330750 and 330752 High Temperature

Velomitor System

Datasheet

Bently Nevada Machinery Condition Monitoring

Description

The 330750 and 330752 High Temperature Velomitor System

sensor head and integral cable are designed for high

temperature environments. This enables you to mount the

sensing head on surfaces with temperatures as high +400°C

(+752°F).

To accomplish this, the transducer design segregates the

sensing element from the signal conditioning electronics. The

two are permanently connected using an integrated cable.

The integrated cable eliminates connectors which are a

significant source of transducer failures.

The cable enables you to position the signal conditioning

electronics in a cooler location. The internal electronics

withstands temperatures of 55°C to +121°C (−67°F to +250°F).

The integrated design makes it possible to capture

machinery performance data comparable to other Bently

Nevada Velomitor transducers, but at significantly higher

temperatures.

141639 Rev. R

For lower temperature environments, use the standard

330500 Velomitor Piezo-velocity Sensor. You can install it in

locations with a maximum operating temperature of +121°C

(+250°F).

330750 and 330752 High TemperatureVelomitor System

Datasheet 141639 Rev. R

Measuring Housings for Transducer

Placement

If you are measuring a machine housing to

determine where to place transducers,

consider which kinds of measurements you

want to obtain. Most common machine

malfunctions like imbalance or misalignment

originate at the rotor and cause a change—

usually an increase—in rotor vibration.

To obtain the best quality data, you need to

place the transducer on the bearing housing or

machine casing where machine vibration is

best transmitted through the housing. Choose

a location that maximizes amplitude and

frequency response and avoids detecting

signals that don’t represent actual machine

vibration. Improper installation can degrade

the transducer’s performance or produce

signals that don’t represent actual machine

vibration.

Bently Nevada provides engineering services to

determine the optimum location to place

transducers. We also can install transducers if

needed. For assistance, contact your local

customer care representative or Bently Nevada

at Bently.com.

Earlier versions of the 330750 and 330752

High Temperature Velomitor System

were limited to environments with a

maximum temperature of +300°C

(+572°F). The serial number of current

versions are preceded by the letter "G".

2/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Cable Length no degradation of signal.

