Page 1

MT1828

BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN M9446 Rev B (6/01)

E 2000 --- G.S. Blodgett Corporation

Page 2

MT1828 Series Conveyor Oven Owner -- Operator Manual

Installation 3..........................................................................

Operation 9...........................................................................

Maintenance 11........................................................................

MT1828 serie Transportørovn Ejer -- og brugermanual

Installation 16..........................................................................

Betjening 22...........................................................................

Vedligeholdelse 24......................................................................

MT1828 Serie Transportoven Gebruikershandleiding

Installatie 29...........................................................................

Bediening 35...........................................................................

Onderhoud 37..........................................................................

Four à convoyeur Série MT1828 Manuel de l’utilisateur

Installation 42..........................................................................

Fonctionnement 48.....................................................................

Maintenance 50........................................................................

MT1828--Serie Förderofen -- Bedienerhandbuch

Installation 55..........................................................................

Bedienung 61..........................................................................

Wartung 63............................................................................

Serie MT1828 Forno a convogliatore Manuale d’uso

Installazione 69.........................................................................

Funzionamento 75......................................................................

Manutenzione 77.......................................................................

Série MT1828 Forno de Correia Manual do Utilizador -- Proprietário

Instalação 82...........................................................................

Operação 88...........................................................................

Manutenção 90.........................................................................

Norno del transportador Serie MT1828 Manual del operario

Instalación 95..........................................................................

Funcionamiento 101......................................................................

Mantenimiento 103.......................................................................

MT1828 Serien Ugn med transportband Ägarens -- Användarmanual

Installation 108..........................................................................

Användning 114.........................................................................

Underhåll 116...........................................................................

Page 3

MT1828 Series

Conveyor Oven

Owner --- Operator Manual

2

Page 4

Installation

Oven Specifications

SPECIFICATIONS MT1828G/AB MT1828E/AA

Belt Width 46 cm (18”)

Cooking Zone Length 71 cm (28”)

Baking Area .34 m2(3.7 Sq. Ft.)

Dimensions (single unit) 104 cm x 89 cm x 46 cm (41” x 35” x 18”)

Maximum Operating

Tem per atur e

Product Clearance 9.5 cm (3.75”)

Maximum Input 11.7 kW/Hr. (40,000 BTU/HR ) 11.1 KW/hr.

Power Supply 230 VAC, 1Φ, 50Hz, 3 wire, 15 Amp 230/400 VAC, 3Φ, 50Hz, 5 wire, 17 amp

Gas Supply See chart on page 8 None

315_C (600_F)

3

Page 5

Installation

Delivery and Location

DELIVERY AND INSPECTION

All Blodgett ovens are shipped in containers to

prevent damage. Upon delivery of your new oven:

D

Inspect the shipping container for external damage. Any evidence of damage should be noted

on the delivery receipt which must be signed by

the driver.

D

Uncrate the oven and check for internal damage. Ca rriers will accept claims for concealed

damage if notified within fifteen days of delivery

and the shipping container is retained for inspection.

The Blodgett Oven Company cannot assume

responsibility for loss or damage suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a cl aim is necessary.

OVEN LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

D

Place the oven at least 5 cm from the rear wall

and50cmfromthesidewall.

D

Place the oven in a properly ventilated area.

D

Place the oven under an exhaust hood, according to Localand National InstallationStandards.

D

Position the oven so the supply plug is accessible.

The oven can now be moved to the installation

site. Check the list below with Figure 1 to be sure

all items were received.

Part Description

Qty.

Main oven body 1

Conveyor belt assembly 1

Crumb pans 2

Hardware packets 2

Product Stop 1

Conveyor Assembly

(shown without belt)

Product

Stop

Crumb Pans

Figure 1

4

Page 6

NOTE: This appliance shall be installed in accor-

dance with current regulations and used

only in a well-ventilatedspace.Refertothe

instructions before installing and using

this appliance. Installation must be performed by a qualified installer only.

LEGS

1. Remove the oven from it’s packing crate.

2. Lay the oven on it’s back. Screw one leg into

each of the four holes located on the bottom

of the oven chamber.

3. Tighten the hex nut at the top of each leg.

4. Lift the oven upright onto the legs.

Installation

Oven Assembly

Leg

Stand

Frame

Figure 3

Top o f

Stand

Shelf

Bottom of

Oven

Figure 2

OVEN STAND WITH CASTERS

1. Attach each leg to the stand frame with a lock

washer and nut. DO NOT tighten completely.

2. Position the shelf between the legs with the

smooth surface facing the top of the stand.

Aligntheshelfwiththeholesineachleg.Attach the shelf to each leg with a nut and bolt.

3. Tighten the bolts installed in step 1.

4. Place the oven onto the stand. Bolt the oven

to the stand from underneath.

5. Attach a strain relief bracket on gas models.

STACKING THE OVENS

1. Rest the top oven on it’s back. Install an oven

alignment pin into each of the four holes in the

bottom of the oven.

2. Carefully lift the upper oven off the pallet and

placeitontheloweroven.Besurethealignment pins are inserted into the holes in the top

of the lower oven.

Alignment Pin

Bottom oven

Figure 4

5

Page 7

Installation

Oven Assembly

CONVEYOR

1. Slide the conveyor assembly through t he left

hand tunnel opening until the sprocket is insidethecontrolbox.SeeFigure5.

2. Install the drive belt on the motor and then

around the pulley on the conveyor assembly.

See Figure 6. Push the conveyor assembly

back to tighten the belt.

Figure 5

NOTE: To reverse the direction of the drive motor

(if necessary), exchange A1 and A2. See

Figure 7.

WARNING!!

Disconnect the power supply before re-

versing the drive motor.

W

AC

AC

L2 L1

A1 A2 A3

W

V

BK

GND

DC MOTOR

Y OR BL

S2

S3

SPEED

CONTROL

S1

Figure 7

CRUMB PANS

1. Install crumb pans under each end of the conveyor.

Figure 6

Figure 8

6

Page 8

Installation

Utility Connections

GAS CONNECTIONS (if applicable)

Connect the oven to the gas line with the proper

type of gas according to Local and National Installation Standards.

Setting Equipment for Other Types of Gas

1. Remove the control box door and belt guard.

2. Remove the entire gas piping and burner assembly from the oven.

3. Remove the four screws holding the blower

and belt guard to the burner mounting flange.

Remove the blower and belt guard from the

burner.

4. Unscrew the gas piping at the inlet of the gas

valve.

5. France and BelgiumOnly --- Thenippleatthe

inlet of the gas valve must be changed. On

natural gas ovens this nipple will have a

3.2mm restrictor inside.

To convert from natural gas to propane/bu-

tane the nipple with the restrictor must be removed and replaced with a nipple without a

restrictor.

To convert from propane/butane to natural

gas the nipple without a restrictor must be removed and replaced with a nipple with a restrictor. Orient the nipple so the restrictor is

close to the valve and the open end is close to

the piping elbow.

6. Unscrew the gas valve and remaining piping

up to and including the coupling where it enters the burner tube.

7. Remove the grommet that hold the spark and

flame sense wires.

8. Grasp the front of the oriface assembly while

pushing down on the fitting at the top of the

burner tube. Pull the oriface assembly out of

the front of the burner tube.

NOTE: Be careful not to lose the spacer ring

thatgoes around the nipple at the inlet

of the orifice assembly, it will be reused.

9. Remove the spark and flame sense electrodes

from the oriface assembly . Reinstall in the same

position on the new oriface assembly.

10. Reverse the procedure to reassemble the

burner.

NOTE: Be sure to reinstall the spacer ring and

use thread sealant when reconnecting

the piping fittings.

11. Reinstall the gas valve and burner assembly

into the oven.

Gas pressure

adjustment

Disconnect gas

piping here

Pressure Tap

Blower

mounting screws

Disconnect

gas piping

here

Grommet for

spark & flame

sense wires

Belt guard

mounting bracket

Figure 9

7

Page 9

Installation

/

A

G20/G2520/25TotallyInscrewe

d

1,40N/A11,7Na

t.Gas

Utility Connections

Type o f

Gas

Inlet

Pressure

mbars

Burner Pressure

mbars

Injector

Diameter

mm

Air

Opening

mm

Standard Delivery

Value kW (H

G25 25 12 1,40 N/A 11,7 Nat. Gas

G20 20 8,0 1,40 N/A 11,7 Nat. Gas

G20/G25 20/25 Tot allyInscrewed 1,40 N

11,7 Nat. Gas

Pressure Regulator

G30 30/50 6 1,1 N/A 11,7 Butane

G31 30/37/50 8 1,1 N/A 11,7 Propane

ELECTRICAL CONNECTIONS

NOTE: Electrical connection must be performed

by a qualified installer only.

NOTE: The electrical connection must comply

with National and Local codes.

For Gas Models:

NOTE: Gasmodels have a phase sensitiveburner

control unit. If the phase and neutral are

switched the control locks out.

Connect exhaust fan connector 1 and 2. See

Figure 10.

A strain relief for the supply cord is required. The

installer must provide a supply cord bushing that

meets all Local and National Installation Standards.

Connect phase + neutral + ground .

For Electric Models:

Connect t he oven to a separate group 230V, 50 hz

with rigid connection a nd circuit breaker. The circuit breaker should disconnect all poles, including

neutral with a contact separation of at least 3 mm.

ConnectL1+L2+L3+neutral+ground.

)

S

L3

L2

L1

N

Blodgett

Connector

1 --- Burner control solenoid

2 --- Air pressure regulator

N

L

Connector

1

2

Figure 10

8

Fan

A2

2-4-92

s

2

A1

Relay A

1

Page 10

OPERATION

NOTE: Operationis restricted to qualifiedperson-

nel.

To turn the oven on:

1. Turn the manual gas valve to ON. (Gas models

only.)

2. Press and hold the ON/OFF key (2).

3. The display will flash WAIT LOW SET TIME

mmss.

4. The HEAT LIGHT (4) illuminates as the oven

heats to temperature.

NOTE: If in starting, the burner does not ignite

directly, the alarm light will illuminate.

Press the RESET knob to restart the

burner. (Gas models only.)

NOTE: If the oven will not start after several at-

tempts contact a qualified installer.

Operation

Cooking Computer

To view the cook time setting:

1. Press the TIME key (8). The LED on the keywill

light and the display flashes SET TIME mmss.

To display the actual oven temperature:

1. Press the ACT TEMP key (6). The LED on the

key will light and the display reads ACTUAL

nnnn_C.

