Page 1

MT1828G AND MT1828E

CONVEYOR OVENS

INSTALLATION -- OPERATION -- MAINTENANCE

MT1828G ET MT1828E

FOURS À BANDE TRANSPORTEUSE

MANUEL D’INSTALLATION -- FONCTIONNEMENT -- ENTRETIEN

BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN M9946 Rev D (6/01)

E 2000 --- G.S. Blodgett Corporation

Page 2

IMPORTANT

WARNIN G:IMP ROPER INSTALLATION, ADJUSTMENT, ALTERATI O N , SERVIC EOR

MAINTENAN C E CANCAUSE PROP ERTYDA MA GE,INJURY OR DEATH. READ THE

INSTALLA TION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTI SSEMEN T: UNE INSTALLATIO N, UN AJUSTEMENT, UNE ALTÉRATION , UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMESPEUT CAUSER DES

DOMMAGESÀ LA PROPRIÉTE,DES BLESSURESOU LA MORT. LISEZ ATTENTIV EMENT LES DIRECTIVES D’INST A LL ATION, D’OPÉRATION ET D’ENTRETIENAV A N T

DE FAIRE L’INSTALLATION OU L’ENTRETIEN DE CET ÉQUIPEMENT.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS

MUST BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE

OBTAINED BY CONTACTING YOUR LOCAL GAS SUPPLIER.

LES INSTRUCTIONS À RESPECTER AU CAS OÙ L’UTILISATEUR PERÇOIT UNE

ODEUR DE GAZ DOIVENT ÊTRE AFFICHÉES DANS UN ENDROIT BIEN VISIBLE.

VOUS POUVEZ VOUS LES PROCURER AUPRÈS DE VOTRE FOURNISSEUR DE

GAZ LOCAL.

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l’essence ni d’autres vapeurs ou liquides inflammables dans le voisinage de cet appariel, ni de tout autre appareil.

The information contained in this manual is important for the proper installation,

use, and maintenance of this oven. Adherence to these procedures and instructions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Les informations données dans le présent manuel sont importantes pour installer,

utiliser et entretenir correctement ce four. Le respect de ces instructions et procédures permettra d’obtenir de bonsrésultats de cuisson et une longue durée de service sans problèmes. Veuillez lire le présent manuel et le conserver pour pouvoir

vous y reporter à l’avenir.

Errors: Descriptive, typographic or pictorial errors are subject to correction. Specifica-

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d’illustration font l’objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

Page 3

THE REPUTATION YOU CAN COUNT ON

UNE RÉPUTATION SUR LAQUELLE VOUS POUVEZ COMPTER

For over a century and a half, The Blodgett Oven Company has been building

ovens and nothing but ovens. We’ve set the industry’s quality standard for all

kinds of ovens for every foodservice operation regardless of size, application

or budget. In fact, no one offers more models, sizes, and oven applications

than Blodgett; gas and electric, full-size, half-size, countertop and deck, convection, Cook’n Hold, Combi-Ovens and the industry’s highest quality Pizza

Oven line. For more information on the full line of Blodgett ovens contact your

Blodgett representative.

Cela fait maintenant dessus un siècle et demi que Blodgett se spécialise dans

la fabrication de fours. Nous avons établi les normes de qualité qui s’appliquent dans l’industrie à tous les types de fours utilisés dans les services alimentaires, quel qu’en soit la taille, l’exploitation ou le budget. En fait, ni n’offre

plus de modèles, de tailles et d’applications de fours que Blodgett. À gaz et

électriques. De tailles différentes, sur plan de travail et superposables. Qu’il

s’agisse de fours à convection, des modèlesCook’n Hold et Combi-Oven, ou

de la gamme de fours à pizzas de la plus haute qualité offerte sur le marché.

Pour de plus amples informations sur la gamme complète de fours B lodgett,

veuillez contacter votre représentant Blodgett.

Page 4

Your Service Agency’s Address:

Adressedevotreagencedeservice:

Model/Modèl:

Serial Number/Numéro de série:

Your oven w a s installed by/

Installateur de votre four:

Your oven’s installation was checked by/

Contrôleur de l’installation de votre four:

Page 5

Table of Contents/Table des Matières

Introduction

Oven Description and Specifications 2....

Oven Components 3....................

Installation

Delivery and Inspection 4...............

Oven Location and Ventilation 5..........

Oven Assembly 6......................

Oven Stand with casters 6.............

Stacking the ovens (if applicable) 7.....

Conveyor Belt 8......................

Crumb Pans 10........................

Optional Remote Computer Control 10...

Utility Connections ---

Standards and Codes 11.................

Gas Connection 12......................

Electrical Connection 15.................

Operation

Safety Information 17....................

Cooking Computer 18...................

Oven Adjustments for Cooking 20.........

Maintenance

Cleaning 22............................

Control Box Component Locations 24......

Troubleshooting Guide 26................

Introduction

Description et Spécifications du Four 28....

Description et Composantes du Four 30...

Installation

Livraison et Inspection 31................

Implantation et aération du four 32........

Montage du Four 33.....................

Base de Support du Four avec

Roulettes 33...........................

Superposition des Fours

(si applicable) 34......................

Le Convoyeur 35.......................

Plateaux pour Miettes 37................

L’Ordinateur de Cuisson Détaché 37.....

Branchements de Service ---

Normes et Codes 38.....................

Branchement de Gaz 39.................

Raccordement Électrique 42..............

Utilisation

Informations de Sécurité 44...............

L’Ordinateur de Cuisson 45...............

Réglages du Four Pour la Cuisson 47......

Entretien

Nettoyage 49...........................

Emplacement des Composants du

Boîtier de Commande 51.................

GuidedeDépannage 53.................

Page 6

Introduction

Oven Description and Specifications

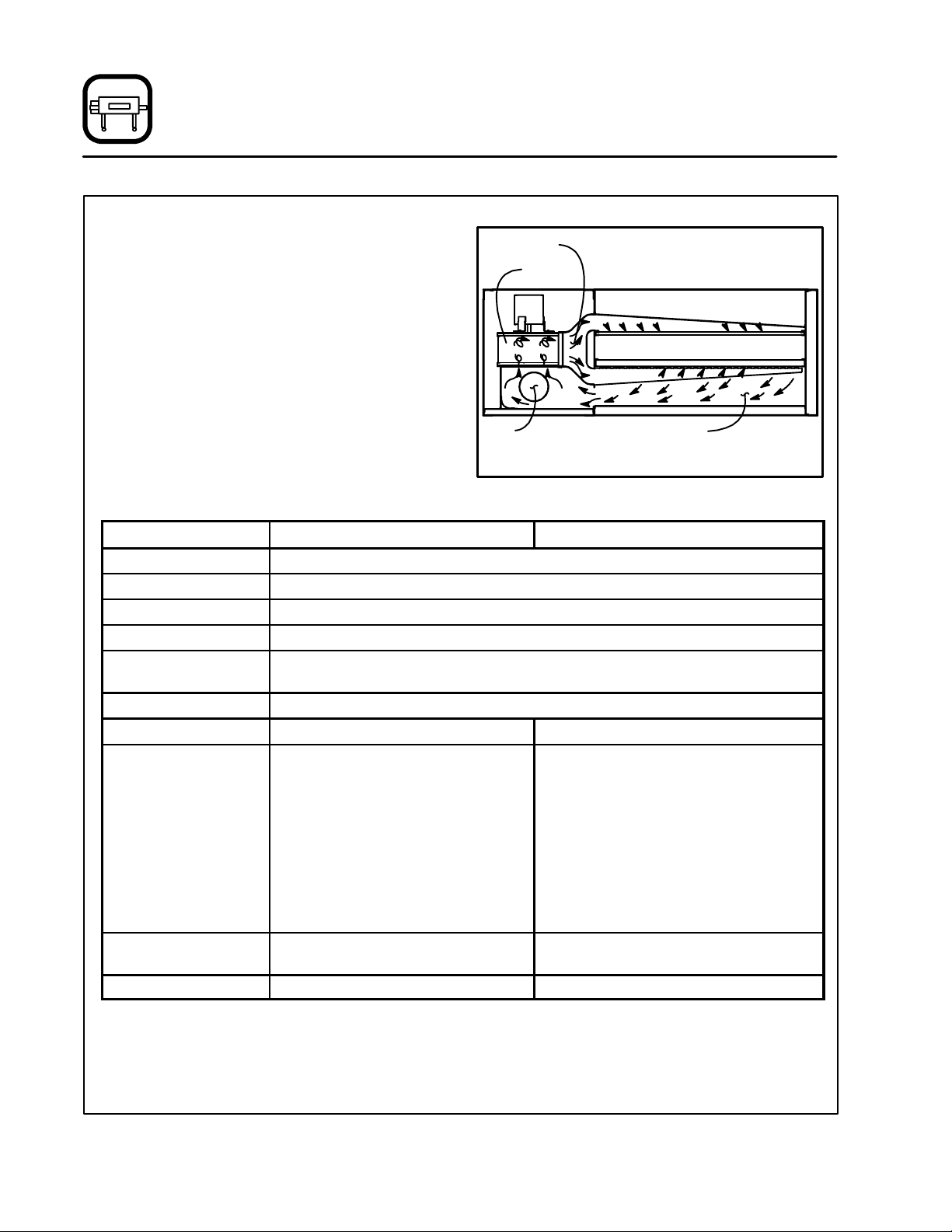

Cooking in a conveyor oven differs from cooking

in a conventional deck or range oven since heated

air is constantly recirculated over the product by

a fan in an enclosed chamber. The moving air con-

Heated Air

Blower

Fan

tinually strips away the layer of cool air surrounding the product, quickly allowing the heat t o penetrate. The result is a high quality product, cooked

at a lower temperature in a shorter amount of time.

Blodgett conveyor ovens represent the latest advancement in energy efficiency, reliability, and

ease of operation. Heat normally lost, is recirculated within the cooking chamber before being

vented from the oven: resulting in substantial reductions in energy consumption, a cooler kitchen

Heat

Source

AirFlowPatternforBlodgettConveyorOvens

environment and enhanced oven performance.

SPECIFICATIONS

MT1828G/AB MT1828E/AA

Belt Width 18” (46 cm)

Cooking Zone Length 28” (71 cm)

Baking Area 3.7 sq. ft. .34 m2)

Dimensions (single unit) 41” x 35” x 18” (104 cm x 89 cm x 46 cm)

Maximum Operating

600_F (315_C)

Tem p er a tur e

Product Clearance 3.75” (9.5 cm)

Maximum Input 40,000 BTU/Hr (11.7 kW) (42.2 MJ) 11.1 KW/hr.

