Installation Tester

BENNING IT 130

Operating Manual

Manufacturer:

BENNING Elektrotechnik und Elektronik GmbH & Co. KG

Münsterstraße 135 - 137

D - 46397 Bocholt

Phone: +49 (0) 2871 - 93 - 0 • Fax: +49 (0) 2871 - 93 - 429

www.benning.de • duspol@benning.de

This symbol on your device ensures that the device complies with the requirements laid

down by the EU (European Union) with regard to safety and electromagnetic compatibility

of devices.

© 10/2018 BENNING

This document must not be reproduced or used in any other form without the express written

consent of BENNING.

IDNo. 20 752 249 Part no.: 10110213.04

BENNING IT 130 Content

Table of contents

1 Preface ............................................................................................................................... 6

2 Safety and operating instructions ................................................................................... 7

2.1

Warnings ..................................................................................................................... 7

2.2

Batteries / storage batteries and charger ................................................................... 11

2.3

Standards applied ..................................................................................................... 13

3 Device description .......................................................................................................... 14

3.1

Front panel ................................................................................................................ 14

3.2

Connection panel ...................................................................................................... 15

3.3

Rear panel ................................................................................................................ 16

3.4

Carrying the installation tester ................................................................................... 17

3.4.1

Attachment of the carrying strap ........................................................................ 18

3.5

Scope of delivery and optional accessories ............................................................... 19

3.5.1

Standard scope of delivery ................................................................................ 19

3.5.2

Optional accessories ......................................................................................... 20

4 Operating the BENNING IT 130 installation tester ........................................................ 21

4.1

Indications and acoustic warning signals ................................................................... 21

4.1.1

Connection monitor ........................................................................................... 21

4.1.2

Battery indication ............................................................................................... 21

4.1.3

Warnings and messages ................................................................................... 21

4.1.4

Evaluation field .................................................................................................. 22

4.1.5

Acoustic warning signals ................................................................................... 22

4.1.6

Help menu ("HELP" key) ................................................................................... 23

4.1.7

Background lighting and contrast ....................................................................... 23

4.2

Function selector switch ............................................................................................ 24

4.3

"AUTO" mode ............................................................................................................ 24

4.4

"SETTINGS" mode .................................................................................................... 25

4.4.1

Memory ............................................................................................................. 25

4.4.2

Language .......................................................................................................... 25

4.4.3

Date and time .................................................................................................... 26

4.4.4

Earthing system (power supply network) ........................................................... 26

4.4.5

RCD testing ....................................................................................................... 27

4.4.6

Isc factor (scaling factor) .................................................................................... 28

4.4.7

Commander ON/OFF ........................................................................................ 29

4.4.8

Initial settings ..................................................................................................... 29

4.4.9

Clamp settings ................................................................................................... 30

5 Measurements ................................................................................................................. 32

5.1

TRMS voltage, frequency and phase sequence ........................................................ 32

5.2

Insulating resistance.................................................................................................. 34

5.3

Low-impedance resistance / continuity test ............................................................... 36

5.3.1

Low-impedance resistance with a testing current of 200 mA ............................. 36

5.3.2

Continuity test with a testing current of 7 mA ..................................................... 37

5.3.3

Compensation (null balance) of the test cable resistance .................................. 38

5.4

RCD testing ............................................................................................................... 40

5.4.1

Contact voltage (Uc) .......................................................................................... 41

5.4.2

Tripping time (RCDt) .......................................................................................... 42

5.4.3

Tripping current (RCD I) .................................................................................... 42

5.4.4

Automatic test .................................................................................................... 43

- 3 -

BENNING IT 130 Content

5.5

Loop impedance and prospective short-circuit current ............................................... 46

5.6

Line impedance and prospective short-circuit current / voltage drop.................... 48

5.6.1

Line impedance and prospective short-circuit current ........................................ 49

5.6.2

Voltage drop ...................................................................................................... 50

5.7

Earthing resistance ................................................................................................... 52

5.8

Testing the protective conductor connection (PE) ..................................................... 54

5.9

TRMS current by means of current clamp adapter .................................................... 56

5.10 Single-fault leakage current (ISFL) in IT networks ..................................................... 57

5.11 Luminous intensity .................................................................................................... 59

6 Management of measured values .................................................................................. 61

6.1

Memory structure ...................................................................................................... 61

6.2

Saving measuring results .......................................................................................... 63

6.3

Recalling measuring results ...................................................................................... 64

6.4

Deleting measuring results ........................................................................................ 65

6.4.1

Deleting the entire measured value memory ...................................................... 65

6.4.2

Deleting all measurements of each storage location and subordinate storage

locations 65

6.4.3

6.5

Renaming installation structure fields ........................................................................ 67

6.5.1

6.5.2

6.6

USB and RS232 interface ......................................................................................... 68

7 Maintenance .................................................................................................................... 69

7.1

Fuse replacement ..................................................................................................... 69

7.2

Cleaning .................................................................................................................... 69

7.3

Periodic calibration .................................................................................................... 69

7.4

Service ...................................................................................................................... 70

8 Technical data ................................................................................................................. 71

8.1

Insulating resistance.................................................................................................. 71

8.2

Low-impedance resistance / continuity test ............................................................... 72

8.2.1

8.2.2

8.3

Residual current protection devices (RCDs) .............................................................. 72

8.3.1

8.3.2

8.3.3

8.3.4

8.4

Loop impedance and prospective short-circuit current ............................................... 75

8.4.1

8.4.2

8.5

Line impedance and prospective short-circuit current / voltage drop ......................... 76

8.6

Earthing resistance ................................................................................................... 77

8.7

TRMS voltage, frequency and phase sequence ........................................................ 77

8.7.1

8.7.2

8.7.3

8.7.4

8.8

TRMS current (AC / DC) via current clamp adapter ................................................... 78

8.9

Single-fault leakage current (ISFL) in IT networks ..................................................... 78

8.10 Luminous intensity .................................................................................................... 79

8.11 General data ............................................................................................................. 80

Deleting an individual measurement .................................................................. 66

Renaming installation structure fields by means of the PC software .................. 67

Renaming the installation structure fields by means of the barcode scanner ..... 67

Low-impedance resistance R LOW ................................................................... 72

Continuity test .................................................................................................... 72

General data ...................................................................................................... 72

Contact voltage (Uc) .......................................................................................... 73

Tripping time (RCD t) ......................................................................................... 73

Tripping current (RCD I) .................................................................................... 74

Zs function (for systems without RCD) ............................................................... 75

Zsrcd function (for systems with RCD) ............................................................... 75

TRMS voltage (AC/DC) ..................................................................................... 77

Voltage of the connection monitor ..................................................................... 77

Frequency ......................................................................................................... 77

Phase sequence (rotary field) ............................................................................ 77

- 4 -

BENNING IT 130 Content

Appendix A

Appendix B

Appendix C

C.1

C.2

C.3

C.4

Batteries ................................................................................................................... 85

Description of the "Commanders" ......................................................................... 86

LED indications of the "Commanders" .................................................................. 87

Fuse table – Prospective short-circuit current .......................................... 81

Standard and optional accessories for specific measuring functions .... 84

"Commander" test probe, "Commander" test plug ................................... 85

Safety warnings ................................................................................................ 85

- 5 -

BENNING IT 130 Preface

1 Preface

BENNING would like to congratulate you on purchasing this BENNING IT 130 installation tester

and its accessories. The BENNING IT 130 installation tester is a multifunctional tester for testing

electrical installations in compliance with IEC 60364-6 (DIN VDE 0100-600) and EN 50110

(DIN VDE 0105-100).

The device is intended for the following measurements and tests:

TRUE RMS voltage, frequency and rotary field (phase sequence)

low-impedance resistance, continuity test

insulating resistance

residual current protection devices (RCD)

loop impedance without RCD tripping

line impedance and voltage drop

TRUE RMS current by means of optional current clamp adapters

earthing resistance by means of optional earthing kit

luminous intensity by means of optional luxmeter

single-fault leakage current in IT networks

The graphic display with background lighting allows easy reading of measuring results,

indications, measuring parameters and messages. Two "PASS" / "FAIL" indications (red / green

LEDs) are located next to the LC display.

The BENNING IT 130 installation tester is equipped with all accessories necessary for

comfortable testing. It is kept in a padded carrying case together with all accessories.

- 6 -

BENNING IT 130 Safety and operating instructions

2 Safety and operating instructions

The following symbols are used both in the operating manual and on the installation tester:

Attention! Danger! Please observe the operating manual!

Warning of dangerous voltage!

Protection class II

Earth (voltage to earth)

2.1 Warnings

In order to ensure a high degree of operational safety during the tests and measurements and

to avoid damaging of the BENNING IT 130 installation tester, the general warnings listed in the

following must be adhered to.

Warnings – general information:

In case the installation tester is not used according to this operating manual, the

protection provided by the installation tester might be impaired!

Please read this operating manual carefully, because otherwise the use of the

installation tester might involve dangers for the user, the installation tester or the

test object!

Never use the installation tester or the corresponding accessories, if they exhibit

visible damages!

Absolutely observe all general safety instructions in order to avoid the risk of an

electric shock when handling dangerous voltages!

If the fuse F1 has blown, please follow the instructions of this operating manual to

replace it! Only use a fuse complying with the specification (see chapter 7.1) as

replacement.

If one of the fuses F2 or F3 has blown, the device must not be used anymore. In

this case, the device must be sent to BENNING for inspection and repair.

Never use the installation tester in AC supply systems with voltages higher than

550 V AC.

Any service, repair or adjustments of the installation tester and of the

corresponding accessories must be carried out by authorized qualified personnel

only!

Please use standard or optional BENNING accessories only which are available

from your authorized specialty retailer!

- 7 -

BENNING IT 130 Safety and operating instructions

Please observe that the measuring category of some accessories might be lower

than that of the installation tester. Test probes and "Commander" test probes are

provided with detachable protective caps. If these attachable protective caps are

removed, the measuring category will be reduced to CAT II. Please check the

markings of the accessories!

without attachable protective cap, 18 mm tip: CAT II 1000 V to earth

with attachable protective cap, 4 mm tip: CAT II 1000 V / CAT III 600 V /

CAT IV 300 V to earth

The installation tester comes with rechargeable NiMh storage batteries. The

storage batteries must be replaced only as shown on the label at the battery

compartment cover or as described in this operating manual and must be

replaced with storage batteries of the same type only. Do not use standard

alkaline batteries while the charger is connected, because otherwise these

batteries might explode!

Dangerous voltages are applied to the interior of the device! Disconnect all test

cables, disconnect the charger and switch off the installation tester before

opening the cover of the battery / fuse compartment.

Do not connect any voltage source to the C1 input. This input must be used for

connection of the current clamp adapters only. The maximum input voltage is 3 V!

Absolutely observe all common safety instructions in order to avoid the risk of an

electric shock when working on electrical installations!

Warnings with regard to measurements:

Insulating resistance

Measurements of the insulating resistance must be carried out only at test objects which

are free of voltage!

Never touch the test object during measurement before it is completely discharged!

Danger of life-threatening electric shocks!

If the insulating resistance is measured on capacitive test objects, discharging might

take place time-delayed! During discharge, the warning as well as the current

voltage are displayed until the voltage falls below 30 V.

Do not connect any measuring input to an external voltage higher than 550 V (AC or DC)

in order not to damage the installation tester!

Low-impedance measurement / continuity test

Low-impedance measurements / continuity tests must be carried out on discharged test

objects only!

The test result might be influenced by parallel impedances.

Testing the PE connection

If a phase voltage is detected at the PE connection, immediately stop all measurements.

Make sure that the error in the installation is eliminated before going on with the

measurements!

- 8 -

BENNING IT 130 Safety and operating instructions

Remarks with regard to measurements:

General

The icon means that the selected measurement cannot be carried out due to

irregular conditions at the input terminals.

Carry out measurements of the insulating resistance, low-impedance resistance,

continuity and earthing resistance on discharged objects only!

The "PASS" / "FAIL" indication is activated, if a limiting value has been defined. Choose

appropriate limiting values for evaluating the measuring results.