To view the temperature set point:

1. Press the SET TEMP key (6). The LED on the

key will light and the display flashes SET TEMP

nnnn_C.

To turn the oven off:

1. Press the ON/OFFkey (2). The fans willcontinue to run until the oven cools down.

2. TurnthemanualgasvalvetoOFF.(Gasmodels only.)

10

1

56789

4

Figure 11

2

3

9

Page 11

Operation

Cooking Computer

PROGRAMMING PROCEDURES

Programming the Cook Time:

1. Press the PROGRAM/ENTER key (9).

2. Press the TIME key (8). The display reads

PROG-?SETTIME-?____.

3. Use the NUMERIC keys (3) to enter the desired cook time. If an error is made, press the

CLEAR key (5) and re-enter the number.

4. Press the PROGRAM/ENTER key (9) twice to

store the new time.

Programming the Temperature:

1. Press the PROGRAM/ENTER key (9).

2. Press the SET TEMP key (6). The display

reads PROG-?SETTEMP-?____C.

3. Use the NUMERIC keys (3) to enter the desired temperature set point. If an error is

made, press the CLEAR key (5) and re-enter

the number.

4. Press the PROGRAM/ENTER key (9) twice to

store the new temperature.

10

Page 12

Maintenance

Cleaning and Parts Replacement

CLEANING

NOTE: DO NOT spray the oven with a water jet.

Daily

1. Remove and clean the crumb pans.

2. Clean the conveyor belt with a brush.

Every 3 months

1. Clean the axial fan guards.

Every 6 months

1. Remove the conveyor belt and guides.

2. Clean the inside of the oven.

Every 12 months

A factory authorized service person should:

1. Clean the control panel, oven cavity, burner

and fans.

2. Check the main electrical connections.

3. Check the drive motor. Replace the carbon

brushes.

4. Clean and lubricate the drive chain.

5. Check and adjust the gas setting. (Gas models only.)

PARTS REPLACEMENT

Electrical Components

1. Shut off the gas (if applicable). Turn off the

main electrical connection.

2. Remove the control box cover.

3. Replace the defective components.

4. Replace the control box cover.

5. Turn on the main electrical connection. Turn

on the gas (if applicable).

Gas Control Combination

NOTE: Gas models only.

1. Shut off the gas. Turn off the main electrical

connection.

2. Removethegasconnectiononbothsidesof

the control combination.

3. Replace and adjust the gas connection.

Check for gas leaks.

4. Turn on the main electrical connection. Turn

on the gas.

Removal of Burner

NOTE: Gas models only.

1. Shut off the gas. Turn off the main electrical

connection.

2. Remove the gas connection.

3. Remove the four screws from the burner

mounting plate. Remove the burner.

4. Replace pilot if necessary .

5. Reinstall the burner.

6. Turn on the main electrical connection. Turn

on the gas.

Cooling Fans

1. Shut off the gas (if applicable). Turn off the

main electrical connection.

2. Remove the oven back panel. Remove the insulation if necessary.

3. Disconnect and replace the defective fans.

4. Reinstall the insulation and oven back panel.

5. Turn on the main electrical connection. Turn

on the gas (if applicable).

Combustion Chamber

NOTE: Gas models only.

1. Shut off the gas.

2. Remove the combustion chamber cover plate

and insulation.

3. Clean the combustion chamber.

4. Reinstall the insulation and cover plate.

5. Turn on the gas.

Operating Panel Components

1. Shut off the gas (if applicable). Turn off the

main electrical connection.

2. Remove the screws located on the bottom of

the oven holding the control. Slide the operating panel out.

3. Replace the defective component.

4. Reinstall the operating panel.

5. Turn on the main electrical connection. Turn

on the gas (if applicable).

11

Page 13

Maintenance

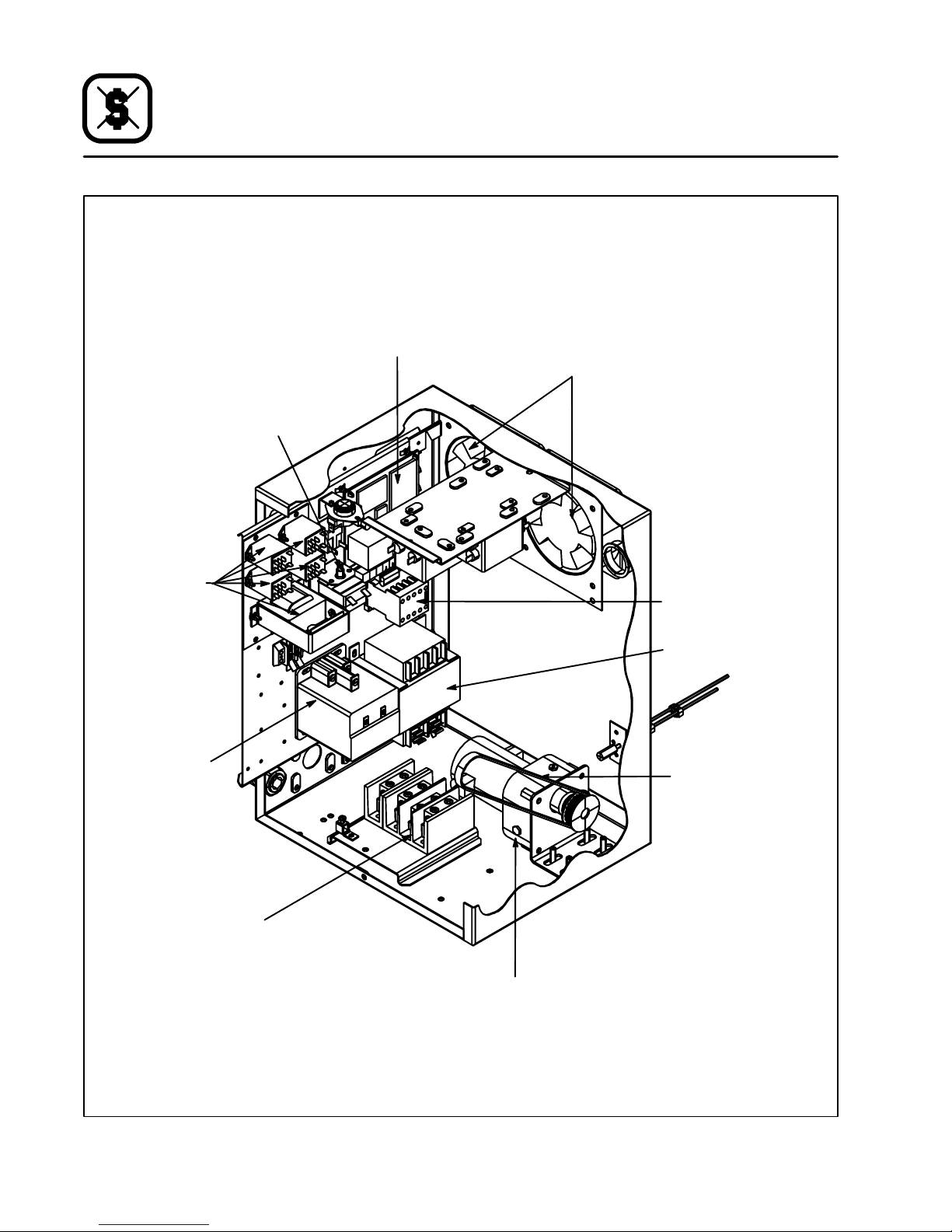

Component Locations

High L imit

Reset Button

MT1828G

Motor Drive Board

Cooling Fans

Air Flow

Pressure Switch

Air Flow

Pressure

Switch

Burner

Ignition

Control

Power Supply

Connection

Burner Blower

Assembly

Drive Belt

Gas Regulator Valve

Conveyor Drive Motor

Figure 12

12

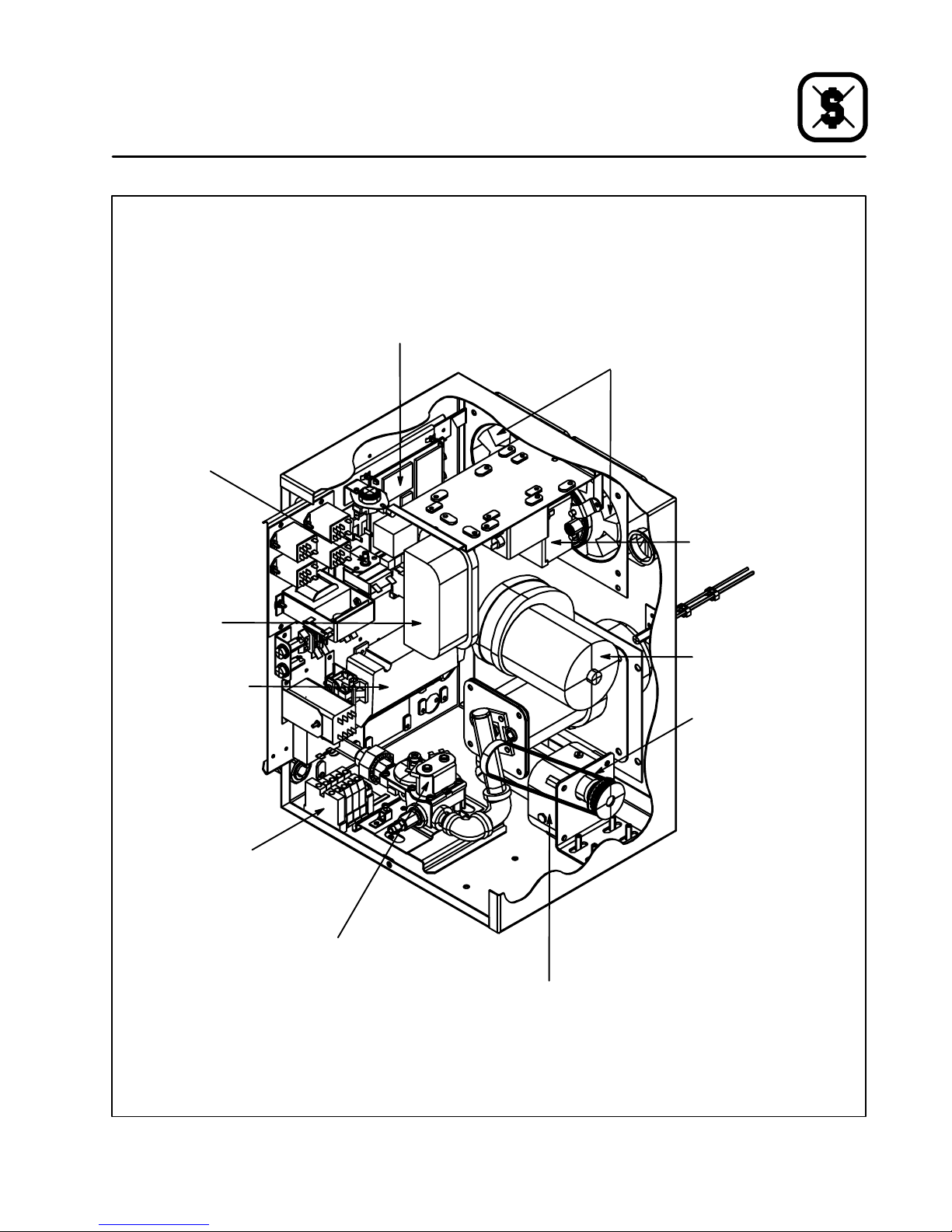

Page 14

High L imit

Reset Button

Control Power

Supply and

Relay Assembly

Maintenance

Component Locations

MT1828E

Motor Drive Board

Cooling Fans

Blower Motor

Contactor

Heating

Element

Contactor

Power Supply Connection

Step Down

Transformer

Drive Belt

Conveyor Drive Motor

Figure 13

13

Page 15

Maintenance

Troubleshooting

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Blower motor(s) not running

S

Blower control turned off

S

No power to oven

S

Motor fuses blown

S

Control circuit fuse blown

SYMPTOM: Burner will not fire or elements do not heat

S

Control turned off

S

Blower motor(s) not running

S

Oven not set above ambient temperature

S

Manual gas valve closed (gas models only)

