Page 1

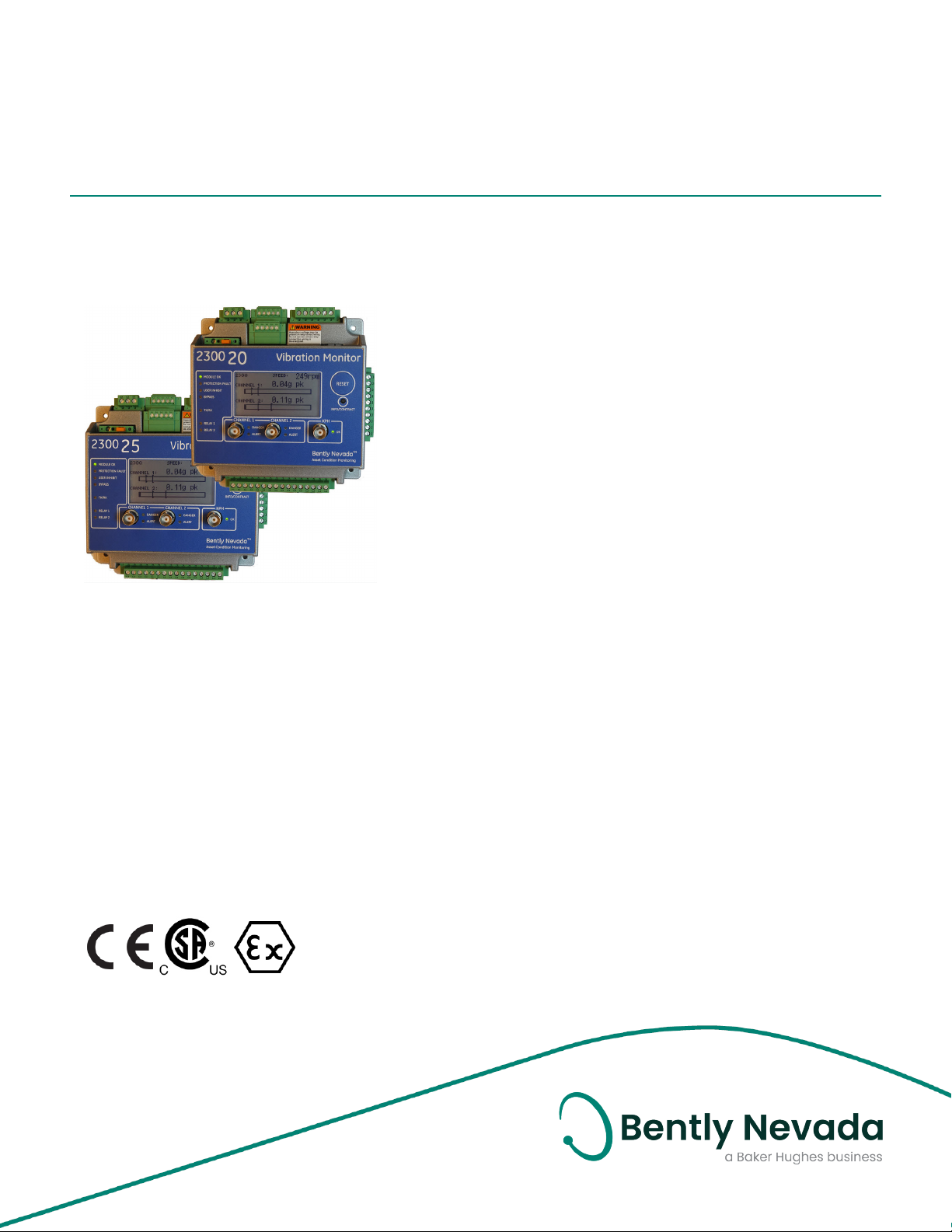

2300 Series Vibration Monitors

Datasheet

Bently Nevada Machinery Condition Monitoring

Description

The 2300 Vibration Monitors provide cost-effective

continuous vibration monitoring and protection capabilities

for less critical and spared machinery. They are specifically

designed to continuously monitor and protect essential

medium to low criticality machinery in a wide range of

industries including: oil & gas, power generation, water

treatment, pulp and paper, manufacturing, mining, cement,

and other industries.

