Page 1

Model 680

Microplate Reader

Instruction Manual

Catalog Numbers 168-1000

168-1001

168-1002

168-1003

Page 2

Warranty Statement

This warranty may vary outside of the continental United States. Contact your local

Bio-Rad office for exact terms of your warranty.

Bio-Rad Laboratories warrants to the customer that the Model 680 Microplate Reader

(catalog number 168-1000, 168-1001, 168-1002, and 168-1003) will be free from defects

in material and workmanship, and will meet all performance specification for period of

one year from the date of shipment. This warranty covers all parts and labor.

In the event that the instrument must be returned to the factory for repair under warranty,

the instrument must be packed for return in original packaging.

Bio-Rad shall not be liable for any incidental, special, or consequential loss, damage, or

expense directly or indirectly arising from the use of the Model 680 Microplate Reader.

Bio-Rad makes no warranty whatsoever in regard to products or parts furnished by third

parties, such being subject to the warranty of their respective manufacturers. Service

under this warranty shall be requested by contacting your nearest Bio-Rad office.

The following items are considered Customer-installable consumables: thermal printer

paper and light bulbs. These parts are not covered by this warranty. All

customer-installed parts are warranted only to be free from defects in workmanship.

This warranty does not extend to any instrument or parts thereof that have been subject

to misuse, neglect, or accident, or that have been modified by anyone other than

Bio-Rad or that have been used in violation of Bio-Rad instructions.

The foregoing obligation are in lieu of all other obligations and liabilities including

negligence and all warranties, of merchantability, fitness for a particular purpose or

otherwise, expressed or implied in fact or by law, and state Bio-Rad’s entire and

exclusive liability and buyer’s exclusive remedy for any claims or damages in connection

with the furnishing of goods or parts, their design, suitability for use, installation or

operation. Bio-Rad will in no event be liable for any special, incidental or consequential

damages whatsoever, and Bio-Rad’s liability under no circumstances will exceed the

contract price for the goods for which liability is claimed.

i

Page 3

Regulatory Notices

Electro Magnetic Compatibility:

This instrument is designed to meet the Class-A emissions and immunity levels of the

EN61326 product family standard for the CE mark. This rating requires that it only be

used in a laboratory environment.

Note: This instrument has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his/her own expense.

Safety:

This instrument is designed to meet EN61010-1 requirements for the CE mark, which

are internationally accepted safety standards for electrical equipment for measurement,

control and laboratory use. EN61010-1 applies to equipment which is used under the

following conditions;

Indoor use

Altitude up to 2,000 m

MAINS supply voltage fluctuations up to ±10%

This instrument has been tested, and its compliance has been confirmed under the

following environmental conditions;

Overvoltage category II

Pollution degree 2

If the instrument is used in a manner not specified in this manual, the protection provided

by the instrument may be impaired. This instrument should not be modified or altered

in any way. Alteration of this instrument will result in the following:

Void the manufacture’s warranty.

Void regulatory compliance.

Create a potential safety hazard.

Protective Ground: This instrument has detachable, three-wire power cord for

connection to both the power source and protective ground. The protective ground

contact is connected to the accessible metal parts of the instrument. To prevent

electrical shock, always use a power source outlet that has a properly grounded

protective-ground contact.

ii

Page 4

Table of Contents

Section 1. ........Introduction ................................................................................................ 1

1.1 Description and accessories for Model 680 Microplate Reader..........................2

Section 2. ........Product Description ..................................................................................... 3

2.1 Contents of Shipping Carton ..........................................................................3

2.2 External Features..........................................................................................4

2.3 Membrane Keypad........................................................................................5

Section 3. ........Instrument Set-up........................................................................................ 6

3.1 Initial Start-up................................................................................................6

Section 4. ........Operation ................................................................................................... 7

4.1 Instrument Overview .....................................................................................7

4.2 Functions Overview.....................................................................................10

4.2.1 Calculations ..................................................................................................... 10

4.2.2 Security password .......................................................................................... 10

4.2.3 Memory Back-up............................................................................................. 10

4.2.4 Limits................................................................................................................. 11

4.2.5 Reports............................................................................................................. 11

4.2.6 RS-232C Interface..........................................................................................16

4.2.7 Printer ............................................................................................................... 17

4.3 Detailed Operation ...................................................................................... 18

4.3.1. Initial Start-up .................................................................................................. 18

4.3.2. Configuring the system .................................................................................. 19

4.3.3. Printing Reports and Protocol information..................................................21

4.3.4. Memory Recall operation............................................................................... 22

4.3.5. Editing Kinetic protocol .................................................................................. 23

4.3.6. Checkmark value setting (by Administrator only) ...................................... 25

4.3.7. Editing End Point Protocol ............................................................................26

4.3.8. Cutoff setting procedure ................................................................................ 27

4.3.9. Standard setting procedure........................................................................... 31

4.3.10. Mode setting procedure................................................................................. 34

4.3.11. Plate Map setting procedure......................................................................... 36

4.4 Quick Guide – Reading a plate ..................................................................... 39

4.5 Language choice......................................................................................... 40

Section 5. ........Instrument service by the user..................................................................... 42

5.1 Installing Interference Filters ........................................................................ 42

5.2 Changing the Lamp ..................................................................................... 42

Section 6. ........Troubleshooting and Error Messages........................................................... 43

Section 7. ........Specifications ........................................................................................... 45

7.1 Instrument Specifications ............................................................................. 45

7.2 Interface Specifications................................................................................ 47

7.3 Command Language for Model 680 Microplate Reader ..................................48

7.3.1 Command Language for Remote control mode ........................................48

7.3.2 Error Codes ..................................................................................................... 63

iii

Page 5

Section 1. Introduction

The Model 680 Microplate Reader is an eight-channel, vertical pathlength photometer that

measures the absorbance of the contents in the wells of a 96-well microtitration plates. It can

perform single or dual wavelength measurements and can report absorbance values to three

decimal places.

The Model 680 reader can be programmed by entering commands through the membrane

keypad to define plate reading and data analysis parameters as testing protocols and select

report types. Hard copy reports can be produced by an optional on-board thermal printer or

external printer.

The Model 680 reader can also be controlled by the Windows’ based Microplate Manager

software (catalog number 170-9520) program, through its built-in RS232C serial interface

device. Microplate Manager software program provides a complete, user-friendly package for

protocol programming as well as data analysis, for all absorbance microplate readers from

Bio-Rad Laboratories.

1

Page 6

1.1 Description and accessories for Model 680 Microplate Reader

Catalog Number Description

168-1000 Model 680 microplate reader

168-1001 Model 680 microplate reader with temperature control

168-1002 Model 680 microplate reader with internal printer

168-1003 Model 680 microplate reader with temperature control and internal

printer

168-1011 405 nm filter

168-1013 415 nm filter

168-1020 450 nm filter

168-1028 490 nm filter

168-1038 540 nm filter

168-1040 550 nm filter

168-1044 570 nm filter

168-1049 595 nm filter

168-1056 630 nm filter

168-1061 655 nm filter

168-1080 750 nm filter

168-1005 Serial PC Cable

168-1006 Replacement lamp for Model 680 microplate reader

168-1007 Printer paper, 2 rolls

Custom filters between 400 and 750 nm may be ordered, corresponding catalog numbers can

be found on www.bio-rad.com, or you can order by specifying the wavelength and the model

number of the reader.

2

Page 7

Section 2. Product Description

2.1 Contents of Shipping Carton

The shipping carton contains the following items:

• Model 680 Microplate Reader, with 415nm, 450nm, 490nm and 655nm interference

filters installed on the filter wheel.

• Power cord

• Serial PC Cable

• Spare fuse

• Dust cover

• Instruction manual

• Warranty card

• One roll of thermal printer paper (for units equipped with internal printer)

Inspect the exterior of the instrument for any signs of shipping damage. Contact your local

Bio-Rad representative if any of these items are damaged or missing.

