Page 1

MT3255E

CONVEYOR OVENS

FOR GENERAL EXPORT

INSTALLATION -- OPERATION -- MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN M9126 Rev B (6/01)

E 2000 --- G.S. Blodgett Corporation

Page 2

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

The information contained in this manual is important for the proper

installation, use, and maintenance of this oven. Adherence to these

procedures and instructions will result in satisfactory baking results

and long, trouble free service. Please read this manual carefully and

retain it for future reference.

Errors: Descriptive, typographic or pictorial errors are subject to correc-

tion. Specifications are subject to change without notice.

Page 3

BLODGETT - THE REPUTATION YOU CAN COUNT ON

For nearly a century and a half, The Blodgett Oven Company

has been building ovensand nothing but ovens. We’ve set the

industry’s quality standard for all kinds of ovens for every foodservice operation regardless of size, application or budget. In

fact, no one in the foodservice industry has more oven engineering experience than Blodgett, and no one offers more

models, sizes, and oven applications than Blodgett; gas and

electric, full-size, half-size, countertop and deck, convection,

Cook’n Hold, Combi-Ovens and the industry’s highest quality

Pizza Oven line. For more information on the full line of

Blodgett ovens contact your Blodgett representative.

Page 4

Your Service Agency’s Address:

Model:

Serial Number:

Your oven w a s installed by:

Your oven’s installation was checked by:

Page 5

Tab l e o f C o n t e n t s

Introduction

Oven Description and Specifications 2................................

Oven Components 3...............................................

Installation

Delivery and Inspection 4...........................................

Oven Location 5...................................................

Oven Assembly 6..................................................

Oven Supports and Casters 6....................................

Return Air Diverters 6............................................

Nozzles 7......................................................

Conveyor Belt Support 7.........................................

Conveyor Belt 8................................................

End Plugs 10....................................................

Crumb Pans 10..................................................

Electrical Connection 11.............................................

Operation

Safety Information 12................................................

Standard Controls 13................................................

Oven Adjustments for Cooking 14.....................................

Maintenance

Cleaning 16........................................................

Troubleshooting Guide 18............................................

