User´s Manual

E

Bedienungsanleitung

DSP9024

PRO

®

D

Version 1.0 October 1998

ULTRA-DYNE

www.behringer.de

1

EC Declaration of Conformity

acc. to the Directives

89/336/EWG and 73/23/EWG

We, BEHRINGER INTERNATIONAL GmbH

Hanns-Martin-Schleyer-Strasse 36-38

D - 47877 Willich, Germany

Name and address of the manufacturer or the introducer of the product on the market who is established in the EC

herewith take the sole responsibility to confirm that the product:

ULTRA-DYNE PRO DSP9024

Type designation and, if applicable, Article-No

INTERNATIONAL GmbH

which refers to this declaration, is in accordance with the following standards or

standardized documents:

x EN 60065 x EN 61000-3-2

x EN 55020 x EN 61000-3-3

x EN 55013 x EN 55022

The following operation conditions and installation arrangements have to be

presumed:

acc. to Operating Manual

B. Nier, President Willich, 1.10.1998

Name, address, date and legally binding signature of the person responsible

2

SAFETY INSTRUCTIONS

CAUTION: To reduce the risk of electrical shock, do not remove

the cover (or back). No user serviceable parts inside; refer servicing to qualified personnel.

WARNING: To reduce the risk of fire or electrical shock, do not

expose this appliance to rain or moisture.

This symbol, wherever it appears,

alerts you to the presence of

uninsulated dangerous voltage inside

the enclosure - voltage that may be

sufficient to constitute a risk of shock.

DETAILED SAFETY INSTRUCTIONS:

All the safety and operation instructions should be read before the appliance is operated.

Retain Instructions:

The safety and operating instructions should be retained for future reference.

Heed Warnings:

All warnings on the appliance and in the operating instructions should be adhered to.

Follow instructions:

All operation and user instructions should be followed.

Water and Moisture:

The appliance should not be used near water (e.g. near a bathtub, washbowl, kitchen sink, laundry tub, in a

wet basement, or near a swimming pool etc.).

Ventilation:

The appliance should be situated so that its location or position does not interfere with its proper ventilaton.

For example, the appliance should not be situated on a bed, sofa rug, or similar surface that may block the

ventilation openings, or placed in a built-in installation, such as a bookcase or cabinet that may impede the

flow of air through the ventilation openings.

Heat:

The appliance should be situated away from heat sources such as radiators, heat registers, stoves, or other

appliance (including amplifiers) that produce heat.

Power Source:

The appliance should be connected to a power supply only of the type described in the operating instructions

or as marked on the appliance.

Grounding or Polarization:

Precautions should be taken so that the grounding or polarization means of an appliance is not defeated.

Power-Cord Protection:

Power supply cords should be routed so that they are not likely to be walked on or pinched by items placed

upon or against them, paying particular attention to cords and plugs, convenience receptacles and the point

where they exit from the appliance.

Cleaning:

The appliance should be cleaned only as recommended by the manufacturer.

Non-use Periods:

The power cord of the appliance should be unplugged from the outlet when left unused for a long period of

time.

Object and Liquid Entry:

Care should be taken so that objects do not fall and liquids are not spilled into the enclosure through openings.

Damage Requiring Service:

The appliance should be serviced by qualified service personnel when:

- The power supply cord or the plug has been damaged; or

- Objects have fallen, or liquid has been spilled into the appliance; or

- The appliance has been exposed to rain; or

- The appliance does not appear to operate normally or exhibits a marked change in performance; or

- The appliance has been dropped, or the enclosure damaged.

Servicing:

The user should not attempt to service the appliance beyond that is described in the Operating Instructions.

All other servicing should be referred to qualifield service personnel.

This symbol, wherever it appears, alerts

you to important operating and maintenance instructions in the accompanying

literature. Read the manual.

E

3

ULTRA-DYNE PRO

Ultra-high performance Digital Stereo Mainframe powered by two 24-bit High-Speed Signal Processor

DSP9024

s High-end 24-bit AD/DA converters for ultra-high dynamic range and resolution of detail with selectable

Sampling Rate of 44.1 or 48 kHz

s Ultimate 6-way Multiband Dynamics Processor for analog and digital Mastering and Sound Reinforcement

systems

s 6-Band Compressor with separate Peak Limiter section for inaudible compression. No side-effects,

such as bass pumping etc.

s 6-Band Gate with adjustable threshold, hold time, release time and peak width

s ULTRAMIZER® automatically adjusts output level and signal density for maximum perceived loudness

s VIRTUOSO® function for super-easy, program-dependent and self-learning program setup

s 3-Band Harmonics Exciter with user-definable balance for odd / even harmonics and unique kick control

s Extremely sophisticated Tube emulation with selectable tube types (12AX7, 12AY7, EL34, EL84) for ultra-

warm sound

s Internal 600 msec. Delay enables a Look Ahead for intelligent, anticipating processor function

s Ultra-accurate Level Peak Meter with Peak Hold and selectable Reference Levels (+4 dBu / -10 dBV / Dig Max)

s Full MIDI parameter and snapshot control allow for real time editing

s Free ULTRA-DYNE software allows for total remote control via PC (download at www.behringer.de)

s Extremely versatile presets give you outstanding and instant sound results for numerous standard

applications

s 100 settings can be stored under any alphabetic name. Memory backed up by a long life battery

s Security Key Password can be installed for programs or unattended use

s Open-ended and future-proof architecture allows for future software upgrades

s Extremely flexible Stereo Link, Band Link & Clone functions

s 24-bit AES/EBU Interface for Digital inputs and outputs at 32, 44.1 and 48 kHz (optional)

s Large high-resolution LCD Graphic Display with high-contrast LED backlight

s Servo-balanced inputs and outputs on gold-plated XLR and jack connectors for high signal integrity

s Relay-controlled hard bypass with an auto bypass function during power failure (fail-safe relay)

s High-quality components and exceptionally rugged construction ensure long life and durability

s Internal power supply design for professional applications

s Manufactured under the stringent ISO9000 management system

4

FOREWORD

Dear Customer,

Welcome to the team of ULTRA-DYNEPRO users and thank you very much for expressing your confidence

in BEHRINGER products by purchasing this unit.It is one of my most pleasant tasks to write this preface for

you, because it is the culmination of many months of hard work on the part of our engineering team to reach

a very ambitious goal:to present an outstanding device, which due to its flexibility is suitable for deployment in

studios and PA rental companies, as well as discotheques and clubs.The task of developing our new

ULTRA-DYNE PRO certainly meant a great deal of responsibility, which we assumed by focusing on you, the

discerning user and musician. It also meant a lot of work and night shifts to accomplish this goal. But it was

fun, too. Developing a product always brings a lot of people together, and what a great feeling it is when

everybody who participated in such a project can be proud of what they've achieved.

It is our philosophy to share our joy with you, because you are the most important member of our team.

You've contributed greatly to shaping our company and making it successful with your highly competent

suggestions for new products. In return, we guarantee you uncompromising quality (manufactured under an

ISO9000 certified management system) as well as excellent technical and audio properties at an extremely

favorable price. All of this will enable you to fully unfold your creativity without being hampered by budget

constraints.

We are often asked how we can produce such high-grade devices at such unbelievably low prices. The

answer is quite simple: it's you, our customers! Many satisfied customers means high sales volumes, enabling us to get better terms of purchase for components, etc. Isn't it only fair to pass this benefit back to you?

We know that your success is our success, too!

E

I would like to thank everyone whose help on the ULTRA-DYNE PRO project made it all possible. Everyone

involved made very personal contributions, starting from the designers of the unit, to the many staff members

in our company, to you, the user of BEHRINGER products.

My friends, it's been worth the effort!