3

Page 8

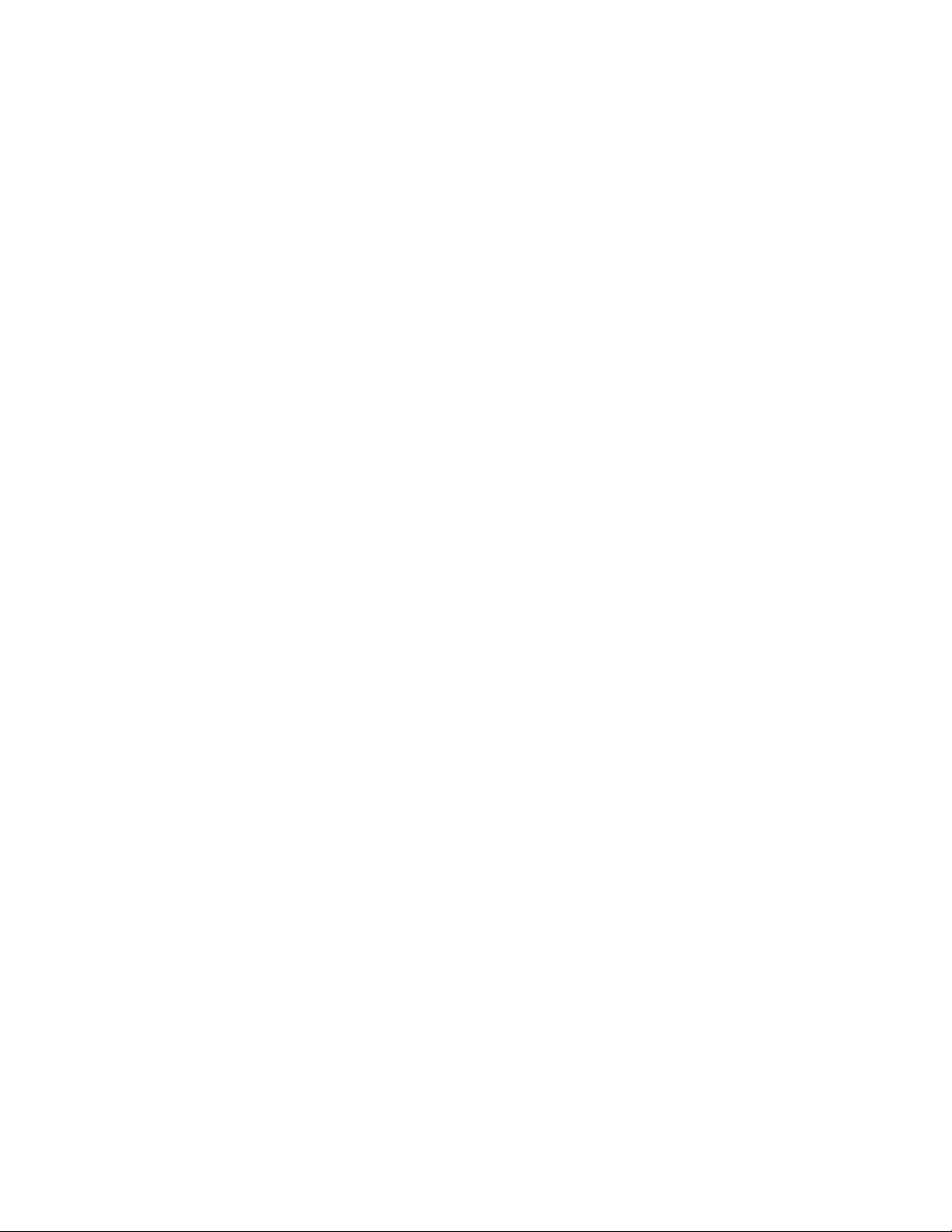

2.2 External Features

1

4

5

2

3

6

1. Release latch for rear cover 4. Rear cover

2. Liquid crystal display (LCD) 5. Printer slot (when optional built-in printer is installed)

3. Membrane keypad 6. Reading chamber door

7. RS-232C serial interface 11. Printer port (only when optional built-in printer is not installed)

8. Serial number Label 12. Power cord receptacle

9. Fuse 13. Cooling Fan

10. Power switch 14. Cooling Vents

8

11

10

7

14

9 12 13

4

Page 9

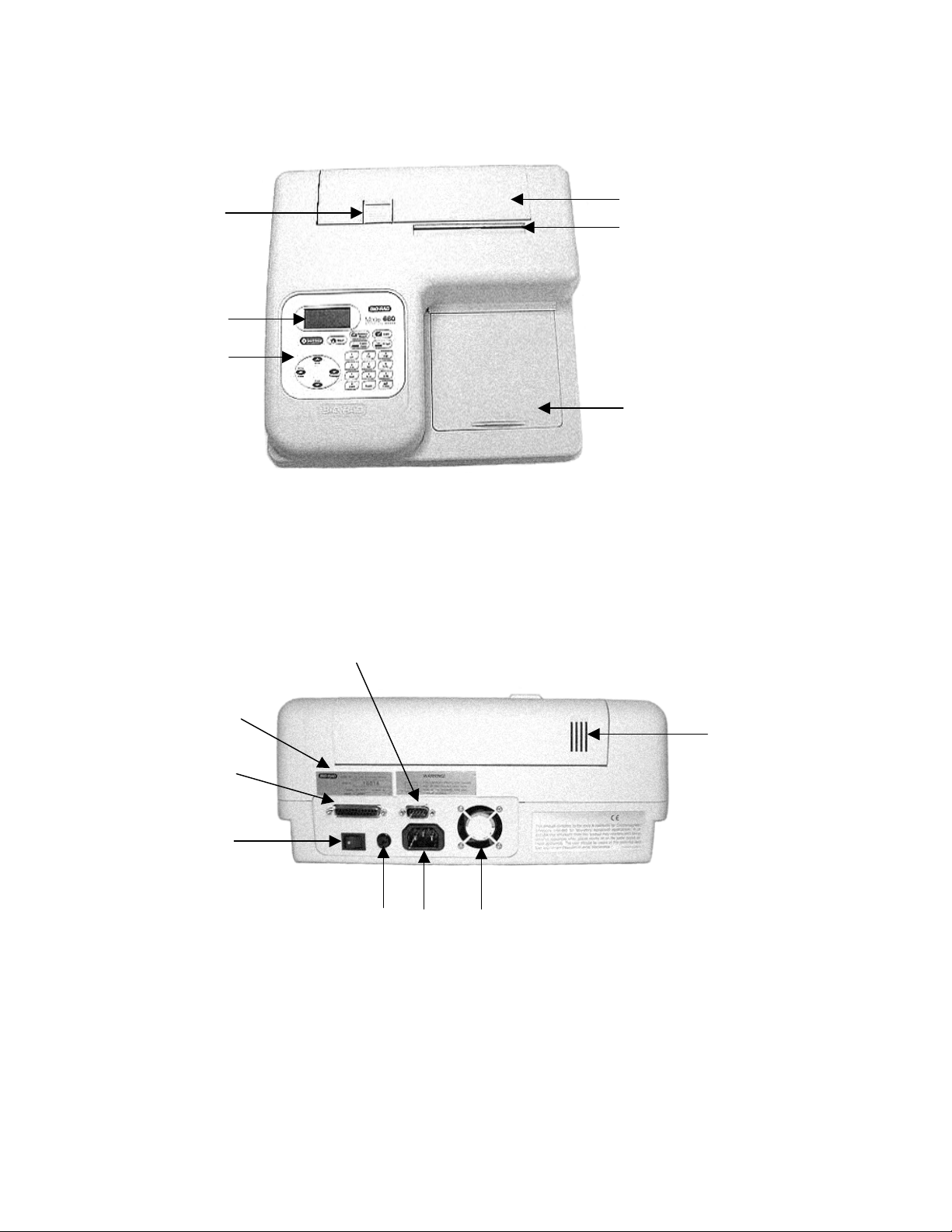

2.3 Membrane Keypad

1

2

3

4

5

Star t/Sto p

AZ⇒

+-・・

Bac k Ch ange

ZA⇒

Main

CP

CO

SMP

EMP

7

4

1

0

Memory

Recall

Paper

Fee d

8

CN

5

QC

2

BLK

.

FUNC

Edit

Print

9

CW

6

CAL

3

STD

6

7

8

9

1. Main Returns to MAIN SCREEN.

2. Start/Stop Initiates plate reading using current active protocol.

Stops plate reading and printing.

3. Paper Feed Advances paper strip in internal printer.

4. Up Arrow Moves the cursor upward. Selects the alphabet or the symbol.

5. Left Arrow Returns to the previous screen. Moves the cursor to the left.

6. Down Arrow Moves the cursor downward. Selects the alphabet or the symbol.

7. Right Arrow Moves the cursor to the right. Changes or selects the value and type.

8. Dot/Function Inputs the dot. Changes the input mode.

9. Enter Completes or seals a field entry.

10. Ten Keys Inputs numbers or well type in plate mapping.

0 / EMP : Empty 5 / QC : QC control

1 / SMP : Sample 6 / CAL : Calibrator

2 / BLK : Blank 7 / CP : Positive Control

3 / STD : Standard 8 / CN : Negative Control

4 / CO : Cutoff control 9 / CW : Weak Positive Control

11. Print Prints out the plate data and protocol information.

12. Edit Enter the Edit Menu, and set up the instrument.

13. Memory Recall Read out protocol and plate data.

13

12

11

10

5

Page 10

Section 3. Instrument Set-up

3.1 Initial Start-up

1 Place the instrument on a clean, sturdy table or bench. It is important to keep the

instrument in a clean, relatively dust free environment to ensure optimal

performance.

2 Connect the power cord to the back of the instrument. Before connecting the

instrument to the main electrical supply, check that the AC voltage is appropriate

for the instrument.

3 Turn on the power switch on the rear panel. The LCD will display the version

number of the on-board firmware. After about three seconds, the instrument will

perform an initial self-diagnosis that requires about fifteen seconds. The Login

Screen will now be displayed for you to choose your user level (administrator or

common user), and enter the password (Initial password: 00000). Please allow

three minutes for the instrument to warm up (reach thermal equilibrium) before

reading plates.

4 Install the printer paper (if the optional internal printer is installed). The thermal

printer paper is treated on one side only and must be properly installed for the

printer to function. The side of the paper that faces out from the roll is the treated

side.

a. Open the rear cover of the instrument.

b. Tear off a small piece at the beginning of a new roll at an angle to form a point.

c. Place the roll of paper in the small pan-like holder positioned below the printer.

The roll should be positioned so that it will feed from the bottom.

d. While pressing the PAPER FEED key, feed the pointed end of the paper into

the paper feed slot in the underside of the printer until the printer grabs the

paper and feeds it through the slot in the top of the instrument.

e. Securely close the rear compartment.

6

Page 11

Section 4. Operation

4.1 Instrument Overview

The Model 680 Microplate Reader has built-in software that allows the user to set the plate

reading and data analysis conditions as a protocol data, read a microplate under the defined

reading conditions, and get the printout reports from the internal or external printer. The

software communicates through the 4-line, 20-character LCD and is controlled through the

instrument's membrane keypad.

The display shows the current mode of the on-board software. The software has three

different protocol types: End-point analysis, Kinetic analysis, and the Checkmark validation

protocols. The user presses the Memory Recall key to select analysis mode passing through

the choice of the protocol or the collected data.

