oven, supplied with remote

control, is equipped with an emerĆ

gency shut down switch.

Should you need to stop the heat

press the emergency switch.

Do not use the emergency switch as

a GENERAL on/off switch!

NOTE:

WARNING:

1

2

8

3

4567

??????

Rev - 10/9/96

Page 1 of 3

Page 5

Literature Addendum

Operation - Cooking Computer without Conveyor Control

OPERATION

To turn the oven on:

1. Turn the manual gas valve to ON.

2. Press and hold the ON/OFF key (2). The disĆ

play reads OFF when the oven is idle.

3. The display will flash WAIT LOW SET

TIME 0.

4. The FAN and HEAT status lamps (9) light.

The fans begin to run. The heat rises to the

temperature setting stored in the computĆ

er's memory. The conveyor default time is 0.

To display the actual oven temperature:

1. Press the ACT TEMP key (6). The LED on

the key will light and the display reads ACĆ

TUAL nnnnF.

To view the temperature set point:

1. Press the SET TEMP key (5). The LED on the

key will light and the display flashes SET

TEMP nnnnF.

To turn the oven off:

1. Press the ON/OFF key (2). The fans will conĆ

tinue to run until the oven cools to a safe

temperature.

OVEN SHUTĆDOWN

Turn the Computer Controller off (press and moĆ

mentarily hold the ON/OFF key). Since the Cool

Down circuit is already energized, the blower

motor(s) will continue to run until the oven

reaches approximately180F (82C). The blowĆ

er motor(s) will then automatically shut off.

COOLĆDOWN CIRCUIT

Blodgett Mastertherm conveyor ovens are

equipped with a coolĆdown feature for motor

shaft and bearing protection. When the oven

reaches approximately 180F (82C), the relay

contacts close allowing the blower motor(s) to

continue to run regardless of the Computer

Controller status. As noted previously, the blowĆ

er(s) will continue to run until the temperature

drops below 180F (82C).

NOTE:

This oven, supplied with remote

control, is equipped with an emerĆ

gency shut down switch.

Should you need to stop the heat

press the emergency switch.

WARNING:

Do not use the emergency switch

as a GENERAL on/off switch!

2

M7260.1

Rev - 9/5/96

Page 6

Literature Addendum

Operation - Cooking Computer without Conveyor Control

PROGRAMMING PROCEDURES

Programming the Cook Time:

1. The conveyor belt default time is 0.

Programming the Temperature:

1. Press the PROGRAM/ENTER key (8).

2. Press the SET TEMP key (5). The display

reads PROGĆ? SET TEMPĆ? _ _ _ _F.

3. Use the NUMERIC keys (3) to enter the deĆ

sired temperature set point. The control disĆ

plays the numbers as they are entered. If an

error is made, press the CLEAR key (4) and

reĆenter the number.

4. Press the PROGRAM/ENTER key (8) again.

5. Press the PROGRAM/ENTER key (8) a secĆ

ond time to lockĆin the new temperature.

The new temperature setpoint will be stored

in the computer's memory.

Operation at the Programmed Settings:

1. Press and hold the ON/OFF key (2).

2. The FAN and HEAT status lamps (9) light.

The fans begin to run. The heat rises to the

temperature setting stored in the computĆ

er's memory.

3. The display will flash WAIT LOW SET

TIME 0 until the programmed bake temperĆ

ature is reached. The HEAT lamp (9) will reĆ

main lit until the oven reaches the temperaĆ

ture set point.

4. The display reads READY and the HEAT

lamp (9) goes out.

5. The oven is now ready to accept product.

6. Press and hold the ON/OFF key (2) to turn

the oven off. The fans continue to run while

the oven cools to a safe temperature.

DISPLAY INFORMATION

WAIT LOW - indicates that the present oven

temperature is lower than the set point temĆ

perature. When the oven reaches the set

point temperature the display changes to

READY.

READY - indicates that the oven is ready to

accept product.

SET TIME 0 - indicates the current cook

time setting.

HIGH TIME - indicates that the temperature

is well above the set point. This usually occurs

when moving from a higher āto a lower temperĆ

ature. Wait until the display reads ready beĆ

fore loading product.

HIGH TEMP LIMIT - indicates that the oven

temperature exceeds the high limit. The Over

Temperature Alarm buzzer will sound. Shut

the oven off and wait for the unit to cool down.

HIGH TEMP PANEL - indicates that the

control area reaches an excessive temperaĆ

ture. Shut the oven off and wait for the unit to

cool down.

PROBE OPEN PROBE SHORT - indicates

that the temperature sensor has failed. The

Alarm buzzer sounds. Shut the oven off and

contact a service representative.

NOTE:

This oven, supplied with remote

control, is equipped with an emerĆ

gency shut down switch.

Should you need to stop the heat

press the emergency switch.

WARNING:

Do not use the emergency switch

as a GENERAL on/off switch!

??????

Rev - 10/9/96

Page 3 of 3

Page 7

CHAPTER 1

INTRODUCTION

Page 8

MT3870

OVEN SPECIFICATIONS

VENTILATION REQUIREMENTS

The hood should completely cover the unit with an

overhang of at least 6" (15 cm) on all sides not adjaĆ

cent to a wall. The distance from the floor to the

lower edge of the hood should not exceed 7' (2.1

m). The ventilation system should replace 80% of

the exhaust volume with fresh make up air.

TABLE 1 should be used as a guideline.

Single Double Triple

CFM 1200Ć1650 2400Ć3300 3600Ć5000

M3/min 34 Ć 47 68Ć93 102Ć142

TABLE 1

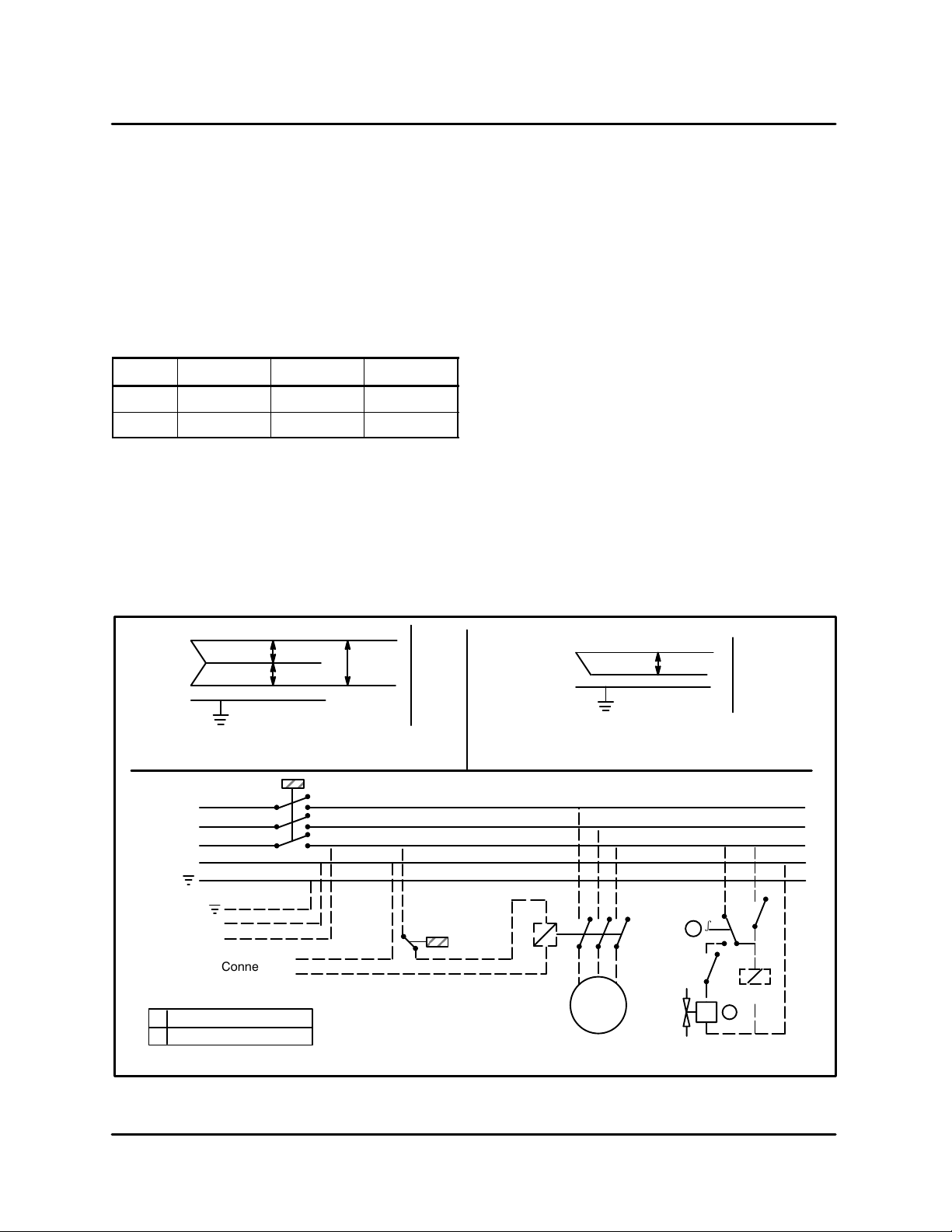

ELECTRICAL SPECIFICATIONS

NOTE: Three Phase hookup is not permitted.

WARNING: DO NOT INSTALL A HIGH LEG" TO

ANY CONVEYOR OVEN!

L1

N

L2

120

120

208Ć240

OvenSupply

Installations within the U.S.

The MT3870 requires a 15 Amp, 60HZ, 1F,

208Ć240VAC, 4 wire service consisting of L1, L2,

neutral and ground. See FIGURE 1. Use 90C wire

and size to National Electric or local codes.

Installations outside the U.S.

The MT3870 requires a 15 Amp, 50Hz, 1F, 230

VAC, 3 wire service consisting of L1, neutral and

ground. See FIGURE 1. Use 90C wire and size

wire according to local codes.

CE approved installations

Connect the oven to a separate group 230V, 50 hz

with rigid connection and circuit breaker. The cirĆ

cuit breaker should disconnect all poles, including

neutral with a contact separation of at least 3 mm.

NOTE: The burner control unit is phase sensitive.

If the phase and neutral are switched the

control locks out.

Connect exhaust fan connector 1 and 2. See

FIGURE 1. Connect phase + neutral + ground.

