Page 1

GB

D

Notes on installation and operation

Hinweise zur Installation und Bedienung

F

Conseils pour l’installation et l’utilisation

VXW 250, VXW 300, VXW 380

Page 2

GB

Thanks for choosing

Congratulations on your purchase of your new

in the de-sign process of the new

performance.

For maximum performance and reliability we highly recommend that your new

be installed by an authorised Velocity dealer. By using our

amplifiers you can be as-sured of making the best out of your high-quality audio hi-fi system without

spoiling the sound by using com-ponents of inferior quality.

For additional information on the

simulation programme for subwoofer housings) visit our Internet site at: http://www.velocity.de.

NEW COMPONENT FEATURES

High Power handling

Incredibly flexible installation: The new

bandpass boxes.

Due to the low resonance values, the new

installations in which the woofer is mounted on the rear deck, using the trunk of the car for its acoustical

enclosure.

New ultra-linear long-throw suspension.

Corrugated mica polypropylene design yields tremendous rigidity.

Additional loudness is achieved through longer cone travel, so we designed the

with 6 to 9 mm peak-to-peak excursion.

The new reinforced spider renders spider tears a thing of the past.

Butyl rubber surrounds offer linear cone movement without compression or the risk of tearing from

over-excursion even for longer cone travel.

New strontium ceramic ferrite magnets yield smaller magnet sizes without reduced magnet strength

but retain their magnet power far beyond the expected life of the woofer.

Four layers of high-temperature wire on DuPont Kapton Polyamide voice coil bobbins allow for voice

coil temperatures exceeding nearly 225 degrees Celsius without damage.

Rear vented T-yokes allow fresh air to move in from behind the woofer to cool the voice coil.

Velocity!

Velocity

Velocity

Velocity

subwoofer series, in order to achieve superior musical

Product Line (technical data, user notes and soon also a

Velocity

Velocity

product! We have invested tremendous effort

Velocity

subwoofers perform well in sealed, vented and

subwoofers also work well in infinite baffle

line component speakers and

Velocity

Velocity

subwoofers

subwoofers-

Safety precautions

Before starting to mount your speakers, please read carefully the instructions on installation and

connection.

Disconnect the negative terminal of the battery before carrying out installation and connection work.

Observe the vehicle manufacturer’s safety instructions (regarding airbags, alarm systems, trip

computers, vehicle immobilisers).

When drilling holes, take care to avoid damage to vehicle components (battery, cables, fuse boxes).

Do not mount the subwoofer onto flexible rear decks (hatchback vehicles) or anywhere where they may

fall for-ward.

8 622 401 256

2

Page 3

DUAL VOICE COIL ADVANTAGES

The dual voice coil woofer is actually quite old in the home audio industry but still relatively new to the

car audio world. The largest advantage of the DVC woofer is in the flexibility in installation. In order to

raise the sound pressure level (loudness) in a car, you can either add more speakers or add more

amplifier power to drive a single speaker. Many cars cannot fit two subwoofers and their necessary

enclosure volumes but can easily fit large power amplifiers and a single woofer. Simply speaking, the

DVC woofer allows you to make up for speaker deficiencies with additional amplifier power.

SUBWOOFER ENCLOSURE TYPES

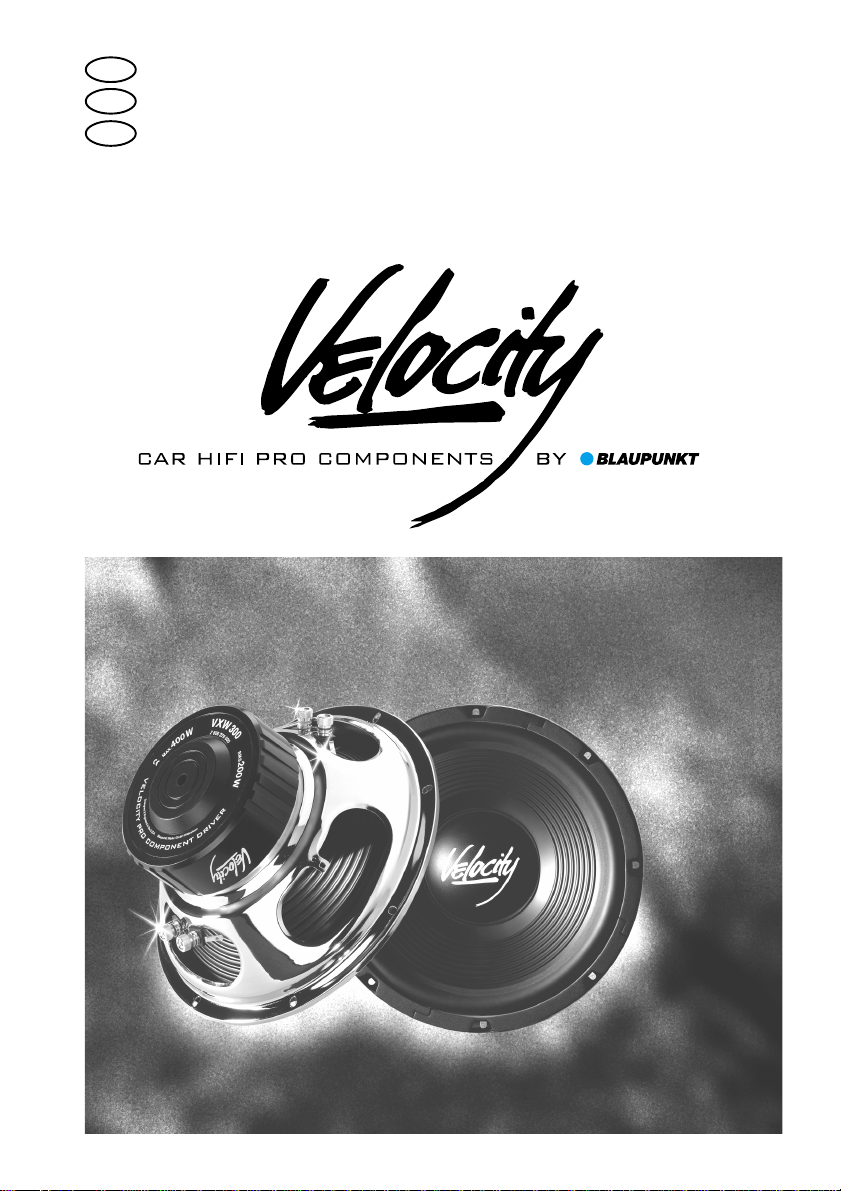

Sound is created by the movement of the woofer

cone back and forth. If a woofer cone moves

FRONT PLATE

FRAME

SURROUND

forward creating a positive pressure wave, this

same motion creates a negative pressure at the

back of the woofer. If these two waves combine

due to the lack of a wall separating the front of the

speaker sound from the back, the output from

the woofer is effectively cancelled thus substan-

YOKE

VENT

CONE

DUST CAP

tially reducing the bass output of the speaker.

This wall is absolutely necessary and is referred

VOICE COIL

to as an acoustical „baffle“. It can be accomplished using a box of some kind or simply the

rear package shelf of an automobile to isolate

the front and back waves of the speaker.

MAGNET

SPIDER

THIELE-SMALL PARAMETERS

Every woofer has its own electromechanical characteristics which are called THIELE-SMALL

parameters. The three most important parameters include RESONANT FREQUENCY („fs“- the

frequency where the speaker moves with the least mechanical resistance), TOTAL Q („Qts“- the

„magnification“ of the cone movement at its resonant frequency), and VOLUMETRIC COMPLIANCE

(„Vas“- the equivalent volume of air that the woofer cone can displace for a given power input). Using

these parameters we can then calculate an optimum box volume for a particular woofer and reasonably

predict its frequency response.

COMMON ENCLOSURE TYPES

In the car audio world there are five types of subwoofer enclosures commonly used: INFINITE

BAFFLE, SEALED BOX (closed box), VENTED BOX (bass reflex), SINGLE-VENTED BANDPASS

(often incorrectly referred to as „5th“ order), DUAL-VENTED BANDPASS (often incorrectly referred

to as „7th“ order). No single design is superior because each has its own compromise in performance,

power handling and design complexity. The bandpass name implies a „built-in“ acoustical response

which has a natural highpass response (@ 30 Hz for example) but also a lowpass response

suppressing high frequencies (e.g., > 80 Hz).