If only two of the three test cables are connected to the electrical installation to be

tested, only the voltage value between those two test cables shall be valid.

Insulating resistance

The three-wire test cable as well as the "Commander" test probe can be used for

measuring the insulating resistance.

If a voltage higher than 30 V (AC or DC) is measured at the testing terminals, the

measurement of the insulating resistance cannot be carried out.

The installation tester automatically discharges test objects after the measurement is

finished.

Double-click the "TEST" key to carry out a continuous measurement.

Low-impedance measurement / continuity test

If a voltage higher than 10 V (AC or DC) is measured at the testing terminals, the lowimpedance measurement / continuity test cannot be carried out.

Before carrying out a low-impedance measurement / continuity test, compensate the test

cable resistance (if necessary).

Earthing resistance

If a voltage higher than 30 V (AC or DC) is measured at the testing terminals, the

measurement of the earthing resistance cannot be carried out.

If an interference voltage higher than 5 V is detected at the testing terminals H and E or

S, the warning symbol " ” will be displayed indicating that the measuring result might

have been influenced!

Residual current protection devices (RCDs)

The parameters set for a measuring function will be taken over for other RCD

measurements as well!

Contact voltage measurement usually does not involve any tripping of the residual

current protection devices (RCD). However, the tripping threshold might be exceeded

due to leakage currents via the protective conductor (PE) or via capacitive connections

between the conductors L and PE.

Compared to the loop impedance RL (contact voltage subresult), the measurement of

the loop impedance Zs

rcd

needs more time, but offers a considerably higher degree of

accuracy.

The tripping time and tripping current measurement is only carried out, if the contact

voltage at nominal differential current is lower than the preset limiting value of the

contact voltage.

The automatic test sequence (RCD AUTO function) is stopped, if the tripping time is

outside the admissible value.

- 9 -

BENNING IT 130 Safety and operating instructions

Loop impedance

The lower limiting value of the prospective short-circuit current depends on the fuse type,

on the fuse current rating and tripping time as well as on the I

The stated accuracy of the parameters tested shall only apply, if the mains voltage is

SC

scaling factor.

stable during measurement.

Loop impedance measurements (Zs) involve tripping of residual current protection

devices (RCDs).

Loop impedance measurements (Zs

rcd

) normally do not involve tripping of the residual

current protection device (RCD). However, the tripping threshold might be exceeded due

to leakage currents flowing to the protective conductor (PE) or via the capacitive

connection between the conductors L and PE.

Line impedance / voltage drop

During phase-to-phase measurements of the line impedance ZI(L-L) with the test cables

PE and N being connected, a warning of dangerous PE voltages is displayed. However,

the measurement will be carried out.

The stated accuracy of the parameters tested shall only apply, if the mains voltage is

stable during measurement.

Depending on the connection voltage detected, the test terminals L and N are inverted

automatically.

Luminous intensity

Shadows and irregular exposure to light might influence the measuring result!

Artificial light sources reach their full capacity (see Technical Data of the light sources)

only after a certain time and therefore should be switched on until they reach this

capacity before carrying out measurements.

Testing the protective conductor connection (PE)

The PE connection can be tested only in switch positions "FI/RCD", "ZS(L-PE)" and

"ZI(L-N/L)"!

For correct measurement of the PE connection, the "TEST" key must be touched for

several seconds.

Make sure not to stand on an insulated floor, because otherwise the test result might be

incorrect!

- 10 -

BENNING IT 130 Safety and operating instructions

+

-

2.2 Batteries / storage batteries and charger

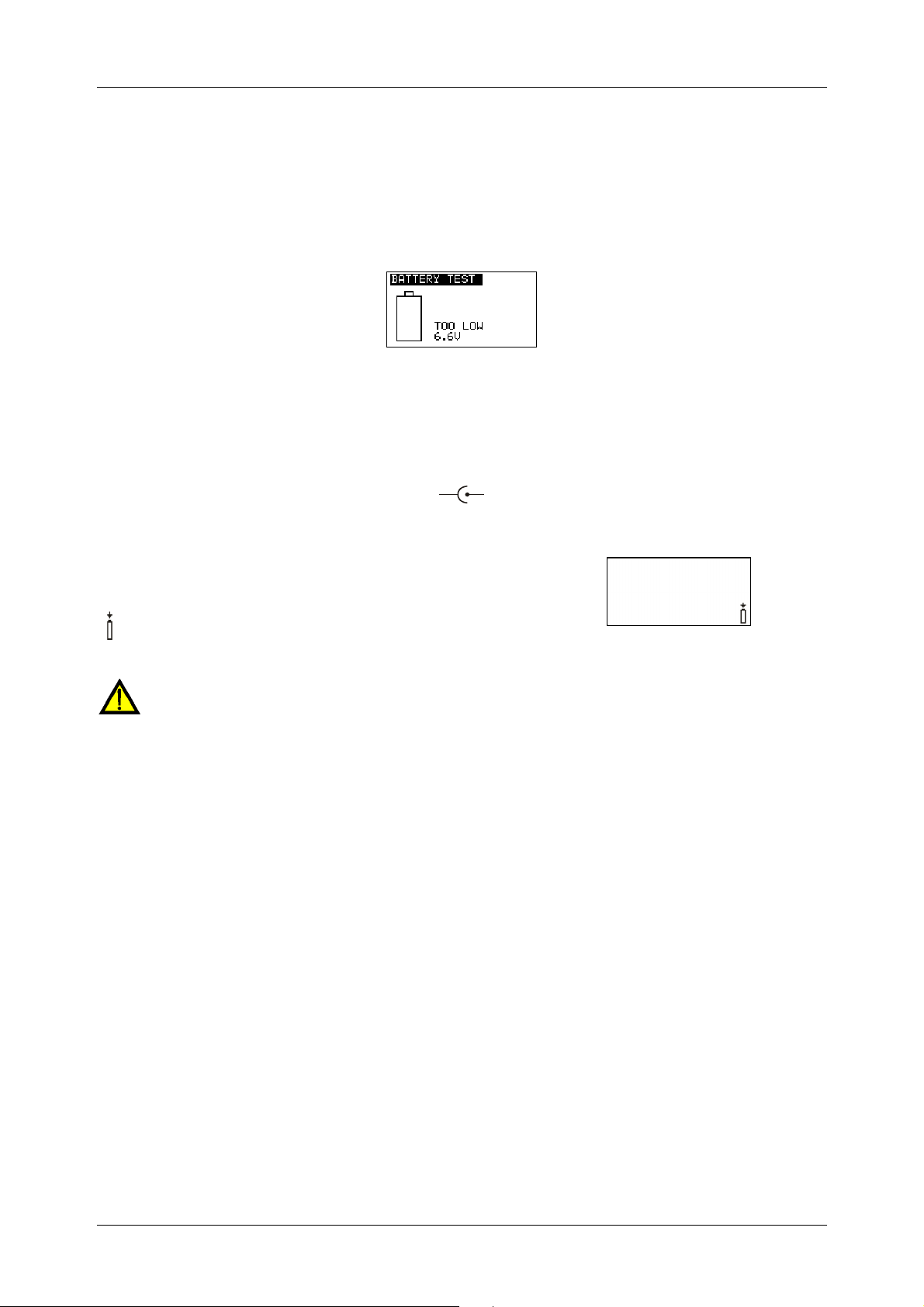

The installation tester can be operated with six alkaline batteries (type AA) or with rechargeable

NiMh batteries (storage batteries). The specified operating time refers to storage batteries with

a nominal capacity of 2500 mAh. The batteries' state of charge is permanently displayed in the

lower right part of the LC display. If the battery voltage is too low, this will be displayed as

shown in figure 2.1. This indication is shown several seconds before the tester switches off.

Figure 2.1: Indication of discharged batteries

The rechargeable NiMh storage batteries will be charged automatically as soon as the charger

is connected with the charging jack of the installation tester. The polarity of the charging jack will

be displayed as shown in figure 2.2. An integrated protective circuit controls the charging

process and ensures an optimum battery lifetime.

Figure 2.2: Polarity of the charging jack

Symbol:

General warnings:

If the installation tester is connected to an installation, a dangerous voltage might be

applied to the battery compartment! Disconnect all test cables / accessories from the

installation tester and switch the installation tester off before replacing the batteries /

storage batteries and before opening the cover of the battery / fuse compartment!

Please make sure that the batteries / storage batteries are inserted correctly, because

otherwise the installation tester cannot be operated and the storage batteries will

discharge.

Do not recharge alkaline batteries!

Use only the charger included in the delivery!

Notes:

Before the first use! Insert the storage batteries into the battery compartment and charge

the storage batteries for at least 16 hours.

The charger inside the installation tester is a cell pack charger. This means that the

storage batteries are connected in series during charging. For this reason, the storage

batteries must be equivalent (same state of charge, same condition, same type and

same age).

If the installation tester is not used for a longer period of time, remove all storage

batteries from the battery compartment.

Use alkaline batteries or rechargeable NiMh batteries of size AA only! It is recommended

to use storage batteries with a minimum capacity of 2500 mAh.

Indication of the storage battery

charging process

Figure 2.3: Charging in progress

- 11 -

BENNING IT 130 Safety and operating instructions

Unpredictable chemical processes might occur during the charging of storage batteries

that have not been used for a longer period of time (more than 6 months). In this case, it

is recommended to repeat the charging / discharging cycle at least 2 to 4 times.

If no improvement is achieved after several charging / discharging cycles, every storage

battery should be tested individually (by comparing the storage battery voltages, testing

by means of a cell charger etc.). It is very likely that only some of the storage batteries

have lost capacity. If one storage battery differs from the other ones, this might affect the

correct functioning of the entire storage battery block!

The effects described above must not be confused with the normal battery capacity

decrease over time. All rechargeable batteries (storage batteries) lose some of their

battery capacity when being charged / discharged several times. This information is

provided in the technical data specified by the battery manufacturer.

- 12 -

BENNING IT 130 Safety and operating instructions

2.3 Standards applied

The BENNING IT 130 installation tester is manufactured and tested in compliance with the

following regulations:

Electromagnetic compatibility (EMC)

EN 61326-1 Electrical equipment for measurement, control and laboratory use

– EMC requirements

Class B (hand-held equipment in controlled EM environments)

Safety (LVD)

EN 61010-1 Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

EN 61010-2-030 Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 2-030: Particular requirements for testing and

measuring circuits

EN 61010-031 Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 031: Safety requirements for hand-held probe

assemblies for electrical measurement and test

EN 61010-2-032 Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 2-032: Particular requirements for hand-held and

hand-manipulated current sensors for electrical test and measurement

Functionality

EN 61557 Electrical safety in low-voltage distribution systems up to 1000 VAC and

1500 VDC – Equipment for testing, measuring or monitoring of protective

measures

Part 1: General requirements

Part 2: Insulation resistance

Part 3: Loop impedance

Part 4: Resistance of earth connection and equipotential bonding

DIN 5032 Photometry

Reference standards for electrical installations and components

EN 61008 Residual current operated circuit-breakers without integral overcurrent

EN 61009 Residual current operated circuit-breakers with integral overcurrent

EN 60364-4-41 Low-voltage electrical installations – Part 4-41: Protection for safety –

BS 7671 IEE Wiring Regulations (17th edition)

AS / NZS 3017 Electrical installations – Verification guidelines

Note on EN and IEC standards:

This operating manual contains references to European standards. All standards of the

series EN 6XXXX (e.g. EN 61010) correspond to the respective IEC standards with the

same number (e.g. IEC 61010). They only differ in the modified parts due to the

European harmonization procedures.