Thank you very much,

Uli Behringer

5

TABLE OF CONTENTS

1. INTRODUCTION..................................................................................................................... 8

1.1 The concept .................................................................................................................................... 8

1.2 Before you begin ............................................................................................................................. 9

1.3 Control elements ............................................................................................................................. 9

2. OPERATION .......................................................................................................................... 11

2.1 The ULTRA-DYNE PRO operating concept..................................................................................... 11

2.1.1 The program level ................................................................................................................ 12

2.1.2 The editing level .................................................................................................................. 12

2.1.3 The meter level.................................................................................................................... 12

2.1.4 The setup level .................................................................................................................... 12

2.2 PROCESS mode .......................................................................................................................... 12

2.2.1 Editing parameters .............................................................................................................. 13

2.2.2 Program administration ....................................................................................................... 13

2.2.3 Loading a program .............................................................................................................. 14

2.2.4 Saving programs ................................................................................................................. 14

2.2.5 Activating VIRTUOSO ......................................................................................................... 14

2.2.6 Band-specific editing ........................................................................................................... 15

2.2.7 Tube Simulation .................................................................................................................. 15

2.3 METER mode ............................................................................................................................... 16

2.3.1 Advanced level meter .......................................................................................................... 16

2.3.2 Editing in METER mode......................................................................................................17

2.4 Setup level 1 ................................................................................................................................. 18

2.4.1 Input/output menu ............................................................................................................... 18

2.4.2 Band menu ......................................................................................................................... 19

2.5 Setup level 2 ................................................................................................................................. 20

2.5.1 Global setup ....................................................................................................................... 20

2.5.2 MIDI setup .......................................................................................................................... 22

3. APPLICATIONS ..................................................................................................................... 22

3.1 Compression/Leveling/Limiting/Clipping ......................................................................................... 23

3.2 The Gate section .......................................................................................................................... 23

3.2.1 Suppression of crosstalk in multi-channel operation ............................................................ 24

3.2.2 Basic settings of the Gate section ...................................................................................... 24

3.2.3 Reduction of crosstalk from stage microphones .................................................................. 25

3.2.4 Reduction of feedback from stage microphones .................................................................. 25

3.2.5 Noise reduction in effects chains......................................................................................... 25

3.2.6 Creative application of the Gate section .............................................................................. 25

3.3 The Compressor section ............................................................................................................... 26

3.3.1 Basic settings of the Compressor section ........................................................................... 27

3.3.2 The ULTRA-DYNE PRO as an effect device ........................................................................ 27

3.3.3 The "dull" sound of compressors ......................................................................................... 28

3.4 The VIRTUOSO function ............................................................................................................... 28

3.5 The ULTRAMIZER function ............................................................................................................ 29

3.6 Peak Limiter section ..................................................................................................................... 29

3.6.1 Basic settings of the Peak Limiter section .......................................................................... 30

3.7 Tube simulation ............................................................................................................................. 30

3.7.1 Application.......................................................................................................................... 30

3.8 The Exciter function ...................................................................................................................... 31

3.8.1 Audio enhancement during the copying process ................................................................. 31

3.8.2 Audio enhancement of instruments ..................................................................................... 31

3.8.3 Audio enhancement of PA systems .................................................................................... 31

3.9 The ULTRA-DYNE PRO in the recording and copying fields .......................................................... 32

3.9.1 The ULTRA-DYNE PRO for digital recording and sampling .................................................. 32

3.9.2 Mastering with the ULTRA-DYNE PRO ............................................................................... 32

6

3.10The ULTRA-DYNE PRO as a protective device for sound systems ................................................ 33

3.10.1Protecting a system with passive crossovers ...................................................................... 33

3.10.2 Protecting a system with active crossovers ........................................................................ 34

3.10.3 Audio enhancement of processor-controlled PA system ..................................................... 34

3.11 The deployment of the ULTRA-DYNE PRO in conjunction with multitrack machines ..................... 34

3.12The ULTRA-DYNE PRO in the broadcasting field........................................................................... 34

3.12.1 The deployment of the ULTRA-DYNE PRO in the broadcasting field ................................... 35

3.12.2 The deployment of the ULTRA-DYNE PRO in telephone and transmission lines................. 35

4. TECHNICAL BACKGROUND .............................................................................................. 35

4.1 Audio dynamics ............................................................................................................................ 35

4.1.1 Noise as a physical phenomenon ....................................................................................... 35

4.1.2 Audio dynamics .................................................................................................................. 36

4.1.3 Compressors/limiters .......................................................................................................... 37

4.1.4 Expanders/noise gates ....................................................................................................... 38

4.2 Digital audio processing ................................................................................................................ 38

4.2.1 The AES/EBU and S/PDIF standards.................................................................................. 40

4.3 Artificial generation of harmonics................................................................................................... 41

4.4 Tube technology ............................................................................................................................ 41

4.5 The structure of the ULTRA-DYNE PRO ........................................................................................ 42

5. INSTALLATION ..................................................................................................................... 42

5.1 Rack mounting .............................................................................................................................. 43

5.2 AC power connection .................................................................................................................... 43

5.3 Analog audio connections ............................................................................................................. 43

5.4 Digital audio connections per AES/EBU (optional)......................................................................... 44

5.5 MIDI connections .......................................................................................................................... 45

6. APPENDIX ............................................................................................................................. 45

6.1 AES8024 ...................................................................................................................................... 45

6.2 Operating software ........................................................................................................................ 46

6.3 Changing the memory buffer battery .............................................................................................. 46

6.4 In planning .................................................................................................................................... 46

6.5 MIDI implementation ..................................................................................................................... 47

6.6 Technical specifications ................................................................................................................ 48

E

7. WARRANTY .......................................................................................................................... 50

7

1. INTRODUCTION

With the BEHRINGER ULTRA-DYNE PRO, you have purchased a fully digital sound processing device

based on DSPs and 24-bit A/D and D/A converters. The high speed DSPs are capable of performing any

process in fractions of a second, the only element governing their performance being the software.

The BEHRINGER ULTRADYNE PRO has two channels which can be used independently or coupled via

software.

+ The following user's manual will introduce you to the BEHRINGER ULTRA-DYNE PRO and its

various functions. After reading the manual carefully, make sure it is always on hand for future

reference.

1.1 The concept

Unlike analog technology with its response speed limitations regarding changes in amplitude, digital signal

processing permits differences in amplitude to be identified in advance using a preliminary signal delay.

Increasing this preliminary delay also increases the potential for the intelligent control. Even looking ahead

by only a few samples is sufficient to ensure the intelligent application of dynamic processing such as

limiting, which ensures an absolutely reliable signal ceiling without clipping.

The signal delay may make itself unpleasantly noticeable in live use due to the mix of direct and delayed

sound. Very short delay times are thus advisable!

You are probably familiar with the effect of a solo instrument or voice being briefly "swallowed" by a bass

drum beat or a solid bass guitar pulse. This is a typical problem with broad-band compressors and limiters.

The powerful low frequencies generally dictate the overall level of the complete frequency spectrum. When

these high amplitudes exceed the set threshold of the compressor, the compression process is activated,

resulting in a muffled sound when the high frequencies are also attenuated. This problem does not occur

when using multiband technology as the low frequencies are controlled independently, effectively preventing

adverse effects on the other frequency bands. In multiband operation, the program material is divided into

several frequency bands. Unlike broadband units, a separate compressor or limiter is available for each of

these bands. The frequency ranges are merged once again downstream of these control units.

The ULTRA-DYNE PRO breaks the audio spectrum down into six frequency bands, thus offering "inaudible",

but highly effective compression. A completely new, intuitive operating concept permits the easy modification

of parameters, either for the individual bands, or globally. In addition, the ULTRA-DYNE PRO offers a Gate with

a wide range of user-definable parameters, a lightning-fast Peak Limiter, Tube Simulation and an Exciter. The

ULTRA-DYNE PRO also includes the VIRTUOSO and ULTRAMIZER functions for program material analysis to

facilitate your work, adapting the Compressor parameters quickly and automatically to suit your audio material.

The philosophy behind BEHRINGER products guarantees a no-compromise circuit design and the best choice

of components. Top-quality 24-bit AD/DA converters which belong to the best components available owing to

their outstanding specifications and excellent sonic characteristics are the heart of the BEHRINGER

ULTRADYNE PRO. Two 24-bit DSPs perform the precise calculations needed for the processing of the

complex algorithms. Additionally, the unit uses resistors and capacitors with very tight tolerances, high-grade

integrated circuits and other selected components.