SYMPTOM: Oven will not reach desired temperature

S

Turn to blower on

S

Replace main fuses or reset breakers

S

Replace fuses

S

Replace fuses

S

Turn control on

S

Check control switch and/or fuses

S

Set to desired temperature

S

Open valve

S

Gas pressure to oven is too low (gas models

only)

S

Heat control turned off

S

No power to oven

S

Blower motor(s) not running

SYMPTOM: Conveyor belt will not run

S

Conveyor control turned off

S

Control circuit fuse blown

S

Belt hooked on something in oven

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

S

Contact local gas representatives

S

Turn control on

S

Replace main fuses

S

Check control switch and/or fuses

S

Turn control on

S

Replace fuse

S

Turn oven off, unhook and resolve problem

14

Page 16

MT1828 serie

Transportørovn

Ejer --- og brugermanual

15

Page 17

Installation

Ovn specifikationer

SPECIFIKATIONER MT1828G/AB MT1828E/AA

Bæltevidde 46 cm (18”)

Længde på bagezone 71 cm (28”)

Bageområde 0,34 m2(3,7 Sq. Ft.)

Dimensioner

(enkelt enhed)

Maksimum

driftstemperatur

Min. afstand til væg 9,5 cm (3,75”)

Maksimum indgang 11,7 kW/time (40,000 BTU/TIME ) 11,1 kW/time

Strømtilførsel 230V, 1Φ, 50Hz,3wirer,15amp 230/400V, 3Φ, 50Hz,5wirer,17amp

Gastilførsel Se tabellen på side 21 Ingen

104 cm x 89 cm x 46 cm (41” x 35” x 18”)

315_C (600_F)

16

Page 18

Installation

Levering og placering

LEVERING OG INSPEKTION

Alle ovne fra Blodgett sendes i containere for at

forhindre beskadigelse. Når Deres nye ovn afleveres:

D

Inspicér forsendelsescontaineren for alle ydre

skader. Ethvert tegn på beskadigelse skal noteres på leveringskvitteringen, som chaufføren

skal underskrive.

D

Tag ovnen ud af kassen og kontrollér, om der er

skader indvendigt. Transportfirmaera ccepterer

krav for skjulte skader, hvis de får besked indenfor 15 dage efter leveringen og forsendelsescontaineren tilbageholdes for inspektion.

Blodgett Oven Company tager intet ansvar for

tab eller skader, der pådrages i transit. Transportfirmaet påtog sig fuldt ansvar for levering

i god stand, da forsendelsen bl ev accepteret.Vi

er dog klar til at være behjælpelige, hvis det er

nødvendigt at gøre krav på erstatning.

OVNENS PLACERING

Deres ovns gennemtænkte og k orrekte placering

vil på langt sigt forenkle operatørens opgaver og

sikre tilfredsstillende ydelse.

D

Placer ovnen mindst 5 cm fra den bageste væg

og 50 cm fra sidevæggen.

D

Placer ovenen i et område, som er tilstrækkeligt

ventileret.

D

Placer ovnen under en udsugningsemhætte, i

henhold til lokale og nationale installation standarder.

D

Placer ovnen, så elstikket er tilgængeligt.

Ovnenkan nu flyttes til installationsstedet.KontrollerlistenfornedenmedFigur1foratsikre,atalle

dele blev modtaget.

Delbeskrivelse

Kva

n.

Hovedovnens hus 1

Samling af transportbæltet 1

Krummepander 2

Beslag pakker 2

Produktstop 1

Samling af transportbæltet

(vist uden bælte)

Produktstop

Krummepander

Figur 1

17

Page 19

Installation

Samling af ovn

BEMÆRK: Dette apparat skal installeres i henhold

til gældende regulativer og kun bruges

i et godt -ventileret område. Se instruktionerne før installation og brug af dette

apparat. Installation må kun udføres af

en kvalificeret tekniker.

BEN

1. Fjern ovnen fra dens forsendelseskasse.

2. Læg ovnen på dens bagside. Skru et ben i

hver af de fire huller, som findes i bunden af

ovnhuset.

3. Stram møtrikken foroven på hvert ben.

4. Løft ovnen op på benene.

Ben

Stativ

ramme

Figur 3

Stativets

top

Hylde

Ovnens

bund

Figur 2

OVNSTATIV MED HJUL

1. Sæt hvert ben på stativrammen med en låseskive og møtrik. Stram IKKE helt.

2. Placer hylden mellem benene med den glatte

overflade vendende op mod stativets top. Ligestil hylden med hullerne i hvert ben. Fastgør

hylden til hvert ben med møtrik og bolt.

3. Stram boltene, som blev installeret i punkt 1.

4. Placerovnen på stativet. Bolt ovnen fast tilstativet fra undersiden.

5. Sæt et trækaflast n ingsbeslag på gasmodeller.

STAKNING AF OVNENE

1. Lægden øverste ovn på bagsiden. Installer en

ovnflugtningsstift i hvert af de fire huller i bunden af ovnen.

2. Løft forsigtigt den øverste ovn af pallen og placer den på den nederste ovn. Sørg for at flugtningsstifterne er s at i hullerne foroven på den

nederste ovn.

Flugtningsstift

Nederste ovn

Figur 4

18

Page 20

Installation

Samling af ovn

TRANSPORTØR

1. Glid transportsamlingen gennem åbningen til

venstre, til kædehjulet er inde i kontrolboksen.

Se Figur 5.

2. Installer drivremmen på motoren og derefter

rundt om remskiven på transportsamlingen.

Se Figur 6. Skub transportsamlingen tilbage

for at stramme remmen.

Figur 5

BEMÆRK: F or at ændre retningen på drivmotoren

(omnødvendigt)bytompåA1ogA2.

Se Figur 7.

ADVARSEL!!

Sluk for strømforsyningen, før retningen

på drivmotoren ændres.

W

AC

AC

L2 L1

A1 A2 A3

W

V

BK

GND

DC MOTOR

Y OR BL

S2

S3

HASTIGHEDS---

S1

KONTROL

Figur 7

KRUMMEPANDER

1. Installer krummepander under hver ende af

transportøren.

Figur 6

Figur 8

19

Page 21

Installation

Tilslutninger af forsyninger

GASTILSLUTNING (hvis anvendt)

Tilslut ovnen til gaslinien med den korrekte type

gas i henhold til lokale og nationale installationsstandarder.

Opstilling af udstyr til andre gastyper

1. Fjern kontrolboksdøren og afskærmningen.

2. Fjern gasrør og brændersamling fra ovnen.

3. Fjerndefireskruer,somholderblæserenog

afskærmningen til brænderens monteringskant. Fjern blæseren og a fskærmningen fra

brænderen.

4. Skru gasrøret af ved gasventilens indgang.

5. Kun Frankrig og Belgien --- S p i d s e n p å ga s ventilens indgang skal ændres. På naturgasovne vil denne spids have en indre begrænser på 3,2 mm.

For at konvertere fra naturgas til kosan/butangas skal spidsen med begrænseren fjernes

og udskiftes med en spids uden begrænser.

For at konvertere fra kosan/butangas til naturgas skal spidsen uden en begrænser fjernes

og udskiftes med en spids med en begrænser. Sæt spidsen, så begrænseren er tæt på

ventilen og den åbne ende er tæt på rørets al bue.

6. Skru gasventilen og det resterende rør til og

med samlingen, hvor det går ind i brænderrøret af.

7. Fjern kordelstroppen, som holder gnisten og

flamme sensorledninger.

8. Tag fat om det forreste af åbningssamlingen,

mens der skubbes ned på brænderrørets

øverste samling. Træk åbningen ud foran på

brænderrøret.

BEMÆRK: Vær forsigtig ikke at miste mellem-

lægsskiven, som er rundt om spidsen ved åbningssamlingens indgang, den vil blive brugt igen.

9. Fjern gnisten og flamme sensorelektroderne fra

åbningssamlingen. Installer igen i samme position på den nye åbningssamling.

10. Udfør proceduren omvendt for at samle brænderen igen.

BEMÆRK: Sørg for at installere mellemlægs-

skiven igen og brug gevindforsegling, når rørsamlingerne samles

igen.

11. Installer gasventilenog brændersamlingen inde i ovnen igen.

Justering af

gastryk

Afbryd gasrør her

Trykventil

Blæser

monteringsskruer

Afbryd gasrør her

Kordelstrop til

gnist og flamme

sensorledninger

Afskærmning

monteringsbeslag

Figur 9

20

Page 22

Installation

Anv

G20/G2520/25Heltskruetind

1,40Anvendesikke1

1,7na

t.gas

Tilslutninger af forsyninger

Gastype Indga ng-

stryk

mbar

Brændertryk

mbar

Injektordia-

meter

mm

Luftåbning

mm

Standard leverings-

værdi kW (H

G25 25 12 1,40 Anvendes ikke 11,7 nat. gas

G20 20 8,0 1,40 Anvendes ikke 11,7 nat. gas

G20/G25 20/25 Helt skruet ind 1,40

endes ikke 11,7 nat.gas

trykregulator

G30 30/50 6 1,1 Anvendes ikke 11,7 butan

G31 30/37/50 8 1,1 Anvendes ikke 11,7 kosan

ELEKTRISKE TILSLUTNINGER

BEMÆRK: Elektrisk tilslutning må kun udføres af

en autoriseret installatør.