Page 6

Introduction

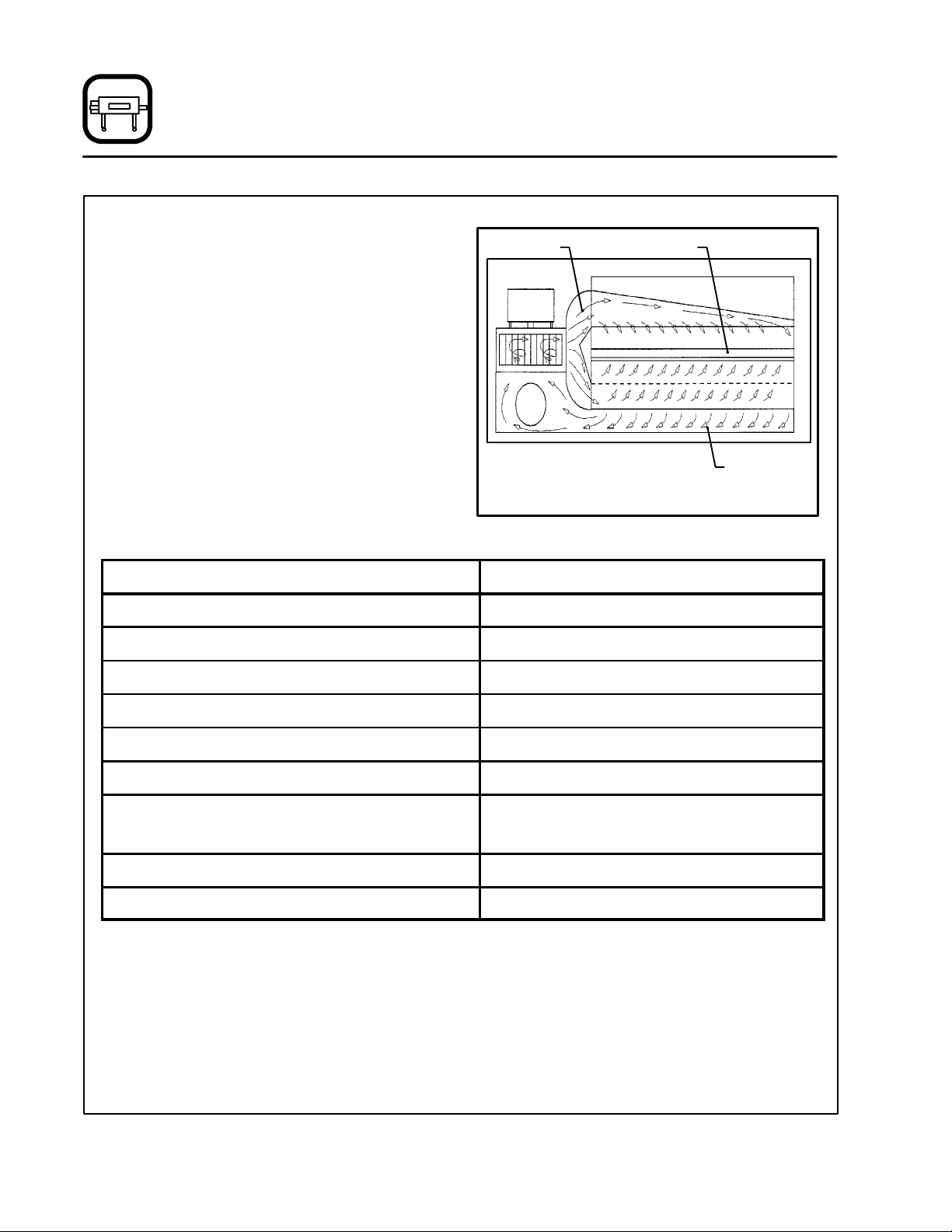

Oven Description and Specifications

Cooking in a conveyor oven differs from cooking

in a conventional deck or range oven since heated

air is constantly recirculated over the product by

a fan in an enclosed chamber. The moving air continually strips away the layer of cool air surrounding the product, quickly allowing the heat to penetrate. The result is a high quality product, cooked

at a lower temperature in a shorter amount of time.

Blodgett conveyor ovens represent the latest advancement in energy efficiency, reliability, and

ease of operation. Heat normally lost, is recirculated within the cooking chamber before being

vented from the oven: resulting in substantial reductions in energy consumption, a cooler kitchen

environment and enhanced oven performance.

SPECIFICATIONS

Belt Width 32” (81 cm)

Cooking Zone Length 55” (140 cm)

Baking Area 12.2 Sq. Ft. (1.13 m2)

Heated Air Conveyor

AirFlowPatternforBlodgettConveyorOvens

Return Air

Figure 1

MT3255E

Dimensions (single unit) 85” x 62” x 44.5” (216 cm x 158 cm x 113 cm)

Maximum Input 34 kW/Hr.

Maximum Operating Temperature 600_F (315_C)

Power Supply 380/220VAC ,3Φ,50Hz.,4wirew/ground

415/240VAC ,3Φ,50Hz.,3wirew/ground

Product Clearance 3.5” (6.4 cm)

