Page 1

L8542771 ITA/ENG/FRA/ESP

09/2013 rev 5

BULLOCK 424

BULLOCK 424 115

UNIONE NAZIONALE COSTRUTTORI

AUTOMATISMI PER CANCELLI, PORTE

SERRANDE ED AFFINI

Page 2

EC Declaration of Conformity

Directive 2004/108/EC(EMC); 2006/95/EC (LVD)

Manufacturer:

Automatismi Benincà SpA.

Address:

Via Capitello, 45 - 36066 Sandrigo (VI) – Italy

It is hereby stated that the product

automatic system 24Vdc for sliding gates

BULLOCK 424.

is compliant with provisions set forth in the following EC Directives:

- DIRECTIVE 2004/108/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 15 December 2004, on the harmonisa-

tion of the laws of Member States relating to electromagnetic compatibility and which cancels Directive 89/336/EEC, according to the following

harmonised regulations: EN 61000-6-2:2005, EN 61000-6-3:2007.

- DIRECTIVE 2006/95/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 12 December 2006, on the harmonisation

of the laws of Member States relating to electrical equipment designed for use with certain voltage limits, according to the following harmonised

regulations: EN 60335-1:2002 + A1:2004 + A11:2004 + A12:2006 + A2:2006 + A13:2008; EN 60335-2-103:2003.

- DIRECTIVE 2006/42/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 17 May 2006, on machinery, which amends

Directive 95/16/EC, and complies with the requisites for the !partly completed machinery (almost machinery)" set forth in the EN13241-1:2003

regulation.

# Moreover, Automatismi Benincà SpA declares that the pertaining technical documentation has been drawn up in compliance with Attach-

ment VII B of the 2006/42/ EC Directive and that the following requirements have been complied with: 1.1.1 - 1.1.2 - 1.1.3 - 1.1.5 - 1.2.1 - 1.2.3

- 1.2.6 - 1.3.1 - 1.3.2 - 1.3.3 - 1.3.4 - 1.3.7 - 1.3.9 - 1.5.1 - 1.5.2 - 1.5.4 - 1.5.5 - 1.5.6 - 1.5.7 - 1.5.8 - 1.5.10 - 1.5.11 - 1.5.13 - 1.6.1 - 1.6.2 - 1.6.4

- 1.7.2 - 1.7.4 - 1.7.4.1 - 1.7.4.2 - 1.7.4.3.

# The manufacturer undertakes that information on the !partly completed machinery" will be sent to domestic authorities. Transmission ways

are also included in the undertaking, and the Manufacturer$s intellectual property rights of the !almost machinery" are respected.

# It is highlighted that commissioning of the !partly completed machinery" shall not be provided until the ¿nal machinery, in which it should

be incorporated, is declared compliant, if applicable, with provisions set forth in the Directive 2006/42/EC on Machinery.

# Moreover, the product, as applicable, is compliant with the following regulations:

EN 12445:2002, EN 12453:2002, EN 12978:2003.

Benincà Luigi, Legal 2f¿cer.

Sandrigo, 22 November 2010.

WARNING

The product shall not be used for purposes or in ways

other than those for which the product is intended for and

as described in this manual. Incorrect uses can damage

the product and cause injuries and damages.

The company shall not be deemed responsible for the

non-compliance with a good manufacture technique of

gates as well as for any deformation, which might occur

during use.

Keep this manual for further use.

Qualified personnel, in compliance with regulations in force,

shall install the system.

Packaging must be kept out of reach of children, as it can

be hazardous. For disposal, packaging must be divided

the various types of waste (e.g. carton board, polystyrene)

in compliance with regulations in force.

The installer must supply all information on the automatic,

manual and emergency operation of the automatic system

and supply the end user with instructions for use.

An omnipolar switch/section switch with remote

contact opening equal to, or higher than 3mm

Make sure that before wiring an adequate differential

switch and an overcurrent protection is provided.

Pursuant to safety regulations in force, some types of in-

stallation require that the gate connection be earthed.

During installation, maintenance and repair, cut off power

supply before accessing to live parts.

Descriptions and figures in this manual are not binding.

While leaving the essential characteristics of the product

unchanged, the manufacturer reserves the right to modify

the same under the technical, design or commercial point

of view without necessarily update this manual.

must be provided on the power supply mains..