BEMÆRK: Den elektriske installation skal være i

overensstemmelse med nationale og

lokale koder.

En strækholder til forsyningskablet er påkrævet.

Installatøren skal sørge for, at tilførselskablets bøsning imødekommer alle lokale og nationale installationsstandarder.

Til gasmodeller:

BEMÆRK: Gasmodeller har en fasefølsom bræn-

der kontrolenhed. Hvis fasen og neutral byttes om, låser kontrollen.

Forbind udsugninsemhætte forbinder 1 og 2. Se

Figur 10.

Tilslut fase + neutral + jord .

Til elektriske modeller:

Tilslut ovnen til separat 230 V, 50 Hz strømforsyning med stiv tilslutning og afbryder. Afbryderen

og stikproppen skal adskille alle poler, inklusive

neutral, med kontaktadskillelse på mindst 3 mm.

Tilslut L1 + L2 + L3 + neutral + jord.

)

S

L3

L2

L1

N

Blodgett

Forbinder

1 – Brænder kontrolsolenoide

2 --- Lufttrykregulator

N

L

Forbinder

2-4-92

s

2

1

2

Blæser

A2

A1

Relæ A

1

Figur 10

21

Page 23

Betjening

Bagecomputer

BETJENING

BEMÆRK: Betjening er begrænset til kvalificeret

personale.

Sådan tændes ovnen:

1. Drej den manuelle gasventil til ON (Kun gasmodeller.)

2. Tryk og hold på ON/OFF knappen (2).

3. Displayet vil blinke WAIT LOW SET TIME

mmss.

4. HEAT LYSET (4) lyser op, mens ovnen varmer

op til temperatur.

BEMÆRK: Hvis brænderen ikke antændes di-

rekte ved opstart, vil alarmlyset lyse op. Tryk på RESET knappen for

at genstartebrænderen. ( Kun gasmodeller.)

BEMÆRK: Hvis ovnen ikke vil starte efter adskilli-

ge forsøg, kontakt en kvalificeret tekniker.

Sådan ses bag etidens indstilling:

1. Tryk på TIME knappen (8). Lyset på knappen

vil lyse og displayet blinker SET TIME mmss.

Sådan ses den faktiske ovntemperatur:

1. Tryk på ACT TEMP knappen (6). Lyset på

knappen vil lyse og displayet viser ACTUAL

nnnn_C.

Sådan ses temperaturens indstillingspunkt:

1. Tryk på SET TEMP knappen (6). Lyset på

knappen vil lyse og displayet blinker SET

TEMP nnnn_C.

Sådan slukkes ovnen:

1. Tryk på ON/OFF knappen (2). Blæserne vil

fortsætte med at køre, til ovnen køler af.

2. Drej den manuelle gasventil til OFF. (Kun gasmodeller.)

10

1

56789

4

Figur 11

2

3

22

Page 24

PROGRAMMERINGSPROCEDURER

Programmering af bagetiden:

1. Tryk på PROGRAM/ENTER knappen (9).

2. Tryk på TIME knappen (8). Displayet viser

PROG-?SETTIME-?____.

3. Brug NUMERIC knapper (3) til indtastning af

den ønskede bagetid. Hvis der laves en fejl,

tryk på CLEAR knappen (5) og indtast -nummeret igen.

4. Tryk på PROGRAM/ENTER knappen (9) to

gange for at gemme den nye tid.

Betjening

Bagecomputer

Programmering af temperaturen:

1. Tryk på PROGRAM/ENTER knappen (9).

2. Tryk på SET TEMP knap (6). Displayet viser

PROG-?SETTEMP-?____C.

3. Brug NUM E R I C kn a pper (3) for at indtaste

den ønskede indstillingstemperatur. Hvis der

laves en fejl, tryk på CLEAR knappen (5) og

indtast - nummeret igen.

4. Tryk på PROGRAM/ENTER knappen (9) to

gange for at gemme den nye temperatur.

23

Page 25

Vedligeholdelse

Rengøring og udskiftning af dele

RENGØRING

BEMÆRK: Spray IKKE ovnen med en vandsprøjte.

Dagligt

1. Fjern og rengør krummepanderne.

2. Rengør transportbæltet med en børste.

Hver 3. måned

1. Rengør de aksiale blæserskærme.

Hver 6. måned

1. Fjern transportbæltet og guiderne.

2. Rengør ovnens inderside.

Hver 12. måned

En serviceperson, som fabrikkens har autoriseret,

bør:

1. Rengør kontrolpanelet, ovnudhulingen,

brænderen og blæserne.

2. Kontroller overordnede elektriske tilslutninger.

3. Kontroller drivmotoren. Udskift kulstofbørsterne.

4. Rengør og smør drivkæden.

5. Kontroller og juster gasindstillingen. (Kun gasmodeller.)

UDSKIFTNING AF DELE

Elektriske komponenter

1. Sluk for gassen (hvis anvendt) Afbryd den

overordnede elektriske tilslutning.

2. Fjern kontrolbokslåget.

3. Udskift de defekte komponenter.

4. Sæt kontrolbokslåget på igen.

5. Tænd for den overordnede elektriske tilslutning. Tænd for gassen (hvis anvendt).

Gaskontrol kombination

BEMÆRK: Kun gasmodeller.

1. Sluk for gassen. Afbryd den overordnede

elektriske tilslutning.

2. Fjern gastilslutningen på begge sider af kontrol kombinationen.

3. Udskift og juster gastilslutningen. Undersøg

for gasudslip.

4. Tænd for den overordnede elektriske tilslutning. Tænd for gassen.

Fjernelse af brænder

BEMÆRK: Kun gasmodeller.

1. Sluk for gassen. Afbryd den overordnede

elektriske tilslutning.

2. Fjern gastilslutningen.

3. Fjern de fire skruer fra brænderens monteringsplade. Fjern brænderen.

4. Udskift om nødvendigt tændblus.

5. Installer brænderen igen.

6. Tænd for den overordnede elektriske tilslutning. Tænd for gassen.

Afkølingsblæsere

1. Sluk for gassen (hvis anvendt). Afbryd den

overordnede elektriske tilslutning.

2. Fjern ovnens bagpanel. Fjern om nødvendigt

isoleringen.

3. Afbryd og udskift de defekte blæsere.

4. Installerisoleringen og ovnens bagpanel igen.

5. Tænd for den overordnede elektriske tilslutning. Tænd for gassen (hvis anvendt).

Forbrændingskammer

BEMÆRK: Kun gasmodeller.

1. Sluk for gassen.

2. Fjern forbrændingskammerpladen og isoleringen.

3. Rengør forbrændingskammeret.

4. Installer isoleringen og pladen igen.

5. Tænd for gassen.

Komponenter til betjeningspanel

1. Sluk for gassen (hvis anvendt). Afbryd den

overordnede elektriske tilslutning.

2. Fjern skruerne i bunden af ovnen, som holder

kontrollen. Før betjeningspanelet ud.

3. Udskift det defekte komponent.

4. Installer betjeningspanelet igen.

5. Tænd for den overordnede elektriske tilslutning. Tænd for gassen (hvis anvendt).

24

Page 26

Høj b egrænsning

nulstillingsknap

Vedligeholdelse

Komponent placeringer

MT1828G

Motordrevskort

Afkølingsblæsere

Luftstrøm

trykknap

Luftstrøm

trykknap

Brænder

tænding

kontrol

Strømforsyning

tilslutning

Brænderblæser

samling

Drivrem

Gasregulator ventil

Drivmotor til transportbælte

Figur 12

25

Page 27

Vedligeholdelse

Komponent placeringer

Høj b egrænsning

nulstillingsknap

Ko n t r o l s t r ø m --forsyning og

relæ samling

MT1828E

Motordrevskort

Afkølingsblæsere

Blæsermotor

kontakt

Va r me --element

kontakt

Strømforsyning tilslutning

Punkt ned

transformer

Drivrem

Drivmotor til transportbælte

Figur 13

26

Page 28

Vedligeholdelse

MULIG(E) ÅRSAG(ER) FORESLÅET LØSNING

SYMPTOM: Blæser motor(er) kører ikke

S

Blæserkontrol slukket

S

Ingen strømforsyning til ovn

S

Motorsikringer gået

S

Kontrolkredsløbssikring gået

SYMPTOM:Brændervilikkeantændeellerelementervarmerikke

S

Kontrol er slukket

S

Blæser motor(er) kører ikke

S

Ovn ikke indstillet over rumtemperatur

S

Manuel gasventil lukket (kun gasmodeller)

SYMPTOM: Ovnen når ikke op på den ønskede temperatur.

S

Tæn d for blæ se r

S

Udskift hovedsikringer eller nulstil afbrydere

S

Udskift sikringer

S

Udskift sikringer

S

Tænd for kontrol

S

Kontroller kontrolknap og/eller sikringer

S

Indstil til ønsket temperatur

S

Åbn ventil

Problemløsning

S

Gastryk til ovnen er for lavt (kun gasmodeller)

S

Varmekontrol slukket

S

Ingen strømforsyning til ovn

S

Blæser motor(er) kører ikke

SYMPTOM: Transportbælte vil ikke køre

S

Transportbælte slukket

S

Kontrolkredsløbssikring gået

S

Bæltesidderfastinogetiovn

ADVARSEL!!

Adskil altid strømtilførslen, før ovnen rengøres eller serviceres.

S

Kontakt lokale gasrepræsentanter

S

Tænd for kontrol

S

Udskift hovedsikringer

S

Kontroller kontrolknap og/eller sikringer

S

Tænd for kontrol

S

Udskift sikring

S

Sluk ovn, få det løst og løs problem

27

Page 29

MT1828 Serie

Transportoven

Gebruikershandleiding

28

Page 30

Installatie

Specificaties van de oven

SPECIFICATIES MT1828G/AB MT1828E/AA

Bandbreedte 46 cm (18)

Lengte van de oven-

ruimte

Bakruimte 0,34 m2(3,7 Sq. ft.)

Afmetingen

(één unit)

Hoogste

bedrijfstemperatuur

Vrije ruimte voor het

product

Maximale

warmtetoevoer

Stroomtoevoer--- 230 VAC, 1Φ, 50 Hz, 3-dradig, 15 A 230/400 VAC, 3Φ, 50 Hz, 5-dradig,

Gastoevoer Ziedetabelopblz.34 n.v.t.

