Bertazzoni MAST365INMXE, PROF304INMXE, PROF304INMXT, PROF304INSART, PROF304INSBIT Installation Guide

...

BERTAZZONI

INSTALLATION MANUAL

FREESTANDING ELECTRIC RANGES

3100295

WWW.BERTAZZONI.COM

/ Table of contents

TABLE OF CONTENTS

WARNINGS ___________________________________________________________________

DATA RATING LABEL ___________________________________________________________

BEFORE INSTALLATION ________________________________________________________

VENTILATION PREPARATION ____________________________________________________

SPECIFICATIONS ______________________________________________________________

CLEARENCE DIMENSIONS ______________________________________________________

INSTALLATION REQUIREMENTS _________________________________________________

Electrical ___________________________________________________________________

ELECTRICAL CONNECTION ____________________________________________________

WIRING DIAGRAM _____________________________________________________________

INSTALLATION ________________________________________________________________

Unpackaging the range ________________________________________________________

Removing the oven door _______________________________________________________

Installing the legs _____________________________________________________________

Installing the worktop frontguard ________________________________________________

Installing the island trim _______________________________________________________

Installing backguard (optional) __________________________________________________

INSTALLING THE ANTI-TIP DEVICES ______________________________________________

Anti-tip brackets ______________________________________________________________

Anti-tilt chain ________________________________________________________________

INSTALLATION CHECKLIST ______________________________________________________

FINAL PREPARATION ___________________________________________________________

BERTAZZONI SERVICE _________________________________________________________

4

5

6

7

7

8

9

9

10

11

13

13

13

14

14

15

15

16

16

16

17

17

18

2

/ Models

Models

MAST365INMXE

MAST365INSXT

Models

PROF304INMXE

PROF304INMXT

PROF304INSART

PROF304INSBIT

PROF304INSGIT

PROF304INSNET

PROF304INSROT

PROF304INSXT

PROF365INSART

PROF365INSBIT

PROF365INSGIT

PROF365INSNET

PROF365INSROT

PROF365INSXT

3

/ Warnings

WARNINGS

To ensure proper and safe operation, the appliance must be properly installed and grounded by a

qualifi ed technician. DO NOT attempt to adjust,

repair, service, or replace any part of your appliance unless it is specifi cally recommended in this

manual. All other servicing should be referred to

a qualifi ed servicer.

FOR THE INSTALLER: Before installing the Bertazzoni appliance, please read these instructions

carefully. This appliance shall be installed in accordance with the manufacturer’s installation instructions. Leave these instructions with the owner, who should save them for local inspector’s

use and for future reference. DO NOT remove

permanently affi xed labels, warnings, or plates

from product. This may void the warranty.

Installation must conform with all local codes.

This range is NOT designed for installation in manufactured (mobile) homes or recreational park

trailers.

DO NOT install this range outdoors.