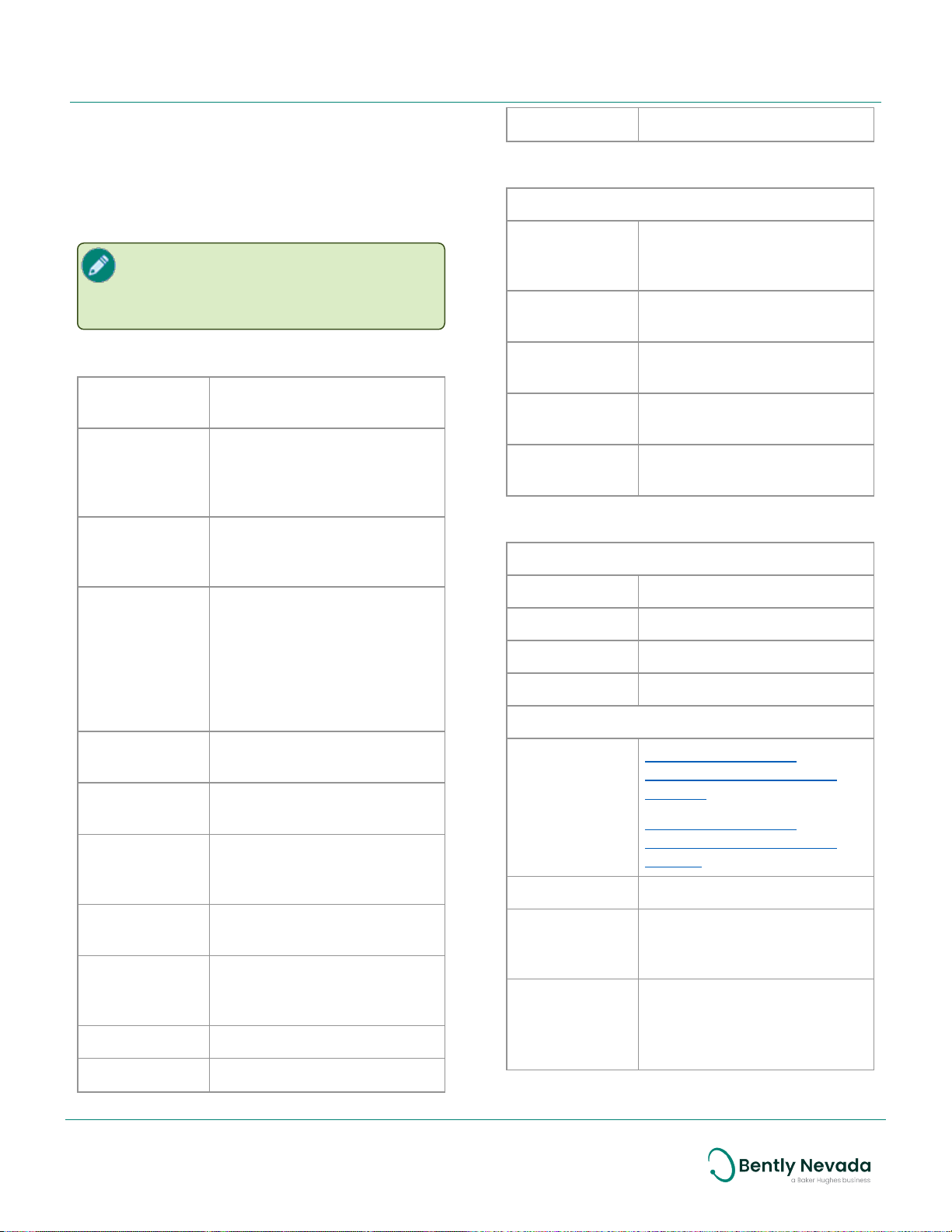

Specifications

Environmental Limits

Parameters are specified from +20 to +30°C

(+68 to +86°F) and 100 Hz unless otherwise

indicated.

Operating the Velomitor transducer

outside the specified limits may result in

false readings, failure of the transducer

or loss of machine monitoring.

Electrical

Sensitivity 5.7 mV/mm/s (145 mV/in/s)

±5%

Frequency

Response

Transient

Temperature

Sensitivity

Amplitude

Range

Transverse

Sensitivity

Amplitude

Linearity

Mounted

Resonant

Frequency

15 to 2000 Hz (900 to 120,000

cpm) ± 3.0 dB;

20 to 1000 Hz (1,200 to 60,000

cpm) ± 0.9 dB

0.0762 mm/s/°C (0.003

in/s/°C), typical, as defined

in ISO 5347-18:1993(E)

635 mm/s (25 in/s) peak

below 680 Hz.

2940 m/s2 (300 g) peak

above 680 Hz.

Vibration at frequencies

above 2 kHz decreases this

range.

Less than 5% of Sensitivity

±2% to 152 mm/s (6 in/s)

peak

Greater than 5 kHz

Operating and Storage Temperature Range

Sensing Head Maximum mounted surface

temperature −55°C to

+

400°C (−67°F to +752°F)

Integral

Hardline Cable

Electronics

Shock

Survivability

Relative

Humidity

−55°

to +400°C (−67° to

+

752°F)

−55°

to +121°C (−67° to +250°F)

24,535 m/s2 (2500 g) peak

To 100% non-submerged;

case is hermetically sealed.

Physical

Weight (typical)

2 meters 635 grams (1.40 lb)

4 meters 794 grams (1.75 lb)

6 meters 953 grams (2.10 lb)

8 meters 1,111 grams (2.45 lb)

Mounting

Case 300 series stainless steel

See 330750 System

Dimensional Drawing on

page10.

See 330752 System

Dimensional Drawing on

page11.

Output Bias

Voltage

Broadband

Noise Floor

(15Hz to 2kHz)

Grounding Case Isolated

Maximum 305 meters (1000 feet) with

-12 ±2.0 VDC

0.127 mm/s (0.005 in/s) rms

nominal

Connector 2-pin Mil-C-5015 receptacle,

hermetically-sealed, 304

stainless steel shell.

Polarity When the applied velocity is

from the base to the top of

the transducer, Pin A

becomes positive with

3/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

respect to Pin B.

