Page 1

Data Sheet

Multi-Range Programmable DC Power Supplies

9115 Series

1200 W Multi-Range DC Power Supplies

Any 9115 series model can replace several supplies on your bench or in your rack. Unlike conventional

supplies with fixed output ratings, these multi-range power supplies automatically recalculate voltage and

current limits for each setting, providing full output power in any Volt/Amp combination within the rated

voltage and current limits.

For benchtop applications, this series provides a numerical keypad for direct data entry along with

convenient cursors and analog style knobs to quickly make incremental voltage or current changes. System

integrators benefit from the standard USB (USBTMC-compliant), RS-232, GPIB, and RS-485 interfaces

supporting SCPI commands. Alternatively, users can control the power supply, execute test sequences or

log measurements using the provided PC software application. This software also integrates with Data

Dashboard for LabVIEW apps enabling iOS, Android or Windows 8 compatible tablets or smart phones to

remotely monitor select measurement indicators.

The 9115-AT provides automative power test waveforms compliant to DIN 40839 and ISO 16750-2

standards that can simulate common test conditions for electrical and electronic devices installed in

automobiles.

Model 9115 9115-AT 9116

Max. Voltage 0 - 80 V 0 - 150 V

Max. Current 0 - 60 A 0 - 30 A

Max. Power 1200 W

Features & Benefits

■ Multi-ranging operation (output up to 1200 W

within maximum voltage and current rating)

■ Compact, high density, 1U rackmount form

factor

■ High programming and readback resolution of

1 mV/1 mA

■ Adjustable voltage slope (rise and fall time)

■ Sequence programming (list mode)

■ Save and recall up to 100 instrument settings

■ Standard USB (USBTMC-compliant), RS-232,

GPIB, and RS-485 interfaces supporting SCPI

commands for remote control

■ Analog interface with control and monitoring

functions

■ Master/Slave mode for parallel and series

operation

■ Remote sense

■ Overvoltage/overpower/overtemperature

protection, and key-lock function

■ Test functions compliant to automotive

standards (Model 9115-AT only)