71 cm (28)

104 cm x 89 cm x 46 cm (41 inch x 35 inch x 18 inch)

315_C (600_F)

9,5 cm (3,75 inch)

11,7 kW/Hr. (40,000 BTU/HR ) 11, 1 KW/u.

17 A

29

Page 31

Installatie

Levering en plaatsing

LEVERING EN INSPECTIE

Alle Blodgett---ovens worden verzonden in containers om beschadiging te voorkomen. Na aflevering van uw nieuwe oven moet u:

D

de verzendcontainer inspecteren op uiterlijke

schade. Alle bewijs van schade moet op het verzendontvangstbewijs worden genoteerd, dat

door de chauffeur moet worden ondertekend.

D

de oven uit de verpakking halen en hem op in wendige schade controleren. De expediteur accepteert claims voor verborgen beschadiging

indien op de hoogte gesteld binnen vijftien dagen na aflevering, en indien de verzendcontainer wordt bewaard voor inspectie.

De Blodgett Oven Company aanvaardt geen

aansprakelijkheid voor verlies of schade die

werd opgelopen tijdens vervoer. De expediteur

aanvaardde volledige verantwoordelijkheid

voor aflevering in go ede staat toen de verzending werd geaccepteerd. Wij zijn echter b ereid

u te helpen al s het no odzakelijk is een schadeclaim in te dienen.

PLAATS VAN DE OVEN

De goed geplande en juiste plaatsing van uw oven

heeft langdurig bedieningsgemak voor de gebruikerenbevredigendeprestatiestotgevolg.

D

Zet de oven op ten minste 5 cm afstand van de

achterwand en op 50 cm afstand van de zijmuur.

D

Zet de oven in een goed geventileerd gebied.

D

Zet de oven onder een ventilatiekap, volgens de

plaatselijke en nationale installatienormen.

D

Plaats de oven zodanig, zodat de stekker kan

worden bereikt.

De oven kan nu op de plaatsvan installatieworden

gezet. Vergelijk onderstaande lijst met afbeelding

1 Figuur 1 om te verzekeren dat alle items werden

ontvangen.

Beschrijving van onderdeel

Aan-

tal

Hoofdbehuizing oven 1

Transportbandmontage 1

Kruimelbakken 2

Hardwarepakketten 2

Productstop 1

Transportbandmontage

(afgebeeld zonder ban d)

Product---

stop

Kruimelbakken

Figuur 1

30

Page 32

Installatie

Ovenmontage

OPMERKING: Dit toestel moet volgens de gelden-

de voorschriften worden geïnstalleerd, en uitsluitend worden gebruikt in een goed-geventileerde

ruimte. Raadpleeg de instructies,

alvorens dit toestel wordt geïnstalleerd en gebruikt. De installatie

moet uitsluitend door een bevoegde installateur worden uitgevoerd.

POTEN

1. Haal de oven uit de verpakking.

2. Legdeovenopzijnachterkant.Schroef één

poot in elk van de vier gaten aan de onderkant

van de ovenruimte.

3. Draai de zeskantbout bovenaan elke poot

vast.

4. Zet de oven rechtop op zijn poten.

Onderkant

van de

oven

5. Bevestig een spanningsontlastingbeugel op

de gasmodellen.

Poot

Boven-

kant van

S t a n d e r ---

constructie

stander

Rek

Figuur 3

DEOVENSOPELKAARZETTEN

1. Legdebovensteovenopzijnachterkant.Installeer de vier afstelpennen voor de oven in

de vier gaten aan de onderkant van de oven.

2. Til de bovenste oven voorzichtig van de pallet

af, en zet hem op de onderste oven. Verzeker

dat de afstelpennen in de gaten in de boven kant van de onderste oven gestoken zijn.

Figuur 2

OVENSTANDER MET ZWENKWIELEN

1. Maak elke poot vast aan de standerconstructie met een sluitring en moer. NIET helemaal

vastdraaien.

2. Plaats het rek tussen de poten met het gladde

oppervlak naar de bovenkant van de stander

gekeerd. Zet het rek op één lijn met de gaten

in elke poot. Bevestig het rek aan elke poot

met een bout en moer.

3. Draai de in stap 1 geïnstalleerde bouten vast

1.

4. Zetdeovenopdestander.Maakdeovenvanaf de onderkant met bouten aan de stander

vast.

Afstelpen

Onderste oven

Figuur 4

31

Page 33

Installatie

Ovenmontage

TRANSPORTBAND

1. Schuif de transportbandmontage door de linker---tunnelopening, totdat het bandwiel binnen de control---box zit. Zie afbeelding 7

Figuur 5.

2. Installeer de aandrijfband op de motor en

daarna om de katrol op de transportbandmontage. Zie afbeelding 7 Figuur 6. Duw de

transportbandmontage naar achteren om de

band te spannen.

OPMERKING: Omde richting van de aandrijfmotor

(indiennoodzakelijk)om te schakelenmoetenA1enA2wordenverwisseld. Zie afbeelding 7 Figuur 7.

WAARSCHUWING!!

Sluit de elektriciteit af voordat de richting

van de aandrijfmotor wordt omgeschakeld.

W

AC

AC

L2 L1

A1 A2 A3

W

V

BK

GND

D C --- M O T O R

Y OR BL

S2

S3

S N E L H EI D S ---

CONTROLE

S1

Figuur 5

Figuur 6

Figuur 7

KRUIMELBAKKEN

1. Installeerde kruimelbakken onder elk uiteinde

van de transportband.

Figuur 8

32

Page 34

Installatie

Aansluitingen op openbare voorzieningen

GASAANSLUITINGEN (indien van toepassing)

Sluit de oven aan op een gasleiding met het juiste

soortgas, in overeenstemming met plaatselijke en

nationale normen.

De oven instellen voor andere soorten gas

1. Verwijder het deurtje van de control---box en

de bandbeschermer.

2. Verwijder alle gasleidingen en de brandermontage uit de oven.

3. Verwijder de vier schroeven die de aanjager

en bandbeschermer aan de brandermontageflens vastzetten. Haal de aanjager en bandbeschermer uit de brander.

4. Schroef de gasleiding bij de inlaat van de gasklep los.

5. Alleen voor Frankrijk en Bel gië --- D e n i p p e l

op de inlaat van de gasklep moet worden vervangen. Bij aardgasovens zit binnenin deze

nippel een 3,2 mm groot restrictie---apparaat.

Om over te schakelen van aardgas naar propaan/butaangas moet de nippel met het restrictie---apparaat worden verwijderd, en worden vervangen door een nippel zonder

restrictie---apparaat.

Om over te schakelen van propaan/butaangas naar aardgas moet de nippel zonder restrictie---apparaat worden verwijderd, en worden vervangen door een nippel met

restrictie ---apparaat. Plaats de nippel zodanig

zodat het restrictie---apparaat dichtbij de klep,

en het open uiteinde dichtbij de elleboog van

de leiding zit.

6. Schroef de gasklep en de rest van de leiding

los, tot en met de koppeling waar het de slang

van de brander binnengaat.

7. Verwijderdepakkingringdiedevonk---en

vlamvoeldraden vastzetten.

8. Pak de voorkant van de meetschijfmontage

beet, en duw de fitting bovenop de branderslang tegelijkertijd omlaag. Trek de meetschijfmontageuitde voorkant van de branderslang.

OPMERKING: Wees voorzichtig en verlies de

afstandsring niet die om de nippel bij de inlaat van de meetschijfmontage past; deze ring

moet opnieuw worden gebruikt.

9. Verwijder de vonk--- en vlam- --meetelektrodes

uit de meetschijfmontage. Installeer ze opnieuw

op dezelfde plaats op de nieuwe meetschijfmontage.

10. Voer de procedure in omgekeerde volgorde

uit om de brander opnieuw te monteren.

OPMERKING: Vergeet niet de afstandsring

weer te installeren en schroefdraad ---afdichtingsmiddel te

gebruiken als de fittingen van

de leidingen weer worden aangesloten.

11. Installeer de gasklep en brandermontage

weer in de oven.

G a s d r u k --bijstelling

Ontkoppel de

Ontkoppel de

gasleiding hier

Drukkraan

A a n j a g er --montageschroeven

gasleiding hier

Pakkingring voor

vonk- en vlamvoeldraden

Bandbeschermer--montagebeugel

Figuur 9

33

Page 35

Installatie

V

G20/G2520/25Volledigingeschroefde

1,40N.v.t.1

1,7Aardga

s

Aansluitingen op openbare voorzieningen

Soort

gas

Inlaat--

druk

mbar

Branderdruk

mbar

Injector--

diameter

mm

Lucht--

opening

mm

Standaard-- toeleve-

rings--

waarde kW (H

G25 25 12 1,40 N.v.t. 11,7 Aardgas

G20 20 8,0 1,40 N.v.t. 11,7 Aardgas

G20/G25 20/25

olledigingeschroefde 1,40 N.v.t. 11,7Aardgas

drukregulateur

G30 30/50 6 1,1 N.v .t. 11,7 Butaan

G31 30/37/50 8 1,1 N.v.t. 11,7 Propaan

ELEKTRISCHE AANSLUITINGEN

OPMERKING: Elektrische aansluitingen moeten

uitsluitend door een bevoegde installateur worden uitgevoerd

OPMERKING: De elektriciteitsaansluiting moet

voldoen aan nationale en plaatselijke normen.

Een spanningsontlasting voor het netsnoer is vereist. De installateur moet een netsnoerdraagbus

leverendieaan alleplaatselijkeen nationaleinstallatienormen voldoet.

Voor gasmodellen:

OPMERKING: Gasmodellen hebben een fase---

Sluit uitlaatventilator---aansluitingen 1 en 2 aan.

Zie afbeelding 10 Figuur 10.

Aansluitfase + neutraal + aarding.

Voor elektrische modellen:

Sluit de oven aan op een aparte 230 V, 50 Hz

stroomvoorziening met een starre aansluiting en

stroomverbreker. De stroomverbreker moet alle

polen inclusief neutraal uitschakelen, met een

contactafscheiding van minstens 3 mm.