12

Page 3

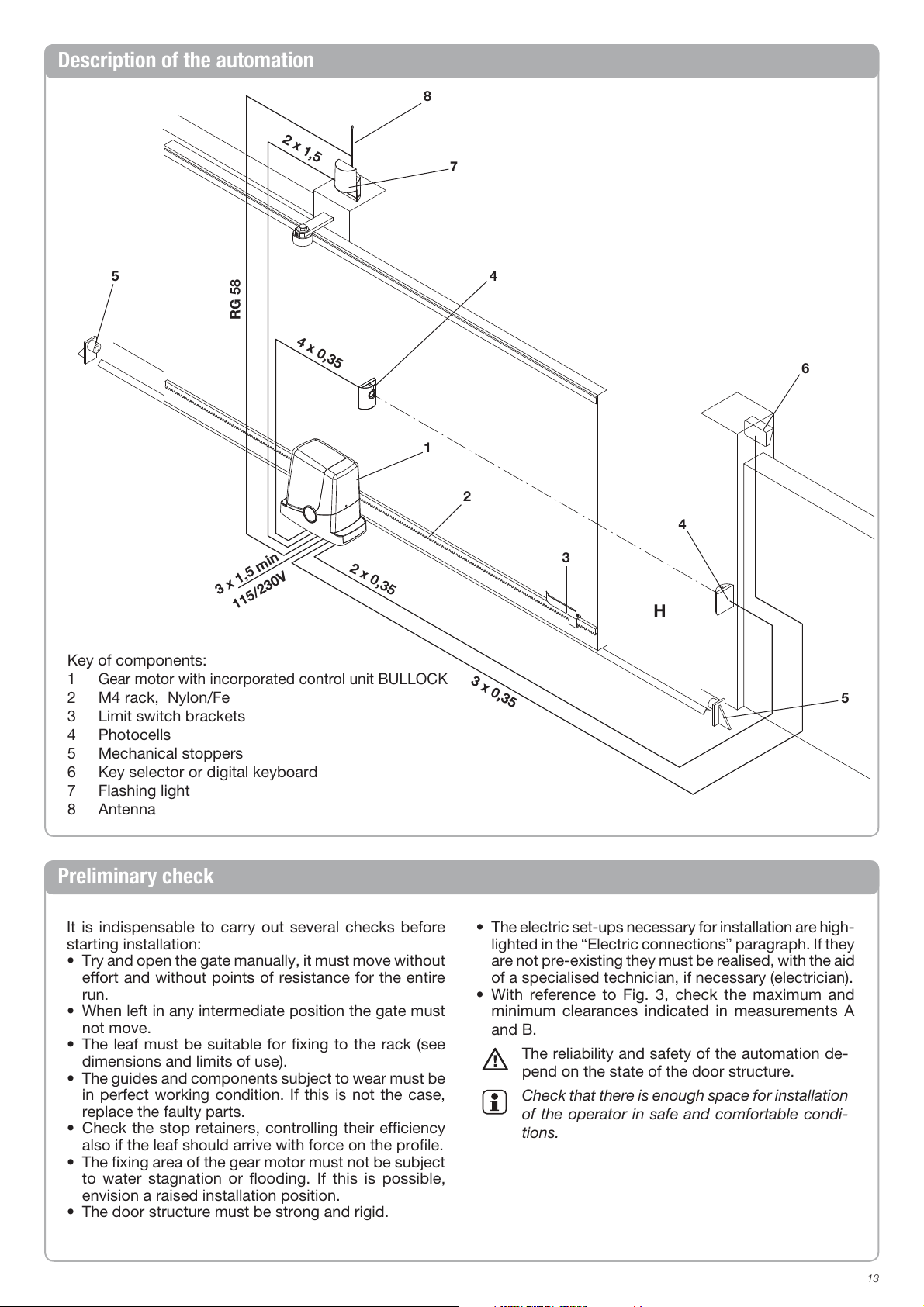

Description of the automation

2 x 1,5

8

7

5

RG 58

4 x 0,35

1

2 x 0,35

3 x 1,5 min

115/230V

Key of components:

1 Gear motor with incorporated control unit BULLOCK

2 M4 rack, Nylon/Fe

3 Limit switch brackets

4 Photocells

5 Mechanical stoppers

6 Key selector or digital keyboard

7 Flashing light

8 Antenna

4

6

2

4

3

H

3 x 0,35

5

Preliminary check

It is indispensable to carry out several checks before

starting installation:

• Try and open the gate manually, it must move without

effort and without points of resistance for the entire

run.

