Page 1

MARK V SERIES

CONVECTION OVEN

SERVICE AND REPAIR MANUAL

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (802) 658Ć6600 Fax: (802)864Ć0183

PN 33144 Rev F (7/02)

Duplication of the information in this manual is prohibited without the consent of the Blodgett Service Department.

E 2002 - G.S. Blodgett Corporation All rights reserved.

Page 2

TABLE OF CONTENTS

1. INTRODUCTION

Oven Specifications 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. OPERATION

Sequence of Operations 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cook Only - 18459 Rev D 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Approved Cook Only - 33339 Rev C 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cook and Hold - 18791 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Digital - 30070 Rev B 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Approved Solid State Digital - 33345 Rev C 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Delay with Pulse Plus - 18466 Rev D 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Humidaire - 1846 Rev M 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellihold and Intelliplus - 22027 Rev A 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch - 19361 Rev A 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blodgett IQ Control - 33078 Rev A 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CALIBRATION AND ADJUSTMENT

Doors 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Blower Switch 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostat 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Manual 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Digital Control 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellihold and Intelliplus Controls 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch Control 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch II Control 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blodgett IQ Control 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blodgett IQ2T Control Factory Level Programming 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IQ VVCĆ208 Control 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Resistance vs Heating Elements 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Resistance vs Temperature 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. TROUBLESHOOTING

Heat System 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Error Codes 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellihold and Intelliplus 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blodgett IQ Control 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 3

TABLE OF CONTENTS

5. PARTS REPLACEMENT

Door Assembly 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Arm Support Assembly 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window Assembly 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compartment Liner Bottom 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor and Blower Assembly 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Wheel 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Components 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bulb and Capillary Thermostat 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Components Located in the Control Module 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Switch 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 4

CHAPTER 1

INTRODUCTION

Page 5

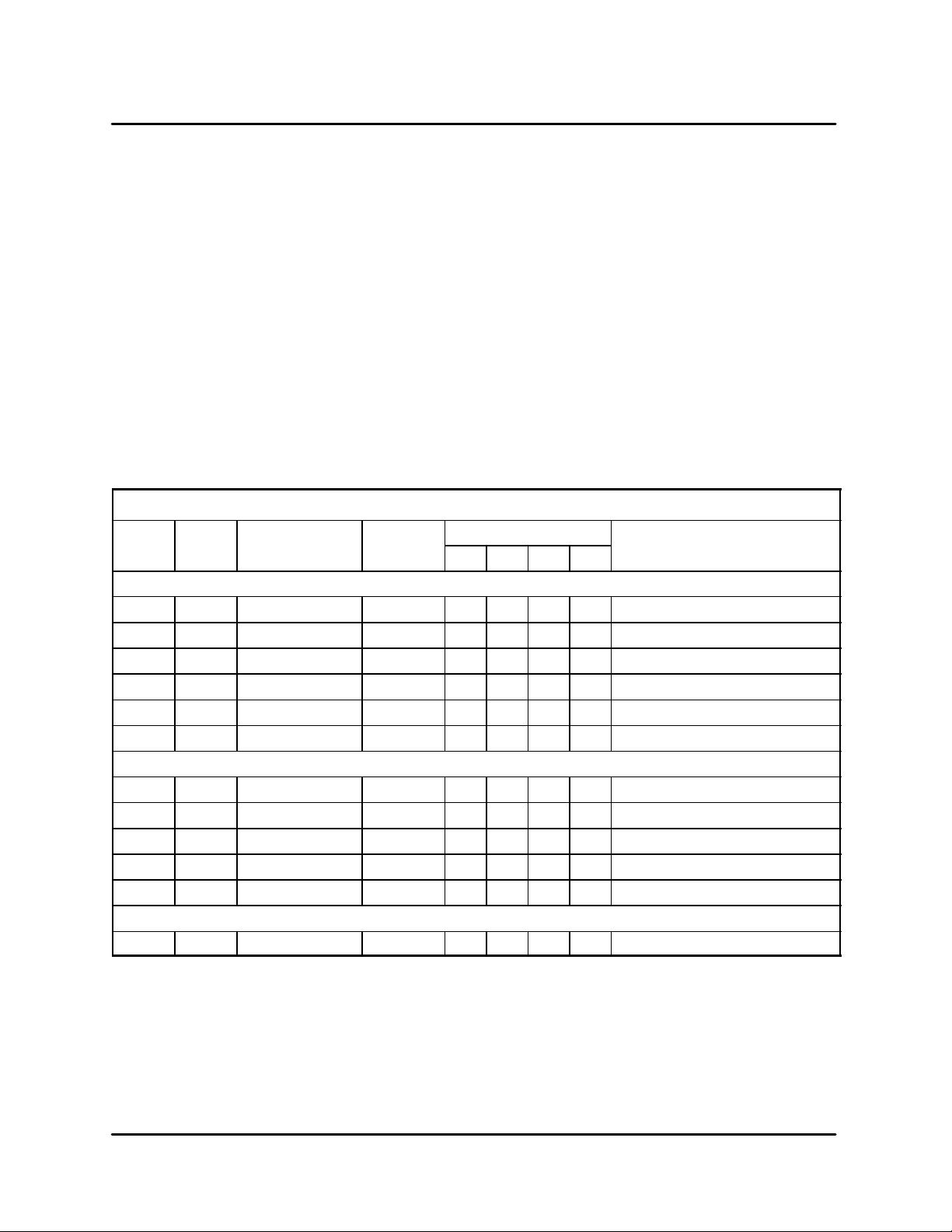

MARK V

OVEN SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

Installations within the U.S. and Canada

Single phase models require a 60 Hz,

208/240VAC, 3 wire service consisting of L1, L2

and ground. Three phase models require a 60 Hz,

208/240/440/480, 4 wire service consisting of L1,

L2, L3 and ground. Wiring from the power source

to any of the single phase units must be a minimum

of #6 AWG copper stranded wire. Wiring from the

power source to the 208/240 three phase units

must be a minimum of #8 AWG copper stranded

wire. Wiring from the power source to the 440/480

three phase units must be a minimum of #12 AWG

copper stranded wire.

ELECTRICAL SPECIFICATIONS (per section)

KW Hz Volts Phase

U.S. and Canadian installations

11.0 60 208 1 51 - 51 - 6 AWG

11.0 60 208 3 31 29 29 - 8 AWG

11.0 60 220Ć240 1 44 - 44 - 6 AWG

11.0 60 220Ć240 3 26 24 24 - 8 AWG

11.0 60 440 3 15 14 14 - 12 AWG

11.0 60 480 3 14 13 13 - 12 AWG

General Export installations

11.0 50 208 3 18 18 18 4 Size per local code

11.0 50 220Ć240 1 48 - - 48 Size per local code

11.0 50 220/380 3 18 16 16 2 Size per local code

11.0 50 240/415 3 18 14 14 4 Size per local code

11.0 50 230/400 3 18 15 15 3 Size per local code

CE installations

11.0 50 400 3N 18 15 15 3 Size per local code

General Export Installations

Single phase models require a 50 Hz,

220/240VAC, 3 wire service consisting of L1, L2

and ground. Three phase models require a 50 Hz,

415/240 or 380/220 VAC, 5 wire service consisting

of L1, L2, L3, neutral and ground. Use 90_C wire

and size according to local codes.

CE approved installations

Single phase models require a 50 Hz, 230VAC 3

wire service consisting of L1, neutral and ground.

Three phase models require a 50 Hz, 400/230VAC,

5 wire service consisting of L1, L2, L3, neutral and

ground. Use 90_C wire and size according to local

codes.

Amps

L1 L2 L3 N

Electrical Connection

(minimum size)

1-1

Page 6

CHAPTER 2

OPERATION

Page 7

MARK V

SEQUENCE OF OPERATIONS

NOTE: The following instructions represent the most common controllers. For questions regarding other

options call the Blodgett Service Department at (800)331Ć5842.

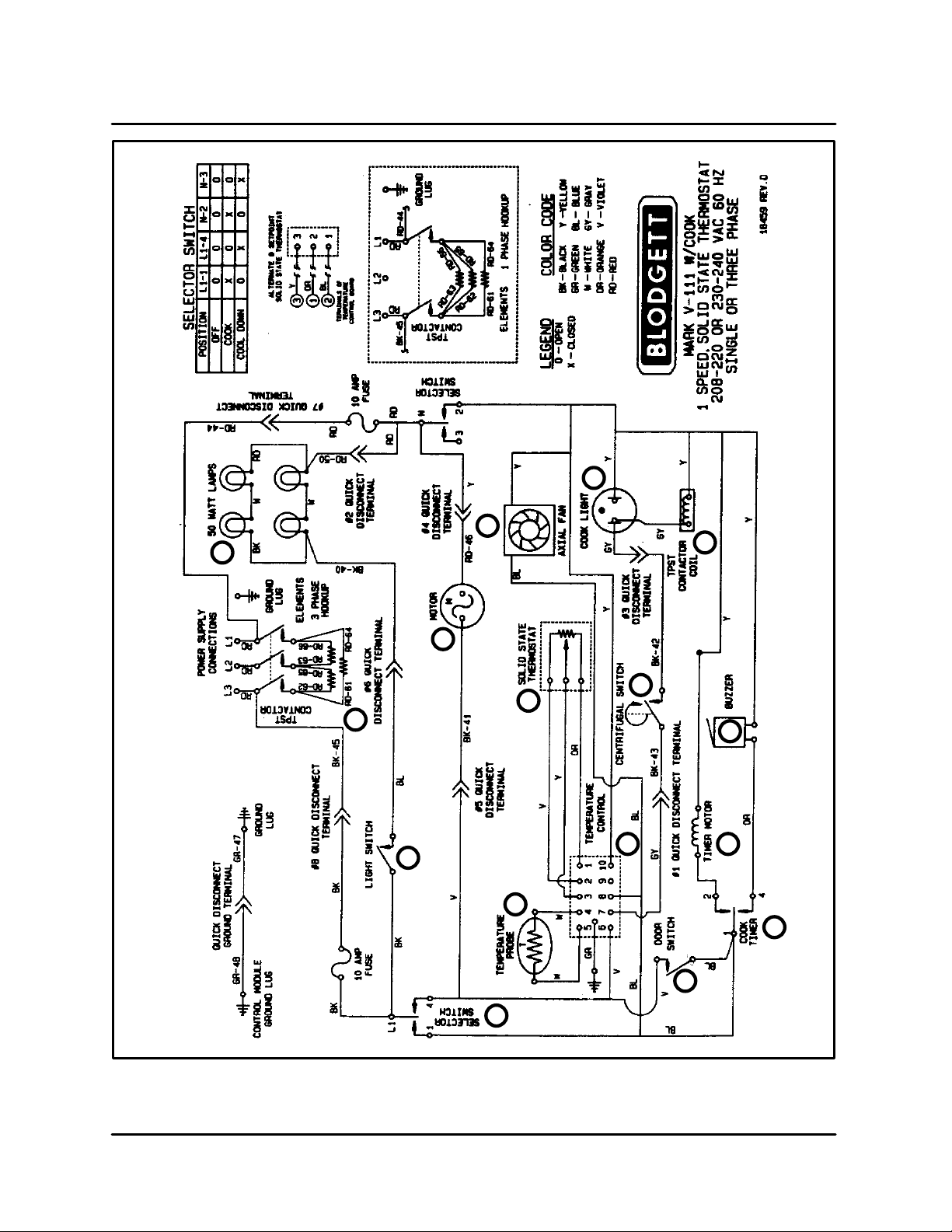

COOK ONLY - 18459 REV D

Component Reference

NOTE: Refer to FIGURE 1 page 2-2 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOK TIMER

3. DOOR SWITCH

4. TEMPERATURE CONTROL BOARD

5. AXIAL FAN

6. CONV ECTION FAN MOTOR

7. TEMPERATURE PROBE

8. SOLID STATE POTENTIOMETER

9. CENTRIFUGAL SWITCH

10. COOK LIGHT

11. ELEMENT CONTACTOR

12. HEATING ELEMENTS

13. 50 WATT LAMPS

14. LIGHT SWITCH

15. TIMER MOTOR

16. BUZZER

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to terminal #1 of the

cook timer (2), one side of the door switch (3),

terminal #8 of the temperature control board

(4) and the axial fan (5).