7

Page 12

r

A

A

r

A

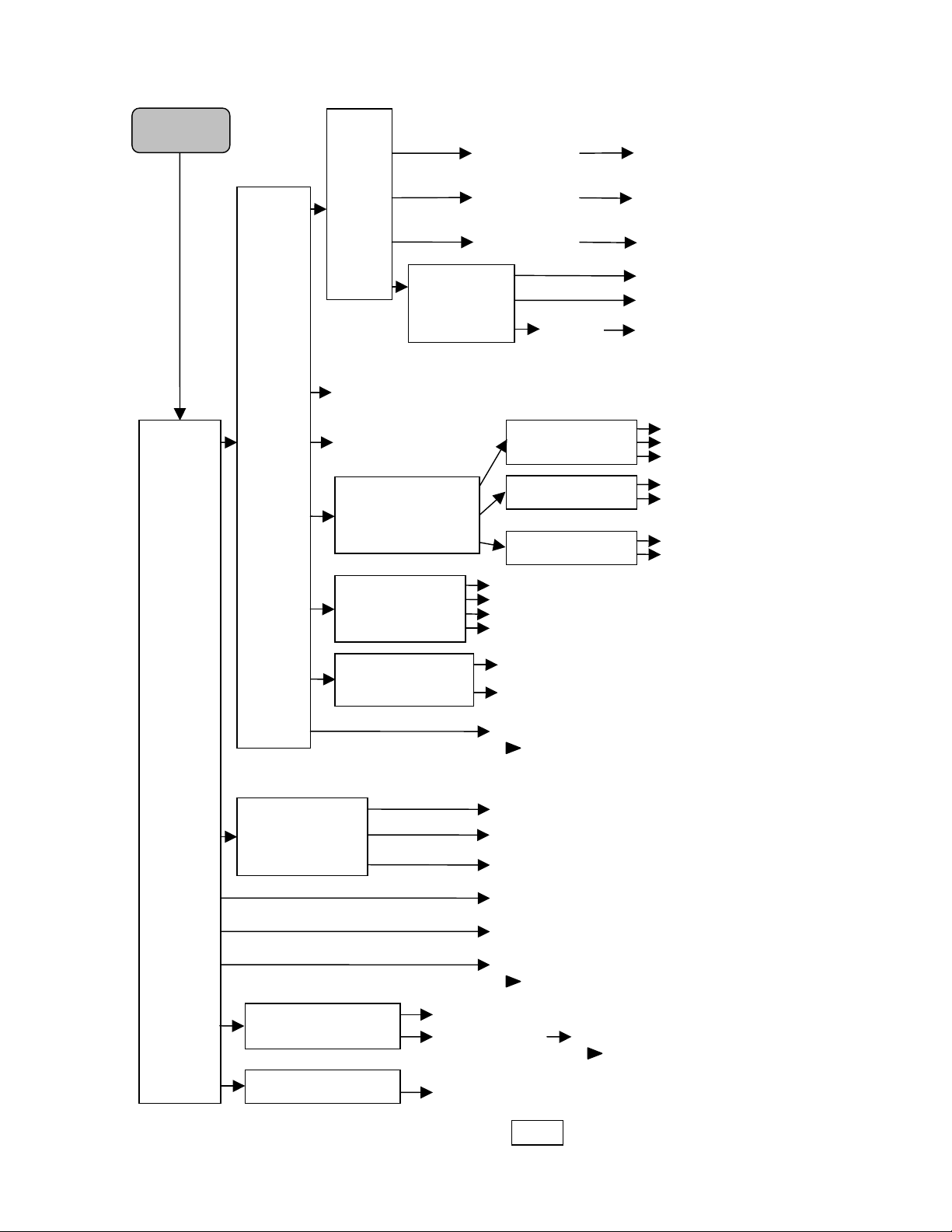

Operation flow when End point protocol selected

Edit

Protocol

Cutoff

Report

Limit

STDs

Mode

Not Use

Constant

Control

Formula

Ratio

Raw(Raw data), Abs(Absorbance), Lim(Limit), Mtx(Matrix), Cut(Cutoff)

Crv(Curve fit), Cnc(Concentration), Dif(Difference)

Upper Limit

Lower Limit

For Limit Report

Standard information

Recall STD Curve

Set Photo mode

Set Read mode

Concentration

Cutoff value

Curvefit

Set Shaking

Incubation

Ranged Cutoff

Single Cutoff

Ranged Cutoff

Single Cutoff

12 choices of

cutoff formula

Unit

Ranged

Cutoff

Single

Cutoff

Number of STD

Concentration

Curvefit type

Graph axis

Recall Setting

Select STD Curve

Single/Dual Wavelength

Shake (Yes, No), Speed (High, Low, Mid), Time

Read Speed (Fast//Step) and Read Mode (Normal/Eval)

Disable/Enable, Temperature

Cutoff Values setting

Gray zone setting when single Cutoff

Cutoff Control setting

Gray zone setting when single Cutoff

Coefficient setting of selected formula

0 - 9999

17 choices of unit

Cutoff Values setting

Gray zone setting when single Cutoff

Up to 12 Standards

0 to 9999

Unit

17 choices

12 choices of curve fit type

4 choices of graph axis

combination of Log and Linear

Recall Yes/No Selection

5 choices of memorized STD

curve

Security

Filters

Date Set

Lab name

SaveSTDC

Printer

Mapping

Kit name

Change password

Change use

Lock/Unlock

Save STD Curve

Rename STD Curve

Select Ext.Printe

ASCII / ESC/P

Manual mapping

Automatic mapping

5 choices of storage number

5 choices of STD

curve

SCII / ESC/P Printer Selection for external printer

.Func key to switch [N] to [F]

[N] for sample number, [F] for sample type

Blank,CN,CW,CP,CO,QC,Calibrator,Sample,Replicate well

.Func key to switch from [ABC] to [abc] to [sym]

key to move cursor

For current user mode

dministrator or Common user

dministrator has power to switch

Filter wavelength setting for 1-8 positions, “0” for no filter

Day/Month/Year, Hour:Min

.Func key to switch from [ABC] to [abc] to [sym]

key to move cursor

.Func key to switch from [ABC] to [abc] to [sym]

key to move cursor

Bold for menu

Italic for program pages

8

Page 13

r

r

A

A

r

A

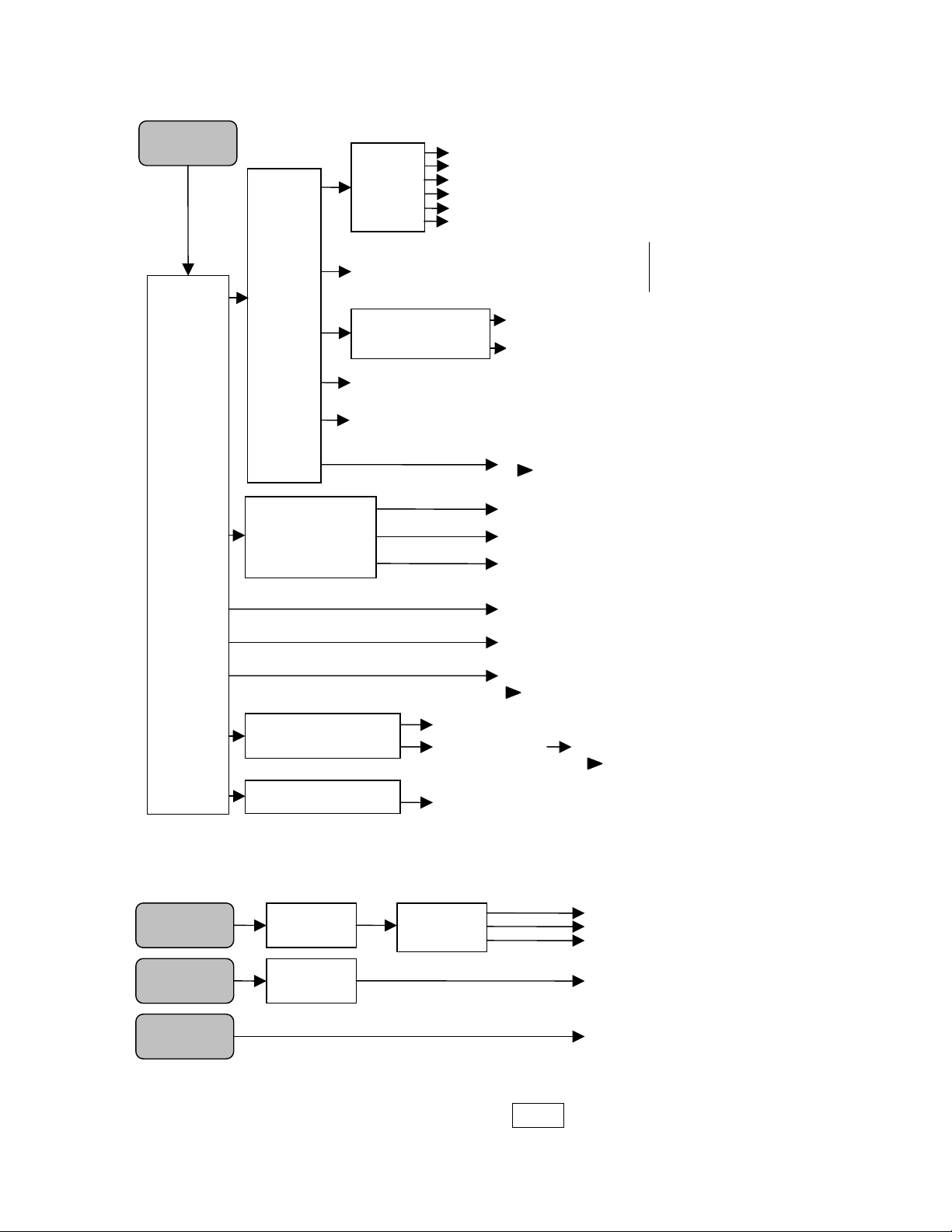

Operation flow when Kinetic protocol selected

Edit

Protocol

Security

Mode

Calc

Mapping

Assay

Report

Kit name

Change password

Change use

Lock/Unlock

Absorbance, KINETIC Plots, Linear regression when General Kinetic Assay selected

GALT report when GALT Kinetic assay selected

Reading

Inte

Shaking

Ph.mode

Speed

Incu

CC Limit (correlation coefficient limit)

