Page 1

MT1828

CONVEYOR OVEN

SERVICE AND REPAIR MANUAL

BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (802) 658Ć6600 Fax: (802)864Ć0183

PN M8560 Rev C (6/01)

Duplication of the information in this manual is prohibited without the consent of the Blodgett Service Department.

2001 - G.S. Blodgett Corporation All rights reserved.

Page 2

TABLE OF CONTENTS

2. INTRODUCTION

Oven Specifications 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation Requirements 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. OPERATION

Computer Controller 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Description 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Operation 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Procedures 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Information 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequence of Operation 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MT1828G Domestic and General Export Ovens Internal Mount - M7296 Rev B 2-3. . . . . . .

MT1828G Domestic and General Export Ovens External Mount - M9776 Rev B 2-5. . . . . .

MT1828E Domestic and General Export Ovens - M6314 Rev C 2-7. . . . . . . . . . . . . . . . . . . .

MT1828G CE Ovens - M6462 Rev B 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MT1828E CE Ovens - M6453 Rev A 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. CALIBRATION AND ADJUSTMENT

Convection Blower Motors 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To check motor rotation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To check lowĆlimit 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulated Gas Pressure 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Computer Control Configuration 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Calibration 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Belt Speed Calibration 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closed Loop System 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open Loop System 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Control Board 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. ENHANCEMENTS

Burner 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Igniter and Flame Rods 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. TROUBLESHOOTING

DC Drive System 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Computer Control System 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heating System 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Convection System 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 3

CHAPTER 1

INTRODUCTION

Page 4

MT1828

OVEN SPECIFICATIONS

VENTILATION REQUIREMENTS

The hood should completely cover the unit with an

overhang of at least 6" (15 cm) on all sides not adjaĆ

cent to a wall. The distance from the floor to the

lower edge of the hood should not exceed 7' (2.1

m). The ventilation system should replace 80% of

the exhaust volume with fresh make up air.

TABLE 1 should be used as a guideline.

Single Double Triple

CFM 400Ć500 900Ć1000 1200Ć1500

M3/min 14 Ć 17 28Ć34 42Ć51

TABLE 1

L1

N

L2

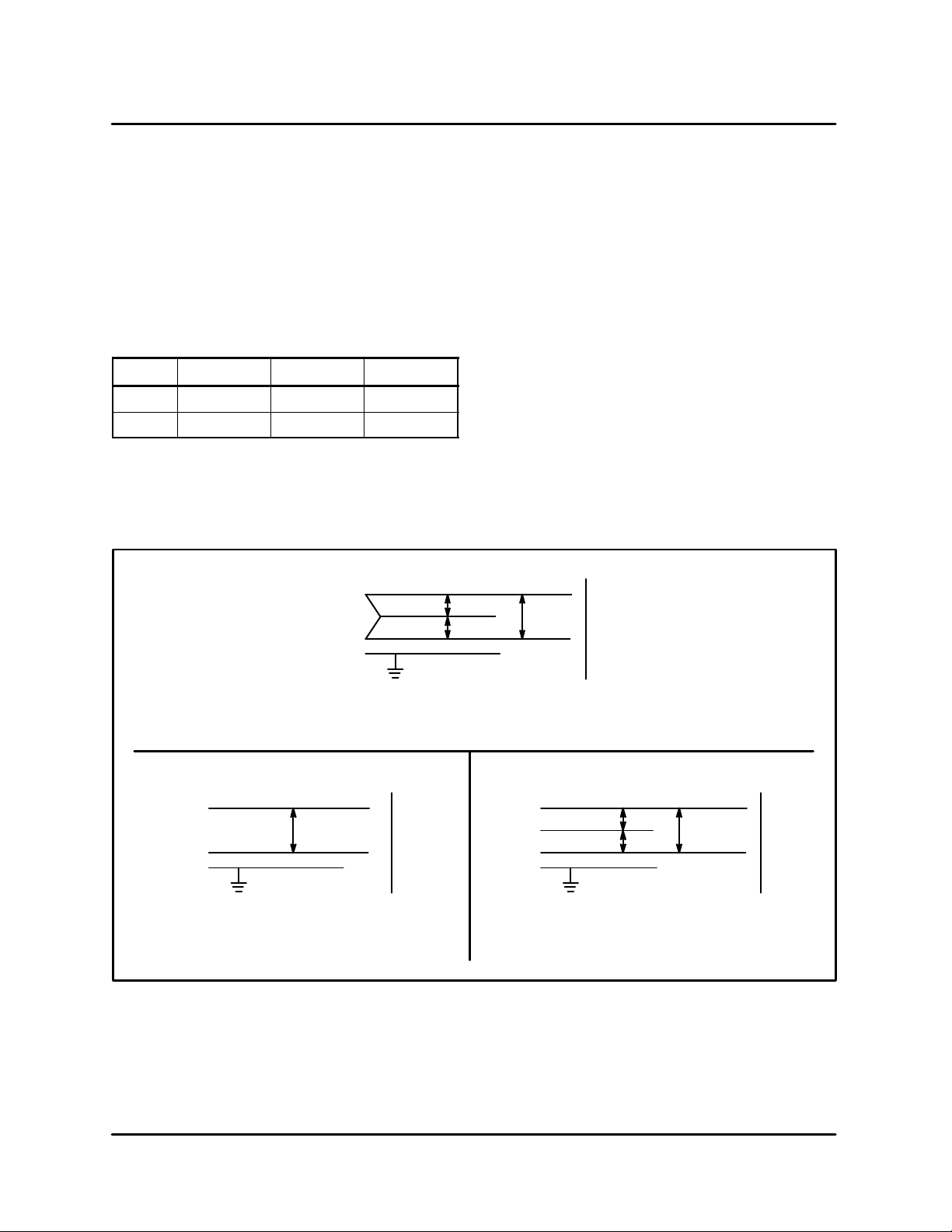

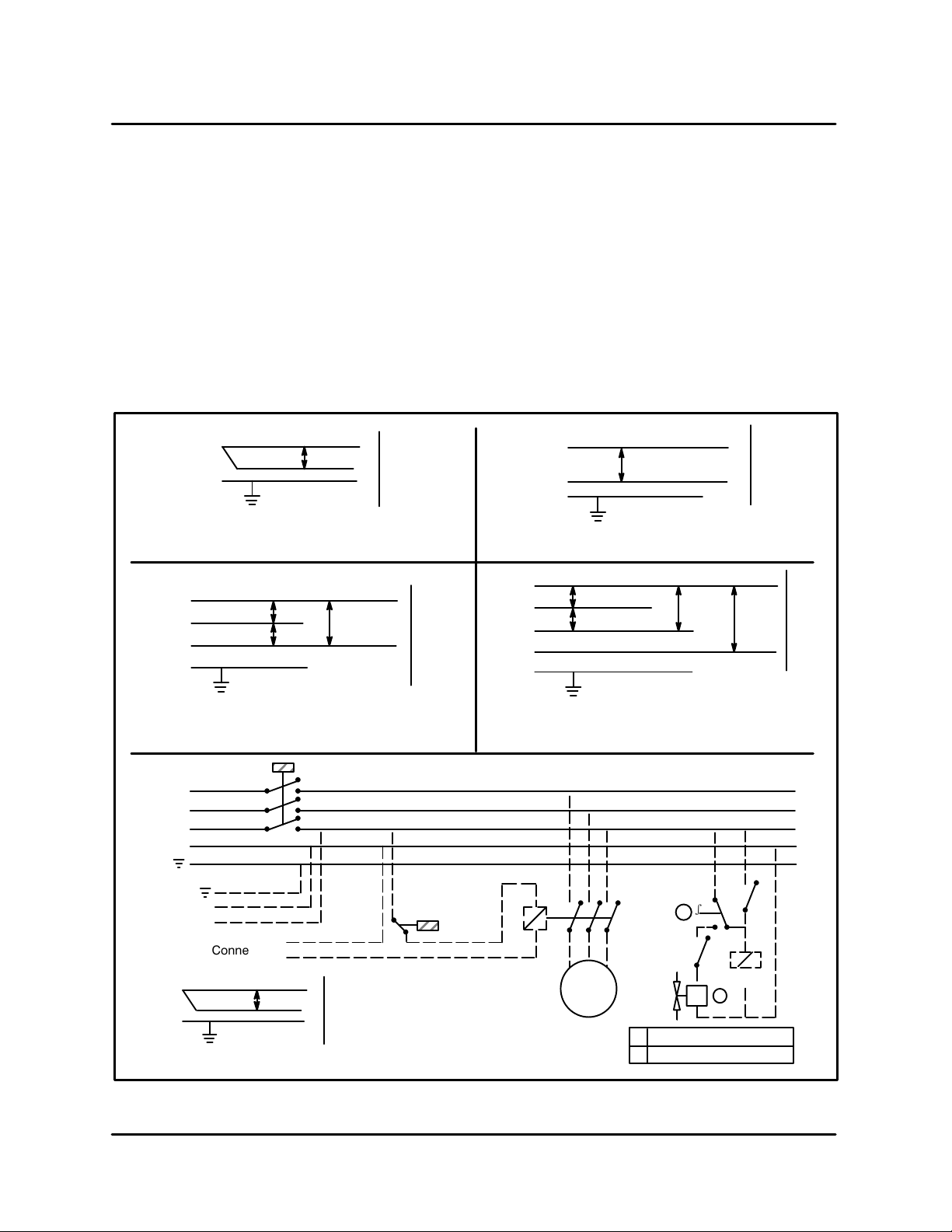

ELECTRICAL SPECIFICATIONS

NOTE: Three Phase hookup is not permitted on

gas models.

Installations within the U.S.

The MT1828G requires a 15 Amp, 60HZ, 1F,

208Ć240VAC, 4 wire service consisting of L1, L2,

neutral and ground. See FIGURE 1. Use 90C wire

and size to National Electric or local codes.

The MT1828E is available in either 1F or 3F modĆ

els. Single phase models require a 60Hz,

208/240VAC, 3 wire service consisting of L1, L2

and ground. Three phase models require a 60Hz,

208/240VAC, 4 wire service consisting of L1, L2, L3

and ground. See FIGURE 1. Wiring from the power

source to any of these units must be a minimum of

#8 AWG copper stranded wire or larger for 3 phase

and #4 AWG for 1 phase.

120

120

208Ć240

OvenSupply

MT1828G

L1

L2

208/240

OvenSupply

L1

L2

L3

208/240

MT1828E Single Phase MT1828E Three Phase Delta System

FIGURE 1

OvenSupply

1

Page 5

MT1828

Installations outside the U.S.