The 2300 Vibration Monitors deliver vibration monitoring and

high vibration level alarming. They include two channels of

seismic or proximity measurement inputs from various

accelerometer, Velomitor and Proximitor types, a speed input

channel for time-synchronous measurements, and outputs

for relay contacts. The 2300/20 monitor features a

configurable 4-20 mA output which interfaces more points to

a DCS. The 2300/25 monitor features System 1connectivity for

Trendmaster SPA interface which enables users to leverage

existing DSM SPA infrastructure.

The 2300 Vibration Monitors are designed for use on a broad

range of machine trains or individual casings where the

sensor point count fits the monitor’s channel count and

where advanced signal processing is desired.

105M0340 Rev. U

Page 2

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

2300/25

Monitor Key Features

2300/20

l Two 4-20mA outputs with internal

current loop power supply.

l Continuous monitoring and protection

l Two acceleration/velocity/proximity

inputs with synchronized sampling for

advanced diagnostics.

l One dedicated speed channel

supporting Proximity probes, Magnetic

pickup and Proximity switch type sensors.

l Supports process variable on all three

input channels.

l Key measurements (Acceleration pk,

Acceleration rms, Acceleration pk/rms,

Velocity pk, Velocity rms, Displacement

pp, Displacement rms, Speed) real-time

provided with alarm configuration.

l Each channel has one measurement

group and two bandpass

measurements.

l LCD and LED for real time value and status

display.

l Ethernet 10/100 Base-T communication

for configuration using Bently Nevada

Monitor Configuration software

(Included) with RSA encryption.

l Local contacts for positive engagement

of channel bypass, configuration lockout,

and reset.

l Two relay outputs with programmable

setpoints.

l Three buffered transducer outputs

(including Keyphasor signal) providing

short circuit and EMI protection. Buffered

outputs for each signal are through BNC

connectors.

l Modbus over Ethernet.

l Trendmaster SPA interface.

l Continuous monitoring and protection.

l Two Acceleration/Velocity/Proximity

inputs with synchronized sampling for

advanced diagnostics.

l One dedicated speed channel

supporting Proximity probes, Magnetic

pickup and Proixmity switch type sensor.

l Support process variable on all three

input channels.

l Key measurements (Acceleration pk,

Acceleration rms, Acceleration pk/rms,

Velocity pk, Velocity rms, Displacement

pp, Displacement rms, Speed) real-time

provided with alarm configuration.

l Each channel has one measurement

group and two bandpass

measurements.

l LCD and LED for real time value and status

display.

l Ethernet 10/100 Base-T communication

for configuration using Bently Nevada

Monitor Configuration software

(included) with RSA encryption.

l Local contacts for positive engagement

of channel bypass, configuration lockout,

and reset.

l Two relay outputs with programmable

setpoints.

l Three buffered transducer outputs

(including Keyphasor signal) providing

short circuit and EMI protection. Buffered

outputs for each signal are through BNC

connectors.

l Modbus over Ethernet.

Caution: Two 4-20 mA outputs will NOT

work with an external powered loop.

2/19

Page 3

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Specifications

Inputs

Power Input

DC Input 18~36VDC, max 7.5W

Channel Types

ICP Accelerometers

Configurable

Bandpass filter

Scale Factor

range

Full scale range 2 to 80 g peak

Current Sink

Source

Open Circuit

Voltage

Configurable

Bandpass filter

0.2 Hz to 20 kHz

5 to 1000 mV/g

3.3 mA ± 5%

-21 to -24 VDC

Velocity

0.2 Hz to 20 kHz

Configurable

Lower OK limit

Accuracy: +1% of full scale range

Independent 24-bit ADCs on input channels

Supports Bently transducer or 2/3 wires

custom transducer for Accelerometers,

Velomitor and Proximitor.

Keyphasor transducers support multiple

events per revolution and event ratios for

speed inputs up to 20 kHz.