Part 5: Resistance to earth

Part 6: Effectiveness of residual current devices (RCD) in TT, TN and IT

systems

Part 7: Phase sequence

Part 10: Combined measuring equipment for testing, measuring or

monitoring of protective measures

Part 7: Classification of illuminance meters and luminance meters

protection for household and similar uses (RCCBs)

protection for household and similar uses (RCBOs)

Protection against electric shock

- 13 -

BENNING IT 130 Device description

LCD

UP

DOWN

ESC

TAB

Backlight,

Green / red LED

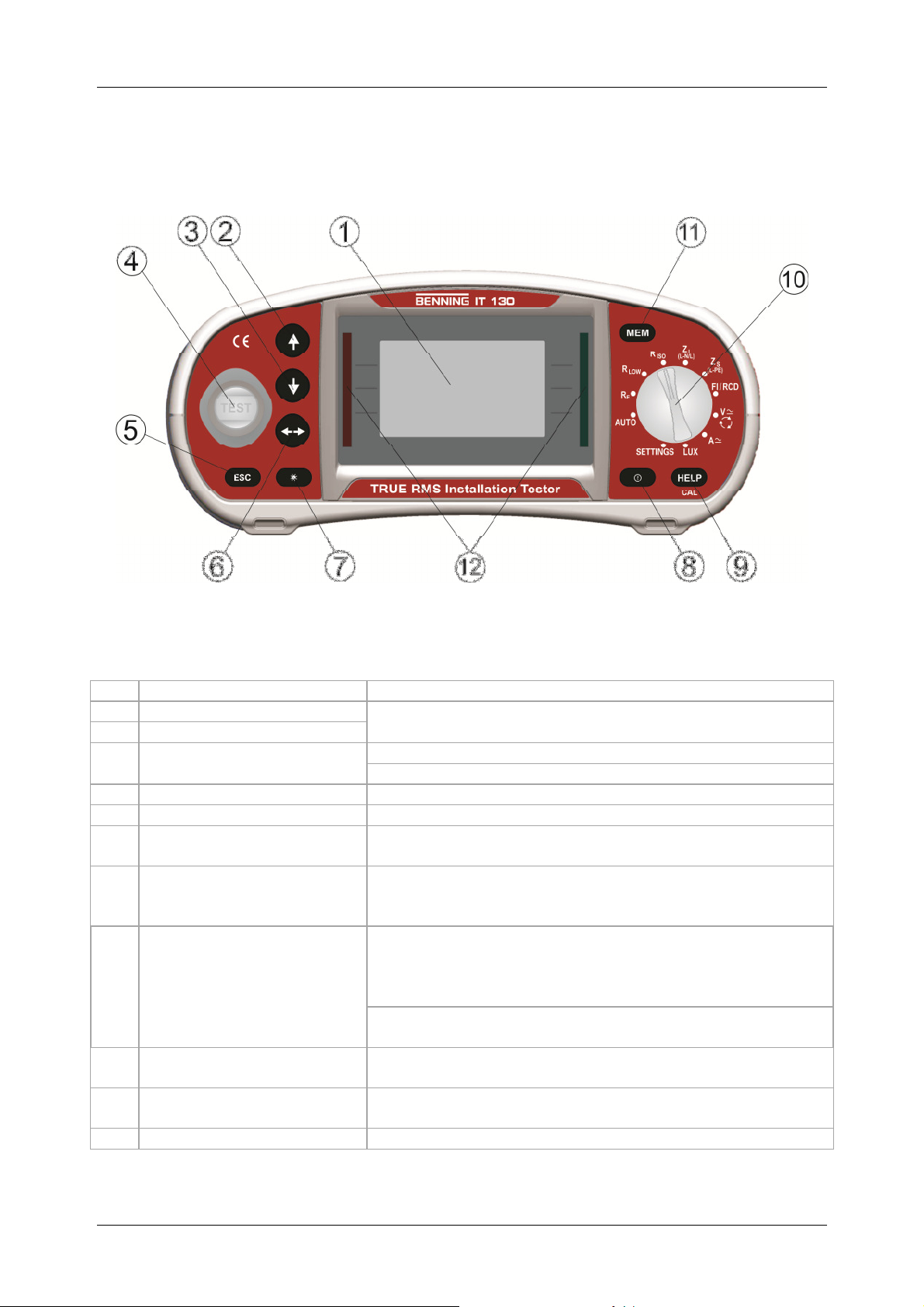

3 Device description

3.1 Front panel

Caption:

1

2

3

TEST

4

5

6

7

Contrast

ON / OFF

8

HELP / CAL

9

Function selector switch

10

MEM

11

12

Figure 3.1: Front panel

Matrix display with 128 x 64 pixels and background lighting

Modifies selected parameters

Start of measurement

PE contact electrode for protective conductor connection

Back / cancel

Selects parameters in the measuring function selected

Modifies background lighting and contrast

Switches the tester on or off;

automatic switch-off ("APO") after 15 minutes without

pressing a key

Help function with connection diagrams

(press approx. 2 seconds for R LOW and ∆U)

For calibrating the test cables in the R LOW and

CONTINUITY function

Starts the Z

voltage drop

Rotary switch for selecting the measuring functions,

"AUTO" switch position and "SETTINGS" mode

Storage / recall of measuring results;

stores the settings of the current clamp adapter

PASS / FAIL indication of the measuring results

measurement in the sub-function ∆U

REF

- 14 -

BENNING IT 130 Device description

Test connection

Charging jack

USB port

Protective cover

3.2 Connection panel

Figure 3.2: Connection panel

Caption:

1

2

3

4

5

6

C1

PS/2 port

Measuring inputs / outputs

For charging rechargeable NiMh storage batteries

USB interface (1.1) for PC connection

Measuring input for optional current clamp adapter BENNING

CC 1 / BENNING CC 2 / BENNING CC 3

Serial RS232 interface for PC connection;

connection for optional BENNING luxmeter type B (044111) and

barcode scanner (009371)

Warnings!

The maximum admissible voltage between the testing terminals and earth is 550 V!

The maximum admissible voltage between the testing terminals is 550 V!

The maximum admissible voltage at the measuring input C1 is 3 V!

The maximum admissible short-term voltage of the external charger is 14 V!

- 15 -

BENNING IT 130 Device description

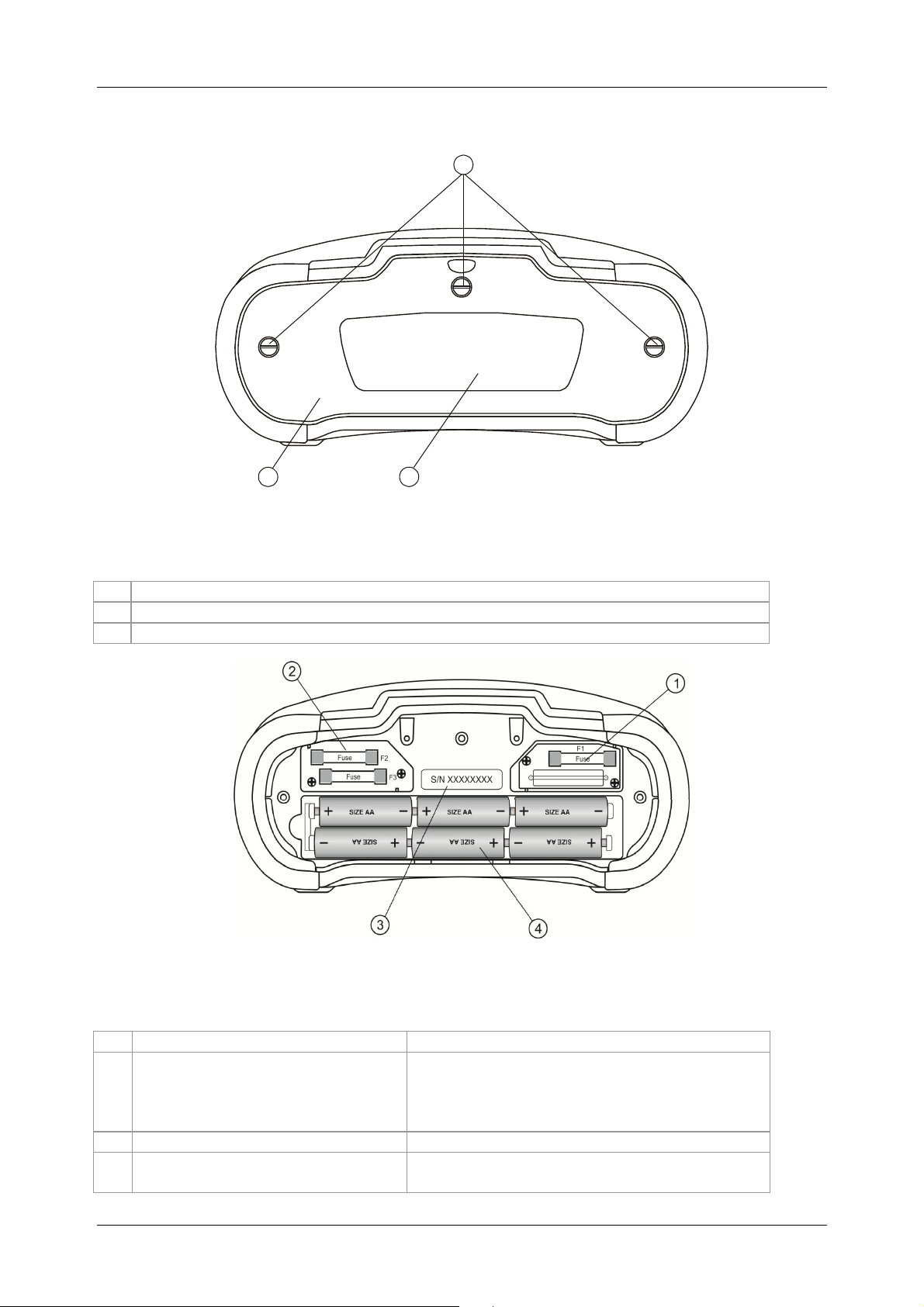

3

Cover of the battery / fuse compartment

Information label

Screws for the battery / fuse compartment cover

Fuse F1

Fuses F2 and F3

Serial number label

Storage batteries / batteries

3.3 Rear panel

Caption:

1

2

3

1

2

Figure 3.3: Rear panel

Figure 3.4: Battery / fuse compartment

Caption:

1

2

3

4

M 315 mA / 250 V

If one of the fuses F2 or F3 has blown, the

device must not be used anymore. In this

case, the device must be sent to BENNING for

inspection and repair.