The MT1828G requires a 15 Amp, 50Hz, 1F, 240

VAC, 3 wire service consisting of L1, neutral and

ground. See FIGURE 2. Use 90C wire and size

wire according to local codes.

The MT1828E is available in either 1F or 3F modĆ

els. Single phase models require a 50 Hz,

220/240VAC, 3 wire service consisting of L1, L2

and ground. Three phase models are available in

either Delta or WYE configurations. Delta models

require 50Hz, 208/240VAC, 4 wire service consistĆ

ing of L1, L2, L3 and ground. WYE models require

50 Hz, 220/240 VAC, 5 wire service consisting of

L1

N

240

OvenSupply

MT1828G Export Installations

L1

L2

L3

208/240

OvenSupply

L1, L2, L3, neutral and ground. See FIGURE 2. Use

2

a minimum of 8.37 mm

copper stranded wire or

larger for 3 phase and 21.15 mm2 for 1 phase.

CE approved installations

The MT1828G requires 15 Amp, 50Hz, 1F, 230

VAC, 3 wire service consisting of L1, neutral and

ground. Connect exhaust fan connector 1 and 2.

See FIGURE 2. Use 90C wire and size according

to local codes.

The MT1828G requires 50 Hz, 3F, 230VAC, 5 wire

service consisting of L1, L2, L3, neutral and

ground. See FIGURE 2. Use 90C wire and size

according to local codes.

L1

L2

220/230/240

OvenSupply

MT1828E Single Phase Export Installations

L1

L2

L3

N

415/400*/380

415/400*/380

415/

400*/

380

240/

230*/

220

OvenSupply

MT1828E Three Phase Delta System

Export Installations

L3

L2

L1

N

Blodgett

Connector

N

L

Connector

L1

N

230

1

2

OvenSupply

MT1828G CE Approved Installations

FIGURE 2

* - CE Approved Installations

MT1828E Three Phase WYE System

Export and CE Installations

2Ć4Ć92

A1

Relay A

1

Fan

s

2

A2

21Air Pressure Regulator

Burner Control Solenoid

2

Page 6

MT1828

GAS SPECIFICATIONS

GAS CONNECTIONS

Domestic and General Export installations

The gas line should be large enough to accommoĆ

date the peak demand of all the gas appliances.

TABLE 2 reflects a straight line, 50 foot run with no

coupling restrictions and no other appliances

drawing service. Gas line installations MUST conĆ

form to National Fuel Gas Code NFPA 54/ANSI

Z223.1 Sec. 1.4 (Latest Edition). TABLE 2 should

be used as a guideline only.

NOTE: For any pipe runs over 50 feet (15 m), conĆ

sult the factory.

CE approved installations

1. Connect the oven to the gas line with the propĆ

er type of gas according to Local and National

Installation Standards. See TABLE 2.

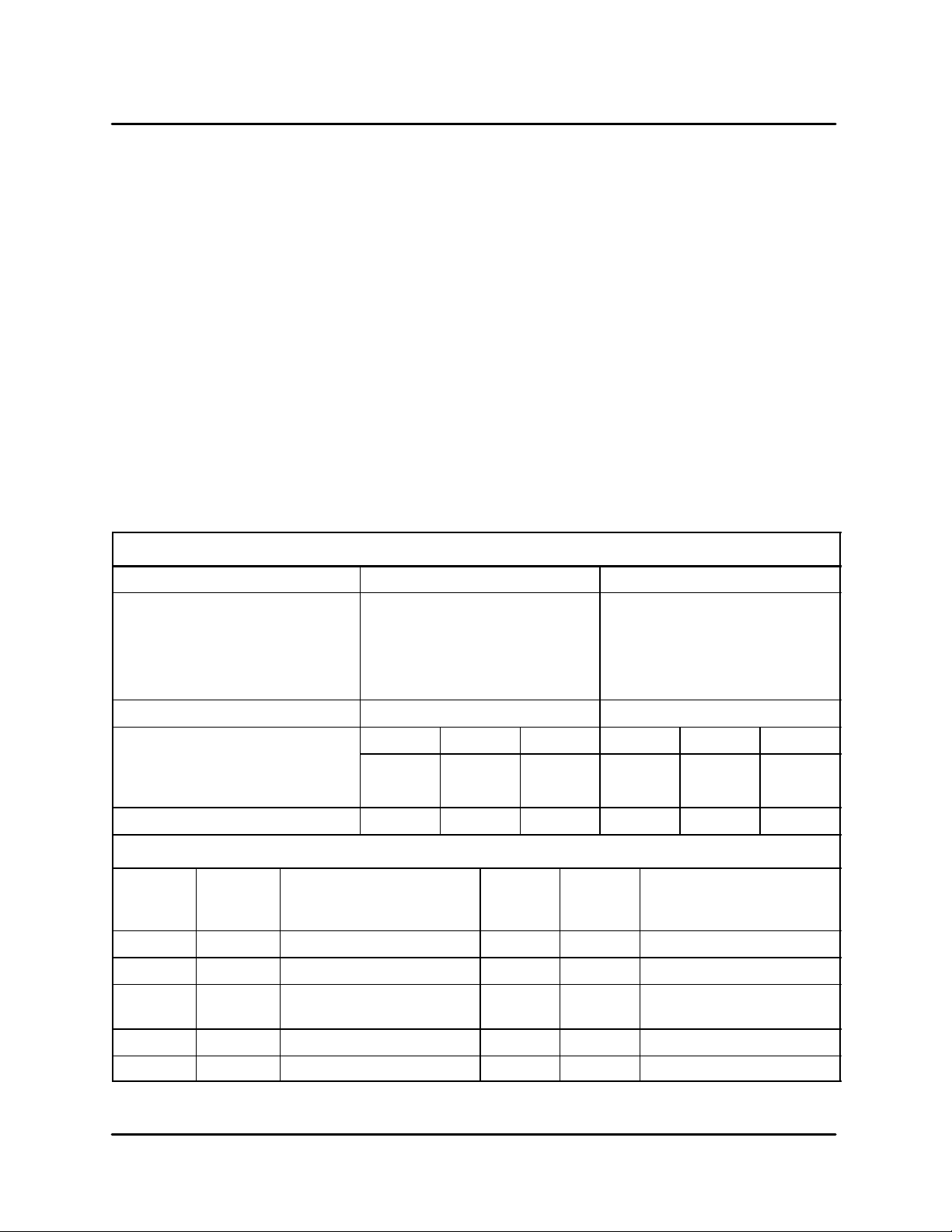

DOMESTIC AND GENERAL EXPORT

Natural Gas Propane Gas

Gas Line Sizing

GAS REQUIREMENTS

The firing rate for the MT1828G is 33,000 BTU/Hr.

(9.7 kW/Hr.)

NOTE: For natural gas meter sizing, consult your

local gas company to ensure that your meĆ

ter will provide the proper supply.

Installations within the U.S.

1. Add the total BTU's/hr of all the gas

appliances.

2. Convert BTU's to cubic ft/hr using the formula

Cu Ft/Hr = 1000 BTU/Hr for natural gas.

3. Size the meter accordingly.

Installations outside the U.S.

1. Add the total M3/min of all the appliances.

2. Size the meter accordingly.

Single

Double

Triple

Orifice Size #34 MTD #49 MTD

Incoming Gas Pressure W.C. kPa mbar W.C. kPa mbar

Static

Operational

Manifold Gas Pressure 3.5" 0.87 9 10" 2.49 25

CE APPROVED UNITS

Type of

Gas

G25 25 8 3,1 22,3 9,8 Nat. Gas

G20 20 8 2,7 22,3 9,8 Nat. Gas

G20/G25 20/25 Totally Inscrewed

G30 30/50 24 1,55 22,3 9,8 Butane

G31 30/37/50 24 1,7 22,3 9,8 Propane

Inlet

Pressure

mbars

Burner Pressure

Pressure Regulator

7"

5.5"

mbars

3/4" line

3/4" line

3/4" line

1.74

1.36

Injector

Diameter

3/4" line

3/4" line

3/4" line

17.4

13.7

Opening

mm

2,3 22,3 9,8 Nat. Gas

Air

mm

12.5"

11"

3.11

2.73

Standard Delivery

Value kW (HS)

31.1

27.4

TABLE 2

3

Page 7

CHAPTER 2

OPERATION

Page 8

MT1828

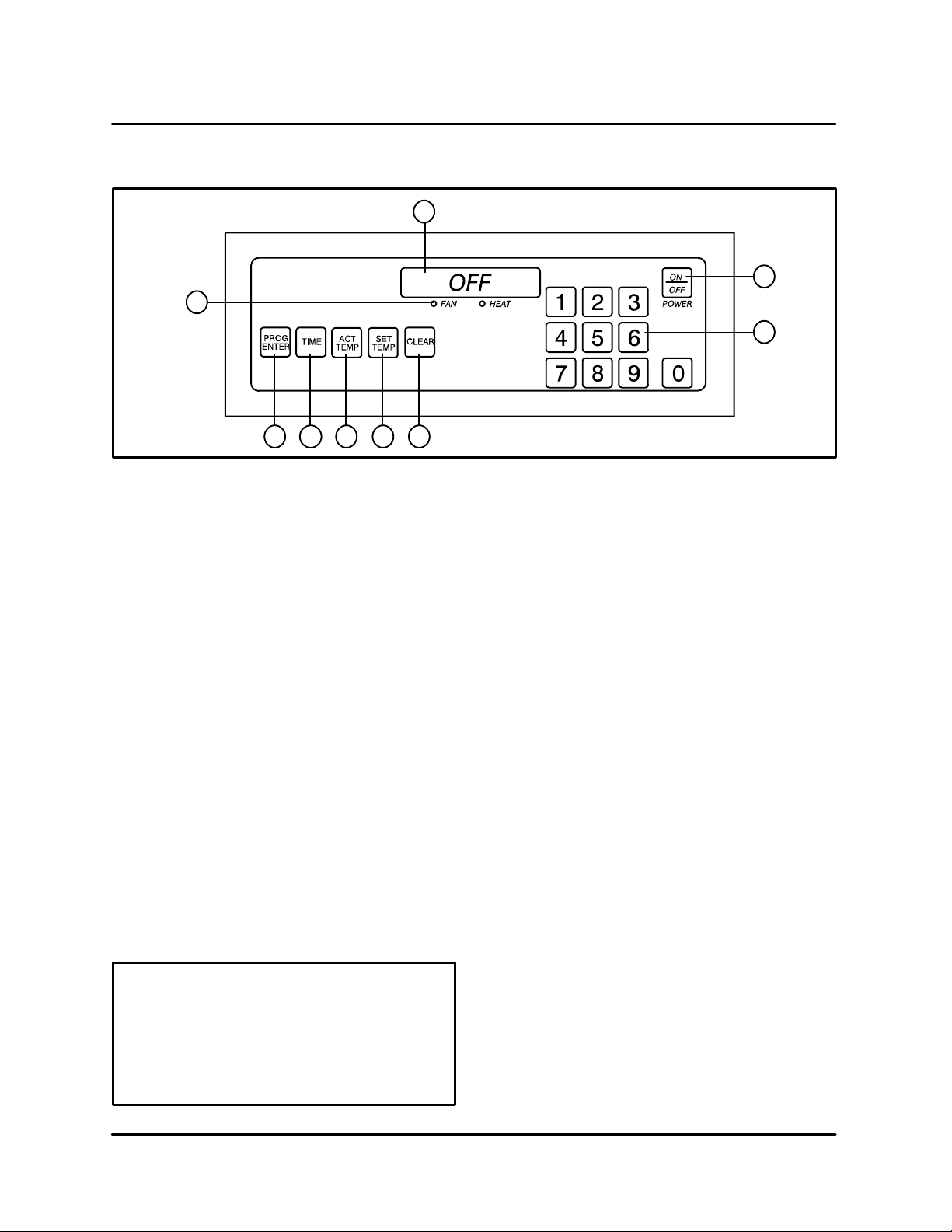

COMPUTER CONTROLLER

9

1

2

3

45678

FIGURE 1

CONTROL DESCRIPTION

1. DIGITAL DISPLAY - Displays the time, temĆ

perature and controller related information.