Sluit L1 + L2 + L3 + neutraal + aarding aan.

brander. Als de draden voor fase en

neutraal worden verwisseld wordt

de regelaar afgesloten.

gevoelige regelinstallatie voor de

)

S

L3

L2

L1

N

B l o d g e t t ---

Aansluiting

1 – Branderregelaar---solenoïde

2 --- Luchtdrukregulateur

N

L

Aansluiting

1

2

Figuur 10

34

Ventilator

A2

2-4-92

s

2

A1

Relais A

1

Page 36

BEDIENING

N.B.: De bediening is beperkt tot bevoegd per-

soneel.

De oven aanzetten:

1. Zet de handbediende gask lep op AAN. (Al-

leen voor gasmodellen.)

2. Houd de AAN/UIT---knop (2) ingedrukt.

3. Het display geeft weer:WACHTEN – LAGE

INSTELTIJD min/s ec.

4. Het WARMTE---LICHTJE (4) gaat branden als

de oven op temperatuur is.

N.B.: Indienindestartmodusendebrander

komt niet dadelijk aan, gaat het alarmlichtje branden. Druk op de RESET--knop om de brander opnieuw aan te

steken. (Alleen voor gasmodellen.)

N.B.: Als de oven na verscheidene pogingen

nog niet aankomt, moet contact worden

opgenomen met een bevoegde installateur.

Bediening

Bakcomputer

De instellingen voor baktijden zien:

1. Druk op de TIJD---knop (8). De LED op de

knop gaat branden en het display knippert en

geeft weer:TIJD INSTELLEN min/sec.

De ware oventemperatuur weergeven:

1. Druk op de WARE TEMP---knop (6). De LED

op de knop gaat branden en het display geeft

weer: WARE TEMP nnnn C.

Het temperatuurinstelpunt zien:

1. Druk op de TEMP INST---knop (6). De LED op

de knop gaat branden en het display knippert

en geeft weer: INSTELTEMP nnnn C.

De oven afzetten:

1. Druk op de AAN/UIT---knop (2). De ventilatoren blijven draaien totdat de oven afgekoeld

is.

2. Zet de handbediende gasklep op UIT. (Alleen

voor gasmodellen.)

10

1

56789

Afbeelding11

4

2

3

35

Page 37

Bediening

Bakcomputer

PROGRAMMEERPROCEDURES

De baktijd programmeren:

1. Druk op de PROGRAMMEREN/INVOEREN --knop (9).

2. Druk op de TIJD ---knop (8). Het display geeft

weer: PROG-?TIJDINSTELLEN-?____.

3. Gebruik de CIJFER---knoppen (3) om de gewenste baktijd in te stellen. Druk op de WISSEN --- k n o p (5) a l s u e e n v e r g i s s i n g ma a k t e n voer het getal opnieuw in.

4. Druk tweemaal op de PROGRAMMEREN/INVOEREN ---knop (9) om de nieuwe tijd op te

slaan.

De temperatuur programmeren:

1. Druk op de PROGRAMMEREN/INVOEREN --knop (9).

2. Druk op de TEMP INST---knop (6). Het display

geeft weer: PROG-? TEMP INSTELLEN-? _ _ _ C.

3. Gebruik de CIJFER---knoppen (3) om het gewenste temperatuurinstelpunt in te voeren.

Druk op de WISSEN---knop (5) als u een vergissing maakt en-voer het getal opnieuw in.

4. Druk tweemaal op de PROGRAMMEREN/INVOEREN---knop (9) om de nieuwe temperatuur in te stellen.

36

Page 38

Onderhoud

Reinigen en onderdelen vervangen

REINIGEN

OPMERKING: Besproei de oven NIET met een wa-

terstraal.

Dagelijks

1. Haal de kruimelbakken eruit en reinig ze.

2. Reinig de transportband met een borstel.

Elke drie maanden

1. Reinig de axiale ventilatorbeschermers.

Één keer per half jaar

1. Verwijder de transportband en geleiders.

2. Maak de binnenkant van de oven schoon.

Jaarlijks

Een bevoegd onderhoudstechnicus van de fabriek moet:

1. Het bedieningspaneel, de ovenruimte, brander en ventilatoren reinigen.

2. De elektrische hoofdaansluitingen controleren.

3. De aandrijfmotor controleren. De koolborstels

vervangen.

4. De aandrijfketting reinigen en smeren.

5. De gasinstelling controleren en bijstellen. (Alleen voor gasmodellen.)

VERVANGING VAN ONDERDELEN

Elektrische onderdelen

1. Draai het gas af (indien van toepassing).

Schakel de elektrische hoofdaansluiting uit.

2. Haal de hoes van de control---box af.

3. Vervang de kapotte onderdelen.

4. Zet de hoes weer op de control---box.

5. Schakel de elektrische hoofdaansluiting in.

Draai het gas aan (indien van toepassing).

Gasregelcombinatie

OPMERKING: Alleen voor gasmodellen.

1. Draai het gas af. Schakel de elektrische

hoofdaansluiting uit.

2. Verwijder de gasaansluiting aan beide kanten

van de regelcombinatie.

3. Vervang de gasaansluiting en stel hem a f.

Controleer op gaslekken.

4. Schakel de elektrische hoofdaansluiting in.

Draai het gas aan.

De brander verwijderen

OPMERKING: Alleen voor gasmodellen.

1. Draai het gas af. Schakel de elektrische

hoofdaansluiting uit.

2. Verwijder de gasaansluiting.

3. Verwijderdevierschroevenuit demontageplaat van de brander. Verwijder de brander.

4. Vervang indien nodig de waakvlaminstallatie.

5. Installeer de brander weer.

6. Schakel de elektrische hoofdaansluiting in.

Draai het gas aan.

Koelventilatoren

1. Draai het gas af (indien van toepassing).

Schakel de elektrische hoofdaansluiting uit.

2. Haal het achterpaneel van de oven af. Verwijder indien nodig de isolatie.

3. Ontkoppel en vervang de defecte ventilatoren.

4. Zet de isolatie er weer in en het achterpaneel

vandeovererweerop.

5. Schakel de elektrische hoofdaansluiting in.

Draai het gas aan (indien van toepassing).

Verbrandingsruimte

OPMERKING: Alleen voor gasmodellen.

1. Draai het gas af.

2. Verwijder de afdekplaat van de verbrandingsruimte en de isolatie.

3. Maak de verbrandingsruimte schoon.

4. Zet de isolatie er weer in en de afdekplaat er

weer op.

5. Draai het gas aan.

Onderdelen van het bedieningspaneel

1. Draai het gas af (indien van toepassing).

Schakel de elektrische hoofdaansluiting uit.

2. Verwijder de schroeven uit de onderkant van

de oven, die de control---box vastzetten.

Schuif het bedieningspaneel eruit.

3. Vervang het defecte onderdeel.

4. Zet het bedieningspaneel er weer in.

5. Schakel de elektrische hoofdaansluiting in.

Draai het gas aan (indien van toepassing).

37

Page 39

Onderhoud

Plaatsen waar de onderdelen zich bevinden

MT1828G

Motoraandrijfkaart

H o g e l i m i e t --resetknop

Koelventilatoren

Luchtstroming --drukschakelaar

Luchtstroming --drukschakelaar

B r a n d e r --ontstekings--controle

Stroomtoevoer-- aansluiting

Branderaanjager--montage

Aandrijfband

Gasregulateurklep

Aandrijfmotor transportband

Figuur 12

38

Page 40

H o g e l i m i e t --resetknop

Onderhoud

Plaatsen waar de onderdelen zich bevinden

MT1828E

Motoraandrijfkaart

Koelventilatoren

Bedieningsstroom- -toevoer--- en

relaismontage

Ve r w a r m in g s --element--schakelaar

Stroomtoevoeraansluiting

A a n j a g er m o t o r --schakelaar

Neer--transformator

Aandrijfband

Aandrijfmotor

transportband

Figuur 13

39

Page 41

Onderhoud

Problemen oplossen

MOGELIJKE OORZA(A)K(EN) AANBEVOLEN OPLOSSING

SYMPTOOM: Aanjaagmotor(en) loopt (lopen) niet

S

Aanjaagregeling staat uit

S

Geen stroom naar de oven

S

Motorzekeringen doorgeslagen

S

Regelcircuitzekering doorgeslagen

SYMPTOOM: Brander komt niet aan of de elementen worden niet warm

S

Besturing is uitgeschakeld

S

Aanjaagmotor(en) loopt (lopen) niet

S

Oven niet ingesteld boven omgevingstemperatuur

S

Handbediende gasklep gesloten (alleen voor

gasmodellen)

S

Op Aanjager aan zetten

S

Vervanghoofdzekeringen of reset de stroomverbrekers

S

Vervang zekeringen

S

Vervang zekeringen

S

Zet de regelaar aan

S

Controleer regelschakelaar en/of zekeringen

S

Stel in op gewenste temperatuur

S

Open de gaskraan

SYMPTOOM: de oven bereikt niet de gewenste temperatuur

S

Gasdruk naar oven is te laag (alleen voor gasmodellen)

S

Warmteregelaar staat uit

S

Geen stroom naar de oven

S

Aanjaagmotor(en) loopt (lopen) niet

SYMPTOOM: Transportband loopt niet

S

Transportbandregeling staat uit

S

Regelcircuitzekering doorgeslagen

S

Band vastgeraakt aan iets in de oven

WAARSCHUWING!!

Trek altijd de stekker uit het stopcontact a lvorens de oven te reinigen of een onderhoudsbeurt

te geven.

S

Neem contact op met plaatselijke vertegenwoordigers gasbedrijf

S

Zet de regelaar aan

S

Vervang hoofdzekeringen

S

Controleer regelschakelaar en/of zekeringen

S

Zet de regelaar aan

S

Vervang de zekering

S

Draai de oven uit, maak band los en los het probleem op

40

Page 42

Four à convoyeur

Série MT1828

Manuel de l’utilisateur

41

Page 43

Installation

Caractéristiques techniques du four

Caractéristiques

techniques

Largeur du tapis 46 cm (18”)

Longueur zone de

cuisson

Surfacedecuisson .34 m2(3.7 Sq. Ft.)

Dimensions

(une seule unité)

Tem pér atu r e de

fonctionnement

maximum

Espace de dégagement 9,5 cm (3,75”)

Apport maximum 11.7 kW/h. (40,000 BTU/h.) 11.1 KW/h.

Alimentation 230 VCA, 1Φ, 50Hz, 3 fils, 15 Amp 230/400 VCA, 3Φ, 50Hz, 5 fils, 17 amp

Alimentation gaz Voir le schéma en page 47 Aucune

71 cm (28”)

104 cm x 89 cm x 46 cm (41” x 35” x 18”)

315_C (600_F)

MT1828G/AB MT1828E/AA

42

Page 44

Installation

Livraison et emplacement

LIVRAISON ET INSPECTION

Tous les fours Blodgett sont livrés dans des conteneurs afin de prévenir tout dommage. A lalivraison

de votre nouveau four:

D

Inspectez le conteneur de transport afin de vérifier qu’il ne présente aucun dommage extérieur.