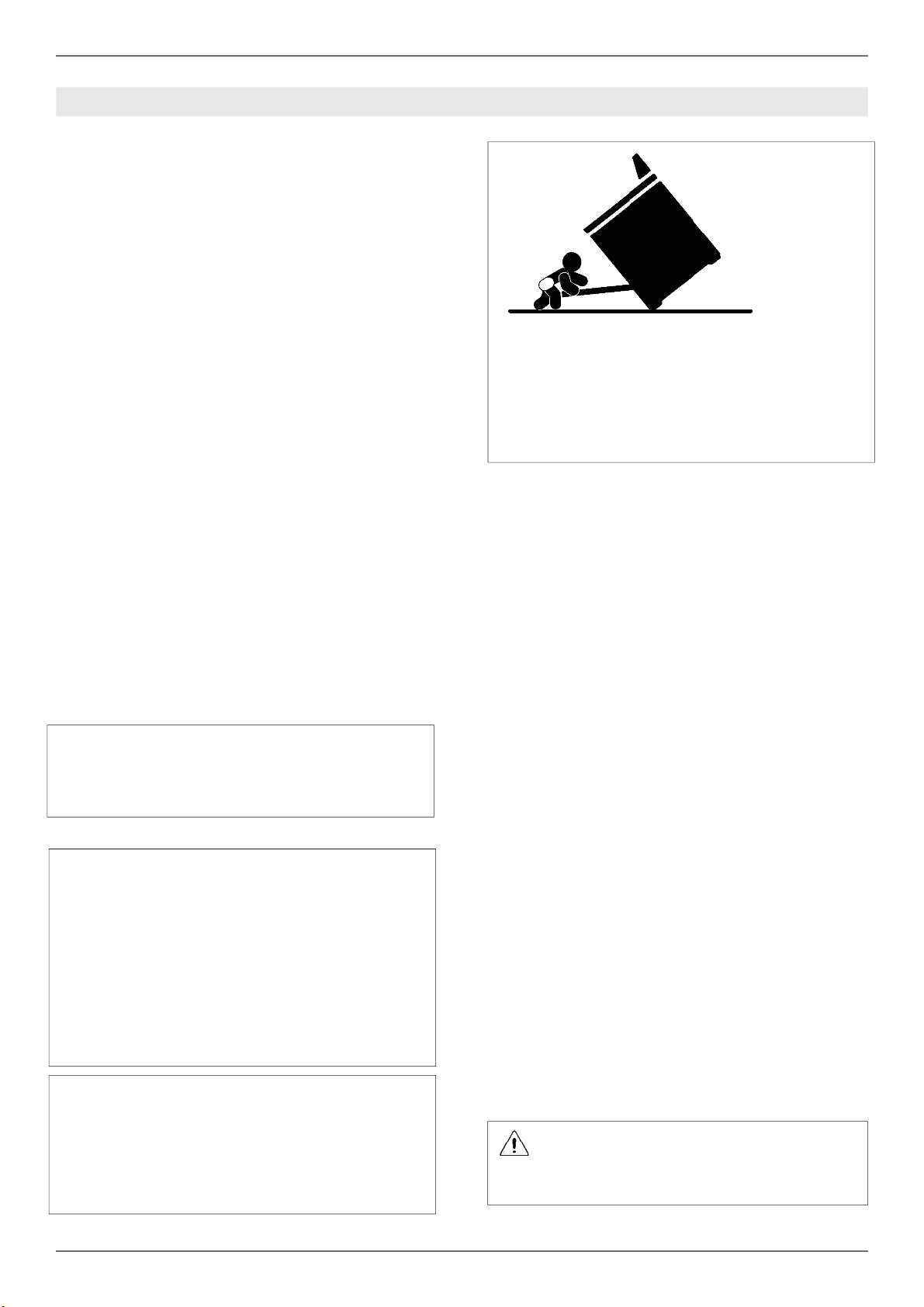

Warning - tipping hazard

Children and adults can tip over the range if it has

not been secured.This may lead to fatal injuries.

To reduce the risk of the appliance tipping, it must

be secured and connected using the anti-tip device according to the installation instructions.

Re-engage the anti-tip device if the range is

moved. Do not operate the range without te

anti-tipdevice in place and engaged. Do not

use the range if the anti-tip device has not been

properly installed and engaged. See installation

instructions for details.

This appliance must be properly grounded.

Grounding reduces the risk of electric shock by

providing a safe pathway for electric current in the

event of a short circuit.

Warning!

To avoid risk of property damage, personal

injury or death; follow information in this manual exactly to prevent a fi re or explosion.

Warning!

To avoid risk of property damage, personal injury

or death; follow information in this manual exactly to prevent a fi re or explosion. DO NOT store

or use gasoline or other fl ammable vapors and

liquids nearbythis or any appliance.

NOTE: Installation and service must be performed by a qualifi ed installer, service agency or the

gas supplier.

DANGER!!! ELECTRIC SHOCK HAZARD!!!

To avoid risk of electrical shock, personal injury

or death, verify that the appliance has been properly grounded in accordance with local codes or

in absence of codes, with the National Electrical

Code (NEC). ANSI/NFPA 70- latest edition.

Failure to observe the information contained in the installation instructions can

lead to serious or fatal injuries for children and adults.

DO NOT lift the range by the oven door’s handle,

as this may damage the door hinges and cause

the door to fi t incorrectly.

DO NOT lift the appliance by the range’s control

panel.

The unit is heavy and should be handled accordingly. Proper safety equipment such as gloves

and adequate manpower of at least two people

must be used in moving the range to avoid injury

and to avoid damage to the unit or the fl oor.

Rings, watches, and any other loose items that

may damage the unit or otherwise might become

entangled with the unit should be removed.

Hidden surfaces may have sharp edges. Use caution when reaching behind or under appliance.

DO NOT use a hand truck or appliance dolly on

the back or front of the unit. Handle from the side

only.

WARNING:

Cancer and Reproductiv Harm www.P65Warnings.ca.gov

.

