Page 1

H5000

Operation Manual

ENGLISH

www.bandg.com

Page 2

Preface

As Navico is continuously improving this product, we retain the right to make changes to the

product at any time which may not be refl ected in this version of the manual. Please contact

your nearest distributor if you require any further assistance.

It is the owner’s sole responsibility to install and use the instrument and transducers in a

manner that will not cause accidents, personal injury or property damage. The user of this

product is solely responsible for observing safe boating practices.

NAVICO HOLDING AS AND ITS SUBSIDIARIES, BRANCHES AND AFFILIATES DISCLAIM ALL

LIABILITY FOR ANY USE OF THIS PRODUCT IN A WAY THAT MAY CAUSE ACCIDENTS, DAMAGE

OR THAT MAY VIOLATE THE LAW.

Governing Language: This statement, any instruction manuals, user guides and other

information relating to the product (Documentation) may be translated to, or has been

translated from, another language (Translation). In the event of any confl ict between any

Translation of the Documentation, the English language version of the Documentation will be

the offi cial version of the Documentation.

This manual represents the product as at the time of printing. Navico Holding AS and its

subsidiaries, branches and affi liates reserve the right to make changes to specifi cations

without notice.

Copyright

Copyright © 2014 Navico Holding AS.

Warranty

The warranty card is supplied as a separate document. In case of any queries, refer to the

brand website of your display or system:

www.bandg.com

Declarations and conformance

This equipment is intended for use in international waters as coastal sea area administered by

countries of the E.U. and E.E.A.

The H5000 system complies with the following regulations:

• CE under EMC directive 2004/108/EC

• Level 2 devices of the Radio communications (Electromagnetic Compatibility) standard 2008

The relevant Declaration of conformity is available in the H5000 section on the following

website: www.bandg.com

| H5000 Operation Manual

| 1

Page 3

Contents

5 Introduction

5 About this manual

7 System overview

7 H5000 components

8 H5000 Central Processor Unit - CPU

8 Webserver - Network portal

8 Graphic display

9 Race display

9 HV Displays

10 Analog disp lays

10 Expansion modules

11 S en s or mo du l es

11 A la r m m od u le

12 H5000 Pilot Controller

13 System examples

13 Hydra

14 H ercules

15 Performance

16 Autopilot minimum system requirement

16 Basic System - No H5000 CPU

17 Operation

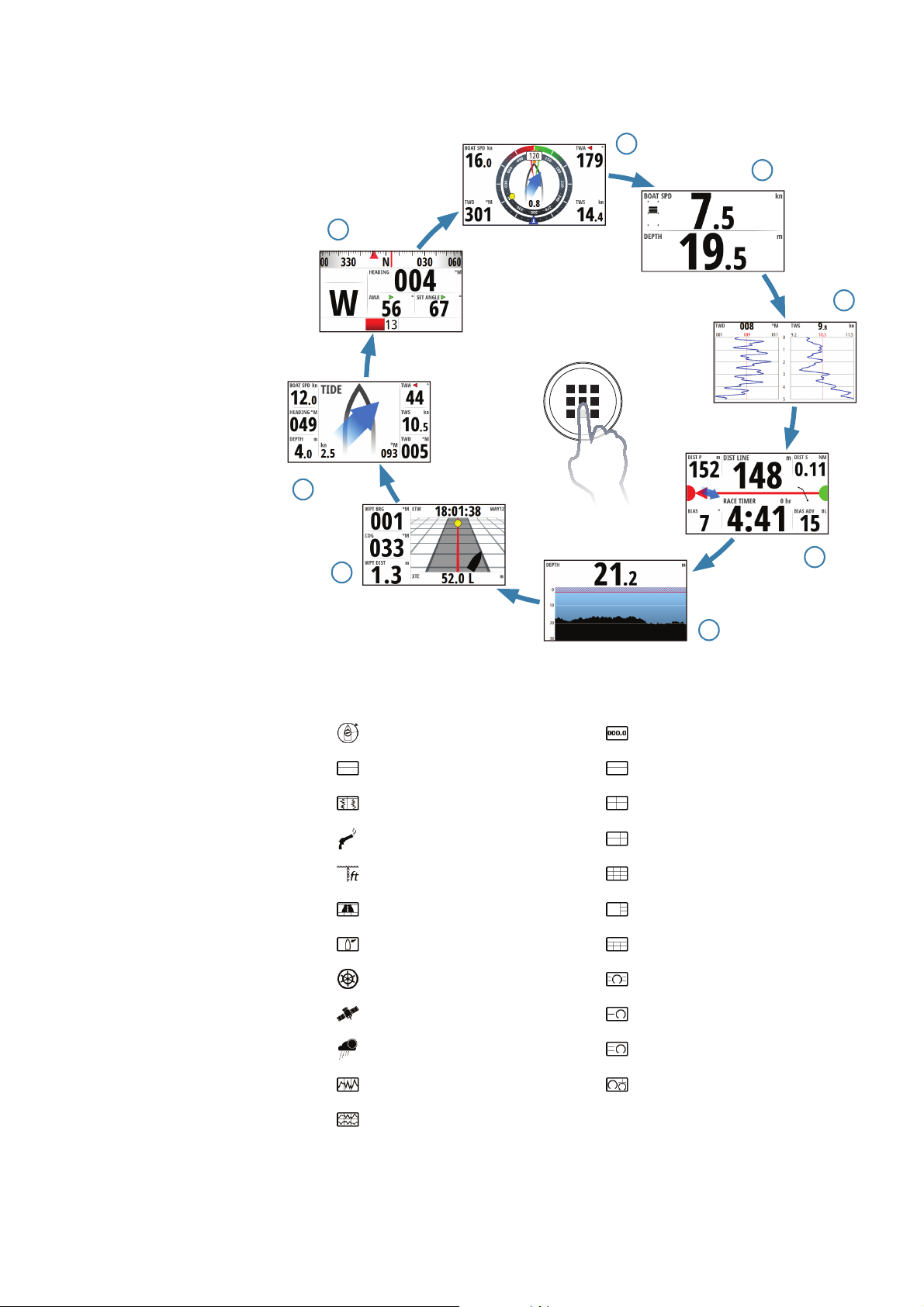

17 Graphic display

18 Default graphic display pages

25 Data page transition

25 Available data pages

26 Replacing a data page

27 Menus

28 Race timer

30 Man Over Board

31 HV display support

32 Alarms

34 Damping

34 Trip log

34 Log

35 Race display

40 Diagnostics

43 H5000 Pilot Controller

44 Autopilot operation

45 Autopilot modes

48 Sensor calibration

48 Depth

49 Boat speed

52 Environment

53 Masthead unit adjustment

55 Heading (compass)

Contents | H5000 Operation Manual

| 3

Page 4

57 System setup

57 Network

59 Units

60 Language

60 Time

60 Simulate

61 Restore defaults

61 Global reset

61 About

62 Autopilot setup

62 Source selection

62 Rudder drive

64 Commissioning

67 Response

68 Sailing

69 Steering

71 Setup

73 Webserver

78 Operating variables

105 Example data tables

105 Polar table

106 Boat speed / Heel correction table

106 True wind angle correction table

106 True Wind Speed correction table

106 Down wind speed correction table

107 Maintenance

107 Basic maintenance procedures

108 Winter Storage / Laying Up

4 |

Contents | H5000 Operation Manual

Page 5

1

Introduction

About this manual

This manual is a reference guide for operating the B&G H5000 instrument system. It assumes

that all equipment is installed correctly, and that the system is ready to use.

The manual assumes that the user has basic knowledge of navigation, nautical terminology

and practices. The manual does not cover basic background information about how

equipment such as radars, echo sounders and AIS work.

Important text that requires special attention from the reader is emphasized as follows:

¼ Note: Used to draw the reader’s attention to a comment or some important information.

Warning: Used when it is necessary to warn personnel that they

should proceed carefully to prevent risk of injury and/or damage to

equipment/personnel.

Introduction | H5000 Operation Manual

| 5

Page 6

6 |

Introduction | H5000 Operation Manual

Page 7

2

System overview

The H5000 instrument and autopilot systems combine unique sailing features with raceproven technology in a straightforward package. Developed for blue water cruisers and

racing yachts alike, the range brings powerful system options to match your exacting

requirements. From an ultra-fast CPU to a convenient web-browser interface access, full-color

and custom displays and a dedicated autopilot controller, the H5000 system was developed

to provide the best instrument and autopilot system available. The H5000 range comprises

several units which network with other onboard electronics including the Zeus range of chart

plotters.

The H5000 system is driven by a powerful Central Processing Unit (CPU) reaching speeds

up to 50 times greater than its predecessor, with Hydra, Hercules and Performance level

software options tailored for all users from serious cruisers to professional racers. It works with

B&G’s H3000 Wind, Speed, Heel and meteorological sensors for straightforward upgrades.

The high resolution H5000 Graphic Display is highly intuitive and delivers information on a

5-inch bonded screen with fast, smooth display updates. The H5000 Race Display provides

segmented text, numbers and target indicator for the race information you need in a glance.

The H5000 Autopilot brings the functionality and dedicated sailing algorithms of its recordbreaking predecessor , supporting the exact needs of a performance sailboat and its crew –

whether short-handed cruising or solo racing. In addition, the H5000 Pilot Controller provides

dedicated access to autopilot functions.

B&G’s web-browser interface lets you connect your PC or tablet to the network for setup,

calibration and control of every part of your H5000 system. It utilizes a familiar web browser

interface to allow quick calibration of instruments, easy setup of displays and confi guration of

features. You can also access online product manuals, data backups and network diagnostics.

H5000 components

• H5000 Central Processor Unit - CPU

• Webserver - Network portal

• Graphic display

• Race display

• HV displays

• Analog displays

• Expansion modules

• Sensor modules

• Alarm module

• H5000 Pilot Computer

• H5000 Pilot Controller

System overview | H5000 Operation Manual

| 7

Page 8

H5000 Central Processor Unit - CPU

The H5000 CPU takes sensor inputs and uses a dedicated processor to calculate and calibrate

the data and distribute it to display units and external devices.

Connect a router via the ethernet port to take advantage of the webserver interface via a PC,

tablet or smart-phone.

There is a USB port to upgrade the CPU with the latest software.

Webserver - Network portal

The browser-based confi guration of the H5000 system enables advanced calibration, set-up

and diagnostics. Its web-style interface can be accessed via PC, tablet or smartphone.

8 |

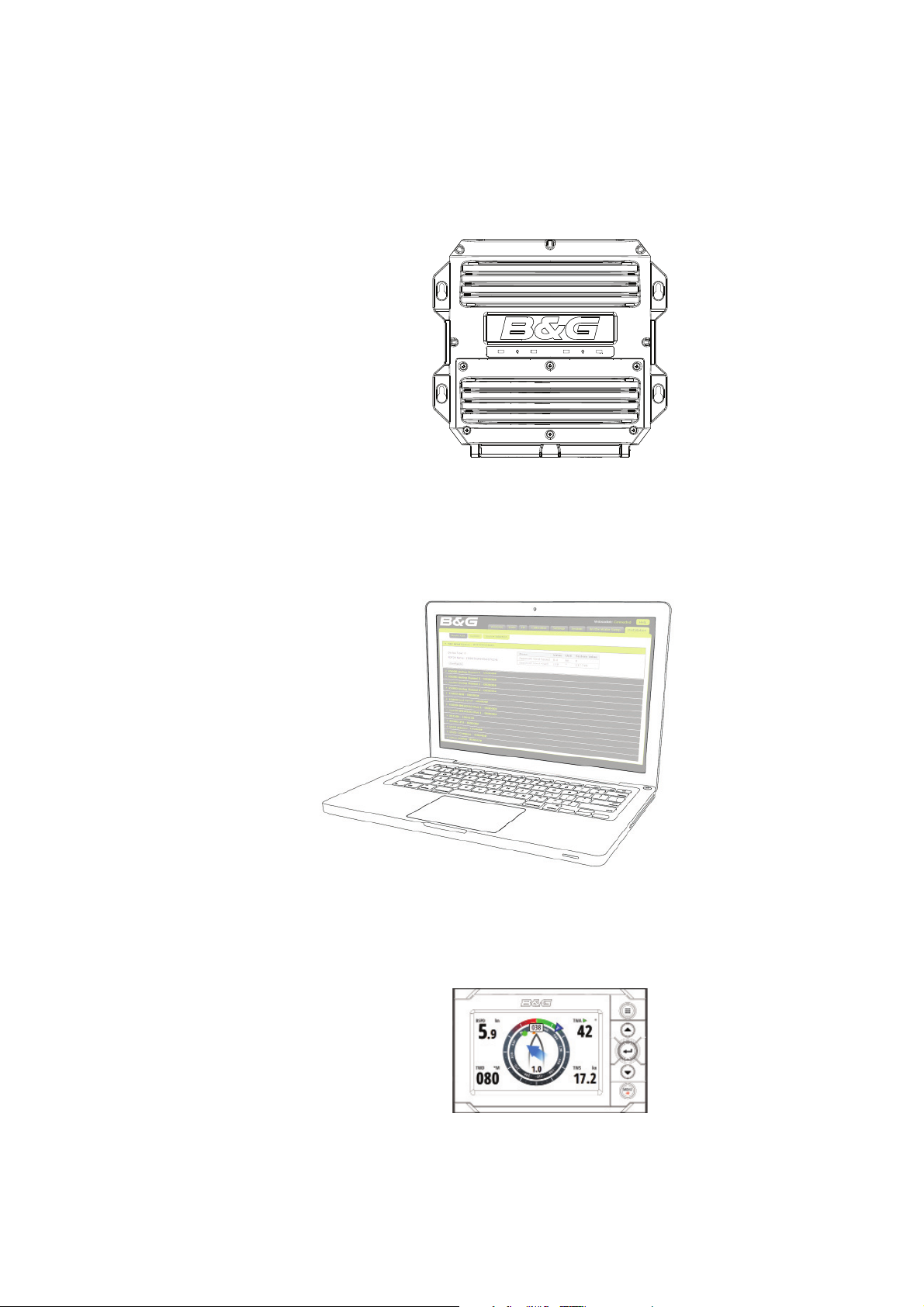

Graphic display

The H5000 Graphic Display is a 5-inch, sunlight viewable, color display. It shows sailing data in

digital or graphical form.

System overview | H5000 Operation Manual

Page 9

Race display

The H5000 Race Display is a 7 segment display, 5-inch screen designed for viewing essential

data at a glance. A dedicated page key allows quick switching between stored pages

displaying 2 data values on each page alongside a unique bargraph providing immediate

visual indication of performance targets, countdown timer status and more.

MENU

HV Displays

The HVision range of displays are lightweight, single-line data units incorporating B&G’s

unique HV technology. HV technology ensures the maximum contrast, perfect backlighting

and no possibility of condensation. HV displays are the clearest displays available.

¼ Note: There are four displays in the HV range, each with their ideal application:

10/10 HV

The 10/10 is a compact display that allows data to be positioned where it is

needed, rather than where it fi ts. Its compact dimensions allow the 10/10

to be installed almost anywhere – typical installation areas are the base of

winch pedestals, alongside hydraulic control panels, steering pedestals or

as a companionway display on the smaller yacht.

20/20 HV

The latest generation of the classic 20/20 mast display. The 20/20 is the

de facto standard for mast displays on yachts up to 70’ (21m). The 20/20

is also ideal for use as a cockpit, saloon or bridge display.

30/30 HV

The 30/30 is designed as a mast display for yachts in the range

60-90’ (18-27m) LOA. Providing these larger yachts with the

perfect size of display. The 30/30 is also the ideal display for deck

or bridge displays on super yachts.

40/40 HV

The 40/40 is the largest instrument display available.

Designed specifi cally for mast mounting applications on

super yachts, it also is the ideal display for forward beam

mounting on maxi-multi hulls or as a deck or helipad

display on large motor yachts.

System overview | H5000 Operation Manual

| 9

Page 10

Analog displays

Before a value will be shown on an analog display ensure that a sensor (source) has been

selected via the CPU or Graphic Display. Go to source selection to achieve this.

The analog display backlighting is achieved by a long press of the MENU key on any of the

Graphic displays.

There is a wide range of analog indicators available, all listed below.

• Apparent Wind Angle

• Apparent Wind Speed

• Boat Speed 12.5 Knot

• Boat Speed 25 Knot

• Depth 200 Meters

• Depth Ft / Fathom

• Heading

• Rudder

• True Wind Angle

• True Wind Speed

• Magnifi ed Apparent Wind

Expansion modules

There are two types of Expansion module, Analog and Serial. The modules act as the interface

between analog sensors, serial devices and other in and outputs to and from the CPU.

The correct module must be used in conjunction with its corresponding sensors. All modules

are powered from the network and can supply power to the sensors connected.

10 |

Analog

The analog module has 6 analog inputs and 2 pulse inputs. This allows the unit to act as an

interface for masthead units, speed sensor, analog rate-gyros, potentiometer etc.

Serial

The serial module has 2 COM ports, each with input & output. The modules support RS232,

RS422, RS485 and NMEA 0183 devices.

