Page 1

BioFrac Franction Collector

F3 F4 F5

F1 F2

A B

VALVE A VALVE B

BIOLOGIC DUOFLOW™

CHROMATOGRAPHY SYSTEM

INSTRUCTION MANUAL

(BioLogic DuoFlow™ Software Version 5.0)

1 2 3

4 5 6

7 8 9

0

Copyright © (2003) Bio-Rad Laboratories, Inc. All rights reserved.

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY

SECTION 1. SYSTEM OVERVIEW

Chapter 1.0 Introduction ...............................................................................................................1-1

1.1 Overview .....................................................................................................................1-1

1.2 Features ......................................................................................................................1-2

1.3 Unpacking ...................................................................................................................1-3

1.4 System Configurations ................................................................................................1-4

1.5 Quick Start Procedure.................................................................................................1-5

Chapter 2.0 Description of System Components .......................................................................2-1

2.1 Controller and USB Bitbus Communicator .................................................................2-2

2.1.1 Controller........................................................................................................2-2

2.1.2 USB Bitbus Communicator ............................................................................2-5

2.2 Workstation .................................................................................................................2-6

2.3 BioLogic Maximizer™ Valve System ..........................................................................2-11

2.4 Mixers..........................................................................................................................2-18

2.4.1 MX-1 Mixer.....................................................................................................2-18

2.4.2 Maximizer Mixer .............................................................................................2-19

2.4.3 Changing Mixer Capacity ...............................................................................2-20

2.5 Detection Systems ......................................................................................................2-21

2.5.1 UV Detector....................................................................................................2-21

2.5.2 Conductivity Monitor.......................................................................................2-23

2.5.3 BioLogic QuadTec™ UV/Vis Detector............................................................2-23

2.5.4 pH Monitor......................................................................................................2-25

2.5.5 Other Detectors..............................................................................................2-25

2.6 Valves..........................................................................................................................2-26

2.6.1 AVR7-3 Sample Inject Valve ..........................................................................2-26

2.6.2 AVR9-8 Stream Select Valve .........................................................................2-29

2.6.3 SV5-4 Buffer Select and Automated Sample Loading Valve .........................2-31

2.6.4 SVT3-2 Diverter Valve....................................................................................2-33

2.7 Fraction Collectors ......................................................................................................2-35

2.7.1 BioFrac™ Fraction Collector ..........................................................................2-35

2.7.2 Model 2110 Fraction Collector .......................................................................2-37

2.7.3 Model 2128 Fraction Collector .......................................................................2-38

2.7.4 Generic Fraction Collectors............................................................................2-39

2.8 Sample Loading Options.............................................................................................2-40

2.8.1 DynaLoop Large Volume Sample Injection Loop...........................................2-40

2.8.2 Model EP-1 Econo Pump...............................................................................2-42

2.8.3 EGP Econo Gradient Pump ...........................................................................2-43

2.8.4 Other Gradient Pumps ...................................................................................2-44

2.9 System Peripherals .....................................................................................................2-45

2.9.1 System Rack ..................................................................................................2-45

2.9.2 Starter Kit .......................................................................................................2-47

2.9.3 Fittings Kit, including Tubing Kit.....................................................................2-47

2.9.4 Fittings Tightener............................................................................................2-48

2.9.5 Backpressure Regulator.................................................................................2-49

2.9.6 Signal Import Module (SIM) ...........................................................................2-50

2.9.7 Pump Kits.......................................................................................................2-51

iii

Page 3

2.9.8 Model 1327 Chart Recorder...........................................................................2-52

2.9.9 Generic Chart Recorders ...............................................................................2-52

2.9.10 Uninterruptible Power Supply.........................................................................2-53

2.9.11 Printers...........................................................................................................2-53

2.10 Columns and Column Fittings .....................................................................................2-54

2.10.1 Anion Exchange: Q-Strong Anion Exchange ................................................2-54

2.10.2 Cation Exchange: S-Strong Cation Exchange..............................................2-54

2.10.3 Anion Exchange: DEAE Weak Anion Exchange...........................................2-55

2.10.4 Cation Exchange: Carboxy Methyl (CM) Weak Cation Exchange ................2-55

2.10.5 Ceramic Hydroxyapatite (CHT) ......................................................................2-55

2.10.6 Size Exclusion Chromatography (SEC) .........................................................2-56

2.10.7 High Pressure Reversed Phase Columns .....................................................2-56

2.10.8 Hydrophobic Interaction Chromatography (HIC)............................................2-56

2.10.9 Affinity Chromatography.................................................................................2-57

2.10.10 Empty Columns..............................................................................................2-57

2.10.11 Column Fittings ..............................................................................................2-58

SECTION 2. SYSTEM INSTALLATION AND SETUP

Chapter 3.0 System Setup ............................................................................................................3-1

3.1 Controller Cable Connections .....................................................................................3-2

3.2 USB Bitbus Communicator Cable Connections..........................................................3-3

3.3 Workstation Cable Connections..................................................................................3-4

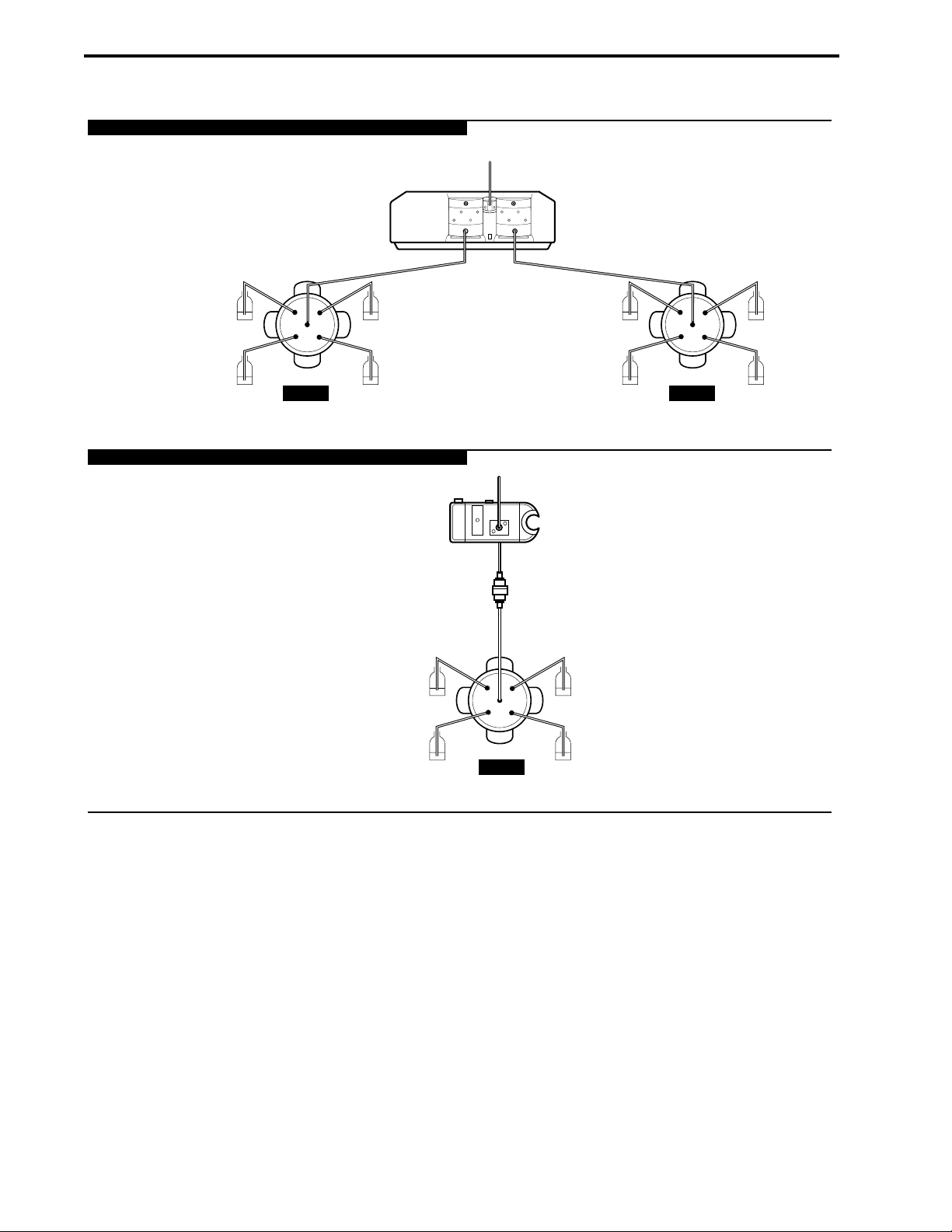

3.3.1 Systems without a Maximizer ........................................................................3-4

3.3.2 Systems with a Maximizer .............................................................................3-5

3.4 System Rack Setup.....................................................................................................3-6

3.5 Mixers..........................................................................................................................3-7

3.6 Detection System Connections ..................................................................................3-9

3.6.1 UV Detector and Conductivity Monitor...........................................................3-9

3.6.2 QuadTec UV/Vis Detector ..............................................................................3-10

3.6.3 pH Monitor......................................................................................................3-12

3.6.4 Non-Bio-Rad Detectors ..................................................................................3-13

3.7 Valve Connections .....................................................................................................3-14

3.8 Fraction Collector Connections ..................................................................................3-15

3.8.1 BioFrac Fraction Collector..............................................................................3-15

3.8.2 Model 2110 Fraction Collector .......................................................................3-15

3.8.3 Model 2128 Fraction Collector .......................................................................3-15

3.9 Pump Connections .....................................................................................................3-16

3.9.1 Model EP-1 Econo Pump...............................................................................3-16

3.9.2 Econo Gradient Pump (EGP).........................................................................3-17

3.10 Model 1327 Chart Recorder Connections ..................................................................3-19

3.11 Completing System Setup...........................................................................................3-19

3.11.1 DuoFlow System Network Connections.........................................................3-19

3.11.2 System Power Up ..........................................................................................3-19

3.11.3 BioLogic Configuration Utility Software..........................................................3-20

Chapter 4.0 System Plumbing ......................................................................................................4-1

4.1 General Guidelines for Creating Your Own Tubing Connections................................4-2

4.2 Plumbing a DuoFlow System......................................................................................4-3

4.3 Priming the System.....................................................................................................4-8

TABLE OF CONTENTS

iv

Page 4

SECTION 3. SYSTEM OPERATION

Chapter 5.0 Introduction to the System Software ......................................................................5-1

5.1 System Interface .........................................................................................................5-1

5.2 Standard Mouse and Keyboard Functions .................................................................5-2

5.3 System Menus ............................................................................................................5-3

5.3.1 Toolbar Buttons ..............................................................................................5-3

5.3.2 Drop-down Menus..........................................................................................5-5

Chapter 6.0 Introduction to the Browser Screen........................................................................6-1

6.1 Overview .....................................................................................................................6-1

6.2 Method Templates.......................................................................................................6-7

6.3 Creating and Running a Queue ..................................................................................6-9

6.4 Creating and Viewing a Compare...............................................................................6-11

6.5 Trace Compare ...........................................................................................................6-12