Threshold

voltage

resolution

Proximity Transducer Interface

Supply Voltage -22.8 to –25.2 VDC

Maximum Rated

Current

Short Circuit

Current

Accuracy ±1% of full scale range

-0.25 to -22 V (less than

upperOK)

Speed/Keyphasor

0.1VDC

15 mA

15.1 mA to 23.6 mA

Scale Factor

range

Full scale range

Configurable

Bandpass filter

Scale Factor

range

Full scale range 0 to 160 mil peak-peak

Scale Factor

range

Process Variable Channel

Support most of unit with default on

Temperature

Channel Hardware Specification

Configurable

Upper OK limit

5 to 1000 mV/in/s

0 to 50 in/s peak

Radial Vibration

0.2 Hz to 20 kHz

5 to 1000 mV/mil

Thrust Channel

5 to 1000 mV/mil

-0.25 to -22 V (greater than

lowerOK)

Input

Impedance

RPM range 6 to 120,000

Proximity Switch Interface

Supply Voltage -10 to -24 VDC

Lower Not Ok

limit

Rpm range 6 to 60,000

Input voltage Adapt to sensor 284947

RPM range 200 to 120,000

Monitor provides

3 contact

capabilities with

input terminals

3-wire Voltage Mode, 10 kΩ

-2.75 ±0.05 V

Magnetic Pick up

output

Contact Inputs

Configuration lock

Latched alarm/relay reset

function

Monitor Alarm/Relay Inhibit

3/19

Page 4

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Activate 0 to 10 kΩ

De-activate 150 kΩ to infinite

Button Inputs

External button to reset latched alarm and

relay

One buried

button provides

3 functions

Display Monitor Information

Reset listed

settings to

Default

Jumper between COM & Chassis GND

Jumpers are 2-pin terminal interfaces that

connects COM to the Chassis ground (GND).

Alternatively, COM can be connected to an

earth ground separately through a terminal.

l Display monitor

information

l LCD contrast

adjustment

l Reset settings to

default

l User account name

l IP Address

l FW/HW version

Type

Sealing

Contact life

Insulation

resistance

Relay closed

contact

resistance

Relay open

contact

resistance

Maximum

switched

contact

voltage

Maximum

breaking

contact

current

Single pole, double throw

Epoxy sealed

100,000 cycles @ 5 amps

250 VAC

200,000 @ 1 amp, 24 VDC

1000 MΩ minimum @ 500 VDC

1 Ω maximum

1 MΩ minimum

250V AC /250V DC

6A @250VAC / 6A @24VDC

Outputs

Buffered Output

Three

buffered

outputs are

available on

the monitor

through BNC

connectors

Relays

Relays

provide two

dry-contact

outputs

Relay Circuit Specification in Non-

2 Vibration Outputs

1 Speed Output

May be normally energized or

de-energized

No output feedback

determination

Hazardous Area

Maximum

switched

power

Relay Circuit Specification in Hazardous

Maximum

switched

contact

voltage and

current

1500VA AC / 150 Watts DC

Area

6A @24VAC / 5A @30VAC / 5.8A

@24VDC / 4A @30VDC

4-20mA Output (2300/20)

Two 4-20mA outputs with internal current

loop power supply

4 to 20mA output values are proportional to

the full-scale of the associated measurement.

Software configuration may determine the

variable of each output.

Voltage compliance: 0 to +12Vdc range

across load

Load resistance: 0 to 600Ω

4/19

Page 5

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Resolution: 0.3662uA

Accuracy: 1% over operating temperature

range

Update rate: 100ms

Configurable with default 2mA clamp current.

No output feedback determination.

Two 4-20 mA outputs will NOT work

with an external powered loop.

SPA Output (2300/25)

Input signal

range

Accuracy High/Low AC: ±1% of Full-Scale

Frequency

response

High AC: 8Vpp

Low AC: 1.6Vpp

DC GAP: 0 to -20Vdc (max

measurable AC signal is 1Vpp).

at 100Hz

DC GAP: ±0.5V (measurable AC

accuracy: ±20mV)

10Hz to 3000Hz ±5%

LEDs

Channel Alarm Status

Alert LED

Danger LED

Allows viewing machine speed, vibration

measurements value, setpoints, and

configuration information.

Engages if any channel is in

alert state.

Engages if any channel is in

danger state.