L1

N

220Ć230

OvenSupply

U.S. Installations Export Installations

L3

L2

L1

N

Blodgett

Connector

21Air Pressure Regulator

N

L

Connector

Burner Control Solenoid

2Ć4Ć92

s

2

1

2

Fan

A2

A1

Relay A

1

CE Approved Installations

FIGURE 1

1-1

Page 9

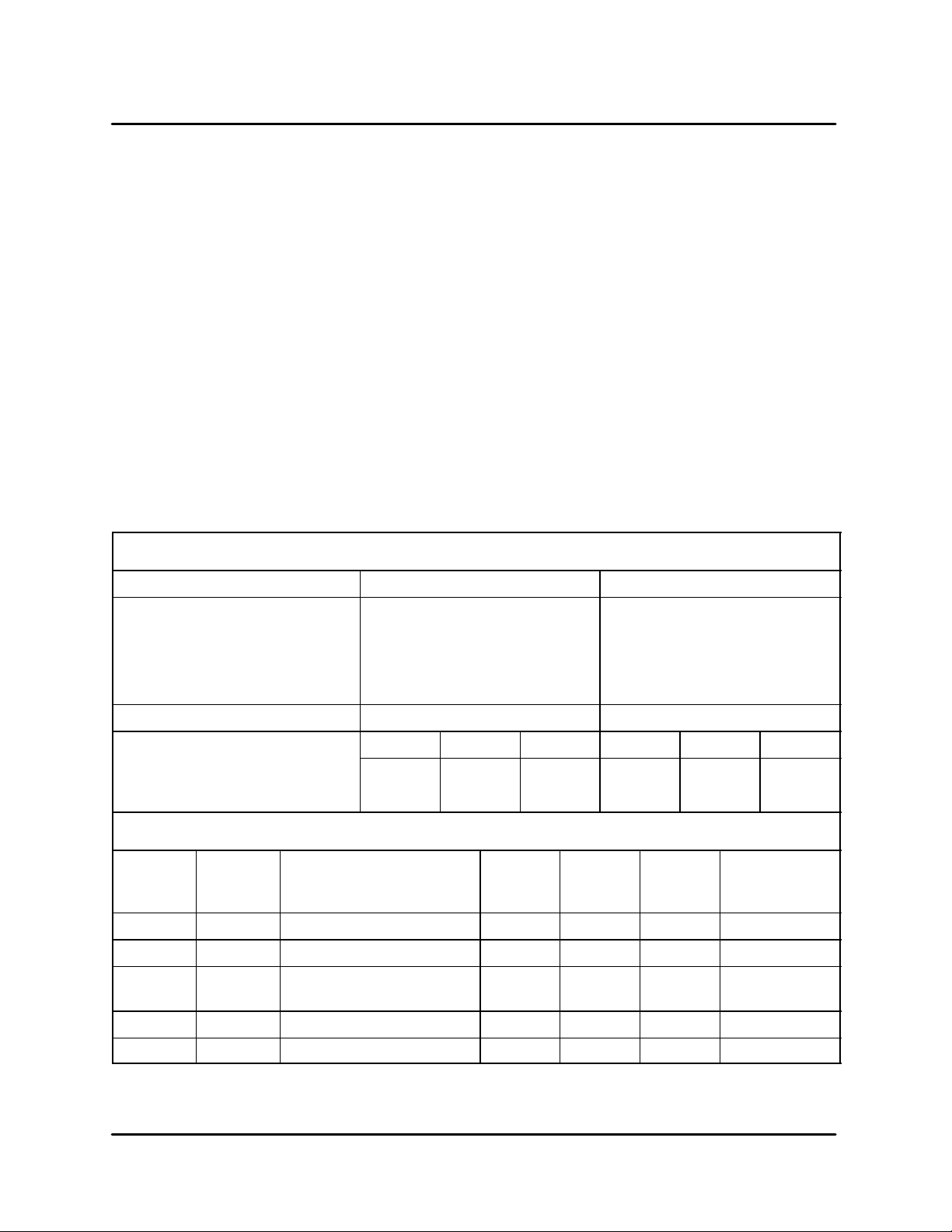

GAS SPECIFICATIONS

INTRODUCTION

GAS CONNECTIONS

Domestic and General Export installations

The gas line should be large enough to accommoĆ

date the peak demand of all the gas appliances.

TABLE 2 reflects a straight line, 50 foot run with no

coupling restrictions and no other appliances

drawing service. Gas line installations MUST conĆ

form to National Fuel Gas Code NFPA 54/ANSI

Z223.1 Sec. 1.4 (Latest Edition). TABLE 2 should

be used as a guideline only.

NOTE: For any pipe runs over 50 feet (15 m), conĆ

sult the factory.

CE approved installations

1. Connect the oven to the gas line with the propĆ

er type of gas according to Local and National

Installation Standards. See TABLE 2.

DOMESTIC AND GENERAL EXPORT

Natural Gas Propane Gas

Gas Line Sizing

GAS REQUIREMENTS

The firing rate for the MT3870 is 150,000 BTU/Hr.

(43.9 kW/Hr.)

NOTE: For natural gas meter sizing, consult your

local gas company to ensure that your meĆ

ter will provide the proper supply.

Installations within the U.S.

1. Add the total BTU's/hr of all the gas

appliances.

2. Convert BTU's to cubic ft/hr using the formula

Cu Ft/Hr = 1000 BTU/Hr for natural gas.

3. Size the meter accordingly.

Installations outside the U.S.

1. Add the total M3/min of all the appliances.

2. Size the meter accordingly.

Single

Double

Triple

Orifice Size #1 #29

Incoming Gas Pressure W.C. kPa mbar W.C. kPa mbar

Static

Operational

CE APPROVED UNITS

Type of

Gas

G25 25 12 5,80 16 2 x 0,63 46 Nat. Gas

G20 20 8 5,80 16 2 x 0,63 46 Nat. Gas

G20/G25 20/25 Totally Inscrewed

G30 30/50 17 3,48 16 2 x 0,30 46 Butane

G31 30/37/50 24 3,48 16 2 x 0,30 46 Propane

Inlet

Pressure

mbars

Burner Pressure

Pressure Regulator

7"

5.5"

mbars

3/4" line

1Ć1/4" line

1Ć1/4" line

1.74

1.36

Injector

Diameter

TABLE 2

3/4" line

1 line

1Ć1/4" line

17.4

13.7

Opening

mm

5,15 16 2 x 0,63 46 Nat. Gas

Air

mm

12.5"

11"

Pilot

Injector

mm

3.11

2.73

Standard

Delivery

Value kW (HS)

31.1

27.4

1-2

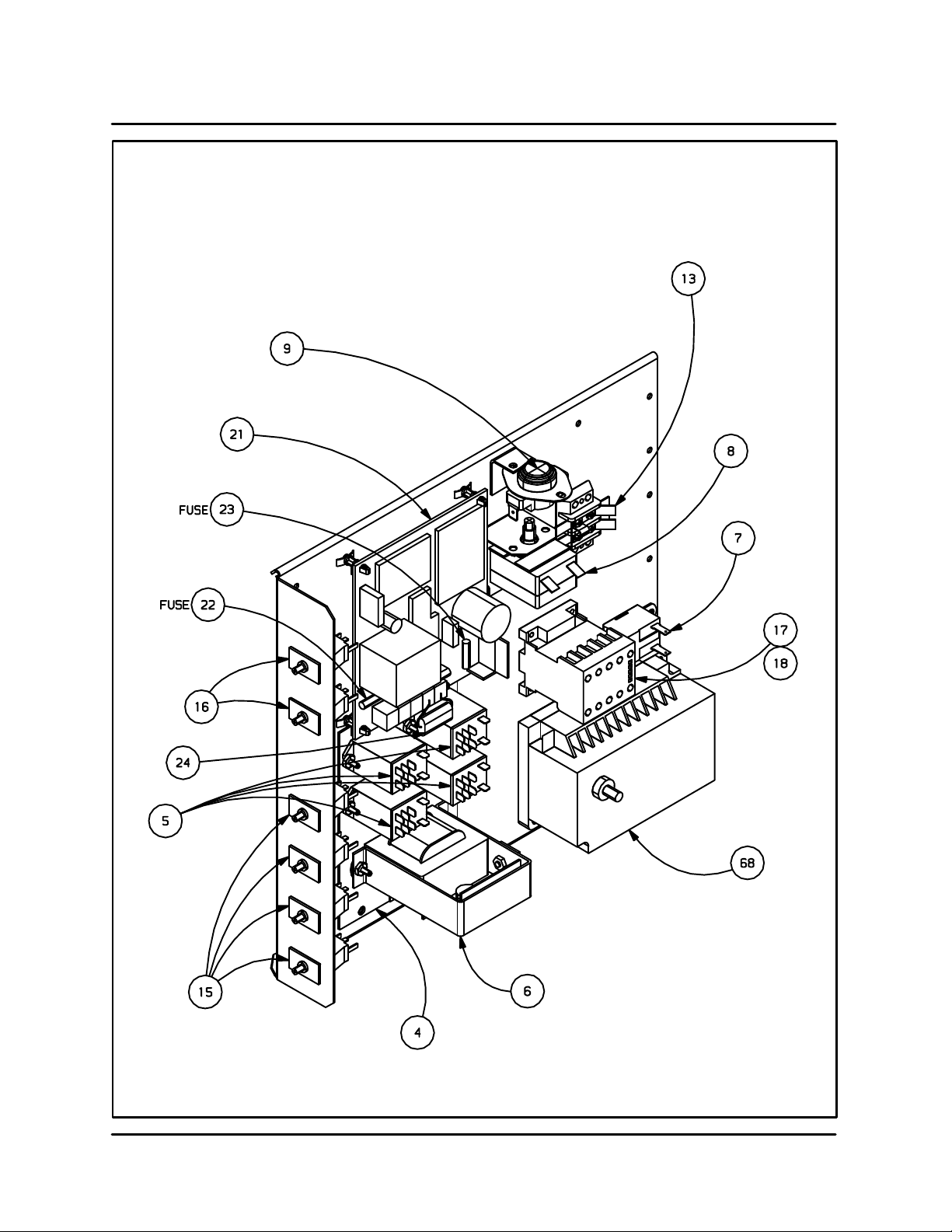

Page 10

MT3870

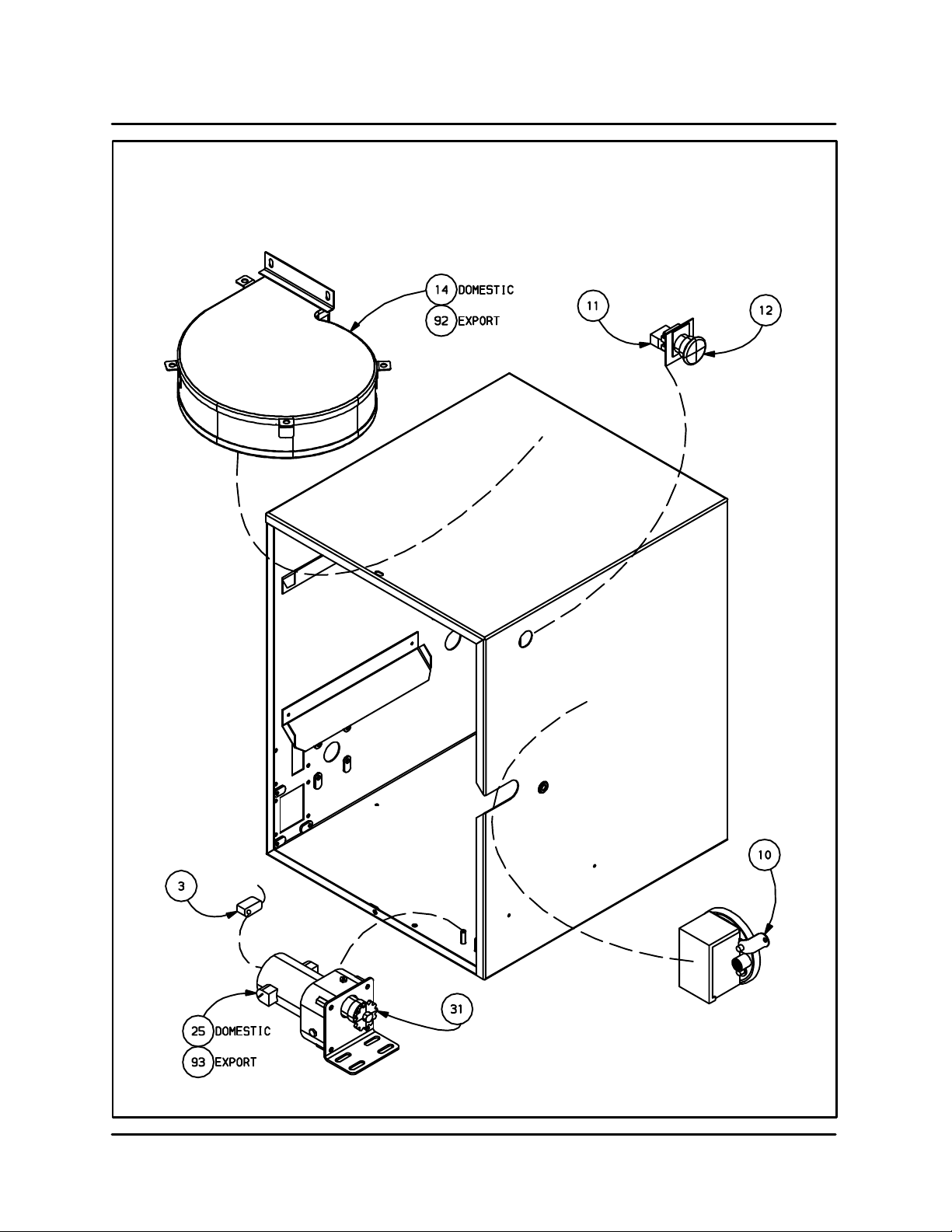

ILLUSTRATED PARTS LISTS

ELECTRICAL COMPONENTS

NOTE: = ASAP Distributor Required Stocking Parts

Ref.