Modules can be located wherever is most convenient for the installer and can connect

anywhere on the network.

System overview | H5000 Operation Manual

Page 11

Sensor modules

There are two types of H5000 sensor module.

Barometric & temperature sensor

Measures the atmospheric pressure and air temperature, allowing the CPU to record

atmospheric pressure changes over varying periods of time and current air temperature.

3D Motion

The Tri-Axis Motion Sensor provides accurate measurement of the heel and trim angles as

well as pitch, roll and yaw rates of the yacht, allowing the CPU software to correct the wind

data for errors induced by this motion.

Alarm module

The alarm module is a network audible alarm that can be positioned anywhere on the

network.

H5000 Pilot Computer

The H5000 Pilot Computer links with the H5000 instrument system. The instrument system

transmits sensor information over the network to the Pilot Computer. This information is

processed by the Pilot Computer and sends signals to the drive system (linear ram, rotary

drive or hydraulic pump) to steer the vessel on the desired heading/course.

System overview | H5000 Operation Manual

| 11

Page 12

H5000 Pilot Controller

The H5000 Pilot Controller manages all autopilot functions as well as setup and

commissioning. Use the H5000 Pilot Controller to select autopilot modes or manually steer

the vessel.

12 |

System overview | H5000 Operation Manual

Page 13

3

System examples

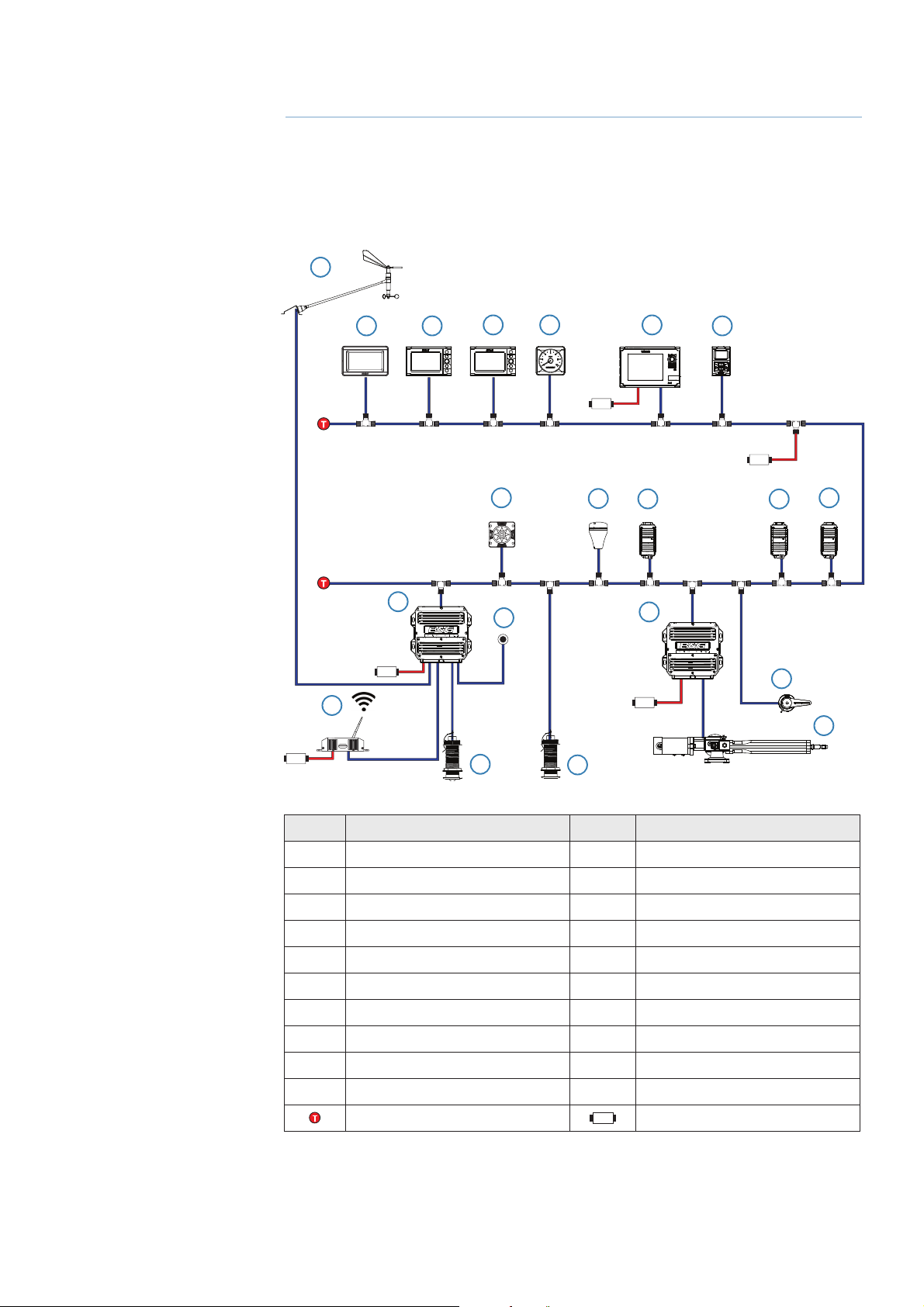

Hydra

An example of a typical H5000 system. At the centre of the system is the H5000 Central

Processor Unit (CPU). All sensor information is fed back to the CPU and can be easily

controlled and confi gured via the Graphic display.

1

12V

T

T

13

2 3

14

12V

WIFI-1

PILOT

4 5 6

12V

8

15

19

9

20

10

12V

16

7

12V

11

17

12

18

No. Description No. Description

1

Masthead unit

2

HV Display

3

Graphic display

4

Race display

5

Analogue display

6

Zeus Touch

7

H5000 Pilot Controller

8

RC42N compass

9

GPS

10

Baro / Air temp sensor

T

Terminator

System examples | H5000 Operation Manual

11

12

13

14

15

16

17

18

19

20

12V

Motion sensor (Heel / Trim only)

Alarm module

Wireless access point WiFi-1

Central processor unit

Man Overboard Button - MOB

H5000 Pilot Computer

Rudder reference unit

Hydraulic ram

Speed sensor

Depth sensor

12 Volt DC power supply

| 13

Page 14

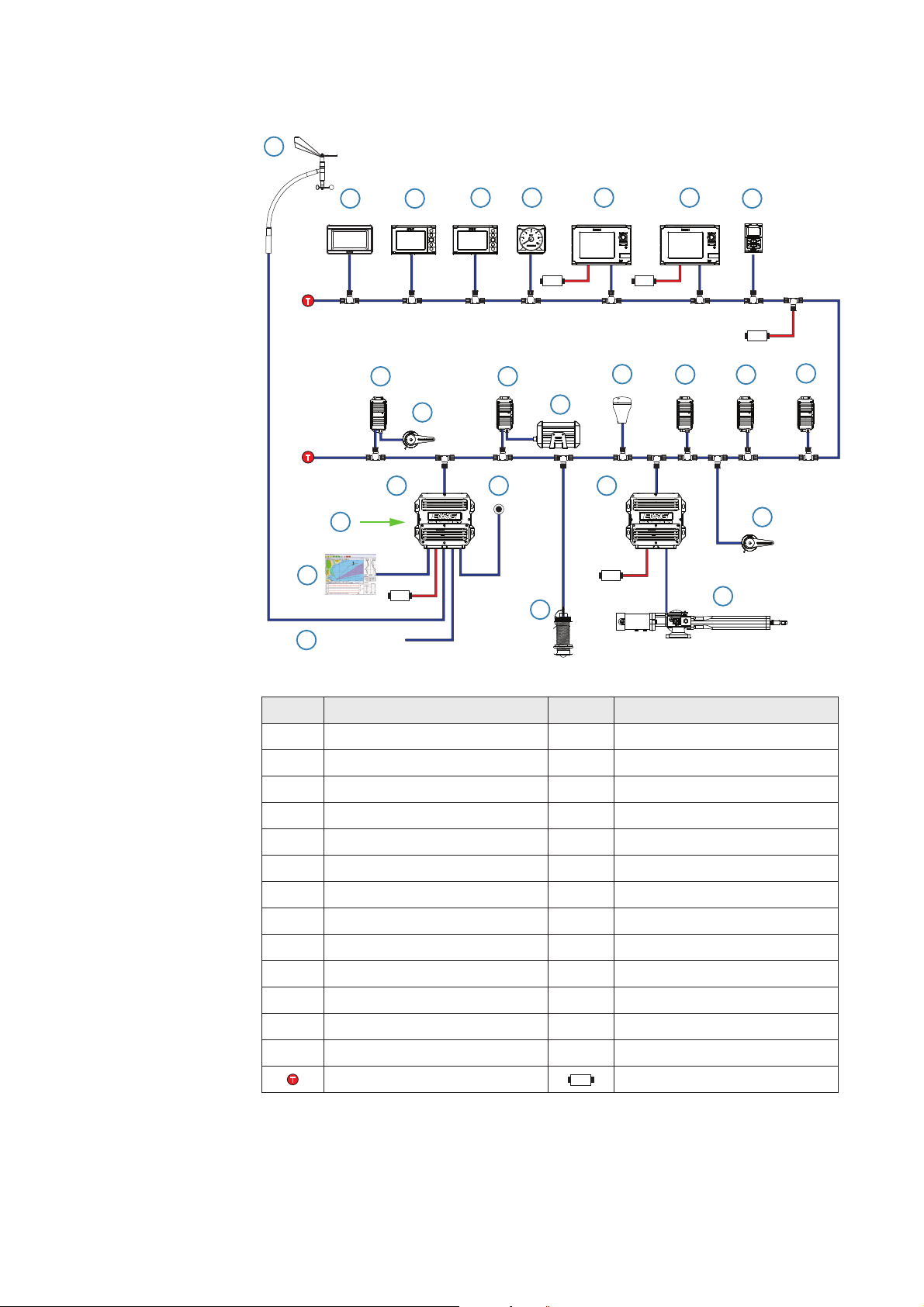

Hercules

1

T

T

20

21

NMEA0183 Tx/Rx

24

2 3

9

12V

10

4 5 6

11

12

25

191817

12V

13

7

12V12V

14

15

8

12V

16

22

23

No. Description No. Description

1

Vertical masthead unit

2

HV Display

3

Graphic display

4

Race display

5

Analogue display

6

Zeus Touch

7

Zeus

8

H5000 Pilot Controller

9

Analog module

10

Mast rotation sensor

11

Serial module

12

Halcyon Gyro Stabilized Compass

13

GPS

T

Terminator

14

15

16

17

18

19

20

21

22

23

24

25

26

12V

Barometric / temperature sensor

Motion sensor

Alarm module

Central processor unit

Man Overboard Button - MOB

H5000 Pilot Computer

Webserver

Deckman

Rudder reference unit

Hydraulic ram

NMEA 0183 Tx / Rx

Speed sensor

Depth sensor

12 Volt DC power supply

14 |

System examples | H5000 Operation Manual

Page 15

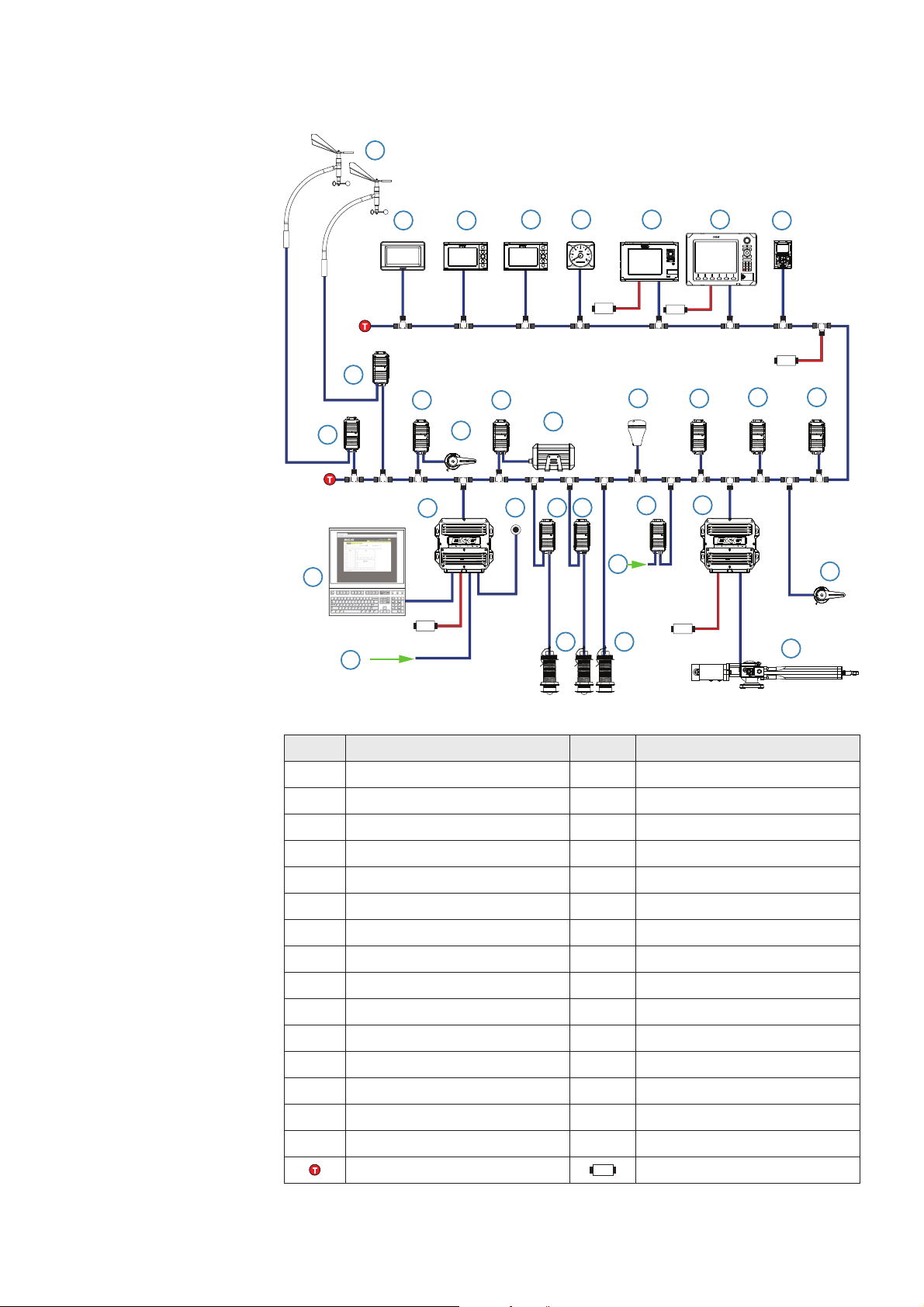

Performance

1

26

T

2 3

4 5 6

12V

12V

7

ECHORADARCHART NAV INFO PAGES

8

PLOT

GO TO

MARK

VESSEL

MENU

WIN

IN

OUT

MOB

ABC DEF

123

JKLGHI MNO

456

TUV

PQRS

WXYZ

7

809

STBY

PWR

AUTO

12V

9

1210

19

13

20 20

9

T

11

18

14

21

15

23

22

12V

12V

28 29

27

16 17

24

25

No. Description No. Description

1

Fwd & Aft vertical masthead unit

2

HV Display

3

Graphic display

4

Race display

5

Analogue display

6

Zeus Touch

7

Zeus

8

H5000 Pilot Controller

9

Analog module

10

Analog module

11

Mast rotation sensor

12

Serial module

13

Halcyon Gyro Stabilized Compass

14

GPS

15

Barometric / temperature sensor

T

Terminator

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

12V

Motion sensor

Alarm module

Central processor unit

Man Overboard Button - MOB

Analog module

Analog module

Analog device *

H5000 Pilot Computer

Rudder reference unit

Hydraulic ram

Webserver

Deckman

Port & Starboard speed sensor

NMEA 0183 Depth sensor

Depth sensor

12 Volt DC power supply

¼ Note: * See analog expansion for more information on type and quantity of devices