6.5.1 Chromatogram Display Screen ......................................................................6-13

6.5.2 Toolbar Buttons ..............................................................................................6-14

6.5.3 Drop-down Menus..........................................................................................6-15

6.5.4 Active Traces and Valves at Cursor...............................................................6-17

6.5.5 Chromatogram Settings Tab ..........................................................................6-17

Chapter 7.0 Modes of Operation...................................................................................................7-1

7.1 Manual Screen ............................................................................................................7-2

7.2 Setup Screen ..............................................................................................................7-4

7.2.1 Device Selection ............................................................................................7-5

7.2.2 Inlet and Valve Naming ..................................................................................7-6

7.2.3 Buffer Editor ...................................................................................................7-8

7.3 Protocol Screen...........................................................................................................7-10

7.4 Run Screen .................................................................................................................7-30

7.4.1 Pausing/Stopping a Method in Progress........................................................7-33

7.4.2 Working Offline During a Run ........................................................................7-34

7.4.3 Editing a Method During a Run......................................................................7-35

7.4.4 Run Notebook Screen....................................................................................7-37

7.4.5 Run Log Screen .............................................................................................7-37

7.5 Post Run Screen.........................................................................................................7-38

7.5.1 Resizing..........................................................................................................7-39

7.5.2 Chromatogram Information (Values at Cursor) ..............................................7-39

7.5.3 Annotating (“tagging”) the Chromatogram .....................................................7-40

7.5.4 Entering Activity Data .....................................................................................7-41

7.5.5 Exporting Chromatogram Data to other Software Applications .....................7-43

7.5.6 Exporting Chromatogram Images ..................................................................7-44

SECTION 4. SAMPLE LOADING APPLICATIONS

Chapter 8.0 Sample Loading ........................................................................................................8-1

8.1 Automatic Loop Fill and Rinse ....................................................................................8-2

8.2 Aux Pump Direct Inject ...............................................................................................8-3

8.3 Gradient Pump Direct Injection ...................................................................................8-4

8.4 DynaLoop Sample Injection ........................................................................................8-6

Chapter 9.0 Column and Buffer Flow Switching Applications..................................................9-1

9.1 Column Switching .......................................................................................................9-1

9.1.1 AVR7-3 Two-Column Switching .....................................................................9-1

9.1.2 AVR9-8 Eight Column Switching....................................................................9-2

9.2 Reverse Flow Chromatography ..................................................................................9-4

9.3 Multi-dimensional Chromatography ............................................................................9-5

TABLE OF CONTENTS

v

Page 5

Chapter 10.0 Buffer Blending .........................................................................................................10-1

10.1 Doubled Flow Rate Capacity Using a Maximizer .......................................................10-1

10.2 Buffer Blending with the Maximizer.............................................................................10-2

10.3 pH Measurement and Corrections ..............................................................................10-4

SECTION 5. MAINTENANCE AND TROUBLESHOOTING

Chapter 11.0 Maintenance...............................................................................................................11-1

11.1 Care of the Outer Surfaces of the Instruments...........................................................11-1

11.2 Storage of the DuoFlow System.................................................................................11-1

11.3 Care and Maintenance of the Workstation Pumps .....................................................11-2

11.3.1 Priming the Workstation Pumps and Removing Trapped Air Bubbles...........11-2

11.3.2 Daily Maintenance..........................................................................................11-2

11.3.3 Routine Maintenance of the Workstation Pumps...........................................11-3

11.4 Maintenance of the UV Detector and the Conductivity Flow Cell...............................11-6

11.4.1 Cleaning the UV Detector and the Conductivity Flow Cell ............................11-6

11.4.2 Replacing the Lamp in the UV Detector ........................................................11-7

11.5 Mixers..........................................................................................................................11-8

11.6 Valves..........................................................................................................................11-10

11.6.1 SVT3-2 Diverter Valve....................................................................................11-10

11.6.2 AVR7-3 and AVR9-8 Valves ...........................................................................11-11

11.7 Maximizer Valves ........................................................................................................11-13

Chapter 12.0 Troubleshooting DuoFlow Systems........................................................................12-1

12.1 Troubleshooting the DuoFlow Controller and Software ..............................................12-1

12.2 Troubleshooting the DuoFlow Workstation Pumps.....................................................12-3

12.3 Troubleshooting the UV Detector and UV Trace ........................................................12-7

12.4 Troubleshooting the Conductivity Flow Cell and Trace...............................................12-9

12.5 Troubleshooting the Maximizer Buffer Blending .........................................................12-10

12.6 Troubleshooting Other Bio-Rad Instruments and Devices..........................................12-11

SECTION 6. APPENDICES

Appendix A. Specifications............................................................................................................A-1

Appendix B. Pressure Conversion Table......................................................................................B-1

Appendix C. Warranty Statement ..................................................................................................C-1

Appendix D. Ordering Information ................................................................................................D-1

Index..................................................................................................................................................IN-1

TABLE OF CONTENTS

vi

Page 6

LIST OF FIGURES

1-1. BioLogic DuoFlow System .......................................................................................................1-1

2-1. BioLogic DuoFlow Pathfinder™ System Components ............................................................2-1

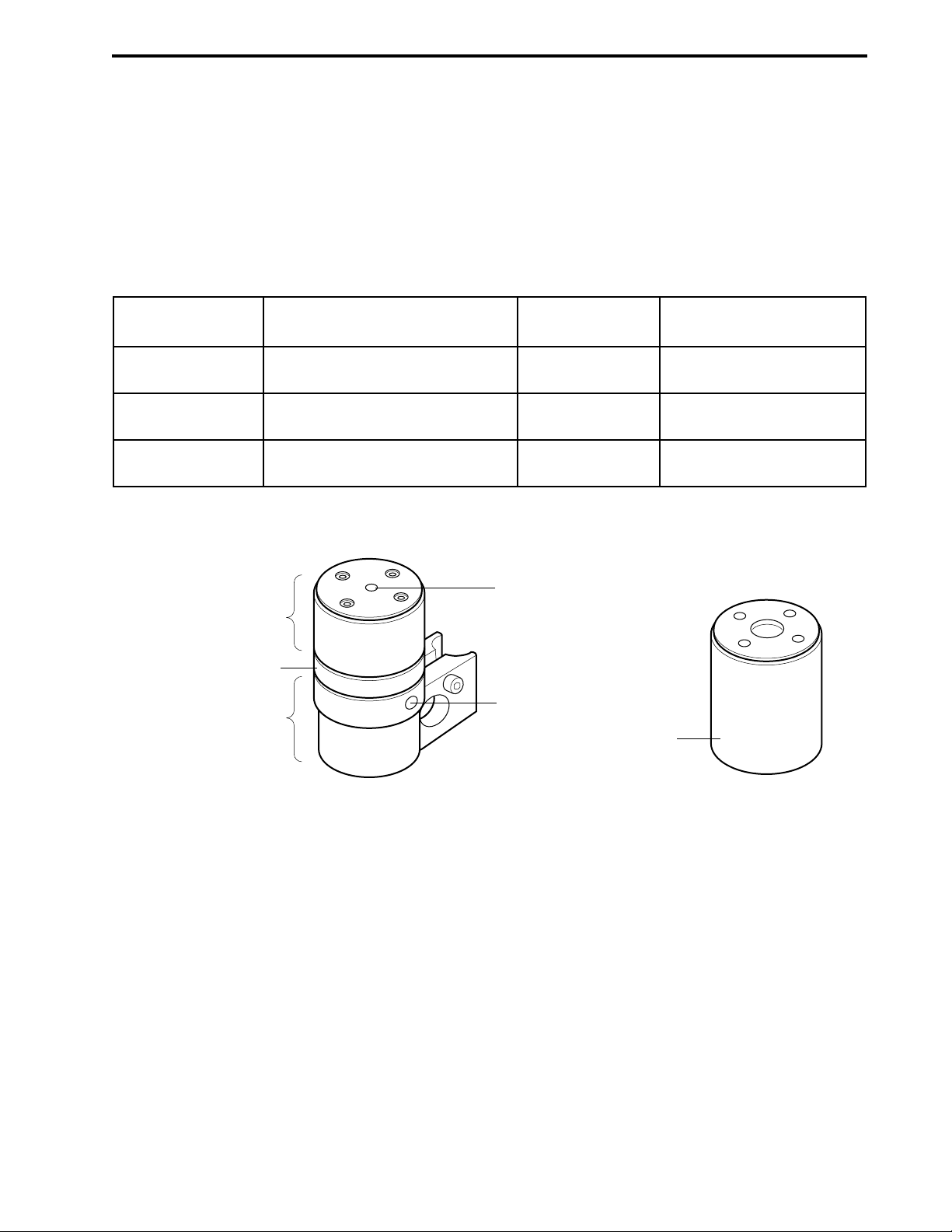

2-2. MX-1 Mixer and Mixer Barrel Extender....................................................................................2-18

2-3. Maximizer Mixer and Mixer Barrel Extender............................................................................2-19

2-4. Assembly of Mixers..................................................................................................................2-20

2-5. UV Detector, with Mercury Lamp, 254 & 280 nm Filters, and Conductivity Flow Cell.............2-21

2-6. UV Detector, with Zinc Lamp, 214 nm Filter, and Conductivity Flow Cell ...............................2-22

2-7. Conductivity Monitor.................................................................................................................2-23

2-8. QuadTec UV/Vis Detector ........................................................................................................2-24

2-9. pH Monitor................................................................................................................................2-25

2-10. AVR7-3 Sample Inject Valve....................................................................................................2-26

2-11. Sample Load Positions ............................................................................................................2-27

2-12. Examples of AVR7-3 Valve Tubing ..........................................................................................2-28

2-13. AVR9-8 Stream Select Valve ...................................................................................................2-29

2-14. Two Examples Using AVR9-8 Valves.......................................................................................2-30

2-15. SV5-4 Buffer Select Valve........................................................................................................2-31

2-16. Two Examples Using SV5-4 Valves.........................................................................................2-32

2-17. SVT3-2 Diverter Valve..............................................................................................................2-33

2-18. Two Configurations of the SVT3-2 Valve.................................................................................2-34

2-19. BioFrac Fraction Collector .......................................................................................................2-35

2-20. Model 2110 Fraction Collector with Optional Dust Cover........................................................2-37

2-21. Model 2128 Fraction Collector.................................................................................................2-38

2-22. DynaLoop.................................................................................................................................2-40

2-23. Plumbing the DynaLoop for use with an Inject Valve ..............................................................2-41

2-24. Model EP-1 Econo Pump.........................................................................................................2-42

2-25. EGP Econo Gradient Pump .....................................................................................................2-45