Part

No.

No. Description

Ref.

Part

No.

No. Description

1 M6474 Computer Control Kit, Closed

Loop SB (Qty 1)

1 FW525 Computer Control Kit, Closed

Loop SB (Qty 1)

(Reconditioned)

M5635 Computer Control Kit, Open

Loop TB (Qty 1)

M3175 Decal, Lexan Control (Qty 1)

M7427 Probe, Temperature RTD, 500

OHMS (Qty 1)

M7202 Conversion Kit, Open Loop to

Closed Loop (Qty 1)

M3347 Cable, Computer Control, 25

Pin, 10' (Qty 1)

M3348 Cable, Computer Control, 9

Pin, 10' (Qty 1)

M3490 Cable, Computer Control, 25

Pin, 50' (Qty 1)

M3491 Cable, Computer Control, 9

Pin, 50' (Qty 1)

M3349 Harness, Inter-Connecting DC

Drive, 3-Wire (For 9 Pin)

(Qty 1)

M3353 Harness, Relay Board

(Open Loop) (For 25 Pin)

(Qty 1) (Before 9/15/95)

M7237 Harness, Relay Board (Closed

Loop) (For 25 Pin) (Qty 1)

(After 9/15/95)

2 M3314 Bracket, Computer Wall (Qty 1)

M5661 Bracket Assy., Cable Clamp

(Qty 1)

3 M0984 Pick Up, PV-2 (Qty 1) (After

9/15/95)

4 M7236 Board, Relay/Transformer

(Qty 1)

5 22672 Relay, Control (Qty 4)

6 M3352 Transformer, 120V to 24V

(Qty 1)

7 20349 Buzzer, 120V (Qty 1)

8 M3295 Thermostat, High Limit

(Manual Reset) (Qty 1)

9 M1362 Snap Disc, L140/20F, 2 Pole

SPST (Qty 1)

M2453 Snap Disc, L140/20F, 3 Pole

SPDT (Qty 1)

10 M0595 Switch, Air Pressure SPDT

(Qty 1)

11 M0152 Contact, Emergency Stop

Switch (Qty 1)

12 M3296 Activator, Emergency Stop

Switch (Mushroom Shape)

(Qty 1)

M3297 Nameplate, Emergency Stop

(Qty 1)

13 M0593 Terminal Block, 2 Pole (Qty 1or

CE Qty 2)

M2469 Fan, Axial 110 CFM 4 1/2" (Qty

4) (Before 11/14/95)

22718 Fan Guard & Hardware (Qty 3)

(Before 11/14/95)

M0572 Cord, Axial Fan 30" Power (Qty

4) (Before 11/14/95)

14 M6381 Blower, Cooling (Qty 1) (After

11/14/95)

15 M3136 Breaker, 7 AMP Circuit (Qty 4)

16 M2772 Breaker, 4 AMP Circuit (Qty 2)

M6590 Plate Assy., Control SB (Qty 1)

M7482 Plate Assy., Control TB (Qty 1)

M1694 Cord Set & Plug Assy., 10 Foot

(Qty 1)

M0772 Receptacle, Twist Lock (Qty 1)

17 M0708 Contactor, 3 Pole, 120V Coil

(Qty 1)

18 M3322 Hood Interlock, Mechanical

(Qty 1)

1-3

Page 11

CONVEYOR COMPONENTS

NOTE: = ASAP Distributor Required Stocking Parts

* = Item is Too Large for UPS

Ref.

Part

No.

No.

Description

Ref.

No.

Part

No.

INTRODUCTION

Description

19 M6338 Belt, Wire S/S (Total Length

38" SB (Per Foot) MT3870 18

FT, MT3855 16 FT)

M7889 Belt, Wire S/S (Total Length

18-1/2" TB (Per Foot)

MT3870 18 FT)

20 M7272 Tensioner (After Assy., Belt

MT3870 (Qty 2) 9/15/95)

21 M2379 Speed Control Board, Bodine

(Qty 1)

M2254 Fuse, Line, 22 Bodine Board, 5

AMP, 125V (Qty 1)

M2316 Fuse, (Qty 1) 23 Armature,

Bodine Board, 200 MA, 250V

24 M3301 Capacitor, (SB Qty 1 or Speed

Control Board TB Qty 2)

25 M2378 Motor, (SB Qty 1 or Conveyor

Drive, Bodine 130V TB Qty 2)

M2500 Brush Set, Bodine (Qty 1)

M0391 Chain, Drive & Order (SB SpecĆ

ify 2 FT or TB Specify 4 FT

M0112)

M0112 Masterlink, Drive Chain (Qty 1)

M6791 Guard, Drive 26 Chain SB (Qty

1)

M6482 Guard, Drive Chain TB (Qty 1)

* M3981 Conveyor (Before Assy., Drive

SB MT3870 (Qty 1) 9/15/95)

27 * M6154 Conveyor (After Assy., Drive SB

MT3870 (Qty 1) 9/15/95)

* M3982 Conveyor (Before Assy., Idle

SB MT3870 (Qty 1) 9/15/95)

28 * M6155 Conveyor (After Assy., Idle SB

MT3870 (Qty 1) 9/15/95)

* M7592 Conveyor Assy., Drive TB

MT3870 (Qty 1)

* M7593 Conveyor Assy., Idle TB

MT3870 (Qty 1)

* M4432 Conveyor (Qty 1) Assy., Drive

SB MT3855G (Before 11/14/95)

* M4433 Conveyor (Qty 1) Assy., Idle SB

MT3855G (Before 11/14/95)

* M6777 Conveyor MT3855G Assy.,

Folding (Drive & Idle) SB (Qty

1) (After 11/14/95)

29 M2672 Shaft, Conveyor Drive (Qty 1)

30 M2673 Shaft, Conveyor Idle (Qty 1)

31 M0109 Sprocket, Motor Drive, 12 Tooth

(Qty 1)

M0110 Sprocket, Conveyor Drive, 15

Tooth (Qty 1)

32 M0108 Sprocket, Conveyor Belt, 11

Tooth (Qty 18)

1-4

Page 12

MT3870

CONVECTION COMPONENTS

NOTE: = ASAP Distributor Required Stocking Parts

Part

Ref.

No.

No.

33 M4224 Motor & Blower Assy. CW

34 M4225 Motor & Blower Assy. CCW

M5419 Motor & Blower Assy. CCW

M2564 Capacitor, Motor MT3870

NOTE: Call factory if MT3855G oven was

manufactured before 2/27/94 to verify

motor part number.

M5722 Insulation Kit for Blowers

M7991 Insulation Kit for Blowers

35 M6466 Nozzle Assy. w/ Diverter

M5466 Nozzle Assy. w/ Diverter

M7105 Nozzle Assy. w/ Diverter

M7106 Nozzle Assy. w/ Diverter

Description

MT3870 (Qty 2)

MT3870 (Qty 2)

MT3855G (Qty 3) (After

2/27/94)

(Qty 4)

MT3870 (Qty 1)

MT3855G (Qty 1)

MT3870 (Qty 14) Generic

MT3855G (Qty 12) (Before

11/14/95)

MT3855G (Qty 6) (After

11/14/95) (See L-497)

MT3855G (Qty 6)

(After 11/14/95) (See L-497)

Ref.

Part

No.

No.

M1962 Hold Down, Nozzle MT3870

M7399 Hold Down, Nozzle MT3870

M5486 Hold Down, Nozzle MT3855G

M7380 Hold Down, Nozzle MT3855G

36 M3106 Diverter, Air (LH & RH) MT3870

M3106 Diverter, Air (LH & RH)

M5179 Diverter, Air (LH & RH)

M5453 Diverter, Air (Center) MT3855G

M7372 Diverter, Air (LH) MT3855G

M7374 Diverter, Air (RH) MT3855G

M7373 Diverter, Air (Center) MT3855G

Description

(Qty 1) (Before 9/15/95)

Qty 1) (After 9/15/95)

(Qty 1) (Before 11/14/95)

(Qty 1) (After 11/15/95)

(Qty 2)

MT3855G (Qty 2) (Before

11/14/95)

MT3855G (Qty 2) (Before

11/14/95)

(Qty 1)(Before 11/14/95)

(Qty 1) (After 11/14/95)

(See L-495 & L-496)

(Qty 1) (After 11/14/95)

(See L-495 & L-496)

(Qty 1) (After 11/14/95)

(See L-495 & L-496)

AIR PLATES

NOTE: = ASAP Distributor Required Stocking Parts

Ref.

Part

No.

No. Description

37 M6470 Plate Assy., Air RH MT3870

Generic (Qty 1)

38 M6469 Plate Assy., Air LH MT3870

Generic (Qty 1)

M5767 Plate Assy., Air RH (R to L)

MT3855G Generic (Qty 1)

M5768 Plate Assy., Air LH (R to L)

MT3855G Generic (Qty 1)

M5648 Plate Assy., Air RH (L to R)

MT3855G Generic (Qty 1)

1-5

Ref.

Part

No.

No. Description

M5649 Plate Assy., Air LH (L to R)

MT3855G Generic (Qty 1)

24613 Hook, Air Pan (Qty 1)

39 M6597 Plate Assy., Block Off MT3870

Generic (Qty 6)

M6079 Plate Assy., Block Off MT3855G

Generic (Qty 6)