Power Supply U.S. and Canadian

120/208-240 VAC, 1Φ, 60 Hz, 4 wire,

15 amp,

General Export and Australia

220/240 VAC, 1Φ, 50/60Hz, 3 wire,

15 amp

U.S. and Canadian

208 VAC, 1Φ, 60Hz, 3 wire, 52 amp

240 VAC, 1Φ, 60Hz, 3 wire, 45 amp

208 VAC, 3Φ, 60Hz, 4 wire, 30 amp

240 VAC, 3Φ, 60Hz, 4 wire, 26 amp

General Export and Australia

240 VAC, 1Φ, 50Hz, 3 wire, 45 amp

208-240 VAC, 3Φ, 50Hz, 4 wire, 30 amp

380/220 VAC, 3Φ, 50Hz, 5 wire, 18 amp

415/240 VAC, 3Φ, 50Hz, 5 wire, 17 amp

Gas Supply 4.5” W.C. (1.1 kPa) minimum

None

10.5” W.C. (2.61 kPa) maximum

Gas Connection 3/4” (1.9 cm) NPT None

Air Plate

Conveyor

Nozzle

Return Air

Figure 1

2

Page 7

Introduction

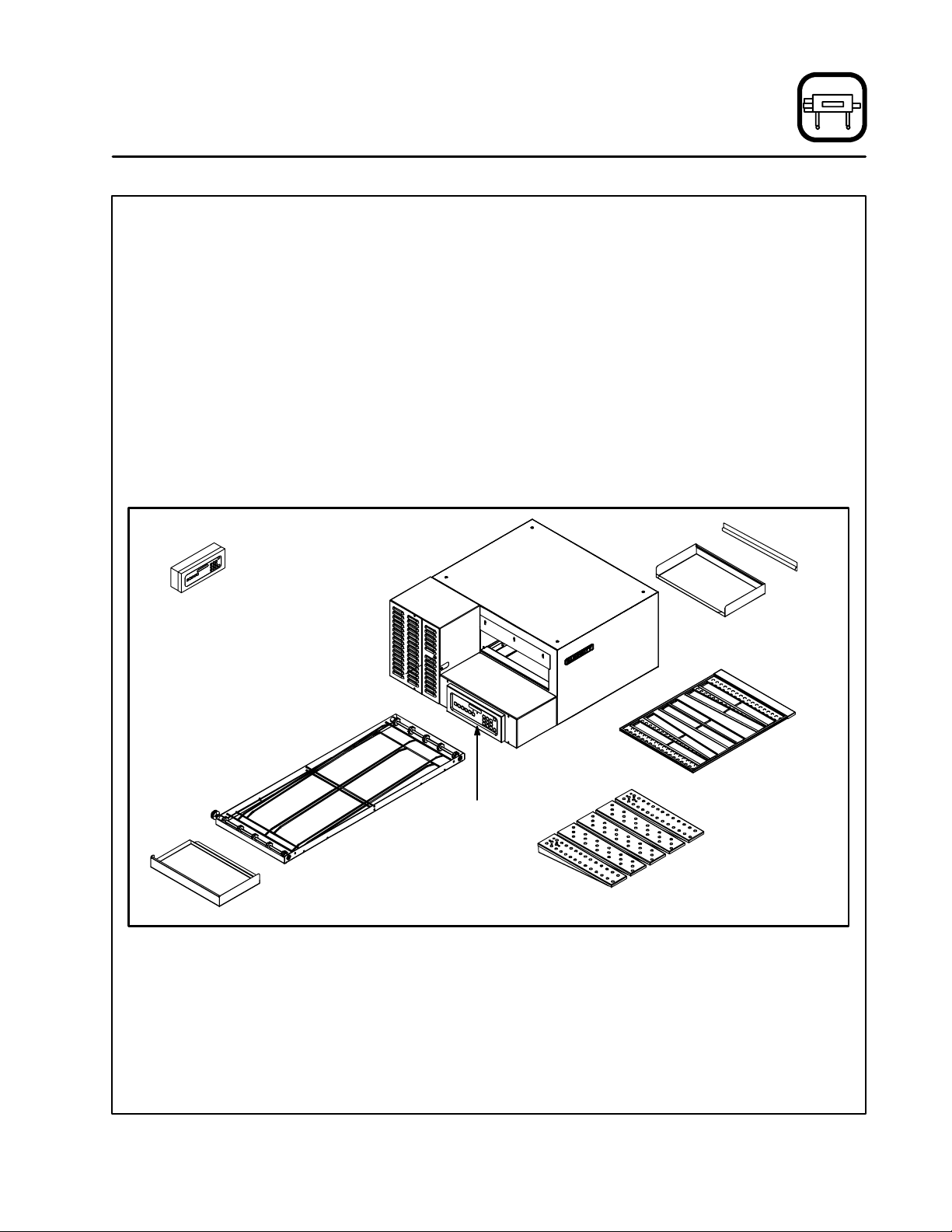

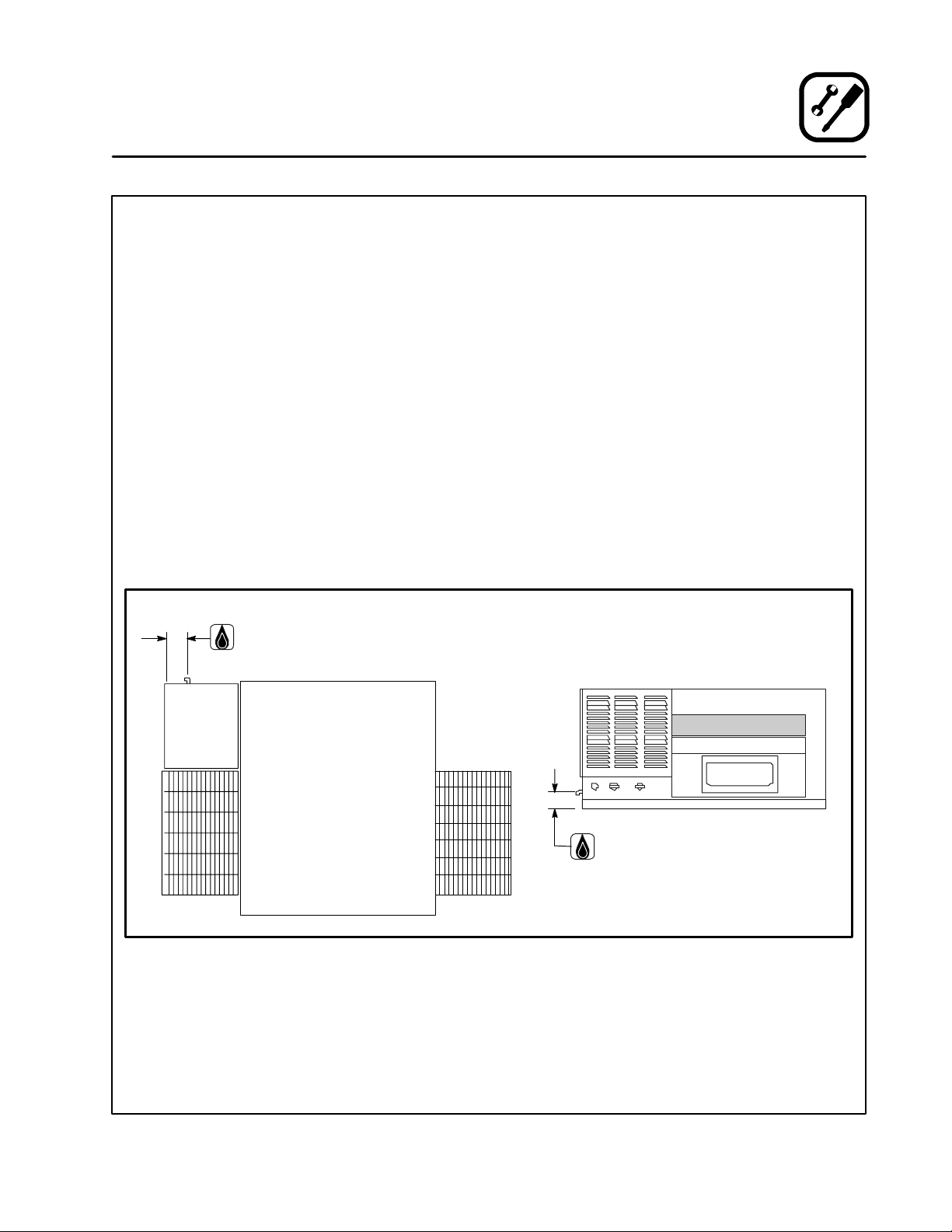

Oven Components

Conveyor Assembly -- conveyor belt and rack

assembly that carries product through the oven.

Control Box --- contains electrical wiring, cooling

fan, drive motor and drive chain.

Drive Motor --- provides power to move the con-

veyor belt. Located inside the control box.

Drive Chain --- connects the drive motor sprocket

to the drive side conveyor belt support sprocket.

Located inside the control box.

Baking Chamber --- products pass through the

baking chamber on the conveyor belt for cooking.

Oven Controls --- used to control oven temperature, belt speed and other functions.

Optional

Remote

Oven Control

Contro l Box

Nozzles --- distribute heated air to bottom of the

baking chamber. Located inside the oven, under

theconveyorbelt.

Crumb Pan --- catches crumbs from products on

the conveyor. Located under conveyor belt at both

ends of the baking chamber.

Air Flow Plates --- distribute heated air to the top

of baking chamber. Located inside of oven at the

top of baking chamber.

Emergency Shut Down Switch --- o n re mote c o n trol ovens, allows user to turn oven and conveyor

offinanemergency.Do not use for general shut

down.

Product

Stop

Idle Side

Crumb Pan

Conveyor Assembly

(shown without belt)

Drive Side

Crumb Pan

Air Flow Plate

Integral

Oven Control

Nozzles

Figure 2

3

Page 8

Installation

Delivery and Inspection

All Blodgett ovens are shipped in containers to

prevent damage. Upon delivery of your new oven:

D

Inspect the shipping container for external damage. Any evidence of damage should be noted

on the delivery receipt which must be signed by

the driver.

D

Uncrate the oven and check for internal damage. Ca rriers will accept claims for concealed

damage if notified within fifteen days of delivery

and the shipping container is retained for inspection.

The Blodgett Oven Company cannot a ssume

responsibility for loss or damage suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a cl aim is necessary.

The oven can now be moved to the installation

site. Check the followinglist with Figure 2 on page

3 to be sure all items were received.

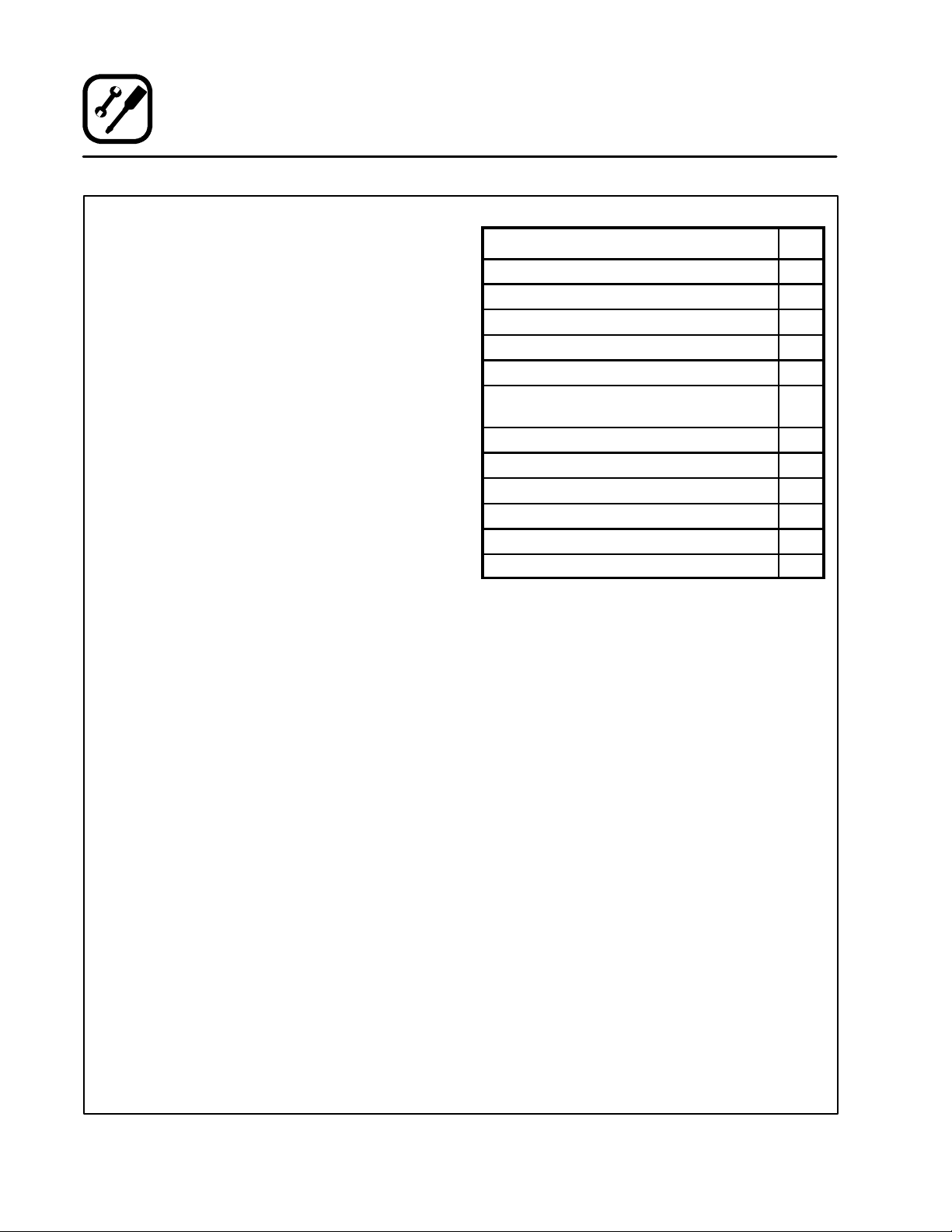

Part Description

Main oven body 1

Conveyor belt assembly 1

Crumb pans 2

Product stop 1

Nozzles 5

Packet containing:

1/2-13 alignment pins & washers

Owner’s manual 1*

Oven stand 1**

Triple stack casters 1**

Optional remote oven control 1**

Optional remote oven control bracket 1**

Optional remote oven control cables 1**

NOTE: * Item not shown.

**Optional

Qty.

1*

4

Page 9

Installation

Oven Location and V entilation

LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

The following clearances must be maintained between the oven and any combustible or non-combustible construction.

D

Oven body sides --- 16” (40.6 cm)

D

Oven body back --- 0” (0 cm)

The following clearances must be available for servicing.

D

Oven body left side --- 38” (96.5 cm)

D

Oven body back --- 28” (71 cm)

NOTE: On gas models, routine servicing can usu-

ally be accomplished within the limited

movement provided by the gas hose restraint. If the oven needs to be moved further from the wall, the gas must first be

turned off and disconnected from the oven

before removing the restraint. Reconnect

the restraint after the oven has been returned to its regular position.

It is essential that an adequate air supply to the

oven be maintained to provide a sufficient flow of

combustion and ventilation air.

D

Place the oven in an area that is free of drafts.

D

Keep the oven area free and clear of all combustiblessuch as paper, cardboard, and flammable

liquids and solvents.

D

Do not place the oven on a curb base or seal to

a wall. This will restrict the flow of air and prevent

proper ventilation to the blower motors. This

condition must be corrected to prevent permanent damage to the oven.

D

On all models, tripping of the blower motor’s

thermal overload device indicates an excessive

ambient temperature at the back of the oven.

This condition must be corrected to avoid permanent damage to the oven.

VENTILATION

Ongasmodelsthenecessityforaproperlydesigned and installed ventilation system cannot be

over-emphasized. This system allows the oven to

function properly while removing unwanted vapors and products of combustion from the operating area.