4

DATA RATING LABEL

The data rating label shows the model and serial

number of the range. It is located under the control panel and in the last page of this manual

/Data rating label

5

/ Before installation

BEFORE INSTALLATION

• This appliance shall only be installed by an au-

thorized professional.

• This appliance shall be installed in accordance

with the manufacturer’s installation instructions.

• This appliance must be installed in accordance

with the norms & standards of the country where it will be installed.

• The appliance, when installed, must be electri-

cally grounded in accordance with local codes

or, in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

All opening and holes in the wall and fl oor, back

and under the appliance shall be sealed before

installation of the appliance.

Room ventilation

An exhaust fan may be used with the appliance;

in each case it shall be installed in conformity

with the appropriate national and local standards.

Exhaust hood operation may aff ect other vented

appliances; in each case it shall be installed in

conformity with the appropriate national and local

standards.

Warning

This appliance should not be installed with a

ventilation system that directs air in a downward

direction toward the range. This type of ventilation system may cause ignition and combustion

problems with the appliance resulting in personal

injury, property damage, or unintended operation.

Ventilating systems that direct the air upwards do

not have any restriction.

Do not use aerosol sprays in the vicinity of

this appliance while it is in operation.

6

VENTILATION PREPARATION

/ Ventilation preparation / Specifi cations

This range will best perform when installed with

Bertazzoni exhaust hoods. These hoods have

been designed to work in conjunction with the

Bertazzoni range and have the same fi nish for a

perfect look.

Before installation of the exhaust hood, consult local or regional building and installation codes for

additional specifi c clearance requirements.

Refer to the range hood installation instructions

provided by the manufacturer for additional information.

Select Hood and Blower Models:

• For wall installations, the hood should be equal

or larger width than the range. Where space

permits, a hood larger than the range may be

desirable for improved ventilation performance.

• For island installations, the hood width should

overhang the range by a minimum of 3” (76

mm) on each side.

Hood Placement:

• For best removal of smoke and odors, the

lower edge of the hood should be installed

between 25 1/2” (65 cm) and 31 1/2” (80 cm)

above the range cooking surface.

• If the hood contains any combustible materials

(i.e. a wood covering), it must be installed at a

minimum of 36” (914 mm) above the cooking

surface.

Consider Make-Up Air:

Due to the high volume of ventilation air, a source of outside replacement air is recommended.

This is particularly important for tightly sealed

and insulated homes. A qualifi ed heating and

ventilating contractor should be consulted.

SPECIFICATIONS

A

/8

27''

A

MAX

1/2

37''

30’’ 36’’ 48’’

5/8

1''

5''

/

''

2''

A

/16

25''

15/16

1''

32''

7/8

23''

1/2

- 5''

3/4

5/8

1''

1/8

1''

3''

7/16

3''

3 ''

7/16

2''

11/16

7

/ Clearence dimensions

CLEARENCE DIMENSIONS

Installation adjacent to kitchen cabinets

This range may be installed directly adjacent to

existing countertop high cabinets (36” or 91.5 cm

from the fl oor).

For the best look, the worktop should be level with

the cabinet countertop. This can be accomplished

by raising the unit using the adjustment spindles

on the legs.

ATTENTION: the range CANNOT be installed directly adjacent to kitchen walls, tall cabinets, tall

appliances, or other vertical surfaces above 36”

(91.4 cm) high. The minimum side clearance in

such cases is 6” (15.2 cm).

Wall cabinets with minimum side clearance must

be installed 18” (45.7 cm) above the countertop

with countertop height between 35 ½” (90.2 cm)

and 37 ¼” (94.6 cm). The maximum depth of wall

cabinets above the range shall be 13” (33.0 cm).

Cabinet

30’’ (76,2 cm)

A

36’’ (91,5 cm) hood with combustible materials

B

13’’ (33,0 cm)

C

18’’ (45,7 cm)

D

35’’ 1/2(90,2 cm) / 37”

E

F

6’ (15,2 cm)

1/4

(94,6 cm)

Metal hood

A

30’’ (76,2 cm)

B

25 1/2’’(65 cm) and 31 1/2’’ (80 cm)

C

13’’ (33,0 cm)

D

18’’ (45,7 cm)

E

35’’ 1/2(90,2 cm) / 37”

F

6’ (15,2 cm)

G

12”(30,50 cm)

H

1” 9/16(4 cm)

1/4

(94,6 cm)

B

G

H

D

F

B

A

C

E

/

If installing toekick, verify that the sum of the cutout areas equal the recommended ventilation (L)

30” area 40 sq. inches ( 25840 mm2)

36” area 51 ½ sq. inches ( 33107 mm2)

48” area 73 ½ sq.inches ( 47547 mm2)

8

Shaded area behind range indicates minimum

clearance to combustible surfaces, combustible

materials cannot be located within this area.

