Page 1

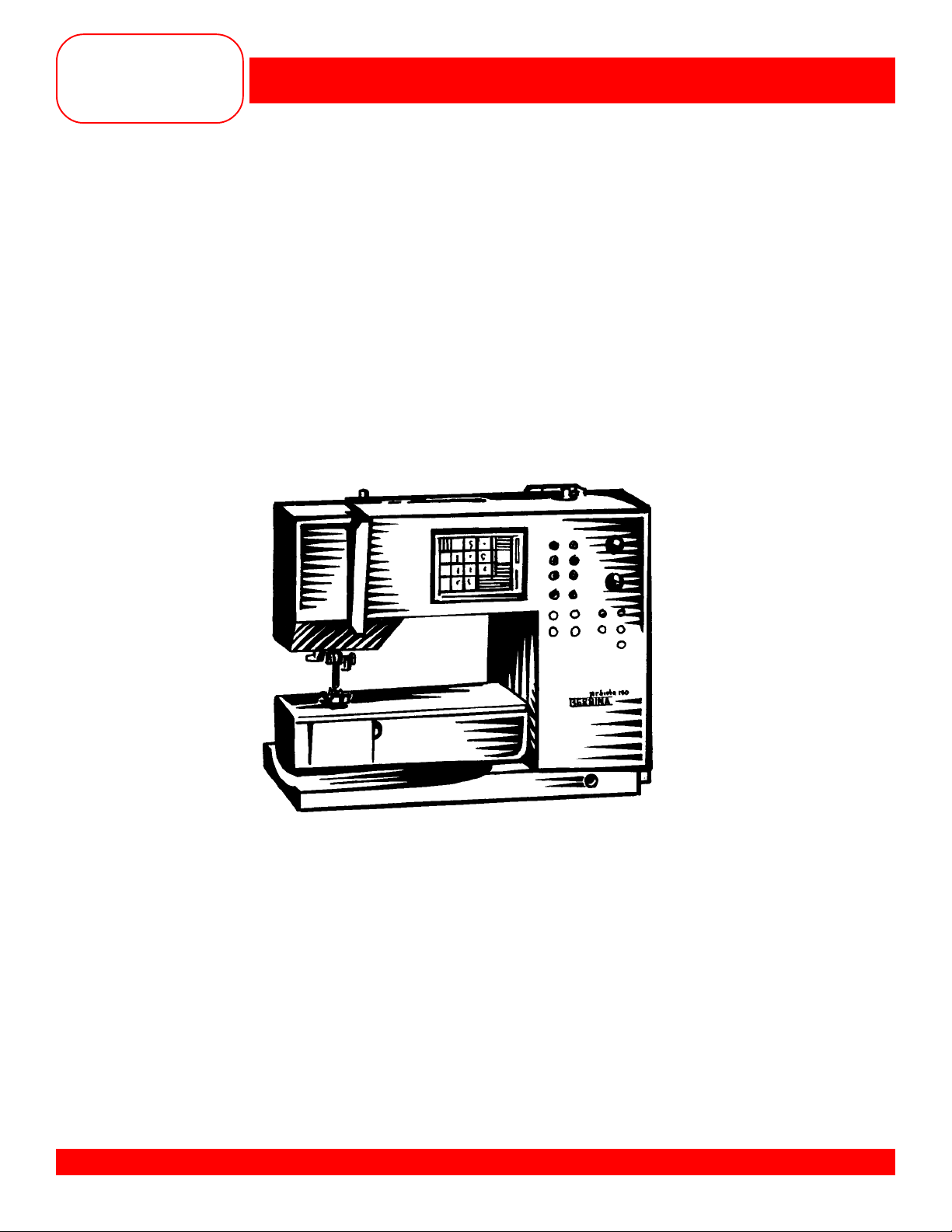

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

MASTERING YOUR

BERNINA

artista 170 QPE/180

®

OWNER’S WORKBOOK

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/1

Page 2

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

Table of Contents

SECTION A Pages 3-16

Care and Feeding of Your Machine

SECTION B Pages 17-36

Let’s Start WIth The Basics

SECTION C Pages 37-59

On The Edge

SECTION D Pages 60-74

Gather It Up and Tuck It Down

SECTION E Pages 75-91

Miscellaneous Magic

SECTION F Pages 92-99

Creative Sewing

SECTION G Pages 100-111

Programming Pizzazz

SECTION H Pages 112-121

Fabulous Features

SECTION G Pages 122-131

Decorative Directions (180 only)

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/2

Page 3

MASTERING

YOUR

BERNINA

MASTERING YOUR

®

BERNINA® artista 170 QPE/180

®

BERNINA

artista 170 QPE/180

OWNER’S WORKBOOK

Section A

Care and Feeding of Your Machine

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/3

Page 4

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

Care and Feeding of Your Machine

Machine Set Up

Owner’s manual pg.____

• Cover/Storage of foot control, FHS bar, etc.

• Accessory storage – how box slides on & opens

• Attach foot control; note storage of cords

• Power switch – Owner’s manual pg____

• Light - on/off function (in setup) – Owner’s

manual pg____

• Extension table + sliding guide

• Presser foot lifter

- acts as a “third hand”

- extra 2mm of presser foot lift

- drops feed dog to give extra space between

presser foot and feed dog

- speeds sewing by 20%

- alternate size available for use with a sewing

machine cabinet

Presser Feet

Owner’s manual pgs.____

• Importance of using the correct foot

• On-screen indicator

• Overview of included presser feet

Feed Dog

Owner’s manual pg. ____

Threads

Owner’s manual pg. ____

• Types of thread

• Uses for each type of thread

Needles

Owner’s manual pg.____

Bobbins

Owner’s manual pg.____

• Removing the bobbin case

• Winding a bobbin

• Use bobbin thread cutter

• Quick start bobbin – use thread cutter located in

the bobbin area

• Clip the thread close to the case before

removing the bobbin

SECTION A

Threading the Upper Thread

Owner’s manual pg.____

• Spool pins and discs – Owner’s manual pg.____

- vertical spool pin for stacked and decorative

threads

- horizontal spool pin for crosswound threads

- use disc closest to diameter of the spool

• Optional supplementary thread guide

• Optional BERNINA

• Thread machine with the presser foot up until

ready to thread the needle

Threading the Needle

• Needle threader – Owner’s manual pg.____

• Side thread cutter – Owner’s manual pg.____

• After the needle is threaded, put the thread

under the presser foot

• Lower the presser foot

• Insert the thread into the cutter; it is cut to the

proper length to begin sewing

Needle Stop Adjustment

• With the foot control – Owner’s manual pg.___

• With the Needle Stop Up/Down function –

Owner’s manual pg.___

Needle Positions

Owner’s manual pg. ____

• Eleven positions

Practical/Decorative Stitches

Owner’s manual pgs.____

• Stitches programmed in the machine

• Stitches available from CPS software

• Uses for the stitches – Owner’s manual pgs.____

• How to select stitches – Owner’s manual pgs.____

- touch screen

- scroll arrows

- selection by stitch number

- external buttons for stitch groups

®

thread stand

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/4

Page 5

MASTERING

YOUR

BERNINA

Straight Stitching

• Seam measuring – stitch plate marks – Owner’s

manual pg.____

- the following measurements are indicated on

the stitch plate: ¼”, 3/8”, ½”, 5/8”, ¾”, and 1”

- the line just behind the needle is 4mm

- the horizontal lines to the far back and the

line in front of the needle are

• Quilting/seam guide is included with the machine

• Left seam guide and seam guides with rulers are

available as optional accessories

• Straight stitch throat plate available

• 5.5mm throat plate available for 180

Basting

Owner’s manual pgs.____

• Loosening the top tension helps in the removal

of stitches.

• Using the maximum stitch length gives a 1”

stitch.

Topstitching/Edgestitching

Owner’s manual pgs.____

• Machine sews every second stitch when the

Long Stitch function is activated; stitch length is

10mm when using the maximum stitch length.

Securing Stitches

Owner’s manual pgs.____

• Options

• Stitch

• Functions

Satin Stitches

• Tension adjustments

- Function icon - must be placed on the

function bars (artista 180 only)

- TTC button (artista 180 only)

- Creative Consultant (artista 180 only)

- Setup function (artista 180 only)

- Thread bobbin case finger to adjust tension

(artista 170 QPE only)

• Can taper while sewing

• Stabilizer – important to the success of stitches

Altering Stitches

Owner’s manual pg.____

®

BERNINA® artista 170 QPE/180

5

/8” from needle

Restoring Basic Settings

Owner’s manual pg.____

Presser Foot Pressure

Owner’s manual pg.____

Speed Controls

• Three ways to control – Owner’s manual pg.___

- function box in Setup

- function box on the screen

- ½ stitch at a time by tapping the back of the

foot control

Changing the Light Bulb

Owner’s manual pg.____

• Use only 12V 5W. W 2.1 x 9.5d bulbs

Cleaning the Feed Dog

• Periodically remove thread fluff and fabric fuzz

which collects under the stitch plate. Refer to

manual for step-by-step instructions (pg.___).

Cleaning and Lubricating the Hook

• Low mass hook system does not require

lubrication

• See Owner’s manual page ____ for step-by-step

cleaning instructions

Cleaning the Screen

• Wipe only with a damp cloth

Cleaning the Outside of the Machine

• Wipe with damp cloth. If needed, use a solution

of water and a few drops of liquid soap.

IMPORTANT: Never use oil, alcohol, or

solvents of any kind on any part of the

external surface of the machine.

Here’s an idea...

Use your birthday month as a

reminder to have your BERNINA

machine serviced. Take it to an

authorized BERNINA® technician

during the month of your birthday

and you’ll never have to remember

when it was last serviced.

®

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/5

Page 6

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

THREADS

Poor quality or the wrong type of thread can cause poor stitches on any machine. Thread passes through

the eye of the needle approximately 37 times in a “see-saw” action before it forms a single stitch. Poor

quality thread results in crooked and looped stitches, puckered seams, frayed thread, and/or needle

breakage. To achieve quality stitches, a sewing machine needs three things: correct thread, correct size

needle, and properly adjusted thread tensions.

Several factors such as the fiber, twist, ply, finish, and size of thread must be considered for use with today’s

fabrics for fine stitches.

Staple – refers to the length of fibers used to twist together to form a single ply. Domestic thread

fiber lengths are usually 1½” to 2½” long while European threads use 5½” to 6½” lengths.

Ply – the number of single strands twisted together to make a single thread.

Roll – the tendency of thread to roll to the right or left during stitching, causing the stitch to

appearslightly crooked. Poor quality threads are more likely to roll.

Twist – the crimping of fibers which causes them to interlock firmly into a single ply. Thread should

not untwist during stitching. This will cause skipped stitches, thread breakage, crooked stitches, and

weak spots in seams.

Right twist – most American threads are twisted to the right, causing some rolling.

This gives average stitch quality.

Left twist – Most commercial and imported threads are twisted to the left, giving better

than average stitch quality. Left twist resists rolling and makes a larger loop for the hook

point to enter, reducing skipped stitches.

Wearable art embellishment has necessitated the creation and marketing of many new thread types, such

as Sulky’s rayons and metallics. Made in West Germany, these are left twist threads; Mettler and Isacord

threads are also left twist. To test the twist of a thread: while holding the spool in the left hand, roll the strand

of thread towards you with one thumb. Left twist will tighten, right twist will loosen.

Fiber – refers to the typ eof material used to produce the thread. Some commonly used threads:

• Polyester 2 ply – such as Metrosene 100. Good for clothing construction on man-made,

natural or blended fabrics. Will tolerate heat up to 450° Fahrenheit. Also Isacord

embroidery thread – excellent for embroidery, very abrasion resistant.

• Polyester 3 ply cordonnet – topstitching or buttonhole twist – such as Mettler 30/3.

• Cotton 2 ply – such as Mettler 60/2 – excellent for French Machine Sewing, delicate

machine embroidery, and darning.

• Cotton 2 ply – such as Mettler 30/2 – loose twist for a soft, shiny look in machine

embroidery, applique, and buttonholes.

• Cotton 3 ply – such as Mettler 50/3 – excellent for clothing construction on natural fibers.

Tighter twist than embroidery cotton thread and less puckering on problem fabrics. Cotton

thread stretches less than polyester.

• Rayon – a lustrous embroidery thread. Weaker than cotton, it is used for decorative work only.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/6

Page 7

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

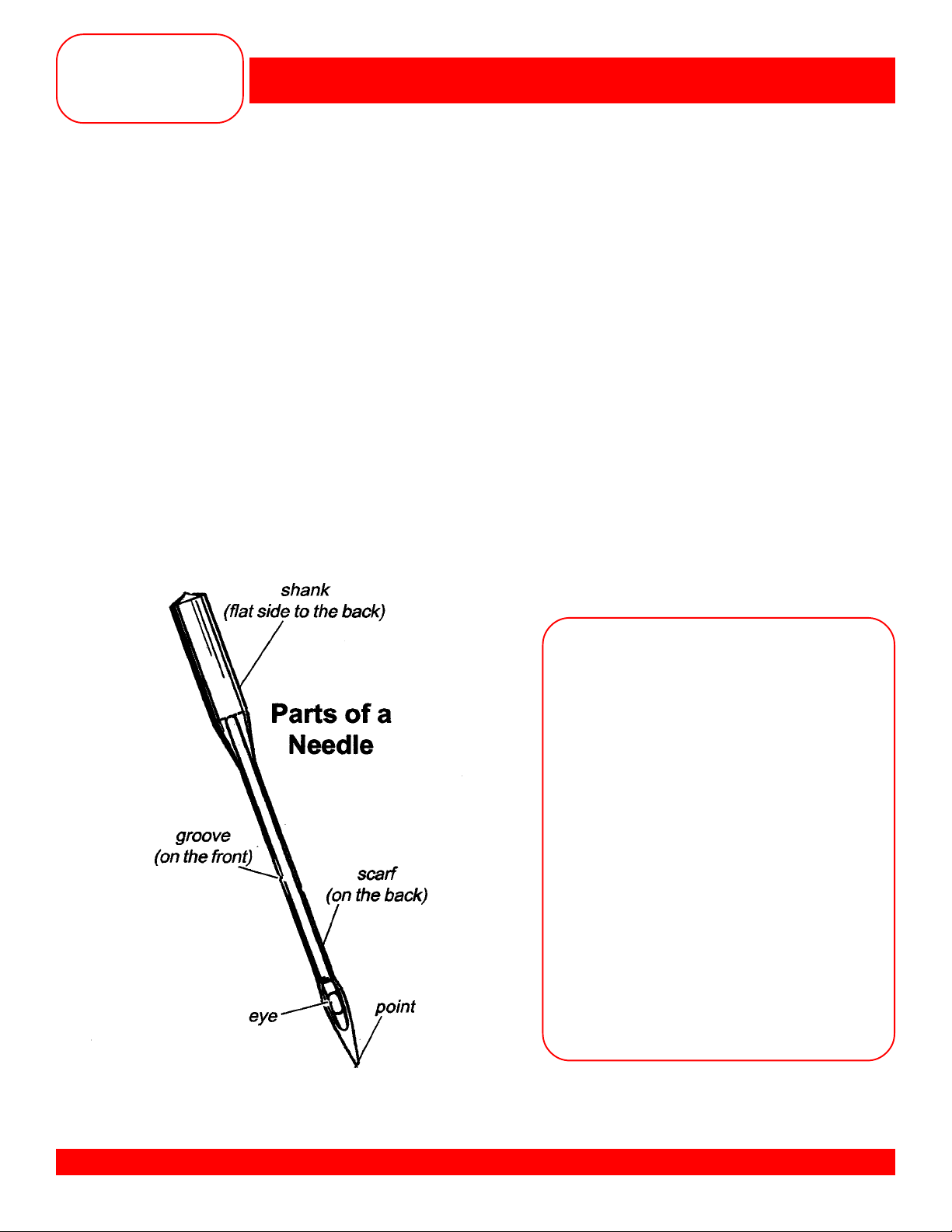

NEEDLES

Along with thread, needles are very important to stitch formation. Many “mechanical” problems and damage

to fabrics can be traced to a bent, damages, or incorrect size or type needle. Approximately 60% of all

needles made are discarded at some stage of production. When selecting the correct needle for any sewing

project, three things must be considered:

