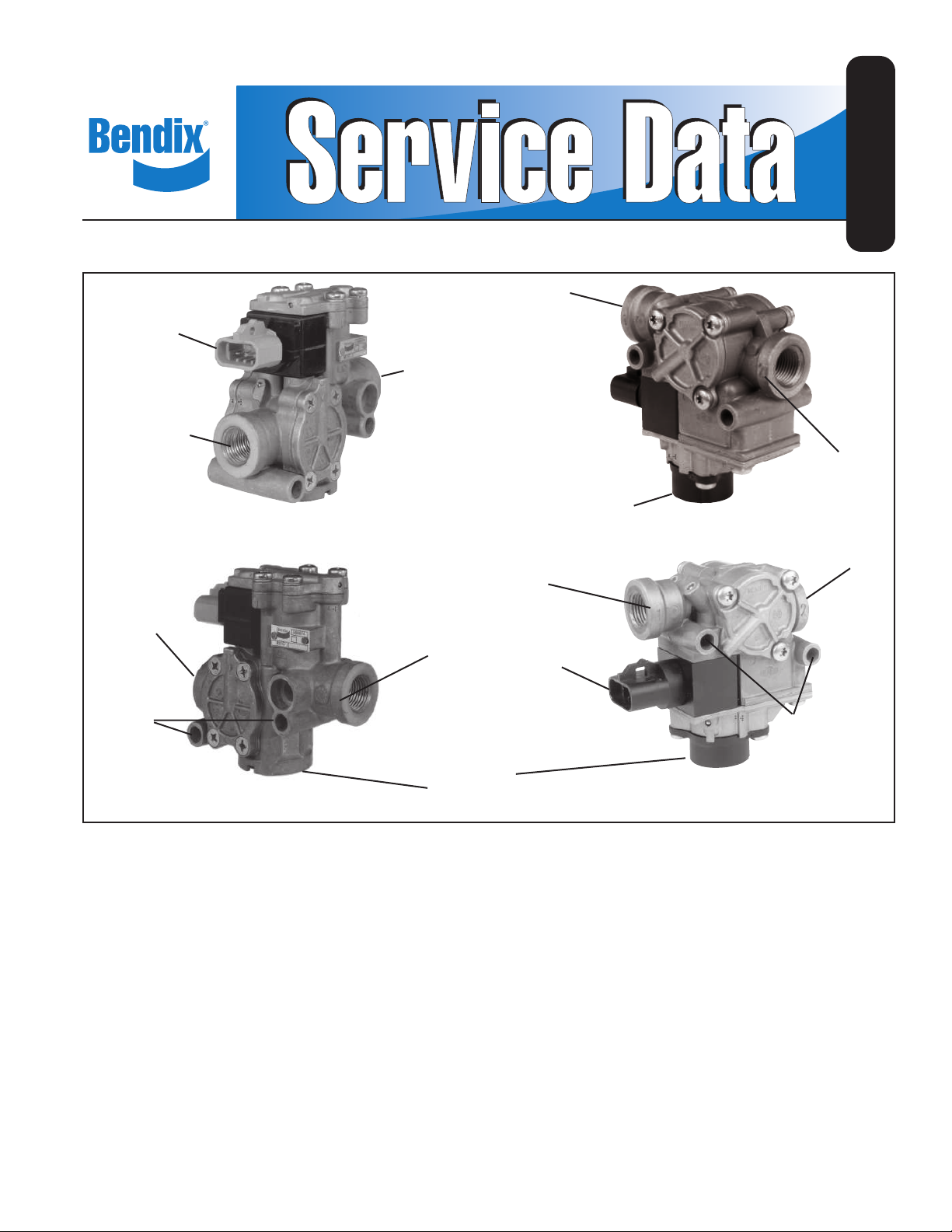

BENDIX SD-13-4793 User Manual

Bendix® M-21™ and M-22™ AntiLock Modulator Assembly

SUPPLY

SOLENOID

CONNECTOR

SUPPLY

DELIVERY

(CAST-IN ID #2)

EXHAUST

(CAST-IN ID #3)

SD-13-4793

DELIVERY

(CAST-IN ID #2)

DELIVERY

MOUNTING

HOLES

SUPPLY

(CAST-IN ID #1)

EXHAUST

(CAST-IN ID #3)

M-21™ MODULATOR M-22™ MODULATOR

FIGURE 1 - M-21™ AND M-22™ MODULATOR

DESCRIPTION

There are two Bendix antilock modulators available from

Bendix Commercial Vehicle Systems LLC, the older M-21

™

modulator and the newer M-22

modulator. Both are

functionally the same.