■ Softpanel for remote control, test sequence

generation and data logging

Technical data subject to change

© B&K Precision Corp. 2014

www.bkprecision.com

Page 2

Multi-Range Programmable DC Power Supplies

115 Series

9

ront panel

F

Rear panel

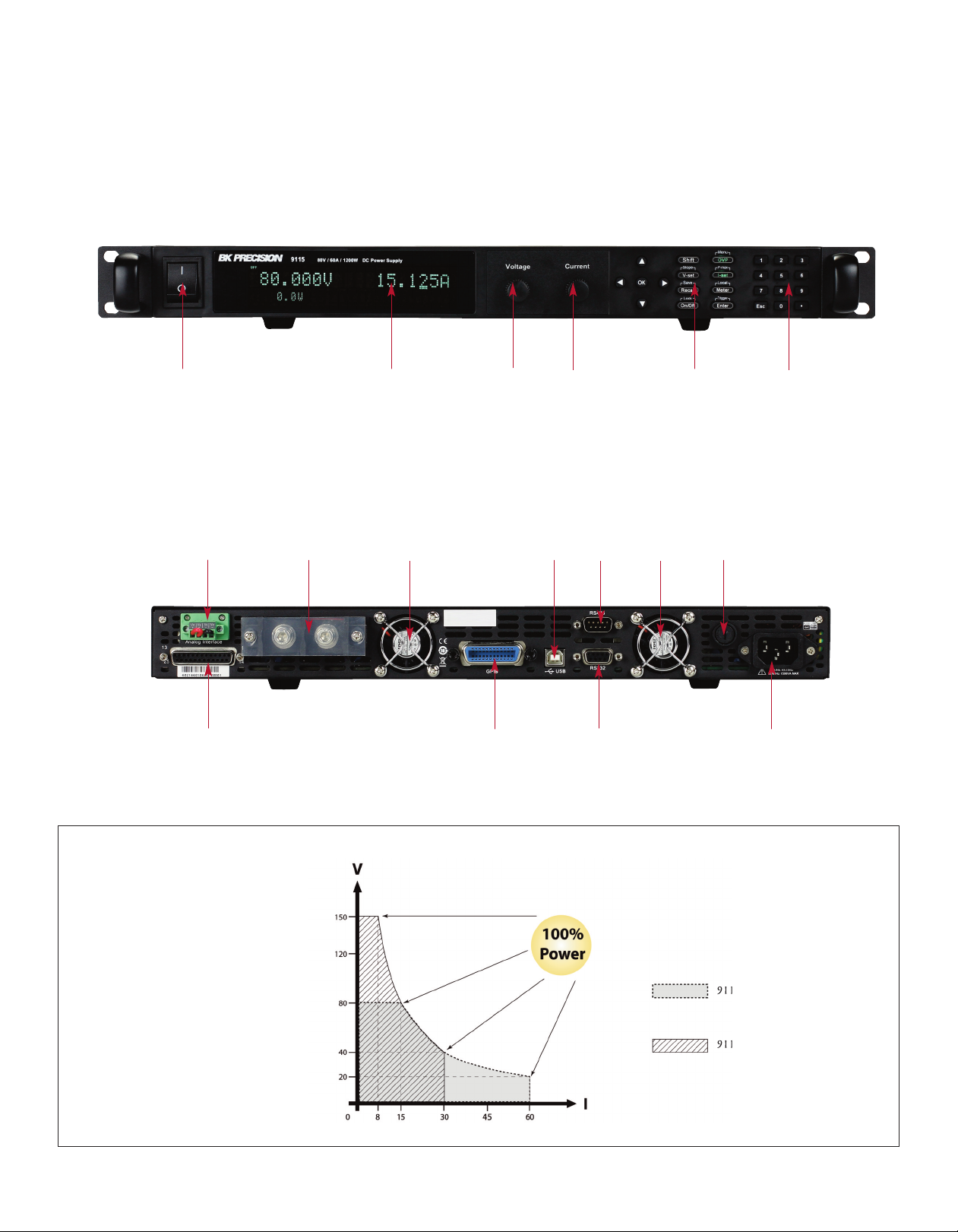

Function keys Numeric keypadPower On/Off switch Bright VFD display Voltage and current adjust knobs

Remote sense

terminal

Analog control interface GPIB interface RS-232 interface AC line input

Multi-Range Operation

The multi-ranging feature of the 9115 Series

offers exceptional flexibility by providing any

combination of the rated voltage and current up

to the maximum output power of the supply.

These wide ranges of voltage and current allow

users to replace multiple supplies on a bench or

system rack.

Output

terminal

Cooling fan

USB

interface

RS-485

interface

Cooling

fan

Fuse

9115 & 9115-AT (80 V/60 A)

9116 (150 V/30 A)

2

www.bkprecision.com

Page 3

Multi-Range Programmable DC Power Supplies

115 Series

9

Flexible operation

Easy-to-use interface

a

t

o

r

,

d

pa

key

umeric

n

e

h

T

et

s

o

t

y

wa

y

s

ea

n

a

e

id

v

o

pr

pus

a

h

Wit

.

ely

is

prec

d

n

a

ien

en

v

n

o

c

be

n

a

c

y

pla

is

d

n

a

e

g

a

lt

o

v

ured

s

mea

d

n

a

s

wer

po

e

h

t

,

lly

a

n

io

it

d

d

A

up

f

o

e

g

ra

o

t

s

r

o

f

y

r

memo

c

t

a

h

t

s

g

in

t

et

s

t

rumen

t

s

in

a

el

n

pa

t

n

o

r

f

e

h

t

h

t

bo

ia

v

n

k

y

r

ut

o

f

o

h

o

t

ly

t

ur

c

d

upplies

100

o

t

be

n

a

remo

d

n

a

g

o

put

ren

but

g

s

bs

led

pr

et

rs

o

urs

c

d

n

a

,

ly

k

quic

els

lev

e

h

t

,

n

o

t

et

s

ween

bet

.

lues

a

v

t

l

a

ern

t

in

e

id

v

o

t

eren

f

if

d

lled

a

rec

d

n

a

.

es

c

a

erf

t

in

e

t

Programmable voltage rise/fall times

The power supply is capable of programming the

slope of the output voltage during changes

etween voltage settings by allowing users to set

b

the rising and falling edge times of the voltage.

Master/Slave operation

More than one unit of the same power supply

model can be connected in parallel or series

onnection to increase the overall current or

c

voltage output respectively. Using the RS-485

interface, the power supplies can operate in

master/slave mode. In this mode, the master unit

can control all other power supplies connected

in parallel or series. Additionally, the RS-485

interface can be used for multi-unit control of

up to 31 daisy chained units.

Test sequence execution in list mode

The list mode feature lets users store, recall, and

run program sequences in the power supply’s

internal memory. A total of 10 steps can be

configured for each sequence (up to 10). These

sequences can then be saved into a program

configuration that can run one sequence after

another, which allows for a maximum of 100

steps in one program configuration.

External analog control interface

The power supply output voltage and current can

be controlled from zero to full range by either

external DC voltage sources (0-5 V or 0-10 V)

or resistances (0-5 kΩ or 0-10 kΩ). The DB25

analog control interface also provides a source

for monitoring the voltage and current output.

Parallel Configuration

Series Configuration

Application software

PC software is provided for front panel emulation, generating and executing test sequences or logging measurement data without the need to write source code.