Needle system – 130/705H

Needle point – to assure stitch formation and avoid fabric damage

Needle size – small size for lightweight fabrics; larger needle for heavier fabrics

If the needle is:

Too small – the thread can’t stay in the groove to form a loop to be picked up by the hook point

Bent – thread loop forms too far away from hook point; hook can’t enter loop to form stitch

Blunt – needle won’t pierce fabric so no thread loop forms to make a stitch

Need To Know

• Needle should be changed every 4-6

hours of sewing. The needle is the most

inexpensive part in your sewing machine

but is one of the most crucial for getting

good results and keeping your machine

running well. Don’t let false economy

keep you from doing what is best for

your sewing projects and your machine.

• European needles are chrome-plated

to glide in and out of fabric easily.

• The selected thread should fit in the

groove on the front of the needle. If it

isn’t protected by the groove, a needle

with a larger groove should be used.

• Always make sure the needle is fully

inserted as high as possible when

installing a new one.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/7

Page 8

MASTERING

YOUR

BERNINA

Ball Point

Stretch

Stretch

Double

Universal

Double

Universal

Triple

(Drilling)

Jeans

Jeans

Double

70-90

70-90

2.5/75

4.0/75

60-110

1.6/70-

8.0/100

3.0/90

70-90

4.0/100

®

BERNINA® artista 170 QPE/180

SEWING MACHINE NEEDLES

Has a rounder point. 70 for

lingerie, nylon, jersey; 80 for

T-shirt; 90 for sweatshirt fleece.

A stretch needle has a more

rounded point and a blue anticling coating which helps to

prevent skipped stitches in knits

and elastic. Sometimes used on

Ultrasuede

Two ballpoint needles on one

shank; each needle has a large

scarf. Used for hemming and for

stitching on knit fabric.

A compromise between a sharp

and a ballpoint needle; can be

used on both wovens and knits.

60 – very fine batiste

70 – broadcloth

80 – trigger and gabardine

90 – denim and twill

100 & 1 10 – canvas

Two needles attached to one

shank. Used for pintucks, hems,

and decorative work. Note: The

170 QPE can use up to a 4.0mm

and a 180 can use up to an

8.0mm.

Three needles attached to one

shank. Used to create mock

smocking and other decorative

effects.

Has a sharp point and a shaft

that is less prone to flex. The

sharpness of the needles makes

it better for use on denim and

woven fabrics where a clean

stitch is desired.

Two Jeans needles attached to

one shank. For topstitching on

denim with heavy thread; can

also be used for decorative

®

, vinyl, and plastic.

Microtex

Sharp

(Schmetz)

Microfiber

(Lammertz)

Quilting

Topstitch

Embroidery

(Schmetz)

Metafil

(Lammertz)

Metafil

Double

Wing

Double

Wing

Leather

60-90

assort’d

(75 &

90)

80-100

75-90

3.0/75

100120

100

80-90

stitching with metallic thread.

A sharp point with a thin shaft.

60-90 corresponds to the weight

of the fabric; as the fabric gets

heavier, the number is higher.

The thin, tapers point of this

needle causes less damage to

fabric when seaming and cross

seaming.

A sharp point with a large eye

and deep groove. For use with

heavier fabrics – the large

groove cradles heavier threads.

Sharp needle with a large eye

and groove; also has a coating

and a larger scarf. For use with

embroidery thread – prevents

shredding of rayon or metallic

threads. Two threads may be

used through the eye of an 80

or 90 needle.

Two Metafil needles attached to

one shaft; for double needle

work with embroidery threads.

Sharp pointed needle with a noncutting wedge of metal on each

side. Needle makes a hole in the

fabric without cutting the threads

of the fabric. Used for decorative

and heirloom work, such as

hemstitching. Works best on

natural fibers or on the bias.

One regular needle and one wing

needle attached to a single shaft.

Use the same as a Wing; makes

one large and one regular hole.

Point is a sharp cutting wedge.

Used for sewing leather only. Not

for vinyl or simulated leathers.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/8

Page 9

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

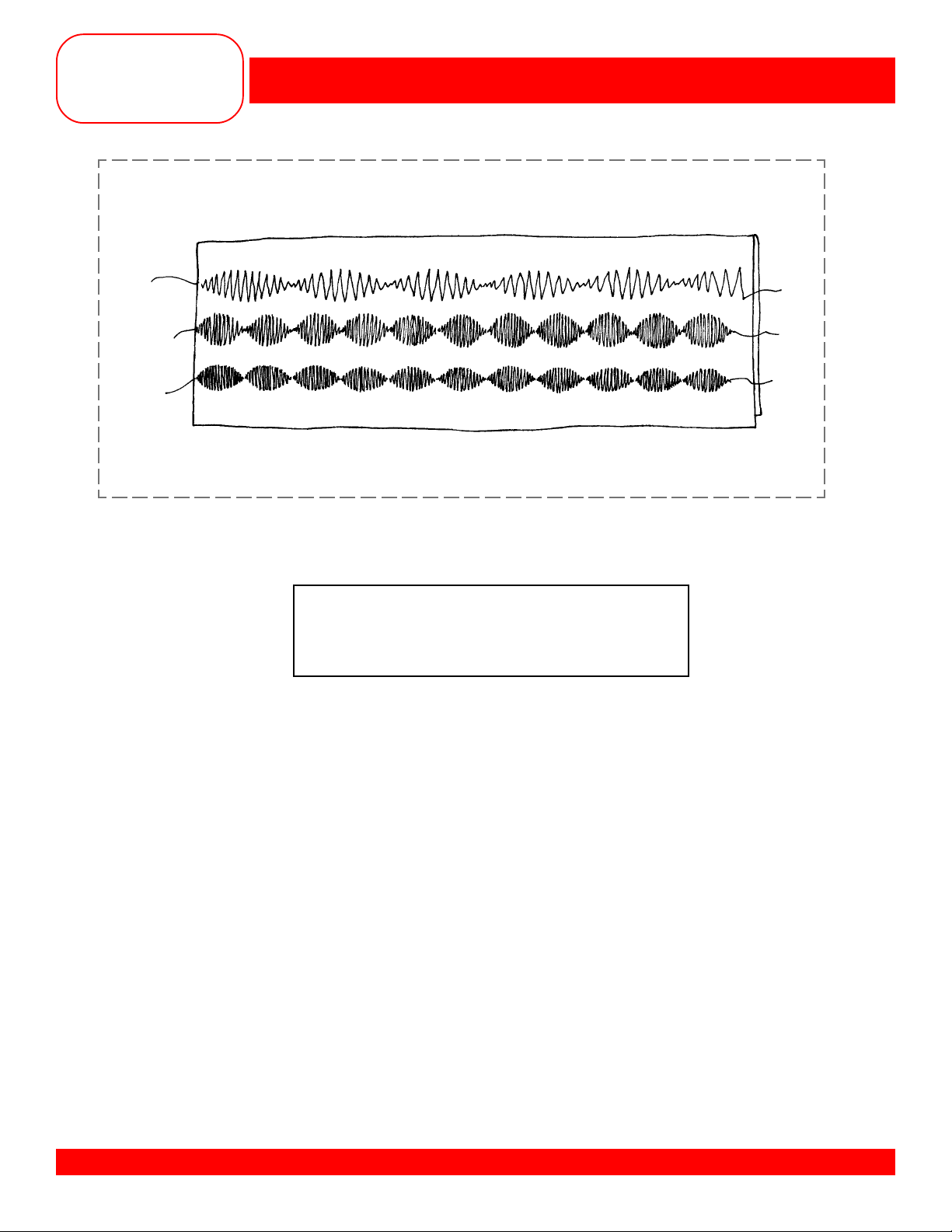

NEEDLE POSITIONS

Fabric: Firmly woven fabric, 4” x 6”

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Contrasting color

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.____

• The 170 QPE/180 has 11 fixed needle positions.

• Fold fabric in half to 2” x 6”.

• Select Straight Stitch. The basic settings are displayed

on the screen. The needle position indicator is just

below the stitch width scale; the needle should be in

center position.

• Position the fold of the fabric on the 1” mark on the

right side of the stitch plate.

• Select Pattern End 3x; sew until the machine stops.

• Move the needle one position to the left.

• Sew until the machine stops.

• Repeat until all six positions have been sewn.

• Leaving the fabric under the foot – move the needle

position back to center.

• Sew until the machine stops.

• Move the needle one position to the right.

• Sew until the machine stops.

• Move the needle one more position to the right – sew

until the machine stops.

• Repeat until all six positions have been sewn.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/9

Page 10

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

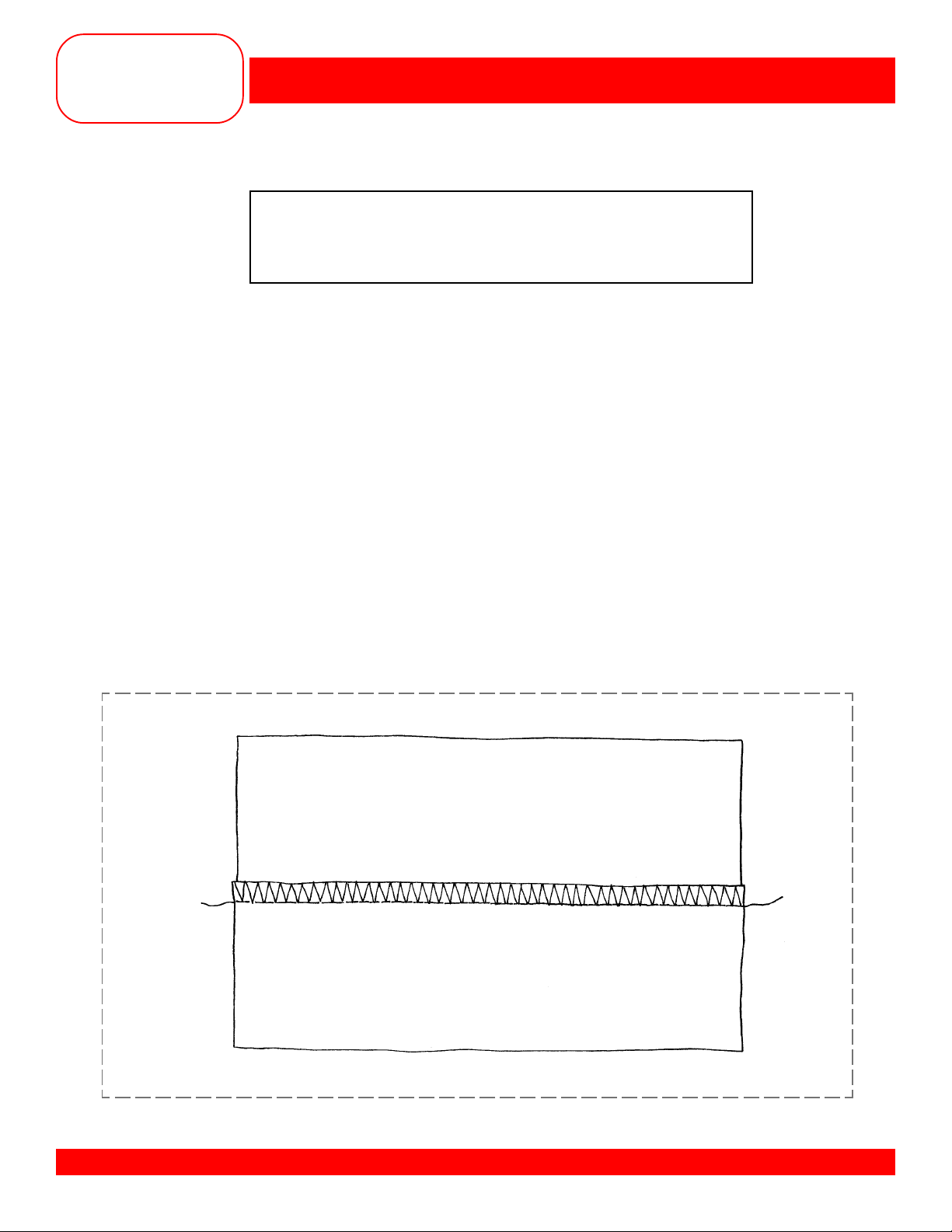

SEAMING

Fabric: Firm fabric – 2 pieces, 4” x 6” each

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Contrasting color

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.____

• Find the 5/8” guide line on the stitch plate.

• Place fabric pieces right sides together and

align them with the guide line.

• Sew a 5/8” seam on one 6” edge.