This oven must be vented with a properly designed mechanically driven exhaust hood. The

hood should be sized to completely cover the

equipment plus an overhang of at least 6” (15 cm)

on all sides not adjacent to a wall. The distance

from the floor to the lower edge of the hood should

not exceed 7’ (2.1m). The capacity of the hood

should be sized appropriately and provisions

should be made for adequate makeup air.

U.S. and Canadian installations

Refer to your local ventilation codes. In the absence of local codes, refer to the National ventilation code titled, “Standard for the Installation of

Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking Equipment”, NFPA-96-Latest Edition.

General export and Australian installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installationand/or

operation of your Blodgett oven, please contact

your local distributor. If you do not have a local distributor, please call the Blodgett Oven Company at

0011-802-860-3700.

WARNING:

Failure to properly vent the oven can be

hazardous to the health of the operator

and may result in operational problems,

unsatisfactory baking and possible dam age to the equipment.

Damage sustained as a direct result of improper ventilation will not be covered by

the Manufacturer’s warranty.

5

Page 10

Installation

Oven Assembly

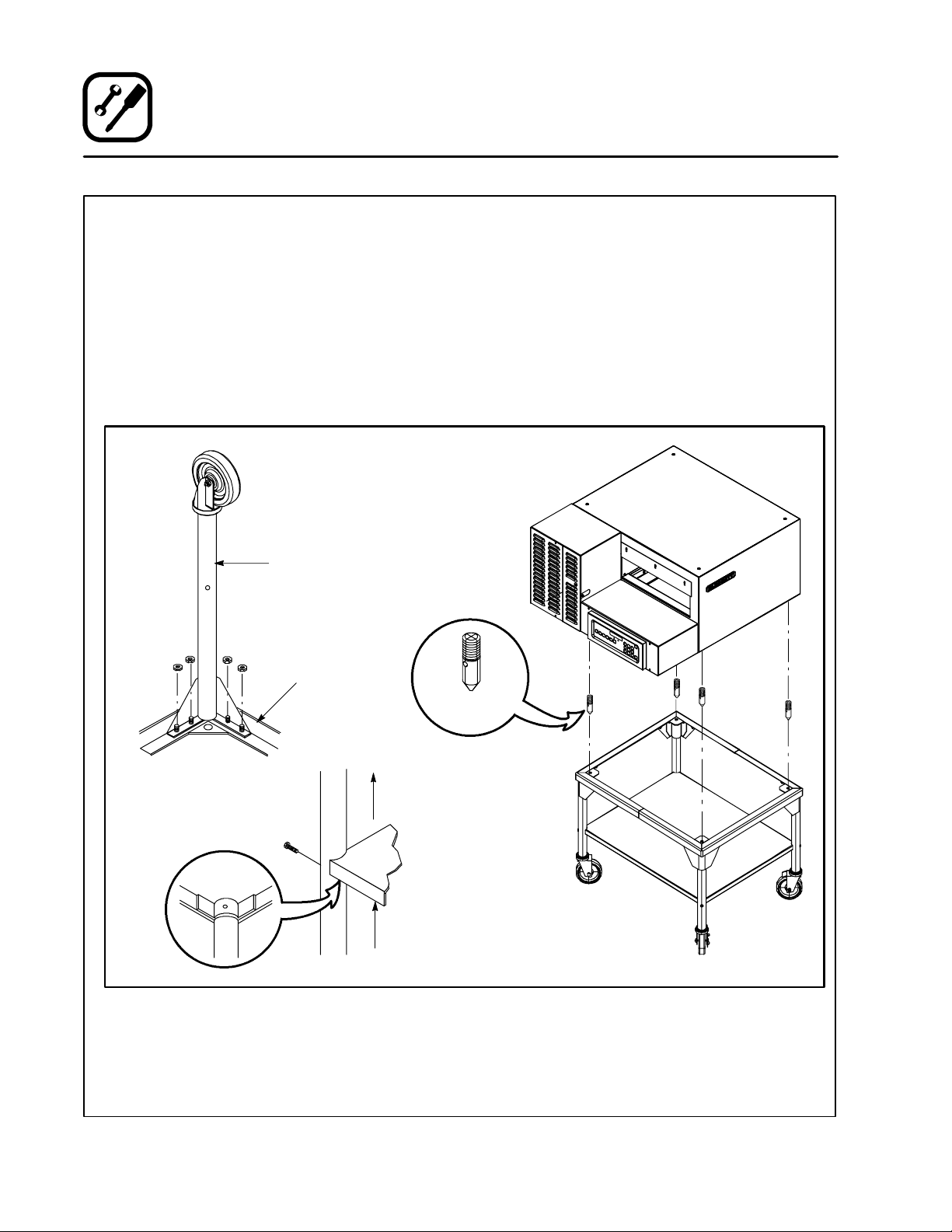

OVEN STAND WITH CASTERS

NOTE: Install the locking casters on the front of

the stand.

1. Attach each leg with casters to the stand

frame w ith a lock washer and nut. DO NOT

tighten completely.

2. Position the shelf between the legs with the

smooth surface facing the top of the stand.

Aligntheshelfwiththeholesineachleg.Attach the shelf to each leg with a nut and bolt.

Leg

3. Tighten the bolts installed in step 1.

4. Rest the oven on its back. Install the oven

alignment pins (4) into the four holes provided

on the bottom of the oven.

5. Place the oven onto the stand. Locate alignment pins with holes in frame of oven stand.

Stand

Frame

Alignment

Pin

Top o f

Stand

Shelf

Figure 3

6

Page 11

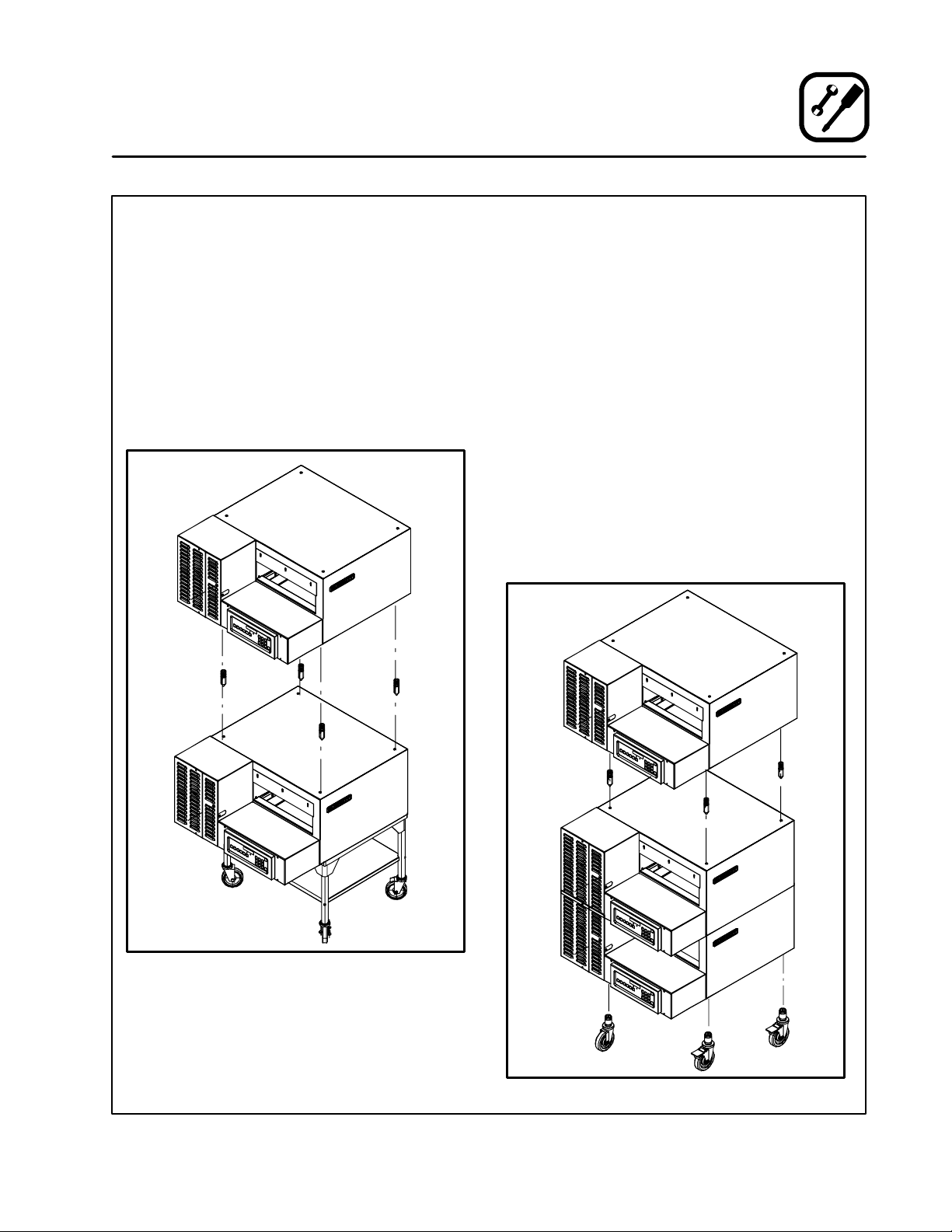

STACKING THE OVENS (if applicable)

Double Stacked

1. Assemble the bottom oven to the stand.

2. Rest the top oven on its back. Install the oven

alignment pins (4) into the four holes provided

on the bottom of the oven

3. Remove the four knock-outs in the top of the

bottom oven.

4. Carefully lift the upper oven off the pallet and

place it on the lower oven. Locate alignment

pins w ith holes in frame of lower oven.

Installation

Oven Assembly

Triple Sta cked

1. Rest the bottom oven on its back. Install a

caster into each of the four holes in the corners

of the oven bottom.

NOTE: Install the locking casters on the front

of the oven.

2. Carefully lift the bottom oven onto the casters.

Lock the front casters.

3. Rest the middle oven on its back. Install the

oven alignment pins (4) into the four holes provided on the bottom of the oven

4. Remove the four knock-outs in the top of the

bottom oven.

5. Carefully lift the middle oven off the pallet and

place it on the lower oven. Locate alignment

pins w ith holes in frame of lower oven.

6. Repeat steps 3 and 5 for the top oven.

Figure 4

Figure 5

7

Page 12

Installation

Oven Assembly

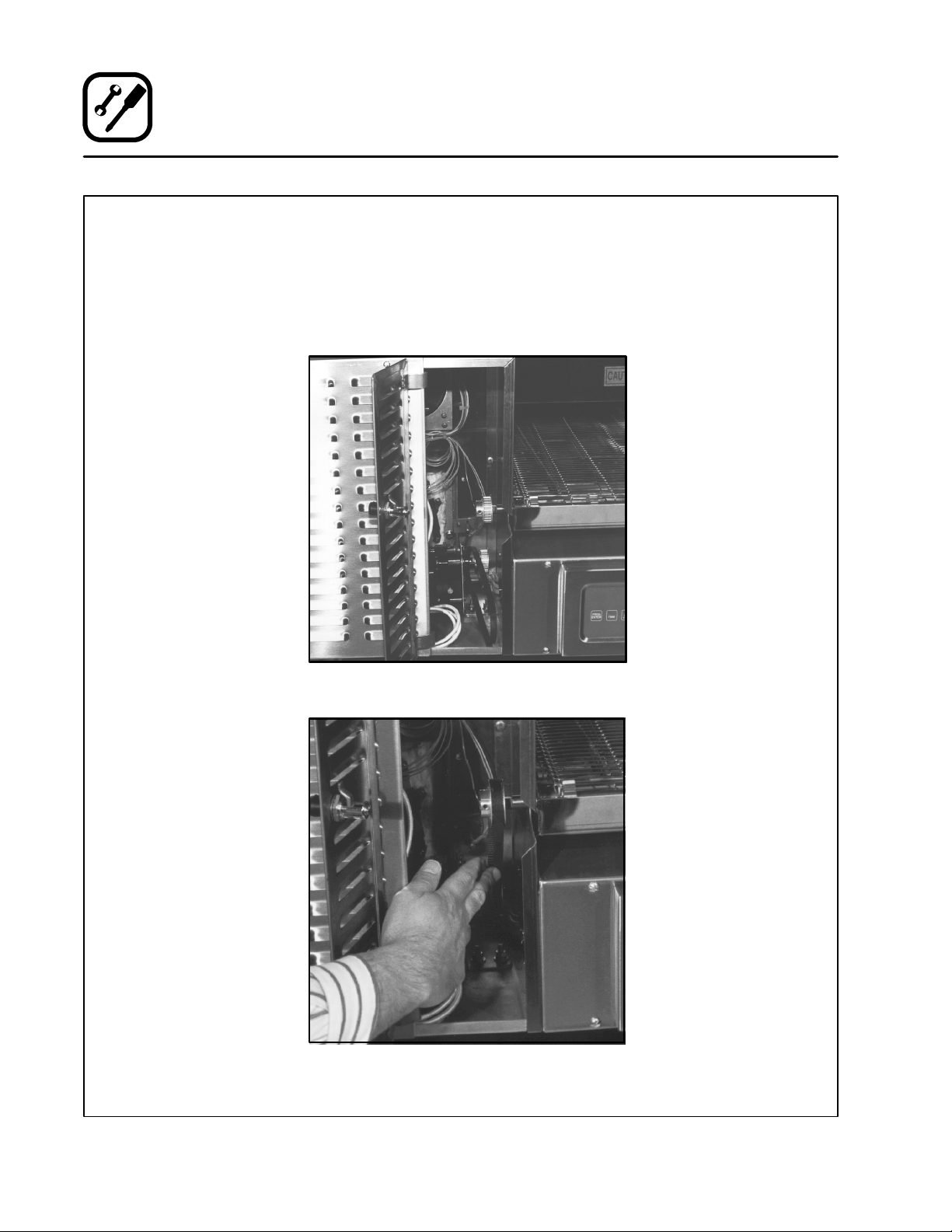

CONVEYOR BELT

1. Slide the conveyor assembly (with pulley on

end of shaft) through the left hand tunnel

opening. The sprocket must be located inside

the control panel after being pushed into the

oven. R efer to Figure 6.