2. OVEN ON/OFF - Controls power to the oven.

3. NUMERIC KEYS - Used to enter numerical

data in the programming mode.

4. CLEAR KEY - Used to clear the display if an

error is made in the programming mode.

5. SET TEMP KEY - Used to view or program the

temperature setpoint.

6. ACT TEMP KEY - Used to view the current

oven temperature.

7. TIME KEY - Used to view or program the cook

time.

8. PROG/ENTER KEY - Used to enter and exit

the programming mode. Also used to lock in

programmed settings.

9. STATUS LAMPS - When lit indicate that the

fan or burners are operating.

This oven, supplied with remote control, is

equipped with an emergency shut down

switch. Should you need to stop the belt,

fans, or heat press the emergency switch.

Do not use the emergency switch as a

GENERAL on/off switch!

CONTROL OPERATION

To turn the oven on:

1. Press and hold the ON/OFF key (2). The disĆ

play reads OFF when the oven is idle.

2. The display flashes WAIT LOW SET TIME

mmss.

3. The FAN and HEAT status lamps (9) light. The

fans begin to run. The heat rises to the proĆ

grammed temperature. The conveyor belt

travels at the programmed speed.

To view the cook time setting:

1. Press the TIME key (7). The LED on the key

lights and the display flashes SET TIME

mmss.

To display the actual oven temperature:

1. Press the ACT TEMP key (6). The LED on the

key lights and the display reads ACTUAL

nnnnF.

To view the temperature set point:

1. Press the SET TEMP key (5). The LED on the

key lights and the display flashes SET TEMP

nnnnF.

To turn the oven off:

1. Press the ON/OFF key (2). The blower moĆ

tor(s) continue to run regardless of the controlĆ

ler status until the temperature drops below

180F (82C).

2-1

Page 9

OPERATION

PROGRAMMING PROCEDURES

Programming the Cook Time:

1. Press the PROGRAM/ENTER key (8).

2. Press the TIME key (7). The display reads

PROGĆ? SET TIMEĆ? _ _ _ _.

3. Use the NUMERIC keys (3) to enter the desired

cook time. The display will read the numbers

as they are entered. If an error is made, press

the CLEAR key (4) and reĆenter the number.

4. Press the PROGRAM/ENTER key (8) a second

time to lockĆin the new time. The new cook time

will be stored in the computer's memory.

Programming the Temperature:

1. Press the PROGRAM/ENTER key (8).

2. Press the SET TEMP key (5). The display reads

PROGĆ? SET TEMPĆ? _ _ _ _F.

3. Use the NUMERIC keys (3) to enter the desired

temperature set point. The control displays the

numbers as they are entered. If an error is

made, press the CLEAR key (4) and reĆenter

the number.

4. Press the PROGRAM/ENTER key (8) a second

time to lockĆin the new temperature. The new

temperature setpoint will be stored in the comĆ

puter's memory.

Operation at the Programmed Settings:

1. Press and hold the ON/OFF key (2).

DISPLAY INFORMATION

WAIT LOW - indicates that the present oven

temperature is lower than the set point temperĆ

ature. When the oven reaches the set point

temperature the display changes to READY.

READY - indicates that the oven is ready to acĆ

cept product.

SET TIME mmss - indicates the current

cook time setting.

HIGH TIME - indicates that the temperature

is well above the set point. This usually occurs

when moving from a higher āto a lower temperaĆ

ture. Wait until the display reads ready before

loading product.

HIGH TEMP LIMIT - indicates that the oven

temperature exceeds the high limit from the

2nd level program. The Over Temperature

Alarm buzzer will sound. Shut the oven off and

wait for the unit to cool down.

MTR SPD - indicates speed of the motor

does not match the set point.

MOTOR - indicates the computer is not reĆ

ceiving the signal back from the pickup.

HI TEMP MOTOR - N.A.

PROBE OPEN PROBE SHORT - indicates

that the temperature sensor has failed. The

Alarm buzzer sounds. Shut the oven off and

contact a service representative.

2. The FAN and HEAT status lamps (9) light. The

fans begin to run. The heat rises to the temperĆ

ature setting stored in the computer's memory.

The conveyor belt begins to travel at the timed

speed stored in memory.

3. The display will flash WAIT LOW SET TIME

mmss until the programmed bake temperaĆ

ture is reached. The HEAT lamp (9) will remain

lit until the oven reaches the temperature set

point.

4. The display reads READY and the HEAT lamp

(9) goes out.

5. The oven is now ready to accept product.

6. Press and hold the ON/OFF key (2) to turn the

oven off. The fans continue to run while the

oven cools to a safe temperature.

2-2

Page 10

MT1828

SEQUENCE OF OPERATION

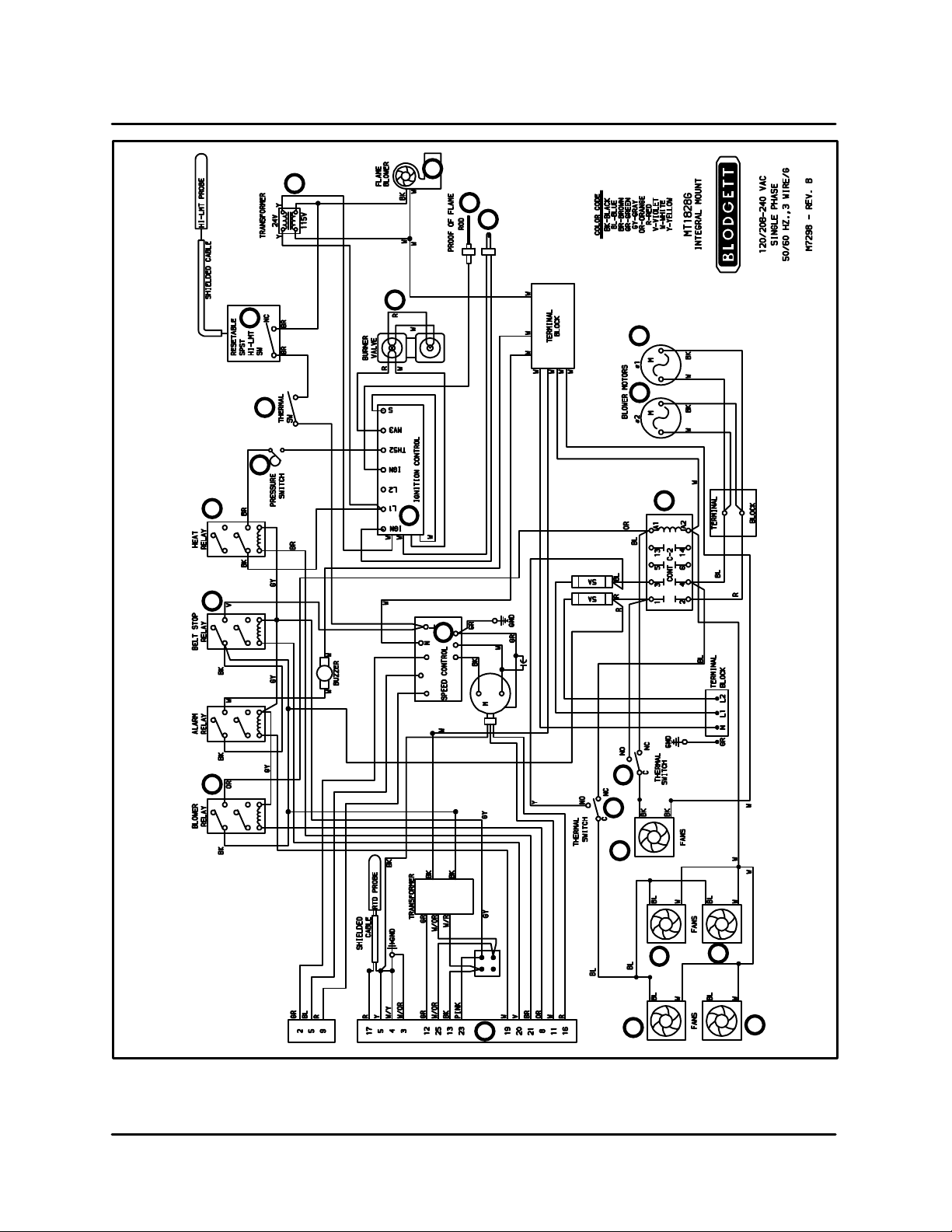

MT1828G DOMESTIC AND GENERAL EXPORT OVENS INTERNAL MOUNT - M7296

REV B

COMPONENT REFERENCE

NOTE: Refer to FIGURE 2 for component locaĆ

tions.

1. BLOWER RELAY

2. BELT STOP RELAY

3. HEAT RELAY

4. MOTOR CONTACTOR

5. SINGLE POLE DOUBLE THROW THERMAL

SWITCH

6. MOTOR CONTROL BOARD

7. SINGLE POLE SINGLE THROW THERMAL

SWITCH

8. RESETABLE HI LIMIT

9. 115/24 VOLT TRANSFORMER

10. FLAME BLOWER

11. IGNITION CONTROL MODULE

12. COOKING COMPUTER

13. PRESSURE SWITCH

14. H.S.I.

15. BURNER VALVE

16. PROOF OF FLAME ROD

17. SINGLE POLE DOUBLE THROW THERMAL

SWITCH

18. CONVECTION BLOWERS

19. COOLING FANS

OPERATION

1. Apply power to the oven. Program time and

temperature into the computer (12). The blowĆ

er relay (1), belt stop relay (2) and heat relay (3)

close.