LCD Display

Communications

Ethernet

Ethernet, 10Base-T and

100Base-TX. Conforms to

IEEE802.3

RJ-45 for 10Base-T/100Base-TX

Ethernet cabling

Cable length: 100 meters (328 ft.)

maximum

Environmental Limits

Operating

Temperature

-30 °C to +65 °C

(-22 °F to +149 °F)

OK Indicates when the monitor is

operating properly.

Protection

fault

User inhibit Indicates the alarm/relays

Bypass Indicates user initiated bypass

Relay status Indicates if relays have been

TX/RX Indicates the Ethernet status

SPEED/AUX

channel

status

Indicates hardware fault that is

impacting alarm

determination.

have been intentionally

inhibited from operation.

action.

activated.

and monitor communicating

with remote software.

Indicates the speed channel

has valid speed signal input OR

operating correctly when AUX.

Storage

Temperature

Humidity Up to 95%, non-condensing

Vibration

Limitation

Battery Life for

Real Time

Clock

-40 °C to +85 °C

(-40 °F to +185 °F)

3g

Powered: 38 years @ 50°C (122

°F)

Un-powered: 12 years @ 50°C

(122 °F)

Physical

Dimensions

(Width x

Depth x

Height)

Weight 1.03kg (2.26lbs)

Mounting Panel mount or DIN rail

127mm x 127mm x 76.2mm (5in

x 5in x 3in)

(adapter included)

5/19

Page 6

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Compliance and Certifications

FCC

This device complies with part 15 of the

FCC Rules. Operation is subject to the

following two conditions:

l This device may not cause harmful

interference.

l This device must accept any

interference received, including

interference that may cause

undesired operation.

EMC

EN 61000-6-2 : 2005

EN 61000-6-4: 2007 +A1

EN 61326-1: 2013

EN 61326-2-3: 2013

EMC Directive 2014/30/EU

Electrical Safety

EN 61010-1:2010

LV Directive 2014/35/EU

ATEX

EN60079-0: 2012/A11:2013

EN 60079-11: 2012

EN60079-15: 2010

EN60079-7: 2015

ATEX Directive 2014/34/EU

RoHS

RoHS Directive 2011/65/EU

6/19

Page 7

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Hazardous Area Approvals

For the detailed listing of country and product

specific approvals, refer to the Approvals Quick

Reference Guide (108M1756) available from

Bently.com.

CSA/NRTL/C

Class I, Division 2/ Zone 2

AEx nA nC [ic] IIC T4 Gc

Class I, Division 2, Groups A, B, C,

and D; T4

ATEX/IECEx

2300/20

II 3 G

Ex na nC [ic] IIC T4 Gc

Ex ec nC [ic] IIC T4 Gc

T4 @ Ta = -30°C to +65°C

2300/25

II 3 G

Ex na nC ic [ic] IIC T4 Gc

Ex ec nC ic [ic] IIC T4 Gc

T4 @ Ta = -30°C to +65°C

7/19

Page 8

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

cable

Ordering Information

For the detailed listing of country and

product specific approvals, refer to the

Approvals Quick Reference Guide

(108M1756) available from Bently.com.

2300 Series Vibration Monitor

l 1 - Housing Kit: 105M6193-01

(fiberglass housing for

nonhazardous area) or 105M619302 (stainless steel housing for

hazardous area) 12 x 14 in.

l 2 - Accelerometer sensors (200350)

l 2 - 17 ft. (5.2 m) cables (9571)

l (Excluding Keyphasor sensor and

24 VDC power supply1)

2300/20-AA: Monitor with 4-20ma

Outputs

(including DIN rail mount assembly, manual

and monitor configuration software)

A: Approvals Option

00 None

02

Multiple Explosive Atmosphere

Certifications(ATEX/IECEx/CSA)

2300/25-AA: Monitor with SPA Outputs

(including DIN rail mount assembly, manual

and monitor configuration software)

A: Approvals Option

00 None

02

Multiple Explosive Atmosphere

Certifications(ATEX/IECEx/CSA)

2300/20_KIT-AAA-BB

Bently Nevada 2300/20 Condition Monitoring

System Kit

1

Provided are 3 kinds of power supplies

with different temperature and power

ranges. Verify the necessary details in

the Accessories section to follow.