2. If the doors are closed the door switch (3)

should also be closed sending power to termiĆ

nal #6 of the temperature control board (4)

and to the convection fan motor (6).

NOTE: This motor has a built in centrifugal

switch (9) that closes when the motor

reaches full speed. If found faulty do

not bypass, the whole motor should be

replaced.

temperature control board (4) and the

solid state potentiometer (8).

Power is sent out of terminal #7 to one side of

the centrifugal switch (9). If the convection fan

motor (6) is at full speed the centrifugal switch

(9) closes sending power to the cook light (10)

and one side of the element contactor (11).

When the contactor closes the heating eleĆ

ments (12) power up.

4. The 50 watt lamps (13) only receive power when

the light switch (14) is activated. These lamps

are 115 volt and are wired in series parallel.

5. When the cook timer (2) is set for a time a cirĆ

cuit is made between terminals #1 and #2

powering up the timer motor (15). At the expiĆ

ration of the set time the switch in the cook timĆ

er (2) toggles from 1-2 to 1-4 powering up

the buzzer (16).

NOTE: Put the timer in the home position to siĆ

lence the buzzer.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 1.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the resistive values of the

heating elements. The reading should be

taken in a cold state.

3. On a call for heat from the temperature control

circuit, a circuit is completed between termiĆ

nals #6 and #7 of the temperature control

board (4).

NOTE: The temperature control circuit conĆ

sists of the temperature probe (7), the

2-1

Page 8

13

OPERATION

10

5

11

12

14

6

FIGURE 1

9

8

16

4

7

1

15

2

3

2-2

Page 9

MARK V

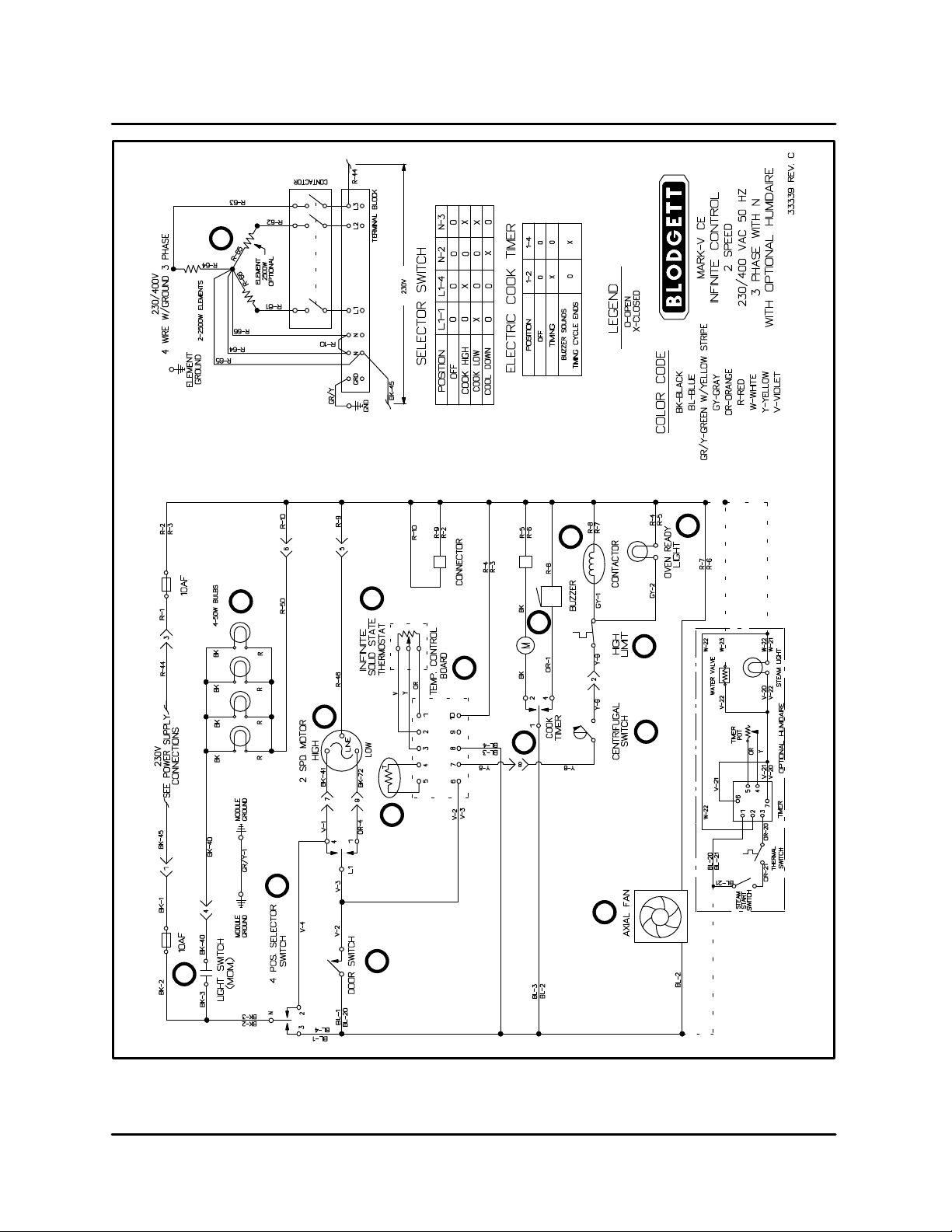

CE APPROVED COOK ONLY - 33339 REV C

Component Reference

NOTE: Refer to FIGURE 2 page 2-4 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOK TIMER

3. DOOR SWITCH

4. TEMPERATURE CONTROL BOARD

5. AXIAL FAN

6. CONVECTION FAN MOTOR

7. TEMPERATURE PROBE

8. SOLID STATE POTENTIOMETER

9. CENTRIFUGAL SWITCH

10. HIGH LIMIT SWITCH

11. ELEMENT CONTACTOR

12. COOK LIGHT

13. HEATING ELEMENTS

14. 50 WATT LAMPS

15. LIGHT SWITCH

16. TIMER MOTOR

17. BUZZER

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to terminal #1 of the

cook timer (2), one side of the door switch (3),

terminal #8 of the temperature control board

(4) and the axial fan (5).

2. If the doors are closed the door switch (3)

should also be closed sending power to termiĆ

nal #6 of the temperature control board (4)

and to the convection fan motor (6).

Power is sent out of terminal #7 to one side of

the centrifugal switch (9). If the convection fan

motor (6) is at full speed the centrifugal switch

(9) closes sending power to one side of a high

limit switch (10), if the high limit is closed then

power will be sent to one side of the contactor

(11) and an indicator light (12). When the conĆ

tactor closes the heating elements (12) power

up.

4. The 50 watt lamps (13) only receive power when

the light switch (14) is activated.

5. When the cook timer (2) is set for a time a cirĆ

cuit is made between terminals #1 and #2

powering up the timer motor (15). At the expiĆ

ration of the set time the switch in the cook timĆ

er (2) toggles from 1-2 to 1-4 powering up

the buzzer (16).

NOTE: Put the timer in the home position to siĆ

lence the buzzer.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 2.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the resistive values of the

heating elements. The reading should be

taken in a cold state.

NOTE: This motor has a built in centrifugal

switch (9) that closes when the motor

reaches full speed. If found faulty do

not bypass, the whole motor should be

replaced.

3. On a call for heat from the temperature control

circuit, a circuit is completed between termiĆ

nals #6 and #7 of the temperature control

board (4).

NOTE: The temperature control circuit conĆ

sists of the temperature probe (7), the

temperature control board (4) and the

solid state potentiometer (8).

2-3

Page 10

13

OPERATION

15

14

11

8

17

4

6

2

7

1

5

3

12

10

9

FIGURE 2

2-4

Page 11

MARK V

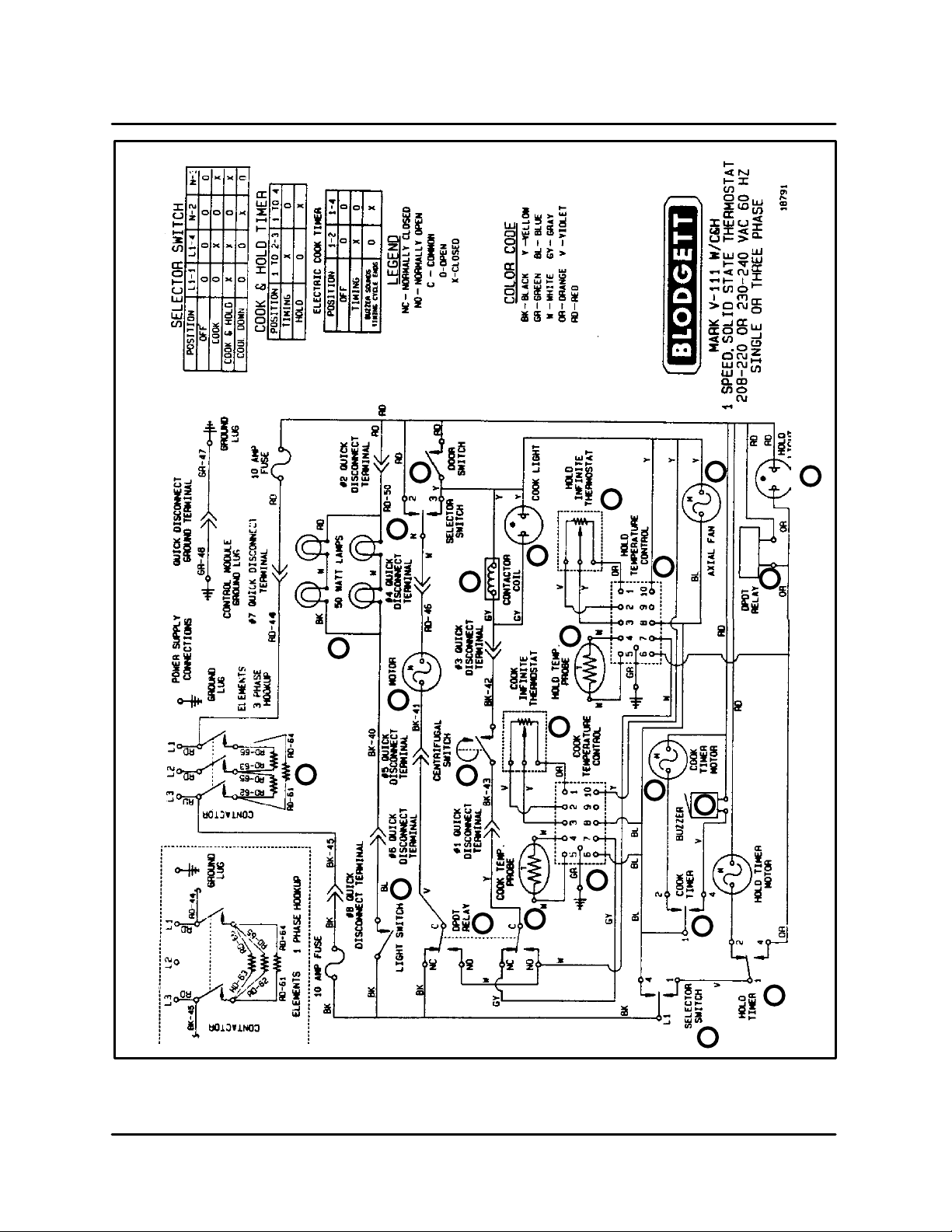

COOK AND HOLD - 18791

Component Reference

NOTE: Refer to FIGURE 3 page 2-7 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOK TIMER