Gas Supply Connection None

2

Page 7

Introduction

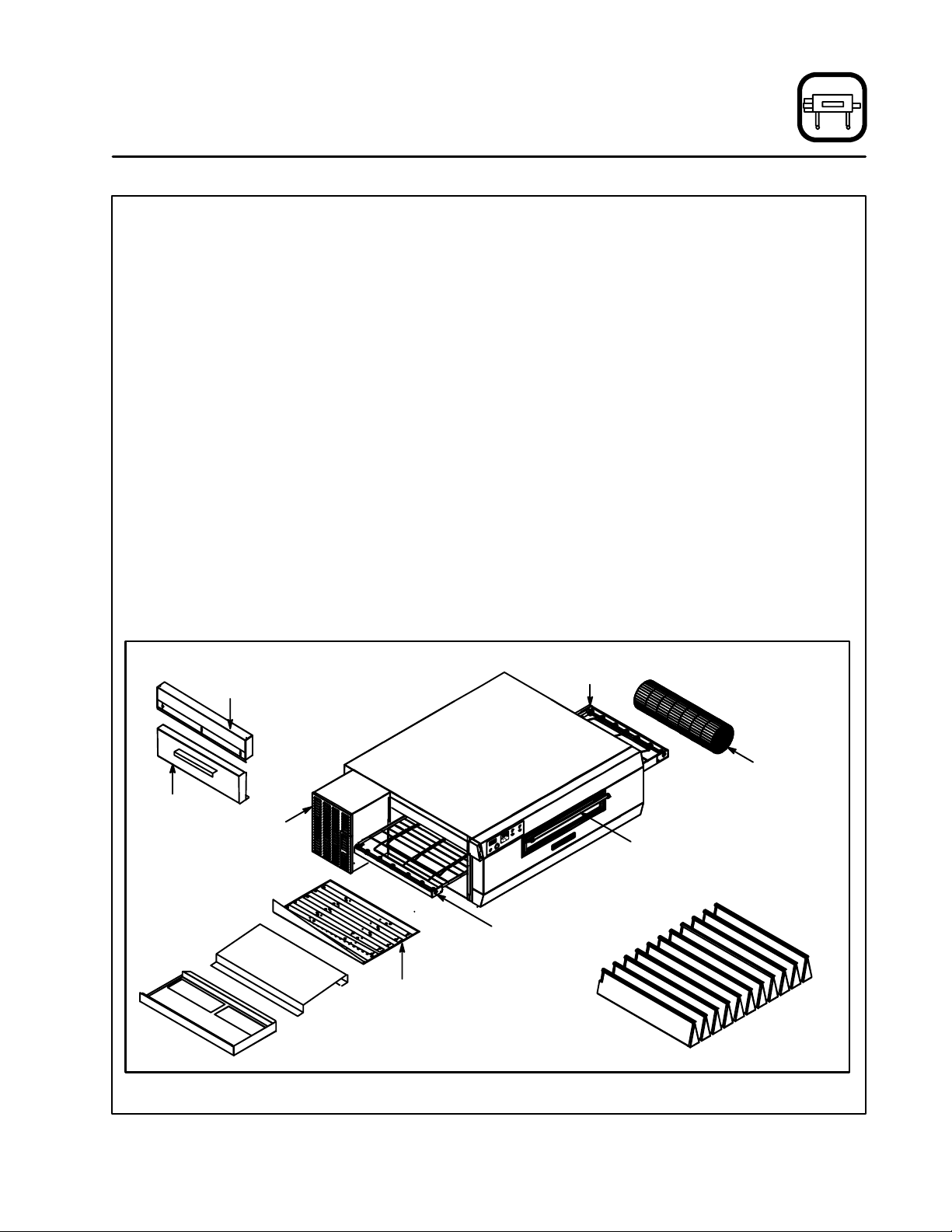

Oven Components

Conveyor Belt --- stainless steel chain link (con-

veyor) belt that carries product through the oven.

Conveyor Belt Master Links --- a l l o w e a s y r e m o v al of the conveyor belt for maintenance and cleaning. Identified by locating double spaces between

regular links on belt.

Conveyor Belt Support Assembly (drive & idle

sides) ---locatedonbothendsofovendeck.Drive

side support drives conveyor belt.

Control Box --- contains electrical wiring, cooling

fan, drive motor and drive chain.

Drive Motor --- provides power to move the conveyor belt.

Drive Chain --- connects the drive motor sprocket

to the drive side conveyor belt support sprocket.

Baking Chamber --- products pass through the

baking chamber on the conveyor belt for cooking.

Nozzles --- distribute heated air to the bottom of

the baking chamber. Located inside the oven, under the conveyor belt.

Upper

End Plug

Nozzle Hold-Down Bracket --- holds the front end

of the nozzles in position. Located inside the oven.

Return Air Diverters (2, drive and idle sides) --diverts return air from the baking chamber back to

the combustion chamber. Ensures even baking

throughout oven. Located inside the oven, beneath the nozzles.

Upper End Plug --- keeps heat in the baking

chamber. Located on each end above the conveyor belt.

Lower End Plug --- helps keep heat in the baking

chamber. Located at each end below t he conveyor belt.

Crumb Pan --- catches crumbs from products on

the conveyor. Located under conveyor belt at both

ends of the baking chamber.

Pull Down Door --- open for auxiliary product insertion.

Air Flow Plates (2, drive and idle sides) --- d i s tribute heated air to top of baking chamber. Located inside of oven at the top of baking chamber.