The M-21

™

and M-22™ antilock system modulators (Figure

1) are essentially high capacity, on/off air valves that

incorporate a pair of electrical solenoids for control. The

solenoids provide the electro-pneumatic interface or link

between the antilock controller electronics and the air brake

system. The modulator can be used to control the braking

function on an individual wheel or two service actuators.

When used to control both service chambers on an axle

or two chambers on the same side of a tandem axle, the

modulator is sometimes mounted ahead of a quick release

™

SUPPLY

(CAST-IN ID #1)

SOLENOID

CONNECTOR

DELIVERY

MOUNTING

HOLES

valve, which provides quick exhaust of service applications

during normal braking. (Figure 2) In the case of individual

wheel control applications, the modulator is always the

last control valve through which air passes on its way

to the service brake actuator and a solenoid assembly

which contains one normally open solenoid (NOS), one

normally closed solenoid (NCS), and two inlet and exhaust

diaphragm valves. A Packard, three pin, 280 series weather

resistant electrical connector is an integral part of the

modulator solenoid assembly and serves to carry control

commands from the antilock controller to the modulator.

Two, .35 inch diameter, mounting holes are provided for

frame or cross member mounting. The single supply,

delivery and exhaust port on both modulators is identifi ed

with a cast, embossed numeral for positive identifi cation.