2. Install the drive belt around the drive motor

and then around the pulley on the conveyor

assembly. Refer to Figure 7. Push the conveyor assembly back into the locating pins to

tighten the belt.

Figure 6

Figure 7

8

Page 13

Installation

Oven Assembly

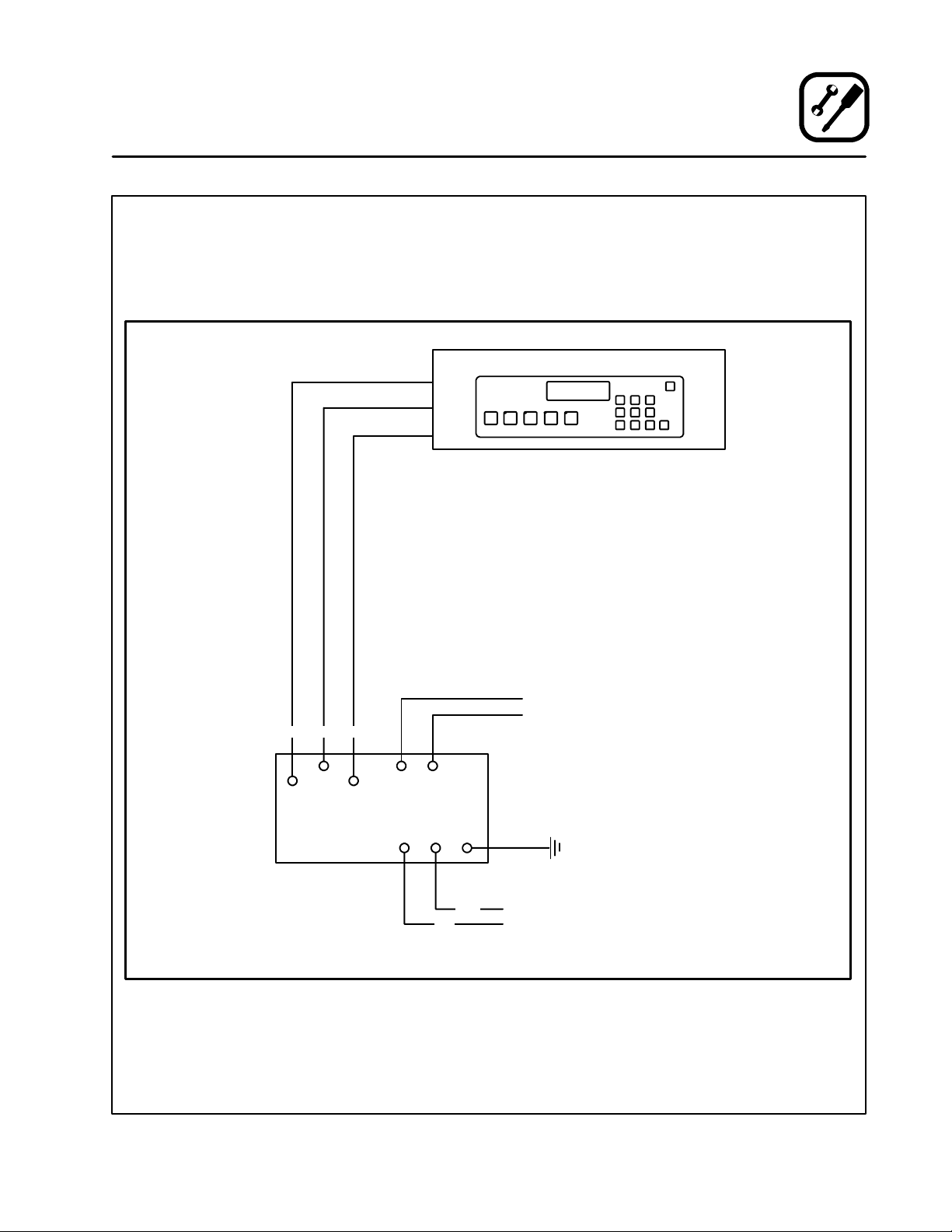

3. Unless specified otherwise, conveyor travel is

factory set for left to right operation when facing the front of the oven. If a direction change

is required, the polarity of the drive motor must

be reversed. Turn the oven OFF and inter-

change the black and white motor leads at the

D.C. controller located in the control panel.

Refer to Figure 8. In addition, the conveyor

belt must be installed from the left side of the

oven vs. the right side.

Y OR BL

S2

S3

SPEED

CONTROL

S1

L2 L1

A1 A2 A3

W

Figure 8

BK

W

V

AC

AC

GND

DC MOTOR

9

Page 14

Installation

Oven Assembly

CRUMB PANS

1. Install crumb pans under each end of the conveyor.

2. Slide the product stop over the outer edge of

theidlesidecrumbpan.

Figure 9

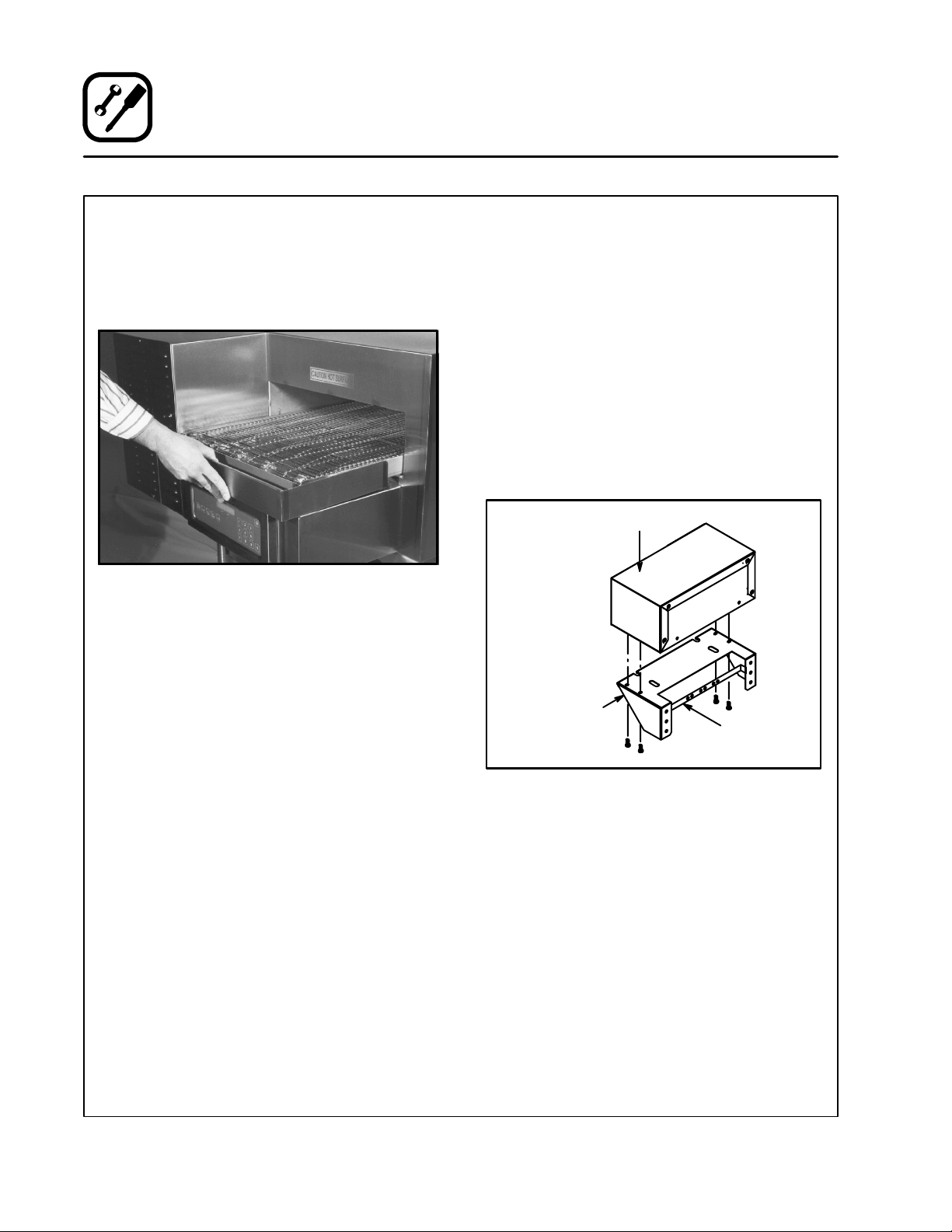

OPTIONAL REMOTE COMPUTER CONTROL

1. Drill the mounting holes for the cooking computer support base.

2. Mount the support base and cable support

bracket to the wall.

3. Stack the cooking computer(s) on the support

base. Connect the cables at the rear of the

controller .

4. Secure the cables to the cable clamp support

bracket and to the rear of the oven using cable

clamps and screws.

NOTE: DO NOT overtighten the cable clamps.

Damage to the wires may occur causing the computer to fail.

Cooking Computer

Cooking Computer

Support Base

Cable Clamp

Support Bracket

Figure 10

10

Page 15

Installation

Utility Connections --- Standards and Codes

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and responsible for:

D

the installation or replacement of gas piping

and the connection, installation, repair or servicing of equipment.

D

the installation of electrical wiring from the electric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experienced in such w ork, familiar with all precautions

required, and have compliedwith all requirements

of state or local authorities having jurisdiction.

U.S. and Canadian installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1 ---Latest Edition,

the Natural Gas Installation Code CAN/CGAB149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

All ovens, when installed, must be electrically

grounded in accordance with local codes, or in the

absence of localcodes, with the National Electrical

Code, ANSI/NFPA 70 ---Latest Edition and/or Canadian National Electric Code C22.2 as applicable.

General export and Australian installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installationand/or

operation of your Blodgett oven, please contact

your local distributor. If you do not have a local distributor, please call the Blodgett Oven Company at

0011-802-860-3700.

11

Page 16

Installation

L

t

h

p

g

Gas Connection

GAS PIPING

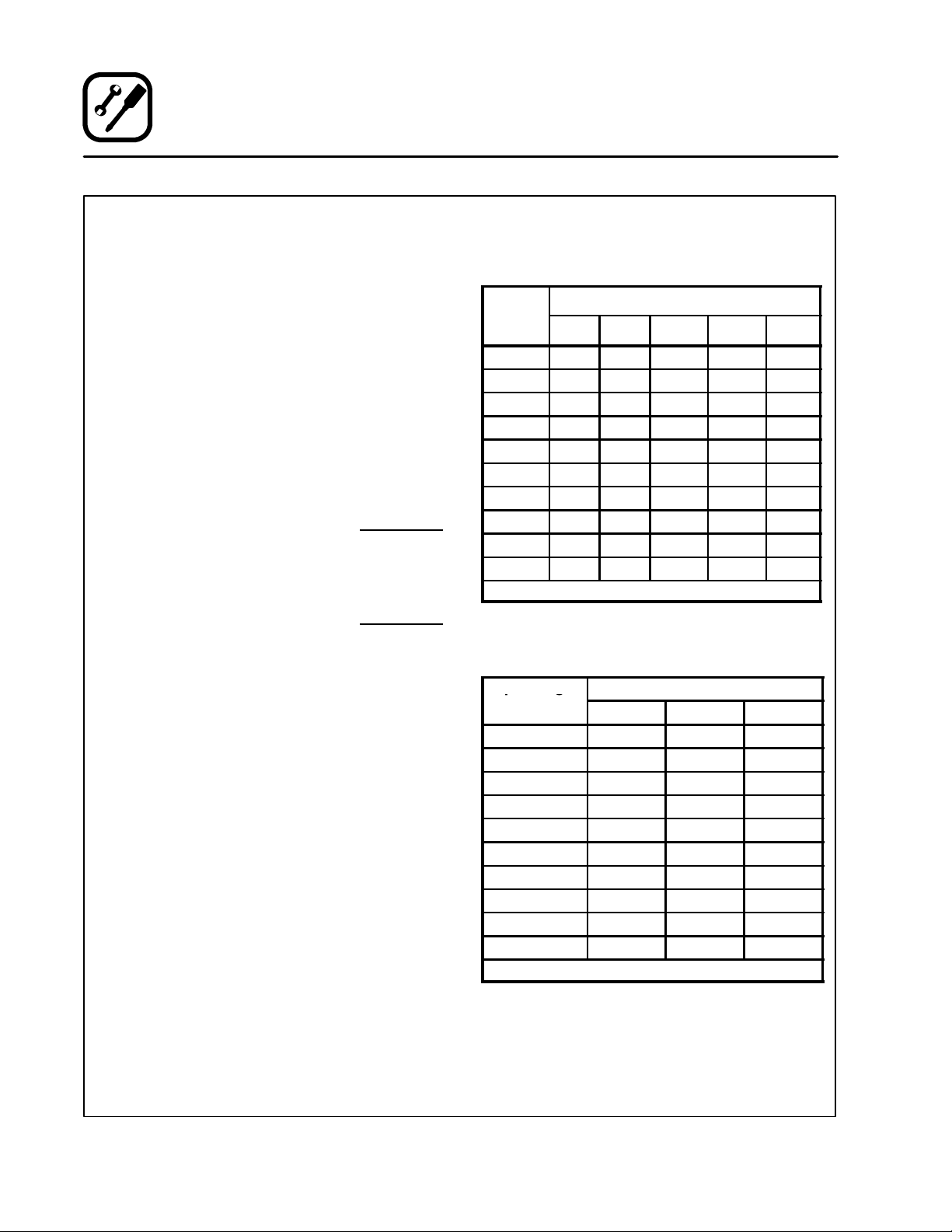

A properly sized gas supply system is essential for

maximum oven performance. Piping should be

sized to provide a supply of gas sufficient to meet

the maximum demand of all appliances on the line

without loss of pressure at the equipment.