• Attach the Quilting/Seam Guide to the foot

and sew a 2” seam on the other side.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/10

Page 11

MASTERING

YOUR

BERNINA

®

Basting Stitch #21

Preprogrammed settings

BERNINA® artista 170 QPE/180

Basting Stitch #21 - 5mm length

Long Stitch function engaged

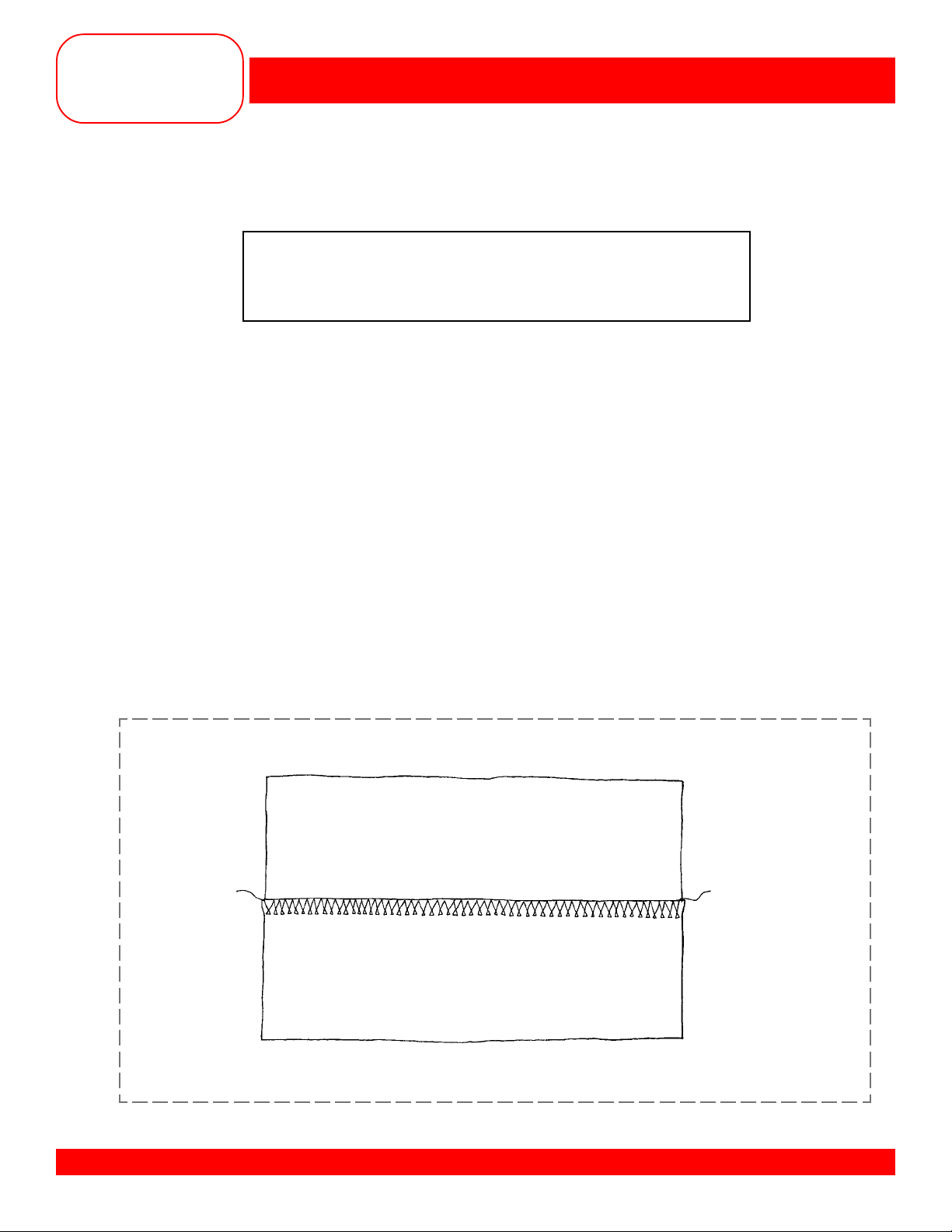

BASTING

Fabric: Firm fabric – 2 pieces, 4” x 6” each

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Contrasting color

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.____

• Place fabric pieces right sides together.

• Using Basting Stitch #21 with the preprogrammed length, baste a

• Using the same stitch with a 5.5mm stitch length, engage the Long Stitch function and baste another 5/8”

seam along the opposite edge.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/11

5

/8” seam along one side of the fabric.

Page 12

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

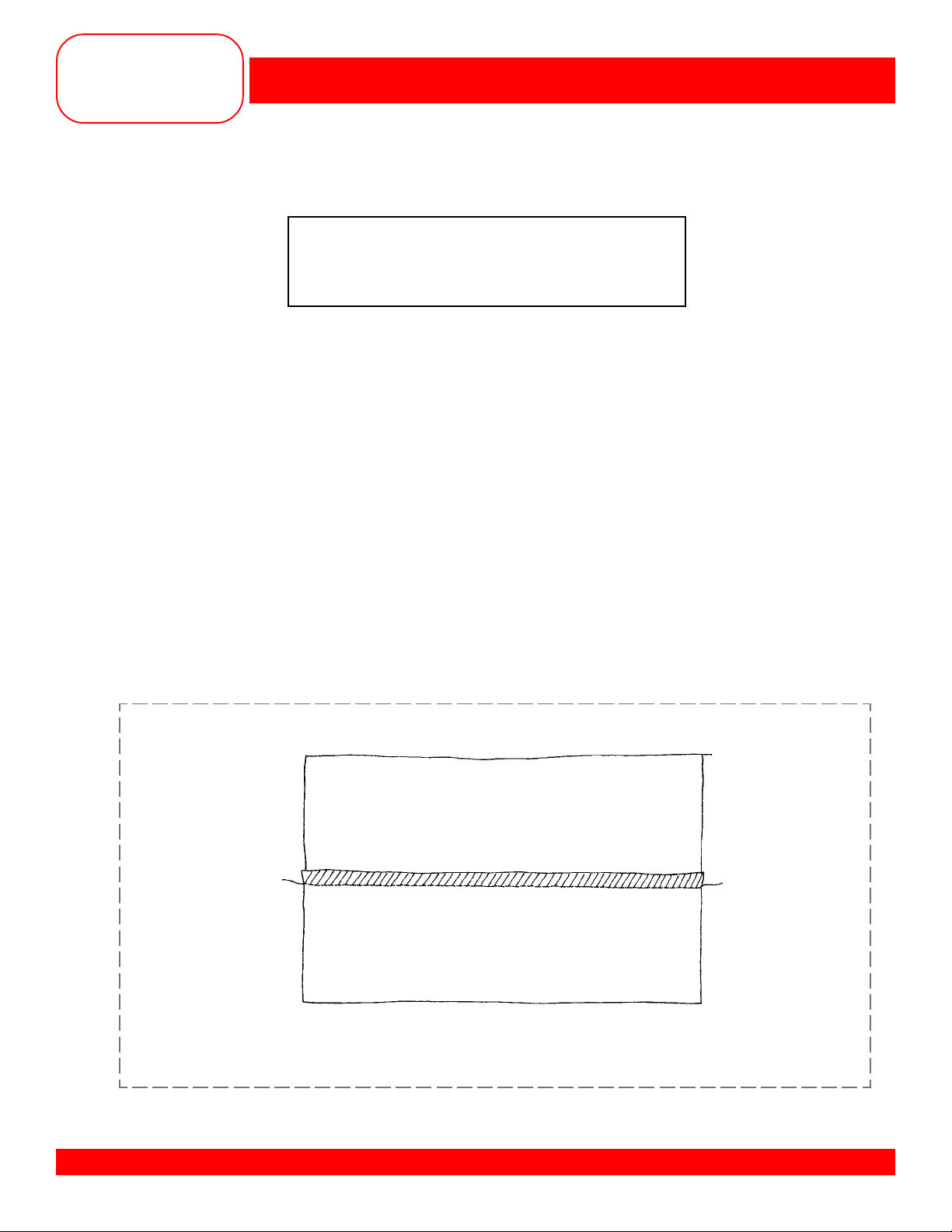

TOPSTITCHING/EDGESTITCHING

Fabric: Firm fabric – 4” x 6”

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Contrasting color

Presser Foot: Edgestitch Foot #10/10C (optional accessory)

Owner’s manual pg.____

• Cut fabric in half to create 2 pieces each 2” x 6”.

• Sew two pieces together with a

• Press the seam open.

• From the right side, position the blade of the foot in the ditch of the seam.

• Select Triple Straight Stitch #6.

• Move the needle position 3 places to the left.

• Sew the length of the seam.

• Select the Long Stitch function.

• Move the needle position 4 places to the right.

• Start at the top of the seam as before.

• Sew down the length of the seam again.

5

/8” seam on the 6” sides.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/12

Page 13

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

SECURING STITCHES

Fabric: Firm fabric – 3 pieces, 3” x 6” each

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.____

• Fold each fabric piece in half to 1½” x 6”.

• Find the

• The BERNINA® 170 QPE/180 secures in three ways:

5

/8” seam line on the guide plate.

1 – Select stitch #3 and sew a few stitches. Press the Quick Reverse button located on the front

of the sewing machine and the machine will sew in reverse until the button is released. Continue

stitching the seam and secure the end in the same manner.

2 – Select stitch #5 and stitch. The machine will automatically reverse after five stitches, then

continue in a forward motion. Stitch to the end of the seam, then press and release the Quick

Reverse button. The machine will stitch backward five stitches, and then continue forward again

five stitches and stop.

3 – Select stitch #332. Engage the Securing function to put a securing stitch at the beginning and the

end of each pattern repeat. In regular sewing, turn the Securing function off after the first stitch and

back on again after the last stitch is taken.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/13

Page 14

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

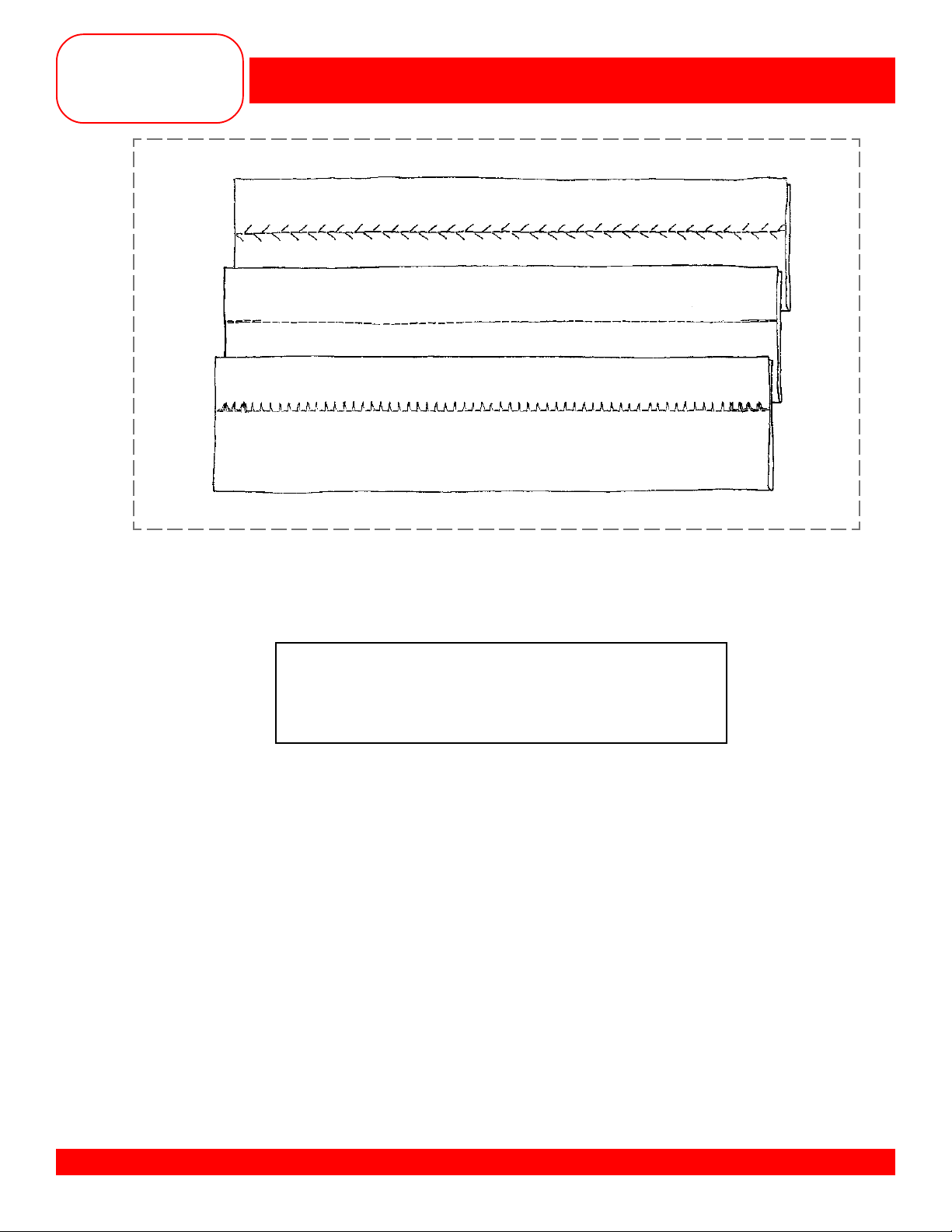

SATIN STITCH

Fabric: Firm fabric – 3 pieces, 3” x 6” each

Needle: 90/14 Embroidery

Thread: 30 wt. Cotton Embroidery

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.____

• Fold fabric in half to 3” x 6”. Use stabilizer as needed.

• Select Stitch #2. Change the stitch length to satin stitch and the stitch width to the maximum setting.

• Thread the bobbin thread through the hole in the finger of the bobbin case (170 QPE only).

• Move the needle position all the way to the left.

• Position the raw edge of the fabric on the 3/8” line (on the right side of the stitch plate).

• Sew down this edge about 1”. While continuing to sew, turn the stitch width knob to taper the stitch to

0mm. Then widen the stitch back to maximum. Repeat until the stitching reaches the end of the fabric.

• Position the fold of the fabric on the 3/8” line (on the left side of the stitch plate).

• Move the needle position all the way to the right and stitch along the right side of the fabric, tapering

and widening the stitching while sewing.