3. COOK TEMPERATURE CONTROL BOARD

4. HOLD TEMPERATURE CONTROL BOARD

5. AXIAL FAN

6. DPDT RELAY COIL

7. DOOR SWITCH

8. CONV ECTION FAN MOTOR

9. TEMPERATURE PROBE

10. SOLID STATE POTENTIOMETER

11. CENTRIFUGAL SWITCH

12. COOK LIGHT

13. ELEMENT CONTACTOR

14. HEATING ELEMENTS

15. TIMER MOTOR

16. BUZZER

17. COOK AND HOLD TIMER

18. COOK AND HOLD LIGHT

19. TEMPERATURE PROBE

20. SOLID STATE POTENTIOMETER

21. 50 WATT LAMPS

22. LIGHT SWITCH

Cook Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to terminal #1 of the

cook timer (2), terminals #6 and #8 of the cook

temperature control board (3), terminal #8 of

the hold temperature control board (4) and the

axial fan (5). Power is also applied to the N.C.

set of contacts in a DPDT relay (6).

NOTE: The coil of this relay will only be actiĆ

vated when the hold timer is set.

2. If the doors are closed the door switch (7)

should also be closed sending power to termiĆ

nal #3 of the mode selector switch (1). The

mode selector switch should already be made

between terminals #3 and N completing the

circuit to the convection fan motor (8).

NOTE: This motor has a built in centrifugal

switch (11) that closes when the motor

reaches full speed. If found faulty do

not bypass, the whole motor should be

replaced.

3. On a call for heat from the cook temperature

control system a circuit is completed between

terminals #6 and #7 of the temperature conĆ

trol board (3).

NOTE: The temperature control system conĆ

sists of the temperature probe (9), the

temperature control board (3) and the

solid state potentiometer (10)

Power is sent out of terminal #7 to the N.C. terĆ

minal of the DPDT relay (6). This relay should

be made between the N.C. terminal and the

common terminal sending power to one side

of the centrifugal switch (11). If the convection

fan motor (8) is at full speed the centrifugal

switch (11) closes sending power to the cook

light (12) and one side of the element contactor

(13). When the contactor closes the heating

elements (14) power up.

4. When the cook timer (2) is set for a time a cirĆ

cuit is made between terminals #1 and #2

powering up the timer motor (15). At the expiĆ

ration of the set time the switch in the cook timĆ

er (15) toggles from 1-2 to 1-4 powering up

the buzzer (16).

NOTE: Put the timer in the home position to siĆ

lence the buzzer.

5. The 50 watt lamps (21) only receive power when

the light switch (22) is activated. These lamps

are 115 volt and are wired in series parallel.

Cook and Hold Operation

1. Turn the mode selector switch (1) to the cook

and hold position. Power goes to terminal #1

of the cook and hold timer (17). When the cook

and hold timer is set power goes to terminal #6

of the hold temperature controller (4), the coil

of the DPDT relay (6) and the cook and hold

light (18). When the DPDT relay powers up the

switches in the relay toggle from the N.C. to the

N.O. position.

2. On a call for heat from the hold temperature

control system, a circuit is completed beween

terminals #6 and #7 of the hold temperature

control board (4).

2-5

Page 12

OPERATION

NOTE: The hold temperature control system

consists of the temperature probe (19),

the hold temperature control board (4)

and the solid state potentiometer (20).

Power goes to the N.O. terminals of the DPDT

relay (6). Circuits should be made between the

N.O. and common terminals of the DPDT relay

(6) allowing power to run to the convection fan

motor (8) and one side of the centrifugal switch

(11). If the convection fan motor (8) is at full

speed the centrifugal switch (11) closes sending

power to the cook light (12) and one side of the

element contactor (13). When the contactor

closes the heating elements (14) power up.

NOTE: In cook and hold mode only, the conĆ

vection fan cycles on and off with the

hold thermostat system.

3. The 50 watt lamps (21) only receive power when

the light switch (22) is activated. These lamps

are 115 volt and are wired in series parallel.

NOTE: The potentiometer and probes for cook

and cook & hold are identical. The cook

and cook & hold temperature boards are

NOT interchangeable.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 3.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the reistive values of the

heating elements. The reading should be

taken in a cold state.

2-6

Page 13

MARK V

14

21

7

20

1

12

13

19

8

10

11

22

6

9

3

4

15

5

16

2

18

6

FIGURE 3

2-7

17

1

Page 14

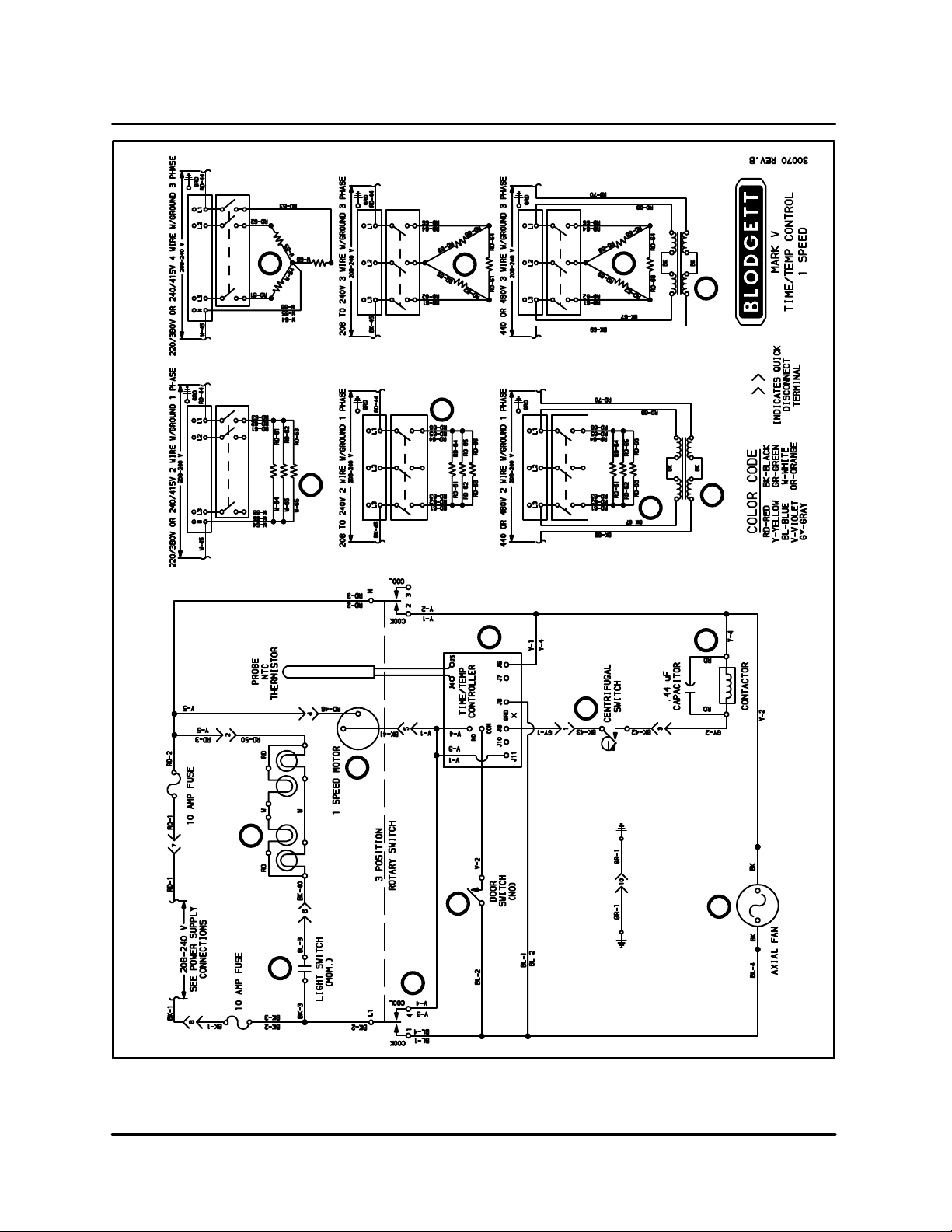

SOLID STATE DIGITAL - 30070 REV B

OPERATION

Component Reference

NOTE: Refer to FIGURE 4 page 2-9 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. DOOR SWITCH

3. TIME AND TEMPERATURE CONTROLLER

4. AXIAL FAN

5. CENTRIFUGAL SWITCH

6. CONVECTION FAN MOTOR

7. HOT AIR ELEMENT CONTACTOR

8. HEATING ELEMENTS

9. TRANSFORMER

10. 50 WATT LAMPS

11. LIGHT SWITCH

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to one terminal of the

door switch (2), terminal J8 of the temperature

controller (3), and the axial fan (4). The main

blower fan starts. If a temperature is proĆ

grammed into the controller, the power goes

from J9 to the centrifugal switch (5) in the conĆ

vection fan motor (6).

2. If the doors are closed, the door switch (2)

should also be closed, sending power to the

common terminal of the time and temperature

controller (3). The relay on this controller

should be closed since a temperature has

been programmed into the controller. A circuit

is made between common and N.O. sending

power to, and starting the convection fan moĆ

tor (6).

NOTE: The relay in the time and temperature

controller is not field repairable. If

diagnosed as defective, the entire

board must be replaced.

3. When the convection fan motor (6) reaches full

speed the centrifugal switch (5) closes sendĆ

ing power to the coil of the hot air element conĆ

tactor (7). When the contactor closes power is

sent to the heating elements (8).

4. The 50 watt lamps (10) only receive power when

the light switch (11) is activated. These lamps

are 115 volt and are wired in series parallel.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 4.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the reistive values of the

heating elements. The reading should be

taken in a cold state.