1

bw

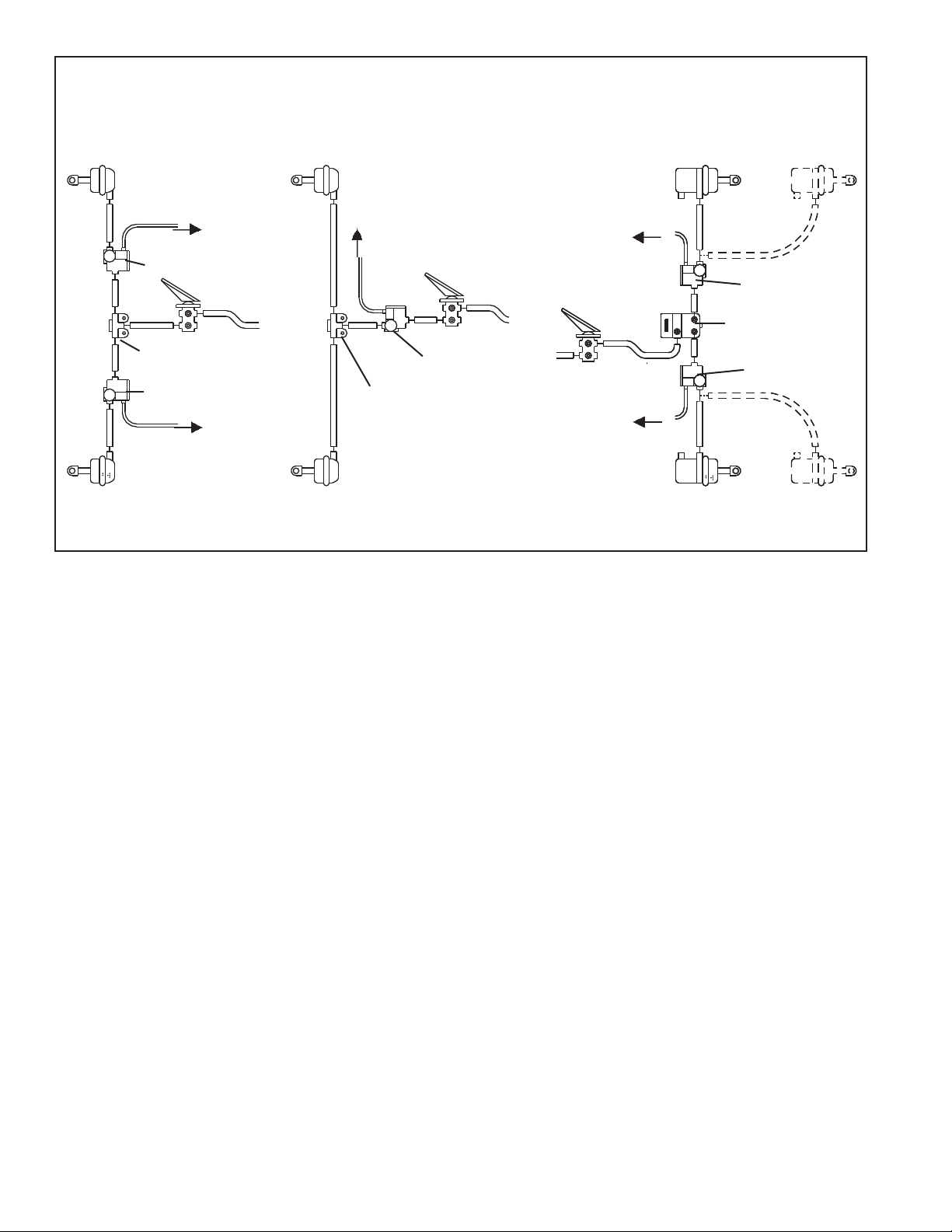

AXLE CONTROLWHEEL CONTROL WHEEL CONTROL

TO

ANTILOCK

CONTROLLER

M-21™ OR M-22™ MODULATOR

QUICK RELEASE VALVE

M-21™ OR M-22™ MODULATOR

TO ANTILOCK

CONTROLLER

TO

ANTILOCK

CONTROLLER

M-21™ OR M-22™ MODULATOR

QUICK RELEASE VALVE

TO

ANTILOCK

CONTROLLER

TO

ANTILOCK

CONTROLLER

REAR AXLE SYSTEMFRONT AXLE SYSTEMS

M-21™ OR M-22

MODULATOR

CONTROLLER/

RELAY ASSEMBLY

M-21™ OR M-22

MODULATOR

™

™

SERVICE BRAKE

CHAMBER

FIGURE 2 - WHEEL AND AXLE CONTROL SYSTEMS

SERVICE BRAKE

CHAMBER

They are as follows;

Identifi cation Air Line Connection

1 Supply

(incoming air from foot valve or relay)

2 Delivery

(air delivery to service actuators)

3 Exhaust

(air exhaust during antilock control)