Size AA, alkaline / rechargeable NiMh,

quantity: 6 pieces

- 16 -

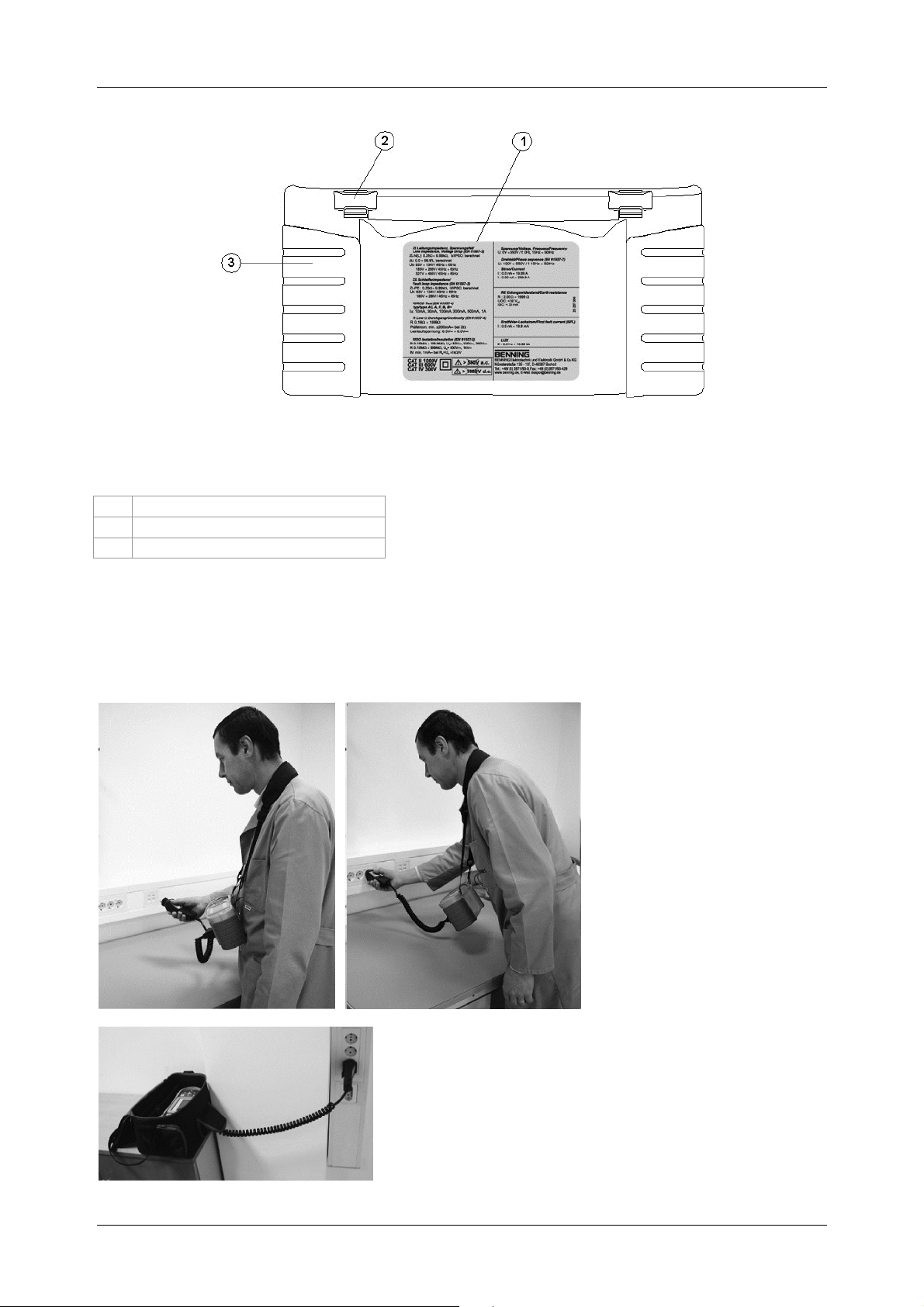

BENNING IT 130 Device description

Information label

Carrying strap openings

Lateral co

vers

Figure 3.5: Bottom view

Caption:

1

2

3

3.4 Carrying the installation tester

The installation tester can be carried in different ways by means of the accessories included in

the standard scope of delivery.

The tester can be hung

around the operator's neck by

means of the carrying strap.

It is also possible to carry the tester in the padded carrying

case and to use it in a horizontal position. The carrying

case is provided with an aperture for passing through the

test cable.

- 17 -

BENNING IT 130 Device description

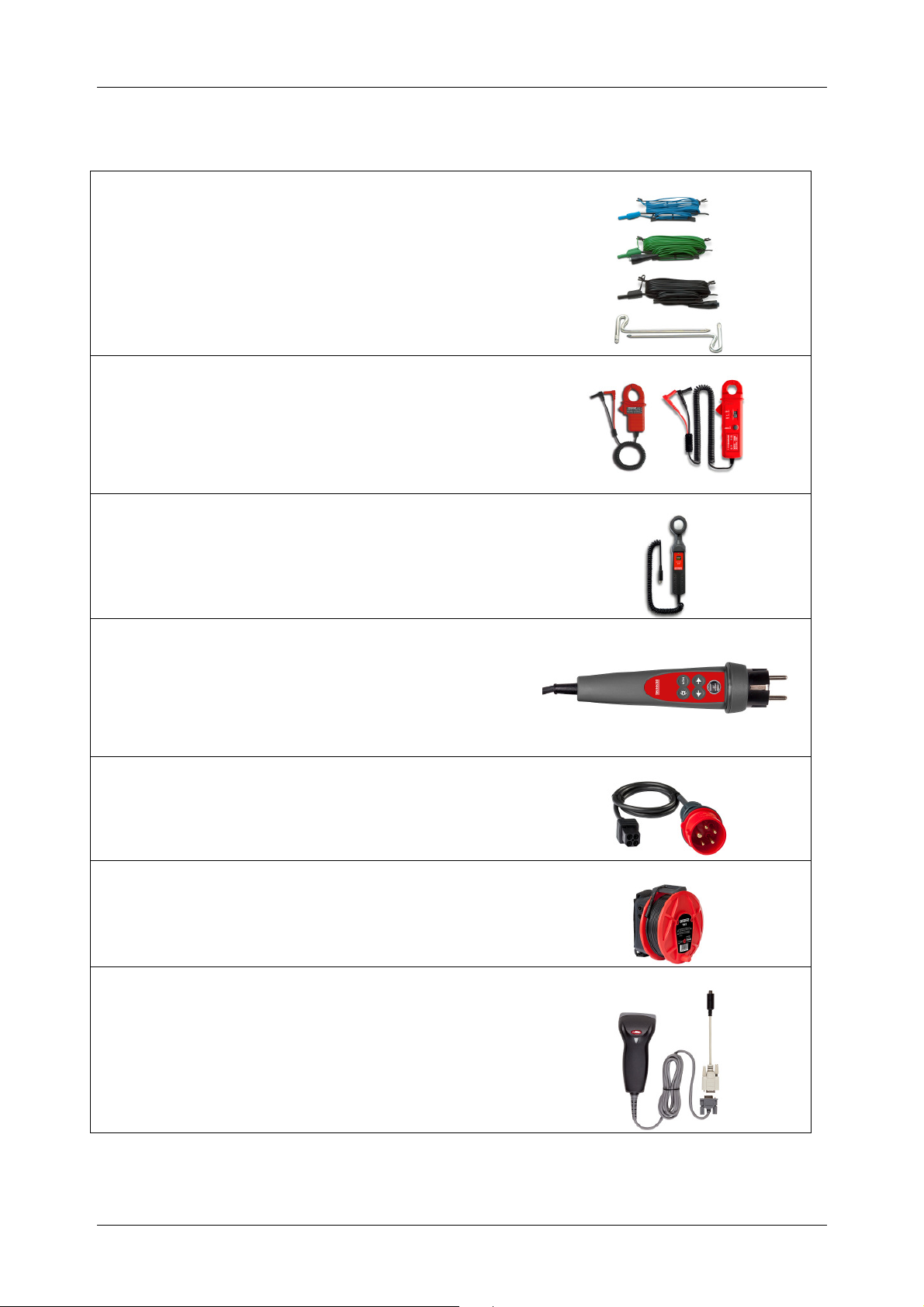

3.4.1 Attachment of the carrying strap

Please choose one of the two methods shown:

Figure 3.6: First method

Figure 3.7: Alternative method

Please check the carrying strap for safe fastening regularly.

- 18 -

BENNING IT 130 Device description

3.5 Scope of delivery and optional accessories

3.5.1 Standard scope of delivery

1 x BENNING IT 130 installation tester

1 x padded carrying case (item no. 10008291)

1 x "Commander" test probe (switchable by means of "TEST" key) (item no. 044155)

1 x test cable with shock-proof plug (item no. 10008295)

1 x universal three-wire test cable (black, blue, green) (item no. 10008296)

1 x set of test probes (black, blue, green) (item no. 10008304 - 10008306)

1 x set of alligator clips (black, blue, green) (item no. 10008301 - 10008303)

1 x carrying strap (item no. 10008290)

1 x RS 232-PS/2 interface cable (item no. 10008313)

1 x USB interface cable (item no. 10008312)

6 x rechargeable NiMh storage batteries of size AA

2 x batteries of size AAA

1 x charger (item no. 10008308)

1 x CD-ROM with BENNING PC-WIN IT 130 logging software, operating manual and

quick reference guide in PDF format

1 x quick reference guide

1 x calibration certificate

- 19 -

BENNING IT 130 Device description

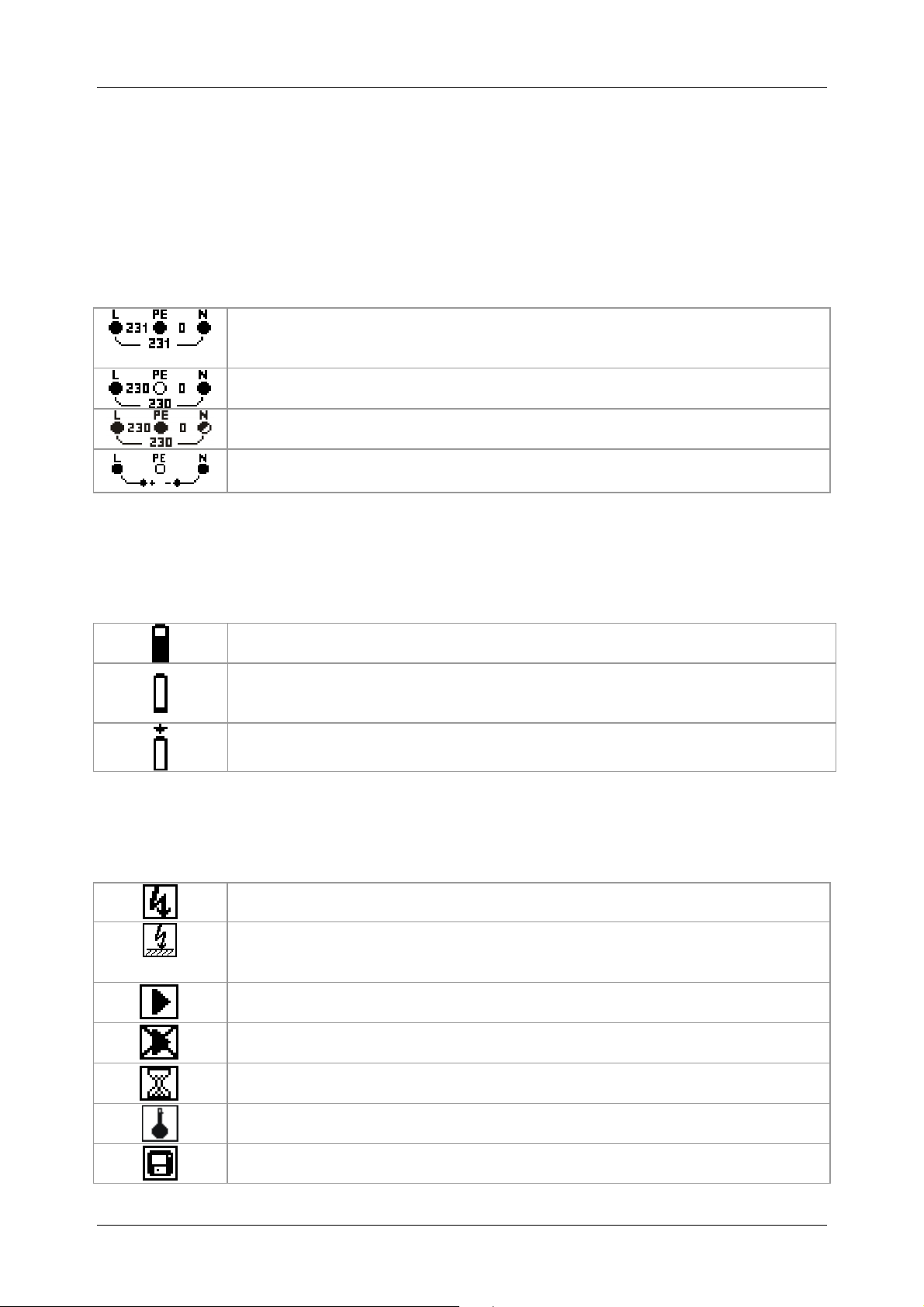

Earthing kit

Current clamp adapters

BENNING CC 1

Luminous intensity sensor

BENNING

L

uxmeter type B

"Commander" test plug

CEE measuring adapter

Measuring line (40 m)

Barcode scanner

3.5.2 Optional accessories

Earthing kit, 2 earth rods, 3 test cables,

2 x L = 20 m, 1 x L = 4.5 m

Item no.: 044113

, 1 A to 400 A AC

Output: 1 mV per 1 A

Item no.: 044037

BENNING CC 3, 0.2 A to 300 A AC / DC

Output: 1 mV / 10 mV per 1 A

Item no.: 044038

For the planning and installation of interior and exterior

lighting.