Calc.range (calculation range of reading number)

for Linear regression Report

Manual mapping

Automatic mapping

General Kinetic or GALT assay

assay type selection

Number of reads (2-30), Start delay time (0-999)

Reading interval time

Shake (First/Every/disable), Speed (High, Low, Mid), Time

Single / Dual Wavelength

Read Speed (Fast/Step)

Disable/Enable Temperature

.Func key to switch [N] to [F]

[N] for sample number, [F] for sample type

Blank,CN,CW,CP,CO,QC,Calibrator,Sample,Replicate well

.Func key to switch from [ABC] to [abc] to [sym]

key to move cursor

For current user mode

dministrator or Common user

dministrator has power to switch

GALT factor k input (0- 9999)

Result = (2nd read – 1st read)*k

for GALT Report

Filters

Date Set

Lab Name

SaveSTDC

Printer

Special Buttons

Memory

Recall

Print

Main

Save STD Curve

Rename STD Curve

Select Ext.Printe

ASCII / ESC/P

Protocol

Plate Data

Report

Protocol

Filter wavelength setting for 1-8 positions, “0” for no filter

Day/Month/Year, Hour:Min

.Func key to switch from [ABC] to [abc] to [sym]

key to move cursor

5 choices of storage number

5 choices of STD

curve

SCII / ESC/P Printer Selection for external printer

End point

Kinetic

Checkmark

.Func key to switch from [ABC] to [abc] to [sym]

key to move cursor

1-64 End point protocol storage

1-2 Kinetic protocol storage

Checkmark reader test

Printout

Returns to MAIN screen

Bold for menu

Italic for program pages

9

Page 14

4.2 Functions Overview

4.2.1 Calculations

The Microplate Reader uses Beer's Law to calculate the absorbance value of each well.

Beer's Law states that absorbance is equal to the log10 of the ratio of the baseline

measurement intensity (Io) to the sample measurement intensity (I).

Beer's Law

Absorbance = Log10 (Io/I)

Before measuring the plate, the reader takes a reading for all eight photodiode channels.

These values are recorded as the baseline measurement (Io) values for each channel,

respectively. The reader then records the sample measurement (I) value for each well, and

calculates the absorbance using these values. Channel-to-channel error is significantly

reduced because the Io value for a given channel is used only in determining the absorbance

of the wells of that channel.

4.2.2 Security password

The Model 680 Microplate Reader requires user login with password. This security feature

helps to prevent any unwarranted modifications to the analysis conditions/protocols and data

stored in the instrument, and identifies operator on reports. The reader has two user settings,

the Administrator and the Common user. Each user level has its own security password.

4.2.3 Memory Back-up

The battery back-up provides memory even after the reader is turned off.

The following information will be saved in the memory until new reading parameters are set

by the user or a new plate is read by the instrument. Note that if a run is aborted before it is

finished, all the previous plate reading data remain in memory and none of the data from the

aborted reading is stored.

1. 10 latest plate reading result for End-point protocol

2. 2 latest sets of Kinetic plate reading result (Max 30 series of readings for each

Kinetic)

3. 64 End-point Protocol settings and 2 Kinetic Protocol settings

4. A set of Checkmark reference data and one latest set of Checkmark reading

result

5. 5 set of Standard curve data for the storage of standard curves and graphs

6. 8 wavelength values for filters

7. Laboratory name

8. Two security passwords (for the Administrator and the Common user)

9. External printer type (ASCII or ESC/P type)

In addition to the battery back-up memory, the instrument has a small amount of none volatile

memory to keep the system information after the battery is dead. The Serial Number is stored

10

Page 15

in this memory.

The first time the instrument is turned on, or after a battery failure, the following default

information will be held in the memory.

1. Both of Administrator and Common user security password are set to "00000".

2. Laboratory name is "Bio-Rad Laboratories".

3. All wavelength values of the filters are set to "---" nm.

4. The date and time of the calendar chip are set to 1 day, 1 month, 00 year, 0 hour

and 0 minute.

5. None of plate reading data is available.

6. End-point protocol is chosen and the protocol number is set to #1.

7. None of Standard curve data for the storage of standard curves and graphs is

available.

8. External printer type is set to ASCII type.

4.2.4 Limits

The Microplate Reader displays absorbance readings with absolute values as 3.500.

Out-of-range absorbance values, i.e. those with absolute values greater than 3.500, are

displayed as either "*.***" or "-*.***". For example, if the absorbance is 4.500, then the display

will read "*.***", and if the absorbance is -4.500, the display will read "-*.***".

4.2.5 Reports

The Microplate Reader can generate nine types of reports for End-point protocol: Raw data,

Absorbance, Limit, Matrix, Cutoff, Curve fit, Concentration, Difference, and TeSeE Screening

report. And four types of Kinetic protocol can be generated by the reader: Absorbance,

Kinetic Plots, Linear regression, and GALT report.

Reports of End-point Protocol

(1) Raw data report

The Raw data report is the uncorrected absorbance values (without blank

subtraction). In single-wavelength mode, the reported value is the measured

absorbance. In dual-wavelength mode, the reported value is the difference between

the uncorrected readings taken with the measurement filter and with the reference

filter.

(2) Absorbance report

The Absorbance report is the blank-corrected absorbance values. The mean

absorbance value of all of the wells designated as assay blanks is calculated and

then subtracted from all 96 values of the raw data set to produce the Absorbance

report.

Abs = Raw – Blank mean

11

Page 16

Blank mean = X/n

S.D. = [{X^2 – n*(Blank mean)^2}/{n-1}]^1/2

Where:

S.D. = Standard deviation

X = Sum total of the raw absorbance for each blank

X^2 = Sum total of the squared raw absorbance for each blank

n = Number of blanks

(3) Limit report

The Limit report provides a qualitative YES/NO report. Wells with blank-subtracted

absorbance values between the upper and lower limits are represented with an

asterisk (*), wells with absorbance values below the lower limit by minus signs (-),

and wells with absorbance values greater than the upper limit by positive signs (+).

(4) Matrix report

The Matrix report provides a qualitative report of the relative magnitude of the

absorbance values on the plate. The absorbance range defined by the upper and

lower limits is divided into 10 equal partitions, numbered 0 through 9. The

blank-subtracted absorbance value of each well is classified according to the

partition of the matrix to which it corresponds, and is reported as a signal digit. Wells

with absorbance values greater than the upper limit are reported by plus signs (+),

and wells with absorbance values less than the lower limit by minus signs (-).

(5) Cutoff report

The Cutoff report provides a qualitative report of the relative magnitude of the

absorbance values or converted concentrations on the plate.

Four types of cutoff report are supported as listed below.

a. Cutoff Constant

Ranged Cutoff Constant

The user inputs Positive and Negative values to be used as the cutoff.

For units designated "Abs", if the absorbance of a well is within the positive and

negative cutoff values, the well is scored "*". If the absorbance of a well is

greater than the positive value, the well is scored "+", and if the absorbance of a

well is below the negative value, the well is scored "-".

For units not designated "Abs", the absorbance value of each well is converted

to the concentration value using the curve fit constants of the curve fit report. If

the concentration of a well is within the positive and negative cutoff values, the

well is scored "*". If the concentration of a well is greater than the positive value,

the well is scored "+", and if the concentration of a well is below the negative

value, the well is scored "-".

Single Cutoff Constant

The user inputs Positive and Gray zone values to be used as the cutoff.

For units designated "Abs", if the absorbance of a well is within the gray zone

value of the positive cutoff value, the well is scored "*". If the absorbance of a

well is more than the gray zone value and greater than the positive value, the

well is scored "+", and if the absorbance of a well is more than the gray zone

value below the positive value, the well is scored "-".

12

Page 17

Upper cutoff absorbance = Positive absorbance + ((Gray zone/100) * Positive absorbance)

Lower cutoff absorbance = Positive absorbance – ((Gray zone/100) * Positive absorbance)

For units not designated "Abs", the absorbance value of each well is converted

to the concentration value using the curve fit constants of the curve fit report. If

the concentration of a well is within the gray zone value of the positive cutoff

value, the well is scored "*". If the concentration of a well is more than the gray

zone value greater than the positive value, the well is scored "+", and if the

concentration of a well is more than the gray zone value below the positive

value, the well is scored "-".

Upper cutoff conc. = Conc. of positive controls + ((Gray zone/100) * Conc. of positive controls)

Lower cutoff conc. = Conc. of positive controls - ((Gray zone/100) * Conc. of positive controls)

b. Cutoff Control

Ranged Cutoff Control

The mean absorbance values of the Positive and Negative wells defined in the

plate map are used for the cutoff.

The absorbance range of the Positive and Negative is divided into 10 equal

partitions, numbered 0 through 9. The absorbance value of each well is

classified according to the partition of the matrix to which it corresponds, and is

reported as a signal digit. Wells with absorbance values greater than the

Positive are reported by plus signs (+), and wells with absorbance values less

than the Negative by minus signs (-).

Single Cutoff Control

The mean absorbance value of the Negative wells that defined in the plate map

and the gray zone value that is entered by the user are used to the cutoff. The

upper and lower cutoff values are:

Upper cutoff absorbance = Mean of negative controls + ((Gray zone/100) * Mean of negative controls)

Lower cutoff absorbance = Mean of negative controls – ((Gray zone/100) * Mean of negative controls)

The absorbance range of the upper and lower cutoff is divided into 10 equal

partitions, numbered 0 through 9. The absorbance value of each well is

classified according to the partition of the matrix to which it corresponds, and is

reported as a signal digit. Wells with absorbance values greater than the upper

cutoff are reported by plus signs (+), and wells with absorbance values less than

the lower cutoff by minus signs (-).

c. Cutoff Formula

The mean absorbance values of the Positive and Negative wells defined in the

plate map are used for the cutoff formula calculation.