System examples | H5000 Operation Manual

| 15

Page 16

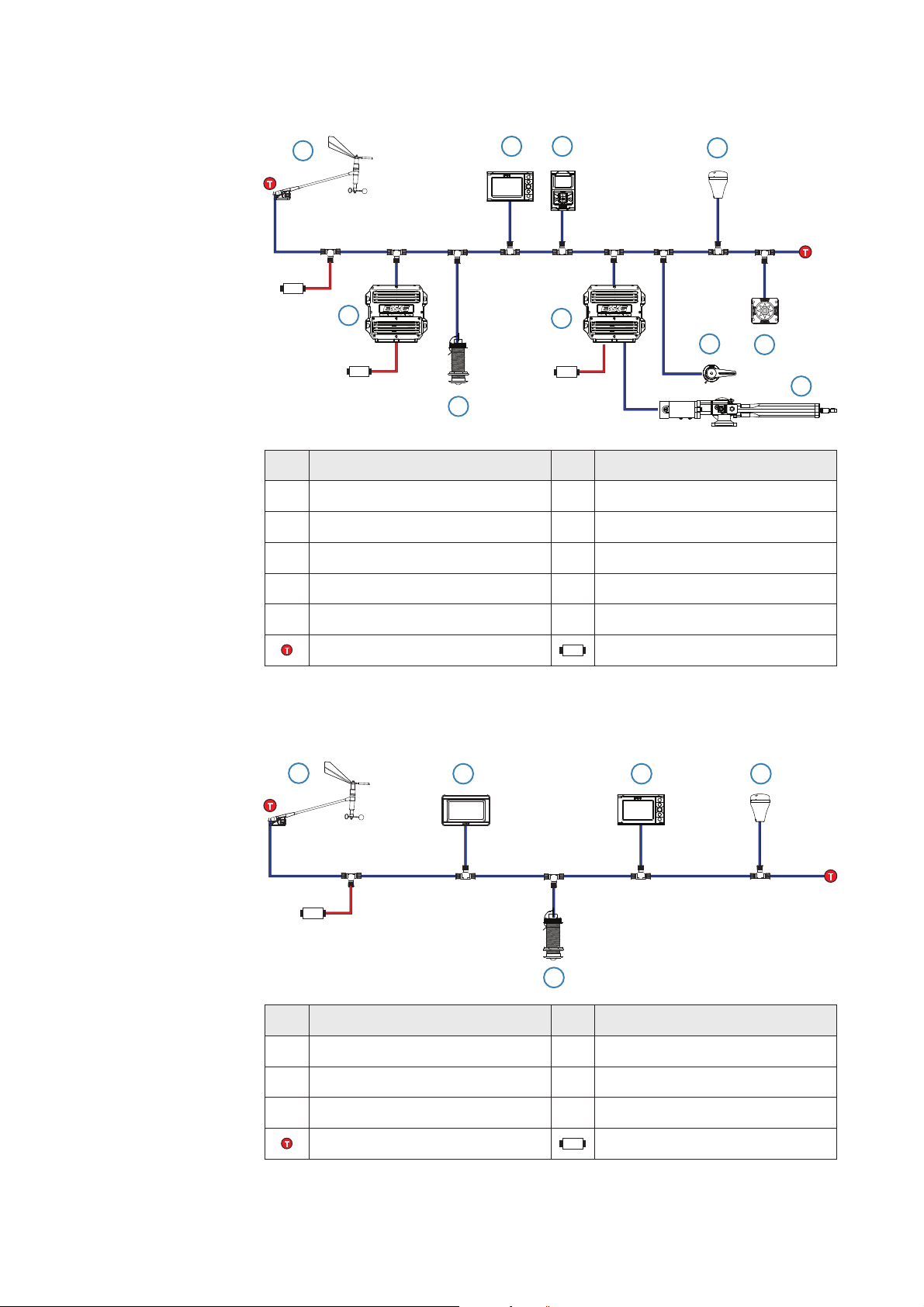

Autopilot minimum system requirement

1

T

12V

2

5

12V

3

7

12V

6

DPT

No. Description No. Description

1 Masthead unit 6 Speed sensor

2 Graphic display 7 H5000 Pilot Computer

3 H5000 Pilot Controller 8 Rudder Reference Unit

4 GPS antenna 9 Hydraulic Ram

4

T

8

10

9

5 H5000 Central Processor Unit 10 Compass

T

Terminator

12V

12 Volt DC power supply

Basic System - No H5000 CPU

1

T

12V

No. Description No. Description

1 Masthead unit 4 ZG100 GPS

2 3 4

5

T

16 |

2 HV Display 5 DST800 Speed & Depth sensor

3 Graphic Display

T

Terminator

12V

12 Volt DC power supply

¼ Note: A system without an H5000 CPU will only provide data from the available sensors

on the network and limited functionality. Only those menu options visible on the Graphic

Display will be available to the user.

System examples | H5000 Operation Manual

Page 17

4

MENU

Operation

Graphic display

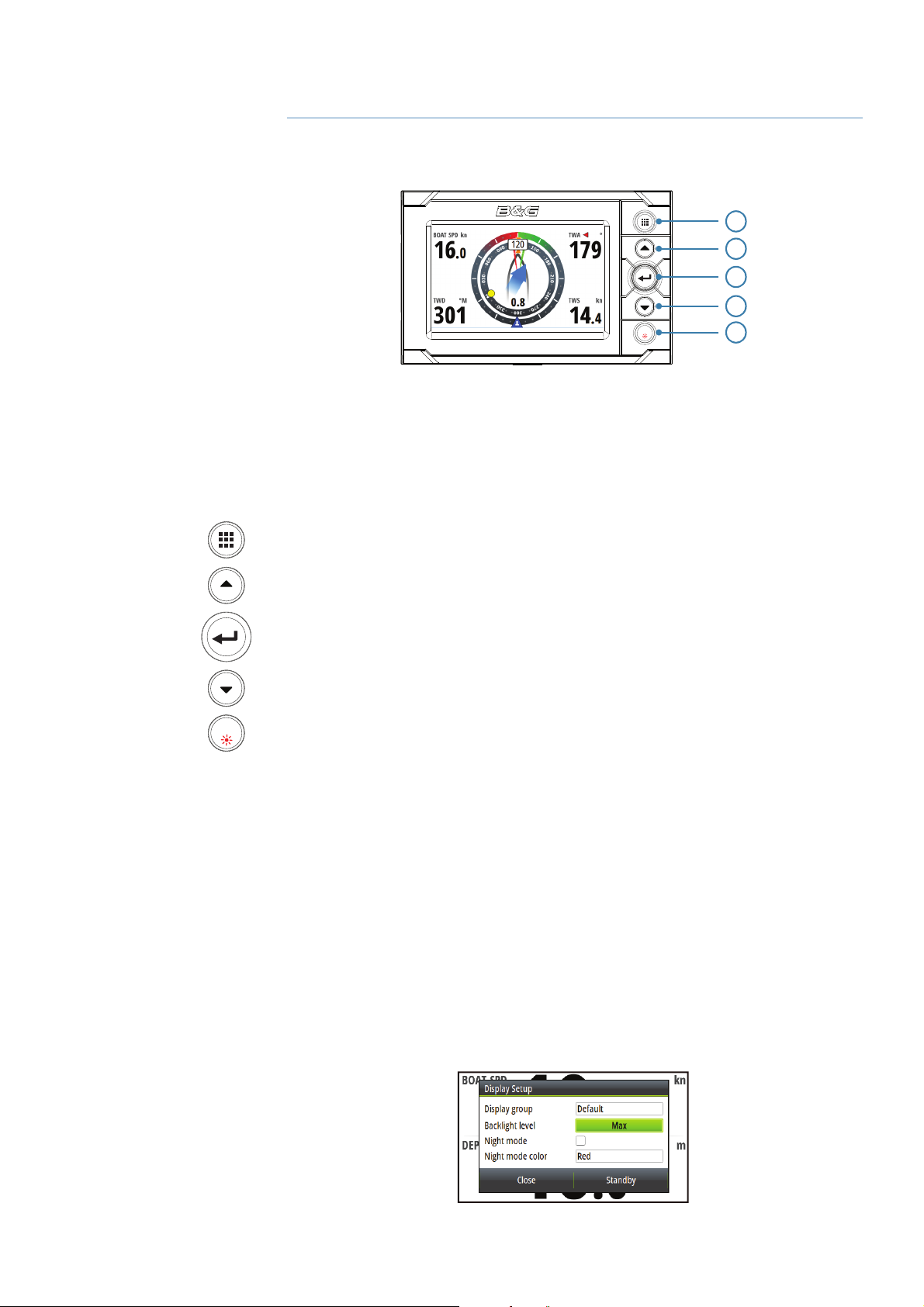

1

2

3

4

MENU

Basic operation

The fi rst display added to the network will go into a startup wizard when it is fi rst powered on.

The startup wizard will need to be completed before the display can be used.

Using the wizard, set the desired language, time, units and network source selection.

1 PAGE

Each short press of the PAG E key scrolls through the data pages. When viewing a data page a long

press of the PAGE key will bring up the pages menu, from here the required page can be selected

directly from a list. From any dialog screen, pressing the PAG E key navigates back to the data pages.

When using a menu the PAGE key navigates back a step.

2 UP

Scrolls up through selected menus / set values

3 ENTER

Used to enter the selected sub menus and confi rm selection

4 DOWN

Scrolls down through selected menus / set values

5 MENU / LIGHTS

Single press of the MENU key – displays the Page menu

Double press of the MENU key – displays the

Long press of the MENU key - Enters the display setup dialog and light settings menu.

Settings menu

5

Display group

Light settings are replicated on all displays set to the same group.

Backlight level

Min to Max in 10% increments

Night mode

Alternative display palette for low light conditions.

Night mode color

Red, green, blue, white text color

¼ Note: Adjusting the backlight settings will eff ect all other displays in the same display group.

See Network groups for more information.

Operation | H5000 Operation Manual

| 17

Page 18

MENU

3sec

Standby

All of the displays can be placed in Standby mode via any display Setup dialog.

¼ Note: Once in Standby mode a single press of the MENU key will turn the displays back on.

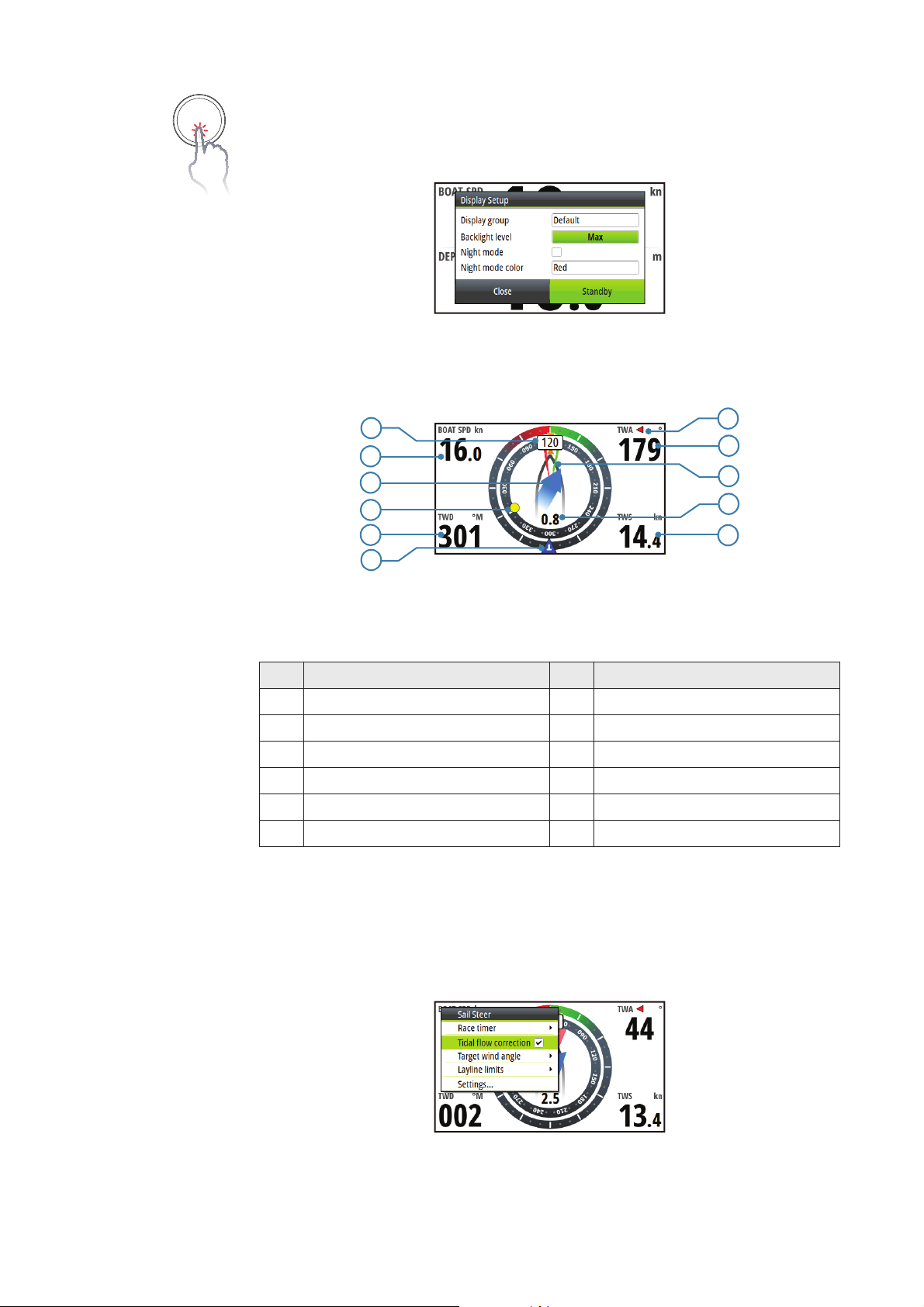

Default graphic display pages

Sail Steer

1

2

3

4

5

6

7

8

9

10

11

Displayed data

No. Description No. Description

1

Course / Heading

2

Boat speed

3

Tide set

4

Waypoint

5

True wind direction

6

True wind indicator

7

Port / Starboard indicator

8

True Wind Angle

9

Laylines

10

Tide rate

11

True Wind Speed

¼ Note: See confi guring the Sail Steer page for more information on using this page

Con guring the Sail Steer page

When navigating to a waypoint you can confi gure the Sail Steer page to show laylines to aid

navigation.

18 |

Tidal ow correction

Tidal fl ow correction will calculate the tidal fl ow and off set the laylines accordingly.

Operation | H5000 Operation Manual

Page 19

Target wind angle

There are 3 sources available for target wind angle.

Polar

Takes the target wind angle from your polar table

Actual

Takes the current value of target wind angle

Manual

Manually input the upwind and downwind numbers into the dialog boxes.

Layline limits

When selected will show a dotted line indicating the minimum and maximum tack/gybe time

period either side of the layline. This can be set from 5 to 30 minutes in 5 minute increments.

Speed / Depth

1

2

3

Displayed data

No. Description No. Description

1

Speed

2

Acceleration bargraph

Operation | H5000 Operation Manual

3

Depth

| 19

Page 20

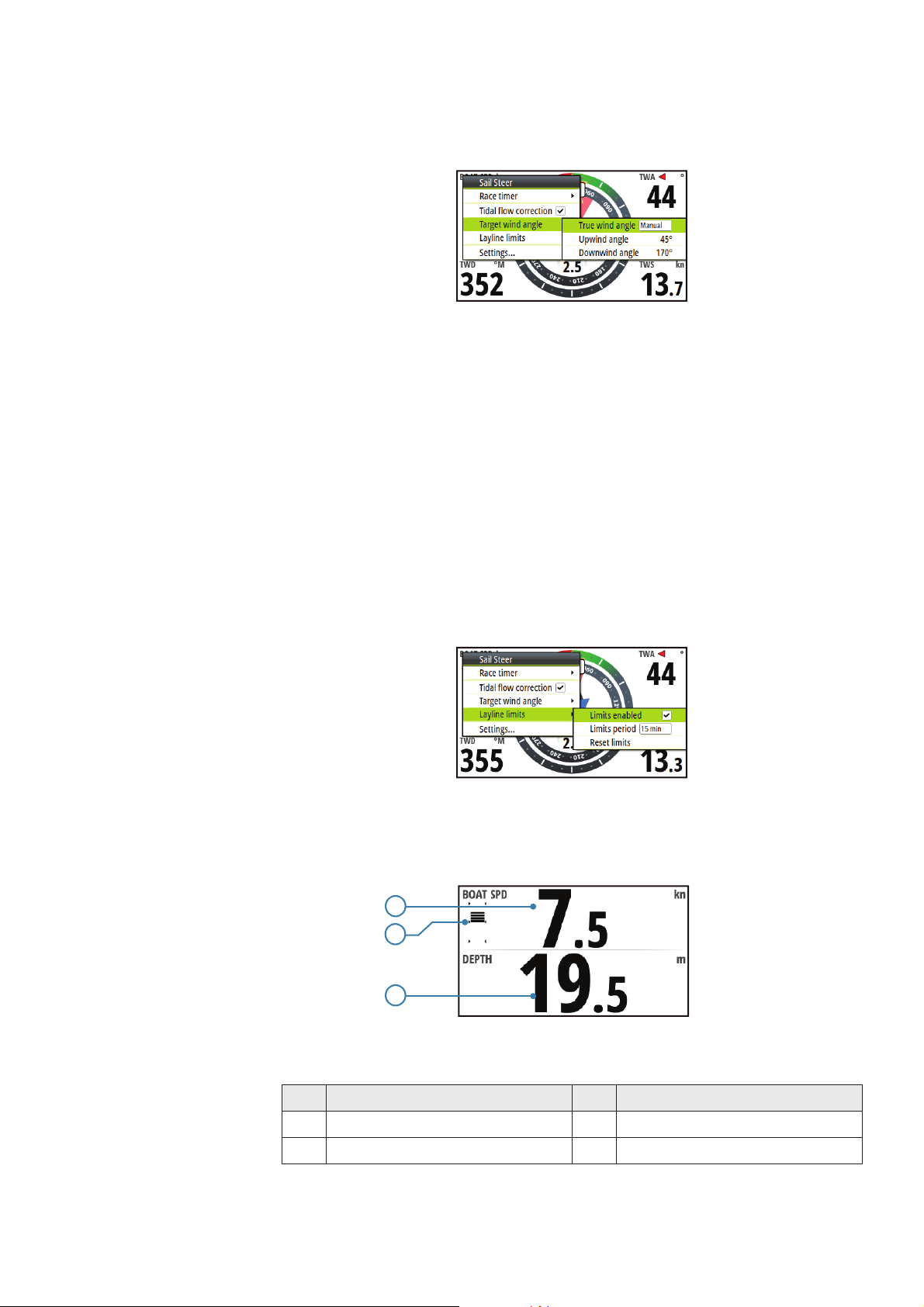

Wind plot

1

3

4

2

5

6

Displayed data

No. Description No. Description

1

True wind direction

2

True wind direction histogram

3

True Wind Speed

4

Mean value

5

True Wind Speed histogram

6

Time period (5 to 60 minutes)

¼ Note: Wind histogram time periods can be set to show 1, 5, 10, 30 or a 60 minute history.