Mentionneztoutetracededommagesurlerécépissé de livraison, lequel doit être signé par

le chauffeur.

D

Déballez le four et vérifiez qu’il ne présente aucun dommage. Les transporteurs n’acceptent

les réclamations pour dommages non apparentsques’ilssontnotifiésdanslesquinzejours

de la livraison et si le conteneur de transport est

conservé pour inspection.

La Bl odgett Oven Company ne peut être tenue

responsable d’aucune perte ou dommage survenu durant le transport. Après acceptation du

transport, le transporteur est tenu de livrer la

marchandise en bon état. Nous sommes toutefois disposés à vous aider à déposer une réclamation, si nécessaire.

EMPLACEMENT DU FOUR

Le choix d’ un emplacement bien étudié et approprié sera décisif pour garantir à l’utilisateur du four

une facilité d’emploi à long terme et des performances satisfaisantes.

D

Placez le four au moins à 5cm du mur arrière et

à 50 cm du mur latéral.

D

Placez le four dans un endroit suffisamment

ventilé.

D

Placez le four en dessous d’une hotte, conformément aux normes d’installation locales et nationales.

D

Installezlefourdetellesortequelaprised’alimentation soit accessible.

Le four peut maintenant être déplacé vers le lieu

d’installation. Vérifier la liste ci--- dessous à l’aide

de la Figure 1 pour s’assurer de la réception de

tous les composants.

Description de la pièce

Qté

Corps principal du four 1

Ensemble tapis du convoyeur 1

Collecteurs de déchets 2

Paquets 2

Barre de retenue du produit 1

Ensemble convoyeur

(illustré sans tapis)

Barre de retenue

du produit

Collecteurs de déchets

Figure 1

43

Page 45

Installation

Montage du four

NOTE: Cet appareil doit être installé conformé-

ment aux normes en vigueur et être utilisé

dans une pièce bien- ventilée. Consultez

les instructions avant l’installation et l’utilisation de cet appareil. L’installation doit

être effectuée par un installateur qualifié.

PIEDS

1. Enlevezlefourdesacaissed’emballage.

2. Couchez le four sur sa face arrière. Vissez un

pied dans chacun des quatre trous situés

dans le fond de la chambre de cuisson.

3. Fixez l’écrou hexagonal au ---dessus de chaque pied.

4. Soulevez le four et faites---le reposer sur ses

pieds.

Face inférieure du

four

Pied

Sommet

Cadre du

bâti

du bâti

Etagère

Figure 3

EMPILAGE DES FOURS

1. Couchez le four supérieur sur sa face arrière.

Placez une goupille d’alignement du four

dans chacun des quatre trous pratiqués dans

le fond du four.

2. Soulevez avec précaution le four de la palette

et placez---le sur le four inférieur. Veillez à ce

que les goupilles d’alignement soient insérées dans les trous au sommet du four inférieur.

Figure 2

BÂTI DU FOUR AVEC ROULETTES

1. Fixez chaque pied au cadre du bâti avec une

rondelleet un écrou. NEPA S visser complètement.

2. Placez l’étagère entre les pieds avec la surface lisse tournée vers le haut du bâti. Alignez

l’étagère avec les trous pratiqués dans chaque pied. Fixez l’étagère à chaque pied avec

unécrouetunboulon.

3. Serrez les écrous placés lors de l’étape n˚ 1.

4. Placez le four sur le bâti. Boulonnez le four au

bâti par le bas.

5. Fixez une patte de retenue sur les modèles au

gaz.

Goupille d’alignement

Four inférieur

Figure 4

44

Page 46

Installation

Montage du four

CONVOYEUR

1. Faites passer l’ensemble convoyeur à travers

le tunnel de gauche jusqu’à ce que le pignon

soit à l’intérieur du boîtier de commande. Voir

Figure 5.

2. Placez la courroie d’entraînement sur le mo-

teur, puis autour de la poulie sur l’ensemble

convoyeur. Voir Figure 6. Poussez l’ensemble

convoyeur vers l’arrière pour tendre la courroie.

NOTE: Pour inverser le sens du moteur d’entraî-

nement (si nécessaire), intervertir A1 et

A2. Voir Figure 7.

AVERTISSEMENT!!

Débranchez le cordon d’alimentation

avant d’inverser le moteur d’entraînement.

B

CA

CA

L2 L1

A1 A2 A3

B

V

N

TERRE

MOTEUR CC

J OU BL

S2

S3

COMMANDE

S1

VITESSE

Figure 5

Figure 6

Figure 7

COLLECTEURS DE DÉCHETS

1. Placez les collecteurs de déchets sous chaque extrémité du convoyeur.

Figure 8

45

Page 47

Installation

Raccordements

RACCORDEMENT AU GAZ (s’il y a lieu)

Branchez le four à l’amenée de gaz (type de gaz

approprié) conformément aux normes d’installation locales et nationales.

Préparation de l’équipement pour d’autres typesdegaz

1. Enlevezlaporteduboîtierdecommandeetle

pr otège --- c o u r r o i e .

2. Retirez du four toutes les conduites de gaz et

l’ensemble brûleur.

3. Enlevez les quatre vis qui maintiennent la

soufflerie et le protège---courroie à la bride de

fixation du brûleur. Enlevez la soufflerie et le

protège---courroie du brûleur.

4. Dévissezlaconduitedegazàl’entréedurobinet de gaz.

5. Franceet Belgique uniquement --- Lemamelon à l’entrée du robinet de gaz doit être remplacé. Sur les fours au gaz naturel, l’intérieur

du mamelon est muni d’un réducteur de 3.2

mm.

Pour passer du gaz naturel au propane/butane, le mamelon avec réducteur doit être enlevé et remplacé par un mamelon sans réducteur.

Pour passer du propane/butane au gaz naturel, le mamelon sans réducteur doit être enlevé et remplacé par un mamelon avec réducteur. Orientez le mamelon de sorte que le

réducteur soit contre le robinet et que l’extrémitélibresoitcontrelecoudedutuyau.

6. Dévissezlerobinetdegazetlerestedutuyau

jusqu’au raccord (celui---ci compris) via lequel

ilentredansletubedubrûleur.

7. Enlevez le passe- --fils qui retient les fils de lecture de flamme et d’étincelle.

8. Saisissez l’avant du nez de buse tout en poussant vers le bas sur la pièce de raccord au

sommet du tube du brûleur. Retirez le nez de

buse à l’avant du tube du brûleur.

NOTE: Veillez à ne pas perdre la rondelle

d’espacement qui entoure le mamelon à l’entrée du nez de buse; elle sera

réutilisée.

9. Enlevez les électrodes de lecture de flamme et

d’étincelle du nez de buse. Replacez---les dans

lamêmepositionsurlenouveaunezdebuse.

10. Inversez la procédure pour remonter le brûleur.

NOTE: Veillez à remettre la rondelle d’espa-

cementet utilisez une pâted’étanchéité pour joints filetés lors de la remise

en place des raccords de tuyauterie.

11. Replacez le robinet de gaz et l’ensemble brûleur dans le four.

Réglage

pression de gaz

Débrancher le

Débrancher le

tuyau de gaz ici

Robinet manométrique

Vis de montage

de la soufflerie

tuyau de gaz ici

Passe---fils

pour fils de

lecture

flamme &

étincelle

Support de montage

du protège--- courroie

Figure 9

46

Page 48

Installation

G20/G2520/25Régulateurdepressio

n

1,40s.o.1

1,7gaznat

Raccordements

Type d e

gaz

Pression

d’entrée

mbars

Pression bûleur

mbars

Diamètre

injecteur

mm

Ouverture

d’air

mm

Débit standard

en kW (H

G25 25 12 1,40 s.o. 11,7 gaz nat.

G20 20 8,0 1,40 s.o. 11,7 gaz nat.

G20/G25 20/25 Régulateur depression 1,40 s.o. 11,7gaz nat.

totalement dévissé

G30 30/50 6 1,1 s.o. 11,7 butane

G31 30/37/50 8 1,1 s.o. 11,7 propane

BRANCHEMENT ÉLECTRIQUE

NOTE: Le branchement électrique doit être effec-

tué par un installateur qualifié.

NOTE: Le branchement électrique doit être

conforme aux règlements nationaux et locaux.

Le cordon d’alimentation doit être muni d’un serre---câble. L’installateur doit fournir un manchon

pour le cordon d’alimentation répondant à toutes

les normes d’installation locales et nationales.

Pour les modèles au gaz:

NOTE: Sur les modèles au gaz, l’unité de com-

Raccordez les connecteurs 1 et 2 du ventilateur

d’extraction. Voir Figure 10.

Branchez phase + neutre + terre.

Pour les modèles électriques:

Connectez le four à un groupe 230V, 50 hz distinct

avec une connexion rigide et un disjoncteur. Le

disjoncteur doit débrancher tous les pôles, y compris le neutre, avec un écartement de contact d’au

moins 3 mm.

Branchez L1 + L2 + L3 + neutre + terre.

Silaphaseetleneutresontintervertis,la

commande est verrouillée.

mande du brûleur est asservie en phase.

)

S

.

L3

L2

L1

N

Connecteur

Blodgett

1--- Solénoïdedecommandedubrûleur

2 --- Régulateur de pression d’air

N

L

Connecteur

2-4-92

s

2

1

2

Ventilateur

A2

A1

Relais A

1

Figure 10

47

Page 49

Fonctionnement

Commande électronique

FONCTIONNEMENT

NOTE: L’utilisation de l’appareil est réservée au

personnel qualifié.

Pour allumer le four:

1. Tournez le robinet de gaz manuel sur ON. (Modèles au gaz uniquement.)

2. Appuyez s ur la touche ON/OFF et maintenez---la enfoncée (2).

3. Le message WAIT LOW SET TIME mmss. clignote sur l’écran.

4. Le voyant HEAT (4) s’allume pendant que le

four se met à température.

NOTE: En phase de démarrage, le brûleur ne

s’enflamme pas immédiatement et le

voyant d’alarme s’allume. Appuyez

sur le bouton RESET pour relancer le

brûleur. (Modèles au gaz uniquement.)

NOTE: Si le four ne démarre pas après plusieurs

tentatives, contactez un installateur qualifié.