The 12 types of formula supported are:

i. k * CNx vii. k + CNx

ii. k * CPx viii. k + CPx

iii. k * COx ix. k + COx

iv. CNx / k x. k*CNx + CPx

v. CPx / k xi. (CNx + CPx) / k

vi. COx / k xii. k1*CNx + k2*CPx

13

Page 18

The result absorbance value of the formula calculation and the gray zone value

that is entered by the user are used for the cutoff. The upper and lower cutoff

values are:

Upper cutoff absorbance = Result of a Formula + ((Gray zone/100) * Result of a Formula)

Lower cutoff absorbance = Result of a Formula - ((Gray zone/100) * Result of a Formula)

The absorbance range of the upper and lower cutoff is divided into 10 equal

partitions, numbered 0 through 9. The absorbance value of each well is

classified according to the partition of the matrix to which it corresponds and is

reported as a signal digit. Wells with absorbance values greater than the upper

cutoff are reported by plus signs (+), and wells with absorbance values less than

the lower cutoff by minus signs (-).

d. Cutoff Ratio

The mean absorbance value of the Calibrator wells defined in the plate map and

the concentration value entered by the user are used for the cutoff ratio. Before

the cutoff, the absorbance value of each well is converted into the concentration

value. The ratio of Concentration/Absorbance of Calibrator is applied to the

conversion. Then, the cutoff is done with the defined Positive and Negative or

the defined Positive and Gray zone values.

Ranged Cutoff Control

The concentration range of the Positive and Negative is divided into 10 equal

partitions, numbered 0 through 9. The concentration value of each well is

classified according to the partition of the matrix to which it corresponds, and is

reported as a signal digit. Wells with concentration greater than the Positive are

reported by plus signs (+), and wells with concentration less than the Negative

by minus signs (-).

Single Cutoff Control

The concentration value of the Negative and the gray zone value entered by the

user are used for the cutoff. The upper and lower cutoff values are:

Upper cutoff concentration = Positive + ((Gray zone/100) * Positive)

Lower cutoff concentration = Positive - ((Gray zone/100) * Positive)

The concentration range of the upper and lower cutoff is divided into 10 equal

partitions, numbered 0 through 9. The concentration value of each well is

classified according to the partition of the matrix to which it corresponds, and is

reported as a signal digit. Wells with concentrations greater than the upper

cutoff are reported by plus signs (+), and wells with concentrations less than the

lower cutoff by minus signs (-).

(6) Curve fit report

The Curve fit report provides a regression analysis based on the absorbance values

of a series of standards. There are ten types of curve fits supported with the

onboard software on Model 680 microplate readers:

14

Page 19

i. 5P Logistic Rodbard

ii. 4P Logistic Rodbard

iii. 5P Logistic Cook-Wilkenson

iv. 4P Logistic Cook-Wilkenson

v. 5P Exponential

vi. Sigmoid Logistic

vii. Linear regression

viii. Quadratic regression

ix. Cubic spline

x. Point To Point regression

The onboard software calculates the best fit of the defined curve between each set

of two consecutive data points in the standard curve of absorbance vs.

concentration. And then it generates the report with the coefficients of regression,

the correlation coefficient, and the standard error.

For readers with the optional internal printer or with an external ESC/P printer which

accepts ESC/P code, a graph of the standard curve may be generated when

selected in the report parameter.

(7) Concentration report

In case of the curve fit, the Concentration report also provides the regression

analysis. After the calculation of the curve fit, it calculates the concentrations values

of the samples, and generates the report.

In case of the cutoff constant with the unit not designated "Abs" and in case of the

cutoff ratio, the reader generates the list of concentration of each well.

(8) Difference report

The Difference report is the subtraction report between the neighboring columns or

row.

(9) TeSeE Screening report

Analysis of the TeSeE screening assay results can be done with two

pre-programmed protocols: “TeSeE” protocol is stored in Endpoint Protocol

position #5 and “TeSeE eq” is stored in Endpoint Protocol position #6 as factory

default setting. Both protocols are locked.

TeSeE screening report is generated only if these protocols are selected as current

active protocol. Plate is first validated according to negative and positive controls

validation criteria; samples are then compared to the calculated cut-off.

Criteria for plate validation are set as follow:

Criteria #1: Individual Negative Control must be < 0.150

Number of valid Negative Control must be >= 3

Criteria #2: Individual Negative Control must be < 1.400 * Negative Control average

Number of valid Negative Control must be >= 2

Criteria #3: Positive Control average must be >= 1.000

Cutoff is calculated as follow:

TeSeE:

Positive cutoff = Negative Control average + 0.210

15

Page 20

Negative cutoff = (Negative Control average + 0.210) * 0.900

TeSeE eq:

Positive cutoff = Negative Control average + 0.210

Negative cutoff = Negative Control average + 0.090

Samples are interpreted as follow:

“POS”: Positive when sample OD >= Positive cutoff

“NEG”: Negative when sample OD < Negative cutoff

“???”: Gray zone: NEG cutoff =< sample OD < POS cutoff

Reports of Kinetic Protocol

(1) Absorbance report

The Kinetic Absorbance report is the series of absorbance data in the kinetic

sequence.

(2) Kinetic Plots

The Kinetic plots are the absorbance plots of each well in the plate. It is available for

readers with the optional internal printer or with an external ESC/P printer which

accepts ESC/P code.

(3) Linear Regression report

The Linear Regression report provides the calculation of Kinetic reaction rate for

each well using the linear regression.

(4) GALT report

The GALT report calculates the following formula for each well between two

readings of a plate.

GALT = (R2 – R1) * k

Where: R1 = Absorbance value of 1st reading

R2 = Absorbance value of 2nd reading

k = GALT factor

4.2.6 RS-232C Interface

The Model 680 Microplate Reader has a built-in bi-directional RS-232C interface (9 pin D-sub

connector, Bio-Rad catalog number: 168-1005). This allows external computers to control the

instrument. When an external computer is in control of the microplate reader, the printer and

the membrane keys, except for the "Start/Stop" key, are automatically deactivated and the

LCD display as below.

Remote mode

The reader will remain in remote control mode until it receives "RL" command from the host

computer or until the "Start/Stop" key on the microplate reader is pressed.

16

Page 21

4.2.7 Printer

The Model 680 Microplate Reader has a built-in printer interface connector (25 pin D-sub) or

an optional factory built-in printer.

The printer interface connector allows the user to connect an external printer for the printout

of reports or protocol. This external printer interface is based upon Centronics interface

standards.

Two types of printer, ASCII type and ESC/P type, are allowable to connect. The ASCII type

printer can only accept ASCII character based codes which does not include any graphic

codes. Next, the ESC/P type printer can accept ESC/P codes which include graphic codes.

The optional factory built-in internal printer and the external ESC/P type printer can generate

all types of report including graphs and kinetic plots.

17

Page 22

A

4.3 Detailed Operation

4.3.1. Initial Start-up

Self-diagnosis

Model 680

Microplate Reader

13:05 18/09/01

Self-Diagnosis

This screen will appear upon power-up and during self-diagnosis. Date and Time shall

also be indicated on this screen.

Initializing reader

Initialization

fter self-diagnosis, the system shall initialize all the hardware.

Login SCREEN

System Login

User: Administrator

Password:*****

Press ENTER

Security Check

The system requires input of Password to confirm that the user is the authorized

operator.

Pressing the Change/Right arrow key will switch the user mode between Common

user and Administrator.

Password for both Common user and Administrator is set as “00000” initially upon

factory shipment.

Operator can change the password in the EDIT menu. See Security later.

MAIN SCREEN

01:EndPoint Assay01

M405(1)R655(6)

Shake:999s,Mid

38.2/40.2 18/09/01

End point mode

01:Kinetic-1

M405(1)R605(6)30read

Shake:999s,Mid,Every

38.2/40.2 18/09/01

Kinetic mode

Checkmark

Validation Program

Incu:OFF 18/09/01

Checkmark mode

End point

01:EndPoint Assay01

M405(1)R655(6)

Shake:999s,Mid

38.2/40.2 18/09/01

System Ready

When this MAIN screen is on the LCD, Start/Stop key is activated for microplate

reading. Pressing Start/Stop key will begin reading according to the setting of the

current active protocol.

There are three kind of MAIN screen depending on the active protocol type: Endpoint,

Kinetic, and Checkmark program.

Four arrow keys, Numeral keys, Main key and Enter key are inactive.

Start/Stop, Memory Recall, Edit, Print and Paper Feed keys are active.

Storage number in memory of

current active protocol

Temperature setting (if available)

Temperature reading if Incubator activated

Kinetic

01:Kinetic-1

M405(1)R605(6)30read

Shake:999s,Mid,Every

38.2/40.2 18/09/01

Kit name for current active protocol

M: Measurement wavelength and its position in the filter disk.

R: Reference wavelength and its position in the filter disk.

Plate shaking parameters: period in seconds and speed

Date (day / month / year)

M: Measurement wavelength and its position in the filter disk.

R: Reference wavelength and its position in the filter disk.

Number of reading for KINETIC

Plate shaking parameters:

period in seconds

speed (Fast, Middle, Slow)

mode (before every read, before first read and no shake)

18

Page 23

w

4.3.2. Configuring the system

Note: To return to the previous screen, use the back/left arrow key.

