Page 1

L8542928

11/2011 rev 2

CELL.P

UNIONE NAZIONALE COSTRUTTORI

AUTOMATISMI PER CANCELLI, PORTE

SERRANDE ED AFFINI

Page 2

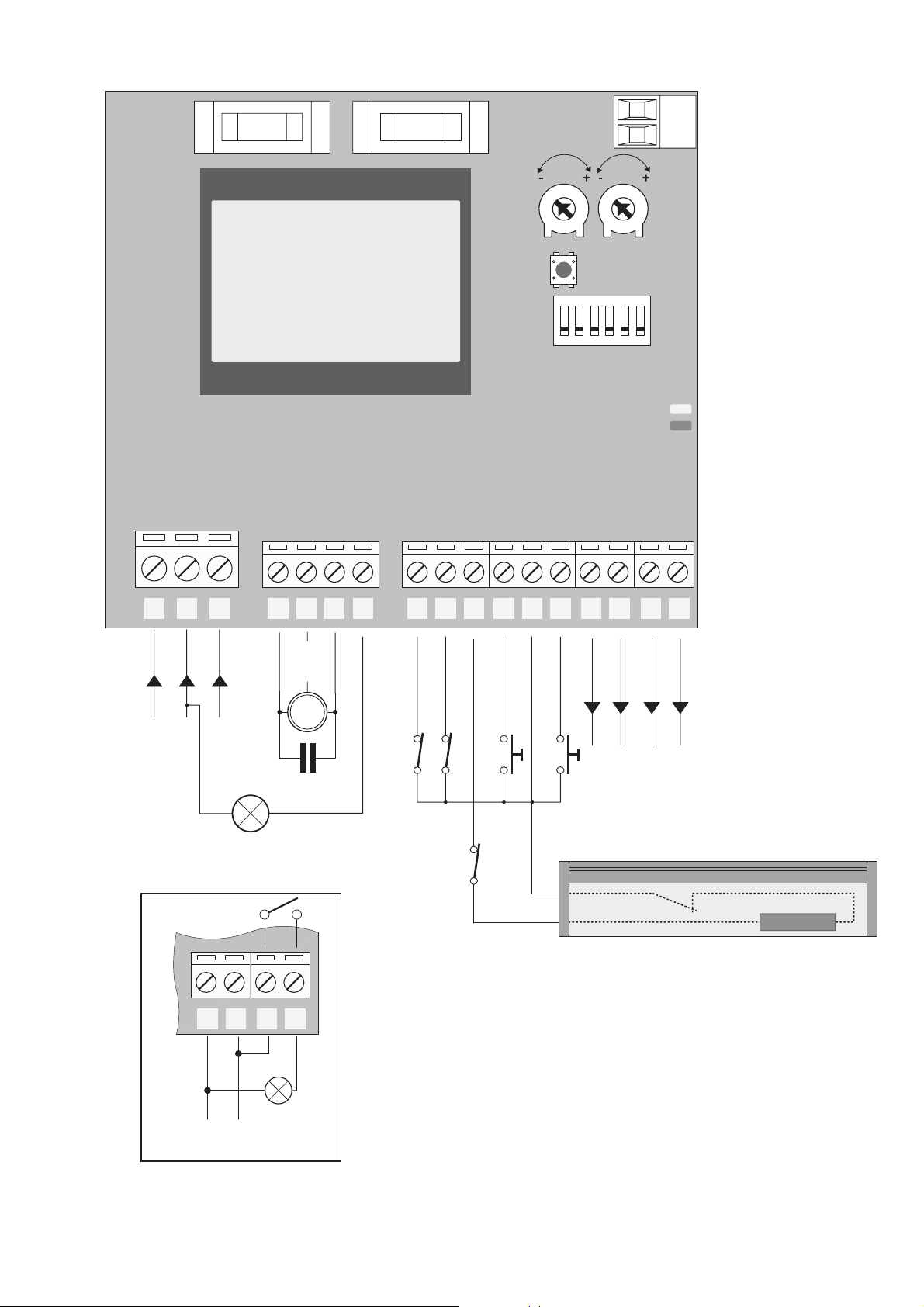

3

DL1

DL2

N

G N D

L

LAMP 115/230Vac

40W max

SWO

SWC

DAS

PHOT

CHIUDE

COM

APRE

SCA

SCA

P1

SW

1 6

TW TCA

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

18 19

F3: F6,3A

F2: F315 mA

F3

F2

8K2

R

24Vac

300mA max

16 17

14 15 16 17

SCA 24Vac

3W max

COM

M

C

Page 3

8

CELL.P control unit with microcontroller

INPUT/OUTPUT FUNCTIONS

Terminals Function Description

1, 2, 3 Power supply Input, 230VAC 50/60Hz

(1-Phase/2-Neutral/GND-Ground connection)

4, 5, 6 Motor Connection to motor:

(MOT-move/COM-Common/MOT-move)

7 LAMP Output, connection to Flashing light: 230 Vac 40W max.

8 SWO Input, OPENING limit switch (Normally Closed contact)

9 SWC Input, CLOSING limit switch (Normally Closed contact)

10 DAS/ PHOT Safety edge or photocell Input

See DIP-SWITCH 3.

TECHNICAL DATA

Control unit power supply

230 Vac

Power supply

230 Vac 50/60 Hz or 115Vac 50/60Hz according to the version

Output supply

1 motore230 Vac

Power maximum motor

1000 W

Output supply accessories

24 Vac, 7W max.

Protection level

IP54

Operating temp.

-20°C / +70°C

WARNINGS

This manual has been especially written to be use by

qualified fitters.

None of the information provide in this manual can be

considered as being of interest for the end users.

Preserve this manual for future needs.

The technician has to furnish all the information related to the step by step function, the manual and the

emergency function of the operator, and to deliver the

manual to the final user.

;

Foresee on the supply net an onnipolar switch

or selector with distance of the contacts equal

or superior to 3 mms.

Verify that of the electrical system there is an awry differential interrupter and overcurrent protection.

Some typologies of installation require the connection of

the shutter to be link at a conductive mass of the ground