Page 13

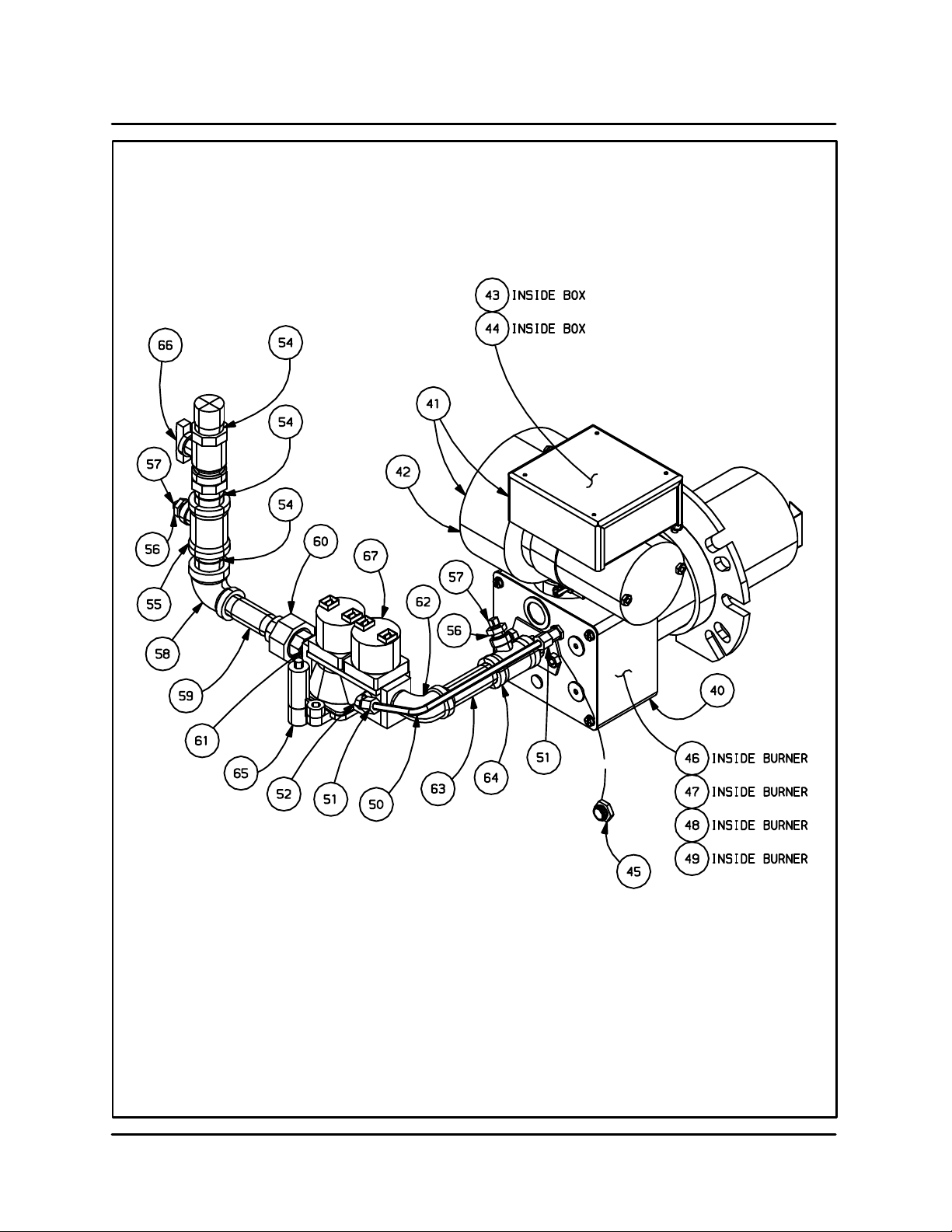

GAS BURNER COMPONENTS

NOTE: = ASAP Distributor Required Stocking Parts

INTRODUCTION

Part

Ref.

No.

No.

40 22132 Burner Assy. Complete (Specify

41 M0767 Blower Motor, Comb. w/ ConĆ

42 M2383 Blower Motor, Combustion

43 M2381 Transformer, 120V to 24V

44 M2382 Relay, Time Delay (Qty 1)

45 M0454 Orifice, Main Burner LP (Qty 1)

45 M0455 Orifice, Main Burner Natural

46 M2727 Pilot Burner & Igniter Assy. LP

46 M2726 Pilot Burner & Igniter Assy.

47 M6378 Shield, Pilot Burner (Qty 1)

48 M0415 Flame Sensor (Qty 1)

49 M2690 Orifice, Pilot LP (Qty 1)

49 M0697 Orifice, Pilot Natural (Qty 1)

50 M0248 Tube, Pilot Aluminum 1/4"

51 M0959 Fitting, Compression 1/4

52 M2799 Union, Compression (Qty 1)

53 21225 Fitting, Elbow (Qty 1)

54 4588 Nipple, Pipe 3/4 x 1-3/8 Close

55 M0280 Tee, 3/4 x 3/4 x 1/4 (Qty 1)

56 M0278 Bushing, 1/4 x 1/8 Hex (Qty 2)

57 M0281 Plug, Pipe 1/8 Black (Qty 2)

58 17874 Ell, Black 1/2 x 3/4 (Qty 1)

59 M0590 Nipple, Pipe 1/2 x 2-1/2

60 M0279 Union, 1/2 Inch Black (Qty 1)

61 1949 Nipple, Pipe 1/2 x 1-3/16

62 M0317 Elbow, 1/2 Inch Street 90 Deg

Description

Model & Gas Type) (Qty 1)

trol Box (Qty 1)

(Qty 1)

(Qty 1)

(Qty 1)

(Qty 1)

Natural (Qty 1)

(1.583 Feet)

(Qty 2)

(Qty 3 or CE Qty 2)

(Qty 1)

Close (Qty 1)

(Qty 1)

Ref.

Part

No.

No.

63 21278 Nipple, Pipe 1/2 x 3-1/2

64 M3238 Tee, 1/2 x 1/2 x 1/4 (Qty 1)

65 23007 Spring, Solenoid Valve, LP to

65 18612 Spring, Solenoid Valve, Natural

23114 Conversion Kit, LP to Natural

21389 Conversion Kit, Natural to LP

M5259 Conversion Kit, LP to Natural

M5290 Conversion Kit, Natural to LP

66 M0282 Valve, Manual Gas (Qty 1)

67 M5495 Dual Solenoid/Pressure ReguĆ

67 22190 Dual Solenoid/Pressure ReguĆ

68 M1054 Spark Box, Johnson (Qty 1)

21242 Connector Kit, Gas Flex 48"

21826 Connector Kit, Gas Flex 36"

69 M7280 Flame Tube Assy., MT3870

M7390 Flame Tube Assy., MT3855G

Description

(Qty 1)

Natural (Qty 1)

to LP (Qty 1)

MT3870 (Qty 1)

MT3870 (Qty 1)

MT3855G (Qty 1)

MT3855G (Qty 1)

lator, Nat 24V (Qty 1)

lator, LP 24V (Qty 1)

(Qty 1)

(Qty 1)

(Qty 1)

(Qty 1)

1-6

Page 14

MT3870

EXTERIOR COMPONENTS

NOTE: = Doors are not returnable

Part

Ref.

No.

No.

M2868 Door Assembly, Pull Down S/S

M2188 Handle Kit, Door 2" (used

70 M3944 Door Assembly (used w/ false

71 M4275 Handle Kit, Door 22" (used w/

72 M1871 Plate, RH Pivot Slotted (Qty 1)

73 M1872 Plate, LH Pivot Slotted (Qty 1)

74 M3602 Bracket Assy., Mounting (Qty 2)

75 M3603 Bracket Assy., Mounting (Qty 2)

M5475 Filter Assy., MT3855G (Qty 1)

76 M3751 False Front Assy., MT3870

M4563 False Front Assy., MT3855G

M3751 Tape, Closed Cell Foam

M5032 Chimney Kit, Single (Qty 1)

M7464 Chimney Kit, Single (Qty 1)

M7160 Chimney Kit, Double (Qty 1)

M7463 Chimney Kit, Double (Qty 1)

21390 Legs, 17-1/4" w/ Casters

21391 Legs, 23-1/4" w/ Casters

14444 Casters, Cradle (Triple Oven)

77 M3783 Stop, Product S/S (Qty 1)

78 M3779 Extension Assy., Product 6"

M4223 Extension Assy., Product 10"

Description

(used w/enclosed Greenheck

hood system) (Qty 1)

w/M2868) (Qty 1)

front) (Qty 1)

M3944) (Qty 1)

(Before 11/14/ 95)

(Qty 1)

(Qty 1)

(Before 11/95)

(After 11/95)

(Before 11/95)

(After 11/95)

(Double) (Set of 4)

(Single) (Set of 4)

(Set of 4)

(Qty 1)

(Qty 1)

Ref.

Part

No.

No.

M7575 Extension Assy., Product 15"

M2824 Crumb Pan, Idle MT3870

79 M6168 Crumb Pan, Idle MT3870

M2823 Crumb Pan, Drive MT3870

80 M6167 Crumb Pan, Drive MT3870

M6910 Crumb Pan, Idle MT3855G

M6906 Crumb Pan, Drive MT3855G

M5612 Plug Assy., Lower RH MT3870

81 M7276 Plug Assy., Lower RH MT3870

82 M5612 Plug Assy., Lower LH MT3870

M7386 Plug Assy., Lower MT3855G

83 M3116 Plug Assy., Upper MT3870 &

84 M2460 Air Curtain, Upper End Plug

M3728 Support Assy., Upper End Plug

M3729 Support Assy., Upper End Plug

M7149

M7150

85 M3724 Handle, End Plug (Qty 2)

22229 Stacking Assy., Double (Qty 1)

M4633 Panel & Filter Assy. (Qty 1)

Description

(LaRosa's) (Qty 1)

(Qty 1) (Before 9/15/95)

(Qty 1) (After 9/15/95)

(Qty 1) (Before 9/15/95)

(Qty 1) (After 9/15/95)

(Qty 1)

(Qty 1)

Qty 1) (Before 9/15/95)

(Qty 1) (After 9/15/95)

(Qty 1)

(Qty 2)

MT3855G (Qty 2)

(Qty 2)

RH MT3870 (Qty 2)

LH MT3870 (Qty 2)

Support Assy., Upper End Plug

RH MT3855G (Qty 2) Support

Assy., End Plug LH MT3855G

(Qty 2)

MT3870 (All) & MT3855G

(Before 11/14/95)

1-7

Page 15

Ref.

Part

No.

No. Description

Ref.

Part

No.

No. Description

INTRODUCTION

M5485 Panel & Filter Assy. MT3855G

(Qty 1) (After 11/14/95)

XXXXX Control Box Cover w/ Louvers

MT3855G (Qty 1) (Before

11/14/95)

M6799 Control Box Cover w/ Access

Door MT3855G (Qty 1) (After

11/14/95)

XXXXX Control Box Cover w/ Louvers

MT3870 (Qty 1) (Before

9/15/95)

86 M7266 Control Box Cover w/ Access

Door MT3870 (Qty 1)

(After 9/15/96)

87 M6035 Latch, Access Door (Qty 1)

M2689 Body Back, MT3870 (Qty 1)

(Before 9/15/95)

M7254 Body Back, MT3870 (Qty 1)

(After 9/15/95)

M4248 Body Back, MT3855G (Qty 1)