Item no.: 044111

For shock-proof socket, switchable with "TEST" and

"MEM" keys, with "PASS" / "FAIL" indication by means

of green/red LED, PE contact electrode for detecting

the phase voltage at the protective conductor

connection (PE).

Item no.: 044149

16 A, 5-pin, for measuring the voltage and phase

sequence (rotary field) at 16 A CEE sockets.

Item no.: 044148

40 m measuring line with rewinder and wrist strap, for

measuring protective conductor connections.

Item no.: 044039

Barcode scanner with PS/2 interface for identifying the

measuring point and renaming the storage location.

Item no.: 009371

- 20 -

BENNING IT 130 Measurements

Warning!

4 Operating the BENNING IT 130 installation tester

4.1 Indications and acoustic warning signals

4.1.1 Connection monitor

The connection monitor shows the voltages applied to the testing terminals as well as

information on active testing terminals in the AC mains.

The voltage applied is displayed together with the testing terminal indication.

All three testing terminals L, N and PE are used for the selected

measurement.

The voltage applied is displayed together with the testing terminal indication.

The testing terminals L and N are used for the selected measurement.

The testing terminals L and PE are active testing terminals. The testing

terminal N should be connected as well to show a correct input voltage.

The polarity of the testing voltage applied (R LOW, R ISO) is displayed at the

output terminals L and N.

4.1.2 Battery indication

The battery indication shows the current state of charge of the storage battery as well as

whether an external charger is connected.

Battery capacity indication

Low state of charge.

The storage battery's state of charge is too low to ensure correct measuring

results. Replace the batteries or recharge the storage batteries.

Charging in progress (with the charger being connected)

4.1.3 Warnings and messages

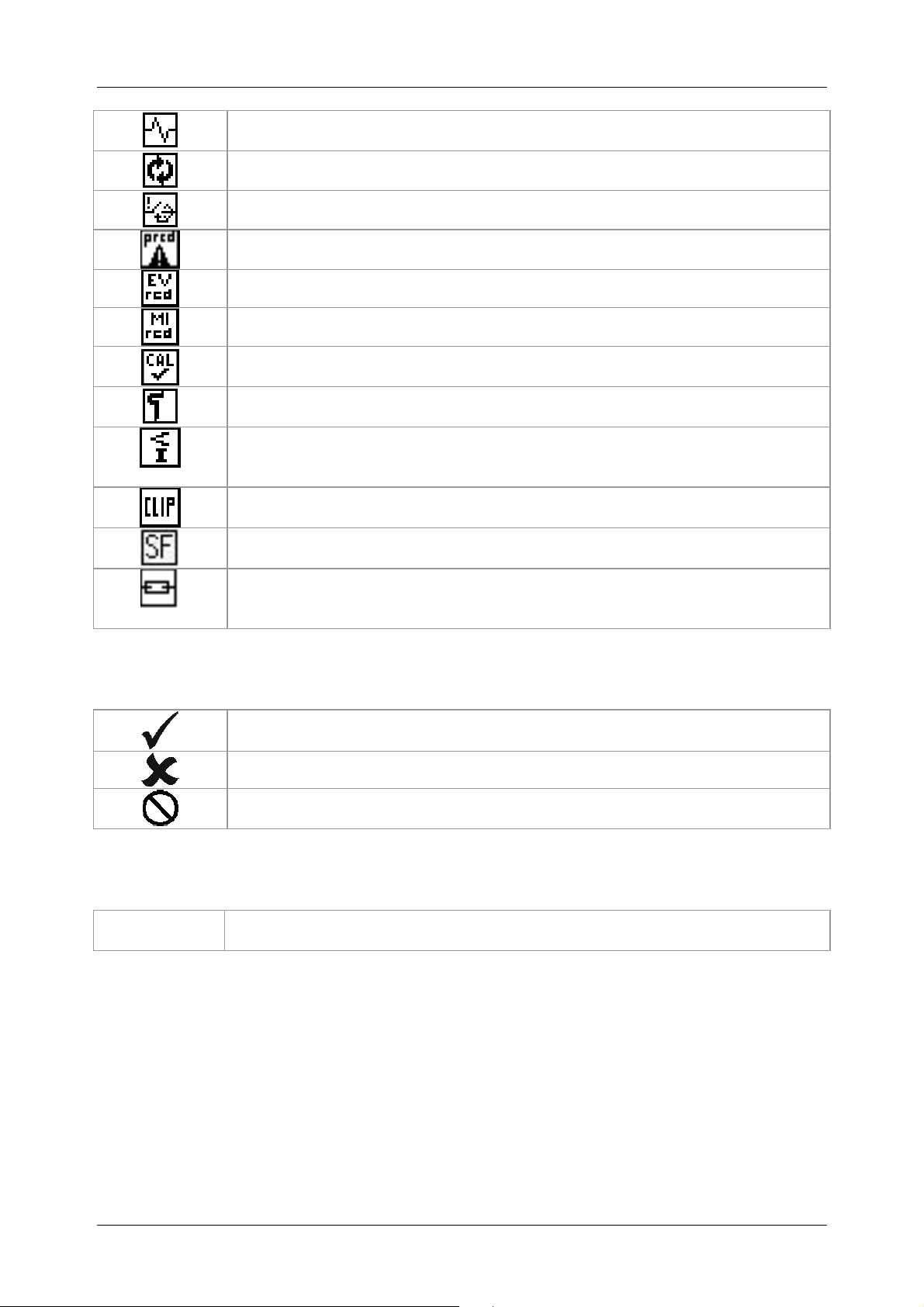

The following warnings and messages are displayed:

Warning! High voltage is applied to the testing terminals.

Dangerous voltage at the PE connection! Immediately stop the

measuring process and eliminate the fault / the connection problem before

continuing with the measurement!

The conditions at the input terminals allow starting the measurement. Please

observe further warnings and messages!

The conditions at the input terminals do not allow starting the measurement.

Please observe further warnings and messages!

Measurement is in progress. Please observe warnings that might be

displayed!

The tester is overheated. Measurements are interrupted until the internal

temperature has dropped below the admissible limiting value.

Results can be saved.

- 21 -

BENNING IT 130 Measurements

A high interference voltage has been detected during measurement. This

might result in incorrect measuring results.

L and N have been interchanged.

RCD has been tripped during measurement (in RCD functions).

Portable RCD (PRCD) has been selected (only for documentation purposes).

RCD type EV (Electric Vehicle)

RCD type MI (Mobile Installation)

The test cable resistance for low-impedance measurement / continuity test

has been compensated.

High earthing resistance of the measuring probes. This might result in

incorrect measuring results.

The current is too low for the accuracy specified. This might result in incorrect

measuring results. Please check in the current clamp adapter settings whether

the sensitivity of the current clamp adapter can be increased.

The measuring signal is outside the measuring range This might result in

incorrect measuring results.

Single fault in the IT network.

Fuse F1, F2 or F3 is defective.

If one of the fuses F2 or F3 has blown, the device must not be used anymore.

In this case, the device must be sent to BENNING for inspection and repair.

4.1.4 Evaluation field

The measuring result is within the preset limiting values (green LED).

The measuring result is outside the preset limiting values (red LED).

Measurement has been aborted. Please observe the warnings and messages

displayed.

4.1.5 Acoustic warning signals

Continuous

sound

Warning! Dangerous voltage at the PE connection!

- 22 -

BENNING IT 130 Measurements

HELP

UP / DOWN

ESC / HELP /

Briefly

UP

DOWN

TEST

ESC

4.1.6 Help menu ("HELP" key)

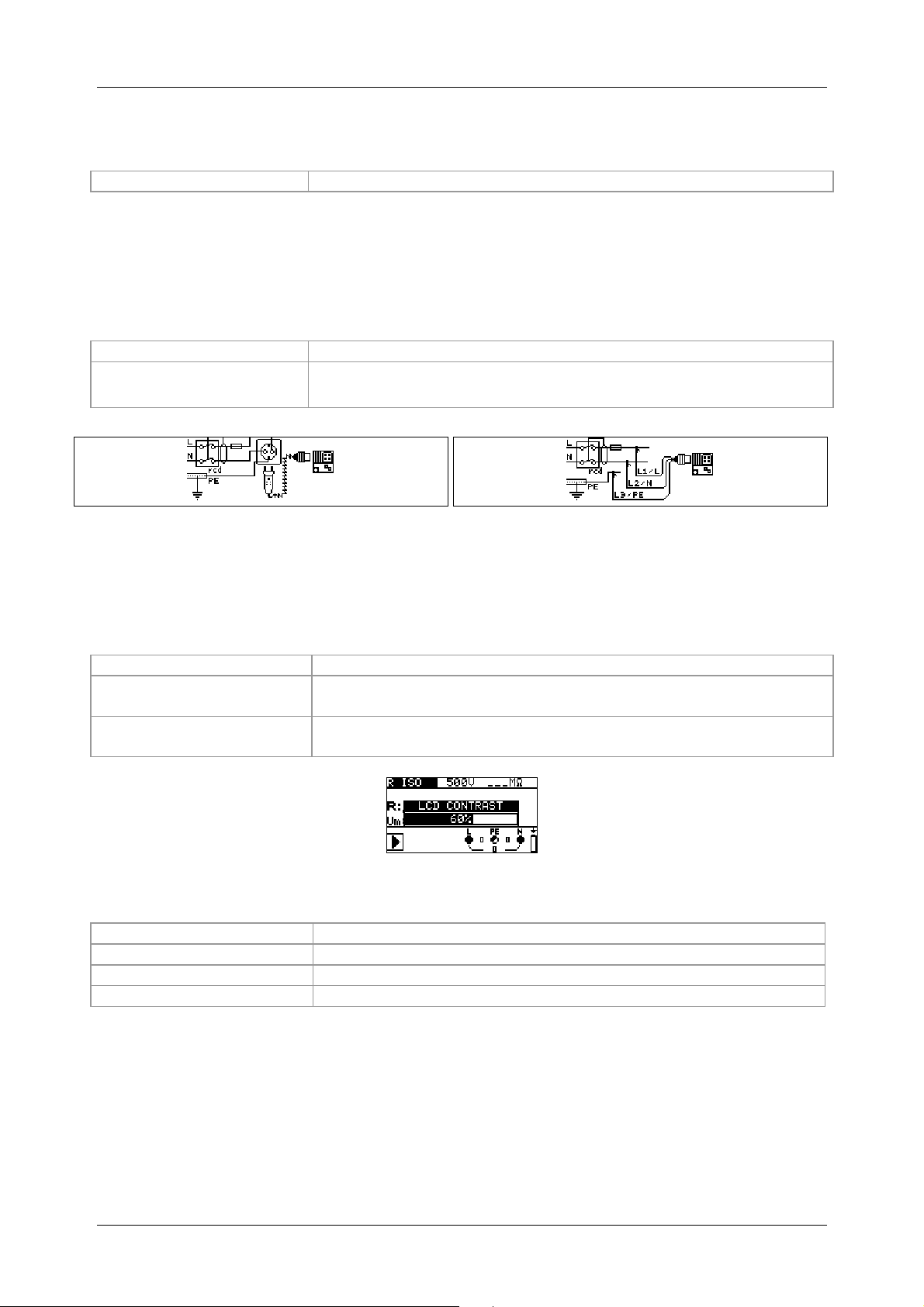

Opens the help menu.

Help menus are available for all measuring functions. The help menu contains graphic

connection diagrams showing how to connect the installation tester to the electrical installation.

After having selected the desired measuring function, press the "HELP" key to view the

corresponding help menu.

Keys used in the help menu

Selects the next / previous connection diagram

function selector switch

Use these keys to exit the help menu.