according to the regulations in force.

The electrical installation and the operating logic must

comply with the regulations in force.

The leads fed with different voltages must be physically

separate, or they must be suitably insulated with additional insulation of at least 1 mm.

The leads must be secured with an additional fixture

near the terminals.

During installation, maintenance and repair, interrupt

the power supply before opening the lid to access the

electrical parts

Check all the connections again before switching on

the power.

The unused N.C. inputs must be bridged.

The descriptions and the present illustrations in this manual are not binding. Leaving the essential characteristics of the product unchanged, the manufacturer reserves

himself the right to bring any change of technical, constructive or commercial character without undertaking

himself to update the present publication.

Page 4

9

11 CLOSE Input, CLOSE key (N.C. contact)

12 COM Common, all control inputs.

13 OPEN Input, OPEN key (N.O. contact).

14, 15 24Vac Output, 24Vac/400mA max accessory power supply.

16,17 SCA Contact free from voltage, not insulated for the connection

of open gate indicator lamp.

Open contact with closed door leaf. Flashing light during

the door leaf movement. With open door leaf, the contact

is closed.

18, 19

Antenna

Connection to radio receiver antenna insertable board and

incorporated radio module

(SHIELD-screen/ANT-signal).

CHECKING CONNECTIONS:

1) Cut off power supply.

2) Manually release the door, move it at around half stroke and lock it again.

3) Reset power supply.

4) Send an opening control signal through the OPEN input.

5) The door leaves should open. If not, with stopped motor, it is sufficient to invert the move wires

of the motor (MOT/MOT) of the motor and the limit switches (SWO/SWC), if used.

6) Adjust Times and operating Logics.

TRIMMER FUNCTIONS

TW It allows the maximum duration of opening and closing.