1-8

Page 16

MT3870

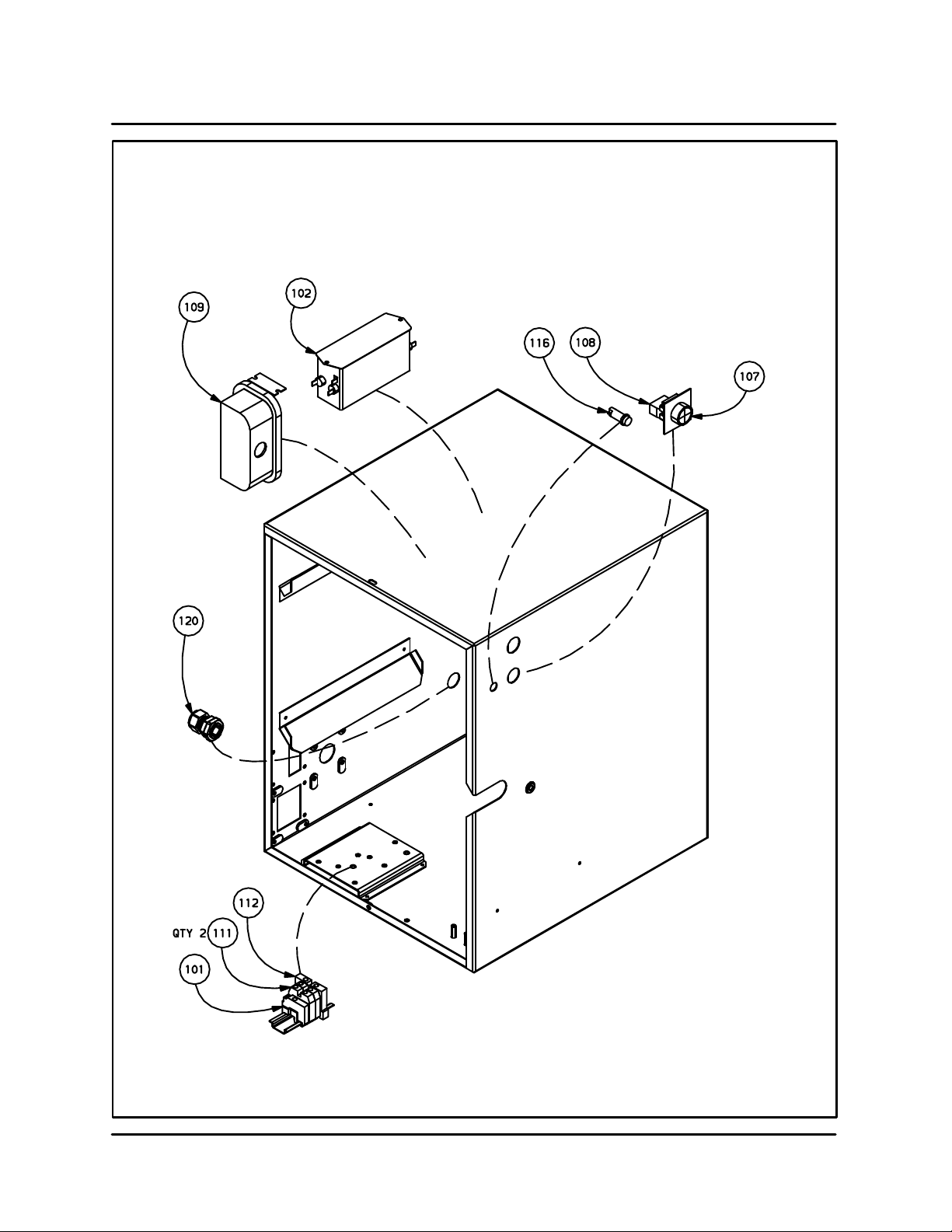

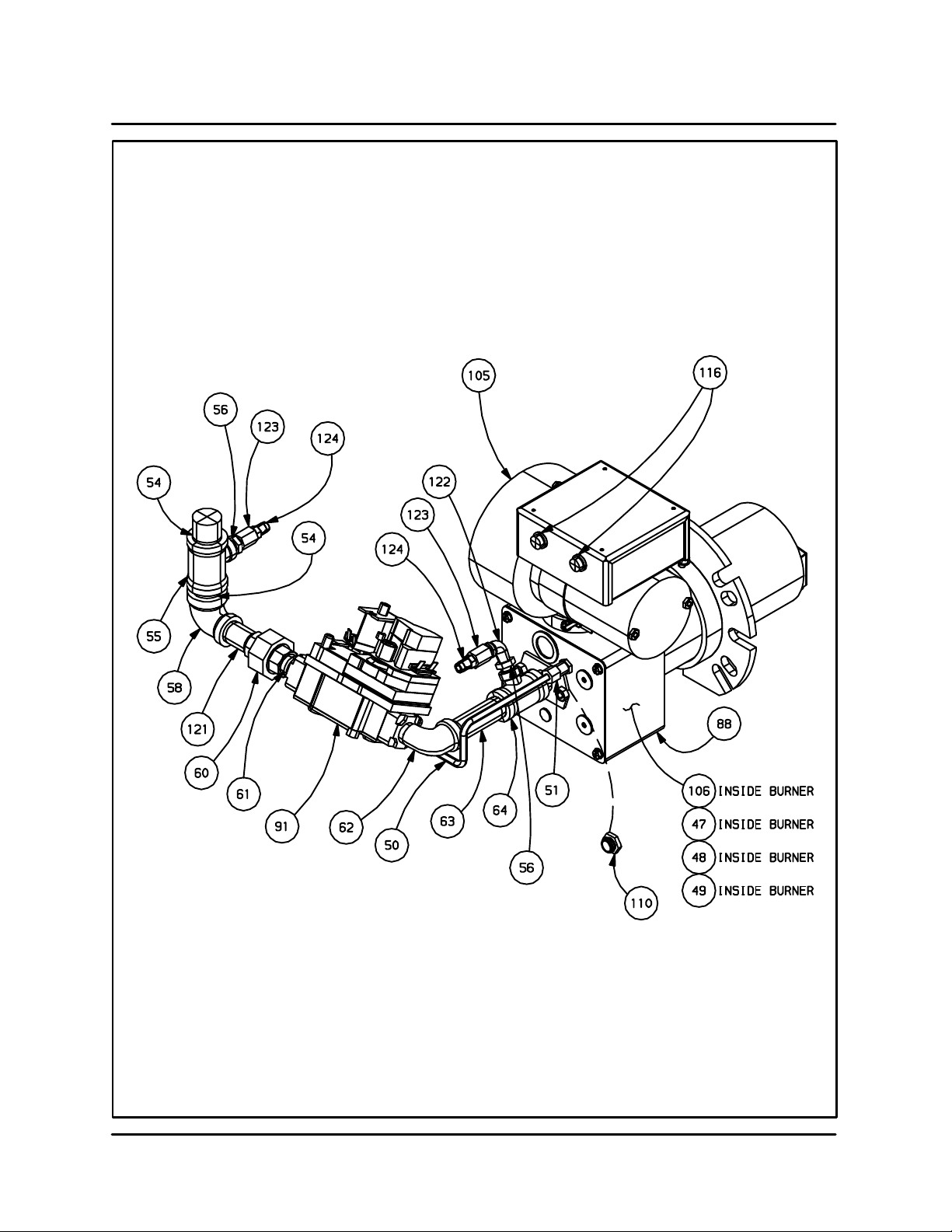

EXCLUSIVE TO EXPORT

NOTE: = ASAP Distributor Required Stocking Parts

Ref.

No.

88 M2276 Burner Assy., Complete

89 M4597 Motor & Blower Assy., CW

90 M4598 Motor & Blower Assy., CCW

91 M6000 Dual Solenoid/Pressure

91 M6001 Dual Solenoid/Pressure

92 M7283 Blower, Cooling Export (Qty 1)

93 M3128 Motor, Conveyor Drive

94 M3153 Digital Speed Control Board,

95 M2630 Fuse, Line, Bodine Board, 500

96 M2316 Fuse, Armature, Bodine

97 M7282 Board, Relay (Closed Loop)

98 M6025 Fuse, 25V 80 ma (Qty 1)

99 M6024 Transformer, 220V to 24V

100 20350 Buzzer, 240V (Qty 1)

101 R1580 Stop, End (Qty 1)

102 M6449 Filter, Noise (Qty 1) CE

103 M7880 Computer Control Kit, Closed

104 M7888 Relay, 1 Second Time Delay

105 M2386 Blower Motor, Combustion

106 M7333 Pilot Burner & Ignitor Assy.,

106 M7334 Pilot Burner & Ignitor Assy.,

107 M2497 Switch, Push Button (Qty 1)

Part

No.

M5717 Board, Relay (Open Loop) SB

Description

(Qty 1)

MT3870 (Qty 2)

MT3870 (Qty 2)

Regulator, Nat. (Qty 1)

Regulator, LP (Qty 1)

Bodine, 180V (Qty 1)

Bodine (Qty 1)

MA (Qty 1)

Board, 200 MA, 250V (Qty 1)

(Qty 1)

SB (Qty 1)

(Qty 1)

Loop SB (Qty 1) CE

(Qty 1) CE

(Qty 1) CE

LP (Qty 1) CE

Nat. (Qty 1) CE

CE

Ref.

No.

108 M2498 Switch, Contact (Qty 1) CE

109 M3330 Switch, Air Pressure DifferenĆ

110 M0706 Orifice, Main Burner (Specify

111 R0164 Terminal Block, Power (Qty 2)

112 R0166 Terminal Block, Ground

113 M3168 Spark Box, 240V (Landis &

114 M2247 Contactor, 240V, 50 HZ (Qty 1)

115 XXXXX Indicator Light (Qty 2) CE

116 16037 Indicator Light, 250V, Red,

117 16775 Relay, SPST, 240V, 30 Amp.

118 M3172 Timer, Fixed, 2 Second (Qty 1)

119 M3173 Timer, Fixed, 10 Second (Qty

120 M6029 Connector, Liquid Tight (Qty

121 10809 Nipple, Pipe 1/2 x 2 (Qty 1)

122 M2835 Fitting, Elbow 90 Street 1/8"

123 M3443 Bushing, Adapter (Qty 2) CE

124 M2841 Fitting, Pressure Tap (Qty 2)

Part

No.

M2819 Switch, Air Pressure (in/wc)

18265 Indicator Light, 28V, Red,

M6589 Plate Assy., Control SB (Qty 1)

M7323 Plate Assy., Control SB Qty 1)

M6982 Piping Assy. (Qty 1) CE

Description

tial (mbr) (Qty 1) CE

(Qty 1) Australia

MTD) (Qty 1) CE

CE

(Qty 1) CE

Gyr) (Qty 1) CE

CE

Round (Qty 1) CE

Round (Qty 1) CE & Australia

(Qty 1) CE

CE

1) CE

CE

Australia

1) CE

CE

(Qty 1) CE

CE

1-9

Page 17

INTRODUCTION

MT3870 DOMESTIC & GENERAL EXPORT CONTROL BOX

(Control Plate and/or Gas Burner Components not Shown)

1-10

Page 18

MT3870

MT3870 CE CONTROL BOX

(Control Plate and/or Gas Burner Components not Shown)

1-11

Page 19

MT3870 DOMESTIC GAS BURNER COMPONENTS

(Control Box not Shown)

INTRODUCTION

1-12

Page 20

MT3870

MT3870 CE GAS BURNER COMPONENTS

(Control Box not Shown)

1-13

Page 21

INTRODUCTION

MT3870 DOMESTIC & GENERAL EXPORT SB CONTROL PLATE ASSY

(M6590)

1-14

Page 22

MT3870

MT3870 CE SB CONTROL PLATE ASSY

(M6589)

1-15

Page 23

MT3870 EXTERIOR OVEN VIEW

INTRODUCTION

1-16

Page 24

MT3870

This page intentionally left blank.

1-17

Page 25

CHAPTER 2

ASSEMBLY

Page 26

MT3870

OVEN ASSEMBLY PROCEDURES

RETURN AIR DIVERTERS

1. Slide the return air diverters into the oven and

clip to the lower rear of the baking cavity. The

edge of the diverter should be 3" (7.6 cm) from

the outside edge of the oven cavity.

IMPORTANT:

Note Orientation Of Return Air Diverters!

WIRE CONVEYOR BELT

NOTE: The conveyor belt has loops on all four

sides. The belt must be installed so the

loops travel as shown in FIGURE 2.

1. Thread the wire belt from the right side of the

oven, lower level first.

2. After pushing the belt through on the lower levĆ

el, leave about 12" (30.5 cm) hanging out on

the left side.

3. Take the remainder of the belt, loop it around

the right shaft, and push it through on the upĆ

per level. The two ends of the belt should be

approximately 6Ć9" (15Ć22 cm) past the left

shaft (right shaft if right to left travel is required)

on the upper level of the belt support.

Side Belt Loops

FIGURE 1

AIR NOZZLES

1. Install the nozzles from the center of the oven

to the ends. The bottom of the nozzle must fit

into the slot of the nozzle support located at the

front of the oven.

2. Secure the nozzle holdĆdown strip across the

inside front of the oven using the existing

screws attached to the oven wall.

CONVEYOR RACK ASSEMBLIES

1. Slide the drive side conveyor rack assembly

(with the sprocket on the end of the shaft) into

the support tracks.

2. Push until the end sprocket is inserted into the

control compartment.