2-8

Page 15

MARK V

8

8

8

8

3

8

9

9

8

7

5

10

11

6

2

1

4

FIGURE 4

2-9

Page 16

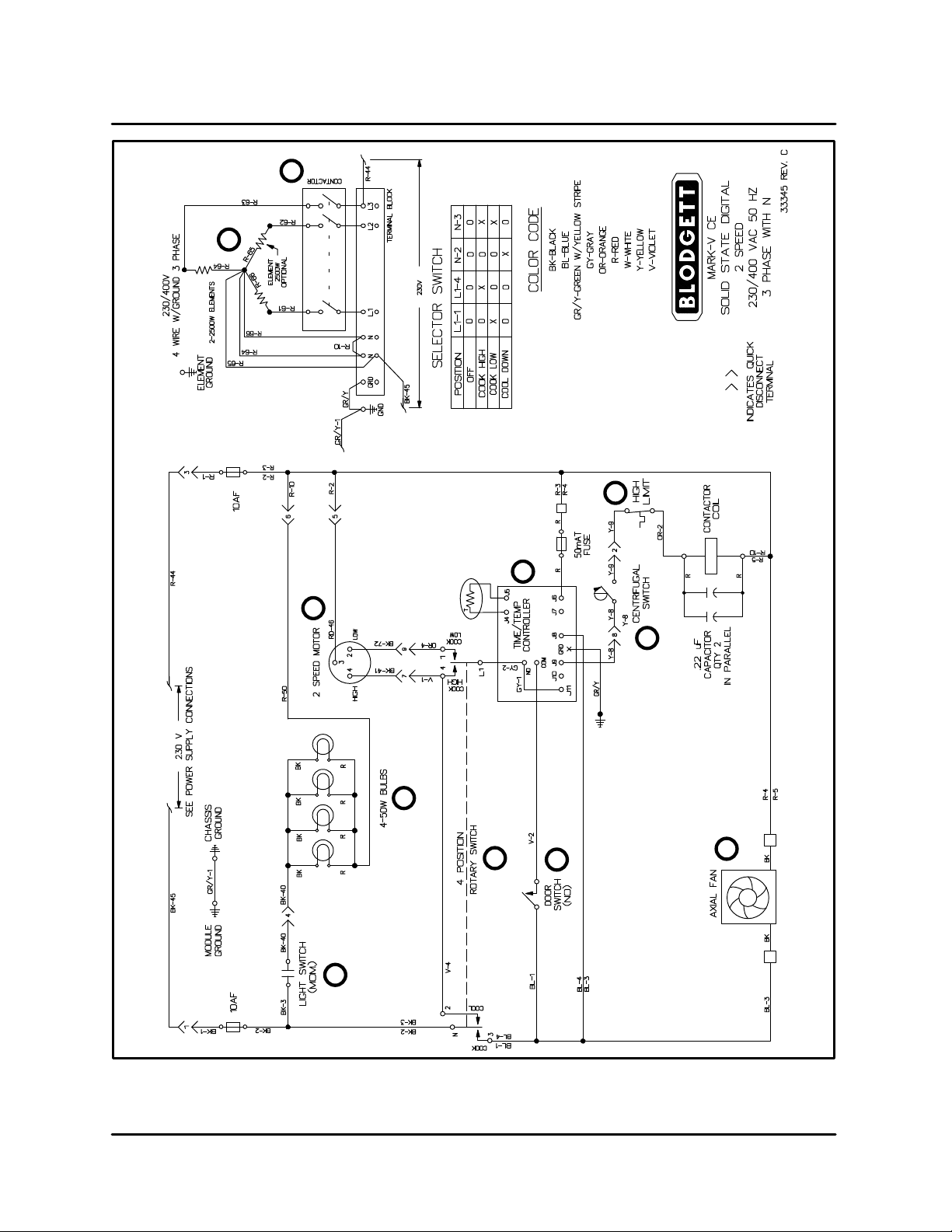

CE APPROVED SOLID STATE DIGITAL - 33345 REV C

OPERATION

Component Reference

NOTE: Refer to FIGURE 5 page 2-11 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. DOOR SWITCH

3. TIME AND TEMPERATURE CONTROLLER

4. AXIAL FAN

5. CENTRIFUGAL SWITCH

6. CONVECTION FAN MOTOR

7. HIGH LIMIT SWITCH

8. HOT AIR ELEMENT CONTACTOR

9. HEATING ELEMENTS

10. 50 WATT LAMPS

11. LIGHT SWITCH

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to one terminal of the

door switch (2), terminal J8 of the temperature

controller (3), and the axial fan (4). The main

blower fan starts. If a temperature is proĆ

grammed into the controller, the power goes

from J9 to the centrifugal switch (5) in the conĆ

vection fan motor (6).

4. The 50 watt lamps (10) only receive power when

the light switch (11) is activated.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

2. If the doors are closed, the door switch (2)

should also be closed, sending power to the

common terminal of the time and temperature

controller (3). The relay on this controller should

be closed since a temperature has been proĆ

grammed into the controller. A circuit is made

between common and N.O. sending power to,

and starting the convection fan motor (6).

NOTE: The relay in the time and temperature

controller is not field repairable. If

diagnosed as defective, the entire

board must be replaced.

3. When the convection fan motor (6) reaches full

speed the centrifugal switch (5) closes sending

power to the high limit (7). If the high limit is

closed, power goes to the coil of the hot air eleĆ

ment contactor (8). When the contactor closes

power is sent to the heating elements (9).

2-10

Page 17

MARK V

8

9

7

3

6

5

10

4

11

1

2

FIGURE 5

2-11

Page 18

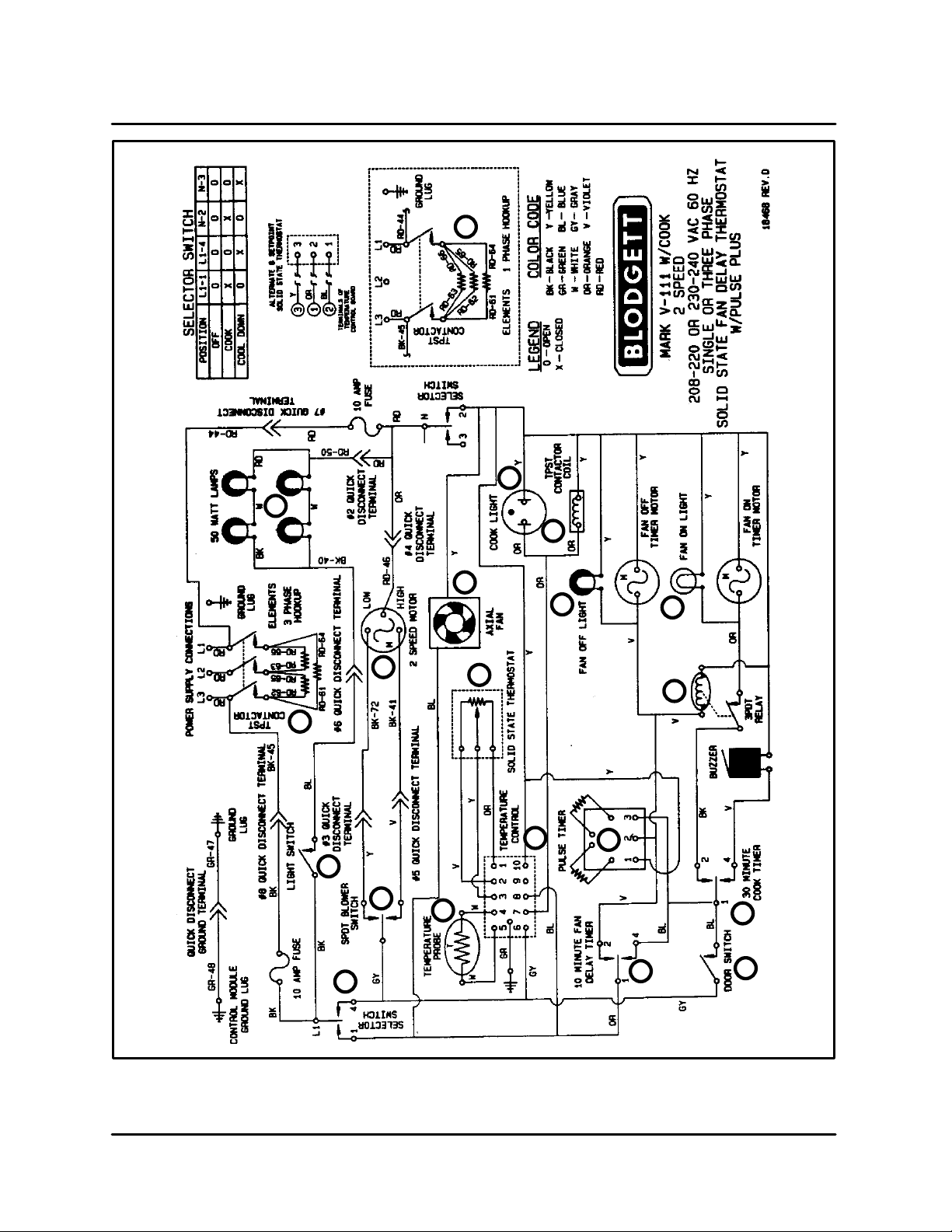

FAN DELAY WITH PULSE PLUS - 18466 REV D

OPERATION

Component Reference

NOTE: Refer to FIGURE 6 page 2-13 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOLING FAN

3. TEMPERATURE CONTROLLER

4. 10 MINUTE FAN DELAY TIMER

5. 30 MINUTE COOK TIMER

6. DOOR SWITCH

7. SPDT BLOWER SWITCH

8. CONVECTION FAN MOTOR

9. TEMPERATURE PROBE

10. POTENTIOMETER

11. HOT AIR ELEMENT CONTACTOR

12. COOK LIGHT

13. HOT AIR ELEMENTS

14. REPEAT SHOT PULSE TIMER

15. TPDT RELAY

16. FAN ON LIGHT

17. FAN OFF LIGHT

18. 50 WATT LAMPS

19. LIGHT SWITCH

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to the cooling fan (2), terĆ

minal #8 of the temperature controller (3), and

terminal #1 of the ten minute fan delay timer (4).

2. If the ten minute fan delay timer is in the timed

out position a switch is made between terminals

#1 and #4 sending power to terminal #1 of the

thirty minute cook timer (5). Power is also sent

to one side of the door switch (6). If the doors are

closed the door switch should also be closed

sending power to terminal #6 of the temperature

control board (3) and the common terminal of a

SPDT blower switch (7). The speed of the conĆ

vection fan motor (8) is dependant on the posiĆ

tion of the SPDT blower switch.

temperature control board (3) and the

solid state potentiometer (10)

Power is sent out of terminal #7 to one coil of

the hot air element contactor (11) and the cook

light (12). When the contactor is energized the

hot air element (13) powers up.

4. To enable the pulse plus feature, the ten minĆ

ute fan delay timer (4) must be set to a time. A

switch is then made between terminals #1 and

#2 sending power to terminal #2 of a repeat

shot pulse timer (14).

NOTE: By setting the ten minute fan delay timer

(4) power is interrupted to the thirty minĆ

ute cook timer (5) making it inoperative.

The repeat shot pulse timer cycles a TPDT relay

(15) interrupting the circuit to the convection fan

motor (8). The convection fan motor cycles on

and off for approximately thirty second intervals

for the duration of the time set on the ten minute

fan delay timer (4). The fan on light (16) illumiĆ

nates whenever the TPDT relay closes. The fan

off light (17) illuminates whenever the ten minute

fan delay timer is set for a time.