Conveyor Support

Assembly

Lower

End Plug

Crumb

Pan

Return Air

Diverter

Control

Box

Conveyor Belt

Handle for

Pull Down Door

Conveyor

Support

Assembly

Air Flow Plate

Nozzles

Figure 2

3

Page 8

Installation

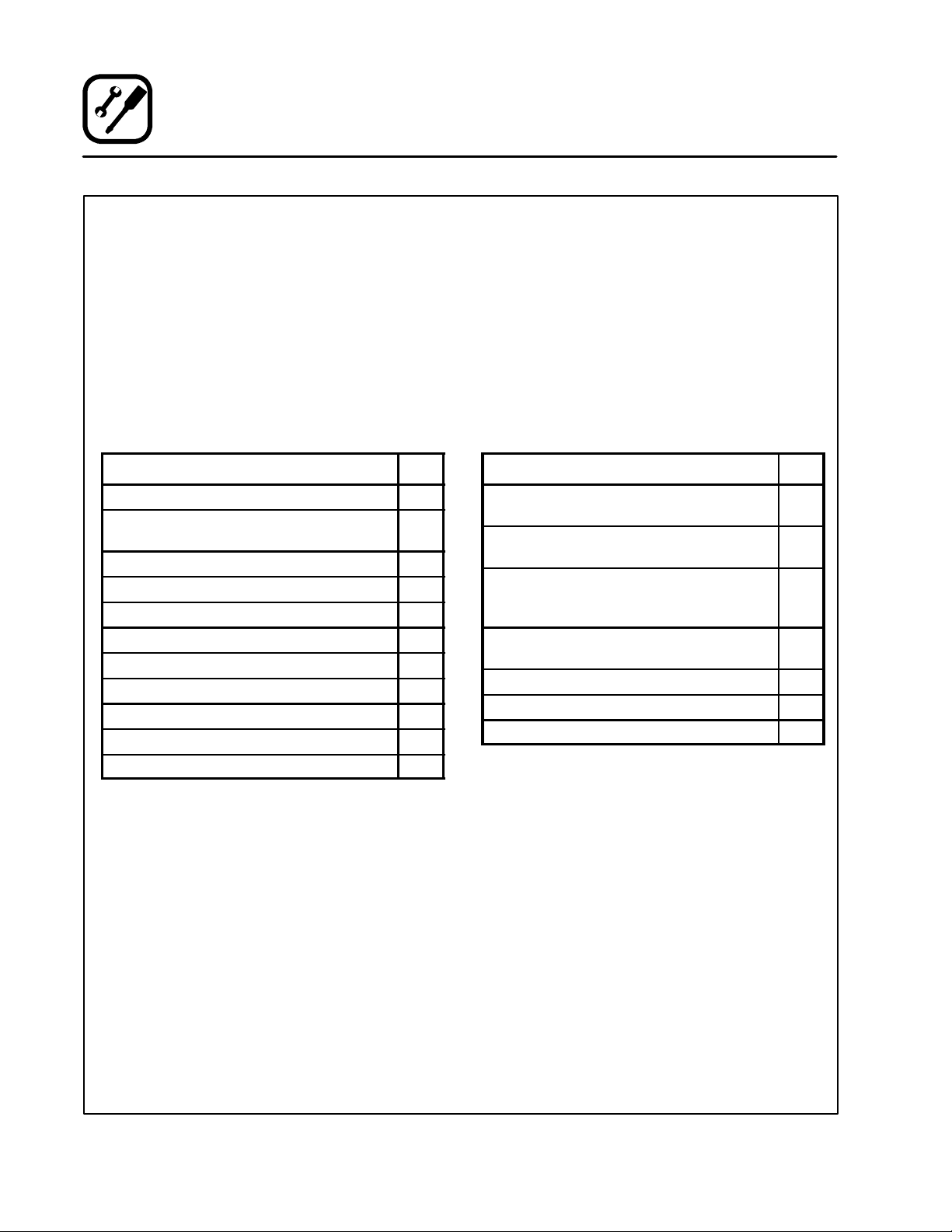

Delivery and Inspection

All Blodgett ovens are shipped in containers to

prevent damage. Upon delivery of your new oven:

D

Inspect the shipping container for external damage. Any evidence of damage should be noted

on the delivery receipt which must be signed by

the driver.

D

Uncrate the oven and check for internal damage. Ca rriers will accept claims for concealed

damage if notified within fifteen days of delivery

and the shipping container is retained for inspection.

Part Description

Main oven body 1

Oven support/with caster

(2 locking, 2 non-locking)

Left conveyor belt support assembly 1

Rightconveyorbeltsupportassembly 1

Upper end plug assemblies 2

Lower end plug assemblies 2

Rolled wire belt** 1

Crumb pan 2

Nozzles 11

Window assembly 1

Air flow plate removal handle 1*

Qty.

4*

The Blodgett Oven Company cannot assume

responsibility for loss or damage suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a cl aim is necessary.

The oven can now be moved to the installation

site. Check the following list with Figure 2 on page

3 to be sure all items were received.

Part Description Qty.

Packet containing:3/8”-16 bolts

(for oven supports)

Packet containing: flat & lock washers

(for oven supports)

Packet containing:

(2) 10 amp. motor circuit fuses,

(2) 2 amp. control circuit fuses

Packet containing: conveyor belt master

links**

Extra piece of wire conveyor belt** 1*

Owner’s manual 1*

Return air diverters 2

NOTE: * not shown on Figure 2

** Two of these items are included for

dual belt models

1*

1*

1*

1*

4

Page 9

Installation

Oven Location

LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

The following clearances must be maintained between the oven and any combustible or non-combustible construction.

D

Oven body sides --- 20” (51 cm)

D

Oven body back --- 2” (5 cm)

The following clearances must be available for servicing.

D

Oven body sides --- 38” (96.5 cm)

D

Oven body back --- 28” (71 cm)

It is essential that an adequate air supply to the

oven be maintained.

D

Place the oven in an area that is free of drafts.

D

Keep the oven area free and clear of all combustibles such as paper, cardboard, and flammable

liquids and solvents.

D

Do not place the oven on a curb base or seal to

a wall. This will restrict the flow of air and prevent

proper ventilation to the blower motors. This

condition must be corrected to prevent permanent damage to the oven.

General export installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your Blodgett oven, please contact

your local distributor. If you do not have a local distributor, please call the Blodgett Oven Company at

0011-802-860-3700.

5

Page 10

Installation

Oven Assembly

OVEN SUPPORTS AND CASTERS

1. Bolt the supports to the oven with 3/8-16 hex

head bolts.

NOTE: Install the locking casters on the front

of the oven.