DEUTSCH ENGLISH

FRANÇAIS

8 622 401 256

3

Page 4

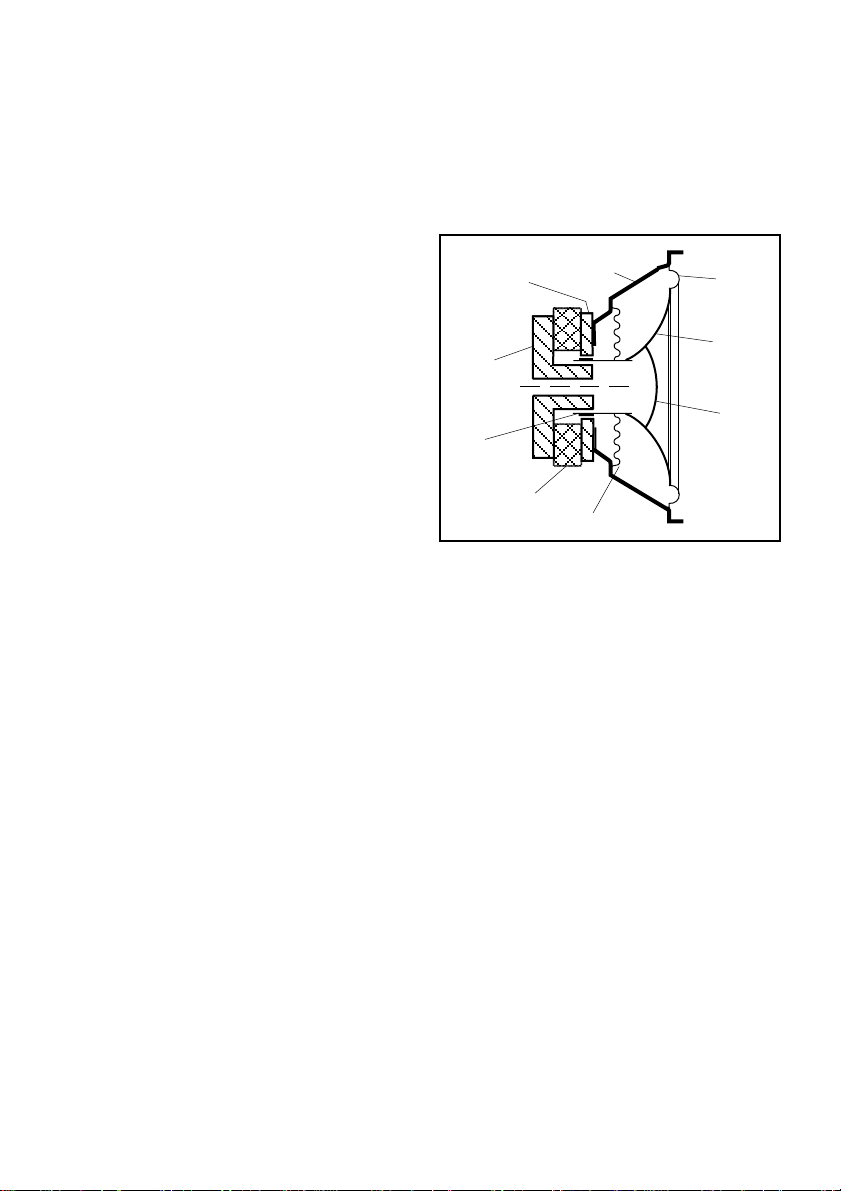

INFINITE BAFFLE (fig.a)designs simply use the trunk of the car for its

acoustical enclosure and the rear deck to isolate the front and rear

sound paths. Advantages include simple installation and adequate

performance for most systems. Disadvantages include poor power

handling capacity and substandard transient response.

SEALED boxes (fig.b) offer one of the best compromises in power

handling and performance. Because of the „air spring“ provided by the

box the advantages include simple box construction, higher power

handling, excellent transient response, and smooth low frequency rolloff. Disadvantages include only moderate efficiencies at low frequencies and the need for large box volumes.

VENTED boxes (fig.c) extend the low frequency response below that

of the sealed box by using a port tube. Advan-tages include extended

low frequency response, lower distortion due to smaller cone movements in its passband, good efficiency, good transient response,

moderate size boxes and higher power capacity. Disadvantages include increased complexity in box design and possible woofer damage

due to over-excursion of the woofer cone below the cut-off frequency

of the vented box.

a)

b)

c)

SINGLE-VENTED BANDPASS boxes (fig.d) are relatively new

(about 5 years in the car) but offer some advantages of both the sealed

and vented designs. Advantages include reasonable efficiency, small

box volumes, good transient response, extended low frequency performance and can be used with very high power amplifiers. Disadvantages include slightly lower efficiency compared to a vented box and

increased complexity in box design and construction.

DUAL-VENTED BANDPASS boxes (fig.e) vent the sound from the

front and back of the woofer through individually tuned enclosure on the

front and rear of the woofer. The advantage of this design is its high

efficiency over a narrow frequency band. Disadvantages include complex design and construction, large box volumes, poor transient response and susceptibilities to cone over-excursions (damage) for

sound outside its primary frequency band.

8 622 401 256

4

d)

e)