OPERATION

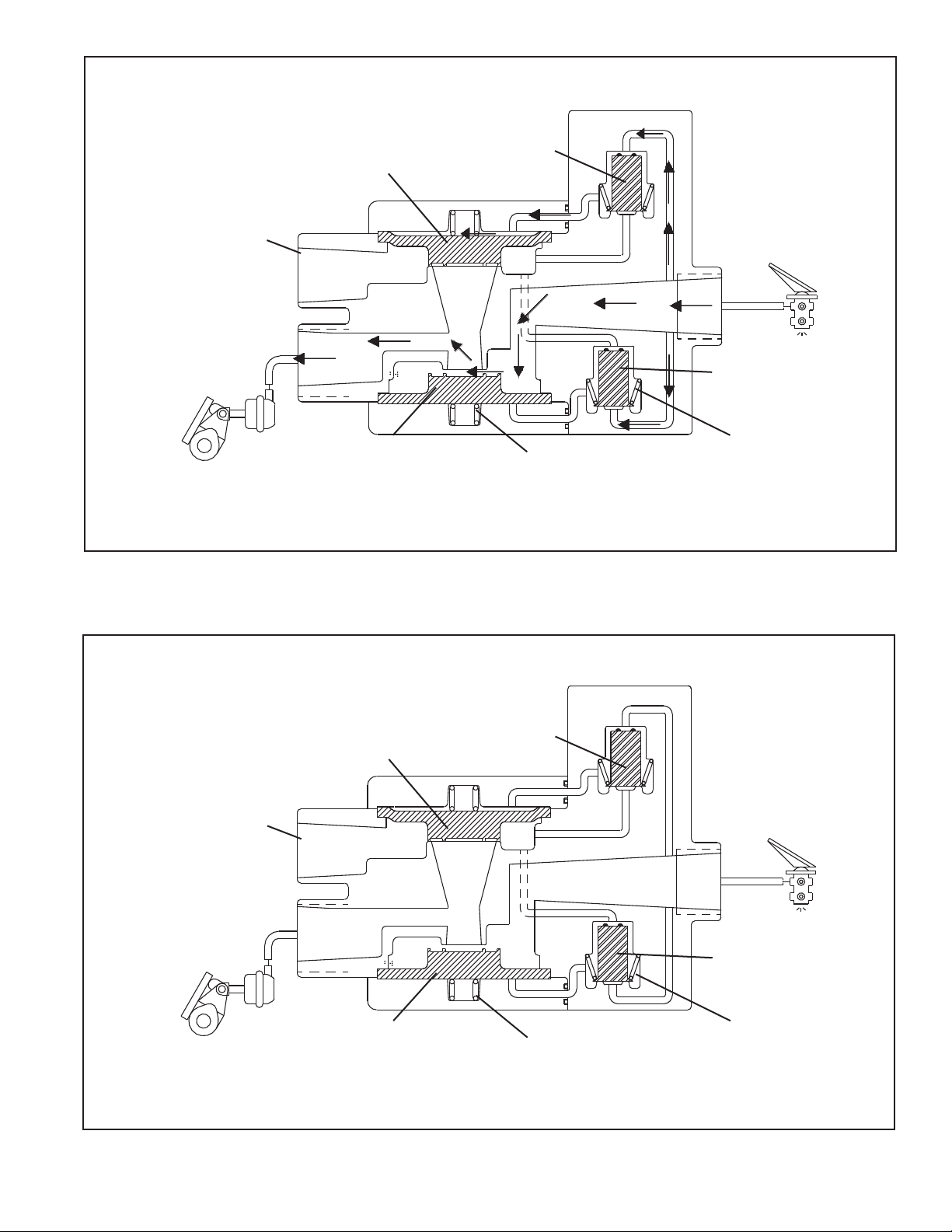

NON-ANTILOCK APPLICATION (FIGURE 3)

During normal non-antilock braking, both solenoids are

de-energized (no electrical power). Brake application air

enters the supply port of the modulator and fl ows to, and

through, the open exhaust solenoid then to the exhaust

diaphragm. Air pressure, along with spring force, seats

the exhaust diaphragm on the exhaust passage thus

preventing the escape of service air. Simultaneously,

application air fl ows to the supply diaphragm and forces it

away from its seat. Air fl ows past the open supply and out

the modulator delivery port to the service brake chambers.

SERVICE &

SPRING BRAKE

CHAMBER

NON-ANTILOCK HOLD (FIGURE 4)

When the desired air pressure is attained in the service

brake chambers, the brake system is in the holding position.

In the holding position both solenoids in the modulator

remain de-energized and the balance of the internal

components remain in the same position as they assumed

during application.