It must be preset approx. 4s more with respect to the actual stroke time of the

system.

The adjustment ranges from 3s to 180s maximum.

TCA It allows to adjust the automatic closure time.

The adjustment ranges from 3s to 180s maximum.

DIP-SWITCH FUNCTION

Dip-Switches Function Description

DIP1 TORQUE To be used for the programming of the torque, as shown

hereunder. After presetting the parameters, move to OFF

again.

DIP2 TCA The automatic closure is enabled or disabled.

Off: disabled automatic closure.

On: enabled automatic closure.

DIP3 DAS/PHOT The operating mode of input DAS/PHOT is selected:

Off: partial reversion (3s) at activation of safety edge.

On: total reversion at activation of edge/photocell.

DIP4 SWC MODE Off: during closure, if SWC is pressed, the motor is

blocked.

On: during closure, if SWC is pressed, the motor continues

its closing movement for further 2 seconds or until the

SAFETY EDGE is activated.

Page 5

10

DIP5 BLI Select how OPEN input (13) works:

ON: during opening an OPEN command is ignored

During closing an OPEN command reverse the motion.

OFF: Works according DIP 6 setting

DIP6 OPEN/PP The operating mode of input 13 (Open) is selected.

Available only with DIP 5 OFF

On: PP Operation: OPEN > STOP > CLOSE > STOP>.

Off: OPEN operation always.

SERVICE MAN MODE

With all DIPs on ON, the control unit switches to SERVICE MAN mode.

The SWO and SWC inputs are deactivated.

The OPEN/CLOSE push-buttons must be kept pressed during operation. The opening of the

STOP input stops the motor.

ADJUSTMENT OF THE TORQUE (DIP1:ON)

When DIP1 is moved to ON, the board indicates that the torque has been applied during a

number of flashes (from 1 to 4) of the DL2 green LED, followed by a 3-s interval.

The max torque is indicated with DL2 green LED with fixed light.

To increase the torque, press P1. The DL2 LED changes the number of flashes to indicate the

selected torque value.

Once the desired torque is selected, move DIP 1 to OFF to memorise this presetting.

Note: with actuators for rolling shutters, preset torque at the maximum value.

RADIO SELF-LEARNING (DIP1:OFF/DIP6:ON)

The CELL.P control unit is equipped with a built-in radio module for the fixed or roll-on code of

remote controls, with 433.92MHz frequency.

To use a remote control, it is first necessary to store its code in memory. The memorisation

procedure is described hereunder. The device is able to store up to 64 different codes in

memory.

By pressing P1, the control unit enters the radio learning phase: DL1 red LED flashes 1 time per

second, awaiting the key to the matched to the Step-by-Step/OPEN function (see DIP6);

When the key is stored in memory, exit from the programming mode;

By pressing P1 twice, the control unit enters the radio learning phase: DL1 red LED flashes 2 time

per second, awaiting the key to the matched to the CLOSE function;

When the key to be matched is memorised, exit from the programming mode.

If the programming mode must be left without storing any remote control signal, press P1 key

until DL1 red LED starts to flash in “power on” mode (see LED diagnostics on page 7).

To reset the memory of the receiver, press and keep P1 and P2 keys pressed for around 10

seconds (during this period of time, both DL1 and DL2 flash rapidly).

After 10 seconds, when the two LEDs are switched on with fixed light, release the pushbuttons.

When the LEDs switch back again to the original configuration, the control unit has completed

the memory reset.

NOTE:

The transmitters are memorised on an EPROM memory (U2), which can be extracted from the

control unit and inserted in a new CELL.P control unit should a replacement is required.

For safety reasons, the transmitters can be stored in memory during the opening/closing of the

motor.

Page 6

11

LED DIAGNOSTICS

The red LED indicates the activation of inputs according to the legend hereunder:

STOP on with fixed light

DAS/PHOT rapid flashing

SWO 1 flash with 2-second interval

SWC 2 flashes with 2-second interval

OPEN+CLOSE 3 flashes with 2-second interval

By flashing slowly, the red LED also indicates that the unit is powered.