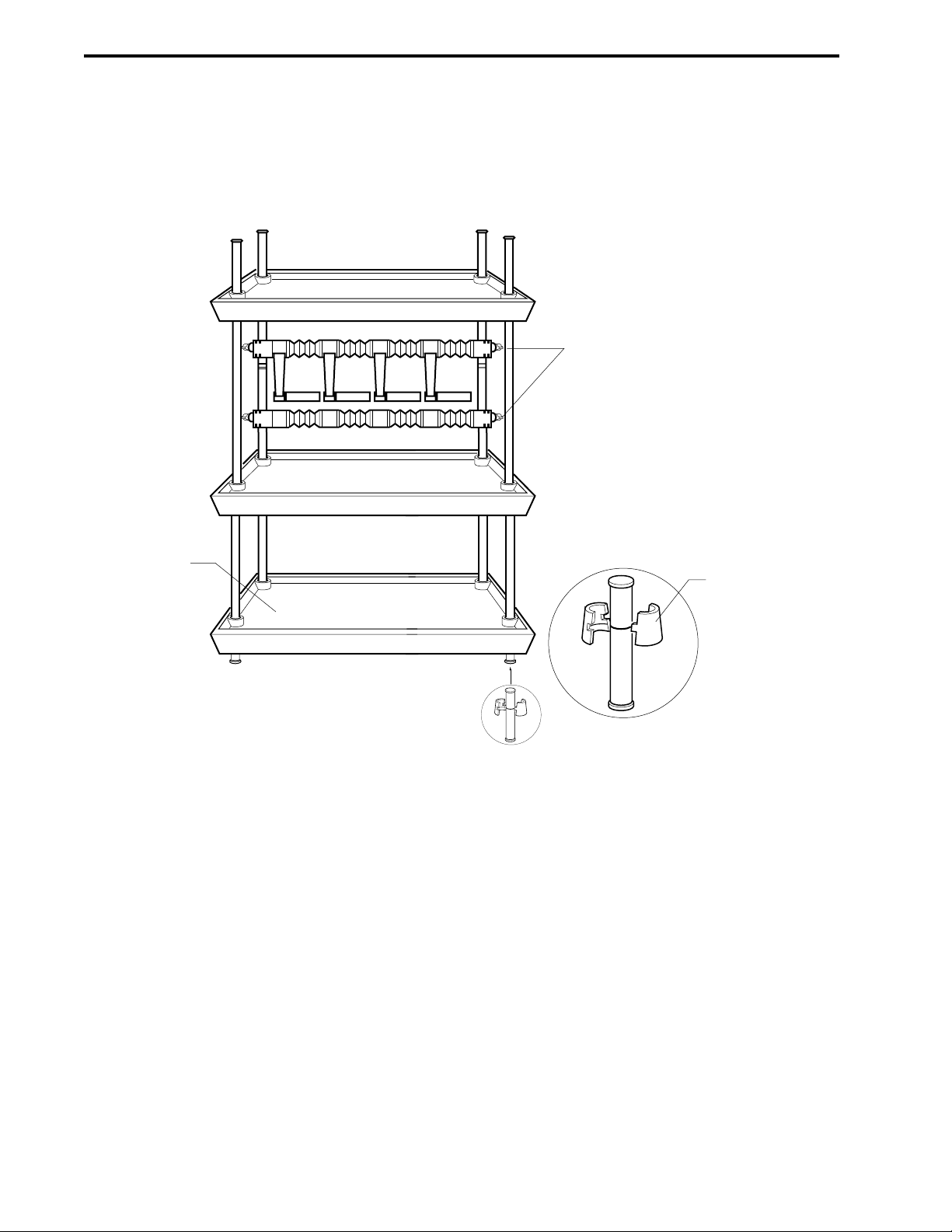

2-26. Rack Assembly.........................................................................................................................2-46

2-27. Making 1/4-28 Flat Bottom Fittings..........................................................................................2-48

2-28. Backpressure Regulator...........................................................................................................2-49

2-29. Signal Import Module (front and rear views)............................................................................2-50

2-30. Cable Connections to the Signal Import Module .....................................................................2-50

2-31. Model 1327 Chart Recorder.....................................................................................................2-52

3-1. Example of a DuoFlow Pathfinder System Configuration........................................................3-1

3-2. DuoFlow Pathfinder Setup in Non-Condensing Environment..................................................3-2

3-3. USB Bitbus Communicator Cabling .........................................................................................3-3

3-4. System Cable Connections (without Maximizer) .....................................................................3-4

3-5. System Cable Connections (with Maximizer) ..........................................................................3-5

3-6. Rack Assembly.........................................................................................................................3-6

3-7. Mixers.......................................................................................................................................3-7

3-8. UV Detector and Conductivity Monitor.....................................................................................3-9

3-9. QuadTec Detector ....................................................................................................................3-10

3-10. Instrument Control Module (ICM).............................................................................................3-10

3-11. pH Monitor................................................................................................................................3-12

3-12. SIM Connections......................................................................................................................3-12

3-13. DuoFlow Valves .......................................................................................................................3-14

3-14. Connecting an EP-1 Econo Pump to the BioLogic DuoFlow Workstation...............................3-16

3-15. Example of Direct Inject Sample Loading using an Econo Pump...........................................3-17

3-16. Example of Multiple Sample Loading using an Econo Pump..................................................3-17

3-17. Example of Large Sample Loading using an Econo Gradient Pump (EGP)...........................3-18

3-18. Example of Multiple Sample Loading using an Econo Gradient Pump (EGP)........................3-18

3-19. BioLogic™ Configuration Utility Software Screen....................................................................3-20

4-1. System Plumbing using Pre-cut Tubing from Fittings Kit.........................................................4-1

4-2. Making 1/4-28 Flat Bottom Fittings ..........................................................................................4-2

4-3. System Plumbing with Maximizer ............................................................................................4-3

4-4. Maximizer Plumbing.................................................................................................................4-4

TABLE OF CONTENTS

vii

Page 7

4-5. Plumbing Connections to the Workstation Pump ....................................................................4-5

4-6. Inject Valve Plumbing for an AVR7-3.......................................................................................4-6

4-7. Backpressure Device ...............................................................................................................4-7

5-1. Layout of the Screen Display, showing the Manual Screen ....................................................5-1

6-1. The Browser Screen ................................................................................................................6-1

6-2. The CopyIn Window.................................................................................................................6-4

6-3. CopyIn with Information in Browser Tab Window ....................................................................6-5

6-4. Set Browser Options Window ..................................................................................................6-6

6-5. New Method Dialog Showing Method Templates ....................................................................6-7

6-6. Queues Displayed in the Browser Window..............................................................................6-9

6-7. Compare Displayed in the Browser Window ...........................................................................6-11

6-8. Trace Compare Window: Tiled View........................................................................................6-12

6-9. Trace Compare Window Overlay View....................................................................................6-13

7-1. Relationships between Modes of Operation ............................................................................7-1

7-2. Manual Screen, for the BioLogic DuoFlow System Connected to a Maximizer,

BioFrac Fraction Collector, QuadTec Detector, Econo Gradient Pump, and Four Valves.......7-2

7-3. Setup Screen ...........................................................................................................................7-4

7-4. Protocol Screen........................................................................................................................7-10

7-5. Run Screen showing a Run in Progress..................................................................................7-30

7-6. Run Screen’s Abort, Pause, and Hold Buttons........................................................................7-33

7-7. Editing during a Run ................................................................................................................7-35

7-8. Protocol Screen during a Run..................................................................................................7-36

7-9. Run Notebook Screen..............................................................................................................7-37

7-10. Run Log Screen.......................................................................................................................7-37

7-11. Post Run Screen......................................................................................................................7-38

7-12. Post Run Tags for UV Detector................................................................................................7-40

7-13. Activity Trace Editor .................................................................................................................7-41

7-14. Activity Trace............................................................................................................................7-42

7-15. Export Data Setup Screen .......................................................................................................7-43

7-16. Exporting a Chromatographic Image .......................................................................................7-44

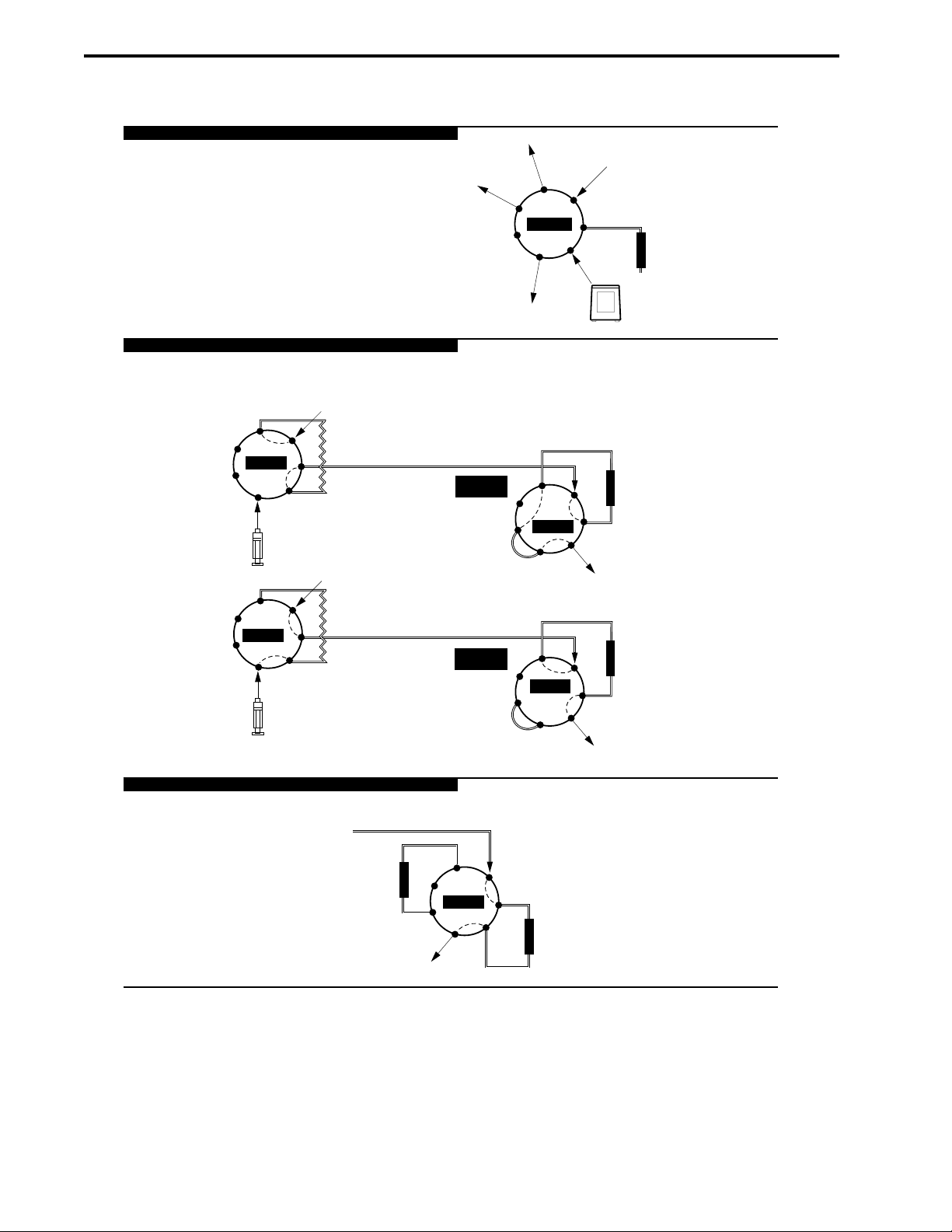

8-1. Multiple Sample Loading with an Auxiliary Load Pump and an AVR9-8 Valve........................8-2