Example:

NOTE: BTU values in the following example are

for natural gas.

You purchase a M T1828G conveyor oven to add

to your existing cook line.

1. Add t he BTU rating of your currentappliances.

Pitco Fryer 120,000 BTU

6 Burner Range 60,000 BTU

Deck Oven 50,000 BTU

Total 230,000 BTU

2. Add the BTU rating of the new oven to the total.

Previous Total 230,000 BTU

MT1828G 40,000 BTU

New Total 270,000 BTU

3. Measure the distance from the gas meter to

the cook line. This is the pipe length. Let’s say

the pipe length is 40’ (12.2 m) and the pipe

size is 1” (2.54 cm).

4. Use the appropriate table to determine the total capacity of your current gas piping.

The total capacity for this example is 320, 000

BTU. Since the total required gas pressure,

270,000 BTU is less than 320,000 BTU, the

current gas piping will not have to be increased.

NOTE: The BTU capacities given in the tables are

for straight pipe lengths only. Any elbows

or other fittings will decrease pipe capacities. Contact your local gas supplier if you

have any questions.

Maximum Capacity of Iron Pipe in Cubic Feet

of Natural Gas Per Hour

(Pressure drop of 0.5 Inch W.C.)

Pipe

eng

(ft)

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

From the National Fuel Gas Code Part 10 Table 10-2

Maximum Capacity of Pipe in Thousands of

BTU/hr of Undiluted P.P. Gas at 11” W.C.

Pipe Length

From the National Fuel Gas Code Part 10 Table 10-15

3/4” 1” 1-1/4” 1-1/2” 2”

(Pressure drop of 0.5 Inch W.C.)

(ft)

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

Nominal Size, Inches

Outside Diameter, Inches

3/4” 1” 1-1/2”

12

Page 17

PRESSURE REGULATION AND TESTING

Each oven has been adjusted at the factory to operate with the type of gas specified on the rating

plate attached to the left side of the control panel.

Each oven is supplied with a regulator to maintain

thepropergaspressure.The regulator is essen-

tial to the proper operation of the oven and

shouldnot be removed. It is preset to provide the

oven with 3.5” W.C. (0.87 kPa) while the flame is

on. The regulator is located on top of the gas valve,

between the manual shutoff and solenoid valves.

DO NOT INSTALL AN ADDITIONAL REGULATOR

WHERE THE OVEN CONNECTS TO THE GAS

SUPPLY UNLESS THE SUPPLY EXCEEDS THE

MAXIMUM.

NOTE: The maximum gas supply pressure to the

oven i s 10.5” W.C. (2.61 kPa). The minimum gas supply pressure to the oven is

4.5” W.C. (1.1 kPa).

Installation

Gas Connection

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1 ---Latest Edition,

the Natural Gas Installation Code CAN/CGAB149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of t hat system at test

pressuresinexcessof1/2psig(3.45kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (3.45kPa).

Gas Connection 2” (51 mm)

Gas Connection 2” (51 mm)

Figure 11

13

Page 18

Installation

Gas Connection

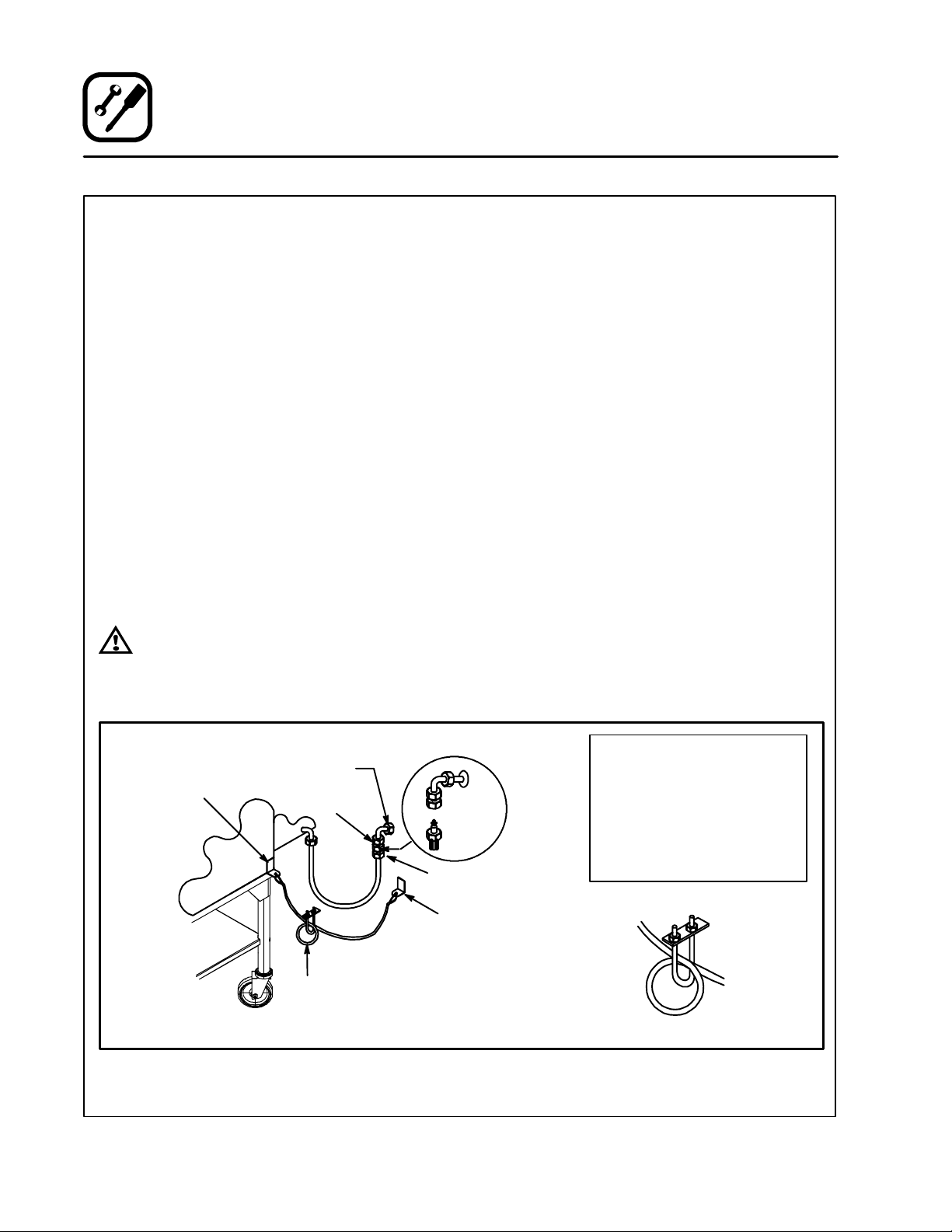

GAS HOSE RESTRAINT

If the oven is mounted on casters, a commercial

flexible connector with a minimum of 3/4” (1.9 cm)

inside diameter must be used along with a quick

connect device.

The restraint, supplied with the oven, must be

used to limit the movement of the unit so that no

strain is placed upon the flexible connector. The

restraint should be fastened to the base frame of

the oven as close to the flexible connector as possible. It should be short enough to prevent any

strain on the connector. With the restraint fully

stretched the connector should be easy to install

and quick connect.

The restraint (ie: heavy gauge cable) should be attached without damaging the building. DO NOT

use the gas piping or electrical conduit for the attachment of the permanent end of the restraint!

Use anchor bolts in concrete or cement block. On

wooden walls, drive hi test wood lag screws into

the studs of the wall.

WARNING!!

If the restraint is disconnected for any

reason it must be reconnected when the

oven is returned to its original position.

U.S. and Canadian installations

The connector must comply with the Standard for

Connectors for Movable Gas Appliances, ANSI

Z21.69 or Connectors For Moveable Gas Appliances CAN/CGA-6.16 and a quick disconnect

device that complies with the Standard for QuickDisconnect Devices for Use With Gas Fuel, ANSI

Z21.41 or Quick Disconnect For Use With Gas Fuel

CAN 1-6.9. Adequate means must be provided to

limit the movement of the appliance without depending on the connection and the quick disconnect device or its associated piping.

A drip leg must be used at each appliance. Refer

to NFPA54/ANSI Z223.1 - Latest Edition (National

Fuel Gas Code) for proper drip leg installation.

General export and Australian installations

The restraint and quick connect must conform

with Local and National installation standards. Local installation codes and/or requirements may

vary. If you have any questionsregarding the proper installation and/or operation of your Blodgett

oven, please contact your local distributor. If you

do not have a local distributor, please call the

Blodgett Oven Company at 0011-802-860-3700.

Attachment Plate

(secure with screw

on back panel)

Gas

Supply Line

Socket

Gas

Hose

(See VIEW A)

Socket

Plug

Quick Connect

Installation of Gas Hose and Restraint

Figure 12

14

IMPORTANT:

Cable restraint should be fastened as close as possible to flexible connector and short enough

to prevent any strain on flexible

connect. At maximum stretch of

shortened restraint the flexible

connector should be easy to

install and quick connect.

VIEW A

Tighten after

adjustment

Page 19

Installation

Electrical Connection

Before making any electrical connections to this

unit, check that the power supply is adequate for

the voltage, amperage, and phase requirements

stated on the rating plate.

A wiring diagram accompanies this manual and is

also attached to the inside of the control box.

MT1828G

U.S. and Canadian installations

The MT1828G requires a 15 Amp, 60HZ, 1Φ,

208-240VAC, 4 wire service consisting of L1, L2,

neutral and ground. Wiring from the power source

to these units must be a minimum of #16 AWG

copperstrandedwireorlarger.

General export and Australian installations

The MT1828G requires a 15 Amp, 50 or 60Hz, 1Φ,

220/240 VAC, 3 wire service consisting of L1, neutral and ground. Use 90_Cwireandsizewireaccording to local codes.

MT1828E

U.S. and Canadian installations

The MT1828E is available in either 1Φ or 3Φ models. Single phase models require a 60Hz,

208/240VAC, 3 wire service consisting of L1, L2

and ground. Three phase models require a 60Hz,

208/240VAC, 4 w ire service consisting of L1, L2,

L3 and ground. Wiring from the power source to

any of these units must be a minimum of #8 AWG

copper stranded wire or larger for 3 phase and #4

AWG for 1 phase.

General export and Australian installations

The MT1828E is available in either 1Φ or 3Φ models. Single phase models require a 50 Hz,

220/240VAC, 3 wire service consisting of L1, L2

and ground. Three phase models are available in

either Delta or WYE configurations. Delta models

require 50Hz, 208/240VAC, 4 wire service consisting of L1, L2, L3 and ground. WYE models require

50 Hz, 415/240 VAC, 5 wire service consisting of

L1,L2,L3,neutralandground.Useaminimumof

8.37 mm

phase and 21.15 mm

CAUTION:

Single phase units MUST NOT be connected to

the high phase of a three (3) phase system.

High phase refers to a potential o f 240 volts between one leg and neutral. The remaining two

legs will have a potential of 115 vol ts between

each phase and neutral. FAILURE TO DO SO

WILL RESULT IN EXTENSIVE DAMAGE TO

ELECTRICAL COMPONENTS AND POSSIBLE

FIRE IN THE CONTROL BOX.

THE BLODGETT OVEN COMPANY CANNOT ASSUME RESPONSIBILITY FOR LOSS OR DAMAGE

SUFFERED AS A RESULT OF IMPROPERLY IN STALLED UNITS.

2

copper stranded wire or larger for 3

WARNING!!

Incorrect wiring will result in extensive

damage to electrical components and

possible fire in the control panel.

2

for 1 phase.

15

Page 20

Installation

Electrical Connection

U.S. and Canadian Installations

L1

L1

N

L2

L1

N

120

120

MT1828G

General Export and Australian Installations

220/240

208-240

OvenSupply

L2

OvenSupply

L1

L2

L3

MT1828E Single Phase

208/240

208/240

OvenSupply

OvenSupply

MT1828E Three Phase Delta System

L1

L2

L3

208/240

OvenSupply

L1

L2

MT1828G

220/230/240

MT1828E Three Phase Delta System

L1

L2

L3

OvenSupply

N

415/380

415/380

415/

380

240/

220

OvenSupply

MT1828E Three Phase WYE SystemMT1828E Single Phase

Figure 13

16

Page 21

Operation

Safety Information

THE INFORMATION CONTAINED IN THIS SECTION IS PROVIDED FOR THE USE OF QUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATIONOF THE EQUIPMENT DESCRIBED. ADHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

and operating instructions. They are the key to the

successful operation of your Blodgett conveyor

oven.