2. Carefully place the oven onto casters. Have

several persons lift the oven off the pallet and

set it onto the casters.

3. Engage the brakes on the front casters.

4. Remove the crating supports from the rear of

the oven.

RETURN AIR DIVERTERS

1. Slide the left and right air diverters into the bottom of the baking chamber. See Figure 4 for

proper orientation. The outside edges of the

diverters should be 3” (11.8 cm) from the edge

of the oven.

Front of

Oven

Figure 3

3” (11.8 cm)

Figure 4

Crating

Support

6

Page 11

Installation

Oven Assembly

NOZZLES

1. Install nozzles from center of oven working toward the ends. Make sure the bottom of

nozzle fits into the slot in the nozzle support toward the front of the oven.

2. Secure the nozzle hold-down strip across the

inside front of the oven using the existing

screws located on the oven wall.

Figure 5

CONVEYOR BELT SUPPORT

1. Slide the left conveyor support (with sprocket

on the end of the shaft) into the support tracks.

The sprocket must be inside the control box

after being pushed into the oven.

Figure 6

2. Install the drive chain around the drive motor

and the sprocket on the conveyor support.

Push the support back to tighten the chain.

Figure 7

3. Tighten the four bolts on the control box.

4. Slide the right conveyor support into the support tracks until it touches the left stop.

7

Page 12

Installation

Oven Assembly

CONVEYOR BELT

Be sure to install the belt from left to right. The conveyor belt has loops on both sides. The loops must

travel backwards on the conveyor support. See

Figure 8.

Belt Top

Direction of

Conveyor Travel

To thread the conveyor belt

1. Start from the right hand side of the oven, lowerlevelfirst.Unrollthebeltasshownin

Figure 9, otherwise the belt will be upside

down. Leave about one foot hanging out on

the left side

NOTE: If belt travel is from left to right, start

fromtheleftsideoftheoven.

2. Take the remainder of the belt, loop it around

the right shaft. Push through on the upper level.

3. The two ends of the belt should be approximately 6-9 inches past the left shaft on the upper level of the belt support. Right shaft if right

to left travel is required.

Figure 8

Unless specified otherwise, conveyor travel is factory set for left to right operation when facing the

front of the oven. To change direction:

D

Reverse the polarity of the drive motor. Interchange the black and white motor leads at the

D.C. controller located in the control panel.

D

Install the conveyor belt from the left side of the

oven.