Additionally, this application software integrates with NI Data Dashboard for LabVIEW apps which allows users to create a custom dashboard on a tablet computer

or smart phone to remotely monitor 9115 series power supplies via this PC software.

• Remote monitoring on iOS, Android or Windows 8 compatible tablets or smart phones via NI Data Dashboard for LabVIEW apps. Quickly develop a custom

dashboard consisting of one (smart phone) or several (tablet) indicators, charts or gauges to monitor your power supply.

• Log voltage, current and power values as well as time stamp, CV/CC and output status.

• Save and load list files to/from the power supply’s internal memory.

• Create an unlimited number of external list files to be executed from PC memory. Save and recall list files to/from the PC.

3

www.bkprecision.com

Page 4

Multi-Range Programmable DC Power Supplies

115 Series

9

Model 9115-AT Automotive Test Functions

In order to ensure electronic systems used in a vehicle are able to function

in an automotive environment, automotive component manufacturers test

electronic modules to industry standards. The 9115-AT provides built-in

simulations compliant to these automotive test standards to help automate

and speed up development time.

SO 16750-2

I

This standard applies to electric and electronic systems/components

for vehicles. It describes the potential environmental conditions and

specifies tests and requirements recommended for the specific mounting

location on/in the vehicle. These test simulations include measurement

of discontinuities in supply voltage, voltage drops, tests applicable to

equipment with reset functions, and tests to insure modules do not

malfunction during an engine start routine with cranking.

Simulate the effect when a conventional fuse element

melts in another circuit.

DIN 40839 (ISO 7637)

This standard insures EMC (electromagnetic compatibility) in road vehicles by

injection of supply line transients. The 9115-AT can output a 12 V or 24 V

system voltage sequence, which simulates the behavior in supply voltage

reduction caused by an engine starter motor circuits (Fig. 1).

Fig. 1 - Motor startup curve

Fig. 2 - Short voltage drop test

Verify the reset behavior of your DUT at various

voltage drops.

Fig. 3 - Reset behavior voltage drop test

Verify the behavior of a DUT during and after cranking.

Fig. 4 - Starting profile test

4

www.bkprecision.com

Page 5

Multi-Range Programmable DC Power Supplies

115 Series

9

Specifications

Output Rating

M

odel

115 & 9115-AT

9

9

116

Voltage 0 – 80 V 0 – 150 V

Current 0 – 60 A 0 – 30 A

Max Output Power 1200 W

oad Regulation

L

(1)(2)

Voltage 0.01 % + 5 mV

Current 0.1 % + 10 mA

2)

Line Regulation

(

Voltage 0.02 % + 1 mV

Current 0.02 % + 1 mA

rogramming/Readback Resolution

P

Voltage 1 mV 3 mV

Current 1 mA

Programming/Readback Accuracy

(2)

Voltage 0.02 % + 30 mV 0.05 % + 30 mV

Current 0.1 % + 60 mA 0.2 % + 30 mA

Ripple (20 Hz – 20 MHz)

Voltage ≤ 60 mVpp

Current 100 mArms 50 mArms

Temperature Coefficient (0 °C – 40 °C)

(2)

Voltage 0.02 % + 30 mV

Current 0.05 % + 10 mA

Readback Temperature Coefficient (0 °C – 40 °C)

(2)

Voltage 0.02 % + 30 mV

Current 0.05 % + 5 mA

General

Efficiency

73% (120 VAC)

75% (220 VAC)

75% (120 VAC)

80% (220 VAC)

Power Factor > 0.99 (full load)

Standard Interface USBTMC, GPIB, RS-232, RS-485

AC Input 115/230 VAC ± 10 %, 47 Hz – 63 Hz

Input Current (nominal)

13.8 A (120 VAC)

7.3 A (220 VAC)

13.3 A (120 VAC)

6.9 A (220 VAC)

Operating Temperature 32 ° F – 104 ° F (0 °C – 40 °C)

Storage Temperature -4 ° F – 158 ° F (-20 °C – 70 °C)

Safety EN61010-1:2001, EU Low Voltage Directive 2006/95/EC

Meets EMC Directive 2004/108/EC, EN 61000-3-2:2006,

Electromagnetic Compatibility

EN 61000-3-3:1995+A1:2001+A2:2005

EN 61000-4-2/-3/-4/-5/-6/-11, EN 61326-1:2006

Dimensions (W x H x D)

16.34” x 1.73” x 19.68”

(414.5 x 44.5 x 483.2 mm)

Weight 18.74 lbs (8.5 kg)

One-Year Warranty

Included Accessories User manual, power cord, certificate of calibration and test report

(1)

With remote sense connected

(2)

Accuracy specified as ±(% of output + offset) after a temperature stabilization time of 15 minutes over an ambient temperature range of 23 ºC ±5 ºC

5 www.bkprecision.com

v051514

Loading...

Loading...