Figure 4.1: Connection diagrams of the help menu

4.1.7 Background lighting and contrast

Use the key for background lighting and contrast to make the following settings:

press the key

Press and hold the key for

1 second

Press and hold the key for

2 seconds

Activates the background lighting for approx. 10 seconds

Switches the background lighting on permanently until the tester

switches off or the key is pressed again

Allows to set the LCD contrast

Figure 4.2: LCD contrast setting

Keys used for contrast setting

Increases the contrast

Reduces the contrast

Applies the adjusted contrast

Exits the settings without any changes

- 23 -

BENNING IT 130 Measurements

LOW

TAB

TEST

MEM

ESC

UP / DOWN

TAB

MEM

WITHOUT

4.2 Function selector switch

The function selector switch is intended for selecting the

test and measuring functions

"AUTO" mode

"SETTINGS" mode

Key functions after having selected the test / measuring function:

UP / DOWN

Selects the sub-function of the adjusted test / measuring function

(only for rotary switch positions R

, ZI, ZS, FI/RCD)

Selects the parameters and limiting values

Start of measurement

Storage / recall of the measuring results

Back / cancel

Key functions in the Parameters field:

Modifies the selected parameter

Selects the next parameter

Storage / recall of the measuring results

Parameters and limiting values for evaluating the measuring results:

Parameter,

limiting value

ON

No parameters / limiting values, indication: _ _ _.

Measuring results – will be marked as "PASS" / "FAIL" according to

the parameters and limiting values set

Please find further information on how to use the test / measuring functions of the installation

tester in chapter 5. Measurements.

4.3 "AUTO" mode

Turn the function selector switch to the "AUTO" mode to select the test / measuring functions

carried out by means of the "Commander" test probe or the optional "Commander" test plug for

shock-proof sockets (044149).

Select the test / measuring function by means of the keys of the "Commander".

Please find a detailed description of the "Commander" test probe and the optional

"Commander" test plug for shock-proof sockets (044149) in Appendix C.

- 24 -

BENNING IT 130 Measurements

MEMORY

UP / DOWN

TEST

ESC /

function selector

UP / DOWN

TEST

ESC

Function selector switch

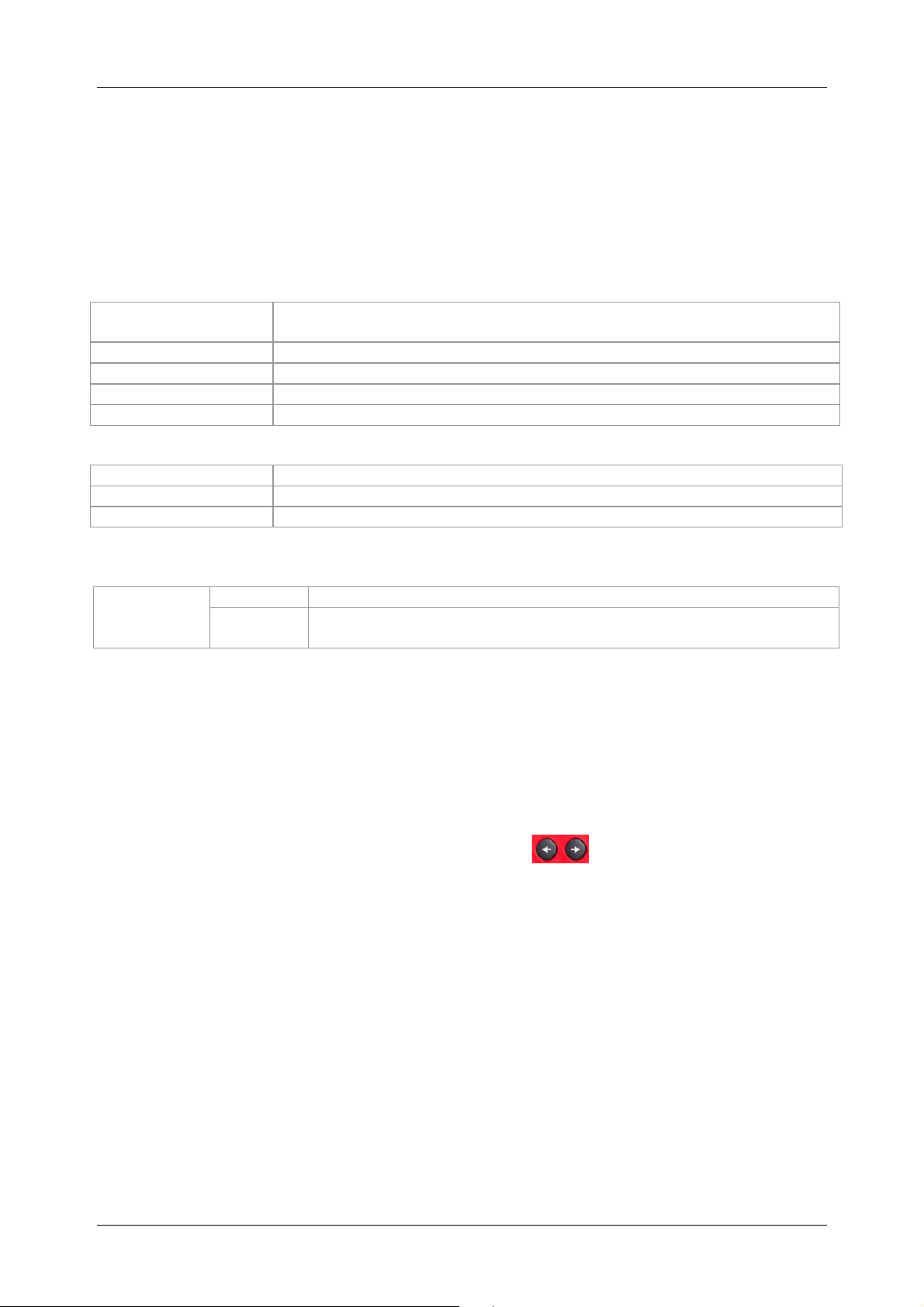

4.4 "SETTINGS" mode

Turn the measuring function selector switch to the "SETTINGS" mode in order to make the

following settings at the tester:

memory)

SELECT LANGUAGE (GB, D, E, F, NL)

SET DATE / TIME

EARTHING SYSTEM (TN/TT or IT network)

RCD TESTING (according to EN 61008 / EN 61009,

IEC 60364-4-41, BS 7671, AS/NZS 3017)

SET ISC FACTOR (0.20 - 3.00)

COMMANDER ON/OFF

INITIAL SETTINGS (reset to factory settings)

CLAMP settings (selection of the optional current clamp

adapters BENNING CC 1 (044037), BENNING CC 3

(044038))

Keys used:

switch

4.4.1 Memory

(recall data, delete data, delete entire

Figure 4.3:

"SETTINGS" mode

Selects the respective option

Confirms the selected option

Back / cancel without any changes

In this menu, it is possible to recall stored data and

to delete the data of a measuring point or even the

entire memory.

Please refer to chapter 6 Management of

measured values

for further information.

Keys used:

Selects the respective option

Confirms the selected option

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

4.4.2 Language

In this menu, it is possible to select the respective

language.

Figure 4.4: Memory options

Figure 4.5: Selecting the language

- 25 -

BENNING IT 130 Measurements

UP / DOWN

TEST

ESC

Function selector switch

TAB

UP / DOWN

TEST

ESC

Function selector switch

UP / DOWN

ESC

Function selector switch

Keys used:

Selects the language

Confirms the selected language and returns to the Settings menu

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

4.4.3 Date and time

In this menu, it is possible to set the date and time.

Keys used:

Selects the date / time field

Modifies the selected field

Confirms the change and returns to the Settings menu

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

Note:

If the batteries are removed for more than 1 minute, the date and time settings will be

lost.

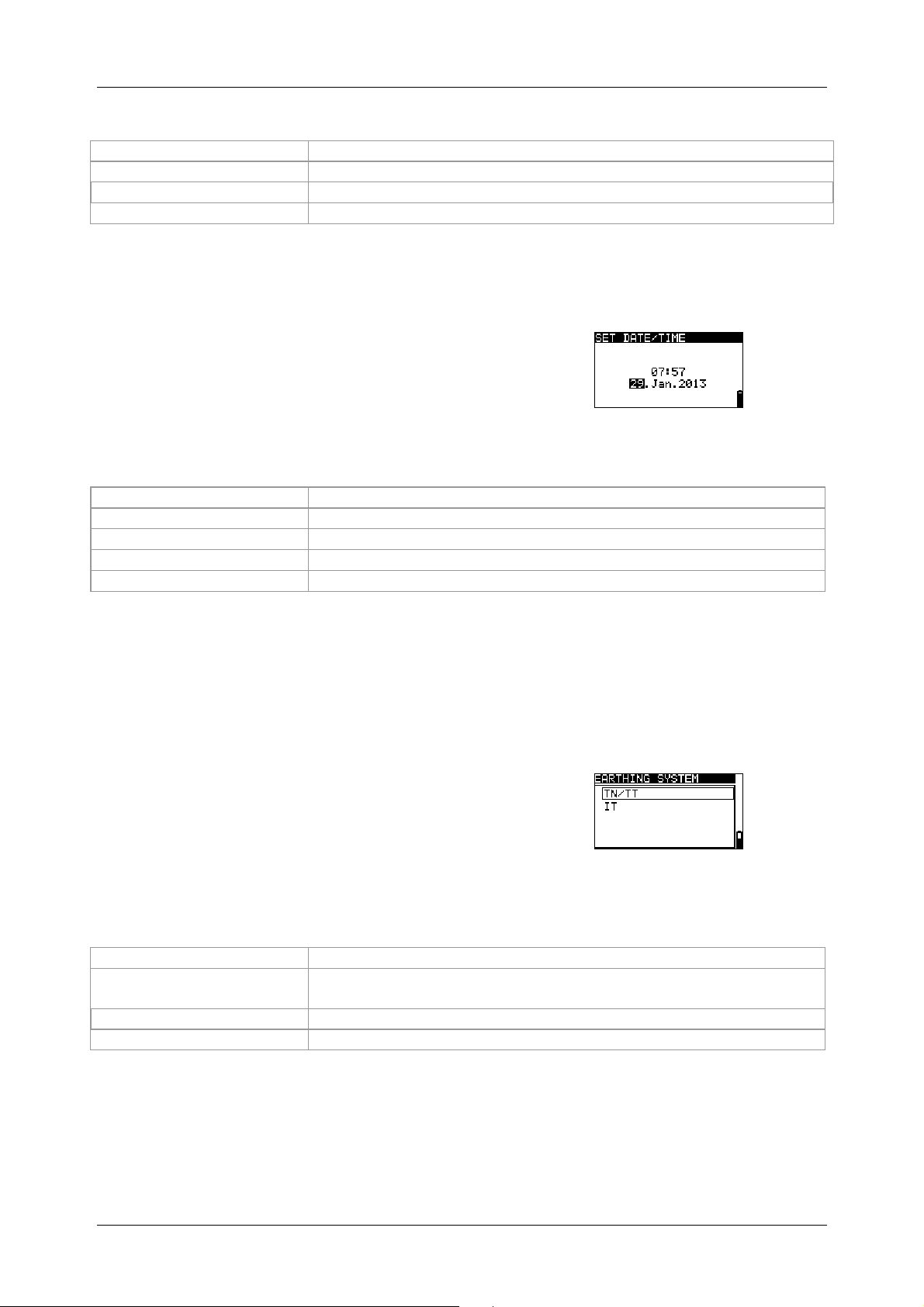

4.4.4 Earthing system (power supply network)

In this menu, it is possible to set the available

earthing system (power supply network).

The following options are available:

TN / TT network

IT network

Figure 4.6:

Setting date and time

Figure 4.7:

Selecting the earthing system

Keys used:

TEST

Selects the earthing system

Confirms the selected earthing system and returns to the Settings

menu

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

- 26 -

BENNING IT 130 Measurements

UP / DOWN

TEST

ESC

Function selector switch

∆

N

*)

∆

N

∆

N

∆

N

∆

∆

∆

∆

∆

∆

∆

∆

∆

∆

∆

∆

N

*)

∆

N

∆

N

∆

N

*)

∆

N

∆

N

4.4.5 RCD testing

In this menu, it is possible to set the standard

used for RCD testing.

Figure 4.8:

Selecting the RCD standard

Keys used:

Selects the standard

Confirms the selected standard and returns to the Settings menu

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

The maximum RCD tripping times vary from standard to standard.

The times specified in the individual standards are listed in the following.