The ULTRADYNE PRO DSP 9024 uses SMD (Surface Mounted Device) technology. These subminiature

components known from aerospace technology allow for an extreme packing density and enhance the unit's

reliability. Additionally, the unit is manufactured in compliance with an ISO 9000 certified management system.

Fail-safe relays have been incorporated into the design of the BEHRINGER ULTRA-DYNE PRO. These

automatically and silently bypass the unit in the event of power supply disconnection or failure. These relays

are also active at switch-on to isolate the unit from potentially damaging switch-on thump.

8

1. INTRODUCTION

1.2 Before you begin

Your BEHRINGER ULTRA-DYNE PRO was carefully packed in the factory and the packaging was designed

to protect the unit from rough handling. Nevertheless, we recommend that you carefully examine the packaging and its contents for any signs of physical damage which may have occurred in transit.

+ If the unit is damaged, please do not return it to us, but notify your dealer and the shipping

company immediately, otherwise claims for damage or replacement may not be granted.

The BEHRINGER ULTRA-DYNE PRO fits into two standard 19" rack units of space (3 1/2). Please allow at

least an additional 4" depth for the connectors on the back panel.

Be sure that there is enough space around the unit for cooling and please do not place the ULTRA-DYNE PRO

on high-temperature devices such as power amplifiers to avoid overheating.

+ Please ensure that the ULTRA-DYNE PRO is set to the correct supply voltage before connecting

the unit to the power supply system!

The AC power connection of the ULTRA-DYNE PRO is made using a standard power supply cable and IEC

receptacle. It meets all of the international safety certification requirements.

+ Please make sure that all units have a proper ground connection. For your own safety, never

remove or disable the ground conductor of the unit or of the AC power cable.

As standard, the BEHRINGER ULTRA-DYNE PRO is installed with electronically servo-balanced inputs and

outputs. The circuit design features automatic hum rejection for balanced signals, permitting trouble-free

operation even at the highest operating levels. Externally induced power-line hum, etc. is thus suppressed

effectively. The automatic servo function recognizes the presence of unbalanced connectors and adjusts the

nominal level internally to avoid level differences between the input and output signals (6dB correction).

The optional digital input and output (AES/EBU interface) connections are balanced with a negative ground.

High-quality connectors ensure isolated, noise-free signal throughput. The MIDI connections (IN/OUT/THRU)

have been realized with standardized DIN plug-in connectors. Optocouplers have been used for isolated data

communications.

E

1.3 Control elements

Fig. 1.1: The ULTRA-DYNE PRO front panel

The front panel of the ULTRA-DYNE PRO is equipped with four mode keys, four softkeys, four cursor keys

and a MIDI monitor LED. Status information is displayed on the backlit 240 x 64 panel.

1. INTRODUCTION

9

Fig. 1.2: The front panel controls

1

Press the PROCESS key to quickly and conveniently access all of the unit's major program functions

via virtual faders. This permits you to call up, save and edit programs with ease. The ULTRA-DYNE

PRO's factory presets are a solid foundation for a variety of applications. The automatic

VIRTUOSO and ULTRAMIZER functions permit the convenient customization of these applications to

suit your audio material. The first setup level provides global access to the parameters of all bands

simultaneously, while the second permits the manual adjustment of band-specific controls.

Here you will also find a screen for access to the Tube and Exciter functions.

2

Press the METER key for a multiple level display with the levels of the individual bands, as well as those

of the input and output signals. In addition, the respective level differences to the original signal are

also displayed.

+ The last fader used remains active when switching from the PROCESS to the METER operating

mode. The parameter in question may still be modified using the vertical cursor keys while

monitoring changes to the signal processing on the corresponding display.

3

Press the IN/OUT key to include the ULTRA-DYNE PRO in the signal path (green LED) or switch to

bypass mode (LED is dark). The LED flickering red indicates DSP overflow. This does not necessarily

mean clipping. Flickering starts as soon as an internal processing overflow occurs, while input and

output levels may be OK. When this LED lights up often, reduce the input level.

4

Press the SETUP key to access the setup levels which permit the individual numerical editing of each

parameter. Pressing the SETUP key briefly accesses the first setup level in which the complete range

of values for all available ULTRA-DYNE PRO parameters can be edited (see Chapter 2.1.4).

Holding the SETUP key for about two seconds switches to the second SETUP level. Here all the basic

settings of the device can be found, such as the choice of input source, sample rate, password

protection, MIDI configuration etc.

5

Four SOFTKEYS marked A, B, C and D are arranged vertically to the left of the display. The functions

of these keys are defined by the user software and are indicated by a pictogram or text to the right of

each key in the display. Each pictogram and its associated functions will be explained in detail in

Chapter 2.

6

Central in the control of the ULTRA-DYNE PRO is the LED-backlit 240 x 64 DISPLAY.

7

The MIDI LED which displays the input of MIDI data is located to the right of the display.

8

The CURSOR KEYS are also positioned to the right of the display. These keys can be used for the

selection (horizontal) and operation (vertical) of the faders shown on the display, as well as the selection

of parameter fields in the SETUP menu.

+ In each case if you hold the key being used and then press the opposite key you will acceler-

ate whatever operation you are undertaking.

10

1. INTRODUCTION

Fig. 1.3: The back panel layout of the ULTRA-DYNE PRO

9

FUSE HOLDER / VOLTAGE SELECTOR. Before connecting the unit to AC power, ensure that the

operating voltage is set to your local AC voltage. Always use replacement fuses of the same type. In

some units, the fuse holder can be inserted in two positions to switch between 220 - 240 V and 100 120V. Please note that a higher fuse rating must be used when operating the unit outside of Europe

with 115 V (See the INSTALLATION chapter).

10

Use the POWER switch to activate your ULTRA-DYNE PRO.

11

AC POWER CONNECTION. Use only the included AC cable to connect the unit to your AC power

supply. Please also ensure that your AC power socket has a ground. This ground conductor must NOT

be disabled to prevent hum pick-up. If you experience AC hum problems, use a DI box such as the

BEHRINGER ULTRA-DI to preserve the protective function.