2

EXHAUST PORT

EXHAUST

DIAPHRAGM

EXHAUST

SOLENOID

BRAKE VALVE

SUPPLY

SOLENOID

BRAKE

CHAMBER

FIGURE 3 - M-21™, M-22™ MODULATOR NON-ANTILOCK APPLICATION OF SERVICE BRAKES

EXHAUST PORT

SUPPLY

DIAPHRAGM

EXHAUST

DIAPHRAGM

SPRING

EXHAUST

SOLENOID

SPRING

BRAKE

CHAMBER

FIGURE 4 - M-21™, M-22™ MODULATOR NON-ANTILOCK APPLICATION HELD POSITION

SUPPLY

DIAPHRAGM

SPRING

BRAKE VALVE

SUPPLY

SOLENOID

SPRING

3

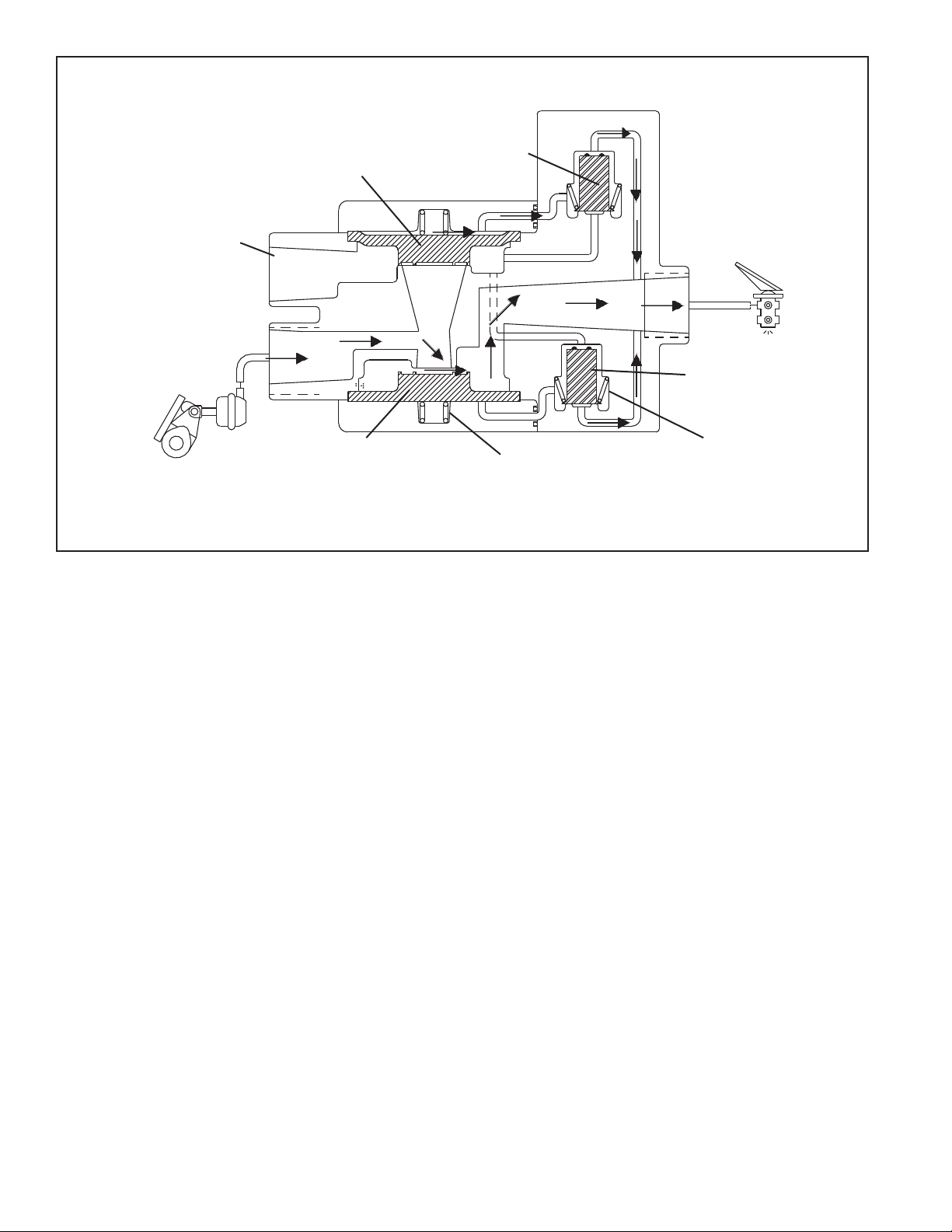

EXHAUST PORT

EXHAUST

DIAPHRAGM

EXHAUST

SOLENOID

BRAKE VALVE

SUPPLY

SOLENOID

BRAKE

CHAMBER

FIGURE 5 - M-21™, M-22™ MODULATOR NON-ANTILOCK EXHAUST OF SERVICE BRAKES (NORMAL)

SUPPLY

DIAPHRAGM

SPRING

SPRING

NON-ANTILOCK EXHAUST

The manner in which air exhausts through the modulator

differs, depending upon how rapidly the brake application

is released by the driver.

fl ow past the open supply diaphragm and back to the

application device's exhaust.

ANTILOCK OPERATION

Normal Exhaust (Figure 5) - During a normal, relatively

"slow", brake release, air moves back through the

modulator in the reverse direction as it fl owed during

application. The internal components of the modulator

will remain in the same position as they assumed during

application until air pressure decreases to approximately

one half psi, at which time the supply diaphragm will seat on

the supply passage. Air will generally not be expelled from

the modulator exhaust port during normal brake release.

Rapid Exhaust (Figure 6) - The rapid exhaust operation

described in the following text only occurs when the

modulator is controlling two type 30 (or larger) service

chambers. During a very rapid brake release the modulator

will exhaust air in a different manner. An example of this

would be the case if the driver made a severe brake

application then lifted his foot from the foot valve. During

a rapid brake release, air from the exhaust diaphragm

fl ows back through the open exhaust solenoid and to the

application device's exhaust. With pressure removed from

the control side of the exhaust diaphragm, air, returning to

the modulator from the service chambers, lifts the exhaust

diaphragm from its seat. Returning air fl ows past the open

exhaust and out the modulator exhaust port. Air will also

GENERAL

If a service brake application is made and the antilock

system detects an impending wheel lockup, the antilock

controller will immediately begin modifi cation of the brake

application using the modulator.

In order to modify the brake application, the coils of the two

solenoid valves contained in the modulator are energized

or de-energized in a pre programmed sequence by the

antilock controller. When a solenoid coil is energized, a

shuttle within the solenoid moves, and depending upon

the function of the specifi c solenoid, it either opens or

closes thereby causing the exhaust or re-application of

air pressure to the brake actuator. The solenoids in the

modulator are controlled independently by the antilock

controller. By opening and closing the solenoid valves in

the modulator, the antilock controller is able to simulate

what the driver does when he "pumps the brakes". It must

be remembered, however, that unlike the driver the antilock

controller is able to "pump" each modulator, along with the

brakes connected to it, independently and with far greater

speed and accuracy.

4

Loading...

Loading...