5. The 50 watt lamps (18) only receive power when

the light switch (19) is activated. These lamps

are 115 volt and are wired in series parallel.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 6.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

3. On a call for heat from the cook temperature

control system a circuit is completed between

terminals #6 and #7 of the temperature conĆ

trol board (3).

NOTE: The temperature control system conĆ

sists of the temperature probe (9), the

2-12

Page 19

MARK V

13

12

18

11

13

19

2

17

8

7

1

10

3

9

14

16

15

5

4

6

FIGURE 6

2-13

Page 20

HUMIDAIRE - 1846 REV M

OPERATION

Component Reference

NOTE: Refer to FIGURE 7 page 2-16 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOK TIMER

3. DOOR SWITCH

4. TEMPERATURE CONTROL BOARD

5. SPDT BLOWER SWITCH

6. SINGLE SHOT TIMER

7. SPST THERMAL SWITCH

8. TEMPERATURE PROBE

9. POTENTIOMETER

10. COOK LIGHT

11. ELEMENT CONTACTOR

12. HEATING ELEMENTS

13. 50 WATT LAMPS

14. LIGHT SWITCH

15. TIMER MOTOR

16. BUZZER

17. STEAM DURATION POTENTIOMETER

18. STEAM CYCLE START SWITCH

19. WATER SOLENOID VALVE

20. STEAM LIGHT

21. CONVECTION FAN

22. AXIAL COOLING FAN

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to terminal #1 of the

cook timer (2), one side of the door switch (3),

terminal #8 of the temperature control board

(4) and the axial cooling fan (22)

2. If the doors are closed the door switch (3) should

also be closed sending power to terminal #6 of

the temperature control board (4), the SPDT blowĆ

er switch (5), terminal #1 of a single shot timer (6),

and one side of a SPST thermal switch (7).

3. On a call for heat from the temperature control

circuit a circuit is completed between terminals

#6 and #7 of the temperature control board (4).

NOTE: The temperature control circuit conĆ

sists of the temperature probe (8), the

temperature control board (4) and the

solid state potentiometer (9).

Power is sent out of terminal #7 sending power

to the cook light (10) and one side of the eleĆ

ment contactor (11). When the contactor

closes the heating elements (12) power up.

4. The 50 watt lamps (13) only receive power when

the light switch (14) is activated. These lamps

are 115 volt and are wired in series parallel.

5. When the cook timer (2) is set for a time a cirĆ

cuit is made between terminals #1 and #2

powering up the timer motor (15). At the expiĆ

ration of the set time the switch in the cook timĆ

er (2) toggles from 1-2 to 1-4 powering up

the buzzer (16).

NOTE: Put the timer in the home position to siĆ

lence the buzzer.

6. If the oven is above 212_F (100_C) as sensed by

the thermal switch (7) the switch closes sending

power to the steam cycle start switch (18).

NOTE: The thermal switch is located in the

rear of the oven. The face of the thermal

switch is in contact with the oven liner.

The switch toggles closed if the oven

temperature exceeds 212_F (100_C).

NOTE: The steam cycle start switch is a moĆ

mentary switch located on the front

control panel.

When the steam duration potentiometer (17) is

set and the steam cycle start switch (18) is

pressed the single shot timer (6) is activated for

the duration of time on the steam duration poĆ

tentiometer. This allows the water solenoid

valve (19) to open spraying atomized water

onto the blower wheel. The steam light (20) is

illuminated during the humidaire cycle.

7. The convection fan (21) receives power from

the SPDT blower switch (5). This switch deterĆ

mines hi and lo speed.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 7.

2-14

Page 21

MARK V

NOTE: The resistive values for the probes used in

this oven have descending temperature coĆ

efficients. As the temperature increases the

resistive values decrease.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the reistive values of the

heating elements. The reading should be

taken in a cold state.

2-15

Page 22

OPERATION

13

13

12

21

12

1846M

10

22

9

11

15

16

19

20

14

7

5

8

1

2

3

17

18

6

FIGURE 7

2-16

Page 23

MARK V

INTELLIHOLD AND INTELLIPLUS - 22027 REV A

Component Reference

NOTE: Refer to FIGURE 8 page 2-18 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. DOOR SWITCH

3. AXIAL FAN

4. TEMPERATURE CONTROL BOARD

5. CONVECTION FAN

6. OVEN READY LIGHT

7. HEATING ELEMENT CONTACTOR

8. HEATING ELEMENTS

9. 50 WATT LAMPS

10. LIGHT SWITCH

11. PROBE

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to one side of the door

switch (2), the axial fan (3) and to either E1 or

E2 of the temperature control board (4).

NOTE: This control is multiĆvoltage. It may be

used on 240, 208 and 120. FIGURE 8

shows connections to E1 and E2 indiĆ

cating a 240 or 208 volt application.

changed due to the difference in amp

draw. Reference detail inset in FIGURE 8.

NOTE: The resistive values for the probe (11) used

in this oven have ascending temperature

coefficients. As the temperature increases

the resistive values also increase.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the reistive values of the

heating elements. The reading should be

taken in a cold state.

2. If the doors are closed the door switch (2)

should also be closed sending power to termiĆ

nal E10 of K2, E8 of K3 and E6 of K1. If a time

and temperature is programmed into the conĆ

troller either K2 or K3 close sending power to

the convection fan (5).

NOTE: K2 is for high fan, K3 is for low fan.

3. On a call for heat the contacts in K1 close,

sending power to the oven ready light (6) and

one side of the heating element contactor (7).

When the contactor closes the heating eleĆ

ments (8) power up.

4. The 50 watt lamps (9) only receive power when

the light switch (10) is activated. These lamps

are 115 volt and are wired in series parallel.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

2-17

Page 24

OPERATION

8

7

9

6

4

5

8

3

10

2

1

FIGURE 8

2-18

Page 25

MARK V

INTELLITOUCH - 19361 REV A

Component Reference

NOTE: Refer to FIGURE 9 page 2-20 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOLING FAN

3. DOOR SWITCH

4. STEP DOWN TRANSFORMER

5. INTELLITOUCH CONTROL

6. CONVECTION FAN

7. TEMPERATURE PROBE

8. CENTRIFUGAL SWITCH

9. ELEMENT CONTACTOR

10. HOT AIR ELEMENTS

11. 50 WATT LAMPS

12. LIGHT SWITCH

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to the cooling fan (2), one

side of the door switch (3) and terminal #5 of

a 208/24 volt step down transformer (4). 24

volts are applied to terminal #T2 of the intelliĆ

touch controller (5).

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 9.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the reistive values of the

heating elements. The reading should be

taken in a cold state.

NOTE: To calibrate the oven operation perforĆ

mance characteristics see page 3-8 of the

Calibration and Adjustment section.

2. If the doors are closed the door switch should

also be closed sending power to the convecĆ

tion fan (6).

3. On a call for heat, as sensed by the temperaĆ

ture probe (7), a set of contacts close between

terminals T2 and T5 sending 24 volts to one

side of the centrifugal switch (8).

NOTE: The centrifugal switch is a nonĆrepairĆ

able item. It is located in the convecĆ

tion fan motor. This switch closes when

the convection fan reaches full speed.

It is considered a safety switch and

should not be bypassed.

If the centrifugal switch is closed, 24 volts are

applied to the coil of the hot air element contacĆ

tor (9). When the contactor is energized, the

hot air elements (10) power up.

4. The 50 watt lamps (11) only receive power when

the light switch (12) is activated. These lamps

are 115 volt and are wired in series parallel.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

2-19

Page 26

11

OPERATION

2

5

10

12

1

6

4

9

3

8

FIGURE 9

2-20

Page 27

MARK V

BLODGETT IQ CONTROL - 33078 REV A

Component Reference

NOTE: Refer to FIGURE 10 page 2-22 for compoĆ

nent locations.

1. POWER SWITCH

2. STEP DOWN TRANSFORMER

3. RELAY BOARD

4. AXIAL FAN

5. COMPUTER

6. TEMPERATURE PROBE

7. ELEMENT CONTACTOR

8. HEATING ELEMENTS

9. CONVECTION FAN MOTOR

10. DOOR SWITCH

Operation

1. Toggle the power switch (1) to the on position.

Power goes to the primary side of a 208/24 volt

step down transformer (2), terminal #2 of K1 of

the relay board (3), terminal #4 of K2 of the

relay board, terminal #7 of K3 of the relay

board and the axial fan (4).

2. On a call for heat from the computer (5) as

sensed by the temperature probe (6), the coil

of K1 powers up closing the contacts between

terminals #2 and #1 of K1 on the relay board

(3). The coil of the element contacator (7) powĆ

ers up. When the contactor closes the heating

elements (8) power up.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the reistive values of the

heating elements. The reading should be

taken in a cold state.

3. The speed of the convection fan motor (9) is

determined by the program in the computer

(5). The computer either closes K2 for high

speed or K3 for low speed.

4. When the doors are closed the door switch

(10) is activated. The computer closes relays

K1, K2 and K3. If the doors are open or the

switch is broken these relays drop out and the

LED displays door.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 10.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease

2-21

Page 28

OPERATION

8

8

8

8

8

8

9

7

6

10

4

1

2

3

FIGURE 10

2-22

Page 29

MARK V

This page intentionally left blank.

2-23

Page 30

CHAPTER 3

CALIBRATION AND

ADJUSTMENT

Page 31

MARK V

DOORS

The Mark V ovens feature double side mounted

doors which operate simultaneously by means of

a chain and turnbuckle linkage assembly. Should

field adjustment be necessary, the two turnbuckles

are located immediately behind the combustion

compartment cover.

For units manufactured prior to August 1984.

1. Adjust one turnbuckle, then the other until the

doors are properly synchronized.

NOTE: The doors are properly adjusted if the

right door is fully closed when the left

door (the door with the handle) has

1/2"Ć1" of travel remaining.

Both turnbuckles must be adjusted to prevent

strain on the door operating mechanism.

2. Tighten the turnbuckle lock nuts.

Turnbuckle

(not shown)

For units manufactured after August 1984

Be sure the doors are in line with each other when

viewed from the top and front. If the doors are misaĆ

ligned adjust as follows:

1. Remove the bottom trim.

2. Loosen the five (5) bolts in the UĆshaped lower

door hinge and sprocket assembly.

3. Slide the assembly until the doors are aligned.

4. Tighten the bolts.

5. Replace the bottom trim.

Door Hinge

Sprocket

Assembly

Turnbuckle

Turnbuckle

FIGURE 1

To adjust the ball plunger catch:

1. Insert a spanner key in the notches on both

sides of the ball plunger. Loosen the lock nut

with a wrench.

2. Adjust the ball plunger by turning left or right

with the spanner key until the plunger engages

in the striker plate on the door.

3. With the spanner key still inserted in the ball

plunger notches, tighten the lock nut.

FIGURE 2

To adjust the doors for proper operation, open the

doors until the right hand door back flange is even

with the front line of the oven as viewed from above.

The left hand door should be positioned so the

door pressure lock touches the right hand door. If

the doors need adjustment proceed as follows:

1. Loosen the chain drive.

2. Adjust for proper location.

3. Tighten the chain drive.

Front of Oven

Left

Door

Right Door

Pressure Lock

FIGURE 3

3-1

Page 32

CALIBRATION AND ADJUSTMENT

DOOR BLOWER SWITCH

The door activated blower switch should be adĆ

justed so the doors are about 1Ć1/2" (4 cm) from

the liner when the switch shuts the blower off. If

field adjustment is necessary, the switch can be

reached by removing the combustion compartĆ

ment cover.