3. Install the alignment bolt through the conveyor

and control box.

4. Slide the idle side conveyor rack assembly into

the support tracks from the exit end of the

oven.

Direction of

Travel

FIGURE 2

4. Install the inner and outer master links as

shown in FIGURE 3.

Master

Link

Direction of

Travel

FIGURE 3

Unless otherwise specified, the conveyor travel is

factory set for leftĆtoĆright operation when facing

2-1

Page 27

ASSEMBLY

the front of the oven. If a direction change is reĆ

quired, the polarity of the drive motor must be reĆ

versed. To change the polarity of the drive motor,

disconnect the oven from the power source and inĆ

terchange the black and white motor leads at the

D.C. Controller Board located within the control

box. If the polarity of the motor is changed to

rightĆtoĆleft belt travel, the conveyor belt must

be installed from the left side of the oven inĆ

stead of the right side.

NOTE: Change the air plates whenever the conĆ

veyor belt direction of travel is changed.

See FIGURE 4.

DRIVE CHAIN

1. Install the drive chain around the drive motor

and then around the sprocket on the conveyor

belt support.

2. Push the conveyor motor back to tighten the

drive chain.

3. Lock the motor into position by tightening the

four 1/4Ć20 hex head screws between the conĆ

veyor motor and the control box.

END PLUGS

1. Install the upper end plug support brackets at

both ends of the oven.

2. Install the upper and lower end plugs at both

ends of the oven.

CONVEYOR BELT TENSIONERS

Each tensioner installs between the idle end of the

conveyor (the side opposite the drive) and the

oven's body side.

1. Compress the spring by hand to engage the

tensioner pin with the hole in the oven's body

side. (Refer to FIGURE 5).

Oven Body Side

AIR PLATES

Verify that the proper air plates were received. InĆ

spect the orientation of the air plates. Refer to

FIGURE 4.

NOTE: Standard air plates shown. Alternate plates

available for some installations.

Left Air Plate

P/N M6469

Right Air Plate

P/N M6470

FIGURE 5

CRUMB PANS

1. Install the crumb pans under each end of the

conveyor.

MOUNT REMOTE CONTROL

1. Mount the remote control unit on a wall within

reach of the computer cables.

2. Connect the computer cables from the controlĆ

ler's rear connector to the connector located at

the rear of the oven.

FALSE FRONT (IF APPLICABLE)

Hang false front. Install door handle.

FIGURE 4

2-2

Page 28

MT3870

This page intentionally left blank.

2-3

Page 29

CHAPTER 3

OPERATION

Page 30

MT3870

COMPUTER CONTROLLER

9

1

2

3

45678

FIGURE 1

CONTROL DESCRIPTION

1. DIGITAL DISPLAY - Displays the time, temĆ

perature and controller related information.

2. OVEN ON/OFF - Controls power to the oven.

3. NUMERIC KEYS - Used to enter numerical

data in the programming mode.

4. CLEAR KEY - Used to clear the display if an

error is made in the programming mode.

5. SET TEMP KEY - Used to view or program the

temperature setpoint.

6. ACT TEMP KEY - Used to view the current

oven temperature.

7. TIME KEY - Used to view or program the cook

time.

8. PROG/ENTER KEY - Used to enter and exit

the programming mode. Also used to lock in

programmed settings.

9. STATUS LAMPS - When lit indicate that the

fan or burners are operating.

This oven, supplied with remote control, is

equipped with an emergency shut down

switch. Should you need to stop the belt,

fans, or heat press the emergency switch.

Do not use the emergency switch as a

GENERAL on/off switch!

CONTROL OPERATION

To turn the oven on:

1. Press and hold the ON/OFF key (2). The disĆ

play reads OFF when the oven is idle.

2. The display flashes WAIT LOW SET TIME

mmss.

3. The FAN and HEAT status lamps (9) light. The

fans begin to run. The heat rises to the proĆ

grammed temperature. The conveyor belt

travels at the programmed speed.

To view the cook time setting:

1. Press the TIME key (7). The LED on the key

lights and the display flashes SET TIME

mmss.

To display the actual oven temperature:

1. Press the ACT TEMP key (6). The LED on the

key lights and the display reads ACTUAL

nnnnF.

To view the temperature set point:

1. Press the SET TEMP key (5). The LED on the

key lights and the display flashes SET TEMP

nnnnF.

To turn the oven off:

1. Press the ON/OFF key (2). The blower moĆ

tor(s) continue to run regardless of the controlĆ

ler status until the temperature drops below

180F (82C).

3-1

Page 31

OPERATION

PROGRAMMING PROCEDURES

Programming the Cook Time:

1. Press the PROGRAM/ENTER key (8).

2. Press the TIME key (7). The display reads

PROGĆ? SET TIMEĆ? _ _ _ _.

3. Use the NUMERIC keys (3) to enter the desired

cook time. The display will read the numbers

as they are entered. If an error is made, press

the CLEAR key (4) and reĆenter the number.

4. Press the PROGRAM/ENTER key (8) a second

time to lockĆin the new time. The new cook time

will be stored in the computer's memory.

Programming the Temperature:

1. Press the PROGRAM/ENTER key (8).

2. Press the SET TEMP key (5). The display reads

PROGĆ? SET TEMPĆ? _ _ _ _F.

3. Use the NUMERIC keys (3) to enter the desired

temperature set point. The control displays the

numbers as they are entered. If an error is

made, press the CLEAR key (4) and reĆenter

the number.

4. Press the PROGRAM/ENTER key (8) a second

time to lockĆin the new temperature. The new

temperature setpoint will be stored in the comĆ

puter's memory.

Operation at the Programmed Settings:

DISPLAY INFORMATION

WAIT LOW - indicates that the present oven

temperature is lower than the set point temperĆ

ature. When the oven reaches the set point

temperature the display changes to READY.

READY - indicates that the oven is ready to acĆ

cept product.

SET TIME mmss - indicates the current

cook time setting.

HIGH TIME - indicates that the temperature

is well above the set point. This usually occurs

when moving from a higher āto a lower temperaĆ

ture. Wait until the display reads ready before

loading product.

HIGH TEMP LIMIT - indicates that the oven

temperature exceeds the high limit from the

2nd level program. The Over Temperature

Alarm buzzer will sound. Shut the oven off and

wait for the unit to cool down.

HIGH TEMP PANEL - indicates that the conĆ

trol area reaches an excessive temperature.

Shut the oven off and wait for the unit to cool

down.

PROBE OPEN PROBE SHORT - indicates

that the temperature sensor has failed. The

Alarm buzzer sounds. Shut the oven off and

contact a service representative.

1. Press and hold the ON/OFF key (2).

2. The FAN and HEAT status lamps (9) light. The

fans begin to run. The heat rises to the temperĆ

ature setting stored in the computer's memory.

The conveyor belt begins to travel at the timed

speed stored in memory.

3. The display will flash WAIT LOW SET TIME

mmss until the programmed bake temperaĆ

ture is reached. The HEAT lamp (9) will remain

lit until the oven reaches the temperature set

point.

4. The display reads READY and the HEAT lamp

(9) goes out.

5. The oven is now ready to accept product.

6. Press and hold the ON/OFF key (2) to turn the

oven off. The fans continue to run while the

oven cools to a safe temperature.

3-2

Page 32

MT3870

SEQUENCE OF OPERATION

DOMESTIC AND GENERAL EXPORT OVENS

COMPONENT REFERENCE

NOTE: Refer to FIGURE 3 for component locaĆ

tions.

1. COOKING COMPUTER

2. BURNER VALVE RELAY

3. BLOWER RELAY

4. MAIN CONTROL RELAY

5. SPEED CONTROL BOARD

6. SINGLE POLE SINGLE THROW THERMAL

SWITCH

7. MANUAL RESET HIGH LIMIT SWITCH

8. CONVECTION FAN PRESSURE SWITCH

9. TRANSFORMER

10. COMBUSTION MOTOR

11. RELAY

12. CENTRIFUGAL SWITCH

13. IGNITION CONTROL MODULE

14. PILOT VALVE

15. MAIN VALVE

16. MOTOR CONTACTOR

17. CONVECTION FANS

18. COOLING BLOWER

19. SINGLE POLE DOUBLE THROW THERMAL

SWITCH

OPERATION

1. Apply power to the oven. Program the time and

temperature into the computer (1). The burner

valve relay (2), blower relay (3) and main conĆ

trol relay (4) energize powering up the oven.

2. The main control relay (4) sends power to the

speed control board (5) and the single pole

single throw thermal switch (6). If this switch is

closed, power will be supplied to the manual

reset high limit switch (7). If this switch is

closed power flows to the convection fan presĆ

sure switch (8).

NOTE: The convection fan pressure switch (8)

will close only if the convection fans

are operating and putting a positive

pressure on the switch.

When this switch closes power goes to the priĆ

mary side of the transformer (9) located inside

of the box mounted on top of the combustion

motor (10). When the relay (11) mounted in the

same box is energized the combustion motor

(10) should start.

3. Next the centrifugal switch (12) in the motor

closes sending 24 volts to the ignition control

module (13). This powers up the pilot valve

(14). After the pilot valve is lit and the pilot flame

is established through rectification, then termiĆ

nal three of the ignition control module (13) will

send 24 volts to the burner valve relay (2). If this

relay is closed, power goes to the main valve

(15) allowing it to open and send gas into the

burner for ignition.

4. The blower relay (3) sends 115 volts to the coil

of the motor contactor (16). Once energized

the three convection fans (17) in the rear of the

oven and a cooling blower (18) located in the

combustion burner compartment start. There

is also a single pole double throw thermal

switch (19) in this circuit that allows the cooling

blower to come on when the oven is turned off

just in case the convection fan compartment

should overheat.

3-3

Page 33

OPERATION

11

10

9

12

7

8

6

13

15

14

17 17 17 17

16

3

2

1

4

5

18

19

1

FIGURE 2

3-4

Page 34

MT3870

CE OVENS

COMPONENT REFERENCE

NOTE: Refer to FIGURE 3 for component locaĆ

tions.

1. BLOWER RELAY

2. MOTOR CONTACTOR

3. CONVECTION FANS

4. CONVECTION PRESSURE SWITCH

5. BELT STOP RELAY

6. DC SPEED CONTROL BOARD

7. MANUAL RESET HI LIMIT SWITCH

8. HEAT RELAY

9. SINGLE POLE SINGLE THROW THERMAL

SWITCH

10. SINGLE POLE SINGLE THROW RELAY

11. TRIPLE POLE DOUBLE THROW RELAY

12. DIFFERENTIAL BURNER PRESSURE

SWITCH

13. COMBUSTION BLOWER MOTOR

14. TEN SECOND PURGE TIMER

15. LANDIS & GYR IGNITION CONTROL SYSTEM

16. 2 SECOND TIMER

17. DUAL SOLENOID GAS VALVE

OPERATION

1. Apply power to the oven. Program the time and

temperature into the computer. The blower

relay (1), belt stop relay (5) and heat relay (8)

pull in and power up three separate circuits.

The voltage to the relay coils is 12 VDC.

2. The blower relay (1) closes sending 230 volts

to the coil of the motor contactor (2). Points 1,

2, 5 and 6 close powering the convection fans.

3. The convection fan pressure switch (4) closes

due to the vacuum that is established in the

burner tube chamber by the operation of the

convection fans.

4. The belt stop relay (5) sends 230 volts to the

DC drive board (6) and the manual reset hi limit

switch (7).

NOTE: This relay will only be powered if there

is a time programmed into the computĆ

er. THE OVEN WILL NOT HEAT IF TIME

IS NOT PROGRAMMED INTO THE

COMPUTER.