2. When the blower relay (1) closes, 110 V.A.C.

are sent to the coil of the motor contactor (4)

starting the convection blowers (18) and N.C.

terminal of a single pole double throw thermal

switch (5).

3. When the belt stop relay (2) closes, 110 V.A .C.

are sent to the motor control board (6) and the

single pole single throw thermal switch (7). If

this switch is closed, power goes to the resetĆ

able hi limit switch (8).

4. If the resetable hi limit switch is closed power

goes to the 115/24 volt transformer (9) located

in the box mounted on the flame blower (10).

The flame blower starts.

5. The secondary side of the transformer (9)

sends 24 volts to L1 of the ignition control modĆ

ule (11) and one side of the heat relay (3). If the

computer (12) closes the heat relay, the 24

volts will go to the pressure switch (13).

6. If the pressure switch is closed, a circuit will be

completed back to the ignition module (11).

7. The ignition module initiates its firing sequence

by sending power to the H.S.I. (14). After a

warm up period both solenoids on the burner

valve (15) open allowing gas to enter for igniĆ

tion. If no flame is sensed by the proof of flame

rod (16) the system shuts down.

NOTE: Some ignition control modules may try

to refire up to 3 times. However, there

will be a longer warm up period beĆ

tween each attempt at ignition.

8. The thermal switches (5 and 17) toggle from

common to N.O. only when they reach the temĆ

perature stated on the back of the switch.

9. The convection blowers (18) receive their powĆ

er from the motor contactor (4) only.

10. The cooling fans (19) come on only when the

motor contactor (4) is energized or if the therĆ

mal switches (5 and 17) have toggled.

2-3

Page 11

OPERATION

9

8

7

13

10

16

14

15

18

18

4

11

6

17

19

5

19

19

19

19

1 2 3

12

FIGURE 2

2-4

Page 12

MT1828

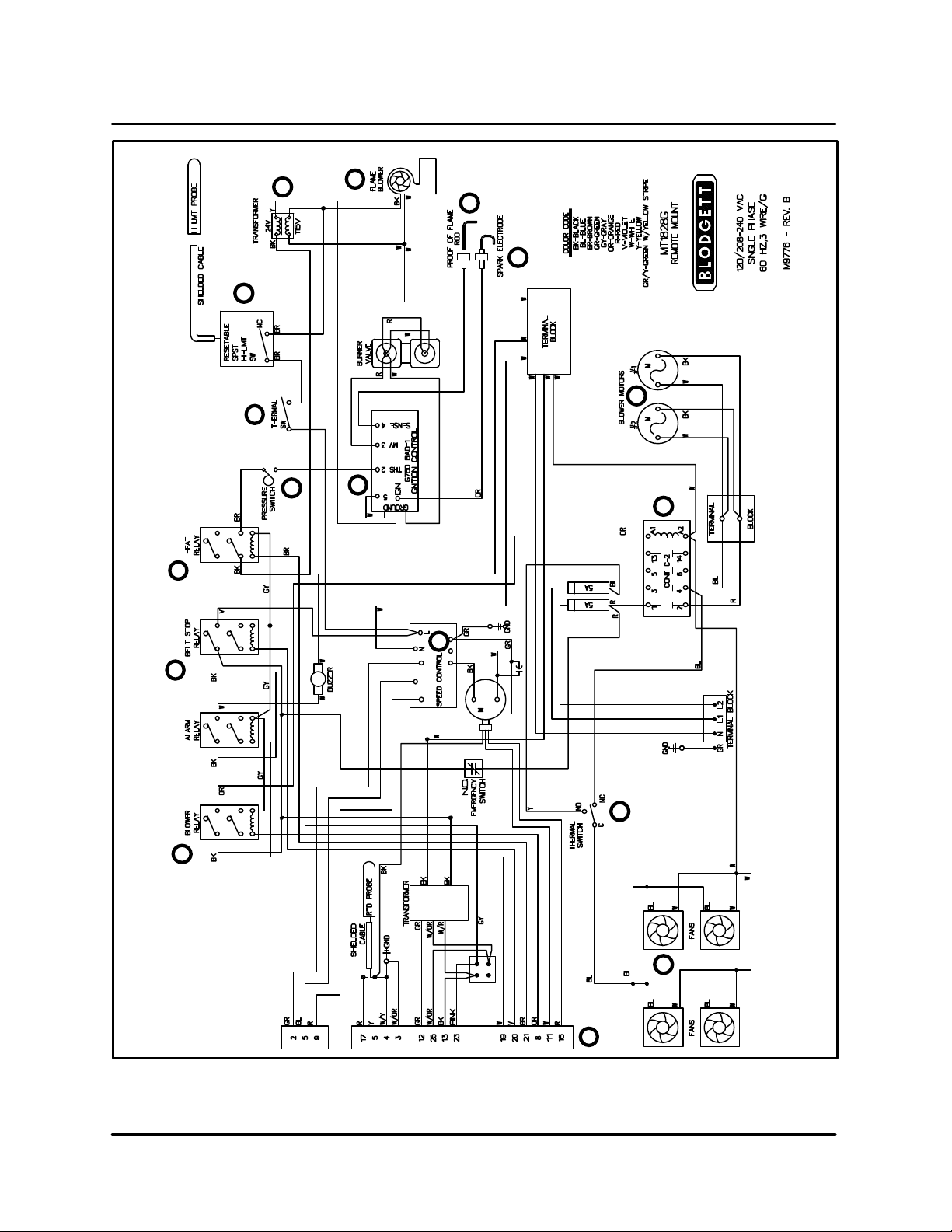

MT1828G DOMESTIC AND GENERAL EXPORT OVENS EXTERNAL MOUNT - M9776

REV B

COMPONENT REFERENCE

NOTE: Refer to FIGURE 2 for component locaĆ

tions.

1. BLOWER RELAY

2. BELT STOP RELAY

3. HEAT RELAY

4. MOTOR CONTACTOR

5. SINGLE POLE DOUBLE THROW THERMAL

SWITCH

6. MOTOR CONTROL BOARD

7. SINGLE POLE SINGLE THROW THERMAL

SWITCH

8. RESETABLE HI LIMIT

9. 115/24 VOLT TRANSFORMER

10. FLAME BLOWER

11. IGNITION CONTROL MODULE

12. COOKING COMPUTER

13. PRESSURE SWITCH

14. H.S.I.

15. BURNER VALVE

16. PROOF OF FLAME ROD

17. SINGLE POLE DOUBLE THROW THERMAL

SWITCH

18. CONVECTION BLOWERS

19. COOLING FANS

OPERATION

1. Apply power to the oven. Program time and

temperature into the computer (12). The blowĆ

er relay (1), belt stop relay (2) and heat relay (3)

close.

2. When the blower relay (1) closes, 110 V.A.C.

are sent to the coil of the motor contactor (4)

starting the convection blowers (18). When the

motor contactor closes, power is also applied

to the NIC terminal of a single pole double

throw thermal switch (5).

3. When the belt stop relay (2) closes, 110 V.A .C.

are sent to the motor control board (6) and a

single pole single throw thermal switch (7). If

this switch is closed, power goes to the resetĆ

able hi limit switch (8).

4. If the resetable hi limit switch is closed power

goes to the 115/24 volt transformer (9) located

in the box mounted on the flame blower (10).

The flame blower starts.

5. The secondary side of the transformer (9)

sends 24 volts to one side of the heat relay (3).

If the computer (12) closes the heat relay, the

24 volts will go to the pressure switch (13).

6. If the pressure switch is closed, a circuit will be

completed to the ignition module (11).

7. The ignition module initiates its firing sequence

by starting to spark at the spark electrode (14)

and opening both solenoid valves on the burnĆ

er valve (15) allowing gas to enter for ignition.

If no flame is sensed by the proof of flame rod

(16) the system shuts down.

NOTE: Some ignition control modules may try

to refire up to 3 times. However, there

will be a longer interpurge period beĆ

tween each attempt at ignition.

8. The thermal switch (17) toggles from common

to N.O. only when it reaches the temperature

stated on the back of the switch.

9. The convection blowers (18) receive their powĆ

er from the motor contactor (4) only.

10. The cooling fans (19) come on only when the

motor contactor (4) is energized or if the therĆ

mal switch (17) has toggled.

2-5

Page 13

OPERATION

9

8

7

13

3

10

16

14

18

11

4

6

2

17

1

19

12

FIGURE 3

2-6

Page 14

MT1828

MT1828E DOMESTIC AND GENERAL EXPORT OVENS - M6314 REV C

COMPONENT REFERENCE

NOTE: Refer to FIGURE 4 for component locaĆ

tions.

1. COMPUTER

2. BLOWER RELAY

3. BELT STOP RELAY

4. HEAT RELAY

5. 208/120 STEP DOWN TRANSFORMER

6. MOTOR CONTACTOR

7. SINGLE POLE DOUBLE THROW THERMAL

SWITCH

8. CONVECTION FANS

9. COOLING FANS

10. SPEED CONTROL BOARD

11. D.C. MOTOR

12. SINGLE POLE SINGLE THROW THERMAL

SWITCH

13. RESETABLE HI LIMIT

14. CONTACTOR

15. ELEMENTS

OPERATION

1. Apply power to the oven. Program the time and

temperature into the computer (1). The blower

relay (2), belt stop relay (3) and heat relay (4)

are energized.

2. If the contacts in the blower relay close the 110

V.A .C. supplied from the 240/120 step down

transformer (5) will go to the coil of the motor

contactor (6) and the N.C. terminals of two

single pole double throw thermal switches (7).

These switches toggle when ambient air passĆ

ing the face of the switch exceeds the rating on

the back of the switch.

3. If the motor contactor (6) and the thermal

switches (7) are closed the convection fans (8)

and cooling fans (9) will start.

4. The belt stop relay (3) should be closed sendĆ

ing 110 V. A.C. to the speed control board (10).

5. If the speed control board is working it sends

out a variable amount of D.C. voltage to the

D.C. motor (11). The voltage can vary from 20

to 130 VDC depending on the amount of time

programmed into the computer (1).

6. The heat relay (4) closes with a call for heat

sending power to a single pole single throw

thermal switch (12). This switch acts as a temĆ

perature limiting device for the controls and

opens if the ambient air around the control exĆ

ceeds the rating on the back of the switch.