12” (305 mm) min. to combustible surface with

Flush Island Trim

For Flush Island installations, counter surface

should have a cantilever edge meeting the back

section of the Flush Island Trim accessory.

/ Installation requirements / Electrical connection

INSTALLATION REQUIREMENTS ELECTRICAL CONNECTION

ELECTRICAL

A properly-grounded horizontally- mounted electrical receptacle should be installed no higher than

3” (7.6 cm) above the fl oor, no less than 2” (5 cm)

and no more than 8” (20,3 cm) from the left side

(facing product).

Check all local code requirements.

.

Warning!

ELECTRICAL SHOCK HAZARD

Disconnect electrical power at the circuit breaker box or fuse box before installing the appliance.

Provide appropriate ground for the appliance.

Use copper conductors only.

Failure to follow these instructions could result in serious injury or death.

Electrical grounding

This appliance is equipped with a three-prong

plug for your protection against shock hazard and

should be plugged directly into a properly grounded socket. Do not cut or remove the grounding

prong from this plug.

Caution

Label all wires prior to disconnecting when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Verify proper operation after servicing.

installation area for the connection

The appliance shall be connected to a single phase electric line rated at 120/208Vac or 120/240Vac

and 60Hz frequency.

Type Voltage Circuit rating Electrical

supply

30” INDDFM

30” INDDFS

36” INDDFM

36” INDDFS

Install a suitable electric power supply receptacle

connection type NEMA 14-50R able to support a

load of at least 30 A (per line) according to local

code requirements. For four or three wires power

supply connection system see diagram below.

120/208V

120/240V

120/208V

120/240V

120/208V

120/240V

120/208V

120/240V

10300W 46A

11000W 48A

11700W 53A

13000W 56A

14000W 62A

14800W 64A

15600W 70,5A

17000W 73,5A

40A

40A

40A

40A

40A

40A

50A

50A

9

/ Electrical connection

FOUR-WIRE CONN.RECEPTACLE NEMA 14-50R

THREE-WIRE CONN.RECEPTACLE NEMA 14-50R

The appliance is equipped at the factory with

an electric supply cord set 4 wires type with ring

terminals (L1, L2, N, Ground) suitable for range

use UL/CSA listed type SRDT/DRT 2x6AWG (L1,

L2)+2x8AWG (N, G) rated 300V, 40 or 50A with

fused plug type NEMA 14-50P; cable length 1,5

m.; in case the supply cord set must be replaced,

it shall be replaced with an identical set having the

same technical specs and following carefully the

instructions and diagrams below:

Check your local code for which of the options below should be used in grounding the receptacle

power supply connections.

OPTION 1 – FOUR Wires connection:

-Connect the L1 receptacle terminal to the incoming BLACK electrical supply wire (L1-hot wire)

-Connect the L2 receptacle terminal to the incoming RED electrical supply wire (L2-hot wire)

-Connect the NEUTRAL receptacle terminal to

the incoming NEUTRAL (WHITE) electrical supply wire

-Connect the GROUND receptacle terminal to the

incoming GROUND (GREEN) electrical supply

wire

OPTION 2 - THREE-Wires connection:

-Connect the L1 receptacle terminal to the incoming BLACK electrical supply wire (L1-hot wire)

-Connect the L2 receptacle terminal to the incoming RED electrical supply wire (L2-hot wire)

-Connect the NEUTRAL with the GROUND receptacle terminal to the incoming NEUTRAL (WHITE)

electrical supply wire

DO NOT USE EXTENSION CORDS WITH

THIS APPLIANCE AS IT MAY RESULT IN FIRE,

ELECTRIC SHOCK OR OTHER type of PERSONAL INJURY.

10

/ Wiring diagram

WIRING DIAGRAM

The electric wiring diagrams and schematics are attached behind the range, and should not be removed

except by a service technician, then replaced after service.