12

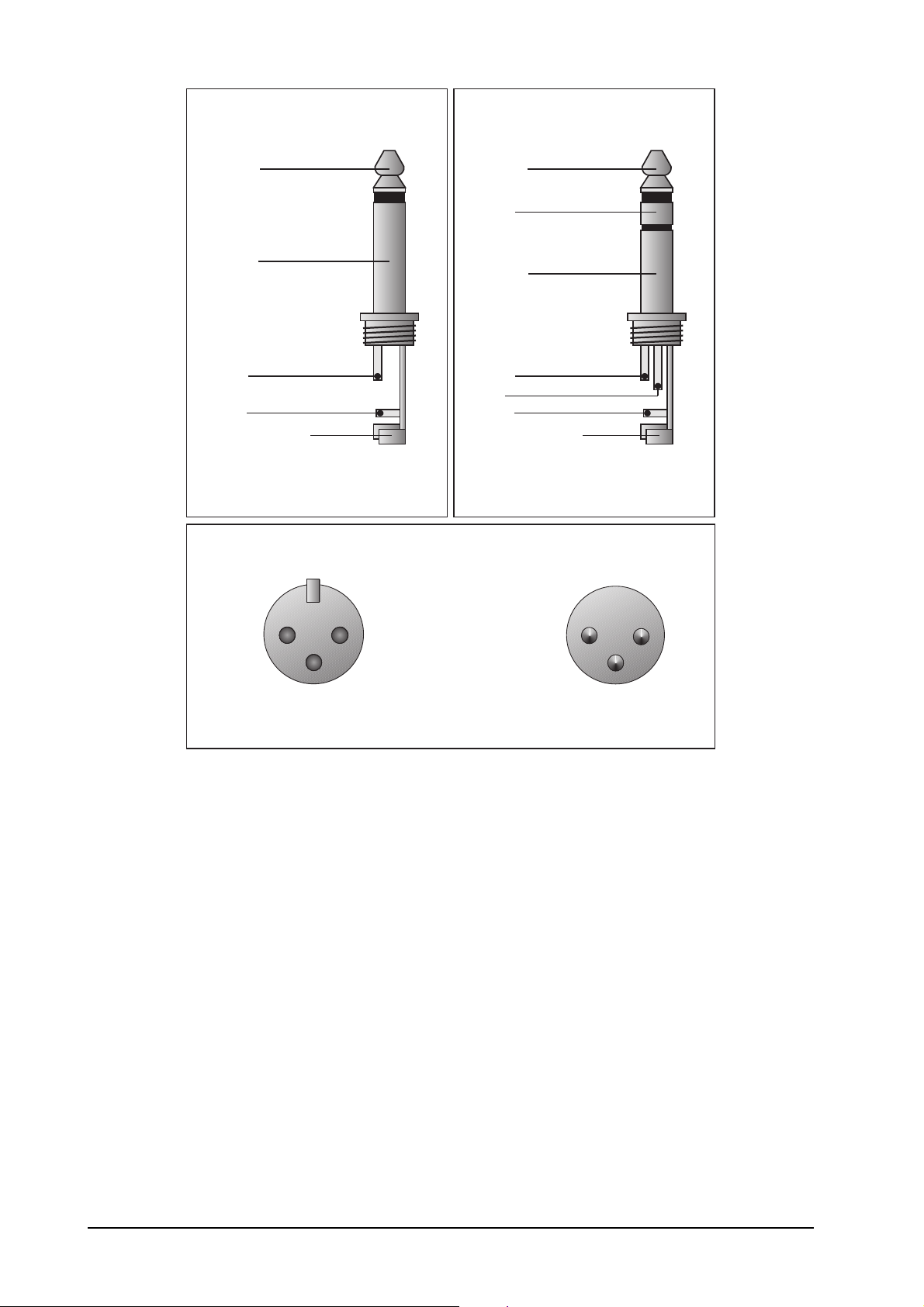

ANALOG INPUTS. The ULTRA-DYNE PRO has balanced XLR and jack connector inputs designed for

maximum levels of +22 dBu. Microphone signals thus require pre-amplification, e.g. via a mixer.

13

ANALOG OUTPUTS. The analog outputs of the ULTRA-DYNE PRO have also been realized as balanced XLR and jack connectors. A maximum output level of +16 dBu is available at the internal digital

maximum (DIGIMAX).

E

14

AES/EBU INPUTS (optional). An optionally available female XLR digital interface can be installed here.

15

AES/EBU OUTPUTS (optional). The optional male XLR digital interface output can be installed here.

The AES/EBU option transfers 24-bit data words at 32, 44.1 or 48 kHz.

16

MIDI IN, OUT and THRU. These connectors permit the MIDI remote control of the ULTRA-DYNE PRO.

17

SERIAL NUMBER. Please take the time to have the warranty card completed by your dealer and

return it to us within 14 days of the purchase date for protection by the extended warranty.

2. OPERATION

2.1 The ULTRA-DYNE PRO operating concept

The complex nature of the parameter settings required the development of a new operating concept for the

ULTRA-DYNE PRO. This permits quick, simple editing of the key parameters, as well as the fine optimization

of each of the individual parameters to suit the program material.

The operation of the ULTRA-DYNE PRO can be broken down into four different levels:

1. The programming level, with the selection and editing of presets.

2. The editing level, which permits the convenient optimization of nearly all available parameters.

3. The METER menu, which in addition to its graphical display of levels also permits editing.

2. OPERATION

11

4. The SETUP menu, which provides access to all of the global and band-specific parameters for the six

frequency bands on several text pages.

2.1.1 The program level

The ULTRA-DYNE PRO has over 100 program memory locations, some of which contain factory-preset programs. These programs contain a large number of basic settings to cover a wide variety of applications. These

programs can be called up very quickly and generally provide good results in practice. Of course, user-defined

settings can be saved as required and recalled at a later time.

2.1.2 The editing level

Use the editing level to modify the preset programs to suit the program material.

The editing window contains eight faders which can be used to optimize these programs. Please note that the

faders do not represent absolute levels, but parameter changes relative to the presets, with the adjustment

limited to a suitable range. These limits only apply to the factory presets and to programs based on the preset

programs.

2.1.3 The meter level

The input and output levels of the six individual bands is displayed in the meter level. It also permits the editing

of parameters while monitoring the effects of the changes on the meters.

2.1.4 The setup level

The full range of all available ULTRA-DYNE PRO parameters can be edited on the setup level. The results can

range from "interesting" to "surprising" to "brilliant". Completely new applications can also be created. The

setup level is thus the domain of experts and those with a passion for experimentation.

The programs and parameters of the editing level can be accessed by pressing the PROCESS key.

2.2 PROCESS mode

The ULTRA-DYNE PRO is in PROCESS mode immediately after being switched on.

Fig. 2.1: <PROCESS> menu

Use this mode to call up the <MEMORY> menu for loading and saving programs. It also provides direct

access to the main parameters of the individual ULTRA-DYNE PRO functions. The VIRTUOSO function can

also be called up directly from the <PROCESS> menu. ULTRA-DYNE PRO uses this function to analyze the

program material and automatically set the Compressor parameters. An information window appears with the

exact designation and value of the selected parameter when using a fader. The softkey C (EDIT) takes you to

the band-specific editing level which permits the individual editing of the Gate and Compressor values for all six

bands. The softkey D (TUBE) provides access to the Tube Simulation and Exciter parameters.

12

2. OPERATION

2.2.1 Editing parameters

Please refer to Table 2.1 for the structure of the parameters and the meanings of the abbreviations.

Display Function Parameter Range Default Value

GTH Gate Threshold -90 to -40 dB, OFF OFF

CTH Threshold -70 to 0 dB, OFF OFF

CRA Ratio 1:1 to 88:1, INF:0 1:1

CAT Attack Time 0 to 250 ms 0 ms

CRT Release Time 0.05 to 5 s 5 s

ULT Ultramizer Process 0 to 100 0

OUT Outgain Gain -24 to +24 dB 0 dB

LTH Limiter Threshold -36 to 0 dB, OFF 0 dB

The first five parameters in the <PROCESS> menu are contained in all six bands. The last three entries pertain

to the complete frequency range, however. Please see chapters 2.4.1 and 2.4.2 for the definitions of the

parameters.

Compressor

Tab. 2.1: Fader functions in PROCESS mode

+ Parameters edited in the <PROCESS> menu have a global effect on all six bands.

E

2.2.2 Program administration

A program stores all of the parameter settings affecting the signal. Global hardware settings such as the

configuration of the inputs and MIDI interface, i.e. the setup level 2 settings, are not stored in the respective

programs. The ULTRA-DYNE PRO has over 100 program memory locations that contain the factory presets,

as well as room for your own creations.

Fig. 2.2: <MEMORY> menu

Press the softkey B (Memory) in the <PROCESS> menu to access the <MEMORY> menu. The Up and Down

cursor keys can be used to select and listen to programs in this menu. An information window displaying the

selected program appears as soon as you press one of the cursor keys. At the same time, the displayed

preset is automatically played. Use softkey D (A/B) to compare it with the program you have been editing.

The currently active program is indicated by a bold letter in the pictogram: A is the edited version, while B is

the selected program. To load the program, press softkey A (LOAD) and follow the instructions in Chapter

2.2.3. Softkey C (CLEAR) clears your current program from the memory and permits the selection of a

default preset.

+ The message CLEAR WORKSPACE is displayed when the softkey C (CLEAR) is pressed.

Confirm the query with OK to reset all current parameters to their defaults. Be sure to save

the edited program first if desired.

2. OPERATION

13

2.2.3 Loading a program

Fig. 2.3: <LOAD> menu

Press the softkey A (Load) in the <PROCESS> menu to access the <LOAD> menu. The same information

window is displayed in the fader area as when operating a fader. Use the Up and Down cursor keys to select

a program and listen to it with the softkey D (LISTEN). The listening function is indicated by a highlighted

LISTEN in the pictogram. Next, select the desired program with softkey A (OK) or return to the

<PROCESS> menu with softkey B (CANCEL).