7. If the switch is closed, 110 VAC goes to the reĆ

setable hi limit (13). This switch acts as an oven

hi limit and opens if the temperature in the oven

exceeds 630F (333C).

8. If the resetable high limit switch is closed the

power will go to one side of the contactor coil

(14). This contactor powers the elements (15).

9. When the motor contactor (6) closes the conĆ

vection fans (8) start. If the thermal switches

are closed between the N.C. and C. terminals

the cooling fans (9) will start.

2-7

Page 15

15

OPERATION

8

13

12

2 3 4

14

8

6

5

10

11

7

7

1

FIGURE 4

2-8

9

9

9

9

9

Page 16

MT1828

MT1828G CE OVENS - M6462 REV B

COMPONENT REFERENCE

NOTE: Refer to FIGURE 5 for component locaĆ

tions.

1. COMPUTER

2. MAIN CONTROL RELAY

3. BLOWER RELAY

4. BURNER VALVE RELAY

5. MOTOR CONTACTOR

6. SINGLE POLE DOUBLE THROW THERMAL

SWITCH

7. CONTROL COMPARTMENT COOLING FAN

8. SPEED CONTROL BOARD

9. RESETABLE HI LIMIT

10. CONVECTION BLOWER PRESSURE SWITCH

11. CONVECTION BLOWERS

12. FLAME BLOWER

13. BURNER PRESSURE SWITCH

14. LATCHING RELAY

15. PURGE TIMER

16. SINGLE POLE SINGLE THROW RELAY

17. SINGLE POLE SINGLE THERMAL SWITCH

18. IGNITION CONTROL MODULE

19. H.S.I.

20. DUAL SOLENOID GAS VALVE

21. PROOF OF FLAME ROD

22. SINGLE POLE DOUBLE THROW SWITCH

23. COOLING FANS

24. D.C. DRIVE MOTOR

OPERATION

1. Apply power to the oven. Program time and

temperature into the computer (1). The main

control relay (2) blower relay (3) and burner

valve relay (4) will energize.

2. The blower relay (3) sends power to the coil of

the motor contactor (5) and the N.C. terminal

of a single pole double throw thermal switch

(6). This switch starts the control compartment

cooling fan (7). The motor contactor energizes

the convection blowers (11) and the N.C. terĆ

minal of another thermal switch (22).

3. The main control relay (2) sends 230 VAC to

the speed control board (8) and the resetable

hi limit (9).

4. If the hi limit (9) is closed, power goes to the

convection blower pressure switch (10). This

switch closes when the convection blowers

(11) are operating. If the switch is closed, powĆ

er goes to the flame blower (12), the common

terminal of the burner pressure switch (13) and

terminal #7 of the latching relay (14).

5. If the burner pressure switch (13) is closed beĆ

tween COM and N.C., power goes to #4 and

the coil of the latching relay (14). This closes

the relay from #4 to #7 and #6 to #9. The relay

remains latched due to the power on #7 runĆ

ning through #4 to the coil.

6. When the flame blower (12) reaches speed, a

differential in pressure is created in the burner

pressure switch (13). The switch toggles from

COM and N.C. to COM and N.O. This supplies

power to #9 of the latching relay (14) which

should be closed through to #6, sending powĆ

er to a purge timer (15).

7. When the purge timer (15) times out it sends

power to the coil of a single pole single throw

relay (16).

8. If the burner valve relay (4) is closed, power

goes to a single pole single throw thermal

switch (17). This switch acts as a control hi limĆ

it. It opens if the ambient air temperature

reaches the range on the back of the switch.

9. If the switch is closed, power goes through the

closed set of contacts in the relay (16) to termiĆ

nal #17 of the ignition module (18).

10. After a warmup period for the H.S.I. (19), the

ignition control module (18) powers up the

dual solenoid gas valve (20). If the proof of

flame rod (21) does not sense a flame in 1 secĆ

ond, the ignition control module shuts the sysĆ

tem down.

11. The single pole double throw switch (22) gets

its power from the motor contactor (5). This

switch is closed between the common and

N.C. terminals, powering the cooling fans (23).

The switch toggles if the ambient air passing

the facing of the switch exceeds the number on

the back of the switch.

12. The D.C. drive motor (24) gets voltage from the

speed control board (8). The speed of the drive

motor varies with the time programmed into

the computer. The voltage range for this board

is from 20 to 180 V.D.C. measured at A1 and A2

of the speed control board (8).

2-9

Page 17

OPERATION

14

15

16

13

17

10

20

9

4

3

18

12

19

21

11

11

5

8

24

2

1

22

7

23

23

6

23

23

FIGURE 5

2-10

Page 18

MT1828

MT1828E CE OVENS - M6453 REV A

COMPONENT REFERENCE

NOTE: Refer to FIGURE 6 for component locaĆ

tions.

1. COOKING COMPUTER

2. BLOWER RELAY

3. BELT STOP RELAY

4. HEAT RELAY

5. 240/120 STEP DOWN TRANSFORMER

6. MOTOR CONTACTOR

7. SINGLE POLE DOUBLE THROW THERMAL

SWITCHES

8. COOLING FANS

9. SPEED CONTROL BOARD

10. D.C. DRIVE MOTOR

11. SINGLE POLE SINGLE THROW THERMAL

SWITCH

12. RESETABLE HI LIMIT

13. ELEMENT CONTACTOR

14. ELEMENTS

15. CONVECTION MOTORS

OPERATION

1. Apply power to the oven. Program the time and

temperature into the computer (1). The blower

relay (2), belt stop relay (3) and heat relay (4)

are energized.

2. Voltage is applied to the contacts of these reĆ

lays by a 240/120 volt step down transformer

(5).

3. If the blower relay (2) is closed voltage is apĆ

plied to the coil of the motor contactor (6). The

contactor is energized and voltage is supplied

to the normally closed terminals of the single

pole double throw thermal switch (7).

4. If both of these switches are closed between C

and N.C. All five cooling fans start. The

switches toggle from C and N.C. to C. and N.O.

when the temperature of the air passing them

exceeds the rating on the back of the switches.

5. If the belt stop relay (3) is closed, power goes

to the speed control board (9). The board

sends D.C. voltage to the D.C. drive motor (10).

The voltage output varies with the time proĆ

grammed into the computer (1).

6. If the heat relay (4) is closed, power goes to a

single pole single throw thermal switch (11). If

this switch is closed, power goes to a manual

resetable hi limit (12). If this switch is closed,

power goes to the coil of the hot air element

contactor (13). The element is energized and

power is sent to the heating elements (14).

7. The thermal switches (7 and 11) react to ambiĆ

ent air moving across the face of the switch.

They react only when the temperature exĆ

ceeds the rating on the back of the switch. The

single pole double throw thermal switch (7)

toggles when the temperature rises. The

single pole single throw thermal switch (11)

opens when the temperature rises.

8. The manual hi limit (12) opens when the temĆ

perature inside the oven cavity exceeds 690F

(366C).

9. The convection motors (15) are powered when

the motor contactor (6) is energized.

2-11

Page 19

14

OPERATION

15

12

11

2 3 4

13

15

6

9 5

10

7

7

1

FIGURE 6

2-12

8

8

8

8

8

Page 20

MT1828

This page intentionally left blank.

2-13

Page 21

CHAPTER 3

CALIBRATION AND

ADJUSTMENT

Page 22

MT1828

CONVECTION BLOWER MOTORS

TO CHECK MOTOR ROTATION

1. Remove the back of the oven body and verify

proper motor rotation. (See FIGURE 1)

For motor placement, the direction of rotation is

viewed from the oven's rear, working from left to

right, beginning at the control box. In most cases,

the motor direction is referenced to the end of the

shaft (EOS). However, due to the vertical positionĆ

ing of the motors in Mastertherm ovens, it is more

instructive to reference the end of the motor (EOM)

as looking from the rear of the oven. In FIGURE 1

all directions are taken from EOM. The correct roĆ

tation amperage draw is approximately .6 amp

cold/.3 amp hot. If the measured amperage is less

than .3 amp cold/.1 amp hot, check for proper moĆ

tor rotation direction.

(Side view rotation of Blower Wheel)

Blower

Motor

Slinger

Cooling

Blade

TO CHECK LOWĆLIMIT

1. Turn the oven on and let it heat up to approxiĆ

mately 200F (93C).

2. Shut the oven off. The blowers should come

back on in several seconds.

3. Wait for the blowers to shut off.

4. Once the blowers are off, turn the oven back

on. Press the ACT TEMP" key to verify that the

blowers shut off between 135F (57C) and

170F (77C). If the blowers do not shut off reĆ

fer to the Troubleshooting section page 5-6.

Blower

Motor

Motor #1 Motor #2

(Top view rotation of Blower Wheel)

Motor #1

CCW

Motor #2

CCW

FIGURE 1

Control

Box

Control

Box

3-1

Page 23

REGULATED GAS PRESSURE

CALIBRATION AND ADJUSTMENT

1. Let the oven run up to 510F (266C). Program

the belt for 7 minutes. You may now verify the

operational and regulated gas pressures.

Incoming static gas pressure to the unit, with all the

gas appliances drawing from the supply, should be

a minimum of 5.5" W.C. (13.7 mbar) for natural gas

and 11" W.C. (28 mbar) for propane gas. The manĆ

ifold pressure, if measured after the regulator loĆ

cated inside the control box, must be 3.5" W.C. (9

mbar) for natural gas and 10" W.C. (25 mbar) for

propane gas.

The pressure can be checked at the tap on the dual

regulated gas valve. If pressure adjustments are

needed, turn the adjusting screw located under a

screw cap on the left front side of the dual reguĆ

lated valve. Adjust the gas pressure by turning the

screw clockwise to raise the gas pressure and

counterĆclockwise to lower the gas pressure. Be

sure to reinstall the screw cap; should the diaĆ

phragm rupture this cap acts as a flow limiter

Setting Equipment for Other Types of Gas - CE

Models

1. Shut off the gas valve and turn off the operating

switch.

2. Dismantle the gas block by means of couĆ

plings.

3. Replace the gas valve.

4. Dismantle the main burner and replace the inĆ

jector.

5. Unscrew 4 screws from the burner mounting

plate. Remove the burner from the combustion

chamber.

6. Install the burner and gas block.

7. Check for leakage and possible loose electriĆ

cal connections.

8. Adjust gas pressure if necessary, See

FIGURE 3.