SAFETY TIPS

For your safety read before operating

What to do if you smell gas:

D

DO NOT try to light any appliance.

D

DO NOT touch any electrical switches.

D

Use an exterior phone to call your gas supplier

immediately.

D

If you cannot reach your gas supplier, call the

fire department.

What to do in the event of a power failure:

D

Turn all switch es to off.

D

DO NOT attempt to operate the oven until the

power is restored.

NOTE: In the event of a shut-down of any kind, al-

low a five (5) minute shut off period before

attempting to restart the oven.

What to do for emergency shut down:

D

For ovens w ith remote control, the unit is

equipped with an emergency shut down switch.

Should you need to stop the belt, fans, or heat

press the emergency switch. DO NOT use the

emergency switch as a general on/off switch.

General safety tips:

D

DO NOT use tools to turn off the gas control. If

the gas cannot be turned off manually do not try

to repair it. Call a qualified service technician.

D

If the oven needs to be moved for any reason,

the gas must be turned off and disconnected

from the unit before removing the restraint

cable. Reconnect the restraint after the oven

has been returned to its original location.

D

DO NOT remove the control box cover unless

the oven is unplugged.

17

Page 22

Operation

Cooking Computer

CONTROL DESCRIPTION

1. DIGITAL DISPLAY --- displays the time, temperature and controller related information.

2. OVEN ON/OFF --- controls power to the oven.

3. NUMERIC KEYS --- used to enter numbers in

the programming mode.

4. CLEAR KEY --- clears the display if an error is

made in the programming mode.

5. SET TEMP KEY --- press to view or program

the temperature setpoint.

6. ACT TEMP KEY --- press to view the current

oven temperature.

7. T I M E K E Y --- p r e s s t o v i e w o r p r o g r a m t h e

cook time.

8. PROG/ENTER KEY --- press t o enter and exit

the programming mode and lock in programmed settings.

9. STATUS LAMPS --- when lit indicate the fan or

burners are operating.

PROGRAMMING

Programming the Cook Time:

1. Press the PROGRAM/ENTER key (8).

2. Press the TIM E key (7). The display reads SET

D

TIME-?.

3. Use the NUMERIC keys (3) to enter the desired cook time. If an error is made, press the

CLEAR key (4) and re-enter the number.

4. Press the PROGRAM/ENTER key (8) to store

the new cook time in the computer’s memory.

Programming the Temperature:

1. Press the PROGRAM/ENTER key (8).

2. Press the SET TEMP key (5). The display

D

reads SET

3. Use the NUMERIC keys (3) to enter the desired temperature set point. If an error is

made, press the CLEAR key (4) and re-enter

the number.

4. Press the PROGRAM/ENTER key (8) to store

the new temperature setpoint in the computer’s memory.

TEMP-?.

1

9

45678

Figure 14

18

2

3

Page 23

Operation

Cooking Computer

OPERATION

To turn the oven on:

1. Turnthe manual gas valve to ON. (Gas models

only)

2. Press and hold the ON/OFF key (2). The display reads OFF when the oven is idle.

3. The STATUS LAMPS (9) light. The fans begin

to run. The heat rises to the temperature setting stored in the computer’s memory. The

conveyor belt begins to travel at the speed

stored in memory.

4. The display flashes WAIT

D

mmss until the oven reaches the pro-

D

LOWDSETDTIME

grammed bake temperature.

5. The display reads READY and the HEAT lamp

(9) goes out. The oven is now ready to accept

product.

To view the cook time setting:

1. Press the TIME key (7). The LED on the key

lights and the display flashes SET

D

TIME

mmss.

To display the actual oven temperature:

1. Press the ACT TEMP key (6). The LED on the

key lights and the display flashes ACTUAL

nnn_F.

To view the temperature set point:

1. Press the SET TEMP key (5). The LED on the

key lights and the display flashes SET

D

nnn_F.

D

TEMP

To turn the oven off:

1. Press the ON/OFF key (2). The oven is

equipped with a cool-down feature for motor

shaft and bearing protection. This enables the

blower motor(s) to run regardless of the controller status. The blower(s) continue to run

until the oven cools to a safe temperature.

DISPLAY INFORMATION

WAIT

D

LOW --- the present oven temperature is

lower than the set point temperature. When the

oven reaches the set point temperature the display changes to READY.

READY --- the oven is ready to accept product.

SET

D

TIMEDmmss --- the current cook time set-

ting.

D

HIGH

TEMP --- the temperature is above the set

point. Wait until the display reads ready before

loading product.

HIGH

D

TEMPDLIMIT ---the oven temperature ex-

ceeds the high limit. The Over Temperature Alarm

buzzer sounds. Shut the oven off and w ait for the

unit to cool down.

HIGH

D

TEMPDPANEL --- the control area reaches

an excessive temperature. Shut the oven off and

wait for the unit to cool down.

PROBE

D

D

OPENDPROBEDSHORT --- t h e t e m p e r a -

ture sensor has failed. The Alarm buzzer sounds.

Shut the oven off and contact a service representative.

D

19

Page 24

Operation

Oven Adjustments for Cooking

The combination of belt time, oven temperature,

and air flow are important for achieving quality results from your Blodgett conveyor oven. Use the

following guidelines to adjust the belt time and

oven temperature of your unit. For questions regarding further oven adjustments, please contact

your local Blodgett Sales Representative for a ssistance.

CONVEYOR SPEED AND OVEN TEMPERATURE

Conveyor belt speed (cook time) and oven temperature are the two variables used when fine tun ing your oven for a specific product. To determine

the optimum bake time and temperature, make

small changes for each trial and keep one variable

constant. For example, if the oven temperature is

460_F (238_C) and the belt speed is 7 minutes,

but the pizza is not browned enough, increase the

temperature to 475_F (246_C) and keep the belt

speed the same. However, if the center of the pizza

is not completely cooked, keep the oven temperature the same, and increase the bake time to 7

minutes and 30 seconds. I n general, raise the

bake temperature to increase browning, and

lengthenthebaketimetoincreasedoneness.

FINISHED PRODUCT TEMPERATURES

Internal temperatures of the cooked products

should be measured immediately after the product exits the cooking chamber to ensure a safe

food temperature. Internal pizza temperatures

should be over 165_F(74_C). Minimum tempera-

ture guidelines vary depending on the food items.

AIR FLOW AD JUSTMENTS

Slide the product clearance adjustment plates to

the lowest possible setting for your menu items.

Lowering the clearance plates will reduce the

amount of hot air escaping from the chamber

openings.

Most often, the ideal oven settings can be dialed

in without making any changes to the airplate. The

oven configuration should not be modified unless

the oven time and temperature adjustments have

proven unsuccessful.

Air flow adjustments may be necessary to fine

tune the oven for your particular product. The air

plate, located at the top of the baking chamber,

containsholesthat can be covered using Block-off

Plates. The plates can easily be adjusted to regulate the air flow for your particular needs. Use the

following guidelines to adjust the Block-off Plates.

SeeFigure15.

1. Ensure the oven is OFF and completel y cooled.

2. Remove the product clearance adjustment

plate from the idle side of the oven.

3. Pulltheairplateoutoftheoven.

4. Remove the wing nuts, screws, and washers

holding the Block-off Plates.

5. Adjust the plates.

6. Replace the wing nuts, screws, and washers

to tightly secure the Block-off plates in their

new locations. Make a sketch of the final airplate setup for future reference.

7. Replace the air plate and product clearance

adjustment plate.

The following examples illustrate air flow regulation.

NOTE: The first half of the oven chamber greatly

affects the initial baking of the product,

while the last half largely affects the browning.

D

A good bake time and t emperature have been

established, but more top browning is desired.

Slide one of the Block-off Plates to uncover a

row of holes toward the exit end of the oven.

D

The bottom of the pizza is golden brown, but the

top is too dark. Close rows at the exit end of the

oven to reduce final browning.

D

The center of the pizza is still doughy and the

toppings are not fully cooked. Open up rows at

the chamber entrance and close rows at the

chamber exit.

20

Page 25

Air Flow Plate

Operation

Oven Adjustments for Cooking

Block-Off

Plate

Figure 15

21

Product Clearance

Adjustment Plate

Page 26

Maintenance

Cleaning

WARNING!!

Always disconnect the power supply be-

fore cleaning or servicing the oven.

WARNING!!

If a gas oven needs to be moved, the gas

must be turned off and disconnected f rom

the unit before removing the restraint. Reconnect the restraint after the oven has

been returned to its original location.

Follow this recommended cleaning schedule for

proper oven performance.

Daily:

1. Clean the conveyor belt using a wire brush. Allow any foreign material to drop into the crumb

pans.

2. Empty and clean the crumb pans. Use a hot

water and detergent mix. Rinse with clean water.

3. Make sure cooling fans are operating.

Every Three Months:

1. Brush and clean the guards of the cooling

fans.

Every Six Months:

1. Unplug the oven. On gas models, disconnect

the gas connections.

2. Remove the crumb pans.

3. Remove the conveyor assembly as follows:

a.) Pull the conveyor assembly out of the lo-

cating pins to loosen the drive belt.

b.) Remove the drive belt from the drive mo-

tor and then around the pulley on the conveyor assembly.

c.) Slide the conveyor assembly out through

the left hand tunnel opening.

4. Slide the nozzles out of the baking chamber.

5. Remove the product clearance adjustment

plate. Slide the air plate out of the baking

chamber.

6. Clean the oven interior with an appropriate

oven cleaner safe for aluminum.

7. Clean the conveyor assembly, crumb pans air

plate and nozzles. Wash in a hot water, detergent mix and rinse with clean water. For difficult cleaning areas, use a “heavy-duty degreaser” or oven cleaner that is safe for

aluminum.

8. Move the oven (if not already moved) and clean

under it. Be careful not to damage oven’s gas

hose or electrical cords when moving.

9. Reassemble the oven. Install the nozzles as

follows:

NOTE: Install the nozzles in the order shown

in Figure 16.

a.) Start from the center of t he oven and work

toward the ends.

b.) Make sure the rear opening of each

nozzlefitsovertherectangularframein

thenozzlesupportplateattherearofthe

oven.

c.) The front of the nozzle rests in the support

at the front of the oven.

d.) Trytomovethenozzlefromsidetoside.

It should not move any appreciable distance.

Figure 16

22

Page 27

Every 12 Months:

A factory authorized service person should:

1. Open and clean the inside of the control panel.

2. Check and tighten a ll electrical connections.

3. Check DC gear motor brushes for wear.

4. Check the drive belt for cleanliness.

5. MT1828G --- Lubricate the combustion air

blower motor with six drops of Anderal #465

oil

If maintenance is required contact your local service company, a factory representative or the

Blodgett Oven company.

Maintenance

Cleaning

WARNING!!

Always disconnect the power supply be-

fore cleaning or servicing the oven.

WARNING!!

If the oven needs to be moved, the g as

must be turned off and disconnected f rom

the unit before removing the restraint. Reconnect the restraint after the oven has

been returned to its original location.

23

Page 28

Maintenance

Control Box Component Locations

MT1828G

Cooling Fans

Motor

Drive

Board

Gas

Regulator

Valve

Burner

Blower

Assembly

Figure 17

24

Page 29

Motor

Drive Board

Maintenance

Control Box Component Locations

MT1828E

Cooling Fans

Heating

Elements

Contactor

Heating

Element

Conveyor

Motor

Figure 18

25

Page 30

Maintenance

Troubleshooting Guide

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Blower motor(s) not running

S

Computer control turned OFF

S

No power to oven

S

Motor circuit breaker open

S

Control circuit breaker open

S

Motor(s) burned out

S

Computer cable loose

SYMPTOM: Computer controller displays: HIGH TEMP LIMIT, PROBE OPEN, or PROBE SHORT

S

Computer controller not properly installed

S

Internal problem with computer controller

S

Loose probe connections at computer controller

S

Short in probe

S

Press ON/OFF key

S

Replace main fuses or reset breakers

S

Reset breaker

S

Reset breaker

S

*

S

*

S

Reinstall

S

*

S

*

S

*

SYMPTOM: Burner will not fire (MT1828G) or Elements will not heat (MT1828E)

S

Computer control turned OFF

S

Blower motor(s) not running

S

Computer temperature not set above ambient

temperature

S

Cooling fan not working properly

S

Defective computer controller

S

Manual gas valve closed (MT1828G)

*Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

All repairs and/or adjustments be done by your local Blodgett service agency and not by the owner/operator. Blodgett cannot assume responsibility for damage as a result of servicing done by unqualified personnel.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

S

Press ON/OFF key

S

Blower motor(s) must be running. Check circuit

breakers

S

Set to desired temperature

S

*

S

*

S

Open valve

26

Page 31

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Oven will not reach desired temperature

S

Computer control turned OFF

S

No power to oven

S

Blower motor(s) not running

S

Shorted temperature probe

S

Temperature hi-limit sw itch out of adjustment or

defective

S

Internal problem with main temperature controller

S

Cooling fan not working properly

S

Defective heating element relay

S

Gas pressure to oven is t oo low (MT1828G)

SYMPTOM: Conveyor belt will not run

Maintenance

Troubleshooting Guide

S

Press ON/OFF key

S

Replace main fuses

S

Check control switch and/or fuses

S

*

S

*

S

*

S

*

S

*

S

Contact local gas representative

S

Computer control turned OFF

S

Control circuit fuse blown

S

Belt hooked on something in oven

S

Defectiveconveyordrivemotor

S

Defectiveconveyordrivemotorcontroller

S

Loose cable

SYMPTOM: Burner operates sporadically (MT1828G)

S

Manual gas valve closed

*Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

All repairs and/or adjustments be done by your local Blodgett service agency and not by the owner/operator. Blodgett cannot assume responsibility for damage as a result of servicing done by unqualified personnel.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

S

Press ON/OFF key

S

Replace fuse

S

Turn oven OFF, Unhook and resolve problem

S

*

S

*

S

*

S

Open valve

27

Page 32

Introduction

Description et Spécifications du Four

La cuisson dans un four à bande transporteuse

diffère de celle qui se fait dans un four superposable ou juxtaposable traditionnel en ce qu’un ventilateur monté dans une chambre fermée fait

constamment circuler l’air chaud au-dessus des

aliments, ce qui permet une pénétration plus rapide de la chaleur. Le résultat est un produit d’une

qualité comparable à celle obtenue dans un four

traditionnel, cuit à une température inférieure

dans un délai plus court.