Toggle between the time periods using the UP/DOWN keys.

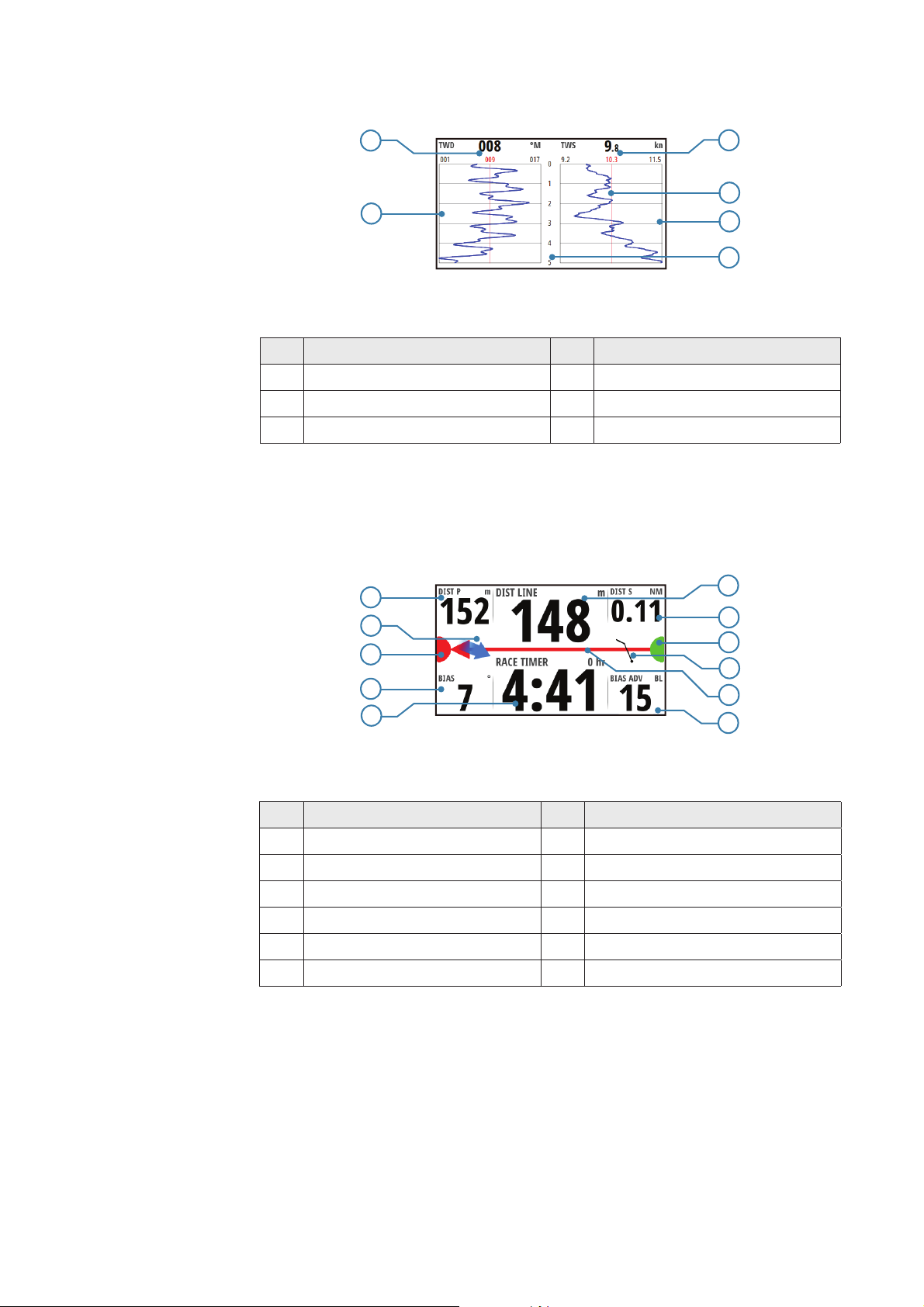

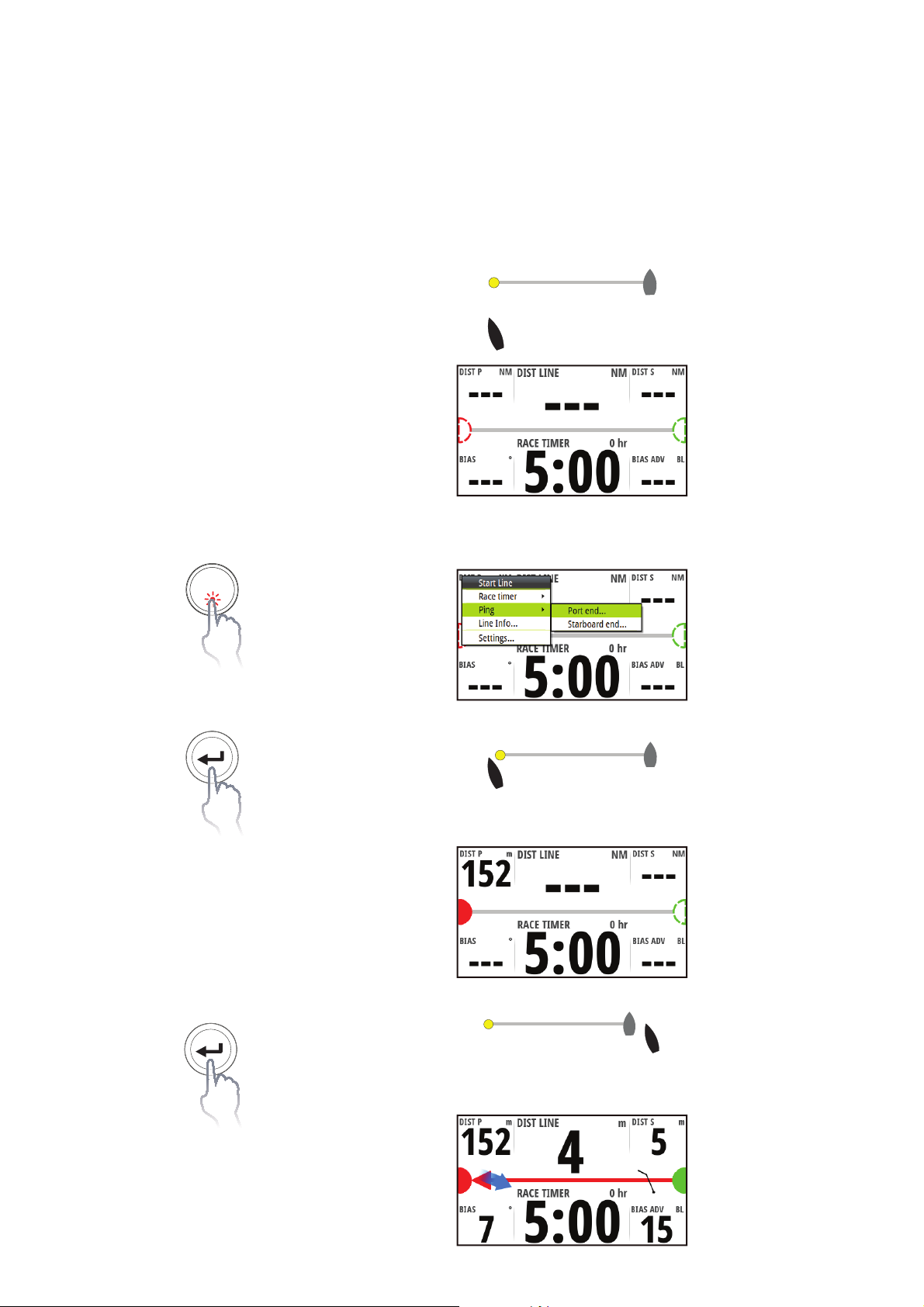

Start line

1

2

3

4

5

6

7

8

9

10

11

Displayed data

No. Description No. Description

1

Distance to port end of start line

2

Tide direction indicator

3

Port end start line indicator

4

Start line bias angle

5

Race timer

6

Distance to start line (perpendicular)

7

Distance to starboard end of start line

8

Starboard end start line indicator

9

Wind indicator (wind barb)

10

Start line - Arrow points to favored end

11

Bias advantage (boat lengths)

20 |

Operation | H5000 Operation Manual

Page 21

Setting up a Start line page

The Start Line page is used as a visual aid to boat distance from the start line, tide direction,

recommended start end bias and what advantage in degrees and boat lengths the biased

end will give.

¼ Note: Before setting the start line position It is important that the Bow off set is updated to

negate the diff erence between the GPS postion and the bow of the vessel.

1 Approach the port end of the start line

2 Select ping from the start Line menu

3 Highlight Port end...

MENU

4 When the bow touches the start line, press the ENTER key.

5 The port end mark on the start line screen will go to solid red indicating it has been pinged

6 Repeat steps 1 to 4 at the starboard end selecting ping starboard end as the bow touches the line

7 The starboard end mark on the start line screen will go to solid green indicating it has been pinged

Operation | H5000 Operation Manual

| 21

Page 22

Start line screen explained

1

2

3

Start line end not pinged (position not recorded)

Start line end pinged (position recorded)

Start line end stale (historic start line position)

Start line end becomes stale at 23:59 hrs on the day it was recorded but

remains valid.

Invalid start line - One or more ends invalid (position not recorded)

Start line - Blue - Square line - No bias advantage

4

5

6

Start line - Red & Arrow left - Port end bias

Start line - Green & Arrow right - Starboard end bias

Tide direction indicator

Wind speed and direction indicator (wind barb)

1 DIST P: Distance to port end of start line

2 BIAS: Start line bias angle

3 Race timer

4 DIST LINE: Distance to start line (perpendicular)

22 |

5 DIST S: Distance to starboard end of start line

6 BIAS ADV: Bias advantage (boat lengths)

Operation | H5000 Operation Manual

Page 23

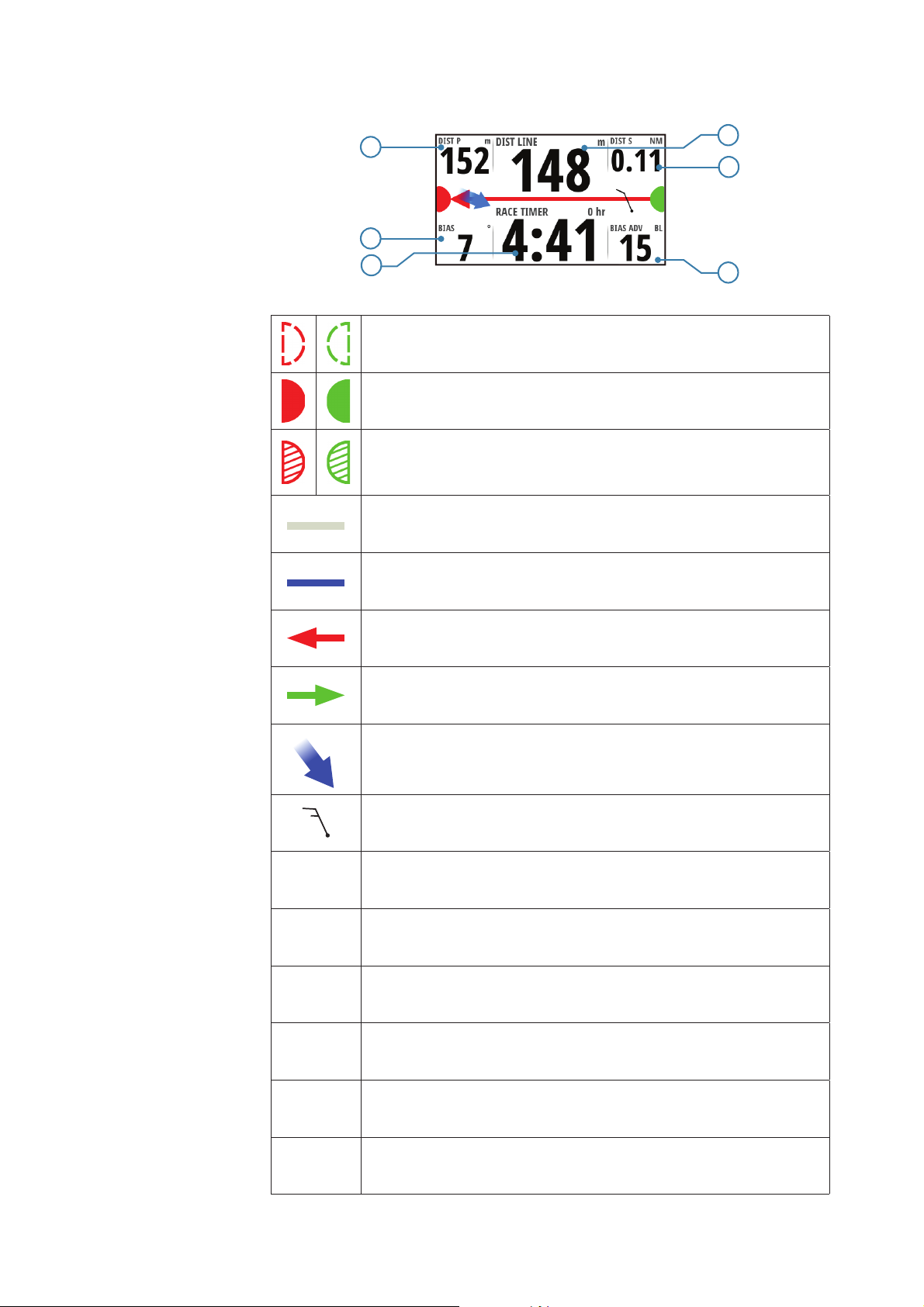

Depth history

1

2

4

3

5

Displayed data

No. Description No. Description

1

Current depth

2

Shallow water limit

3

Depth scale

4

Water line

5

Depth histogram

¼ Note: Depth histogram time periods can be set to show 5, 10, 30 or a 60 minute history.

Toggle between the time periods using the UP/DOWN keys.