8-2. Plumbing an AVR7-3 Inject Valve with an Auxiliary Load Pump..............................................8-3

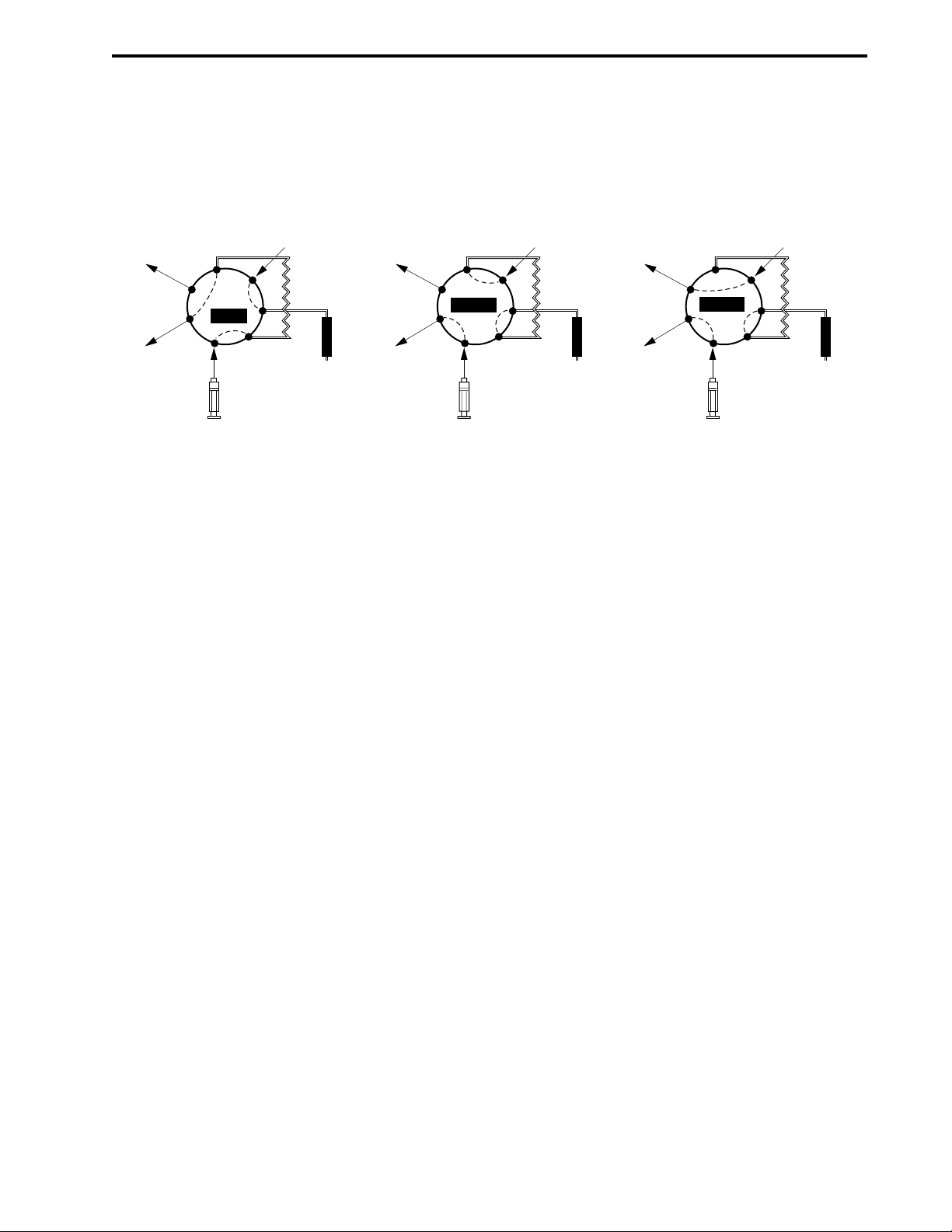

8-3. AVR7-3 Valve Positions During a Run with Direct Sample Loading and Injection ..................8-4

8-4. Sample Loading through the Workstation Pump .....................................................................8-5

8-5. Plumbing the DynaLoop for use with an Inject Valve ..............................................................8-6

8-6. Valve Positions During a Run using the DynaLoop .................................................................8-8

9-1. Column Switching using Two AVR7-3 Valves ..........................................................................9-1

9-2. Column Switching using two AVR9-8 Valves ...........................................................................9-3

9-3. Reverse Flow Affinity Chromatography with an AVR7-3 Valve................................................9-4

10-1. Buffer Blending Setup Dialog for a Single Component Buffer.................................................10-5

10-2. Buffer Blending Setup Dialog for a Multi-Component Buffer ...................................................10-5

11-1. Workstation Pump Mechanism Parts.......................................................................................11-3

11-2. Piston Assembly and Access to the Piston Seal......................................................................11-4

11-3. Pumphead Assembly ...............................................................................................................11-5

11-4. Replacing a Mercury Lamp in a Model OM-II UV Detector .....................................................11-7

11-5. Replacing a Zinc Lamp in a Model OM-II UV Detector ...........................................................11-7

11-6. Mixer Assembly ........................................................................................................................11-9

11-7. SVT3-2 Valve Assembly...........................................................................................................11-10

11-8. AVR7-3 and AVR9-8 Valve Assembly ......................................................................................11-12

11-9. Replacing a Maximizer Valve...................................................................................................11-13

TABLE OF CONTENTS

viii

Page 8

LIST OF TABLES

1-1. DuoFlow System Configurations..............................................................................................1-4

2-1. Front View of the Dell PC Computer as the DuoFlow Controller.............................................2-2

2-2. Rear View of the Dell PC Computer as the DuoFlow Controller .............................................2-4

2-3. USB Bitbus Communicator ......................................................................................................2-5

2-4. F10 and F40 Pumphead Flow Rates .......................................................................................2-6

2-5. Workstation Front Panel Controls ............................................................................................2-7

2-6. Workstation Rear Panel Connectors........................................................................................2-9

2-7. Maximizer Front Panel Controls...............................................................................................2-12

2-8. Maximizer Rear Panel Connectors ..........................................................................................2-14

2-9. Maximizer Screens...................................................................................................................2-16

2-10. Mixer Barrels and Mixer Capacity for the MX-1 Mixer.............................................................2-18

2-11. Mixer Barrels and Mixer Capacity for the Maximizer Mixer .....................................................2-19

2-12. BioFrac Racks Available ..........................................................................................................2-36

2-13. Model 2128 Racks Available ....................................................................................................2-38

2-14. Workstation Pump Configuration Flow Rates ..........................................................................2-51

2-15. Columns and Column Fittings..................................................................................................2-58

3-1. Mixer Flow Rates .....................................................................................................................3-7

4-1. Tubing Guidelines ....................................................................................................................4-2

5-1. Special Function Keys .............................................................................................................5-2

5-2. Toolbar Buttons ........................................................................................................................5-3

5-3. File Drop-down Menu...............................................................................................................5-5

5-4. Edit Drop-down Menu ..............................................................................................................5-7

5-5. View Drop-down Menu.............................................................................................................5-9

5-6. Utilities Drop-down Menu.........................................................................................................5-10

5-7. Options Drop-down Menu ........................................................................................................5-11

5-8. Window Drop-down Menu........................................................................................................5-12

6-1. Toolbar Buttons ........................................................................................................................6-14

6-2. File Drop-down Menu...............................................................................................................6-15

6-3. Options Drop-down Menu ........................................................................................................6-15

6-4. View Drop-down Menu.............................................................................................................6-16

6-5. Tools Drop-down Menu ............................................................................................................6-16

6-6. Window Drop-down Menu........................................................................................................6-16

7-1. Valve Setup Information ...........................................................................................................7-7

7-2. Buffer Editor .............................................................................................................................7-9

7-3. Isocratic Flow ...........................................................................................................................7-11

7-4. Load/Inject Sample ..................................................................................................................7-12

7-5. Linear Gradient ........................................................................................................................7-15

7-6. Change Valve...........................................................................................................................7-16

7-7. Column Switching ....................................................................................................................7-17

7-8. Hold..........................................................................................................................................7-18

7-9. Miscellaneous Buttons .............................................................................................................7-19

7-10. Fraction Collection Button........................................................................................................7-20

7-11. Scouting ...................................................................................................................................7-25

7-12. Protocol Screen’s Editing Toolbar Buttons...............................................................................7-29

7-13. Run Screen’s Control Buttons..................................................................................................7-32

9-1. Common Multidimensional Chromatography Experiments......................................................9-5

10-1. Buffer Blending Buffer Systems ...............................................................................................10-2

B-1. Pressure Conversion................................................................................................................B-1

TABLE OF CONTENTS

ix

Page 9

1.0 INTRODUCTION

1.1 OVERVIEW

The BioLogic DuoFlow chromatography system is specifically designed for the high resolution purification of

proteins, peptides, and other biomolecules where recovery of biological activity is of primary concern. The

DuoFlow F10 pumphead operates at up to 20 ml/min and 3500 psi (233 bar, 23 MPa) when used with the

Maximizer. The DuoFlow F40 pumphead operates at up to 80 ml/min and 1000 psi (66 bar, 6.6 MPa) when

used with the Maximizer.

The BioLogic DuoFlow system software provides an easy-to-use graphic interface and menu-driven software

for manual operation, system setup, method editing, and run operations. The system software may be run

on any PC running Microsoft

®

Windows®2000.

The flexible control architecture allows the seamless integration of a wide variety of configurations with other

Bio-Rad and non-Bio-Rad components to meet your purification requirements.

Figure 1-1. BioLogic DuoFlow System

INTRODUCTIONSYSTEM OVERVIEW

1-1

AVR7-3 SAMPLE

INJECT VALVE

MAXIMIZER MIXER

USB BITBUS COMMUNICATOR

DELL CONTROLLER

TM

UNO Q1 COLUMN

A B

MAXIMIZER

VALVE A VALVE B

QUADTEC DETECTOR

pH MONITOR

CONDUCTIVITY

MONITOR

WORKSTATION

BioFrac Franction Collector

F1 F2

F3 F4 F5

1 2 3

4 5 6

7 8 9

0

BIOFRAC

KEYBOARD

MOUSE

Page 10

1.2 FEATURES

BioLogic DuoFlow systems provide the following features:

• Setup Flexibility. A space saving modular design that is stackable and easily configured to meet

your exact needs and fit into your desired bench space. Trays and vertical bars are moveable and

removable. Horizontal bars can be placed in the optimal position for valves, columns, detectors, etc.

The system fits easily into a cold box.

• Modular components provide an easy upgrade path to fit all applications and financial

requirements. For example, the BioLogic DuoFlow™ Basic system may be purchased and upgraded

to a BioLogic DuoFlow QuadTec™, BioLogic DuoFlow Maximizer or BioLogic DuoFlow Pathfinder

system as needed. (See Section 1.4 for a description of the DuoFlow systems and upgrades.)

• Intuitive, user-friendly software programming. Users become an expert in only a few runs.

• Four easy steps to set up new devices/instruments, create a new method, and start to run

samples:

Step 1. Browser, to enter new user name, project name and method name.

Step 2. Setup, to specify devices required for the method.

Step 3. Protocol, to enter sequential method steps.