Les fours à bande transporteuse Blodgett sont

des fours à gaz à chauffage direct qui utilisent des

produits à combustion à haute température pour

la cuisson. Cela représente le progrès le plus récent en termes de rendement énergétique, de fiabilité et de facilité d’utilisation. La chaleur normalement perdue recircule à l’intérieur de la chambre

de cuisson avant d’être évacuée du four. Des réductions substantielles de consommation d’énergie sont obtenues en même temps qu’une amélioration des performances du four.

Ventilateur

Source du

Chaleaur

Circulation de l’air dans les four à band transporteuse

Air chauffé

Plateau d’air

Tap i s du C o nv o ye u r

Buses

Air de Retour

Figure 19

28

Page 33

Introduction

Description et Spécifications du Four

CARACTÉRISTIQUES MT1828G/AB MT1828E/AA

Largeurdelabande 46 cm (18 po)

Longueur de la zone de

cuisson

Surfacedecuisson .34 m2(3.7 Sq. Ft.)

Dimensions

(Appareil simple)

Tem p ér a tur e d e f o nc -

tionnement maximum

Dégagement du produit 9.5 cm (3. 75 po)

Puissance maximum à

l’entrée

Source d’alimentation É. U. et Canada

71 cm (28 po)

104 cm x 89 cm x 46 cm (41 po x 35 po x 18 po)

315_C (600_F)

40,000 BTU/Hr (11.7 kW) (42 .2MJ) 11.1 KW/hr.

120/208-240 VAC, 1Φ, 60Hz, 4 fils,

15 Ampères

Exportation et l’Australie

220/240 VAC, 1Φ, 50/60Hz, 3 fils, 15

Ampères

É. U. et Canada

208 VAC, 1Φ, 60Hz, 3 fils, 52 ampères

240 VAC, 1Φ, 60Hz, 3 fils, 45 ampères

208 VAC, 3Φ, 60Hz, 4 fils, 30 ampères

240 VAC, 3Φ, 60Hz, 4 fils, 26 ampères

Exportation et l’Australie

240 VAC, 1Φ, 50Hz, 3 fils, 45 ampères

208-240 VAC, 3Φ, 50Hz, 4 fils, 30

ampères

380/220 VAC, 3Φ, 50Hz, 5 fils,

18 ampères

415/240 VAC, 3Φ, 50Hz, 5 fils,

17 ampères

Source d’alimentation

au gaz

Branchement

d’alimentation en gaz

4.5 po W.C. (1.1 kPa) minimum

10.5 po W.C. (2.61 kPa) maximum

3/4 po (1.9 cm) NPT Aucun

29

Aucun

Page 34

Introduction

Description et Composantes du Four

Montage à convoyeur: Ce sont la courroie du

convoyeur et le montage à crémaillère qui portent

l’aliment à travers le four.

Boîtier de commande: contient les câblages électriques, ventilateur de refroidissement ou volets, moteur d’entraînement et courroie d’entraînement.

Moteur d’entraînement: Il fournitla puissancenécessaire au déplacement de la courroie du convoyeur. Located inside the control box.

Courroie d’entraînement: connecte le pignon du

moteur d’entraînement au pignon de support de

la bande transporteuse du côté de l’entraînement.

Chambredecuisson:Les aliments sur la courroie passent par la chambre de cuisson.

Contrôles du Four: On les utilise pour contrôler

la température du four, la vitesse de la courroie et

aussi pour d’autres fonctions.

Contrôle à Distance

de l’opérateur

Boîtier de

commande

Buses: Situées à l’intérieur du four, sous la courroie du convoyeur, elles distribuent l’air chauffé à

partir du fond de la chambre de cuisson.

Ramasse-miettes: Situés sous la courroie du

convoyeur aux deux extrémités de la chambre de

cuisson, ils attrapent les miettes des aliments laisséessurleconvoyeur.

Plaque de circulation d’air: Elle distribue l’air

chaufféàpartirdelapartiesupérieuredufour

Interrupteur d’arrêt d’urgence: permet, en cas

d’urgence, à l’utilisateur d’arrêter le four et la

bande transporteuse. Ne pa s utiliser pour l’arrêt

normal.

Barred’arrêt

des aliments

Côté libre du

ramassemiettes

Montage à Convoyeur

(montré sans courroie)

Côté guide du

ramassemiettes

Plaque de

Circulation d’Air

Contrôle Intégral

de l’opérateur

Buses

Figure 20

30

Page 35

Installation

Livraison et Inspection

Tous les fours sont expédiés en conteneurs. A la

réception de votre four Blodgett vous devez:

D

Vérifierque les emballages ne sont pas abimés.

Toute défection dans l’emballage doit être notée sur l’accusé de recept ion de la marchandise; celui-ci doit être signé par le chauffeur.

D

Sortir le four de son emballage et vérifier son bon

état. Les transporteurs n’acceptent les réclamationsetplaintesquesiellessontfaitesdansles

quinze jours qui suivent la livraison et si l’emballage a été conservé afin d’être inspecté.

La Blodgett Oven Co., n’est p as responsa ble

des dégâts subis pendant le transport. Le

transporteur est seul responsable de la livraison du matériel en bon état lorsque l’expédition a été acceptée. Néanmoins, nous sommes

à votre disposition pour vous aider à composer

votre dossier de réclamation.

Le four peut alors être déplacé jusqu’à son lieu

d’installation. Comparez la liste ci-dessous à la

Figure 20 page 30 pour vous assurer que vous

avez reçu toutes les pièces.

Description des Pièces

Partie principale du four 1

Montage à convoyeur 1

Plateau pour miettes 2

Arrête du produit 1

Buses 5

Paquet contenant 4 broches d’alignement 1*

Manuel d’utilisation 1*

Chariot 1**

Roulettes à triple empilage 1**

L’ordinateur de cuisson détaché 1**

Base de support de l’ordinateur de

cuisson détaché

Lescâblesd’ordinateurdecuisson

détaché

REMARQUE:* Article non illustré.

**En Option

Qté.

1**

1**

31

Page 36

Installation

Implantation et aération du four

IMPLANTATION DU FOUR

L’implantation correcte et bien étudiée du four

seraàl’avantageàlongtermedel’opérateuret

permettra d’obtenir un rendement satisfaisant.

Les espaces de dégagement ci-dessous doivent

être prévus entre lefour et toute construction combustible ou non.

D

Côté du four --- 40. 6 cm (16 po)

D

Arrièredufour---0cm(0po)

Les espaces de dégagement ci-dessous doivent

êtrepossiblepourpermettrel’entretien.

D

Côté du four --- 96.5 cm (38 po)

D

Arrière du four --- 71 cm (28 po)

REMARQUE:L’entretien régulier peut en général

être effectué dans les limites du déplacement que permet la chaîne de

retenue. Si le four doit être plus écarté du mur, l’alimentation en gaz doit

être coupée et la canalisation débranchée du four avant d’enlever la

chaîne.Celle-cidoit être utilisée pour

empêcher d’exercer toute contrainte

surlecoupleurdegaz.

Il est essentiel qu’une circulation d’air adéquate

au four soit maintenue pour apporter un débit d’air

de combustion et de ventilation suffisant.

D

L’emplacement ne doit pas avoir de courants

d’air.

D

Maintenez la zone du four libre et dégagée de

tous matériaux combustibles tels que le papier,

le carton, ainsi que les liquides et solvants inflammables.

D

NE placez PAS le four sur un socle à bordure.

L’une comme l’autre de ces installations gênera

la circulation d’air vers le compartiment de combustion et empêchera une bonne ventilation

des moteurs de soufflantes. Une telle situation

doit être rectifiée si l’on veut empêcher que le

four ne soit définitivement endommagé.

D

Le déclenchement du dispositif de surchauffe

de ces moteurs indique une température ambiante excessive à l’arrière du four. Une telle situation doit être rectifiée si l’on veut empêcher que

le four ne soit définitivement endommagé.

AÉRATION DU FOUR

On ne saurait trop insister sur la nécessité de prévoir un système d’aération bien conçu. Un tel

système permettra au four de bien fonctionner,

tout en évacuant les vapeurs et produits de combustion gênants de la zone d’utilisation.

L’extraction des fumées de combustion de l’appareil

doit se faire au moyen d’un groupe d’aspiration à

commande mécanique. Celui-ci doit être dimensionné de façon à ce qu’il recouvre entièrement l’appareil, tout en dépassant d’au moins 15 cm (6 po)

de tous les côtés qui ne sont pas contigüs à un mur.

La distance entre le sol et le bord inférieur du groupe

d’aspiration ne doit pas dépasser 2,10 mètres (7’).

Le groupe doit avoir la capacité qui convient et un

appointd’airadéquatdoitêtreprévu.

Installations aux États-Unis et au Canada

Se reporter aux codes locaux de la ventilation. En

l’absencedecodeslocaux,sereporteraucode

national de la ventilation intitulé “Normes pour

l’installation d’équipements pour l’enlèvement des

fumées et vapeurs grasses provenant d’équipements commerciaux pour la cuisine”, NFPA-96Édition la plus récente.

Installations des appareils exportés et l’Australie

La bride et le dispositif de branchement rapide

doivent être conformes aux normes locales et nationales. Les codes d’installation et/ou les exigences peuvent varier d’une localité à l’autre. Si

vous avez des questions portant sur l’installation

et/ou l’utilisation adéquate de votre four Blodgett,

veuillezcontacter votre distributeur local. Si aucun

distributeur local n’est situé dans votre localité,

veuillez appeler Blodgett Oven Company au

0011-802-860-3700.

AVERTISSEMENT!!

Une mauvaise extraction des fumées de

combustion du four peut mettre en danger la santé de l’opérateur. Elle aura

également pour résultats des problèmes

de fonctionnement, une cuisson laissant

à désirer et de possibles dégâts subis par

le matériel.

Les dégâts résultant directement d’une

aération inadéquate ne seront pas couvertspar la garantieofferte par le fabricant.

32

Page 37

BASE DE SUPPORT DU FOUR AVEC ROULETTES

REMARQUE:Les roulettes freinées doivent être tour-

nées vers le devant du chariot.

1. Fixezchaquepieddotéderoulettesaucadre,

à l’aide d’une rondelle de blocage et d’un

boulon. NE serrez PA S complètement.

2. Placez l’étagère entre les pieds en veillant à ce

que sa surface lisse soit dirigée vers le haut du

support. Alignez l’étagère avec les trous qui

se trouvent dans chaque pied. Fixez l’étagère

àchaquepiedunboulonetunécrou.

Pied

Installation

Montage du Four

3. Serrez les boulons installés à l’étape 1.

4. Placez le four sur son dos. Installez les tiges

d’alignement (4) du four dans les quatre trous

situés au fond du four.

5. Placez le four sur le support en insérant les

tiges d’alignement dans les trous qui se

trouvent dans le cadre du support du four.

Cadre du

support

Tige

d’alignement

Partie

supérieure

du support

Étagère

Figure 21

33

Page 38

Installation

Montage du Four

SUPERPOSITION DES FOURS (si applicable)

Section Double

1. Attachez la partie inférieure du four au

support.

2. Poser le four du haut sur le dos. Insérer les

broches d’ a lignement (4) dans les quatre tr

3. Enlevez les quatre bouchons éjectables

situés sur le dessus du four inférieur.

4. Sortir le four de la palette en le soulevant avec

précaution et le placer sur ses broches d’al ignement. Situer les broches d’alignement

avec les trous dans le bâti du four du bas.

Section Triple

1. Coucherlefourdubassurledos.Insérerles

roulettes dans les quatre trous qui se trouvent

en bas du four.

REMARQUE:Les roulettes freinées doivent être

tournées vers le devant du four.

2. Faites reposer avec précaution le four sur les

roulettes. Serrez les freins des roulettesavant.

3. Poserlefourducentresurledos.Insérerles

broches d’alignement (4) dans les quatre

trous qui se trouvent en bas du four .

4. Enlevez les quatre bouchons éjectables

situés sur le dessus du four inférieur.