Highway

6

1

2

3

4

5

7

8

9

10

11

Displayed data

No. Description No. Description

1

Waypoint bearing

2

Course over ground

3

Off course limit (user setting)

4

Distance to waypoint

5

Cross track error

6

Waypoint name

7

Estimated waypoint arrival time

8

Waypoint

9

Course line

10

Vessel indicator

11

XTE correction direction Left or Right

Operation | H5000 Operation Manual

| 23

Page 24

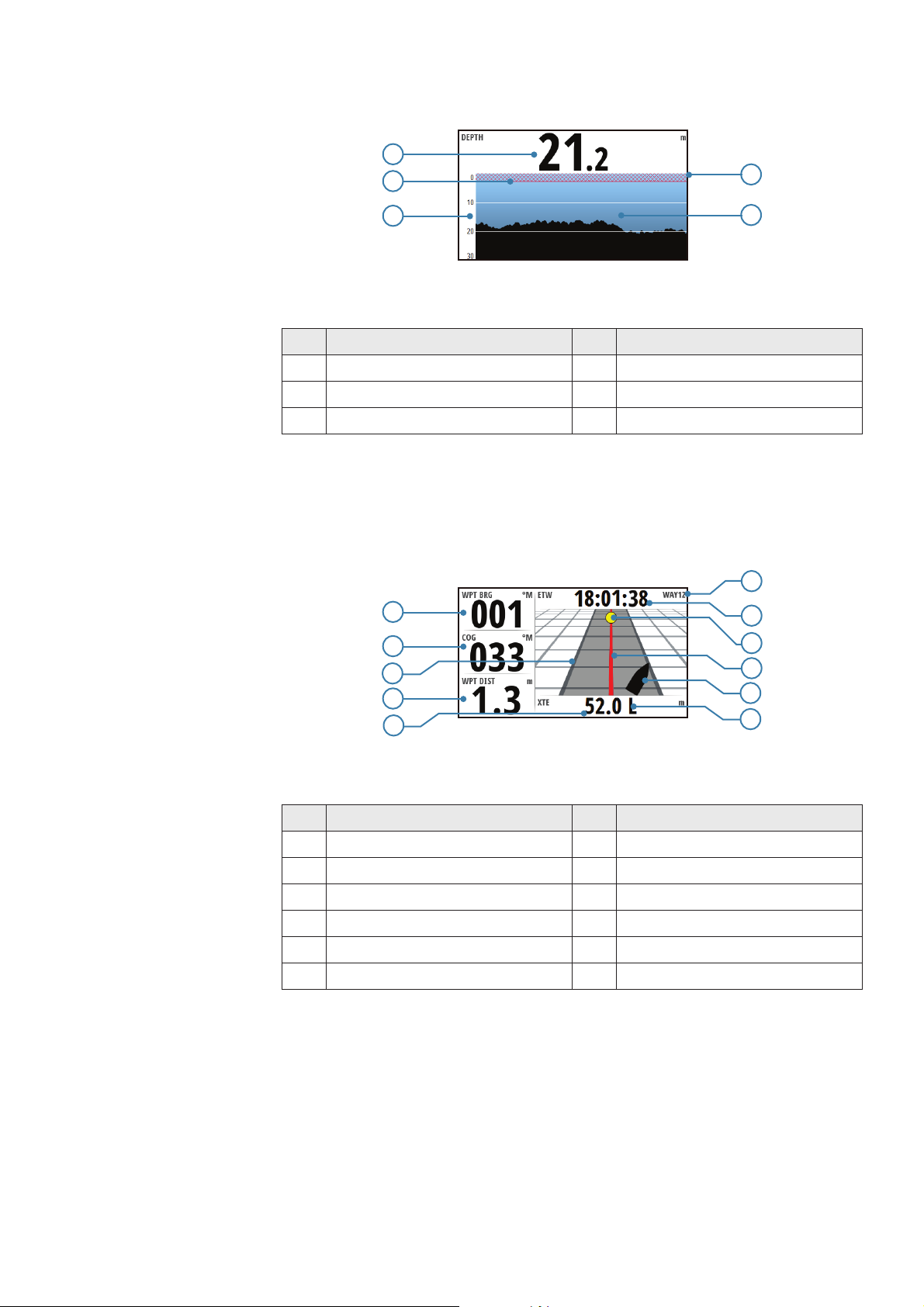

Tide

6

1

2

3

4

5

Displayed data

No. Description No. Description

1

Boat speed

2

Tide angle relative to vessel

3

Heading

4

Depth

5

Tide rate

6

TWA Port / Starboard indicator

7

True Wind Angle

8

True Wind Speed

9

True wind direction

10

Tide direction

Autopilot

7

8

9

10

1

2

3

4

5

Displayed data

No. Description No. Description

1

Set heading / Wind angle

2

Compass scale

3

Heading

4

Autopilot mode indicator

5

Rudder angle indicator

6

Heading indicator

7

Set heading / Wind / Rudder angle

8

Wind angle

9

Rudder angle

6

7

8

9

24 |

Operation | H5000 Operation Manual

Page 25

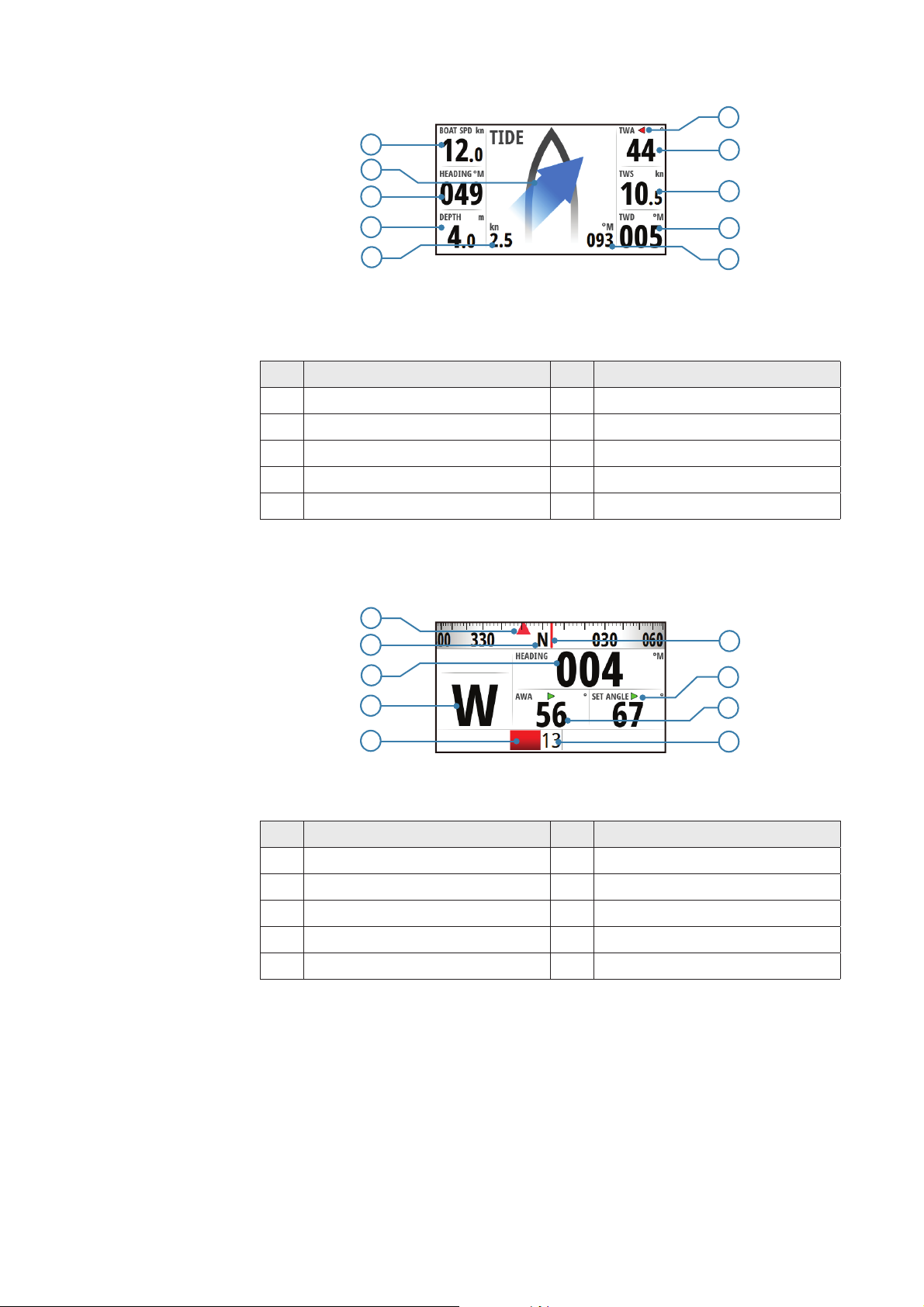

Data page transition

8

7

1

2

3

6

Available data pages

1 Sail steer (default) Full screen*

2 Speed / Depth 2x1 grid (default) 2x1 grid*

3 Wind plot (default) 2x2 grid*

4 Start line (default) 2x2 grid off set*

5 Depth history (default) 3x3 grid*

6 Highway (default) 1+3 digital*

7 Tide (default) 1+6 digital*

8 Autopilot (default) Centre analog*

4

5

Satellites Analog +2*

Weather Analog +3*

Single time plot* Dual analog*

Dual time plot*

¼ Note: * indicates, User confi gurable page

Operation | H5000 Operation Manual

| 25

Page 26

MENU

x2

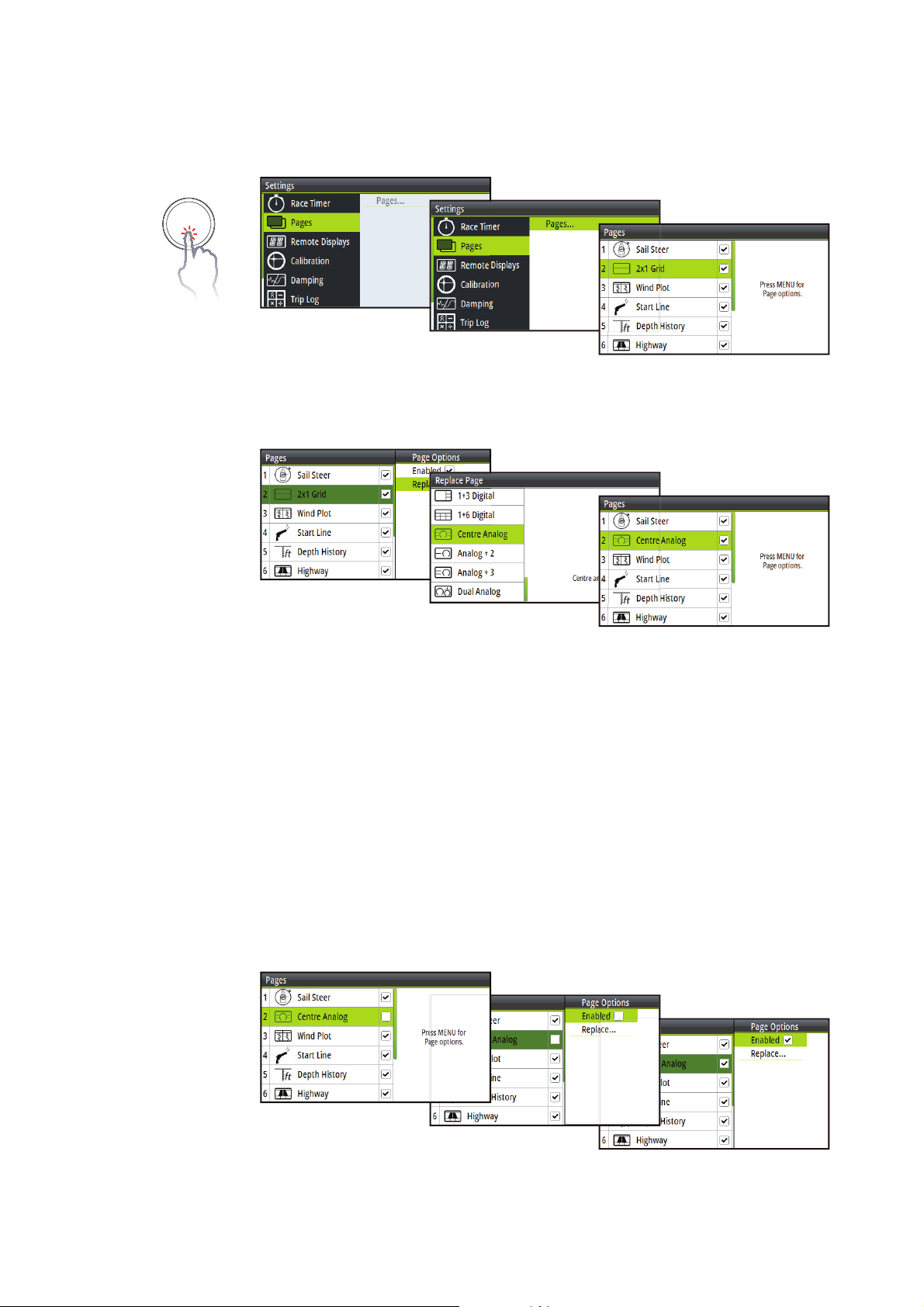

Replacing a data page

1 Go to the pages menu.

2 Highlight the page you wish to replace

3 Press MENU

4 Highlight Replace and press the ENTER key

5 Highlight the desired page and press the ENTER key

The new chosen page will be shown in the pages list.

Enabling / Disabling a data page

To make a data page available via the PAGE key you will need to fi rst ensure it has been

selected as one of the eight available pages.

Once the page has been selected as one of the eight data pages you can enable / disable it

1 Highlight the required page via the pages menu

2 Press MENU

3 Highlight Enabled

4 Press the ENTER key to switch the page on or off .

¼ Note: A tick symbol next to the page denotes that the page is active.

26 |

Operation | H5000 Operation Manual

Page 27

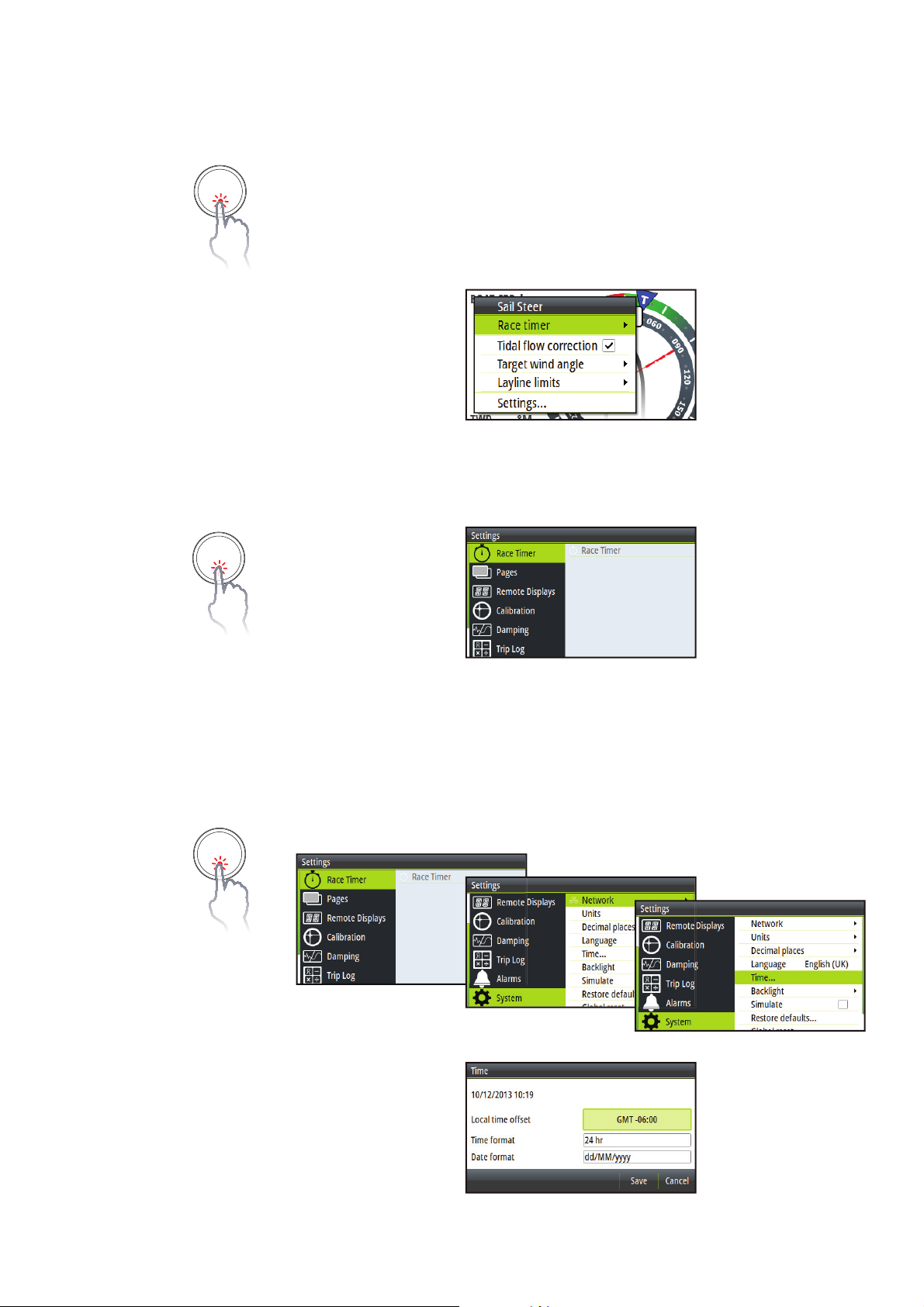

Menus

From a data page a single press of the MENU key will open the Page menu for that specifi c

page. A double press of the MENU key will open up the Settings menu.

MENU

MENU

x2

Page menu

The Page menu options vary from page to page. All Page menus have a race timer and

settings option to access the Settings menu. All other options listed will relate directly to the

current data page.

Settings menu

The Settings menu is where display options, display and system settings and calibration can

be accessed.

MENU

x2

Example menu structure

1 Select a menu as above.

2 Use the UP/DOWN and ENTER keys to navigate through the menu options.

¼ Note: Whilst navigating a menu a single press of the PAGE key will return to the previous

menu option.

Example below: How to access the Time dialog via the Settings menu.