A: Configuration

001

2 Sensors and 1 Housing

l 1 - 2300/20 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

002

003

004

1 Sensor and 1 Housing

l 1 - 2300/20 or 2300/25 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 1 - Housing Kit: 105M6193-01

(fiberglass housing for

nonhazardous area) or 105M619302 (stainless steel housing for

hazardous area) 12 x 14 in.

l 1 - Accelerometer sensor (200350)

l 1 - 17 ft. (5.2 m) cable (9571)

l (Excluding Keyphasor sensor and

24VDC power supply

2 Sensors

l 1 - 2300/20 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 2 - Accelerometer sensors (200350)

l 2 - 12 ft. (3.6m) cables (9571)

l (Excluding Keyphasor sensor and

24VDC power supply1)

2 Velomitors and 1 Housing

l 1 - 2300/20 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 1 - Housing Kit: 105M6193-01

(fiberglass housing for

nonhazardous area) or 105M6193-

02 (stainless steel housing for

hazardous area) 12 x 14 in.

l 2 - Velomitor sensors (330500)

l 2 - 17 ft. (5.2 m) cable (9571)

1

)

8/19

Page 9

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

l (Excluding Keyphasor sensor and

24VDC power supply1)

005

006

B: Approvals Options

00

02

1 Velomitor and 1 Housing

l 1 - 2300/20 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 1 - Housing Kit: 105M6193-01

(fiberglass housing for

nonhazardous area) or 105M619302 (stainless steel housing for

hazardous area) 12 x 14 in.

l 1 - Velomitor sensor (330500)

l 1 - 17 ft. (5.2 m) cable (9571)

l (Excluding Keyphasor sensor and

24VDC power supply1)

2 Velomitors

l 1 - 2300/20 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 2 - Velomitor sensors (330500)

l 2 - 12 ft. (3.6 m) cable (9571)

l

(Excluding Keyphasor sensor and

24VDC power supply1)

None

Multiple Explosive Atmosphere

Certifications (ATEX/IECEx/CSA

2300/25_KIT-AAA-BB

Bently Nevada 2300/25 Condition Monitoring

System Kit

A: Configuration

001

2 Sensors and 1 Housing

l 1 - 2300/25 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 1 - Housing Kit: 105M6193-01

(fiberglass housing for

nonhazardous area) or 105M6193-

002

003

004

02 (stainless steel housing for

hazardous area) 12 x 14 in.

l 2 - Accelerometer sensors

(200350)

l 2 - 17 ft. (5.2 m) cables (9571)

l (Excluding Keyphasor sensor and

24 VDC power supply 1)

1 Sensor and 1 Housing

l 1 - 2300/25 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 1 - Housing Kit: 105M6193-01

(fiberglass housing for

nonhazardous area) or 105M6193-

02 (stainless steel housing for

hazardous area) 12 x 14 in.

l 1 - Accelerometer sensor (200350)

l

1 - 17 ft. (5.2 m) cable (9571)

l

(Excluding Keyphasor sensor and

24VDC power supply1)

2 Sensors

l 1 - 2300/25 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 2 - Accelerometer sensors

(200350)

l 2 - 12 ft. (3.6m) cables (9571)

l (Excluding Keyphasor sensor and

24VDC power supply1)

2 Velomitors and 1 Housing

l 1 - 2300/25 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 1 - Housing Kit: 105M6193-01

(fiberglass housing for

nonhazardous area) or 105M6193-

02 (stainless steel housing for

hazardous area) 12 x 14 in.

l 2 - Velomitor sensors (330500)

l 2 - 17 ft. (5.2 m) cable (9571)

l (Excluding Keyphasor sensor and

9/19

Page 10

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

24VDC power supply1)

System 1 2300 Series Device Import

005

006

1 Velomitor and 1 Housing

l 1 - 2300/25 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 1 - Housing Kit: 105M6193-01

(fiberglass housing for

nonhazardous area) or 105M619302 (stainless steel housing for

hazardous area) 12 x 14 in.