Gas Pressure

Adjustment

Regulator Cap

Regulator

Adjustment

Pressure Regulator (Domestic & General Export)

FIGURE 2

Pressure

Cap

Pressure Tap

Pressure Regulator (CE models)

FIGURE 3

3-2

Page 24

MT1828

COMPUTER CONTROL CONFIGURATION

INITIATING ACCESS MODE

The Cooking Computer provides a special Access

Mode for setting and displaying certain computer

special functions. To initiate the Access Mode

place the control in the OFF state, (OFF is shown

in the display when power is first applied to the

control). Press the following sequence of keys to

set the control to Access Mode: CLEAR 1 2 3 4 5

6 ENTER. The display will show ACCESS.

DISPLAY ACTION

DISPLAY ACTION TAKEN

TAKEN

F/CMODE? Press

POS OFFSET? Press

NEG OFFSET? Press

MAXĆT ENTRY? Press

PROG

T F(C)

ENTER

PROG

0(0) Press

ENTER

PROG

0(0) Press

ENTER

PROG

600(315) Press or change then

ENTER

CONFIGURATION

When the controller is in the ACCESS" mode,

press the following buttons: CLEAR 1 1 1 ENTER.

With the exception of the positive and negative offĆ

sets, to be addressed later, all display data should

correspond to the entries in the chart below. If the

data does not match the chart, it should be

changed accordingly. When the correct data is disĆ

played press the PROG/ENTER key, the display

will cycle on to the next screen. If a step is missed,

press the CLEAR button to backup.

Press again or hit any number and

press again.

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

it will change.

MAXĆT LIMIT? Press

READY BAND? Press

MINĆHT ON? Press

DISPLAY INTEG? Press

TĆCTRL INTEG? Press

PROG

625(330) Press

ENTER

PROG

10 Press

ENTER

PROG

60 Press

ENTER

PROG

30 Press

ENTER

PROG

10 Press

ENTER

TABLE 1

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

PROG

ENTER

3-3

Page 25

Boost Option - (versions 2.00 or 3.00)

When the controller is in the ACCESS" mode,

press the following buttons: CLEAR 2 1 2 ENTER

to enter the boost option.

CALIBRATION AND ADJUSTMENT

DISPLAY

ACTION

DISPLAY ACTION TAKEN

TAKEN

BOOST / MODEĆ?

(Flash alternately)

Press

PROG

ENTER

OPTĆ1 or

OPTĆ2

Select OPTĆ1 to turn off boost mode.

OPTĆ1 Press

PROG

ENTER

DONE

SAVE

EXIT

EXITING THE ACCESS MODE

After pressing PROG/ENTER the last time, the disĆ

play will show EXIT" then beep and return to the

ACCESS" mode. Pressing and holding the ON/

OFF key will turn the oven on. A new time and temĆ

perature must be entered upon exiting the ACĆ

CESS" mode since the oven will automatically

default to 0. The oven will not fire until both time and

temperature are entered.

TABLE 2

Press any numeric key to toggle between

OPTĆ1 and OPTĆ2

Press

PROG

ENTER

Firmware Model Version Display from Access

Password: CLEAR 1 2 3 ENTER

MODEL Ć Computer Model Number - 6028

(Blodgett Conveyor Oven With Speed Control)

SWĆVER Ć Firmware version number. VĆxxyy xx =

major version, yy = minor version

DATEĆ? ĆFirmware release date

CHKSUM Ć ROM checksum stored in PROM. xxxx

Ć Value is display in hexadecimal format.

3-4

Page 26

MT1828

TEMPERATURE CALIBRATION

TO ENTER THE CALIBRATION MODE

1. Press the ON/OFF key until OFF is displayed.

2. Press CLEAR 1 2 3 4 5 6 ENTER to enter the

access mode. The display reads ACCESS.

3. Press CLEAR ACT_TEMP ACT_TEMP

ACT_TEMP ENTER to access the Temperature

Calibration mode.

4. On open loop models disconnect the white

wire from the D.C. motor. Secure so the wire

will not ground against any part of the oven.

This will disable the conveyor.

NOTE: Disregard the controller display. The only

numbers of concern are the pyrometer

reading and the temperature set point.

TO CALIBRATE THE OVEN TEMPERATURE

During operation, the temperature control is based

on the measured temperature and the temperaĆ

ture offset which is programmed into the control. If

the temperature measured in the center of the

oven is below the oven setpoint a positive offset is

needed. If the temperature measured in the center

of the oven is above the oven setpoint a negative

offset is needed.

NOTE: In the calibration mode the display gives

the current measured temperature only.

1. Press PROG/ENTER followed by ACT_TEMP.

The display flashes either POS * OFFSET or

NEG * OFFSET

NOTE: POS OFFSET is displayed if a value has

been programmed in for a positive offĆ

set. NEG OFFSET is displayed if a valĆ

ue has been programmed for a negaĆ

tive offset. The only time both will be

displayed is if a value of 0 has been enĆ

tered for both.

2. Enter a value for the desired offset. The display

flashes DISPLAY * INTEG?.

3. Press the PROG/ENTER key. The default value

of 30 will be displayed.

4. Press the PROG/ENTER key. The display will

flash TĆCTRL * INTEG?.

5. Press the PROG/ENTER key. The default value

of 10 will be displayed.

6. Press the PROG/ENTER key.

The control will now resume using the new paramĆ

eters.

Verify the temperature calibration once the unit has

cycled for 5 minutes with the new settings. Repeat

calibration using a new offset value if necessary.

TO EXIT THE CALIBRATION MODE

To view the current temperature setpoint:

1. Press the SET_TEMP key.

To change the temperature setpoint :

1. Press PROG/ENTER SET_TEMP.

2. Enter the desired setpoint.

3. Press the PROG/ENTER key.

To program the temperature offset:

To change the temperature calibration an offset,

positive or negative, must be programmed.

1. Press the CLEAR key twice.

2. The display flashes REBOOT then displays the

set time and temperature. You must reĆenter a

temperature for the oven to start heating again.

A.) Press PROG/ENTER SET_TEMP

B.) Enter the desired temperature.

C.) Press the PROG/ENTER key. The heat

light turns on and the burner begins to

cycle at set point.

3-5

Page 27

BELT SPEED CALIBRATION

CLOSED LOOP SYSTEM

CALIBRATION AND ADJUSTMENT

To enter the calibration mode:

1. Press the ON/OFF key until OFF is displayed.

2. Press CLEAR 1 2 3 4 5 6 ENTER to enter the

Access mode. The display reads ACCESS.

3. Press CLEAR TIME TIME TIME ENTER to acĆ

cess the Belt Speed Calibration mode. The disĆ

play flashes INIT.

Belt speed calibration:

1. OVEN LENGTH - Set the length of the conveyĆ

or belt using the information from TABLE 3.

2. MOTOR RATIO - Set the motor gear ratio from

the information from TABLE 3.

3. SHAFT TEETH - Set the shaft teeth number

from the information from TABLE 3.

4. MOTOR TEETH - Set the motor teeth number

from the information from TABLE 3.

5. BELT RADIUS - Set the belt radius from the inĆ

formation from TABLE 3.

NOTE: The values given are estimates. If you

reenter the calibration mode after setĆ

ting the belt speed, the belt radius may

differ from the table.

6. The display gives a four digit value followed by

the letter K. Press ENTER twice to verify the

belt time.

Belt speed verification:

1. ENTER TEST TIME - Enter a test time to verify

the belt speed. The default setting is 7 minutes.

2. WAIT - 1 second delay before the belt moves.

3. ENTER ACTUAL TIME - Place an object on

the belt. Note the time from entrance to exit.

Enter the actual measured time.

4. ENTER TEST TIME - If the actual measured

time is not within 5 seconds of the test time, reĆ

peat the belt verification test to obtain better

accuracy. If the actual measured time is acĆ

ceptable, press the CLEAR key to continue the

belt speed calibration.

5. MAX/MIN CALC TIME - The control sets the

fastest and slowest cook time the user can proĆ

gram. This requires a 1 minute delay in the calĆ

ibration process.

NOTE: If the control cannot read the shaft enĆ

coder the display reads ERROR then

ABORT before exiting belt calibration.

Verify the connection of the encoder

Restart the belt speed calibration.

6. The display flashes MIN SET TIME? Press the

PROG/ENTER key to display the calculated

minimum set time. Press the PROG/ENTER

key to accept this value or enter a new time

with a value higher than the default. Press

PROG/ENTER again to accept.

7. The display flashes MAX SET TIME? Press the

PROG/ENTER key to display the calculated

maximum set time. Press the PROG/ENTER

key to accept this value or enter a new time

with a value lower than the default. Press

PROG/ENTER again to accept.

8. The display reads DONE.

To save the new belt speed:

1. Press ENTER to save the belt speed calibraĆ

tion program in the control's memory.

Oven Type Oven Length Motor Ratio Shaft Teeth Motor Teeth Belt Radius

MT3870 70 600 15 12 8,712

MT3855 55 600 15 12 8,712

MT3270 70 600 15 12 8,712

MT3240 40 600 15 12 8,893

MT2136 36 600 15 12 8,712

MT1828 28 600 24 24 7,209

TABLE 3

3-6

Page 28

MT1828

OPEN LOOP SYSTEM

To enter the calibration mode:

1. Press the ON/OFF key until OFF is displayed.

2. Press CLEAR 1 2 3 4 5 6 ENTER to enter the

Access mode. The display reads ACCESS.

3. Press CLEAR TIME TIME TIME ENTER to acĆ

cess the Belt Speed Calibration mode. The disĆ

play flashes INIT.

To calibrate the belt speed:

1. The display reads BELT SIZE-?. Enter the

length of the conveyor belt, see TABLE 4.

Press the PROG/ENTER key.

2. The display reads STEP-1. The controller is in

Step 1 of the calibration procedure: maximum

belt speed. The motor control is automatically

set to its maximum output. Place an object on

the belt and note the time from entrance to exit.

NOTE: Be certain to measure either the leadĆ

ing edge in and out or the trailing edge

in and out. Do not use the leading edge

in and the trailing edge out.

A.) The display reads STEP-1TIME-?. Enter

the time measured in STEP-1. Min: 0

Max: 59:59 (min:sec). Press the PROG/

ENTER key. Measured voltage at A1 and

A2 should be 130 VDC.

B.) The display reads STEP-1DIST-?. Enter

the belt length, see TABLE 4. Press the

PROG/ENTER key.

3. The display reads STEP-2. The controller is in

Step 2 of the calibration procedure: minimum

belt speed. The motor control is automatically

set to its minimum output.

The belt will travel very slowly during this part

of the calibration procedure. To minimize the

time spent on STEP-2, measure off 10" on the

conveyor support. Place an object on the belt

and note the travel time for the 10" measured

distance.