Operation | H5000 Operation Manual

| 27

Page 28

MENU

x2

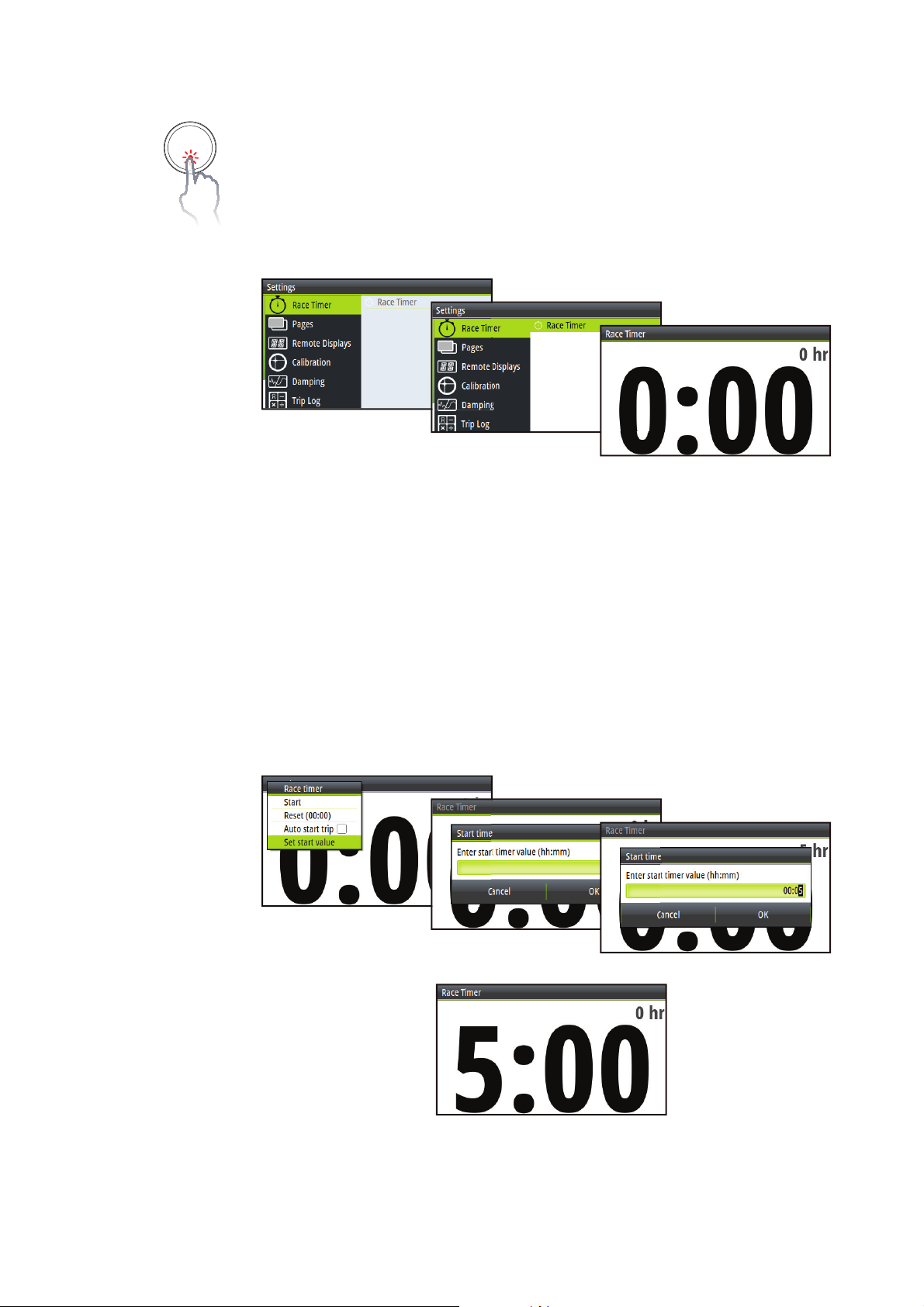

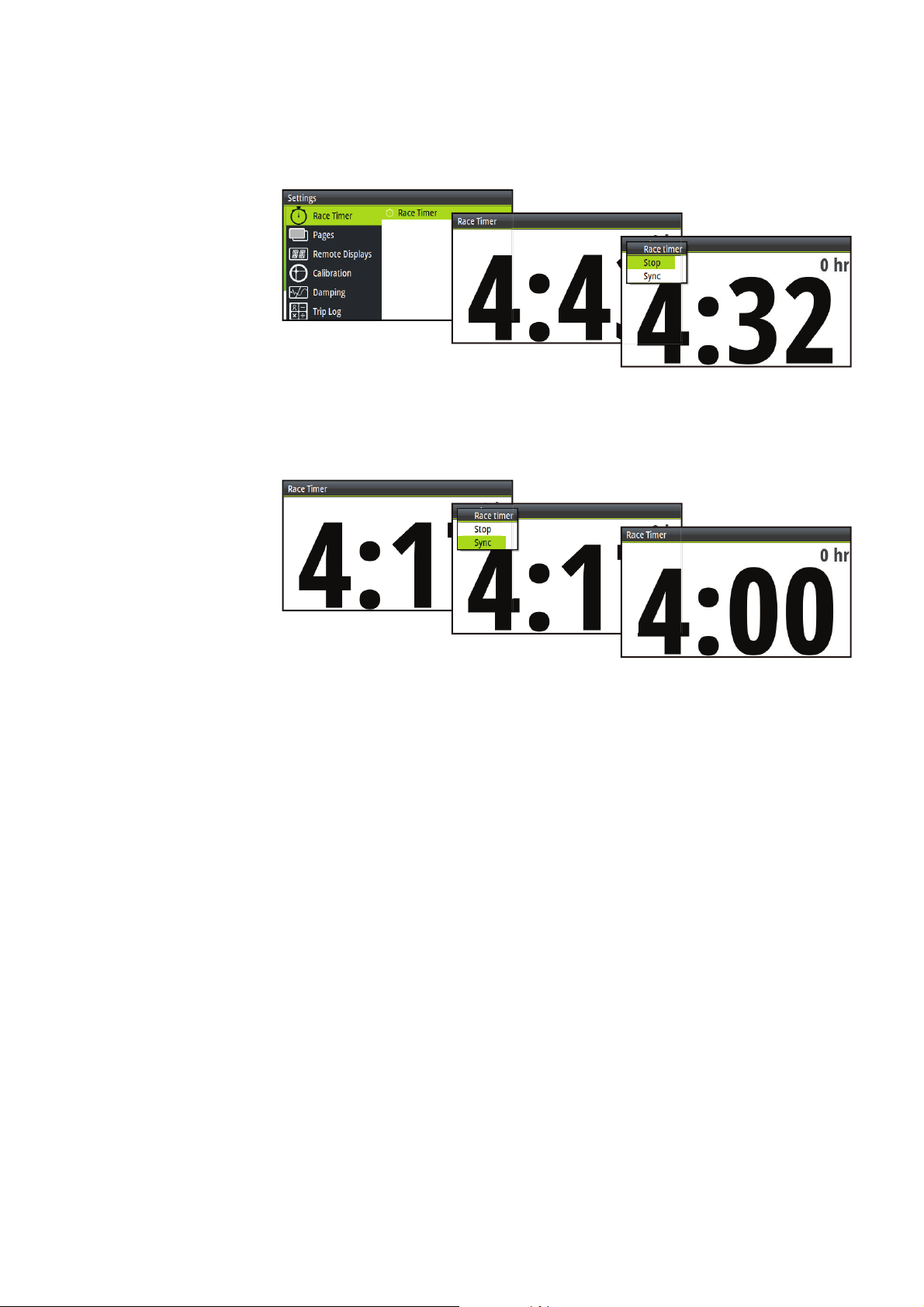

Race timer

The race timer can be used to countdown to zero from a specifi ed time, ideal for counting

down to a race start. It can also be used to count up from zero to record the elapsed time.

The timer can be started at any time by selecting Start Timer from the timer setup menu. If

the start value is set to zero (00:00) when the timer is started the timer will begin counting up,

recording the elapsed time.

¼ Note: The timer is shared between all displays on the network. All timer values are

synchronized.

¼ Note: The timer set value is in Hours : Minutes (hh:mm), the timer counter will show Minutes :

Seconds (mm:ss) with the hours shown in the top right hand corner of the display.

Countdown timer

To count down to a race start, a time value can be set in the Set start value fi eld in the Race

Timer setup menu.

Set start value

1 Select the Start Time fi eld.

2 Use the UP & DOWN keys to set the desired number

3 Press the the ENTER key to move to each consecutive number.

4 Press the PAGE key to exit the number edit fi eld.

5 Once complete select OK to confi rm.

28 |

¼ Note: Selecting Cancel or navigating away using the PAG E key will lose any changed settings.

When a time is present in the start value fi eld the timer will begin to count down from that

number when the timer is started. Once the time reaches zero it will begin counting up

recording the elapsed time.

Operation | H5000 Operation Manual

Page 29

Start/Stop timer

To start the timer, select Start in the Race Timer menu. When the timer is started it will return

to the previous data page. To stop the timer from counting select Stop in the Race Timer

menu.

Sync

When the timer is counting down selecting Sync will synchronize the time up or down to the

nearest full minute.

Reset

Selecting Reset will reset the timer to the start value. If the timer was running, it will continue

to run from the start value.

Auto start trip

Selecting Auto trip start will enable the Trip Log to record your time and mileage from the

moment the countdown timer begins counting up from zero.

Operation | H5000 Operation Manual

| 29

Page 30

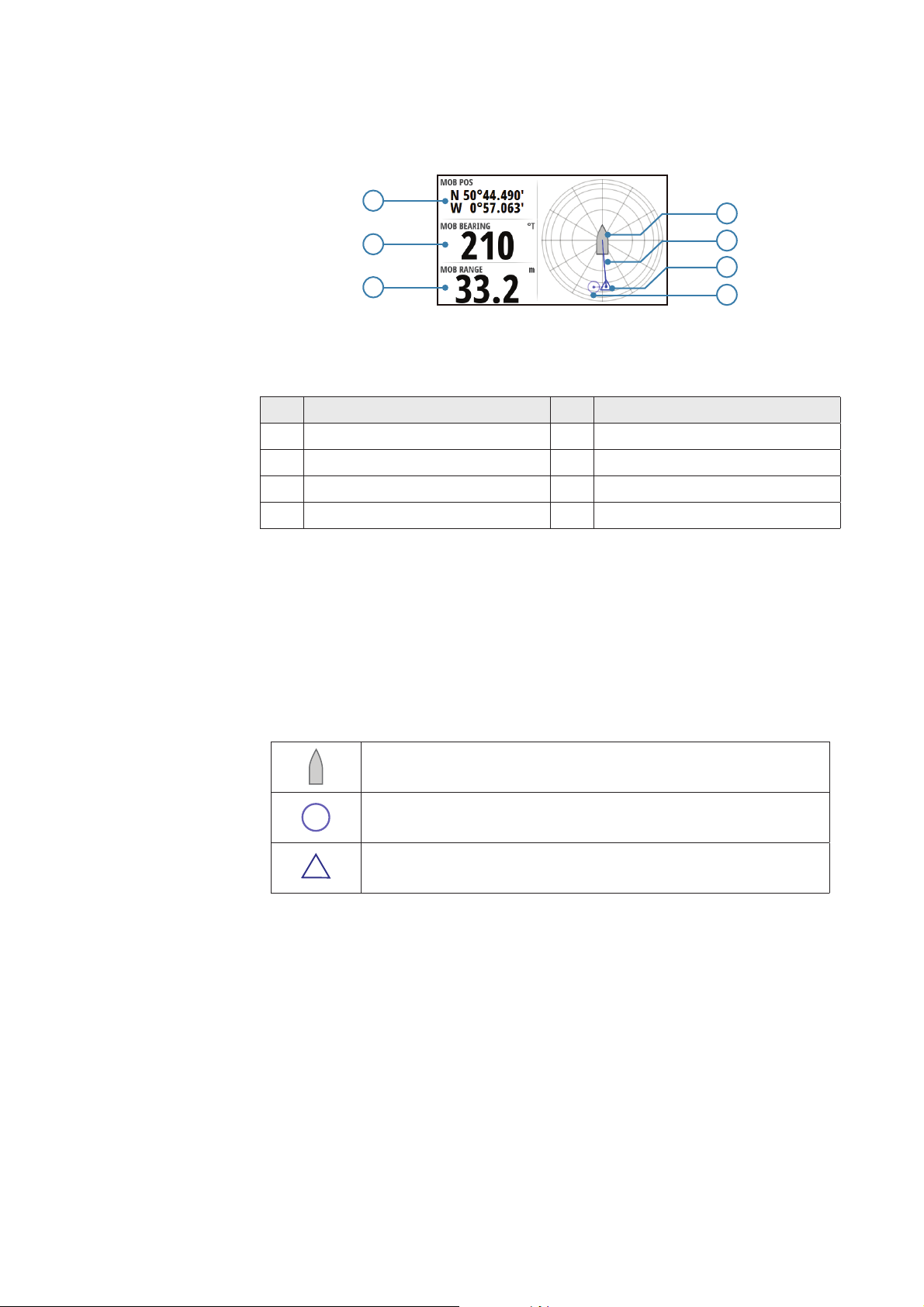

Man Over Board

If an emergency situation should occur and a man over board event is triggered, the display

automatically switches to the MOB screen.

1

4

2

5

6

3

7

Displayed data

No. Description No. Description

1

Last known MOB position

2

Bearing to MOB

3

Range to MOB

4

Vessel (Always points up)

5

Direction to MOB from vessel

6

Dead reckoned MOB position

7

Last known MOB position

• A waypoint becomes active at the position the man over board is activated. This is indicated

with a circular symbol. If the man over board event is activated via an AIS-SART then this

position will update via the AIS-SART signal.

• The GPS longitude and latitude co-ordinates of the last known position are shown in the top

left of the screen with the bearing and range MOB waypoint data listed below.

• If you have an H5000 CPU on the network the CPU will perform dead reckoning calculations

to provide the estimated position of the man over board. This position will be displayed as a

triangle symbol.

Vessel

Last known MOB position (H5000 CPU or MFD required)

Dead reckoned MOB position (H5000 CPU required)

¼ Note: To cancel the man over board event press MENU and select cancel.

30 |

Operation | H5000 Operation Manual

Page 31

HV display support

Any compatible B&G HV display e.g. 20/20 HV mast display connected to the network can be

confi gured via the H5000 CPU webserver, Graphic Display or Race Display to show desired

data e.g. speed, depth, wind speed.

¼ Note: When a new HV display is added to the network the default data displayed will be boat

speed. If no boat speed data source is available the display will show the word ‘OFF’

Remote displays

The remote display page can be accessed from the Settings menu. Here all HV Displays will

be listed by size. Any displays that are not present on the network will be greyed out.

To change what data is shown on a HV display, highlight the display in this menu, press

ENTER key

and select the required data type from those listed.

the

Con guring an HV display

From the remote display menu, select the HV display that you wish to confi gure.

Select the information source you wish to show on the selected HV display.

Once selected the screen will revert to the remote display page.

Operation | H5000 Operation Manual

| 31

Page 32

Alarms

If you have the relevant sensor connected to the network you can enable that alarm by

selecting it/them from the alarm list.

Alarm on / o

Turn an alarm on or off from the alarm list. A tick symbol next to the alarm in the alarm list will

indicate that the alarm is on.

¼ Note: It is possible to enable / disable all alarms by selecting the ‘Alarms Enabled’ fi eld from

the Alarms menu.

Alarm settings

1 Press MENU on an alarm that requires parameters to be set will take you to the Enabled / Set limit

menu.

2 Select Set limit

3 Set the required alarm parameter

4 Press the PAGE key once you have fi nished editing

5 Select OK to confi rm.

32 |

Operation | H5000 Operation Manual

Page 33

Alarm indication

The alarm system is activated if any alarm settings are exceeded. Alarms are indicated with an

alarm text and with an audible alarm (optional).

¼ Note: See Alarm settings for further details on how to set an alarm. If an autopilot is not on

the network, autopilot alarms will not be accessible.

If no specifi c alarm text is available, an alarm code will appear.

Acknowledging an alarm

An alarm is acknowledged by pressing the ENTER key. This will remove the alarm notifi cation,

and silence the alarm from all units that belongs to the same alarm group. A reminder will

reappear at given intervals for as long as the alarm condition exists.

¼ Note: An alarm received from non B&G units on the network must be acknowledged on the

unit generating the alarm.

Alarm history

The alarm history can be accessed via the Alarm history menu. This stores alarm messages

until they are manually cleared.

Clear alarm history

To clear the alarm history list, select ‘Clear All’ from the Alarm history menu.

Operation | H5000 Operation Manual

| 33

Page 34

Damping

The damping rate aff ects the frequency that the sensor data is updated, the greater the

damping value the smoother the number change will be but the slower the response will be

to data change.

Damped parameters

Below is a list of parameters that a damping value can be applied to. Set the damping value

(response rate) for each parameter from 0 to 9 seconds.

• Heading

• Apparent wind (angle & speed)

• True win d

• True wind direction

• Boat speed

• Dynamic boat speed (Bspd)

• Tide

• Speed Over Ground (SOG)

• Course Over Ground (COG)

Trip log

There are two recorded trip logs. Trip log 1 records distance traveled through the water, trip

log 2 records distance traveled via GPS input.

¼ Note: Trip log 2 requires a compatible GPS connected to the network.

1

2

No. Description No. Description

1

Trip distance

2

Average speed

¼ Note: Correctly calibrated boat speed is essential for accurate trip records.