DFM

INDUCTION COOKTOP

1

2

R1 R2 R3 R4 R5

12345

3

5

4

Simb. De scription

mBrown

gv Green

bBlue

nBlack

aOrange

gr Grey

v Violet

rRed

COLOURS

bi White

v

b

RP

[to A-L2]

[to ground]

[to A-L1]

b

a

MV MV

RCRC

MVT

GROUND

M

bi

a

G

IGN

bi

r

a

bi

RG+RC

LF

L1 N L2

LF

n

n

bi

b

r

b

S

P2

P1

P6

P7

P8

P3

P5

P4

Commutatore.9+0

P1

P2

COM

1

6

7

8

1

2

5

gr

a

2

3

4

104

3P125678

9

P2

P3

P4

P5

P6

P7

P8

P1

P2

a

RC+RG Upper/grill elem ent

TSS Safety Thermos tat

S Signal lights

T Thermostat

MVT Cooling fan motor

MV Fan motor

RC Round elem ent

RP Lower element

MTerminal Block

LF Oven lamp

Simb. Description

COM Oven Functi on Selector

CMV Cooling fan air sensor switch

IGN Ignition Micro swit ches

LEGENDA

b

CMV

v

v

T

1

2

TSS

11

/ Wiring diagram

DFS

nBlack

aOrange

gr Grey

bi Whit e

bBlue

vViolet

gv Green

rRed

COLOURS

down

CMV

TS

to MV

to MV

Simb. Description

mBrown

MVMV

LF

up

PT

up

CMV

to CN23 - 3

to CN23 - 2

to CN23 - 1

to CN23 - 3

to CN23 - 2

to CN23 - 1

to CN1 - 1

to CN1 - 2

to CN1 - 3

to CN1 - 4

to CN1 - 5

to CN1 - 6

EG

FS

A

MT

MVT

B

b

n

bi

a

a

RCRC

to MV

CN30

1.3

CN23

1.3

CN24

CN21

1..4

CN2

CN1- 1....6

v

r

b

v

RP

b

gr

CN22 -3.1

CN27 - 6.....1

bi

CN28 - 6.....1

to DL

to M-N

to M-L1

gr

n

n

n

to M-L1

to M-L1

to M-L1

to M-L1

to DL

to M-GROUND

to MV

RG+RC

a

to DL

to DL

LF

MVT

down

GROUND

M

L1 N L2

bi

to RP

to M-L1

to M-N

to GROUND

DL

n

K

to CN26 - 3

to CN27 - 6

to CN26 - 2

to CN27 - 5

n

to M-L1

[to M-L2]

[to ground]

[to M-L1]

R1 R2 R3 R4 R5

1

12345

3

INDUCTION COOKTOP

2

bi

1

bi

n

NOT USED

2

r

r

5

4

TSS

bi

n

n

RC+RG Upper/grill element

MVT Cooling fan motor

MV Fan motor

RC Round eleme nt

PT Oven sensor Temp. (PT1000)

MT M eat Probe

MTerminal Block

LF Oven lamp

IGN Ignition Micro switches

TS Oven Temperature Selec ton

K Termal cut out

EG Electronic Gauge

DL Door Loc k - Door Switc h

FS Oven Functio n Selec tor

G S park Generator

Simb. Description

CMV Cooling fan ai r sens or switc h

B Therm al cut-out

LEGENDA

r

B

12

INSTALLATION

/ Installation

APPLIANCE INSTALLATION

Unpacking the range

• Remove all packing materials from the ship-

ping pallet but leave the adhesive-backed foam

layer over brushed-metal surfaces to protect it

from scratches until the range is installed in its

fi nalposition. Only the fi lm on the side panels

should be removed before inserting the range

between the cabinets.

• Examine the appliance after unpacking it. In the

event of transport damage, do not plug it. Take

pictures of the damage and report it immediately to the freight forwarder.

• Remove the oven door(s). This will reduce the

weight of the range.

• The grates, griddle plate, burner caps, and oven

racks should be removed to facilitate handling.

• Before moving the range, protect the fl oor to

prevent damage.

REMOVING THE OVEN DOOR

Prepare the door for removal. Flip up the locking

clamps on each door hinge. Slowly shut the door

until the protruding clamps stop the movement.

Pull oven door upwards and remove.

Do not lift or carry the oven door by its handle!

This may damage the hinges.

1

2

3

13

/ Installation

INSTALLING THE LEGS

Bertazzoni ranges must be used only with the legs

properly installed.

Four height-adjustable legs are supplied with the

range in the polysterene container situated over

the appliance.

Before installing the legs, position the appliance

near its fi nal location as the legs are not suitable

for moving the appliance over long distances.