A.) The display reads STEP-2 TIME-?. Enter

the measured travel time for STEP-2. Min:

0 Max: 59:59 (min:sec). Press the PROG/

ENTER key. Measured voltage at A1 and

A2 should be 20 VDC.

B.) The display reads STEP-2 DIST-?. Enter

10". Press the PROG/ENTER key.

4. The display reads MIN-TM ENTRY? (the fastĆ

est belt speed). Limits of this value are deterĆ

mined by the Step-1 and Step-2 calibration

values. See TABLE 4 for correct entry for this

model. Press the PROG/ENTER key.

5. The display reads MAX-TM ENTRY? (slowest

belt speed). Limits of this value are determined

by the Step 1 and Step 2 calibration values.

Use 1600 (16 min). Press the PROG/ENTER

key.

6. The display flashes DONE and SAVE. Press

the PROG/ENTER key to permanently store

the calibration values in nonĆvolatile memory

(NOVRAM).

NOTE: If any voltage adjustments were made hit

the CLEAR key to abort the calibration

mode. Reenter the calibration mode to

verify that voltage is locked in.

NOTE: During these adjustments, pressing the

clear button will abort all entries and reĆ

quire reprogramming of belt time mode.

When exiting the Belt Speed Calibration

Mode, enter a time. Otherwise the time deĆ

faults to zero and the oven will not heat, and

the belt will not move.

Oven

Type

MT1828 28 330 (3 min, 30 sec) MT3270 70 330 (3 min, 30 sec)

MT2136 36 200 (2 min) MT3855 55 330 (3 min, 30 sec)

MT3240 40 300 (3 min, 00 sec) MT3870 70 330 (3 min, 30 sec)

MT3255 55 300 (3 min, 00 sec)

Belt Length/

Distance

Minimum

Oven Entry

TABLE 4

3-7

Oven

Type

Belt Length/

Distance

Minimum

Oven Entry

Page 29

MOTOR CONTROL BOARD

CALIBRATION AND ADJUSTMENT

High/low speed motor control board adjustĆ

ment for 180 and 130 volt DC motors

NOTE: The motor control board is located on the

slide out control panel.

High Speed Motor Adjustment:

For closed loop systems follow Belt Speed VerificaĆ

tion through STEP 5 (see page 3-6). For open

loop systems follow Belt Speed Calibration

through STEP 2 (see page 3-7).

1. With the motor connected (make no open cirĆ

cuit voltage readings) measure the voltage at

the motor leads (A1 & A2 in FIGURE 4) on the

DC control board. If the voltage is not within 3

VDC of the specified voltage continue with

step 3.

2. Turn the MAX trim pot counterĆclockwise to

lower and clockwise to raise the voltage until

it is within 3VDC of the specified voltage.

NOTE: For closed loop systems this adjustĆ

ment must be made quickly.

Low Speed Motor Adjustment:

For closed loop systems the computer automaticlĆ

ly proceeds to low speed. For open loop systems

continue Belt Speed Calibration through STEP 3

(see page 3-7).

1. With the motor connected (make no open cirĆ

cuit voltage readings) measure the voltage at

the motor leads on the DC control board (A1 &

A2 in FIGURE 4). If the voltage is not 26VDC

+/Ć 1 VDC, continue with step 3.

COMPUTERIZED OVENS

130 Volt System 180 Volt System

Model Low High Low High

MT1828 20 130 26 180

MT2136 20 130 26 180

MT3240 20 130 26 180

MT3270 26 130 26 180

MT3855 26 130 26 180

MT3870 26 130 26 130

NONĆCOMPUTERIZED OVENS

MT2136 20 130 26 180

MT3255 26 130 26 180

MT3270 26 130 26 180

MG3270 26 130

24 VDC SYSTEM

MT1820 3.0 21

TABLE 5

2. Turn the MIN SPEED pot clockwise to lower the

voltage and counterĆclockwise to raise the voltĆ

age.

NOTE: If any voltage adjustments were made hit

the CLEAR key to abort the calibration

mode. Reenter the calibration mode to

verify that voltage is locked in.

3-8

Page 30

MT1828

Acceleration Adjustment

Yellow or Violet (pin 12)

Orange or Gray (pin 10)

Blue (pin 8)

Violet

Gray

Blue

Speed Pot

NOTE: Colors may vary

between early ovens.

Line Fuse

Minimum Speed

Maximum Speed

Socket J1

FL

ACC MAX MIN

Test

Points

TB1

L N A1 A2

TP1

TP2

Torque (current) limiting adjustment

(DO NOT ADJUST)

Switches 2,4,5,6,7

TORQ

ON

DIP Switch on

early models only

REG

Regulation

Adjustment

Armature

Fuse

FA

+

Ć

Line Hot (VAC)

Line Neutral (VAC)

PM Motor

Armature

Barrier Terminal Block TB1

Power Line and Motor Ground

REMOVE RED PLUG FROM TOP OF DC MOTOR PRIOR TO OPERATING!

Warning: Circuit components are not at ground potential! Use only a nonĆmetallic or

insulated adjustment tool. Shock hazards may occur with conducting tools!

FIGURE 4

3-9

Page 31

CHAPTER 4

ENHANCEMENTS

Page 32

MT1828

BURNER

NEW BURNER INSTALLATION

1. Disconnect the power to the oven. Shut off the

main gas valve to the oven.

2. Disconnect the incoming gas line to the oven.

3. Remove the two screws securing the control

box cover. Remove the control box cover.

4. Some ovens have a lower panel below the conĆ

trol box cover containing two fuses. If so, remove

this panel. Disconnect the fuses. Note the way

the fuses are wired. They will need to be rewired

the same way when reconnecting them.

5. Remove the chain guard.

6. Remove the bracket securing the external gas

piping on the back of the oven.

7. Remove the external gas valve assembly at the

elbow on the back of the oven. See FIGURE 2.

8. Open the union on the gas stack if applicable. This

will disconnect the burner from the gas stack.

9. Disconnect the burner blower pressure sense

tube from the burner and pressure switch. DisĆ

card.

10. Disconnect the burner blower wires, igniter wire

and flame sense wire.

11. Loosen the three 1/4"Ć20 screws securing the

burner assembly to the burner support. Remove

the burner assembly and all remaining gas piping.

12. Remove the red and white wires from the burnĆ

er valve and ignition control. Install the wires on

the burner valve of the new gas stack.

13. Remove the four 1/4"Ć20 nuts and washers seĆ

curing the conveyor drive motor bracket to the

control box floor. Remove the drive motor.

14. Remove the ignition control from the control

plate. Install the new ignition control module as

follows:

A.) Mount the new ignition control to the control

plate in place of the old one. The control terĆ

minals (not ground) should be oriented up.

B.) Transfer the yellow wire from ground on the

old ignition control to ground on the new

ignition control.

C.) Transfer the wire from THS2 on the old igniĆ

tion control to THS2 on the new ignition

control.

D.) Remove the black and yellow wires conĆ

nected to L1 on the old ignition control. ReĆ

place with the black wire provided to conĆ

nect the transformer to the relay.

NOTE: Refer to the new wiring diagram.

15. Install the new probes as follows:

NOTE: Refer to FIGURE 1 for correct probe

locations.

A.) Slide the high limit and RTD probes out of

the probe hole. Separate the two probes.

Set aside the 6" RTD probe.

B.) Install the high limit probe well in the locaĆ

tion indicated in FIGURE 1. If there is no

hole for the probe well, drill a .38 dia. hole

through the body side and inner liner at the

correct location.

NOTE: Be sure to drill the hole as level as posĆ

sible. Deburr the hole and remove the

drill chips from the inside of the control

box. Drill chips will damage wires.

C.) Insert the high limit probe well into the hole.

Attach the mounting bracket to the body

side with the self drilling screws provided.

NOTE: It may be helpful to drill a small pilot

hole to start the self drilling screws.

D.) Insert the high limit probe into the well all the

way.

E.) Put a small dab of silicone on the probe well

opening to secure the high limit probe.

F.) Install the new RTD probe into the location

indicated. Find the leads from the old probe.

Disconnect the leads from the wiring harĆ

ness. Connect the leads from the new probe

to the harness.

NOTE: The probe bracket may not sit flush

against the oven side due to interference

with the burner support assembly. If so,

use the shim provided.

16. Reinstall the drive motor.

17. Place the attention plate as close to the existĆ

ing rating plate as possible. Drill two 1/8" diamĆ

eter holes and mount the plate using the 1/8"

rivets supplied.

18. Separate the union on the new gas stack and

burner assembly.

19. Slide the new burner assembly into the burner

support until the blower mounting flange is 5.6"

from the back wall of the control box. Be sure

the burner assembly is level and straight. SeĆ

4-1

Page 33

ENHANCEMENTS

cure the burner assembly to the burner support

by tightening the three 1/4"Ć20 screws.

20. Reattach the union between the gas stack and

the new burner assembly. the nipple should

extend through the hole in the side of the conĆ

trol box.

21. Connect and seal the gas stack to the external

gas piping assembly. Use pipe joint comĆ

pound resistant to LP gases.

22. Reinstall the piping support bracket.

23. Connect the flame sense wire to the ignition

control (sense 4). Refer to FIGURE 3.

24. Attach the spark wire to the ignition control.

25. Reconnect the burner blower pressure sense

port on the side of the new burner to the presĆ

sure switch using the tubing provided.

26. Connect the new burner blower wires.

NOTE: On some units it may be necessary to

use the 1/4 male terminals provided.

27. Connect the burner valve as follows:

A.) Connect the red wire from the burner valve

to MV3 on the ignition control.

B.) Connect the white wire from the burner

valve to the ground on the ignition control.

28. Replace any existing schematic diagrams with

the new ones provided. Schematics are proĆ

vided for both integral control and remote conĆ

trol ovens. Be sure to use only those appropriĆ

ate for the oven being upgraded. Discard the

inapplicable schematics.

29. Install the new chain guard onto the chain

guard bracket using the #10 pan had screws,

washers and lockwashers provided. Mount

the chain guard to the floor of the control box

reusing the hardware from the old chain

guard. Refer to FIGURE 4.

30. If there was a lower panel with fuses below the

control box door, replace it with the new panel

provided. Move the fuses to the new panel. ReĆ

wire the fuses exactly as they were.

31. Reconnect the power to the oven.

32. Cycle the oven on to ensure all systems are

working properly, particularly the burner blowĆ

er and drive motor.

33. Reconnect the incoming gas line. Turn on main

gas valve and check all fittings for leaks using

proper leak checking procedures.