l 1 - Velomitor sensor (330500)

l 1 - 17 ft. (5.2 m) cable (9571)

l (Excluding Keyphasor sensor and

24VDC power supply1)

2 Velomitors

l 1 - 2300/25 Monitor

l 1 - 6 ft. (1.8 m) shielded Ethernet

cable

l 2 - Velomitor sensors (330500)

l 2 - 12 ft. (3.6 m) cable (9571)

l (Excluding Keyphasor sensor and

24VDC power supply1)

A: Not available for 2300 monitor

00

B: Quantity of 2300 Monitoring Systems

## Numeric [1->n]

B: Approvals Option

00 None

02

Multiple Explosive Atmosphere

Certifications (ATEX/IECEx/CSA

1

Provided are 3 kinds of power supplies

with different temperature and power

ranges. Verify the necessary details in

the Accessories section to follow.

System 1 Software

2300/20 can interface to System 1 V16.2 or

higher for expanded condition monitoring and

analysis. System 1 software and the 2300 device

connectivity (P/N 3071/13) are sold separately.

Refer to document 108M5214 for System 1

detailed information.

3071/13-AA-BB

10/19

Page 11

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Accessories

106M7607-01 Power supply for DIN rail

mounting, 100/240AC to

24DC/1.5ACertifications

(ATEX) (-25°C ~70°C,

35*99*95 mm) (One power

can drive max 4 monitors)

110M7102-01

106M6694-01 Power supply for DIN rail

105M6193-02

105M6193-01

ower supply for DIN rail

P

mounting, 100/240AC to

24DC/1.3ACertifications

(CID2 by UL)

22.5*99*107 mm)

power can drive max 4

monitors.)

mounting, 110/220AC to

24VDC/5ACertifications

(ATEX, IECEx, CID2 by UL)

C ~70°C, 40*130*125 mm)

40°

(One power can drive max

10 monitors.)

Stainless Steel Housing for

2300 KIT (can be used in

hazardous area)

Fiberglass NEMA 4X/IP66

weatherproof housing with

window in door (includes

mounting plate for

monitor)

(-25°C ~70°C,

(One

(-

Figure 1: 105M6193-02 Weatherproof

Housing

Dimensions

Width: 338.3 mm (13.3 in)

Height: 389.1 mm (15.3 in)

Depth: 209.8 mm (8.2 in)

(used in nonhazardous

area)

11/19

Page 12

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Figure 2: 105M6193-01 Weatherproof

Housing

Figure 3: 200350 Accelerometer Sensor

Figure 4: AM3100T2-Z2 Accelerometer

Sensor

12/19

Page 13

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Figure 8: 330525 Velomitor

Figure 5: 330400/330425 Accelerometer

Sensor

Figure 6: 330500 Velomitor

Figure 7: 330505 Velomitor

Figure 9: 190501 Velomitor

Figure 10: 100M0741 Proximity Switch

13/19

Page 14

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Figure 11: 284947 Magnetic Pickup

Proximity Transducer System

Refer to the following proximity transducer

system datasheets for details.

172036 3300 5mm

141194 3300 XL 8mm

146256 3300 XL 11mm

147385 3300 XL NSV

02120015 Bulk Cable from Proximity sensor to

monitor (500 ft.)

CB2W100AAA

Cable for 2 -wire transducer

The CB2W100 cable is not

recommended for use with the 200350

Accelerometer. The O-ring will not form

a proper seal with the accelerometer.

A: Cable Length

015 15 ft. (4.8 m)

032 32 ft. (9.8 m)

064 64 ft. (19.5 m)

112 112 ft. (34.1 m)

125 125 ft. (38.1 m)

150

200 200 ft. (61.0 m)

250 250 ft. (76.2 m)

150 ft. (45.7 m)

Splash Proof Cable for 2-wire

transducer

9571-AA

A: From “02” to “99” Increments of 1.0 foot

2

Low cost cable for accelerometer

84661-AA2Armored cable for 2 -wire transducer

A: From “03” to “99” Increments of 1.0 foot

9571 Mod: 285031-AA

2

Cable for 2-wire extension with Splash Proof

Connection. This cable assembly provides an

equivalent IP66 level of protection.