• When left in any intermediate position the gate must

not move.

• The leaf must be suitable for fixing to the rack (see

dimensions and limits of use).

• The guides and components subject to wear must be

in perfect working condition. If this is not the case,

replace the faulty parts.

• Check the stop retainers, controlling their efficiency

also if the leaf should arrive with force on the profile.

• The fixing area of the gear motor must not be subject

to water stagnation or flooding. If this is possible,

envision a raised installation position.

• The door structure must be strong and rigid.

• The electric set-ups necessary for installation are high-

lighted in the “Electric connections” paragraph. If they

are not pre-existing they must be realised, with the aid

of a specialised technician, if necessary (electrician).

• With reference to Fig. 3, check the maximum and

minimum clearances indicated in measurements A

and B.

The reliability and safety of the automation de-

pend on the state of the door structure.

Check that there is enough space for installation

of the operator in safe and comfortable condi-

tions.

13

Page 4

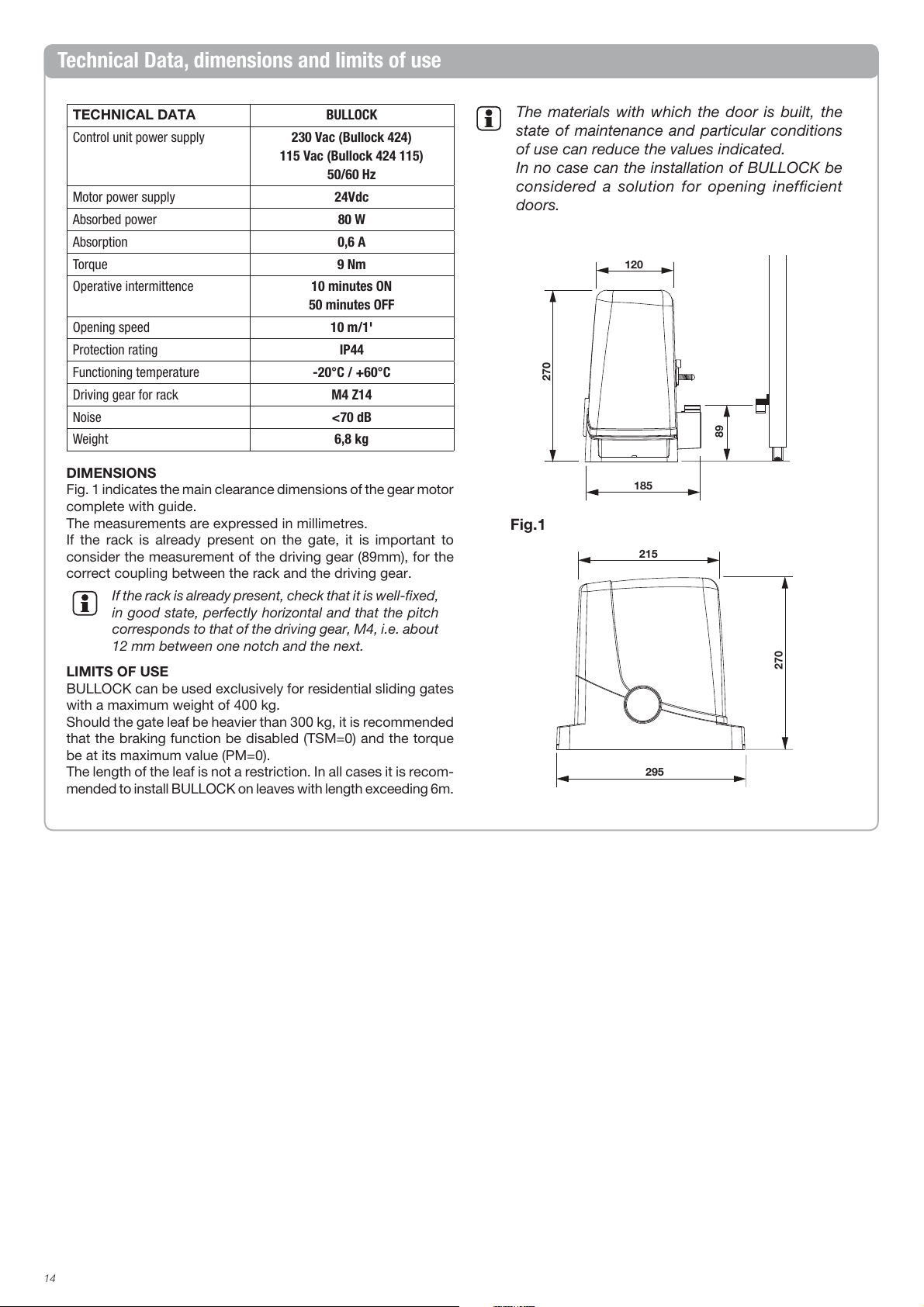

Technical Data, dimensions and limits of use

TECHNICAL DATA BULLOCK

Control unit power supply 230 Vac (Bullock 424)

115 Vac (Bullock 424 115)

50/60 Hz

Motor power supply 24Vdc

Absorbed power 80 W

Absorption 0,6 A

Torque 9 Nm

Operative intermittence 10 minutes ON

50 minutes OFF

Opening speed 10 m/1'

Protection rating IP44

Functioning temperature -20°C / +60°C

Driving gear for rack M4 Z14

Noise <70 dB

Weight 6,8 kg

DIMENSIONS

Fig. 1 indicates the main clearance dimensions of the gear motor

complete with guide.

The measurements are expressed in millimetres.

If the rack is already present on the gate, it is important to

consider the measurement of the driving gear (89mm), for the

correct coupling between the rack and the driving gear.

If the rack is already present, check that it is well-fixed,

in good state, perfectly horizontal and that the pitch

corresponds to that of the driving gear, M4, i.e. about

12 mm between one notch and the next.

LIMITS OF USE

BULLOCK can be used exclusively for residential sliding gates

with a maximum weight of 400 kg.

Should the gate leaf be heavier than 300 kg, it is recommended

that the braking function be disabled (TSM=0) and the torque

be at its maximum value (PM=0).

The length of the leaf is not a restriction. In all cases it is recom-