Figure 9

Figure 10

8

Page 13

Installation

Oven Assembly

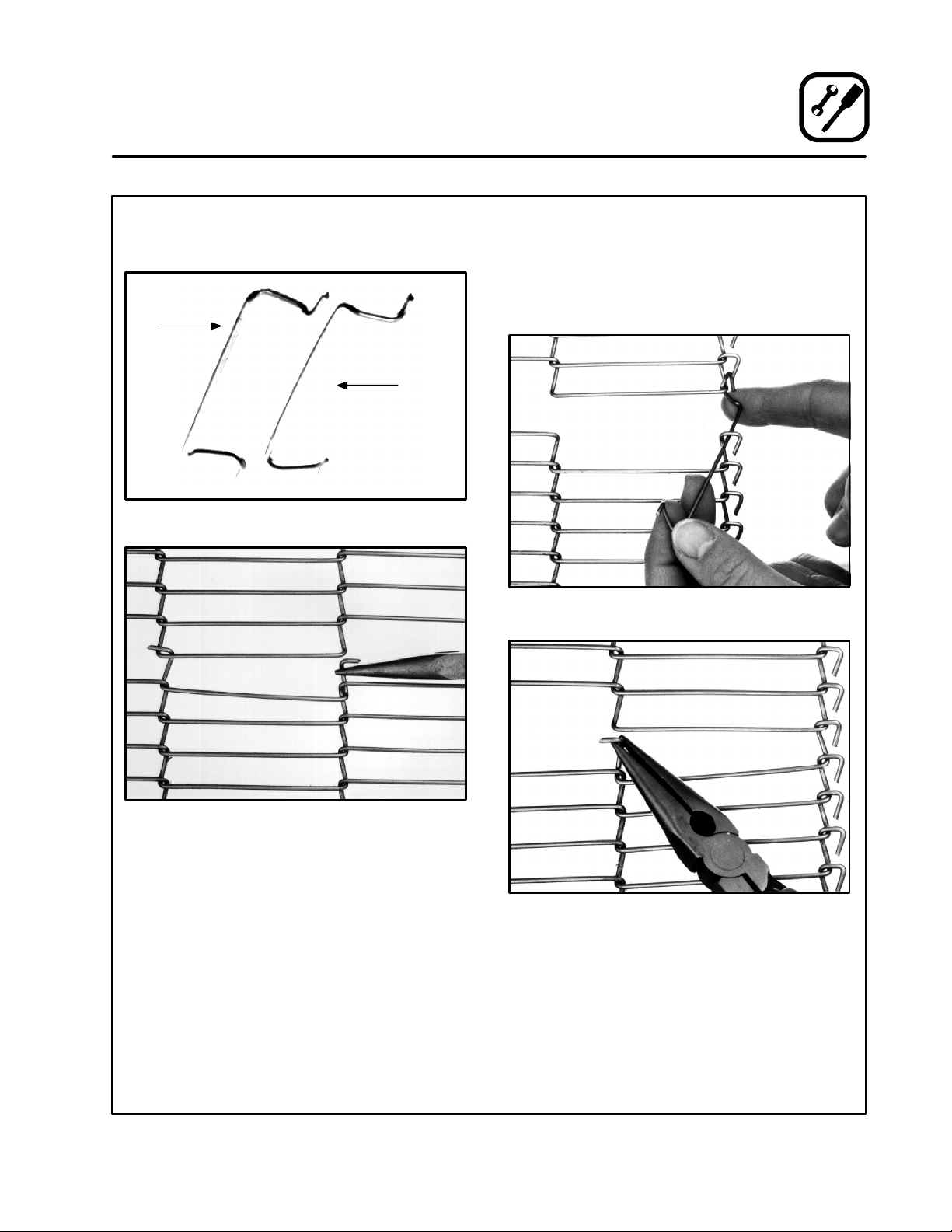

4. Install inner master links. See Figure 11 and

Figure 12.

Upside-down

Proper

Position

Figure 11

5. Install the outer master links. See Figure 13

and Figure 14

NOTE: The extra piece of wire belt can be used to

make additional master links if the original

links are lost or damaged.

Figure 13

Figure 12

Figure 14

9

Page 14

Installation

Oven Assembly

END PLUGS

1. Install the upper and lower end plugs at both

ends of the oven. Secure the upper end plugs

with two wing nuts on the bottom of each plug.

Upper End Plug

CRUMB PANS

1. Install crumb pans under each end of the conveyor. The oven is now ready to be rolled into

place and connected to gas/power supplies

for adjustment and start-up procedure.

Figure 16

Lower End Plug

Figure 15

10

Page 15

Before making any electrical connections to this

unit, check that the power supply is adequate for

the voltage, amperage, and phase requirements

stated on the rating plate.

NOTE: The rating plate is mounted on the control

box.

A wiring diagram accompanies this manual and is

also attached inside the control panel.

The MT3255E is available in two voltage options.

D

The 380/220 VAC oven requires a 60 Amp,

50Hz, 3Φ, 4 wire service consisting of L1, L2

neutral and ground.

D

The 415/240 oven requires a 60 Amp, 50Hz, 3Φ,

3 wire service consisting of L1, neutral an d

ground.

Use 90_C wire and size wire according to local

codes.

Installation

Electrical Connection

L1

415/380

L2

415/380

L3

N

Figure 17

THE BLODGETT OVEN COMPANY CANNOT ASSUME RESPONSIBILITY FOR LOSS OR DAMAGE

SUFFERED AS A RESULT OF IMPROPER INSTALLATION.

415/

380

240/

220

OvenSupply

11

Page 16

Operation

Safety Information

THE INFORMATION CONTAINED IN THIS SECTION IS PROVIDED FOR THE USE OF QUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATIONOF THE EQUIPMENT DESCRIBED. ADHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

and operating instructions. They are the key to the

successful operation of your Blodgett conveyor

oven.

SAFETY TIPS

For your safety read before operating

General safety tips:

D

DO NOT remove the control box cover unless

the oven is unplugged.

12

Page 17

Operation

Standard Controls

CONTROL DESCRIPTION

1. COOK TIME DISPLAY --- gives the belt speed.

2. UP and DOWN ARROW KEYS --- used to increase/decrease desired cook time

3. ACTUAL TEMPERATURE KEY --- press to display the actual oven temperature.

4. ACTUAL TEMPERATURE LIGHT --- when lit indicates the control is displaying the actual

oven temperature.

5. SETPOINT LIGHT --- when lit indicates control

is displaying desired cook temperature.

6. HEAT LIGHT --- when lit indicates that the control is calling for heat.

7. UP and DOWN ARROW KEYS --- used to increase/decrease desired cook temperature.

8. HEAT SWITCH --- used to ignite the burner.

9. BLOWER SWITCH --- controls power to the

blowers.

10. CONVEYOR SWITCH --- turn to ON to begin

conveyor travel.

OPERATION

1. TurnthemanualgasvalvetoOPEN.Thisis

only necessary on initial start-up.

2. Turn the BLOWER SWITCH (9) to ON.

3. Press the UP or DOWN ARROW keys (7) to

scroll to the desired cook temperature.

4. Turn the HEAT SWITCH (8) to ON.

NOTE: If the oven fails to ignite after the thirty

(30) second purge, turn the blower

switch to OFF. Wait five minutes before

turning the blower switch back to ON.

