Beninca BULLOCK 424, BULLOCK 424 115 User Manual

L8542771 ITA/ENG/FRA/ESP

09/2013 rev 5

BULLOCK 424

BULLOCK 424 115

UNIONE NAZIONALE COSTRUTTORI

AUTOMATISMI PER CANCELLI, PORTE

SERRANDE ED AFFINI

EC Declaration of Conformity

Directive 2004/108/EC(EMC); 2006/95/EC (LVD)

Manufacturer:

Automatismi Benincà SpA.

Address:

Via Capitello, 45 - 36066 Sandrigo (VI) – Italy

It is hereby stated that the product

automatic system 24Vdc for sliding gates

BULLOCK 424.

is compliant with provisions set forth in the following EC Directives:

- DIRECTIVE 2004/108/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 15 December 2004, on the harmonisa-

tion of the laws of Member States relating to electromagnetic compatibility and which cancels Directive 89/336/EEC, according to the following

harmonised regulations: EN 61000-6-2:2005, EN 61000-6-3:2007.

- DIRECTIVE 2006/95/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 12 December 2006, on the harmonisation

of the laws of Member States relating to electrical equipment designed for use with certain voltage limits, according to the following harmonised

regulations: EN 60335-1:2002 + A1:2004 + A11:2004 + A12:2006 + A2:2006 + A13:2008; EN 60335-2-103:2003.

- DIRECTIVE 2006/42/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 17 May 2006, on machinery, which amends

Directive 95/16/EC, and complies with the requisites for the !partly completed machinery (almost machinery)" set forth in the EN13241-1:2003

regulation.

# Moreover, Automatismi Benincà SpA declares that the pertaining technical documentation has been drawn up in compliance with Attach-

ment VII B of the 2006/42/ EC Directive and that the following requirements have been complied with: 1.1.1 - 1.1.2 - 1.1.3 - 1.1.5 - 1.2.1 - 1.2.3

- 1.2.6 - 1.3.1 - 1.3.2 - 1.3.3 - 1.3.4 - 1.3.7 - 1.3.9 - 1.5.1 - 1.5.2 - 1.5.4 - 1.5.5 - 1.5.6 - 1.5.7 - 1.5.8 - 1.5.10 - 1.5.11 - 1.5.13 - 1.6.1 - 1.6.2 - 1.6.4

- 1.7.2 - 1.7.4 - 1.7.4.1 - 1.7.4.2 - 1.7.4.3.

# The manufacturer undertakes that information on the !partly completed machinery" will be sent to domestic authorities. Transmission ways

are also included in the undertaking, and the Manufacturer$s intellectual property rights of the !almost machinery" are respected.

# It is highlighted that commissioning of the !partly completed machinery" shall not be provided until the ¿nal machinery, in which it should

be incorporated, is declared compliant, if applicable, with provisions set forth in the Directive 2006/42/EC on Machinery.

# Moreover, the product, as applicable, is compliant with the following regulations:

EN 12445:2002, EN 12453:2002, EN 12978:2003.

Benincà Luigi, Legal 2f¿cer.

Sandrigo, 22 November 2010.

WARNING

The product shall not be used for purposes or in ways

other than those for which the product is intended for and

as described in this manual. Incorrect uses can damage

the product and cause injuries and damages.

The company shall not be deemed responsible for the

non-compliance with a good manufacture technique of

gates as well as for any deformation, which might occur

during use.

Keep this manual for further use.

Qualified personnel, in compliance with regulations in force,

shall install the system.

Packaging must be kept out of reach of children, as it can

be hazardous. For disposal, packaging must be divided

the various types of waste (e.g. carton board, polystyrene)

in compliance with regulations in force.

The installer must supply all information on the automatic,

manual and emergency operation of the automatic system

and supply the end user with instructions for use.

An omnipolar switch/section switch with remote

contact opening equal to, or higher than 3mm

Make sure that before wiring an adequate differential

switch and an overcurrent protection is provided.

Pursuant to safety regulations in force, some types of in-

stallation require that the gate connection be earthed.

During installation, maintenance and repair, cut off power

supply before accessing to live parts.

Descriptions and figures in this manual are not binding.

While leaving the essential characteristics of the product

unchanged, the manufacturer reserves the right to modify

the same under the technical, design or commercial point

of view without necessarily update this manual.

must be provided on the power supply mains..