2.2.4 Saving programs

Fig. 2.4: <STORE> menu

Use the softkey B to access the <STORE> menu. This also displays an information window in which you can

select a program location to save your own creation using the Up and Down cursor keys. Use softkey A (OK)

to assign a name to the program or softkey B (CANCEL) to cancel the save operation and return to the

<PROCESS> menu. If a program location is already occupied, the warning OVERWRITE PROGRAM? will

appear.

Press softkey A (OK) again to assign a name to your program. A window with a character map will now

appear in the display. Choose the character you require with the cursor keys and it will appear at the flashing

cursor in the name field. Use the softkeys B and C to move the cursor in the name field. Softkey D (CLEAR)

deletes any characters which may have already been entered. Program names can have a maximum of 12

characters. Once the name is complete, press softkey A (OK) to return to the <PROCESS> menu.

2.2.5 Activating VIRTUOSO

The VIRTUOSO function can reduce your setup work considerably by analyzing your audio material and

automatically determining the compression values. Press the softkey A in the <PROCESS> or <METER>

menus to access the VIRTUOSO function. This brings you to the <VIRTUOSO> menu in which you can select

the required degree of compression using the four softkeys.

14

Fig. 2.5: <VIRTUOSO> menu

2. OPERATION

The ULTRA-DYNE PRO now analyzes the audio material until you end the analysis with softkey C (OK) or

cancel it with softkey D (CANCEL). The analysis is indicated by the flashing VIRTUOSO pictogram.

Fig. 2.6: VIRTUOSO analysis window

Next, the ULTRA-DYNE PRO automatically sets the Threshold parameters of all six Compressors for the

individual bands to suit the audio material, ensuring optimal compression (see Chapter 3.4, VIRTUOSO

function). The compression can also be corrected subsequently by changing the INGAIN parameter in the

setup menu. If the compression is too powerful, reduce the INGAIN value and vice versa.

2.2.6 Band-specific editing

E

Fig. 2.7: <EDIT> menu

Press the softkey C (EDIT) in the <PROCESS> menu to access the <EDIT> menu, which permits bandspecific editing via the faders. Select one of the six bands with softkey B. The pictogram shows the currently

selected band. Pressing the key once more will switch to the next higher band.

The first six parameters (1 Gate, 4 Compressor, 1 Outgain) are available for each band, whereas the last two

(1 Ultramizer, 1 Limiter) apply to the entire frequency range.

+ BANDLINK must be OFF to change settings per band

Softkey D (A/B) allows you to compare the current setting with the settings of the program as it was loaded.

The B in the pictogram is displayed in bold whenever you modify a loaded program. If you are not satisfied

with the new setting, you can return to the original program by pressing softkey D a second time and trying a

new setting from there. As soon as you change a value, the B in the pictogram will once again be displayed in

bold. Upon loading a new program, neither A nor B will be highlighted as long as no changes have been

made.

Use the softkey A (CLONE) to copy the parameters of the selected frequency band to any or all other

frequency bands of the given channel. The settings are also copied to all bands of the other channel when in

stereo mode (setup level 2). The message COPY BAND X TO ALL BANDS will be displayed. Use the Up and

Down cursor keys to select whether the parameters of the current band should be copied to all other bands

(ALL BANDS) or to a specific band (BAND X).

2.2.7 Tube Simulation

Press the softkey D (TUBE) in the <PROCESS> menu to access the <TUBE> menu.

2. OPERATION

15

Fig. 2.8: <TUBE> menu

Use this menu to set up the Exciter and Tube Simulation. Please refer to Table 2.2 for the structure and the

meanings of the abbreviations. Softkey D (A/B) allows you to compare the current setting with the settings of

the program as it was loaded. The B in the pictogram is displayed in bold whenever you modify a loaded

program. If you are not satisfied with the new setting, you can return to the original program by pressing

softkey D a second time and trying a new setting from there. As soon as you change a value, the B in the

pictogram will once again be displayed in bold. Upon loading a new program, neither A nor B will be highlighted as long as no changes have been made.

Display Function Parameter Range Default Value

EXC Exciter Process 0 to 100 0

O/E Exciter Odd/Even 1/19 to 19/1 10/10

PRC Tube Process 0 to 100 0

TYP Tube Type 12AX7, 12AY7, EL34, EL84 12AX7

Tab. 2.2: Fader functions in the <TUBE> menu

2.3 METER mode

Press the Meter key to enter the METER mode.

Fig. 2.9: METER mode

This mode displays the input and output levels of all frequency bands (ascending from left to right) and the

overall levels of the two channels. Information is also shown regarding level changes made by the ULTRADYNE PRO. Gain reductions are displayed as a small bar extending downward from the 0 dB mark. It is

possible to activate the VIRTUOSO mode while in METER mode by pressing softkey A (see 3.4). Softkey D

toggles between the display of the input and output levels. IN or OUT are highlighted accordingly.

2.3.1 Advanced level meter

Press the softkey B (SINGLE) to call up the advanced level meter.

16

2. OPERATION

Fig. 2.10: Advanced level meter

You can use the advanced level meter to control the input and output levels of the ULTRA-DYNE PRO. The bar

graph displays the effective RMS level (solid parts of the bars), and the peak level (checkered tips of the bars)

simultaneously. To save your eyes, the release time of the peak display is 20 dB/s. Use softkey A (CLEAR) to

erase the maximum levels from the memory. Softkey B switches between the display of the individual bands

(BAND 1 to 6) and the master channel (MASTER). The current selection is shown in the pictogram. Softkey D

(IN/OUT) toggles the display between the input and output levels. Peak Limiter activity is indicated by the "LIM"

in the display. Use softkey C to choose between three different tables of reference levels. The reference

levels are shown with a bold mark on the scale, and the numerical display changes simultaneously.

DIGMAX refers to the digital maximum. This level must not be exceeded under any circumstances. This will

result in a very noticeable form of distortion, which occurs much faster and sounds very much more unpleasant

than the familiar distortion associated with analog devices.

+4 dBu refers to the operating level found in professional audio equipment (analog inputs and outputs of the

ULTRA-DYNE PRO).

-10 dBV refers to the operating level found in home recording and domestic audio equipment, a typical example

being tape recorders with unbalanced RCA connectors.

When setting the ULTRA-DYNE PRO's internal level, or when using the optional AES/EBU interface, the peak

level display of the DIGMAX scale is the ONLY one to use. The +4dBu and -10dBV scales serve to monitor the

analog inputs and outputs of the ULTRA-DYNE PRO. Please note that the RMS level will usually be quoted in

the technical specifications of analog devices, such as for the input sensitivity of power amplifiers.

+ The RMS level will always be lower than the peak level. The difference is dependent upon the

signal structure. For a static sine wave, the RMS level is about 71% of the peak level, a difference of 3 dB.

E

The DIGMAX level is, of course, related to the analog input and output levels, as 0 dB DIGMAX corresponds

to the maximum output level of the ULTRA-DYNE PRO.

The following example, using a sine wave at maximum amplitude, clearly illustrates the relationship between

the various scales:

Sc ale M ax im um level

RMS PE A K

DIGMA X -3 dB 0 dB

+4 dB u +9 dB + 12 dB

-10 dBV +21 dB + 24 dB

Abs olut e value: +16 dB u

Tab. 2.3: Relationship between display and output level

As can be seen from the above table, the ULTRA-DYNE PRO's maximum analog output level is +16 dBu. The

ULTRA-DYNE PRO's analog input can handle a maximum of +22 dBu.

2.3.2 Editing in METER mode

Press the softkey D to access the <EDIT> menu in METER mode. This menu can also be opened by pressing

any cursor key.