Step 4. Run, to inject sample and view the real time chromatogram.

• Two easy steps, if you want to run a sample using a current Setup and Protocol:

Step 1. Browser, to select a user and along with a method or Method Template.

Step 2. Run, to inject sample and view real time chromatogram.

• On screen Help. Includes detailed information and a troubleshooting guide.

• USB Bitbus Communicator. The USB Bitbus communicator allows the BioLogic DuoFlow system

to be controlled from any computer running Windows 2000 and BioLogic software 4.0 or above, over

a USB port.

• Buffer Blending. Buffer Blending is a feature of the BioLogic DuoFlow Maximizer™ and Pathfinder

systems that dynamically "Blends" the conjugate acid and base of a buffer with water and salt to

produce a solution with a specific salt concentration and pH.

• Buffer Editor. The Buffer Editor is a feature used to create buffer systems for use in Buffer Blending

experiments. Both single and multiple component buffers can be created.

• Scouting. This feature facilitates the optimization of a chromatography protocol for a specific target

molecule. Scouting systematically increments a user selected variable and then performs a

chromatography run at each increment. Variables that can be "Scouted" include: pH, %B, step

duration, column, buffer, flow rate, sample and sample volume.

• Method Templates. Includes ready-to-run chromatography protocols for a variety of experiment

types including: affinity, chromatofocusing, hydroxyapatite, hydrophobic interaction, ion exchange

and gel filtration chromatography.

• pH Monitor. The BioLogic pH monitor allows direct pH monitoring during a run. It is included as part

of the DuoFlow Maximizer and Pathfinder systems and is available as an option for all other system

configurations. The pH monitor consists of a Calomel Tris compatible electrode in a PEEK

biocompatible flow cell.

• Flow Rate Flexibility. The DuoFlow Workstation has two pump head options (F10 and F40) that

permit a wide range of flow rates (0.01 ml/min up to 80 ml/min).

• Detection Flexibility

• UV detector with fixed 254 nm and 280 nm filters, long life mercury lamp, and additional drop-in

expansion filters available.

• UV detector can be expanded to 214 nm filter with zinc lamp.

• QuadTec UV/Vis detector analyzes samples simultaneously at 4 different wavelengths from 190-

370 nm with a deuterium lamp or 370-790 with a halogen lamp.

INTRODUCTION SYSTEM OVERVIEW

1-2

Page 11

INTRODUCTIONSYSTEM OVERVIEW

1-3

• Third party detectors, such as refractive index or fluorescence, may be utilized with the DuoFlow

systems via a Signal Import Module (SIM) or Maximizer.

• Conductivity Monitor. Monitors salt concentration to assure reliable gradient formation and pump

function.

• Fraction Collection. The DuoFlow system supports a wide variety of fraction collection options

including: Collect All, Threshold Collection, Collection Windows and Threshold & Collection

Windows. Both Above Threshold and Below Threshold collection are supported. The software also

supports tube numbering by Rack & Tube # and Rack & Grid #.

• Multiple Valve Capabilities

• Workstation provides connection for 3 low pressure and 3 high pressure valves.

• Workstation with the addition of the Maximizer doubles the capacity to 6 low pressure and 6

high pressure valves.

• Starter Kit and UNO Q1 Anion Exchange Column. Includes the necessary reagents, protein

sample and columns for running an anion exchange chromatography experiment. The kit includes

easy to follow, tutorial style instructions for the first time user.

• IQ/OQ Protocols. Validation protocols are available or can be performed by certified Bio-Rad

service engineers.

1.3 UNPACKING

When you receive the BioLogic DuoFlow system, carefully inspect the shipping containers for any damage

which may have occurred in shipping. Severe damage to a container may indicate damage to its contents. If

you suspect damage to the contents, immediately file a claim with the carrier in accordance with their

instructions before contacting Bio-Rad Laboratories.

Caution

Lift items from the bottom as you remove them from their containers!

Open each of the shipping cartons and lift the contents out of its packing. Check the contents of each box

against the supplied packing list. Remove the plastic bag from each unit and inspect the unit for external

damage. If any part is missing or damaged, contact Bio-Rad Laboratories immediately.

Bio-Rad ships DuoFlow systems in a number of different configurations, each with its own catalog number.

These systems are described in the following table. Because of its modular design, any of these systems

can be upgraded any time simply by adding system options.

!

Page 12

INTRODUCTION SYSTEM OVERVIEW

1-4

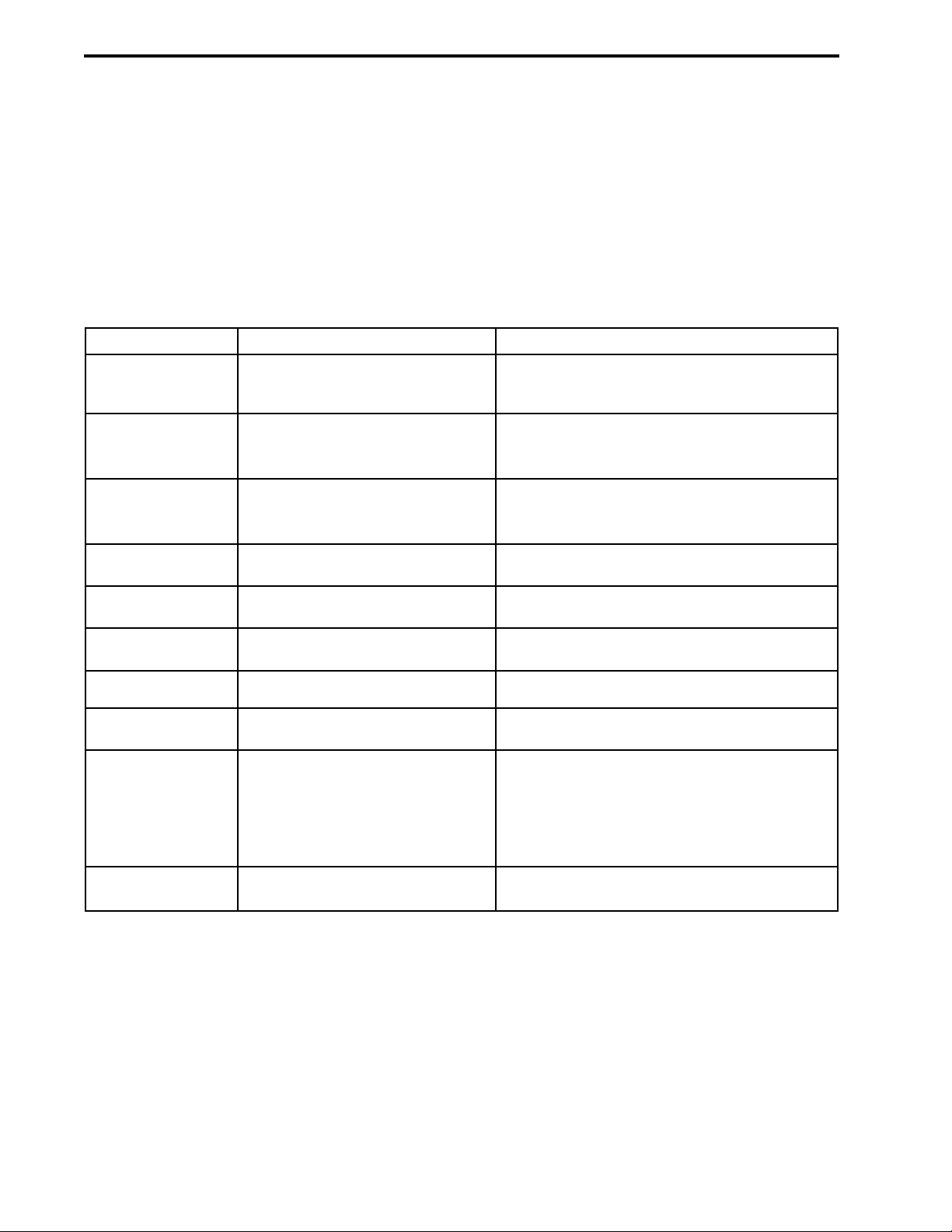

1.4 SYSTEM CONFIGURATIONS

The BioLogic DuoFlow is available in the following system configurations. Each system configuration is

identified by its name, its standard components and devices, and optional components and devices that may

be ordered separately for use with the system.

BioLogic DuoFlow System Guide

Catalog Number

760-0037

760-0036

760-0038

760-0047

760-0046

760-0048

760-1137

760-1136

760-1148

760-1147

760-1146

760-1148

760-2237

760-2236

760-2238

760-2247

760-2246

760-2248

760-2257

760-2256

760-2258

760-2267

760-2266

760-2268

S = Standard U = Upgradable

DuoFlow Basic System 100/120 V

DuoFlow Basic System Japan and Korea

DuoFlow Basic System 220/240 V

10 ml/min flow rate to 3500 psi

254/280 nm detection

DuoFlow Standard System 100/120 V

DuoFlow Standard System Japan/Korea

DuoFlow Standard System 220/240 V

10 ml/min flow rate to 3500 psi

254/280 nm detection

Fraction collection

DuoFlow QuadTec Basic System 100/120 V

DuoFlow QuadTec Basic System Japan/Korea

DuoFlow QuadTec Basic System 220/240 V

10 ml/min flow rate to 3500 psi

UV/Vis detection with 4 simultaneous wavelengths

DuoFlow QuadTec Standard System 100/120 V

DuoFlow QuadTec Standard System Japan/Korea

DuoFlow QuadTec Standard System 220/240 V

10 ml/min flow rate to 3500 psi

UV/Vis detection with 4 simultaneous wavelengths

Fraction collection

DuoFlow Maximizer 20 System 100/120 V

DuoFlow Maximizer 20 System Japan/Korea

DuoFlow Maximizer 20 System 220/240 V

20 ml/min flow rate to 3500 psi

254/280 nm detection

Buffer blending

Fraction collection

DuoFlow Maximizer 80 System 100/120V

DuoFlow Maximizer 80 System Japan/Korea

DuoFlow Maximizer 80 System 220/240 V

80 ml/min flow rate to 1000 psi

254/280 nm detector

Buffer blending

pH monitoring

Fraction collection

DuoFlow Pathfinder 20 System 100/120 V

DuoFlow Pathfinder 20 System Japan/Korea

DuoFlow Pathfinder 20 System 220/240 V

20 ml/min flow rate to 3500 psi

UV/Vis detection with 4 simultaneous wavelengths

Buffer blending

pH monitoring

Fraction collection

DuoFlow Pathfinder 80 System 100/120 V

DuoFlow Pathfinder 80 System Japan/Korea

DuoFlow Pathfinder 80 System 220/240 V

80 ml/min flow rate to 1000 psi

UV/Vis detection with 4 simultaneous wavelengths

Buffer blending

pH monitoring

Fraction collection

F40 Pump Kit

BioFrac

Fraction Collector

QuadTec UV/Vis

F10 Workstation

F10 Pump Kit

F40 Workstation

S

S

SS

SSUUUSUU

SSU

SSU

USSSUSS

U

SSU

UUSSSSSS

UUUUU

U

U

SU

U

SSUU

U

SUSS

U

SSSS

U

Detector

pH Monitor

Maximizer (incl pH)

UU

Page 13

INTRODUCTIONSYSTEM OVERVIEW

1-5

1.5 QUICK START PROCEDURE

The general procedure used to create and run a chromatography experiment on a DuoFlow system is

described below.