12

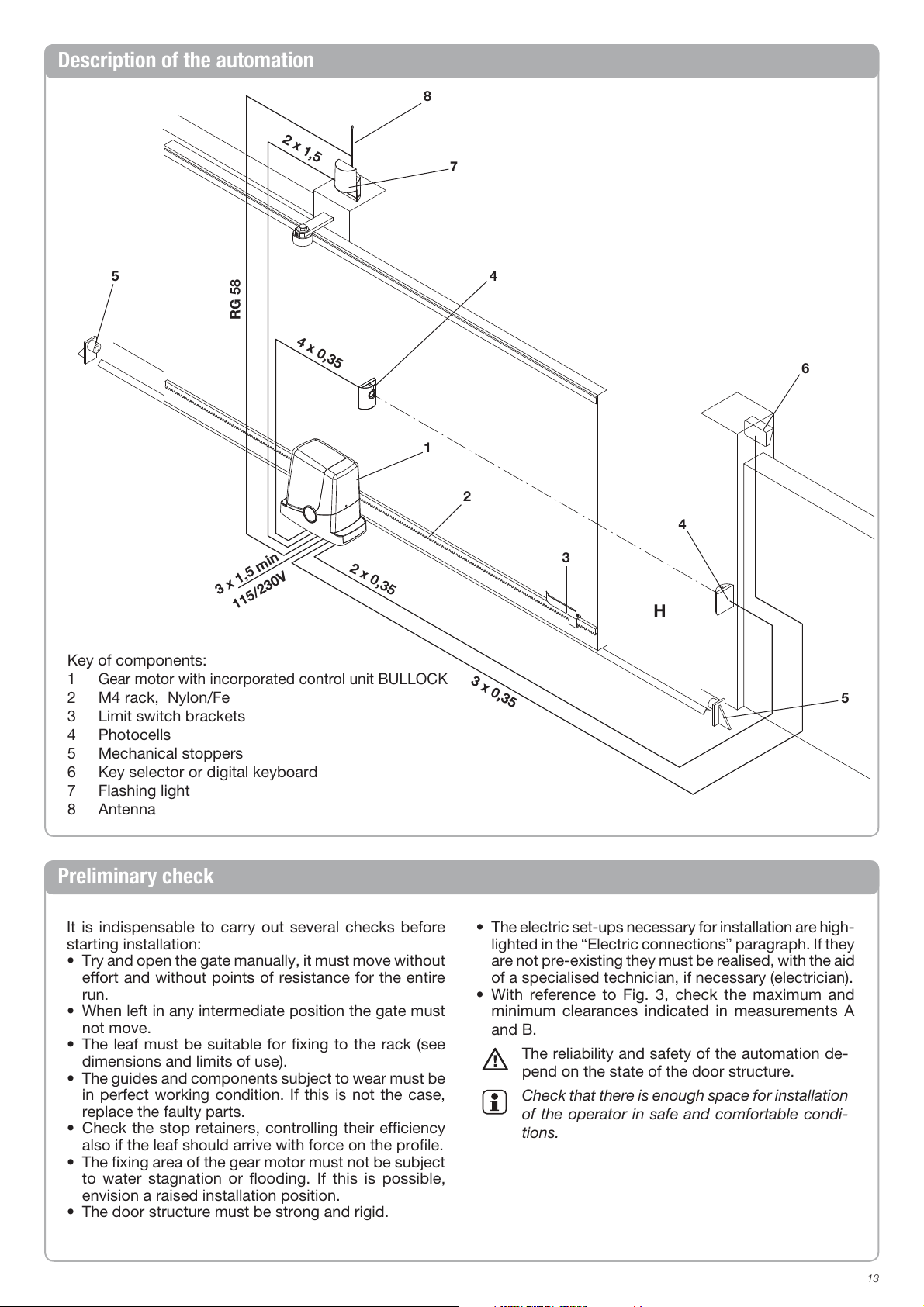

Description of the automation

2 x 1,5

8

7

5

RG 58

4 x 0,35

1

2 x 0,35

3 x 1,5 min

115/230V

Key of components:

1 Gear motor with incorporated control unit BULLOCK

2 M4 rack, Nylon/Fe

3 Limit switch brackets

4 Photocells

5 Mechanical stoppers

6 Key selector or digital keyboard

7 Flashing light

8 Antenna

4

6

2

4

3

H

3 x 0,35

5

Preliminary check

It is indispensable to carry out several checks before

starting installation:

• Try and open the gate manually, it must move without

effort and without points of resistance for the entire

run.

• When left in any intermediate position the gate must

not move.

• The leaf must be suitable for fixing to the rack (see

dimensions and limits of use).

• The guides and components subject to wear must be

in perfect working condition. If this is not the case,

replace the faulty parts.

• Check the stop retainers, controlling their efficiency

also if the leaf should arrive with force on the profile.

• The fixing area of the gear motor must not be subject

to water stagnation or flooding. If this is possible,

envision a raised installation position.

• The door structure must be strong and rigid.

• The electric set-ups necessary for installation are high-

lighted in the “Electric connections” paragraph. If they

are not pre-existing they must be realised, with the aid

of a specialised technician, if necessary (electrician).

• With reference to Fig. 3, check the maximum and

minimum clearances indicated in measurements A

and B.

The reliability and safety of the automation de-

pend on the state of the door structure.

Check that there is enough space for installation

of the operator in safe and comfortable condi-

tions.