Page 5

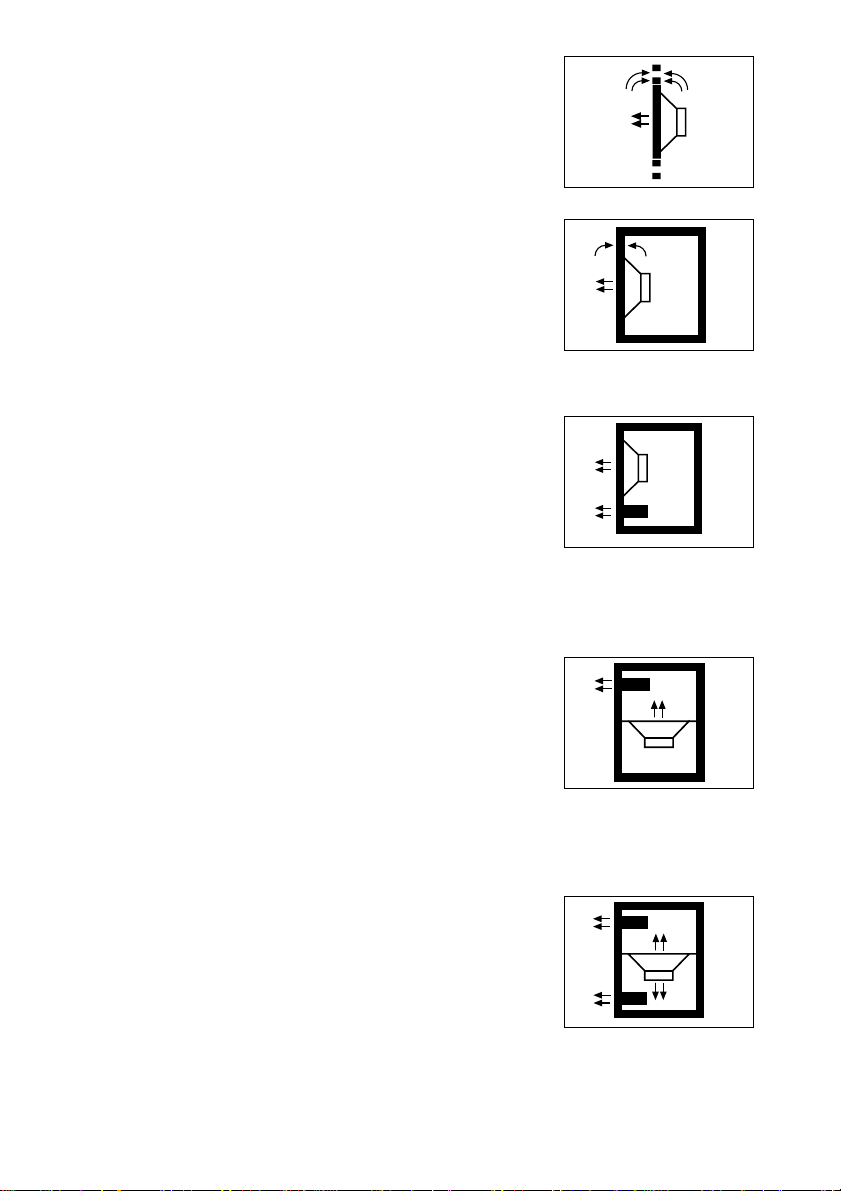

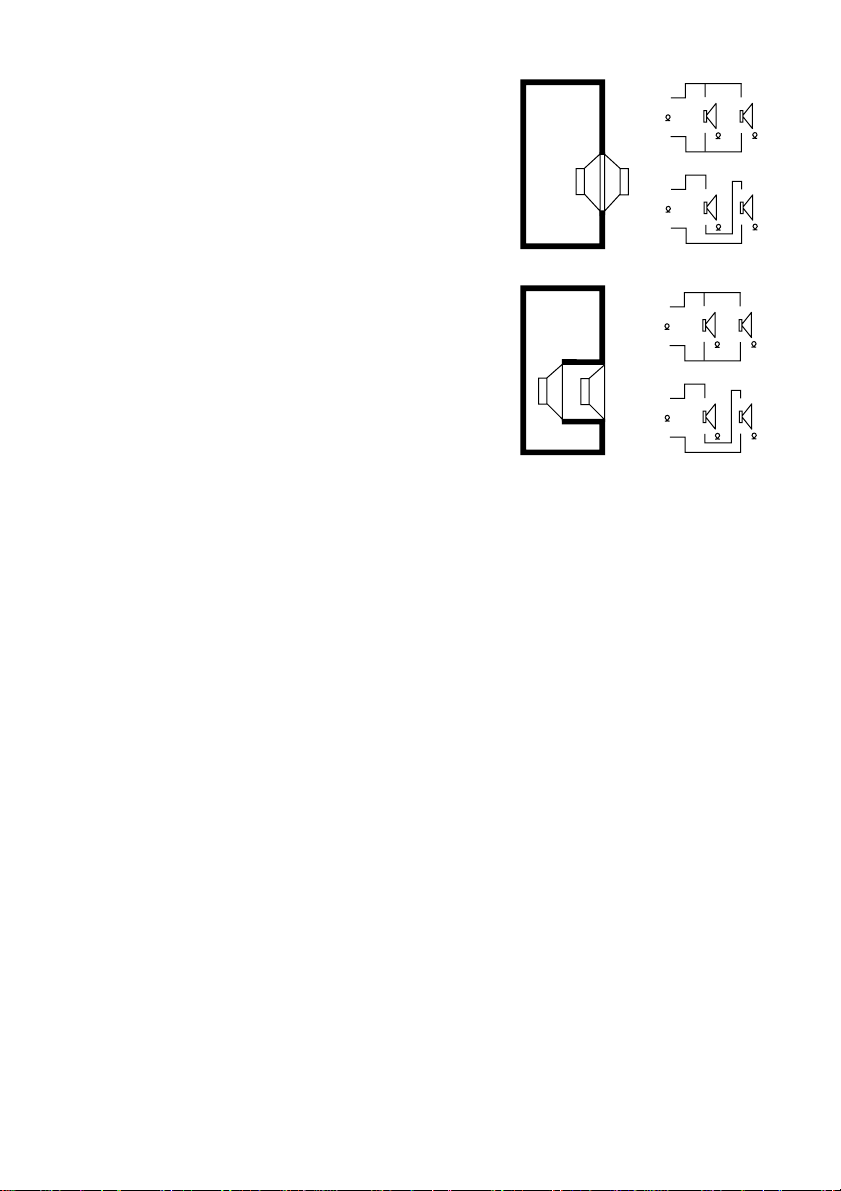

ISOBARIC WOOFER CONFIGURATIONS

+

-

4

+

-

4

+

-

8

SERIES

+

-

4

+

-

4

+

-

2

PARALLE

+

-

4

+

-

4

+

-

8

SERIES

+

-

4

+

-

4

+

-

2

PARALLE

ISOBARIC CONFIGURATION (TANDEM)

Increasing in popularity in recent years is the compound woofer design, more commonly known as the

„Isobaric“ design. Isobaric actually means „constant

pressure“ which is the case having two woofers moving an encapsulated pocket of air between them in

the same direction.

This arrangement acts like a single speaker which

effectively reduces the required box volumes for a

subwoofer system by 50% which is substantial if you

are space-limited. Unfortunately, the trade-off for space is the 3 dB loss in efficiency but this is usually

recovered with increased amplifier power. Care must

be taken to avoid air leaks between the two woofers

and final speaker wiring and impedance loads must

be carefully watched.

SUBWOOFER ENCLOSURE CONSTRUCTION

Before starting final box assembly some basic construction issues should be mentioned:

- Infinite baffle construction in a car is done by simply cutting a piece of wood which will act as an

acoustical divider isolating the front and rear sound of the woofer. This piece of wood is mounted inside

the trunk of the car under the rear deck, or against the back of the rear seat, and should have some

kind of caulking to seal off all residual air leaks.

- Box construction can take on nearly any shape since we are dealing with low frequencies. Odd

shapes that are difficult to cut and glue should be avoided.

- Particle board, MDF, or high grade birch plywood are good materials to build boxes of thicknesses

of 19 to 25 mm.

- All seams in the box should be glued, screwed and caulked to prevent wall separation over time

due to vibration and environmental changes within the car.

- Cross bracing is important for large boxes to prevent wall vibration.

- Acoustical damping material (sheep wool or fibre-glass batting 5 to 10 cm thick), attached to 50%

or more of the interior walls helps reduce box noise and also increases the box volume seen by the

woofer by 10 - 20%. The application of self-adhesive damping mats to the inside walls also helps to

eliminate wall resonances.

- The cables running from the amplifier to the subwoofer should be as short as possible with a cable

cross section of at least 4 mm2.

- The final box should be rock solid and air tight but should also remain serviceable should a woofer

be damaged for any reason.

- When possible, use 10 to 15 cm diameter port tubes to avoid wind noise from smaller diameter

sizes. PVC plumbing pipe in various diameters is available at most hardware stores with „elbow“ pipes

allowing you to bend the tubes inside the box.

- Try to always use active (electronic) crossovers, such as those built into our Velocity amps, for

example.

DEUTSCH ENGLISH

FRANÇAIS

8 622 401 256

5

Page 6

Basic Math Calculations

To build a subwoofer box some very basic math calculations must be made accurately referencing

the formulas below.

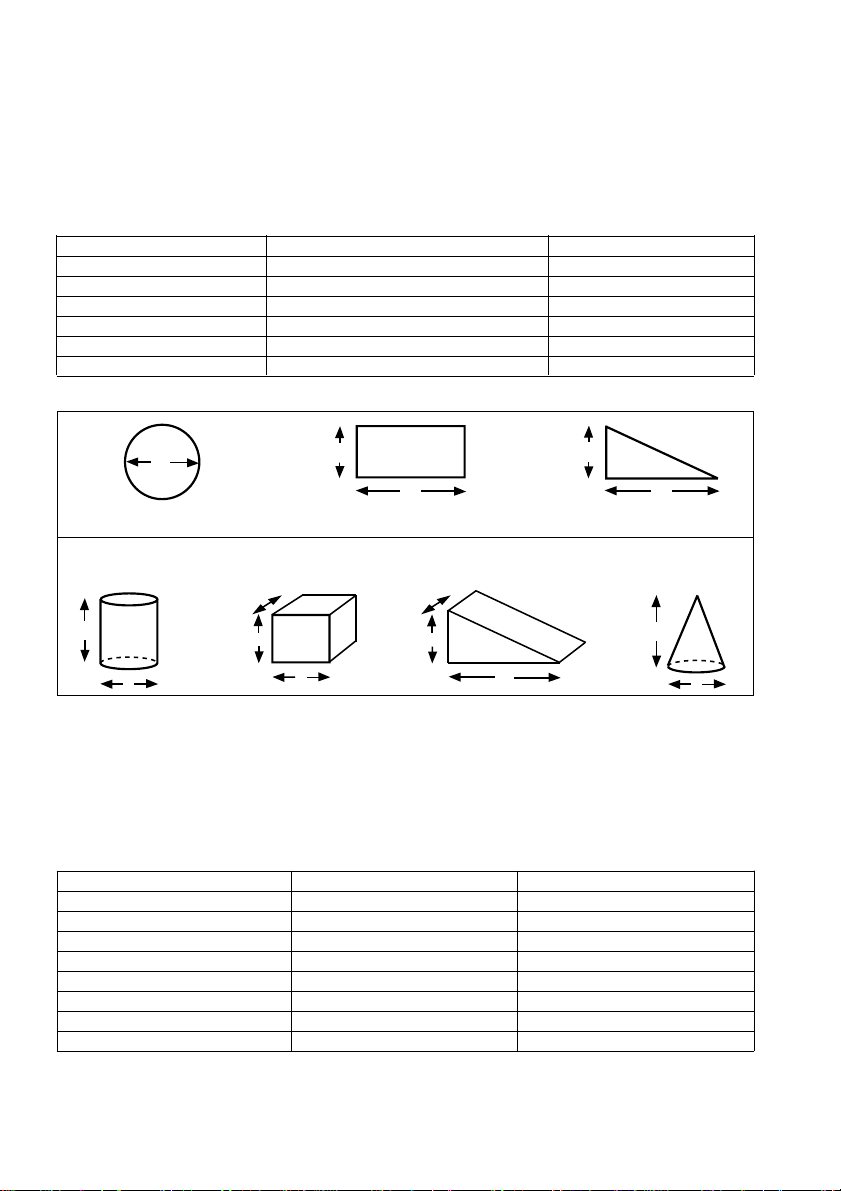

Volume and Area Calculations

Area: Volume:

Circle (port opening) A = 0,79 x d x d Rectangle A = h x w Triangle A = 0,5 x h x w Cylinder (port tube) - V = 0,79 x d x d x h

Rectangular box - V = h x w x d

Triangular box - V = 0,5 x h x w x d

Cone - V = 0,26 x d x d x h

d

d

h

d

h

h

w

d

h

w

w

h

w

h

d

Speaker parameters and box calculations often need some kind of math calculations in order to make

the numbers easy to work with (conversions between metric and Imperial/American units). Some

common conversions are listed below:

Volume and Area Conversions

To convert from: multiply by: to get:

Inches 0.0254 Meters

Meters 39.37 Inches

Square inches 0.007 Square feet

Square feet 144 Square inches

Cubic inches 0.00058 Cubic feet

Cubic feet 1728 Cubic inches

Liters 0.035 Cubic feet

Cubic feet 28.3 Liters

8 622 401 256

6

Page 7

DEUTSCH ENGLISH

FRANÇAIS

8 622 401 256

7

Page 8

D

Schön, daß Sie sich für

Herzlichen Glückwunsch zum Erwerb Ihres neuen

beit haben unsere Ingenieure die neuen Subwoofer der

an Klangqualität bieten.

Um die hohe Systemqualität und Zuverlässigkeit zu gewährleisten, empfehlen wir, die Subwoofer der

Velocity

Komponenten-Lautsprechern und Verstärkern aus unserer

daß die hohe Klangqualität durch Komponenten geringerer Qualität beeinträchtigt wird.

Weitere Informationen (Technische Daten, Anwendungshinweise und demnächst ein Simulationsprogramm für Subwoofergehäuse) über unsere

unter: http://www.velocity.de

TECHNISCHE NEUERUNGEN DER

Hohe Belastbarkeit

Flexibler Einsatz, die neuen

geschlossenen oder ventilierten Gehäusen oder in Bandpaßboxen.

Niedrige Resonanzfrequenzen machen die

unendlicher Schallwand wie z.B. unter der Hutablage eines Fahrzeuges geeignet, wo der Kofferraum

des Fahrzeugs als Gehäuse benutzt wird.

Neue, ultralineare, langhubige Aufhängung

Gewellte Glimmer-Polyprophylenmembranen mit extrem hoher Festigkeit

Hoher maximaler Schalldruck wird durch einen großen Membranhub erreicht. Die

Komponenten wurden für Membranhübe von 6 - 9 mm ausgelegt

Neue hochfeste Zentrierung vermeiden Rißbildungen über die gesamte Lebensdauer

Butyl-Gummisicken sorgen für eine lineare Membranbewegung ohne Kompression oder Rißgefahr

auch bei extremen Membranauslenkungen.

Keramische Strontiumferritmagnete sorgen für Langzeitstabilität der magnetischen Werte im Luft-

spalt, die über die Lebensdauer der Woofer weit hinausgeht

Vierlagenspulen auf DuPont-Kapton-Polyamid-Spulenkörper lassen im Bereich der Schwingspule

Temperaturen bis zu 225 °C zu, ohne das System zu beschädigen. Rückseitig belüftete Polkerne

sorgen für ausreichende Frischluftzufuhr zur Kühlung der Schwingspulen.

-Linie von einem autorisierten

Velocity

Velocity

entschieden haben!

Velocity

Velocity

-Händler einbauen zu lassen. Durch den Einsatz von

Velocity

Velocity

-SERIE

Subwoofer bringen ihre volle Leistung gleichermaßen in

Velocity

-Produktes! In intensiver Entwicklungsar-

Velocity

-Produkte finden Sie auf unserer Internet-Seite

-Linie geschaffen, die ein Höchstmaß

Velocity

Subwoofer auch für offene Einbauten mit

-Serie können Sie vermeiden,

Velocity

-

Sicherheitshinweise

Vor Einbau Ihres Lautsprechers die Einbau- und Anschlußvorschriften lesen.

Für die Dauer der Montage und des Anschlusses ist der Minuspol der Batterie abzuklemmen.

Hierbei sind die Sicherheitshinweise des Kfz-Herstellers (Airbag, Alarmanlagen, Bordcomputer,

Wegfahrsperren) zu beachten.

Beim Bohren von Löchern darauf achten, daß keine Fahrzeugteile (Batterie, Kabel, Sicherungskasten) beschädigt werden.

Subwoofer nicht auf lose Heckablagen (Fließheckfahrzeuge) oder an nach vorne offenen Plätzen

montieren.

8 622 401 256

8

Page 9

DOPPELSPULEN: VORTEILE

Woofer mit Doppelspule werden im Heimbereich schon seit längerer Zeit verwendet; im CarAudioBereich sind sie aber noch relativ neu. Ihr wesentlicher Vorteil liegt in der Einbauflexibilität. Zur

Erhöhung des Schalldrucks im Fahrzeug sind entweder mehr Lautsprecher oder mehr Verstärkerleistung in Verbindung mit einem Lautsprecher erforderlich. In vielen Fahrzeugen ist der Einbau von zwei

Subwoofern mit den entsprechenden Gehäusevolumen nicht möglich, während der Einsatz größerer

Leistungsverstärker und eines Subwoofer in der Regel keine Probleme bereitet. Oder einfach

ausgedrückt: Mit einem Woofer mit Doppelschwingspule können Sie mit erhöhter Verstärkerleistung

mögliche Nachteile eines Lautsprechers ausgleichen.

SUBWOOFER-BOXEN

Klang wird durch die Hin- und Her-Bewegung

der Woofermembran erzeugt. Bewegt sich die

FRONT PLATE

FRAME

SURROUND

Membran eines Woofers nach vorn, entsteht

eine positive Druckwelle. Gleichzeitig wird eine

negative Druckwelle hinter dem Woofer aufgebaut. Vereinen sich diese beiden Wellen durch

das Fehlen einer Trennwand zwischen dem

vorderen und dem hinteren Lautsprecherbereich, so wird der über den Woofer wiedergege-

YOKE

VENT

CONE

DUST CAP

bene Ton fast ausgelöscht und somit die Tiefbaßwiedergabe erheblich geschwächt. Diese

VOICE COIL

Wand ist also zwingend erforderlich und wird als

akustische Schallwand bezeichnet. Die Schallwand kann aus einem Gehäuse bestehen oder

auch ganz einfach aus der hinteren Hutablage

MAGNET

SPIDER

Ihres Fahrzeugs, die die positiven und negativen Schallwellen des Lautsprechers voneinander trennt.

DEUTSCH ENGLISH

FRANÇAIS

THIELE-SMALL-PARAMETER

Jeder Woofer hat seine ganz eigenen elektromechanischen Eigenschaften, die als THIELE-SMALLParameter bezeichnet werden. Zu den drei wichtigsten Parametern gehören die RESONANZFREQUENZ („fs“, also die Frequenz, bei der die Membranbewegung mit dem geringsten mechanischen

Widerstand erfolgt), die GESAMTGÜTE („Qts“, die anzeigt, wie stark die Lautsprecherbewegung bei

der Resonanzfrequenz bedämpft ist), und das ÄQUIVALENTE LUFTVOLUMEN „Vas“. Dieses

Luftvolumen verhält sich bei Kompression wie die Einspannung des Lautsprechers. Anhand dieser

Parameter läßt sich das optimale Gehäusevolumen für einen bestimmten Woofer berechnen und

dessen Übertragungsbereich mit einiger Sicherheit vorhersagen.