mended to install BULLOCK on leaves with length exceeding 6m.

The materials with which the door is built, the

state of maintenance and particular conditions

of use can reduce the values indicated.

In no case can the installation of BULLOCK be

considered a solution for opening inefficient

doors.

120

270

89

185

Fig.1

215

270

295

14

Page 5

Laying the foundation plate - Measurements

The positioning of the plate must respect the distances indi-

cated in figures 2a/b/c/d (seen from above):

- Fig. 2a installation with motor on the left

- Fig. 2b installation with motor on the right

If the rack is already installed on the leaf:

- Fig. 2c installation with motor on the left

- Fig. 2d installation with motor on the right

90 mm

Fig.2a

0-50 mm

90 mm

Fig.2b

50-100 mm

It is also indispensable that the rack projects, with respect to

the centre of the plate, by at least the measurements indicated

in figure 3a (motor on left) and 3b (motor on right) to allow po-

sitioning of the end run brackets.

In some cases it is possible that the rack projects by a

few centimetres with respect to the plumb line of the

gate in order to allow complete closure.

Make note of the measurements indicated before proceeding

with the successive phases.

The foundation plate has two large holes for the pas-

sage of the raceways. They can both be used, thanks

to the space present on the bottom of the gear motor,

but it is easier to use the hole of the left if the pinion,

highlighted in the figures.

190 mm

Fig.3a

40 mm

50-100 mm

0-50 mm

40 mm

Fig.2c

Fig.2d

150 mm

190 mm

Fig.3b

150 mm

15

Page 6

Laying the foundation plate - Cement foundation

m

If there is no cement flooring (or similar material) a cement*

foundation must be prepared. Proceed as follows:

1 - Dig a suitable hole (minimum 40x30cm, at last 35cm deep),

considering the measurements indicated in the previous para-

graph.

2 - Prepare the pipes for the passage of the electric cables

(see “Electric connections”), leaving the pipes longer by about

30/40cm (figure 4-ref.T).

3 - Bend the 4 threaded bars:

a) if the rack is pre-installed at a measurement greater than that

indicated in Figure 1, or in the case of possible water stagnation,

the foundation plate may have to be raised. In this case, bend

the bars at a height of about 45 mm as indicated in Figure 5.

b) if the motor will be fixed to the ground, bend the bars at a

height of about 30 mm as indicated in Figure 6.