The green LED indicates the movement direction of the motor and the status of the gate according

to the legend hereunder:

OPENING 1 flash with 1-second interval

CLOSING 2 flashes with 1-second interval

Open gate without TCA on with fixed light

Page 7

28

Dichiarazione CE di Conformità

Dichiarazione in accordo alle Direttive

2004/108/CE(EMC); 2006/95/CE(LVD)

Fabbricante:

Automatismi Benincà SpA

Indirizzo:

Via Capitello, 45 - 36066 Sandrigo (VI) Italia

Dichiara che il prodotto:

Centrale di comando CELL.P

è conforme alle condizioni delle seguenti Direttive

CE:

• DIRETTIVA 2004/108/CE DEL PARLAMENTO

EUROPEO E DEL CONSIGLIO del 15 dicembre

2004 concernente il ravvicinamento delle legislazioni degli Stati membri relative alla compatibilità elettromagnetica e che abroga la direttiva 89/336/CEE,

secondo le seguenti norme armonizzate:

EN 61000-6-2:2005, EN 61000-6-3:2007.

• DIRETTIVA 2006/95/CE DEL PARLAMENTO

EUROPEO E DEL CONSIGLIO del 12 dicembre

2006 concernente il ravvicinamento delle legislazioni degli Stati membri relative al materiale elettrico

destinato ad essere adoperato entro taluni limiti di

tensione, secondo le seguenti norme armonizzate:

EN 60335-1:2002 + A1:2004 + A11:2004 + A12:2006

+ A2:2006 + A13:2008; EN 60335-2-103:2003.

se applicabile:

• DIRETTIVA 1999/5/CE DEL PARLAMENTO

EUROPEO E DEL CONSIGLIO del 9 marzo 1999

riguardante le apparecchiature radio e le apparecchiature terminali di telecomunicazione e il reciproco

riconoscimento della loro conformità, secondo le seguenti norme armonizzate: ETSI EN 301 489-3 V1.4.1

(2002) + ETSI EN 301 489-1 V1.4.1 (2002) + ETSI

EN 300 220-3 V1.1.1 (2000) + EN 60950-1 (2001)

Benincà Luigi, Responsabile legale.

Sandrigo, 04/03/2011.

EC Declaration of Conformity

Pursuant to Directives

2004/108/CE(EMC); 2006/95/CE(LVD)

Manufacturer:

Automatismi Benincà SpA

Address:

Via Capitello, 45 - 36066 Sandrigo (VI) Italia

It is hereby stated that the item:

CELL.P Control unit

it is compliant with provisions of the following other

EC Directives:

• DIRECTIVE 2004/108/EC OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL of 15

December 2004, on the harmonisation of the laws of

Member States relating to electromagnetic compatibility and which cancels Directive 89/336/EEC, according to the following harmonised regulations:

EN 61000-6-2:2005, EN 61000-6-3:2007.

• DIRECTIVE 2006/95/EC OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL of 12

December 2006, on the harmonisation of the laws

of Member States relating to electrical equipment

designed for use with certain voltage limits, according

to the following harmonised regulations:

EN 60335-1:2002 + A1:2004 + A11:2004 + A12:2006

+ A2:2006 + A13:2008; EN 60335-2-103:2003.

if applicable:

• DIRECTIVE 1999/5/EC OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL of 9

March 1999 on radio equipment and telecommunications terminal equipment and the mutual recognition

of their conformity, according to the following harmonised standards: ETSI EN 301 489-3 V1.4.1 (2002)

+ ETSI EN 301 489-1 V1.4.1 (2002) + ETSI EN 300

220-3 V1.1.1 (2000) + EN 60950-1 (2001)

Benincà Luigi, Legal Officer.

.Sandrigo, 04/03/2011

Loading...

Loading...