BAUARTEN VON SUBWOOFER-BOXEN

Im CarAudio-Bereich werden im wesentlichen fünf verschiedene Subwoofer-Gehäuse verwendet:

LAUTSPRECHER MIT UNENDLICHER SCHALLWAND, GESCHLOSSENE GEHÄUSE, BASSREFLEXBOXEN, EINFACHVENTILIERTE BANDPASSBOXEN (oftmals fälschlicherweise als „Boxen 5.

Ordnung“ bezeichnet) und ZWEIFACHVENTILIERTE BANDPASSBOXEN (oftmals fälschlicherweise als „Boxen 7. Ordnung“ bezeichnet). Keine dieser Gehäusearten ist den anderen überlegen, denn

in jedem Fall müssen individuelle Kompromisse entweder bei der Leistung, Belastbarkeit oder dem

Systemaufbau gemacht werden. Die Bezeichnung „Bandpaß“ impliziert ein „eingebautes“ akustischen Verhalten mit einem natürlichen Hochpaßbereich von z.B. 30 Hz, beinhaltet aber auch ein

Tiefpaß-Verhalten, bei dem die hohen Frequenzen unterdrückt werden (z.B. > 80 Hz).

8 622 401 256

9

Page 10

LAUTSPRECHER MIT UNENDLICHER SCHALLWAND (Fig.a) nutzen den Kofferraum eines Fahrzeugs als akustisches Gehäuse. Dabei

dient die Hutablage zur Trennung der vorderen und hinteren Klangwege. Der Vorteil liegt im einfachen Einbau mit bei den meisten Systemen

völlig angemessener Klangqualität. Nachteile sind die geringe Belastbarkeit und ein eher schwaches Impulsverhalten.

GESCHLOSSENE GEHÄUSE (Fig.b) bilden einen der besten Kompromisse zwischen Belastbarkeit und Leistung, denn durch die im

Gehäuse eingeschlossene Luft wird die Membran praktisch nach

hinten „abgefedert“. Vorteile sind die einfache Gehäusekonstruktion,

hohe Belastbarkeit, ein hervorragendes Impulsverhalten und sanfter

Frequenzübergang im Tieftonbereich. Nachteilig ist der nur mäßige

Wirkungsgrad bei tiefen Frequenzen sowie die Notwendigkeit von

relativ großen Gehäusen.

Verglichen mit geschlossenen Gehäusen weisen BASSREFLEXBO-

XEN (Fig.c) durch Verwendung eines speziellen Tunnels einen größeren Übertragungsbereich bei den Baßfrequenzen auf. Vorteile: größerer Baßbereich, geringere Verzerrungen durch kleinere Membranhübe, hoher Wirkungsgrad, gutes Impulsverhalten, moderate Gehäuseabmessungen und hohe Belastbarkeit. Nachteile: komplizierterer Aufbau, mögliche Schäden am Woofer bei extremen Membranhüben

unterhalb der Abstimmfrequenz der Baßreflexbox.

a)

b)

c)

EINFACHVENTILIERTE BANDPASSBOXEN (Fig.d) sind erst seit

relativ kurzer Zeit für den CarAudio-Bereich verfügbar und bieten

gegenüber geschlossenen Gehäusen und Baßreflexboxen einige Vorteile. Zu diesen Vorteilen zählen ein angemessener Wirkungsgrad,

geringe Abmessungen, gutes Impulsverhalten, bessere Wiedergabe

des Baßfrequenzbereichs sowie die Anschlußmöglichkeit an sehr

leistungsstarke Verstärker. Nachteile sind der etwas geringere Wirkungsgrad gegenüber Baßreflexboxen und der komplexere Aufbau

des Gehäuses.

In ZWEIFACHVENTILIERTEN BANDPASSBOXEN (Fig.e) werden

die front- und rückseitigen Schallanteile des Woofers durch individuell

abgestimmte Kammern geleitet. Der Vorteil dieser Gehäuseart ist der

hohe Wirkungsgrad über einen schmalen Frequenzbereich. Zu den

Nachteilen zählen der komplexe Aufbau, die großen Abmessungen,

das schwache Impulsverhalten sowie die Anfälligkeit bei extremen

Membranauslenkungen (Beschädigungen) bei Klanganteilen außerhalb des primären Frequenzbandes.

8 622 401 256

10

d)

e)

Page 11

ISOBARE WOOFERKONFIGURATIONEN

+

-

4

+

-

4

+

-

8

SERIES

+

-

4

+

-

4

+

-

2

PARALLE

+

-

4

+

-

4

+

-

8

SERIES

+

-

4

+

-

4

+

-

2

PARALLE

ISOBARIC CONFIGURATION (TANDEM)

In den letzten Jahren haben kombinierte Wooferarten an

Bedeutung gewonnen. Sie werden häufig auch als „isobare“

Konfigurationen bezeichnet. Der Ausdruck „isobar“ bedeutet

„konstanter Druck“; dies ist der Fall, wenn ein zwischen zwei

Woofern hermetisch abgeschlossenes Luftvolumen in die

gleiche Richtung bewegt wird.

Diese Bauform funktioniert wie ein einzelner Lautsprecher,

wobei das für einen Subwoofer benötigte Volumen um bis zu

50 Prozent reduziert werden kann - ein wichtiger Aspekt für

Fahrzeugeinbauten, wo der Platz knapp ist. Allerdings steht

diesem Vorteil ein um 3 dB geringerer Wirkungsgrad gegenüber, der jedoch in der Regel mit zunehmender Verstärkerleistung kompensiert wird. Hier ist es besonders wichtig, daß

zwischen den beiden Woofern kein Luftspalt entsteht und daß

sowohl die Lautsprecherverkabelung als auch die Eingangslasten sorgfältig beachtet werden.

AUFBAU VON SUBWOOFERGEHÄUSEN

Bevor Sie mit dem endgültigen Aufbau des Gehäuses beginnen, sollten Sie einige grundlegende Konstruktionshinweise beachten:

• Subwoofer mit unendlicher Schallwand können in einem Fahrzeug einfach mit Hilfe einer

zugeschnittenen Holzplatte aufgebaut werden, die für eine akustische Trennung zwischen den frontund rückseitigen Klanganteilen eines Woofers sorgt. Die Holzplatte wird im Kofferraum unter der

Hutablage oder hinten an der Rückbank angebracht. Eventuell vorhandene Luftspalte sollten mit

Dichtmaterial abgedichtet werden.

• Die Form des Gehäuses spielt bei der Wiedergabe tiefer Frequenzen eine untergeordnete Rolle

und ist daher relativ frei wählbar. Ausgefallene Formen, die sich nur schwierig zuschneiden und

verleimen lassen, sollten allerdings vermieden werden.

• MDF-Platten bzw. hochwertiges Sperrholz aus Birke mit einer Stärke von 19 bis 25 mm sind für

den Bau von Boxen gut geeignet..

• Alle aneinanderstoßenden Gehäusewände sollten verleimt, verschraubt und abgedichtet werden,

um ein fortschreitendes Loslösen durch Schwingungen und Umwelteinflüsse im Fahrzeug zu

vermeiden.

• Um Schwingungen zu vermeiden, sind bei großen Boxen Versteifungsrippen erforderlich.

• Akustisches Dämmaterial (Schafwolle oder Polyesterflies mit einer Stärke von 5 bis 10 cm), mit

dem die Innenwände zu mindestens 50 Prozent ausgekleidet ist, reduziert die Eigenresonanzen des

Gehäuses und erhöht das wirksame Innenvolumen um 10 bis 20 Prozent. Ungewollte Resonanzen

können durch Bekleben der Innenwände mit selbstklebenden Dämmatten reduziert werden.

• Die Kabel vom Verstärker zum Subwoofer sollten so kurz wie möglich sein und einen Querschnitt

von mindestens 4 mm2 haben.

• Das fertige Subwoofergehäuse sollte absolut stabil und luftdicht sein und notwendige Reparaturarbeiten am Woofer zu einem späteren Zeitpunkt ermöglichen.

• Wenn möglich Baßreflextunnel mit einem Durchmesser von 10 bis 15 cm einsetzen, um die bei

kleineren Öffnungen üblichen Luftgeräusche zu vermeiden. PVC-Rohre sind mit verschiedenen

Durchmessern im Handel erhältlich, wobei die Rohrteile mit Gelenkstücken im Gehäuse verlegt

werden können.