After unpacking the range, raise it enough to insert the legs in the appropriate receptacles situated on the lower part of the appliance. Lower the

range gently to keep any undue strain from legs

and mounting hardware. If possible use a pallet or

lift jack instead of tilting the unit.

Adjust leg height to the desired level by twisting

the inside portion of the leg assembly until the proper height is reached. Check with a level that the

cooktop is perfectly level.

INSTALLING THE WORKTOP

FRONTGUARD

To increase the clearance between the front edge

of the worktop and the burners, it is possible to

install a front guard for the worktop.

To install the front guard,

• Locate the two fi xing holes on the end of the

front guard.

• Locate the two fi xing holes on the bottom facet

of the worktop

• Fix the front guard with it’s two screws

1

2

3

14

4

/ Installation

INSTALLING THE ISLAND TRIM

The island trim must be installed prior to operation

of the appliance for appropriate ventilation of the

oven compartment.

The island trim is only placed on the cooktop, remove all tape and packaging before installing it.

INSTALLING BACKGUARD (OPTIONAL)

The backguard must be installed prior to operation of the appliance for appropriate ventilation of

the oven compartment.

The backguard is an optional contact you dealer

for buying it.

1 1

2 2

3

3

4 4

15

/ Installing the anti/tip devices

INSTALLING THE ANTI/TIP DEVICES

ANTI-TIP BRACKETS

The anti-tip bracket shipped with the range must

be properly secured to the rear wall as shown in

the picture below.

The height of the bracket from the fl oor must be

determined after the range legs have been adjusted to the desired height and after the range has

been levelled.

• Measure the distance from the fl oor to the

bottom of the anti-tip bracket receptacle on the

back of the appliance.

• Position the anti-tip brackets on the wall at

the desired height plus 1/8” (0.32 cm). The

brackets must be placed at 2”5/16 (6,0 cm)

from the side of the range.

• Secure the brackets to the wall with appropria-

te hardware.

• Slide the range against the wall until the

brackets are fully inserted into their receptacles on the back of the range.

ANTI/TILT CHAIN

The anti-tilt chain shall be installed on right or left

side alternatively according below instructions.

The chain shall be hand pulled and fi xed to open

hook through closed ring.

Disengage the chain prior to moving the appliance

for service.

Attention:

Once servicing operation have been completed

the anti-tilt devices ( brackets and chain) shall be

re-engaged according above instruction/installations.

1

2

16

CLOSED RING OPEN HOCK

/ Installation checklist / fi nal preparation

INSTALLATION CHECKLIST FINAL PREPARATION

A qualifi ed installer should carry out the following

checks:

Range mounted on its legs

Island trim or Backguard attached according to instruction

Anti-tip device properly installed

Clearance to cabinet surfaces as manufacturer’s guideline

• Before using the oven, remove any protective

wrap from the stainless steel.

• All stainless steel body parts should be wiped

with hot, soapy water and with a liquid stainless

steel cleanser.

• If buildup occurs, do not use steel wool, abrasi-

ve cloths, cleaners, or powders!

• If it is necessary to scrape stainless steel to re-

move encrusted materials, soak with hot, wet

cloths to loosen the material, then use a wood

or nylon scraper.

• Do not use a metal knife, spatula, or any other

metal tool to scrape stainless steel! Scratches

are almost impossible to remove.

• Before using the oven for food preparation,

wash the cavity thoroughly with a warm soap

and water solution to remove fi lm residues and

any dust or debris from installation, then rinse

and wiped dry.

Attention!

When using the oven for the fi rst time it

should be operated for 15-30 minutes at a temperature of about 500°F/260°C (main oven) or

440°F/227°C(auxiliary oven) without cooking

anything inside in order to eliminate any moisture and odours from the internal insulation.

17

/ Bertazzoni service

BERTAZZONI SERVICE

Bertazzoni is committed to providing the best customer and product service. We have a dedicated

team of trained professionals to answer your needs.

If you own a Bertazzoni appliance and need service in the US or Canada please use the following

contact information:

e-mail: aftersaleservice@bertazzoni.com

Telephone - Monday through Friday,

7.30am to 7.30pm EST (except US public holidays).

US 866-905-0010

WESTERN CANADA 866-905-0010 (BC,AB,SK,MB)

EASTERN CANADA 800-561-7265 (ON,QC,NL,NB,NS,PE)

18

Loading...

Loading...