1. Open the right hand door until it is approxiĆ

mately 2" (5 cm) from the liner.

2. Place the arm of the cam assembly, located on

the door sprocket, against the push button.

3. Tighten the set screw.

When the doors are fully closed, the cam arm deĆ

presses the push button enough to allow blower

operation. An audible click will determine if the

switches are operating correctly.

The switch may be moved forward or backward in

the mounting bracket as necessary for alignment.

Door Arm

Sprockets

Door

Chain

Door Switch

Cam Assembly

Hinge Pin

Micro

Switch

THERMOSTAT

BULB AND CAPILLARY THERMOSTAT

For units manufactured prior to August 1984

1. Turn the mode selector/power switch to COOK

ONLY.

2. Toggle the blower switch to ON.

3. Toggle the cool down switch to MANUAL.

4. Place a pyrometer thermocouple at the center

of the thermostat bulb or reliable mercury therĆ

mometer on the middle shelf 6" from the front

edge and in the center of the shelf.

5. Turn the thermostat dial to 350_F (177_C)..

6. When the red indicator light on the control panĆ

el goes out, check the thermometer or pyromĆ

eter to determine oven temperature.

If this reading is within 10_F (6_C) of the therĆ

mostat setting, do not change the thermostat.

If this reading differs more than 10_F (6_C)

from the thermostat setting recalibrate the

thermostat.

For units manufactured after August 1984.

1. Turn the selector switch to COOK.

2. Place a pyrometer thermocouple at the center

of the thermostat bulb or reliable mercury therĆ

mometer on the middle shelf 6" (15 cm) from

the front edge and in the center of the shelf.

3. Turn the thermostat dial to 350_F (177_C). Let

the oven heat for at least 1/2 hour.

FIGURE 4

4. When the red indicator light on the control panĆ

el goes out, check the thermometer or pyromĆ

eter to determine oven temperature. If this

reading is within 10_F (6_C) of the thermostat

setting, do not change the thermostat. If this

reading differs more than 10_F (6_C) from the

thermostat setting recalibrate the thermostat

as follows. See FIGURE 6 page 3-3.

A.) Loosen the set screws in the thermostat

knob. Pull the knob forward.

B.) With a screwdriver, turn the calibration

screw in the center of the thermostat stem

either clockwise to lower the temperature

or counterĆclockwise to raise the temperaĆ

ture.

3-2

Page 33

MARK V

Thermocouple

Bulb Clip

Fluid Filled

Capillary

Thermostat

Pyrometer

Lead

FIGURE 5

For units manufactured prior to December 1987.

1. Loosen the set screws in the thermostat knob.

Pull the knob forward.

2. With a screwdriver, turn the calibration screw

in the center of the thermostat stem either

clockwise to lower the temperature or counterĆ

clockwise to raise the temperature.

Calibration

Screw

NOTE: Do not allow the main stem of the therĆ

mostat to turn when adjusting the calĆ

ibration screw.

3. Open the doors.

4. Turn the selector switch to COOL DOWN. The

blower will continue to operate. Let the temperĆ

ature of the oven decrease 100Ć150_F

(56Ć83_C).

5. Turn the selector switch to COOK.

6. Repeat the steps above until the oven temperĆ

ature is within 10_F (6_C) of the thermostat setĆ

ting.

FIGURE 6

3-3

Page 34

SOLID STATE MANUAL

1. Place a pyrometer in the center of the oven.

2. Turn the mode selector switch to cook.

3. Turn the thermostat to 350_F (177_ C).

4. When the red indicator light goes out, check

the pyrometer to determine oven temperature.

5. If this reading is within 10_ (6_C) of the thermoĆ

stat setting no adjustment is needed.

If the reading is greater than 10_ (6_C) adjust

as follows:

A.) Locate the trim pot on the solid state temĆ

perature board.

CALIBRATION AND ADJUSTMENT

B.) Turn the adjustment screw to raise or lower

the setting.

LIGHT OFF

OVEN READY

THERMOSTAT

TIMER

3-4

FIGURE 7

Page 35

MARK V

SELECTOR SWITCH CALIBRATION

1. Place a pyrometer in the center of the oven.

2. Turn the mode selector switch to cook.

3. Set 8 position selector switch to one of the

eight positions.

NOTE: The 8 individual positions are each set

for a temperature of the customer's

choosing. For example, if position 1 is

set for 350_F (177_C) the red indicator

light should go out when it gets to withĆ

in 10 degrees of setpoint.

4. If the light goes out within 10 degrees, no adĆ

justment is required. If the light does not go out

within 10 degrees of setpoint calibrate the

switch as follows:

A.) Locate the potentiometer on the 8 position

selector switch labeled R1.

NOTE: There are 8 trim pots on this device.

They are labeled R1, R2, R3, etc.

B.) Turn the brass screw on top of the potenĆ

tiometer clockwise to increase the temperaĆ

ture. Turn the brass screw on top of the poĆ

tentiometer counterĆclockwise to decrease

the temperature.

5. Repeat steps 3-4 for all 8 positions.

NOTE: It is possible for all 8 positions to be out

of calibration but highly unlikely.

FIGURE 8

3-5

Page 36

SOLID STATE DIGITAL CONTROL

CALIBRATION AND ADJUSTMENT

To Initiate Programming

1. Set the time to 1 minute.

2. Set the temperature to 151_F (66_C).

To Access Second Level Programming

1. Press and hold the temperature key and the

start/stop key simultaneously.

2. The control beeps and displays the software

version for a few seconds.

3. The control then displays 2NdL. The control

has entered the second level program.

To Change the Temperature Offset

1. Press the temperature key.

2. The control displays OFFS or offset for a few

seconds. It then displays the current offset

which should be 0_F.

3. Rotate the dial to enter a 50_F (28_C) offset.

Use this to calibrate the oven if necessary.

To Set the Display Scales

1. Press the temperature key.

2. The control displays the current setting from

the following menu. See FIGURE 9. This menu

controls 3 separate parameters:

A.) First Digit - the desired time display (ie

hrs/min or min/sec)

DISPLAY SCALE EXAMPLES

DIGITS

ST

1

H = Hrs/Min Display (Factory Setting)

_Ă = Min/Sec Display

ND

2

E = Electric Oven

_ = Gas Oven

RD

3

_C or _F

Temperature Display

TH

4

B.) Second Digit - Electric or Gas oven

C.) Third and Fourth Digit - the desired temĆ

perature scale (ie _F or _C)

3. To adjust the setting turn the dial 1 click at a

time.

NOTE: If the control is set for minutes and seconds

the first digit will be blank. If the control is

set for a gas oven the second digit will be

blank.

FIGURE 9

To Return to Normal Operating Mode

1. Press the temperature key.

2. The control goes through self check then disĆ

plays the set temperature 151_F (66_C).

3. The oven can now be controlled as normal.

3-6

Page 37

MARK V

INTELLIHOLD AND INTELLIPLUS CONTROLS

NOTE: For error code display information see

page 4-3 of the Troubleshooting section.

Temperature Calibration

1. Turn the temperature control knob until the

temperature in the display reads X10 (any

number followed by 10).

2. Turn the time control knob until the time in the

display is 00:00.

3. Press and hold the start/timer key. The display

reads UPO.

4. Place a pyrometer in the center of the oven to

measure the actual oven temperature.

NOTE: During operation, the temperature

control is based on the measured temĆ

perature and the temperature offset

which is programmed into the control.

If the temperature measured in the

center of the oven is below the oven

setpoint a positive offset is needed. If

the temperature measured in the cenĆ

ter of the oven is above the oven setĆ

point a negative offset is needed.

5. Turn the temperature control knob to set the

offset, either positive or negative.

6. Press the act temp key to store the new offset

and exit temperature calibration.

Temperature Display Scales

1. Turn the temperature control knob until the

temperature in the display reads X20 (any

number followed by 20).

2. Turn the time control knob until the time in the

display is 00:00.

3. Press and hold the start/timer key. The display

reads either CCC or FFF.

4. Press and hold the start/timer key to toggle

from _C to _F.

5. Press the act temp key to store the new scale

and exit temperature display.

Time Display Scales

1. Turn the temperature control knob until the

temperature in the display reads X30 (any

number followed by 30).

2. Turn the time control knob until the time in the

display is 00:00.

3. Press and hold the start/timer key. The display

reads either HRS or MIN.

4. Press and hold the start/timer key to toggle

from hours to minutes.

5. Press the act temp key to store the time scale

and exit time display.

3-7

Page 38

INTELLITOUCH CONTROL

CALIBRATION AND ADJUSTMENT

NOTE: For error code display information see

page 4-3 of the Troubleshooting section.

To access 2nd level programming

1. Turn the oven off.

2. Locate the 3 pin header on the bottom right

side of the control. Move the jumper from the

middle and bottom pins to the middle and top

pins exposing the bottom pin.

3. Turn the oven on. The program LED (1) lights.

Programming the 2nd level parameters

1. The #1 LED illuminates.

NOTE: The LED's (3) are located next to the

product and load keys. The LED identiĆ

fication numbers (2) are located to the

left of the product and load keys. See

FIGURE 10.

INTELLITOUCH

HEAT PROGRAM

DISPLAY

2

1

PROD

3

2

PROD

3

PROD

4

PROD

5

PROD

6

PROD

7

PROD

READY

8

1

ENTER

2

TEMP

3

CNCL

4

5

6

7

R

TEMP

R

TIME

LOAD

1

9

LOAD

2

0

LOAD

3

LOAD

4

LOAD

5

1

2

3

NOTE: Use product keys 1Ć7 for numerals 1Ć7.

Use load keys 1Ć3 for numerals 8,9 and

0 respectively.

3. Press the enter key to save the parameter setĆ

ting.

4. The #2 LED illuminates

5. Repeat steps 1Ć3 for each parameter. When

the final parameter setting is entered and

saved the #1 LED illuminates.

LED(s) Parameter Setting

1 Offset 0

2 Hrs/Min timer 0F

1,2 Fahrenheit (0=_F, <1=_C) 0F

3 Proportional 0F

1,3 Integration 1F

2,3 Dead band 3F

1,2,3 Cycle time 12F

4 Minimum on time 3F

1,4 Hi temp alarm 550F

2,4 Ready temp differential 15F

1,2,4 Minimum setpoint 150F

3,4 Maximum setpoint cook 500F

1,3,4 Minimum setpoint hold 0F

2,3,4 Maximum setpoint hold 0F

1,2,3,4 Fan 2 speed 0F

5 Fan rev. 0F

TABLE 1

To exit the 2nd level programming

FIGURE 10

2. Use the product and load keys to enter numeriĆ

cal data. See TABLE 1 for correct parameter

settings.

1. Turn the oven off.

2. Move the jumper from the middle and top pins

to the middle and bottom pins exposing the

top pin.

3. Turn the oven on.

3-8

Page 39

MARK V

INTELLITOUCH II CONTROL

To access 2nd level programming and diagnosĆ

tics

1. The display reads SELECT. Press CLEAR 1, 2,

3, 4, 5, 6, ENTER.