3

Trip time

4

Maximum speed

3

4

Log

Shows total miles run from installation. This is based on distance over the water.

34 |

Operation | H5000 Operation Manual

Page 35

MENU

Race display

1

2

3

4

MENU

Basic operation

1 PAGE

Each press of the PAGE key scrolls through the data pages in rotation or navigates back to the display

pages from within any menu. Press and hold the PAGE key to save the current page confi guration.

2 UP

Selects the upper half of the display to change variables; scrolls through menus and variables; increases

/ decreases values.

3 ENTER

Used to enter the selected sub menus and confi rm selections.

4 DOWN

Selects the lower half of the display to change variables; scrolls through menus and variables; increases /

decreases values.

5 MENU / LIGHTS

Used to enter the Settings menu and scroll through the menu options. Long press enters the lights

settings page.

5

Display information

1

2

5

2

4

No. Description No. Description

1

Data variable name

2

Display data value

3

Units of measure

4

Bargraph data type

5

Bargraph data

6

Page stored / Source select

7

Alarm - Critical

6

3

31

8

Alarm - Warning

9

Alarm - Info

10

Controlling remote (HV) Displays

11

Autopilot engaged

12

Active page number

13

B&G H5000 CPU on the network

7

8

9

10

11

12

13

Operation | H5000 Operation Manual

| 35

Page 36

Menus

To enter the menu function press the MENU key. To operate a menu use the UP and DOWN

directional keys and press

navigate back to the display pages.

the ENTER key to select a menu item. Press the PAG E key to

Pages

The display shows fi ve confi gurable data pages. Data pages show a variety of data and

information available from sensors and devices on the network.

¼ Note: All of the default pages can be edited to show the users preferred boat data.

Each press of the PAG E key will change the current data page to the next page in the cycle.

¼ Note: Pressing the PAGE key will change the data pages in sequence and in continuous

rotation from pages 1 to 5.

Edit data page contents

You can edit any of the fi ve data pages so that they display the specifi c boat data that you

require.

Page data editing

Select the page you wish to edit. Press the UP key to select the top data fi eld or the DOWN

key to select the bottom data fi eld.

Once selected the chosen data fi eld text will fl ash to indicate the menu has been selected.

Using the UP and DOWN keys choose the required data type required, once selected press

the ENTER key. The fi eld text will stop fl ashing and return to the data page. A long press of

the PAG E key will save the display confi guration.

36 |

Operation | H5000 Operation Manual

Page 37

Bargraph data editing

Select Bargraph menu option, use the arrow keys to select the required bargraph variable.

Press the PAGE key to save the change and return to the data page screen.

MENU

x7

Race timer

The race timer can be used to countdown to zero from a specifi ed time, ideal for counting

down to a race start. It can also be used to count up from zero to record the elapsed time.

¼ Note: Once the countdown timer reaches zero it will start counting up showing the elapsed

time from zero. The timer will continue to count until it is stopped.

Set

Sets the value of the timer.

MENU

Once set is selected, use the directional keys to set the required time.

¼ Note: The timer can only be set to whole minutes.

Start

Starts the timer. If a time value is preset the timer will countdown. If the timer is on zero it will

count up.

MENU

Synchronize

Synchronizing the timer will cause the timer to reset to the nearest whole minute.

Operation | H5000 Operation Manual

| 37

Page 38

Stop

Stops the timer. Press

the ENTER key again to restart the timer.

Reset

If the timer is running, selecting reset will automatically start counting down from the

originally set value for the race timer. If the timer is stopped when reset is selected it will set

the clock to the originally set value and will not begin the countdown until start is selected.

Remote displays

Remote displays can be individually set via the race display to show a single variable.

Con guring remote display data

Select the remote menu, then select the remote display (e.g. 20/20 HV) you wish to confi gure.

¼ Note: The remote display will fl ash on and off to indicate it has been selected for editing by

the race display.

MENU

x2

Use the UP/DOWN and ENTER keys to navigate to a variable and select the variable to

display. Exit by pressing the PAGE key.

Lighting zone selection

Set the lighting zone on the display. All units in the selected lighting zone will mirror each

others light settings. Default setting is network.

38 |

MENU

¼ Note: Press and hold the MENU / LIGHTS key to get to the Lighting menu.

Operation | H5000 Operation Manual

Page 39

Backlighting

Set the desired lighting level on the display.

¼ Note: All units in the selected lighting zone will mirror each others light settings. Default

setting is network. To change the lighting zone select the lighting menu and press DOWN

the lighting zone type will fl ash. Select the desired zone and press

MENU

the ENTER key.

Trip log

There are two recorded trip logs. Trip log 1 records distance traveled through the water, trip

log 2 records distance traveled via GPS input.

¼ Note: Trip log 2 requires a compatible GPS connected to the network.

Start trip log

Stop trip log

Reset trip log

MENU

x3

MENU

x3

Alarms

When alarms are set to ‘On’ the race display will show alarm messages when predefi ned

alarm parameters on the network are triggered. When the race display alarm is set to off , no

alarm message will be displayed on the race display.

MENU

x8

Operation | H5000 Operation Manual

| 39

Page 40

Alarm noti cation

When an alarm event is received the display will change to show the variable name that is

alarming and the current value. An icon will be highlighted to indicate the severity of the

alarm.

Alarm icons

There are three alarm icons for the three levels of alarm severity as shown below.

Important / Critical

Warning

Information

Depth alarm example

MENU

Acknowledging an alarm

An alarm is acknowledged by pressing the ENTER key twice in quick succession. This

will remove the alarm notifi cation (text, light and sound) from all units on the network. A

reminder will reappear at given intervals for as long as the alarm condition exists.

x2

Diagnostics

The diagnostic pages show details of the display, instance number, software version, LCD test

and reset options. To access the diagnostic pages, press and hold the MENU key when you

power on the display. Use the UP/DOWN keys to scroll through the pages.

Version

Software version number. Check the B&G website for the current available software version.

40 |

1

No. Description No. Description

R = Indicates released version.

1

Software version number

Operation | H5000 Operation Manual

2

Any other identifi cation is used for

internal testing only

2

Page 41

Checksum

Additional version information in hexadecimal format. This information is for B&G support

only.

1

2

No. Description No. Description

1

Boot code

2

User code

Full reset

Factory reset of the display. All settings will revert to factory default. Select the full reset page,

press

the ENTER key and a full reset will take place and return the display back to the default

speed and depth page.

User reset

Resets page confi guration to their default settings. All other settings will remain unchanged.

Select user reset, press

the ENTER key. The display will show complete once fi nished.

LCD segment test

When the LCD segment test page is selected the display will automatically begin the LCD test.

This is a visual test that needs to be performed by the user. Each segment will switch on in

sequence until all segments are lit. It is the responsibility of the user to visually spot any faulty

/ missing LCD segments.

Missing

segment

Operation | H5000 Operation Manual

| 41

Page 42

Lights test

Select the lights page. Press the ENTER key, the display will go through each of the light

settings in sequence. It is the responsibility of the user to visually check the light levels.

Instance

The display instance is a number that can be set as a reference for the user to distinguish

between diff erent displays. By default the display instance is set to zero.

Voltage

Shows the current voltage supply to the display.

42 |

Operation | H5000 Operation Manual

Page 43

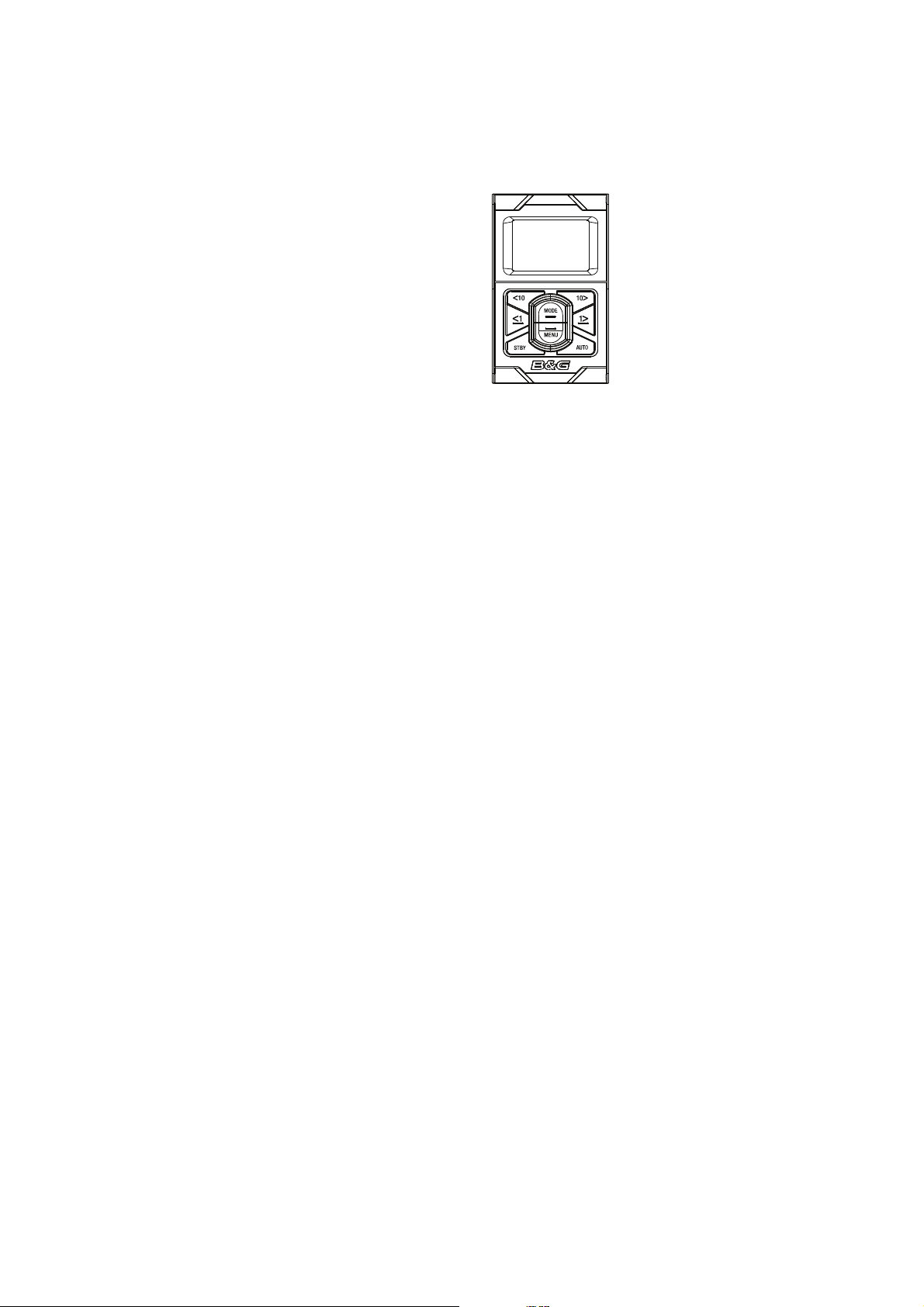

H5000 Pilot Controller

X

X

a

b

d

e

f

c

4

5

6

1

2

3

7

8

Display

The displayed information will change depending which mode is selected.

Description

a

Performance level

b

Autopilot mode

c

Rudder angle indicator

Description

d

Target

e

Compass: ºT = True ºM = Magnetic

f

Heading

Keys

The H5000 Pilot Controller is operated by 8 keys. These are used to operate the autopilot and

adjust autopilot parameters.

MODE

1

Changes the autopilot mode / Scrolls up in menu options / Increases values. With active autopilot:

Toggles between Wind mode and Auto mode

2 10º COURSE CONTROL STARBOARD (10º RIGHT)

Changes target course 10º Starboard

3 1º COURSE CONTROL STARBOARD (1º RIGHT)

Changes target course 1º Starboard / Activates Non Follow Up (NFU) mode when in Standby mode /

Enter menu

4 10º COURSE CONTROL PORT (10º LEFT)

Changes target course 10º Port

5 1º COURSE CONTROL PORT (1º LEFT)

Changes target course 1º Port / Activates Non Follow Up (NFU) mode when in Standby mode / Exit

menu

6 STBY

Disengages the autopilot

7 AUTO

Engages the autopilot

8 MENU

Enter the Main menu / Scrolls down in the menu options / Decreases values. Press and hold for 3 secs

enters the lighting settings

.

Warning: The installation settings must be performed as part of the

commissioning of the autopilot system. Failure to do so correctly may

prohibit the autopilot from functioning properly! The Installation menu

can only be accessed in Standby mode.

Operation | H5000 Operation Manual

| 43

Page 44

Autopilot operation

Turning the autopilot on / o

Engaging the autopilot

At anytime while the autopilot is disengaged press the AUTO key to engage

the autopilot. The autopilot will steer the boat on the current selected

heading.

Disengaging the autopilot

At any time the autopilot is engaged press the STBY key to disengage the

autopilot. The autopilot will go into Standby mode and you will be required

to take manual control of the helm.

Warning: In Standby mode pressing either of the 1º directional keys

will engage the autopilot in Non Follow Up mode!

Menu navigation

Single press of the MENU key will open the Main menu.

¼ Note: Whilst navigating the menu system If no selection is made after 10 seconds the screen

will revert to the autopliot status screen

¼ Note:

At anytime a single press of the STBY key will exit the menu and switch the autopilot

to Standby mode!

Key Action

1º RIGHT Opens highlighted menu option

1º LEFT Return to previous menu - Continued presses

will return the display to the navigation screen.

MODE Scroll up

MENU Scroll down

44 |

Operation | H5000 Operation Manual

Page 45

Autopilot modes

The current heading and Set heading information will change on the display depending

on which mode the autopilot is in. Below is a list of the autopilot modes, autopilot mode

symbol and the current/target data that will be displayed.

Mode Symbol Description Required Input

Press

& Hold

3 sec +

to enter mode

menu then select

required mode

Standby

Auto

Wind

NoDrift

Navigation

Non Follow

Up

S

A

W

ND

N

NFU

Passive mode used when manually

steering the boat at the helm

Keeps the boat on set heading

Cancels a turn and continues on the

heading read from the compass. Press

the MODE key to enter Wind mode.

Press MODE key again to revert to

Auto mode

Steers the boat to maintain the set

wind angle. Press MODE key to enter

to Auto mode. Press MODE key again

to revert to Wind mode

Steers the vessel on a straight bearing

line by compensating for drift

Steers the boat to a specifi c waypoint

location, or along a route

Steer the boat

manually using

the H5000 Pilot

Controller

Heading

Heading, Speed,

True Wind Angle

Heading, Position

Heading, Speed,

Position, Waypoint,

Route information

(MFD)

Standby NFU AUTO

• Heading (True or Magnetic)

• Rudder angle

NAV WIND NoDrift

• Bearing to next

waypoint

• Cross track distance

(XTD), analog and

graphical

• Set wind angle

• Heading

• Set heading

• Heading

• Set course

• Course Over Ground

(COG)

Operation | H5000 Operation Manual

| 45

Page 46

Mode selection

From Standby mode, press the AUTO key once to enter Auto mode. Whilst in Auto mode a

single press of the MODE key will set the autopilot to Wind mode. Press the MODE key again

to revert to Auto mode.

To access other autopilot modes press and hold the MODE key for 2 seconds. Highlight the

required mode and press the 1º RIGHT key to confi rm.

¼ Note: The mode selection menu will time out after a few seconds. Whichever mode is

highlighted at this time will be selected.

2 sec

Non Follow Up mode

Whilst in Standby mode, pressing any of the 1º LEFT / RIGHT keys will move the rudder to

your desired angle and change the autopilot mode to Non Follow Up.

Non Follow Up mode allows you to control the rudder position manually via the autopilot

controller.

¼ Note: The autopliot will remain in Non Follow Up mode until it is disengaged by pressing the

STBY key or a new mode is selected.

46 |

Operation | H5000 Operation Manual

Page 47

Tacking & Gybing in Wind mode

Tacking & Gybing in Wind mode can be performed when sailing with apparent or true wind

as the reference; in either case the True Wind Angle must be less than 90 degrees (tacking)

and more than 120º (gybing).

The tacking/gybing operation will mirror the set wind angle on the opposite tack and a tack

confi rmation window will appear on the display.

To tack or gybe in wind mode press both 1° COURSE CONTROL keys on the H5000 Pilot

Controller simultaneously. Hold them down until the confi rmation window appears. Press 1º

RIGHT to confi rm, 1º LEFT to cancel.

The rate of turn during the tack/gybe is set by the Tack time parameter in the Setup/

Sailing menu. The tack/gybe time is also related to the speed of the boat to prevent excessive

loss of speed during a tack.

¼ Note: The autopilot will temporarily add a 5 degree bear-away on the new tack to allow the

boat to pick up speed. After a short period the wind angle will return to the set angle.

If neither tack/gybe or cancel is selected the tack/gybe pop up will close after 10 seconds and

the requested tack/gybe will not be initiated.

Tacking & Gybing in Auto mode

To tack in Auto mode press and hold the Port 10 & 1º COURSE Keys to set a tack to Port and

the Starboard 10 & 1º COURSE keys to set a tack to Starboard.