• Move the needle position to the center and stitch down the center of the fabric, tapering and widening

the satin stitch while sewing.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/14

Page 15

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

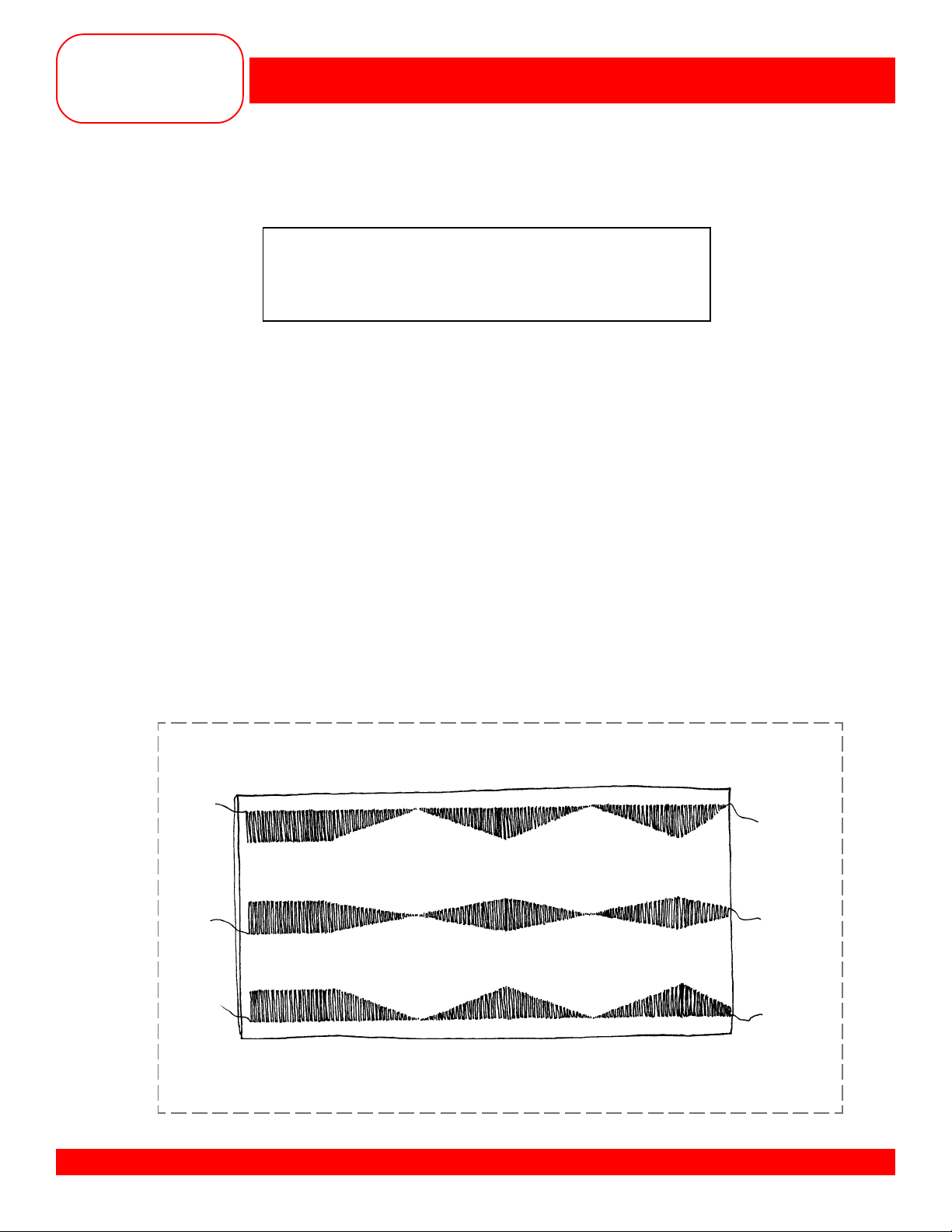

ALTERED MEMORY

Fabric: Firm fabric – 6” x 6”

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.____

• Fold fabric to 3” x 6”.

• Select stitch #407.

• Sew a row of stitching as programmed down the center of the sample.

• Alter stitch length to 1mm and sew a 2nd row on one side of the first row.

• Touch CLR - this clears alterations made to the selected stitch only.

• Select stitch #2 - (the one used for satin stitching in the previous exercise).

Notice the computer remembered all the changes made to the stitch.

• Select stitch #407 again.

• Alter stitch width to 3.5mm (170 QPE) or stitch 6mm (180) and sew a 3rd row on

the other side of the first row.

• Touch CLR ALL- notice the alterations made are gone.

• Select stitch #2 again - notice the changes made to it are gone also. CLR ALL

returns

• The computer will remember any and all stitches you alter, as long as the clear

buttons are not used and as long as the machine is not turned off.

all stitch alterations back to default settings.

RETURNING TO BASIC SETTINGS

• Three options: 1. Press the external CLR button

2. Touch the CLR ALL function.

3. Manually set changes back to the basic mark

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/15

Page 16

MASTERING

YOUR

BERNINA

Feet-ures

Edgestitch Foot #10/10C

Additional bobbin holders for accessory cabinet

Additional presser foot holders for accessory cabinet

Stabilizers – Sampler Pack or type __________

Thread – Assortment or size ____ and type ____

Needles – Assortment or size ____ and type ____

Needle Threader

Bobbins – Baker’s dozen

Spool Bobbin Holders

Magnetic Pin Cushion

Magnetic Bobbin Holder

Straight Stitch Plate

Seam Sealant

Extra Thread Stand

Scissors - 6” or 7” Dressmaker’s shears ____

Left guide (matches right guide included with machine)____

Seam Guide with Rulers (right and left) ____

Set of Magnifying Glasses

®

BERNINA® artista 170 QPE/180

WISH LIST

Care and Feeding of Your Machine

type __________

size ____ and type ____

size ____ and type ____

size ____ and type ____

size ____ and type ____

4” or 5” Trimming scissors ____

Thread nips ____

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/16

Page 17

MASTERING

YOUR

BERNINA

MASTERING YOUR

®

BERNINA® artista 170 QPE/180

®

BERNINA

artista 170 QPE/180

OWNER’S WORKBOOK

Section B

Let’s Start With The Basics

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/17

Page 18

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

Let’ s Start With The Basics

Seams

Triple Straight Stitch – SL 2-3mm

Owner’s manual pg.____

• Jeans Foot #8 prevents needle deflection

• Non-Stick Straight Stitch Foot #53

• This stitch sews strong seams on heavy

fabrics

Zigzag – SL1mm SW1.5mm

Owner’s manual pgs.____

Stretch – SL1mm SW2mm

Owner’s manual pg. ____

Super Stretch – as programmed

Owner’s manual pg. ____

• use to seam curved edges that receive a

lot of stress such as the crotch area of pants.

Vari-Overlock – SL1mm SW4mm NP right

Owner’s manual pg. ____

• Can be used with double needle for a

decorative hem on knits

• Overlock Foot #2 (optional for 170 QPE) or

#2A (included with 180) prevents the seam

from rolling as it is being sewn

• Engage the Needle Down function

SECTION B

Reinforced Overlock – SL2mm SW5mm

Owner’s manual pg. ____

• The artista has several seaming stitches

from which to choose, depending on the

type of fabric being used. With the Creative

Consultant, you can specify the type of fabric

you want to use, and the computer will

suggest the appropriate stitch.

Stitching Corners

• Utilize the FHS system to raise and lower

the presser foot when turning corners.

• Use the 5/8” markings on stitch plate

• Engage the Needle Down function

• Press heel on foot control to lower needle

Oversewing Edges

Blind Hem – Owner’s manual pg.____

• The Blind Hem Foot #5, along with the

blindstitch, produces a superior blind hem.

The zigzag part of the stitch is formed over

the guide on the foot, causing the stitch to

be slightly loose, so that the blind hem will

not pucker and does not form a tuck in the

fabric.

Hand Picked – Feet-ures, Unit B pg.____

Double Overlock – SL2mm SW5mm

Owner’s manual pg. ____

Knit Overlock – as programmed

Owner’s manual pg. ____

• Use Overlock Foot #2 (optional for 170 QPE)

or #2A (included with 180)

Stretch Overlock – SL2mm SW4mm

Owner’s manual pg. ____

Flat Joining – SL2mm SW4mm

Owner’s manual pg. ____

• Good for thick fabrics such as terry cloth

which would be stretched by a straight stitch

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/18

Triple Zigzag – Feet-ures, Unit A pg.____

• This stitch is used for strong, visible hems

on firm, coarse fabrics such as denim and

canvas.

Double Needle – Feet-ures, Units A and K, pgs__

Neckline Hem – Owner’s manual pg.____

Jeans – Feet-ures, Unit B pg.____

• Height Compensation Tool

Page 19

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

TRIPLE STRAIGHT STITCH

Fabric: Denim, 4” x 6”

Needle: 90/14 Jeans

Thread: All-purpose

Presser Foot: Reverse Pattern Foot #1/1C

Edgestitch Foot #10/10C (optional accessory)

Owner’s manual pg.___

• Cut the fabric in half lengthwise forming two pieces, 2” x 6” each.

• Select the Triple Straight Stitch #6.

• Sew the two pieces together with a

• Press the seam open.

• Change to Edgestitch Foot #10/10C and adjust the needle position to stitch through the seam allowance.

• Adjust the stitch length to 3.5mm.

• With the guide of the foot in the ditch of the seam, topstitch the length of the seam on both sides.

5

/8” seam allowance using Reverse Pattern Foot #1/1C.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/19

Page 20

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

ZIGZAG SEAM

Fabric: Firm knit – 4” x 6”

Needle: 80/12 Universal

Thread: All-purpose

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.___

• Cut the fabric piece in half lengthwise, creating two pieces, 2” x 6” each.

• Select the Zigzag Stitch #2 – SW 1mm and SL 0.5mm.

• Position the fabric to produce a

• Stitch the seam.

• Clip one seam allowance in the middle.

• Press one part of the seam open and leave the other half closed, so the stitch is visible.

• Trim and mount the sample.

5

/8” seam down one side.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/20

Page 21

MASTERING

YOUR

BERNINA

Owner’s manual pg.___

• Cut fabric in half lengthwise creating two pieces, 2” x 6” each.

• Select stitch #11.

• Position the fabric to produce a

• Stitch the seam; lighten the presser foot presure if fabric stretches.

• Clip one seam allowance in the middle and press one part of the seam open.

• Trim and mount the sample.

®

BERNINA® artista 170 QPE/180

SUPER STRETCH SEAM

Fabric: Heavy Double Knit, 4” x 6”

Needle: 80/12 Universal

Thread: All-purpose

Presser Foot: Reverse Pattern Foot #1/1C

5

/8” seam down one side.

Note: This stitch is good for an open seam on all knit fabrics; works well for sportswear.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/21

Page 22

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

V ARI-OVERLOCK SEAM

Fabric: Cotton Interlock, 4” x 6”

Ribbing, 2” x 4”

Needle: 80/12 Univeral

Thread: All-purpose

Presser Foot: Overlock Foot #2 (optional accessory) /2A

Owner’s manual pg.___

• Cut an inside curve in one corner of the fabric to simulate a neckline.

• Select the Vari-Overlock Stitch #3.

• Engage the Needle Down function.

• Place folded ribbing along the curved edge of the fabric (ribbing and fabric, right sides together).

• Guide the raw edges of the fabric under the pin of the foot and stitch; stitch length and width can

be adjusted, if needed.

• Trim the sample and mount with the ribbing pressed to the finished position.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/22

Page 23

MASTERING

YOUR

BERNINA

Owner’s manual pg.___

• Cut the fabric in half lengthwise, creating two pieces, 2” x 6’ each.

• Select the Double Overlock Stitch #10.

• Guide the raw edge along the pin of the Overlock Foot.

• The right swing of the needle should go off the fabric edge.

• Trim the sample and mount.

®

BERNINA® artista 170 QPE/180

DOUBLE OVERLOCK SEAM

Fabric: Single Knit – 4” x 6”

Needle: 80/12 Universal

Thread: All-purpose

Presser Foot: Overlock Foot #2 (optional accessory) /2A

Note: This is a good overlock seam for loosely knit fabrics and for cross

seams in other knits and jerseys.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/23

Page 24

MASTERING

YOUR

BERNINA

Owner’s manual pg.___

• Cut the fabric in half lengthwise, creating 2 pieces 2” x 6” each.

• Select the Stretch Overlock stitch #20.

• Guide the fabric so the right swing of the needle goes off the edge of the

seam; lighten presser foot pressure if seam stretches.

• Trim and mount the sample.

®

BERNINA® artista 170 QPE/180

KNIT OVERLOCK SEAM

Fabric: Sweater knit fabric, 4”x 6”

Needle: 80/12 Universal

Thread: Regular sewing

Presser Foot: Overlock Foot #2 (optional accessory) /2A

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/24

Page 25

MASTERING

YOUR

BERNINA

Owner’s manual pg.___

• Cut the fabric in half lengthwise, creating 2 pieces 2” x 6” each.

• Select the Stretch Overlock stitch #13.

• Guide the fabric so the right swing of the needle goes off the edge of the

seam; lighten presser foot pressure if seam stretches.

• Trim and mount the sample.

®

BERNINA® artista 170 QPE/180

STRETCH OVERLOCK SEAM

Fabric: Loosely knit fabric, 4”x 6”

Needle: 80/12 Universal

Thread: Regular sewing

Presser Foot: Reverse Pattern Foot #1/1C

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/25

Page 26

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

FLAT JOINING SEAM

Fabric: Terry cloth - 2 pieces, 2” x 6” each

Needle: 90/14 Universal

Thread: Regular sewing thread to match fabric

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.___

• Select the Stretch Overlock stitch #13.

• Cut a 5/8” seam allowance off one piece of fabric along the long edge.

• Mark a line on the other piece of fabric, 5/8” from one long edge. This will be

the right-hand piece of fabric.

• Overlap the fabric edges left over right, aligning the left raw edge with the

drawn line on the right-hand piece.

• Stitch along the raw edge. Turn the fabric over and stitch along the remaining

raw edge.

NOTE: This is a great seam technique to use on bulky fabrics such as terry cloth.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/26

Page 27

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

REINFORCED OVERLOCK SEAM

Fabric: Bulky knit fabric, 4”x 6”

Needle: 80/12 Universal

Thread: Regular sewing

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.___

• Cut the fabric in half lengthwise, creating 2 pieces 2” x 6” each.

• Select the Reinforced Overlock stitch #19.

• Guide the fabric along the 15mm line for a

• Trim excess seam allowance and mount the sample.

5

/8” seam; lighten presser foot pressure if seam stretches.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/27

Page 28

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

STITCHING CORNERS

Fabric: Firm fabric – 2 pieces, 5” x 5” each

Needle: 80/12 Universal

Thread: All-purpose

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.___

• Select the Straight Stitch #1.