2. OPERATION

17

Fig. 2.11: <EDIT> menu in METER mode

The eight parameters in the <PROCESS> menu can be edited while visually monitoring the effects of the

edits on the level meters. Softkey D (IN/OUT) toggles the display between the input and output levels. Your

selection is indicated by a highlighted IN or OUT in the pictogram. Use the softkeys A and B to select the

parameter to be edited. The Left and Right cursor keys can be used to switch between the individual bands (1

to 6), as well as to change between the left and right channels when in 2-channel mode. Use the Up and Down

cursor keys to edit the selected parameter. Softkey C (SOLO) lets you listen to the current band being

affected by the selected parameter separately. The meter also displays only the selected band while in solo

mode. The other displays are disabled while the solo mode is active.

2.4 Setup level 1

Press the SETUP key to access setup level 1. The LED above the SETUP button will start to flash. This level

contains all of the settings which are related to the actual signal processing. Pressing the SETUP key will take

you to the input/output menu <IN/OUT> and the band menus (BAND 1 to 6). The LEFT and RIGHT entries

in the first line let you switch between the left and right channels. If stereo mode is activated in setup level 2,

this display will not be present, i.e. both channels are linked and will be edited at the same time. The parameters are selected using the cursor keys in all setup menus. Parameters can be modified and modes switched

using the softkeys marked + and -. The two outer softkeys can be used to make modifications over a wider

range than the inner ones. In each case, pressing the opposite key while holding the key being used will

accelerate the operation being carried out. Pressing the PROCESS or METER keys will cause the unit to exit

from either setup level.

+ All of the SETUP settings are stored when switching off the ULTRA-DYNE PRO and remain

unchanged until the next time you edit them.

2.4.1 Input/output menu

Fig. 2.12: <IN/OUT> menu in setup level 1

This window is split vertically, with the parameters related to the input on the left and the output on the right.

The input side:

LEFT/RIGHT

The selected channel is displayed here. The channels can be toggled with the Plus or Minus softkeys.

INGAIN

The input gain can be adjusted in 1 dB increments from -24 to +24 dB.

TUBE TYPE

Four different Tube Types are available for the Tube Emulation: 12AX7, 12AY7, EL34 and EL84.

TUBE PROCESS

The Tube Process value determines the degree of tube-type distortion to be added to the signal. The value

18

2. OPERATION

range is 0 to 100.

EXCITER PROCESS

The addition of harmonics by the Exciter can be set in a range from 0 to 100.

ODD/EVEN

Determines the Ratio of Even to Odd harmonics in the Exciter. This may be varied from 1/19 to 19/1.

The output side:

OUTGAIN

The Output Gain can be adjusted in 1 dB increments from -47 to +24 dB.

ULTRAMIZER PROCESS

This function is a special feature of the ULTRA-DYNE PRO which continuously and automatically optimizes

the Input Gain and Compressor Thresholds to the program material. This parameter determines the degree to

which this automatic function affects the dynamic control. The values for ULTRAMIZER PROCESS range

from 1 to 100.

ULTRAMIZER THRESHOLD

Determines the Ultramizer's range of application. The Ultramizer function does not become active if the input

signal does not have to be raised beyond the value set here. The range can be set between 0 and 24 dB.

PEAK LIMIT

A Peak Limiter with a user-definable Threshold of -70 to +0 dB can be applied to the overall signal. OFF

disables the Gate Threshold.

LIMITER RELEASE

Set the Release time of the Peak Limiter here. The Release time is the time constant after which the attenuation is released once the signal has dropped below the Threshold. Values in the full second range are generally used. The range can be set between 0.5 and 5 seconds.

E

2.4.2 Band menu

Fig. 2.13: <BAND> menu in setup level 1

The BAND X parameter for the selection of individual bands may be found in the top left corner of the band

menu. The LEFT/RIGHT toggle field for the channel is just to the right. This field is not activated in stereo

mode (setup level 2).

The ULTRA-DYNE PRO automatically goes to the SETUP window for the band last selected when switching

from PROCESS mode to SETUP. The cursor will also reappear at the last selected parameter.

LO FRQ

Sets the Lower limit Frequency for the band.

HI FRQ

This parameter determines the Upper limit Frequency for the band.

+ In the case of neighboring bands, the upper limit frequency of the lower band is always iden-

tical with the lower limit frequency of the next higher band. In other words, changing one

value automatically adjusts the related value as required.

2. OPERATION

19

GATE THRESHOLD

Determines the Threshold for the Noise Gate in this band, with a Threshold value between -96 dB and

-25 dB. OFF disables the Gate Threshold.

GATE HOLD

This parameter sets the waiting time before the noise Gate release process starts.

GATE RELEASE

The GATE RELEASE parameter determines the time which the noise Gate requires to return to 1:1.

+ The GATE HOLD and RELEASE times can be set from 20 to 720 ms in 20 ms increments.

PEAK WIDTH

This parameter determines the Width of peaks to be ignored by the Gate. The valid time range for this setting

is 0 to 150 ms. This can be used to specifically suppress clicks.

EXCITER DRIVE

This parameter determines the Exciter Effect control for the three upper bands (4 to 6). The intensity of the

Exciter can be set using the Exciter process parameter in the <TUBE> and <IN/OUT> menus. This parameter

can be adjusted from 0 to 100.

COMPRESSOR THRESHOLD

The Threshold for the Compressor can be set from -70 dB to 0 dB. OFF disables the Compressor Threshold.

COMPRESSOR RATIO

The Compression Ratio can be set from 1:1 (no compression) to INF:0 (INF = infinite). INF:1 corresponds to

the action of a limiter.

COMP. ATT.

The Compressor Attack time is the time in which the Compressor regulates the signal to the set Ratio after the

Threshold has been exceeded.

COMP. REL.

The Compressor Release time is the time in which the Compressor returns the signal to 1:1 after the level has

dropped below the Threshold.

KNEE

The Knee parameter determines whether the compression should become effective abruptly (hard), or gently

and gradually before reaching the actual Threshold value (soft). A total of 36 increments are also available for

this parameter. Factory default is value 18.

2.5 Setup level 2

Hold the SETUP key for about 2 seconds to enter setup level 2. This level contains all of the global unit settings

such as memory management and the configuration of the MIDI interface. At this level, the LED above the

SETUP key remains continuously lit. Use the SETUP key to switch between the <GLOBAL SETUP> and

<MIDI SETUP> menus.

+ The setup level 2 settings are saved globally and do not affect the program memory.

2.5.1 Global setup

20

Fig. 2.14: <GLOBAL SETUP> menu in setup level 2

2. OPERATION

INPUT

The input field is used to determine whether the input signal should be derived from the optional digital input,

or from the analog input. In addition, the sampling frequency is set here for analog operation. The available

frequencies are 32 kHz / 44.1 kHz and 48 kHz (the digital input automatically synchronizes to these frequencies). When changing sample rates, the ULTRA-DYNE PRO will be muted briefly.

+ In purely analog mode the 48 kHz rate should be used. Apart from the fact that the high sample

rate gives the widest frequency response and correspondingly the best possible sound, the

fastest signal processing takes place at this rate.

If the ULTRA-DYNE PRO unexpectedly doesn't output a signal, this may be due to an incorrect input configuration.

VIEWING ANGLE

Viewing Angle controls the contrast adjustment for the display in increments from 0 to 31.

MODE

The two channels of the ULTRA-DYNE PRO can be stereo-linked using this parameter. This automatically

copies all settings to the opposite channel. The channels are also linked in such a manner that both are edited

simultaneously. Both channels operate completely independently in 2CHANNEL mode.

DELAY

The ULTRA-DYNE PRO has an integrated memory for the delay and intermediate storage of the input signal.

This permits the optimal adaptation of the control processes, as the signal can already be analyzed before

processing. Delay times of 20 to 40 ms ensure optimal compression characteristics with your ULTRA-DYNE

PRO. The delay time may be set from 0 to 600 ms. Factory default is 10 ms.

E

+ This signal delay can easily cause unpleasant side effects in live applications, making it advis-

able to keep the delay time as short as possible.