• Aktive (elektronische) Frequenzweichen einsetzen, wie z.B. in unseren

eingebaut .

Velocity

Verstärkern

DEUTSCH ENGLISH

FRANÇAIS

8 622 401 256

11

Page 12

Grundsätzliche mathematische Berechnungen

Für den Bau von Subwoofergehäusen müssen die Volumina berechnet werden, die folgenden

Formeln helfen dabei:

Volumen- und Flächenberechnung

Kreis (Tunnel) A = 0,79 x d x d Rechteck A = h x w Dreieck A = 0,5 x h x w Zylinder (Tunnel) - V = 0,79 x d x d x h

Rechteckige Box - V = h x w x d

Dreieckige Box - V = 0,5 x h x w x d

Membran - V = 0,26 x d x d x h

Fläche: Volumen:

d

d

h

d

h

h

w

d

h

w

w

h

h

Die folgende Tabelle gibt Ihnen die wesentlichen Umrechnungen in verschiedene

Maßsysteme an:

Von: Mutiplikator: In:

Inches 0.0254 Meters

Meters 39.37 Inches

Square inches 0.007 Square feet

Square feet 144 Square inches

Cubic inches 0.00058 Cubic feet

Cubic feet 1728 Cubic inches

Liters 0.035 Cubic feet

Cubic feet 28.3 Liters

w

d

8 622 401 256

12

Page 13

F

Merci d’avoir choisi

Nous vous félicitons pour l’acquisition de votre nouveau produit

Velocity!

Velocity

! Nos ingénieurs ont, après

un travail de conception et de développement intensif, créé les nouveaux subwoofers de la gamme

Velocity

qui offrent une qualité de son optimale.

Afin de garantir la haute qualité du système et la fiabilité de ce dernier, nous vous recommandons de

faire instal-ler les subwoofers de la gamme

En utilisant les haut-parleurs de composants et amplificateurs de notre gamme

Velocity

par un revendeur autorisé de produits

Velocity

, vous pouvez

Velocity

éviter que la haute qualité du son soit entravée par des éléments de qualité inférieure.

Pour de plus amples informations (caractéristiques techniques, instructions concernant les applications et, bien-tôt, un programme de simulation pour le boîtier du subwoofer) relatives à nos produits

Velocity

, veuillez consul-ter notre page sur Internet à l’adresse suivante: http://www.velocity.de

NOUVEAUTES TECHNIQUES DE LA GAMME Velocity

Haute capacité de charge

Utilisation flexible; les nouveaux subwoofers Velocity offrent leur puissance complète aussi bien dans

les boîtiers fermés que dans les boîtiers ventilés ou bien dans les enceintes passe-bande.

Des fréquences de résonance basses permettent également l’utilisation des subwoofers Velocity

dans les instalations ouvertes avec paroi acoustique infinie, comme par exemple sous la tablette

arrière d’un véhicule, où le coffre du véhicule est utilisé comme boîtier.

Nouvelle suspension ultralinéaire et à longue course.

Membranes de polypropylène au mica ondulées avec une résistance extrêmement élevée

Pression acoustique maximale élevée réalisée par une grande course de la membrane. Les éléments

Velocity

ont été conçus pour des courses de membrane de 6 à 9 mm.

Nouveau centrage hautement résistant empêche la formation de fissures pendant toute la durée de

vie.

Des bandes de renforcement en butyl-caoutchouc garantissent un mouvement linéaire de la

membrane sans compression ou risque de fissure, même pour des élongations extrêmes de la

membrane.

Des aimants céramiques en ferrite de strontium garantissent une stabilité de longue durée des valeurs

magné-tiques dans l’entrefer, stabilité qui se maintient bien plus longtemps que la durée de vie du

woofer lui-même.

Des bobines à quatre couches sur corps de bobines en polyamide DuPont-Kapton permettent au

niveau de la bobine mobile des températures allant jusqu’à 225°C sans provoquer l’endommagement

du système.

Des noyaux polaires ventilés à l’arrière garantissent une alimentation suffisante en air frais pour le

refroidissement des bobines mobiles.

DEUTSCH ENGLISH

.

FRANÇAIS

Consignes de sécurité

Avant d’installer votre haut-parleur, prière de lire attentivement les instructions de raccordement.

Pendant toute la durée du montage et du raccordement, débrancher le pôle moins de la batterie.

Pour cela, observer scrupuleusement les consignes de sécurité du constructeur du véhicule (airbag,

dispositifs d’alarme, ordinateur de bord, dispositifs d’antidémarrage).

Lorsque vous percez des trous, veillez à ce qu’aucune pièce du véhicule (batterie, câbles, boîtier de

fusibles) ne soit endommagée.

Prière de pas monter le subwoofer à des endroits ouverts ou sur des tablettes arrières flexibles

(véhicules bicorps).

8 622 401 256

13

Page 14

BOBINES COMPOUND: AVANTAGES

Les woofers avec bobine compound sont déjà utilisés dans le domaine domestique depuis longtemps,

sont ce-pendant relativement nouveaux dans le domaine de l’acoustique automobile. Leur avantage

principal est la flexi-bilité de montage. Pour l’accroissement de la pression acoustique dans le

véhicule, on nécessite soit un plus grand nombre de haut-parleurs soit un amplificateur de puissance

accrue en combinaison avec un haut-parleur.

Dans un grand nombre de véhicules, le montage de deux subwoofers avec les volumes correspondants n’est pas possible, tandis que l’utilisation d’amplificateurs de plus grande puissance ne présente

en règle générale aucun problème avec un subwoofer. En des termes plus simples: avec un woofer

à bobine compound mobile, vous pouvez compenser des éventuels inconvénients d’un haut-parleur

avec une puissance d’amplification accrue.

ENCEINTES DE SUBWOOFER

Le son est créé par le mouvement aller et retour

de la membrane du woofer. Lorsque la membrane d’un woofer se déplace vers l’avant, une onde

FRONT PLATE

FRAME

SURROUND

de surpression positive est créée. En même

temps, une onde de surpression négative est

créée derrière le woofer. Lorsque ces deux ondes se rencontrent; étant donné le manque de

paroi séparatrice entre le domaine avant et le

domaine arrière du haut-parleur, le ton retrans-

YOKE

VENT

CONE

DUST CAP

mis par le woofer est pratiquement annulé, et la

reproduction des graves profonds par conséquent considérablement affaiblie. Cette paroi

VOICE COIL

est donc absolument indispensable et est appelée paroi acoustique. La paroi acoustique peut

se constituer d’un boîtier ou bien tout simple-

MAGNET

SPIDER

ment de la tablette arrière de votre véhicule, qui

sépare les ondes acoustiques positives et négatives du haut-parleur.

PARAMETRES THIELE-SMALL

Chaque woofer a ses propriétés électroniques tout à fait spécifiques appelées paramètres THIELESMALL. Les trois paramètres les plus importants sont la FREQUENCE DE RESONANCE („fs“, c’està-dire la fréquence à laquelle le mouvement de la membrane se fait avec la résistance mécanique la

plus basse), la QUALITE GLOBALE („Qts“ qui indique dans quelle mesure le mouvement du hautparleur est atténué à la fréquence de résonance) et le VOLUME D’AIR EQUIVALENT „Vas“. Ce

volume d’air se comportent en cas de compression comme encastrement du haut-parleur. A l’aide de

ces paramètres, on peut calculer le volume optimal du boîtier pour un woofer précis, et prévoir la

gamme de transmission avec une précision relativement élevée.

MODELES D’ENCEINTES DE SUBWOOFER

Dans le domaine de l’acoustique automobile, on utilise essentiellement cinq types différents

d’enceintes de subwoofer: HAUT-PARLEURS AVEC PAROI ACOUSTIQUE INFINIE, ENCEINTES

FERMEES, ENCEINTES BASS-REFLEX, ENCEINTES PASSE-BANDE A VENTILATION UNIQUE

(très souvent appelées par abus de langage „enceintes du 5ème ordre“) et ENCEINTES PASSEBANDE A DOUBLE VENTILATION (très souvent appelées par abus de langage „enceintes du 7ème

ordre“). Aucun de ces types d’enceintes n’est meilleur que l’autre, car on doit dans chaque cas faire

des compromis individuels, que ce soit au niveau de la puissance, de la capacité de charge ou bien

en ce qui concerne la construction du système. L’appellation „passe-bande“ implique un comportement acoustique „intégré“ avec une gamme passe-haut de par exemple 30 Hz, avec également un

comportement passe-bas pour lequel les hautes fréquences sont supprimée (par exemple > 80 Hz).