• Place fabric pieces right sides together.

• Place the fabric under the foot with the top edge even with the horizontal line behind the foot.

• The right edge should be even with the 5/8” seam line.

• Engage the Needle Down function.

• Sew until the bottom edge touches the horizontal line in front of the needle; stop.

• Pivot and continue sewing until you come to the next corner and do the same thing.

• Stitch only three sides of this sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/28

Page 29

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

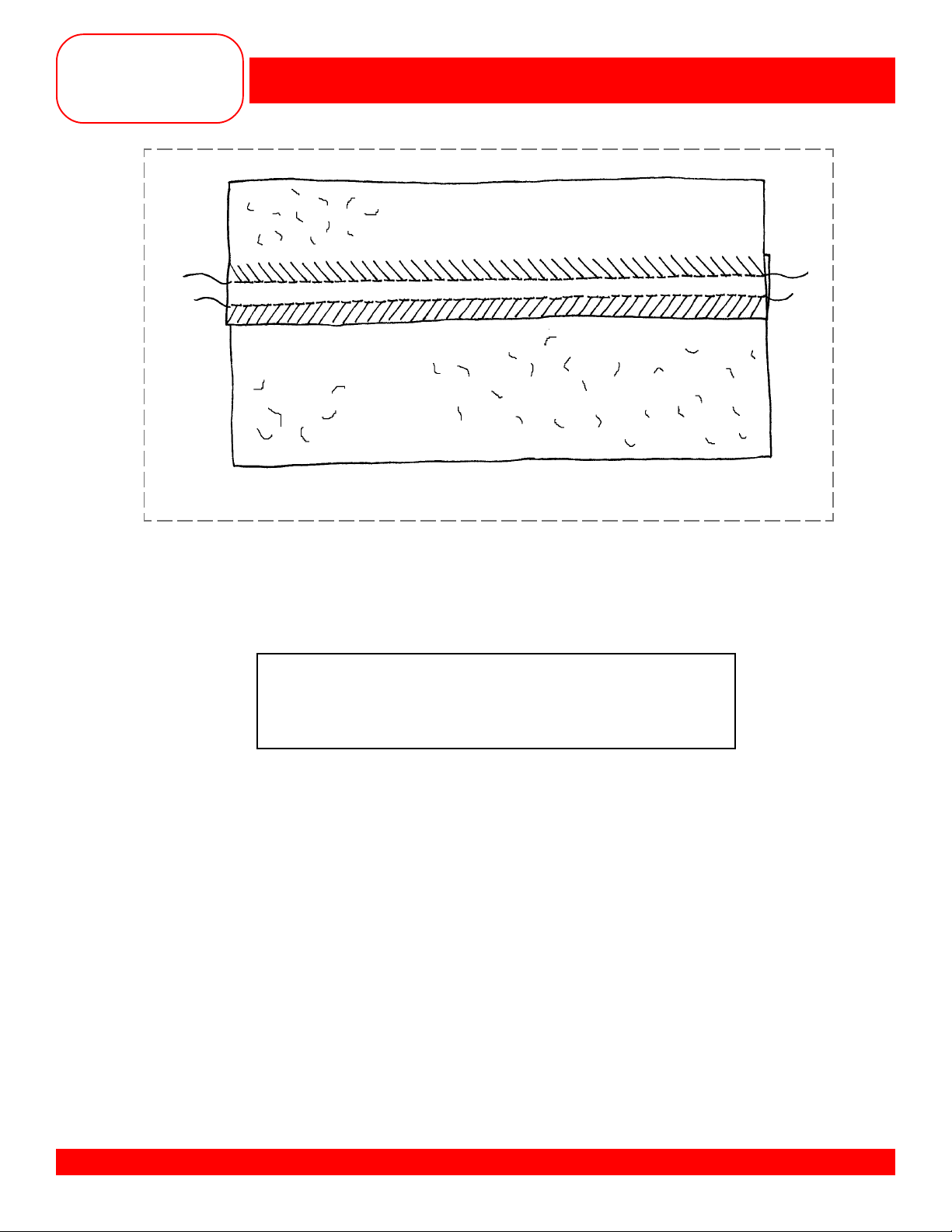

OVERSEWING EDGES

Fabric: Heavy Flannel – 3” x 6”

Needle: 80/12 Universal

Thread: All-purpose

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.___

• Select the Zigzag Stitch #2.

• Finish one 6” edge using the following steps.

• Guide edge of fabric under the middle of the presser foot.

• The needle should go into the fabric on one stroke of the needle and over the edge on the next stroke.

• Do not use too long a stitch or too wide a stitch; the edge should lie flat, not roll.

• Match the weight of the thread to the weight of the fabric.

• Trim and mount the sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/29

Page 30

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

BLIND HEM

Fabric: Heavy Flannel – 6” x 7”

Needle: 80/12 Universal

Thread: All-purpose

Presser Foot: Reverse pattern Foot #1/1C and

Blind Hem Foot #5

Owner’s manual pg.___

• Finish one 6” edge of the fabric following the steps of the previous exercise.

• Fold a 2” hem to the wrong side of the fabric and press.

• Select Basting Stitch #21 and attach Reverse Pattern Foot #1/1C.

• Baste the hem in place, sewing about ¼” from the raw edge.

• Select the Blindstitch #9 and attach Blind Hem Foot #5.

• Fold hem back to the right side over the basting line.

• Sew on the extended hem allowance, keeping the folded edge next to the guide on the foot.

• Adjust the stitch width if needed so that the needle barely stitches into the fold.

• Mount the sample with the edges folded back as shown in the drawing.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/30

Page 31

MASTERING

YOUR

BERNINA

Owner’s manual pg.___

• Turn up a 1” hem along one of the 6” edges and press.

• Turn up the depth of the hem again and press.

• Fold the entire hem toward the right side of the garment, so that the garment fold is

almost even with the top edge of the hem. A scant 1/8” to 1/16” of hem edge should

be visible. This will ensure that both folds are caught by the blind hem pick.

• Place the fabric under the foot just as a traditional blind hem would be placed.

• Sew the hem with Blindstitch #9, making sure that the zigzag pick catches both folds

while the straight stitch falls off the edge and stitches in air forming a chain along the

upper hem edge.

• Press and mount the sample.

®

BERNINA® artista 170 QPE/180

HAND PICKED HEM

Fabric: Lightweight broadcloth – 6” x 7”

Needle: 80/12 Universal

Thread: All-purpose

Presser Foot: Blind Hem Foot #5

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/31

Page 32

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

TRIPLE ZIGZAG HEM

Fabric: Firmly woven – 6” x 7”

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.___

• Fold a 2” hem to the wrong side of the fabric; press.

• Select the Triple Zigzag Stitch #7.

• Adjust stitch length and width as desired.

• From the right side of the fabric, stitch the hem in place, sewing about 1½” from the fold.

• From the wrong side, trim the excess fabric close to the stitches.

• Press and mount the sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/32

Page 33

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

DOUBLE NEEDLE HEM

Fabric: Cotton interlock – 6” x 7”

Needle: Double 3.0/80

Thread: All-purpose, 2 colors

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.___

• Turn up a 2” hem along one of the 6” edges and press.

• Insert a 3.0/80 double needle.

• Thread the needles with two different colors of thread.

• Place the folded edge of the fabric along the 1” guideline on the right side of the stitch plate.

• Select stitch #1; sew half of the hem.

Note: To be sure the needles will not strike the foot, turn the handwheel to “walk” the

machine through the first stitch. Narrow the width as needed to avoid breaking needles.

• Select stitch #9 or experiment with similar stitches; stitch the remainder of the seam.

• Trim excess fabric from the wrong side of the hem.

• Check Feet-ures, Unit A for detailed information on working with Double and Triple needles.

Note: This is a good stitch to use when hemming T-shirts and pajamas. You can use

other stitches with a double needle for other types of fabrics.

• Press and mount the sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/33

Page 34

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

NECKLINE HEM

Fabric: Single knit cotton – 4” x 6”

Needle: 80/12 Universal

Thread: All-purpose

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.___

• Cut a curve to simulate a neck edge in one corner.

• Sew a line of stay-stitching, 3/8” in from the neck edge using the straight stitch and the Long

Stitch function; disengage te Long Stitch function after staystitching.

• Turn the raw edge under and press or baste in place.

• Select the Honeycomb Stitch #8.

• Sew from the right side ¼” from the folded edge.

• Trim surplus fabric from wrong side, close to the stitching.

Notes: - If the hem stretches, add a strip of Stitch Witchery® to the edge as it is

stay-stitched.

- Using the Needle Stop Down function will keep the fabric in place when

sewing curves.

- The Balance function can be used to make the stitches closer together or

farther apart.

• Press and mount the sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/34

Page 35

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

JEANS HEM

Fabric: Denim – 5” x 7”

Needle: 100/16 or 110/18 Jeans

Thread: All-purpose

Presser Foot: Jeans Foot #8 (optional accessory)

Note: Specially designed to sew over heavy seams and fabrics, the Jeans Foot #8 guides the

needle through heavy thicknesses and helps to eliminate needle breakage. It is also effective

for topstitching with buttonhole twist or cordonnet threads.

Owner’s manual pg.___

• Cut fabric in two pieces, 5” x 3½” each.

• Insert a Jeans needle and select stitch #1.

• Sew a 5/8” seam with right sides together.

• Press the seam to one side.

• Topstitch, using the edge of the foot along the seam as a guide, and stitching through the seam

allowances.

• Turn up the lower edge twice, about 3/8” each time.

• Topstitch the hem in place, about 1/8” from the upper edge of the hem.

• Press and mount the sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/35

Page 36

MASTERING

YOUR

BERNINA

Feet-ures, Units A, B, C

Overlock Foot #2

Embroidery Foot #6

Jeans Foot #8

Edgestitch Foot #10/10C

Straight Stitch Foot #13

Cut and Sew Attachment #80

Double Needles

Jeans Needles

Stitch Witchery -

BERNINA Ironing System

Curved Hem Ruler

6” Sewing Gauge

Seam Pressing Stick

BERNINA Cutting Mat

BERNINA 14” Ruler

Rotary Cutter

®

Let’s Start WIth The Basics

2.0mm

2.5mm

3.0mm

90/14

100/16

Double

5

/8” roll

BERNINA® artista 170 QPE/180

WISH LIST

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/36

Page 37

MASTERING

YOUR

BERNINA

MASTERING YOUR

®

BERNINA® artista 170 QPE/180

®

BERNINA

artista 170 QPE/180

OWNER’S WORKBOOK

Section C

On The Edge

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/37

Page 38

MASTERING

YOUR

BERNINA

Buttonholes

Owner’s manual pg.____

Feet-ures, Units A and K

• Types and Uses

• Preparation

- proper stabilizers

- sometimes using two or more layers

- proper adhesion of iron-on stabilizers

• Positioning:

- marking

- full bust can be beginning point

- using spacing tape

- using Simpflex

• Measuring the Button:

- to determine length of buttonhole

• Grading Seams

- using applique scissors

• Height Compensation Tool

- keep foot level

• Buttonhole Leveler

• Tension Adjustments

• Testing:

- always use same fabric, thread and stabilizer

• Cutting Open:

- seam sealant

- block and cutter

• Tricks:

- wash-a-way stabilizer for high pile fabrics

- Stitch Witchery® for loose wovens or knits

• Buttonhole Balance

• Programmed Buttonholes

• Corded Buttonholes:

- with gimp cord

- with threads

®

BERNINA® artista 170 QPE/180

SECTION C

On The Edge

Sewing Buttons On

Owner’s manual page ____

Feet-ures, Unit D

• Button Sew-On Stitch

- regular

- decorative

- snaps, hooks, and charms

- tie a quilt

Edges

• Picot – Feet-ures, Unit D

• Shell

- blindstitch – Feet-ures, Units A and K

- hemmer feet #68 or #69 – Feet-ures, Unit I

• Rolled and Whipped Edge – Feet-ures, Unit A

• Fine Edge – Feet-ures, Units B and K

• Corded Edge – Feet-ures, Units B and K

- for tucks

- for hems

• Designer Hem – Feet-ures, Units B and K

Attaching Elastics

• Types

• Methods of applying

- turn under

- couching over

- lingerie

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/38

Page 39

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

BUTTONHOLES AND EYELETS

TYPES AND USES

ST ANDARD BUTTONHOLE

Fine to medium weight fabrics. Blouses, shirts, trousers, bedlinens.

HEIRLOOM BUTTONHOLE

Fine to medium weight fabrics. Blouses, shirts, dresses, trousers. children’s and baby

clothes, doll clothes, heirloom work.

STRETCH BUTTONHOLE

All stretch fabrics made from cotton, wool, silk, and synthetic fibers.

ROUND BUTTONHOLE WITH NORMAL BART ACK

Medium to heavy weight fabrics of all types. Clothing, jackets, coats, rainwear.

ROUND BUTTONHOLE WITH HORIZONT AL BART ACK

Medium to heavy weight fabrics of all types. Clothing, jackets, coats, rainwear.

KEYHOLE BUTTONHOLE WITH NORMAL BART ACK

Heavy weight, non-stretch fabrics. Jackets, coats, trousers, leisure wear.

KEYHOLE BUTTONHOLE WITH POINTED BARTACK

Non-stretch firm fabric. Jackets, coats, leisure wear.

KEYHOLE BUTTONHOLE WITH NORIZONT AL BARTACK

Firm, non-stretch fabrics. jackets, coats, leisure wear.

STRAIGHT STITCH BUTTONHOLE

For prestitching buttonholes and pocket openings. For bound buttonholes & welt pockets.

BUTTON SEW-ON PROGRAM

For flat buttons with 2 and 4 holes. For sewing on snaps, hooks, and charms.

NARROW ZIGZAG EYELET

Opening for cords and narrow ribbons/bands, other decorative work.

STRAIGHT STITCH EYELET

Opening for cords and narrow ribbons/bands, other decorative work.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/39

Page 40

MASTERING

YOUR

BERNINA

A number of buttonhole feet are available for BERNINA® sewing machines.

The descriptions below will help differentiate between the various feet.

BUTTONHOLE FOOT #3

The standard 5mm buttonhole foot.

Works with any BERNINA

®

BERNINA® artista 170 QPE/180

BUTTONHOLE FEET

BUTTONHOLE FOOT #3C

®

sewing machine

The standard 9mm buttonhole foot.

“C” indicates a “coded” foot, with a light

sensor that allows 9mm wide stitching.