By default, the tripping times in compliance with the EN 60364-4-41 standard are preset. The

EN 60364-4-41 standard defines different tripping times for TN/IT networks and TT networks as

can be seen in table 41.1.

Tripping times in compliance with EN 60364-4-41:

Uo

TN/IT

TT

≤120 V

≤230 V

≤120 V

≤230 V

½×I

t

> 800 ms t

t

> 400 ms t

t

> 300 ms t

t

> 200 ms t

I

2×I

≤ 800 ms

≤ 400 ms

≤ 300 ms

≤ 200 ms

5×I

t∆ < 150 ms t∆ < 40 ms

Uo: Nominal voltage of external conductor to earth

Example of a tripping time evaluation for I∆N, Uo: ≤230 V

Setting Tripping time

t

Evaluation field

IEC 60364-4-41 TN/IT < 400 ms

400 ms <

t

< 999 ms

> 999 ms

IEC 60364-4-41 TT < 200 ms

200 ms <

t

< 999 ms

> 999 ms

Tripping times in compliance with EN 61008/EN 61009:

Standard RCDs

(undelayed)

Selective RCDs

(delayed)

½×I

I∆N 2×I

t∆> 300 ms t∆< 300 ms t∆< 150 ms t∆< 40 ms

t∆> 500 ms 130 ms< t∆< 500 ms 60 ms< t∆< 200 ms 50 ms< t∆< 150 ms

Tripping times in compliance with BS 7671:

Standard RCDs

(undelayed)

Selective RCDs

(delayed)

½×I

I∆N 2×I

t∆> 1999 ms t∆< 300 ms t∆< 150 ms t∆< 40 ms

t∆> 1999 ms 130 ms< t∆< 500 ms 60 ms< t∆< 200 ms 50 ms< t∆< 150 ms

5×I

5×I

- 27 -

BENNING IT 130 Measurements

∆

N

*)

∆

N

∆

N

∆

N

S

∆

N

∆

N

∆

N

∆

N

∆

N

∆

N

UP / DOWN

TEST

ESC

Function selector switch

Tripping times in compliance with AS/NZS 3017

RCD type

I

II

I

[mA] t∆ t∆ t∆ t∆

≤ 10

> 10 ≤ 30

½×I

I∆N 2×I

> 999 ms

40 ms 40 ms 40 ms

300 ms 150 ms 40 ms

III > 30 300 ms 150 ms 40 ms

IV

*)

Minimum testing time for a current of ½×I∆N, RCD must not trip

**)

Testing current and measuring accuracy correspond to the requirements specified by

> 30 > 999 ms

500 ms 200 ms 150 ms

130 ms 60 ms 50 ms minimum non-tripping time

**)

:

5×I

Remark

maximum tripping time

AS/NZS 3017

Maximum testing times and selected testing current for standard (undelayed) RCDs:

Standard

EN 60364-4-41 1000 ms

EN 61008 / EN 61009 300 ms

BS 7671 2000 ms

AS/NZS 3017 (I, II, III) 1000 ms

½×I

I∆N 2×I

1000 ms

1000 ms

300 ms

300 ms

5×I

150 ms

150 ms

150 ms

150 ms

40 ms

40 ms

40 ms

40 ms

Maximum testing times and selected testing current for selective (delayed) RCDs:

Standard

EN 60364-4-41 1000 ms

EN 61008 / EN 61009 500 ms

BS 7671 2000 ms

AS / NZS 3017 (IV) 1000 ms

½×I

I∆N 2×I

1000 ms

1000 ms

500 ms

500 ms

5×I

200 ms

200 ms

200 ms

200 ms

150 ms

150 ms

150 ms

150 ms

4.4.6 Isc factor (scaling factor)

In this menu, it is possible to set the Isc factor

(scaling factor) for calculating the short-circuit

current (Ik) in the functions ZI (L-N/L) and Zs

(L-PE).

Figure 4.9:

Selecting the Isc factor

Keys used:

Modifies the Isc factor

Confirms the adjusted Isc factor

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

The short-circuit current Ik in the power supply system is of particular importance for the

selection and testing of protective circuits (fuses, overcurrent protection devices, RCDs).

The default value of the Isc factor (Ik) is 1.00. The value has to be set according to local

requirements.

The Isc factor can be set within the range of 0.20 ÷ 3.00.

- 28 -

BENNING IT 130 Measurements

UP / DOWN

TEST

ESC

Function selector switch

UP / DOWN

TEST

ESC

Function selector

Settings of the tester

Defaul

t setting

4.4.7 Commander ON/OFF

In this menu, it is possible to enable or disable

the "Commander" (switchable test probe).

Keys used:

Selects Commander ON (enabled) / Commander OFF (disabled)

Confirms the selected option

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

Note:

The "Commander OFF" (disabled) option is intended for deactivating the operating keys

of the "Commander" (except for the background lighting key). It is useful to disable the

"Commander", if strong sources of interference might affect the correct functioning of the

"Commander".

Figure 4.10:

Selecting the "Commander" support

4.4.8 Initial settings

In this menu, it is possible to reset the settings,

measuring parameters and limiting values of the

installation tester to their initial (factory) settings.

Keys used:

Selects the option [YES, NO]

Confirms the selected option

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

switch

Note:

If the tester is reset to its initial (factory) settings, all settings made will be lost!

If the batteries are removed for more than 1 minute, all settings made will be lost.

The initial (factory) settings are defined as follows:

Figure 4.11:

Initial settings dialog

Language German

Contrast 50 %

Earthing system TN / TT

Isc factor 1.00

RCD standards EN 60364-4-41

"Commander" test probe ON

Current clamp settings BENNING CC 3

- 29 -

BENNING IT 130 Measurements

Measuring function

Sub

-

function

REF

Type

Measuring range

Type

Measuring range

UP / DOWN

TEST

MEM

ESC

Function selector switch

Parameter / limiting value

RE No limiting value

R ISO without limiting value,

nominal testing voltage: 500 V

R LOW No limiting value

CONTINUITY No limiting value

ZI (L-N/L) line impedance Fuse type: none selected

∆U voltage drop ∆U: 4.0 %, Z

: 0.00 Ω

Zs (L-PE) loop impedance Fuse type: none selected

Zsrcd Fuse type: none selected

RCD RCD t

Nominal differential current: I∆N=30 mA

RCD type: AC, undelayed

Testing current with initial polarity: (0°)

Limiting value for contact voltage: 50 V

Nominal differential current multiplier: ×1

Note:

It is also possible to reset the tester to its initial (factory) settings by pressing the "TAB"

key when simultaneously switching the tester on.

4.4.9 Clamp settings

In the CLAMP settings menu, it is possible

to configure the C1 measuring input to the

current clamp adapter used.

Setting parameters:

BENNING CC 1

400 A AC

BENNING CC 3

40 A / 300 A AC / DC

Selecting the parameters

Keys used:

Selects the respective options

Confirms the selected option

Saves the settings

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

Figure 4.12:

Configuring the current clamp measuring input

- 30 -

BENNING IT 130 Measurements

UP / DOWN

TEST

MEM

ESC

Function selector switch

Modifying the selected parameters

Keys used:

Modifies the selected parameter

Confirms the selected parameter

Saves the settings

Back / cancel to the Settings menu

Back / cancel to the selected measuring function

Note:

Please pay attention to the measuring range of the installation tester. The measuring

range of the current clamp might be higher than that of the installation tester.

- 31 -

BENNING IT 130 Measurements

5 Measurements

5.1 TRMS voltage, frequency and phase sequence

The voltages applied to the testing terminals are permanently displayed by means of the

connection monitor. In the VOLTAGE TRMS measuring range (true RMS voltage value), the

measured values for voltage (AC/DC) and frequency as well as the phase sequence (rotary

field) detected can be saved. The measurements are carried out in compliance with the

EN 61557-7 standard.

Key function as described in chapter

4.2 Function selector switch

Testing parameters

It is not necessary to set any parameters.

Connection plan

Figure 5.1:

Voltage in a single-phase system

Figure 5.2: Connection of the three-wire test cable and the

optional CEE measuring adapter (044148) in a three-phase system

Figure 5.3: Connection of the optional "Commander" test plug (044149) and the three-wire test

cable in a single-phase / three-phase system

- 32 -

^

BENNING IT 130 Measurements

How to perform voltage measurements

Select the

V≅≅≅≅

function by means of the function selector switch. The display shows

VOLTAGE TRMS.

Connect the test cables to the test object (see figure 5.2 and figure 5.3).

Save the measuring result by pressing the "MEM" key.

The measurement is performed immediately after the VOLTAGE TRMS function has been

selected.

Figure 5.4: Examples for voltage measurements in single-phase and three-phase systems

Results displayed for single-phase systems:

Uln ........... voltage between phases and neutral conductor

Ulpe ......... voltage between phase and protective conductor

Unpe ........ voltage between neutral and protective conductors

f ................ frequency

Results displayed for three-phase systems:

U12........... voltage between testing terminals L1 and L2

U13........... voltage between testing terminals L1 and L3

U23........... voltage between testing terminals L2 and L3

1.2.3 ......... correct connection – clockwise phase sequence

3.2.1 ......... wrong connection – counter-clockwise phase sequence

f ................ frequency

Results displayed for IT systems:

U12........... voltage between testing terminals L1 and L2

U1pe ........ voltage between testing terminals L1 and PE

U2pe ........ voltage between testing terminals L2 and PE

f ................ frequency

- 33 -

BENNING IT 130 Measurements

Uiso

Nominal testing voltage

5.2 Insulating resistance

The measurement of the insulating resistance is performed in order to prove the proper

condition of the insulation and in order to exclude electrical danger.

Typical applications are the following cases:

Insulating resistance between the active conductors (L/N) of an installation and the

protective conductor / earth (PE) => protection against electric shock,

Insulating resistance between the active conductors (L/N) of an installation => protection

against short-circuit (over-current) and guarantee of the functional safety,

Insulating resistance of non-conductive rooms (walls and floors),

Insulating resistance of earthing cables and

Resistance of semiconductive (antistatic) floors.

Key function as described in chapter

4.2 Function selector switch

Figure 5.5:

Insulating resistance

Testing parameters

Limiting value

Minimum insulating resistance [without limits (---), 0.01 MΩ ÷ 200 MΩ]

Connection plan

Figure 5.6: Connection of the three-wire test cable and the "Commander" test probe

[50 V, 100 V, 250 V, 500 V, 1000 V]

- 34 -

BENNING IT 130 Measurements

How to perform insulating resistance measurements

Select the R

Set the required testing voltage and the limiting value (optional).

Make sure that the test object is free of voltage and discharge available capacities.

Connect the test cables to the test object (see figure 5.6).

Press the "TEST" key to start the measurement. Double-click the "TEST" key (MΩ flashes)

function by means of the function selector switch.

ISO

to perform a continuous measurement. Press the key again to finish the measurement.

After measurement, wait until the test object is completely discharged.

Save the measuring result by pressing the "MEM" key (optional).

Figure 5.7: Example of an insulating resistance measurement

Results displayed:

R .............. insulating resistance

Um ........... testing voltage (actual value)

Attention:

Measurements of the insulating resistance must be carried out only at test objects which

are free of voltage!

Disconnect all loads and close all switches for measuring the insulating resistance

between conductors of the installation.

Do not touch the test object during measurement and before it is completely discharged!

There is danger of a life-threatening electric shock!

If the insulating resistance measurement is carried out on a capacitive object, automatic

discharging might take place time-delayed. The warning symbol and the actual voltage

will be displayed during discharging.

Do not connect the test cables to external voltages higher than 550 V (AC or DC) in

order not to damage the BENNING IT 130 installation tester!

- 35 -

BENNING IT 130 Measurements

Test

Sub

-

function

Limiting value

Maximum resistance

Buzzer

5.3 Low-impedance resistance / continuity test

The measurement of the low-impedance resistance / continuity test is intended for testing the

protective conductor, earthing conductor and equipotential bonding conductor connections of an

electrical installation.

Two sub-functions are available:

R LOWΩ – resistance measurement in compliance with EN 61557-4 with a testing

current of 200 mA and polarity reversal

CONTINUITY – continuous continuity test with a reduced testing current of 7 mA.