Edit Menu

»■Protocol •Lab.name

•Security •SaveSTDC

•Filters •Printer

•Date set

Security Menu

Security function

»■Change Password

•Change user

•Lock/Unlock Prtl

Change Password

Change Password

Current:*****

New:*****

Common user

Change user

System Login

User: Administrator

Password:*****

Press ENTER

Lock/Unlock

Security for current

active Protocol

[Lock] Unlock

Edit Menu

This menu can be accessed by pressing the Edit key in the MAIN SCREEN.

Security Setting

Select “Security” in Edit Menu screen above, and press Enter. Then Security

Menu shall be on the screen.

Change Password

Select “Change Password” in the Security Menu.

Enter the current Password then move the cursor to the 3rd line and

enter a new password. Press Enter to complete the field entry. The

system will return to the previous Security Menu.

Change user mode

Select “Change user” in the Security Menu.

Select a desired user mode by pressing the Right Arrow key. Enter the

appropriate Password for the selected user mode. Press Enter to

complete the field entry. The system will return to the previous

Security Menu.

Lock/Unlock Protocol

Select “Lock/Unlock Prtl” in the Security Menu. Move the selected

mark “[ ]” to the desired position: Lock or Unlock using the Right Arro

key. Press Enter to complete the field entry.

The system will return to the previous Security Menu.

If “Lock” is selected, the current active protocol will be protected

against modification made by a Common user. If “Unlock” is selected,

the current active protocol can be modified by any user mode.

NOTE: Only the Administrator has authority to lock and unlock the

Checkmark Protocol.

19

Page 24

A

Filter

1:400nm 5:650nm

2:450nm 6:...nm

3:475nm 7:...nm

4:650nm 8:...nm

Filter setting

Move the cursor to the desired position and using the Up, Down, and Right

arrow keys. Enter the filter wavelength on the selected position using the

number keys.

If the selected position of the filter disk is empty, enter three “...”.

Press Enter to complete the field entry. The system will return to the previous

Edit Menu screen.

Date set

Day/Month/Year

16 / 05 / 01

Hour: Minutes

18 : 55

Calendar setting

Move the cursor to the desirable position for date or time input by using the Up,

Down, and Right arrow keys. Enter the present date or time using number

keys.

Press Enter to complete the field entry. The system will return to the previous

Edit Menu screen.

Lab. name

Enter Lab. name

Bio Rad Laboratories

↑

[ABC]

Lab. name setting

Use the Up and Down arrow keys to select from “A” to “Z” and symbol.

Use the Number keys for numeric input.

Right arrow key to move the cursor to the right.

Left arrow key to slip out of the screen and it returns to the Edit Menu screen.

Pressing “./FUNC” key will change the character mode: Upper case alphabet,

Lower case alphabet, and symbol. Current character mode is indicated on the

lower right corner of the LCD.

Save STDC

Save STD Curve

> Save STD Curve

Rename STD Curve

Save STD Curve

Select STD storage #

> 1:12/03/04 15:00

2:******** *****

3:15/03/04 10:30

Save STD Curve:

#1:16/03/04 11:25

Are you sure?

> Yes No

STD curve does not

exist yet.

Press any key

Save STDC setting

Select “Save STDC” in Edit Menu screen above, and press Enter. Then Save

STD Curve Menu shall be appeared on the screen.

Move the cursor to the desired position by using the Up and Down arrow keys.

Save STD Curve

To save a STD Curve, you should select the storage number between #1

and #5. The Up and Down arrow keys are used to move the cursor to the

desired storage number. And press Enter to complete the selection.

fter the storage number selection, ”Are you sure?” message is appeared.

Select “Yes” or “No” and press Enter. In case of “Yes”, the reader saves

the STD Curve and returns to the Edit Menu screen.

If the curve fit calculation has not done or it has not finished successfully,

an error message will be appeared and saving STD Curve will be

invalidated.

Rename STD Curve

Select for renaming

> 1:16/03/04 11:25

2:****** *****

3:15/03/04 10:30

#1:16/03/04 11:25

>STD Curve #1 <

[ABC]

Rename STD Curve

To change a name of STD Curve, you should select the storage number

between #1 and #5. The Up and Down arrow keys are used to move the

cursor to the desired storage number. And press Enter to complete the

selection.

Use the Up and Down arrow keys to select from “A” to “Z” and symbol.

Use the Number keys for numeric input.

Right arrow key to move the cursor to the right.

Left arrow key to slip out of the screen and it returns to the Edit Menu

screen.

Pressing “./FUNC” key will change the character mode: Upper case

alphabet , Lower case alphabet , and symbol. Current character mode is

indicated on the lower right corner of the LCD.

20

Page 25

Printer

Select ext printer

type

> [ASCII]

ESC/P

Not exist

External Printer

Press any key

External Printer setting

Select “Printer” in Edit Menu screen above, and press Enter.

Then, Select ext printer type menu shall be appeared on the screen.

The Up and Down arrow keys are used to move the cursor to the desired

printer; “

reader returns to the Edit Menu screen.

If the external printer is not connected, an error message, “Not exist External

Printer

The reader will be returned to the Edit Menu screen by pressing any key.

ASCII” type or “ESC/P” type. Pressing Enter accepts the setting and the

“

ASCII” type :Text printer

“

ESC/P” type :Graphic printer

” will be appeared.

4.3.3. Printing Reports and Protocol information

PRINT MENU

Print menu

»■Reports

•Protocol

Print Menu

This menu screen can be accessed by pressing the Print key in the MAIN screen.

Printing Reports

Select “Reports” and press Enter to print the current active plate data report.

Printing Protocol information

Select “Protocol” and press Enter to print all parameter setting in the current active

Protocol.

Stop printing

Pressing Start/Stop key during printing will stop the print job immediately.

When printing is completed, the system will automatically return to the MAIN screen.

21

Page 26

r

4.3.4. Memory Recall operation

MEMORY RECALL MENU

Memory Recall

»■Protocol

•Plate Data

Protocol type menu

Select protocol type

»■End Point

•Kinetic

•Checkmark

End Point

Select Protocol #02

↑»■ *Protocol -2

! Protocol -3

↓ Protocol -4

Kinetic

Select Protocol #01

»■ *Kinetic -1

! GALT

Checkmark

Checkmark program

has been activated.

Press any key

Data type menu

Select data type

»■End Point

•Kinetic

•Checkmark

End Point

01 20/05/00 14:00

02»*21/05/00 17:00

03 20/05/00 18:00

↓04»■20/05/00 19:00

Kinetic

01»*20/05/00 09:00

02»■20/05/00 10:00

Checkmark

20/05/01 09:00

Memory Recall Menu

This menu screen can be accessed by pressing the Memory Recall key in the MAIN

screen.

Changing current active protocol

Select “Protocol” in Memory Recall menu above, and press Enter. The Select

Protocol type

Select a protocol using the Up and Down arrow keys. Press Enter to complete

the selection.

Changing current active plate data

Select “Plate Data” using the Memory Recall button and press Enter. The

Data type menu will appear.

Use the Up and Down arrow keys to select a plate data type. Press Enter to

complete the selection.

menu will appear on the screen.

Selecting protocol

Move the cursor to the position of the desired protocol and press Ente

to complete the selection.

“

*” indicates the currently activated protocol, and “!” indicates a

security locked protocol.

There is no protocol selection with “Checkmark”.

When a protocol is selected, the system will then automatically return

to the MAIN screen.

Selecting plate data

Move the cursor to the position of the desired plate data and press

Enter to complete the selection.

“*” indicates the currently activated plate data.

There is only one storage for “Checkmark” data.

When a plate data is selected, the system will then automatically

return to the MAIN screen.

22

Page 27

r

4.3.5. Editing Kinetic protocol

Edit Menu

»■Protocol ·Lab.name

·Security •SaveSTDC

·Filters •Printer

·Date set

Kinetic Protocol Menu

»■Mode ·Report

·Calc. ·Kit name

·Mapping

·Assay

KINETIC Mode

»■Reading ·Speed

·Inter. ·Incu.

·Shaking

·Ph.mode

Reading

Number of Reading

= 20 (2-30)

Start Delay time

= 25 sec(0-999)

Number of Reading

= 2

Start Delay time

= 25 sec(0-999)

Inter.

Use same interval

between all reads?

1->2:»■ 100 sec

2->3: 100 sec

3->4: 100 sec

↓4->5: 100 sec

Shaking

Ph. mode

Edit Menu

This menu screen can be accessed by pressing the Edit key in the MAIN screen.

Kinetic Protocol Menu

Select “Protocol” in the Edit Menu and press Enter. The Kinetic Protocol Menu will

appear on the screen, if the current active protocol type is Kinetic mode.

Kinetic Mode Menu

This menu screen can be accessed by selecting “Mode” in the Kinetic Protocol

Menu above.

»■Yes No

Shaking parameters

Before: Every read

Speed: Mid

Time: 999 sec

Photometric: Dual

Measurement:405 nm

Reference: 655 nm

Number of reading and Start Delay time setting

The entry field can be changed by pressing the Up or Down arrow key.

Enter the appropriate numbers by using the numeral keys and press Enter

to complete the field entry. The system will return to the Kinetic Edit Menu.

If GALT type is selected as the current Assay type, the number of reading

field is fixed at 2.

Start Delay time can be used for setting delay time after pressing

Start/Stop key until actual start of reading.

Setting Reading Intervals

The system will prompt the operator whether the same interval is used or

not. Move the cursor to the desired selection “Yes” or “No” and press Enter.

The system will generate the interval entry screen.

Move active entry field by pressing the Up and Down arrow keys, and ente

appropriate numbers using numeral keys. Press Enter to complete all field

entries. The system will return to the Kinetic Mode Menu.

Plate Shake parameters

When the “Before” field is activated, pressing the Right arrow key will

change the field entry: “Every”->”--”->”First”->. When the “Speed” field is

activated, pressing the Right arrow key will change the field entry: “Mid”

->”Hi”->”Low”->.