Bend Radius Minimum bend radius of

51mm (2.0in)

Before installing this product, we

recommend you read the 330750 and

330752 High Temperature Velomitor

System User Guide (document 135090)

4/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Compliance and Certifications

FCC

This device complies with part 15 of the

FCC Rules. Operation is subject to the

following two conditions:

l This device may not cause harmful

interference.

l This device must accept any

interference received, including

interference that may cause

undesired operation.

EMC

EMC Directive 2014/30/EU

RoHS

RoHS Directive 2011/65/EU

Maritime

Hazardous Area Approvals

For the detailed listing of country and

product specific approvals, refer to the

Approvals Quick Reference Guide

(108M1756) available from Bently.com.

CSA/NRTL/C

Ex ia IIC

Class I, Zone 0, AEx ia IIC

Class I, Division 1, Groups A, B, C and D

Class II, Division 1, Groups E, F and G

Class III, Division 1

Ex nL IIC

Ex ec IIC

Class I, Division 2, Groups A, B, C and D

ATEX/IECEx

II 1 G

Ex ia IIC or IIB Ta, T4 492°C

330400and 330425 only

ABS 2009 Steel Vessels Rules

1-1-4/7.7,4-8-3/1.11.1,4-9-7/13

II 3 G

Ex na IIC or IIB Ta, T4, T1 492°C Gc

Ex ec IIC or IIB Ta T4, T1 492°C Gc

Ta, T1, T4 492°C

Ta, T4, T1 492°C

Temperature

Class

T4 -40°C to

T1 -40°C to

T1 -40°C to

Entity Parameters for Zone 0/1 and Zone 2

Group IIC IIB

Type

33045 33075 33075

Temperature

Range

+100°C

+400°C

+482°C

Equipment

Electrical

Housing

Sensor and

Cable

Sensor and

Cable

(3509000

35090 35090

5/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

0

0

2

0 0

33075

33045

0

Type S

33075

0

Type

2

Type

S

S

Ui 30V 28V 28V 28V 29.2V

Ii 200mA120mA 120mA153mA279m

A

Pi 1.5W 1.0W 1.0W .84W 1.95W

Ci 7 ηF 1 η F 1 ηF 37 ηF 37 ηF

Li 30 μH 30 μH 30 μH 30 μH 30 μH

6/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Standard Cable Lengths

Ordering Information

For the detailed listing of country and

product specific approvals, refer to the

Approvals Quick Reference Guide

(108M1756) available from Bently.com.

330750-AA-BB

A: Length

20 2 meters

40 4 meters

60 6 meters

80 8 meters

B: Approvals

0 5

Multiple Approvals (CSA, ATEX, and

IECEx)

330752-AA-BB

Feet Meters (approximate)

6 ft 1.8 m

8 ft 2.4 m

10 ft 3.0 m

12 ft 3.6 m

15 ft 4.5 m

17 ft 5.0 m

20 ft 6.0 m

25 ft 7.6 m

30 ft 9.0 m

33 ft 10.0 m

50 ft 15.2 m

99 ft 30.0 m

A: Length

25 2.5 meters

40 4 meters

60 6 meters

80 8 meters

B: Approvals

0 5

Multiple Approvals (CSA, ATEX, and

IECEx)

Interconnection Cables

The standard cable lengths below are available.

You can order custom cable lengths in

increments of one foot at additional cost. Some

cables have a minimum and maximum length.

For details, see each part description below.

7/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Cable Part Numbers

Part number Description

When entering a part number, use ‘NN’

in the part numbers to specify the

length (in feet) of the cable you want

to order.

9571-NN

84661-NN

89477-NN

Standard interconnect

cable

Shielded 0.382 mm2 (22

AWG) cable with a moistureresistant female connector

at the HTVS end and ring

lugs at the monitor end.

Temperature range -29 to

121°C (-20 to 250°F). See

Standard Interconnect

Cable on page13.

Standard armored

interconnect cable

Stainless steel armor over

shielded 0.382 mm2 (22

AWG) cable with a moistureresistant female connector

at the HTVS end and ring

lugs at the monitor end.

Temperature range -29 to

121°C (-20 to 250°F).See

Standard Armored

Interconnect Cable on

page13.

Right angle interconnect

cable

Standard Armored

Interconnect Cable. See

Standard Right-angle

Interconnect Cable on

page13.

Part number Description

at the HTVS end and ring

lugs at the monitor end.