34. Reinstall the control box cover.

35. Perform a temperature calibration on the oven.

7Ć9/16"

New High Limit Probe location

1Ć21/32"

New RTD Probe location

Dimensions are from the inside surface of the control box

FIGURE 1

4-2

Page 34

MT1828

Reuse Gas Valve

Assembly

Gas Stack

Union

Chain Guard

Bracket

Burner Assembly

FIGURE 3

FIGURE 2

Mount to

chain guard bracket here

Mount to floor of control box here

FIGURE 4

4-3

Page 35

IGNITER AND FLAME RODS

FIGURE 5 illustrates the correct location of the igĆ

niter and flame rod.

ENHANCEMENTS

Gap .109 (7/64) from

center of hole to edge

of probe

Gap .109 (7/64) from

center of hole to edge

of probe

Both are fixed and should not move or swing.

FIGURE 5

4-4

Page 36

MT1828

This page intentionally left blank.

4-5

Page 37

CHAPTER 5

TROUBLESHOOTING

Page 38

MT1828

DC DRIVE SYSTEM

POSSIBLE CAUSE(S) SUGGESTED REMEDY

Symptom #1 - Conveyor Belt will not run

Oven in OFF mode.

Loose computer controller cord connection.

Time not programmed into computer.

Turn to ON position.

Adjust and retighten cables and set screws.

Program in a cook time. See Operation Section

(page 2-2).

Emergency stop switch on OFF.

Control circuit breaker tripped.

Belt hooked on something in oven.

5 amp line fuse blown.

200 milliamp armiture fuse blown.

Hall Effect Pickup not connected. (Closed loop

systems only)

Pull switch out to ON.

Reset breaker.

Turn oven OFF, unhook and repair problem.

Replace fuse. Determine amp draw.

Replace fuse. Determine amp draw.

Verify the unit is set for a single pulse pickup. If

not, reset for a single pulse pickup. If yes reattach

the pickup.

Motor brushes worn out.

Defective conveyor drive motor.

Defective conveyor drive motor controller.

Wire from pickup open or faulty connection.

Replace brushes.

Replace conveyor drive motor.

Replace conveyor drive motor controller.

Repair or replace wire.

Symptom #2 - Computer error code MOTOR Ć SPEED Ć ERROR

Belt speed needs calibration. See Technical Appendix (page 3-6).

Voltage from Bodine controller to DAC not presĆ

ent. The DAC (Digital Analog Control) is a nonĆreĆ

pairable component of the computer. There

should be approximately 20 VDC between the

red and green wires on the 3 pin connection of

the DC drive board.

DAC voltage is present but not regulated beĆ

tween 4.7 and .47 VDC when different times are

programmed into the cooking computer. MeaĆ

sure the voltage between the green and blue

wires of the 3 pin connection.

Replace the drive motor controller.

Replace 9 pin computer cable

Replace the computer.

5-1

Page 39

TROUBLESHOOTING

COMPUTER CONTROL SYSTEM

POSSIBLE CAUSE(S) SUGGESTED REMEDY

Symptom #1 - Computer controller displays: PROBE Ć OPEN Ć PROBE Ć SHORT and

alarm buzzer sounds

Internal problem with computer controller.

Verify display integ. in the 2nd level programĆ

ming. If the controller has been programmed the

computer may need to be replaced.

Loose connections at computer controller.

Shorted or open RTD probe.

Tighten connections.

Use the chart in the Technical Appendix (page

NO TAG) to determine if probe is bad. Replace if

necessary.

Symptom #2 - Computer controller displays: ERROR Ć HIGH Ć TEMP Ć LIMIT

Actual temperature exceeds programmed limit

value. Default 605F (319C).

Internal problem with computer controller.

Faulty burner valve relay. Replace relay.

Faulty computer cables

Verify display integ. in the 2nd level programĆ

ming. If the controller has been programmed the

computer may need to be replaced.

Symptom #3 - Computer controller displays: MTRĆSPD

Motor speed does not match set point.

Recalibrate the motor speed. See Calibration

and Adjustment (page 3-8).

Motor indicated that the computer is not receivĆ

ing a signal from the pickup.

Fuses on the control board may have blown.

Check and replace if needed.

Wires from the pickup are not connected or broĆ

ken. Connect or replace.

5-2

Page 40

MT1828

HEATING SYSTEM

POSSIBLE CAUSE(S) SUGGESTED REMEDY

Symptom #1 - Burner will not fire

Oven in OFF mode.

Emergency stop switch on OFF.

Control circuit breaker tripped.

Combustion motor not running.

Main Temperature Controller not set above ambiĆ

ent temperature.

Manual gas valve closed.

Intermittent Ignition Device (IID) system locked

out.

Air pressure switch may be open.

Blower motor(s) not running.

High Limit control tripped.

Turn to ON position.

Pull switch out to ON.

Reset breaker.

Check transformer for primary and secondary

voltage.

Check main control and burner valve relays to

see if closed.

Check relay in combustion burner box. If bad reĆ

place relay.

Set to desired temperature.

Open valve.

Reference Technical Appendix (page NO TAG

through NO TAG).

Check convection blower (or 4 convection fans)

for proper operation.

Verify voltage to motor. If voltage is present, reĆ

place the motor or start capacitor.

Verify that 625F (330C) high limit is proĆ

grammed into the controller. If so reset the high

limit. Set the computer to 500F (260C). Use a

pyrometer to verify the oven temperature. If the

oven climbs significantly above the setpoint, use

the chart in the Technical Appendix (page

NO TAG) to check the probe. If the probe is alĆ

right the computer may need replacement.

Thermal switch in control compartment tripped.

Excessive intake air temperature.

Heat relay defective.

MT1828G CE approved units

Prepurge timers defective.

Triple pole double pole relay defective.

Gas valve defective.

MT1828E only

Contactor coil powered but will not close.

Elements open.

Check hood system.

Check hood system.

Replace heat relay.

Replace timers.

Replace relay.

Replace gas valve.

Bad contactor, replace.

Replace elements.

5-3

Page 41

POSSIBLE CAUSE(S) SUGGESTED REMEDY

Symptom #2 - Oven will not reach desired temperature

TROUBLESHOOTING

Gas pressure to oven is too low.

Top air plates missing.

Faulty RTD probe.

Blower motor(s) running backward.

Controller out of calibration.

Excessive food/debris accumulation blocking

the airflow.

Symptom #3 - Burner operates sporadically

Air pressure switch may be open. General export

and CE approved ovens only.

Contact local gas representatives.

Install air plates.

Use the chart in the Technical Appendix (page

NO TAG) to determine if probe is bad. Replace if

necessary.

Verify voltage to motor. If voltage is present, reĆ

place the motor or start capacitor.

Recalibrate the controller. See Calibration and

Adjustment (page 3-5).

The inside of the oven should be cleaned to reĆ

move any materials that could have dropped off

the conveyor belt and possibly blocked some of

the air flow holes. This would include the removal

of the conveyor belt, conveyor belt supports, and

the nozzles. The oven interior and all parts reĆ

moved should then be cleaned with an appropriĆ

ate oven cleaner safe for aluminum.

Check convection blower (or 2 convection fans)

for proper operation.

Thermal switch tripped.

Faulty RTD probe.

Excessive food/debris accumulation blocking

the airflow.

Determine the ambient temperature in the conĆ

trol compartment. If above 140F (60C) check

the cooling fan operation.

Use the chart in the Technical Appendix (page

NO TAG) to determine if probe is bad. Replace if

necessary.

The inside of the oven should be cleaned to reĆ

move any materials that could have dropped off

the conveyor belt and possibly blocked some of

the air flow holes. This would include the removal

of the conveyor belt, conveyor belt supports, and

the nozzles. The oven interior and all parts reĆ

moved should then be cleaned with an appropriĆ

ate oven cleaner safe for aluminum.

5-4

Page 42

MT1828

CONVECTION SYSTEM

POSSIBLE CAUSE(S) SUGGESTED REMEDY

Symptom #1 - Blower motor(s) not running

Oven in OFF mode.

Remote emergency stop switch on OFF.

No power to oven.

Motor circuit breaker tripped.

Faulty start capacitor.

Motor(s) burnt out.

Motor contactor open.

Thermal overload tripped.

Press ON/OFF key.

Pull switch out to ON.

Verify power to motor(s). If there is voltage presĆ

ent, replace the motor. If voltage is not present,

check the motor contactor.

Replace fuse. Determine amp draw.

Replace capacitor.

Check draw (3amps or greater) when the oven is

cold.

Check that the computer is turned on and that a

cook time and temperature have been proĆ

grammed. Check for voltage to the coil of the moĆ

tor contactor. If voltage is present, replace the

contactor. If voltage is not present, check that the

blower relay is closed. If not, check for voltage at

the blower relay coil. If a 12 VDC voltage is presĆ

ent at the coil the blower relay is bad. If there is

no voltage present at the coil the computer may

need to be replaced.

Determine if the cooling blower (or fans) are operĆ

ating. If not, verify voltage to the cooling blower.

If voltage is present, replace the cooling blower

motor. If voltage is not present, verify voltage

through the thermal switch. If no voltage is presĆ

ent, replace the thermal switch.

Symptom #2 - Blower motor(s) do not shut off

Faulty motor contactor.

Faulty blower motor relay.

Faulty auxiliary contact.

Faulty probe.

Replace contactor.

Replace relay.

Replace auxiliary contactor.

Use the chart in the Technical Appendix (page

NO TAG) to determine if probe is bad. Replace if

necessary.

Symptom #3 - Hood system does not operate when oven is on

Fan exhaust/supply problem.

Defective interlock circuit.

Contact HVAC service.

Replace auxiliary contactor.

5-5

Page 43

POSSIBLE CAUSE(S) SUGGESTED REMEDY

Symptom #36 - Blower motor running backward

TROUBLESHOOTING

Motor off by thermal overload (other fans forcing

blower to spin).

Faulty capacitor.

Symptom #37 - Blower motor does not shut off

Bad temperature probe

Bad blower relay

Faulty computer

Determine if the cooling blower (or fans) are operĆ

ating. If not, verify voltage to the cooling blower.

If voltage is present, replace the cooling blower

motor. If voltage is not present, verify voltage

through the thermal switch. If no voltage is presĆ

ent, replace the thermal switch.

Replace capacitor.

Check the resistance values of the temperature

probe for values from 135Ć170F (57Ć77C). RefĆ

erence NO TAG on page NO TAG of the TechniĆ

cal Appendix. If the values do not agree with the

chart change the probe.

If the temperature probe is good check for voltĆ

age at the coil of the blower relay. If voltage is not

present the relay is bad. Replace the blower

relay.

If voltage is present at the blower relay, the comĆ

puter is bad. Replace the computer.

5-6

Loading...

Loading...