1. Install the required devices and instruments on the system (see Figures 3-4 and 5-5 for cable

connections and 4-1 and 4-3 for plumbing connections).

2. Flush all plumbing with DDI H

2

O to ensure that the system is clean and free of air and then prime

the pumps with starting buffer. See Chapter 4 for more detail.

3. Attach a column and set the pressure limits in the Manual screen. The high limit should be less than

or equal to the pressure limit for the column.

4. Equilibrate the column and system with starting buffer. System equilibration is controlled from the

Manual screen (see Section 7.1).

5. Create a new method in the Browser.

a. Start the Browser using the Browser button on the tool bar and then select or create a user

and project. Refer to Chapter 6 for more information on the Browser screen.

b. Use the New or New/New User option in the Browser tools, on the left side of the screen, to

create a new user and enter a username.

c. Use the New and New Method option in the Browser tools to create and name a new method.

Click OK to proceed to the hardware Setup screen. Alternatively, check the Use Method

Templates box, select a method template and press OK.

6. In the Device Setup screen, select the devices that are connected to the system. Select the

File/Save Setup menu item and save the device setup (check the Default Setup box if this is the

default setup). Refer to Section 7.2 for more information about the Device Setup screen.

7. Start the Protocol Editor using the tool bar Protocol Editor button. Use the protocol screen Add Step

tools to create a new method as illustrated with below for an ion exchange protocol. See Chapter 7

for more information.

a. Add an Isocratic Flow step to equilibrate the column and enter the required flow rate, step

size and %B. The parameters entered here will automatically appear in the next step, but can

be changed at any time.

b. Add a Zero Baseline step to zero the selected detector prior to sample injection.

c. Add a Load Inject Sample step and then enter the sample inject volume and flow rate. If a

static injection loop is used with an AVR7-3 Sample Inject Valve select static loop. For

information about the other injection options see Chapter 8.

d. Add an Isocratic Flow step to wash the column and enter the required flow rate, step size and

%B.

e. Add a Linear Gradient step to elute the column and enter the required flow rate, step size,

initial %B and final %B.

f. Add an Isocratic Flow step to clean the column and enter the required flow rate step size and

%B (usually 100%). This ensures that the entire sample is removed from the column.

g. Add an Isocratic Flow step to re-equilibrate the column and enter the required flow rate step

size and %B (see step a, above).

h. Add a Fraction Collection step to specify how fractions are to be collected for the experiment.

Enter the collection technique (e.g. collect all, threshold, etc), fraction size and any required

threshold or collection windows parameters. Note that the dialog displays the number of tubes

required for the currently defined protocol.

8. Press the New Run button to create a new run, enter a run name and open the Run screen.

9. Set the appropriate pressure limits for the column being used and then press Start on the system

tool bar. Refer to Chapter 7.4 for more information about the Run screen.

Page 14

2.0 DESCRIPTION OF SYSTEM COMPONENTS

The DuoFlow’s modular design supports many types of system components, and allows for a wide variety of

system configurations. This section discusses in detail the function of each component and its connection to

the system.

• Dell PC Computer/Controller and USB Bitbus Communicator (Section 2.1)

• Workstation (Section 2.2)

• Maximizer (Section 2.3)

• Mixers: MX-1 and Maximizer mixers: (Section 2.4)

• Detection Systems: UV detector, Conductivity monitor, pH monitor, and QuadTec detector:

(Section 2.5)

• Valves: AVR7-3, AVR9-8, SV5-4, and SVT3-2 valves: (Section 2.6)

• Fraction Collectors: BioFrac, Model 2128, and Model 2110: (Section 2.7)

• Sample Loading Options: DynaLoop, EP-1 Econo pump, and EGP Econo Gradient Pump:

(Section 2.8)

• System peripherals: (Section 2.9)

• Columns and Column Fittings: (Section 2.10)

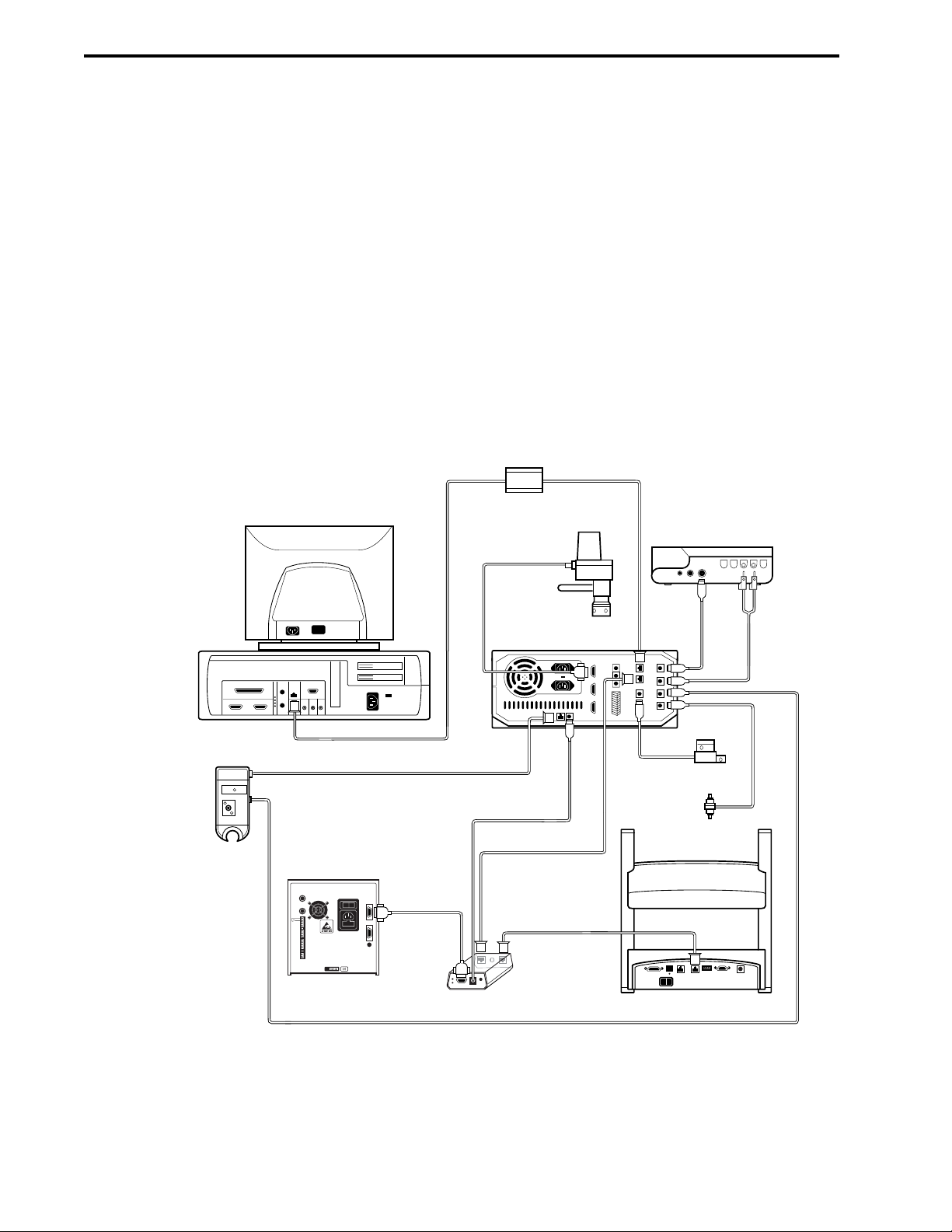

Figure 2-1. BioLogic DuoFlow Pathfinder System Components

DESCRIPTION OF SYSTEM COMPONENTSSYSTEM OVERVIEW

2-1

TM

UNO Q1 COLUMN

AVR7-3 SAMPLE

INJECT VALVE

MAXIMIZER MIXER

USB BITBUS COMMUNICATOR

QUADTEC DETECTOR

pH MONITOR

CONDUCTIVITY

MONITOR

WORKSTATION

BioFrac Franction Collector

F3 F4 F5

F1 F2

A B

VALVE A VALVE B

1 2 3

4 5 6

7 8 9

0

DELL CONTROLLER

KEYBOARD

MOUSE

MAXIMIZER

BIOFRAC

Page 15

2.1 CONTROLLER AND USB BITBUS COMMUNICATOR

The DuoFlow system is controlled by a PC computer, referred to throughout this document as the Controller.

The Dell Controller available from Bio-Rad includes a color display monitor, a keyboard, a mouse device, a

CD-ROM drive, and a floppy disk drive. The Controller communicates with the workstation and other

external devices through its USB connector. The USB Bitbus Communicator serves as the link between the

Controller’s USB port and the DuoFlow’s instrument bus. This link allows the Controller to control the

Maximizer and Workstation, as well as any devices connected to the Maximizer or Workstation, such as

automatic valves, UV detector and conductivity monitor, and peripheral instruments such as the BioFrac

fraction collector, the QuadTec UV/Vis detector, the Model EP-1 Econo pump, the Econo Gradient Pump

(EGP), and Signal Import Modules (SIM).

2.1.1 Controller

The Controller runs the BioLogic DuoFlow software (version 4.0 or higher) on a Windows

®

2000 operating

system. From the Controller you can set up and run methods, perform simple data analysis, and store

method and run data. The following tables show the key features on the Dell computer provided by Bio-Rad.

Table 2-1.

Front View of the Dell PC Computer as the DuoFlow Controller

Description

Turns on/off the Controller and monitor.

To backup methods to - and restore methods from - a floppy disk. Press the button

next to the drive slot to manually eject a floppy disk from the drive.

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEM SYSTEM OVERVIEW

2-2

Feature

Power Switch

Floppy

Disk Drive

USB CONNECTORS (2)

(BEHIND COVER PANEL)

COLOR DISPLAY MONITOR

POWER SWITCH

CD-ROM DRIVE

FLOPPY DISK DRIVE

Page 16

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEMSYSTEM OVERVIEW

2-3

Table 2-1. (continued)

Front View of a Dell PC Computer as the DuoFlow Controller

Description

To load updates of the BioLogic DuoFlow operating software. To open the drive,

press the button on the front of the drive.

The keyboard and mouse interface devices control the system. They are standard

PC compatible input devices. The keyboard includes the following special function

keys:

Hold until Keypress: To start a method that is on Hold during a run when a

method includes a “Hold until Keypress” step.

Help: Displays the Help menu for the currently displayed screen.

Esc: Functions as an alternative to the Cancel selection in a Dialog box.

Alt: Some system commands can be executed either by selecting them from a

drop-down menu or by holding down the Alt key and then pressing the

appropriate character key.

These connect to the USB Bitbus Communicator, which in turn connects to the

instrument bus, and allows components of the BioLogic DuoFlow system to

communicate with the Controller. Components connect to the instrument bus in a

“daisy-chain” and are recognized when the system is switched on. Even when one

component is switched off, other components “daisy-chained” to the system can be

controlled by the Controller.