Port Starboard

The rate of turn during the tack/gybe is set by the Tack time parameter in the Setup/

Sailing menu. The change in heading is controlled by the tack angle parameter in the Setup/

Sailing menu.

¼ Note: Default tack angle setting is 100 degrees.

Operation | H5000 Operation Manual

| 47

Page 48

Sensor calibration

Once the display is setup and before you proceed with calibration ensure all network sources

are selected and confi gured as shown in section 6.

5

Calibration example:

Depth

A typical transducer installation is through the hull in front of the keel. A datum (off set value)

can be set, such that the depth display refers to either the water line or the base of the keel.

+VE: Positive Datum for Waterline

(0.0)

- VE: Negative Datum for Keel

Setting the depth off set displays depth readings from directly below the keel or propellers of

the boat, or from the waterline to the seabed. This makes it easier to see the available depth,

taking into account the draught of the boat.

MENU

x2

The off set value to be entered should represent the distance between the face of the depth

transducer, and the lowest part of the boat below the waterline, or the distance between the

face of the depth transducer and the water surface.

Depth o set value

1 Enter the Settings menu.

2 Select depth via the calibration menu.

3 Select Off set.

4 A dialog box will appear showing the current depth off set value.

¼ Note: The default value is zero

48 |

Sensor calibration | H5000 Operation Manual

Page 49

Setting a calibration value

1 Highlight the value fi eld.

2 Press the MENU key to enable editing of the calibration value. The cursor will fl ash in the value fi eld.

3 Use the UP/DOWN Keys to adjust the value or toggle between plus and minus (+ / -).

4 Press the ENTER key to move to the next number in sequence. The current number will fl ash when

selected.

5 Press the ENTER key when the last digit is highlighted in the calibration fi eld to exit.

6 Select OK.

7 Press ENTER to confi rm and exit. The off set will then be set to the desired value and the

display will return to the calibration page.

¼ Note: If the calibration off set value fails an error message will appear “Setting off set failed”.

Check sensor connection and source selection and retry.

Boat speed

Speed calibration is necessary to compensate for hull shape and paddlewheel location

on your boat. For accurate speed and log readings, it is essential that the paddlewheel is

calibrated. Boat speed values can be shown in knots, kph or mph. Your preferred unit of

measurement can be set in the units page of the setup menu.

Sensor calibration | H5000 Operation Manual

| 49

Page 50

Auto - Calibration via reference to GPS SOG value

This is an AutoCal facility that uses speed over ground (SOG) from your GPS and compares the

average of SOG against the average boat speed from the speed sensor for the duration of the

calibration run.

¼ Note: This calibration should be made in calm sea with no eff ect from wind or tidal current.

1 Bring the boat up to cruising speed (above 5 knots)

2 Select Auto correct on the Calibrate boat speed page

3 When the calibration is completed the Boat speed calibration scale will show the adjusted percentage

value of the boat speed.

4 Select OK once complete to confi rm correction and exit.

50 |

Manual adjustment of boat speed

Adjust the boat speed manually by selecting the Boat speed percentage slider. Adjust the

percentage up or down as desired via the calibrate boat speed page. Confi rm the value.

Select OK once complete.

Sensor calibration | H5000 Operation Manual

Page 51

Distance reference

This facility enables the user to calibrate the log accurately and simply. Calculations are

performed by the display that works out the boat speed over a known distance.

To calibrate the boat speed via a distance reference you will need to complete consecutive

runs, under power at a constant speed made along a given course and distance.

¼ Note: To eliminate the eff ect of tidal conditions it is advisable to perform at least two runs,

preferably three, along the measured course.

How To Calibrate boat speed via Distance Reference

1 Enter the desired distance in nautical miles that you would like to calculate the distance reference over.

2 When the boat gets to the predetermined starting position of the distance reference calculation start

the calibration timer.

3 As the boat passes marks A and B on each run, instruct the system to start (Start Run) and stop (Stop

Run) and fi nally OK to end calibration (End Cal Runs).

4 After the last run is completed and OK has been selected, Select save to store the calibration.

5 A pop up warning will ask you if you wish to replace the current calibration with the new one. Select Yes

to complete or cancel to not replace the calibration value.

Distance reference diagram

Referring to the diagram, A and B are the markers for each run and X is the actual distance for

each run as measured from a suitable chart.

AB

X

Start Run 1 Stop Run 1

Stop Run 2

Start Run 3

¼ Note: It is important to maintain the same constant boat speed over each run.

Start Run 2

End Calibration

Sensor calibration | H5000 Operation Manual

| 51

Page 52

Use SOG as boat speed

If boat speed is not available from a paddle wheel sensor it is possible to use speed over

ground from a GPS. SOG will be used in the true wind calculations.

Environment

Sea / Air Temperature & Barometric pressure

If a suitable sensor is fi tted, the system will monitor the current sea / air temperature and

barometric pressure.

The off set value to be entered should adjust the reading from the sensor to match a

calibrated source, i.e. adjust sea temperature to match reading from a thermometer when

submersed in the water.

52 |

Sensor calibration | H5000 Operation Manual

Page 53

Masthead unit adjustment

This provides an off set calibration in degrees to compensate for any mechanical misalignment

between the masthead unit and the center line of the vessel.

To check the masthead unit alignment error we recommend you use the following method

which involves a sailing trial.

Sail on a starboard tack on a close hauled course and record the wind angle, then repeat the

process on a port tack. Divide the diff erence between the two recorded numbers and enter

this as the wind angle off set.

WIND

Starboard Tack Port Tack

33º

Starboard tack = 33º

Port tack = 27º

Diff erence : 33º - 27º = 6º

Off set : 6º / 2 = 3º

27º

If the starboard apparent wind angle is greater than the port angle then divide the diff erence

by 2 and enter this as a negative off set. If the port angle is greater than the starboard then

divide the diff erence by 2 and enter this as a positive off set.

MHU Align

Once the off set has been calculated enter it into the MHU Align calibration fi eld

TWA / TWS Correction tables

The TWA and TWS Correction tables receive their information from the H5000 CPU and does

not store this information on the display.

¼ Note: TWA / TWS correction tables can also be adjusted from the webserver and the Zeus

family MFDs

Sensor calibration | H5000 Operation Manual

| 53

Page 54

Editing a correction table

1 Highlight the fi eld that requires editing and press the ENTER key

2 Adjust the correction value to the desired number

3 Select OK once complete to return to the correction table

True Wind Angle calibration

There are two methods of calibrating TWA, monitoring true wind direction from tack to

tack or gybe to gybe, or use the compass to verify the angles the yacht is tacking or gybing

through.

Start the TWA calibration process for either method by setting the boat up to do a number of

tacks upwind or gybes downwind in as steady conditions as possible.

Method 1

If an error is seen in true wind direction, then the following rule applies:

• If true direction is lifting you tack to tack then True Wind Angle is reading too wide, half the

error must be subtracted from the TWA correction table.

• If true direction is heading you tack to tack then True Wind Angle is reading too narrow, add

half the error to the TWA correction table.

Method 2

If according to the compass you are tacking through an angle diff erent than the sum of the

True Wind Angles on each tack (Port TWA + Starboard TWA) then the following rule applies:

• If the tack angle < the sum of the TWA’s, the True Wind Angle is reading too wide, half the

error must be subtracted from the TWA correction table.

• If the tack angle > the sum of the TWA’s, the True Wind Angle is reading too narrow, add half

the error to the TWA correction table.

True Wind Speed calibration

True Wind Speed errors are seen from sailing upwind to downwind. This is due to the

acceleration of the airfl ow over the top of the mast and around the sails when sailing

downwind. -10% is the default value for TWA calibration. Monitoring the change in True Wind

Speed from close hauled to fl at running will enable further refi nement of this calibration

value.

54 |

Auto Calibration via webserver

It is possible to auto calibrate both tables via the Webserver. See the Webserver help fi les for

more details.

Sensor calibration | H5000 Operation Manual

Page 55

Heading (compass)

Auto Cal

The compass Auto Cal process records the magnetic fi elds in the yacht that cause deviation

errors. It calculates the corrections when the compass calibration is started provided the

following conditions are met:

• The 360º turn - RC42 compass or 2 x 360º turn Halcyon Gyro Stabilized compass is completed

in the same direction.

• The rate of change of heading does not exceed 3º/s; i.e. the turn should take about 2 minutes

to complete.

• The rate of change of heading must not fall below 0.2 °/s during the 360° turn, i.e. the turn

must not take longer than 12 minutes.

• The rate of change in heading is reasonably constant.

• The compass is installed in a location a safe distance from magnetic interference such as iron

keels, engines, loudspeakers etc.

• Consideration should also be given to electrical cables which may carry high currents (e.g.

large motors).

• The compass is installed in a location as close to the centre line of the boat as possible. Avoid

areas such as the fore peak and the sides of the hull where the eff ects of pitch and roll are at

their greatest.

• On steel hulled vessels, the compass will need to be installed above decks away from the

eff ects of the hull.

1 Select Auto Cal

2 Select Calibrate

3 Steer the vessel through 360º maintaining a steady rate of turn

Sensor calibration | H5000 Operation Manual

| 55

Page 56

O set

The compass off set compensates for fi xed errors (misalignment) between the compass sensor

and the direction of the boat.

To accurately enter a compass off set, the boat’s heading must be referenced to, for example:

a calibrated bowl compass. The off set value will be the diff erence between the known source

and the currently displayed heading. Enter this value as the off set in the compass heading

fi eld as a plus or minus integer up to 180º

Magnetic variation

Adjust how the system handles magnetic variation.

Auto

Automatically calculates variation based on position and date.

Manual

If variation is not available enter a value manually.

Use COG as heading

If heading data is not available from a compass sensor it is possible to use course over

ground from a GPS. COG will be used in the true wind calculations.

¼ Note: The autopilot cannot be operated using COG as the heading source. COG cannot be

calculated when stationary.

56 |

Sensor calibration | H5000 Operation Manual

Page 57

System setup

From the system menu there are several display and system options as listed in the following

section.

6

¼ Note: The graphic display can do most system settings, however the webserver should be

used for more detailed system setup.

Network

Before the system can be used, the data sources need to be confi gured.

Sources

A data source can be a sensor or a device connected to the network, providing information

and commands to other networked devices. The data sources are normally confi gured at fi rst

time turn on. It should only be necessary to update this data if a new source is added, source

is missing (sensor failure), source has been enabled/disabled, sensor replaced or a network

reset.

Auto select

The Auto select option will look for all sources connected to the instrument system. If more

than one source is available for each item, the display will automatically select from the

internal device priority list.

¼ Note: Auto select can be performed via a Graphic Display, Webserver or one of the Zeus

family of MFDs.

1 Verify that all interfaced units are powered on

2 Press the ENTER key to start the auto select procedure

System setup | H5000 Operation Manual

| 57

Page 58

The operator will be informed when the auto select process is completed.

¼ Note: If more than one source is available on the network you can choose your preferred

source from the sources menu. See Manual source selection below for more information.

Manual source selection

If more than one source is available for an item, the preferred source may be selected

manually. As an example, the following illustrations show how the compass source is

changed.

Select the preferred data source. The selected source will be indicated by a tick in the check

box.

Device list

Shows a list of all devices connected to the Network.

Diagnostics

Diagnostic data on the network.

58 |

System setup | H5000 Operation Manual

Page 59

H5000 CPU info

H5000 CPU software version and IP address.

¼ Note: IP address is required for Webserver login.

Groups

The group function is used to globally control parameter settings in groups of units. By

assigning several units to the same group, a parameter update on one unit will have the same

eff ect on the rest in that group.

¼ Note: All groups are shipped from the factory set to ‘Default’.

Units

Set the preferred unit of measurement you want data to be displayed in.

¼ Note: This can be performed via a Graphic Display, Webserver or one of the Zeus family of

MFDs.

System setup | H5000 Operation Manual

| 59

Page 60

Language

Set your preferred language for the display.

¼ Note: This is not a network function. You will need to change all displays separately.

¼ Note: Once the required language is selected the unit will automatically restart and continue

with step 2 of the startup wizard.

Time

From the time menu you can set the preferred time / date format and local time off set. Once

complete select Save to save the settings and return to the settings menu.

Simulate

Simulator mode sends simulated data to the display.

¼ Note: All other displays on the network will remain to display the current boat data and will

not change to simulate mode.

Warning: It is not advisable to enter simulator mode when using your

instrument system as a navigation aid.

60 |

System setup | H5000 Operation Manual

Page 61

Restore defaults

Restore Defaults has the option to wipe all settings or partial settings out of the Graphic

Display. Select the data from the list that you wish to delete.

¼ Note: This is not a network function. This will only reset and delete history on the display that

‘Restore defaults’ is selected on.

Global reset

The global reset will reset all settings in all displays along with performing a network reset

removing all source selection.

¼ Note: After performing a global reset the Graphic Display will ask to do an auto source

selection.

About

Shows the device information and software version currently installed on the display. Press

the ENTER key to navigate back to the menu

System setup | H5000 Operation Manual

| 61

Page 62

Autopilot setup

If an H5000 autopilot computer is connected to the network as per the instructions in the

H5000 installation manual then the installation process can be performed via the H5000 Pilot

Controller.

Source selection

A data source can be a sensor or a device connected to the network, providing information

and commands to other networked devices. The data sources are normally confi gured at fi rst

time turn on. It should only be necessary to update this data if a new source is added, source

is missing (sensor failure), source has been enabled/disabled, sensor replaced or a network

reset.

¼ Note: Source selection can also be performed by a Graphic Display, Webserver or one of the

Zeus family of MFDs.

Auto selection

The Auto select option will look for all sources connected to the network If more than one

source is available for each item, the display will automatically select from the internal device

priority list.

Manual source selection

If more than one source is available for an item, the preferred source may be selected

manually. As an example, the following illustrations show how the compass source is

changed.

Select the preferred data source. The selected source will be highlighted.

Rudder drive

Ensure that the rudder information is set correctly before you continue with the Dockside

commissioning.

62 |

System setup | H5000 Operation Manual

Page 63

Drive voltage (V)

Sets the drive voltage to the type installed on the vessel 12 or 24V

Drive engage

Drive engage has the following settings: Auto and Clutch.

Clutch:

This is the default setting and it allows you to steer the boat from the helm when in Standby

mode. A clutch will be engaged on the drive unit locking out the steering when Auto is

selected.

Auto:

This setting is implemented for future use. Always use the Clutch (default) setting.

Motor output

The Motor output (displayed as a percentage) is the amount of available power needed

to achieve correct rudder speed on automatic steering (Maximum speed is used in NFU

mode). This setting will allow you to adjust the rudder speed to be diff erent from the one

automatically set in the rudder test.

Rudder deadband

The rudder deadband function is adaptive and is continuously updating. It prevents the

rudder from hunting and the adaptive function optimizes the deadband to the speed of the

boat and the load on the rudder.

¼ Note: If the auto-setting does not perform properly due to high inertia from the wheel, it can

be adjusted manually.

Find the lowest possible value that will prevent the rudder from continuous hunting. A wide

deadband will cause inaccurate steering. It is recommended to check rudder stability in Auto

mode when the boat is moving to get pressure on the rudder.

Manual deadband

If rudder deadband is set to manual then you can make manual adjustments to the deadband

value

Rudder feedback

Set the rudder feedback type.

¼ Note: It is important that you select the relevant rudder feedback unit via source selection.

System setup | H5000 Operation Manual

| 63

Page 64

Commissioning

Dockside

Boat length

Set the length of the vessel. Press the 1º LEFT key to return to the dockside menu.

Drive voltage

Select the drive voltage 12 or 24 Volts. Press the 1º PORT key to return to the dockside menu.

Rudder calibration

Make sure the rudder feedback unit is installed and aligned as per it’s installation manual. The

rudder calibration will set the correct relationship between the physical rudder movement

and the rudder angle readout.

Follow the rudder calibration procedure:

Max starboard

• Manually move the helm to starboard until the rudder stops at starboard lock hard over. Press

1º RIGHT to confi rm

• The Enter max starboard angle is the angle read by the rudder feedback unit before any

adjustment is made.

• If the max angle is diff erent from the angle displayed, correct the reading with the UP/DOWN

keys.

• Confi rm Rudder feedback calibration to starboard by pressing 1º RIGHT

Max port

• Manually move the helm to port until the rudder stops at port lock hard over. Press 1º RIGHT

to confi rm

• Adjust the displayed angle the same way as for starboard rudder.

• Confi rm Rudder feedback calibration to port by pressing 1º RIGHT

64 |

¼ Note: Many boats have ±45° (90° H.O. - H.O.) rudder angle as standard. The default angle is set

to 35º Ensure to make adjustments accordingly.

System setup | H5000 Operation Manual

Page 65

Set rudder to 0 (zero)

• Bring the rudder to midship position and confi rm. This will adjust an incorrect reading caused

by misalignment of the rudder feedback unit.

Rudder Test

¼ Note: If the boat uses power assisted steering, it is important that the engine or electric

motor used to enable the power assist steering be turned on prior to this test.