When the “Time” field is activated, enter the time value for plate shaking

period using the numeral keys.

Press Enter to complete all field entries.

Photometric mode setting

When the “Photometric” field is activated, pressing the Right arrow key

will switch the field entry: “Single” <->”Dual”.

Pressing the Up or Down arrow keys will move the cursor to the next entry

field. Pressing the Right arrow key when the wavelength field is activated

will change the wavelength to next available selection installed in the

reader.

Press Enter to complete all field entries.

23

Page 28

A

Speed

Reading speed

[Fast mode]

Step mode

Incubation setting

Set Incubation param

Incubator: Enable

Temperature: 37.5

Kinetic Protocol Menu

»■Mode •Report

•Calc. •Kit name

•Mapping

•Assay

Calculation

Calculation Param.

CC Limit: 0.910

Calc.range: 10 - 20

If GALT

Result = (R2 – R1)*k

k = 9999.99

R1:1st Reading

R2:2nd Reading

Mapping

Select Mapping mode

»■Manual mapping

•Automatic mapping

ssay

Assay type selection

»■[General KINETIC]

GALT assay

Report

»■[Lin.regression]

•Absorbance

•KINETIC Plots

Kit name

Kit name for #01

»G.A.P. TEST IgG«

↑

[ABC]

Selecting Reading Speed

Pressing the Up or Down arrow keys will switch the selection. Press

Enter to complete the selection.

Incubator parameter setting

When the “Incubator” field is activated, pressing the Right arrow key will

switch the field entry: “Enable” <-> ”Disable”.

Pressing the Up or Down arrow keys will move the cursor to the next

entry field. When the Temperature field is activated enter the temperature

value using the numeral keys. Press Enter to complete all field entries.

This setting is available only when the Incubator is installed in the system.

Calculation Parameter setting

When the “CC Limit” field is activated, pressing the numeral key will enter the

desired numbers. Press Enter to complete all field entries.

If the GALT Reports is activated, pressing the numeral keys will enter the

desired numbers. Press Enter to complete all field entries.

Plate Mapping

See Plate Map setting procedure.

Selecting Kinetic Assay type

Move the cursor to the desired Assay type by pressing the Up or Down arrow

keys. Press Enter to complete the selection.

The item with mark “[ ]” is the currently selected item.

GALT assay: Result = factor x (2nd Read – 1st Read)

Selecting report type

Move the cursor to the desired report type by pressing the Up or Down arrow

keys. Pressing the Right arrow key will select or deselect the item.

Press Enter to complete the selection.

Note: When GALT assay is selected “GALT report” shall be the only one option

on this screen.

Kit name setting

Use the Up and Down arrow keys to select alphabet from “A” to “Z” and space.

Use the Number keys for numeric input.

Right arrow key to move the cursor to the right.

Left arrow key to slip out of the screen and it returns to the Protocol Menu

screen.

Pressing “./FUNC” key will change the character mode: Upper case alphabet ->

Lower case alphabet -> symbol. Current character mode is indicated on the

lower right corner of the LCD.

24

Page 29

4.3.6. Checkmark value setting (by Administrator only)

Edit Menu

»■Protocol •Lab.name

•Security •SaveSTDC

•Filters •Printer

•Date set

Checkmark Protocol Menu

»■Serial #/Report

•Linearity ref.

•Max.CV%

•Filter Check ref.

Serial #/Report

»■Serial #: 0000

Rep.type: Simple

Linearity reference

405nm S1:0.158

Linearity S2:0.309

reference S3:1.401

S4:2.109

Max. CV%

Max.CV% »■S1:15%

Linearity S2:05%

reference S3:02%

S4:02%

Filter check reference

Filter max min

405:1.875 0.329

450:1.167 0.954

↓ 492:0.596 0.103

Filter max min

↑ 540:1.875 0.329

620:1.167 0.954

690:0.596 0.103

Edit Menu

This menu screen can be accessed by pressing the Edit key in the MAIN screen.

Checkmark Protocol Menu

Select “Protocol” in the Edit Menu and press Enter. The Checkmark Protocol Menu

will appear on the screen, if the current active protocol type is Checkmark mode.

Serial number and Report type setting

Pressing the Up and Down arrow keys will move the cursor and change the

field entry.

When “Serial #” field is active, enter the serial number that will be shown in the

data sheet of the Checkmark plate using the numeral keys.

When the “Rep. type” filed is active, pressing the Right arrow key will switch

the report type between “Simple” and “Full”.

Linearity reference value setting

Pressing the Up or Down arrow keys will move the field entry from S1 to S4.

Pressing the Right arrow key will change the wavelength:

405nm->450nm->492nm->540nm->620nm->690nm

Use the numeral keys for the reference value setting.

Pressing Enter will complete all field entries at all wavelength.

Max. CV% setting

Pressing the Up or Down arrow keys will move the field entry from S1 to S4.

Use the numeral keys for the Max. CV% setting. Pressing Enter will complete

all field entries.

Filter check reference value setting

Initial screen shall be the reference entries for 405nm to 492nm and pressing

the Down arrow key at the bottom of the screen entries will scroll to the next

page for 540nm to 690nm. Pressing the Up, Down and Right arrow keys will

move the field entry.

Use the numeral keys for the filter check reference value setting. Pressing

Enter will complete all field entries.

25

Page 30

4.3.7. Editing End Point Protocol

Edit Menu

»■Protocol •Lab.name

•Security •SaveSTDC

•Filters •Printer

•Date set

End Point Protocol Menu

»■Cutoff •Mode

•Report •Mapping

•Limit •Kit name

•STDs

Cutoff

»■[Not use] •Ratio

•Constant

•Contrl

•Formula

Report

»[Raw] •Mtx •Cnc

•Abs •Cut •Dif

•Lim •Crv

Limit

Upper Limit= 2.000

Lower Limit= 0.000

input range: 0–3.500

Upper > Lower

STDs

Standard menu

»■STD information

•Curvefit

•Recall STD Curve

Mode

»■Set photo mode

•Set shaking

•Set read mode

•Incubation

Mapping

Select mapping mode

»■Manual mapping

•Automatic mapping

Kit name

Kit name for #01

»G.A.P. TEST IgG«

↑

[ABC]

Edit Menu

This menu screen can be accessed by pressing the Edit key in the MAIN screen.

End Point Protocol Menu

Select “Protocol” in Edit Menu screen above and press Enter. The End point

Protocol Menu will appear on the screen, if the current active protocol type is End

point mode.

See Cutoff setting procedure

If “Dif” selected

[Raw] •Mtx •Cnc

•Abs •Cut [Dif]

•Lim •Crv

»row, odd-even

Limit value setting

Use the Up and Down Arrow key to move the cursor, and enter the OD value

using the numeral keys. The OD value range is 0.000 - 3.500. Press Enter to

complete the selection.

See Standard setting procedure

See Mode setting procedure

See Plate Map setting procedure

See Kit name setting in Editing Kinetic Protocol

Report type setting

Use the Up and Down Arrow key to move the cursor,

and press the Right Arrow key to select or deselect the

report type. Selected report type is marked as “[ ]”.

Press Enter to complete the selection.

26

Page 31

4.3.8. Cutoff setting procedure

»■Not usex •Ratio

[Const]

•Contrl

•Formula

Cutoff setting Menu

This menu is entered by choosing "Cutoff" in the End Point Protocol Menu. It is used to

set the cutoff type. The cutoff type marked with “[ ]” is the current selection. The Up

and Down arrow key moves the cursor to the desired item in the menu list. When the

desired parameters have been selected, press Enter twice to accept the selection and

to resume to the next screen.

"Not use" means that the reader does not generate the cutoff report.

4 types of cutoff are supported as below.

1. Cutoff Constant

2. Cutoff Control

3. Cutoff Formula

4. Cutoff Ratio

a. Cutoff Constant setting

»■Ranged cutoff

[Single cutoff]

Single cutoff

Ranged

»■Positive >= 9999

Gray zone: 50%

Unit: mol/l

»■Positive >= 9999

Negative < 1999

Negative<Positive

Unit: mol/l

Selection of Single/Ranged Cutoff Constant

This menu selects Single or Ranged cutoff type. The cutoff type marked with

“[ ]” is the current selection. The Enter key seals the selection and resumes to

the next setting screen.

Single Cutoff Constant

The Numerical keys and the Decimal point key are used to

enter the positive and gray zone values. The Right arrow key

is used to select the unit. The Up and Down arrow key moves

the cursor to the desired parameter of the single cutoff. The

Enter key sets all values and selection of the cutoff constant

and returns to the previous screen.

Ranged Cutoff Constant

The Numerical keys and the Decimal point key are used to

enter the positive and negative values. The Right arrow key

is used to select the unit. The Up and Down arrow key moves

the cursor to the desired ranged cutoff parameters. The Enter

key sets all values and selection of the cutoff constant and

returns to the previous screen.

NOTE:

Two available Cutoff constant are “Absorbance” and

“Concentration”. If "Abs" is chosen, the Absorbance cutoff will

be done with the cutoff constant parameters defined and the

absorbance report is generated. For other units defined in the

curve fit setting, the Concentration value using the curve fit

and then cutoff is done with the cutoff constant parameters

defined and the concentration value of each well. It is

necessary to set the curve fit parameters.

27

Page 32

b. Cutoff Control setting

»■Ranged cutoff

[Single cutoff]

Single cutoff

Ranged

Selection of Single/Ranged Cutoff Control

This menu screen selects Single or Ranged cutoff type. The cutoff type marked

with “[ ]” is the current selection. The Enter key seals the selection and resumes

to the next setting screen.