Feature

CD ROM Drive

Keyboard,

Mouse, &

Function Keys

USB Connectors

F2

F1

Esc

Alt

Page 17

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEM SYSTEM OVERVIEW

2-4

Table 2-2.

Rear View of the Dell PC Computer as the DuoFlow Controller

Description

USB connectors: These connect to the USB Bitbus Communicator, which in turn

connects to the instrument bus, and allows components of the BioLogic DuoFlow

system to communicate with the Controller. Components connect to the instrument

bus in a “daisy-chain” and are recognized when the system is switched on. Even

when one component is switched off, other components “daisy-chained” to the system

can be controlled by the Controller.

Monitor connector: To connect the color monitor to the Controller.

Keyboard connector: To connect the keyboard to the Controller.

Mouse connector: To connect the mouse to the Controller.

Parallel connector: Devices designed for connection to the parallel port include

printers and external storage devices. Refer to Windows

®

2000 and/or the device

documentation for installation instructions. (Some printer drivers are pre-installed on

the Controller.)

Power connectors: To connect the power cable.

Connector

MONITOR POWER

CONNECTOR

MOUSE

CONNECTOR

KEYBOARD

CONNECTOR

PARALLEL

CONNECTOR

DELL CONTROLLER

MONITOR

SIGNAL CABLE

ETHERNET

CONNECTOR

COLOR MONITOR

CONNECTOR

USB BUS CONNECTORS

CONTROLLER

POWER CONNECTOR

Page 18

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEMSYSTEM OVERVIEW

2-5

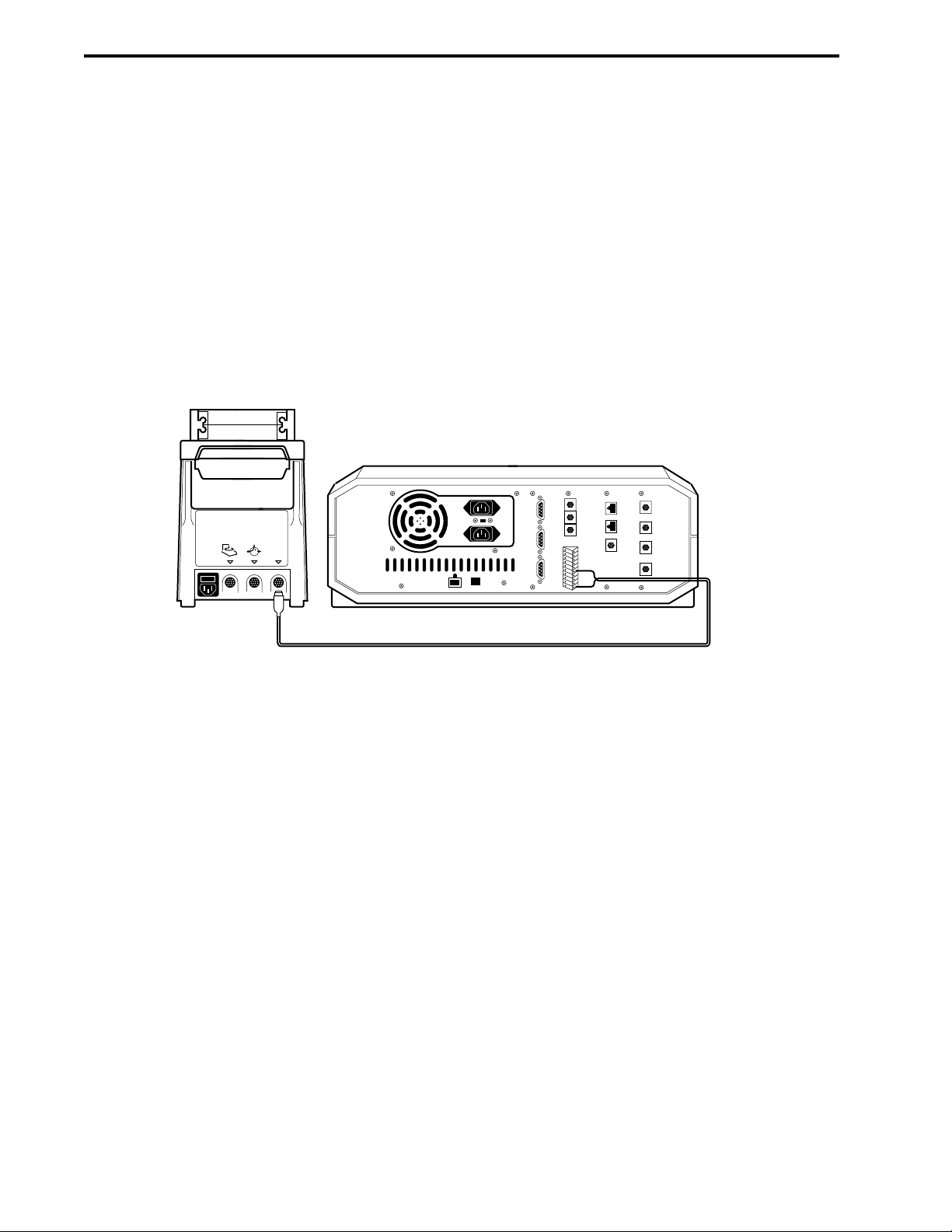

2.1.2 USB Bitbus Communicator

The USB Bitbus Communicator is used to connect the Controller to DuoFlow system instrument bus and to

supply power to the instrument bus when a Signal Import Module (SIM) is used

Table 2-3.

USB Bitbus Communicator

Description

Used to connect to the Controller USB port by way of a USB cable (catalog number

760-2032).

Indicates that there is power to the USB Bitbus Communicator.

Is used to supply power to the USB Bitbus Communicator when a Signal Import

Module (SIM) is connected to DuoFlow instrument bus. The universal AC/DC inline

adapter (catalog number 760-2034) m

ust

be used to supply the power. Use of other

power adapters may damage the USB Bitbus Communicator.

Used to select whether power for the USB Bitbus Communicator is drawn from the

Controller (INT) or the AC/DC inline adapter (EXT). An external power source must

be used if a Signal Import Module (SIM) is connected to the instrument bus

otherwise it is not required.

Indicates that the instrument bus is receiving power from an external power source.

The light is off when the PWR SELCT switch is set to INT. The light will turn on

when the USB Bitbus Communicator is switched to EXT and power is being

received.

Used to connect the USB BitBus Communicator to the DuoFlow instrument bus.

Feature

USB

ON LED

POWER

PWR SELCT

BUS PWR

LED

INSTR BUS

USB

FRONT VIEW REAR VIEW

POWER

ON

+ 5 V

PWR

SELECT

EXT INT

BUS

PWR

INSTR BUS

Page 19

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEM SYSTEM OVERVIEW

2-6

2.2 WORKSTATION

The Workstation contains the following:

• Dual pumpheads, each consists of two biocompatible dual piston pumpheads. A built-in pressure

transducer is located on the workstation at the pump outlet. The pressure transducer measures

system pressure, which is displayed on the lower status bar of the software Manual and Run

screens. Purge and Pause buttons (Purge A, Purge B, and Pause) are present on the front of the

Workstation.

There are two types of pumpheads; the F10 and the F40. All DuoFlow systems have F10

pumpheads, except DuoFlow Maximizer 80 and DuoFlow Pathfinder 80 systems that have F40

pumps.

F10 and F40 pumphead kits are available to easily convert an F10 Workstation to F40 and vise versa.

(See Section 2.9.7)

Table 2-4.

F10 and F40 Pumphead Flow Rates

Pumphead Flow Rate: Flow Rate Flow Rate

Isocratic and with Maximizer: with Maximizer:

Gradient Mode High Flow Non-blending Buffer Blending Mode

F10 0.01 - 10 ml/min 0.02 - 20 ml/min 0.5 - 20 ml/min

3500 psi 3500 psi 3500 psi

(233 bar, 23 MPa) (233 bar, 23 MPa) (233 bar, 23 MPa)

F40 0.5 - 40 ml/min 1.0 - 80 ml/min 1.0 - 80 ml/min

1000 psi 1000 psi 1000 psi

(66 bar, 6.6 MPa) (66 bar, 6.6 MPa) (66 bar, 6.6 MPa)

• The Workstation houses the control circuitry for the Workstation pumps, MX-1 mixer, UV detector,

Conductivity monitor, and system valves (low pressure solenoid and automated high pressure inject

and select valves). Connectors on the rear panel provide inputs for valves and detectors, as well as

output to a chart recorder for UV and conductivity data at 1 V Full Scale and pen up/down, start/stop

control.

If a Maximizer is being used, connect devices to it to connect the mixer, Conductivity monitor, and

pH monitor to it, rather than to the Workstation.

• An AUX combicon connector used for (a) controlling fraction advances of the Model 2110 and

generic fraction collectors, (b) receiving an open/closed signal from a device such as a manual inject

valve, and (c) starting and stopping the Model EP-1 Econo pump for sample loading.

If a Maximizer is being used, connect these devices to its AUX connector, rather than to the

Workstation.

• Power supply for the Workstation electronics as well as all devices connected to and controlled by

the Workstation.

• Output power connectors to the UV lamp and a Model 1327 chart recorder.

• Two instrument bus (phone-type) connectors.

Page 20

Table 2-5.

Workstation Front Panel Controls

Description

Turns power on/off to the Workstation and to the components connected to it.

Stops the Workstation pumps and pauses a running method. When it is pressed, the

status LEDs for pumps A and B change from green to flashing red. To resume the

run,

• Press the button again, to restarts the pumps and the method, or

• Press the Continue button in the Run screen, or

• Press the START button in the Manual screen.

Before you press either purge button switch the AVR7-3 inject valve to the Purge

position in the Manual screen, so that the column is not exposed to high pressures

and flow rates.

The purge buttons flush the tubing lines with the solution connected to pumps A and

B. When the buttons are pressed, the green LEDs for pumps A and B flash. To stop

the flow, press the purge buttons again and the LEDs go off. These buttons do not

operate when the system is running a method.

When the purge buttons are pressed, the pumpheads run at their (default)

maximum flow (F10 purge rate is 10.0 ml/min or 20 ml/min when used with the

Maximizer; F40 purge rate is 40 ml/min or 80 ml/min when used with the

Maximizer.) To alter the default purge flow rate, select Manual Setup from the

Options drop-down menu.

This LED serves two functions:

a. Constant red: Indicates that the pump has shut down due to a mechanical or

electrical problem. This includes a shutdown due to a high or low pressure

limit being exceeded. Pressure limits are set in the Manual and Run screens.

b. Flashing red: Occurs during a method run and indicates that a pre-programmed

ALARM step has been reached. The system operator must respond before the

method continues. Also, the Controller emits an audible tone.

c. Constant green: Indicates the pump is running.