Pour voir le réglage du temps de cuisson:

1. Appuyezsur la touche TIME (8). Le voyant placé sur la touche s’allume et le message SET

TIME mmss. s’affiche en clignotant.

Pour afficher la température réel le du four:

1. Appuyez sur la touche ACT TEMP (6). Le

voyant placé sur la touche s’allume et le message ACTUAL nnnn. s’affiche.

Pour voir le réglage de la température:

1. Appuyez sur la touche SET TEMP (6). Le

voyant placé sur la touche s’allume et le message SET TEMP nnnn. s’affiche en clignotant.

Pour éteindre le four:

1. Appuyez sur la touche ON/OFF (2). Les ventilateurs continueront à tourner jusqu’à ce que

le four soit refroidi.

2. Tournez le robinet de gaz manuel sur OFF.

(Modèles au gaz uniquement.)

10

1

56789

4

Figure 11

48

2

3

Page 50

PROCÉDURES DE PROGRAMMATION

Programmation du temps de cuisson:

1. Appuyezsur la touche PROGRAM/ENTER (9).

2. Appuyez sur la touche TIME (8). L’écran affiche: PROG-?SETTIME-?____.

3. Utilisez les touches NUMERIQUES (3) pour indiquer le temps de cuisson voulu. En cas d’erreur, appuyez sur la touche CLEAR (5) et réintroduisez le chiffre.

4. Appuyez deux fois sur la touche PROGRAM/

ENTER (9) pour mémoriser le nouveau temps

de cuisson.

Fonctionnement

Commande électronique

Programmation de la température:

1. Appuyezsur la touche PROGRAM/ENTER (9).

2. Appuyez sur la touche SET TEMP (6). L’écran

affiche: PROG-?SETTEMP-?____C.

3. Utilisez les touches NUMERIQUES (3) pour indiquer la température voulue. En cas d’erreur,

appuyez sur la touche CLEAR (5) et réintroduisez le chiffre.

4. Appuyez deux fois sur la touche PROGRAM/

ENTER (9) pour mémoriser la nouvelletempérature.

49

Page 51

Maintenance

Nettoyage et remplacement de pièces

NETTOYAGE

NOTE: NE PAS projeter d’eau sur le four.

Chaque jour

1. Enlevez et nettoyez les collecteurs de déchets.

2. Nettoyez le tapis du convoyeur à l’aide d’une

brosse.

Tou s l es 3 m o is

1. Nettoyez la grille de protection du ventilateur

axial.

Tou s l es 6 m o is

1. Enlevez le tapis du convoyeur et les guides.

2. Nettoyez l’intérieur du four.

Tou s l es 1 2 m ois

Un technicien de maintenance a gréé devrait:

1. Nettoyer le panneau de commande, l’orifice

du four, le brûleur et les ventilateurs.

2. Contrôler les principales connexions électriques.

3. Contrôler le moteur d’entraînement. Rempla cer les balais de carbone.

4. Nettoyer et lubrifier la chaîne d’entraînement.

5. Contrôler et ajuster le réglage de gaz. (Modèles au gaz uniquement.)

REMPLACEMENT DE PIÈCES

Composants électriques

1. Fermez l’arrivée de gaz (s’il y a lieu). Coupez

l’alimentation électrique principale.

2. Enlevez le couvercle du boîtier de commande.

3. Remplacez les composants défectueux.

4. Replacez le couvercle du boîtier de commande.

5. Rallumez l’alimentation électrique principale.

Ouvrez l’arrivée de gaz (s’il y a lieu).

Couplage de commande du gaz

NOTE: Modèles au gaz uniquement.

1. Coupez l’arrivée de gaz. Coupez l’alimentation électrique principale.

2. Enlevez le raccord de gaz des deux côtés du

couplage de commande.

3. Replacez et ajustez le raccord de gaz. Assurez---vous de l’absence de fuite.

4. Rallumez l’alimentation électrique principale.

Ouvrez l’arrivée de gaz.

Démontage du brûleur

NOTE: Modèles au gaz uniquement.

1. Coupez l’arrivée de gaz. Coupez l’alimentation électrique principale.

2. Déconnectez le tuyau de gaz.

3. Retirez les quatre vis de la plaque de fixation

du brûleur. Enlevez le brûleur.

4. Replacez le pilote si nécessaire.

5. Réinstallez le brûleur.

6. Rallumez l’alimentation électrique principale.

Ouvrez l’arrivée de gaz.

Ventilateurs de refroidissement

1. Fermez l’arrivée de gaz (s’il y a lieu). Coupez

l’alimentation électrique principale.

2. Enlevez le panneau arrière du four. Enlevez

l’isolation si nécessaire.

3. Déconnectez et remplacez les ventilateurs défectueux.

4. Réinstallez l’isolation et le panneau arrière du

four.

5. Rallumez l’alimentation électrique principale.

Ouvrez l’arrivée de gaz (s’il y a lieu).

Chambredecombustion

NOTE: Modèles au gaz uniquement.

1. Coupezl’arrivéedegaz.

2. Enlevez la plaque de fermeture de la chambre

de combustion et l’isolation.

3. Nettoyez la chambre de combustion.

4. Réinstallez l’isolation et la plaque de fermeture.

5. Ouvrez l’arrivée de gaz.

Composants du tableau de commande

1. Fermez l’arrivée de gaz (s’il y a lieu). Coupez

l’alimentation électrique principale.

2. Enlevez les vis situées dans le bas du four qui

maintiennent la commande. Enlevez le panneau de commande en le faisant glisser.

3. Remplacez les composants défectueux.

4. Réinstallez le panneau de commande.

5. Rallumez l’alimentation électrique principale.

Ouvrez l’arrivée de gaz (s’il y a lieu).

50

Page 52

MT1828G

Maintenance

Emplacements des composants

Bouton de redémarrage

Limite haute

Pressostat

débit d’air

Commande

d’allumage

du brûleur

Panneau moteur

Ventilateurs de

refroidissement

Pressostat

débit d’air

Ensemble soufflerie

du brûleur

Courroie d’entraînement

Raccordement

alimentation

électrique

Vanne régulateur de gaz

Moteur d’entraînement

du convoyeur

Figure 12

51

Page 53

Maintenance

Emplacements des composants

MT1828E

Ensemble relais

et alimentation

de commande

Contacteur

élément

chauffant

Bouton de redémarrage

Limite haute

Panneau moteur

Ventilateurs de refroidissement

Contacteur

moteur de soufflerie

Transformateur

réducteur

Courroie d’entraînement

Raccordement

alimentation électrique

Moteur d’entraînement

du convoyeur

Figure 13

52

Page 54

Maintenance

CAUSE(S) POSSIBLE(S) SOLUTION PROPOSEE

SYMPTOME: Le(s) moteur(s) de la soufflerie ne fonctionne(nt) pas.

S

La commande de la soufflerie est éteinte (off).

S

Le four n’est pas alimenté

S

Les fusibles du moteur ont sauté

S

Le fusible du circuit de commande a sauté

SYMPTOME: Le brûleur ne s’enflamme pas ou les éléments ne chauffent pas

S

La commande est éteinte (off)

S

Le(s) moteur(s) de la soufflerie ne fonctionne(nt)

pas.

S

Le réglage du four ne dépasse pas la température ambiante

S

Le robinet de gaz manuel est fermé (modèles au

gaz uniquement)

S

Mettrelasouffleriesur’on’

S

Remplacer les fusibles principaux ou réamorcer

les disjoncteurs

S

Remplacer les fusibles

S

Remplacer les fusibles

S

Mettre la commande sur ’on’

S

Vérifier l’interrupteur de commande et/ou les fusibles

S

Régleràlatempératurevoulue

S

Ouvrir le robinet

Dépannage

SYMPTOME: Le four n’atteint pas la température voulue

S

La pression de gaz vers le four est trop basse

(modèles au gaz uniquement)

S

La commande de chaleur est éteinte (off).

S

Le four n’est pas alimenté

S

Le(s) moteur(s) de la soufflerie ne fonctionne(nt)

pas.

SYMPTOME: Le tapis du convoyeur ne fonctionne pas

S

La commande du convoyeur est éteinte (off)

S

Le fusible du circuit de commande a sauté

S

Tapis accroché ou objet dans le four

AVERTISSEMENT!!

Toujours débrancher le câble d’alimentation avant de nettoyer ou d’entretenir le four.

S

Appelerleservicelocaldugaz

S

Mettre la commande sur ’on’

S

Remplacer les fusibles principaux

S

Vérifier l’interrupteur de commande et/ou les fusibles

S

Mettre la commande sur ’on’

S

Remplacerlefusible

S

Eteindre le four, décrocher et résoudre le problème

53

Page 55

MT1828---Serie

Förderofen --- Bedienerhandbuch

54

Page 56

Installation

Technische Daten des Ofens

Tec hn isc he D a te n MT1828G/AB MT1828E/AA

BandbreiteBandbreite 46 cm

Länge der Kochzone 71 cm

Backbereich .34 m

Maße (Einzelanlage) 104 cm x 89 cm x 46 cm

2

M a x imale B e t r i e b s --temperatur

Produktspiel 9,5 cm

Maximale

Leistungaufnahme

Netzanschluss 230V~ , 1Φ, 50 Hz, 3 Adern,

Gasversorgung Siehe Abbildung auf Seite 60 Keine

315_ C (600_F)

11,7 kW/h. 11,1 kW/h.

230/400 V~ , 3Φ, 50Hz, 5 Adern,

15 Amp

17 Amp

55

Page 57

Installation

Lieferung und Standort

LIEFERUNG UND ÜBERPRÜFUNG

Alle Blodgett --- Öfen werden in Containern geliefert, um Beschädigungen zu vermeiden. Lieferung

Ihres neuen Ofens:

D

Überprüfen Sie den Transportcontainer nach

äußeren Schäden. Jedes Anzeichen einer Beschädigung sollteauf dem Lieferschein, der von

dem Fahrer unterzeichnet werden muss, notiert

werden.

D

Packen Sie den Ofen aus und überprüfen Sie

ihn auf Beschädigungen. Spediteure a kzeptie ren Ersatzansprüche für versteckte Schäden,

wenn sie innerhalb von 15 Tagen nach Lieferung geltend gemacht werden und der Transportcontainer zum Überprüfen aufbewahrt

wird.

Die Blodgett Oven Company kann für den Verlust oder für Schäden während des Transports

keine Haftung übernehmen. Der Spediteur

trägt die volle Verantwortung für eine ordnungsgemäße Lieferung, sobald die Lieferung