4 - Prepare the plate for the cast, fixing the threaded bars.

With reference to Figure 7 use 4 lower support nuts D and 4

nuts F with the relative washers R to block the plate in posi-

tion. The position of the bars must be similar to that indicated

in figure 7.

5 - Prepare the cement following the manufacturer’s indications.

In some cases it may be necessary to realise a metal cage to

make the foundation more stable.

6 - Sink the bars into the cement, paying attention to the level

of the plate and the parallelism with the leaf (figure 8).

7 - Wait for the cement cast to be reinforced.

8 - Remove the upper screws and washers, which will be suc-

cessively used to fix the gear motor.

9 - Figure 9 shows the plate when fixing is ultimated. If neces-

sary, it is now possible to raise the plate by a maximum of 20

mm, positioning 4 nuts and the relative washers under the plate,

as indicated in figure 10.

* If in doubt, contact qualified staff for realisation of the foun-

dation.

Fig. 7

F

R

D

Fig. 8

The plate must be tightly fixed to the ground, perfectly

levelled and parallel to the leaf.

Fig. 4

T

45 mm

30 m

Fig. 9

Fig. 10

Fig. 5 Fig. 6

16

25 mm

20 mm max.

Max 20 mm

Page 7

Laying the foundation plate - Fixing to the floor

If the floor is in cement (or similar material) it is possible to fix

the plate directly to the ground:

1 - Obtain suitable fixing systems, normally on the market, steel

pressure plugs (figure 11 -ref A) or anchorage with expansion

straps (figure 1 -ref B) to be inserted using a mallet.

2 - Respecting the measurements indicated previously, trace

the drilling points using the plate as a reference, make 4 holes

measuring 10 mm in diameter and fix the plate. Make sure

that the threaded bar projects by at least 25mm as indicated

in figure 10.

3 - In some cases (rack already installed, possible water stag-

nation, etc) it is possible to ix the plate in a raised position with

respect to the floor by a maximum of 20 mm, positioning 4

nuts and the relative washers under the plate as indicated in

figure 12. In this case, the pins must project from the ground

by at least 45mm.

Check that the floor is well-levelled and suitable for fixing

via plugs. Independently from the type of pre-selected

fixing, the plate must result well-fixed, perfectly levelled

and parallel to the leaf.

Fig. 11

B

A

Fig. 10

25 mm

Fixing the gear motor

To fix the motor reducer to the plate, with reference to fig. 13,

proceed as follows:

1 - Remove the two screw-cover sumps C.

2 - Place the gear motor on the plate, making sure that the

threaded bars enter the holes.

3 - Block the gear motor using the 4 washers R and the 4

bolts D.

4 - The slots F allow to regulate the distance of the motor with

respect to the leaf.

Fig. 12

Fig. 13

25 mm

20 mm max.

Max 20 mm

C

D

R

F

B

17

Page 8

Fixing the rack

The rack, appropriately fixed to the leaf, transforms the rotary

movement of the gear into the linear movement of the leaf.

Before fixing the rack, it is necessary to release the gear motor,

proceed as follows:

1) Turn the circular cover by 180°, in a way to view the trian-

gular pin.

2 - Insert the release key FRD.3 and turn it clockwise until a

certain resistance is felt (Fig.13).

About 15 complete rotations of the key are necessary

3 - The gear is now released and free to turn.

Now fix the rack:

1 - Take the leaf into the completely open position.

2 - Place the first tract of the rack on the gear.

Considering the measurements indicated in figures 3a and 3b,

mark the first drilling point. Block the rack temporarily, using a

clamp for example (Fig.15).

3 - Drill and block the first fin of the rack using the screw and

the washer as indicated in figure 16, checking that a space of

about 1 mm remains between the gear and rack (Fig.17).

4 - Make the leaf slide and take the driving gear near to the

second fixing fin, always checking the space of 1mm between

gear and rack (Fig.18).

5 - Proceed in the same way for the other fins, moving the

leaf every time in a way always to have the correct gear/rack

coupling.

6 - Now continue with the remaining tracts of the rack. Every

tract must be attached to the previous one as indicated in Figure

19, in a way to keep the rack pitch constant.