14

Page 15

Les HAUT-PARLEURS AVEC PAROI ACOUSTIQUE INFINIE (fig.a)

exploitent le coffre d’un véhicule comme enceinte acoustique. La

tablette arrière sépare alors les voies avant et arrière des ondes

acoustiques. L’avantage réside dans le montage simple avec la plupart

des systèmes, tout en garantissant une qualité du son absolument

satisfaisante. Inconvénients: capacité de charge peu élevée et réponse d’impulsion relativement faible.

a)

Les ENCEINTES FERMEES (fig.b)constituent l’un des meilleurs com-

promis entre la capacité de charge et la puissance, car l’air enveloppé

dans l’enceinte constitue pratiquement un tampon pour la membrane

vers l’arrière.

Avantages: construction simple de l’enceinte, haute capacité de

charge, excellente réponse d’impulsion et transi-tion de fréquence

douce dans la gamme de graves. Inconvénients: rendement simplement moyen pour les basses fréquences, et nécessité d’enceintes de

dimensions relativement grandes.

En comparaison avec les enceintes fermées, les ENCEINTES BASS-

REFLEX (fig.c) offrent, de par l’utilisation d’un tunnel spécial, une

gamme de transmission plus grande pour les fréquences de graves.

Avantages: gamme de graves plus étendue, distorsions réduites par

des courses plus petites de la membrane, rendement élevé, bonne

réponse d’impulsion, dimensions modérées de l’enceinte et haute

capacité de charge. Inconvénients: construction complexe, éventuels

endommagements du woofer en cas de courses extrêmes de la

membrane au-dessous de la fréquence d’accord de l’enceinte bassreflex.

Les ENCEINTES PASSE-BANDE A VENTILATION UNIQUE (fig.d)

ne sont disponibles que depuis quelques temps dans le domaine de

l’acoustique automobile et présentent quelques avantages par rapport

aux enceintes fermées et aux enceintes bass-reflex. Parmi ces avantages, on compte un rendement satisfaisant, des petites dimensions,

une bonne réponse d’impulsion, une meilleure reproduction de la

gamme des graves ainsi que la pos-sibilité de raccordement à un

amplificateur de très haute puissance. Inconvénients: rendement un

peu inférieur à celui des enceintes bass-reflex et construction plus

complexe de l’enceinte.

DEUTSCH ENGLISH

FRANÇAIS

b)

c)

d)

Dans les ENCEINTES PASSE-BANDE A DOUBLE

VENTILATION(fig.e), les ondes acoustiques avant et arrière du

woofer sont conduites à travers des chambres accordées individuellement. L’avantage de ce type d’enceinte est le haut rendement

pour une gamme de fréquence étroite. Parmi les inconvénients, on

compte la construction complexe, les grandes dimensions, la faible

réponse d’impulsions et sensibilité pour les élongations extrêmes de

la membrane (endommagement) pour les parts de son extérieures à

la bande de fréquence primaire.

e)

8 622 401 256

15

Page 16

CONFIGURATIONS ISOBARES DE WOOFERS

Au cours des dernières années, les types combinés de woofers ont gagné de plus en plus

d’importance. Ils sont aussi souvent appelés configurations „isobares“. L’expression „isobare“ signifie

„pression constante“; c’est le cas lorsqu’un volume d’air hermétiquement fermé entre deux woofers

est déplacé dans le même sens.

Ce modèle fonctionne comme un haut-parleur individuel, le volume nécessaire pour un subwoofer

pouvant être réduit de jusqu’à 50 %, ce qui représente un aspect important pour les montages dans

les véhicules où l’espace disponible est réduit. Cependant, cet avantage est confronté à un rendement

plus réduit d’environ 3 dB, qui est toutefois compensé en règle générale par un accroissement de la

puissance de l’amplificateur. Il est particulièrement important ici qu’il n’existe pas d’espace d’air entre

les deux woofers et qu’on respecte scrupuleusement aussi bien les instructions de câblage du hautparleur que les charges d’entrée admissibles.

4. CONSTRUCTION DES ENCEINTES DE SUBWOOFER

Avant de commencer la construction définitive de l’enceinte, prière d’observer scrupuleusement les

quelques instructions suivantes:

- Les subwoofers avec paroi acoustique infinie peuvent être simplement installées dans un véhicule

à l’aide d’une plaque en bois découpée en conséquence qui assure la séparation acoustique des

ondes acoustiques avant et arrière d’un woofer. La plaque en bois est installée dans le coffre audessous de la tablette arrière ou bien sur le siège arrière. Prière de boucher les espaces d’air

éventuellement existants avec du matériel d’étanchement.

- La forme de l’enceinte joue un rôle peu important pour la reproduction de basses fréquences, et

peut par conséquent être choisi relativement librement. Il est cependant recommandé d’éviter les

formes singulières qui ne peuvent être découpées ou collées que difficilement.

- Les plaques MDF ou en contreplaqué de haute qualité en bois de bouleau d’une épaisseur de 19

à 25 mm sont bien indiquées pour la construction des enceintes.

- Il est recommandé de coller, visser ou d’étancher toutes les parois de l’enceinte se touchant afin

d’éviter un détachement progressif par les vibrations et influences atmosphériques dans le véhicule.

- Pour éviter les vibrations, prévoir absolument des nervures de renforcement pour les enceintes

de grandes dimensions.

- Un matériau d’atténuation acoustique (laine de mouton ou voile de polyester avec une épaisseur

de 5 à 10 cm) revêtant les parois intérieures à 50 % au moins réduit les résonances propres de

l’enceinte et accroît le volume intérieur utile de 10 à 20 pour cent. Les résonances non souhaitées

peuvent être réduites en collant des nattes insonorisantes autocollantes sur les parois intérieures.

- Les câbles reliant l’amplificateur au subwoofer devraient être aussi courts que possible et avoir

une section minimale de 4 mm2.

- L’enceinte de subwoofer finie doit être absolument stable et étanche à l’air, et permettre les travaux

de répara-tion nécessaires sur le woofer à une date ultérieure.

- Si possible, utiliser un tunnel de bass-reflex avec un diamètre de 10 à 15 cm afin d’empêcher les

bruits d’air habituels pour les ouvertures plus petites. Des tubes en PVC sont disponibles avec divers

diamètres dans les magasins spécialisés, les pièces du tubes pouvant être posées avec des raccords

coudés dans l’enceinte.

- Utiliser des répartiteurs actifs (électroniques) tels que ceux intégrés dans nos amplificateurs

Velocity.

8 622 401 256

16

Page 17

Calculs mathématiques fondamentaux

Pour la construction d’enceintes de subwoofers, quelques calculs mathématiques fondamentaux sont

indispensables avec les formules suivantes:

Calcul de volumes et de surfaces

Surface: Volume:

Cercle (tunnel) A = 0,79 x d x d Rectangle A = h x w Triangle A = 0,5 x h x w Cylindre (tunnel) - V = 0,79 x d x d x h

Enceinte rectangulaire - V = h x w x d

Enceinte triangulaire - V = 0,5 x h x w x d

Membrane - V = 0,26 x d x d x h

d

d

h

d

h

h

w

d

h

w

w

h

w

h

d

Pour le calcul de paramètres de haut-parleurs et d’enceintes, il est parfois indispensable d’effectuer

des conversions entre les unités métriques et les unités britanniques/américaines. Veuillez trouver

quelques facteurs de conversion usuels dans le tableau suivant:

DEUTSCH ENGLISH

FRANÇAIS

De: Multiplicateur: En:

pouces 0.0254 mètres

mètres 39.37 pouces

pouces carrés 0.007 pieds carrés

pieds carrés 144 pouces carrés

pouces cubes 0.00058 pieds cubes

pieds cubes 1728 pouces cubes

litres 0.035 pieds cubes

pieds cubes 28.3 litres

8 622 401 256

17

Page 18

VXW 250 Technical specifications • Technische Daten •

Spécifications techniques

10" SUBWOOFER • TECHNICAL DATA

Nominal diameter 10.0 in (250 mm)

Magnet weight 40 oz (1.2 kg)

Nominal impedance 4 Ω (ea. coil)

DC resistance (Re) 3.12 Ω (ea.)