Works with models 1630 and artista 180.

BUTTONHOLE FOOT WITH SLIDE #3B

A 5mm foot with a movable slide indicating

buttonhole length, making it easy to

stitch a series of identical buttonholes.

Works with any BERNINA® sewing machine.

AUTOMATIC BUTTONHOLE FOOT #3A

Automatic foot for machines with a 5mm and

9mm feed system. “A” indicates an “automatic”

foot, with a light sensor for counting stitches.

Works with models 1130-1530 and 150-170 QPE.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/40

AUTOMATIC BUTTONHOLE FOOT #3C

The automatic buttonhole foot for

machines with a 9mm feed system,

indicated by the letter “C”.

Works with models 1630 and artista 180.

AUTOMA TIC BUTTONHOLE FOOT WITH SLIDE #3A

Combines the handy slide measuring system of

Buttonhole Foot #3B with the electronic sensor of the

older Automatic Buttonhole Feet #3A and #3C.

Works with models 135 PE/145 and 150-180.

Page 41

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

STABILIZERS

Tear-Away Stabilizer: The most commonly used type of stabilizer, designed to provide

temporary support of stitching. Placed on the wrong side of the project and carefully

pulled away once stitching is complete. Available in three weights – heavy, medium, and

light. Multiple lightweight layers may be preferable to one heavy layer, as they are easier

to remove.

Cut-Away Stabilizer: The most widely used stabilizer in the commercial market. Does

not break down under dense stitching, due to the high fiber – rather than paper – content.

Excess stabilizer is trimmed away after stitching (leave approximately ¼” of stabilizer

around the edges).

Web/Poly-Mesh Type Stabilizer: A specially formulated cut-away stabilizer developed

for use behind lightweight or light-colored fabrics.

Water-Soluble Stabilizer: Used for backing and topping, in single or multiple layers.

Available in two weights. Excellent for decorative stitching and cutwork as there are

no remnants of stabilizer left after removal (it dissolves). As a topping, it keeps stitches

from being lost in heavily napped fabrics such as velvet and corduroy.

Knit Fusible Interfacing: A very lightweight, flexible interfacing sometimes used as a

stabilizer, it gives permanent support (as an underlining) to a fabric. Perfect for plackets,

garment edges, under buttonholes, and anywhere extra body and stability are needed.

Woven Fusible Interfacing: This interfacing is sometimes used as a stabilizer and is

generally cut on the bias to provide better drape. Gives a firmer hand or finish than knit

or non-woven interfacings. Used for lapels, facings, and anywhere a great deal of extra

body and stability are needed.

Iron-On Stabilizer: A non-woven product similar to paper. Perfect for knits, this tearaway stabilizer is temporarily bonded to the fabric, inhibiting the tendency of the material

to stretch.

Heat Removable Stabilizer: Woven from strands of fiber that are burned away at a low

temperature, heat removable stabilizers are perfect for heirloom stitchery.

Liquid/Spray Stabilizers: Wonderful for sheer fabrics from which all stabilizer must be

removed after stitching, these products are painted or sprayed onto the fabric. Several

light applications of spray stabilizer are preferable to one heavy application.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/41

Page 42

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

MANUAL BUTTONHOLES

Fabric: Heavy flannel, 6” x 6”

Stabilizer: 1 piece, 3” x 6”

Needle: 90/14 Embroidery

Thread: 30 weight cotton embroidery

Presser Foot: Standard Buttonhole Foot #3/3C

Owner’s manual pg.____

• Fold the fabric in half to 3” x 6”. Press and insert the stabilizer.

• Draw a line 1½” from the fold along the 6” length.

• Mark two horizontal lines, running between the fold and the drawn line, spaced about 2” apart.

• Select buttonhole #51 – the standard buttonhole — and MAN from the function toolbar.

• Position the foot over the first short line, aligning the fold of the fabric with the

• Sew the first side of the buttonhole, engaging box #1 on the screen.

• Stop at the drawn line and select box #2.

• Continue stitching the remaining steps of the buttonhole; touch esc.

• Select stitch #57 and MAN. Place the second short line under the presser foot as before.

• Sew the keyhole buttonhole on the second marked line; touch esc.

• Cut one buttonhole open.

• Trim and mount the sample.

5

/8” marking behind the foot.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/42

Page 43

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

BUTTONHOLE BALANCE

Fabric: Heavy flannel, 6” x 9”

Stabilizer: 1 piece, 6” x 9”

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidert

Presser Foot: Buttonhole Foot with #3A/3C

• Owner’s manual page __.

• Select buttonhole #51 and decrease bead density by lengthening the stitch to 1.

• Sew about a 1” buttonhole using the counted stitch method and mark it #1.

• Adjust the balance toward the closed stitch icon.

• Sew the buttonhole and mark it #2.

Note: This buttonhole bead is very dense.

• Turn the balance knob toward the open stitch icon.

• Sew another buttonhole; now the stitches are farther apart.

• Mark the sample with #3.

Note: This buttonhole bead is very open.

• Return the balance knob to mormal.

#1

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/43

#2

#3

Page 44

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

AUTOMATIC BUTTONHOLES

Fabric: Cotton Interlock, 6” x 6”

Heavy Flannel, 6” x 6”

Stabilizer: 2 pieces, 3” x 6” each

Needle: 90/14 Embroidery

Thread: 30 weight cotton embroidery

Presser Foot: Automatic Buttonhole Foot #3A/3C

Owner’s manual pg.____

Sample #1

• Fold the knit fabric in half to 3” x 6”. Press and insert the stabilizer.

• Draw a line 1½” from the fold along the 6” length.

• Mark two horizontal lines, running between the fold and the drawn line, spaced about 2” apart.

• Select buttonhole #53 – the stretch buttonhole.

• Position the foot over the first short line, aligning the fold of the fabric with the 5/8” marking behind the foot.

• Sew a buttonhole on the first drawn line.

• Stop at the drawn horizontal line and press the securing button; as you stitch, the word “auto” appears on

the screen.

• The buttonhole length is programmed and when you start sewing again, the machine completes the

buttonhole automatically.

• Sew the memorized buttonhole on the second line.

Sample #2

• Fold the flannel fabric in half to 3” x 6”. Press and insert the stabilizer.

• Draw a line 1½” from the fold along the 6” length.

• Mark two horizontal lines, running between the fold and the drawn line, spaced about 2” apart.

• Select buttonhole #58 – keyhole buttonhole.

• Stitch a buttonhole on the first drawn line

• Sew the memorized buttonhole on the second line. Note: To determine the buttonhole length, calculate

the bead length only; the eye will sew accordingly.

• Trim and mount the sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/44

Page 45

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

Auto Buttonhole

Foot #3A/3C

Standard Buttonhole

Foot #3/3C

CORDED BUTTONHOLES

Fabric: Heavy flannel, 6” x 6”

Two 10” lengths of gimp cprd

Stabilizer: 1 piece, 3” x 6”

Needle: 90/14 Embroidery

Thread: 30 weight cotton embroidery

Presser Foot: Standard Buttonhole Foot #3/3C and

Automatic Buttonhole Foot #3A/3C

Owner’s manual pg.____

• Fold the fabric in half to 3” x 6”. Press and insert the stabilizer.

• Mark a line 1½” from the fold and running the length of the fabric.

• Mark two horizontal lines between the fold and the line, spaced about 2” apart.

• Select the Standard Buttonhole #51.

• Place the fold so it is on the 5/8” line behind the presser foot.

• Lower the needle (using the foot control) into the fabric on the first line.

• Fold one piece of cord in half; place loop around prong of the Auto Buttonhole Foot #3A or #3C.

Note: The cord strengthens the buttonhole on wovens and prevents it from stretching on knits.

The thickness of the cord depends on the fabric to be sewn. Suitable cords are perle cord #8,

thick hand sewing thread, gimp cord, or crochet cotton.

• Sew the buttonhole.

• Pull the loop of gimp cord snug and cut tails close to bartack.

Note: On knits, pull to back and tie a knot.

• Select MAN from the function bar.

• Sew another corded buttonhole using the Buttonhole Foot #3/3C on the second line.

• The cord may come away from the prong of this foot. Therefore it is advisable to hold the loop of the gimp

down lightly with the finger.

• Pull the cord ends to the back with a large hand sewing needle and tie.

• Trim and mount sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/45

Page 46

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

BUTTONHOLE LENGTH

DIRECT ENTRY

Fabric: Heavy flannel, 6” x 6”

Stabilizer: 1 piece, 3” x 6”

Needle: 90/14 Embroidery

Thread: 30 weight cotton embroidery

Presser Foot: Standard Buttonhole Foot #3/3C

Owner’s manual pg.____

• Fold the fabric in half to 3” x 6”.

• Mark two lines perpendicular to the fold, spacing them about 2” apart.

• Select buttonhole #54.

• Position the foot over the first line, aligning the fold of the fabric with the

the foot.

• Touch the symbol on the function bar that is the buttonhole with a question mark.

• When the length screen appears, program in the buttonhole length of 22 mm.

• Touch OK to confirm; the screen changes automatically. The word auto below the buttonhole

symbol on the screen indicates that the buttonhole is programmed.

• Sew the buttonhole.

• Move the fabric to position the needle over the second line and sew a duplicate buttonhole.

• Trim threads close and mount the sample.

5

/8” marking behind

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/46

Page 47

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

BUTTONHOLE LENGTH

ON-SCREEN MEASURING

Fabric: Heavy flannel, 6” x 6”

Two 10” lengths of gimp cprd

Stabilizer: 1 piece, 3” x 6”

Needle: 90/14 Embroidery

Thread: 30 weight cotton embroidery

Presser Foot: Standard Buttonhole Foot #3/3C and

Automatic Buttonhole Foot #3A or #3C

Owner’s manual pg.____

• Fold the fabric in half to 3” x 6”.

• Mark two lines perpendicular to the fold, spacing them about 2” apart.

• Position the foot over the first line, aligning the fold of the fabric with the 5/8” marking behind the foot.

• Select the Standard Buttonhole #57.

• Open the button measuring screen by touching the button symbol on the function bar; a scale appears

on the screen.

• Hold a button against the scale at the bottom left corner of the screen.

• Use the external stitch width knob to move the vertical line on the screen; the line should be exactly at

the right edge of the button. The buttonhle size is shown in mm above the horizontal line.

Note: 2mm are added automatically to accommodate thickness of the button.

• Sew the buttonhole on the first line.

• Sew a memorized buttonhole on the second line.

• Trim and mount sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/47

Page 48

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

STITCH COUNTER BUTTONHOLES

Fabric: Heavy flannel, 6” x 6”

Stabilizer: 1 piece, 3” x 6”

Needle: 90/14 Embroidery

Thread: 30 weight cotton embroidery

Presser Foot: Standard Buttonhole Foot #3/3C

Owner’s manual pg.____

• Fold the fabric in half to 3” x 6”.

• Mark a parallel line 2” from the fold and a second one 1” from the fold.

• Mark two lines perpendicular to the fold, spacing them about 2” apart.

• Select standard buttonhole #51.

• Touch the “presser foot 3” symbol on the function bar.

• Position the beginning of the buttonhole on the line closest to the fold, aligning the fold with

5

the

/8” marking behind the foot.

• Sew the first bead and stop stitching at the second line.

• Press the quick reverse button - as you stitch, the bottom bartack and second bead are sewn.

• Stop the machine even with the first stitch of the first bead - press quick reverse.

• The machine sews the top bartack, ties the stitches off and stops automatically.

• Auto appears on the screen and the buttonhole is programmed.

Notes:

- The first bead is sewn forward, the second bead backward.

- The buttonhole must be reprogrammed after altering stitch length, width

or balance.

- Practice using the fabric and stabilizer to be used in the finished project.

- Stitch buttonholes at consistent speed.

• Trim threads close and mount the sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/48

Page 49

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

STRAIGHT STITCH BUTTONHOLE

Fabric: Linen, 6” x 6”

Stabilizer: 1 piece, 3” x 6”

Needle: 90/14 Embroidery

Thread: 30 weight cotton embroidery

Presser Foot: Standard Buttonhole Foot #3/3C and

Automatic Buttonhole Foot #3A/3C

Owner’s manual page___

• Attach Automatic Buttonhole Foot #3A/3C to the machine.

• Select stitch #59.

• Use any one of the available methods to make a 29mm buttonhole.

• Mark three lines perpendicular to the fold, spacing them about 2” apart.

• Position the beginning of the buttonhole on the line closest to the fold, aligning the fold with

the 5/8” marking behind the foot.

• Stitch the buttonhole on the first line - Do not remove the fabric.

• Select stitch #51 - sew this buttonhole (the same 29mm size) on top of the straight stitch buttonhole.

• Select stitch #59 again and sew another buttonhole on the second line, making it 27mm this time.

• Change to foot #3/3C - adjust the width of the buttonhole to 5mm (170 QPE) or 9mm (180).

• Sew a second buttonhole about 1” long on the third line.

Notes:

- Straight stitch buttonholes can be used to pre-sew and reinforce buttonholes on fabrics

which fray easily. The buttonhole beads and bartacks will cover the stitching. Any of the

methods for determining the buttonhole lengths can be used.

- Straight stitch buttonholes can be used as a buttonhole on imitation suede and leather.

- The distance between the prestitched lines can be adjusted with the stitch width.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/49

Page 50

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

BUTTON SEW-ON STITCH

Fabric: Heavy flannel, 6” x 6”

Stabilizer: 1 piece, 3” x 6”

Needle: 90/14 Embroidery

Thread: 30 weight cotton embroidery

Presser Foot: Button Sew-On Foot #18 (optional accessory)

Owner’s manual pg.____

• Select stitch #60.

• Lower the feed dogs.

• Fold the fabric in half to 2” x 6”; press. Insert the stabilizer.

Notes: - You can sew buttons on to stay!

- A low shank can be made for dresses and blouses or a high shank

can be made for heavier fabrics such as coats and blazers.

- Use the Button Sew-On Foot #18 to sew on waistband closures,

hook-and-eye fasteners, snaps, curtain rings, and charms.

Tecnique #1

• Use a glue stick to position a button in place.

• Adjust the pin on Foot #18 to the highest position for a long shank.

• Check the distance between the holes of the button by turning the hand wheel.

• Adjust the stitch width if necessary.

• Hold the thread tails as you begin to sew.

• Machine stops automatically when program is completed; threads are secured as part of program.

Technique #2

• Using the lowest shank setting, attach a charm, a length of ribbon, and a hook-and-eye to the same

fabric.