5. Press the ACTUAL TEMPERATURE KEY (3). If

the actual temperature matches the setpoint

the oven is ready to cook.

NOTE: The display flashes until the actual

temperature is within the preset deviation alarm band. The default setting is

¦ 20_F(12_C) of the setpoint.

6. Turn the CONVEYOR SWITCH (10) to ON.The

conveyor belt starts to move. Press the UP or

DOWN ARROW keys (2) to scroll to the desired cook time.

7. Turn the BLOWER (9), CONVEYOR (10) and

HEAT (8) SWITCHES to OFF. The Cool Down

circuit is energized. The blower motor(s) continue to run until the oven temperature is between 135-170_F (57-77_C). The blower motor(s) automatically shut off. For faster cool

down, open the window.

The oven holds these parameters daily and requires no further adjustments unless a new type

of product is placed in the oven.

NOTE: Each oven contains different components

and must be adjusted individually.

10

COOK TIME

ON OFF

CONVEYOR

1

ACTUAL SETPOINT HEAT

TEMPERATURE

6

83 4 5 72

ON OFF

HEAT

9

ON OFF

BLOWER

Figure 18

13

Page 18

Operation

Oven Adjustments for Cooking

The combination of belt time, oven temperature,

and air flow are important for achieving quality re sults from your Blodgett conveyor oven. Use the

following guidelines to adjust the belt time and

oven temperature of your unit. For questions regarding further oven adjustments, please contact

your local Blodgett Sales Representative for assistance.

CONVEYOR SPEED AND OVEN TEMPERATURE

Conveyor belt speed (cook time) and oven temperature are the two variables used w hen fine tuning your oven for a specific product. To determine

the optimum bake time and temperature, make

small changes for each trial and keep one variable

constant. For example, if the oven temperature is

460_F (238_C) and the belt speed is 7 minutes,

but the pizza is not browned enough, increase the

temperature to 475_F (246_C) and keep the belt

speed the same. However, if the center of the pizza

is not completely cooked, keep the oven temperature the same, and increase the bake time to 7

minutes and 30 seconds. In general, raise the

bake temperature to increase browning, and

lengthen the belt time to increase doneness.

FINISHED PRODUCT TEMPERATURES

Internal temperatures of the cooked products

should be measured immediately after the product exits the cooking chamber to ensure a safe

food temperature. Internal pizza temperatures

should be over 165_F(74_C). Minimum tempera-

ture guidelines vary depending on the food items.

Air flow adjustments may be necessary to fine

tune the oven for your particular product. The air

plate, located at the top of the baking chamber,

contains holes that can be covered using Block-off

Plates. The plates can easily be adjusted to regulate the air flow for your particular needs. Use the

following guidelines to adjust the Block-off Plates.

1. Ensure the oven is Off and completely cooled.

2. Remove both upper end plugs. Loosen the

wing nuts on the bottom of each end plug.

3. Loosen the wing screws holding the air plate

retainers in place. Remove the four wing

screws from the control box end of the oven.

Slide the air plates straight out from both ends

of the oven.

4. Remove the wing nuts, screws, and washers

holding the Block-off Plates.

5. Adjust the plates.

6. Replace the wing nuts, screws, and washers

to tightly secure the Block-off plates in their

new locations. Make a sketch of the final airplate setup for future reference.

NOTE: One or two block-off plates may be left

off entirely if appropriate to obtain the

desired results.

7. Replace the air plate and upper end plugs.

AIR FLOW AD JUSTMENTS

Slide the product clearance adjustment plates to

the lowest possible setting for your menu items.

Lowering the clearance plates will reduce the

amount of hot air escaping from the chamber

openings.

Most often, the ideal oven settings can be dialed

in without making any changes to the airplate. The

oven configuration should not be modified unless

the oven time and temperature adjustments have

proven unsuccessful.

Figure 19

14

Page 19

The following examples illustrate air flow regulation.

NOTE: The first half of the oven chamber greatly

affects the initial baking of the product,

while the last half largely affects the browning.

D

A good bake time and t emperature have been

established, but more top browning is desired.

Slide one of the Block-off Plates to uncover a

row of holes toward the exit end of the oven.

D

The bottom of the pizza is golden brown, but the

top is too dark. Close rows at the exit end of the

oven to reduce final browning.

D

The center of the pizza is still doughy and the

toppings are not fully cooked. Open up rows at

the chamber entrance and close rows at the

chamber exit.

Operation

Oven Adjustments for Cooking

Figure 20

15

Page 20

Maintenance

Cleaning

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

Follow this recommended cleaning schedule for

proper oven performance.

Daily:

1. Clean the conveyor belt using a wire brush. Allow any foreign material to drop into the crumb

pans.

2. Empty and clean the crumb pans.

3. Make sure cooling fans are operating.

Every Three Months:

1. Brush and clean the guards of the cooling

fans.