5. The heat relay (8) sends 230 volts to a single

pole single throw thermal switch (9). If closed

the relay continues to send power to one side

of a single pole single throw relay (10). This

relay will not see power at it's coil until a triple

pole double throw relay (11) closes.

6. Once the convection fan pressure switch (4)

closes, 230 volts go to a differential pressure

switch (12), the combustion blower motor (13),

terminal #7 and the coil of the triple pole

double throw relay (11).

7. When a differential is sensed at the differential

pressure switch (12) the switch changes posiĆ

tion allowing power to go to terminal #9 of the

triple pole triple throw relay (11). This relay is

a latching relay and is held closed by power

that was applied at terminal #7.

8. Power flows from terminal #8 of the triple pole

double throw relay (11) to a ten second purge

timer (14). This timer allows the combustion

blower (13) to operate for ten seconds allowing

the combustion chamber to clear of any comĆ

bustible gasses.

9. After the timer times out the voltage is applied

to the other side of the coil of the single pole

single throw relay (10). When that set of conĆ

tacts closes, voltage goes to terminal #1 of the

Landis & Gyr ignition control system (15). TerĆ

minal #8 will send power to one side of a two

second timer (16) and the pilot coil of the dual

solenoid gas valve (17). After two seconds

elapse, the voltage is applied to the main coil

of the dual solenoid gas valve (17). If proof of

flame is strong the ignition system stays powĆ

ered up. Should the flame signal be lost, the

ignition control system will lock out.

10. Two sets of contacts are used as a hood interĆ

lock in the motor contactor (2), terminals #13

and #14. At this point there is no power to

these terminals, they act only as a switch to

turn on the hood when the oven is turned on.

NOTE: This is an option that the customer may

use, it is not a requirement.

3-5

Page 35

OPERATION

11

12

9

7

8

14

13

10

3

4

3

17

3

15

16

3

5

6

1

2

FIGURE 3

3-6

Page 36

MT3870

OVEN ADJUSTMENTS FOR COOKING

TEMPERATURE

The internal temperature of your product is very imĆ

portant; and should be taken as soon as the prodĆ

uct completely exits the cooking chamber. This

reading will give a general indication of whether or

not the product is fully cooked. A multiple topping

pizza, for example, will be cooked if the internal

temperature is over 160Ć165F (64Ć67C). For a

single topping, such as cheese, the temperature

should be greater than 170Ć180F (69Ć74C).

CONVEYOR SPEED TIME VS.

TEMPERATURE

Typically, as the temperature increases, the time

decreases. Conversely, as the temperature deĆ

creases, the time increases. To find a good bake

time and temperature, one or the other should reĆ

main constant. For example, if the temperature is

set at 480F (224C) and the belt speed is set at 7

minutes 30 seconds, but the pizza is not as brown

as desired, keep the time setting the same and inĆ

crease the temperature to 500F (234C).

AIR FLOW ADJUSTMENTS

Since a variety of products can be cooked in this

oven, special settings for air flow must be made for

your product. Unless otherwise specified, Blodgett

Mastertherm conveyor ovens are shipped from

the factory with only partial air flow above the conĆ

veyor. This means that most of the air flow holes are

blockedĆoff" via steel strips which stop the heated

air from reaching the item being cooked. These

strips or blockĆoff plates" can be easily relocated

to regulate the amount of air for your particular

needs. The area below the belt has all air flow holes

open.

EXAMPLE:

A good bake time and temperature have been esĆ

tablished, but more browning on top of the pie is

desired. Relocate one of the blockĆoff plates"

above the belt to open a few rows of holes toward

the exit end of the oven. This will allow more of the

superheated air to brown the top just prior to exitĆ

ing the oven.

EXAMPLE:

The bottom of the pie is golden brown, but the top

is a little too dark. Closing off some of the air flow

from the top at the exit end of the oven will cure this

problem. Leave the time and temperature at the

same settings.

EXAMPLE:

The top of the pie is too dark, but either the bottom

is not done enough, the center of the pie is doughy,

or the ingredients are not fully cooked. Open some

of the rows of holes above the conveyor at the entry

half of the oven and close off the holes at the exit.

This will allow the superheated air to penetrate the

pie from the top and bottom (at the beginning of the

cooking cycle) quicker. As a result the center of the

crust and/or ingredients will be cooked before the

pie starts the browning stage. Leave the time and

temperature at the same settings.

WARNING!!

In the event of a power failure, all

switches should be turned off, and no atĆ

tempt should be made to operate the

appliance until power is restored.

In the event of a shut-down of any kind,

allow a five (5) minute shut off period beĆ

fore attempting to restart the oven.

Here are some suggestions for setting up the air

flow. Keep in mind that the first half of the oven is

used for the initial baking of the product and the

last half is used for browning. We will use pizza as

an example.

3-7

Page 37

CHAPTER 4

CALIBRATION AND

ADJUSTMENT

Page 38

MT3870

CONVECTION BLOWER MOTORS

TO CHECK MOTOR ROTATION

1. Remove the back of the oven body and verify

proper motor rotation. (See FIGURE 1)

For motor placement, the direction of rotation is

viewed from the oven's rear and working from left

to right, beginning at the control box. In most

cases, the motor direction is referenced to the end

of the shaft (EOS). However, due to the vertical poĆ

sitioning of the motors in Mastertherm ovens, it is

more instructive to reference the end of the motor

(EOM) as looking from the rear of the oven. In

FIGURE 1 all directions are taken from EOM. The

correct rotation amperage draw is approximately 1

amp. If the measured amperage is less than .5,

check for proper motor rotation direction.

(Side view rotation of Blower Wheel)

Blower

Motor

Slinger

Cooling

Blade

Blower

Motor

TO CHECK LOWĆLIMIT

1. Turn the oven on and let it heat up to approxiĆ

mately 200F (93C).

2. Shut the oven off. The blowers should come

back on in several seconds.

3. Wait for the blowers to shut off.

4. Once the blowers are off, turn the oven back

on. Press the ACT TEMP" key to verify that the

blowers shut off between 135F (57C) and

170F (77C). If the blowers do not shut off reĆ

fer to the Troubleshooting section page

NO TAG.

Slinger

Cooling

Blade

Blower

Motor

Control

Box

Motor #1 Motor #2 Motor #3

(Top view rotation of Blower Wheel)

Motor #1

CW

Motor #2

CCW

Motor #3

CW

FIGURE 1

Motor #4

Control

Box

Motor #4

CCW

4-1

Page 39

REGULATED GAS PRESSURE

CALIBRATION AND ADJUSTMENT

1. Let the oven run up to 510F (266C). You may

now verify the operational and regulated gas

pressures.

Incoming static gas pressure to the unit, with all the

gas appliances drawing from the supply, should be

a minimum of 5.5" W.C. (13.7 mbar) for natural gas

and 11" W.C. (28 mbar) for propane gas. The manĆ

ifold pressure, if measured after the regulator loĆ

cated inside the control box, must be 3.5" W.C. (9

mbar) for natural gas and 10" W.C. (25 mbar) for

propane gas. For CE pressures reference TABLE 2

on page 1-2 of the Introduction.

The pressure can be checked at the tap on the dual

regulated gas valve or at the tap on the tee valve.

If pressure adjustments are needed, turn the adĆ

Pressure

Ta p

Regulator Cap

Regulator

Adjustment

justing screw located under a screw cap on the left

front side of the dual regulated valve. Adjust the

gas pressure by turning the screw clockwise to

raise the gas pressure and counterĆclockwise to

lower the gas pressure. Be sure to reinstall the

screw cap; should the diaphragm rupture this cap

acts as a flow limiter

The air shutter disc on the burner blower motor, loĆ

cated inside the control box at the top of the asĆ

sembly, is factory adjusted to provide the most effiĆ

cient blue flame possible at sea level. Visually

examine the flame to verify it's quality. Should it

need adjustment, increase or decrease the air mixĆ

ture to attain the best flame quality.

Pressure Tap

Inlet

Regulator

Cap

Regulator

Adjustment

Outlet

Pressure

Ta p

Pressure Regulator (U.S. models)

FIGURE 2

Setting Equipment for Other Types of Gas - CE Models

1. Shut off the gas valve and turn off the operating

switch.

2. Dismantle the gas block by means of couĆ

plings.

3. Dismantle the main burner and replace the inĆ

jector.

4. Replace pilot injector.

5. Install the burner and gas block.

6. Check for leakage and possible loose electriĆ

cal connections.

7. Adjust gas pressure if necessary, See

FIGURE 3.

4-2

Pressure Regulator (Some export models)

Gas Pressure

Adjustment

Pressure

Ta p

Pressure Regulator (CE models)

FIGURE 3

Page 40

MT3870

COMPUTER CONTROL CONFIGURATION

INITIATING ACCESS MODE

The Cooking Computer provides a special Access

Mode for setting and displaying certain computer

special functions. To initiate the Access Mode

place the control in the OFF state, (OFF is shown

in the display when power is first applied to the

control). Press the following sequence of keys to

set the control to Access Mode: CLEAR 1 2 3 4 5

6 ENTER. The display will show ACCESS.

DISPLAY ACTION

DISPLAY ACTION TAKEN

TAKEN

F/CMODE? Press

POS OFFSET? Press

NEG OFFSET? Press

MAXĆT ENTRY? Press

PROG

T F(C)

ENTER

PROG

0(0) Press

ENTER

PROG

0(0) Press

ENTER

PROG

600(315) Press or change then

ENTER

CONFIGURATION

When the controller is in the ACCESS" mode,

press the following buttons: CLEAR 1 1 1 ENTER.

With the exception of the positive and negative offĆ

sets, to be addressed later, all display data should

correspond to the entries in the chart below. If the

data does not match the chart, it should be

changed accordingly. When the correct data is disĆ

played press the PROG/ENTER key, the display

will cycle on to the next screen. If a step is missed,

press the CLEAR button to backup.

Press again or hit any number and

press again.

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

it will change.

MAXĆT LIMIT? Press

READY BAND? Press

MINĆHT ON? Press

DISPLAY INTEG? Press

TĆCTRL INTEG? Press

PROG

625(330) Press

ENTER

PROG

10 Press

ENTER

PROG

60 Press

ENTER

PROG

30 Press

ENTER

PROG

10 Press

ENTER

Boost Option - (versions 2.00 or 3.00)

When the controller is in the ACCESS" mode,

press the following buttons: CLEAR 2 1 2 ENTER

to enter the boost option.

DISPLAY ACTION

DISPLAY ACTION TAKEN

TAKEN

BOOST / MODEĆ?

(Flash alternately)

Press

PROG

ENTER

OPTĆ1 or

OPTĆ2

Select OPTĆ1 to turn off boost mode.

TABLE 1

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

Press any numeric key to toggle between

OPTĆ1 and OPTĆ2

4-3

Page 41

CALIBRATION AND ADJUSTMENT

DISPLAY ACTION TAKENDISPLAYACTION

TAKEN

OPTĆ1 Press

PROG

ENTER

DONE

SAVE

Press

EXIT

OPTĆ2 may be selected for MT3870 ovens only. If OPTĆ2 is selected values will be sequenced by pressing

the PROG/ENTER key. Any value can be changed when its value is displayed, by entering the new nuĆ

merical value followed by the PROG/ENTER key. After sequencing through all values the display will

return to ACCESS.

TEMP BOOST

DEAD BAND?

TEMP BOOST

PLUS FACTOR?

TEMP BOOST

MINUS FACTOR?

TEMP CONTROL

MODE?

TEMP BOOST

STAGE1 TIME?

TEMP BOOST

STAGE1 TEMP?

TEMP BOOST

STAGE2 TIME?

TEMP BOOST

STAGE2 TEMP?

TEMP BOOST

STAGE3 TIME?

TEMP BOOST

STAGE3 TEMP?