5. Sortir le four du centre de la palette en le soulevant avec précaution et le placer sur ses broches

d’alignement. Situer les broches d’alignement

avec les trous dans le bâti du four du bas.

6. Refaiteslesétapes3et5pourlefour

supérieur.

Figure 22

Figure 23

34

Page 39

LE CONVOYEUR

1. Glisser le corvoyeur (avec poulisd’engrenage

à la fin) dans l’ouverture gauche. Le pignon

doit se trouver à l’intérieur du panneau de

commande après avoir été enfoncé dans le

four. Reportez-vous à la Figure 24.

Installation

Montage du Four

2. Installer la ceinture à l’autours du moteur et la

poulis d’engrenage du corvoyeur. Reportezvous à la Figure 25. Pousser le corvoyeur à la

position initiale pour serrer la ceinture.

Figure 24

Figure 25

35

Page 40

Installation

Montage du Four

3. Sauf indication contraire, le déplacement de

la bande transporteuse est réglé à l’usine

pour se faire de gauche à droite lorsqu’on regardeledevantdufour.Siunchangementde

sens s’avère nécessaire, la polarité du moteur

d’entraînement doit être inversée. Il suffit d’in-

tervertir les fils noir et blanc du moteur au niveau du régulateur de courant continu, qui se

trouve dans le boîte de commande. Reportezvous à la Figure 26. La bande transporteuse

doit d’autre part être installée depuis la

gauche du four au lieu de la droite.

Y OR BL

S2

S3

SPEED

CONTROL

S1

L2 L1

A1 A2 A3

BK

W

Figure 26

W

V

AC

AC

GND

DC MOTOR

36

Page 41

Installation

Montage du Four

PLATEAUX POUR MIETTES

1. Installez des plateaux pour miettes sous cha-

que extrémité du convoyeur.

2. Glissez la barre d’arrêt des produits sur l’ex-

trémité du côté libre du ramasse-miettes.

Figure 27

L’ORDINATEUR DE CUISSON DÉTACHÉ

1. Percerlestrousdemontagepourlabasede

support de l’ordinateur de cuisson.

2. Monter au mur, la base de support et l’étrier de

support de câble.

3. Monter l’ordinateur de cuisson sur le support

de base. Brancher le câble de raccordement

à l’arrière du contrôleur.

4. Attacher les câbles au crochet de support de

câble et à l’arrière du four en utilisant les attaches de câble et des vis.

REMARQUE:NEPASsurserrerlesserre-câble.

Les fils peuvent être endommagés causant une défaillance de

l’ordinateur.

Ordinateur

de cuisson

37

Base de

support de

l’ordinateur

de cuisson

Étrier de support

de serre-câble

Figure 28

Page 42

Installation

Branchements de Service --- Normes et Codes

LES CONSEILS D’INSTALLATION ET D’ENTRETIEN CONTENUS DANS CE MANUEL NE

S’ADRESSENT QU’Á UN PERSONNEL QUALIFIÉ. UN PERSONNEL NON QUALIFIE PEUT SE

BLES SER ET/OU ABÎMER LE FOUR LORS DE

SON INSTALLATION ET/OU SON ENTRETIEN.

Un personnel d’installation qualifié est représenté

soit par des personnes physiques, soit par un société, une usine, une corporationqui en personne

ou par l’intermédiaire d’un représentant s’engage

à et est responsable de:

D

l’installation ou du remplacement des conduites de gaz, de même que la connexion, l’installation, la réparation ou le service de l’équipement;

D

l’installation du câblage électrique à partir du

compteur électrique, de la boîte de commande

principale ou de la sortie de commodité vers

l’appareil électrique.

Le personnel qualifié pour l’installation doit avoir

de l’expérience dans ce genre de travail, connaître

toutes les précautions à prendre et se plier à

toutes les normes et à tous les règlements en vigueurdansl’étatetlalocalité.

Installations aux États-Unis et au Canada

Les branchements de gaz doivent être en accord

avec les codes locaux, ou en l’absence de codes

locaux, avec le Code National du Gaz de Chauf-

fage, ANSI Z223.1 le Code d’Installation du Gaz

Naturel CAN/CGA-B149.1 ou le Code d’Installation

du Propane CAN/CGA-B149.2 si applicable.

CAN/CGA---B149.2, selon le cas.Tous les fours

installés doivent être pourvus d’une prise à la terre

répondant a ux normes locales ou, en l’absence

de tels codes, répondant aux normes du Code

Électrique National (National Electrical Code),

ANSI/NFPA 70---Dernière édition et/or Code Électrique Canadien CSA C22.2 si applicable.

Installations des appareils exportés et l’Australie

L’installation doit suivre les normes locales et nationales. Les codes d’installation et/ou les exigences peuvent varier d’une localité à l’autre. Si

vous avez des questions portant sur l’installation

et/ou l’utilisation adéquate de votre four Blodgett,

veuillezcontacter votre distributeur local. Si aucun

distributeur local n’est situé dans votre localité,

veuillez appeler Blodgett Oven Company au

0011-802-860-3700.

38

Page 43

Installation

d

i

t

i

tpied

Branchement de Gaz

CONDUIT DE GAZ

Un système d’alimentation en gaz de bon calibre

est essentiel pour obtenir le meilleur rendement

du four. Les conduits doivent être calibrés pour

fournir suffisamment de gaz pour alimenter tous

les appareils sur le conduit sans perte de pression

à l’équipement.

Exemple:

REMARQUE:Les valeurs en BTU de l’exemple sui-

vant sont pour le gaz naturel.

Achat d’un four à convection MT1828/AB qui doit

être ajouté sur la conduite de cuisson existante.

1. Additionner les valeurs nominales en BTU des

appareils utilisés.

Friteuse Pitco 120,000 BTU

Cuisinière 6 brûleurs 60,000 BTU

Four 50,000 BTU

Total 230,000 BTU

2. À ce total, ajouter la valeur nominale en BTU

du nouveau four.

Total précédent 230,000 BTU

MT1828/AB 40,000 BTU

Nouveau total 270,000 BTU

3. Mesurer la distance entre le compteur à gaz et

la conduite de cuisson. Ceci est la longueur

de tuyau. Disons que la longueur de tuyau est

de 12,2 mètres (40’) et le calibre du tuyau est

de 2,54 cm (1 po).

4. Se reporter au tableau approprié pour déterminerlacapacitétotaledelaconduitedegaz

actuelle.

Pour cette exemple, la capacité totale est de

320,000 BTU, la conduite de gaz actuelle n’a

pas besoin d’être augmentée.

REMARQUE:Les capacités en BTU données sur

les tableaux sont uniquement pour

des longueurs droites de tuyaux.

Touslescoudesetautresraccords

diminuent la capacités de la conduite. Pour toute autre question,

prendre contact avec la compagnie

locale de distribution du gaz.

Capacité maximum du tuyau métallique en

pieds cubiques de gaz naturel à l’heure.

(chutedepressionde13mm(0,5po)

à la colonne d’eau)

Longeur

econdu

pieds (ft)

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

Du Code national du gaz carburant Partie 10 Tableau 10-2

Capacité maximum du tuyau en milliers de

BTU/hr de gaz L.P. non-dilué à 28 cm à la

(chutedepressionde13mm(0,5po)

Longeur de

condu

(ft)

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

Du Code national du gaz carburant Partie 10 Tableau 10-15

Dimensions nominales

3/4” 1” 1-1/4” 1-1/2” 2”

colonne d’eau.

à la colonne d’eau)

Diamètre extérieur

s

3/4” 1” 1-1/2”

39

Page 44

Installation

Branchement de Gaz

RÉGLAGEETTESTDEPRESSION

Tous les fours sont réglés en usine en fonction du

type de gaz s pécifié sur la plaque signalétique.

Cette plaque est fixée au côté gauche du panneau

de commande.

Pour maintenir la bonne pression de gaz, chaque

four est livré avec un régulateur. Le régulateur est

essentiel pour le fonctionnement correct du

four et il ne doit pas être retiré. Il est préréglé

pour alimenter le four avec une pression de gaz au

collecteur de 0,87 kPa (3.5 po WC [à la colonne

d’eau]) lorsque la flamme est allumée. Le bouton

de réglage est situé au-dessus de la soupape à

gaz,entrelesystèmedefermeturemanuelleetles

soupapes solénoïdes.

NE PAS INSTALLER DE RÉGULATEUR SUPPLÉMENTAIREOÙLEFOURSECONNECTESUR

L’ALIMENTATION DE GAZ SAUF SI LA PRESSION

D’ENTRÉE EST AU-DESSUS DU MAXIMUM.

REMARQUE:La pression maximum à la colonne

d’eau de l’alimentation en gaz est

10.5” W.C. (2.61 kPa). La pression

minimum à la colonne d’eau de l’alimentation en gaz est 4.5” W.C. (1.1

kPa).

Les branchements de gaz doivent être en accord

avec les codes locaux, ou en l’absence de codes

locaux, avec le Code National du Gaz de Chauf-

fage, ANSI Z223.1 le Code d’Installation du Gaz

Naturel CAN/CGA-B149.1 ou le Code d’Installation

du Propane CAN/CGA-B149.2 si applicable.

Le four et sa vanne d’arrêt individuelle doivent être

déconnectés du système d’a limentation en casde

test des conduites à pression manométrique supérieure à 1/2 psi (13. 85 po à la colonne d’eau ou

3.45 kPa).

En cas de test à pression manométrique de 1/2 psi

(13.85 po à la colonne d’eau ou 3.45 kPa) ou

moindre, le four doit être isolé du système par la

fermeture de sa vanne d’arrêt manuelle individuelle.

Branchement de Gaz 2” (51 mm)

Branchement de Gaz 2” (51 mm)

Figure 29

40

Page 45

RETENUE DU TUYAU DE GAZ

Si le four est monté sur roulettes, un connecteur

commercial flexible ayant un diamètre intérieur

minimum de 1,9 cm (3/4”) doit être utilisé avec un

dispositif de connexion rapide.

La retenue, fournie avec le four, doit servir à limiter

les mouvements de l’unité de façon qu’ aucune

tension ne soit placée sur le connecteur flexible.

Le cable de retenue doit être fixé aussi près que

possible du coupleur souple et être suffisamment

court pour empécher toute contrainte exercée sur

le coupleur souple. Quand la retenue est entièrement étendue, le connecteur doit être facile à installer et à connecter rapidement.

Ce dispositif (qui consiste en un câble de gros calibre) doit être accroché au mur pour empêcher

d’endommager celui-ci. NE vous servez PAS de la

canalisation de gaz ni d’une canalisation d’électricité pour y accrocher l’extrémité fixée à demeure

du dispositif de retenue ! Servez-vous de boulons

d’ancrage dans le béton ou les parpaings. Sur les

murs en bois, utilisez des tire-fond à bois à résistance élevée que vous enfoncez dans les montants du mur.

AVERTISSEMENT!!

Si la retenue est déconnectée, quelqu’en

soit la raison, elle doit être reconnectée

quand le four estremis à sa po sition d’ori gine.

Installation

Branchement de Gaz

Installations aux États-Unis et au Canada

Le coupleur doit être conforme à la Norme Applicable aux Coupleurs pour Appareils à Gaz Mobiles, ANSI Z21.69 ou Coupleurs pour Appareils à

Gaz Mobiles CAN/CGA-6.16.Ilconvientd’utiliser

également un dispositifde débranchement rapide

conforme à la Norme Applicable aux Dispositifs de

Débranchement Rapide pour Combustibles Gazeux, ANSI Z21.41 ou Dispositifs de Débranchement Rapide pour Combustibles Gazeux CAN

1-6.9. Une entrave fixée à une surface immobile

doit être prévue pour limiter le mouvement du four

et éviter les tensions au niveau du connecteur.

Un élément d’égouttage doit être utilisé pour chaque appareil. Reportez-vous au réglement

NFPA54/ANSI Z223.1 - Dernière édition (Code National d’Alimentation en Gaz) pour l’installation

correcte d’un élément d’égouttage.

Installations des appareils exportés et l’Australie

L’installation doit suivre les normes locales et nationales. Les codes d’installation et/ou les exigences peuvent varier d’une localité à l’autre. Si

vous avez des questions portant sur l’installation

et/ou l’utilisation adéquate de votre four Blodgett,

veuillezcontacter votre distributeur local. Si aucun

distributeur local n’est situé dans votre localité,

veuillez appeler Blodgett Oven Company au

0011-802-860-3700.

Plaque de Fixation

(La fixer au moyen

du boulon de fixation

de pied)

Canalisation

d’alimentation

en gaz

Manchon

Flexible

de Gaz

Voir VUE A

Installation du Flexible de Gaz et du Dispositif de Retenue

Manchon

Raccord

Male

Coupleur Rapide

Plaque de Fixation

pour fixation murale

Figure 30

41

IMPORTANT:

Le cable de retenue doit être fixé aussi

près que possible du coupleur souple

et être suffisamment court pour empécher toute contrainte exercée sur le

coupleursouple.À étirementmaximum

du cable de retenue, le coupleur souple

doitêtre facile à poser et à brancher rapidement.

VUE A

Serrer après

Réglage

Page 46

Installation

Raccordement Électriqu e

Avant d’effectuer tout branchement électrique sur

ces appareils, vérifiez que l’alimentation électrique est conforme aux spécifications de tension,

d’intensité et de phase indiquées sur la plaque

signalétique.