SECURITY

The SECURITY function offers effective protection against unauthorized manipulation of the ULTRA-DYNE

PRO. UNLOCK means that all functions may be accessed, with the exception of programs that are secured

under PROTECT MEMORY. LOCK prevents any of the parameters on the device being accessed, the only

exceptions being the DISPLAY of the present setting, plus the input and output level with the LEVEL METER.

The only other way to access the parameters is via MIDI. To use the SECURITY function, enter a PASSWORD with the cursor keys and softkeys. The softkeys are used to select the letter or symbol to be used, and

have the following functions:

Softkey A confirms entry of the password and immediately activates the LOCK status. Softkeys B and C move

the cursor left and right within the PASSWORD. Softkey D erases any characters which may have already

been entered.

The LOCK status can be cleared by calling up SETUP menu again. The relevant PASSWORD field is

displayed immediately, and the PASSWORD may be re-entered. This returns the ULTRA-DYNE PRO to

UNLOCK status. If the device is locked without entering the PASSWORD, simply enter OK to UNLOCK.

+ Do not forget the password! If this happens, there is only one way to remove it: Open the

casing of the ULTRA-DYNE PRO and take the battery out for a short while. After replacing it

and switching the unit on, the original factory presets will be reloaded. We recommend that

this should only be performed by an experienced engineer to avoid inadvertent damage to the

unit. Warning! Doing this will cause you to lose all your programs, AND void the warranty!

PROTECT MEM

The PROTECT MEMORY parameter switches the write protection for the program memory on and off.

LOW and HIGH

The functions LOW and HIGH determine the area of program memory which will be protected by the PROTECT MEMORY function. LOW determines the lowest, HIGH the highest program number of the protected

area. The PROTECT MEMORY function can be disabled with OFF (also see Security).

2. OPERATION

21

2.5.2 MIDI setup

Fig. 2.16: <MIDI SETUP> menu in setup level 2

MIDI

ON = MIDI interface enabled, OFF = MIDI interface disabled.

CHANNEL

Sets the MIDI send and receive channels; the channels 1-16 may be selected.

SND MEMORY DUMP and RCV MEMORY DUMP

The complete contents of the ULTRA-DYNE PRO memory can be transferred via MIDI to another ULTRADYNE PRO or a PC (SEND MEMORY DUMP). Conversely, the contents of the memory can also be received

via MIDI (RECEIVE MEMORY DUMP). The transmission or readiness to receive is activated in both cases by

simultaneously pressing one Plus and one Minus key each.

OMNI MODE

With the OMNI MODE enabled, the ULTRA-DYNE PRO can receive data on all MIDI channels. This may prove

useful to test the unit's response to incoming MIDI commands or in cases in which you are unsure of the MIDI

channel being used for the transmission.

CNTL, PROG and EXCL

These fields can be used to additionally enable the Sending (SND) and Receiving (RCV) of controller data

(CNTL), Program Change commands (PROG) and System Exclusive data (EXCL).

+ Caution: Receiving a memory dump will overwrite the existing programs!

3. APPLICATIONS

This section will cover a number of typical applications for the BEHRINGER ULTRA-DYNE PRO. Most problems related to dynamics can be solved using the following basic settings.

Please take the time to study the following sample applications in detail in order to ensure the optimum

deployment of the unit's broad range of features.

Primary applications and basic settings

Generally speaking, BEHRINGER ULTRA-DYNE PRO applications can be broken down into seven areas:

1. The GATE section removes noise and suppresses crosstalk in multi-channel operation.

2. The COMPRESSOR section increases the density of the program material and can be used to create

special effects and sounds frequently encountered in the recording and music fields.

3. The VIRTUOSO function ensures compression suited to your requirements and adapted to the characteristics of the program material.

4. The ULTRAMIZER function automatically adjusts the input gain and Compressor parameters to suit your

program material.

5. The PEAK LIMITER section is designed to protect speaker systems, tape machines, transmission lines,

etc. from overload.

6. The TUBE simulation adds additional harmonics to the audio signal for a lively, warm character.

7. The EXCITER function is designed to enhance the audio quality after compression.

22

3. APPLICATIONS

3.1 Compression/Leveling/Limiting/Clipping

After describing the the individual sections in detail, we would now like to acquaint you with further important

concepts pertaining to the processing of dynamics:

Compression

A compressor reduces a broad dynamic range to a limited dynamic band. The resulting dynamic range

depends on the threshold, attack, release and ratio settings. As the desirable effects of a compressor include

the boosting of low-level signals, the threshold value is generally set low. Inaudible compression requires

fast attack and release times and low compression rates. Faster attack and release times and higher compression rates increase the effect on short-term dynamics. This may be put to use to achieve audible,

creative sound effects, for example.

Leveling

The leveling function is used to keep the output level constant, i.e. to compensate for long-term changes in the

input level without restricting short-term dynamics. The threshold is generally set low to ensure that low-level

signals will be boosted. The leveling function uses slow attack and release times in conjunction with a high

ratio. Due to its very long attack times, leveling does not affect signal peaks or short-term changes of the

average level.

Limiting

The limiting function uses short attack times, a high compression ratio and a release time which depends on

the given application and the desired audio effect. The threshold must be set high, as a limiter is only used to

set a ceiling for high signal levels. The degree of dynamic range reduction depends on the ratio setting and

the extent to which the threshold is exceeded. A so-called program limiter uses attack times greater than 20

ms and is designed to control the average level. Short-term signal peaks exceeding the set threshold value can

also pass the limiter in this case. Peak limiters use attack times set to less than 5 ms to control signal peaks

as well.

E

Clipping

Unlike the two previous limiter types, the clipping function is characterized by the use of instantaneous attack

and release, as well as infinite compression rates to ensure absolute limiting for all signals above the set

threshold (brickwall limiting). Clipping has the effect of a radical cutoff of signal peaks exceeding the

threshold without restricting the amplitude of the actual signal form. Under normal circumstances, the clipping

function is inaudible and may even result in improved audio quality under certain circumstances by cutting off

artificial harmonics. Clipping causes conspicuous, harsh distortion, which at its most extreme can result in

rectangular waveforms.

3.2 The Gate section

The main task of a Gate is to separate undesirable background noise from the program signal and "remove" it

inaudibly. As described in Chapter 4.1.4, a so-called Downward Expander automatically reduces the overall

level for all signals below a user-definable threshold and thus increases the dynamic range of the program

material. The Expander can thus be regarded as the opposite of a compressor/limiter. Expanders generally

work with a relatively flat ratio characteristic to ensure that the signal is continuously suppressed. On the other

hand, noise gates can be regarded as high-ratio expanders, which radically cut signals off that drop below the

threshold.

The BEHRINGER ULTRA-DYNE PRO is equipped with six Noise Gates with intelligent look-ahead functions.

The Threshold parameters can be set up individually for each band using faders in the EDIT menu of the

PROCESS mode. Additional parameters such as the Hold and Release times and look-ahead can be found on

setup level 2 in the band menus. The following definitions describe the parameters in greater detail:

Gate Threshold:

This is the value after which the audio signal no longer passes through the Gate.

Gate Hold Time:

The Gate Hold time is the duration of the wait after the Threshold has been passed before the release time

3. APPLICATIONS

23

begins.

Gate Release Time:

The Gate release time is the time in which the Gate returns the signal to 1:1 after the hold time has elapsed.

Peak Width:

Use the Peak Width parameter to set the maximum signal impulse width to be ignored by the Gate.

+ The Peak Width parameter is dependent upon the delay parameter in the <GLOBAL SETUP>

menu. The Peak Width Gate parameter will have no effect if the delay has been set to 0 ms. In

addition, the delay time set in the <GLOBAL SETUP> menu should be twice as long as the

desired Peak Width time of the Gate.

Using the Peak Width parameter permits the ULTRA-DYNE PRO to identify and ignore brief signal peaks on

the basis of their duration. For this reason, select a suitable setting for this parameter corresponding to the

maximum duration of the signal peaks to be ignored. The peak width parameter also ensures that an open

gate does not close for signals shorter than the set duration.