2. The display reads CODE-? Press 1, 2, 3, 4, 5,

6 ENTER.

3. The display reads ACCES S.

To run LED diagnostics

1. Press CLEAR 1, 1, 1 ENTER.

2. The control runs selfĆdiagnostics on each LED

individually. When all of the LED's light togethĆ

er press the CLEAR key.

3. The display flashes EXIT then ACCESS.

To check the software configuration

1. Press CLEAR 1, 2, 3 ENTER.

2. The display lists the software configuration inĆ

formation.

3. The display flashes EXIT then ACCESS.

OVEN CALIBRATION

1. Press CLEAR, TEMP, TEMP, TEMP, ENTER.

Temperature display scale

2. The display flashes _ F/_C then MODE-?

3. Press any key to toggle the scale from _F to _C.

4. Press the PROG/ENTER key to lock in new

scale.

5. The display flashes T'_F ( or T'_C).

Temperature offset

1. Once the temperature scale has been proĆ

grammed, the display flashes either POS *

OFFSET or NEG * OFFSET

NOTE: POS OFFSET is displayed if a value has

been programmed in for a positive offĆ

set. NEG OFFSET is displayed if a valĆ

ue has been programmed for a negaĆ

tive offset. The only time both will be

displayed is if a value of 0 has been enĆ

tered for both.

2. Enter a value for the desired offset. The display

flashes DISPLAY * INTEG?.

3. Press the PROG/ENTER key. The default value

of 30 will be displayed.

4. Press the PROG/ENTER key. The display will

flash TĆCTRL * INTEG?.

5. Press the PROG/ENTER key. The default value

of 10 will be displayed.

6. Press the PROG/ENTER key.

Ready Band

1. The display flashes READY, BAND and POS.

2. Use the numeric keys to enter a value between

1 and 25. Press the PROG/ENTER key.

3. The display flashes READY, BAND and NEG.

4. Use the numeric keys to enter a value between

1 and 25. Press the PROG/ENTER key.

To exit oven calibration

1. The display flashes ACCESS, DONE and EXIT.

2. Press CLEAR, CLEAR, CLEAR.

3. The display flashes REBOOT and SELECT.

3-9

Page 40

BLODGETT IQ CONTROL

CALIBRATION AND ADJUSTMENT

NOTE: For error code display information see

page 4-3 of the Troubleshooting section.

2ND LEVEL PROGRAMMING

Entering the programming mode

1. Press the prog key. The top display reads

CodE.

2. Use the product keys to enter the programĆ

ming access code: 4 5 1 2. Press the enter key.

The top display reads SYS.

Programming hold

1. Press the scan key. The top display reads

Hold. Press the toggle/clear key to toggle beĆ

tween YES and no. Press the scan key.

If no is chosen:

A.) The controller advances to programming

the setback mode.

If yes is chosen:

A.) The top display reads AUTO. Press the

toggle/clear key to toggle between YES

and no. Press the scan key to enter the deĆ

sired hold mode.

B.) The top display reads HOLD. The bottom

display flashes the current hold time. Use

the product keys to enter the desired hold

time. Press the scan key to enter the new

hold time.

C.) The top display reads HOLD. The bottom

display flashes the current hold temperaĆ

ture. Use the product keys to enter the deĆ

sired hold time. Press the scan key to enter

the new hold temperature.

D.) The top display reads FAn. The bottom disĆ

play gives the current fan mode. To

change the fan mode press the toggle/

clear key. The bottom display toggles beĆ

tween Hi and Lo. Press the scan key to enĆ

ter the new fan mode and continue with

programming the setback mode.

Programming the setback mode

1. The top display reads SEtb. The bottom disĆ

play gives the setback mode. To change the

setback press the toggle/clear key. The botĆ

tom display toggles between YES and no.

Press the scan key.

If no is chosen:

A.) The controller advances to programming

the temperature mode.

If yes is chosen:

A.) The bottom display gives the current setĆ

back time. Use the product keys to the enĆ

ter the desired setback time. Press the

scan key to enter the new setback time.

B.) The bottom display gives the current setĆ

back temperature. Use the product keys

to the enter the desired setback temperaĆ

ture. Press the scan key to enter the new

setback and continue with programming

the temperature mode.

Programming the temperature mode (_F or _C)

1. The top display reads dEg. The bottom display

gives the units. To change the units press the

toggle/clear key. The bottom display toggles

between F and C.

2. Press the scan key to enter the new temperaĆ

ture units and continue programming the oven

size.

Programming the oven size

1. The top display reads APPL. The bottom disĆ

play reads either FULL or HALF. Press the

toggle/clear key until the bottom display reads

FULL for the Mark V.

2. Press the scan key to enter the oven size and

continue with exiting the programming mode.

Exiting the programming mode

1. The top display reads SYS. Press the prog key.

The control returns to the operating standby

mode.

3-10

Page 41

MARK V

PROGRAMMING THE OFFSET

Entering the offset programming mode

1. Press the prog key. The top display reads

CodE.

2. Use the product keys to enter the offset proĆ

gramming access code: 4 5 2 3. Press the enĆ

ter key. The top display reads oFF. The bottom

display reads SEt.

Programming the temperature offset

1. Press the scan key. The top display reads

oFST. The bottom display reads either xxF or

-xxF.

2. Press the toggle/clear key to toggle between

positive and negative. Use the product keys to

the enter the desired temperature offset.

3. Press the scan key to enter the new temperaĆ

ture offset.

Exiting the offset programming mode

1. Press the prog key. The control returns to the

operating standby mode.

3-11

Page 42

CALIBRATION AND ADJUSTMENT

BLODGETT IQ2T CONTROL FACTORY LEVEL PROGRAMMING

Entering the programming mode

1. Press the program key. The top display reads

CodE.

2. Use the product keys to enter the factory proĆ

gramming accss code: 4 5 2 3. Press the enter

key. The top dislay reads Fact.

Programming the oven configuration

1. Press the SCAN KEY. The display reads Appl.

2. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween electric oven and gas oven. Set the

choice for the oven type. Press the SCAN KEY

to enter the choice.

3. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween half sized or full sized oven. Set the

choice for the oven type. Press the SCAN KEY

to enter the choice.

NOTE: Mark V and DFGĆ100 are full sized

ovens. CTB and DFGĆ50 are half sized

ovens.

Programming the temperature offset

1. The top display reads oFF. The bottom display

reads SEt.

2. Press the SCAN KEY. The top display reads oFST.

The bottom display reads either xxF or -xxF.

3. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween positive and negative. Use the product

keys to the enter the desired temperature offset.

4. Press the SCAN KEY to enter the new temperaĆ

ture offset.

Enabling/Disabling the fan error detection circuit

1. The top display reads FanC. The bottom disĆ

play reads YES or NO.

2. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween choices.

3. Press scan to move to next operating parameĆ

ter.

Programming fan speed option

1. The top display reads FanS. The bottom disĆ

play reads 1 or 2.

2. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween choices: 1 for a single speed motor or 2

for a two speed motor.

3. Press SCAN to move to the next operating paĆ

rameter.

Programming the maximum temperature setpoint

1. The top display reads tELt (temperature limit)

and the bottom display reads either 500 or 550.

2. Press the TOGGLE/CLEAR key to toggle beĆ

tween choices 500_F or 550_F maximum temĆ

perature setting.

3. Press scan to enter the maximum setpoint

temperature.

NOTE: Use 500_F for the DFGĆ100, DFGĆ200,

Mark V, CTB and DFGĆ50. Use 550_F

for the DFGĆ100 XCEL and Mark V

XCEL.

Exiting the factory programming mode

1. The top display reads Fact. Press the PROG

KEY. The control returns to the operating

mode.

3-12

Page 43

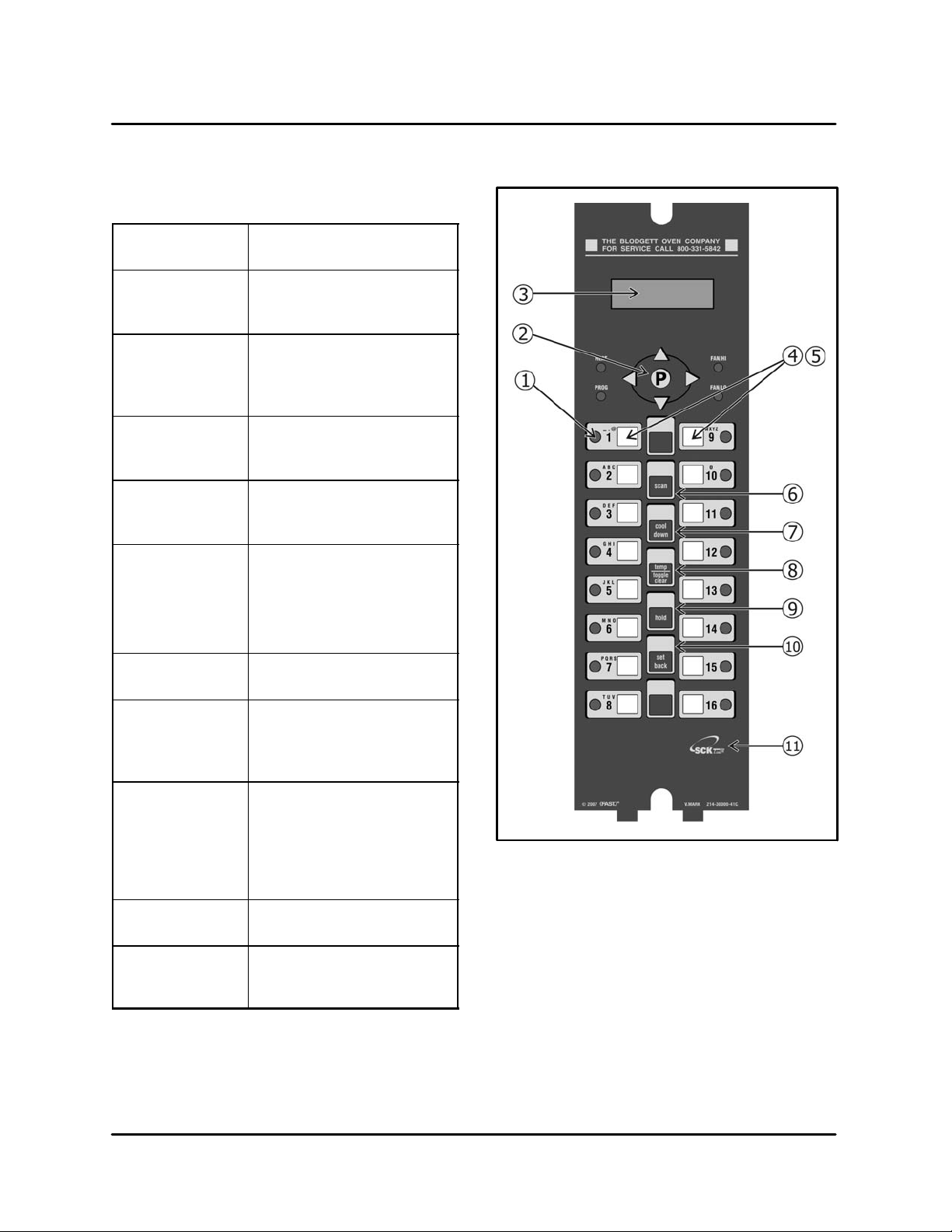

MARK V

IQ VVCĆ208 CONTROL

COMPONENT DESCRIPTION

1. Indicator

Lights

2. ProgramĆ

ming Buttons

D Light up when product

key is activated.