Resonance frequency (fs) 30 Hz

Total Q factor (Qts) 0.42

Mechanical Q (Qms) 10,20

Electrical Q (Qes) 0.44

Equivalent air volume (Vas) 3,2 ft3 (90 ltr’s)

4.96"

126 mm

10.00"

257 mm

0.38"

9,5 mm

Velocity

Effective cone area (Sd) 57 in2 (0.036 m2)

Compliance (Cms) 0,49 mm/N

Moving mass (Mms) 2.0 oz (58 g)

Voice coil diameter 2.0" (50 mm)

Voice coil former material Kapton polyimide

Linear excursion (Xmax) ± 0.16 in (±4 mm)

Force factor (BI) 6.3 Tm

Acoustical efficiency (No) 0.54 %

Continuous power (Pe) 180 W (350 peak)

Sensitivity (SPL) 94 dB, 2.83v / 1m

91 dB, 1 W /1 m

6,61" 168 mm

8,92" 227 mm

8 622 401 256

18

Page 19

VXW 250 Recommended box designs • Boxenempfehlung •

Conception recommandée des enceintes

SEALED

BOX

VT f3 SPL

Total box Freq. Midvolume band

(l) (Hz) (dB)

15 60 91

30 57 91

45 54 91

60 51 91

75 50 91

trunk 60 91

VENTED

BOX

VT f3 fB PL PL SPL

Total box Freq. Port Port Port Midvolume tuning tube tube band

(l) (Hz) (Hz) (mm) (mm) (dB)

25 56 45 26.8 NR 91

40 45 40 14.3 28.3 91

55 38 35 10.3 26.4 91

70 34 30 16 31 91

85 31 30 10.9 22.3 91

100 28 30 8.3 17.7 91

effc’y

sealedbox - 30 l ... 75 l

freq. length length effc’y

for 70 for 100

mm i. D. mm i. D.

ventedbox - 40 l ... 85 l

DEUTSCH ENGLISH

FRANÇAIS

SINGLE VENTED

BANDPASS BOX

VTf3Lf3HfBVFVRPLPLSPL

Total Freq. Freq. Port Vented Sealed Port Port Mid-

box tune front rear tube tube band

vol. freq. box box length length effc’y

(l) (Hz) (Hz) (Hz) (l) (l) (cm) (cm) (dB)

25 55 200 90 15 10 4.5 10.9 92

40 35 140 75 15 25 9.3 19.4 89

55 32 110 60 20 35 12 24.2 88

70 30 85 50 30 40 11.3 22.9 87

85 NR

100 NR

volume volume for 70 for100

mm i. D. mm i. D.

bandpassbox - 25 l ... 70 l

NR = NOT A RECOMMENDED APLICATION

8 622 401 256

19

Page 20

VXW 300

12" SUBWOOFER • TECHNICAL DATA

Nominal diameter 12.0 in (300 mm)

Magnet weight 50 oz (1.4 kg)

Nominal impedance 4 Ω (ea. coil)

DC resistance (Re) 3.12 Ω (ea.)

Resonance frequency (fs) 35 Hz

Total Q factor (Qts) 0.42

Mechanical Q (Qms) 9,80

Electrical Q (Qes) 0.44

Equivalent air volume (Vas) 3,2 ft3 (91 ltr’s)

5,62"

143 mm

12.00"

309 mm

0.41"

10,5 mm

Velocity

Effective cone area (Sd) 79 in2 (0.052 m2)

Compliance (Cms) 0,23 mm/N

Moving mass (Mms) 3,1 oz (88 g)

Voice coil diameter 2.0" (50 mm)

Voice coil former material Kapton polyimide

Linear excursion (Xmax) ± 0.16 in (±4 mm)

Force factor (BI) 8,4 Tm

Acoustical efficiency (No) 0.86 %

Continuous power (Pe) 200 W (400 peak)

Sensitivity (SPL) 94dB,2.83v/1m

91 dB, 1 W/1 m

6,61" 168 mm

10,94" 278 mm

8 622 401 256

20

Page 21

VXW 300

SEALED

BOX

VT f3 SPL

Total box Freq. Midvolume band

effc’y

(l) (Hz) (dB)

15 60 91

30 57 91

45 54 91

60 51 91

75 50 91

trunk 60 91

VENTED

BOX

VT f3 fB PL PL SPL

Total box Freq. Port Port Port Midvolume tuning tube tube band

freq. length length effc’y

for 70 for 100

mm i. D. mm i. D.

(l) (Hz) (Hz) (mm) (mm) (dB)

25 67 55 11,1 22,6 91

40 53 45 10,0 20,6 91

55 45 40 8,7 18,2 91

70 40 35 9,1 19,9 91

85 36 35 6,4 14,1 91

100 33 35 4,4 10,7 91

sealedbox - 30 l ... 75 l

ventedbox - 40 l ... 85 l

DEUTSCH ENGLISH

FRANÇAIS

SINGLE VENTED

BANDPASS BOX

VTf3Lf3HfBVFVRPLPLSPL

Total Freq. Freq. Port Vented Sealed Port Port Mid-

box tune front rear tube tube band

vol. freq. box box length length effc’y

(l) (Hz) (Hz) (Hz) (l) (l) (cm) (cm) (dB)

25 60 160 100 15 10 NR 7,2 94

40 47 140 75 20 20 5,4 12,4 91

55 40 110 65 25 30 6,2 13,8 90

70 30 85 50 30 40 11.3 22.9 87

85 25 70 40 40 45 14,3 28,3 84

100 <NR>

volume volume for 70 for 100

mm i. D. mm i. D.

bandpassbox - 25 l ... 70 l

NR = NOT A RECOMMENDED APLICATION

8 622 401 256

21

Page 22

VXW 380

15" SUBWOOFER • TECHNICAL DATA

Nominal diameter 15.0 in (380 mm)

Magnet weight 65 oz (1.8 kg)

Nominal impedance 4 Ω (ea. coil)

DC resistance (Re) 3.12 Ω (ea.)

Resonance frequency (fs) 30 Hz

Total Q factor (Qts) 0.49

Mechanical Q (Qms) 7,5

Electrical Q (Qes) 0.52

Equivalent air volume (Vas) 7,39 ft3 (210 ltr’s)

Effective cone area (Sd) 133 in2 (0.084 m2)

Compliance (Cms) 0,21 mm/N

Moving mass (Mms) 4,8 oz (136 g)

Voice coil diameter 3" (75 mm)

Voice coil former material Kapton poly mide

(385 mm)

6,96"

(177 mm)

15.00"

0.55"

(14 mm)

Velocity

7,64" (194 mm)

13,89" (353 mm)

Linear excursion (Xmax) ± 0.16 in (±4 mm)

Force factor (BI) 8,9 Tm

Acoustical efficiency (No) 1,1 %

Continuous power (Pe) 220 W (440 peak)

Sensitivity (SPL) 96dB, 2.83 v / 1m

93 dB, 1 W / 1 m

8 622 401 256

22

Page 23

VXW 380

SEALED

BOX

VT f3 SPL

Total box Freq. Midvolume band

effc’y

(l) (Hz) (dB)

40 57 93

80 46 93

120 44 93

160 42 93

200 40 93

trunk 42 93

VENTED

BOX

VT f3 fB PL PL SPL

Total box Freq. Port Port Port Midvolume tuning tube tube band

freq. length length effc’y

for 70 for 100

mm i. D. mm i. D.

(l) (Hz) (Hz) (mm) (mm) (dB)

40 69 50 15,0 NR 93

80 49 40 9,9 28.6 93

120 40 35 7,5 23,3 93

160 34 30 7,8 24,0 93

200 31 30 4,6 16,7 93

240 28 30 NR 11,8 93

DEUTSCH ENGLISH

sealedbox - 80 l ... 200 l

FRANÇAIS

ventedbox - 80 l ... 200 l

SINGLE VENTED

BANDPASS BOX

VTf3Lf3HfBVFVRPLPLSPL

Total Freq. Freq. Port Vented Sealed Port Port Mid-

box tune front rear tube tube band

vol. freq. box box length length effc’y

(l) (Hz) (Hz) (Hz) (l) (l) (cm) (cm) (dB)

40 NR>

80 52 140 800 50 30 NR 3,8 96

120 37 110 65 50 70 NR 12,3 92

160 25 100 50 50 110 10.3 29,6 88

200 15 90 40 50 150 20,9 53,4 84

240 NR

volume volume for 70 for 100

mm i. D. mm i. D.

bandpassbox - 80 l ... 200 l

NR = NOT A RECOMMENDED APLICATION

23

Loading...

Loading...