Key function as described in chapter

4.2 Function selector switch

Testing parameters

[R LOWΩ, CONTINUITY]

[without limits (---), 0.1 Ω ÷ 20.0 Ω]

Additional testing parameter for continuity test sub-function:

ON (sounds if the resistance is lower than the limiting value set) or OFF

Figure 5.8: Low-impedance

resistance RLOW Ω with a testing

current of 200 mA

5.3.1 Low-impedance resistance with a testing current of 200 mA

The resistance measurement is performed with automatic polarity reversal of the testing

voltage.

Connection plan

Figure 5.9: Connection of the three-wire test cable and the

optional 40 m measuring line BENNING TA 5 (044039)

- 36 -

BENNING IT 130 Measurements

How to perform low-impedance measurements R LOWΩ

Select the R

Set the sub-function to R LOWΩ.

Set the limiting value (optional).

Connect the test cables to the installation tester and compensate the test cable

function by means of the function selector switch.

LOW

resistance, if necessary (see section 5.3.3 Compensation (null balance) of the test cable

resistance).

Make sure that the test object is free of voltage and discharge available capacities.

Connect the test cables to the test object (see figure 5.9).

Press the "TEST" key to start the measurement.

Save the measuring result by pressing the "MEM" key (optional).

Figure 5.10: Example of a low-impedance measurement RLOWΩ

Results displayed:

R .............. R LOWΩ – low-impedance resistance

R+ ............ partial result at positive polarity

R- ............. partial result at negative testing polarity

5.3.2 Continuity test with a testing current of 7 mA

This test function can be compared to the continuity test function of a digital multimeter or of a

continuity tester with low testing current. The continuous test is done without polarity reversal

and can be used for testing inductive components.

Connection plan

Figure 5.11: Using the "Commander" test probe and the three-wire test cable

- 37 -

BENNING IT 130 Measurements

How to perform continuity tests

Select the R

Set the sub-function to CONTINUITY.

Set the limiting value (optional).

Connect the test cables to the installation tester and compensate the test cable resistance,

function by means of the function selector switch.

LOW

if necessary (see section 5.3.3 Compensation (null balance) of the test cable resistance).

Make sure that the test object is free of voltage and discharge available capacities.

Connect the test cables to the test object (see figure 5.11).

Press the "TEST" key to start the measurement.

Press the "TEST" key again to stop the measurement.

Save the measuring result by pressing the "MEM" key (optional).

Figure 5.12: Example of a continuity test

Result displayed:

R .............. resistance

5.3.3 Compensation (null balance) of the test cable resistance

This chapter describes how to compensate the test cable resistance in the low-impedance

measurement (R LOWΩ) and continuity test (CONTINUITY) functions. Compensation is

necessary, because the test cable resistance and the internal resistance of the installation

tester might influence the measuring result. The compensation of the test cables is particularly

required when using measuring lines of different lengths.

The icon is displayed, if the test cable resistance has been compensated successfully.

Connection plan

Figure 5.13: Shorted test cables

How to carry out compensation

Select the R LOWΩ or CONTINUITY function.

Connect the test cables to the installation tester and short-circuit the test cables (see figure

5.13.)

Press the "TEST" key to perform the resistance measurement.

Press the "CAL" key to compensate the test cable resistance.

Figure 5.14: Result before calibration Figure 5.15: Result after calibration

- 38 -

BENNING IT 130 Measurements

Note:

The highest value for test cable compensation is 5 Ω. If the resistance is higher, the

compensation value will be reset to the default value.

The icon is displayed, if the test cable resistance has not been compensated.

- 39 -

BENNING IT 130 Measurements

Test

Sub

-

function

RCD

Type

MUL

∆

N

Ulim

Limiting value of contact voltage

5.4 RCD testing

The testing of RCDs in RCD-protected installations requires various tests and measurements.

The measurements are based on the EN 61557-6 standard.

The following measurements and tests can be performed:

Contact voltage, tripping time, tripping current and

Automatic RCD testing

Key function as described in chapter

4.2 Function selector switch

Figure 5.16:

RCD tests

Testing parameters

[Uc, RCDt, RCD I, AUTO]

I

Nominal tripping differential current I

∆∆∆∆N

[10 mA, 30 mA, 100 mA, 300 mA, 500 mA, 1000 mA]

[AC, A, F, B, B+]

type

Initial polarity [ , , , ,

Properties

[selective , standard undelayed , PRCD, PRCD-S, PRCD-K,

EV RCD, MI RCD].

Multiplier of testing current [½x, 1x, 2 x, 5xI

Note:

The limiting value of the contact voltage can be set only in the Uc sub-function.

Selective (delayed) RCDs have delayed tripping times. As the contact voltage

measurement and other RCD tests influence delayed RCDs, it takes a certain time until

they have returned to their normal condition. For this reason, a time delay of 30 seconds

is added before the standard tripping test is performed.

During testing of some portable PRCDs (e.g. PRCD-K) in which the protective conductor

is guided through the converter in opposite direction, this portable RCD trips already at

the 0.5-fold value of the nominal tripping differential current. The installation tester

evaluates the early tripping as "accidental tripping" and aborts the test without any

measuring result. If this test has been carried out with a positive result, i.e. it has been

proven that the portable PRCD trips at the 0.5-fold value of the nominal tripping

differential current and thus the protective conductor is not interrupted, it is possible to

continue the test by changing the contacting of the protective conductor. In this case, it

is necessary to establish a contact to the protective conductor (PE) of an adjacent

socket instead of establishing a contact to the protective conductor (PE) of the coupling

socket for further testing. Then, the test can be performed just as for an ordinary RCD.

The AC part of MI and EV RCDs is tested as standard (non-delayed) RCDs.

The DC part of MI and EV RCDs is tested with a smooth direct test current. The pass

limit is between 0.5 x and 1.0 x I

∆NDC

,

.

∆∆∆∆N

]

[25 V, 50 V]

]

- 40 -

BENNING IT 130 Measurements

Contact voltage Uc

∆

N

∆

N

∆

N

∆

N

∆

N

∆

N

∆

N

∆

N

Connection plan

Figure 5.17: Connection of the optional "Commander" test plug (044149)

and the three-wire test cable

5.4.1 Contact voltage (Uc)

Leakage current flowing to earth via the protective conductor connection causes a voltage drop

at the earthing resistance, i.e. a voltage difference between the PE equipotential bonding and

earth. This voltage difference is called contact voltage and is applied to all accessible

conductive parts connected to protective earth (PE). The contact voltage always should be

lower than the maximum admissible contact voltage. Contact voltage is measured with a testing

current lower than ½ I∆N in order to avoid tripping of the RCD and then to be normalized to the

nominal value I∆N.

How to perform contact voltage measurements

Select the FI/RCD function by means of the function selector switch.

Set the sub-function to Uc.

Set the testing parameters.

Connect the test cables to the test object (see figure 5.17).

Press the "TEST" key to start the measurement.

Save the measuring result by pressing the "MEM" key (optional).

The contact voltage displayed refers to the rated differential current of the RCD and is

multiplied with an appropriate factor for safety reasons.

avoid a negative tolerance of the result.

Table 5.1 describes how the contact voltage is

calculated.

The factor 1.05 is applied in order to

AC, EV/MI (AC part)

RCD type

AC

A, F

A, F

A, F

A, F

B, B+

B, B+

proportional to

1.05×I

2×1.05×I

1.4×1.05×I

2×1.4×1.05×I

2×1.05×I

2×2×1.05×I

2×1.05×I

2×2×1.05×I

≥ 30 mA

Table 5.1: Relation between Uc and I

- 41 -

Nominal value I

∆∆∆∆N

any

<30 mA

any

∆

N

BENNING IT 130 Measurements

Increasing fault current

Initial value

Final value

AC, EV/

MI (AC part)

∆

N

∆

N

∆∆∆∆

N

≥≥≥≥

∆

N

∆

N

∆∆∆∆

N

∆

N

∆

N

B, B+

, EV

/MI (D

C part)

∆

N

∆

N

The loop resistance is a purely indicative value and is calculated from the contact voltage

U

(without additional proportional factors).

R∆=

C

L

.

I

N

Figure 5.18: Example of a contact voltage measurement

Results displayed:

Uc ........ contact voltage

RL ........ loop resistance (fault loop resistance)

5.4.2 Tripping time (RCDt)

The tripping time measurement serves to test the sensitivity of the residual current protection

devices (RCDs) at different nominal tripping differential currents I∆N.

How to perform tripping time measurements

Select the FI/RCD function by means of the function selector switch.

Set the sub-function to RCDt.

Set the testing parameters.

Connect the test cables to the test object (see figure 5.17).

Press the "TEST" key to start the measurement.

Save the measuring result by pressing the "MEM" key (optional).

Figure 5.19: Example of a tripping time measurement

Result displayed:

t ............ tripping time

Uc ........ contact Voltage

5.4.3 Tripping current (RCD I)

For tripping current measurement, a continuously increasing fault current serves to determine

the limiting sensitivity for RCD tripping. The installation tester increases the fault current in small

steps within the whole range as follows:

Norm EN 60364-4-41, (SETTINGS mode → RCD TESTING):

RCD type

0,1×I

A, F (I

A, F (I

30 mA)

= 10 mA)

0,1×I

0,1×I

0,1×I

1,1×I

1,5×I

2,2×I

2,2×I

Curve

shape

sinusoidal

pulsating

DC

- 42 -

BENNING IT 130 Measurements

Increasing fault current

Initial value

Final value

AC, EV/

MI (AC part)

∆

N

∆

N

∆∆∆∆

N

≥≥≥≥

∆

N

∆

N

∆∆∆∆

N

∆

N

∆

N

B, B+

, EV

/

MI (DC part)

∆

N

∆

N

HELP / DISPLAY

HELP

Norm EN 61008/EN 61009, (SETTINGS mode → RCD TESTING):

RCD type

A, F (I

A, F (I

= 10 mA)

30 mA)

0,2×I

0,2×I

0,2×I

0,2×I

1,1×I

1,5×I

2,2×I

2,2×I

Curve shape

sinusoidal

pulsating

DC

The maximum testing current is I∆ (tripping current) or corresponds to the final value, if the RCD

does not trip.

How to perform tripping current measurements

Select the FI/RCD function by means of the function selector switch.

Set the sub-function to RCD I.

Set the testing parameters.

Connect the test cables to the test object (see figure 5.17).

Press the "TEST" key to start the measurement.

Save the measuring result by pressing the "MEM" key (optional).

Figure 5.20: Example of a tripping current measurement

Results displayed:

I ........... tripping current

Uci ....... contact voltage at tripping current I or final value, if RCD does not trip

t ............ tripping time

5.4.4 Automatic test

The automatic RCD test is intended to perform a complete RCD test (tripping time at different

fault currents, tripping current and contact voltage) in a sequence of automatic tests controlled

by the installation tester.

Additional key

As soon as measurement is finished, the "

the upper and lower part of the result field.

" key toggles between

- 43 -

BENNING IT 130 Measurements

Steps of the automatic test

Note

TEST

MEM

How to perform an automatic test

Select the FI/RCD function by means of the function selector

switch.

Set the sub-function to AUTO.

Set the testing parameters.

Connect the test cables to the test object (see figure 5.17).

Press the "

Testing with I∆N, 0° (step 1)

Activating the RCD

Testing with I∆N, 180° (step 2)

Activating the RCD

Testing with 5×I∆N, 0° (step 3)

Activating the RCD

Testing with 5×I∆N, 180° (step 4)

Activating the RCD

Testing with ½×I∆N, 0° (step 5)

Testing with ½×I∆N, 180° (step 6)

Tripping current test, 0° (step 7)

" key to start the measurement.

Start of test

RCD should trip

RCD should trip

RCD should trip

RCD should trip

RCD must not trip

RCD must not trip

RCD should trip

Activating the RCD

Tripping current test, 180° (step 8)

Activating the RCD

Save the measuring result by pressing the "

" key

RCD should trip

End of test

(optional).