Fig. 16

Fig. 17

1 mm

Use several manual opening and closing manoeuvres

to check that the rack is correctly engaged, along its

entire length. If necessary, the holes present on the rack

allow height adjustment.

Fig. 13 Fig. 14

Fig. 15

Fig. 18

Fig. 19

18

Page 9

Fixing the end run brackets

Stopping the movement, in the opening phase and in the clos-

ing phase, takes place via the end run brackets FRD.1, which,

relevantly fixed onto the rack, make the end run spring, present

on the gear motor, intervene.

To position and fix the brackets FRD 1, proceed as follows:

1 -Take the leaf to the desired opening position. If a stop block

is present on the ground, the leaf must stop 2/3 cm before the

block (Figure 20).

2 - Place the right bracket FRD.1 on the rack and make it slide

until the end run spring, bending, effects switch-over of the inter-

nal switch, which can be perceived with a “click” (Figure 21).

3 - Fix the bracket temporarily via the two screws supplied

(Figure 22).

4 - Take the leaf into the completely closed position and then

open by about 2 cm (Figure 23).

5 - Place the left bracket FRD.1 on the rack and make it slide until

the end run spring, bending, effects switch-over of the internal

switch, which can be perceived with a “click” (Figure 24).

6 - Fix the bracket as indicated in previous point 3.

7 - If necessary, use a hacksaw to shorten the end part of the

last tract of the rack, so that it does not project with respect to

the plumb line of the leaf.

In the inspection phase, use several opening and closing

manoeuvres to check whether the end run intervenes

in the correct opening and closing points, before the

respective mechanical profiles.

If necessary, move the brackets FRD.1 to advance or

delay the stop points

8 - When the best stop points have been established, remove

the two screws, and use a drill (45 mm point), to make the holes

with depth of about 2 mm in correspondence with the signs left

by the screws and then fix bracket FRD.1 again (Figure 25).

A seat for the screws is created in this way, which guarantees

the stability of the bracket FRD.1 on the rack.

Fig. 22

Fig. 23

2/3 cm

Fig. 20

Fig. 21

¡CLIC!

CLICK!

2/3 cm

¡CLIC!

CLICK!

Fig. 25

Fig. 24

19

Page 10

User guide

KEEP THIS GUIDE AND MAKE IT AVAILABLE TO ALL USERS OF THE AUTOMATION.

SAFETY STANDARDS

Do not stand in the movement area of the door.

Do not allow children to play with the commands or

in proximity of the leaves.

In the case of functioning anomalies do not at-

tempt to repair the fault but contact a BENINCA'

specialised technician.

MANUAL MOVEMENT FROM INSIDE

In the case of functioning anomalies or power cuts, the automa-

tion can be released and the door moved manually, proceed

as follows:

1 - Turn the circular cover by 180°, in a way to view the trian-

gular pin.

MAINTENANCE

• Periodically check the efficiency of the manual emergency

release.

• The actuator does not require routine maintenance, however it

is necessary to periodically check the safety devices and the

other parts of the plant that could create dangers following

wear.

DISPOSAL

Whenever the product is put out of service, the legislative

provisions in force must be followed regarding differentiated

disposal and re-cycling of the various components (metals,

plastics, electric cables, etc.).

It is advised to contact a BENINCA' specialised technician or a

specialised company that is enabled for this purpose.

2 - Insert the release key FRD.3 and turn it clockwise until a

certain resistance is felt (Fig.20).

About 15 complete rotations of the key are necessary.

3 - The gear is now released and free to turn. Move the leaf

manually to open and close the gate.

4 - To restore automatic functioning, turn the key anti-clockwise

until it stops.

20

Page 11

Parti di ricambio - Spare parts - Lista de recambios

10

9

4

5

7

11

6

2

3

8

8

1

8

12

N. Code Note

1 9688164

2 9688165

3 9686414

4 9688166

5

9686622 Bullock 424

9688142 Bullock 424 115

6 9686623

7 9686624

8 9688169

9 9686626

10

9688170 Bullock 424

9688143 Bullock 424 115

11 9686488

12 9688174

39

Page 12

AUTOMATISMI BENINCÀ SpA - Via Capitello, 45 - 36066 Sandrigo (VI) - Tel. 0444 751030 r.a. - Fax 0444 759728

Loading...

Loading...