Positive >= CNx

Gray zone: 50%

Unit: Abs

Positive >= CPx

Negative < CNx

Unit: Abs

Enter key to accept

Single Cutoff Control

The Numerical keys are used to enter the gray zone value.

The unit is fixed to "Abs". The Enter key sets the value of the

cutoff control and returns to the previous screen.

Ranged Cutoff Control

There is no parameter to set for the ranged cutoff control.

The Enter key returns to the previous screen.

NOTE:

The "CNx" means the mean absorbance value of Negative

control wells and the "CPx" means the mean absorbance

value of Positive control wells. These wells are defined in the

plate map setting. The cutoff is done with the Positive and

Negative value to the absorbance value of each well.

28

Page 33

x

c. Cutoff Formula setting

Select formula

»■[k*CNx ]

•k*CPx

↓ •k*COx

↑ »■CNx / k

•CPx / k

•COx / k

↓ •k + CNx

↑ »■k + CPx

•k + COx

•k*CNx + CPx

↓ •(CNx + CPx)/ k

↑ »■k1*CNx + k2*CPx

k * CNx

k * CPx

k * COx

CNx / k

CPx / k

COx / k

k + CNx

k + CPx

k + COx

k * CNx + CPx

(CNx + CPx) / k

k1 * CNx + k2 * CP

Selection of Formula

Page-1

Page-2

Page-3

Page-4

Input coefficient

k = 0.01 (0.01-10)

Gray zone: 50%(0-99)

Input coefficient

k1 = 0.01 (0.01-10)

k2 = 10.0 (0.01-10)

Gray zone: 50%(0-99)

This menu screen selects a formula for cutoff calculation. The formula marked

with “[ ]” is the current selection. The Up and Down arrow key moves the cursor

to the desired type of the formula. The movement of the cursor also accompanies

the scroll of this screen. The Enter key seals the selection and resumes to the

next setting screen.

The supported formula types are:

1. k * CNx

2. k * CPx

3. k * COx

4. CNx / k

5. CPx / k

6. COx / k

7. k + CNx

8. k + CPx

9. k + COx

10. k*CNx + CPx

11. ( CNx + CPx ) / k

12. k1*CNx + k2*CPx

Coefficient for Cutoff Formula #1 to #11

The Numerical keys and the Decimal point key are used to

enter the coefficient "k" and gray zone values. The Up and

Down arrow key moves the cursor to the desired parameter

of the cutoff formula. The Enter key sets all values of the

cutoff formula and returns to the previous screen.

Coefficient for Cutoff Formula #12

The Numerical keys and the Decimal point key are used to

enter the coefficient "k1" and "k2" and gray zone values. The

Up and Down arrow key moves the cursor to the desired

cutoff formula. The Enter key sets the all values of the cutoff

formula and returns to the previous screen.

NOTE:

The "CNx" means the mean absorbance value of Negative

control wells, the "CPx" is the mean absorbance value of

Positive control wells and the "COx" is the mean absorbance

value of Cutoff control wells. These wells are defined on the

plate map setting. The cutoff value is calculated using the

defined formula with the defined values and coefficients.

29

Page 34

f

d. Cutoff Ratio setting

Ratio to Calibrator

»■Concentration

•Unit

•Cutoff value

Concentration

Unit

Cutoff value

Ratio to Calibrator

In this screen, there are three items for setting the ratio to calibrator. The Up and

Down arrow key moves the cursor to the desired item in the menu list. The Enter

key seals the selection and resumes to the next setting screen.

Concentration: 9999

unit: mol/l

↑»■ 01: ug/dl

02: ng/ml

03:[ pg/ml]

↓ 04: pm/ml

»■Ranged cutoff

[Single cutoff]

Single cutoff

»■Positive >= 9999

Gray zone: 5 0%

Unit: mol/l

Ranged cutof

»■Positive >= 9999

Negative < 9999

Negative<Positive

Unit: mol/l

Concentration of Calibrator

The Numerical keys and the Decimal point key are used to

enter the calibrator concentration value. The Enter key sets

the value and returns to the previous screen.

Unit of Calibrator

17 units are supported, as for the standard's unit. The unit

marked with “[ ]” is the current selection.

The setting procedure is the same as the unit selection of

Standards.

Cutoff value setting

This menu screen selects Single or Ranged cutoff type. The

cutoff type marked with “[ ]” is the current selection. The

Enter key seals the selection and resumes to the next setting

screen

Single Cutoff Control

The Numerical keys are used to enter the Positive cutoff

concentration value and gray zone value. The Enter key sets

these cutoff ratio values and returns to the previous screen.

Ranged Cutoff Control

The Numerical keys are used to input the Positive and the

Negative cutoff concentration value. The Enter key sets these

cutoff ratio and returns to the previous screen.

NOTE:

The calibrator concentration value is used to convert the

absorbance value of each well into concentration value. The

ratio of Concentration/Absorbance of Calibrator well is

applied to the conversion. The cutoff is done with the defined

Positive and Negative values to the converted concentration

value of each well.

30

Page 35

4.3.9. Standard setting procedure

Standard menu

»■STD information

•Curve fit

•Recall STD curve

Standard curve setting Menu

This menu screen is entered by choosing "STDs" in the End Point Protocol Menu

screen. It is used to set the concentration data and the curve fit type for a standard

curve or to recall a memorized standard curve.

The Up and Down arrow key moves the cursor to the desired item in the menu list. The

Enter key seals the selection and resumes to the next setting screen.

a. STD information setting

STD information

»■Number of STD

•Concentration

•Unit

Number of

STD

Concentration

Unit

Number of STD

= 05 (0, 2–12)

STD # 1: 0.512

STD # 2: 1.012

STD # 3: 1.512

↓ STD # 4: 2.053

↑»■ 01: ug/dl

02: ng/ml

03:[ pg/ml]

↓ 04: pm/ml

STD information

In this screen, there are three items for setting the concentration data of

standards. The Up and Down arrow key moves the cursor to the desired item in

the menu list. The Enter key seals the selection and resumes to the next setting

screen.

Number of Standards

The Numerical keys are used to enter the number of

Standards. 0 means that the curve fit report is not used. The

Enter key sets the number and returns to the previous

screen.

The maximum number of standards is 12.

Concentration

The Numerical keys and the Decimal point key are used to

enter the concentration values of Standards. The Up and

Down arrow key moves the cursor to the desired position.

The movement of the cursor also accompanies the scroll of

this screen. The Enter key sets all values of the concentration

of standards and returns to the previous screen.

Unit

17 units are supported as below. The unit marked with “[ ]”

is the current selection. The Up and Down arrow key moves

the cursor to the desired unit type. The movement of the

cursor also accompanies the scroll of this screen. Press

Enter twice to select the unit type and to return to the

previous screen.

The supported types of unit are:

1. mol/l 11. pg/ml

2. m mol/l 12. U/ml

3. u mol/l 13. IU/ml

4. n mol/l 14. uIU/ml

5. p mol/l 15. mIU/ml

6. mg/l 16. EU

7. ng/l 17. Arbit.

8. pg/l

9. ug/dl

10. ng/ml

31

Page 36

b. Curve fit setting

Curve fit setting

»■Curve fit type

•Graph axis

Curve fit type

Graph axis

Curve fit

In this screen, there are two items for setting the curve fit. The Up and Down

arrow key moves the cursor to the desired item in the menu list. The Enter key

seals the selection and resumes to the next setting screen.

↑ 5p logisticRodb

»■ 4p logisticRodb

[5p logisticCook]

↓ 4p logisticCook

»■ X-Log Y-Log

[X-Log Y-Lin]

X-Lin Y-Log

X-Lin Y-Lin

Curve fit type

10 types of curve fit are supported as below. The curve fit type

marked with “[ ]” is the current selection. The Up and Down

arrow key moves the cursor to the desired curve fit type. The

movement of the cursor also accompanies the scroll of this

screen. Press Enter twice to select the unit type and to return

to the previous screen.

The supported curve fit types are:

1. 5P Logistic Rodbard

2. 4P Logistic Rodbard

3. 5P Logistic Cook-Wilkenson

4. 4P Logistic Cook-Wilkenson

5. 5P Exponential

6. Sigmoid Logistic

7. Linear regression

8. Quadratic regression

9. Cubic spline

10. Point To Point regression

Graph axis

4 types of graph are supported as below. The curve fit type

marked with “[ ]” is the current selection. The Up and Down

arrow key moves the cursor to the desired graph type.

Press Enter twice to select the unit type and to return to the

previous screen.

The supported graph types are:

1. Log - Log

2. Log - Linear

3. Linear - Log

4. Linear - Linear

32

Page 37

c. Recall STD curve setting

Recall STD curve

»■Recall setting

•Select STD curve

Recall setting

Recall setting

»■Yes No

Select STD curve

Select STD Curve

»■1:16/03/04 11:25

2:******** *****

↓ 3:15/03/04 10:30

Select STD Curve

↑»■4:******** *****

5:******** *****

Select STD Curve

»■1: STD Curve #1

2: STD Curve #2

↓ 3: STD Curve #3

Select STD Curve

↑»■4: STD Curve #4

5: STD Curve #5

Recall Setting of Standard Curve

In this screen, there are two items for setting the Recall STD curve as below.

The Up and Down arrow key moves the cursor to the desired item in the menu

list.

1. Recall setting (Yes/No)

2. Selecting the storage number of standard curves (1 -> 5)

Recall setting

Move the cursor to the desired position using the Up, Down

or Right arrow keys. Enter key accepts the setting and

returns to the Standard menu screen.

Yes: Recalling of the standard curve is active.

No: Recalling of the standard curve is inactive.

Storage number selection

Five memories are selectable. The vacant memory which is

marked with asterisks on the date and time field is also

selectable. But it is necessary to save any standard curve

before using its protocol.

Move the cursor to the desired position using the Up and

Down keys.

Right arrow key