A: Cable Lengths

16 16 ft. (4.8 m)

32 32 ft. (9.8 m)

64 64 ft. (19.5 m)

For conducted RF performance, metal

conduit with both ends grounded is

required for Proximitor 3300-NSV cables

and Accelerometer 330400 cable.

2Cable lengths greater than 30 meters

(100 feet) will experience some

attenuation of amplitudes at higher

14/19

Page 15

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

frequencies when using the AM3100T2Z2 Accelerometer.

Accessories

286244 Magnetic mounting base ¼-28

threaded hole

Ethernet Cables

138131-AAA

Standard 10 Base-T/100 Base-TX Shielded

Category 5 Cable with RJ-45 connectors (solid

conductor)

A: Cable Length

006 6 ft. (1.8 m)

010 0 10 ft. (3.0 m)

025 25 ft. (7.6 m)

040 40 ft. (12.2 m)

050 50 ft. (15.2 m)

075 75 ft. (22.9 m)

085 85 ft. (25.9 m)

02120015

9571-AA

2

Bulk Cable from Proximity

sensor to monitor (500

ft.)

Low cost cable for 2-wire

transducer

Software

100M9465-01 BN Monitor

Configuration SW/FW

DVD

l BNMC version 5.2

or greater

l 2300 series

monitor firmware

l (DVD includes

2300 Series

Software Guide)

Additional Information

100 100 ft.

(30.5 m)

Spares

105M6203-0135mm DIN rail mount and

screws (included with 2300/20

monitor)

106M3210 10-pin 4-20mA output

connector

106M2223

106M3408

106M3211

106M3212

106M2231 3-pin power input connector

5-pin contact input connector

(Alarm Reset)

5-pin contact input connector

(Alarm Inhibit, Config lock)

16-pin transducer input

connector

6-pin relay output connector

2300 Series Operation and Maintenance

Manual (Document 105M0341)

2300 Field Wiring Diagram (Document

106M5801)

2300 Series Software Guide (Document

107M7626)

2300 Series Monitor Installation Guide

(Document 121M3029)

15/19

Page 16

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Graphs and Figures

Figure 12: 2300 Series Monitor Recommended Clearance

16/19

Page 17

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Wiring Diagram

Figure 13: 2300/20 Wiring Diagram

2300/20 and 2300/25 use the same interface connector for recorder output or SPA output.

17/19

Page 18

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Figure 14: 2300/25 Wiring Diagram

2300/20 and 2300/25 use the same interface connector for recorder output or SPA output.

18/19

Page 19

2300 Series Vibration Monitors

Datasheet 105M0340 Rev. U

Copyright 2020 Baker Hughes Company. All rights reserved.

Bently Nevada, Orbit Logo, System 1, Velomitor, Proximitor and Keyphasor are registered trademarks of Bently Nevada,

a Baker Hughes Business, in the United States and other countries. The Baker Hughes logo is a trademark of Baker

Hughes Company. All other product and company names are trademarks of their respective holders. Use of the

trademarks does not imply any affiliation with or endorsement by the respective holders.

Baker Hughes provides this information on an “as is” basis for general information purposes. Baker Hughes does not

make any representation as to the accuracy or completeness of the information and makes no warranties of any

kind, specific, implied or oral, to the fullest extent permissible by law, including those of merchantability and fitness

for a particular purpose or use. Baker Hughes hereby disclaims any and all liability for any direct, indirect,

consequential or special damages, claims for lost profits, or third party claims arising from the use of the

information, whether a claim is asserted in contract, tort, or otherwise. Baker Hughes reserves the right to make

changes in specifications and features shown herein, or discontinue the product described at any time without

notice or obligation. Contact your Baker Hughes representative for the most current information.

The information contained in this document is the property of BakerHughes and its affiliates; and is subject to

change without prior notice. It is being supplied as a service to our customers and may not be altered or its content

repackaged without the express written consent of Baker Hughes. This product or associated products may be

covered by one or more patents. See Bently.com/legal.

1631 Bently Parkway South, Minden, Nevada USA 89423

Phone: 1.775.782.3611 or 1.800.227.5514 (US only)

Bently.com

19/19

Loading...

Loading...