Every Six Months:

1. Unplug the oven.

2. Remove both crumb pans from the ends of the

conveyor.

3. Remove both upper end plugs. Loosen the

wing nuts on the bottom of each end plug.

b.) Slide the belt out from one end. Be sure to

roll the belt as shown in Figure 22. Otherwisethebeltwillbeupsidedownwhenrethreading.

Figure 22

6. Remove the non-drive side conveyor support.

7. Remove the drive side conveyor support as

follows:

a.) Remove the 1/4” hex bolt and nut (inside

control box), that fastens the drive side

conveyor support to the control box. See

Figure 23.

b.) Remove the drive chain from the sprocket

by pushing the conveyor assembly in to

loosen the chain. If unable to push assembly, loosen motor mounts.

c.) Slide the conveyor support out of the

oven.

Figure 21

4. Remove both lower end plugs.

5. Remove the conveyor belt as follows:

a.) Use needle-nose pliers to remove the

conveyor belt master links.

Figure 23

16

Page 21

Maintenance

Cleaning

8. Using the handle supplied with the oven, pull

out the air plate.

Figure 24

9. Remove the nozzles as follows:

a.) Remove the bolt from the hold down

bracket. Lift the bracket straight up and

slide out either end of the oven.

11. Soak the conveyor in a hot water/detergent

mix.

12. Clean the crumb pans, return air diverters,

nozzles, air plates, and end plugs with a hot

water/detergent mix. Rinse with clean water.

For difficult cleaning use a heavy duty degreaserorovencleanerthatissafeforaluminum.

NOTE: DO NOT immerse the end plugs. They

contain insulation.

13. Clean the oven interior with an all purpose

cleaneroranovencleanerthatissafeforaluminum.

14. Move the oven to clean underneath. DO NOT

damage the gas hose or electrical cords when

moving.

Every 12 Months:

A factory authorized service person should:

1. Open and clean the inside of the control panel.

2. Check a nd tighten all electrical connections.

3. Check DC gear motor brushes for wear.

4. Check conveyor drive chain for cleanliness

and proper lubrication.

If maintenance is required contact your local service company, a factory representative or the

Blodgett Oven company.

Figure 25

b.) Push the nozzles toward the back w all of

the oven. Lift the front end and turn it toward you slipping the back end from the

duct.

10. Slide the return air diverters out of the oven.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

17

Page 22

Maintenance

Troubleshooting Guide

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Blower Motor(s) not running

S

BlowercontrolswitchinOFFposition

S

No power to oven

S

Motor fuses blown

S

Motor(s) burned out

S

Control circuit fuse blown (right fuse on control

panel door)

SYMPTOM: Main temperature control displays EEE

S

Temperature controller not properly installed

S

Internal problem with main temperature control

S

Loose thermocouple connections at main

temperature control

S

Short in thermocouple

S

Turn to ON position

S

Replace main fuses or reset breakers

S

Replace fuses

S

*

S

Replace fuses

S

Reinstall

S

*

S

*

S

*

SYMPTOM: Burner will not fire

S

BlowercontrolswitchinOFFposition

S

Blower motor(s) not running

S

Front cooling fan not working properly

S

Defective main temperature controller

S

Main temperature controller not set above

ambient t emperature

*Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

All repairs and/or adjustments be done by your local Blodgett service agency and not by the owner/operator. Blodgett cannot assume responsibility for damage as a result of servicing done by unqualified personnel.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

S

Turn to ON position

S

Blower motor(s) must be running. Check control

switch and/or fuses.

S

*

S

*

S

Set to desired temperature

18

Page 23

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Oven will not reach desired temperature

S

Heat control switch OFF

S

No power to oven

S

Blower motor(s) not running

S

Defective heating element relay

S

Shorted thermocouple

S

Heating element(s) burned out

S

Temperature hi-limit switch out of adjustment or

defective

S

Internal problem with main temperature control

S

Front cooling fans not working properly

SYMPTOM: Conveyor belt will not run

Maintenance

Troubleshooting Guide

S

Turn to ON position

S

Replace main fuses

S

Check control switch and/or fuses

S

*

S

*

S

*

S

*

S

*

S

*

S

Conveyor control switch in OFF position

S

Control circuit fuse blown (left fuse on back of

control box)

S

Belt hooked on something in oven

S

Defectiveconveyordrivemotor

S

Defectiveconveyordrivemotorcontroller

*Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

All repairs and/or adjustments be done by your local Blodgett service agency and not by the owner/operator. Blodgett cannot assume responsibility for damage as a result of servicing done by unqualified personnel.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

S

Turn to ON position

S

Replace fuse

S

Turn conveyor to OFF, unhook and repair problem

S

*

S

*

19

Page 24

CUSTOMER

INSERT

WIRING DIAGRAM

HERE

Loading...

Loading...