Press

Press

Press

Press

Press

Press

Press

Press

Press

Press

PROG

+/Ć 1F Press

ENTER

PROG

+2 SEC Press

ENTER

PROG

Ć4 SEC Press

ENTER

PROG

TIGHT Press

ENTER

PROG

4 SEC Press

ENTER

PROG

10F Press

ENTER

PROG

7 SEC Press

ENTER

PROG

10F Press

ENTER

PROG

10 SEC Press

ENTER

PROG

10F Press

ENTER

DONE

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

EXITING THE ACCESS MODE

After pressing PROG/ENTER the last time, the disĆ

play will show EXIT" then beep and return to the

ACCESS" mode. Pressing and holding the ON/

OFF key will turn the oven on. A new time and temĆ

perature must be entered upon exiting the ACĆ

CESS" mode since the oven will automatically

default to 0. The oven will not fire until both time and

temperature are entered.

TABLE 2

Firmware Model Version Display

Password: CLEAR 1 2 3 ENTER

MODEL Ć Computer Model Number - 6028

(Blodgett Conveyor Oven With Speed Control)

SWĆVER Ć Firmware version number. VĆxxyy xx =

major version, yy = minor version

DATEĆ? ĆFirmware release date

CHKSUM Ć ROM checksum stored in PROM. xxxx

Ć Value is display in hexadecimal format.

4-4

Page 42

MT3870

TEMPERATURE CALIBRATION

TO ENTER THE CALIBRATION MODE

1. Press the ON/OFF key until OFF is displayed.

2. Press CLEAR 1 2 3 4 5 6 ENTER to enter the

access mode. The display reads ACCESS.

3. Press CLEAR ACT_TEMP ACT_TEMP

ACT_TEMP ENTER to access the Temperature

Calibration mode.

4. Disconnect the white wire from the D.C. motor.

Secure so the wire will not ground against any

part of the oven. This will disable the conveyor.

NOTE: Disregard the controller display. The only

numbers of concern are the pyrometer

reading and the temperature set point.

TO CALIBRATE THE OVEN TEMPERATURE

During operation, the temperature control is based

on the measured temperature and the temperaĆ

ture offset which is programmed into the control. If

the temperature measured in the center of the

oven is below the oven setpoint a positive offset is

needed. If the temperature measured in the center

of the oven is above the oven setpoint a negative

offset is needed.

NOTE: In the calibration mode the display gives

the current measured temperature only.

To view the current temperature setpoint:

1. Press the SET_TEMP, key.

To change the temperature setpoint :

1. Press PROG/ENTER SET_TEMP.

2. Enter the desired setpoint.

3. Press the PROG/ENTER key.

To program the temperature offset:

To change the temperature calibration an offset,

positive or negative, must be programmed.

1. Press PROG/ENTER followed by ACT_TEMP.

The display flashes either POS * OFFSET or

NEG * OFFSET

NOTE: POS OFFSET is displayed if a value has

been programmed in for a positive offĆ

set. NEG OFFSET is displayed if a valĆ

ue has been programmed for a negaĆ

tive offset. The only time both will be

displayed is if a value of 0 has been enĆ

tered for both.

2. Enter a value for the desired offset. The display

flashes DISPLAY * INTEG?.

3. Press the PROG/ENTER key. The default value

of 30 will be displayed.

4. Press the PROG/ENTER key. The display will

flash TĆCTRL * INTEG?.

5. Press the PROG/ENTER key. The default value

of 10 will be displayed.

6. Press the PROG/ENTER key.

The control will now resume using the new paramĆ

eters.

Verify the temperature calibration once the unit has

cycled for 5 minutes with the new settings. Repeat

calibration using a new offset value if necessary.

TO EXIT THE CALIBRATION MODE

1. Press the CLEAR key twice.

2. The display flashes REBOOT then displays the

set time and temperature. You must reĆenter a

temperature for the oven to start heating again.

A.) Press PROG/ENTER SET_TEMP

B.) Enter the desired temperature.

C.) Press the PROG/ENTER key. The heat

light turns on and the burner begins to

cycle at set point.

4-5

Page 43

BELT SPEED CALIBRATION

CLOSED LOOP SYSTEM

CALIBRATION AND ADJUSTMENT

To enter the calibration mode:

1. Press the ON/OFF key until OFF is displayed.

2. Press CLEAR 1 2 3 4 5 6 ENTER to enter the

Access mode. The display reads ACCESS.

3. Press CLEAR TIME TIME TIME ENTER to acĆ

cess the Belt Speed Calibration mode. The disĆ

play flashes INIT.

Belt speed calibration:

1. OVEN LENGTH - Set the length of the conveyĆ

or belt using the information from TABLE 3.

2. MOTOR RATIO - Set the motor gear ratio from

the information from TABLE 3.

3. SHAFT TEETH - Set the shaft teeth number

from the information from TABLE 3.

4. MOTOR TEETH - Set the motor teeth number

from the information from TABLE 3.

5. BELT RADIUS - Set the belt radius from the inĆ

formation from TABLE 3.

NOTE: The values given are estimates. If you

reenter the calibration mode after setĆ

ting the belt speed, the belt radius may

differ from the table.

6. The display gives a four digit value followed by

the letter K. Press ENTER twice to verify the

belt time.

Belt speed verification:

1. ENTER TEST TIME - Enter a test time to verify

the belt speed. The default setting is 7 minutes.

2. WAIT - 1 second delay before the belt moves.

3. ENTER ACTUAL TIME - Place an object on

the belt. Note the time from entrance to exit.

Enter the actual measured time.

4. ENTER TEST TIME - If the actual measured

time is not within 5 seconds of the test time, reĆ

peat the belt verification test to obtain better

accuracy. If the actual measured time is acĆ

ceptable, press the CLEAR key to continue the

belt speed calibration.

5. MAX/MIN CALC TIME - The control sets the

fastest and slowest cook time the user can proĆ

gram. This requires a 1 minute delay in the calĆ

ibration process.

NOTE: If the control cannot read the shaft enĆ

coder the display reads ERROR then

ABORT before exiting belt calibration.

Verify the connection of the encoder

Restart the belt speed calibration.

6. The display flashes MIN SET TIME? Press the

PROG/ENTER key to display the calculated

minimum set time. Press the PROG/ENTER

key to accept this value or enter a new time

with a value higher than the default. Press

PROG/ENTER again to accept.

7. The display flashes MAX SET TIME? Press the

PROG/ENTER key to display the calculated

maximum set time. Press the PROG/ENTER

key to accept this value or enter a new time

with a value lower than the default. Press

PROG/ENTER again to accept.

8. The display reads DONE.

To save the new belt speed:

1. Press ENTER to save the belt speed calibraĆ

tion program in the control's memory.

Oven Type Oven Length Motor Ratio Shaft Teeth Motor Teeth Belt Radius

MT3870 70 600 15 12 8,712

MT3855 55 600 15 12 8,712

MT3270 70 600 15 12 8,712

MT3240 40 600 15 12 8,893

MT2136 36 600 15 12 8,712

MT1828 28 600 24 24 7,209

TABLE 3

4-6

Page 44

MT3870

OPEN LOOP SYSTEM - SINGLE BELT

To enter the calibration mode:

1. Press the ON/OFF key until OFF is displayed.

2. Press CLEAR 1 2 3 4 5 6 ENTER to enter the

Access mode. The display reads ACCESS.

3. Press CLEAR TIME TIME TIME ENTER to acĆ

cess the Belt Speed Calibration mode. The disĆ

play flashes INIT.

Belt speed calibration:

1. The display reads BELT SIZE-?. Enter the

length of the conveyor belt for your model. See

TABLE 4. Press the PROG/ENTER key.

2. The display reads STEP-1. The controller is in

Step 1 of the calibration procedure: maximum

belt speed. The motor control is automatically

set to its maximum output. Place an object on

the belt and note the time from entrance to exit.

NOTE: Be certain to measure either the leadĆ

ing edge in and out or the trailing edge

in and out. Do not use the leading edge

in and the trailing edge out.

A.) The display reads STEP-1TIME-?. Enter

the time measured in STEP-1. Min: 0

Max: 59:59 (min:sec). Press the PROG/

ENTER key.

B.) The display reads STEP-1DIST-?. Enter

the belt length for your model. See

TABLE 4. Press the PROG/ENTER key.

3. The display reads STEP-2. The controller is in

Step 2 of the calibration procedure: minimum

belt speed. The motor control is automatically

set to its minimum output.

The belt will travel very slowly during this part

of the calibration procedure. To minimize the

time spent on STEP-2, measure off 10" on the

conveyor support. Place an object on the belt

and note the travel time for the 10" measured

distance.

A.) The display reads STEP-2 TIME-?. Enter

the measured travel time for STEP-2. Min:

0 Max: 59:59 (min:sec). Press the PROG/

ENTER key.

B.) The display reads STEP-2 DIST-?. Enter

10". Press the PROG/ENTER key.

4. The display reads MIN-TM ENTRY? (the fastĆ

est belt speed). Limits of this value are deterĆ

mined by the Step-1 and Step-2 calibration

values. See TABLE 4 for correct entry for this

model. Press the PROG/ENTER key.

5. The display reads MAX-TM ENTRY? (slowest

belt speed). Limits of this value are determined

by the Step 1 and Step 2 calibration values.

Use 1600 (16 min). Press the PROG/ENTER

key.

6. The display flashes DONE and SAVE. Press

the PROG/ENTER key to permanently store

the calibration values in nonĆvolatile memory

(NOVRAM).

NOTE: During these adjustments, pressing the

clear button will abort all entries and reĆ

quire reprogramming of belt time mode.

When exiting the Belt Speed Calibration

Mode, enter a time. Otherwise the time deĆ

faults to zero and the oven will not heat, and

the belt will not move.

Oven

Type

MT1828 28 330 (3 min, 30 sec) MT3270 70 330 (3 min, 30 sec)

MT2136 36 200 (2 min) MT3855 55 330 (3 min, 30 sec)

MT3240 40 300 (3 min, 00 sec) MT3870 70 330 (3 min, 30 sec)

MT3255 55 300 (3 min, 00 sec)

Belt Length/

Distance

Minimum

Oven Entry

TABLE 4

4-7

Oven

Type

Belt Length/

Distance

Minimum

Oven Entry

Page 45

OPEN LOOP SYSTEM - TWIN BELT

CALIBRATION AND ADJUSTMENT

To enter the calibration mode:

1. Press the ON/OFF key until OFF is displayed.

2. Press CLEAR FRONT BELT, FRONT BELT,

FRONT BELT, PROG/ENTER to enter the AcĆ

cess mode. The display flashes ACCESS.

3. The display reads ACTIVE BELT-?. Press front

belt for Front Belt Calibration

4. The display reads FRONT-INIT-F.

Belt speed calibration:

1. The display reads BELT SIZE-?. Enter the

length of the conveyor belt for your model. See

TABLE 5. Press the PROG/ENTER key.

2. The display reads STEP-1. The controller is in

Step 1 of the calibration procedure: maximum

belt speed. The motor control is automatically

set to its maximum output. Place an object on

the belt and note the time from entrance to exit.

NOTE: Be certain to measure either the leadĆ

ing edge in and out or the trailing edge

in and out. Do not use the leading edge

in and the trailing edge out.

A.) The display reads STEP-1TIME-?. Enter

the time measured in STEP-1. Min: 0

Max: 59:59 (min:sec). Press the PROG/

ENTER key.

B.) The display reads STEP-1DIST-?. Enter

the belt length for your model. See

TABLE 4. Press the PROG/ENTER key.

3. The display reads STEP-2. The controller is in

Step 2 of the calibration procedure: minimum

belt speed. The motor control is automatically

set to its minimum output.

The belt will travel very slowly during this part