Temperature range -29 to

121°C (-20 to 250°F). See

Short Run Interconnect

Cable on page14.

02173034

02173006

02173007

00502025

CE installation interconnect

cable (**required for CE

installations)

Shielded 0.382 mm2 (22

AWG) cable with a splashproof boot over a female

connector at the HTVS end

and flush cut at the monitor

end. Temperature range -55

to 125°C (-67 to 257°F). See

CE Installation Interconnect

Cable on page14.

0.963 mm2 (18 AWG) bulk

cable

Shielded twisted pair. Same

cable as used on 89477-NN

and 122129-NN. Specify the

number of feet.

0.382 mm2 (22 AWG) bulk

cable

Shielded twisted pair. Same

cable as used on 9571-NN

and 84661-NN. Specify the

number of feet. The

maximum length that

should be used with the

HTVS is 305 m (1000 ft)

Spare connector

Same connector as used on

9571-NN and 84661-NN

122129-NN

Short run interconnect

cable

Shielded 0.963 mm2 (18

AWG) cable with a moistureresistant female connector

8/15

101212-01

00531061

Right angle connector

Right angle connector kit.

Same connector as used on

89477-NN.

Spare mating connector

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Part number Description

Mating connector for 330750

and 330752 Velomitor

System.

330535

Standard temperature

cable

22 AWG, double-shielded

cable

00530574

Cable Mounting Clamp

Mating connector clamp to

be used with 00531061

03818073

Electronics Housing Strap

One-inch rigid conduit strap

for securing the electronics

housing.

03818071

Electronics Mounting Hub

One-inch weather tight hub

used to mount the

electronics housing in a

weatherproof enclosure.

Part number Description

169546

Cable Clamp

Stainless steel mesh tie

down clamp for the hardline

cable. For temperatures

greater than 260C (500F).

03818072

Seal Ring

One-inch sealing lock ring

used to mount the

electronics housing. Two

rings are required to mount

the electronics.

9/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Graphs and Figures

Figure 1: 330750 System Dimensional Drawing

(All dimensions are in millimeters (inches))

10/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Figure 2: 330752 System Dimensional Drawing

(All dimensions are in millimeters (inches))

11/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Figure 3: Velocity Amplitude

Figure 4: Velocity Phase Error

12/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

The Velomitor requires a two-conductor cable. We recommend using a double-shielded cable

to minimize noise interference.

Figure 5: Standard Interconnect Cable

Figure 6: Standard Armored Interconnect Cable

Figure 7: Standard Right-angle Interconnect Cable

13/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Figure 8: Short Run Interconnect Cable

Figure 9: CE Installation Interconnect Cable

14/15

330750 and 330752 High Temperature Velomitor System

Datasheet 141639 Rev. R

Copyright 2020 Baker Hughes Company. All rights reserved.

Bently Nevada, Orbit Logo and Velomitor are registered trademarks of Bently Nevada, a Baker Hughes Business, in the

United States and other countries. The Baker Hughes logo is a trademark of Baker Hughes Company. All other

product and company names are trademarks of their respective holders. Use of the trademarks does not imply any

affiliation with or endorsement by the respective holders.

Baker Hughes provides this information on an “as is” basis for general information purposes. Baker Hughes does not

make any representation as to the accuracy or completeness of the information and makes no warranties of any

kind, specific, implied or oral, to the fullest extent permissible by law, including those of merchantability and fitness

for a particular purpose or use. Baker Hughes hereby disclaims any and all liability for any direct, indirect,

consequential or special damages, claims for lost profits, or third party claims arising from the use of the

information, whether a claim is asserted in contract, tort, or otherwise. Baker Hughes reserves the right to make

changes in specifications and features shown herein, or discontinue the product described at any time without

notice or obligation. Contact your Baker Hughes representative for the most current information.

The information contained in this document is the property of BakerHughes and its affiliates; and is subject to

change without prior notice. It is being supplied as a service to our customers and may not be altered or its content

repackaged without the express written consent of Baker Hughes. This product or associated products may be

covered by one or more patents. See Bently.com/legal.

1631 Bently Parkway South, Minden, Nevada USA 89423

Phone: 1.775.782.3611 or 1.800.227.5514 (US only)

Bently.com

15/15

Loading...

Loading...