• Trim threads close and mount the sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/50

Page 51

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

PICOT EDGE

Fabric: Lightweight single knit cotton, 6” x 4”

Needle: 80/12 Universal

Thread: All-purpose sewing thread

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.____

• Select the Vari-Overlock stitch #3 - SW 4-5mm and SL 1.5mm.

• Fold under one 6” edge about ¼” and press.

• Place fabric to the left and position it under the foot so that when the stitch swings to the right, it

will just pass over the folded edge.

• On knit fabrics the surplus can be trimmed from the wrong side close to the stitch.

• On woven fabrics it is advisable to first sew a row of small zigzag stitches about ¼” from where

the picot edge will be. Then you will be able to trim close to these stitches after the picot has

been stitched.

• Trim and mount the sample.

This stitch is suitable only for fine, soft fabrics and is ideal for lingerie and nightwear.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/51

Page 52

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

SHELL EDGE

Fabric: Nylon tricot, 6” x 4”

Needle: 80/12 Universal

Thread: All-purpose sewing thread

Presser Foot: Reverse Pattern Foot #1/1C

Owner’s manual pg.____

• Select the Blind stitch #9 - SW 2.5-5mm and SL 1.5-2mm. The longer the stitch length, the

larger the shells.

• Engage the mirror image function.

• Fold under one 6” edge about ½” and press.

• Place fabric to the left and position it under the foot so that when the stitch swings to the

right, it will just pass over the folded edge.

• On knit fabrics the surplus can be trimmed from the wrong side close to the stitch.

• On woven fabrics it is advisable to first sew a row of small zigzag stitches about ¼” from

where the shell edge will be. Then you will be able to trim close to these stitches after the

edge is finished.

• Trim and mount the sample.

This stitch is suitable for fine, lightweight fabrics and is ideal for lingerie and nightwear.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/52

Page 53

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

ROLLED AND WHIPPED EDGE

Fabric: Lightweight cotton, 6” x 4”

Needle: 80/12 Universal

Thread: All-purpose sewing thread

Presser Foot: Standard Buttonhole Foot #3/3C

Owner’s manual pg.____

• Clean one 6” edge of “whiskers”

• Select the ZigZag Stitch #2 - SW 2.5mm and SL 1mm or less.

• Select the left needle position.

• Loosen the top tension if necessary.

• Place cut edge of fabric between the center and right toes of the presser

foot and sew.

Notes:

- The left swing of the needle should be in the fabric, while the right

swing falls off of the right edge of the fabric.

- As the needle swings left, it should roll the fabric into a tiny rolled edge.

- The finer the fabric, the finer the needle and thread used.

• Trim and mount the sample.

This edge finish is used on a single thickness of fine lightweight fabrics.

It is also use as a seam finish or as an edge on ruffles, hems etc.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/53

Page 54

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

FINE EDGE

Fabric: Batiste, 6” x 4”

Needle: 70/10 Universal

Thread: 60 wt. needle and bobbin

Presser Foot: Edgestitch Foot #10/10C (optional accessory)

Owner’s manual pg.____

• Select the ZigZag Stitch #2 - SW 2mm and SL 1mm.

• Select the left needle position.

• Fold under ½” hem allowance on one 6” edge and press.

• Place the fabric right side up, to the left of the guide on the foot and sew the edge.

• When completed, trim away surplus fabric from the wrong side, close to the stitch.

• Mount the sample.

Note: Reverse Pattern Foot #1/1C can be used - settings as above but use center needle position.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/54

Page 55

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

CORDED EDGE

Fabric: Medium weight cotton, 6” x 4”

Pearl Crown Rayon cord

Needle: 80/12 Universal

Thread: To match cord

Presser Foot: Edgestitch Foot #10/10C (optional accessory)

Owner’s manual pg.____

• Fold under a ½” hem allowance on one 6” edge and press.

• Place the folded edge, right side up, against the left side of the center blade.

• Select the ZigZag stitch #2 - SW 2mm and SL 1mm or adjust as needed.

• Adjust the needle position so the stitch falls on the folded edge.

• The right swing of the needle should barely miss the edge of the fold, stitching in air.

• Sew 2 or 3 stitches and stop with the needle down.

• Raise the foot, insert the cord under the foot from the right, against the needle.

• Pull the cord up through the center slot of the foot and hold it against the left side of the guide.

• Continue stitching - the cord will feed into the zigzag stitch.

• Trim the excess fabric from the wrong side.

• Mount the sample.

Note: Cord can be a variety of types - pearl rayon works well.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/55

Page 56

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

DESIGNER HEM

Fabric: Medium weight cotton, 6” x 4”

Pearl Crown Rayon cord

Needle: 80/12 Sharp

Thread: All-purpose sewing thread

Presser Foot: Edgestitch Foot #10/10C (optional accessory)

• Select Straight Stitch #1.

• Select the left needle position.

• Turn the raw edge under

• Stitch with the fold against the left side of the guide on the presser foot.

• Trim away seam allowance as close to stitching as you can get.

• Turn the first folded edge under again tightly and place the new fold against the left side

of the guide on the foot.

• Stitch again from the wrong side of the fabric as in the first step.

• A successful hem will have two parallel lines of stitching on the wrong side of

the hem and one showing on the right side.

• Trim and mount the sample.

3

/8” and press.

This is a very narrow two-step hem, easily sewn on straight or bias grains.

Works great on sheer farbric.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/56

Page 57

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

ATT ACHING ELASTIC LACE

Fabric: Nylon tricot, 6” x 4”

9” of elastic lace

Needle: 80/12 Universal

Thread: All-purpose sewing thread

Presser Foot: Reverse Pattern Foot #1/1C

• Select the Running stitch #4.

• Adjust stitch length to 1mm.

• Engage the needle down function.

• Position the elastic wrong side down on the right side of the tricot along one of the 6” edges.

• Leave a tail of elastic at the back of the presser foot for a “handle”.

• Position the elastic so the stitching is at the bottom edge of the elastic lace.

• Stretch the elastic lace gently, as it is being sewn.

• After stitching, trim the surplus tricot from the wrong side of the elastic lace, close to the stitching.

• Mount the sample.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/57

Page 58

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

TURNED UNDER ELASTIC

Fabric: Lycra - cotton or nylont, 6” x 5”

9” of cotton swimwear elastic, ½” wide

Needle: 80/12 Universal

Thread: All-purpose sewing thread

Presser Foot: Reverse Pattern Foot #1/1C

• Select the ZigZag stitch #2 - SW 2mm and SL 2mm.

• Position the elastic on the wrong side of the fabric, along one 6” edge.

• Allow a 2” tail of elastic to extend beyond the fabric.

• Using the tail of elastic at the back of the presser foot for a “handle”, stretch the elastic

a bit to simulate the leg of an exercise leotard or swimsuit.

Note: This is the same procedure used to do a turned waistband, using wider elastic.

• Sew the elastic to the fabric keeping the edge of the elastic and the edge of the fabric together.

• If stopping midway, use the Needle Down function to hold the elastic and fabric in place.

• Fold the elastic to the wrong side and overstitch the elastic from the right side using Stitch #16

or #17 with a length of 1mm.

• Adjust presser foot pressure and/or stitch length if elastic stretches out as it is sewn.

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/58

Page 59

MASTERING

YOUR

BERNINA

Presser Feet:

Feet-ures

Gimp or Pearl Crown Rayon

Stitch Witchery - roll

Water-soluable stabilizer

Buttonhole Space Tape

Buttonhole Placement Gauge - Simpflex ruler

½” Drafting Tape

Marking Pens/Pencils

Applique Scissors - for grading seams

Height Compensation Tool

Seam Sealent

Glue Stick

Buttonhole Cutter and Block Set

Double Needles

Cotton elastics

Accessory Box

®

BERNINA® artista 170 QPE/180

WISH LIST

On The Edge

Buttonhole Foot with Slide #3B

Embroidery Foot #6

Edgestitch Foot #10/10C

Button Sew-on Foot #18

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/59

Page 60

MASTERING

YOUR

BERNINA

MASTERING YOUR

®

BERNINA® artista 170 QPE/180

®

BERNINA

artista 170 QPE/180

OWNER’S WORKBOOK

Section D

Gather It Up and Tuck It Down

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/60

Page 61

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

SECTION D

GATHER IT UP AND TUCK IT DOWN

Gathering

• Gathering With A Basting Stitch

- Lengthen stitch all the way

- Tighten top tension for easier removal

• Gathering Over A Single Cord

- Refer to Feet-ures, Unit B

- Embroidery Foot #6 with stitch #2

• Gathering Over Two Cords

- Standard Buttonhole Foot #3/3C with stitch #12

- Can use elastic thread for shirring

Tucks

• Pintuck Feet and Double Needles

- refer to Feet-ures, Unit F

- which feet go with which needle

- how to thread a double needle

- how to use grooves in feet

• Corded Pintucks

- refer to Feet-ures, Unit F

- straight tucks

- gimp hole

- turning corners

• Elastic Thread In Bobbin Case

- Refer to Feet-ures, Unit H

- Use Black Latch or secondary bobbin case

• Narrow Casing Elastic

- Refer to Feet-ures, Unit A

- Open Embroidery Foot #20/20C with stitch #15

• Wide and Extra-Wide Gathering Feet #16

- refer to Feet-ures, Units D and L

- gathering a single layer

- gathering to a flat piece

- short stitch length for easing

• Ruffler Attachment

- refer to Feet-ures, Unit J

• Pleats vs Tucks

- refer to Feet-ures, Units C and K

- Edgestitch Foot #10/10C

- Reverse Pattern Foot #1/1C

• Large Tucks and Pleats

- refer to Feet-ures, Unit D

- Quilting/Seam Guide

- Zipper Foot with Guide #14

- Guide Bars with Rulers

• Decorative Tucks

- refer to Feet-ures, Unit F

- sewn with decorative stitches vs straight

- corded edges

- lace inserted

MASTERING YOUR BERNINA®1/10/02 artista 170 QPE/180/61

Page 62

MASTERING

YOUR

BERNINA

®

BERNINA® artista 170 QPE/180

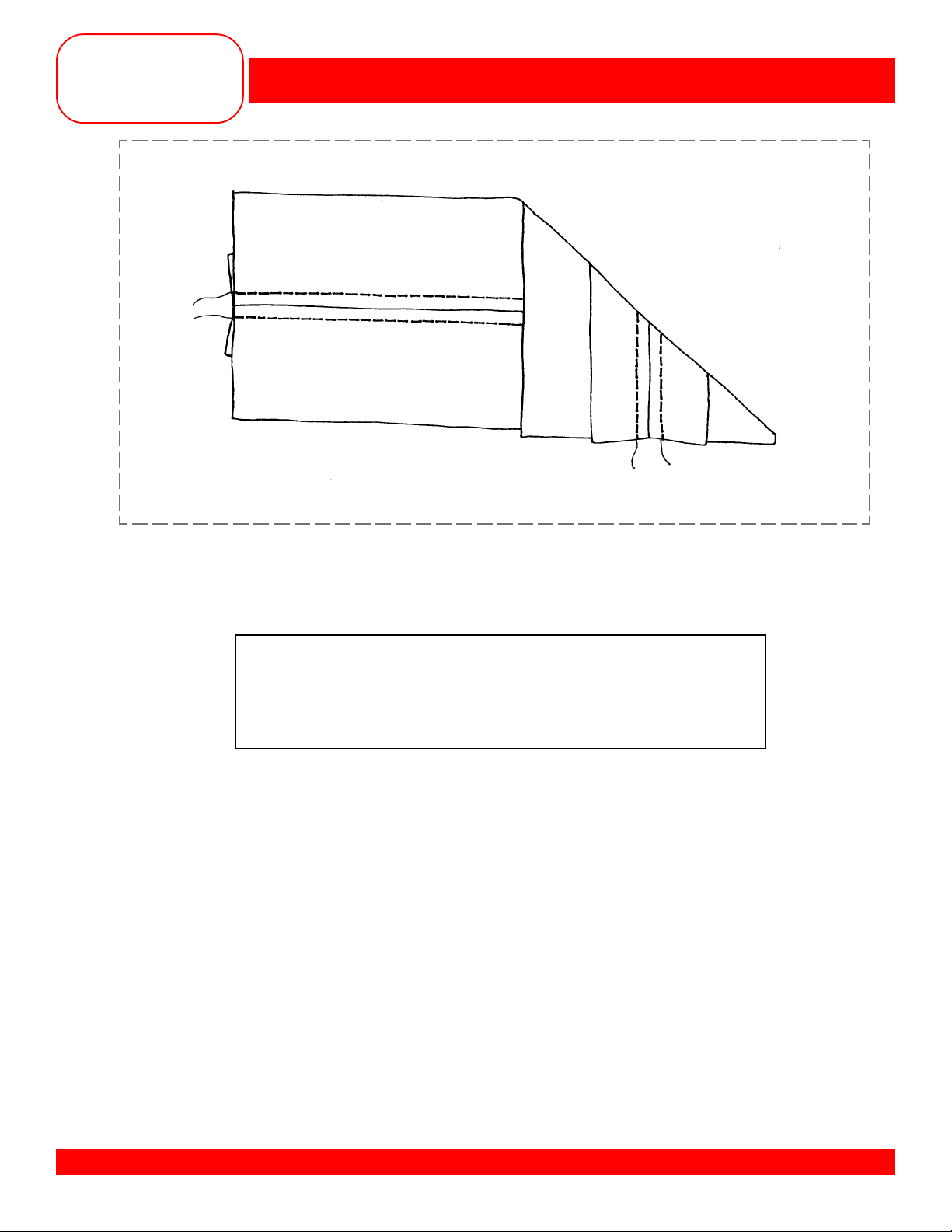

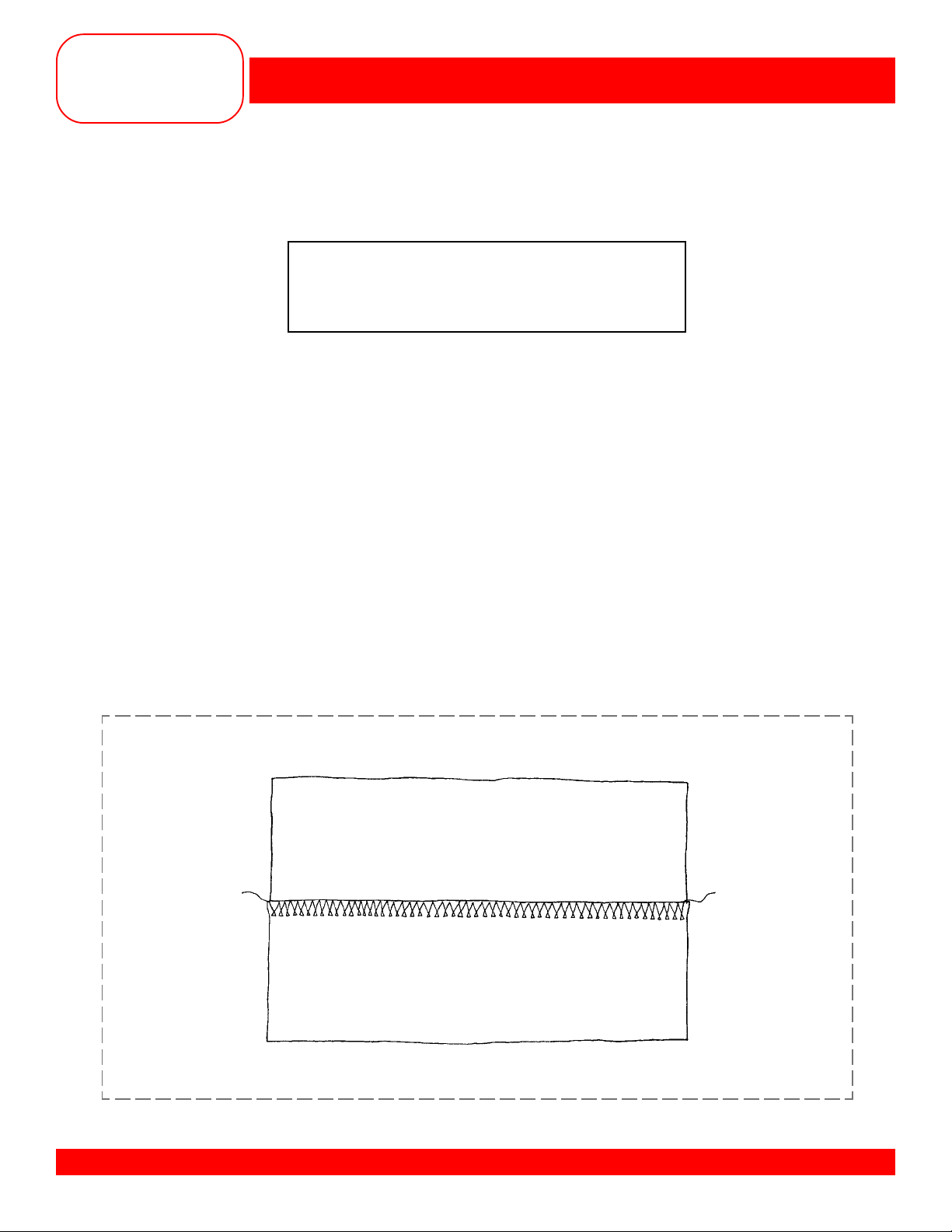

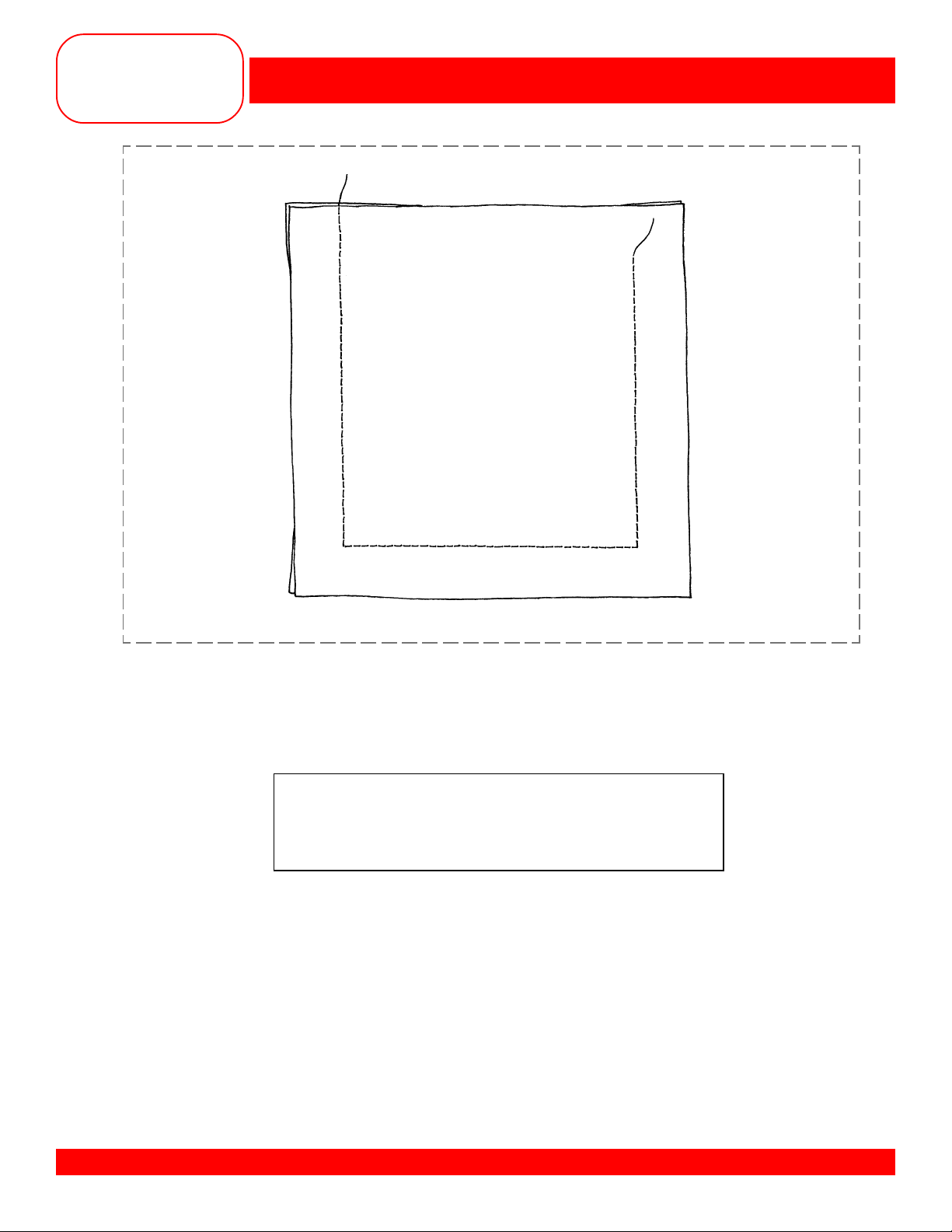

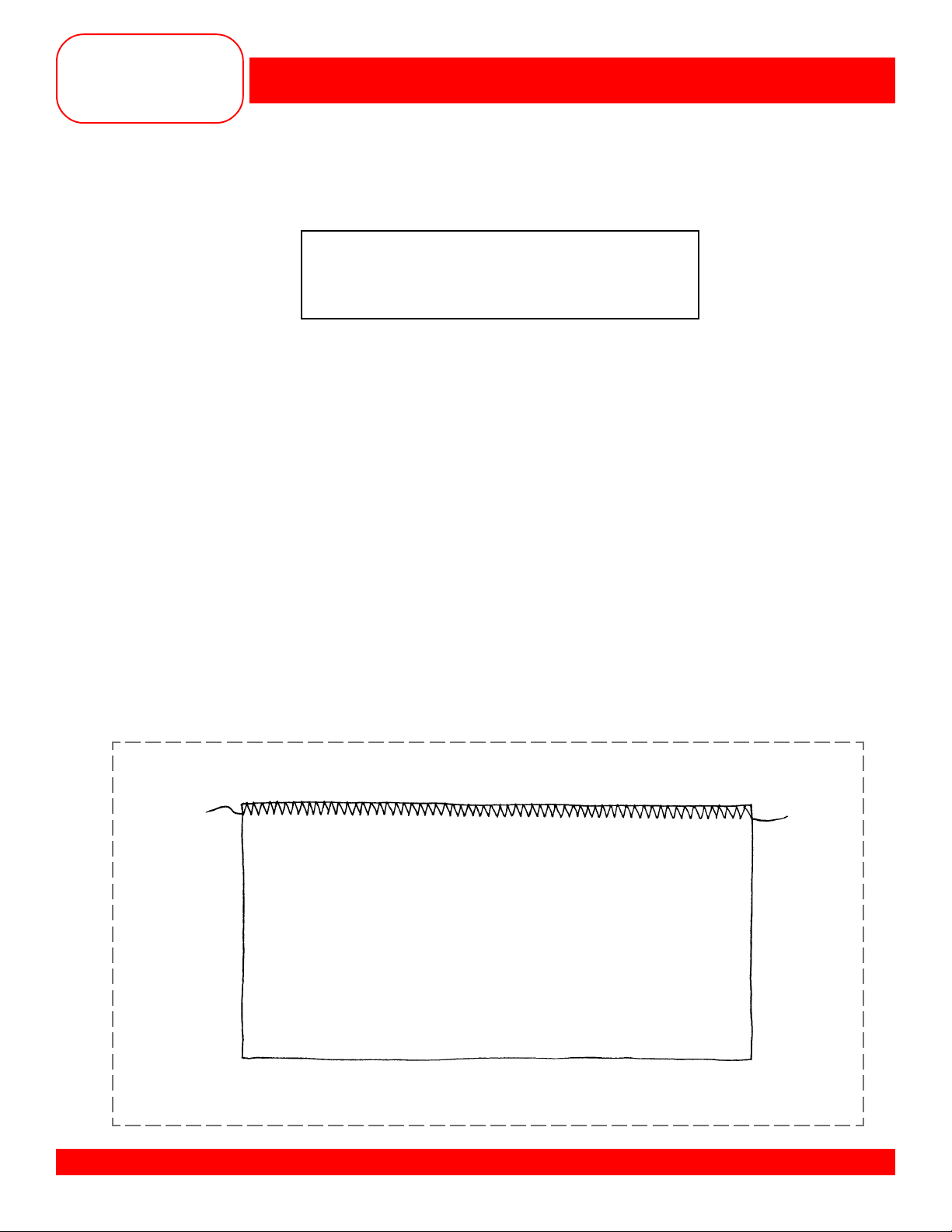

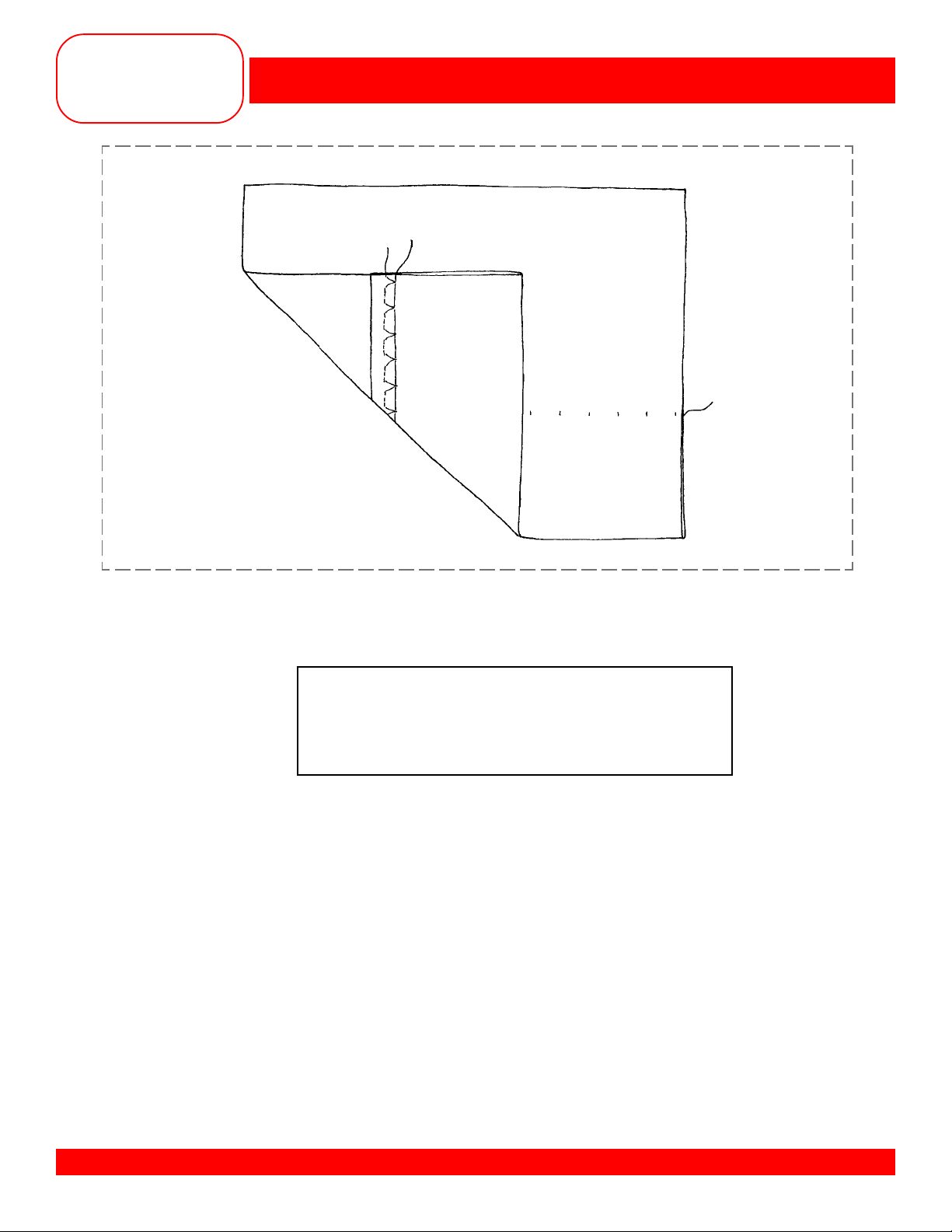

GATHERING WITH A BASTING STITCH

Fabric: Medium weight cotton, 12” x 4”

Needle: 80/12 Universal

Thread: All-purpose sewing

Presser Foot: Reverse Pattern #1/1C

• Trim all 4 edges of fabric piece with a wavy rotary cutter.

• Use all-purpose sewing thread top and bottom.

• Select stitch #21.

• Stitch 5/8” from one 12” edge.

• Tie the threads at the beginning to secure and gather the sample up to 6”.

Notes:

- The machine sews every fourth stitch.