13

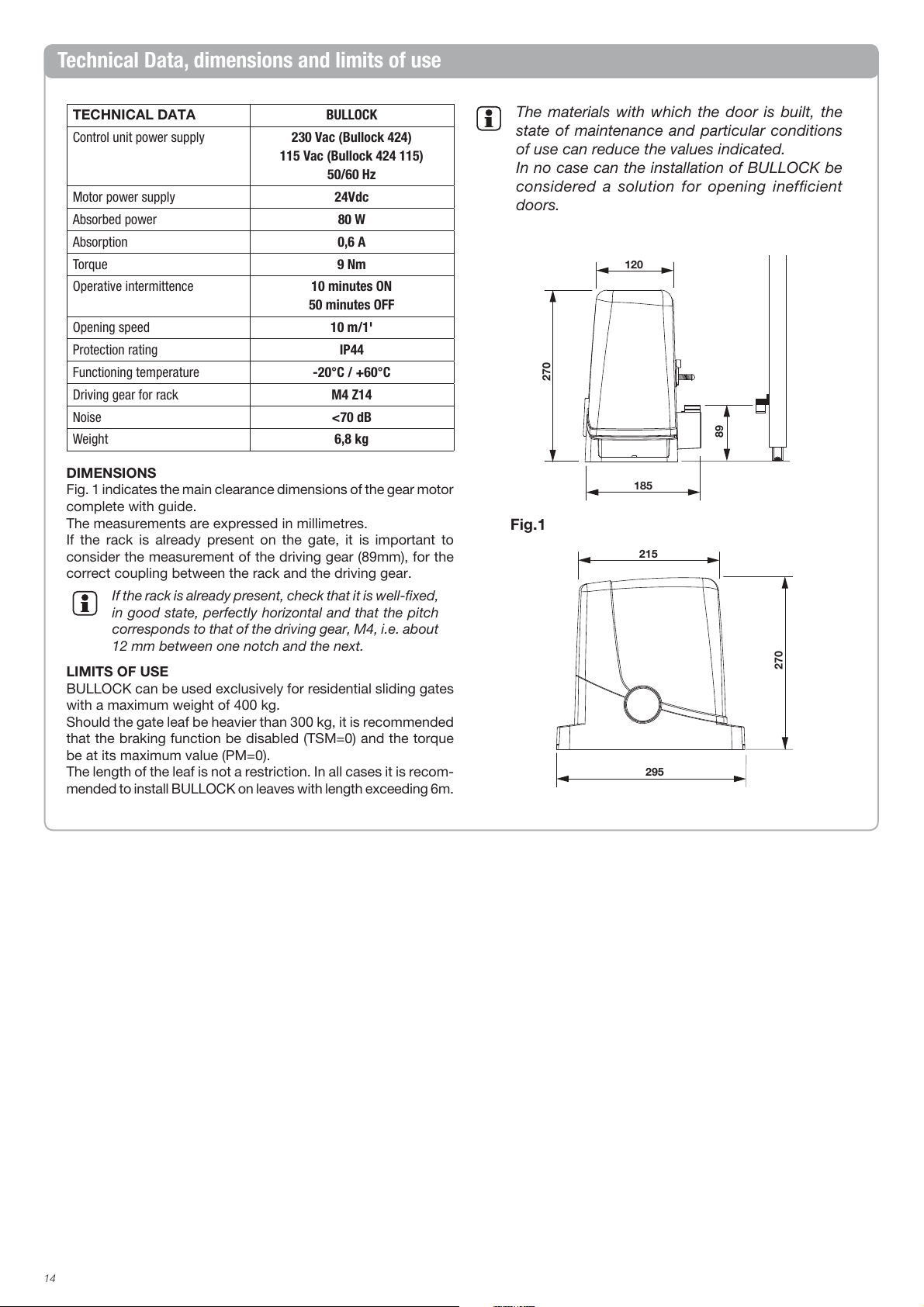

Technical Data, dimensions and limits of use

TECHNICAL DATA BULLOCK

Control unit power supply 230 Vac (Bullock 424)

115 Vac (Bullock 424 115)

50/60 Hz

Motor power supply 24Vdc

Absorbed power 80 W

Absorption 0,6 A

Torque 9 Nm

Operative intermittence 10 minutes ON

50 minutes OFF

Opening speed 10 m/1'

Protection rating IP44

Functioning temperature -20°C / +60°C

Driving gear for rack M4 Z14

Noise <70 dB

Weight 6,8 kg

DIMENSIONS

Fig. 1 indicates the main clearance dimensions of the gear motor

complete with guide.

The measurements are expressed in millimetres.

If the rack is already present on the gate, it is important to

consider the measurement of the driving gear (89mm), for the

correct coupling between the rack and the driving gear.

If the rack is already present, check that it is well-fixed,

in good state, perfectly horizontal and that the pitch

corresponds to that of the driving gear, M4, i.e. about

12 mm between one notch and the next.

LIMITS OF USE

BULLOCK can be used exclusively for residential sliding gates

with a maximum weight of 400 kg.

Should the gate leaf be heavier than 300 kg, it is recommended

that the braking function be disabled (TSM=0) and the torque

be at its maximum value (PM=0).

The length of the leaf is not a restriction. In all cases it is recom-

mended to install BULLOCK on leaves with length exceeding 6m.

The materials with which the door is built, the

state of maintenance and particular conditions

of use can reduce the values indicated.

In no case can the installation of BULLOCK be

considered a solution for opening inefficient

doors.

120

270

89

185

Fig.1

215

270

295

14

Loading...

Loading...