D Used to access programĆ

ming mode and change

parameters.

3. VFD (VacuĆ

um Fluorescent

Display)

D Bright blue for easy viewĆ

ing. Displays

programming and cook

cycle information.

4. SlideĆIn

Menu Strips

D Menu items are printed

directly on easyĆtoĆ

change menu strip.

5. Product

Buttons

D Used to activate cook

cycles and for certain

programming functions.

6. SCAN key D Used for recipe review

during idle.

D Used to review time

remaining during multiple

cooks (press & hold)

7. COOL

DOWN key

D Used to enter or exit cool

down mode.

8. TEMP/

TOGGLE

CLEAR key

D Used to check actual

temperature; also used to

clear value when in

programming mode.

9. HOLD key D Holds are not used for

KFC applications. Used

to toggle between upper

and lower case letters

when programming

libraries.

10. SETBACK

key

11. SCK LINK

logo

D Used to enter or exit

Setback mode.

D Signifies your control is

communicationsĆcapaĆ

ble.

FIGURE 11

3-13

Page 44

OPERATIONAL TEST PROCEDURE

CALIBRATION AND ADJUSTMENT

1

2

3

4

5

6

RECIPE REVIEW - Quickly see what is proĆ

grammed for each product key.

1. Press the SCAN key.

2. Select any product key previously proĆ

grammedĆLED will be lit above the key.

Plug oven into electrical source

Turn the oven power switch on.

NOTE: AP and Mark V computer is unpowered if off. The XCEL is powered if plugged in.

NOTE: This scrolling can be bypassed by pressing SCAN.

The controller will scroll through the following:

A.) Appliance Type

B.) Software #

C.) Download #

D.) SCK Address

E.) PREHEAT"

The oven will enter PREHEAT" mode and begin to warm up. When the set temperature

(default 325°F) is reached, the Preheat timer will count down from 45 minutes to zero.

When LOAD" is displayed, the oven is ready for use.

Press any illuminated product key.

The cook cycle will count down in the display.

COOL DOWN

1. To enter Cool Down, press the COOL DOWN

key while the oven door is closed. When the

display reads COOL," the door can then be

opened.

3. Press the DOWN arrow key to scroll through

the list.

4. Press SCAN to exit.

VIEW TEMPERATURE SETTING

1. Press the TEMP key 'once' to view Actual TemĆ

perature, or

2. Press the TEMP key 'twice' to view Set TemperĆ

ature.

3. Press the TEMP key 'three' times to view Fan

Speed

4. Press the TEMP key 'four' times to view Fan DiĆ

rection

WARNING!!

THE FAN IS STILL MOVING. DO NOT

REACH INTO THE OVEN. The fan will auĆ

tomatically shut off when the actual temĆ

perature reaches 105°F.

2. To exit Cool Down, press the COOL DOWN key

again. The oven will come back up to set temĆ

perature.

WARNING!!

ALWAYS TURN OFF MAIN POWER BEĆ

FORE REMOVING BAFFLE OR PLACING

HANDS NEAR FAN.

3-14

Page 45

MARK V

SYSTEM PROGRAMMING (6647)

KEY PRESS DISPLAY ACTION

Enter Program mode

1

Enter pass code

2

ENTER CODE

****

D To enter programming mode,

press and hold the P" key for

3 seconds.

D Scroll Down to Programming.

D Press the P" key to lock in

your entry.

D The display will prompt user to

enter a pass code.

D Enter pass code 6 6 4 7.

D Press the P" key when SysĆ

tem" is displayed.

D Press the P" key again to enĆ

ter System Programming.

Confirm or Select

Appliance Type

3

Select Language

4

APPLIANCE TYPE

(ELECTRIC HALF,

ELECTRIC FULL)

HALF = AP

FULL = MARK V

SELECT LANGUAGE

(English, Other)

D Press the LEFT or RIGHT arrow

keys to select from a preĆproĆ

grammed list of appliances.

NOTE: Changing appliance

type clears all current recipe

programs.

D Press the P" key to lock in

your entry

D Press the LEFT or RIGHT arĆ

row key to select language

D Press the P" key to lock in

your entry

NOTE: 'Other' is downloadĆ

able.

3-15

Page 46

SYSTEM PROGRAMMING (continued)

KEY PRESS DISPLAY ACTION

CALIBRATION AND ADJUSTMENT

Set Tone Level

5

Set Temperature Mode

6

Program Setback Time

7

Program Setback

Temperature

8

TONE LEVEL

(None, 1, 2, 3, 4)

TEMPERATURE

F = FAHRENHEIT or

C = CELSIUS

SETBACK TIME

HH:MM

SETBACK TEMP

XXX

D Press the LEFT or RIGHT arĆ

row keys to select a tone level.

At each level the controller will

continuously sound the seĆ

lected tone.

D Press the P" key to lock in

your entry

D Press the LEFT or RIGHT arĆ

row keys to select the method

that all temperatures will be

displayed in.

D Press the P" key to lock in

your entry

D Press the numbered product

keys to select the time in

HH:MM format for activating

Setback mode.

NOTE: 0:00 is default to disĆ

able Setback.

D Press the P" key to lock in

your entry

D Press the numbered product

keys to select the Setback

temperature in the range of

140Ć300°F.

9

10

Set Hold Time

Set Hold Temperature

HOLD TIME

HH:MM

HOLD TEMP

XXX

3-16

D Press the P" key to lock in

your entry

D Type in the length of hold time

required. The value is in the

range of 00:00 to 99:59.

D Press the P" key to advance

to the next stage or parameter.

D Type in the desired Hold temĆ

perature. Hold Temperature

Range is 140Ć210°F

D Press the P" key to advance

to the next stage or parameter.

Page 47

MARK V

SYSTEM PROGRAMMING (continued)

KEY PRESS DISPLAY ACTION

11

12

13

14

Set Hold Done

Set Hold Fan Speed

Set Preheat Time

HOLD DONE

(AUTOMATIC, MANUAL)

HOLD FAN SPEED

(HIGH, LOW)

PREHEAT TIME

MM:SS

EXITExit Program Mode

D Press the LEFT or RIGHT arĆ

row keys to select Hold Done.

D Press the P" key to advance

to the next stage or parameter.

D Press the LEFT or RIGHT arĆ

row keys to select Hold Fan

Speed.

D Press the P" key to advance

to the next stage or parameter.

D Type in the desired Preheat

Time.

D Press the P" key to advance

to the next stage or parameter.

D Press the UP or DOWN arrow

keys to scroll to Exit."

15

D Press the P" key to return to

idle mode.

3-17

Page 48

CALIBRATION AND ADJUSTMENT

PROBE RESISTANCE VS HEATING ELEMENTS

Element Resistance

208 volt 12.3-13.6 W

220 volt 13.8-15.2 W

240 volt 16.4-18.1 W

440 volt 58.0-61.0 W

480 volt 65.6-72.6 W

TABLE 2

PROBE RESISTANCE VS TEMPERATURE

Solid State Manual and Digital Controllers

(probe P/N 18588)

_F _C Ohms _F _C Ohms

100 38 53029 310 155 1519

125 52 30785 320 160 1340

150 66 18591 330 166 1186

175 80 11633 340 171 1052

200 93 7528 350 177 936

210 99 6391 360 182 835

220 105 5471 370 188 747

230 110 4705 380 193 669

240 116 4030 390 199 601

250 121 3441 400 205 542

260 127 2967 425 219 421

270 132 2583 450 232 333

280 138 2255 475 246 265

290 143 1970 500 260 216

300 149 1728

Intellitouch II Controller

(probe P/N 32289)

_F _C Ohms _F _C Ohms

32 0 500 212 100 693

68 20 539 250 120 730

75 24 545 300 150 787

86 30 558 356 180 842

125 50 597 392 200 879

140 60 616 450 230 934

175 80 655 500 260 989

200 93 680 554 260 1042

TABLE 3

TABLE 4

3-18

Page 49

MARK V

Intellitouch (probe P/N 20360) and

Blodgett IQ Controllers (probe P/N 33074

_F _C Ohms _F _C Ohms

60 16 1059 235 113 1422

65 18 1067 240 116 1432

70 21 1080 245 118 1442

75 24 1090 250 121 1453

80 27 1099 255 124 1463

85 29 1112 260 127 1473

90 32 1122 265 130 1483

95 35 1133 270 132 1493

100 38 1143 275 135 1503

105 41 1153 280 138 1514

110 43 1164 290 143 1534

115 46 1174 295 146 1544

120 49 1185 300 149 1554

125 52 1195 305 152 1564

130 55 1206 310 155 1574

135 57 1216 315 157 1584

140 60 1226 320 160 1594

145 63 1237 325 163 1604

150 66 1247 330 166 1614

155 68 1258 335 169 1624

160 71 1268 340 171 1634

165 74 1278 345 174 1644

170 77 1289 350 177 1654

175 80 1299 355 180 1664

180 82 1309 360 182 1674

185 85 1320 365 185 1684

190 88 1330 370 188 1694

200 93 1350 375 191 1704

205 96 1361 380 193 1714

210 99 1371 385 196 1724

215 102 1381 390 199 1734

220 105 1391 395 202 1744

225 107 1402 400 205 1754

230 110 1412 405 207 1764

Intellitouch (probe P/N 20360) and

Blodgett IQ Controllers (probe P/N 33074

_F _C Ohms _F _C Ohms

410 210 1774 460 238 1872

415 213 1783 465 241 1882

420 216 1793 470 244 1892

425 219 1803 475 246 1901

430 221 1813 480 249 1911

435 224 1823 485 252 1921

440 227 1833 490 254 1931

445 230 1843 495 255 1940

450 232 1852 500 260 1950

455 235 1862

TABLE 5

3-19

Page 50

CALIBRATION AND ADJUSTMENT

Intellihold and Intelliplus Controllers (probe P/N 23392)

_F Ohms _F Ohms _F Ohms _F Ohms _F Ohms _F Ohms

70 1080 108 1160 146 1239 184 1318 222 1395 260 1473

71 1082 109 1162 147 1241 185 1320 223 1398 261 1475

72 1084 110 1164 148 1243 186 1322 224 1400 262 1477

73 1086 111 1166 149 1245 187 1324 225 1402 263 1479

74 1089 112 1168 150 1247 188 1326 226 1404 264 1481

75 1091 113 1170 151 1249 189 1328 227 1406 265 1483

76 1093 114 1172 152 1251 190 1330 228 1408 266 1485

77 1095 115 1174 153 1253 191 1332 229 1410 267 1487

78 1097 116 1176 154 1255 192 1334 230 1412 268 1489

79 1099 117 1178 155 1258 193 1336 231 1414 269 1491

80 1101 118 1181 156 1260 194 1338 232 1416 270 1493

81 1103 119 1183 157 1262 195 1340 233 1418 271 1495

82 1105 120 1185 158 1264 196 1342 234 1420 272 1497

83 1108 121 1187 159 1266 197 1344 235 1422 273 1499

84 1110 122 1189 160 1268 198 1346 236 1424 274 1501

85 1112 123 1191 161 1270 199 1348 237 1426 275 1503

86 1114 124 1193 162 1272 200 1350 238 1428 276 1505