3.2.1 Suppression of crosstalk in multi-channel operation

One of the most common applications for an expander/gate is the suppression of undesirable crosstalk

between individual channels during recording and playback. This application is used very frequently when

recording acoustic percussion instruments due to the close proximity of the microphones to one another. The

high sound pressure levels of the individual instruments causes crosstalk in all of the neighboring microphones, leading not only to frequency cancellations but also to a lack of definition in the sound (comb filter

effect). The optimal solution is thus to use a separate microphone for each instrument, with individual gating for

each microphone.

Insert the BEHRINGER ULTRA-DYNE PRO in the recording channel in of the snare, for example, and set the

unit to respond to signals from the snare only. Each microphone should be carefully positioned and checked

beforehand, and the Threshold value set to ensure a clean acoustic separation of the drum sound, as if the

instrument were being played alone.

Correct miking technique is decisive for the optimal function of the Expander/Gate. Be especially careful when

instruments with pronounced high frequencies are being played next to or behind a cardioid microphone.

The directional characteristic of most microphones is considerably less effective at high frequencies. A

difference of only 2 to 3 dB in the response sensitivity between the main and lateral axes in the 5 to 10 kHz

range can result in severe cymbal crosstalk in the tom microphones, or masking of the snare by the hi-hat.

Take maximum advantage of the directional characteristics of the respective microphones to ensure the best

possible acoustic isolation of the instruments.

Be sure to do everything possible to isolate the individual sources with proper miking technique alone.

Otherwise, the Expander/Gate will not be able to provide a clear acoustic separation.

3.2.2 Basic settings of the Gate section

Parameter Setting

Threshold -90 dB

Hold Time 20 ms

Release Time 20 ms

Peak Widt h 0 ms

Tab. 3.1 Basic settings of the Gate section

Begin with very low Threshold values so that the entire signal can pass unhindered. Next, move the fader

upwards until all background noise has been removed and only the desired instrument is still audible.

The hold time can be adjusted to optimize the unit for the program material. It may contain many, frequently

short, pauses which can result in the Gate being activated repeatedly in short succession. The Hold function

prevents the disturbing "flutter" common to conventional gates by delaying the release process. This ensures

24

3. APPLICATIONS

that the Gate remains open during short pauses. The Gate closes the audio channel in the preset release time

after the hold time has elapsed.

The release time may also be used to adapt the Gate perfectly to the program material. As a rule, percussive

audio material with little or no reverb is processed with quick release times, whereas longer release times are

used for signals with a slow decay or heavy reverb. You will note that short release times are suitable for most

percussion instruments, while longer times are generally required for toms and cymbals.

Due to its digital design, the ULTRA-DYNE PRO Gate features a look-ahead function. The ULTRA-DYNE PRO

can analyze the audio signal and thus work without losses. As a result, the Gate always opens at the correct

time without cutting off signal flanks.

If you do not want the Gate to remain open during brief signal peaks, set the impulse width of the signals to be

ignored with the peak width parameter. Increase the value until the Gate only opens for the program material.

Drums will sound dry, snappy and well-defined when the parameters are correctly set. If you do not have

enough individual microphones (or ULTRA-DYNE PRO!) at your disposal, try to arrange several microphones

into subgroups.

The objective is to position the group microphones and set the Gate section in such a manner that a signal

from a given instrument opens only one microphone, while the other microphones remain muted.

3.2.3 Reduction of crosstalk from stage microphones

The ULTRA-DYNE PRO has a wide range of applications in live or stage operation and multiple microphone

deployment: The moderate, careful application of the Gate can effectively suppress background noise, compressor-related background noise accentuation, microphone crosstalk, etc. without undesirable side effects.

E

The processing of vocal tracks is a typical application for the Gate. The distance of a vocalist to the microphone

becomes increasingly critical when using a compressor. Increasing amounts of background noise are transmitted the further the vocalist moves away from the microphone. Use the Gate function with long release times

to "inaudibly" eliminate unwanted background noise during pauses. In live applications, drum crosstalk in

piano tracks can be suppressed for example, or recordings cleaned of acoustic "contamination".

3.2.4 Reduction of feedback from stage microphones

A vocalist singing into a stage microphone masks background noises, which are then no longer apparent. In

pauses, however, the microphone picks up noise from the PA and monitor speakers, which can cause

unpleasant feedback.

This susceptibility to feedback can be reduced considerably if the ULTRA-DYNE PRO is inserted into the

vocal channel and set to mute the microphone when it is not in use. In principle, all stage microphones should

be included in this application.

3.2.5 Noise reduction in effects chains

One of the most frequently overlooked sources of noise in a sound system is the effect rack. The prices of

reverb and multi-effect devices have dropped drastically in recent years, making them standard equipment

even in small studios and home recording environments. The noise level increases drastically with the number

of devices, however, quickly spoiling the pleasure to be had from the new effects.

This can be countered by inserting the ULTRA-DYNE PRO as the last unit in the effect chain and using the

noise-reducing function of the Gate section. Set the unit for a long release time to ensure a natural reverb.

3.2.6 Creative application of the Gate section

In addition to the applications described above, the Gate can also be used for the creative modification of audio

characteristics. For example, the quality of environmental reverberation or the spatial impression of instruments

can be modified. During its decay time, the reverberation of an instrument will drop below a user-defined

threshold. The duration of the reverberation can be controlled using the preset threshold and release time. The

adjustment of the release time permits the reproduction of the decay characteristic of the instrument in a

manner that preserves the instrument's character. Take the time to experiment with modification of the decay

of a signal. Long release times result in a slow fade, while short release times can completely remove the

reverberation of the instrument.

3. APPLICATIONS

25

3.3 The Compressor section

The purpose of the Compressor is to reduce the dynamic range of the program material and monitor the levels.

The extensive selection of controls in the Compressor section permit a wide variety of dynamic effects, from

gentle, musical compression, to the limiting of signal peaks, to an extreme, effective compression of the entire

dynamic range.

A low ratio and very low Threshold setting can be used, for example, to provide a soft, musical compression of

the overall dynamic range of the program material. Relatively high ratios in conjunction with a low Threshold

setting will result in a relatively constant volume (leveling) for instruments and vocals. High Threshold values are

generally used to limit the overall level of the program material. Ratios greater than 6:1 effectively prevent the

output levels from significantly exceeding the Threshold value, provided that the Outgain parameter has been

set to 0 dB).

Please note that compression of the entire program material due to low Threshold settings tends to sound

unnatural at higher ratios. Ratios in the range of 3:1 or less have less effect on the dynamic range and are

often used to compress the signals of a bass guitars, snares or vocals. Careful, moderate settings are

generally used for mixes and level control in the broadcasting field.

The ULTRA-DYNE PRO is equipped with six Compressors with intelligent look-ahead functions. The Threshold, Ratio, Attack and Release times can be configured in the <PROCESS> and <EDIT> menus. In addition,

a knee configuration function with 36 increments can be found in the band setup menu. The look-ahead for the

six Compressors can be set using the delay parameter in the <GLOBAL SETUP> menu. The following definitions describe the Compressor parameters in greater detail:

Compressor threshold:

The Compressor Threshold is the Threshold value at which the attack time starts to regulate the Compressor

to the set Ratio.

Compressor Ratio:

The Compressor Ratio is the Ratio of the input gain to the output gain.

Compressor attack time:

The Compressor Attack time is the time in which the Compressor regulates the signal to the set Ratio after the

threshold has been exceeded.

Compressor release time:

The Compressor release time is the time in which the Compressor returns the signal to 1:1 after the level has

dropped below the Threshold.

Compressor knee:

This parameter determines the Compressor characteristic at the Threshold.

"Hard knee" is an abrupt transition to preset gain. The use of a hard knee in conjunction with powerful compres-

sion at high ratios can sound conspicuously unnatural.

Output

Threshold

Hard Knee

Gain 0 dB

Ratio

26

Input

Fig. 3.1: Hard-knee compressor characteristic

3. APPLICATIONS

Therefore, always use a soft-knee compressor characteristic when working with high ratios. This results in a

gradual transition to the preset gain. The ULTRA-DYNE PRO permits the adjustment of the Compressor knee

in 36 increments.

Output