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEMSYSTEM OVERVIEW

2-7

Feature

Power Button

Pause Button

Purge A & B

Buttons

Alert Light

PUMPHEAD WASHOUT

INLET PORTS

PRIMING PORT A

PRESSURE

TRANSDUCER

INLET PORTS

PAUSE

ALERT LEDs

POWER

PURGE

BioLogic DuoFlow Workstation

A B

PRESSURE TRANSDUCER

OUTLET PORT

PUMPHEAD OUTLET

PORTS

PRIMING PORT B

WASHOUT OUTLET

INLET PORTS A & B

Page 21

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEM SYSTEM OVERVIEW

2-8

Feature

Plumbing

Connections

Table 2-5. (continued)

Workstation Front Panel Controls

Description

Ports on the front of the Workstation:

a. Pumphead Inlet ports: Buffer inlet lines attach to the bottom of each

pumphead using standard 1/4-28 flat-bottom fittings. The pumphead inlet

tubing is 1/8” (3.2 mm) OD, 0.062” (1.6 mm) ID PTFE tubing with flat bottom

fittings which are supplied in the Fittings kit.

b. Pumphead Outlet and Pressure Transducer Inlet and Outlet ports: All

plumbing following the pumphead outlet ports uses standard 1/4-28 flatbottom fittings and the following tubing:

Orange PEEK tubing: 1/16” (1.6 mm) OD, 0.020” (0.51 mm) ID. Used with

pressures up to 5000 psi.

Green PEEK tubing: 1/16” (1.6 mm) OD, 0.030” (0.76 mm) ID. Used with

pressures up to 3000 psi, usually for flow rates greater than 20 ml/min.

c. Pumphead Priming ports: This port on each pumphead is used to prime the

pump. The port accepts any size syringe with a luer fitting; a syringe is

included in the Fittings kit. This draws buffer through the inlet line and to the

pumphead. Twist the port counter-clockwise one turn to open it.

d. Pumphead Washout Inlet ports: The port on top of each pumphead is used

to rinse the piston to remove crystallized salts. It accepts any syringe with a

luer fitting. A syringe for this purpose is included in the Fittings kit. The rinse

output is the open trough between the pumpheads. The pumpheads should br

rinsed daily.

Page 22

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEMSYSTEM OVERVIEW

2-9

Table 2-6.

Workstation Rear Panel Connectors

Description

Solenoid Valves: To connect DuoFlow low pressure solenoid valves (SV5-4 and

SVT3-2) to the system. If a Maximizer is in use, connect to its solenoid valve

connectors before those on the Workstation.

Automated Valves: To connect DuoFlow high pressure automated valves (AVR7-3

Inject and AVR9-8 Stream Select) to the system. If a Maximizer is in use, connect

to its automated valve connectors before those on the Workstation.

Cond Flowcell: To connect the Conductivity monitor flow cell to the system. If the

Maximizer is being used, you must

use its Cond Flowcell connector rather than the

connector on the Workstation.

UV Lamp: This specialized 6-pin square connector provides electrical power to the

mercury or zinc lamp in the UV detector lamp housing. This connector is not

available on the Maximizer.

UV Optics: To connect the UV detector to the system.

Mixer: To connect the mixer to the system. If the Maximizer is in use, connect to its

mixer connector before those on the Workstation.

10...25V --0.3A Max: Provides electrical power to the Model 1327 chart recorder or

Instrument Control Module (ICM).

Cond Chart: For conductivity signal output to a single or dual pen chart recorder.

An 8-pin mini-DIN to banana plug cable (System Cable 4) for connection to the

Model 1327 chart recorder is available. Connect the red line to the positive (+)

terminal and the black line to the negative (–) or ground terminal of channel 2 (CH2).

The chart recorder should be set to 1 V full scale. If you are using the Model 1327

chart recorder, move all switches to the “green” settings.

Connector

4

1

2

5

UV LAMP

10..25V 0.3A MAX.

6

AUTOMATED VALVES

3

SOLENOID VALVES

1. INJECT

2. n/c

3. n/c

4. n/c

5. FC ADV

6. AUX PUMP

7. n/c

8. n/c

9. GND

INSTR. BUS

MIXER

UV

CHART

COND

CHART

UV

OPTICS

COND

FLOWCELL

Page 23

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEM SYSTEM OVERVIEW

2-10

Table 2-6. (continued)

Workstation Rear Panel Connectors

Description

UV Chart: For UV signal output to a single or dual pen chart recorder. When the

Bio-Rad Model 1327 is used, chart recorder Pen Up/Down, Stop/Start commands,

and event marks are sent from this connector.

The Bio-Rad Model 1327 dual pen recorder needs an 8-pin mini-DIN to standard DIN

cable (System Cable 2) and a mini-DIN to banana plugs cable (System Cable 4).

Generic chart recorders require an 8-pin mini-DIN to breakout cable (System Cable 7),

available from Bio-Rad.

When a Signal Import Module signal replaces the standard BioLogic UV Detector,

use System Cable 20 to control a Bio-Rad Model 1327 dual pen chart recorder.

The chart recorder should be set to 1V.

Power Cord: The grounded 3-prong connector inputs power to the Workstation

and outputs power to any unit connected to the Workstation. The Workstation’s

input power cord should be plugged into a 3-prong grounded power outlet.

Instr Bus: The RJ-45 modular phone connectors and the bus communication cables

connect the Workstation to the other components in the system. The Instrument Bus

handles all communications between the Controller and each of the components in

the system. For example, the Instrument Bus connects the Workstation to the USB

Bitbus Communicator, Maximizer, BioFrac fraction collector, or Econo Gradient

Pump. Components can be connected to the system in any order.

Aux: The 9-pin AUX PORT connects a variety of peripheral modules that cannot

communicate with the DuoFlow Controller over the Instrument Bus. If the Maximizer

is being used, use its AUX connector before the connector on the Workstation.

Pin # Description

1 Inject. A contact closure between pins 1 and 9 (GND) satisfies a Hold

command which has been programmed in a method protocol.

2 n/c. No connection

3 n/c. No connection

4 n/c. No connection

5 FC Adv. Model 2110 and generic fraction collector Advance output.

6 AUX Pump. A Stop-Start command is sent to a pump (e.g., Bio-Rad EP-1).

7 n/c. No connection

8 n/c. No connection

9 GND. Ground

Reserved for internal Bio-Rad use.

Conector

1 INJECT

2 N/C

3 N/C

4 N/C

5 FC ADV

6 AUX PUMP

AUX PORT

7 N/C

8 N/C

9 GND

Page 24

DESCRIPTION OF BIOLOGIC DUOFLOW SYSTEMSYSTEM OVERVIEW

2-11

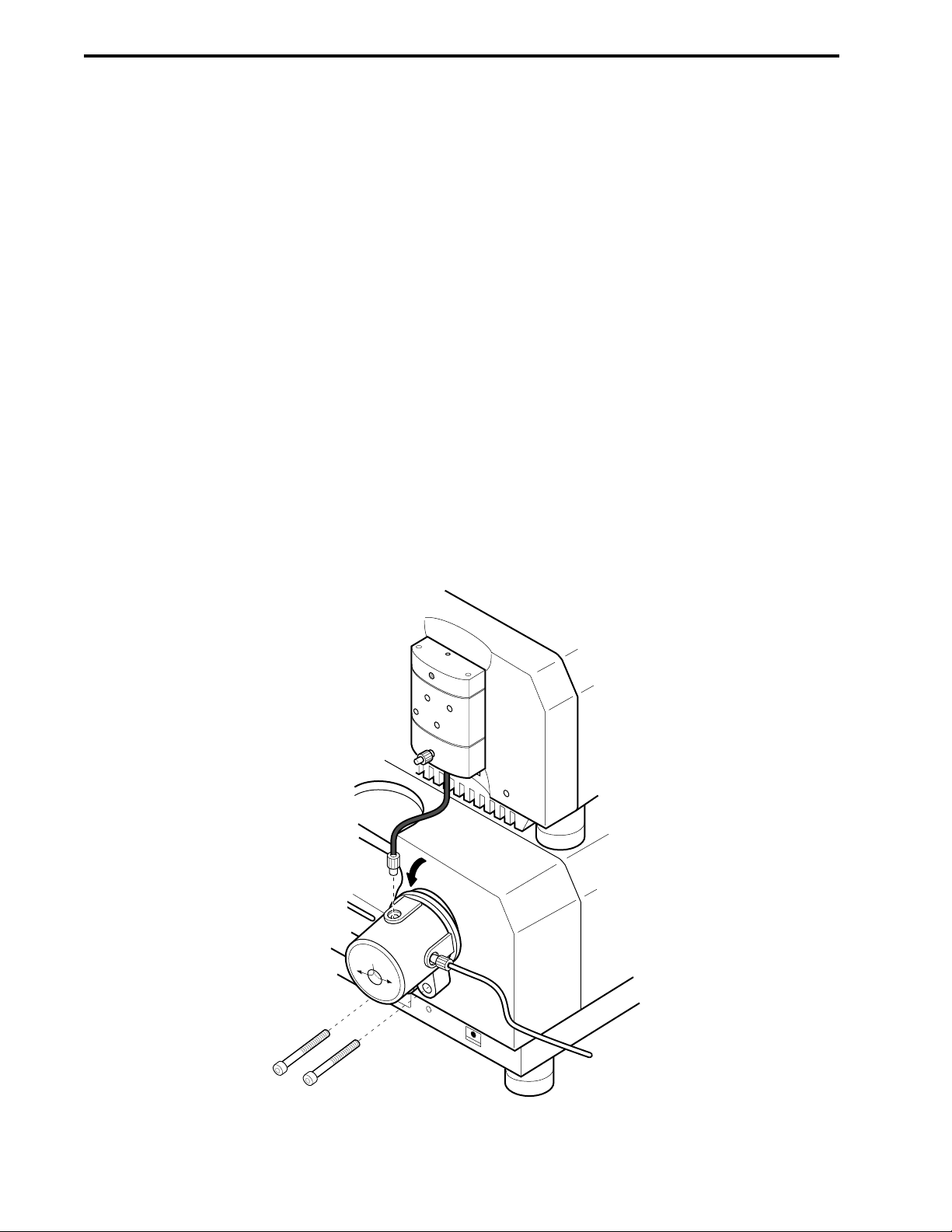

2.3 BIOLOGIC MAXIMIZER VALVE SYSTEM

The Maximizer enables buffer blending applications, doubles the accessible pump flow rate, and doubles

valving capacity to 6 low pressure valves and 6 high pressure valves. The Maximizer includes a separate

Maximizer mixer (see Section 2.4.2) and pH monitor (see Section 2.5.4).

• Proportioning valves on the Maximizer blend water, salt, and the conjugate acid and base of a buffer

to obtain a solution with a user-defined pH and salt concentration. One valve delivers an acid and

base and the other valve delivers a salt and water.

• Pre-defined Buffer Blending buffer systems are provided for virtually all common buffers used in

chromatographic applications. Additional user-defined buffers may be created using the BioLogic

software Buffer Editor feature. The Maximizer uses the buffer system information to determine the

amount of acid, base, water and salt to add to obtained the desired buffer composition and pH.

• When the Maximizer is set to local mode in the software Manual screen, it will not be under

DuoFlow system control. In local mode the Maximizer front panel controls are accessible and can be

used to prime the system, calibrate the pH and conductivity monitor, observe the status of each

device, and control the position of each Maximizer valve.

• The Maximizer is designed to operate under normal laboratory and coldroom conditions (4° - 40° C)

with all commonly used aqueous chromatographic buffers.

The Maximizer includes the following hardware and circuitry: